Numerical control lathe multi-cutter-position device

A CNC lathe, multi-tool technology, applied in the direction of tool holders, etc., can solve the problems of not making full use of the CNC system, affecting the efficiency and precision of processing, and increasing the labor intensity of workers, so as to achieve simple structure, improve efficiency and processing accuracy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

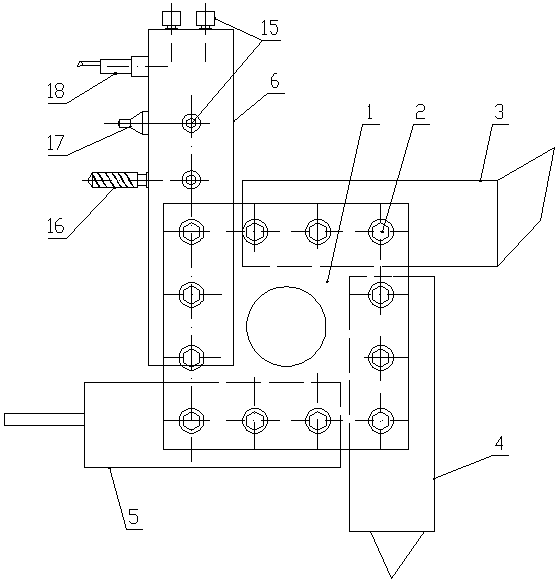

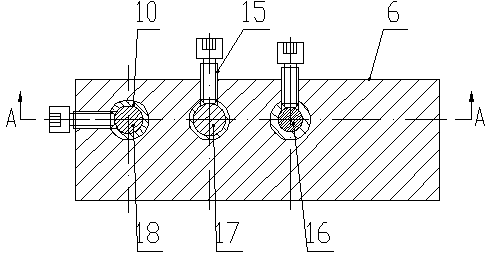

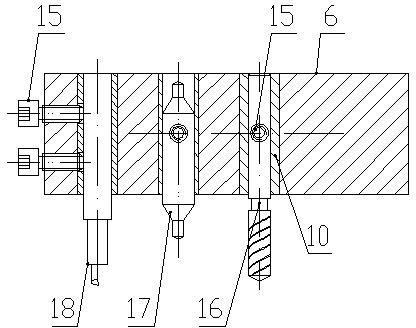

[0021] Such as Figure 1-Figure 9 As shown, the CNC lathe multi-tool position device of the present invention includes an electric square tool rest 1 with four clamping positions, and the three clamping positions of the electric square tool rest 1 are respectively clamped with outer circles by universal compression bolts 2. Turning tool 3, thread turning tool 4 and cutting and grooving turning tool 5, the fourth clamping position of the electric square tool holder 1 is provided with a general-purpose tool installation structure, and the general-purpose tool installation structure includes a general-purpose pressing bolt 2. The body 6 in the shape of a cuboid is clamped, and the body 6 is horizontally provided with a first knife hole 7, a second knife hole 8 and a third knife hole 9 parallel to each other, the first knife hole 7, the second knife hole A bushing 10 is respectively arranged inside the hole 8 and the third tool hole 9, and each bush 10 is respectively equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com