Square hole punch chip used on punch press

A punch and lathe technology, which is used in the field of punches for processing square holes on punching machines, can solve problems such as low production capacity and increase product processing costs, and achieve long service life, wear-resistant punching effects, and increased contact surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

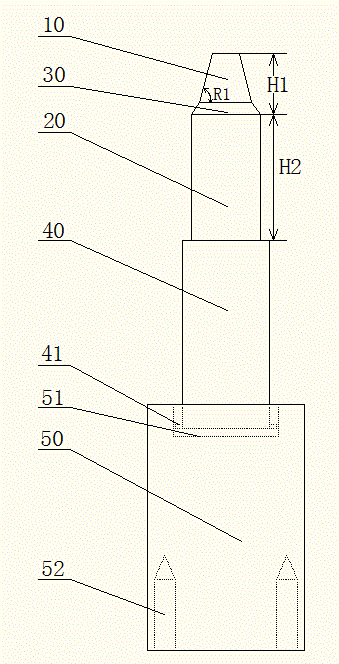

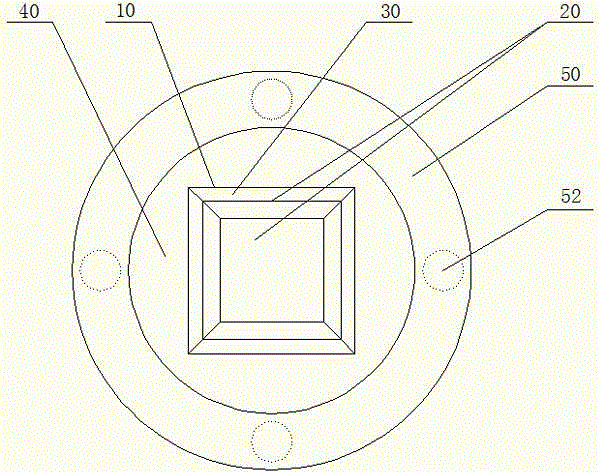

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

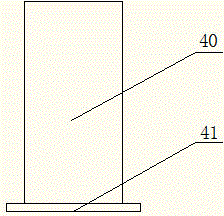

[0017] Such as Figure 1 to Figure 3 As shown, a square hole punch used on a lathe includes a guide head 20, a punch body 10, a resisting portion 40, and a positioning seat 50 arranged axially from top to bottom. The cross section of the punch body 10 It is square, and the guide head 20 is arranged on the end of the punch body 10. The orthographic projection of the guide head 20 is trapezoidal and narrow at the top and wide at the bottom. In the present invention, the cross section of the guide head 20 is also square. The transition surface 30 of 10 is an inclined surface, and the inclination angle of the transition surface 30 is smaller than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com