Stamping device and stamping method thereof

A stamping device and stamping block technology, which is applied in the field of mechanical stamping machines, can solve the problems of complicated stamping procedures and high production costs, and achieve the effects of saving stamping time, reducing working time, and improving stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

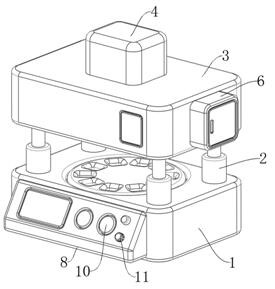

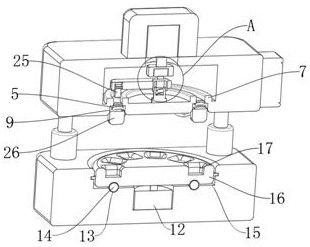

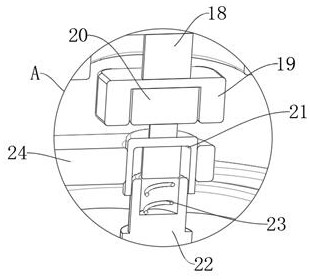

[0036] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0037] like Figure 1-3 As shown, a stamping device includes a lower die 1 and an upper die 3, the upper die 3 includes a stamping part mounting seat, and the stamping part mounting seat is provided with a plurality of mounting grooves 9 along its circumferential direction, and each mounting groove 9 is provided with There is a punching block 26 that can move vertically. Each punching block 26 has a different shape. The first motor 20 makes the swing arm 24 rotate to the top of the punching block 26 to be used. The cylinder 18 makes the pressing block 25 on the swing arm 24 act correspondingly. The stamping block 26 moves downward; correspondingly, a turntable 16 is provided on the lower die 1, and a plurality of stamping grooves 17 are arranged along the circumferential direction of the turntable 16, and stamping parts are placed in each stamping groove 17, and the turntable 16 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com