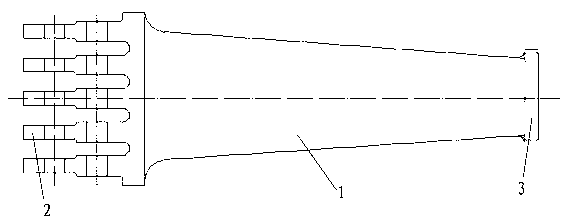

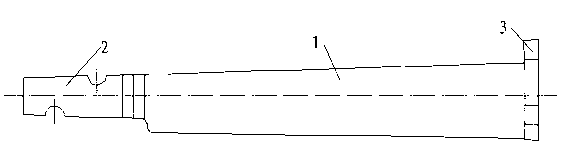

Processing method of five-fork blade-root moving blades with own shrouds

A processing method and technology of moving blades, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the complex structure of the five-pronged blade root with its own crown, increased production costs, and the efficiency and dimensional accuracy cannot be achieved. Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the processing method of the five-fork blade root with crown moving blade of the present invention comprises the following steps:

[0033] Step 1, install the blade blank on the machine tool, use three tops to clamp the positioning reference of the blade, and add a clamping mechanism on both sides of the blade root, and add a floating support under the blade crown;

[0034] Step 2. Rough machining: For the machining of the blade root and blade crown, a milling cutter with a blade with a cutting angle radius of 0.4mm is selected, the rotation speed is 2200 rpm, the feed rate is 3500mm / min, and the cutting depth requirement is 1mm , Cutting width: 12-15mm; Among them, the processing of the steam channel profile adopts a bull-nose knife with a round blade with a cutting angle radius of 5mm, its speed is 2500 rpm, the feed rate is 3000 mm / min, and the cutting depth is 2 mm, and the cutting width is 8mm;

[0035] Step 3, semi-finishing: choose a blade milling ...

Embodiment 2

[0041] Embodiment 2 is similar to Embodiment 1, and mainly changes and controls various parameters affecting blade deformation during processing.

[0042] Step 1. Install the blade blank on the machine tool, use three tops to clamp the positioning reference of the blade, and add a clamping mechanism on both sides of the blade root, and add a floating support under the blade crown;

[0043] Step 2. Rough machining: For the machining of the blade root and blade crown, a milling cutter with a blade with a cutting angle radius of 0.4mm is selected, and its speed is 2000 rpm (can be selected from 2000-2200 rpm). The feeding speed is 3000mm / min (can be selected from 3000-3500mm / min), the cutting depth requirement is 0.8mm (can be selected from 0.8-1mm), and the cutting width can be 12mm (can be selected from 12-15mm); among them For the processing of the steam channel profile, a bull-nose knife with a round blade with a cutting corner radius of 5mm is selected, the speed is 2200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com