A kind of stamping equipment with convenient die replacement

A technology for stamping equipment and die replacement, applied in the stamping field, can solve problems such as low efficiency and labor consumption, and achieve the effects of reducing production costs, improving production efficiency, and ensuring stamping effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

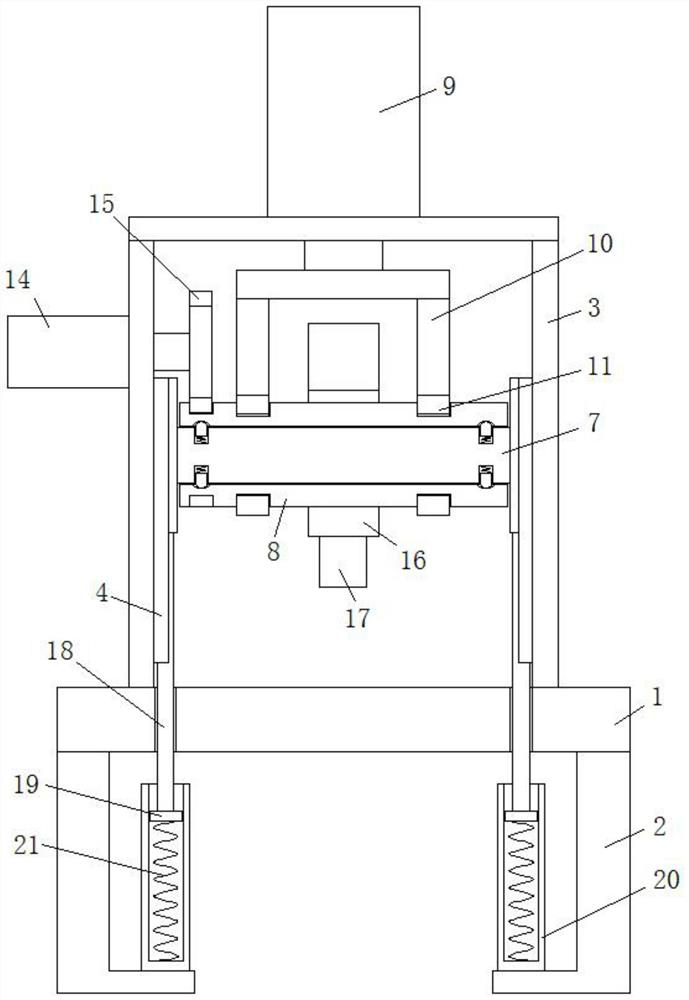

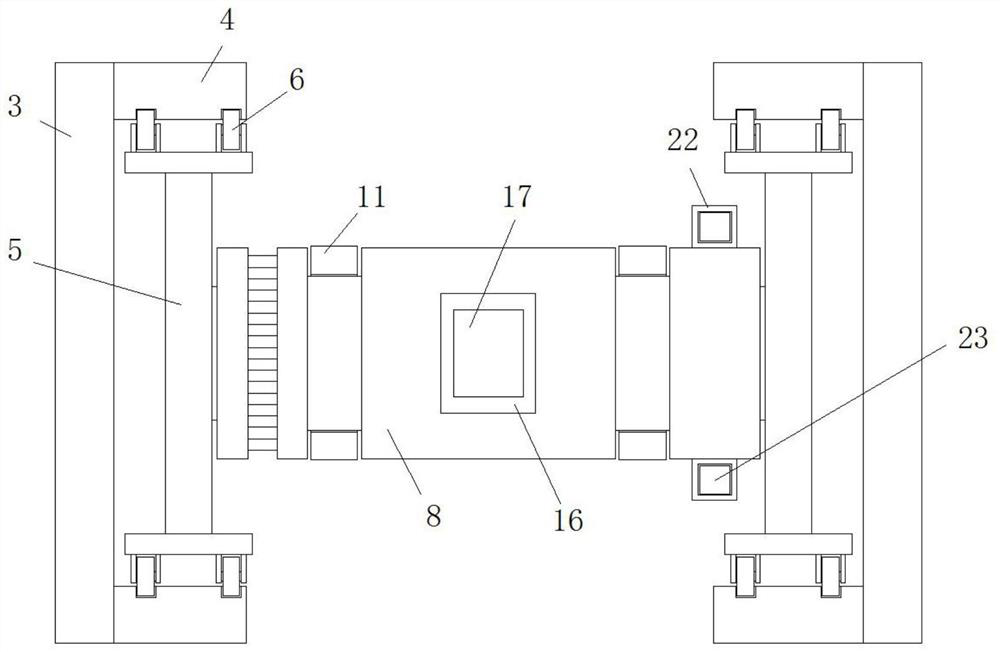

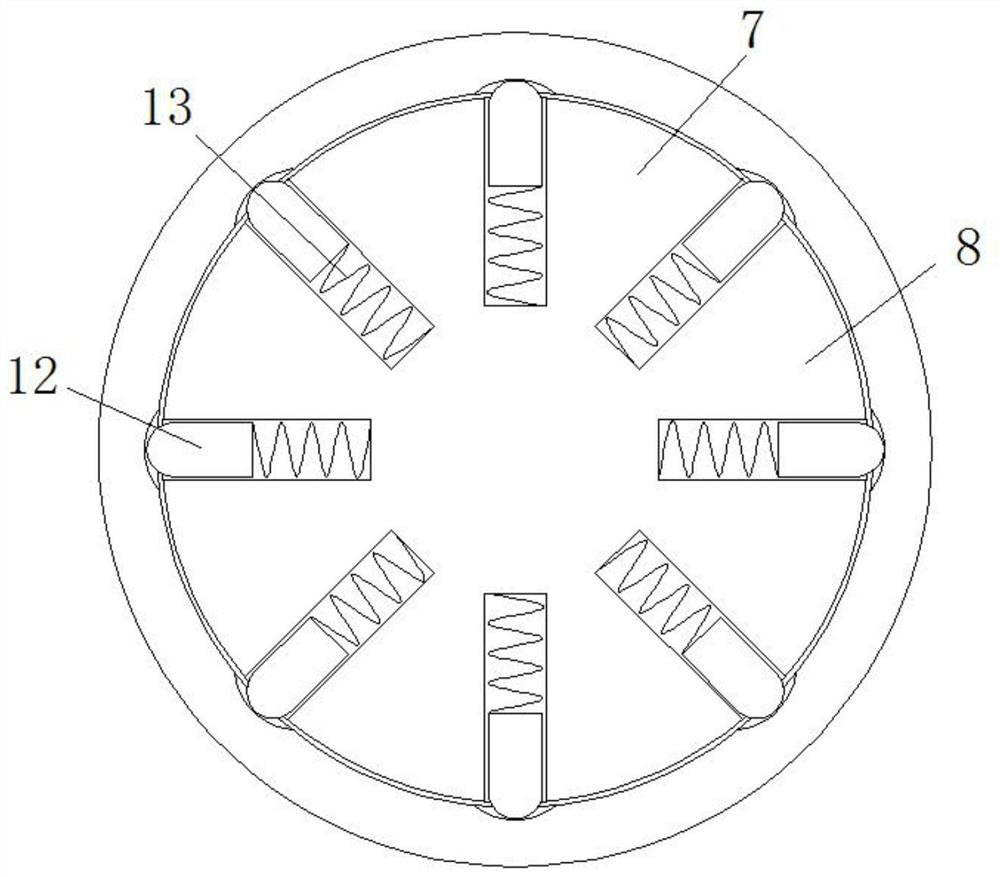

[0023]ReferFigure 1-3One mold replaces the convenient stamping device, including a table 1, and a pin 2 is fixedly connected to the bottom side of the table 1. The top side of the table 1 is provided with a U-shaped plate 3, the U-shaped plate plate 3 is vertical The inner walls of the two sides are fixedly coupled with orbital plates, and the track stands are two and vertical parallel, and the two rail sets are all adjacent to each other, and there is a vertical track slide, and the track is vertically A vertical slide 5 is provided between the plates 4, and the track wheel 6 is provided on both sides of the vertical slide 5, and the track wheel 6 is slidably connected to the vertical track slot, and the center shaft 7 is disposed vertically above the table 1. The two ends of the center shaft 7 are fixed to the vertical slide 5, respectively, and the outer rotating sleeve of the axle body of the center shaft 7 is provided with a drum 8, and an annular groove is opened outside the c...

Embodiment 2

[0026]Such asFigure 1-3As shown, the present embodiment is substantially identical to the first embodiment, preferably, the leg 2 is a L-plate structure, and the bottom end of the bottom barrel 20 is fixed to the horizontal plate of the leg 2.

[0027]In this embodiment, the L-shaped plate structure of the leg 2 facilitates the fixation of the bottom barrel 20.

Embodiment 3

[0029]Such asFigure 1-3As shown, the present embodiment is substantially identical to the first embodiment, preferably, the connecting frame 10 is a U-shaped plate structure, and the connecting ring 11 is two and is located on both sides of the mold base 16.

[0030]In this embodiment, the arrangement of the connecting ring 11 can cause relative rotation of the drum 8 and the center shaft 7 in the vertical direction in the vertical direction, and are provided on both sides, in both sides The cartridge 8 is more stable when moving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com