Patents

Literature

54results about How to "Guaranteed stamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

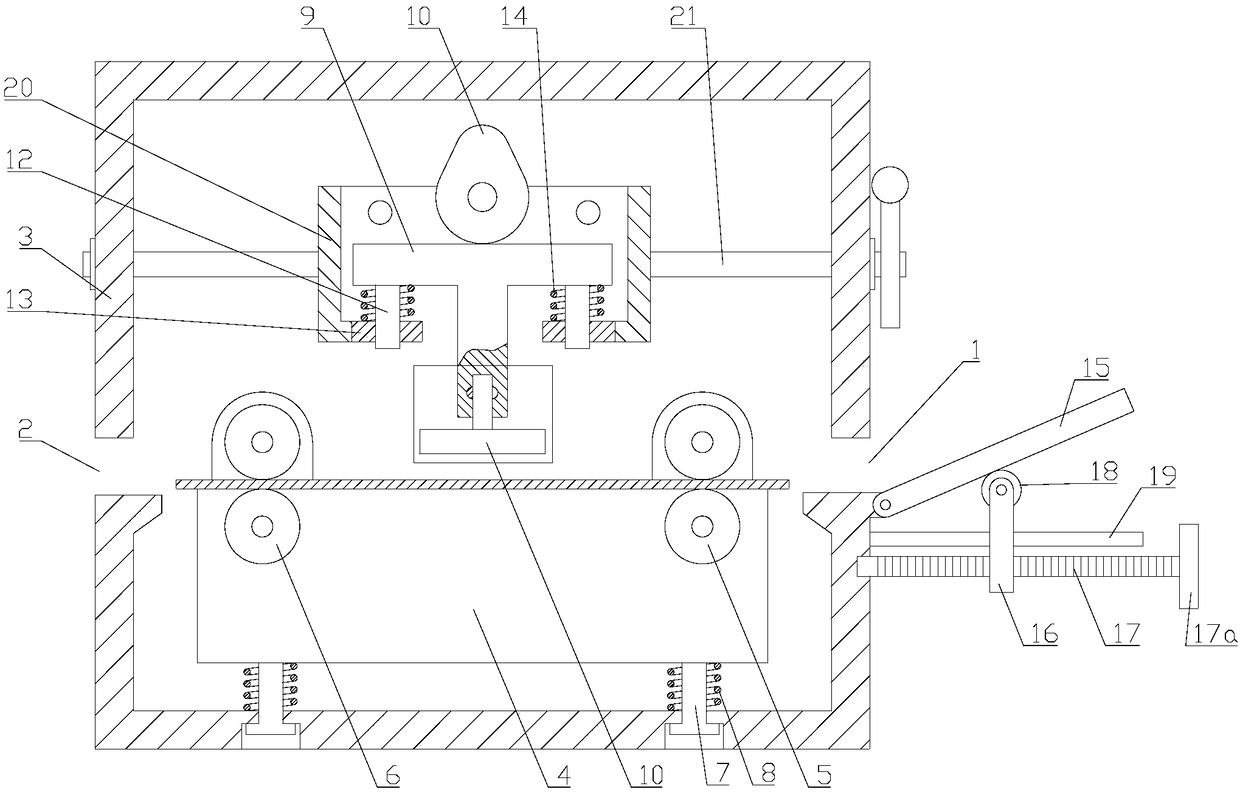

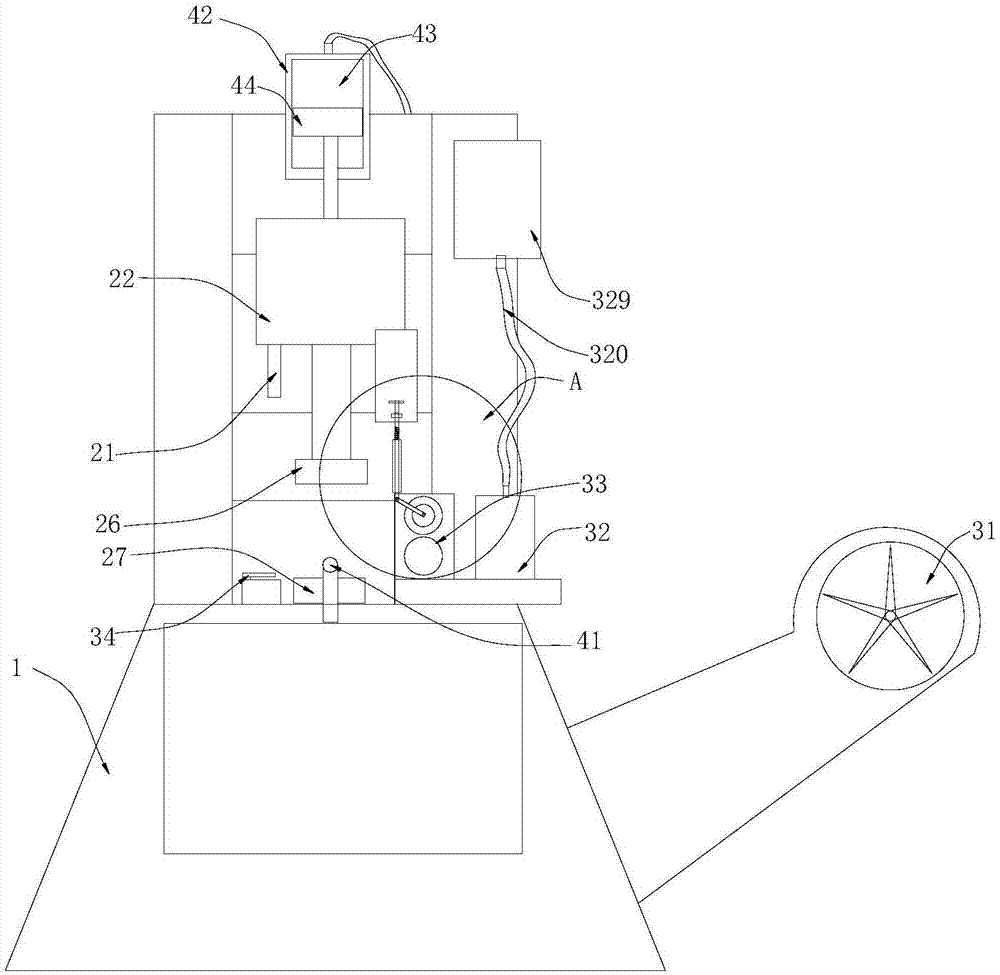

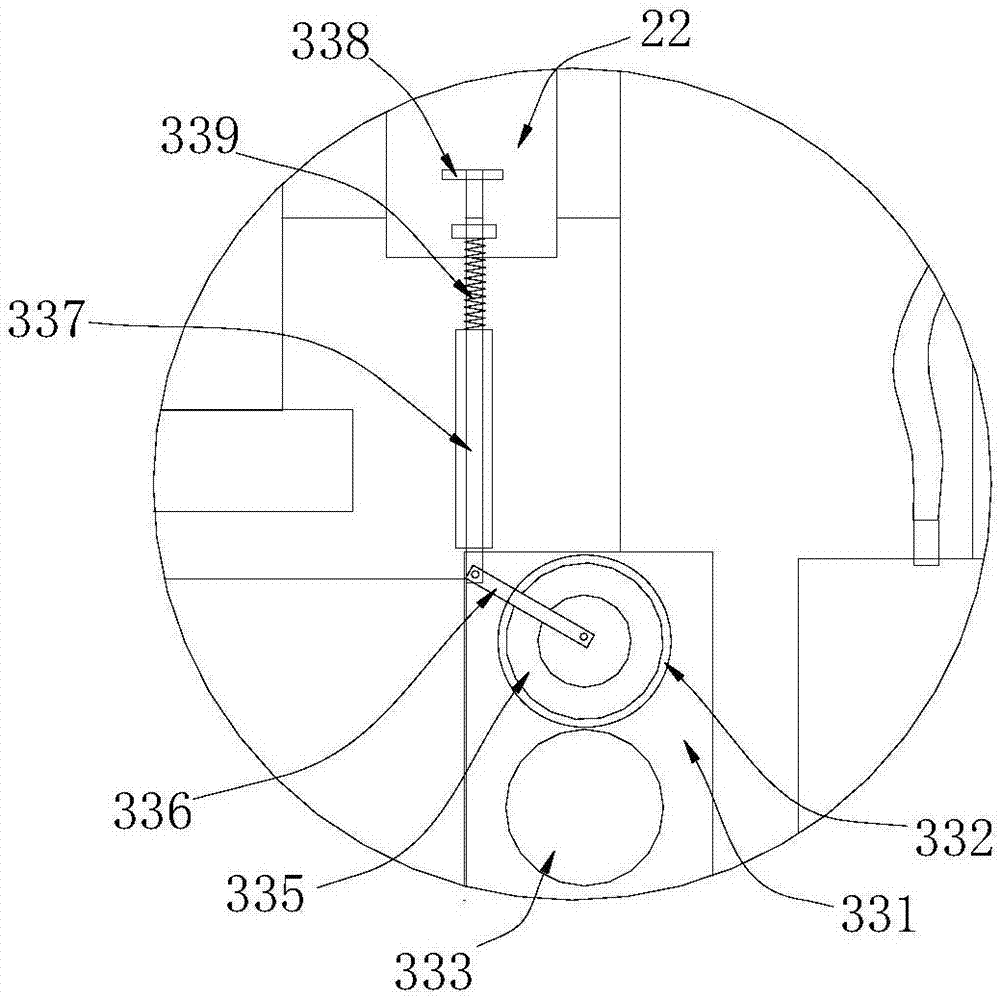

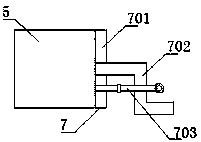

Precise support rod type three-directional punching machine tool

ActiveCN105522741AGuaranteed movement simultaneityGuaranteed motion accuracyPress ramElectricityPunching

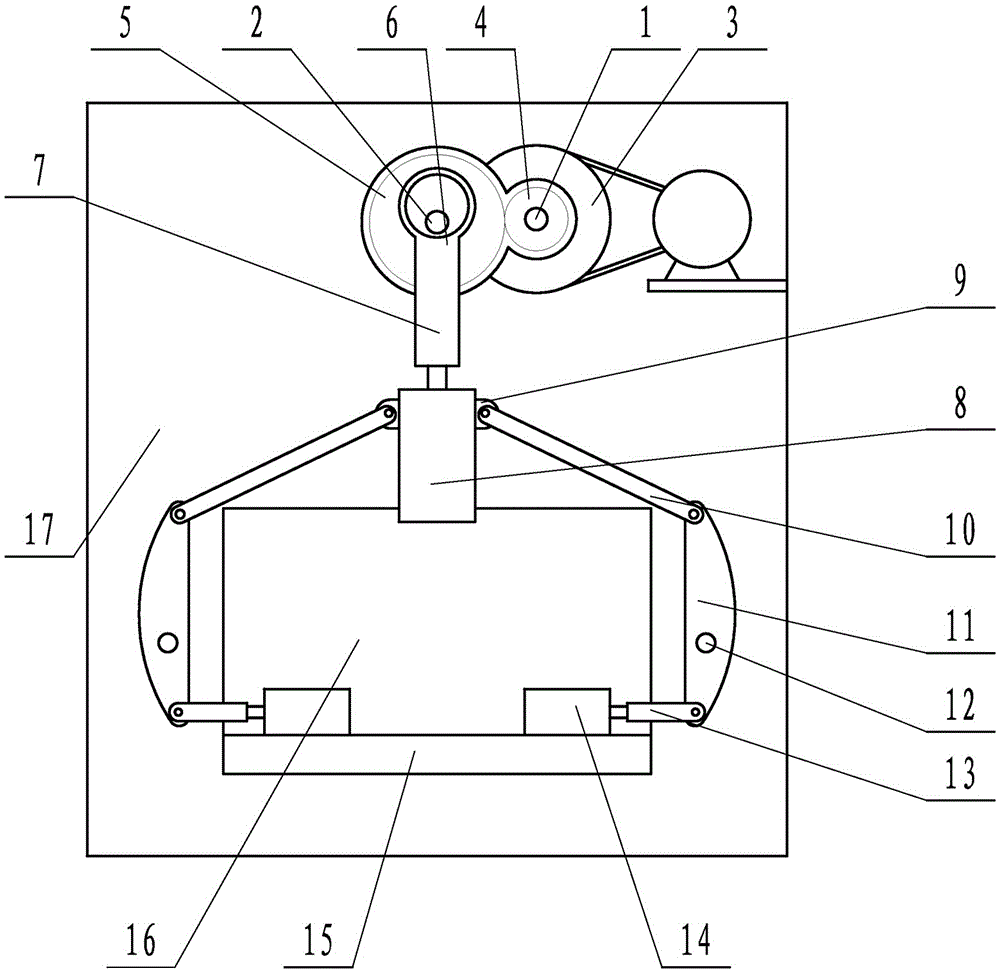

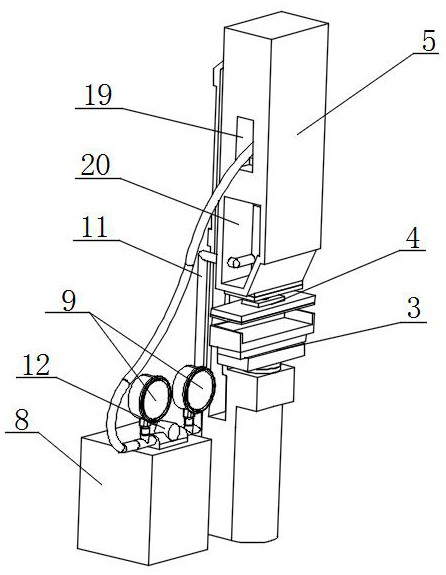

The invention relates to a precise support rod type three-directional punching machine tool. The precise support rod type three-directional punching machine tool comprises a transmission shaft, an eccentric wheel arranged on the transmission shaft, a connecting rod with one end sleeving the eccentric wheel, an upper slide block arranged at the other end of the connecting rod, a horizontal punching device connected with the upper slide block, and a driving device connected with the transmission shaft. The precise support rod type three-directional punching machine tool adopts the eccentric wheel mode to drive the upper slide block to work; meanwhile, the horizontal punching device is connected with the upper slide block; the upper slide block is used for driving; one set of driving device is only adopted; and the precise support rod type three-directional punching machine tool is simple in structure, is lower in requirement on torque input by the driving device, and saves electricity.

Owner:XINGTAI GEXIN MACHINERY EQUIP MFG CO LTD

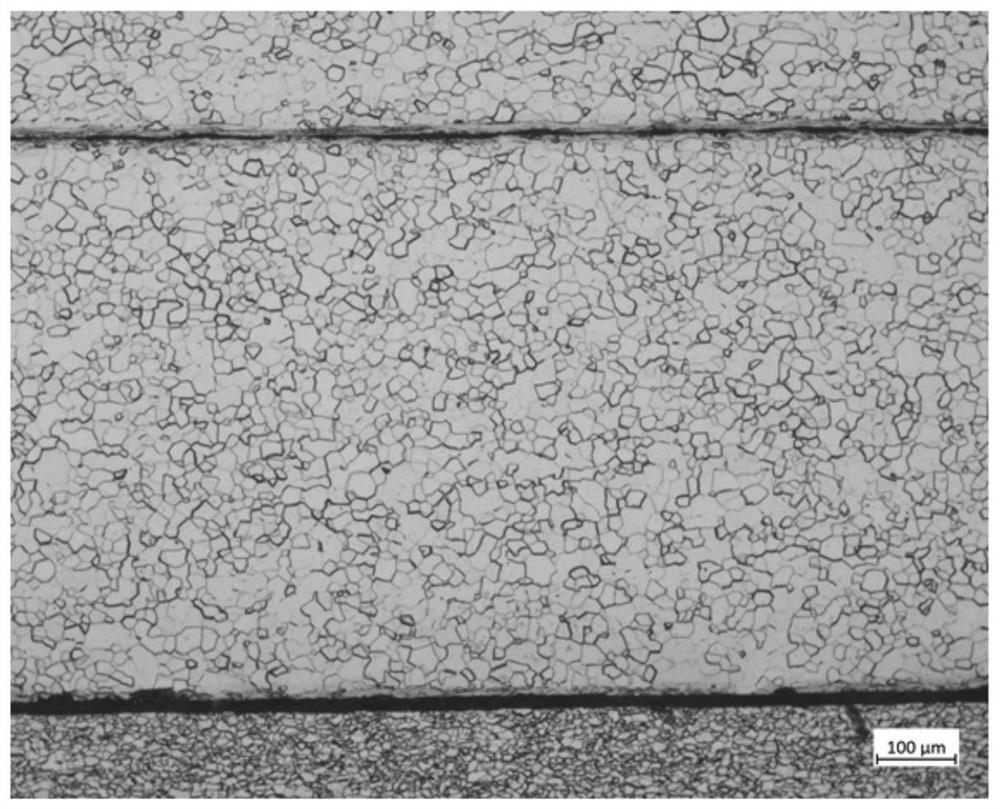

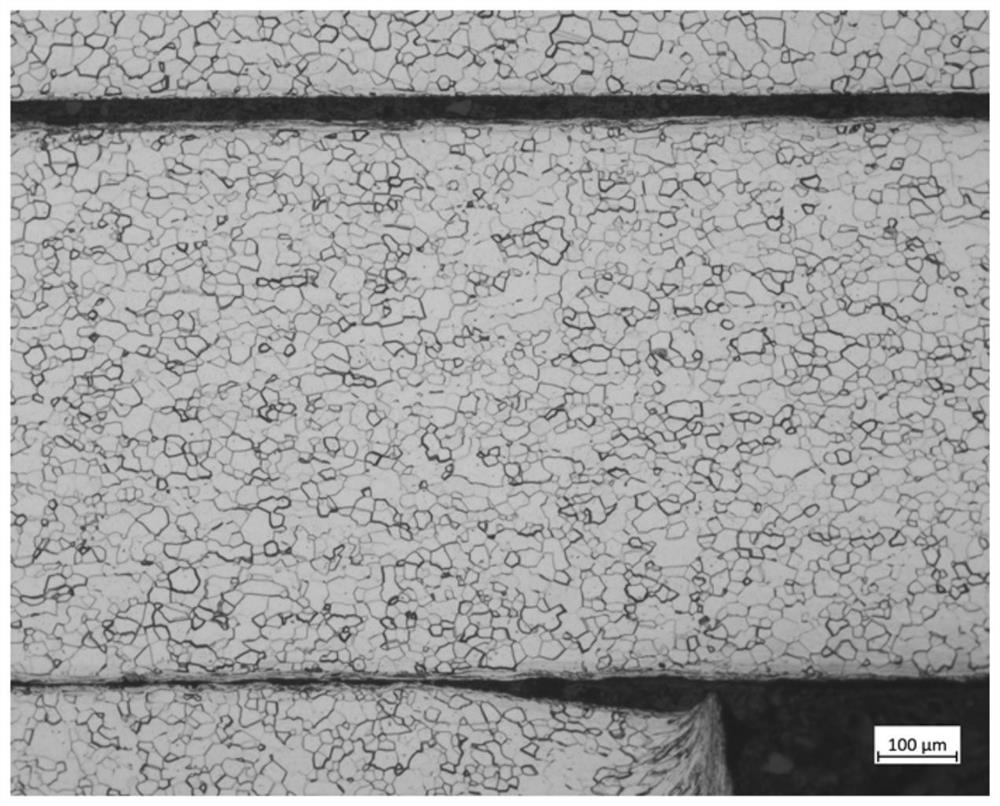

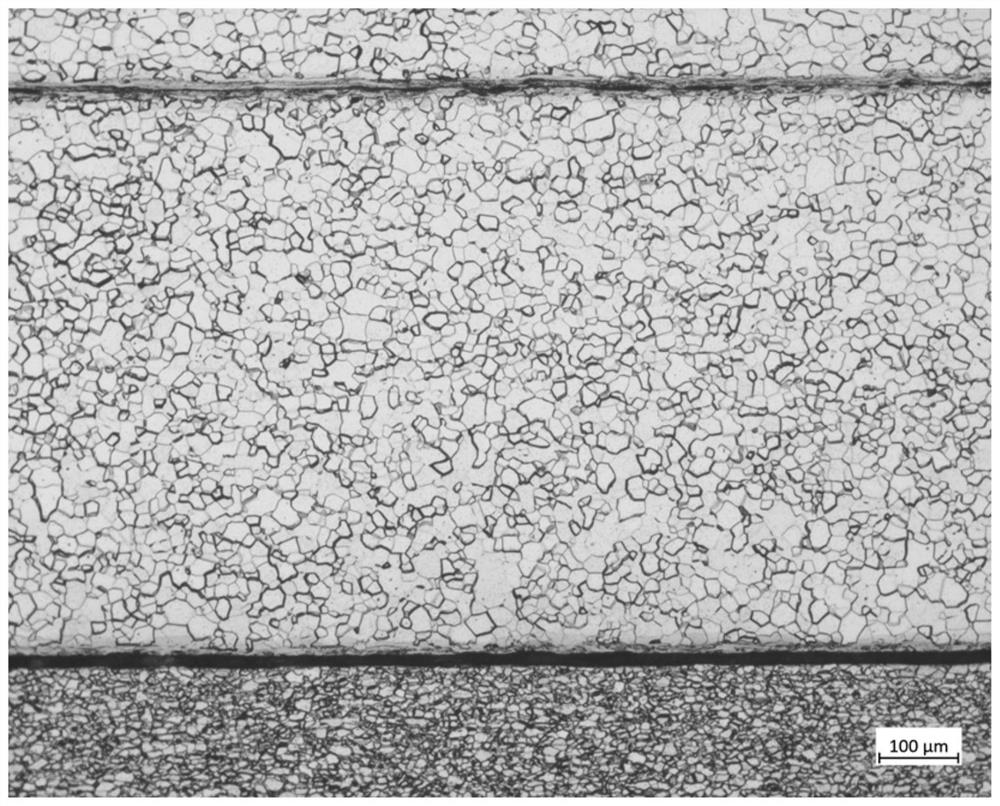

Continuous cast-rolling method of aluminum/aluminum composite boards

InactiveCN101885001ASimple processReduce energy consumptionTemperature control deviceMetal rolling arrangementsAluminum compositesSurface layer

The invention relates to a continuous cast-rolling method of aluminum / aluminum composite boards, comprising the following process steps of cast-rolling aluminum alloy, controlling temperature and heating a composite board. The heat treatment process of the composite board mainly comprises the following steps: firstly selecting the needed aluminum alloy component; cast-rolling the aluminum alloy component into the needed board thickness, wherein the board rolling temperature is 200-400 DEG C; heating the well-designed aluminum alloy board to be composited with a cast-rolling board, wherein the surface layer heating temperature is controlled at 560-720 DEG C, and the surface layer depth is controlled at 10-30% of the board thickness; laminating the heated aluminum alloy board and the cast-rolling board; entering a preheated secondary roller in advance to perform composite rolling, wherein the secondary roller preheating temperature is 100-400 DEG C; delivering a composite metal board after composite rolling into a heat treating furnace to perform diffusion, annealing and discharge; and air cooling to room temperature. The continuous cast-rolling method has the following major advantages that complicated chemical treatment on the aluminum plate surface is not needed, and interface metallurgical bonding of the aluminum / aluminum composite board is realized under smaller deformation conditions and deformation pressure by utilizing a cast-rolling method, thus obviously reducing the heat-rolling cost, and improving the interface bonding strength.

Owner:JIANGSU CAIFA ALUMINUM

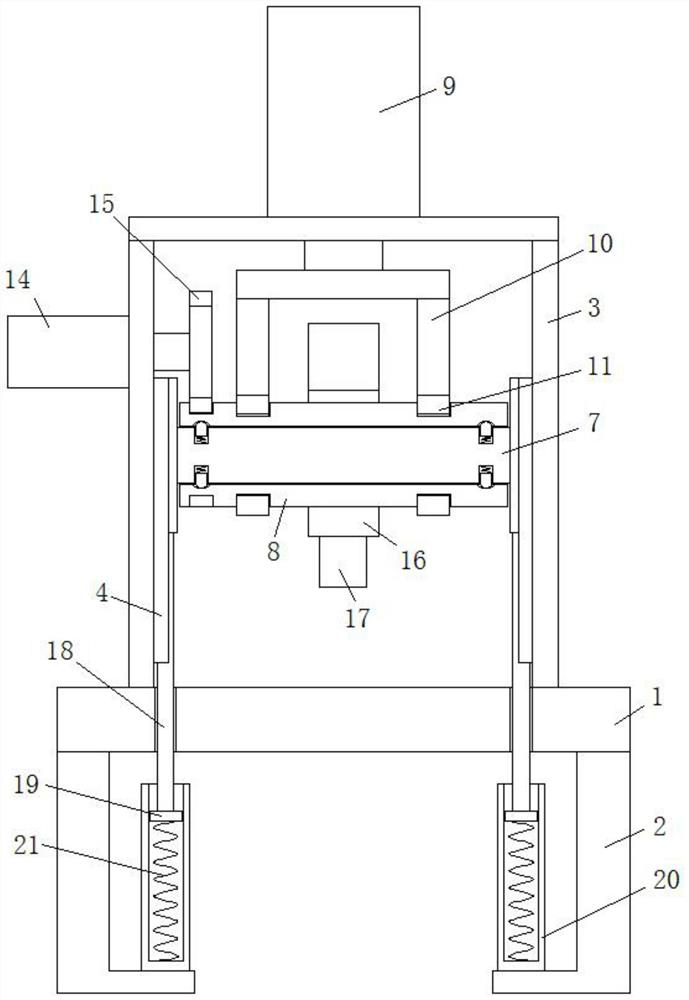

Automatic stamping device

ActiveCN108146089APlay the role of flexible cushioningEasy to adjustStampingCardboardPulp and paper industry

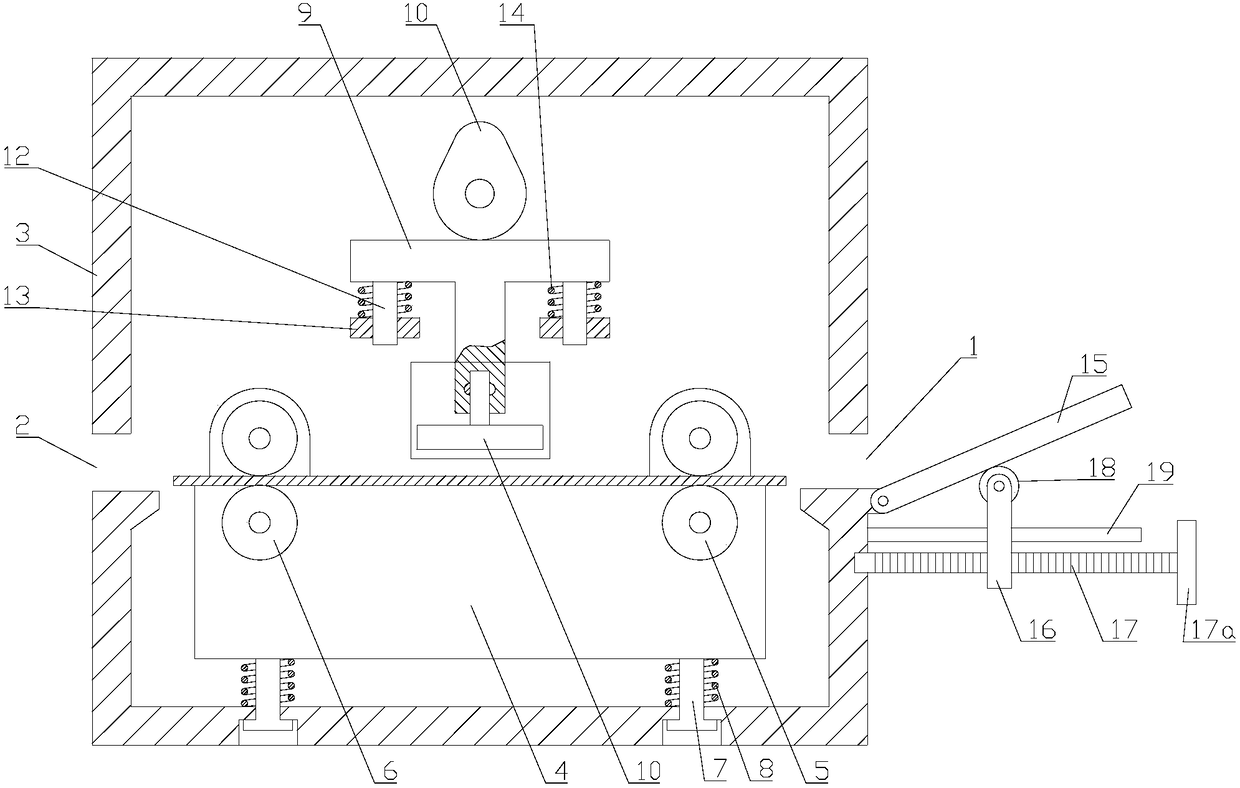

The invention provides an automatic stamping device. The automatic stamping device belongs to the technical field of stamping equipment. The automatic stamping device comprises a housing body providedwith a paper inlet and a paper outlet. A supporting mechanism is arranged on the lower portion of the inner side of the housing, and a stamping mechanism is arranged above the supporting mechanism. The supporting mechanism includes an imprinting platform. Both sides of the imprinting platform are correspondingly provided with a paper feeding roller and a paper discharging roller, and the imprinting platform is arranged on the housing body through a first guiding column and can be moved up and down. The bottom of the imprinting platform and the inner bottom wall of the housing are provided with a first spring, and the first spring is sleeved on the first guiding column. The automatic stamping device can ensure the effect of stamping and prolong the service life; the angle of the paper feeding board can be adjusted conveniently and is suitable for papers of different specifications; the seal adopts the structure of quick disassembly and assembly, and is convenient to replace, so that the working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

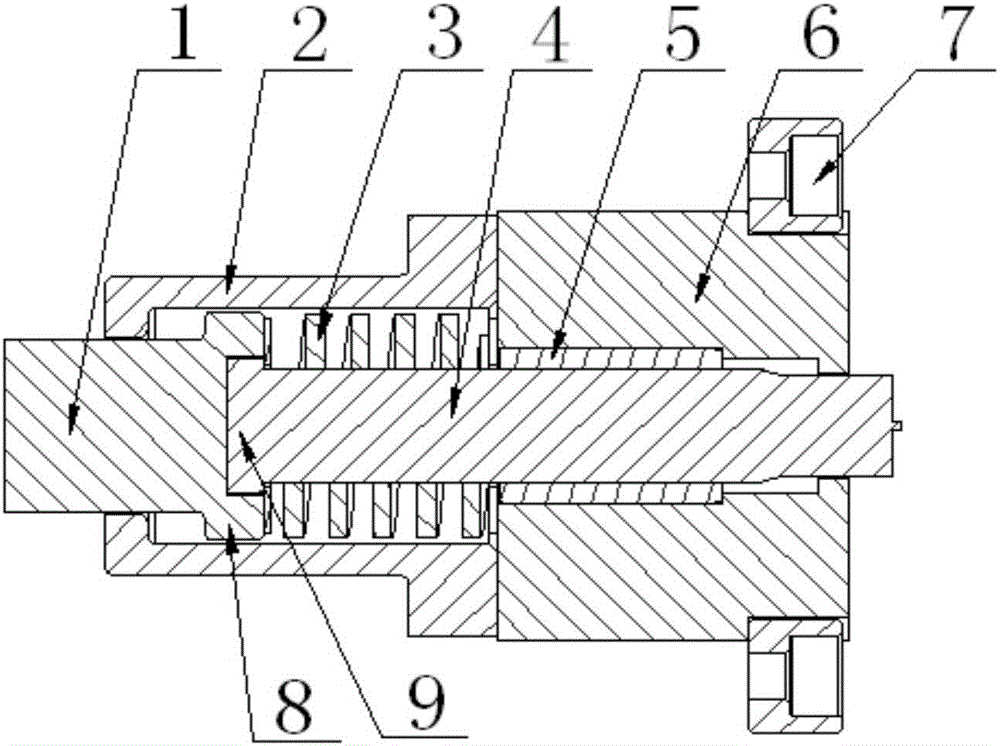

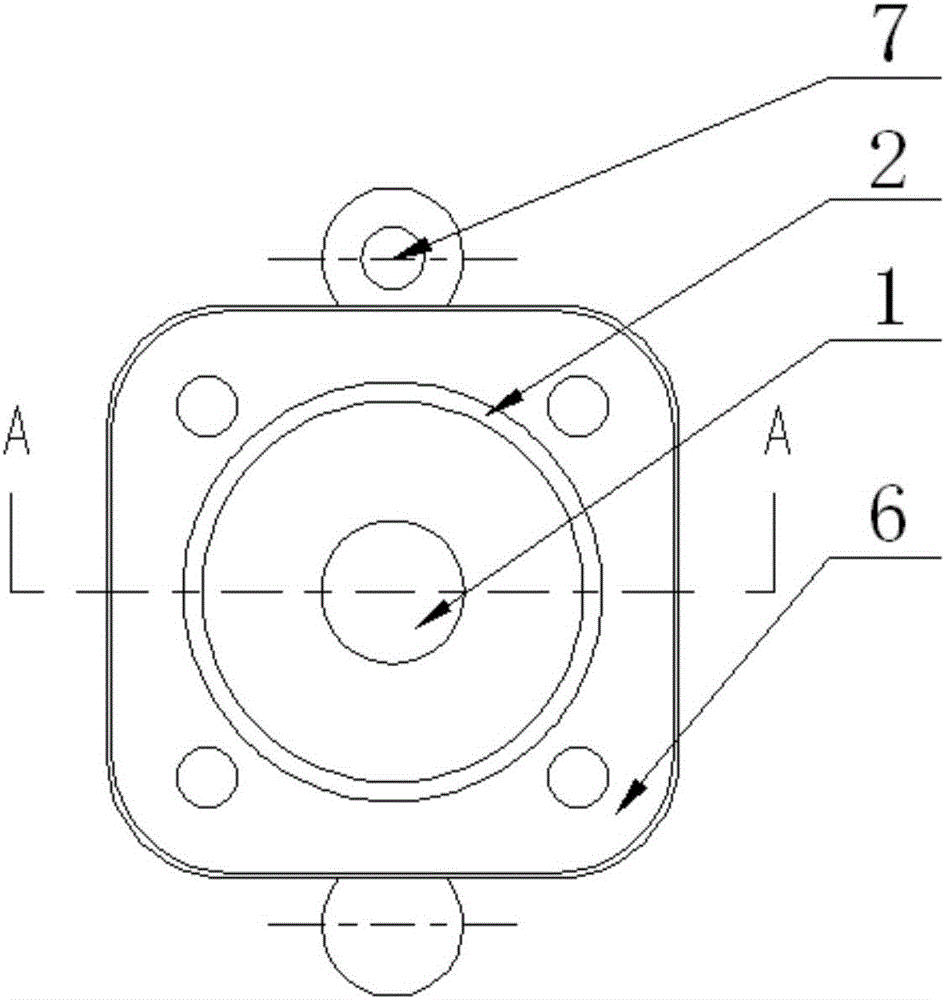

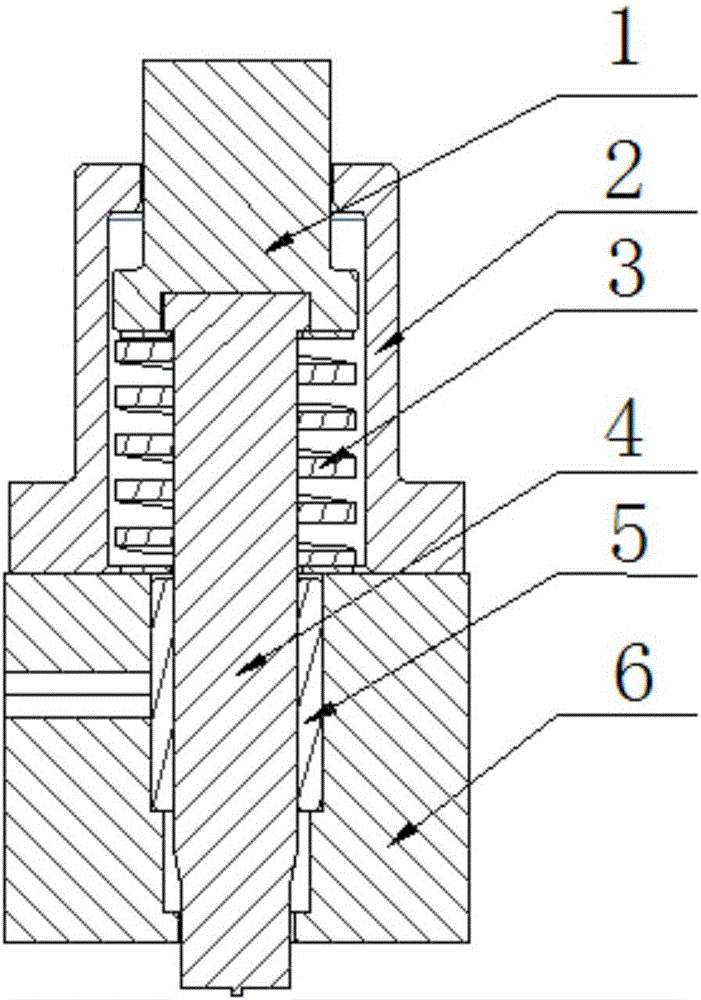

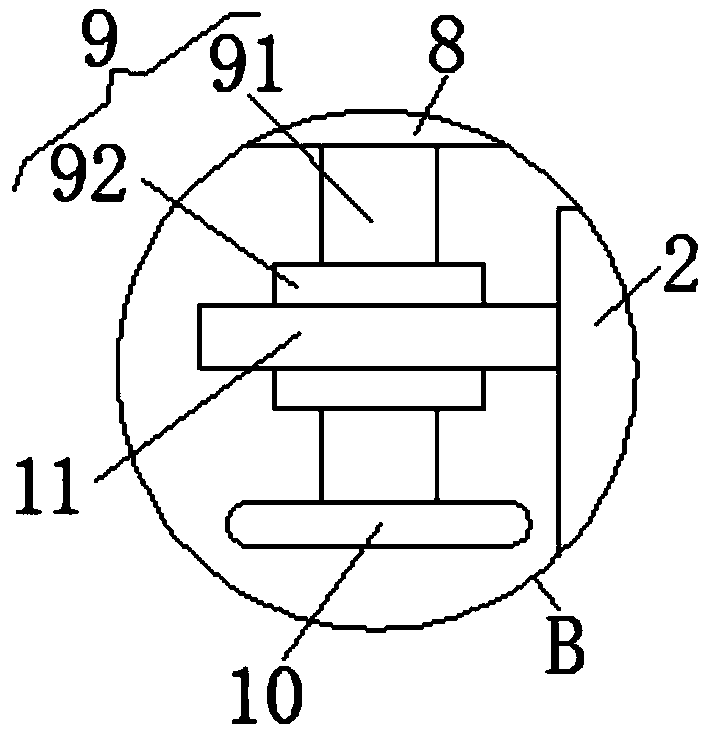

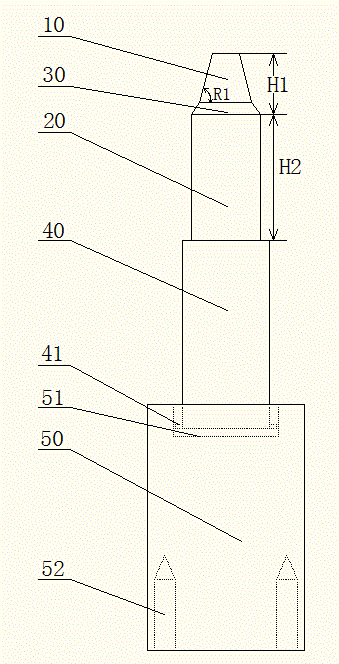

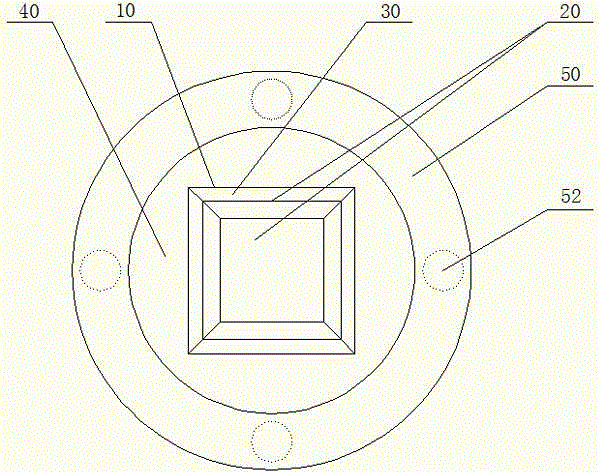

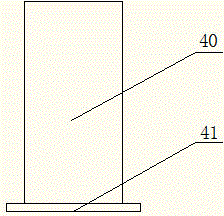

Stretchable punch pin mechanism for thermal stamping die

The invention relates to a stretchable punch pin mechanism for a thermal stamping die. The mechanism is characterized by comprising a punch pin sleeve, a spring sleeve, a punch pin, an impact block, a spring, a guide sleeve and base fixing blocks, wherein the spring sleeve is coaxially and fixedly mounted at the front end of the punch pin sleeve, the punch pin is coaxially mounted in the punch pin sleeve and the spring sleeve, the impact block is fixedly mounted at the front end of the punch pin, the rear end of the impact block is located in the spring sleeve, the front end of the impact block extends out of the spring sleeve, the spring coaxially sleeves between the punch pin and the spring sleeve, the guide sleeve is mounted between the punch pin and the punch pin sleeve, and the base fixing blocks are symmetrically and fixedly mounted on the side wall of the bottom end of the punch pin sleeve. The mechanism provided by the invention is scientific and reasonable in structural design, the punch pin is stretchable, the position is easy to adjust, the stability and safety in a punching process can be guaranteed, and materials are not wasted because a mould is prevented from being damaged.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

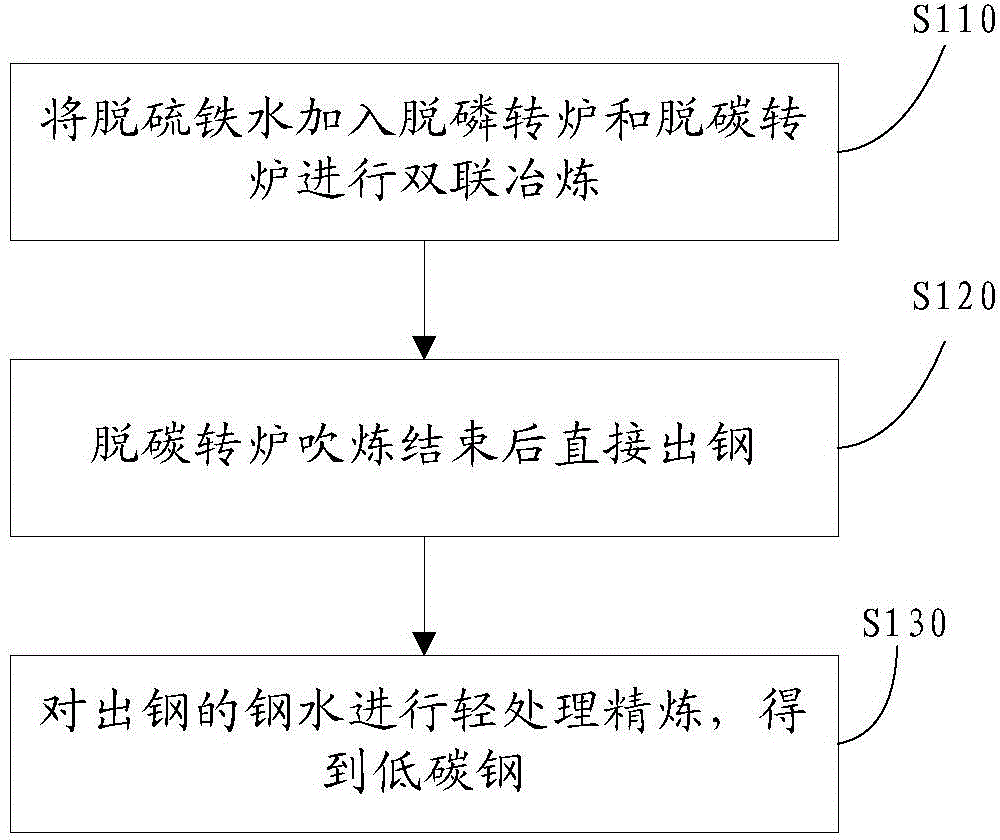

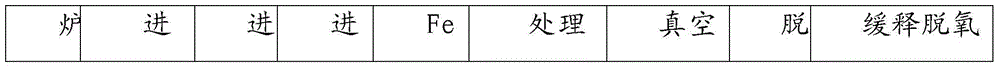

Low-carbon steel for deep drawing and smelting method thereof

InactiveCN104928558AShorten the smelting cycleReduce smelting costManufacturing convertersLight treatmentMolten steel

The present invention relates to the technical field of steel-making, and discloses a low-carbon steel for deep drawing and a smelting method thereof. The method comprises: adding desulfurized molten iron into dephosphorization converter and decarbonization converter for duplex smelting; blowing in decarbonization converter and directly tapping, which is tapping without converter deoxidation; carrying out light treatment refining process on the molten steel after tapping to obtain low-carbon steel for deep drawing. The method not only shortens the refining cycle, but also reduces the cost of smelting.

Owner:SHOUGANG CORPORATION

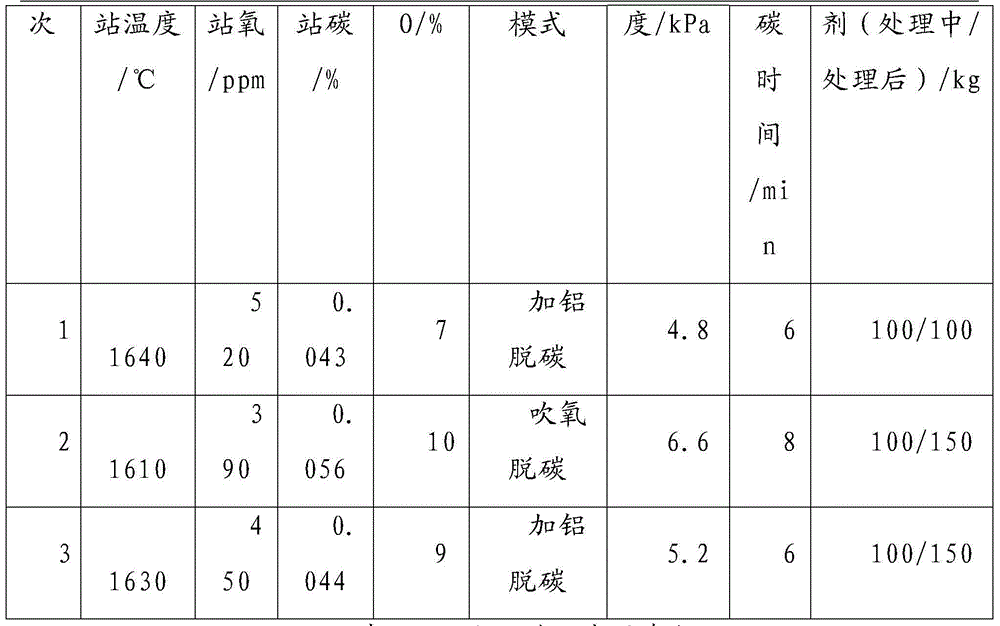

Full-automatic auxiliary stamping equipment for machining packing box base plate holes and operation method

PendingCN106863901AQuick resetGood stepping actionBox making operationsPaper-makingCardboardPunching

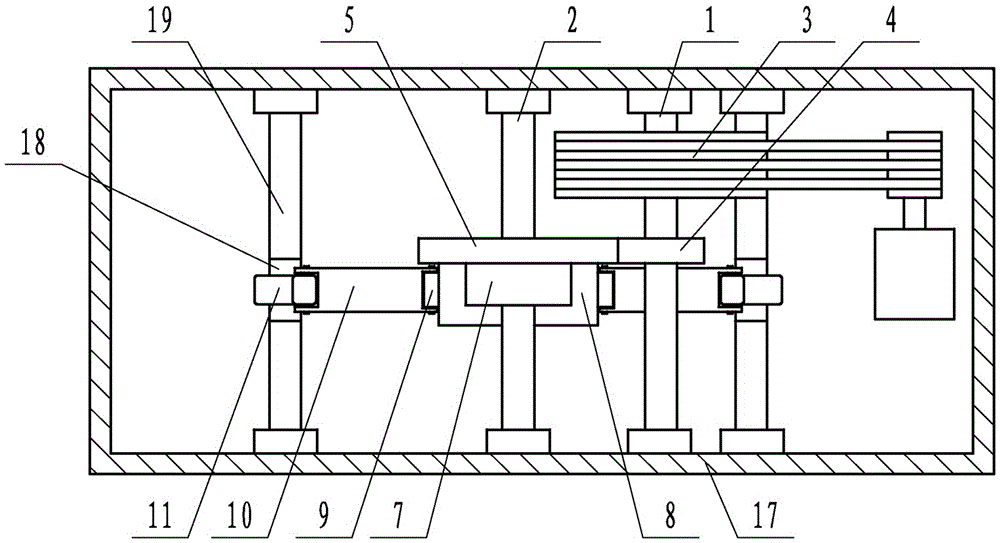

The invention provides full-automatic auxiliary stamping equipment for machining packing box base plate holes and an operation method. An output shaft of a punching drive motor is provided with a first belt wheel, and the first belt wheel and a first driven wheel form belt drive through a first belt. A spindle where the first driven wheel is located is provided with a first gear. The first gear is connected with a crankshaft through a multistage gear reduction mechanism. The crankshaft is provided with a connecting rod in a sleeving mode, and the other end of the connecting rod is hinged to a stamping head. The bottom end of the stamping head is provided with a punching pin making contact with paperboards to be stamped. A stamping die is installed on a paperboard feeding workbench. The paperboard feeding workbench is connected with a finished product collecting device, and the other end of the paperboard feeding workbench is provided with a stepping material return device. According to the full-automatic auxiliary stamping equipment, automatic feeding, automatic stamping, automatic finished product collecting and leftover collecting can be performed, and therefore the machining efficiency of paper box base plates is greatly improved, the labor intensity of operators is relieved, and production cost is reduced.

Owner:宜昌佳艺包装有限责任公司

Stamping die with accurate positioning function

InactiveCN102873192AGuaranteed stamping effectShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses a stamping die with an accurate positioning function. The stamping die comprises a lower die base and a lower die arranged on the lower die base, wherein a front baffle block is arranged on the lower die base on the left side of the lower die; and scale strips are arranged on the upper and lower sides of the front baffle block. The problem that the position of a material cannot be accurately controlled during stamping in the prior art is solved; and the front baffle block which can move in a corresponding sliding groove is arranged on one side of the lower die, and the displacement of the front baffle block is accurately controlled through the scale strips on the two sides of the front baffle block, so that the material is accurately positioned, and a stamping effect is ensured.

Owner:KUNSHAN XINJIASONG TRADE

Automatic device for metal plate stamping

The invention discloses an automatic device for metal plate stamping and relates to the technical field of stamping equipment. The automatic device for metal plate stamping comprises a base, and the upper surface of the base is fixedly connected with the lower surface of a fixed block; the upper surface of the fixed block is provided with a groove; the lower surface of the inner wall of the grooveis provided with a mold groove; the lower surface of the inner wall of the groove is fixedly connected with the bottom ends of two first telescopic devices, and the top ends of the two first telescopic devices are each fixedly connected with a movable plate; and the upper surfaces of the two movable plates are both in lap joint with the lower surface of a plate body. According to the automatic device for metal plate stamping, due to the joint effects of a motor, a first rotating shaft, a threaded column, a threaded cap, a connection rod, a connection plate, an extruding block, a stamping block and a second spring, buffering stamping on the plate body is achieved, stamping of the stamping block on the fixed block is buffered, damage to the stamping block and the fixed block is reduced, andtherefore the service life of the stamping block and the fixed block is guaranteed.

Owner:柳州市钜嘉机械有限公司

Preparation method for high-performance stamping cold-rolled and galvanized steel strip

InactiveCN104946971AGuaranteed concentrationGuaranteed processing performanceHot-dipping/immersion processesChemical compositionStrip steel

The invention discloses a preparation method for a high-performance stamping cold-rolled and galvanized steel strip. The preparation method is characterized in that the steel strip comprises the following chemical components in percentage by mass: 0.01-0.06% of C, 0.10-0.50% of Mn, less than or equal to 0.020% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Si, greater than or equal to 0.020% of Als, greater than or equal to 0.0040% of N, and the balance of Fe and impurities within a permissible range. The method comprises a holt rolling process, a cold rolling process and a galvanizing process, wherein in the hot rolling process, a heating temperature of steel billet is 1100-1200 DEG C, the heat preservation is carried out for 1-2 hours, and a final-rolling temperature is 890-910 DEG C; a cooling mode adopts a front-stage cooling mode, and a rolling temperature is 670-700 DEG C; in the galvanizing process, the heating temperature of the strip steel is 760-830 DEG C, the soaking temperature is 760-810 DEG C, an annealing cooling rate is greater than or equal to 20 DEG C / s, and the strip steel is added into a zinc pot when being cooled to 460-490 DEG C; and during cooling after plating, overaging time of the strip steel is guaranteed to be greater than or equal to 50s. According to the preparation method disclosed by the invention, the stamping surface and the applicability in various purposes of a product are greatly improved; and the product is guaranteed to be prevented from stamping problems such as transverse grains and the like in a processing and forming process.

Owner:TANGSHAN IRON & STEEL GROUP

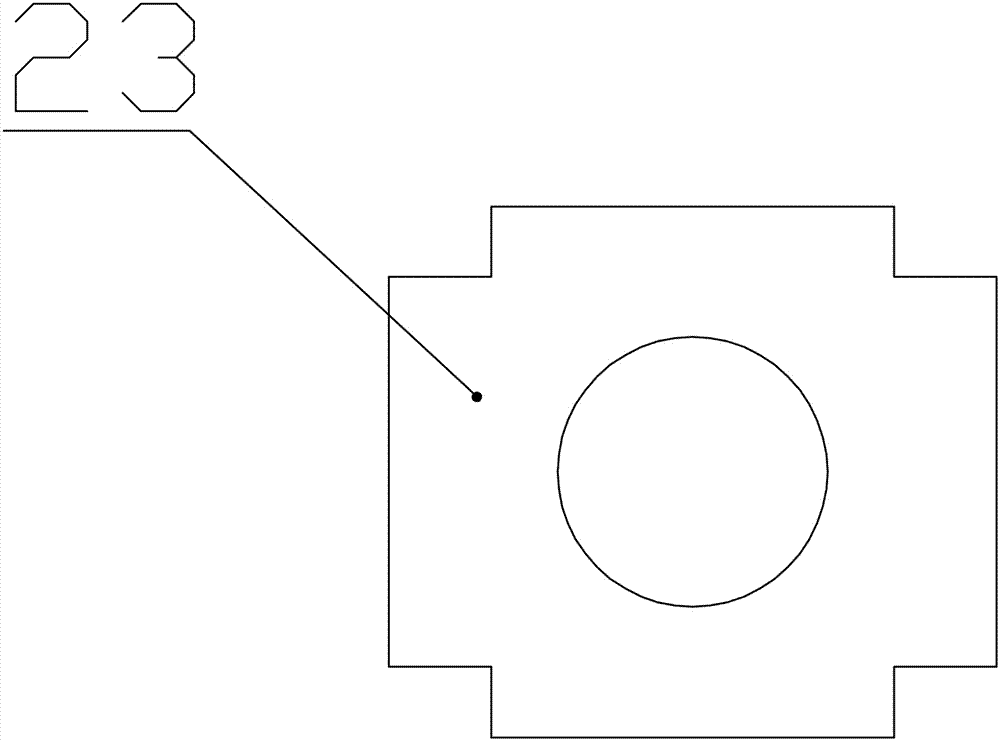

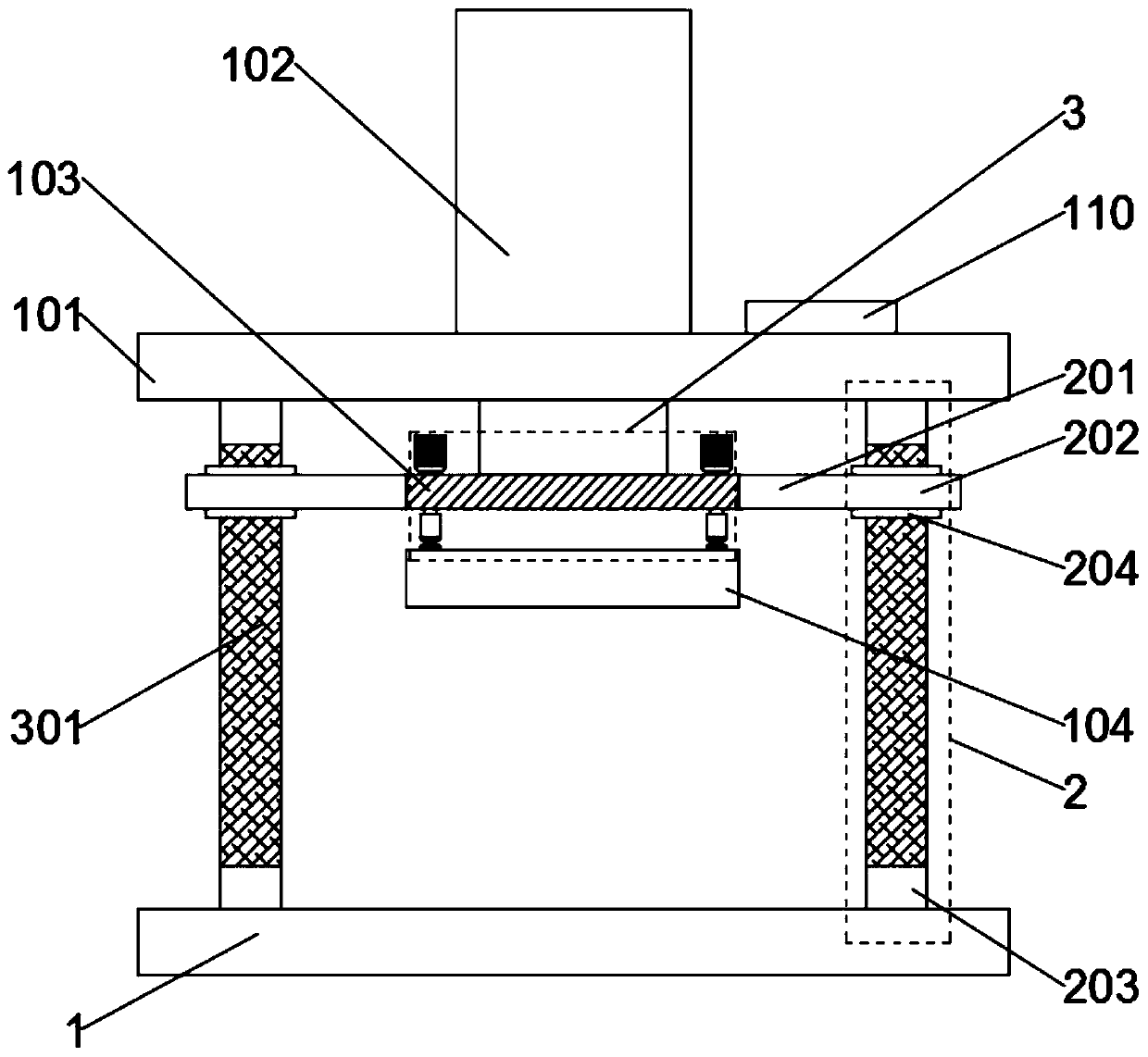

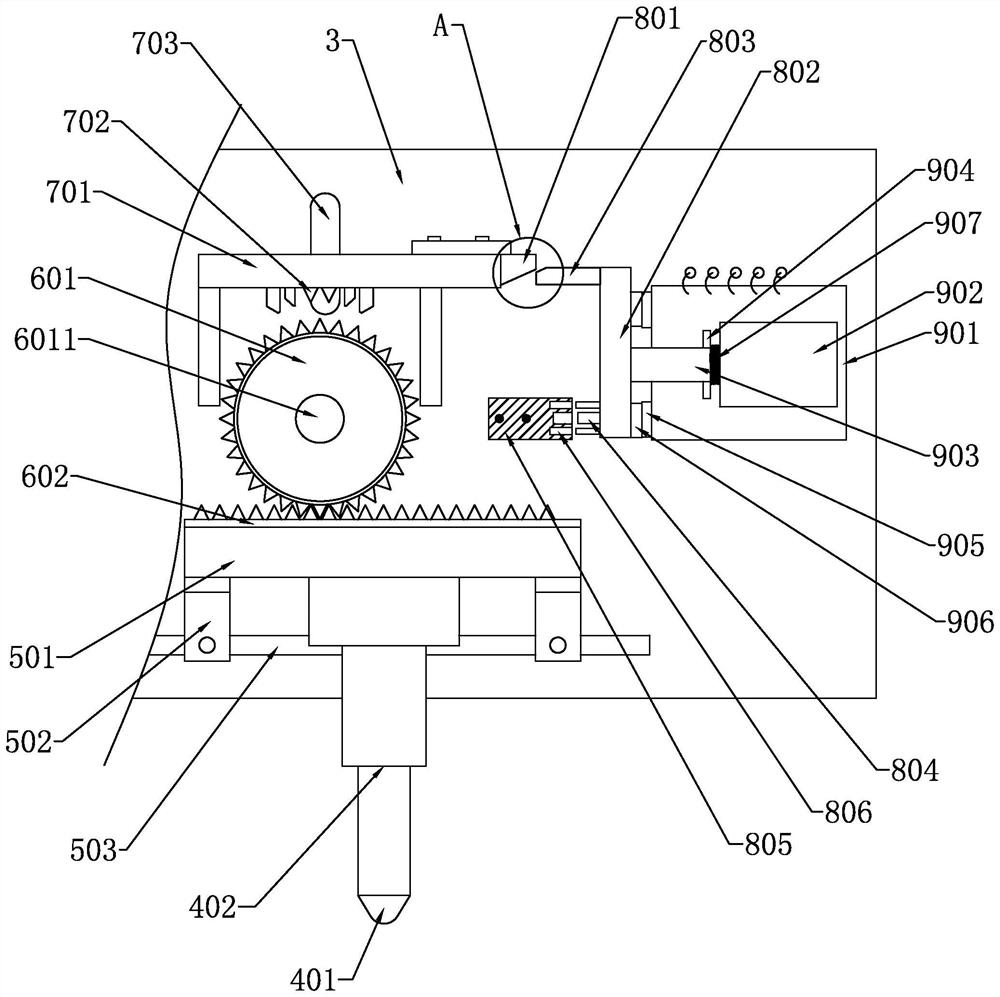

Stamping device for buckle plate of hardware lock body with adjustable rack

InactiveCN108714642AGuaranteed stamping effectNo need for manual removalMetal-working feeding devicesStripping-off devicesEngineeringMotherboard

The invention discloses a stamping device for a buckle plate of a hardware lock body with an adjustable rack. The device comprises the rack and a main bottom plate, wherein vertical main plates are fixed to the left and right sides of the top surface of the main bottom plate; upper supporting blocks are fixed to the upper parts of the outer side walls of the two vertical main plates; a main top plate is fixed to the top surfaces of the two upper supporting blocks; a main stamping oil cylinder is fixed to the top surface in the middle of the main top plate; a push rod of the main stamping oil cylinder penetrates the main top plate and a lifting connecting plate is fixed to the push rod; an upper mold mounting block is fixed to the bottom surface of the lifting connecting plate; an upper mold is fixed to the bottom surface of the upper mold mounting block; and two stamping blocks are formed on the bottom surface of the upper mold; connecting plates are fixed to the upper parts of opposite walls of the two vertical main plates. The height position of the lower mold can be adjusted precisely when plate bodies of different thicknesses are stamped, so that the stamping depth of the stamping block of the lower mold is matched that of the upper mold, and the plate body stamping effect is kept. Moreover, stamping waste can be discharged automatically to discharging through holes, and can fall automatically as a positioning block falls.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

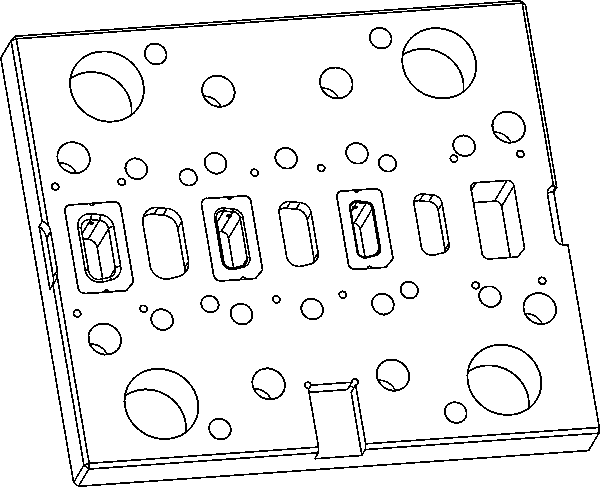

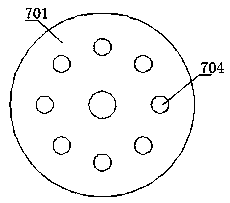

Die device capable of saving stamping oil

The invention discloses a die device capable of saving stamping oil. The device comprises a lower die plate, wherein a plurality of machining die mounting through holes are formed in the top surface of the lower die plate, a die block is inserted into the corresponding machining die mounting through hole, a flow guide oil storage tank is formed in the top surface of the lower die plate, and the flow guide oil storage tank communicates with all the machining die mounting through holes. According to the device, the added stamping oil can be injected into the flow guide oil storage tank, the flowguide oil storage tank communicates with the die blocks, so that when the lower die plate and an upper die plate are pressed together, the stamping oil in the flow guide oil storage tank can enter the die block to lubricate a stretching stamping part, the surface of the stretching stamping part is prevented from being scratched easily, the stamping effect is guaranteed, the stamping oil cannot overflow, and the waste of the stamping oil is reduced.

Owner:DONGGUAN DINGTONG PRECISION METAL CO LTD

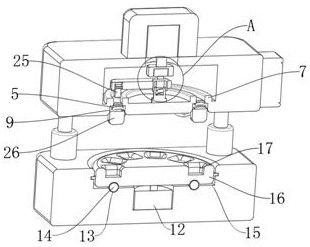

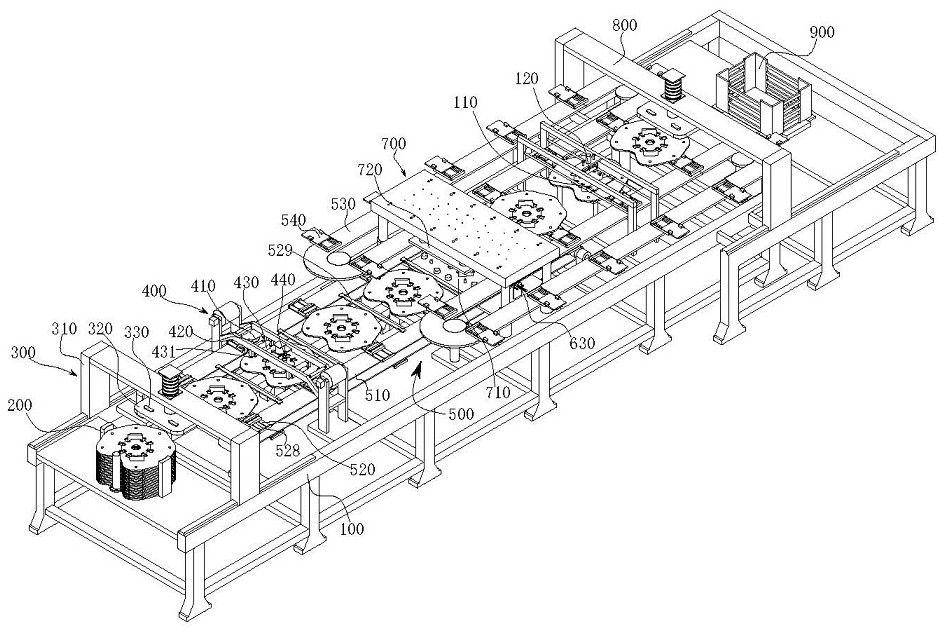

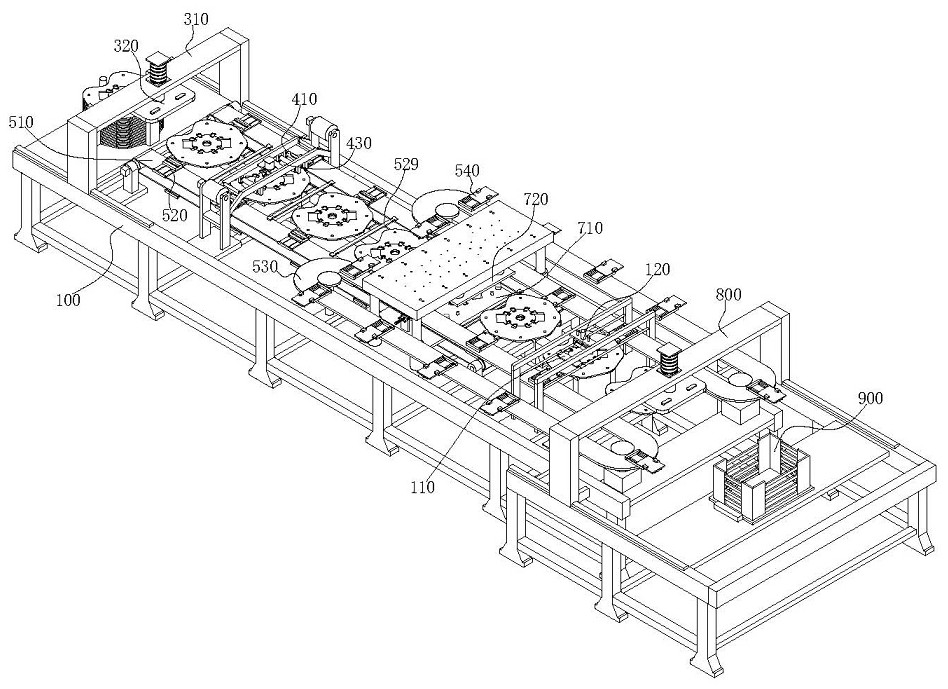

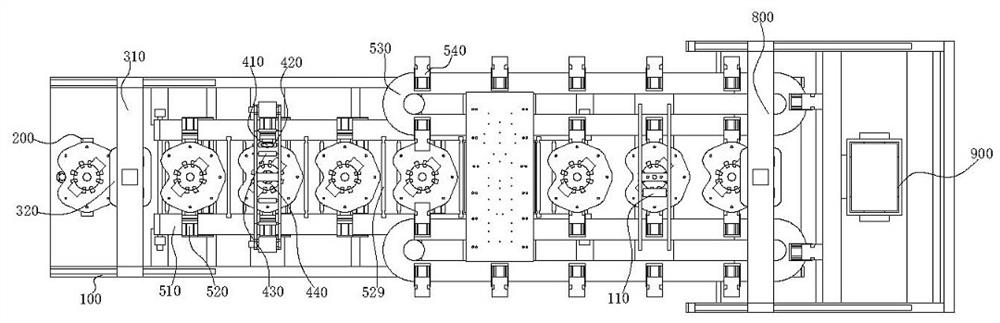

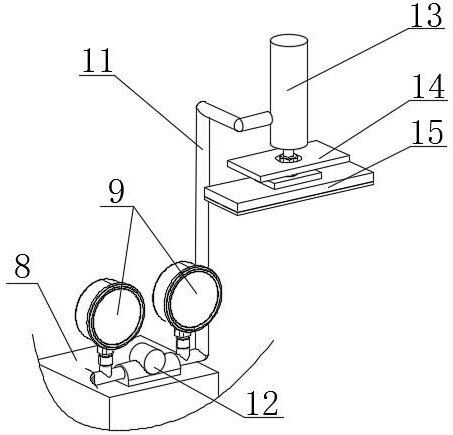

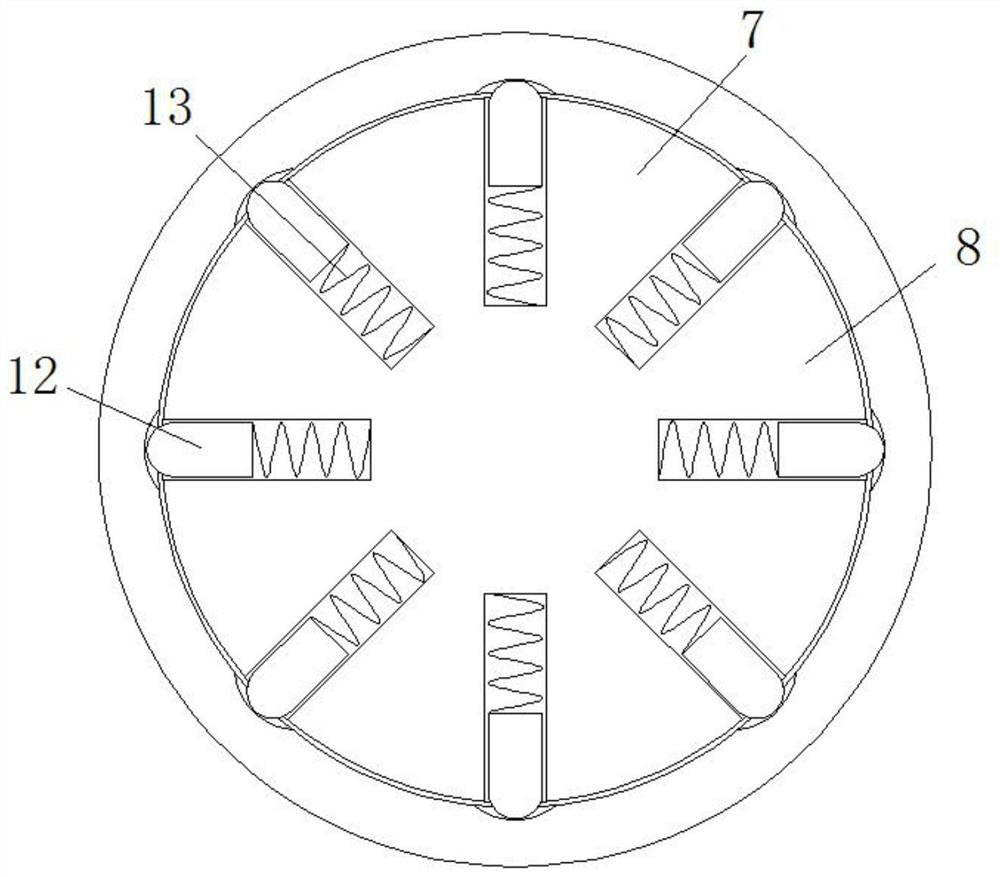

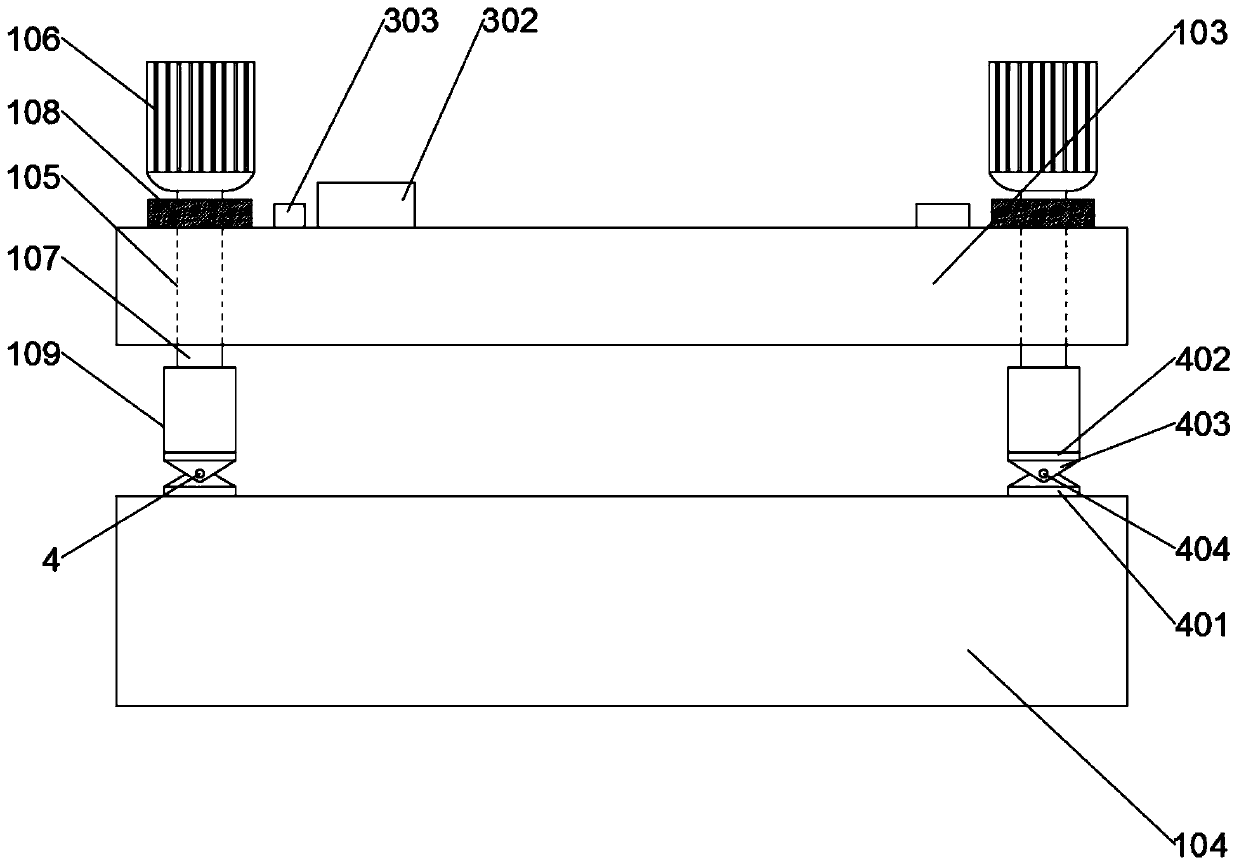

Magnetic shoe stator assembly machine for increasing utilization rate of equipment

ActiveCN106712405AReduce manpower consumptionImprove assembly efficiencyManufacturing stator/rotor bodiesManipulatorStator

The invention relates to a magnetic shoe stator assembly machine for increasing the utilization rate of equipment. The magnetic shoe stator assembly machine comprises a rack and a distribution control box, wherein stamping devices are arranged on the rack, a detection device and a magnetizing device are respectively arranged on both sides of the front part, a material rotating device is arranged on the front side, the material rotating device comprises a fixed automatic universal arm, a material rotating connecting plate is connected to the automatic universal arm, a gripper which is matched with a product is arranged below the material rotating connecting plate, the gripper comprises a clamping cylinder which is arranged below the material rotating connecting plate, clamping movable blocks are connected to both sides of the clamping cylinder, clamping blocks which are matched each other are arranged below the clamping movable blocks, a feeding device which is matched with the product is arranged on the rack, and the feeding device is matched with the stamping devices through a feeding manipulator. According to the magnetic shoe stator assembly machine, integrated automatic operation of a plurality of stator assembly processes is realized, and two stamping devices are designed, so that the utilization efficiency of the material rotating device can be improved, double-line stamping can be matched, and the assembly efficiency can be further improved.

Owner:ANHUI DALAI MOTOR CO LTD

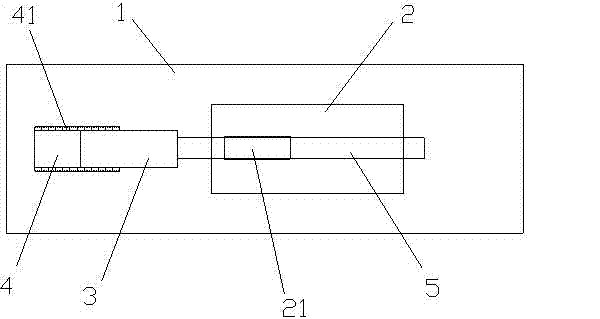

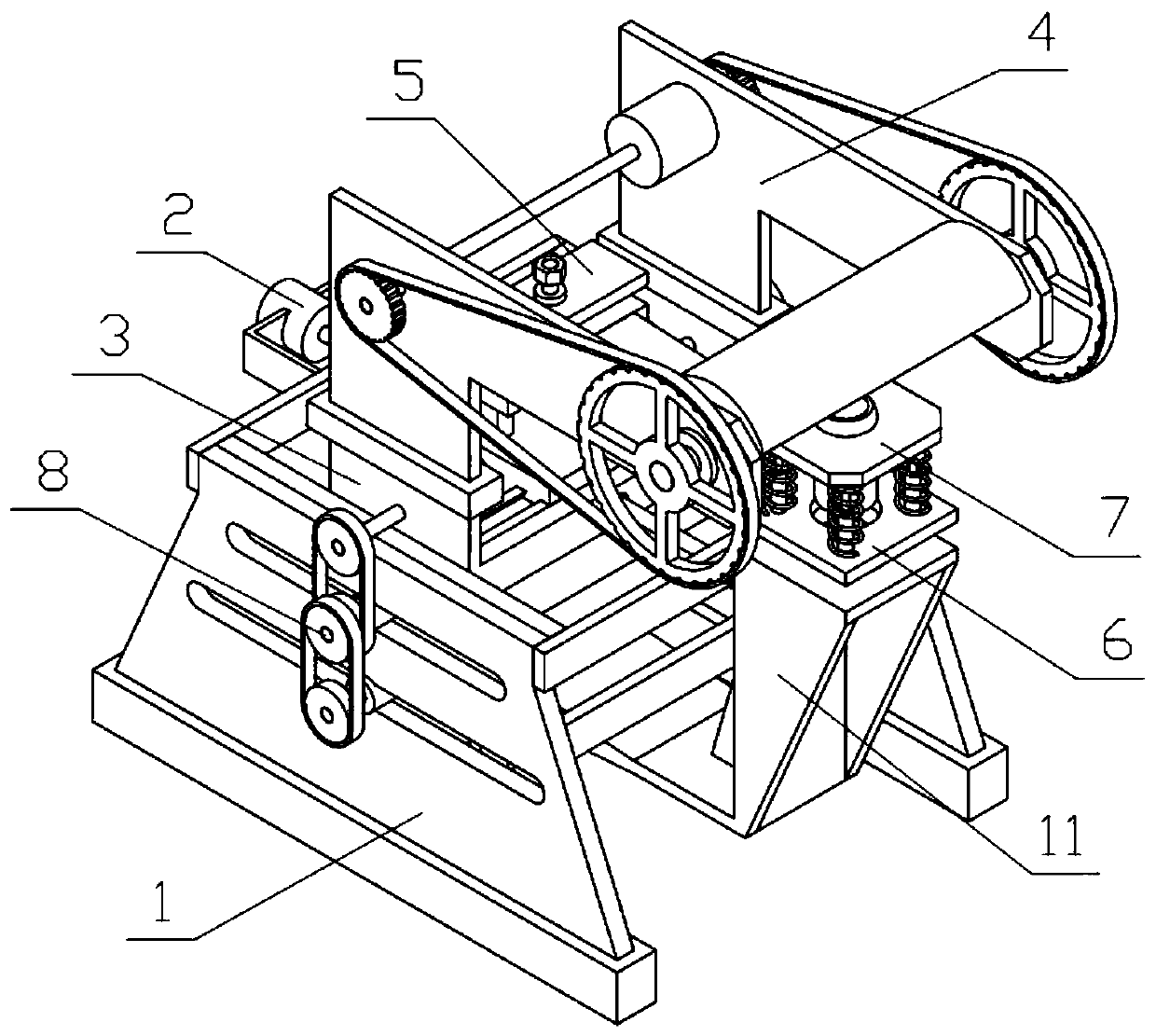

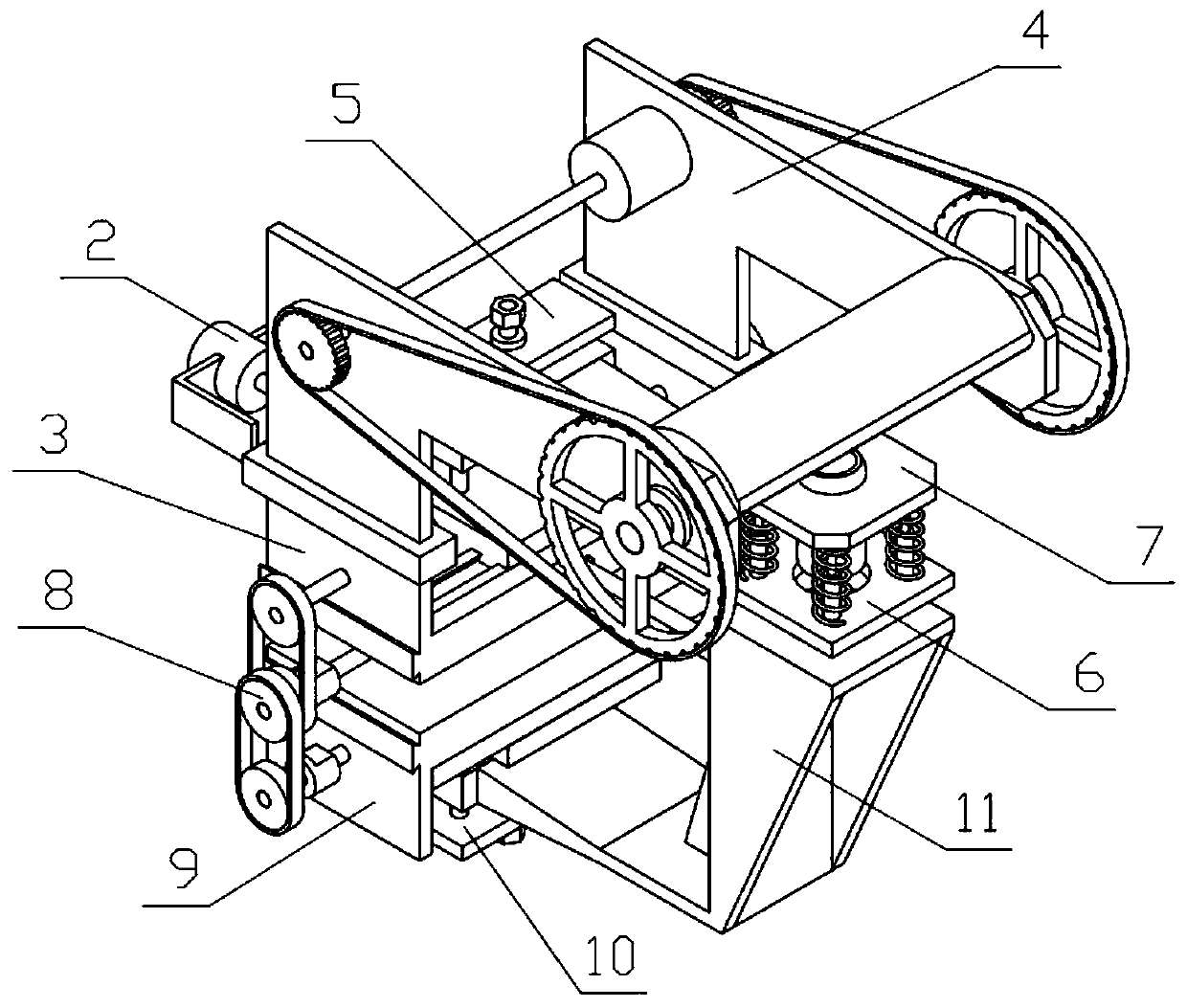

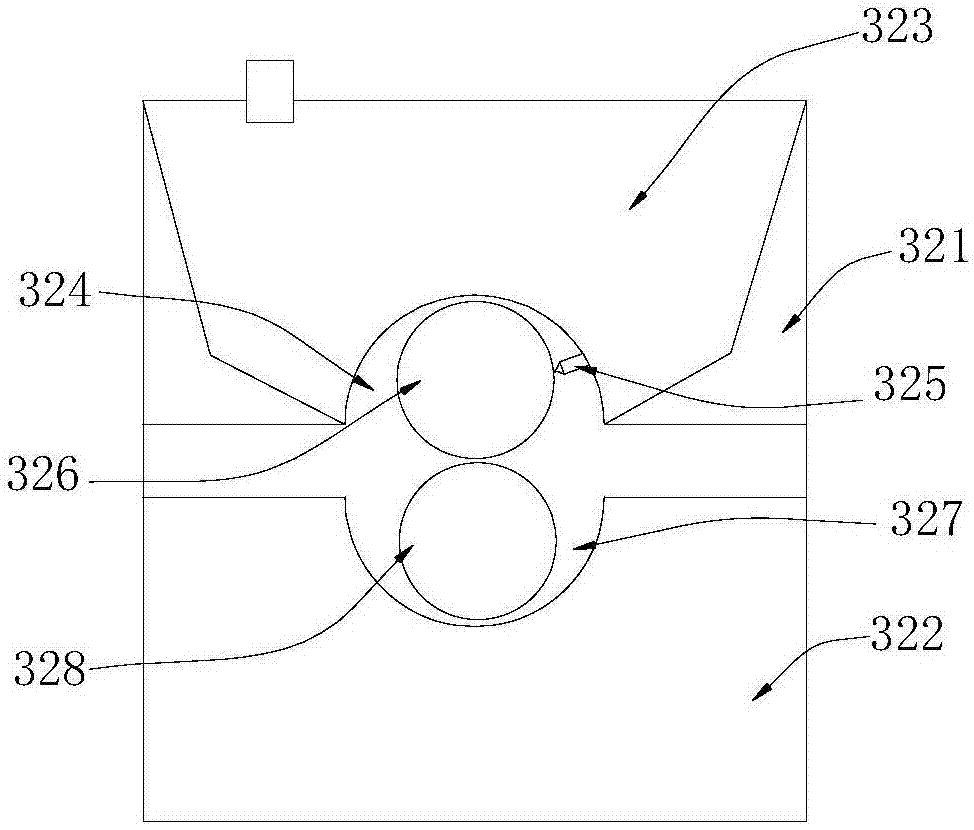

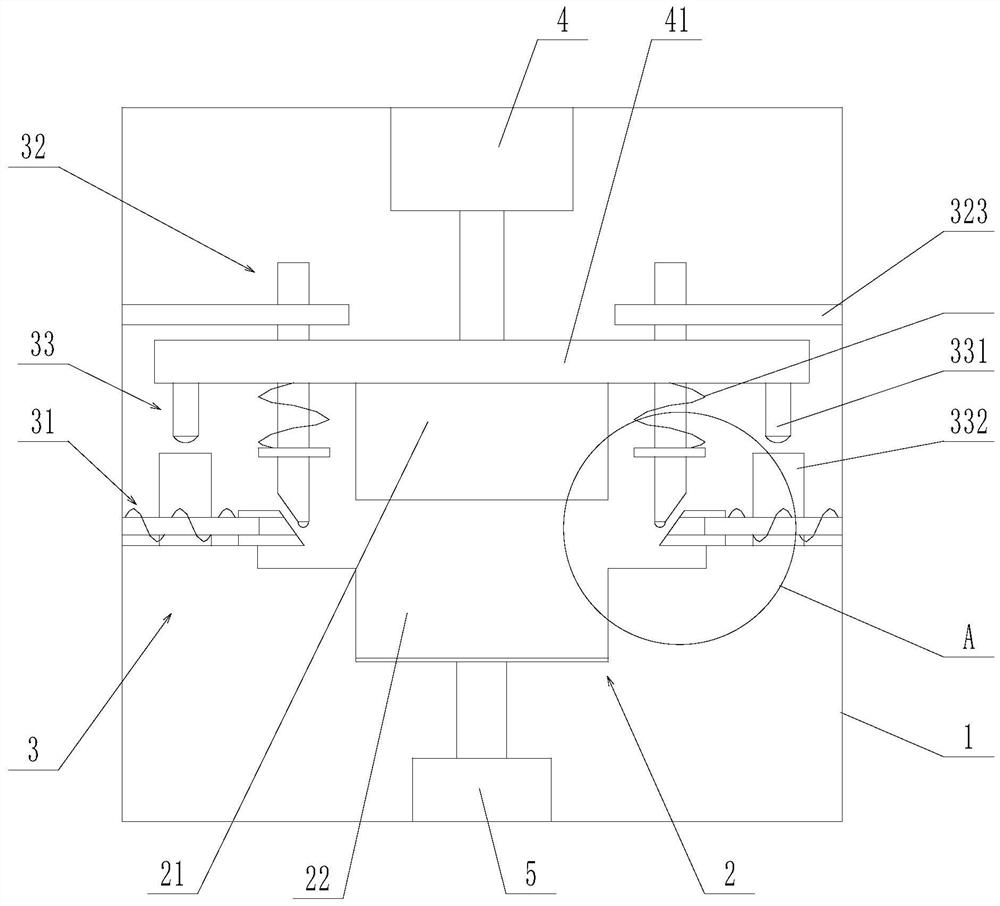

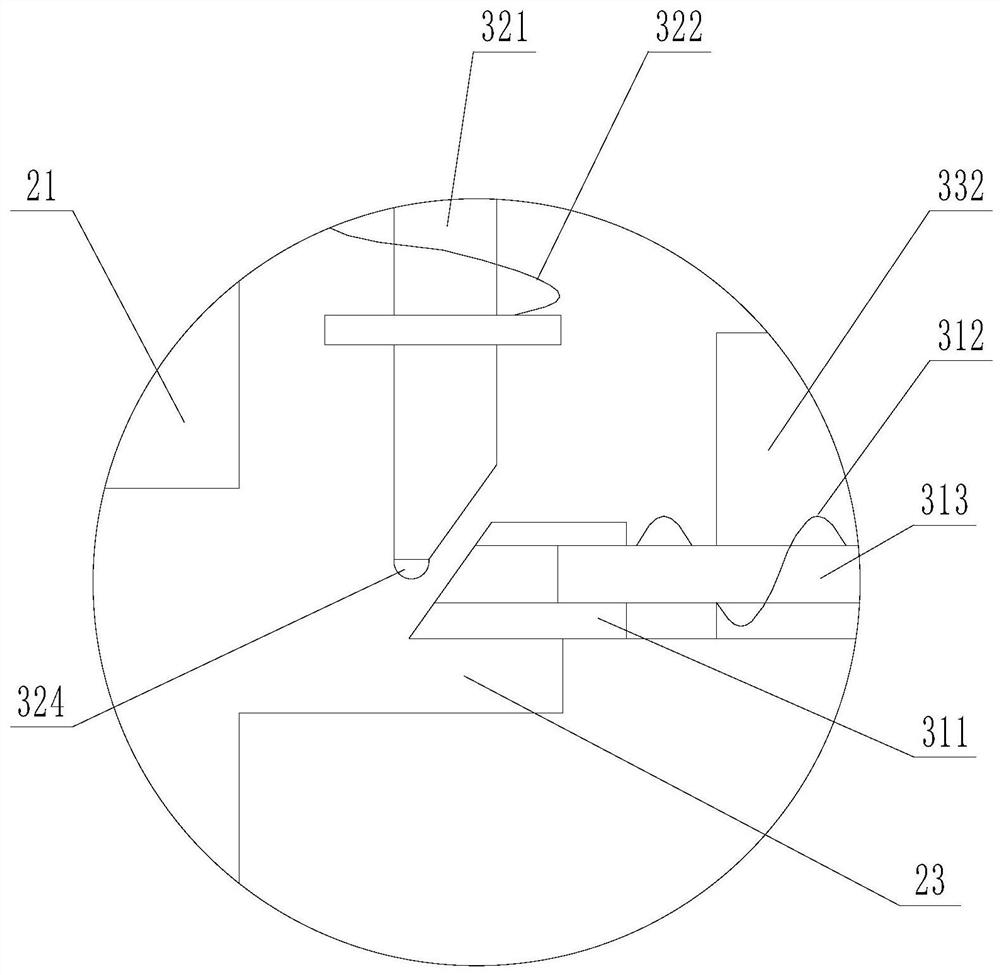

Working method of intelligent stamping device

ActiveCN111531053AReduce punching forceGuaranteed stamping effectMetal-working feeding devicesPositioning devicesStampingCrank

The invention relates to stamping devices, in particular to a working method of an intelligent stamping device. The intelligent stamping device comprises an underframe, a supporting frame, a stampingplatform, a hold-down mechanism, two clamping mechanisms, a lifting gear, a lifting rack, a power mechanism, a transmission mechanism I, a transmission mechanism II, a stamping crank, a stamping connecting rod, a stamping die and a tensioning mechanism. According to the intelligent stamping device, the two clamping mechanisms can be simultaneously driven by the hold-down mechanism to clamp plateswith different thicknesses and lengths; the transmission ratio of the transmission mechanism I to the transmission mechanism II is adjusted while the hold-down mechanism drives the two clamping mechanisms to move to clamp a plate, so that the transmission ratio of the transmission mechanism I to the transmission mechanism II adapts to the change of the plate thickness; the device generates a highstamping force when the plate is thick so as to guarantee the stamping effect; and the device generates a low stamping force when the plate is thin so as to guarantee the stamping efficiency.

Owner:湛江市顺泽实业有限公司

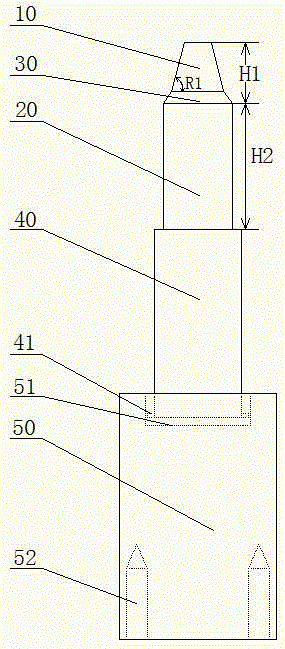

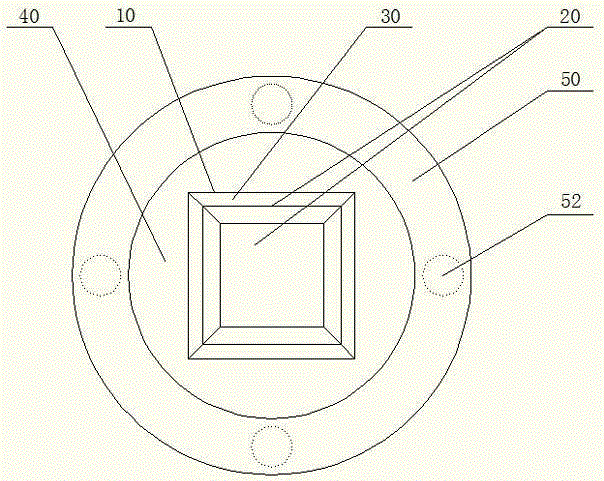

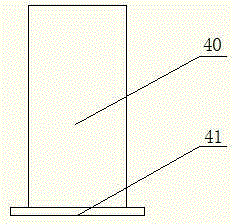

Square hole punch chip used on punch press

InactiveCN104014635AExtended service lifeGood punching effectPerforating toolsPunch pressPositive pressure

The invention relates to a square hole punch chip used on a punch press. The square hole punch chip used on the punch press comprises a punch chip body of which the cross section is square, the end of the punch chip body is provided with a guide head of which the orthographic protection is trapezoidal, the upper portion of the guide head is narrow, the lower portion of the guide head is wide, the cross section of the guide head is square, the transition face of the guide head and the punch chip body is a slope, and the inclination angle of the transition face is smaller than the base angle of the guide head. According to the square hole punch chip used on the punch press, the expansive force of outward deformation of products is increased through the guide head, and consequently positive pressure on the punch chip body from the products is decreased; the contact face of the punch chip body and the products is enlarged through the inclined transition face, impact force between the punch chip body and the products is reduced, and consequently the square hole punch chip is more resistant to abrasion and longer in service life, and the stamping effect of a square hole is ensured.

Owner:SUZHOU CHUANGFENG PRECISION HARDWARE

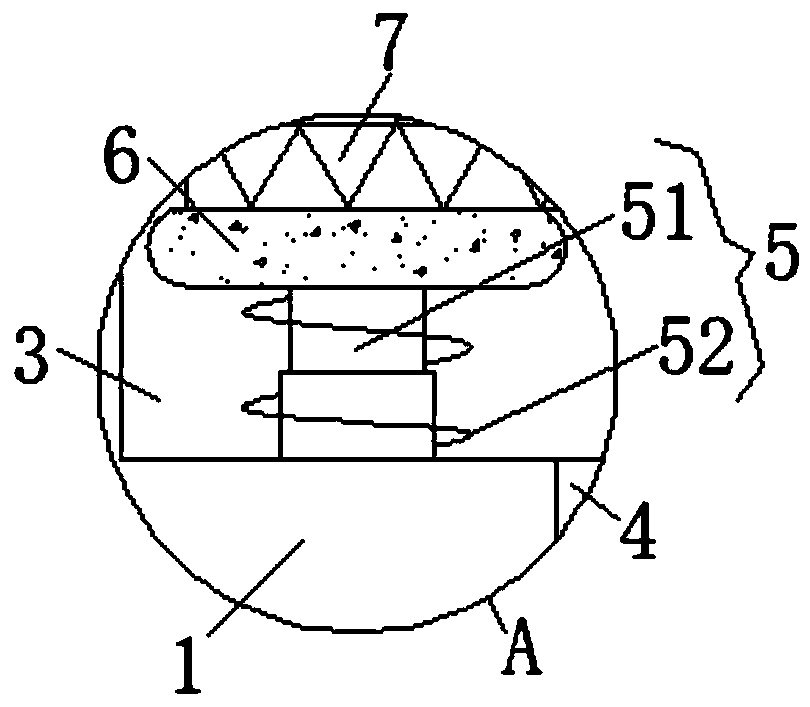

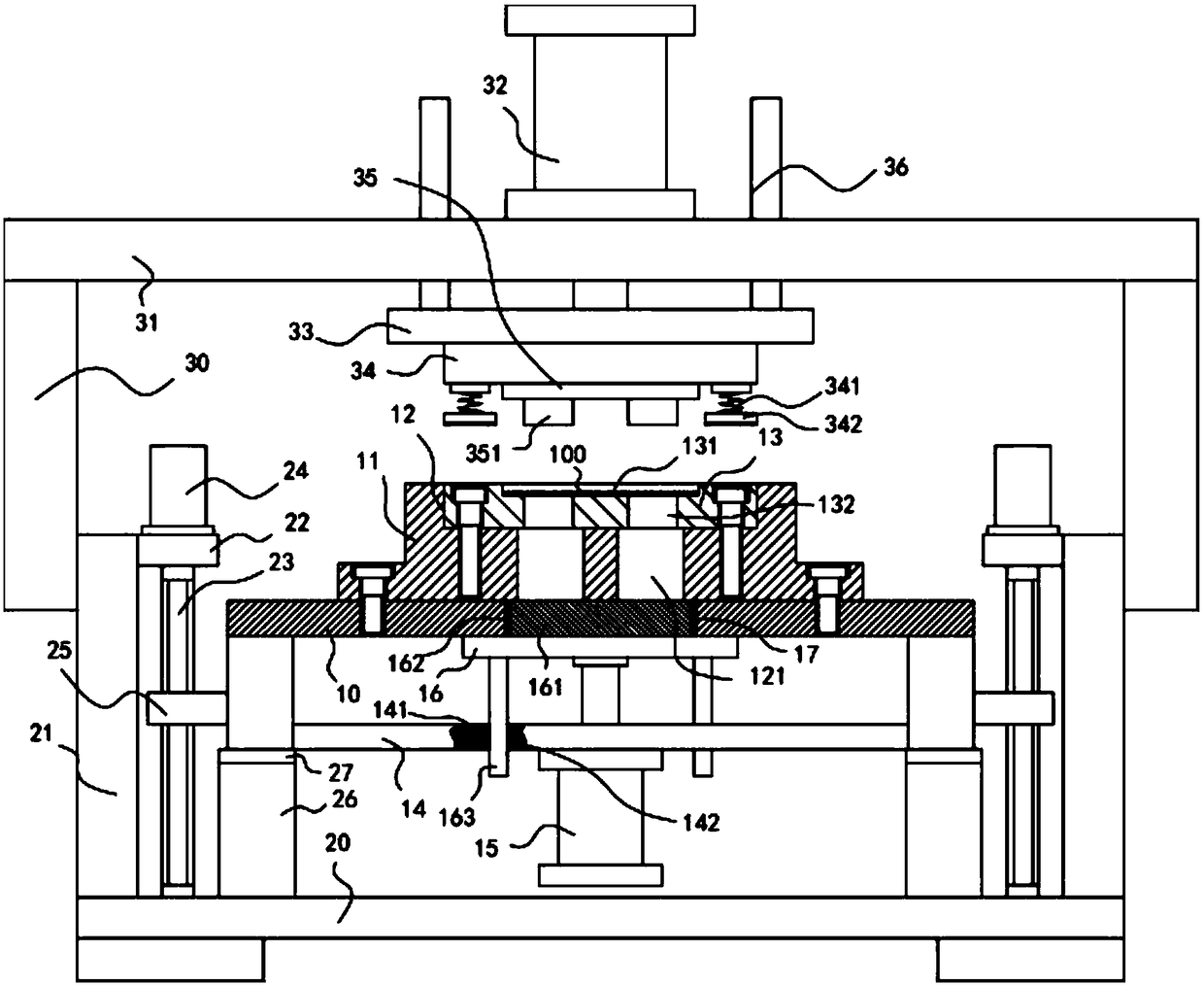

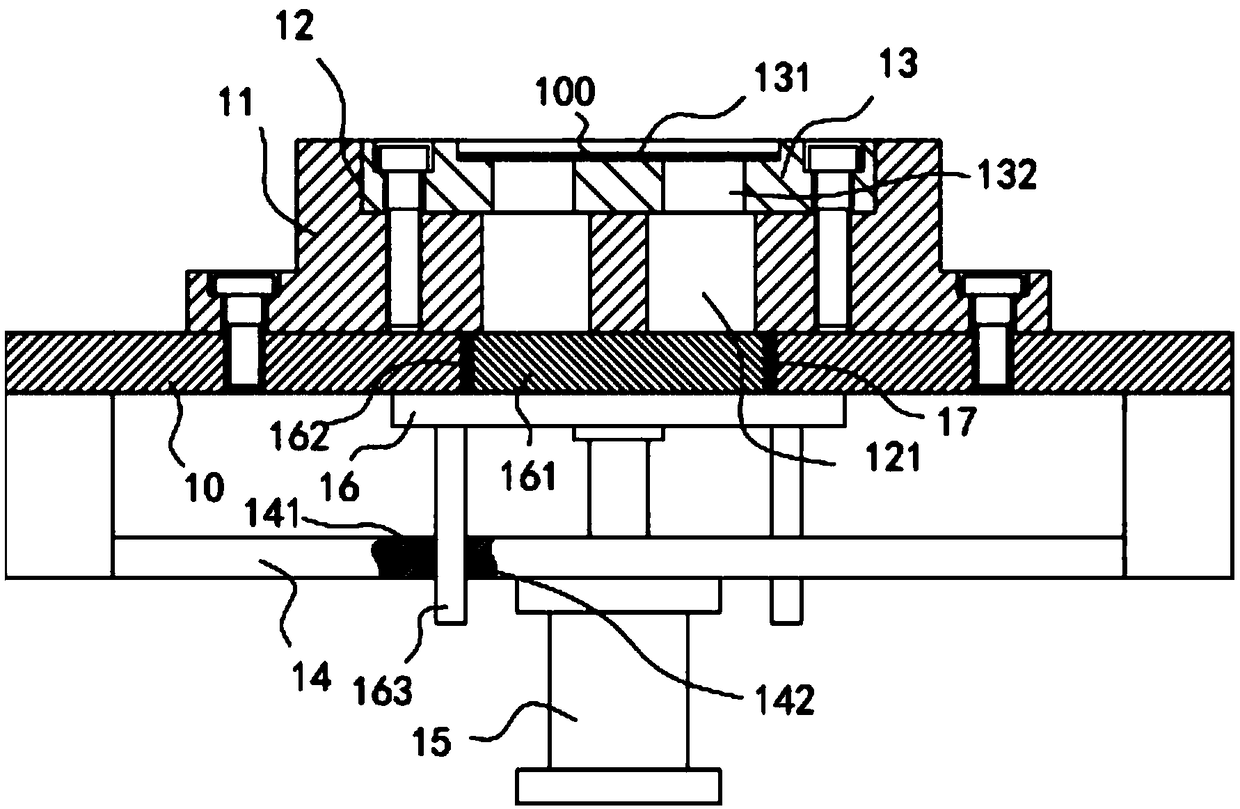

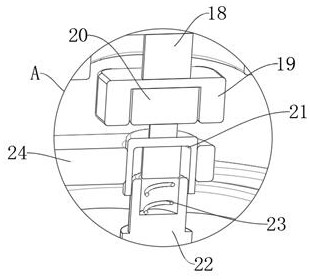

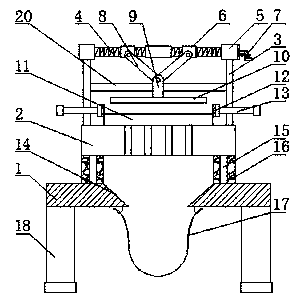

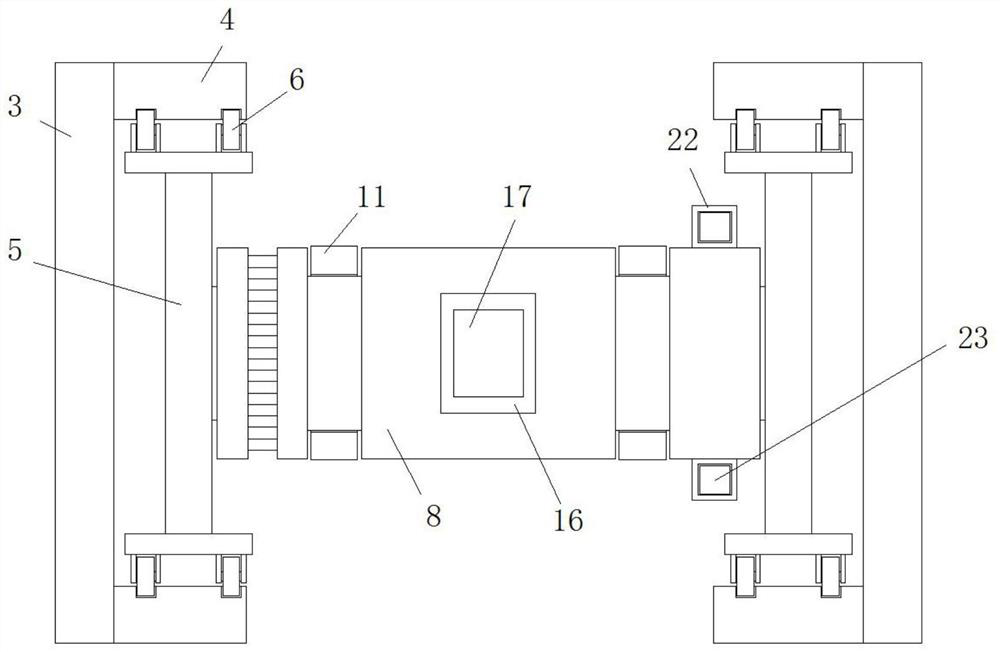

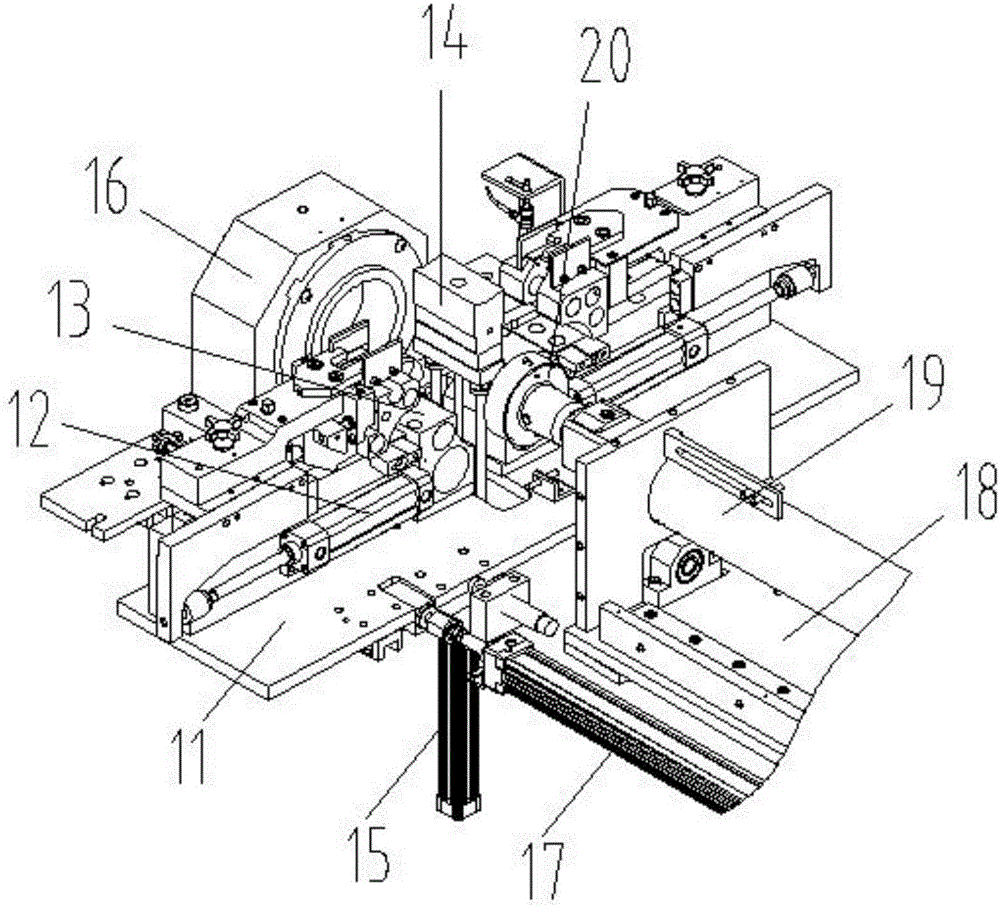

Stamping device and stamping method thereof

ActiveCN113458230ASave time at workImprove stamping efficiencyShaping toolsShaping safety devicesStampingElectric machinery

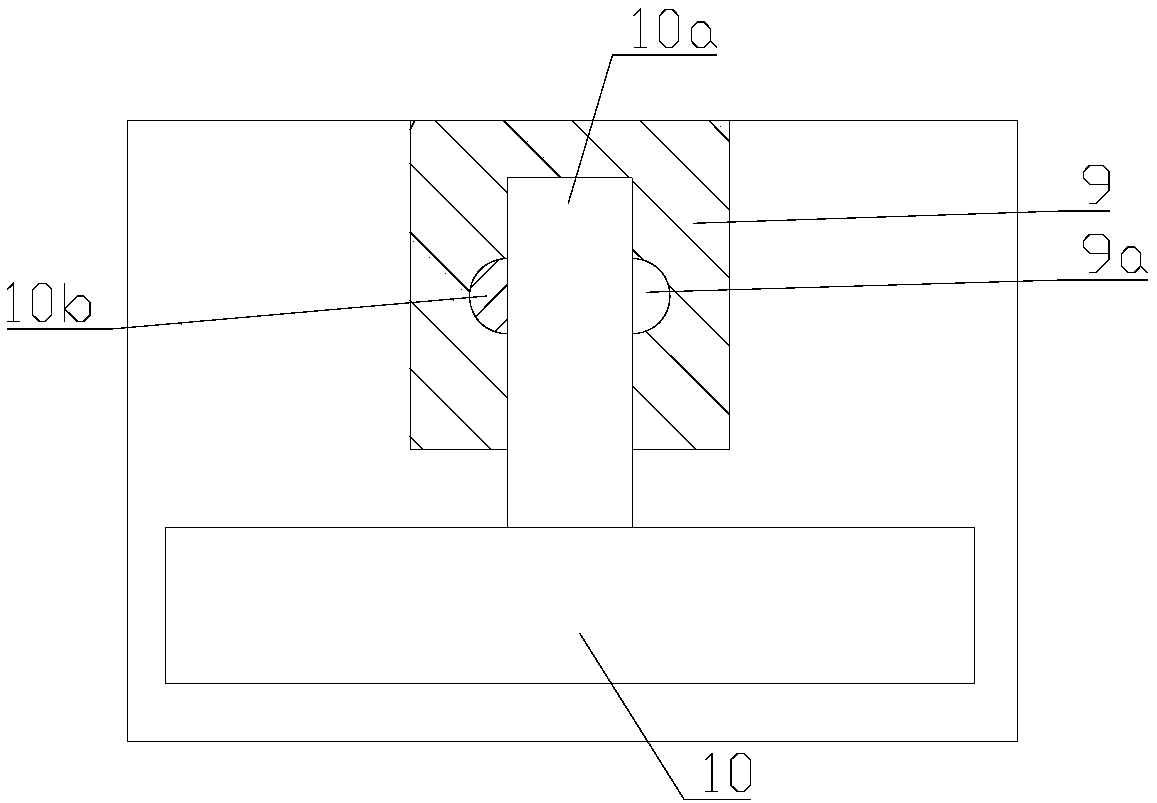

The invention relates to a stamping device and a stamping method thereof. The stamping device comprises a lower die (1) and an upper die (3), the upper die (3) comprises a stamping part mounting seat, a plurality of mounting grooves (9) are formed in the stamping part mounting seat in the circumferential direction of the stamping part mounting seat, a stamping block (26) capable of vertically moving is arranged in each mounting groove (9), the stamping blocks (26) are different in shape, a first motor (20) enables a swing arm (24) to rotate to the position above the stamping block (26) needing to be used, and an air cylinder (18) enables a pressing block (25) on the swing arm (24) to act on the corresponding stamping block (26) to move downwards; correspondingly, a rotating disc (16) is arranged on the lower die (1), a plurality of stamping grooves (17) are formed in the circumferential direction of the rotating disc (16), a stamping part is placed in each stamping groove (17), and the rotating disc (16) rotates under the action of a second motor (12), so that the different stamping blocks (26) can act on the stamping part in the same stamping groove (17).

Owner:珠海市勇诚五金塑胶有限公司

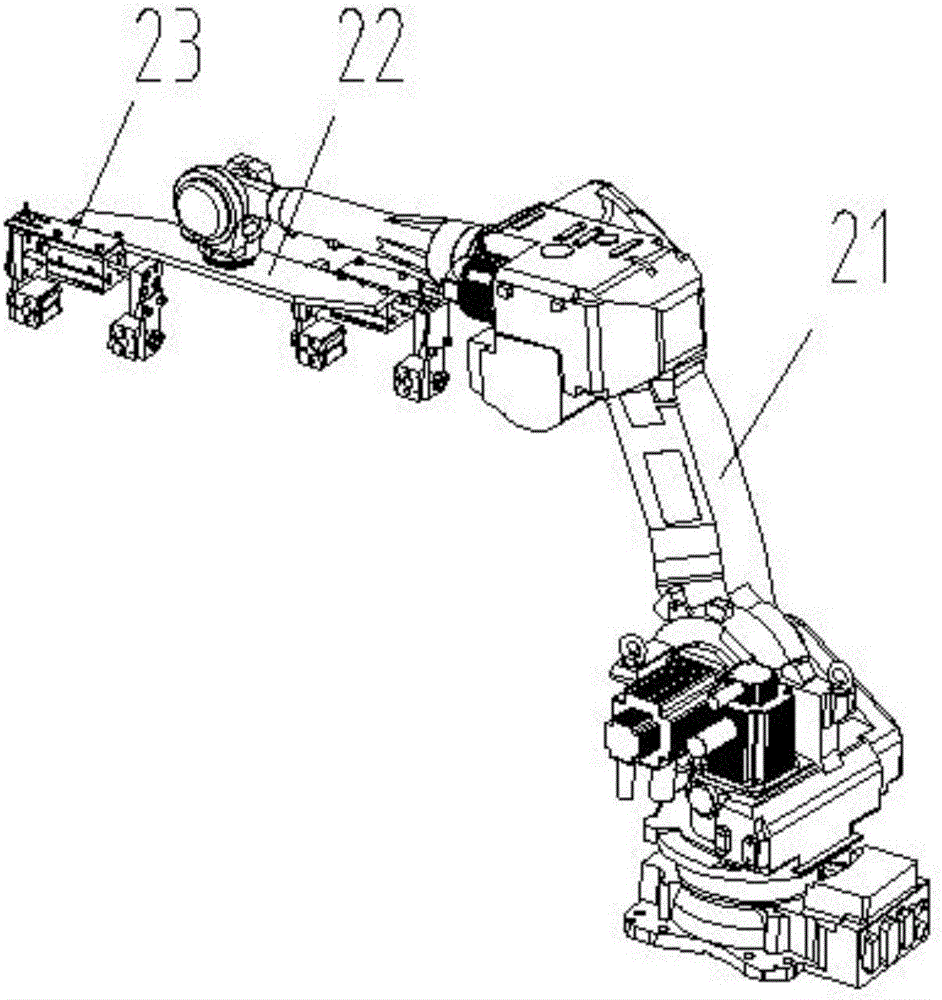

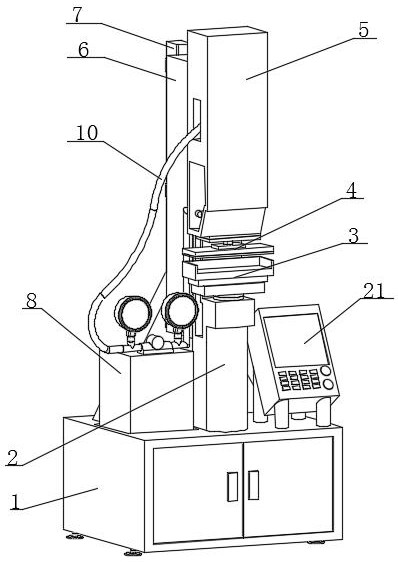

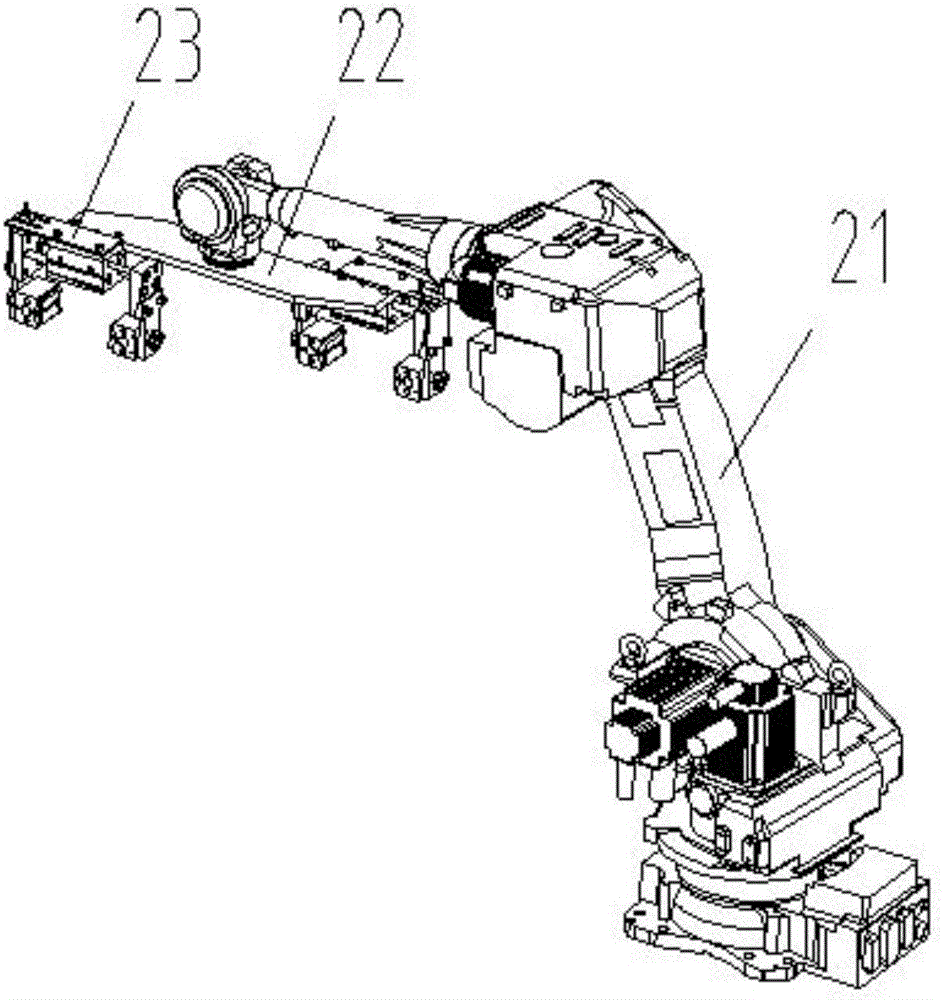

Five-axis stamping robot

ActiveCN110883165AStamping Position GuaranteeGuaranteed stamping effectShaping toolsElectric machineryStructural engineering

The invention relates to a stamping mechanism, in particular to a five-axis stamping robot. The five-axis stamping robot comprises a device support, a moving motor I, a sliding support I, a stamping mechanism, a height support I, a die supporting plate, a stamping die, a moving mechanism, a sliding support II, a height support II and a stamping bottom frame. The sliding support I, the stamping mechanism, the height support I, the die supporting plate, the stamping die, the moving mechanism, the sliding support II, the height support II and the stamping bottom frame can be driven by the movingmotor I to conduct transverse movement, the stamping position of the stamping die on the X axis in the plane is adjusted, the stamping position of the stamping die on the Y axis in the plane is adjusted by the moving mechanism, and therefore the situation that the stamping mechanism is arranged above the stamping die all the time when the stamping operation is conducted at the random position is guaranteed, the stamping mechanism generates the corresponding perpendicular stamping force, and the stamping effect is guaranteed. In addition, the die supporting plate and the stamping bottom frame move together, and therefore the stamping position is guaranteed.

Owner:HARBIN UNIV

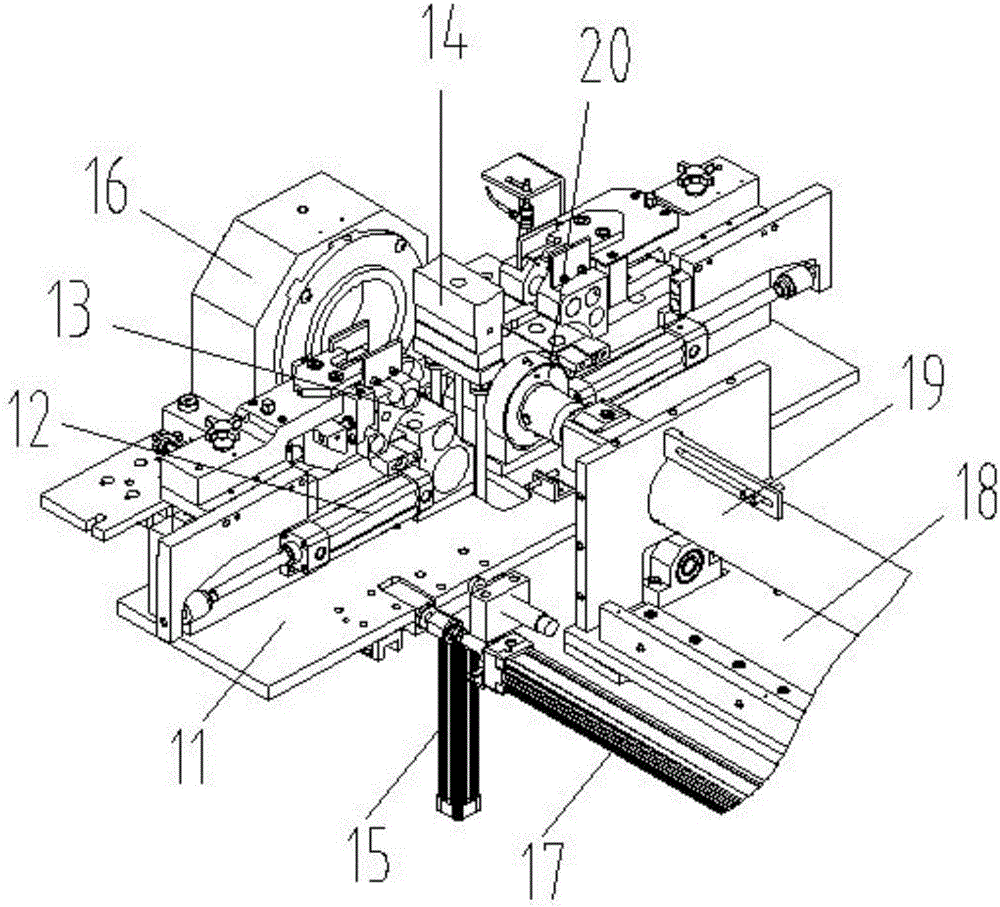

Stamping, drawing and flanging method for middle part of workpiece

InactiveCN112091099AGuaranteed stamping effectEasy loadingMetal-working feeding devicesStripping-off devicesLaundry washing machineStamping

The invention relates to a stamping, drawing and flanging method for a middle part of a workpiece. The method comprises the following steps: S1, transferring the workpiece which prepares to be subjected to stamping machining; S2, conveying the transferred workpiece; S3, stopping conveying the workpiece and stamping the workpiece when the workpiece are conveyed to specified locations; S4, continuously conveying the workpiece which are already subjected to stamping molding; and S5, collecting the conveyed molded workpiece. The workpiece is a speed reducer mounting base of a washing machine. Theequipment is high in production machining efficiency, is high in the automation degree of the equipment is high, can effectively meet stamping molding requirements for the workpiece, and is convenientto use.

Owner:安徽中巨机电设备有限公司

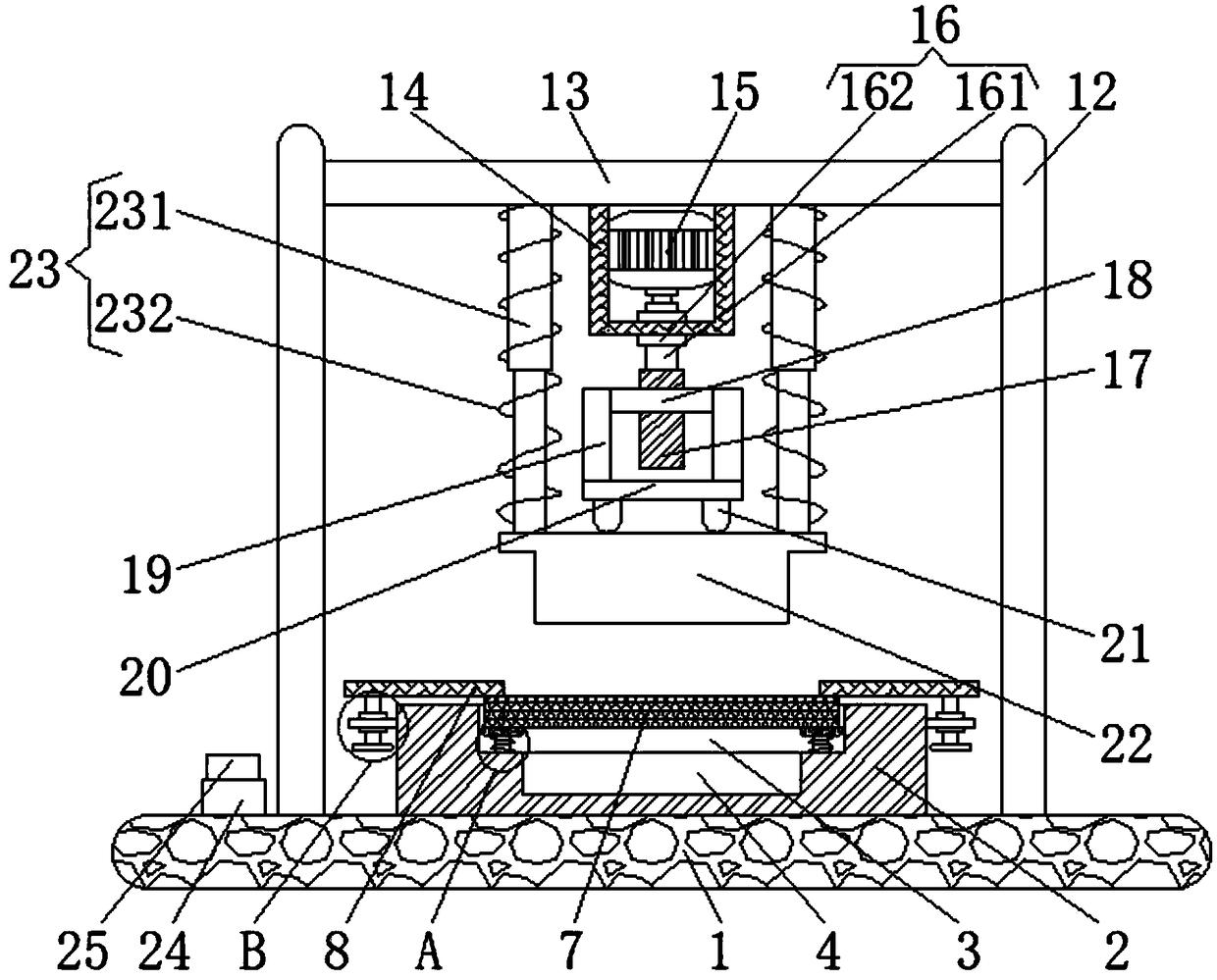

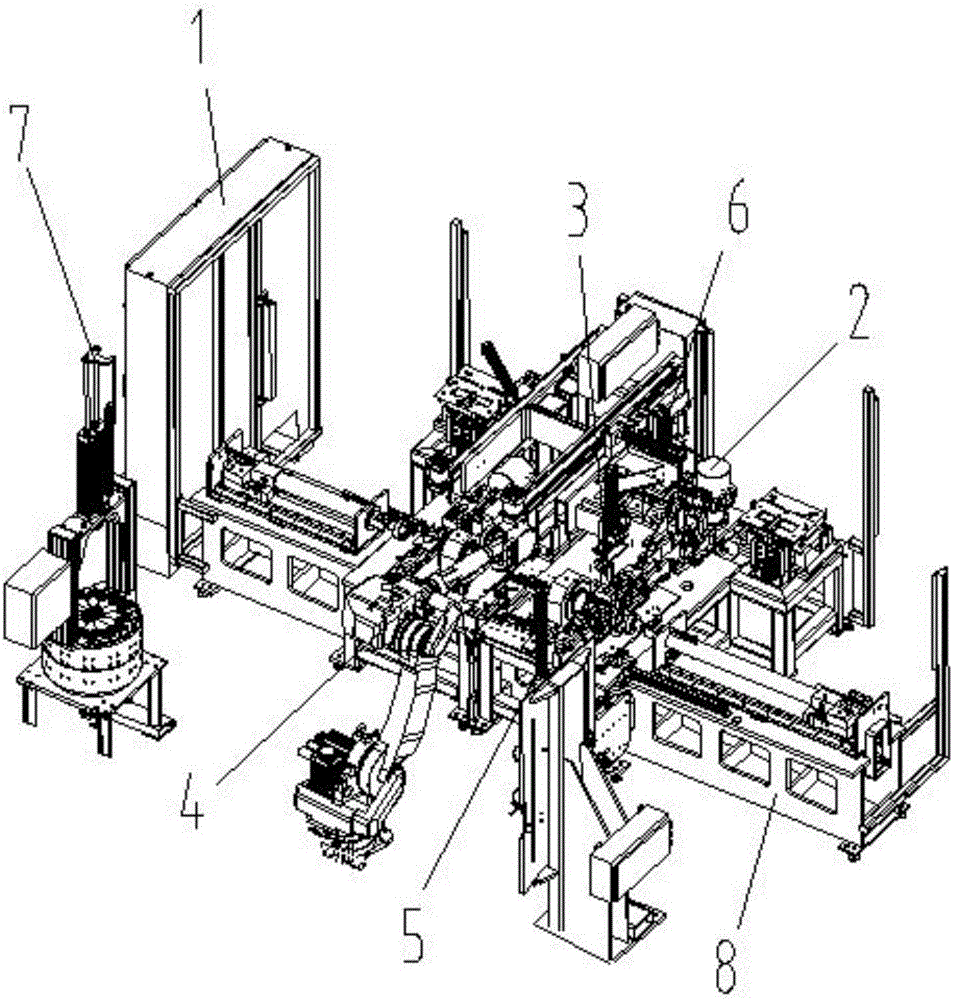

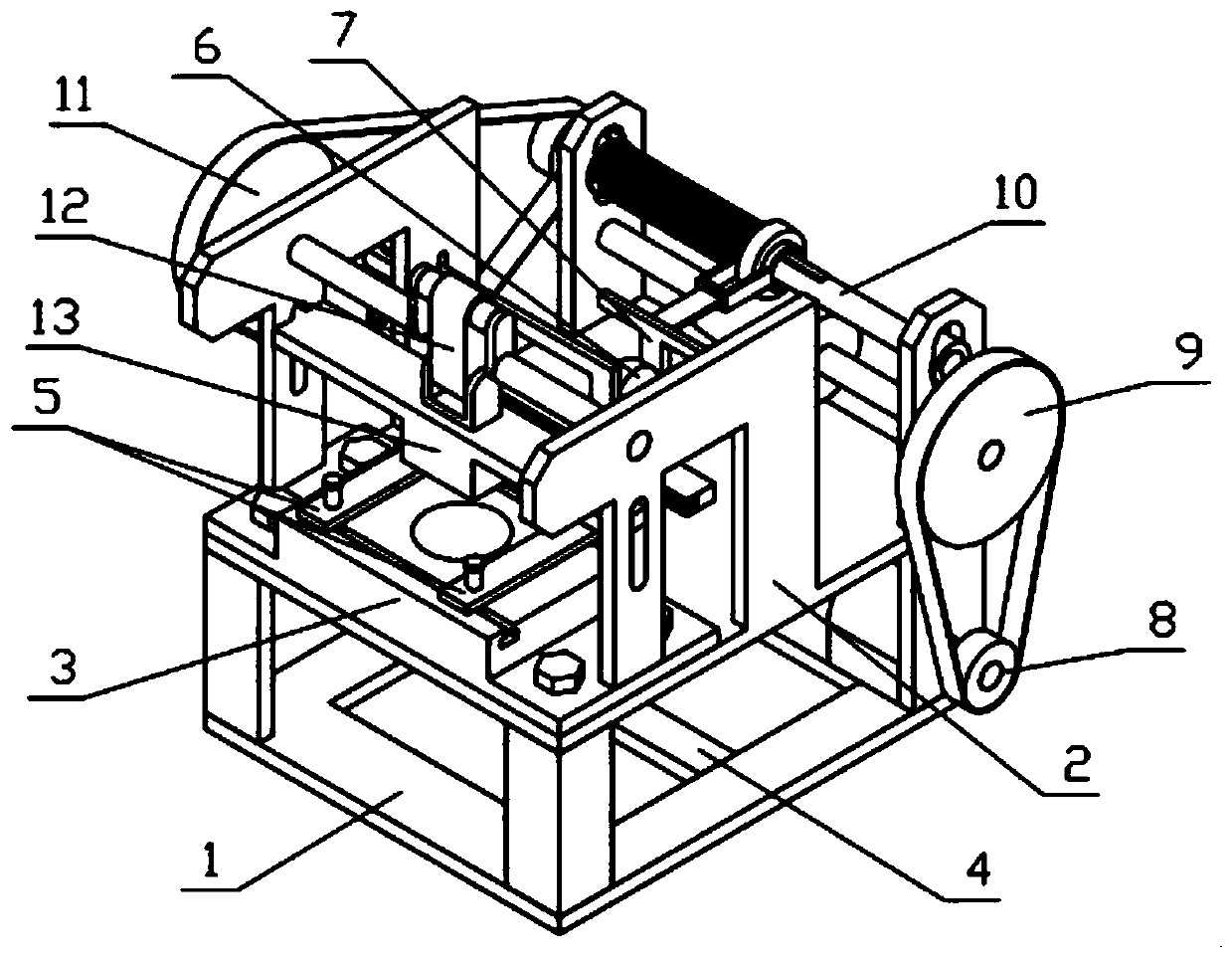

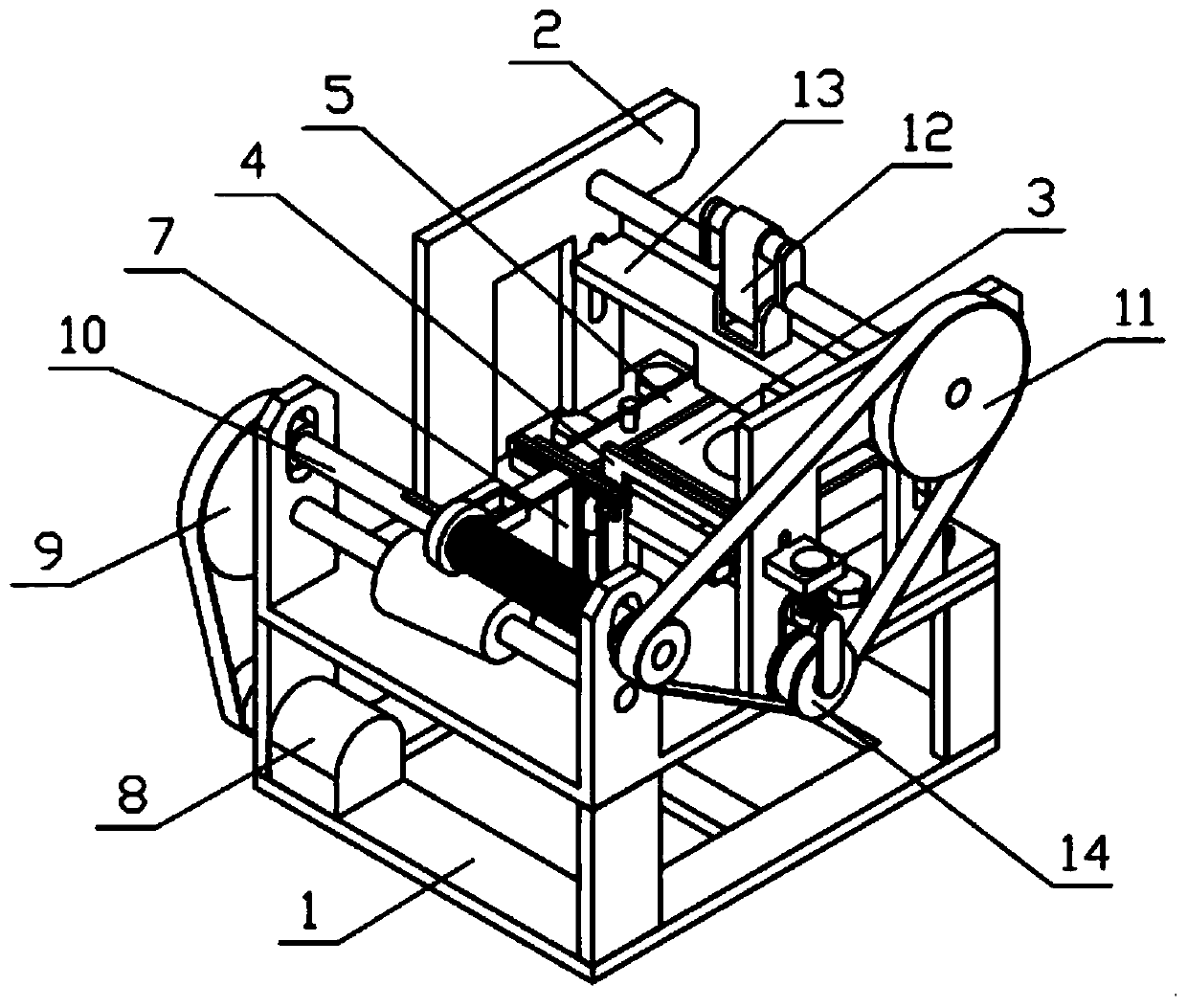

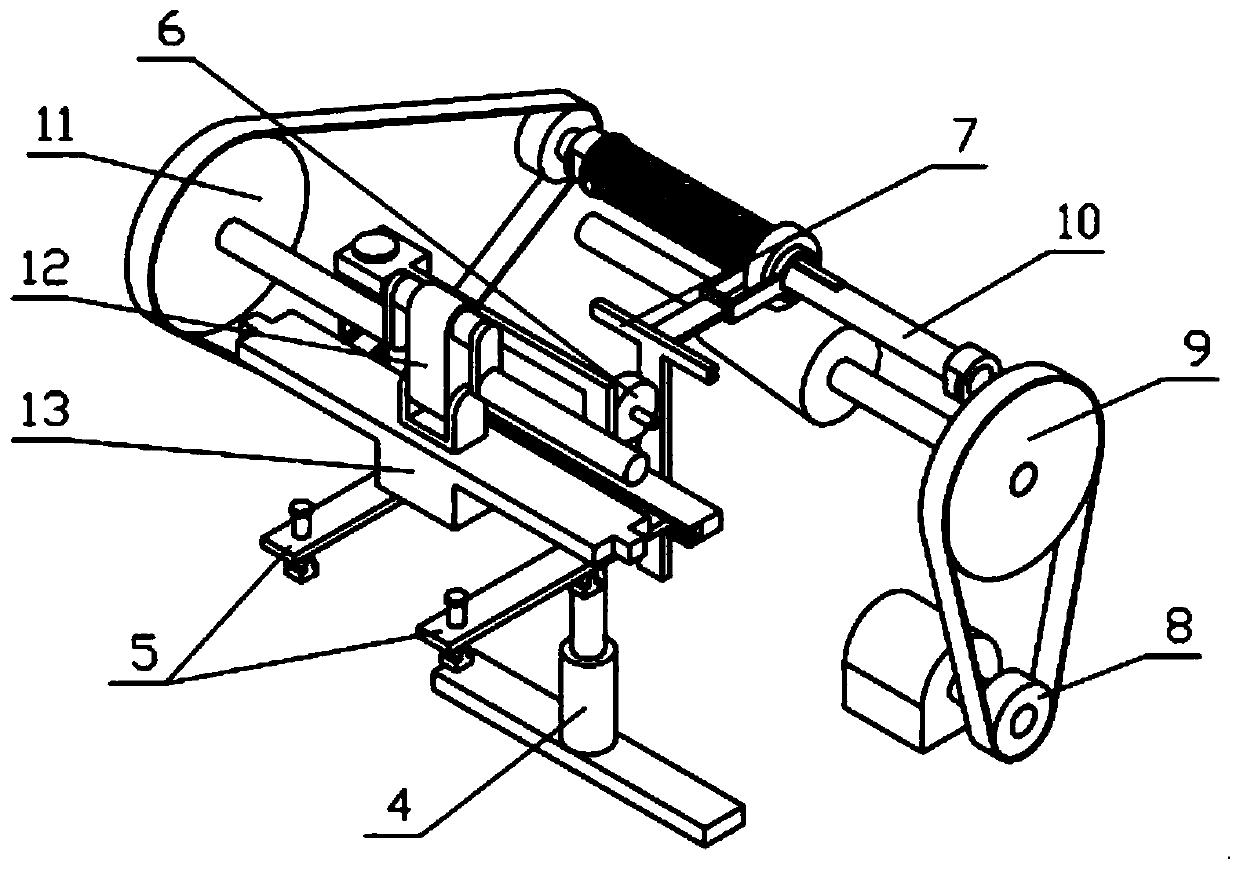

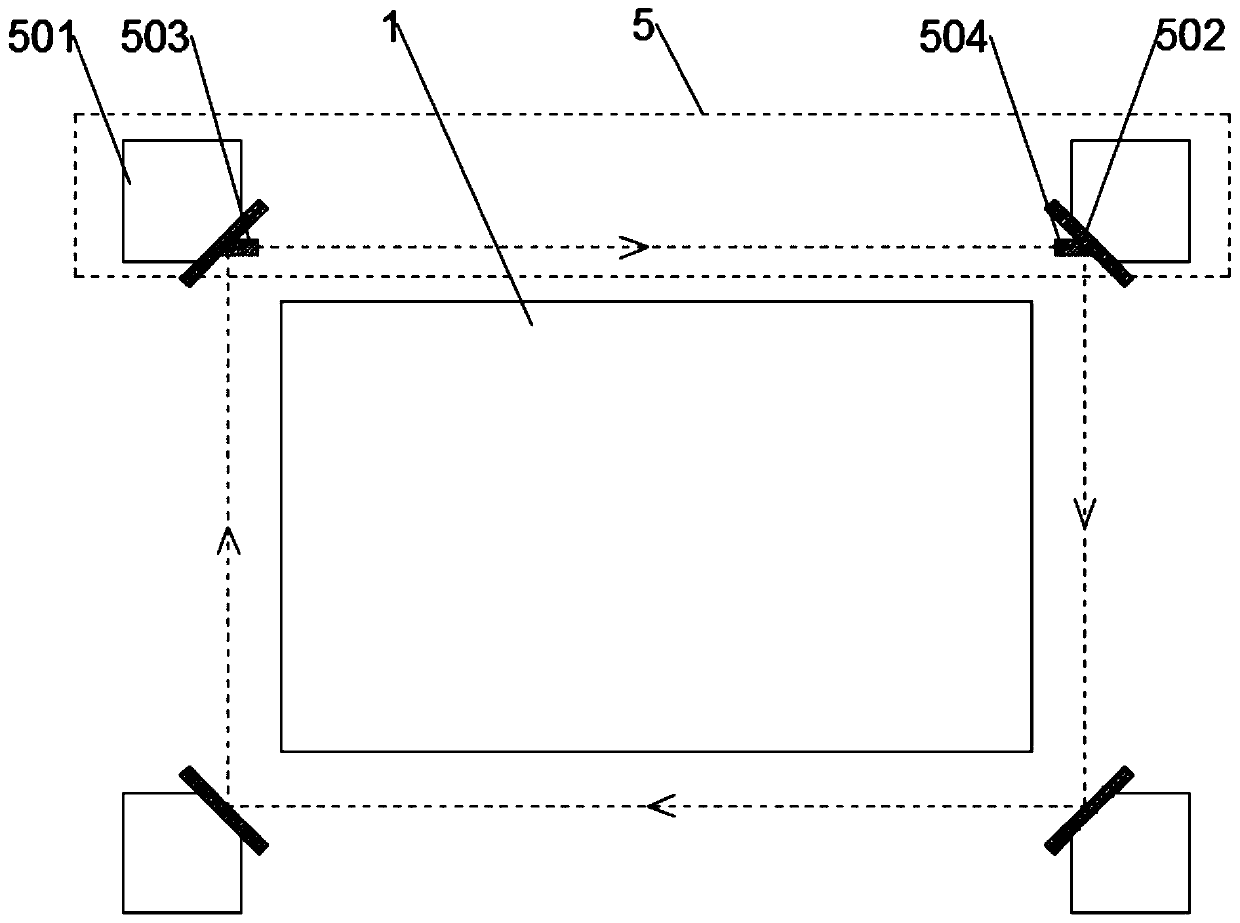

Automatic production equipment for stamping, drawing and flanging middle part of workpiece

InactiveCN112091100AGuaranteed stamping effectEasy loadingMetal-working feeding devicesStripping-off devicesMolding machineMachining

The invention relates to automatic production equipment for stamping, drawing and flanging the middle part of a workpiece. The automatic production equipment comprises a forming mechanism used for stamping and forming the middle part of the workpiece, and a feeding mechanism used for transferring the workpiece; a covering mechanism used for covering a hole part to be stamped and flanged in the middle of the workpiece with a film sheet is arranged on a transferring path of the feeding mechanism; and the size of the film sheet is larger than the size of the hole part, and the edge, attached to the workpiece, of the film sheet is coated with stamping drawing oil. The equipment is high in production and machining efficiency, high in automation degree, and convenient tin use, and the requirement for workpiece stamping and forming is effectively met.

Owner:安徽中巨机电设备有限公司

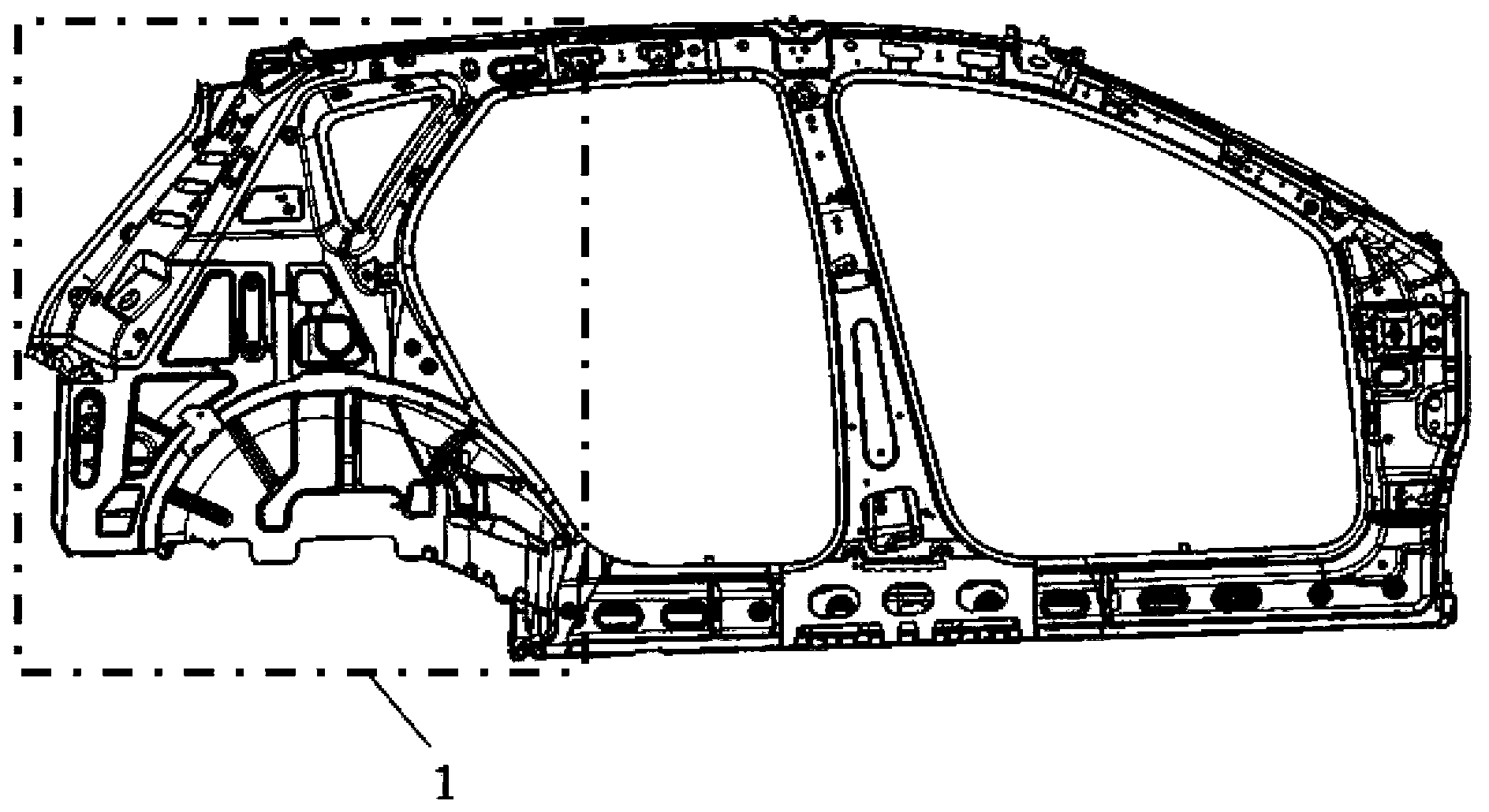

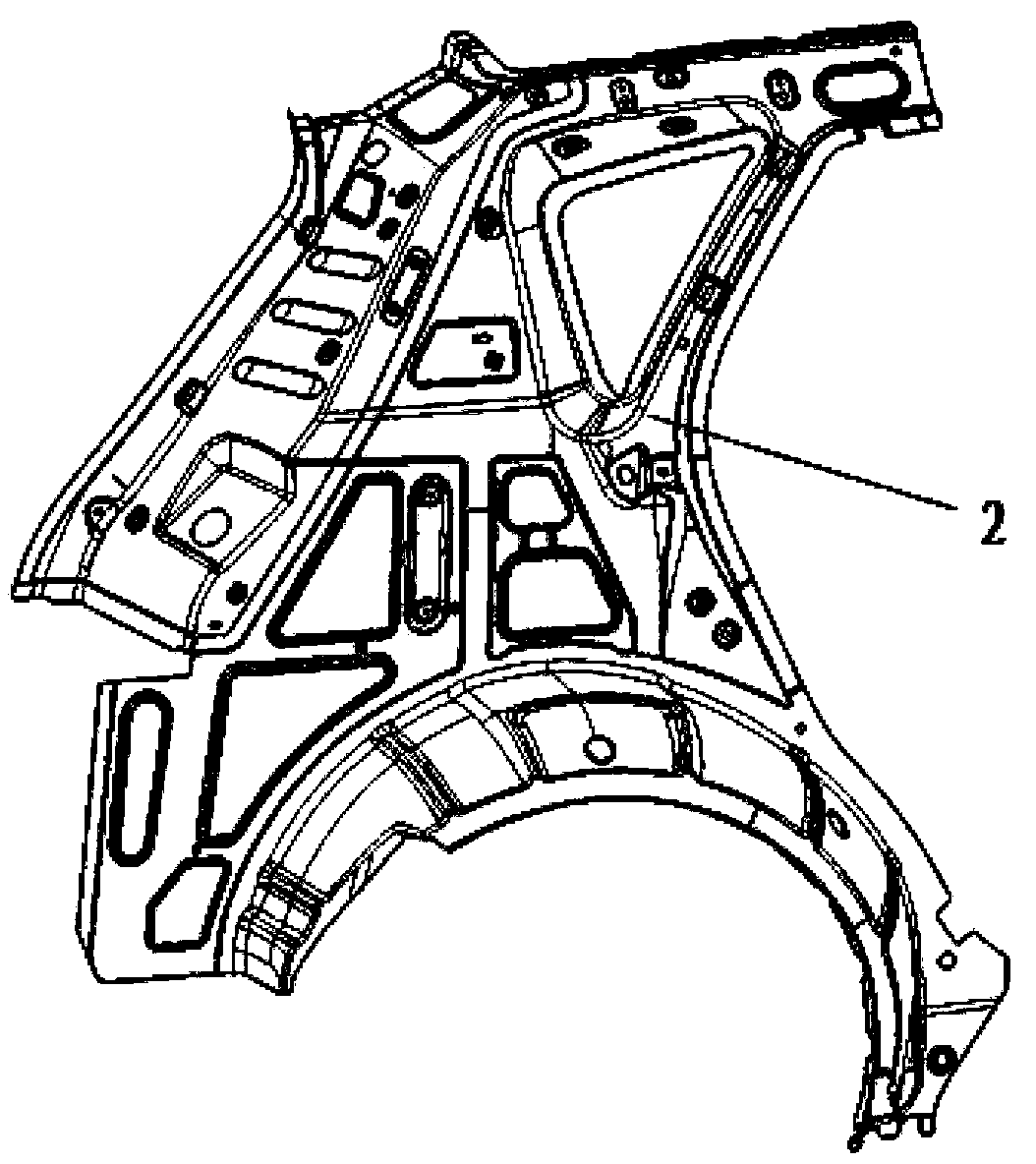

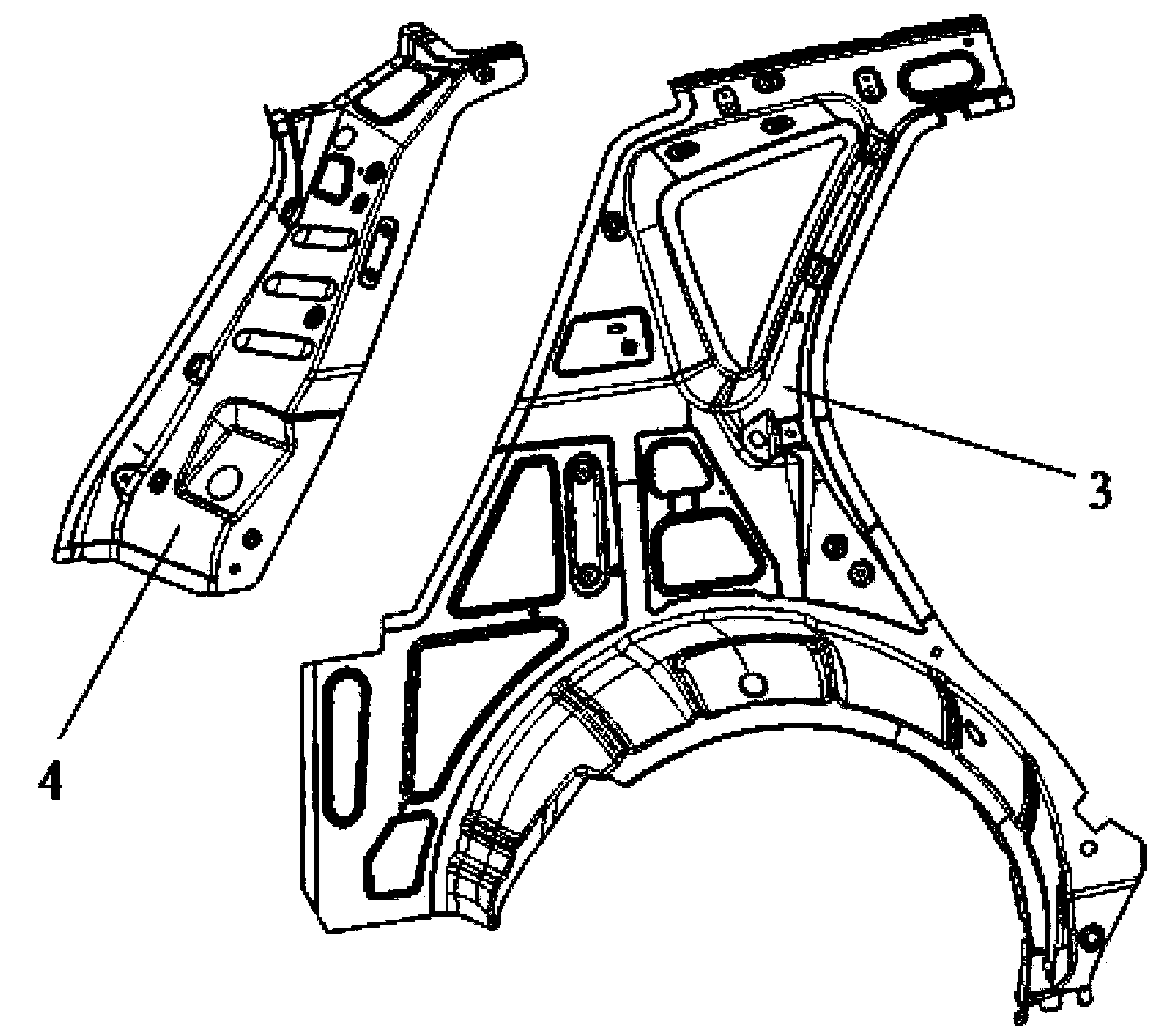

Side body rear supporting column inner plate dividing structure

InactiveCN103832478AGuaranteed stamping effectImprove connection strengthSuperstructure subunitsSoftware engineeringBack door

The invention relates to a side body rear supporting column inner plate dividing structure, and belongs to the technical field of a side body of a passenger car. The side body rear supporting column inner plate dividing structure comprises a rear supporting column inner plate, wherein the rear supporting column inner plate is divided into a rear supporting column inner plate body and a rear supporting column inner plate angle plate, and the rear supporting column inner plate body is provided with a reinforcing plate. The side body rear supporting column inner plate dividing structure is simple and reasonable, the process is easy to carry out, the portion, almost parallel with a back door seam allowance, of the rear supporting column inner plate is divided into two pieces, the two pieces are made of different materials, and accordingly punching forming performance of the rear supporting column inner plate is guaranteed, rigidity of the periphery of a rear back door can be improved, and torsional rigidity of a vehicle body is improved. Meanwhile, the inner side of the rear supporting column inner plate is provided with the reinforcing plate, and the connection strength of the front portion and the rear portion of the rear supporting column inner plate is greatly improved.

Owner:DONGFENG MOTOR CORP HUBEI

Discharging mechanism on medicine bottle cap stamp forming equipment

InactiveCN107344211ASimplify the blanking structureSave energySievingScreeningMedicine bottle capElectric machinery

The invention relates to the field of medicine caps, in particular to a discharging mechanism on medicine bottle cap stamp forming equipment. The discharging mechanism comprises a material blowing assembly and a material receiving assembly. The material blowing assembly comprises a material blowing pipe which is arranged beside a stamping station and a material blowing cylinder which is connected with the material blowing pipe. The material blowing cylinder is fixed to the part, above the stamping mechanism, on the rack, the material blowing cylinder is internally provided with an air cavity, a cylinder body of the material blowing cylinder is provided with an air inlet hole, the air cavity is internally provided with a piston, and a rod body outside the piston is connected to the stamping mechanism. The material receiving assembly comprises a material receiving pipeline, a rolling sieve which is connected to the rear side of the material receiving pipeline and a material cylinder which is arranged on a discharge port of the rolling sieve. An outlet of the material blowing pipe faces the material receiving pipeline through the stamping station, and the rolling sieve is connected with a drive motor through a transmission assembly. The discharging mechanism adopts the material blowing assembly to blow products out of the stamping station, and the discharging structure is greatly simplified; and moreover, the material blowing assembly is in linkage with the stamping mechanism, the energy sources are saved, and the stamping effect is guaranteed.

Owner:浙江冠利新材料股份有限公司

Stably-positioned die for stamping forming of automobile metal plate and stamping process of stably-positioned die

ActiveCN112475041AAvoid breakingImprove pass rateShaping toolsMetal-working feeding devicesSheet metal stampingStamping process

The invention relates to the technical field of stamping forming, in particular to a stably-positioned die for stamping forming of an automobile metal plate and a stamping process of the stably-positioned die. The stably-positioned die for stamping forming of the automobile metal plate comprises a supporting frame, a die body, a positioning device and a stamping device, and the die body, the positioning device and the stamping device are installed on the supporting frame; the die body comprises an upper die and a lower die which are adaptive; the stamping device is connected with an installation plate and drives the installation plate to move up and down, the upper die is installed on the installation plate, and the lower die is provided with a placing groove used for placing the metal plate; and the positioning device comprises a first positioning assembly and a second positioning assembly. The stably-positioned die for stamping forming of the automobile metal plate comprises the supporting frame, the die body, the positioning device and the stamping device, the die body, the positioning device and the stamping device are installed through the supporting frame, the stamping devicedrives the die body to perform stamping forming on the metal plate, the metal plate is positioned through the positioning device, the metal plate is prevented from deviating in the stamping process,the stamping effect is ensured, and the defective rate is reduced.

Owner:吉安市瑞鹏飞精密科技有限公司

Intelligent stamping equipment and stamping method for automobile parts

ActiveCN113333552AImprove stabilityFast replacementMetal-working feeding devicesNon-rotating vibration suppressionStamping processMotor vehicle part

The invention relates to the technical field of intelligent stamping equipment, and discloses intelligent stamping equipment and a stamping method for automobile parts. The intelligent stamping equipment comprises a stamping base, wherein a stamping support is installed at the position, close to the front, of the center of the surface of the stamping base, a stamping power box is installed at the position, close to the left end of the stamping support, of the surface of the stamping base, and a stamping control box is installed at the position, close to the front of the right end of the stamping support, of the surface of the stamping base. According to the intelligent stamping equipment and the stamping method for the automobile parts, an executing part, a second stamping assembly and a first stamping assembly are arranged, so that the stamping of the automobile parts is operated step by step, the stamping process is further detailed, the stamping effect is guaranteed, the problem that the height size of a formed sheet metal part structure is not uniform due to the fact that a sheet metal plate and a punch are asymmetrically placed is solved, and the stability of the equipment during stamping machining is improved through the cooperation of the executing part and a stamping head.

Owner:十堰帝尔科技有限公司

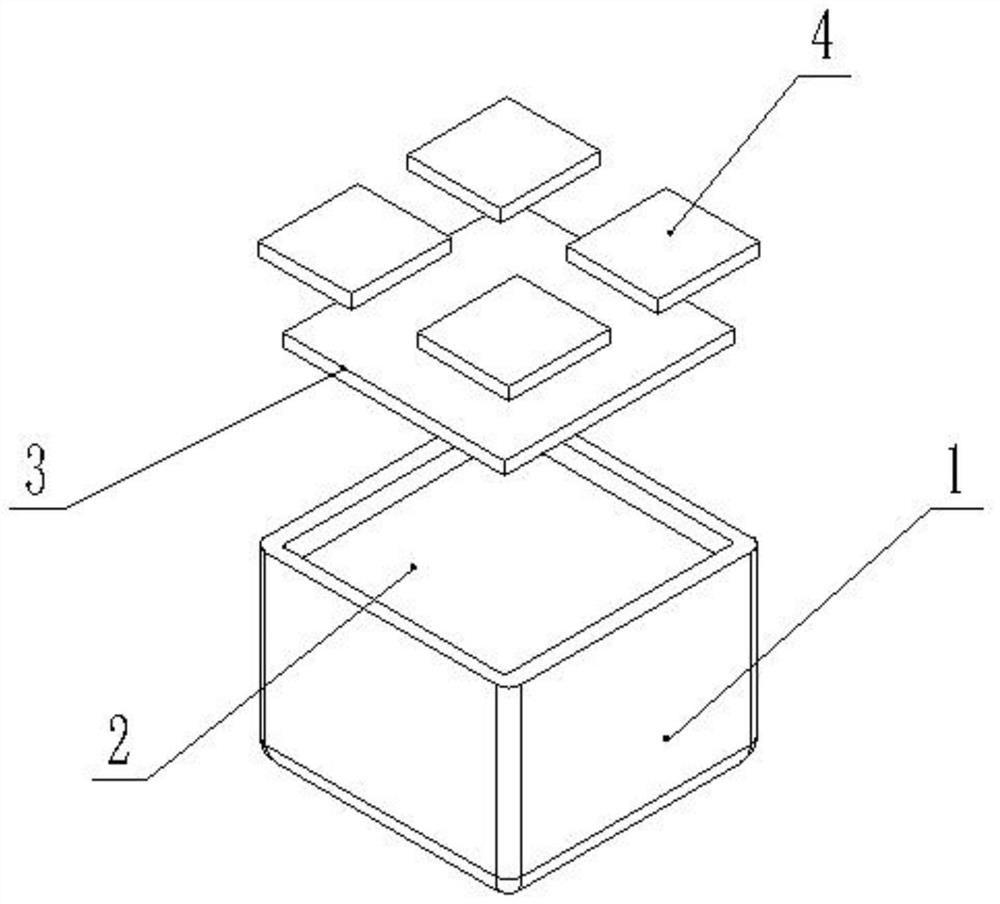

Plywood pressing device

InactiveCN109291166AGuaranteed lamination effectGuaranteed stamping effectWood veneer joiningPunchingEngineering

The invention discloses a plywood pressing device which comprises a worktable and a pressing table. Supporting plates are arranged on two sides of the top of a cone-shaped groove, a lower pressure plate is fixed to the top of the pressing table, clamping screws are arranged on two sides of the lower pressure plate, annular fixed blocks are fixed to the inner sides of the two clamping screws, an upper pressure plate is arranged on the top of the lower pressure plate, bearing pedestals are fixed to the top ends of two columns, a screw is rotatably connected between the two bearing pedestals, andone end of the screw is fixedly connected to a locking device. By means of the locking device, the position of the upper pressure plate can be locked when the upper pressure plate and the lower pressure plate press the plywood, so that layers of the plywood are tightly adhered to bonding resin, and the press fit effect is ensured. As the clamping screws are arranged on two sides of the lower pressure pate, the clamping screws are in threaded connection to the columns and annular fixed blocks are fixed to the inner sides of the two clamping screws, the plywood placed on the top of the fixed plate can be limited, so that the punching effect is guaranteed.

Owner:宿迁市三泰木业有限公司

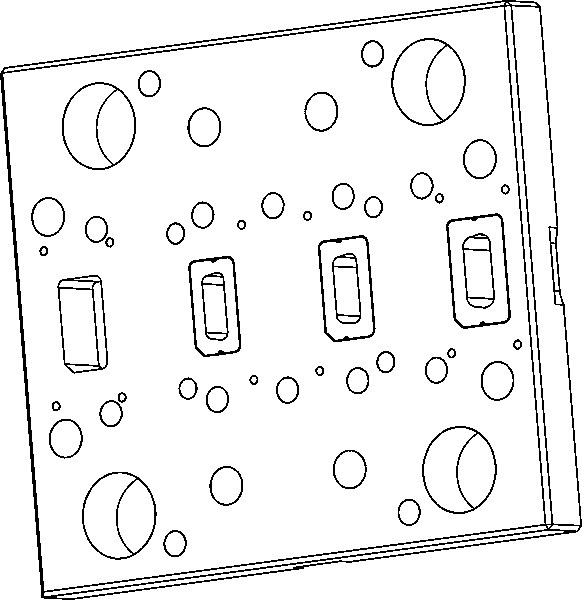

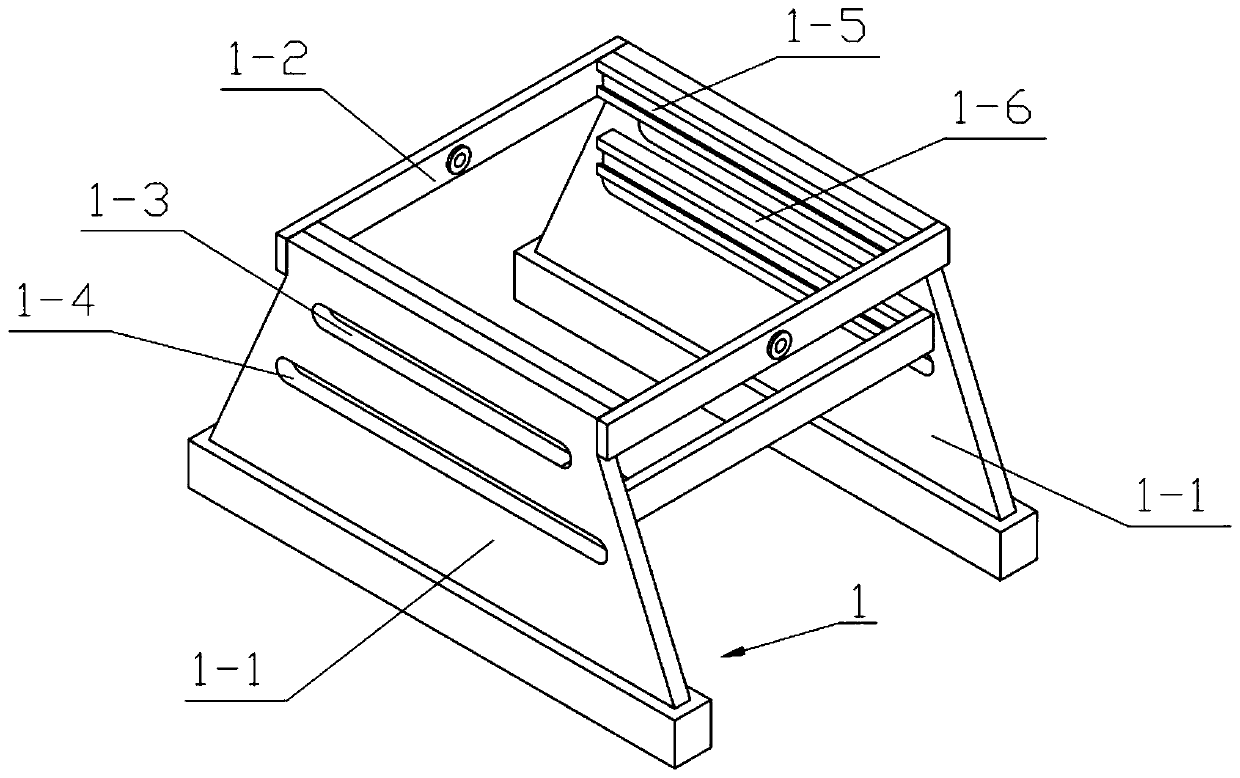

Movable type seal splicing assembly

PendingCN112590413AReduce manufacturing costSolve the problem that easy stamping cannot be printedStampingEngineeringAdhesive

The invention discloses a movable type seal splicing assembly which comprises a seal shell, non-setting adhesive and seal character particles. A seal groove is formed in the bottom of the seal shell,the depth of the seal groove is larger than the thickness of the non-setting adhesive, the non-setting adhesive is movably connected with the seal groove, and the seal character particles are movablyconnected with the non-setting adhesive. Through the structure of the non-setting adhesive and the seal character particles, the problem that common movable type seals must arrange characters in a fixed sequence is solved, and free arrangement and combination according to the own needs are achieved; the seal character particles solve the problem that metal character particles are prone to being stamped out during stamping, and while the same stamping effect is guaranteed, an over-precise combined structure is not needed, so that the production cost of the movable type combined seal is greatlyreduced.

Owner:曲阜市天成电子商务有限公司

Pure zinc coated steel plate with good dezincification resistance and surface quality as well as production method and application of pure zinc coated steel plate

ActiveCN114438417ANo sheddingQuality improvementHot-dipping/immersion processesSurface finishHigh pressure water

The invention provides a pure zinc coated steel plate with good dezincification resistance and surface quality as well as a production method and application of the pure zinc coated steel plate. The steel comprises the following components in percentage by weight: 0.001 to 0.0025 percent of C, 0.05 to 0.10 percent of Si, 0.4 to 0.6 percent of Mn, 0.03 to 0.05 percent of Al, 0.025 to 0.035 percent of Ti, 0.015 to 0.025 percent of Nb, less than or equal to 0.004 percent of N, 0.0002 to 0.0008 percent of B, 0.02 to 0.03 percent of P, less than or equal to 0.008 percent of S and the balance of Fe and inevitable impurities. Compared with the prior art, needle-point-shaped skip plating points with the diameter of 0.1-1.0 mu m are prevented from appearing on the surface through chemical components and matched process design. And meanwhile, by designing the concentration of the finishing liquid and the high-pressure water process design, it is ensured that the bottoms of the surface finishing pits are smooth and free of mechanical damage, and the zinc layer cannot be accumulated in the mold to pollute the mold even if falling off during stamping plastic deformation.

Owner:MAANSHAN IRON & STEEL CO LTD

A kind of stamping equipment with convenient die replacement

The invention discloses a stamping equipment with convenient mold replacement, which comprises a workbench, feet are fixedly connected to both sides of the bottom of the workbench, a U-shaped support plate is arranged on the top side of the workbench, and the U-shaped support plate The inner walls on both sides of the vertical side are respectively fixedly connected with track vertical plates, and there are two track vertical plates respectively arranged vertically and parallelly, and the sides of the two track vertical plates that are close to each other are provided with vertical track chute respectively, and Vertical slide plates are arranged between the track vertical plates, and track wheels are arranged on both sides of the vertical slide plates, and the track wheels are slidably connected in the vertical track chute respectively. shaft, the two ends of the central shaft are respectively fixedly connected with the vertical slide plate, and the outer side of the shaft body of the central shaft is sleeved with a drum. The invention reduces the production cost, improves the production efficiency, ensures the stamping effect, and satisfies the use requirements of people in production and life.

Owner:滁州益佳模具设备制造有限公司

A stamping device for a chassis guard plate for an automobile

ActiveCN108746301BSimple structureCorrect skewShaping safety devicesPressesCouplingElectric machinery

The invention discloses a stamping device for a chassis guarding plate of an automobile. The stamping device comprises a workbench; a driving mounting plate is arranged on the upper portion of the workbench, a driving device is arranged on the driving mounting plate, and the output end of the driving device vertically downwards penetrates through the driving mounting plate and is connected with amounting plate; a stamping plate is arranged on the lower end surface of the mounting plate, a plurality of vertical penetrating fixing holes are formed in the edge of the mounting plate, fixing motors are arranged on the edge of the mounting plate, the number of the fixing holes is equal to that of the fixing motors, fixing rods are rotatably arranged in the fixing holes in a penetrating mode, ananti-stripping ring is arranged on each fixing rod located at the upper end of the corresponding fixing hole, and the output end of each fixing motor is connected with the corresponding fixing rod through a coupling; and the lower ends of the anti-stripping rings are in contact with the upper surface of the mounting plate, and a plurality of vertical positioning cylinders are arranged at the upper end of the stamping plate, and the fixing rods located at the lower ends of the fixing holes are connected within the positioning cylinders in a threaded mode. By means of the stamping device, the structure can be simplified accurately, the equipment cost is reduced, the safety performance is improved, meanwhile, self correcting can be achieved, and the machining quality is improved.

Owner:芜湖众梦电子科技有限公司

A square hole punch used on a punching machine

InactiveCN104014635BGuaranteed stamping effectExtended service lifePerforating toolsPunch pressMechanical engineering

The invention relates to a square hole punch chip used on a punch press. The square hole punch chip used on the punch press comprises a punch chip body of which the cross section is square, the end of the punch chip body is provided with a guide head of which the orthographic protection is trapezoidal, the upper portion of the guide head is narrow, the lower portion of the guide head is wide, the cross section of the guide head is square, the transition face of the guide head and the punch chip body is a slope, and the inclination angle of the transition face is smaller than the base angle of the guide head. According to the square hole punch chip used on the punch press, the expansive force of outward deformation of products is increased through the guide head, and consequently positive pressure on the punch chip body from the products is decreased; the contact face of the punch chip body and the products is enlarged through the inclined transition face, impact force between the punch chip body and the products is reduced, and consequently the square hole punch chip is more resistant to abrasion and longer in service life, and the stamping effect of a square hole is ensured.

Owner:SUZHOU CHUANGFENG PRECISION HARDWARE

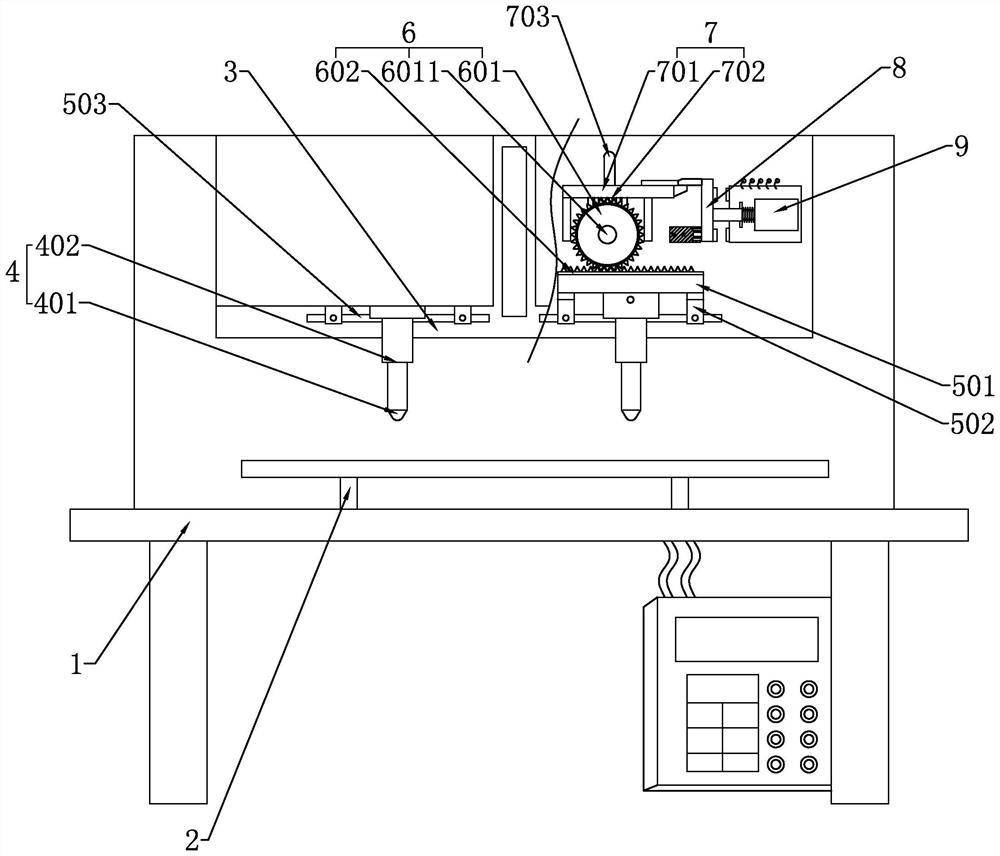

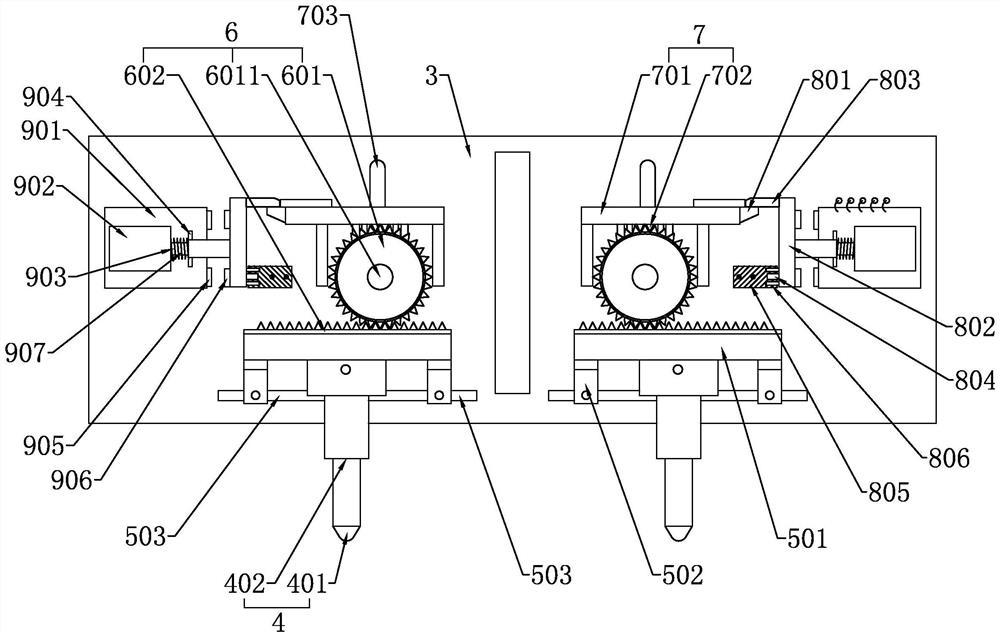

Processing method of bow-shaped cross arm

ActiveCN114535439AReduce the number of clampingIncrease productivityShaping toolsMetal-working feeding devicesStamping processMachining

The invention relates to a machining method for a bow-shaped cross arm, stamping equipment and a workpiece are included, the stamping equipment is provided with two sets of stamping assemblies, in the stamping process, the two sets of stamping equipment can stamp two positions needing to be machined on the workpiece at the same time, and for the workpiece with more than two positions to be stamped, the stamping efficiency is greatly improved. The number of times that workpieces need to be clamped is reduced, the production efficiency of the bow-shaped cross arm is improved, in addition, the distance between the two sets of stamping assemblies can be adjusted, the stamping equipment can machine bow-shaped cross arms of more specifications, the application range is wide, the bent portion of the bow-shaped cross arm formed through the machining method does not have gaps, stability is better, and the production efficiency of the bow-shaped cross arm is improved. And in a long-term use process, the wire cannot be damaged due to outdoor strong wind or strong shaking of the wire.

Owner:维克托电力设备有限公司

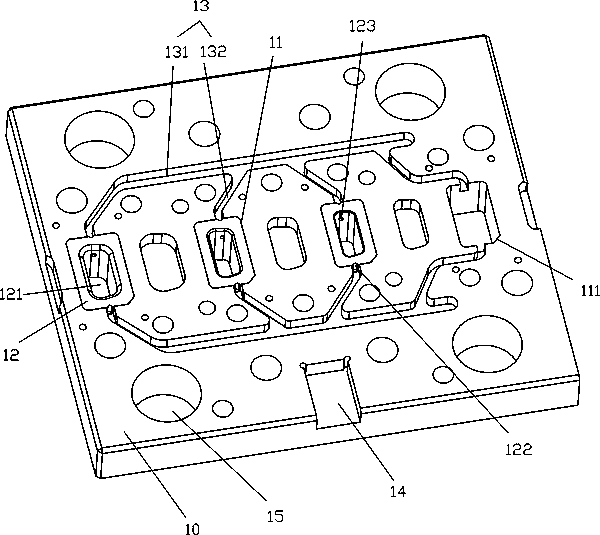

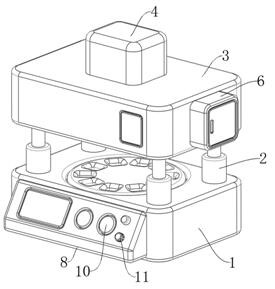

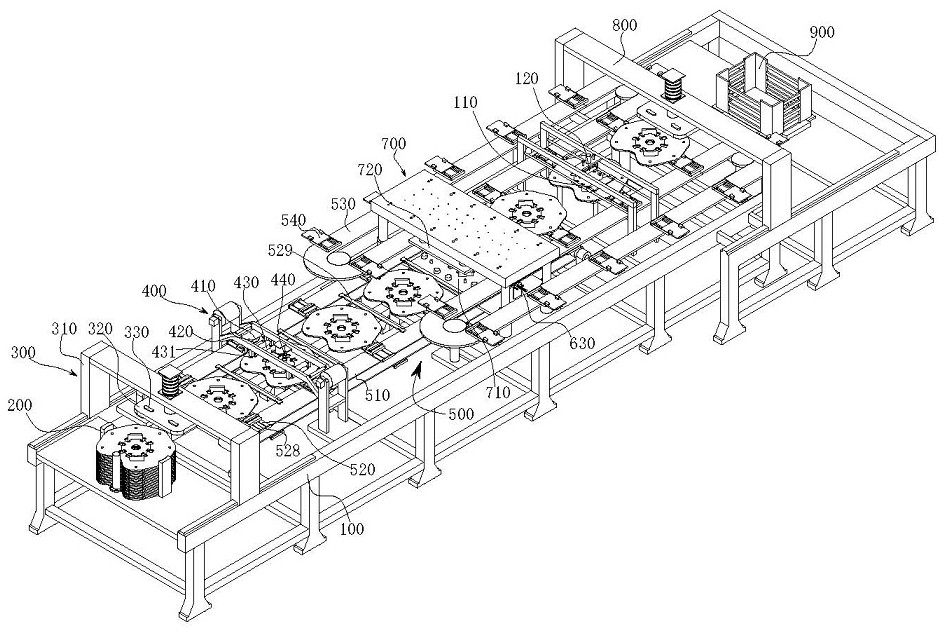

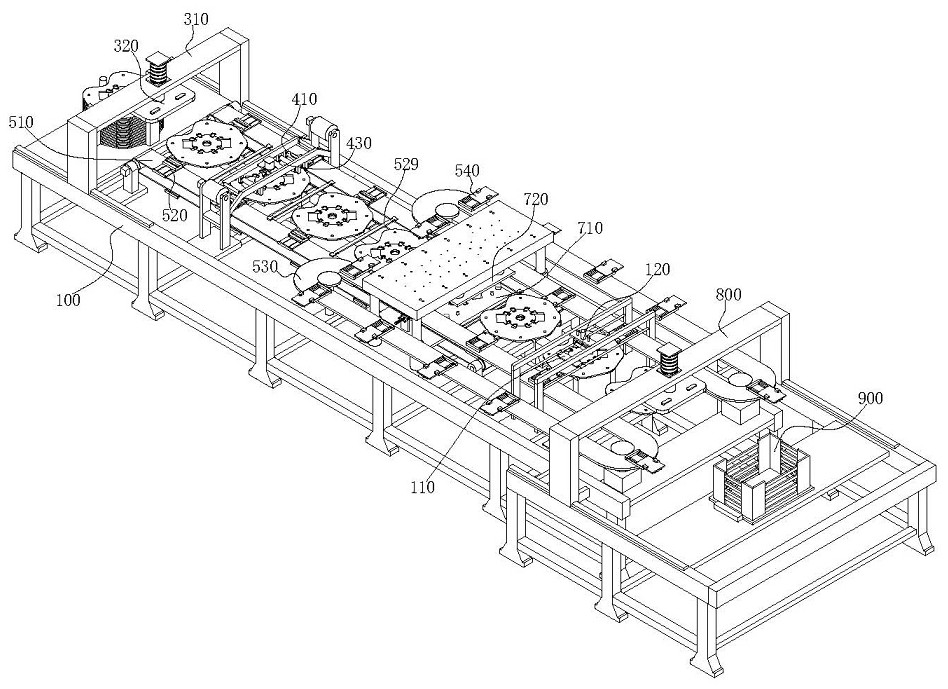

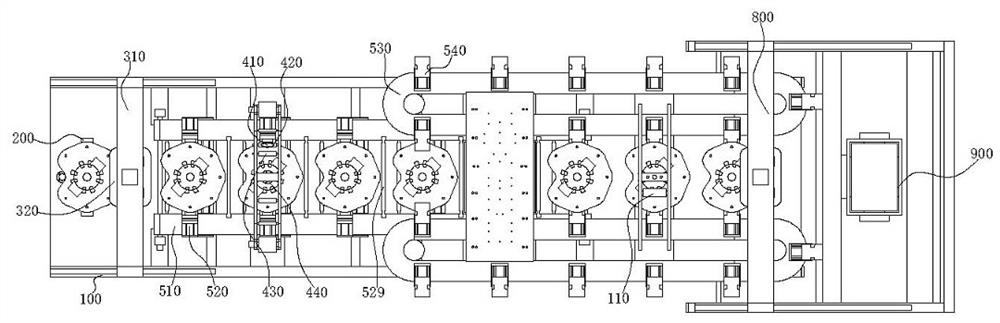

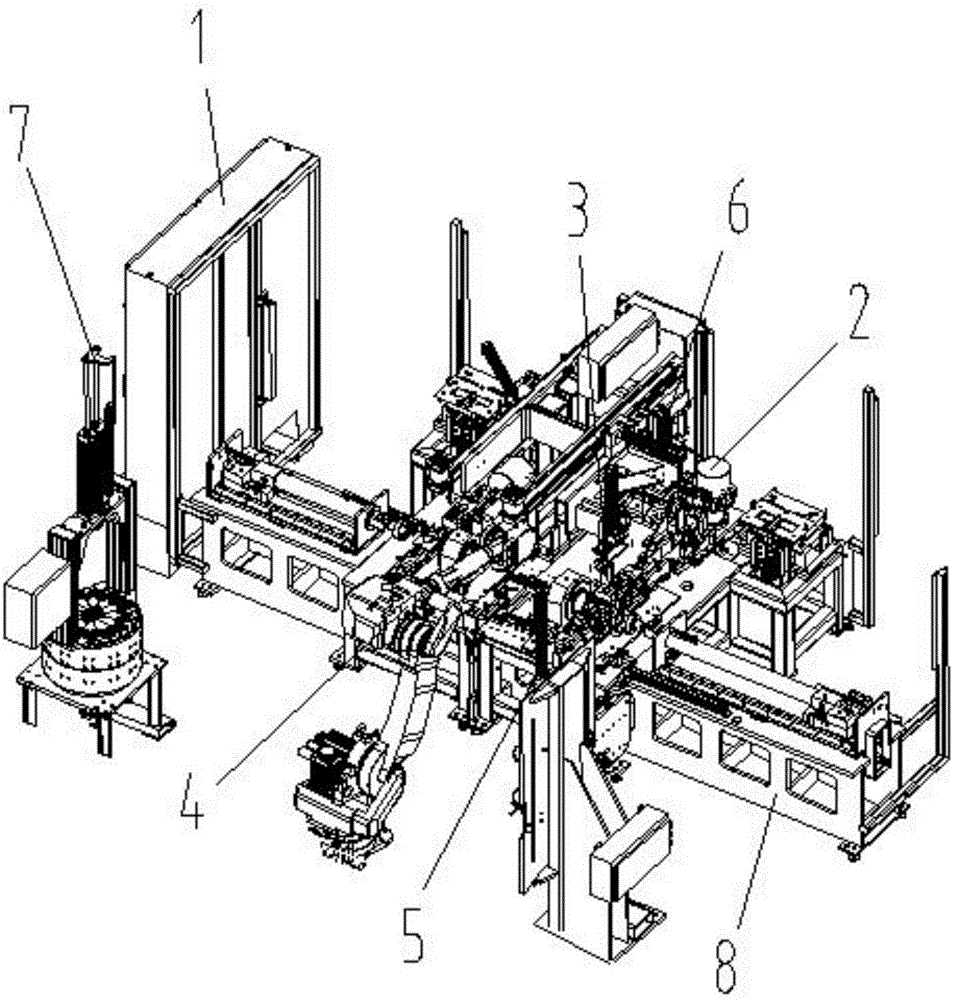

Automatic assembling machine for magnetic tile stator

ActiveCN106712403ARealize integrated automatic operationReduce manpower consumptionManufacturing stator/rotor bodiesPunchingDistribution control

The invention relates to an automatic assembling machine for a magnetic tile stator, and the machine comprises a rack and a distribution control box. The rack is provided with a punching device, and two sides of a front part are respectively provided with a detection device and a magnetizing device. Moreover, the front side is provided with a material rotating device, and the material rotating device comprises a fixed automatic universal arm. The automatic universal arm is connected with a material rotating connection plate, and a clamping device cooperating with a product is disposed below the material rotating connection plate. The clamping device comprises a clamping cylinder below the material rotating connection plate, and two sides of the clamping cylinder are connected with clamping movable blocks. Clamping blocks which cooperate with each other are disposed below the clamping movable blocks. The objective of the invention lies in providing the automatic assembling machine for the magnetic tile stator. The machine is provided with the material rotating device, and the material rotating device consists of the automatic universal arm and the clamping device, so the material rotating device can achieve the ingenious butt joint with the punching device, the detection device and the magnetizing device, thereby achieving the integrated automatic operation of a plurality of processes, reducing the manpower consumption, improving the assembling efficiency, and effectively improving the yield of products.

Owner:ANHUI DALAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com