Stamping device for buckle plate of hardware lock body with adjustable rack

A punching device and adjustable technology, applied in the direction of peeling device, feeding device, storage device, etc., can solve the problems of affecting the punching effect, unsafe, incomplete punching of the gusset plate of the hardware lock body, etc., to maintain the plate body. The effect of the stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

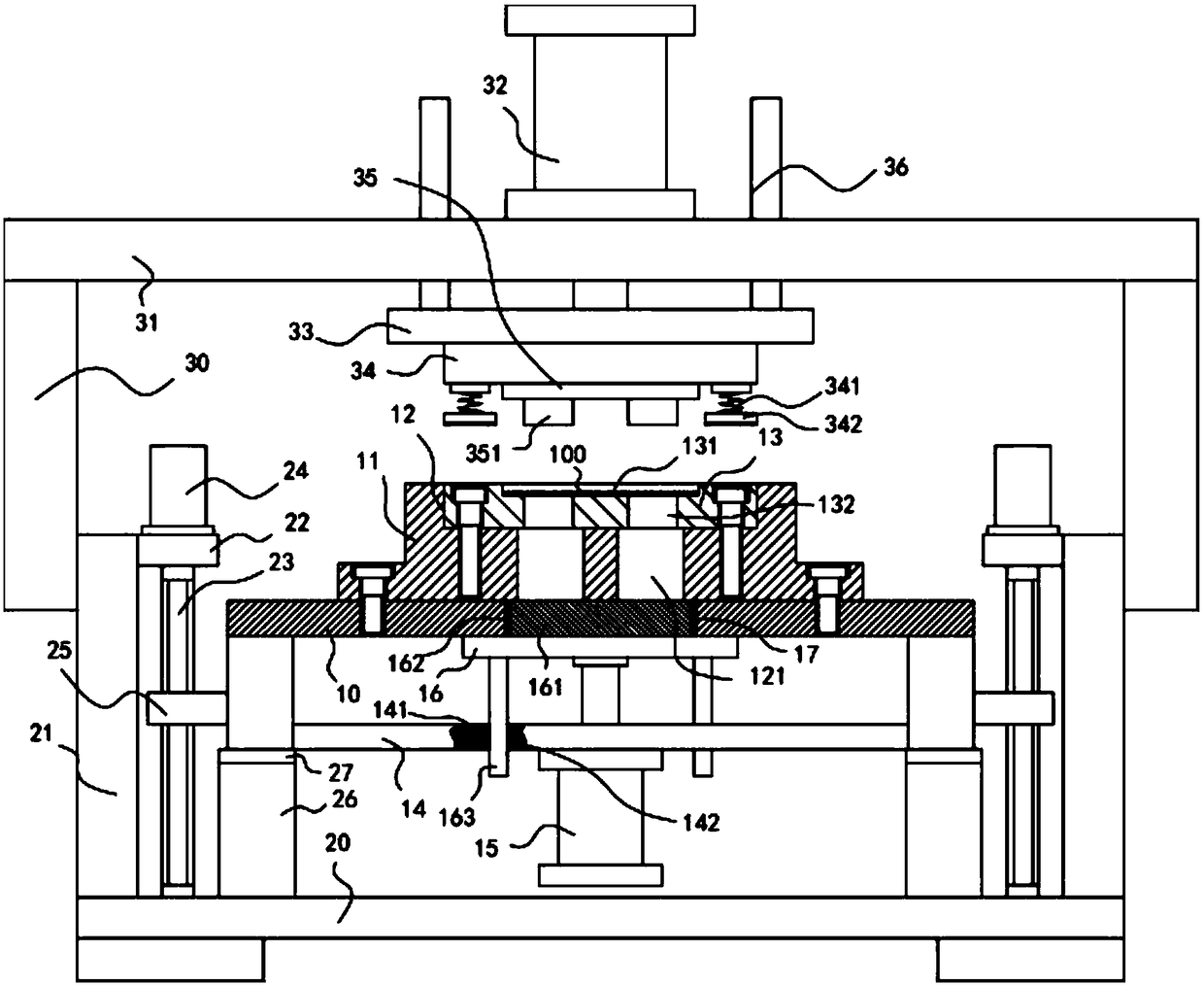

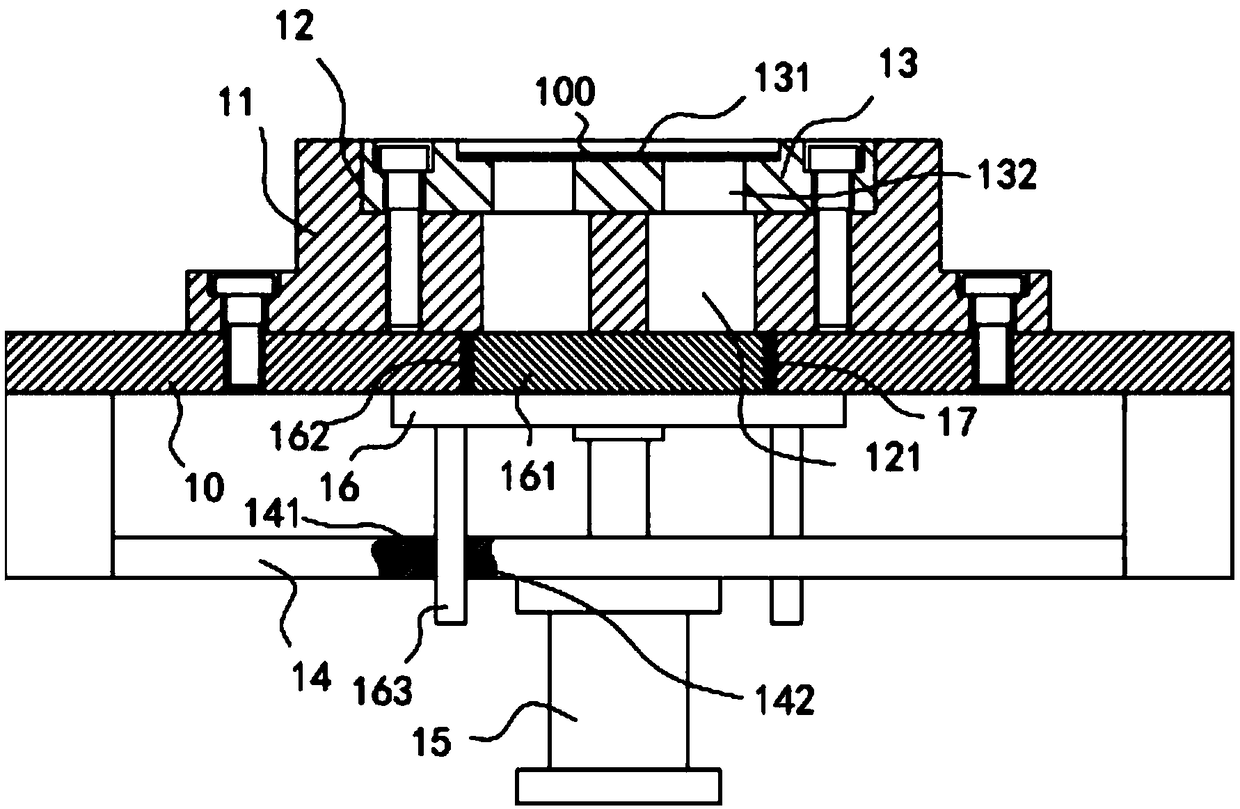

[0019] Example: see Figure 1 to Figure 2 As shown, a frame adjustable metal lock body gusset stamping device includes a frame 10 and a main base plate 20, the left and right sides of the top surface of the main base plate 20 are fixed with vertical main boards 21, two vertical main boards The upper part of the outer wall of 21 is fixed with upper support block 30, and main top plate 31 is fixed on the top surface of two upper support blocks 30, and the middle part top surface of main top plate 31 is fixed with main stamping oil cylinder 32, and the push of main stamping oil cylinder 32 The rod passes through the main top plate 31 and is fixed with a lifting connecting plate 33. The bottom surface of the lifting connecting plate 33 is fixed with an upper mold mounting block 34, and the bottom surface of the upper mold mounting block 34 is fixed with an upper mold 35. The bottom surface of the upper mold 35 is formed with two Stamping block 351;

[0020] The upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com