Die device capable of saving stamping oil

A stamping oil and mold technology, which is applied in the field of stamping oil-saving mold devices, can solve the problems of stamping oil waste, poor working parts, stamping oil overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

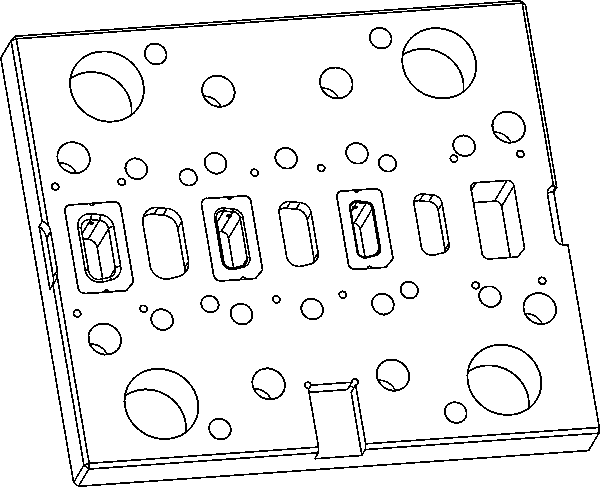

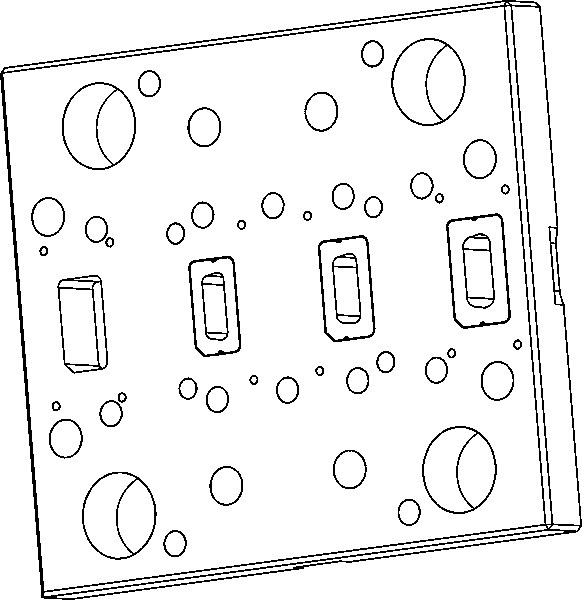

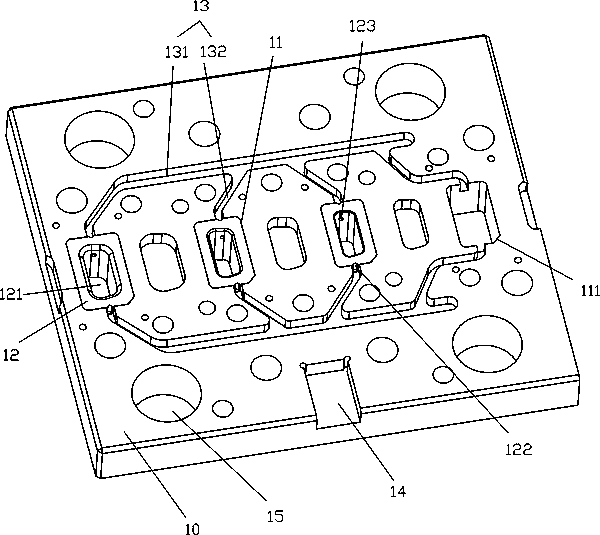

[0018] Examples, see e.g. Figures 3 to 4 As shown, a mold device that saves stamping oil includes a lower template 10, a plurality of processing mold installation through holes 11 are formed on the top surface of the lower template 10, and the mold block 12 is inserted into the corresponding processing mold installation through hole 11, a diversion oil storage tank 13 is formed on the top surface of the lower template 10, and the diversion oil storage tank 13 communicates with all processing mold installation through holes 11.

[0019] Furthermore, the middle part of the mold block 12 has a mold through hole 121 , and the side wall of the mold block 12 is formed with a vertical diversion groove 122 , and the vertical diversion groove 122 communicates with the diversion oil storage tank 13 .

[0020] Furthermore, the inner wall of the mold through hole 121 of the mold block 12 is formed with a radial flow through hole 123 , and the radial flow through hole 123 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com