Gas-liquid mixing system and gas-liquid mixing method

A gas-liquid mixing and bubble generator technology, which is applied in the field of a gas-liquid mixing system in agriculture, can solve the problems that restrict the application and popularization of green and environmentally friendly pesticide alternative technologies, the instability of the gas-liquid mixed solution, and the increase of the gas-liquid mixing ratio. , to achieve the effect of improving gas-liquid mixing effect, strong adsorption capacity, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

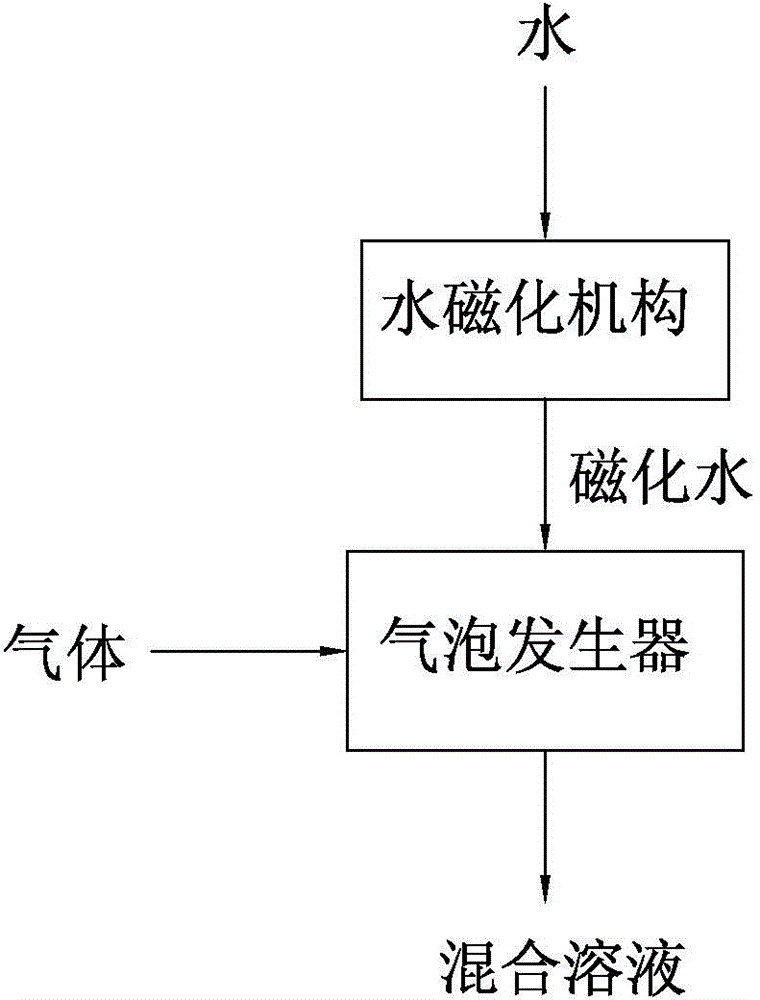

[0027] Such as figure 1 The gas-liquid mixing system shown includes a water magnetization mechanism and a bubble generator, and the water magnetization mechanism is connected to the water inlet of the bubble generator through a pipeline. Wherein, there are one or more bubble generators, and multiple bubble generators are arranged in parallel. The water magnetization mechanism includes a plastic inner tube covered with a magnet with a magnetic strength of 1000--80000 Gauss.

[0028] The bubble generator is one of the following devices: a micro-bubble generator, a nano-bubble generator, a micro-bubble generator, and a micro-nano foam generator. Their working principles are as follows:

[0029] 1) Microbubble generator:

[0030] working principle:

[0031] The liquid is ejected through the nozzle, and the gas is sucked into the receiving chamber through the suction pipe. Due to the viscous effect between the jet boundary layer and the gas in the receiving chamber, the gas is ...

Embodiment 2

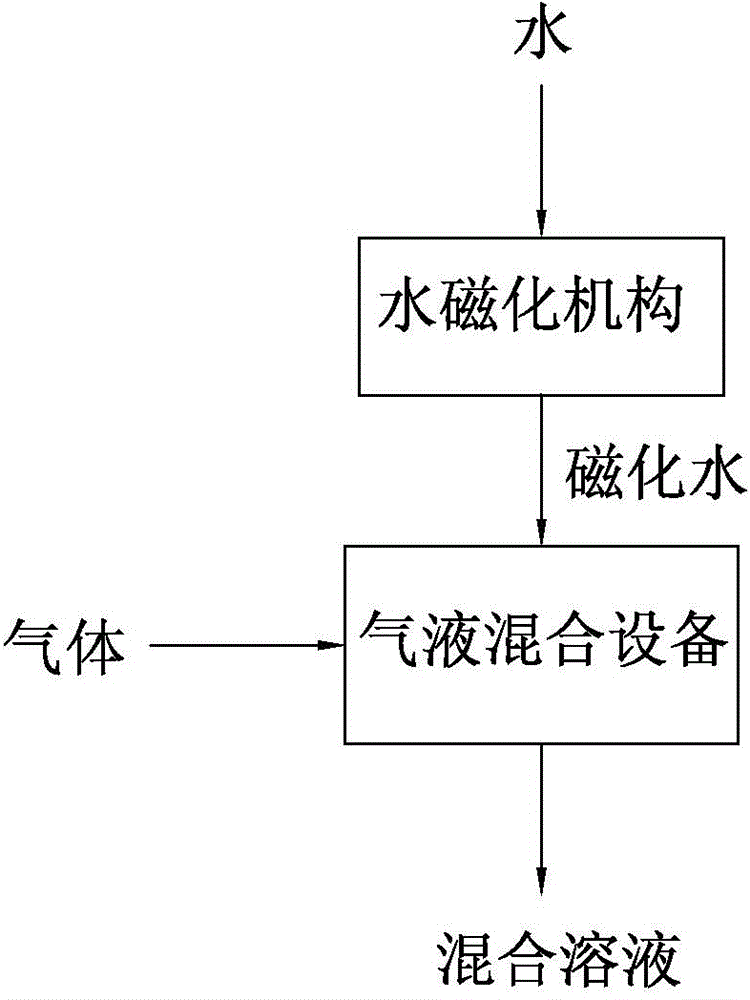

[0056] Such as figure 2 The gas-liquid mixing system shown includes a water magnetization mechanism and gas-liquid mixing equipment, and the water magnetization mechanism is connected to the water inlet of the gas-liquid mixing equipment through a pipeline. Wherein, there are one or more gas-liquid mixing devices, and multiple gas-liquid mixing devices are arranged in parallel. The water magnetization mechanism includes a plastic inner tube covered with a magnet with a magnetic strength of 1000--80000 Gauss.

[0057] The gas-liquid mixing equipment is one of the following devices: a gas-liquid mixing pump, an ejector, and a static mixer. Their working principles are as follows:

[0058] 1) Gas-liquid mixing pump

[0059] working principle:

[0060] The suction port of the gas-liquid mixing pump can use negative pressure to inhale gas, and the high-speed rotating pump impeller mixes the liquid and gas to form a mixed liquid of microbubbles. At the same time, through the p...

Embodiment 3

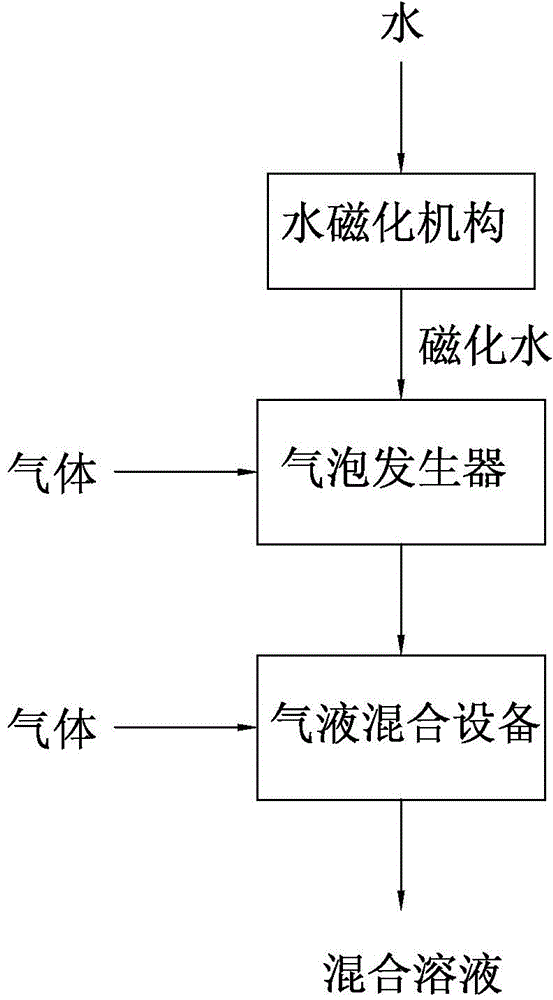

[0082] Such as image 3 The gas-liquid mixing system shown includes a water magnetization mechanism, gas-liquid mixing equipment and a bubble generator. The water magnetization mechanism is connected to the water inlet of the bubble generator through a pipeline, and the water outlet of the bubble generator is connected to the gas-liquid mixing system through a pipeline. water inlet of the device. Among them, the bubble generator and the gas-liquid mixing equipment correspond one-to-one, and more than one can be set. The water magnetization mechanism includes a plastic inner tube covered with a magnet with a magnetic strength of 1000--80000 Gauss. The bubble generator is one of the following devices: a micro-bubble generator, a nano-bubble generator, a micro-bubble generator, and a micro-nano foam generator. The gas-liquid mixing equipment is one of the following devices: a gas-liquid mixing pump, an ejector, and a static mixer.

[0083] The corresponding gas-liquid mixing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com