Processing method of bow-shaped cross arm

A processing method and technology of cross arm, applied in the field of electric power, can solve problems such as low stamping efficiency, and achieve the effects of improving production efficiency, wide application range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment discloses a processing method for a bow-shaped cross-arm, including stamping equipment and workpieces. The stamping equipment has two sets of stamping assemblies 4, and the workpieces are elongated forgings. The following steps are also included:

[0070] S1. Equipment debugging: debug various data of the stamping equipment, and reset the stamping equipment;

[0071] S2. Positioning: Fix the workpiece on the stamping equipment, so that the parts on the workpiece that need to be stamped are opposite to the positions of the two sets of stamping components 4;

[0072] S3. Stamping: Start the stamping equipment and control two sets of stamping components 4 to stamp the workpiece at the same time;

[0073] S4. Shutdown: take off the stamped workpiece and close the stamping equipment.

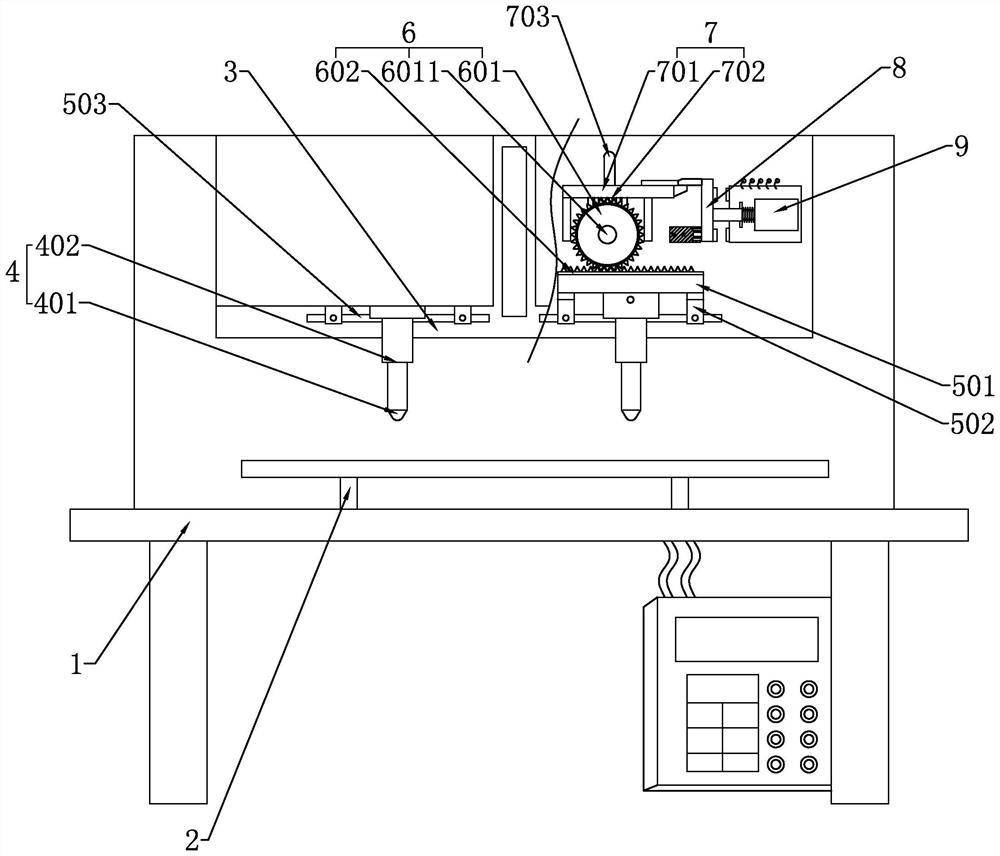

[0074] see figure 1 , in the present embodiment, the stamping equipment includes: frame 1, piece placing table 2, fixed plate 3, two groups of level adjustment components, wh...

Embodiment 2

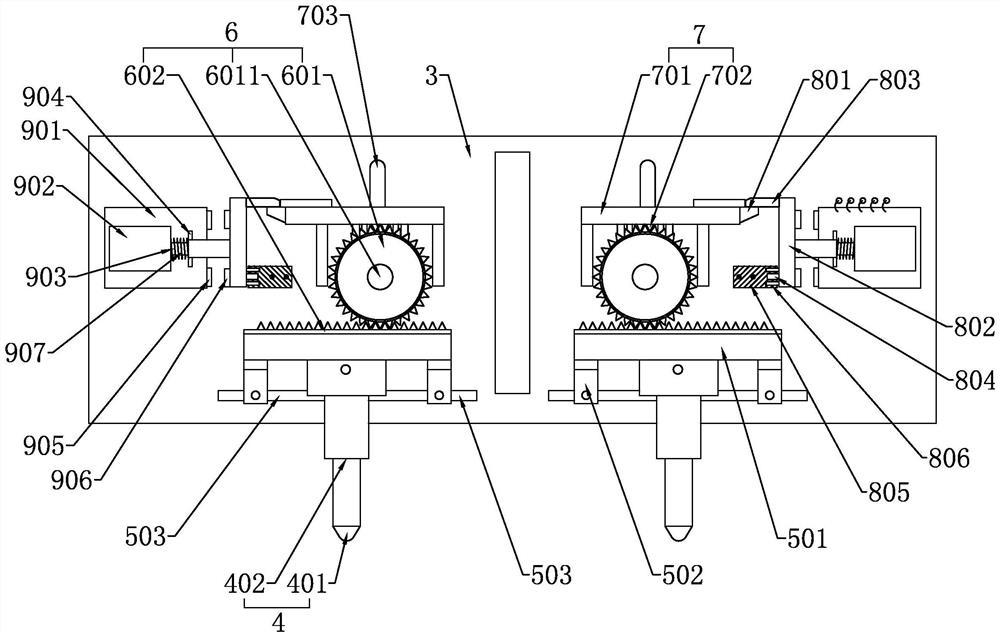

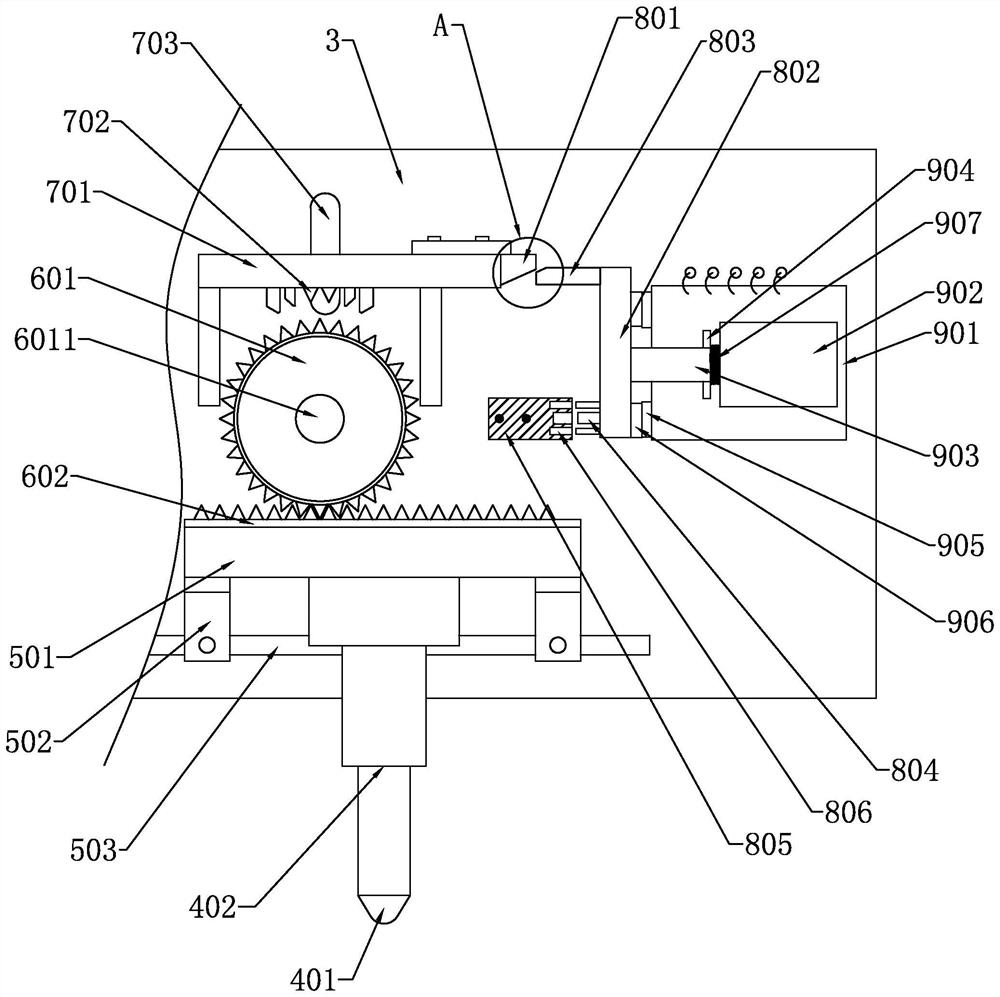

[0084] see Figure 1-Figure 4 , in this embodiment, in addition to including the characteristic structures of the foregoing embodiments, a structure of the horizontal adjustment assembly is further disclosed. The translation seat 501 or the sliding seat 502 moves horizontally; the locking assembly 7 is used to lock the horizontal driving assembly 6 when the stamping assembly 4 does not need to adjust the position; wherein, when the horizontal driving assembly 6 is locked, the sliding seat 502 cannot be relatively fixed. 3 swipe.

[0085] The lifting assembly 402 is connected with the bottom surface of the translation seat 501, one translation seat 501 corresponds to two sliding seats 502, and the two sliding seats 502 are respectively arranged on both sides of the bottom surface of the translation seat 501, the sliding seats 502 are Z-shaped, and the upper end of the sliding seat 502 is in line with the translation The bottom surface of seat 501 is connected, and the surface ...

Embodiment 3

[0093] In this embodiment, in addition to including the characteristic structures of the foregoing embodiments, a structure of the locking component 8 is further disclosed. The specific locking component 8 includes: a limiting block 801, a locking frame 802, a positioning block 805, The electromagnetic drive assembly 9, the specific limit block 801 is fixed on the free end of the locking frame 701 by fasteners; the first end of the clip frame 802 is provided with a clip block 803, and the second end of the clip frame 802 is provided with a positioning insertion rod 804; the positioning block 805 is arranged on the fixed plate 3 and at a position opposite to the second end of the card position frame 802, and the positioning block 805 is provided with a positioning slot 806 on the side surface close to the card position frame 802, and the positioning insertion rod 804 can be snapped into Locate slot 806.

[0094]In the above structure, the position of the positioning block 805 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com