Tapered roller screw rod pair and seal structure

A sealing structure, tapered roller technology, applied in the direction of engine seals, engine components, belts/chains/gears, etc., can solve the problem of not being able to seal with tapered roller screw pairs, achieve reliable contact sealing and reduce leakage amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

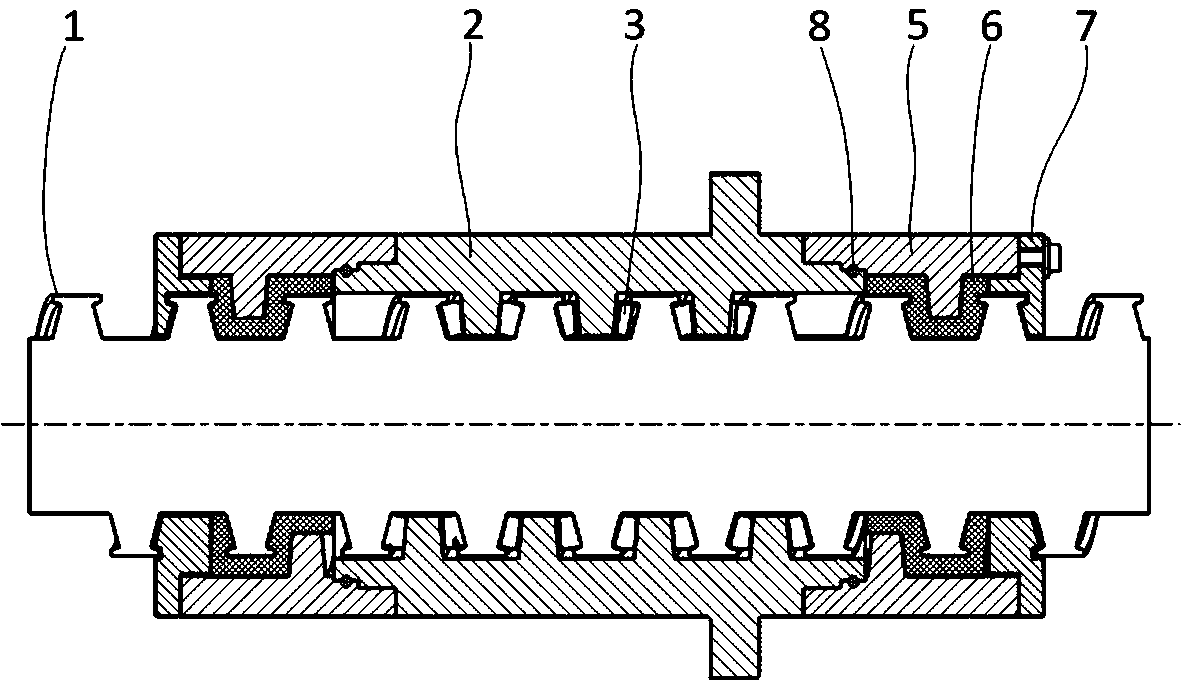

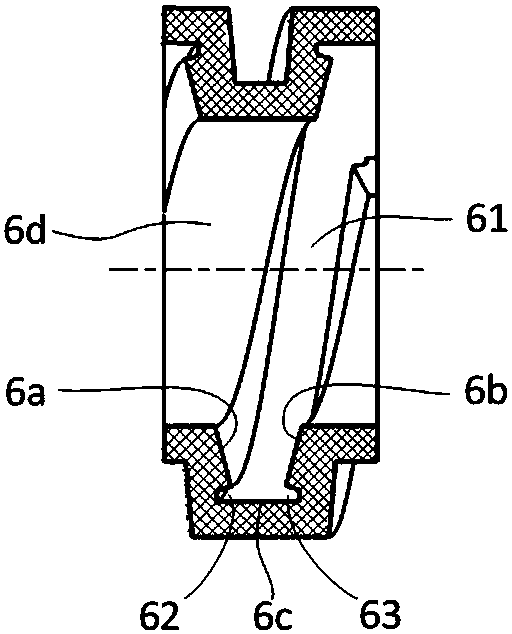

[0070] Below, refer to the attached Figure 1-22 An embodiment of the tapered roller screw pair and its sealing structure of the present invention will be described.

[0071] First of all, regarding the basic structure of the tapered roller screw pair, the basic structure is described in detail in the Chinese patent document CN108561523A. Compared with the present invention, except that the sealing structure used is different, the rest is just a difference in terminology , with exactly the same underlying structure.

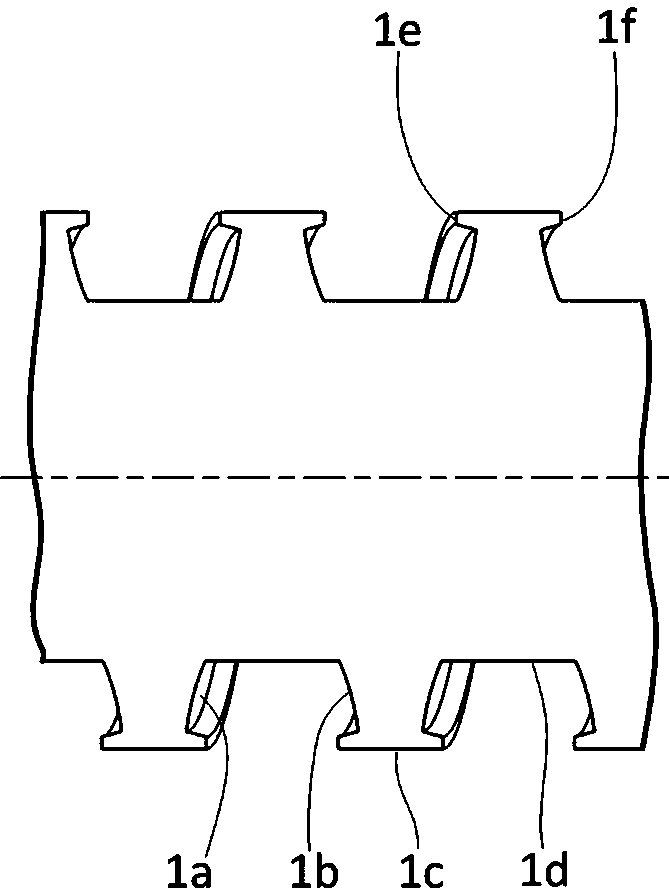

[0072] Such as figure 1 , 2 As shown, conventional screw with figure 1 and 2 The screw 1 shown in the above all adopts the basic external thread structure, the difference is that the profile of the external thread is different, and the profile depth of the conventional screw is relatively small, which is used to partially accommodate the balls, while for figure 1 and figure 2 The lead screw 1 shown in , its profile should have sufficient depth to accommoda...

no. 2 example

[0115] Below, refer to the attached Figure 2-9 And attached Figures 23 to 34 The second embodiment of the tapered roller screw pair and its sealing structure of the present invention will be described.

[0116] Such as Figure 23 , 33 As shown, there are threads on the outer cylindrical surface of the lead screw 1 and the inner cylindrical surface of the nut 2, correspondingly forming external threads and internal threads, and the threads of the lead screw 1 and the nut 2 are arranged in a cross manner in the axial direction, that is The threaded portion on the nut 2 intervenes between adjacent threads of the lead screw 1 to determine the raceway.

[0117] Furthermore, a plurality of tapered rollers 3 are located in the raceway defined by the lead screw 1 and the nut 2, are constrained by the raceway, and flow along the raceway; there are reversers 4 at both ends of the screw thread of the nut 2, and the reverser The reverse guide action surface 4a on 4 is located inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com