Patents

Literature

835results about "Mixing gases/vapours with liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

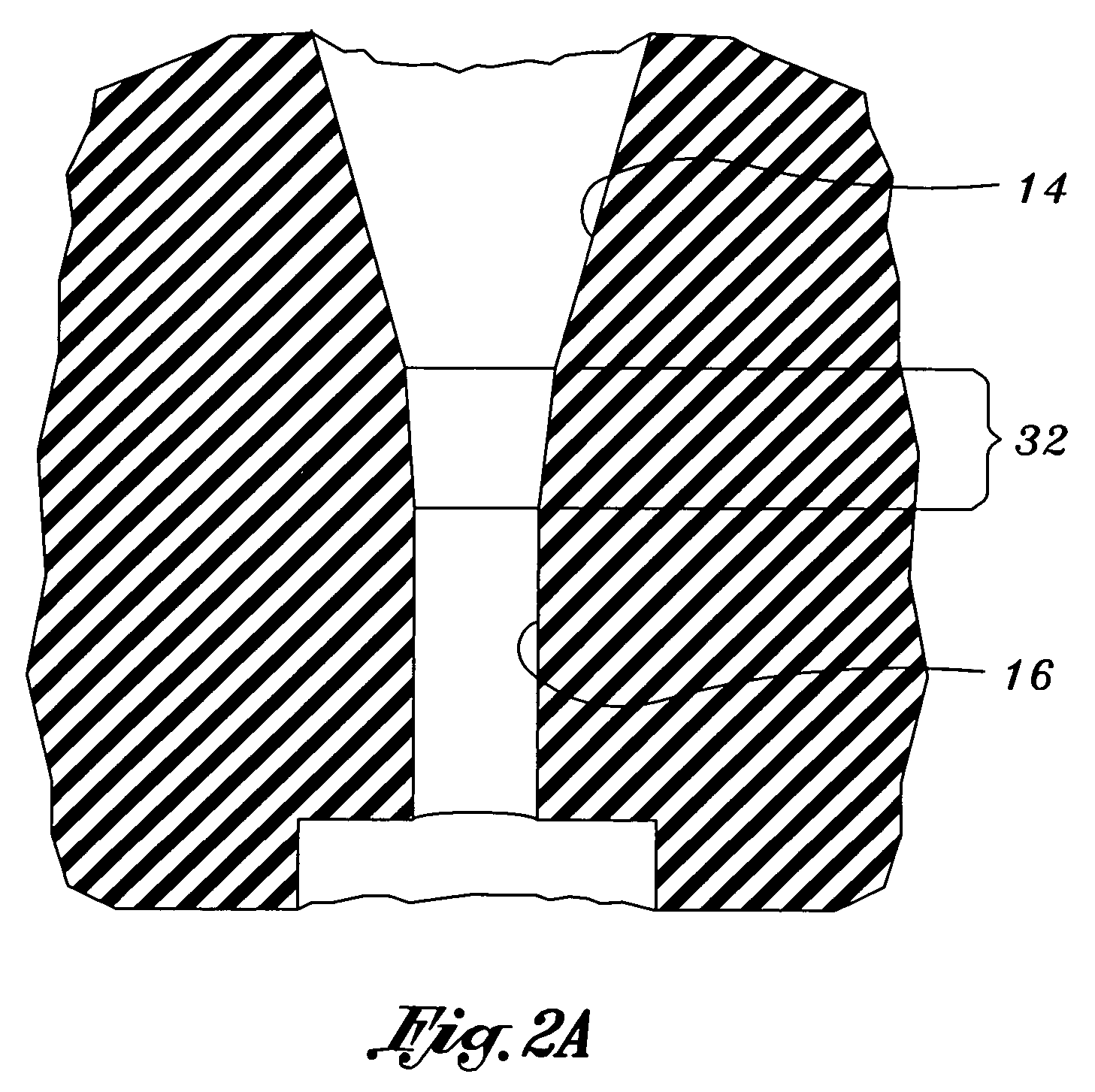

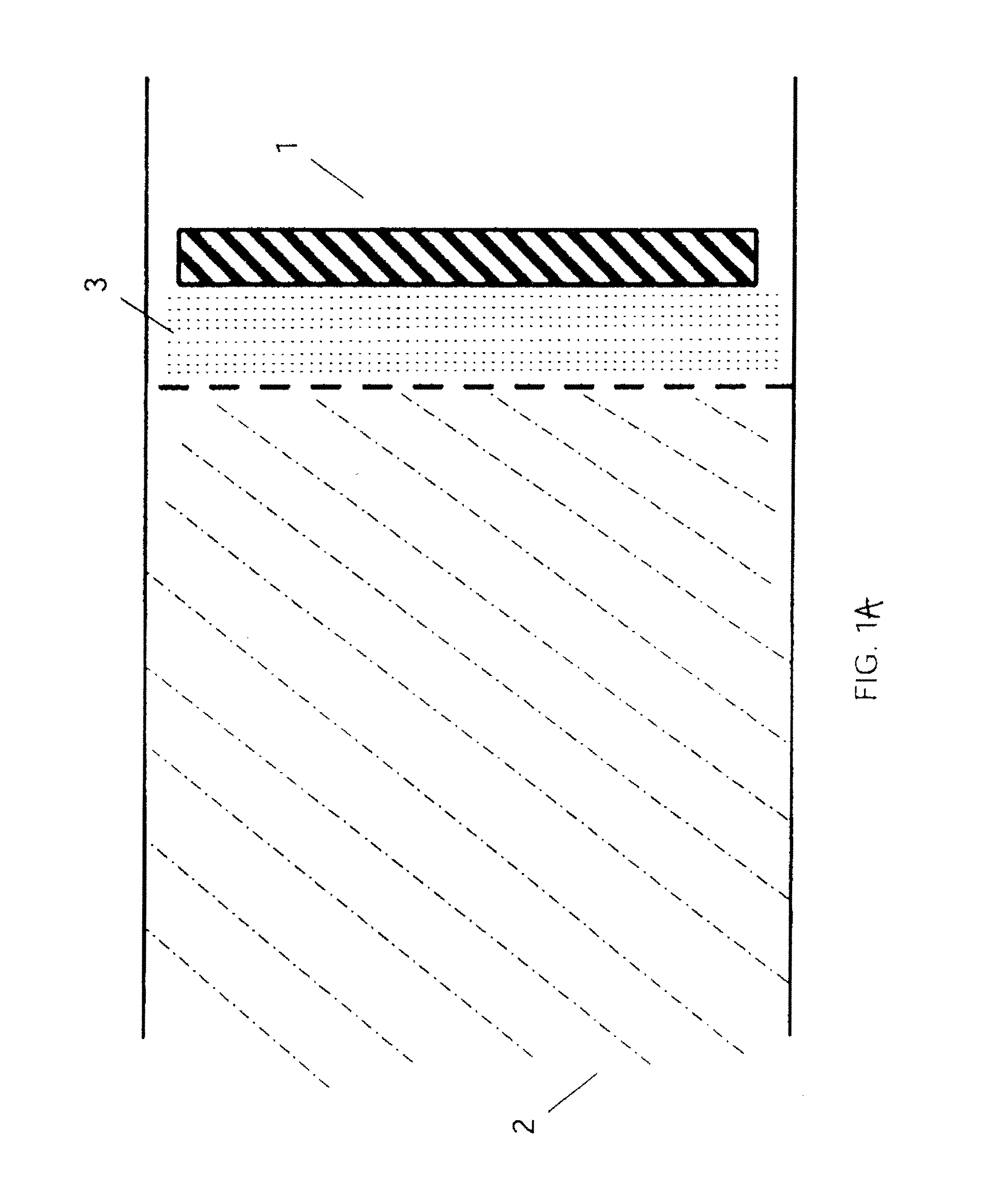

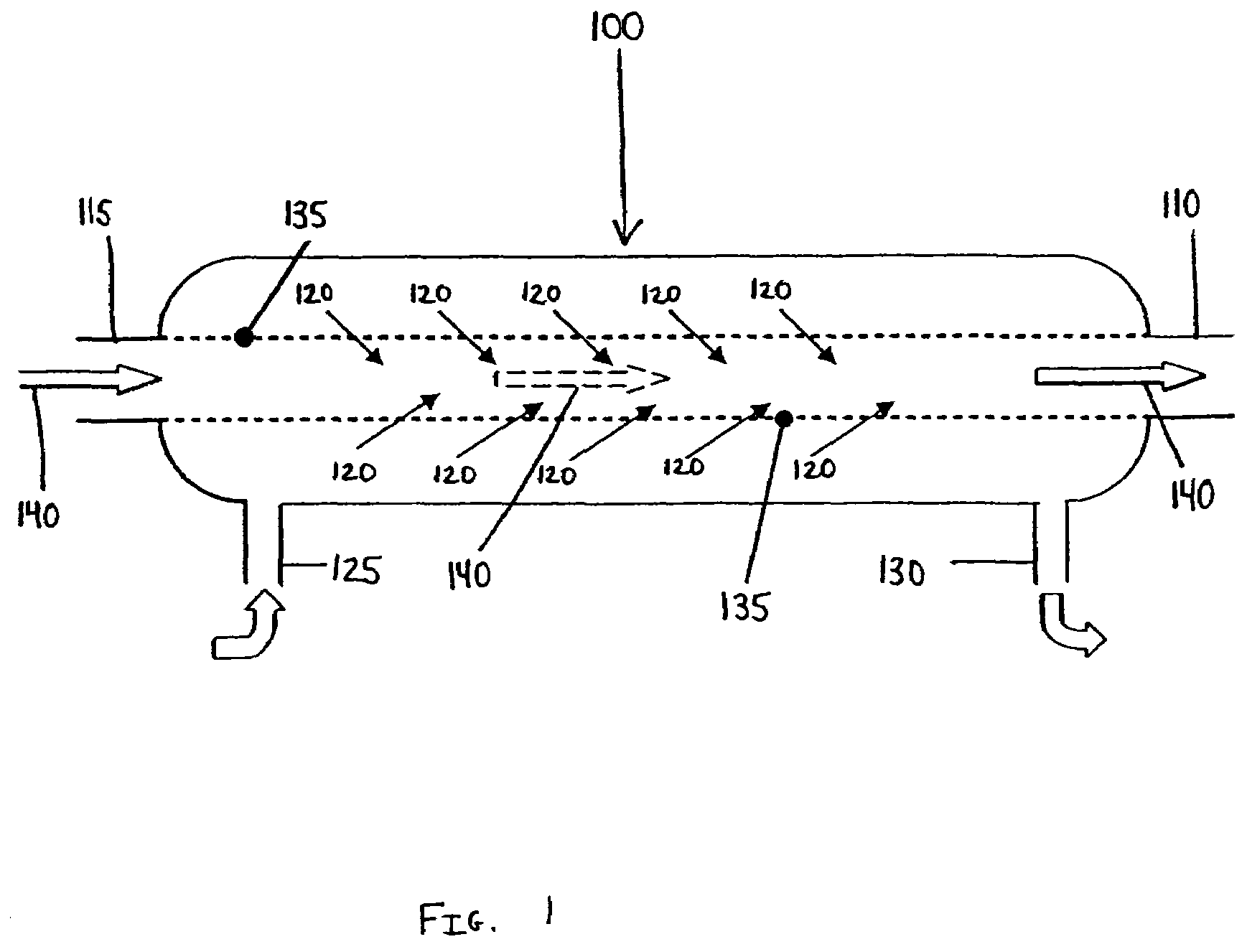

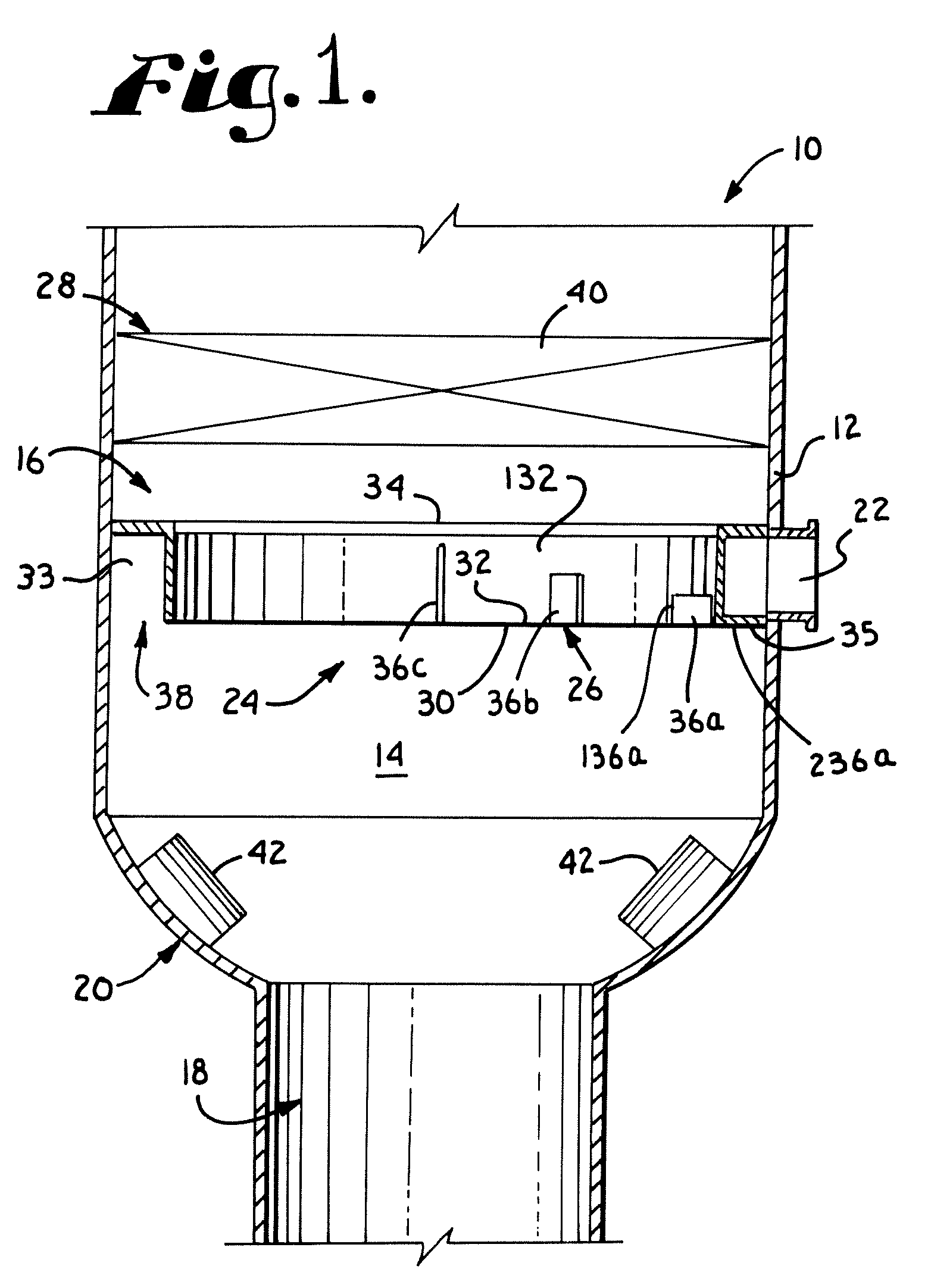

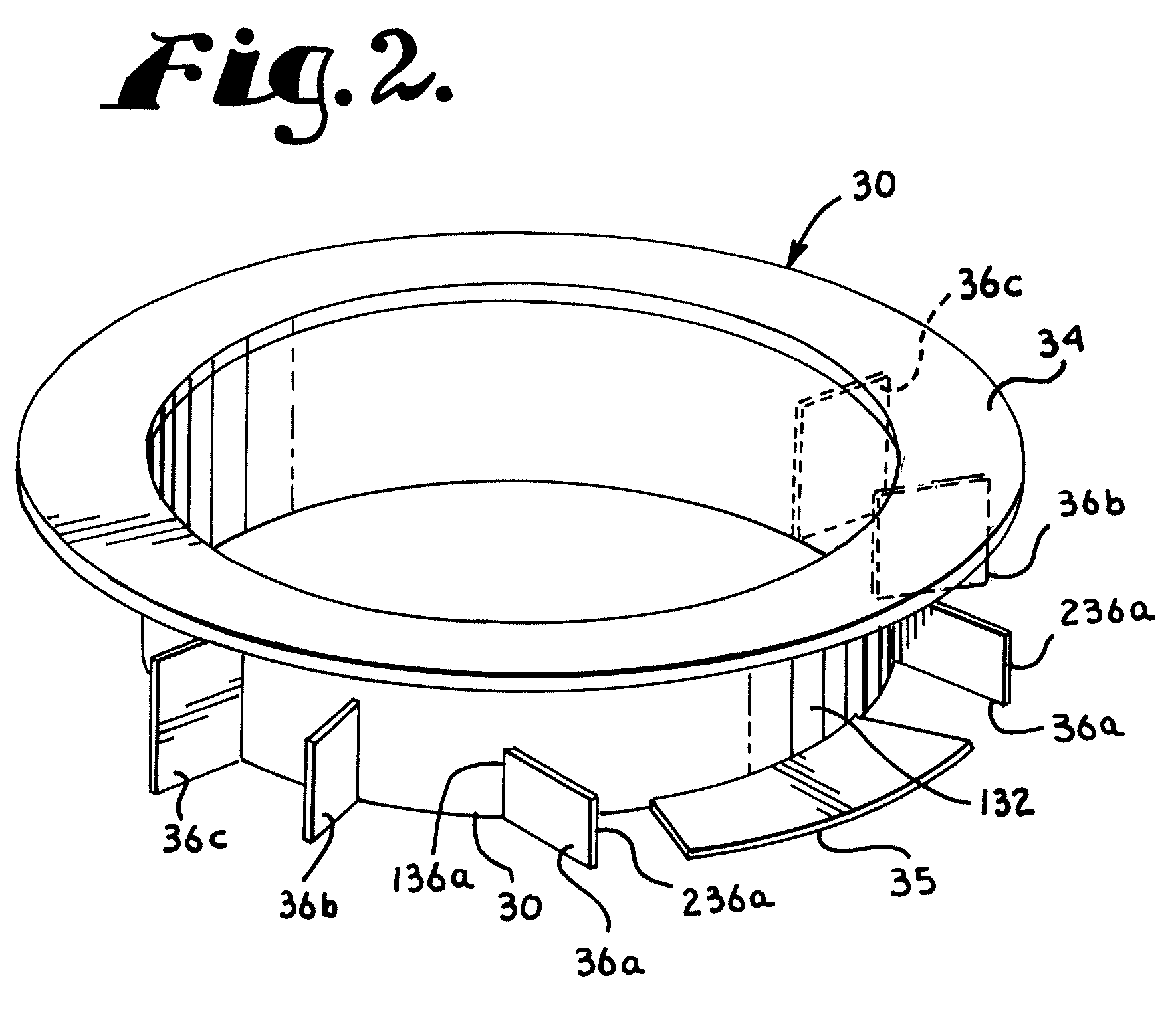

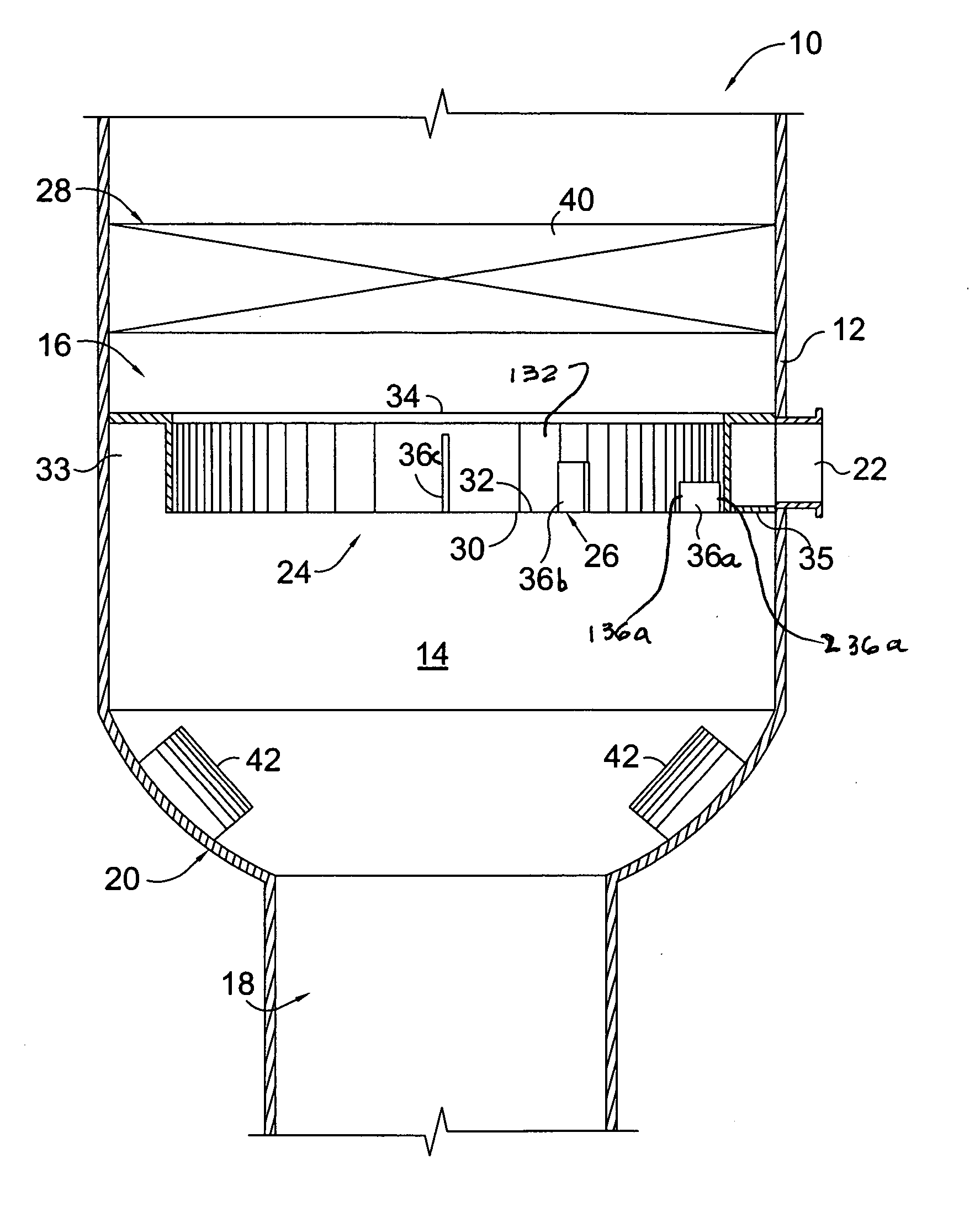

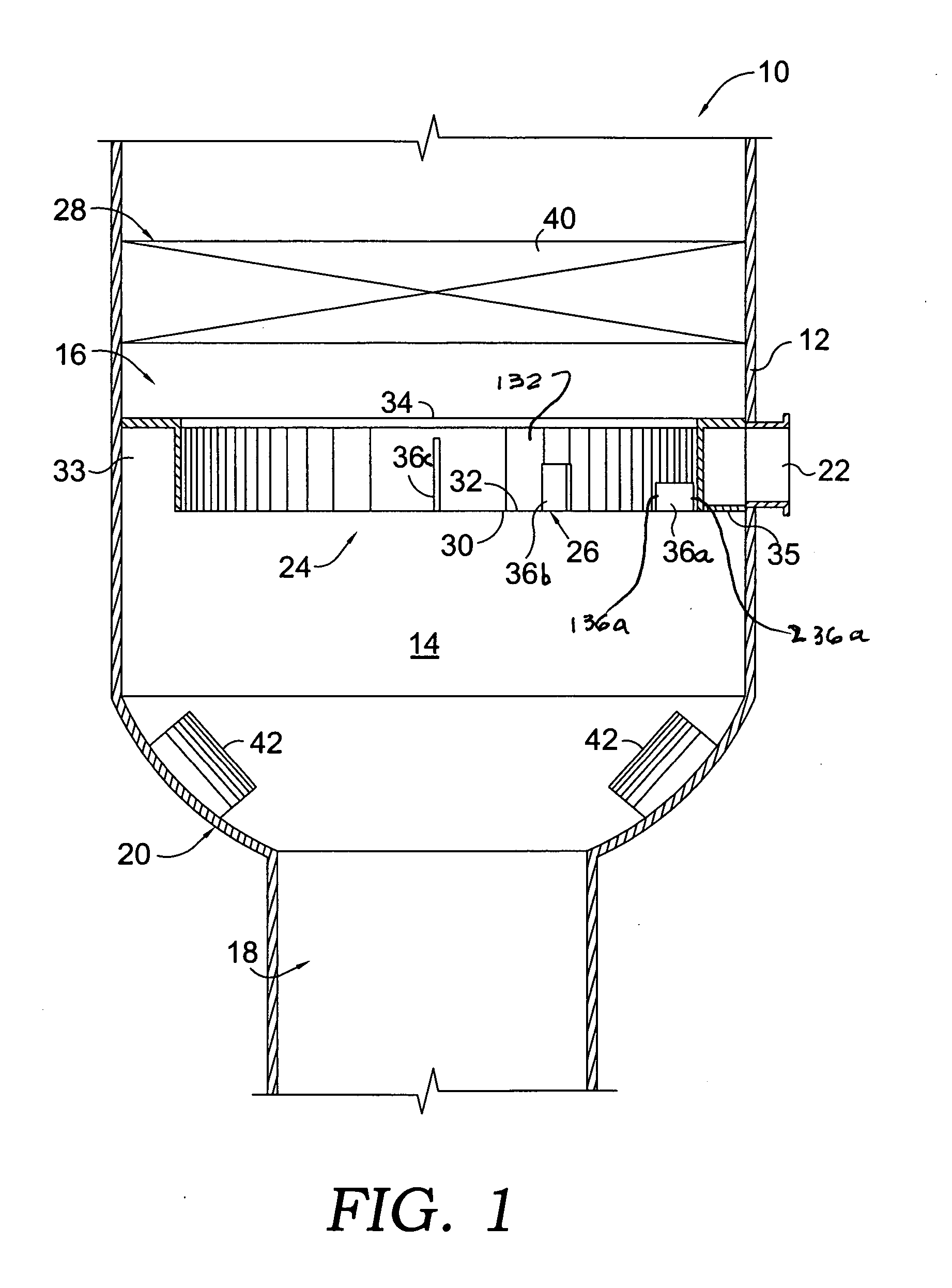

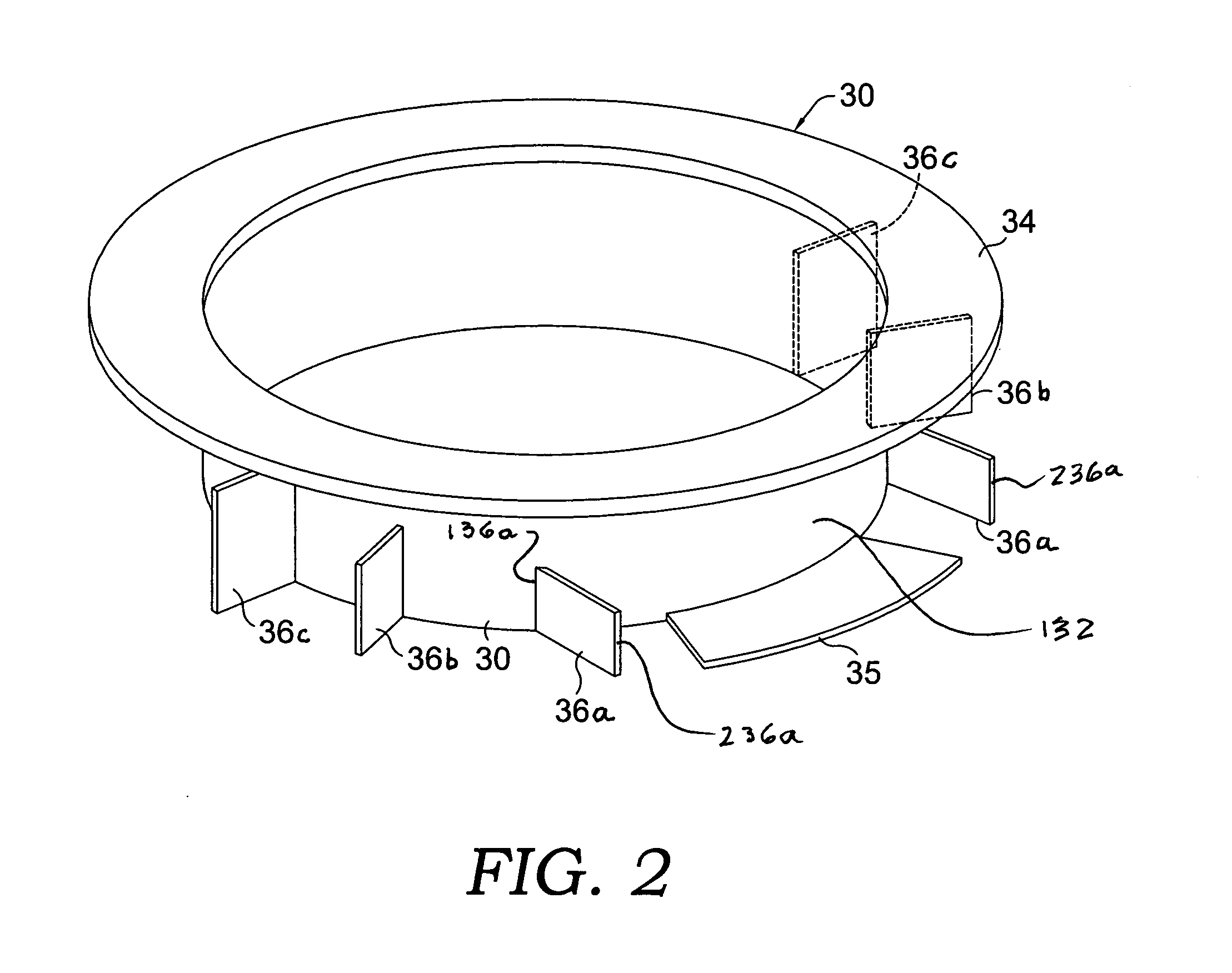

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

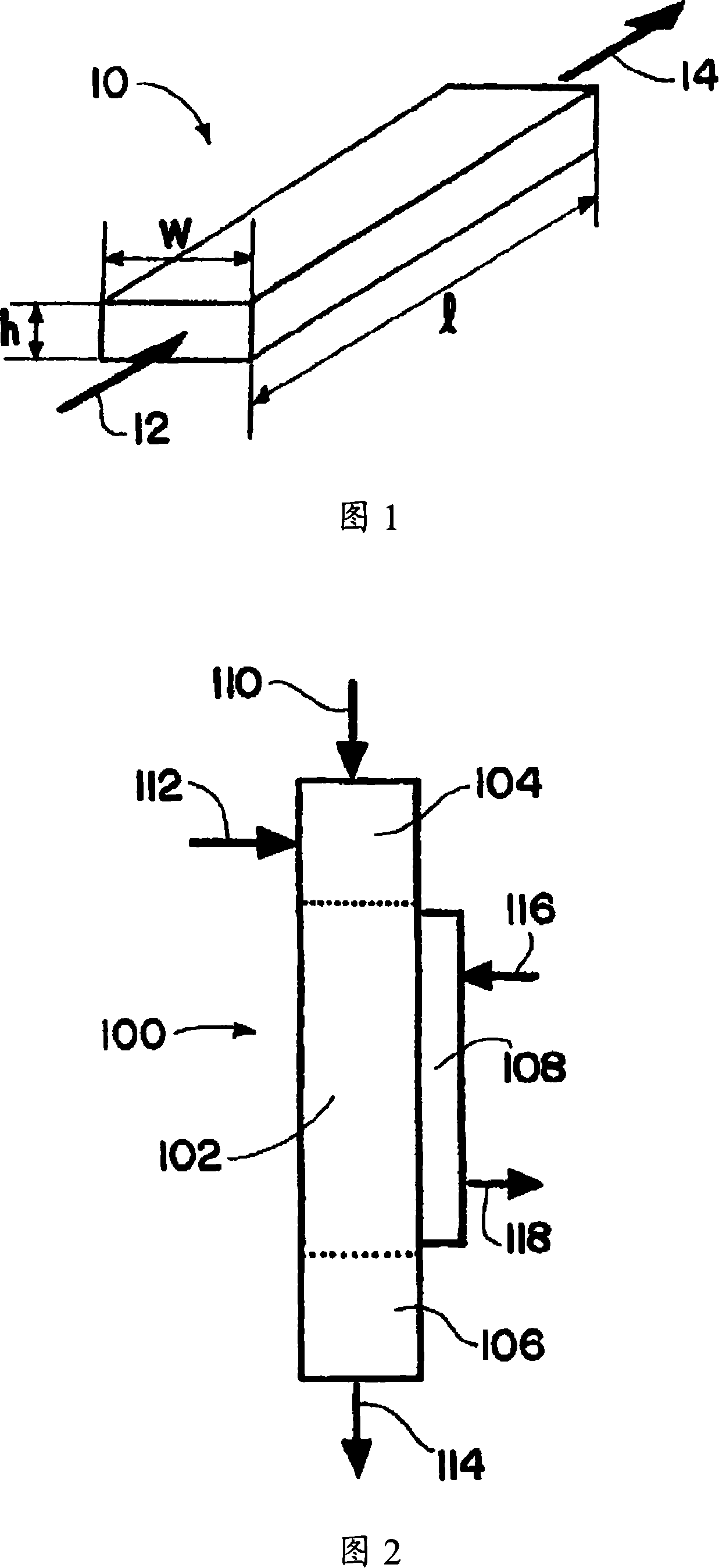

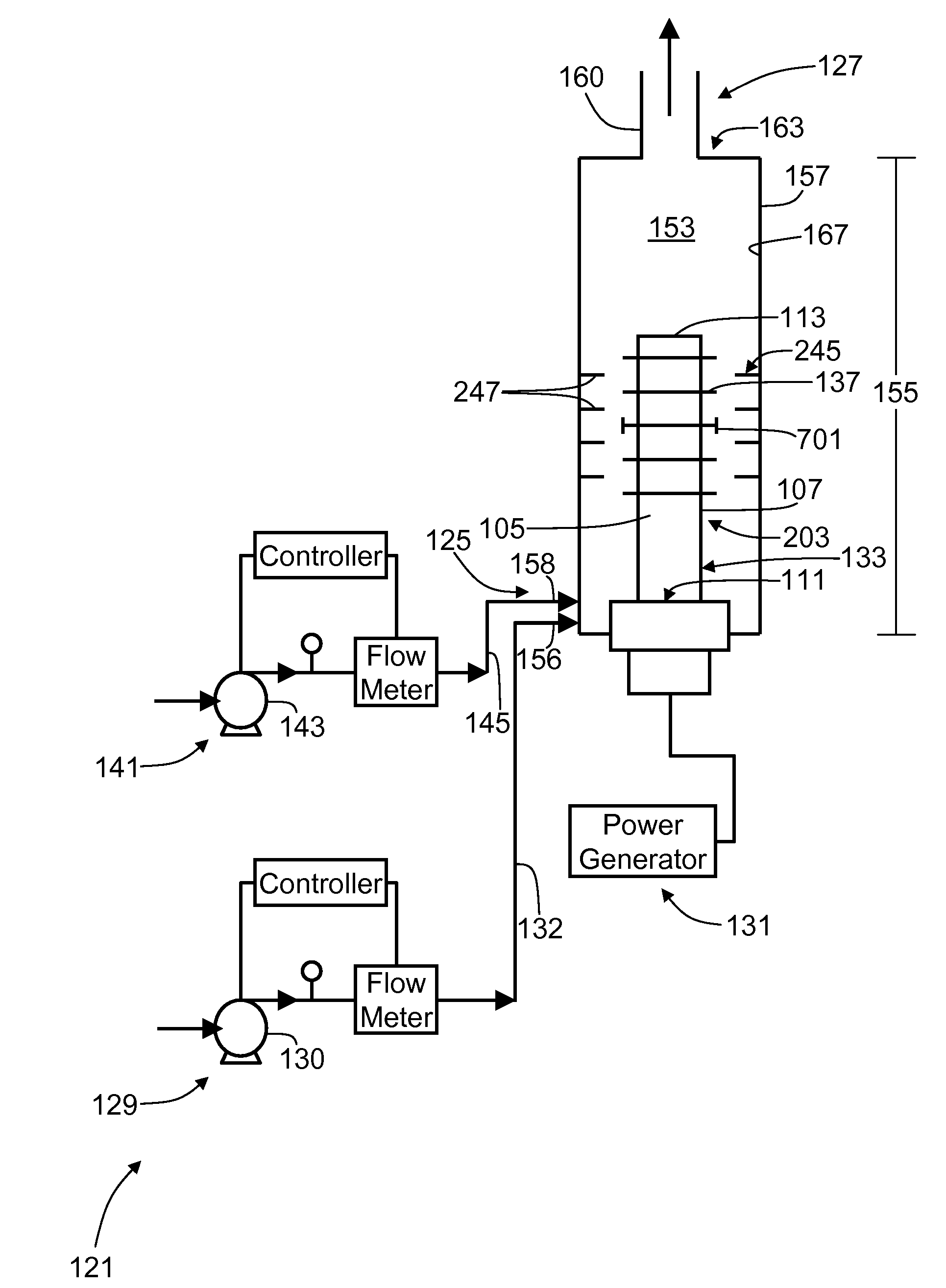

Co-current vapor-liquid contacting apparatus

ActiveUS20070137482A1Easily redistributedIncrease capacityCombination devicesTransportation and packagingVapor liquidFractionating column

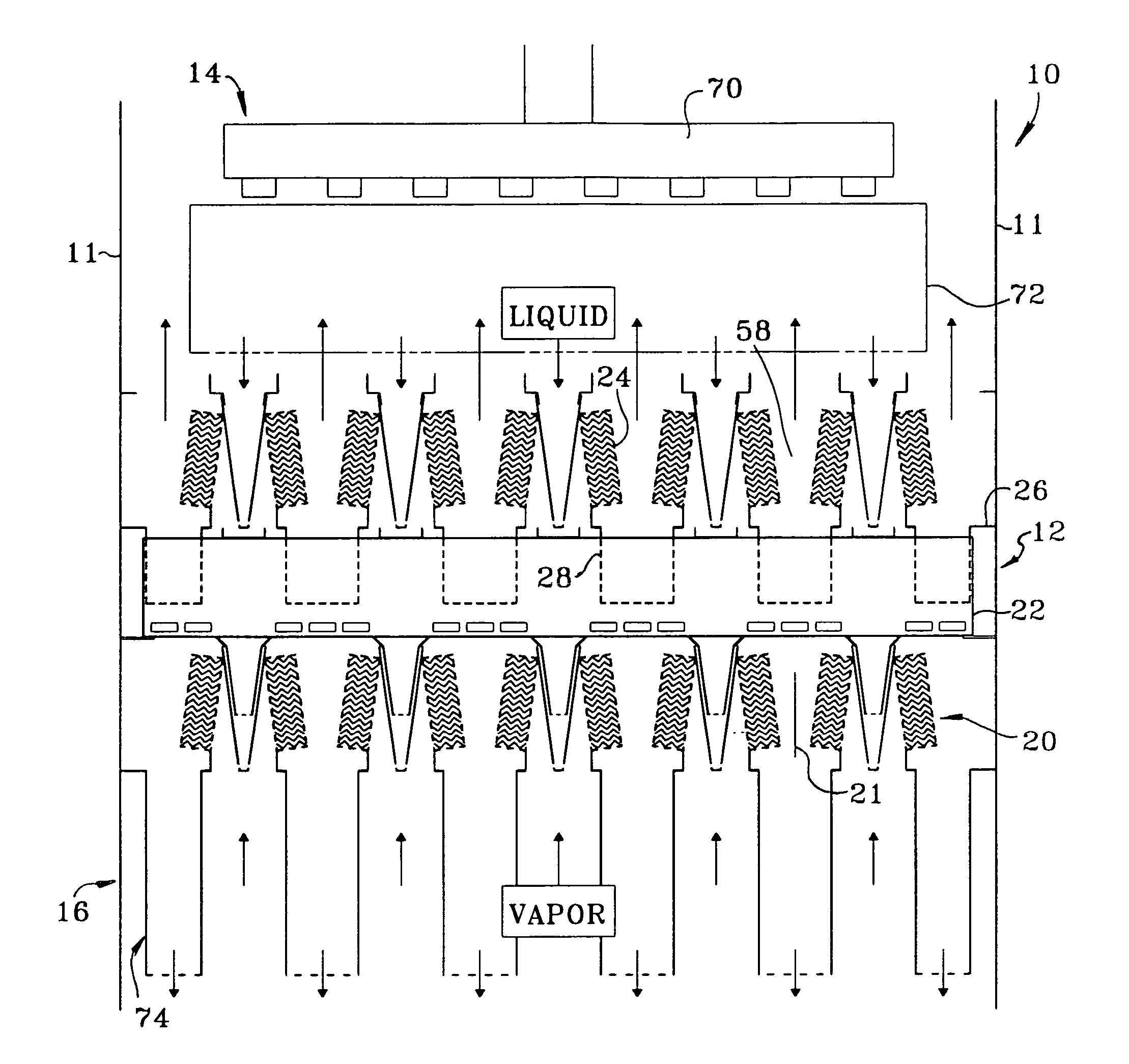

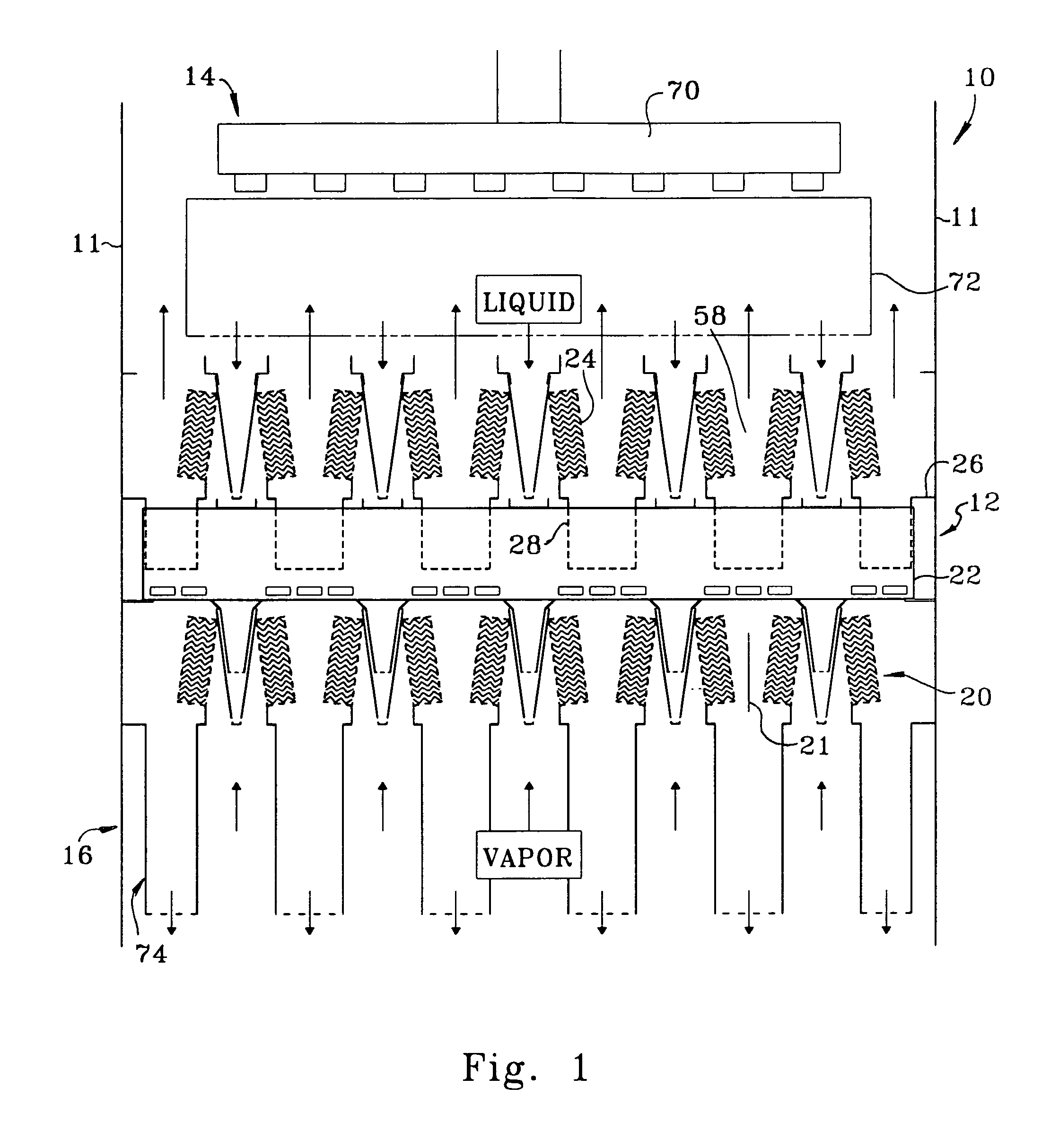

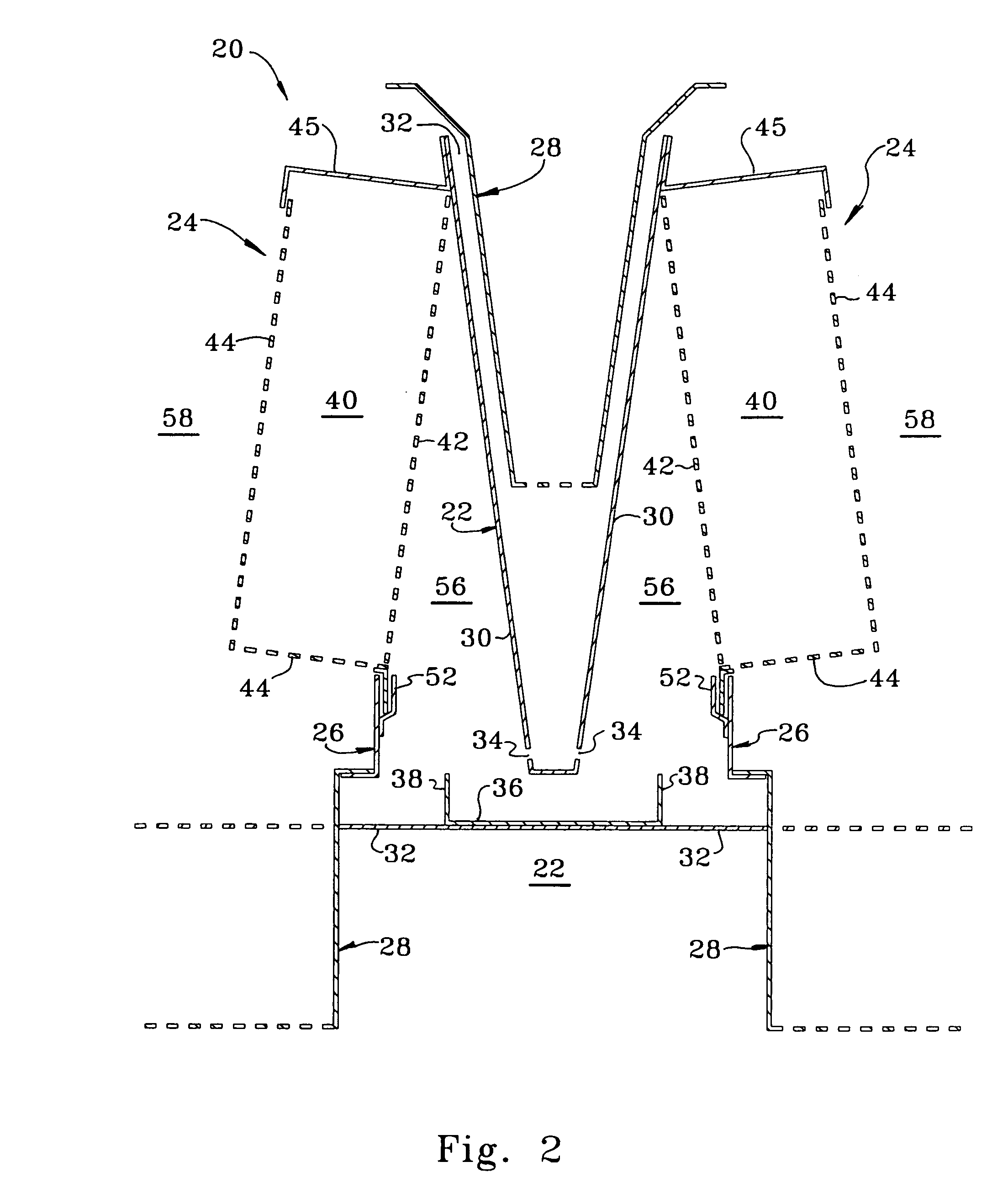

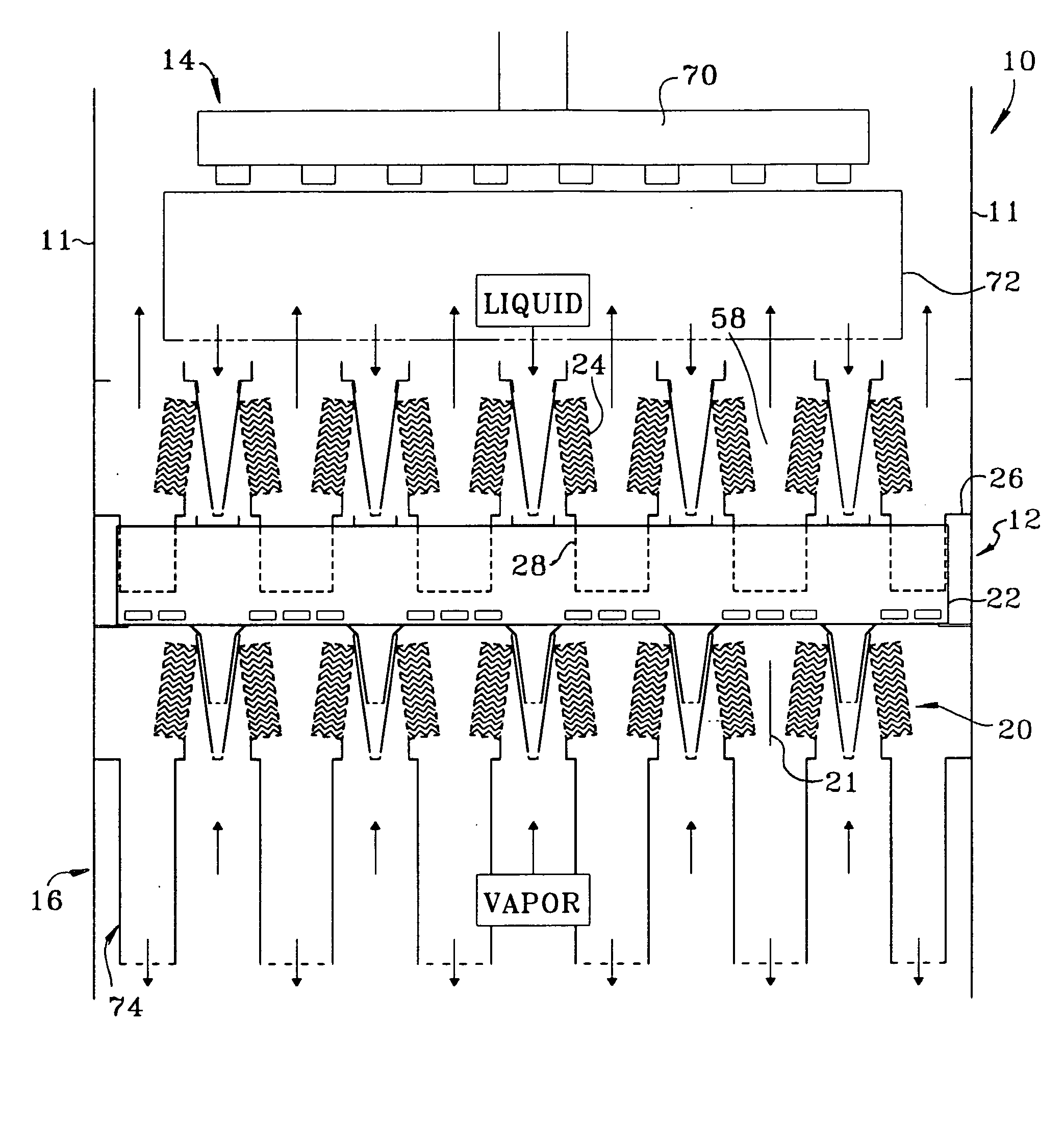

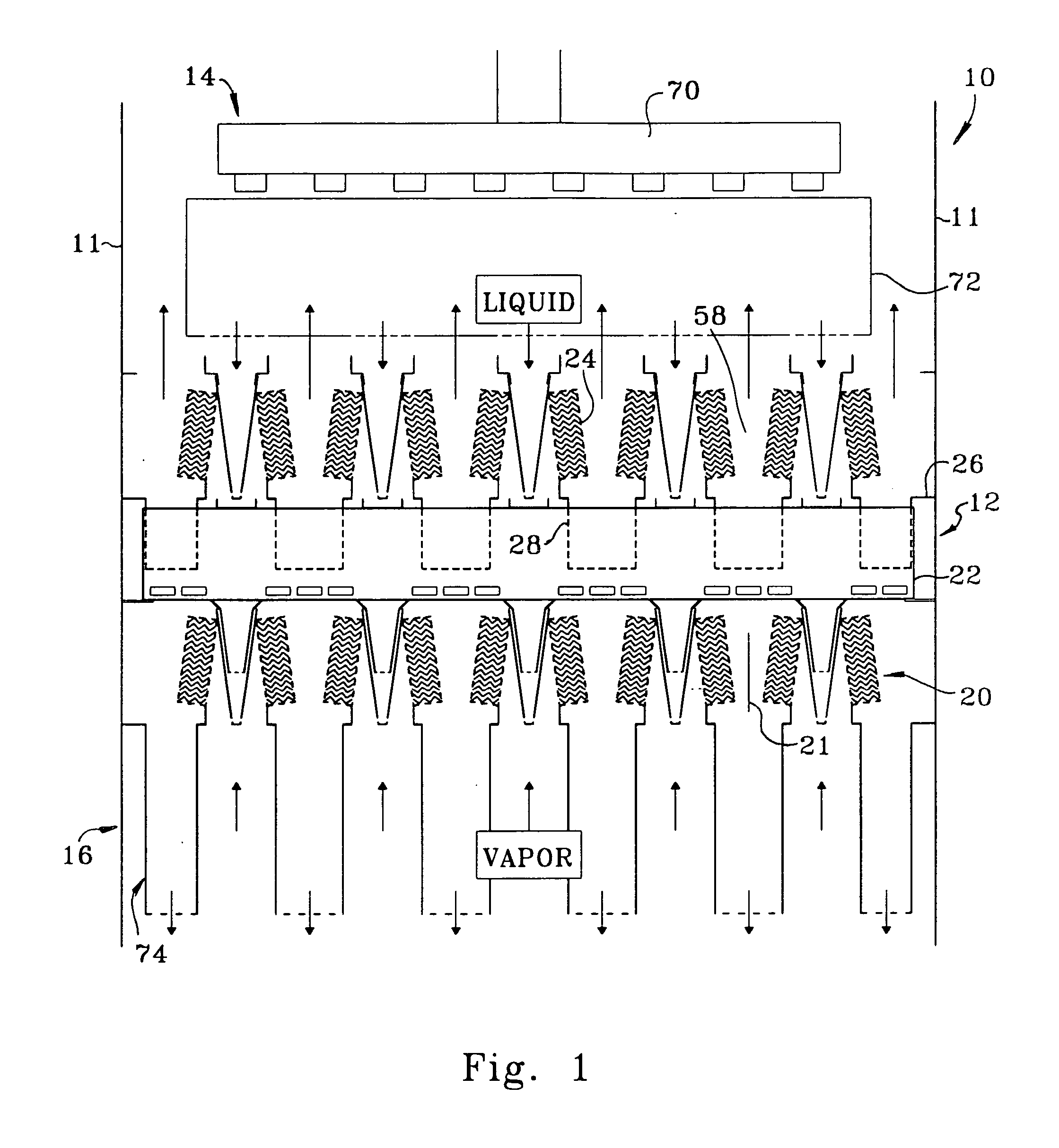

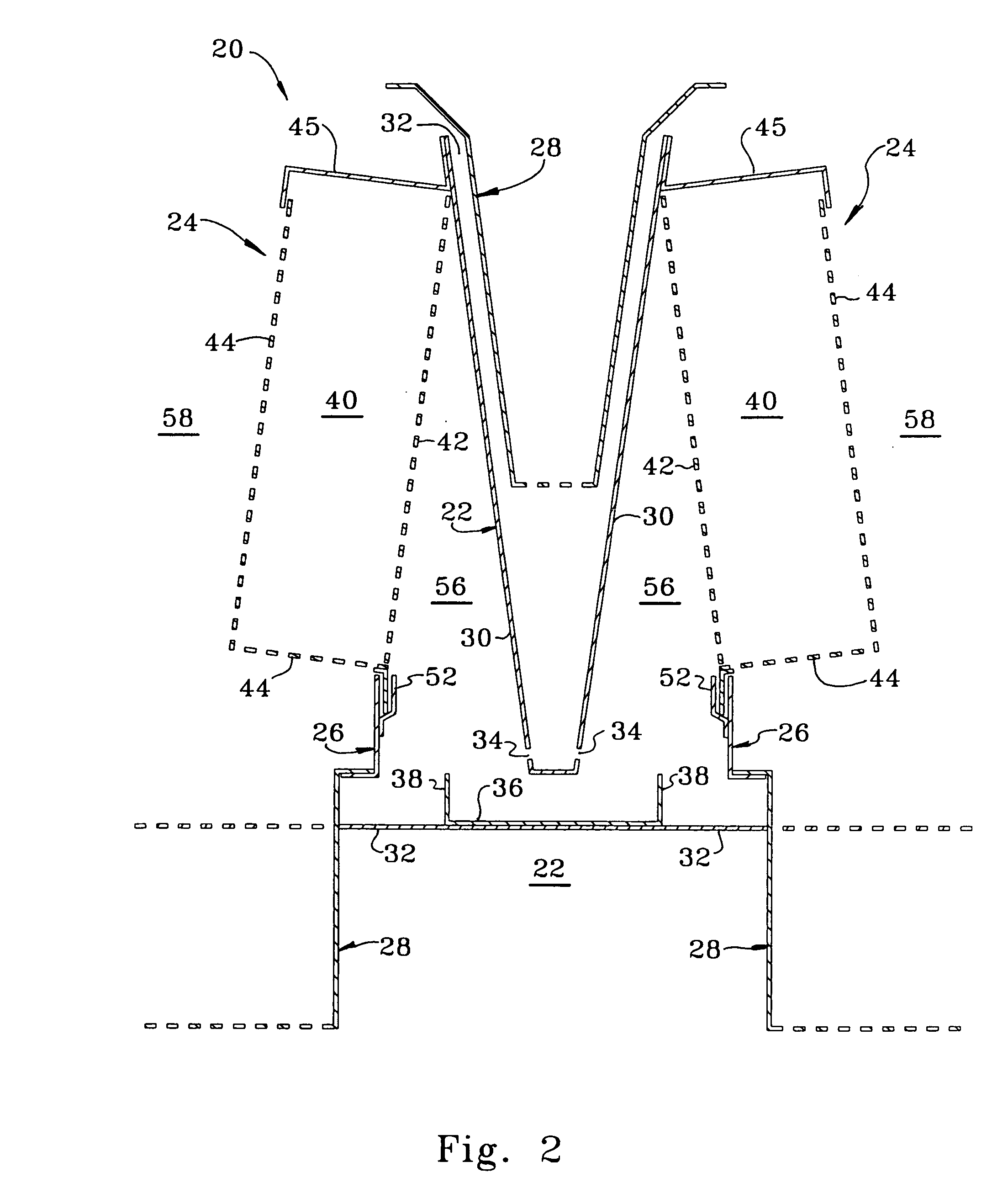

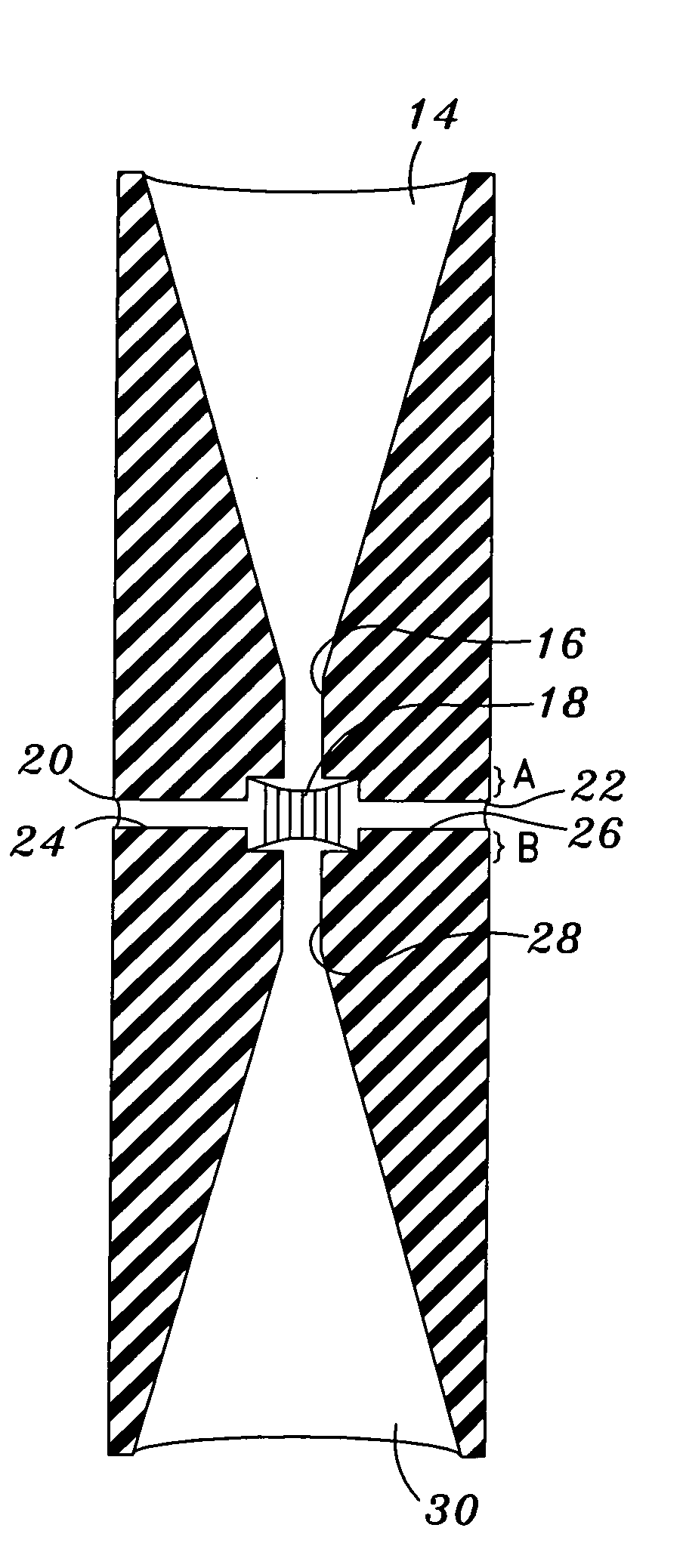

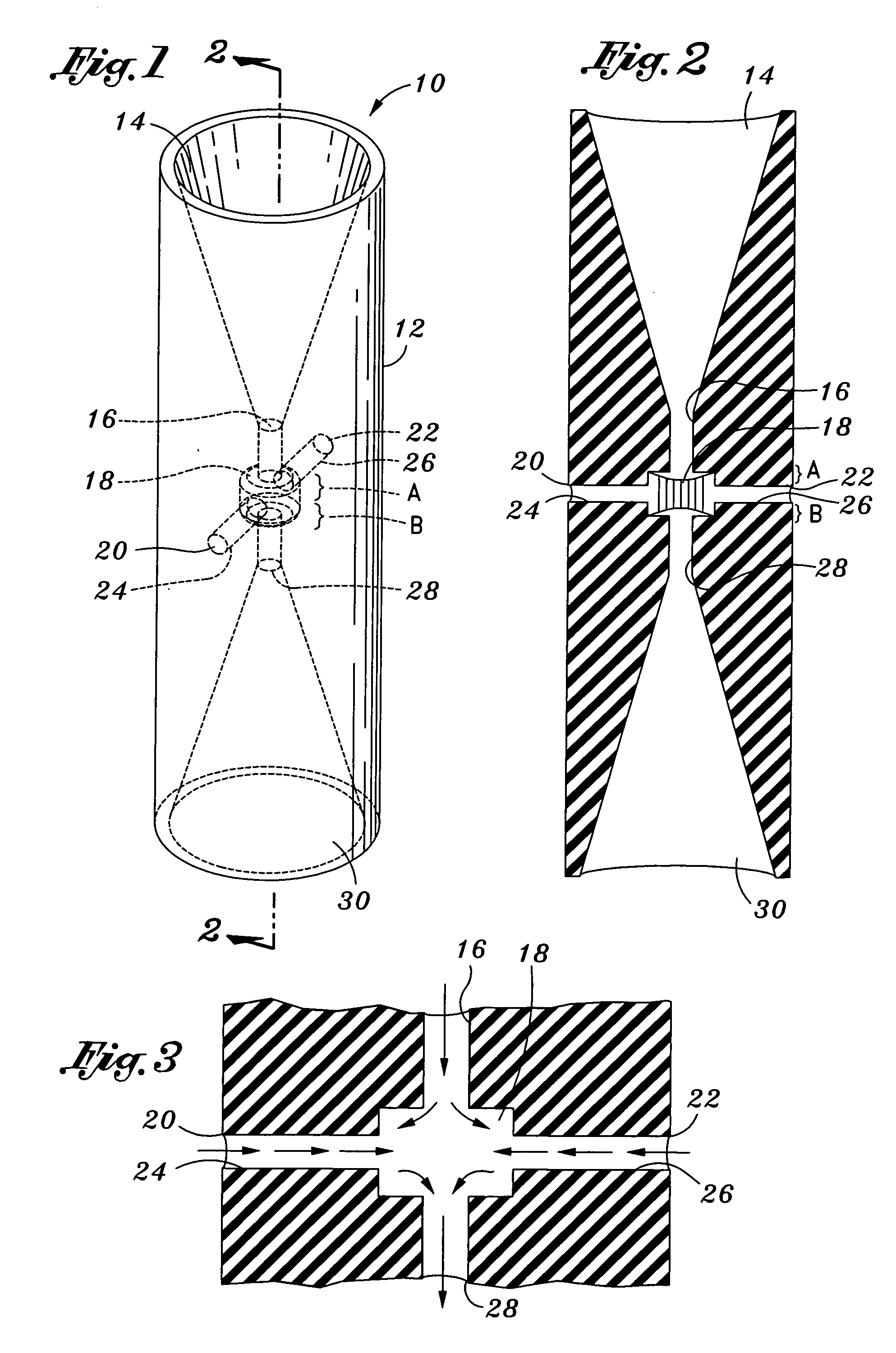

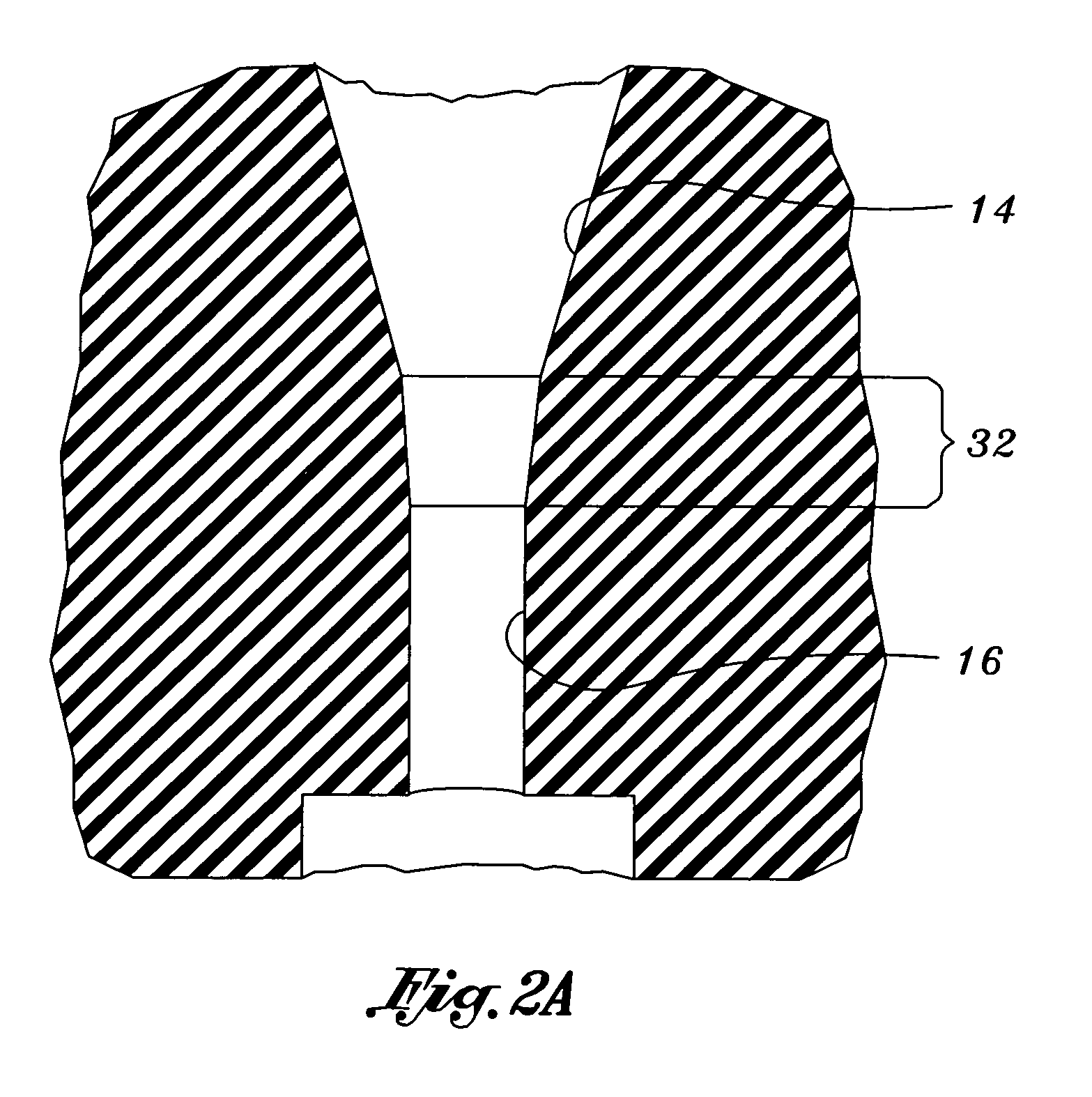

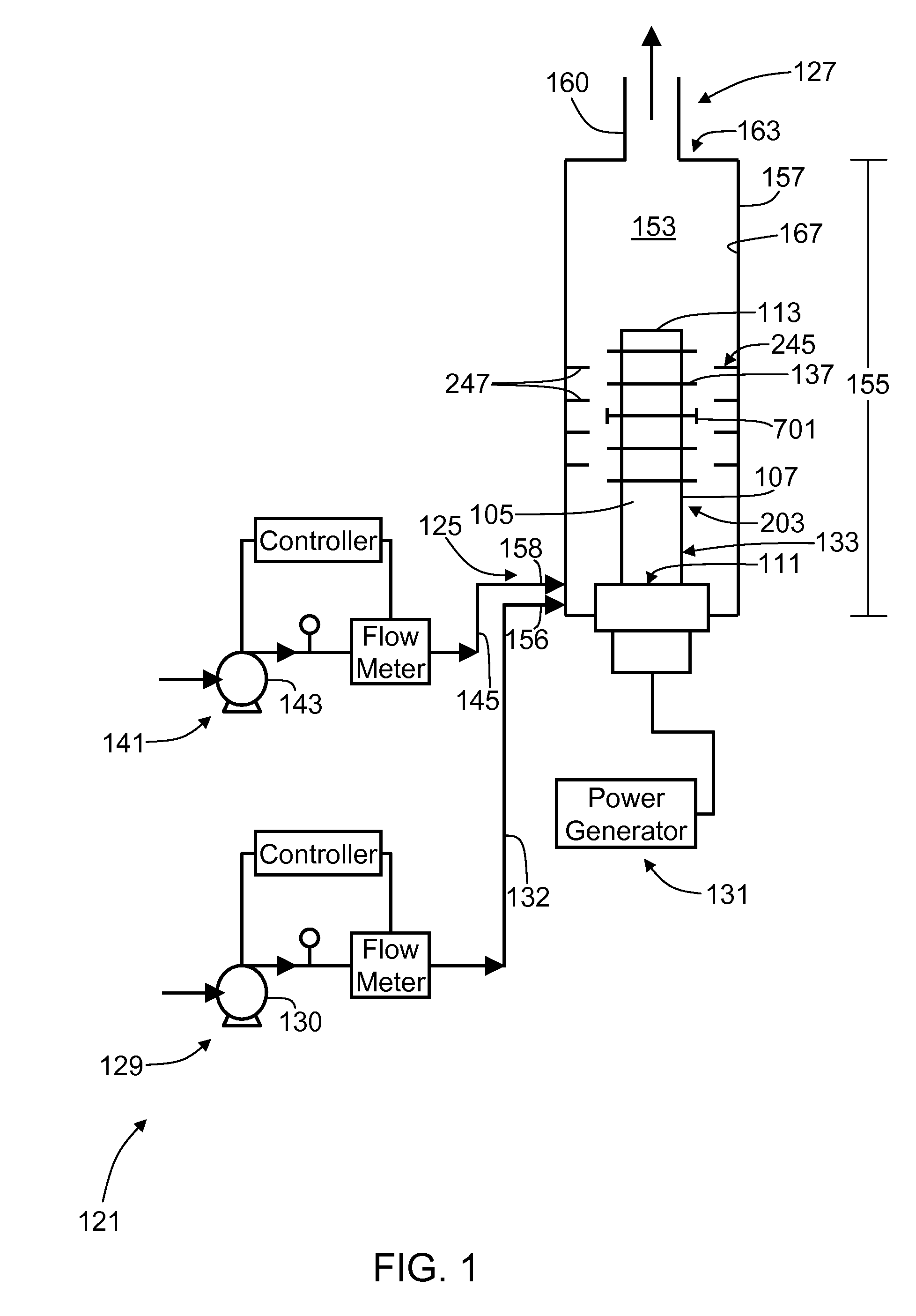

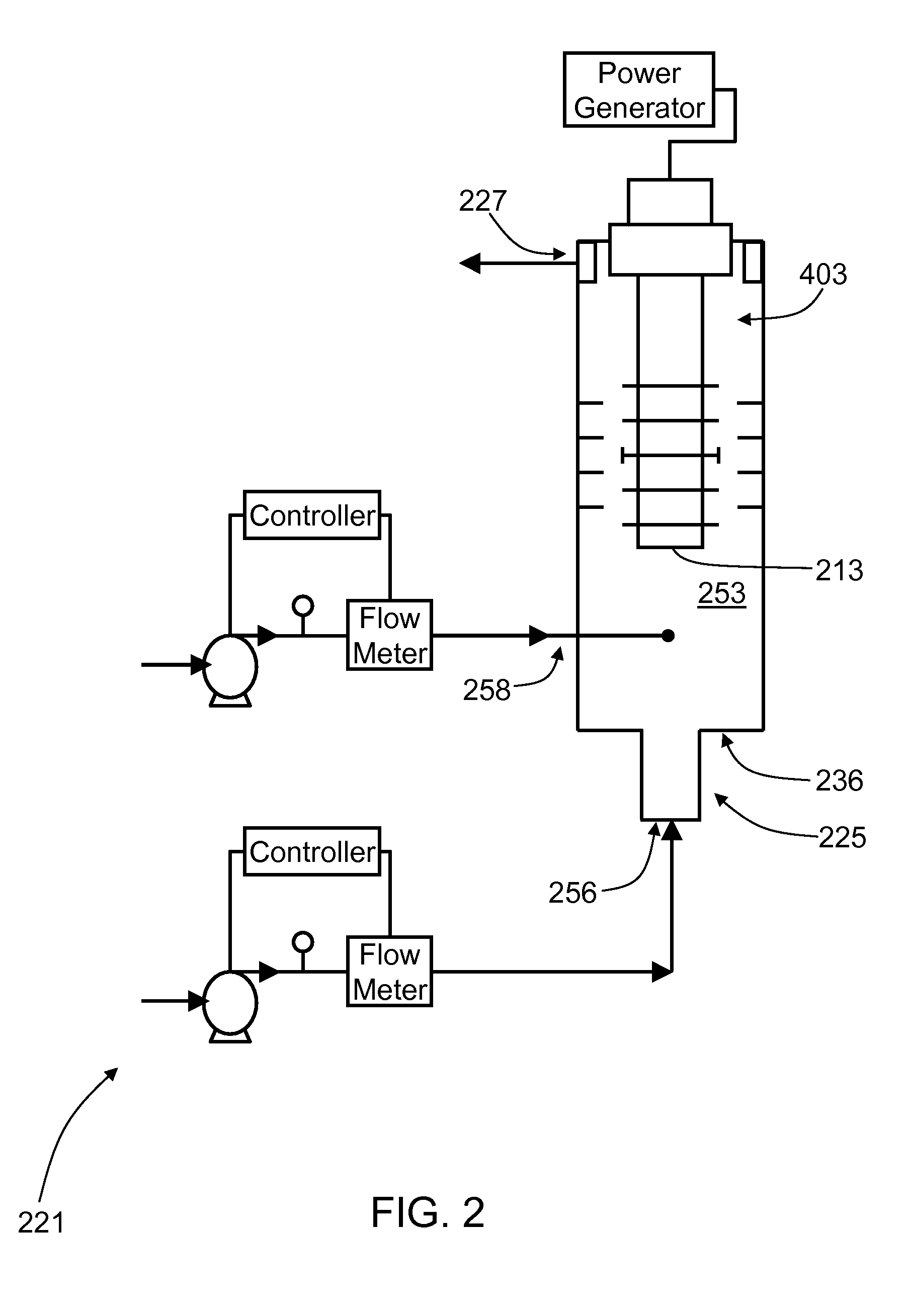

The invention is a high capacity and high efficiency co-current vapor-liquid contacting apparatus for use in distillation columns and other vapor-liquid contacting processes. The apparatus is characterized by an arrangement of modules in horizontal stages rather than tray-like construction. The modules define a co-current contacting volume and in an exemplary configuration the modules include a liquid distributor, a demister, a receiving pan and a duct. The modules of one stage are rotated to be non-parallel with respect to the modules of an inferior stage, a superior stage, or both. Variations relate to the design of the individual elements such as the demister, liquid distributor, ducts, and contacting volumes, and the overall arrangement of the apparatus.

Owner:UOP LLC

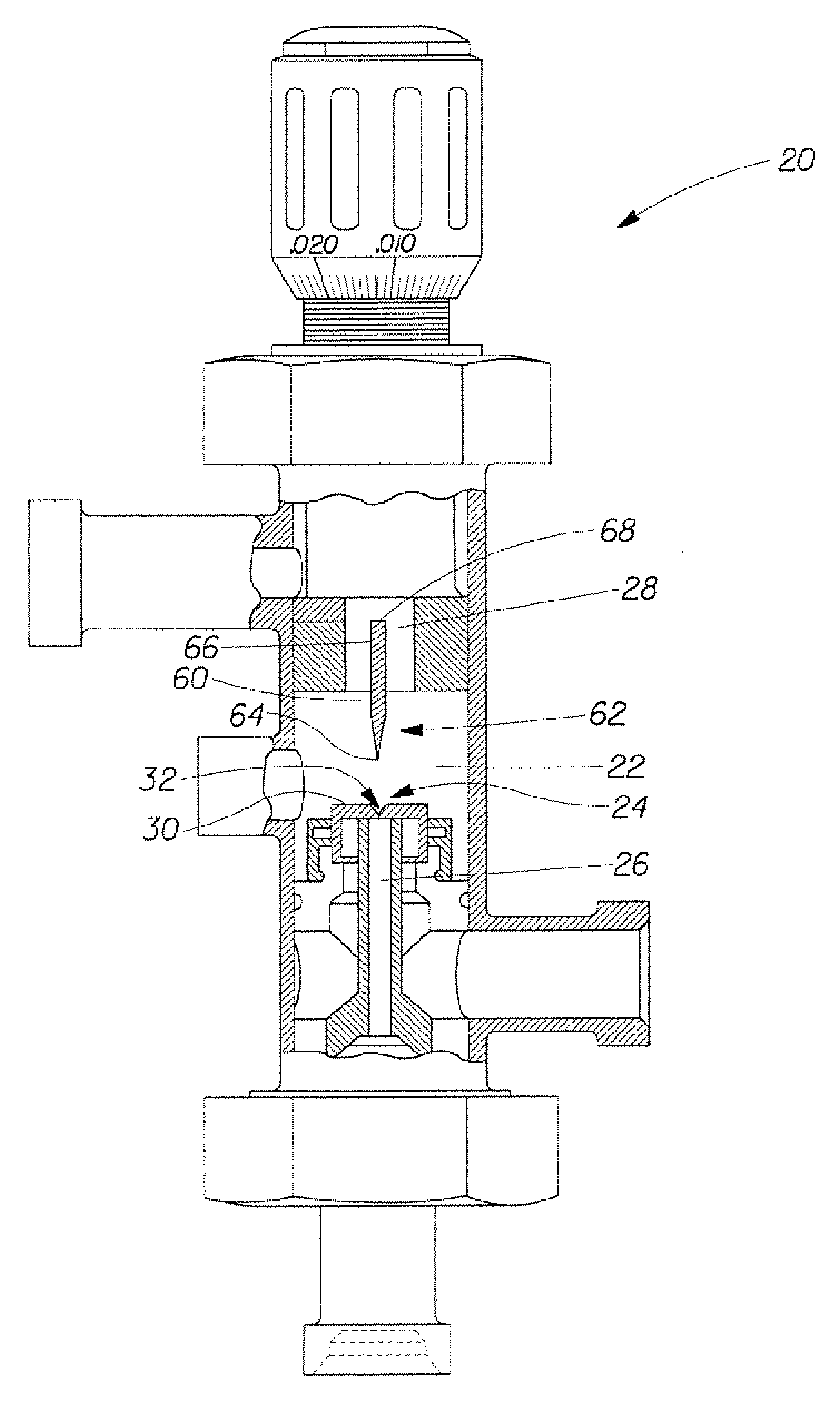

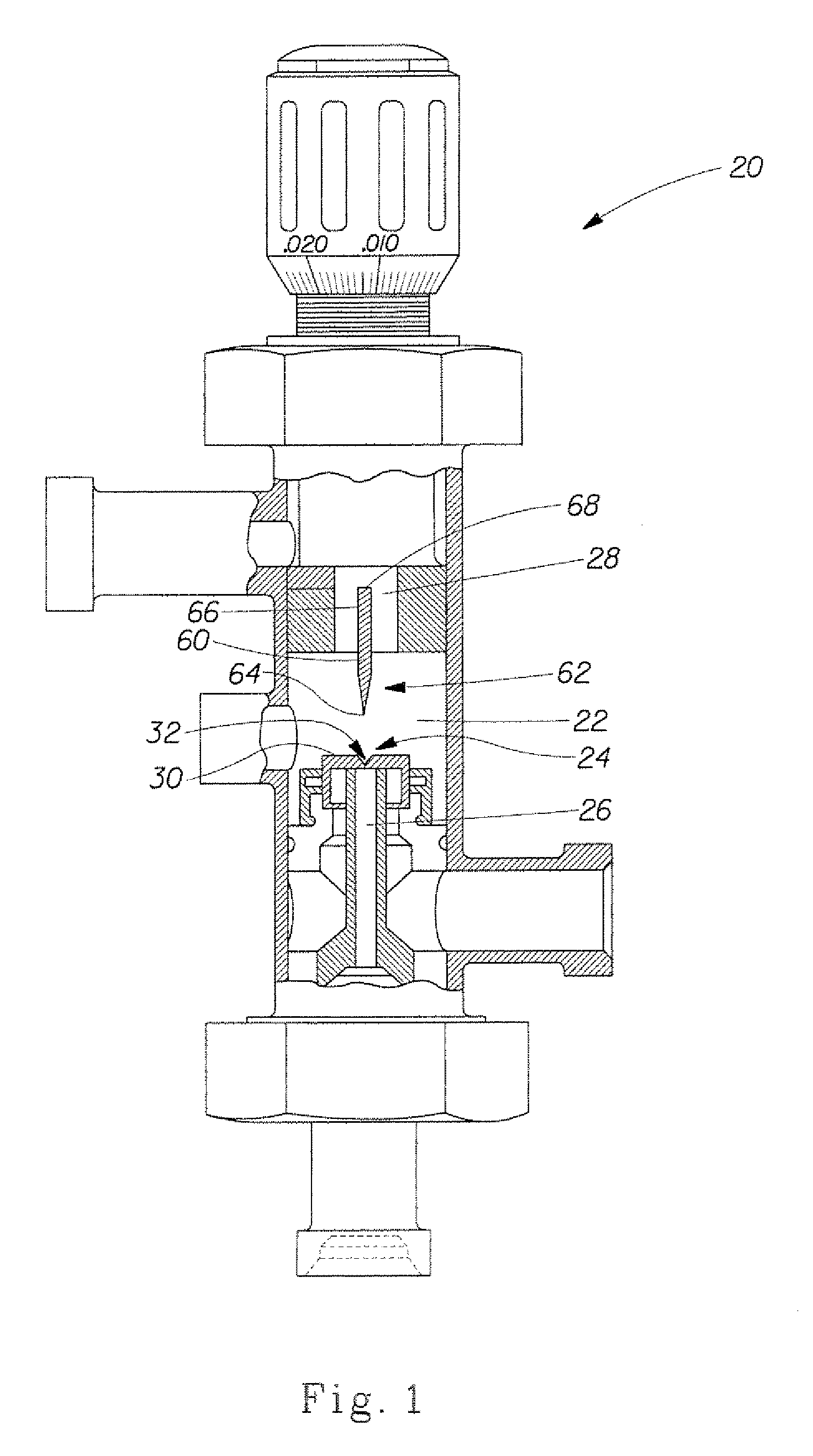

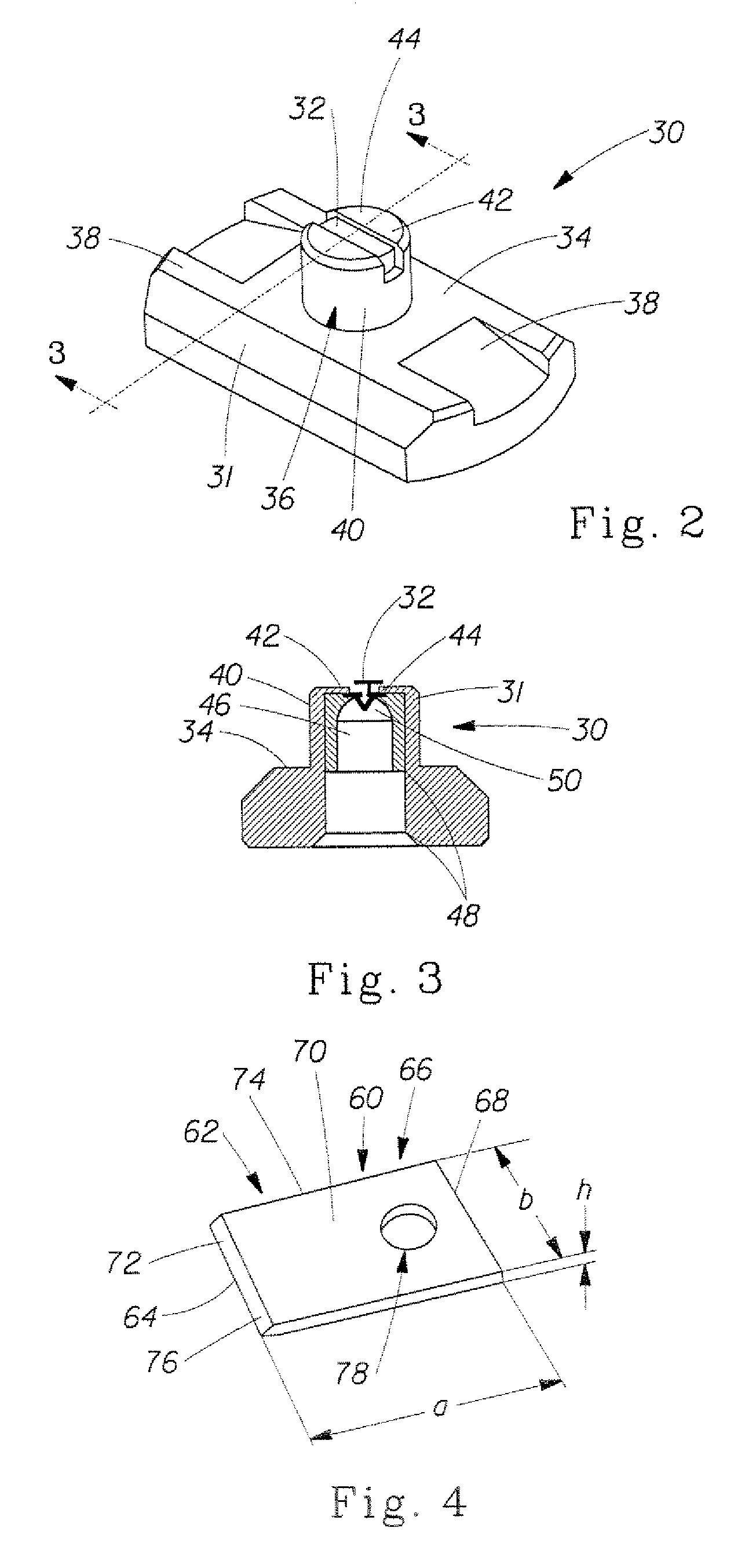

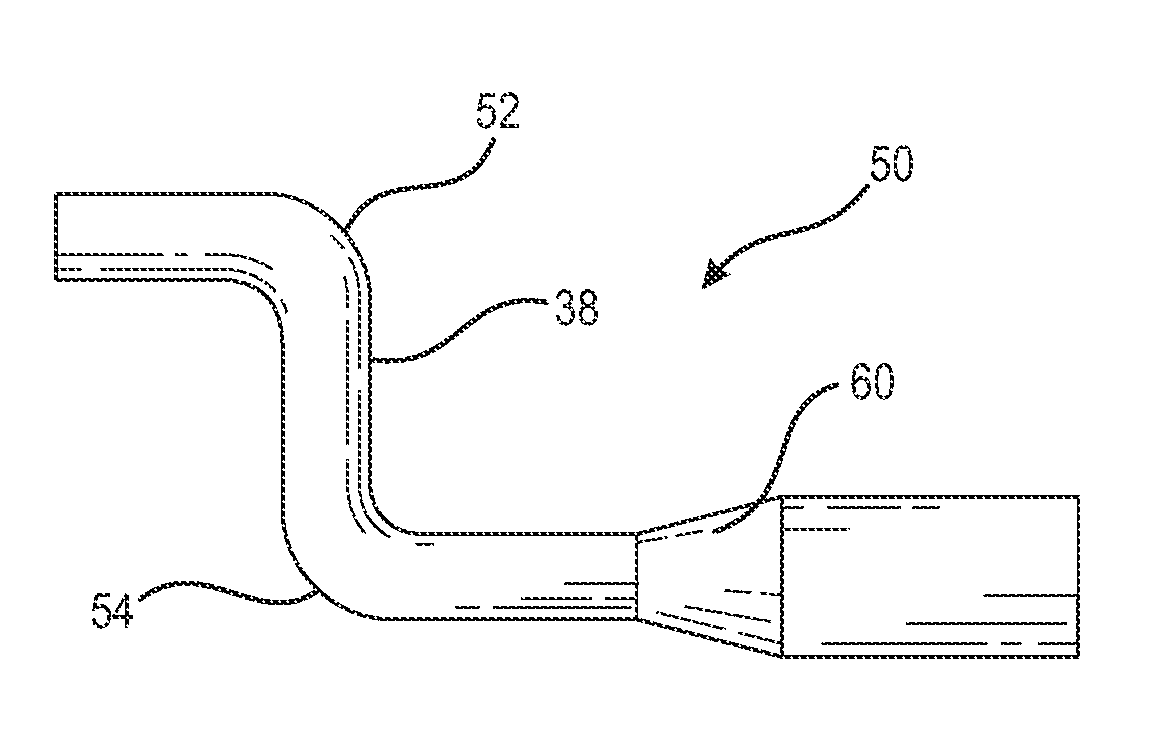

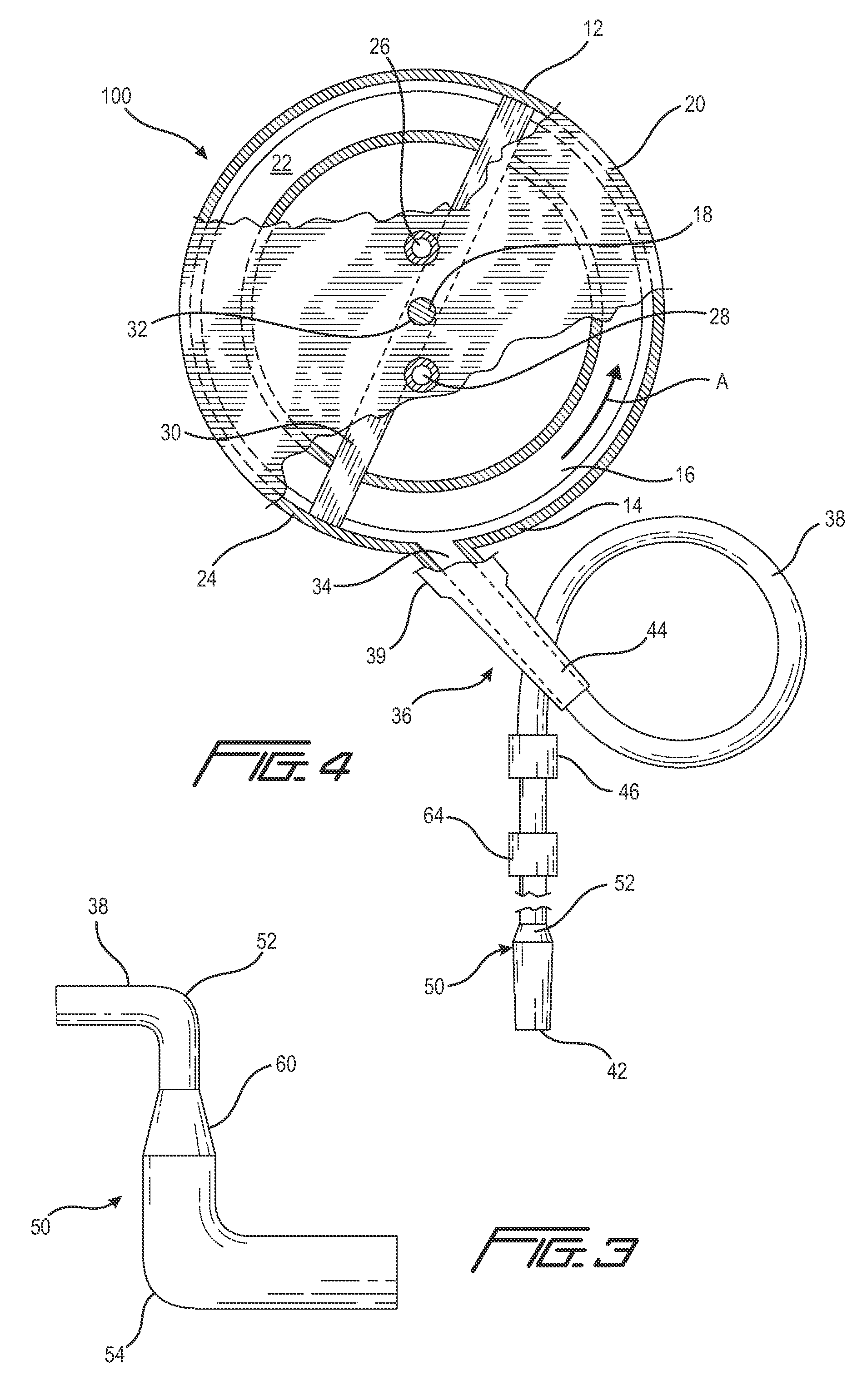

Venturi apparatus

ActiveUS7614614B2Speed up the flowFacilitate and enhance mixingMilk preservationFlow mixersEngineeringFluid - substance

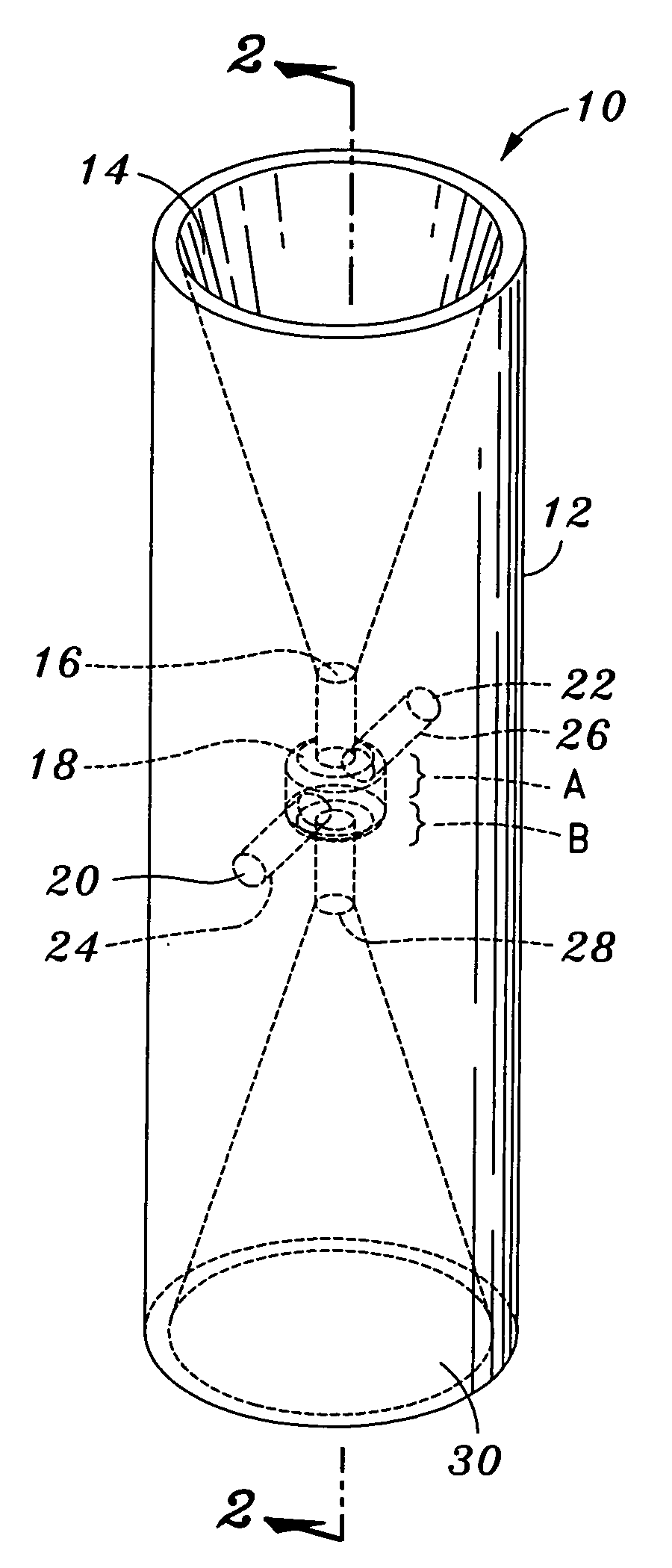

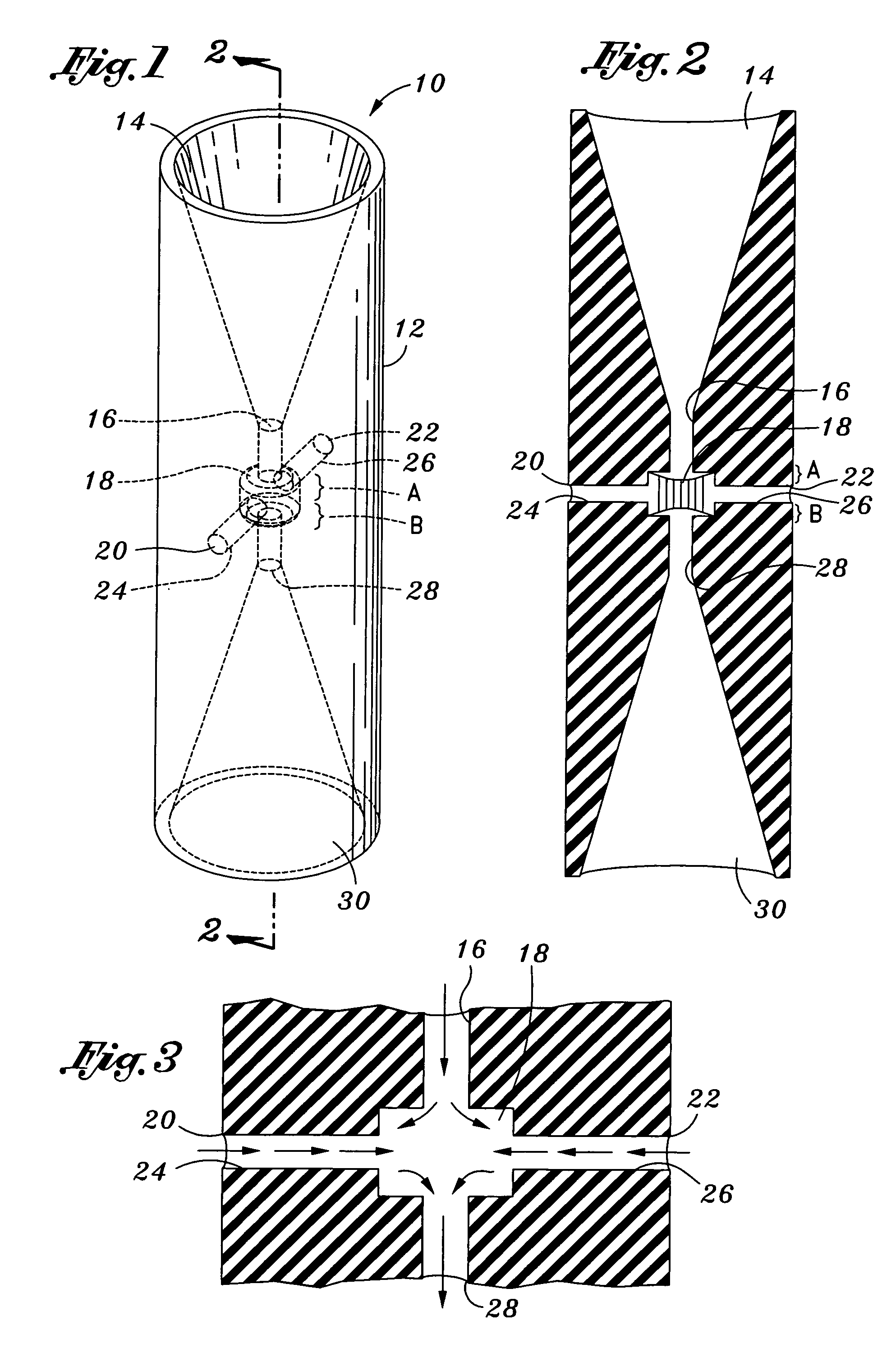

An improved venturi apparatus for facilitating the mixture of fluid substances. The apparatus preferably has first funnel section operative to receive a fluid and channel the same through a first cylindrical section or passageway. The first cylindrical section is fluidly connected to an intermediate passageway having a diameter larger than the first cylindrical section. At least one sidearm passageway is fluidly connected to the intermediate passageway into which at least one second fluid is introduced. The at least one sidearm passageway is preferably configured to fluidly interconnect with the intermediate passageway at approximately the medial portion of the intermediate passageway. Fluidly connected to the intermediate passageway is a second cylindrical section that is operative to direct the flow of the intermixed fluids to a second exit funnel section. The improved venturi apparatus is exceptionally efficient at drawing in a second fluid and effective in facilitating the mixture of two or more gasses, liquids or combinations thereof.

Owner:GREENFIELD WORLD TRADE

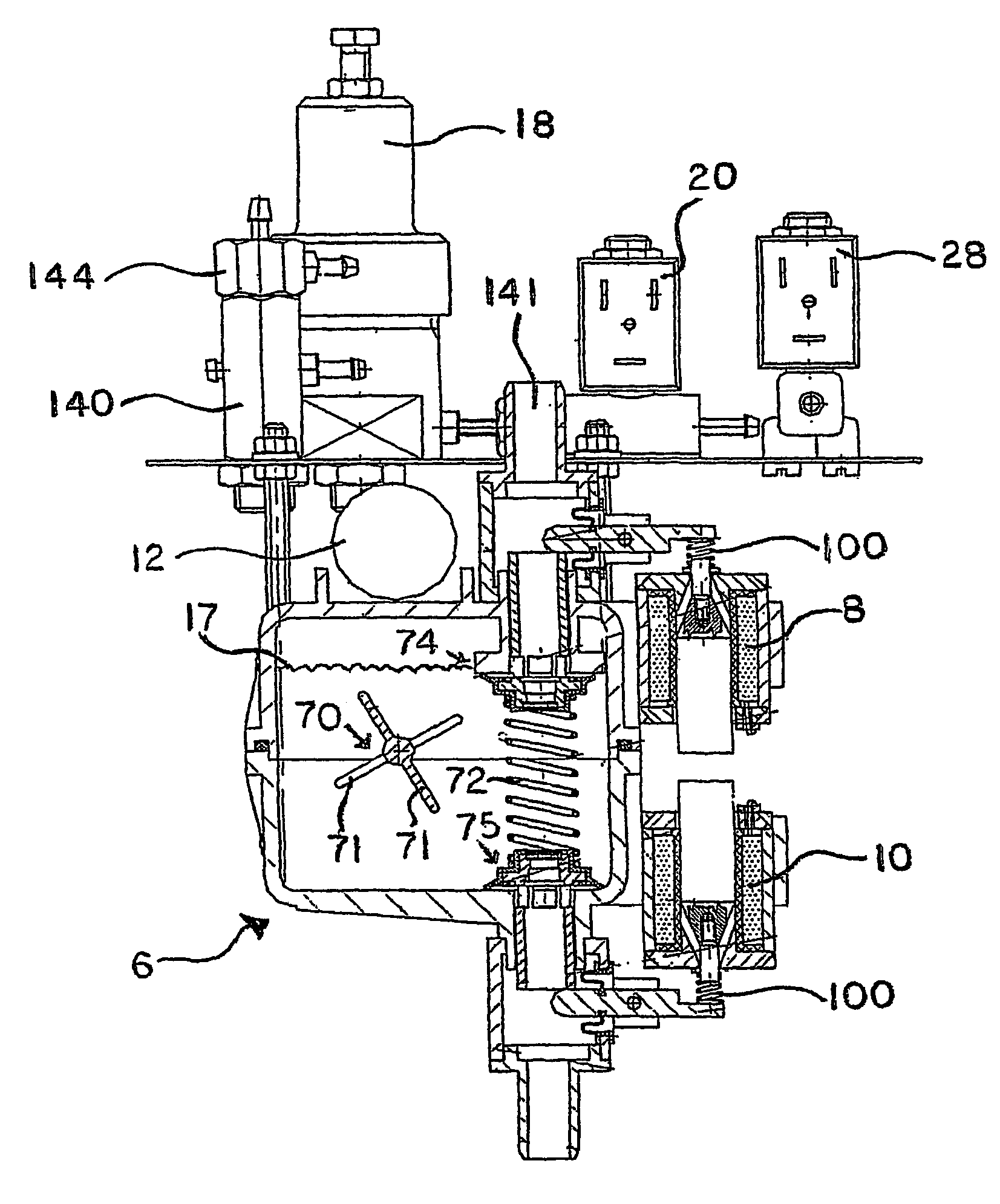

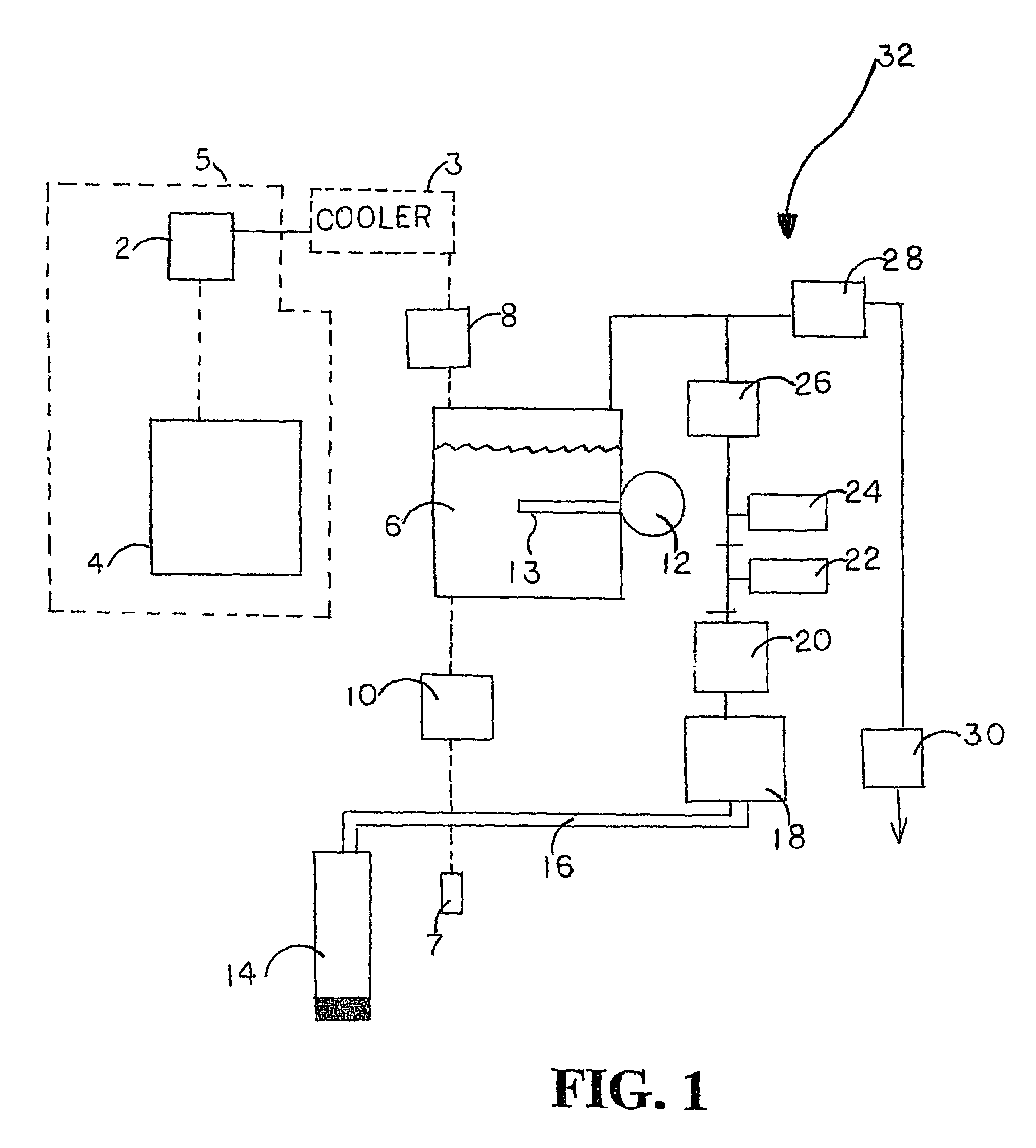

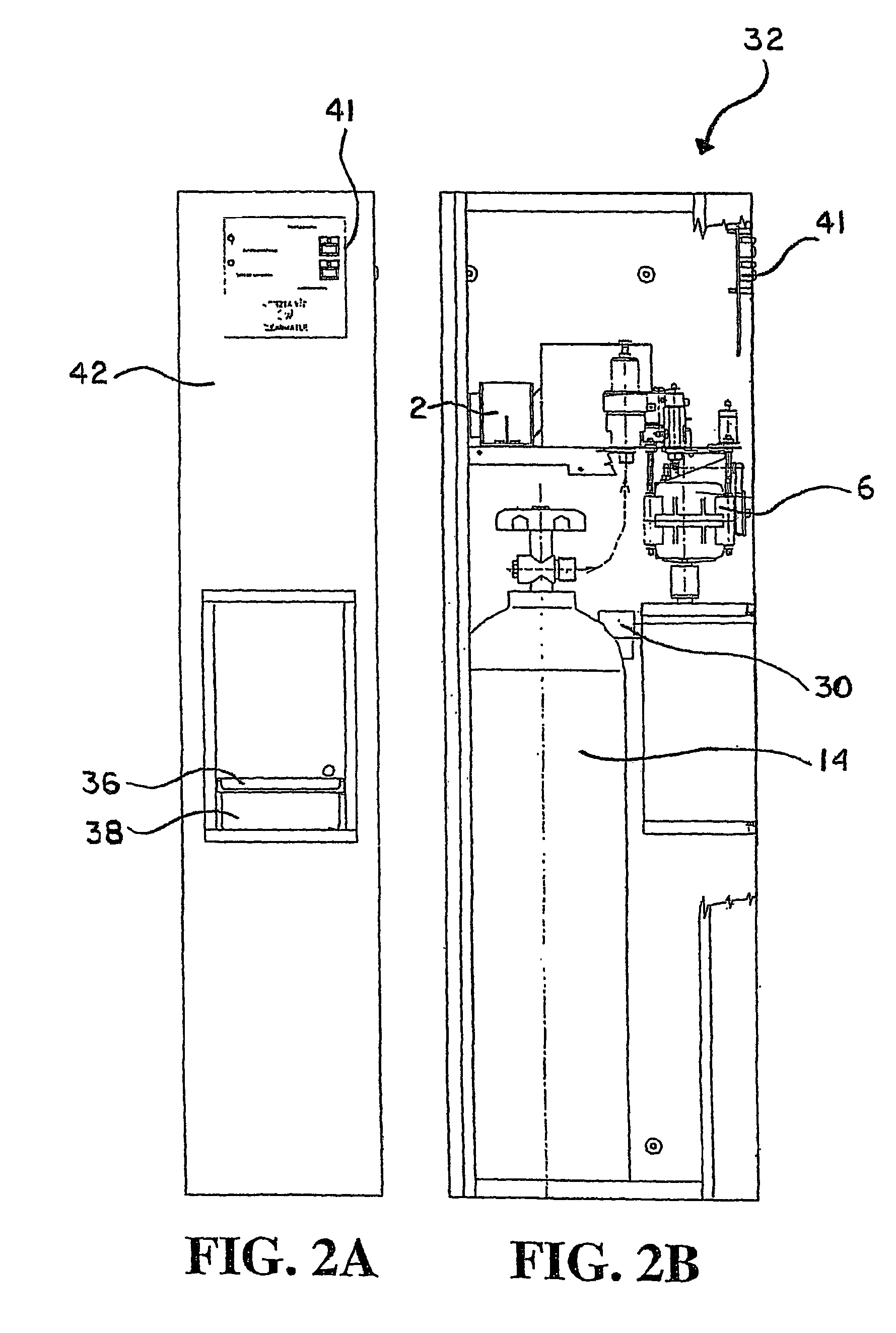

Carbonation system and method

The water carbonation method and apparatus of the present invention consists of a square mixer within a carbonated chamber. The mixer is partially filled with water. Carbon dioxide is then added above the level of water. A rotating member attached to the mixing motor then mixes the water and carbon dioxide to from a carbonated solution. Varying the time for which the carbonation operation is carried on may vary the degree of carbonation. After the specified carbonation cycle, excess carbon dioxide is then relieved through an exhaust solenoid and the remaining carbonated solution is released through the dispensing solenoid into a cup.

Owner:PRIMO WATER HLDG INC

Venturi apparatus

ActiveUS20070187848A1Speed up the flowFacilitate and enhance mixingFlow mixersTransportation and packagingEngineeringFluid - substance

An improved venturi apparatus for facilitating the mixture of fluid substances. The apparatus preferably comprises a first funnel section operative to receive a fluid and channel the same through a first cylindrical section or passageway. The first cylindrical section is fluidly connected to an intermediate passageway having a diameter larger than the first cylindrical section. At least one sidearm passageway is fluidly connected to the intermediate passageway into which at least one second fluid is introduced. The at least one sidearm passageway is preferably configured to fluidly interconnect with the intermediate passageway at approximately the medial portion of the intermediate passageway. Fluidly connected to the intermediate passageway is a second cylindrical section that is operative to direct the flow of the intermixed fluids to a second exit funnel section. The improved venturi apparatus is exceptionally efficient at drawing in a second fluid and effective in facilitating the mixture of two or more gasses, liquids or combinations thereof.

Owner:GREENFIELD WORLD TRADE

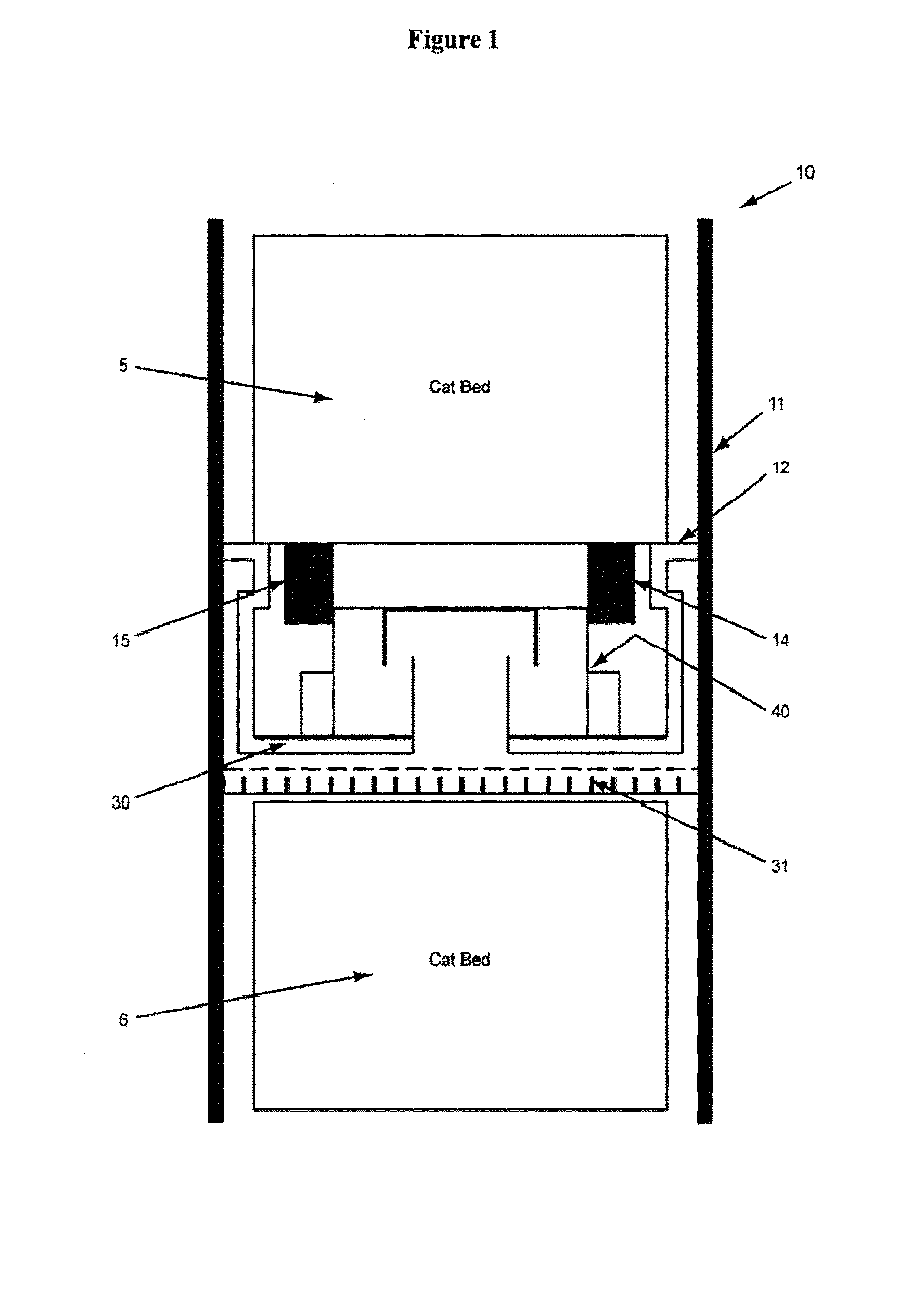

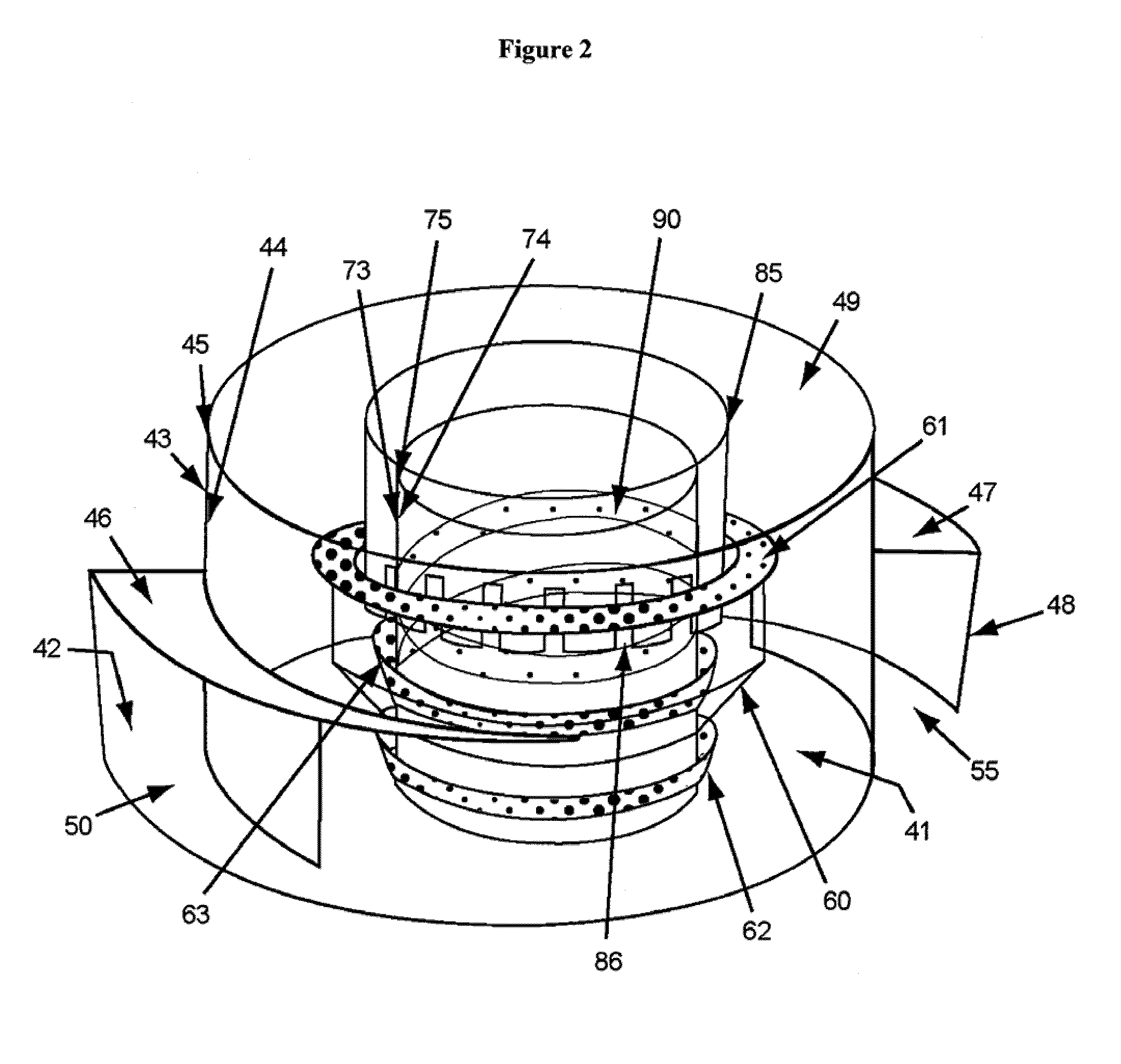

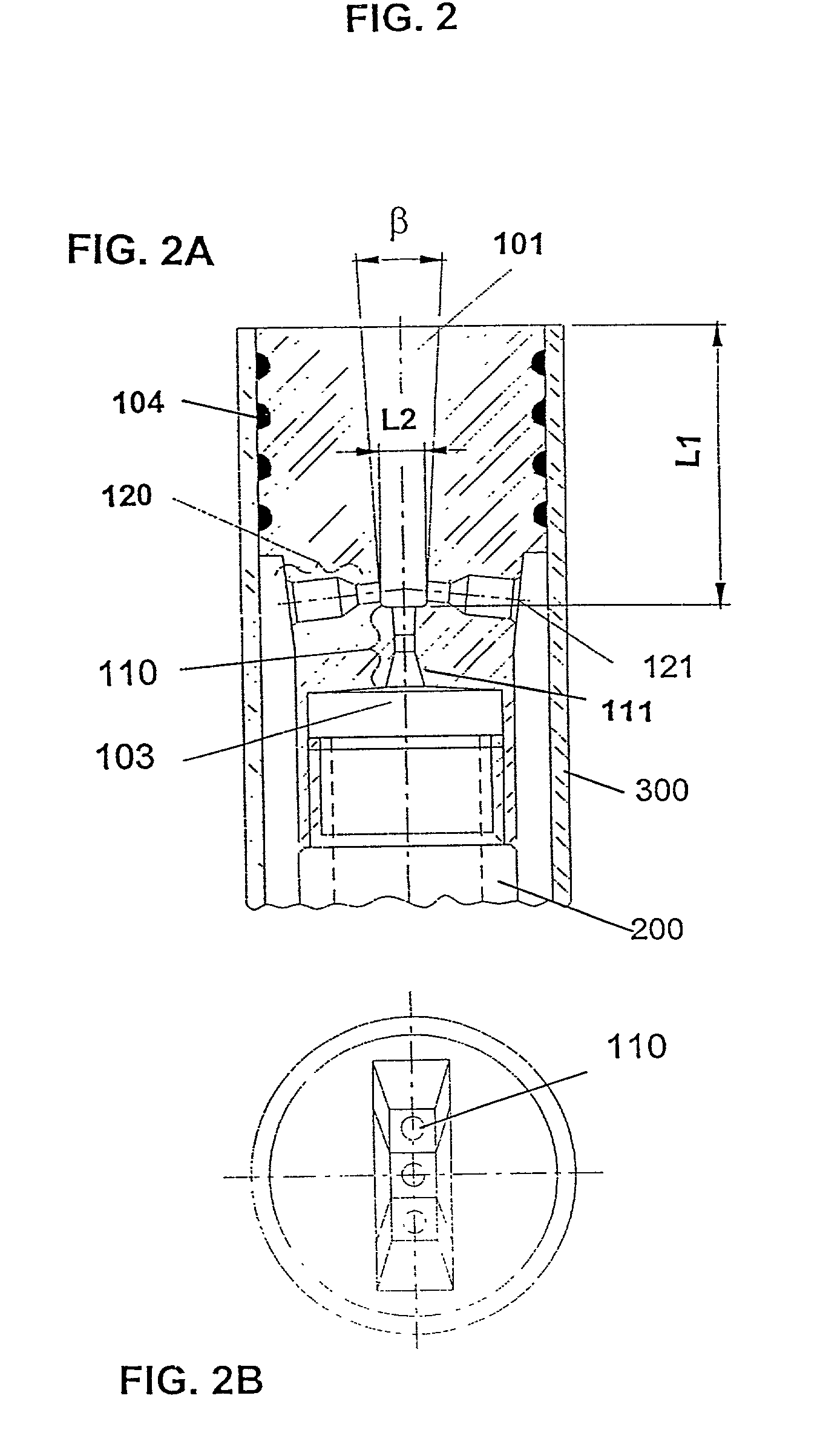

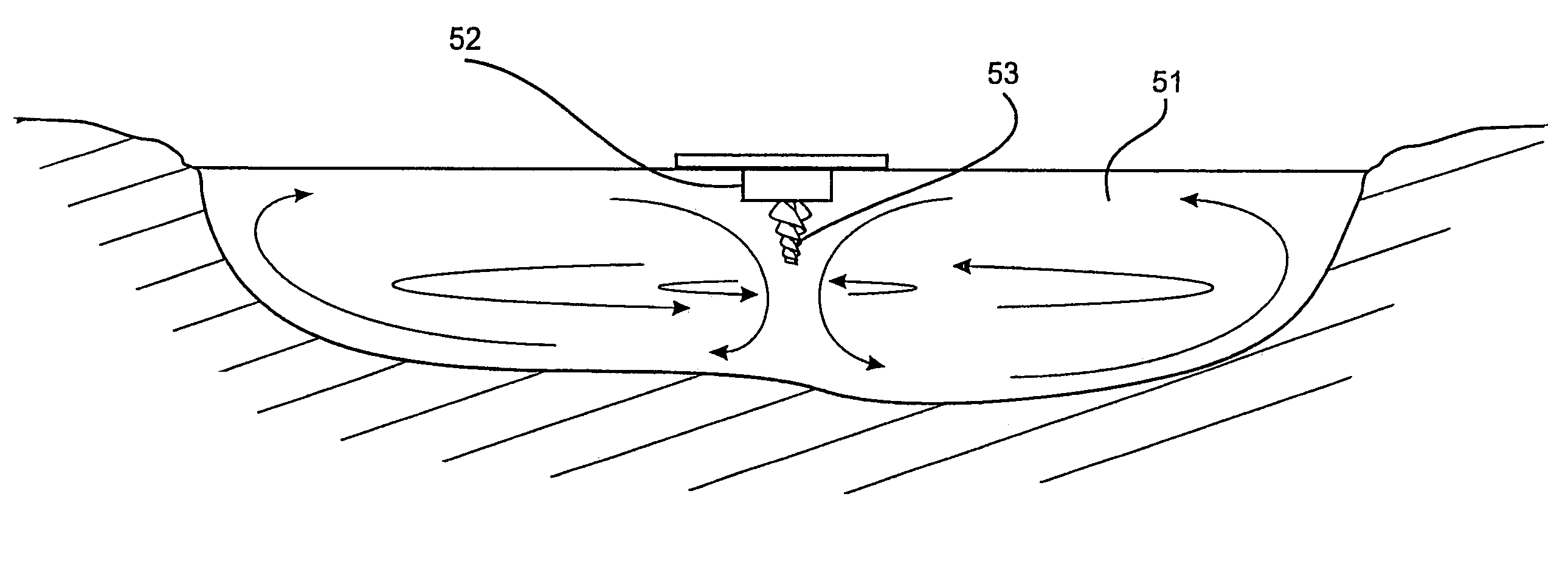

Mixing device for a down-flow reactor

ActiveUS8017095B2Improve efficiencySmall sizePhysical/chemical process catalystsFlow mixersGas phaseProcess engineering

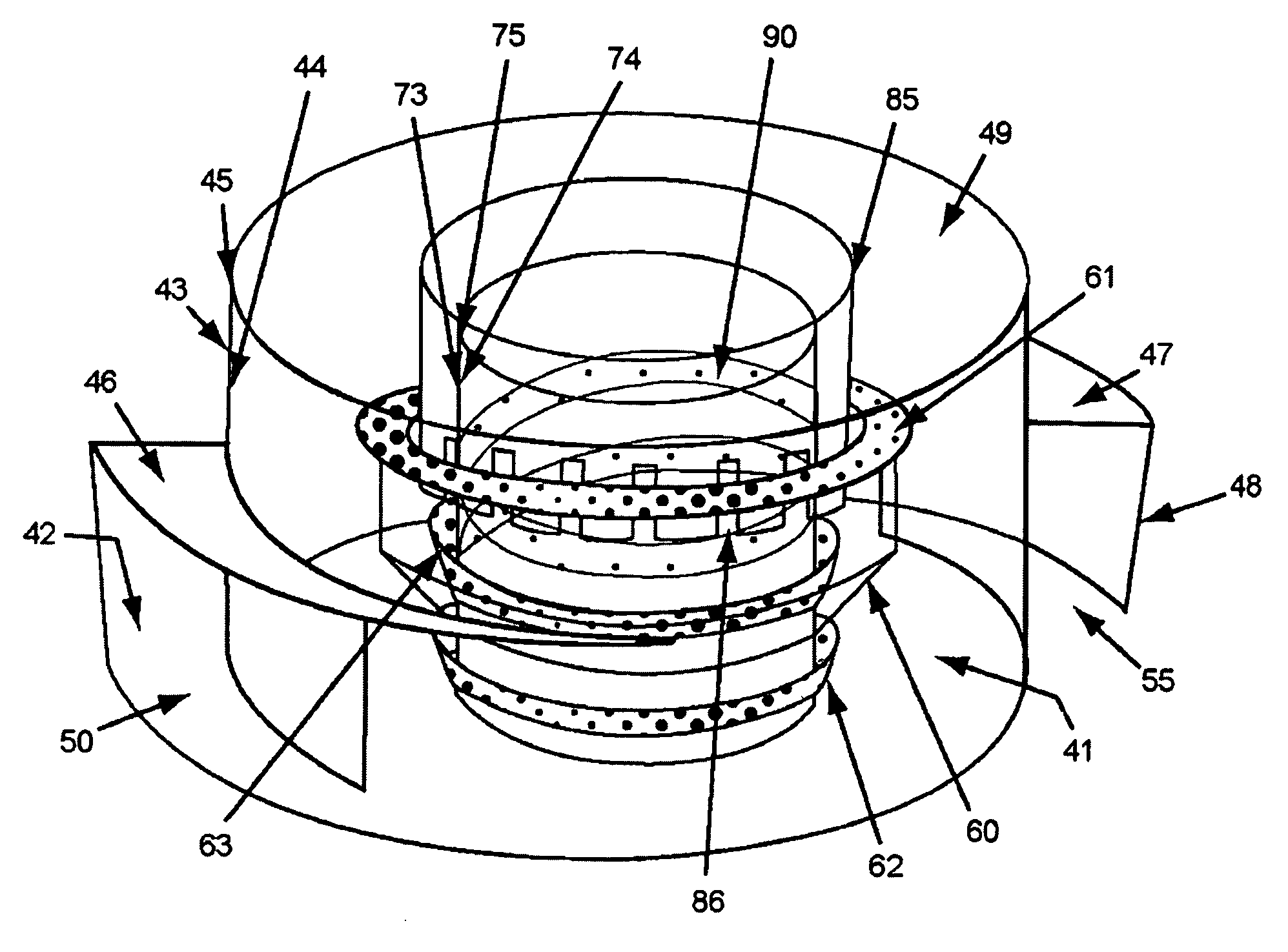

The present invention provides a novel means to provide more effective mixing of gas and fluids in a height constrained interbed space of a catalytic reactor without increasing pressure drop. In particular, the device improves the effectiveness of an existing mixing volume in mixing the gas phase and liquid phase of two-phase systems. According to the present invention, the mixing device helps create a highly arcuate flow to incoming effluents and a high degree of mixing within a constrained interbed space of a catalytic reactor.

Owner:CHEVROU USA INC

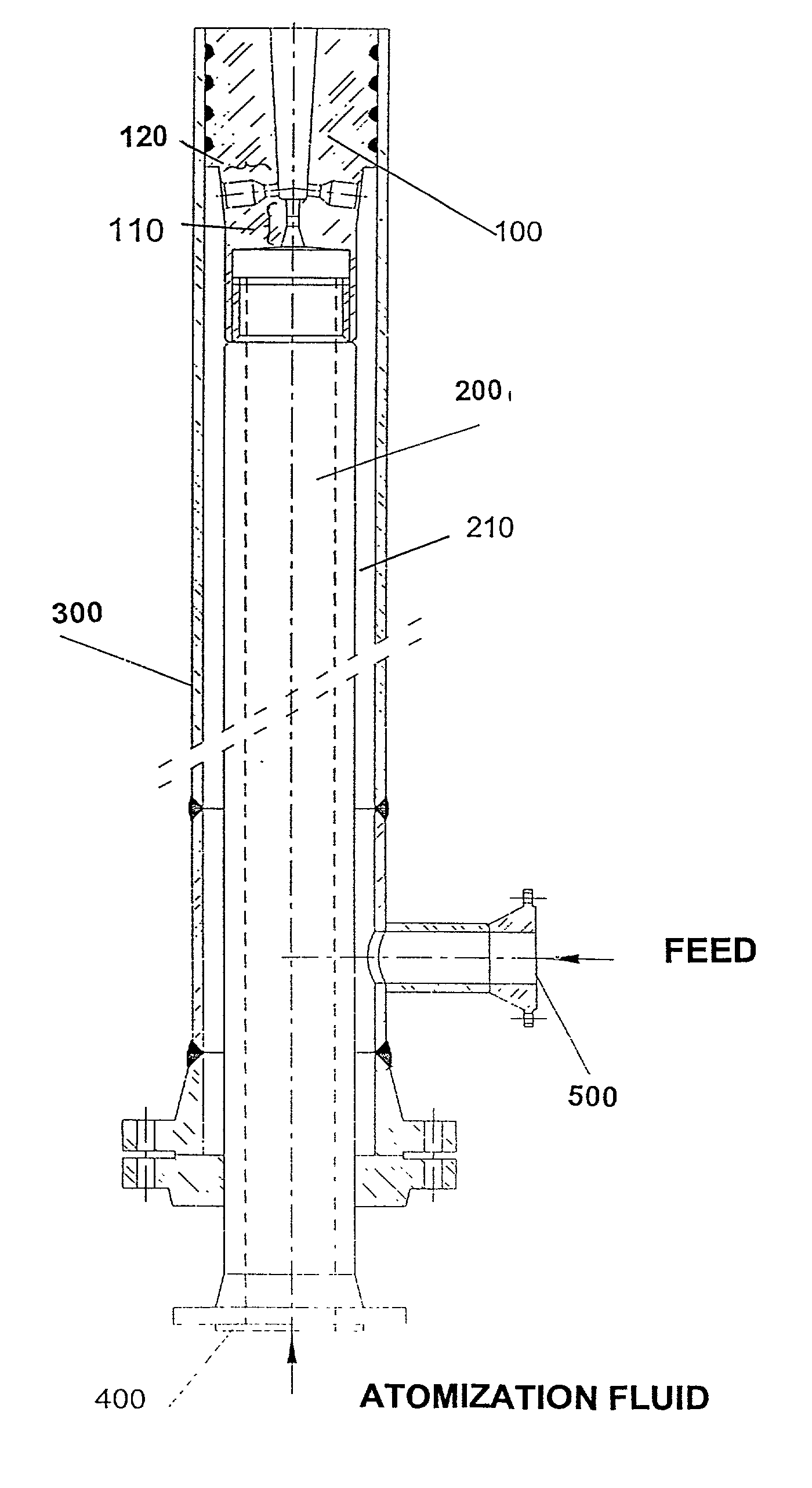

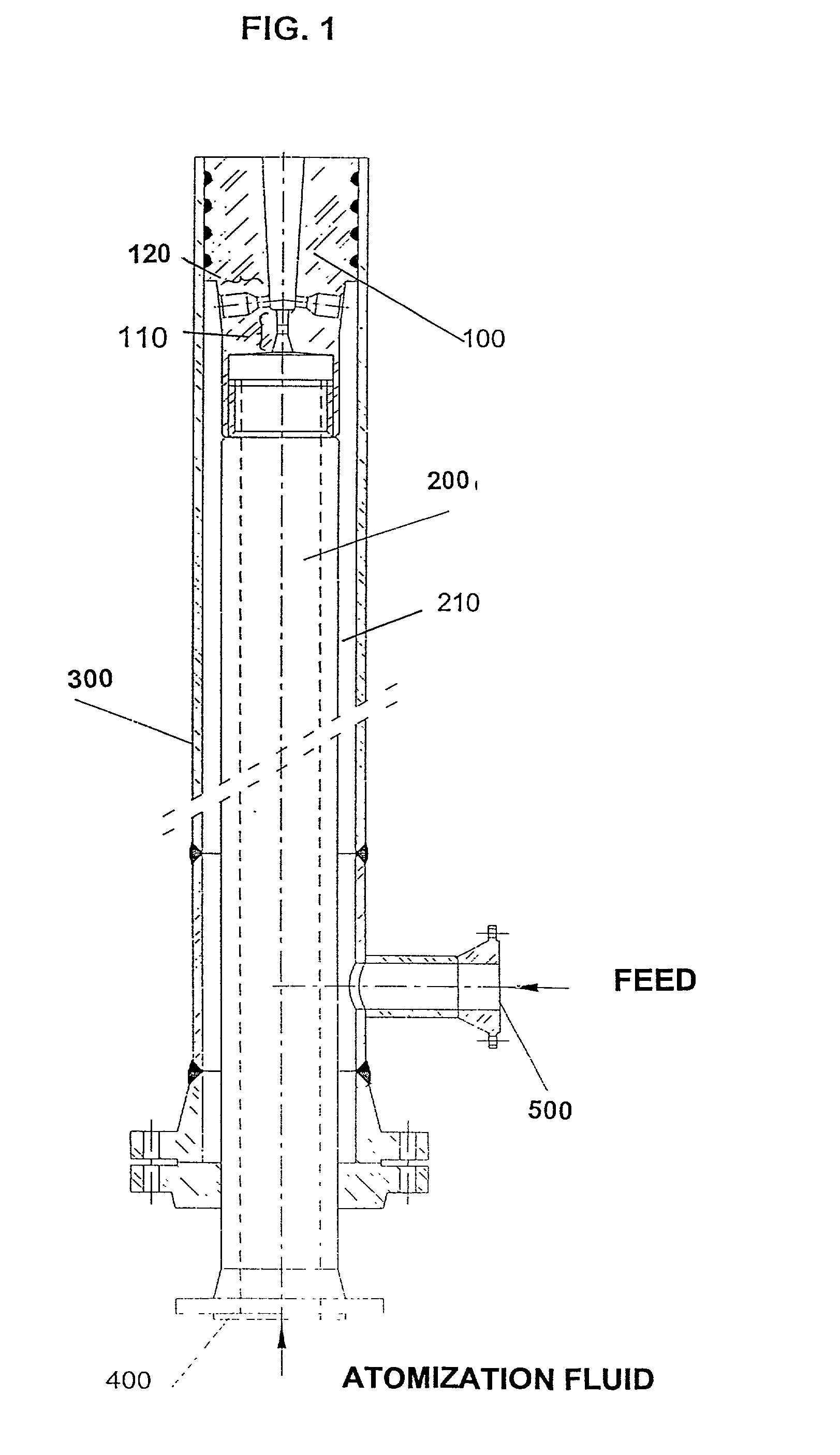

Feed-dispersion system for fluid catalytic cracking units

InactiveUS6936227B1Great feed conversionReduce pump powerCatalytic crackingSpray nozzlesEngineeringGuide tube

A feed-dispersion system for hydrocarbon feeds of fluid catalytic cracking units is described, which comprises:a feed-injection system made up of two concentric conduits, where the atomization fluid flows through the inner conduit, while the liquid feed flows through the annular space formed by the outer surface of the inner conduit and the inner surface of the outer conduit;an atomization unit having nozzles arranged in rows, with one row having central nozzles connected to the inner conduit for atomization fluid, and two or more rows of side nozzles, connected to the outer feed conduit, the central nozzles and side nozzles of the atomization unit being geometrically placed so that the energy of the atomization fluid is fully transferred by contact to the flow of feed, this resulting in the complete atomization of the feed;a mixing chamber formed by the edges of the central nozzles, the dimensions of which are able to prevent the coalescence of the formed oil droplets.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

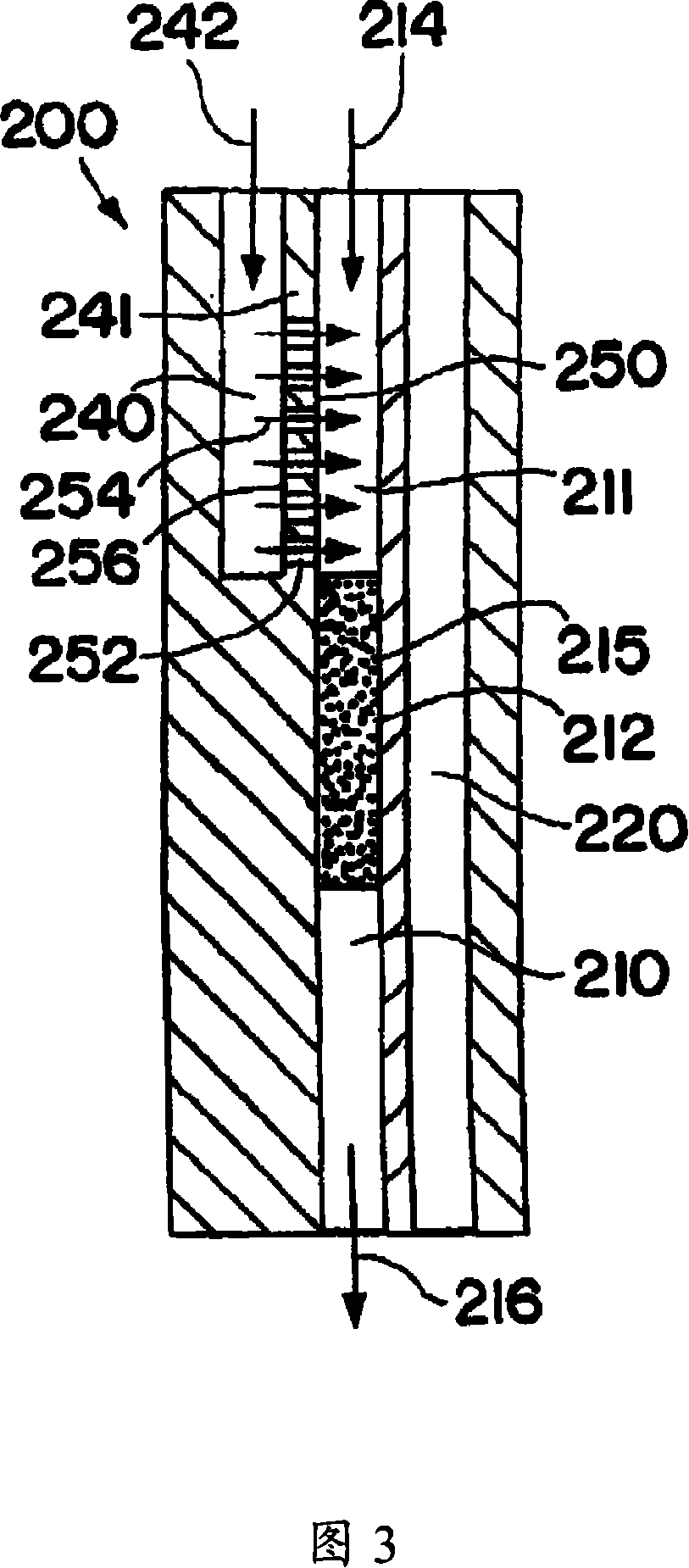

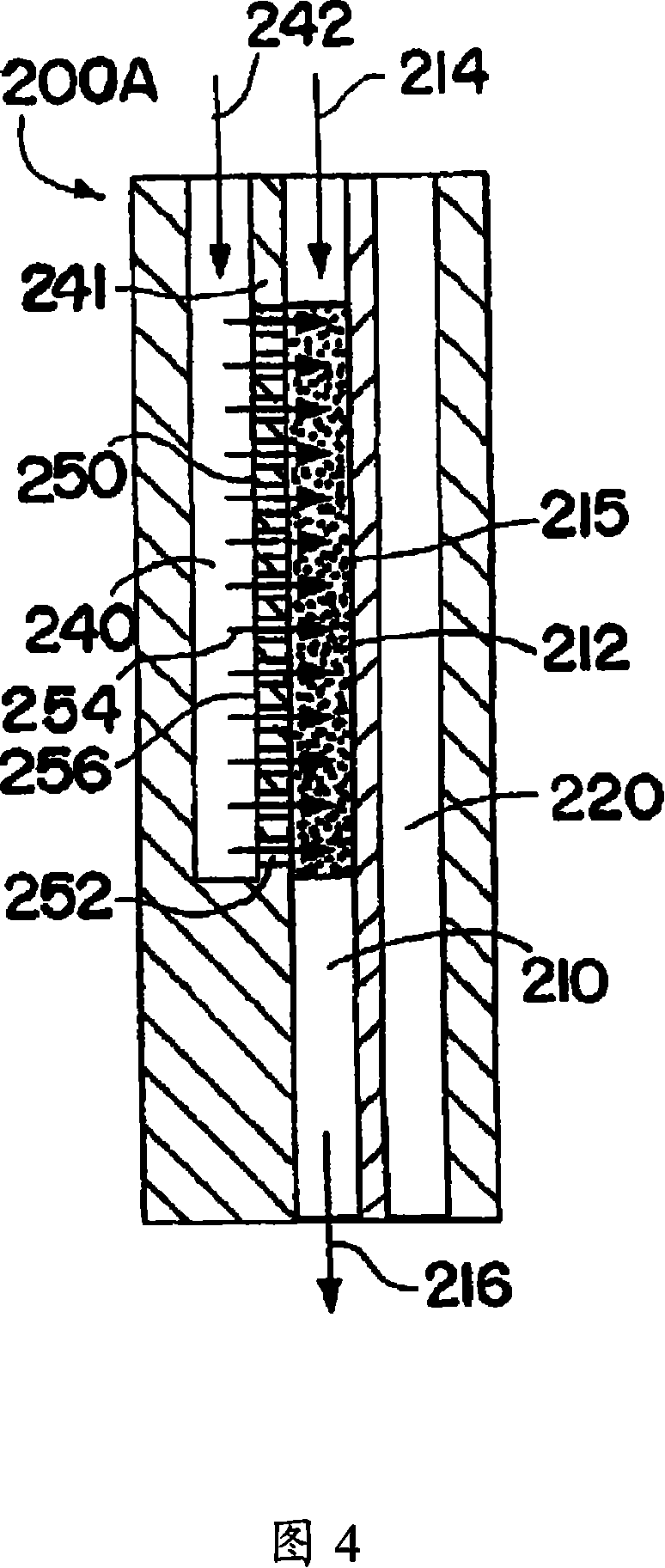

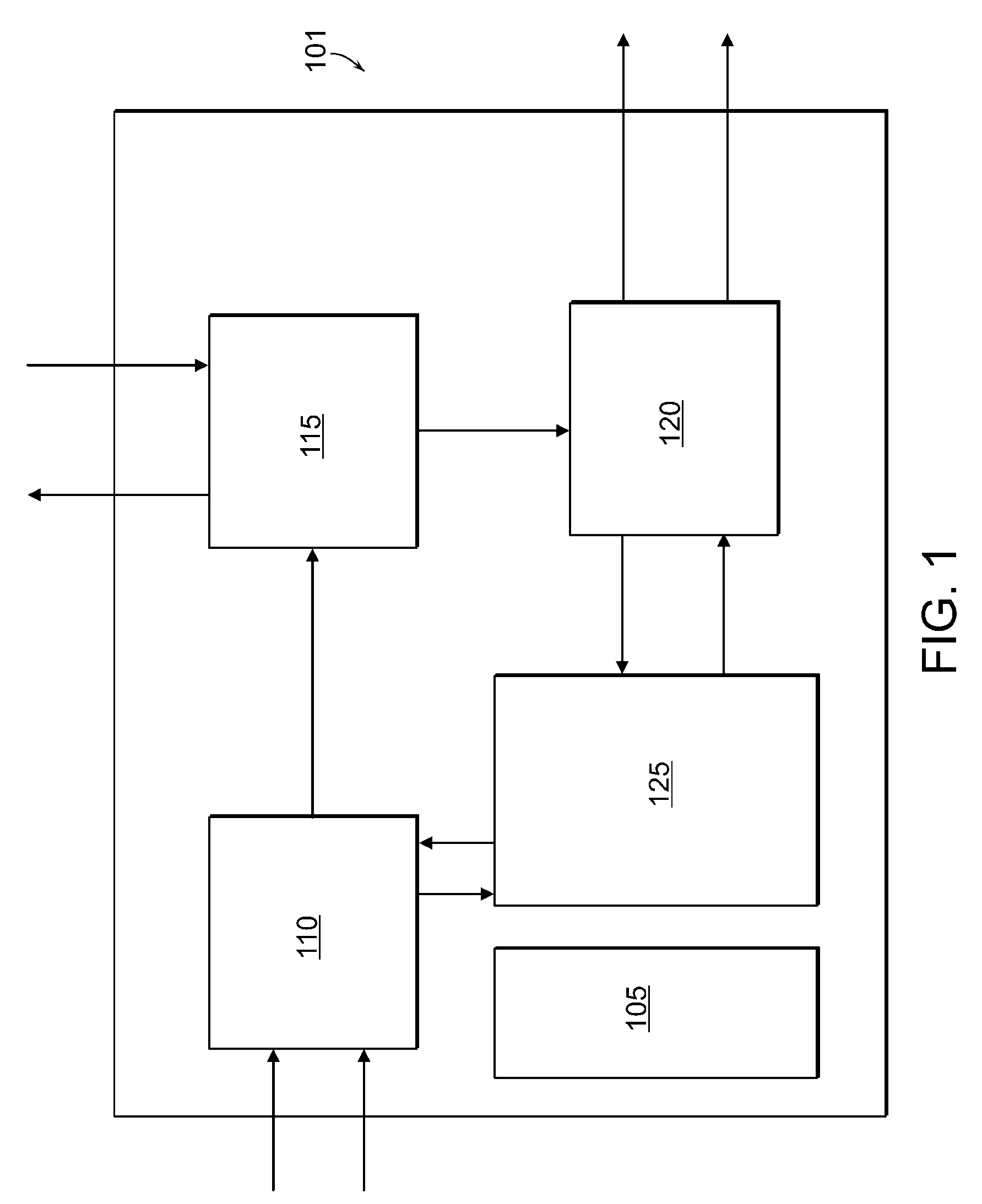

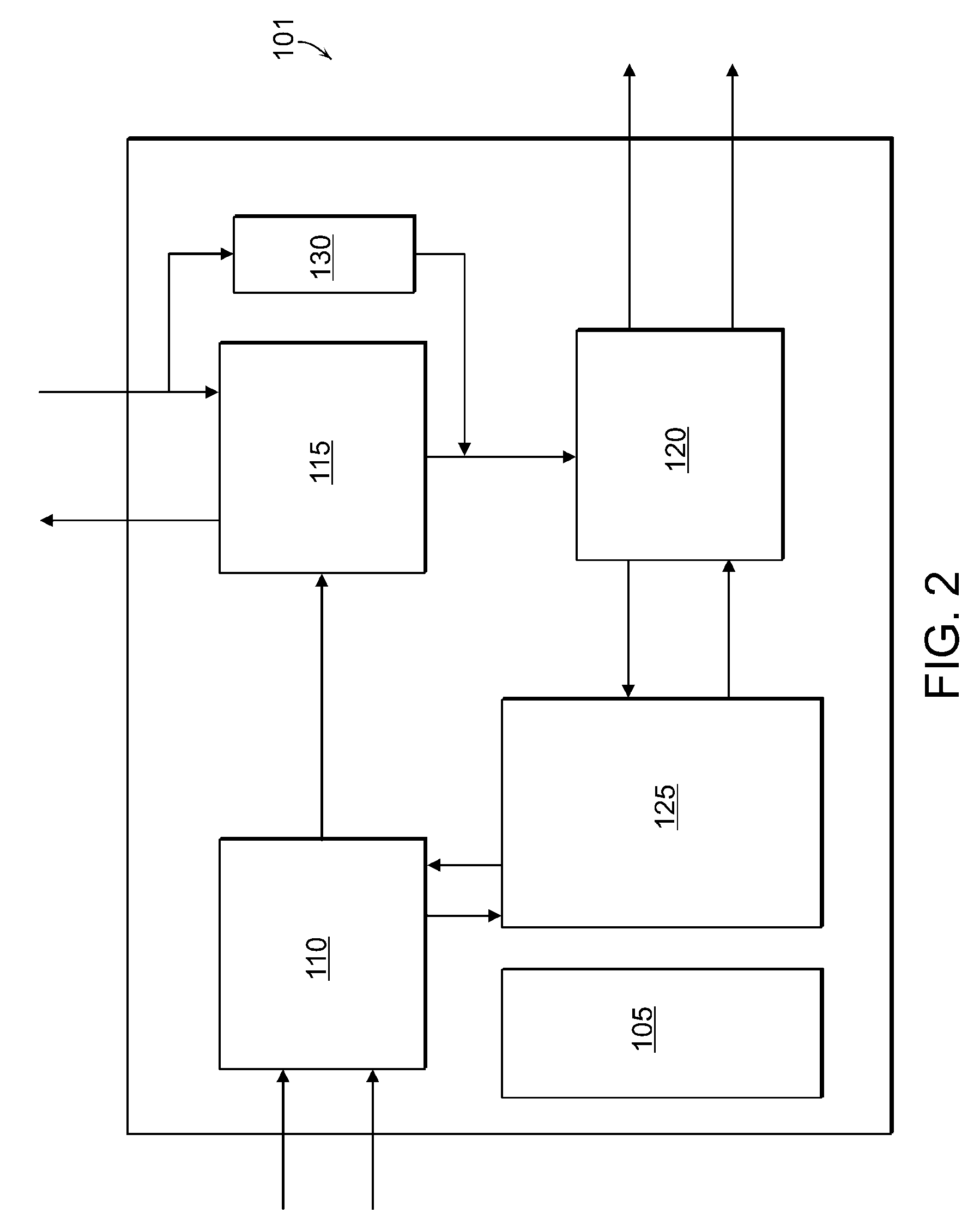

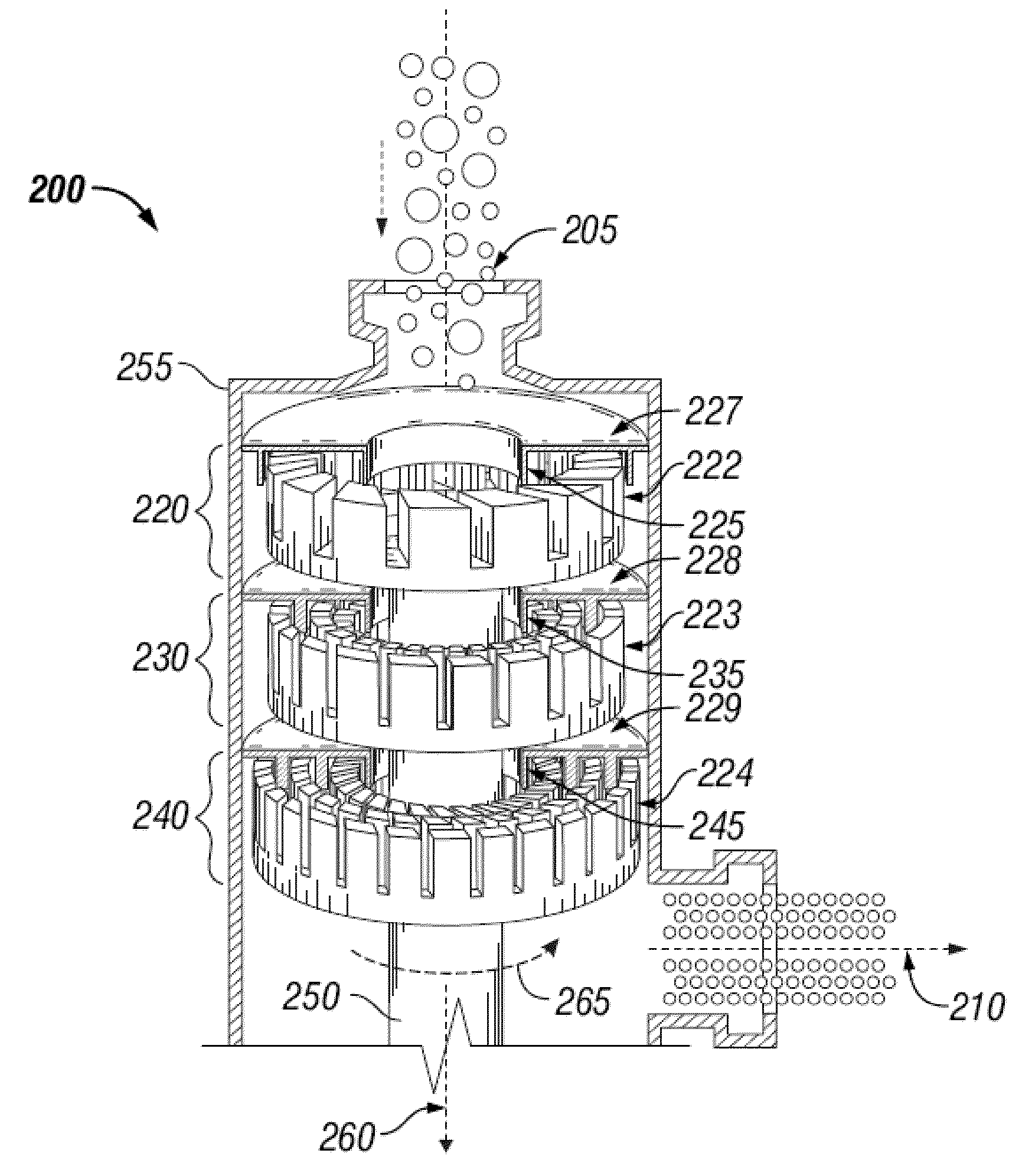

Multiphase reaction process using microchannel technology

InactiveCN101132854AEfficient mixingHigh selectivityFatty acid chemical modificationFlow mixersForming gasOrganic chemistry

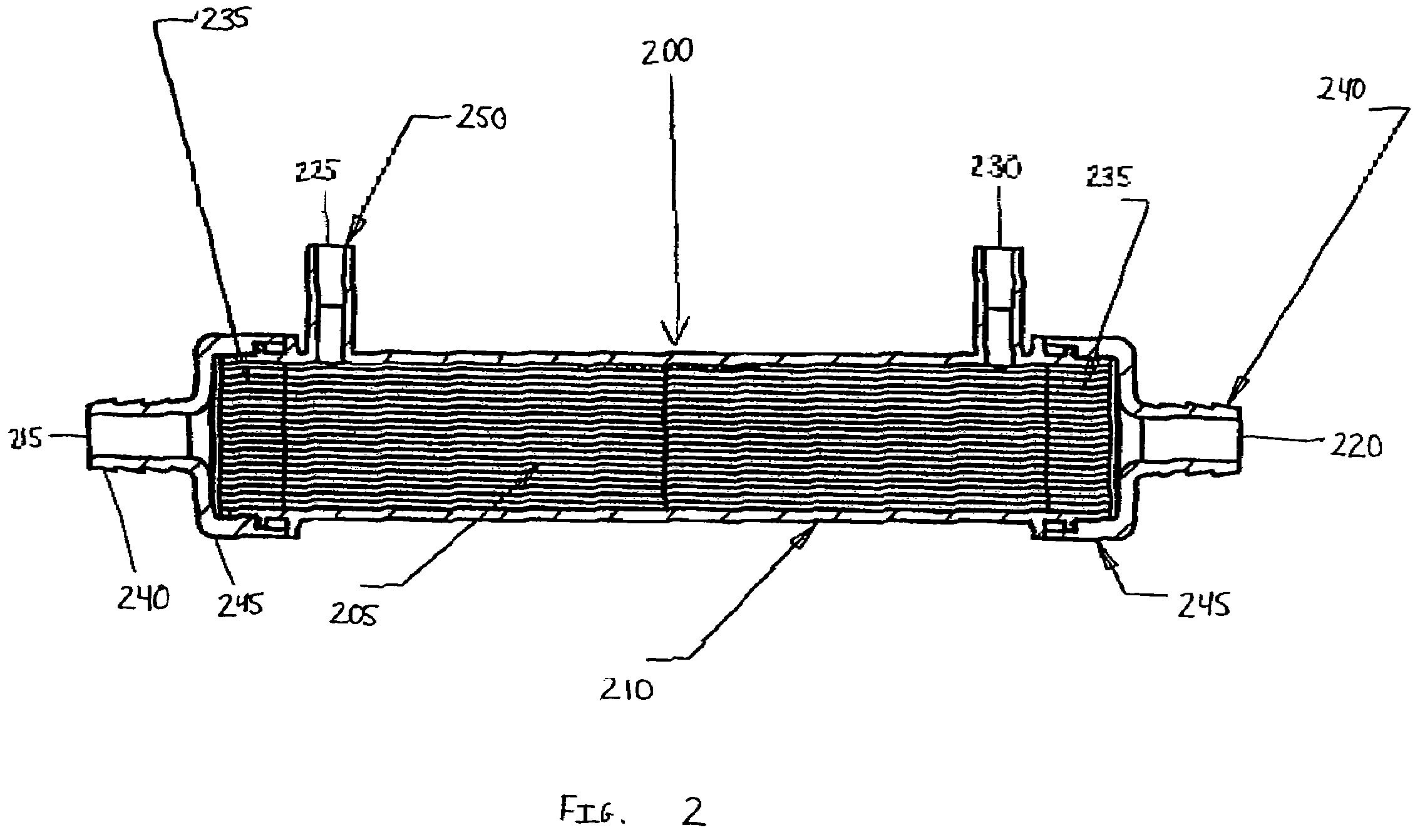

The disclosed invention relates to a process for conducting a multiphase reaction in a microchannel. The process comprises: forming a multiphase reaction mixture comprising a first reactant (214) and a second reactant (242); the first reactant (214) comprising at least one liquid; the second reactant (242) comprising at least one gas, at least one liquid, or a combination of at least one gas and at least one liquid; the first reactant (214) forming a continuous phase in the multiphase reaction mixture; the second reactant (242) forming gas bubbles and / or liquid droplets dispersed in the continuous phase; and reacting the first reactant (214) with the second reactant (242) in a process microchannel (210) in the presence of at least one catalyst (215) to form at least one product (216).

Owner:VELOCYS CORPORATION

Apparatus and method for mixing by producing shear and/or cavitation, and components for apparatus

ActiveUS20090003123A1Improved vibration characteristicsSalicyclic acid active ingredientsShaking/oscillating/vibrating mixersMulti materialCavitation

An apparatus and method for mixing by producing shear and / or cavitation, and components for the apparatus are disclosed. In one embodiment, the apparatus includes a mixing and / or cavitation chamber with an element such as an orifice component that is located adjacent the entrance of the cavitation chamber. The apparatus may further include a blade, such as a knife-like blade, disposed inside the mixing and / or cavitation chamber opposite the orifice component. In one version of such an embodiment, at least some of the portions of the orifice component surrounding the orifice and / or the blade are made of a material or materials that have a Vickers hardness of greater than or equal to about 20 GPa. A process for mixing by producing shear and / or cavitation in a fluid is also contemplated herein.

Owner:THE PROCTER & GAMBLE COMPANY

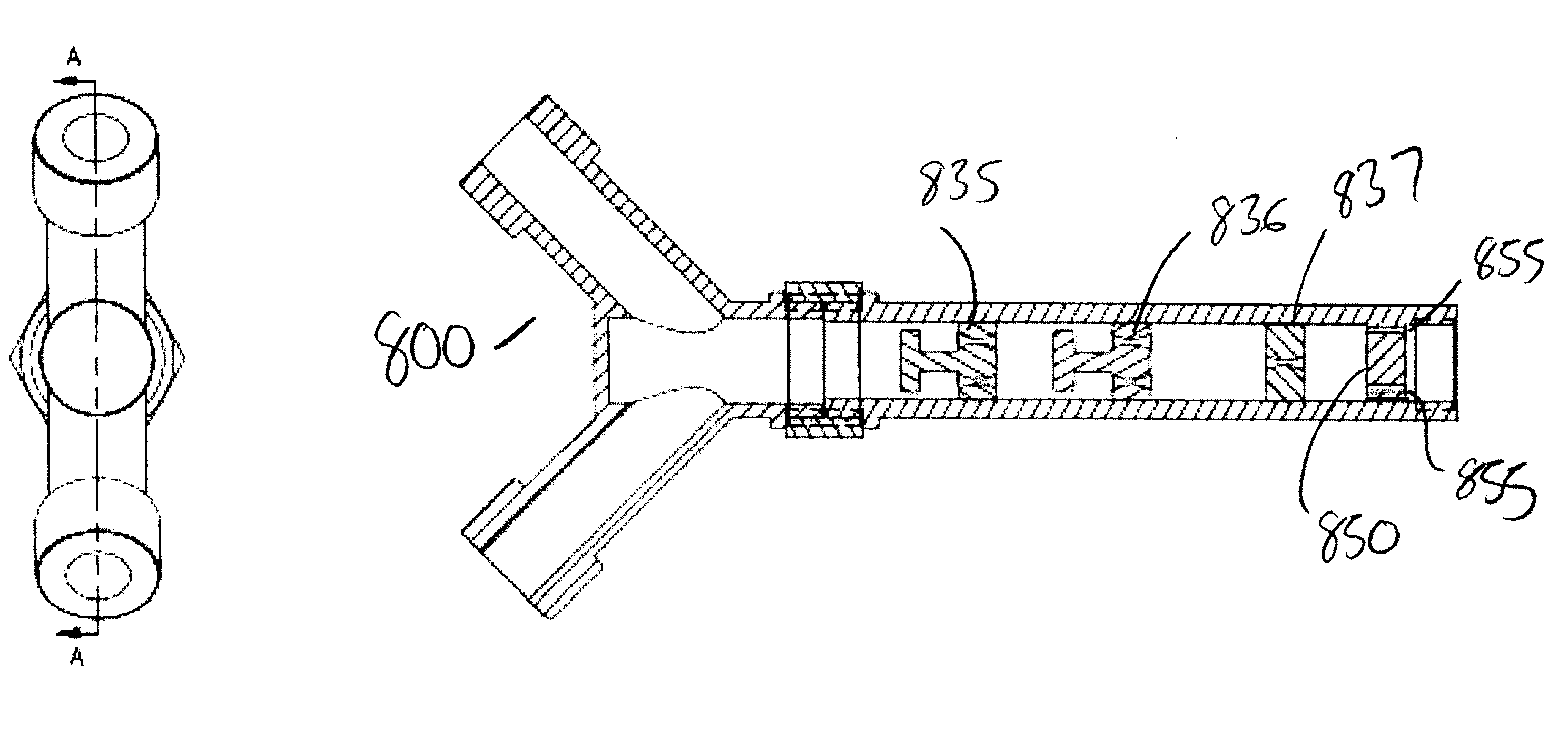

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

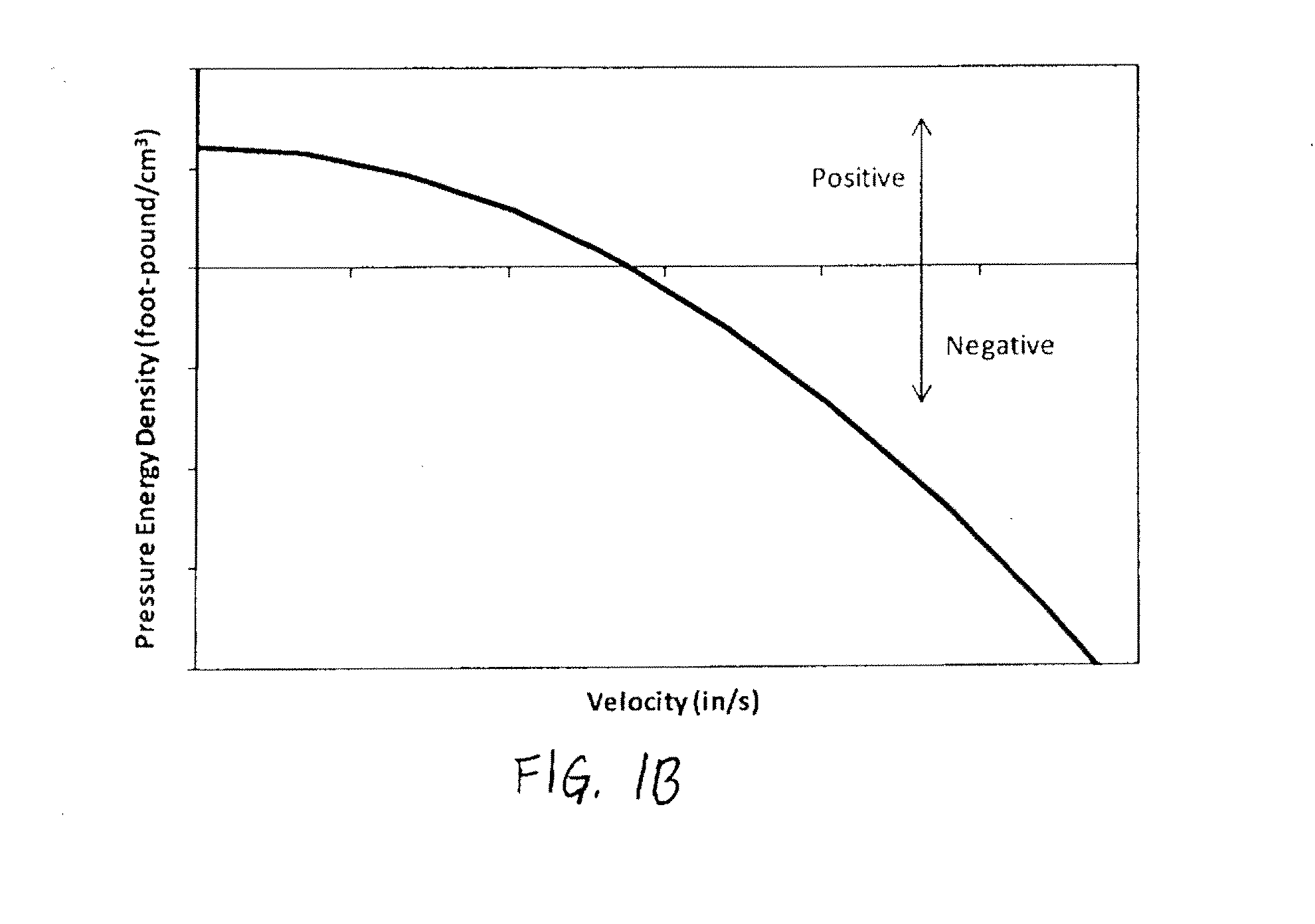

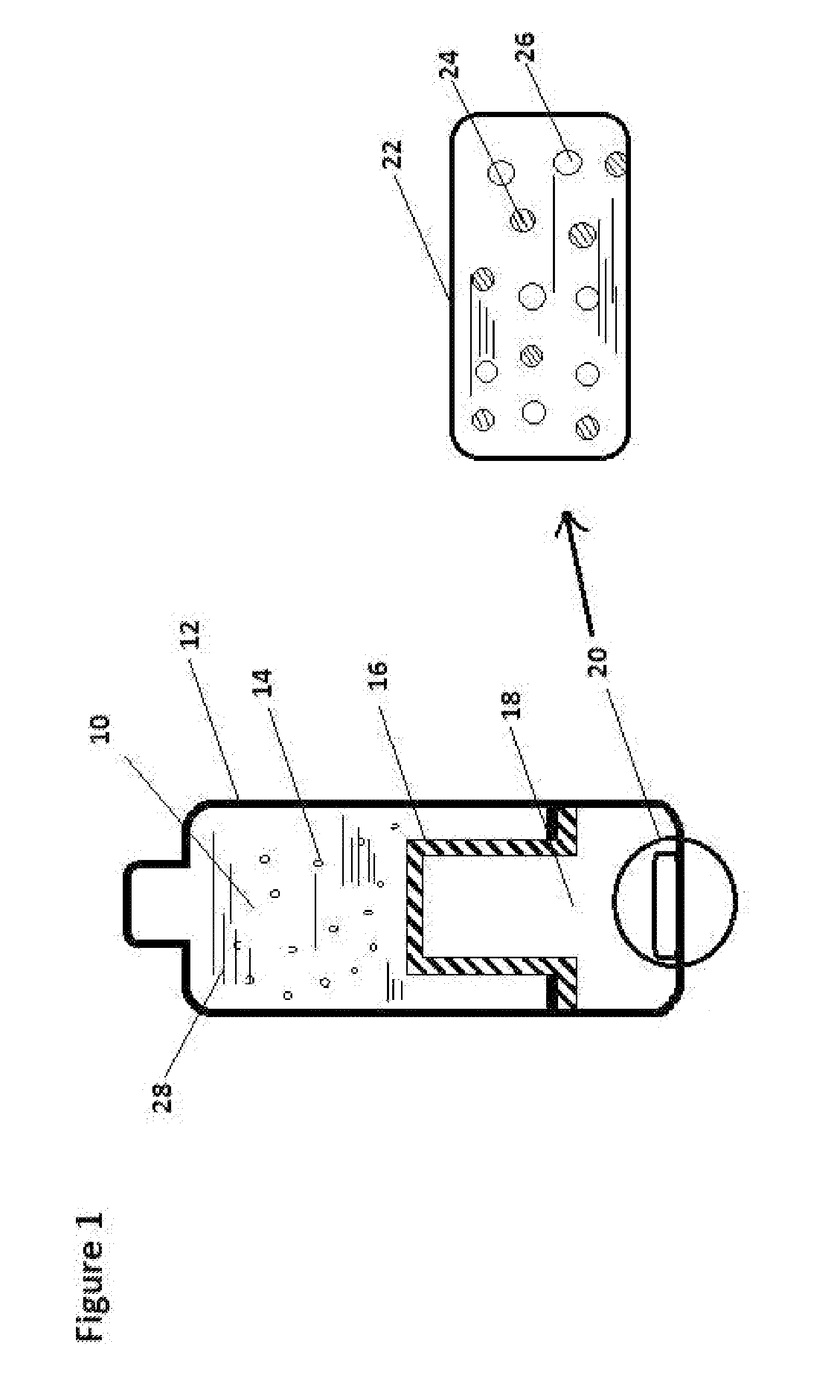

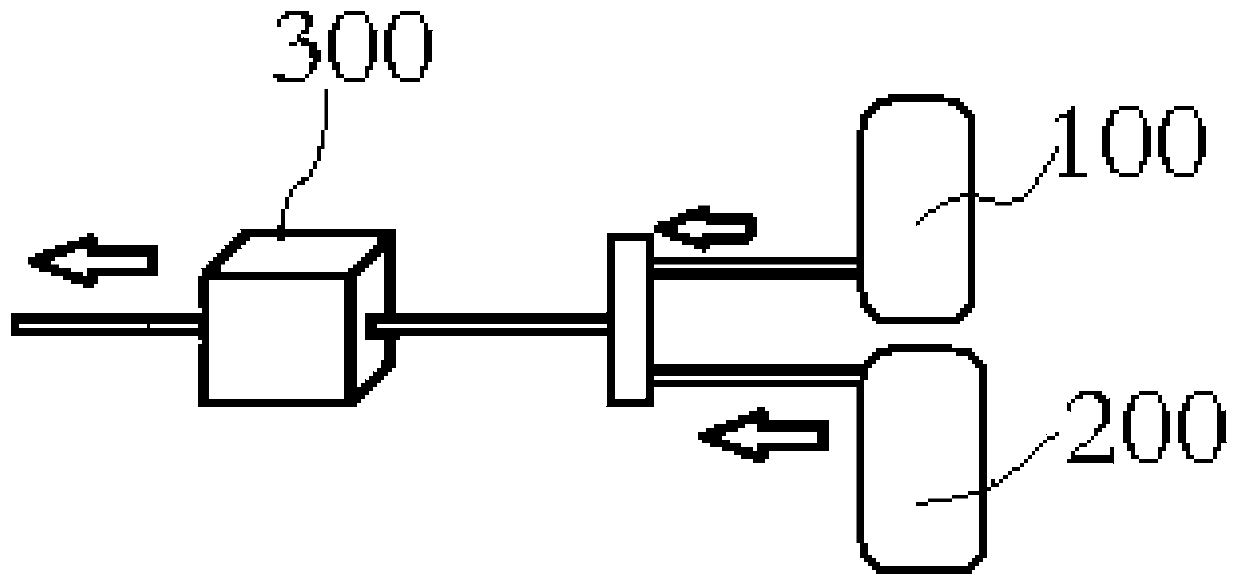

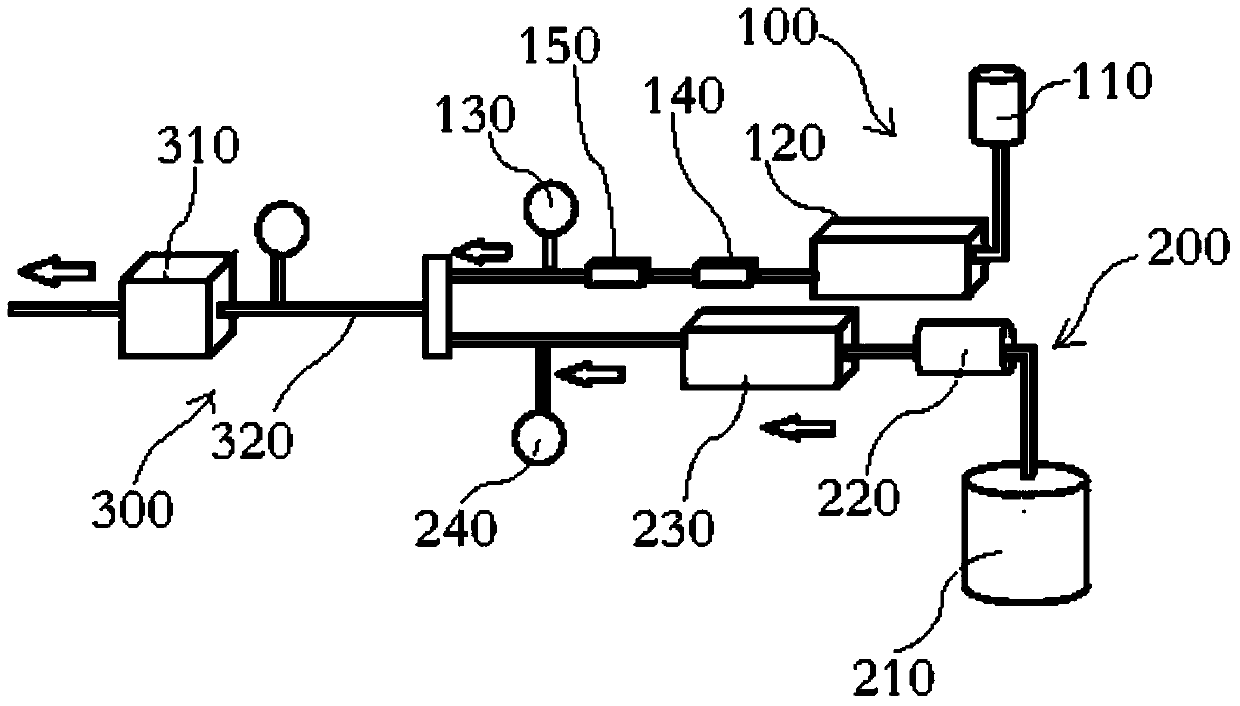

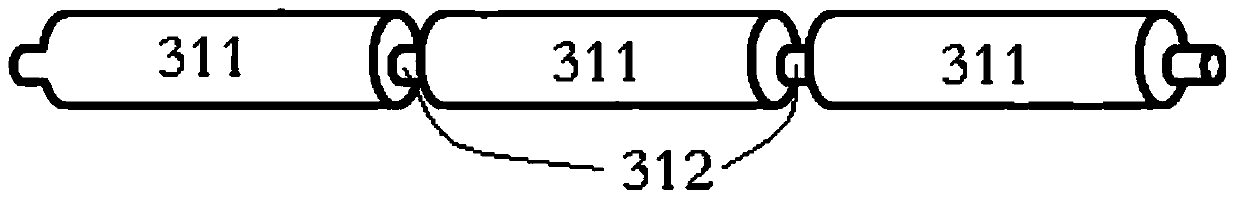

Apparatuses, Systems and Methods For Efficient Solubilization Of Carbon Dioxide In Water Using High Energy Impact

ActiveUS20110268845A1Increase kinetic energyShaking/oscillating/vibrating mixersFlow mixersWater useHigh energy

A method for the efficient solubilization of carbon dioxide in water through the use of high energy impacts is disclosed. The method can optionally includes mixing the carbon dioxide and water to form an annular dispersed flow, accelerating the carbon dioxide and water prior to the collision; providing a retention network to collect the carbonated water flow. Also disclosed are systems and apparatuses for practicing the disclosed methods.

Owner:APIQE HLDG

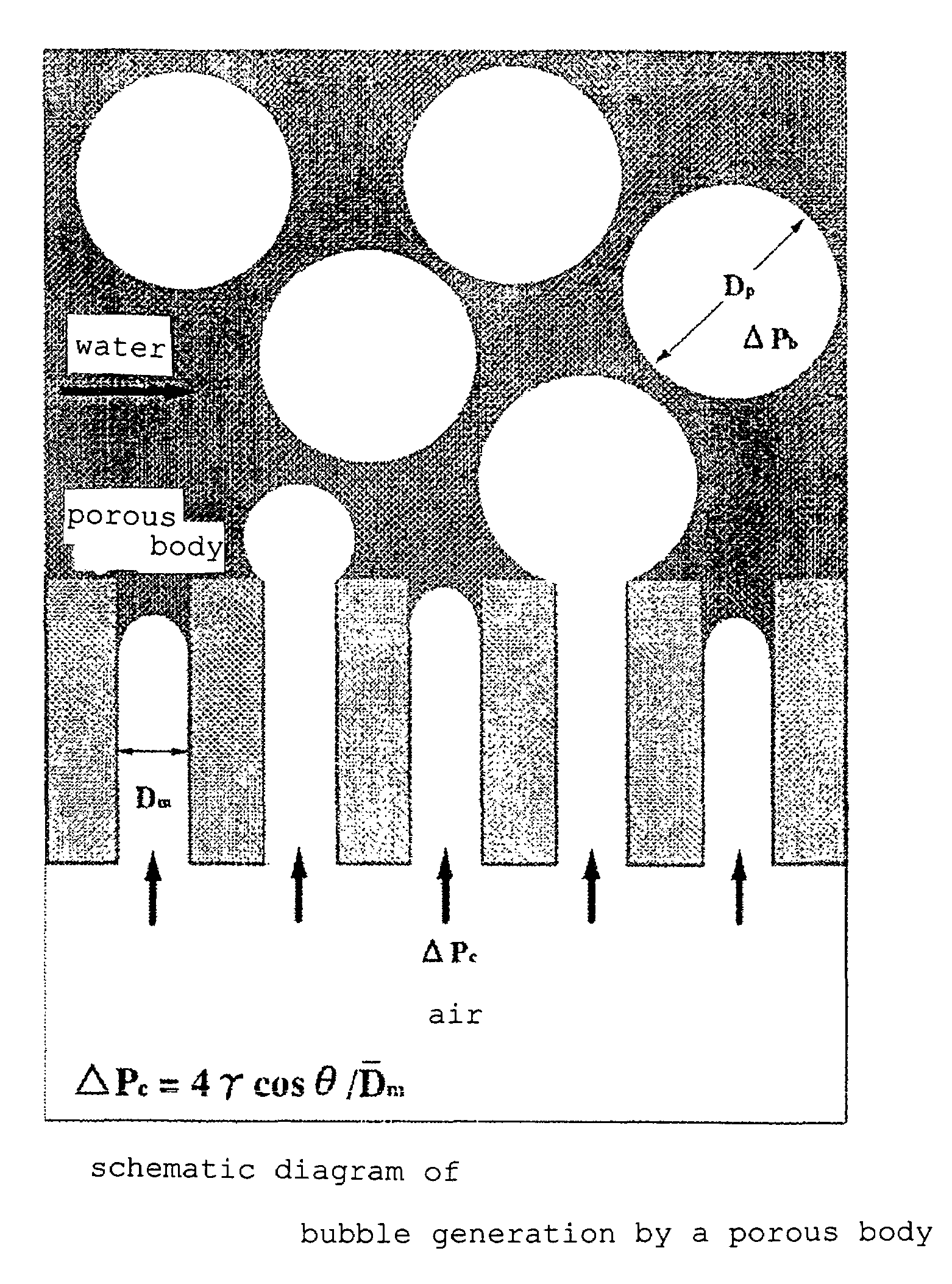

Method of forming monodisperse bubble

InactiveUS20060284325A1Reliably producedCarburetting airTransportation and packagingPore distributionPore diameter

Owner:MIYAZAKI PREFECTURE +1

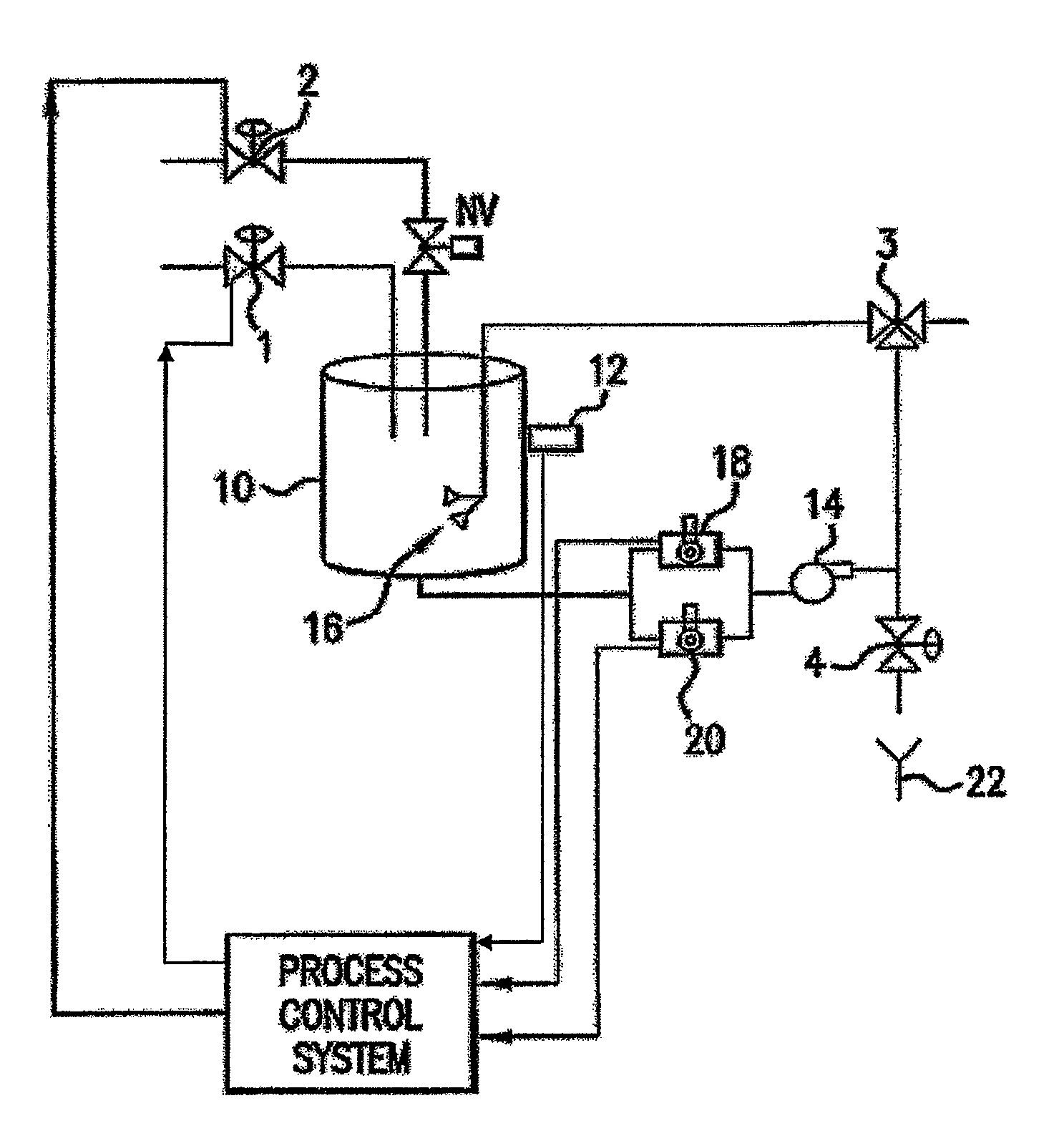

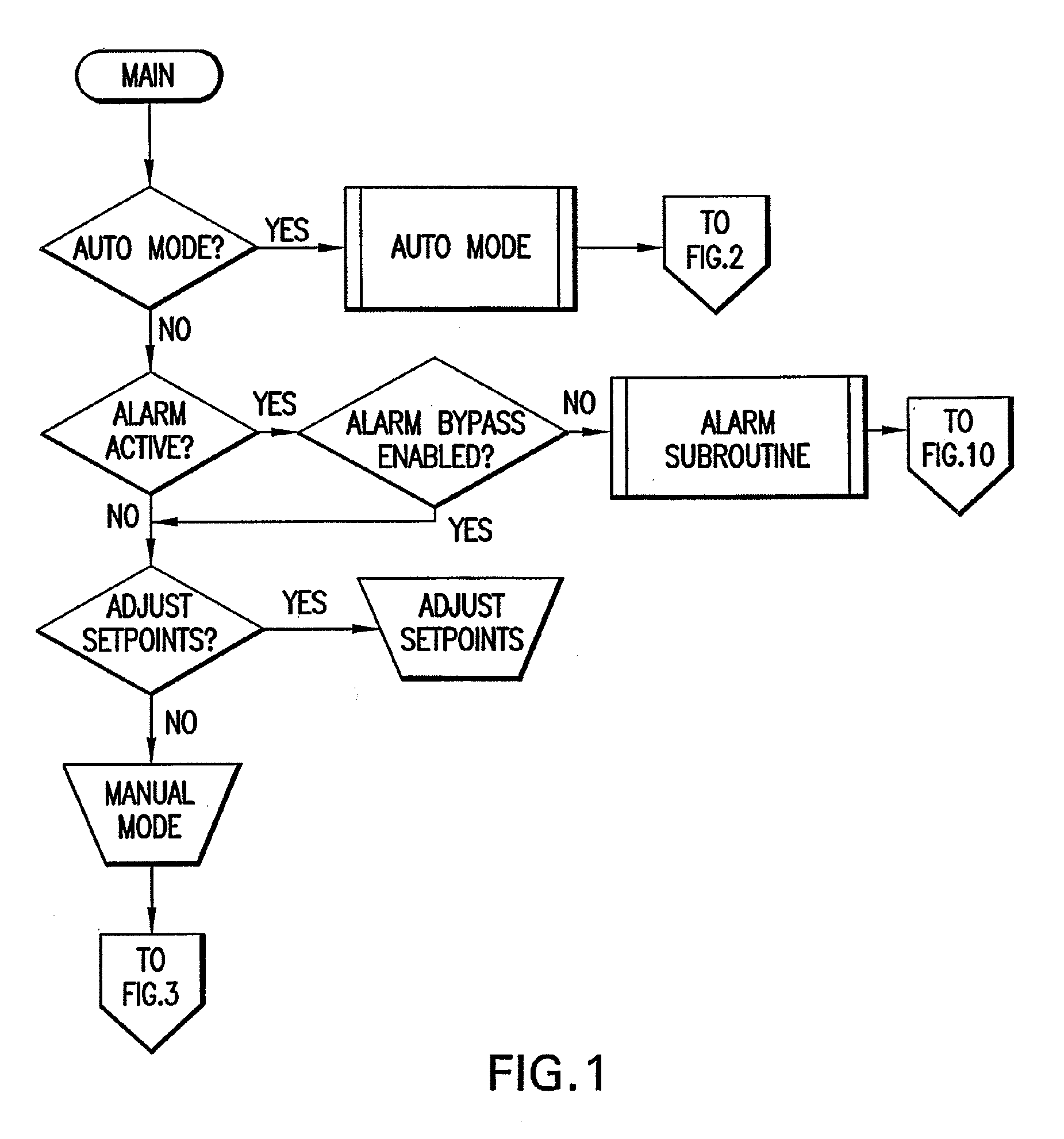

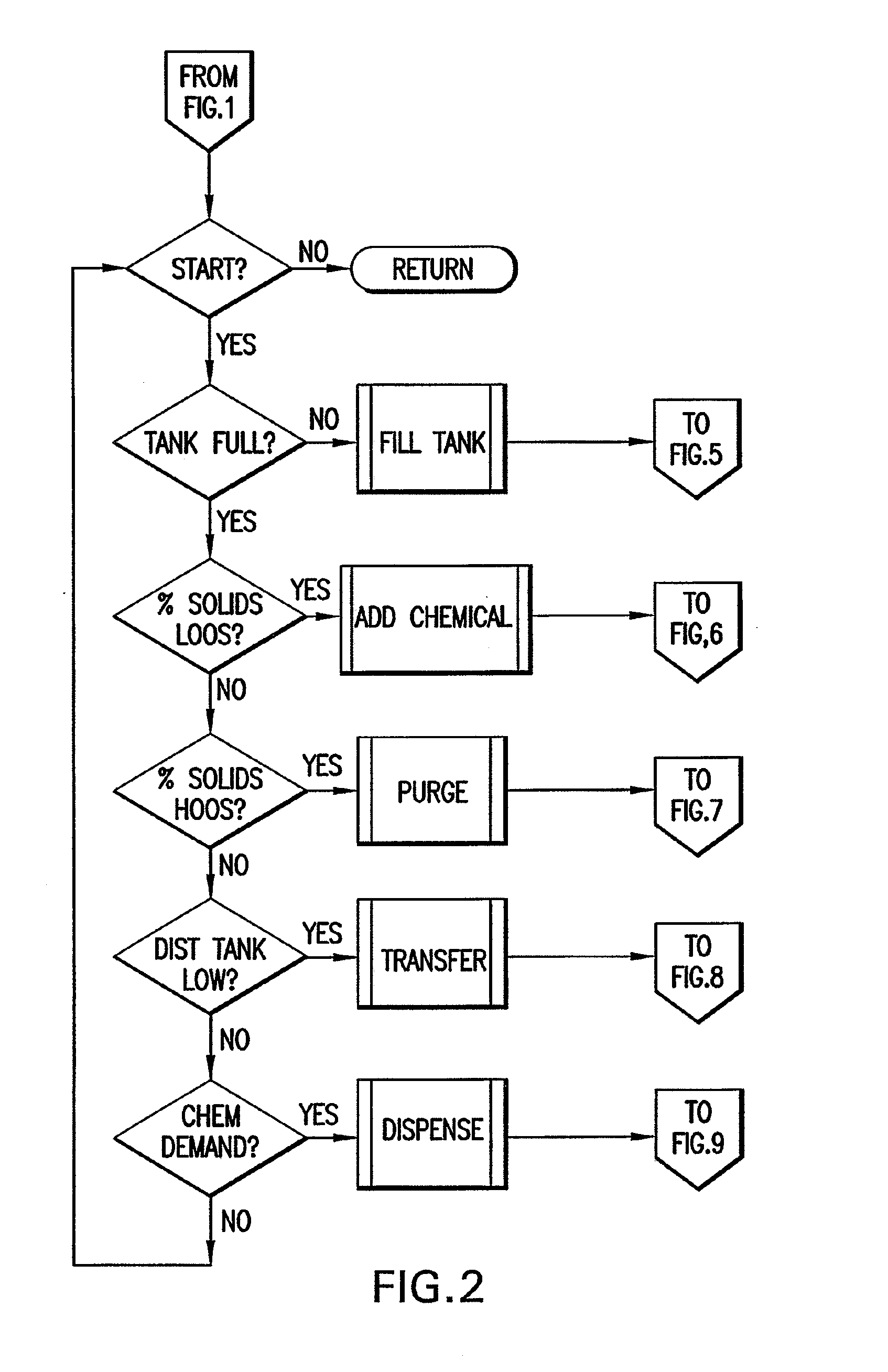

Method and apparatus for blending process materials

ActiveUS7344298B2Controlling ratio of multiple fluid flowsTransportation and packagingProcess engineeringSlurry

A method and apparatus for blending and supplying process materials. The method and apparatus are particularly applicable to the blending of ultra-high purity chemicals, the blending of abrasive slurries with other chemicals for the polishing of semiconductor wafers, and high-accuracy blending of chemicals.

Owner:MEGA FLUID SYST

Ultrasonic treatment chamber for preparing antimicrobial formulations

InactiveUS20090168590A1Shaking/oscillating/vibrating mixersTransportation and packagingUltrasonic cavitationMedicine

Owner:KIMBERLY-CLARK WORLDWIDE INC

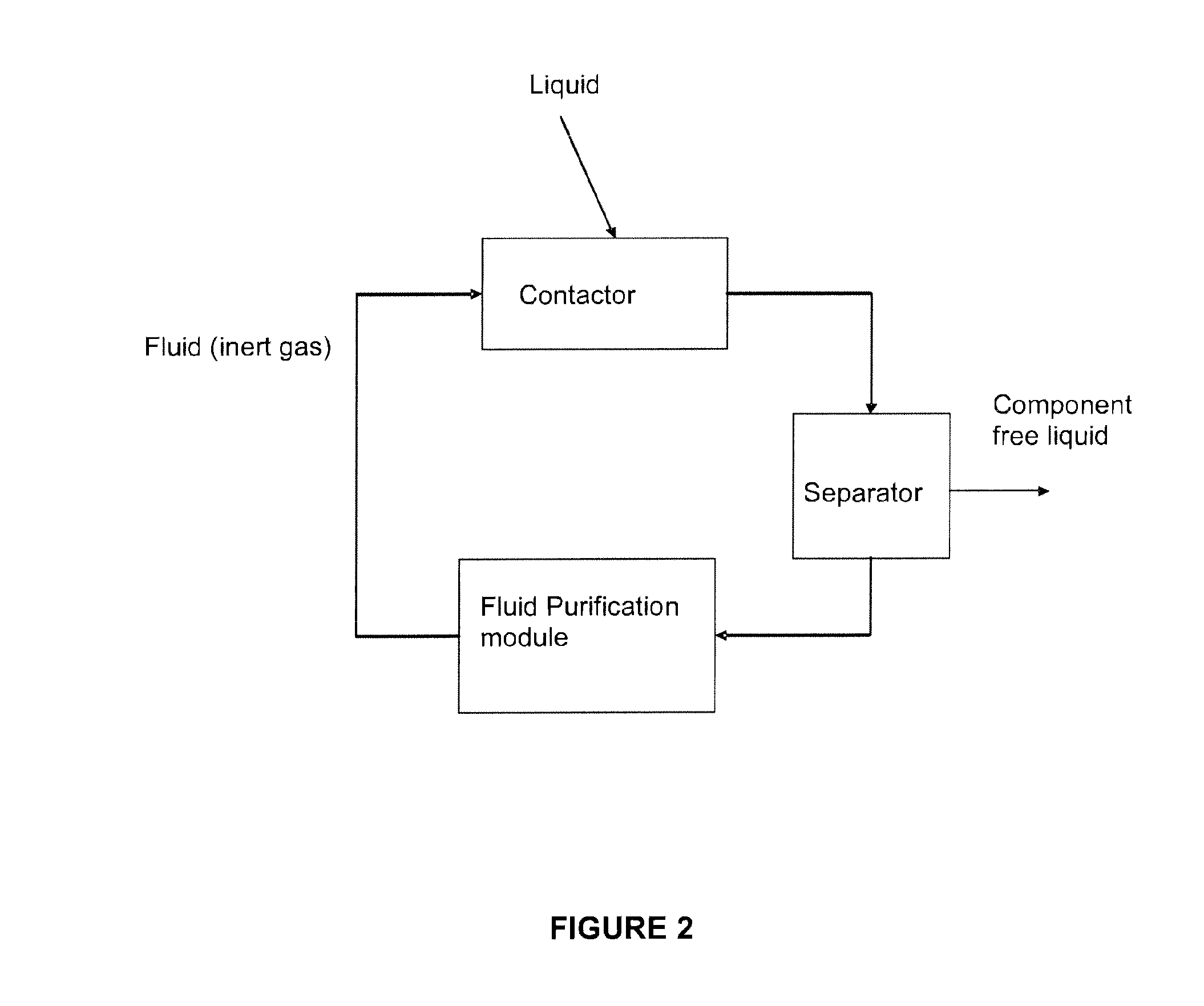

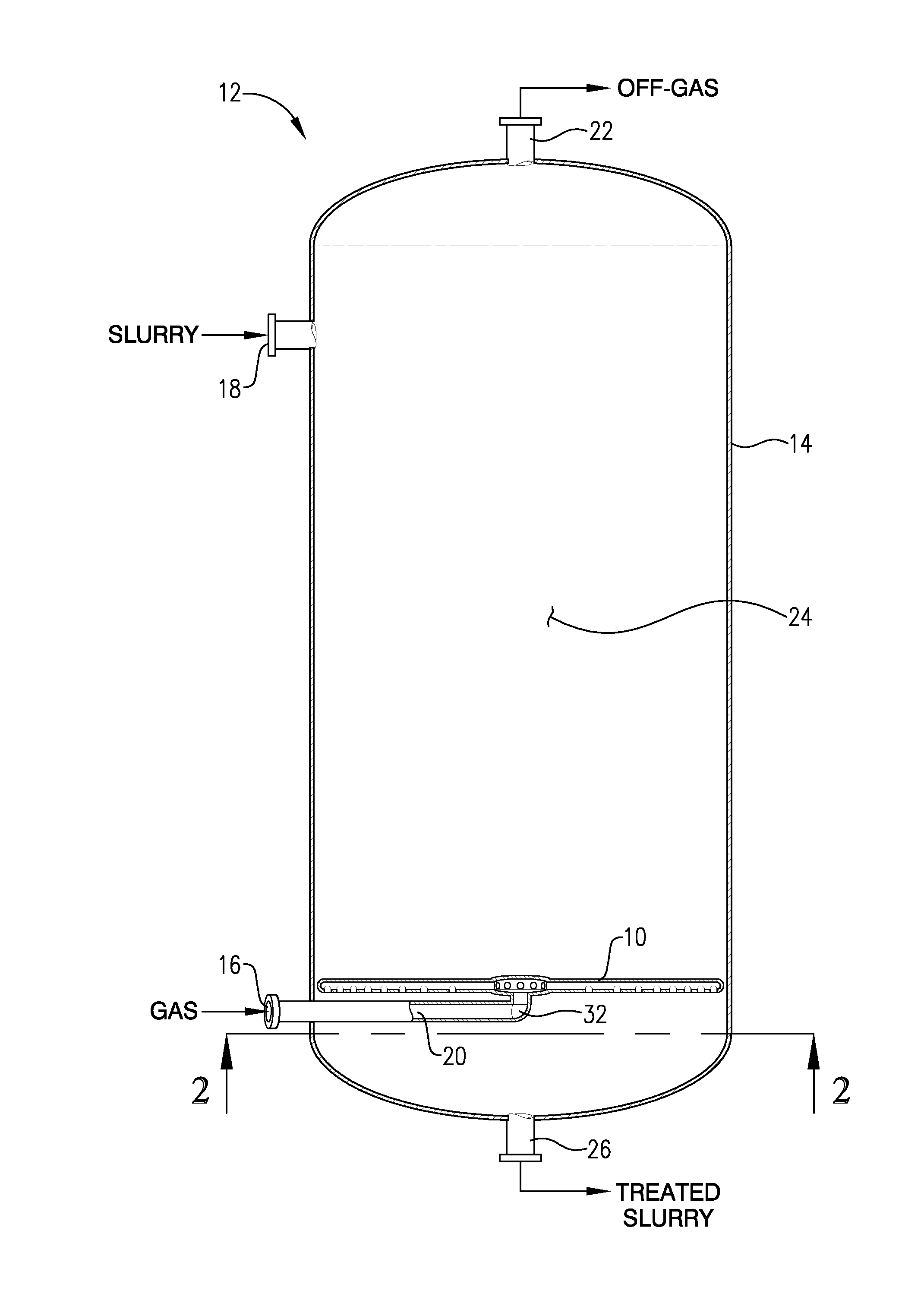

Contacting systems and methods and uses thereof

ActiveUS20120216677A1Facilitates vigorous and intimate mixing of liquidEasy transferLiquid degasification with auxillary substancesUsing liquid separation agentContact systemContact zone

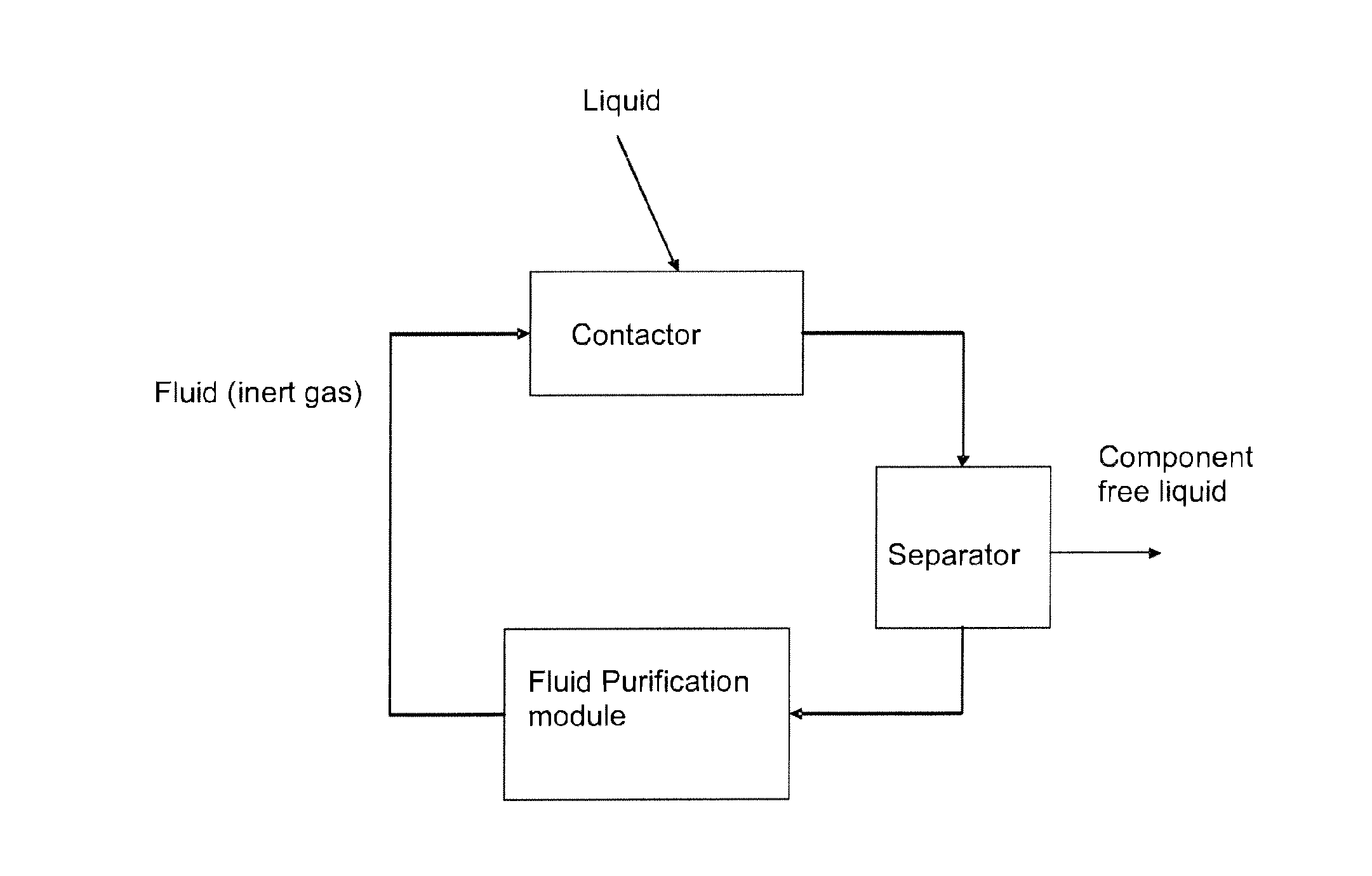

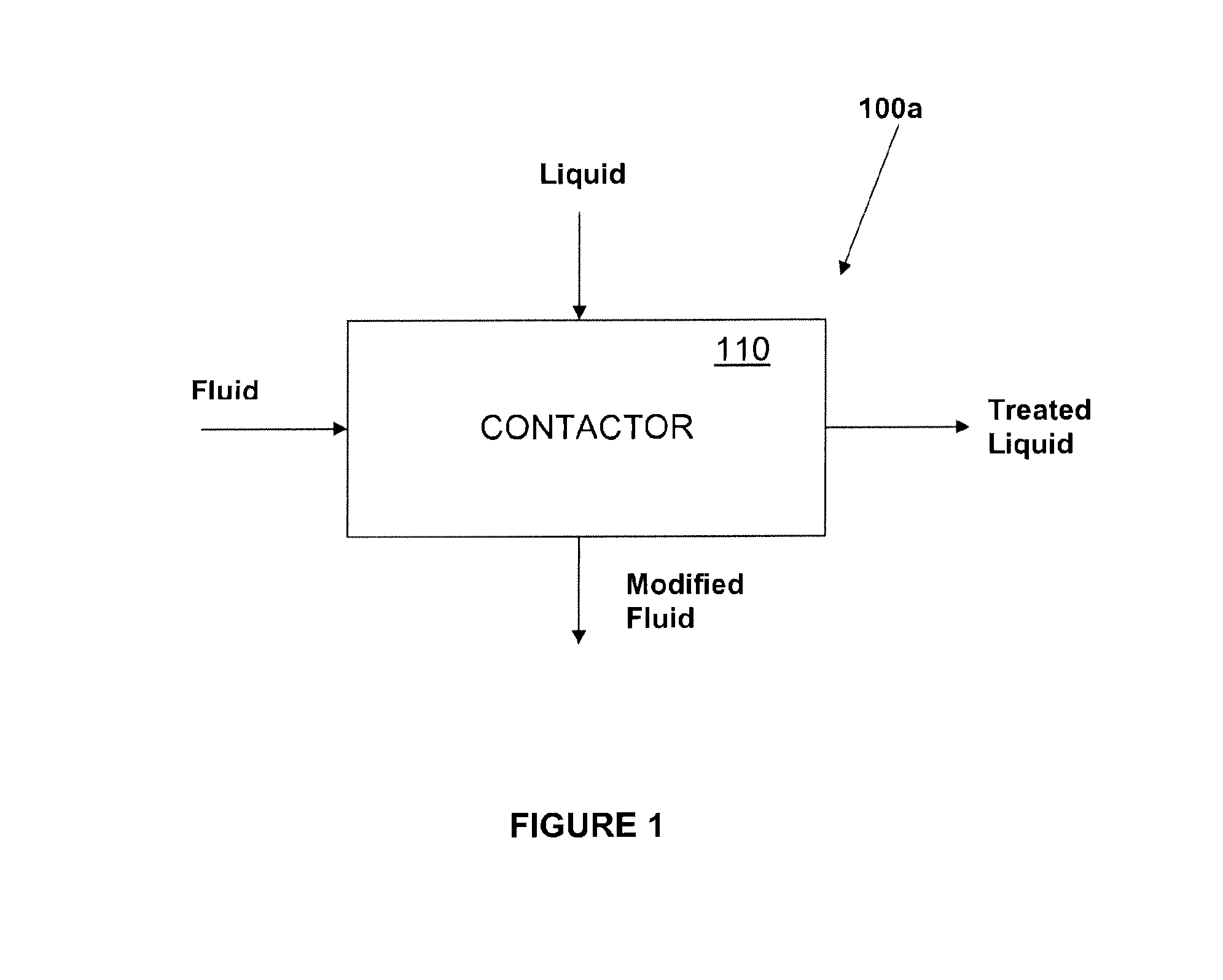

In accordance with the present invention, there are provided systems and methods for contacting two or more fluids, useful, for example for purifying or infusing a fluid (by allowing efficient and / or uniform addition of components to or removal of components from the fluid). The components may be undesirable components to be removed from a fluid, or a desired component or components to be added to the fluid, for example, each of which is referred to herein as “component”. In this regard, the disclosed embodiments provide for the purification or infusion of a fluid by passing a liquid and a fluid through a contacting zone which facilitates intimate mixing of the liquid and the fluid. A differential of partial pressure, activity, fugacity or concentration of the components between the liquid and the fluid facilitates the transfer of the components between the liquid and the fluid in the intimately mixed liquid and fluid.

Owner:GENERAL ELECTRIC CO

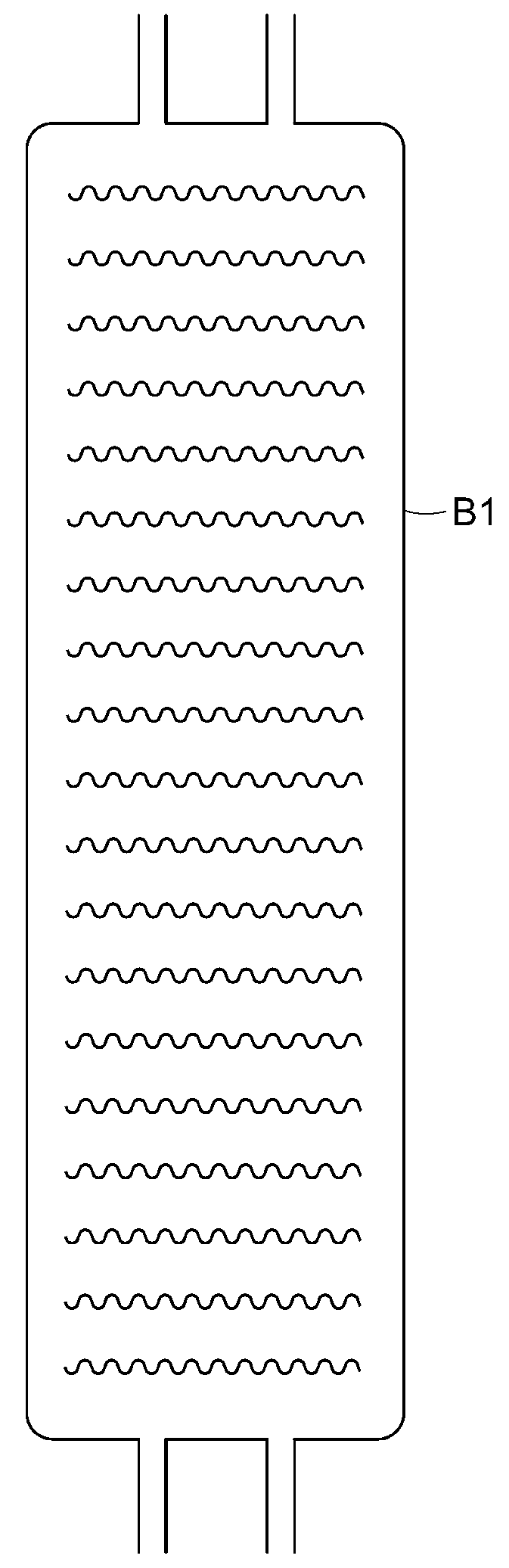

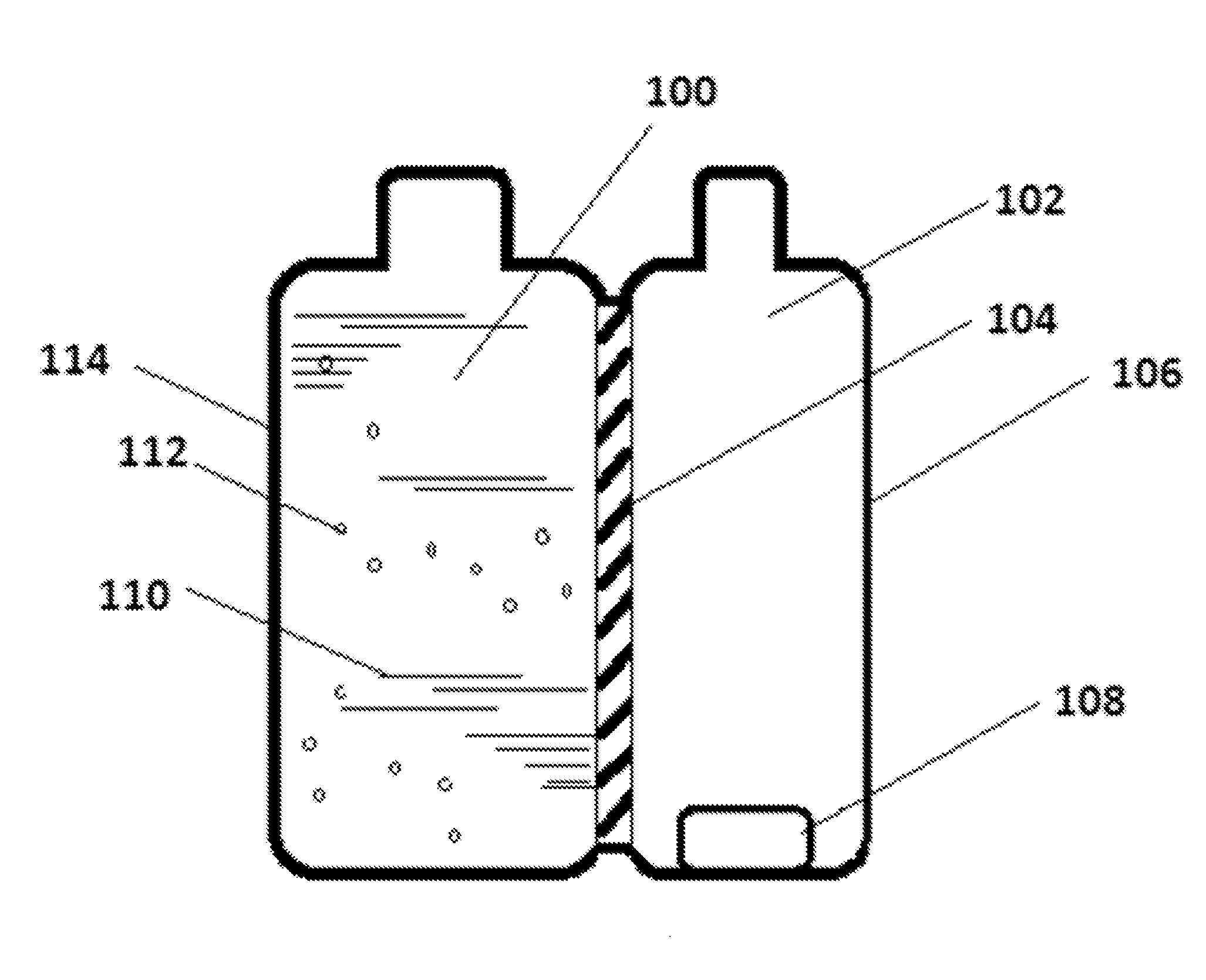

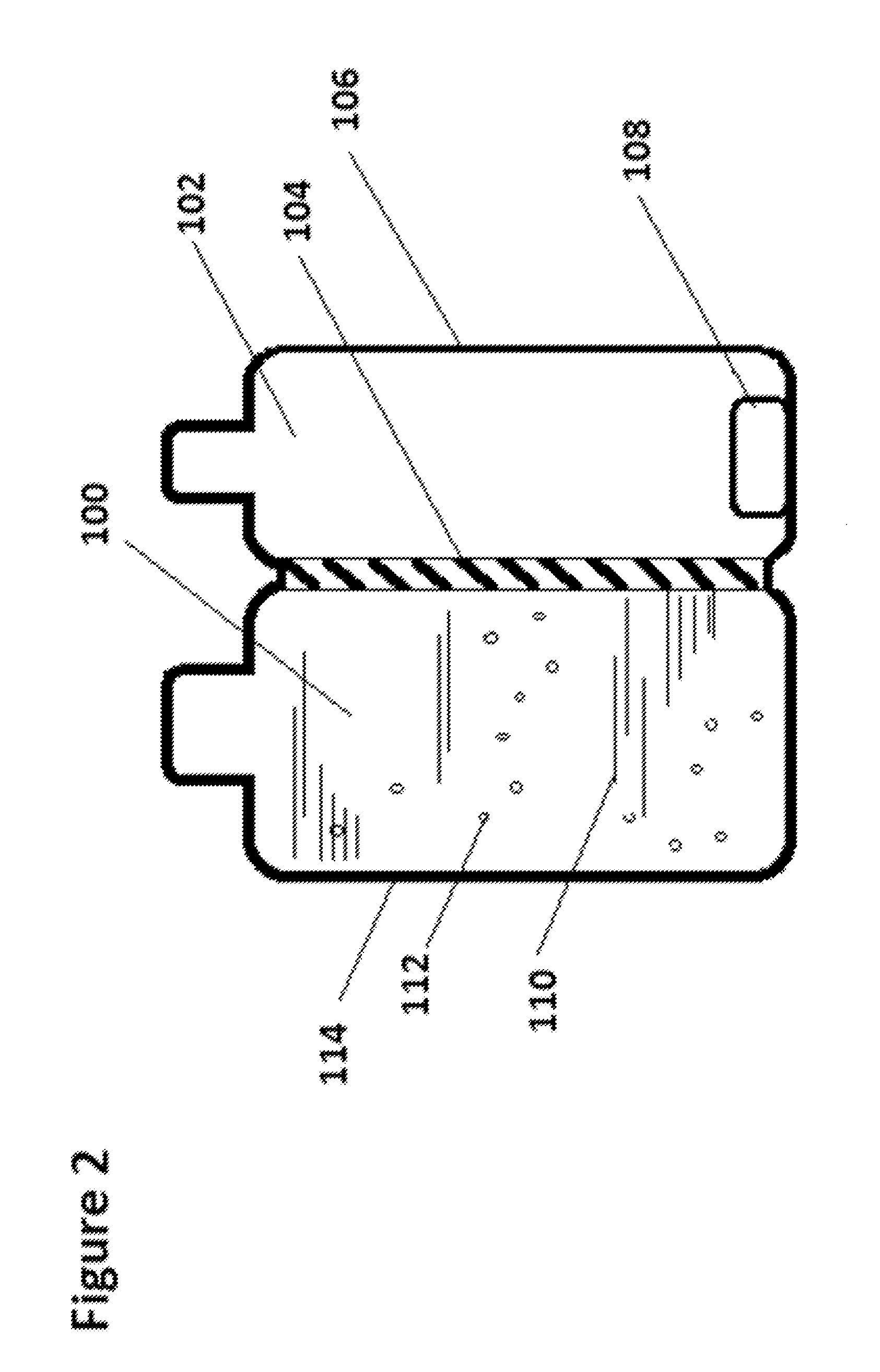

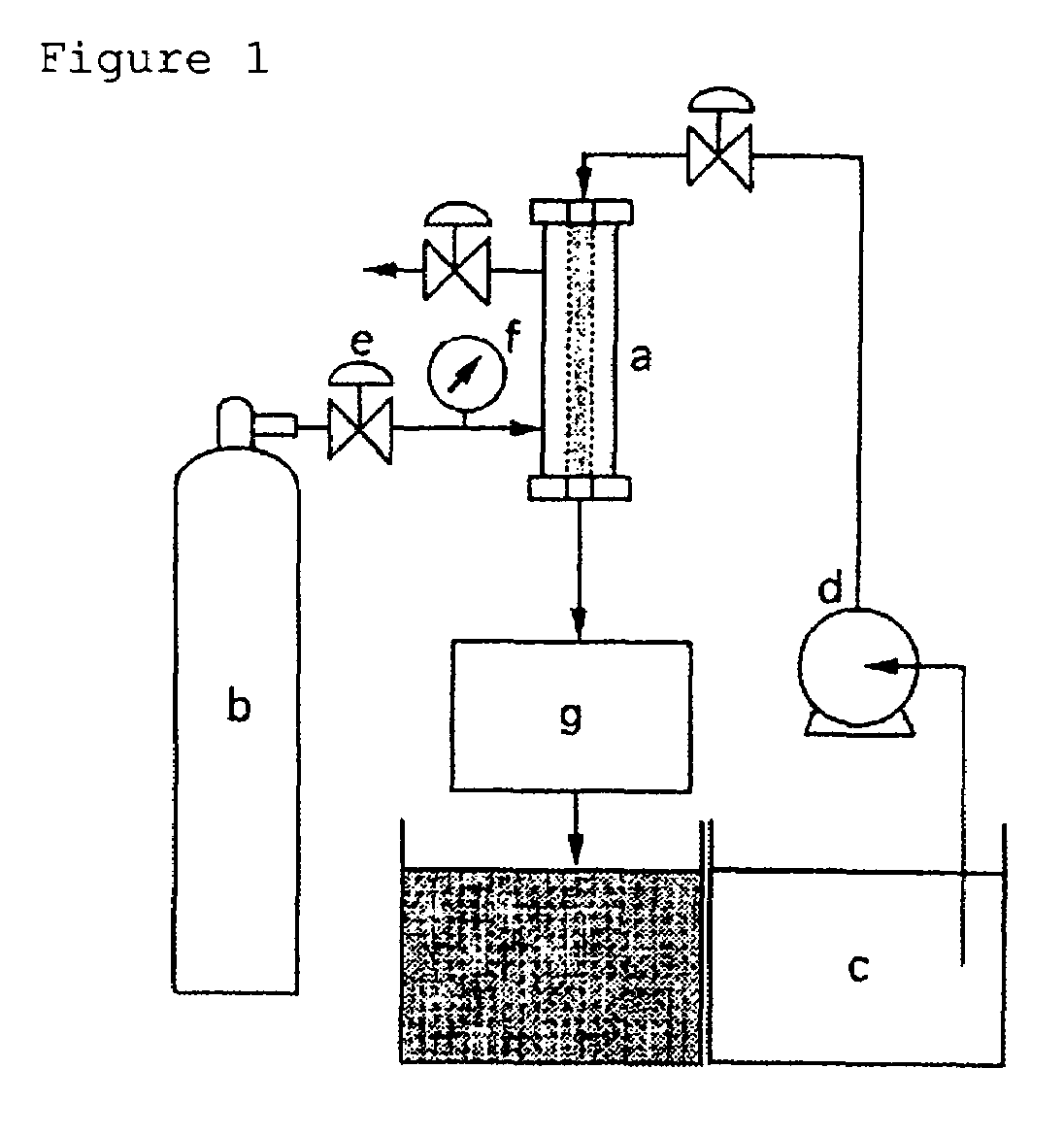

Devices, Systems, and Methods for Carbonation of Deionized Water

ActiveUS20080257738A1Large specific surface areaWell mixedSpace heating and ventilationUsing liquid separation agentEngineeringCarbonation

Devices, systems, and methods employed in wet cleaning semiconductor devices are provided. In particular, systems that can deliver deionized water with the desired concentration of CO2 and methods of generating deionized water with a desired concentration of CO2 for use in wet cleaning of semiconductor devices are provided.

Owner:MKS INSTR INC

Method and Apparatus to Produce Hydrogen-Rich Materials

InactiveUS20140247689A1Increase the concentration of hydrogenImprove hydrogen permeabilityLighting and heating apparatusUsing liquid separation agentHydrogen concentrationCompound (substance)

Hydrogen molecule (H2) has been indicated as a novel anti-oxidant reagent specifically targeting OH free radicals. This invention discloses the methods and apparatus that can be used to increase the hydrogen concentration in water, in beverages, and in other hydrogen absorbing materials through a sealed hydrogen gas producing chamber made of materials that have good hydrogen permeability and can withhold gas pressure. The disclosed method and apparatus can increase the hydrogen concentration quickly without leaking other chemical by-products of the gas producing system into the treated materials.

Owner:CENTAQUA

Method and apparatus to minimize air-slurry separation during gypsum slurry flow

A method and apparatus for providing an evenly mixed additive enhanced gypsum slurry to a web. Calcined gypsum and water are inserted into a mixer through at least one inlet of the mixer. The contents are agitated to form a slurry. The slurry is passed from an outlet of the mixer into a conduit. An additive is introduced into the slurry along a length of the conduit to achieve a flow stream of a slurry / additive mixture. A cross section of the flow stream is expanded in the conduit while not changing direction of the flow stream and a direction of the flow stream is changed while not expanding the cross section of the flow stream and conduit, all prior to the flow steam exiting from an outlet of the conduit.

Owner:UNITED STATES GYPSUM CO

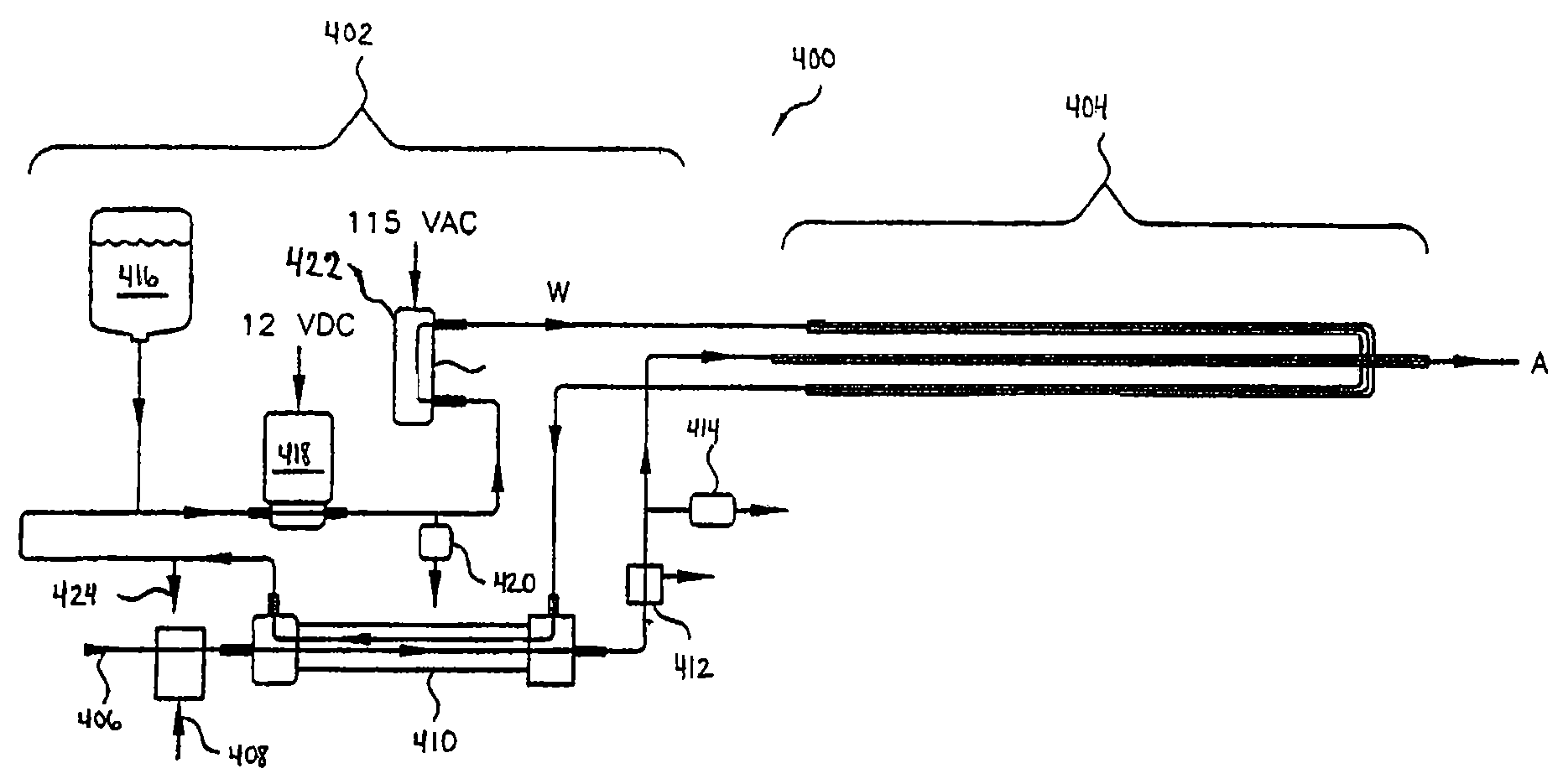

Apparatus and method for delivering water vapor to a gas

An apparatus for delivering water vapor to a gas is formed from a plurality of hollow fiber membranes each defining a passage for the flow of gas from an upstream end of the passage and enclosed by an enclosure. The hollow fiber membranes have a combined surface area in the range of about 90 square centimeters to about 110 square centimeters. The enclosure contains an air inlet positioned to direct air to the upstream end of each of the passages of the hollow fiber membranes and an air outlet positioned to direct air from the downstream end of each of the passages of the hollow fiber membranes. The enclosure preferably has a water inlet positioned to direct water toward the outer surfaces of the hollow fiber membranes and a water outlet positioned to direct water from the enclosure.

Owner:BRIDGE BANK NAT ASSOC

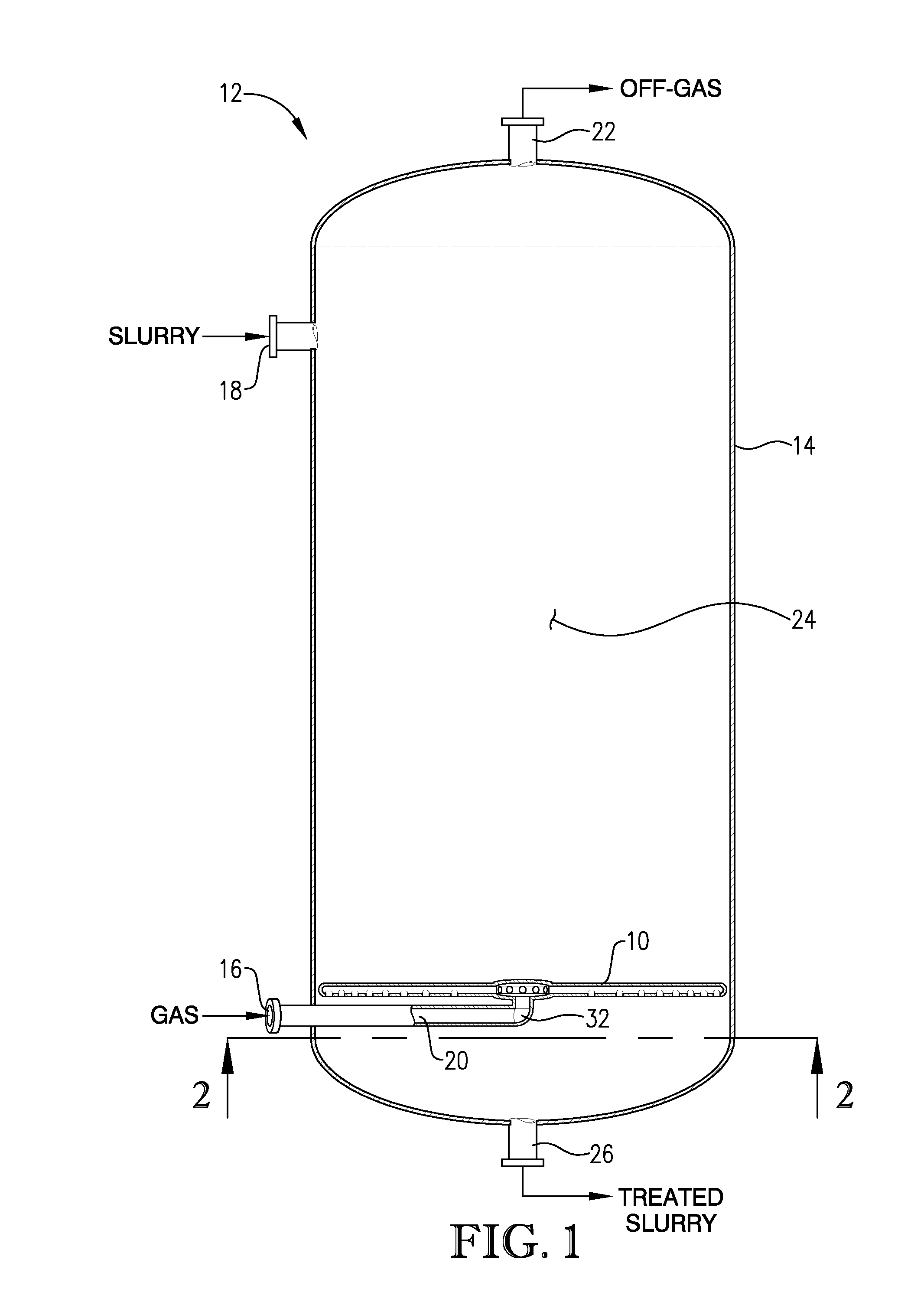

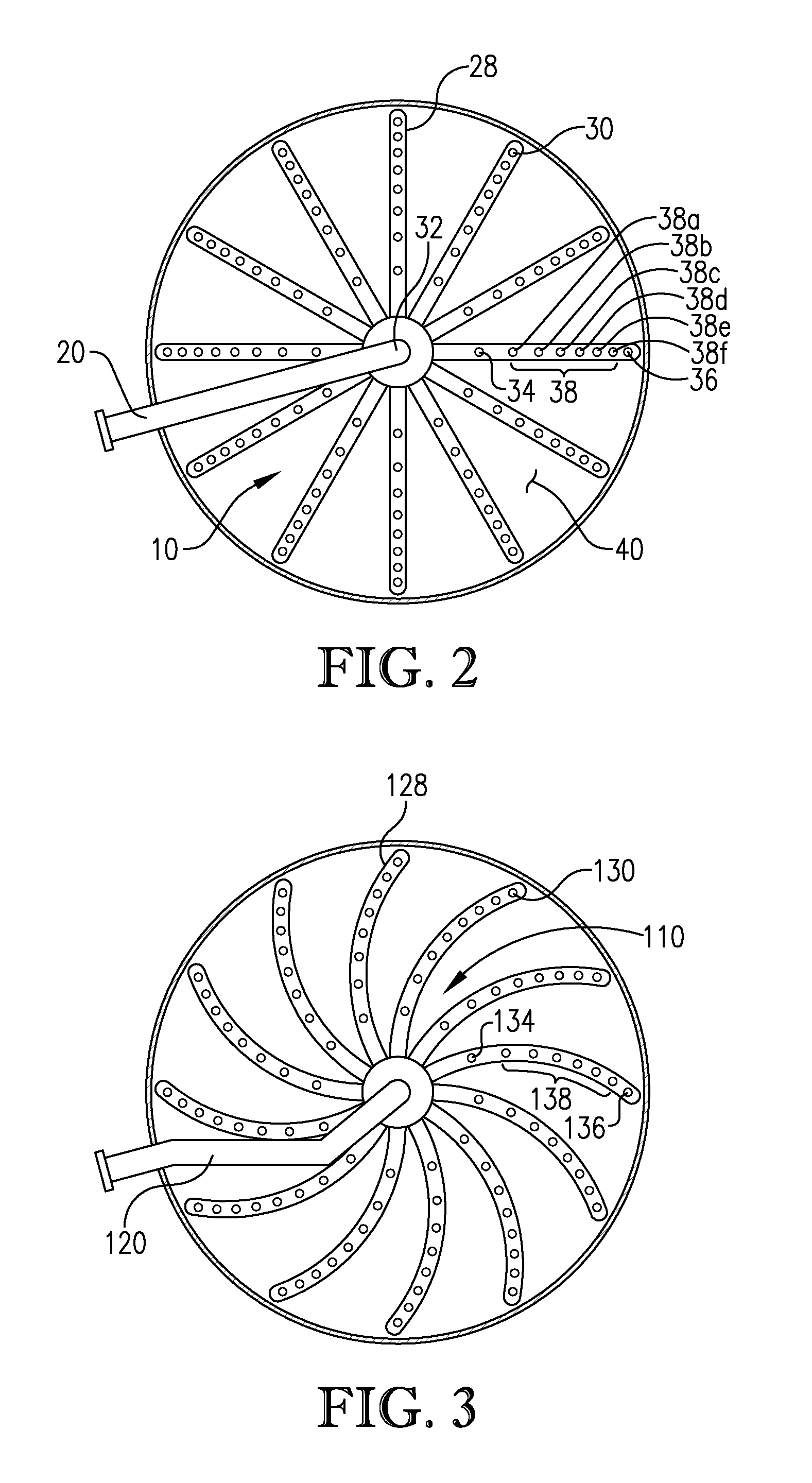

Methods and Apparatus for Enhanced Gas Distribution

ActiveUS20120068111A1Low costLiquid degasificationTransportation and packagingDistribution methodReaction zone

Methods and apparatus for introducing a gas into the reaction zone of a reactor. Such methods and apparatus can more evenly distribute the gas throughout the reaction zone. Spargers for introducing a gas into the reaction zone of a reactor can be employed in systems and methods for carrying out the liquid-phase oxidation of an oxidizable compound, such as para-xylene.

Owner:ALPEK POLYESTER SA DE CV

Nano micro bubble generation device for bathing and bathing system

ActiveCN104174311AImprove solubilityIncrease the dissolution pressureFlow mixersTransportation and packagingEngineeringProduct gas

The invention discloses a nano micro bubble generation device for bathing and a bathing system. The nano micro bubble generation device comprises a gas generator, a water supply device and a mixer, wherein the mixer at least comprises a static mixing element and a mixing pipeline; at least one mixing cavity is formed in the static mixing element and the mixing cavity is filled with particle fillings and / or porous structural matters. The bathing system comprises a bathing device and the nano micro bubble generation device. According to the nano micro bubble generation device and the bathing system, dissolvable gas is mixed with and dissolved in the water in the bubble generation device; the water with the dissolved gas under pressure is output to the bathing device; the water with the dissolved gas under pressure becomes normal pressure after being output to the bathing device and released; as the pressure reduces, the dissolved gas in the water forms nano gas micro bubbles which are slowly released; a to-be-washed surface is hit during the burst of the micro bubbles; and dirt is removed and blood circulation is improved.

Owner:LETSOZONE ENTERPRISE DEV CO LTD

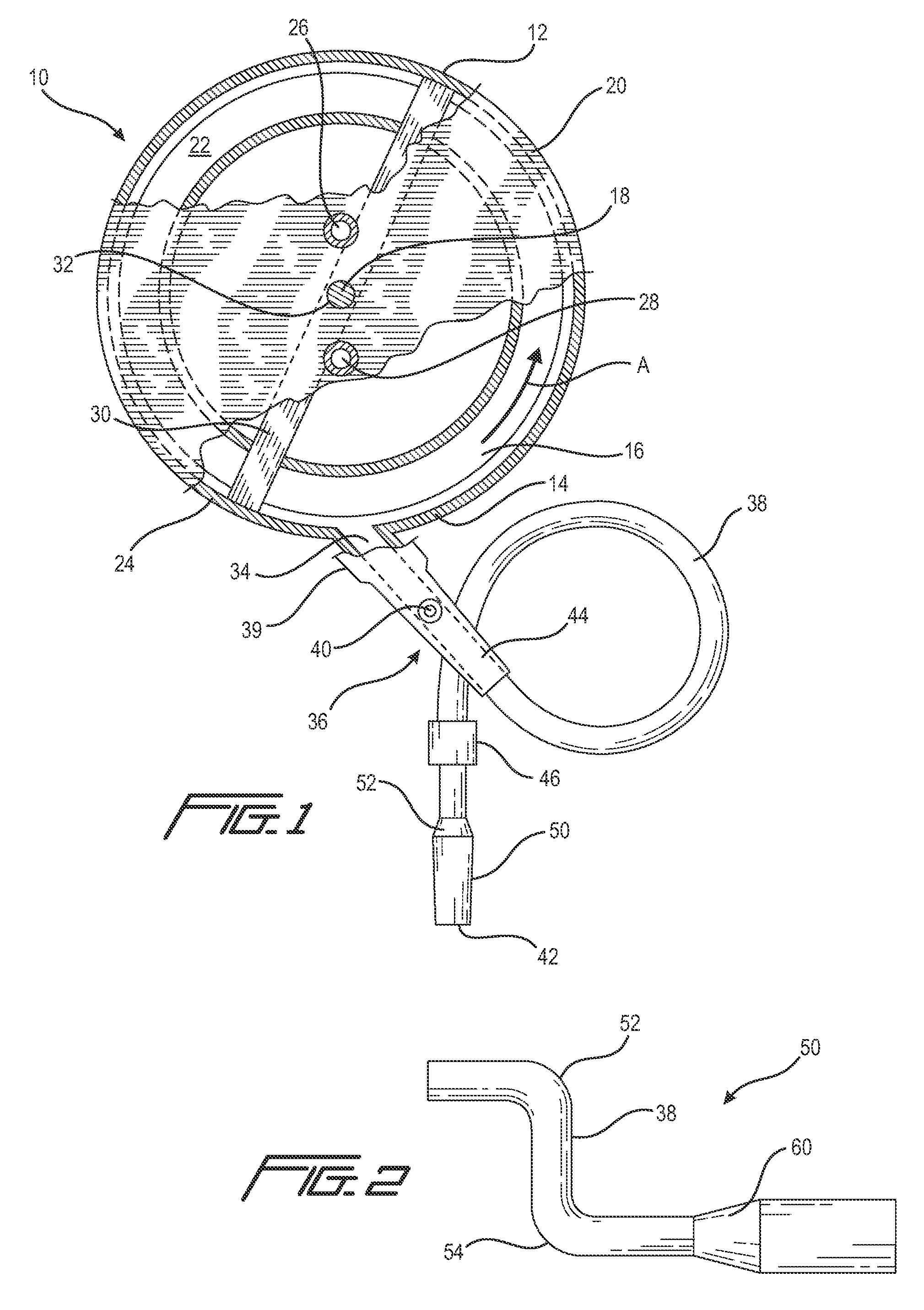

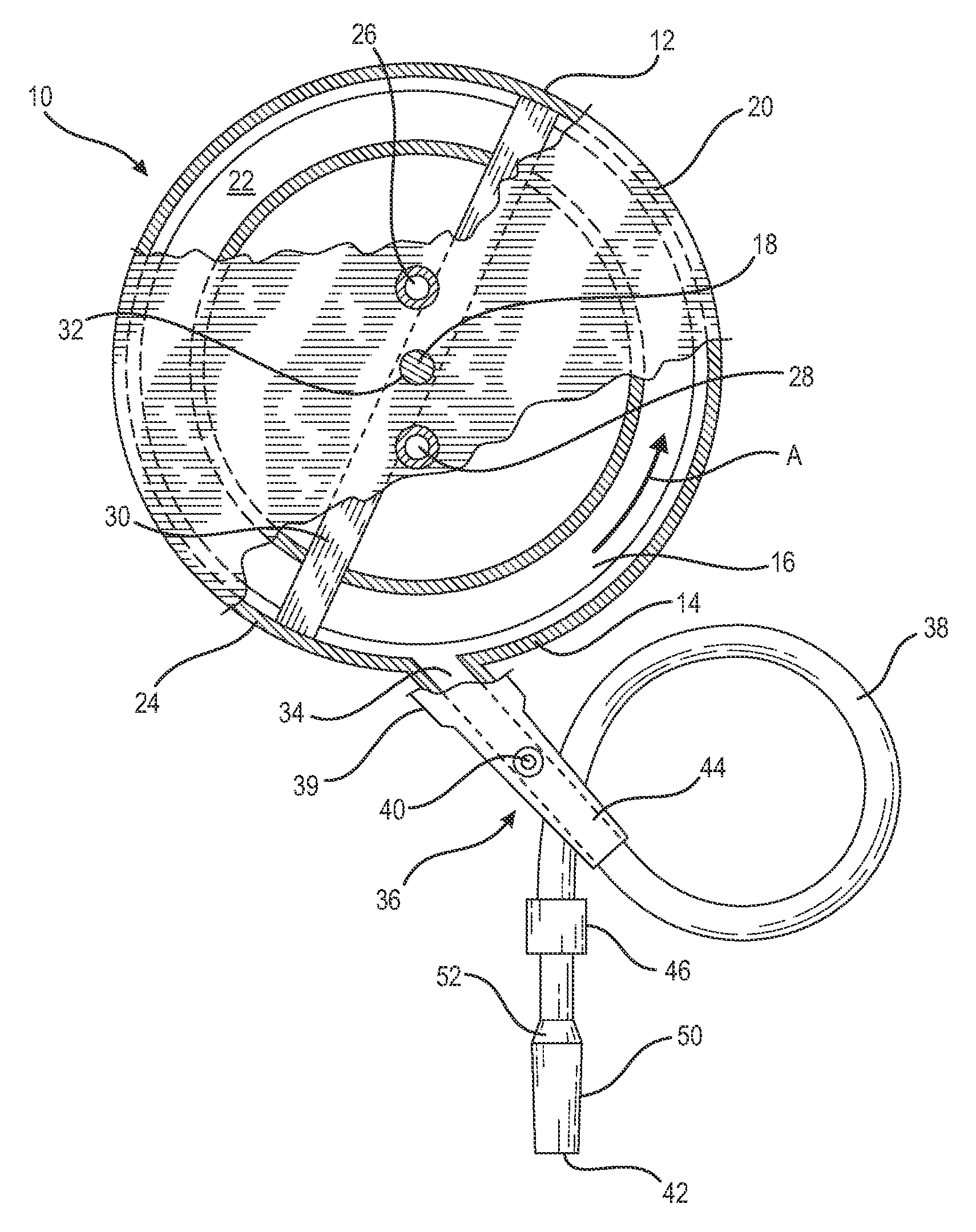

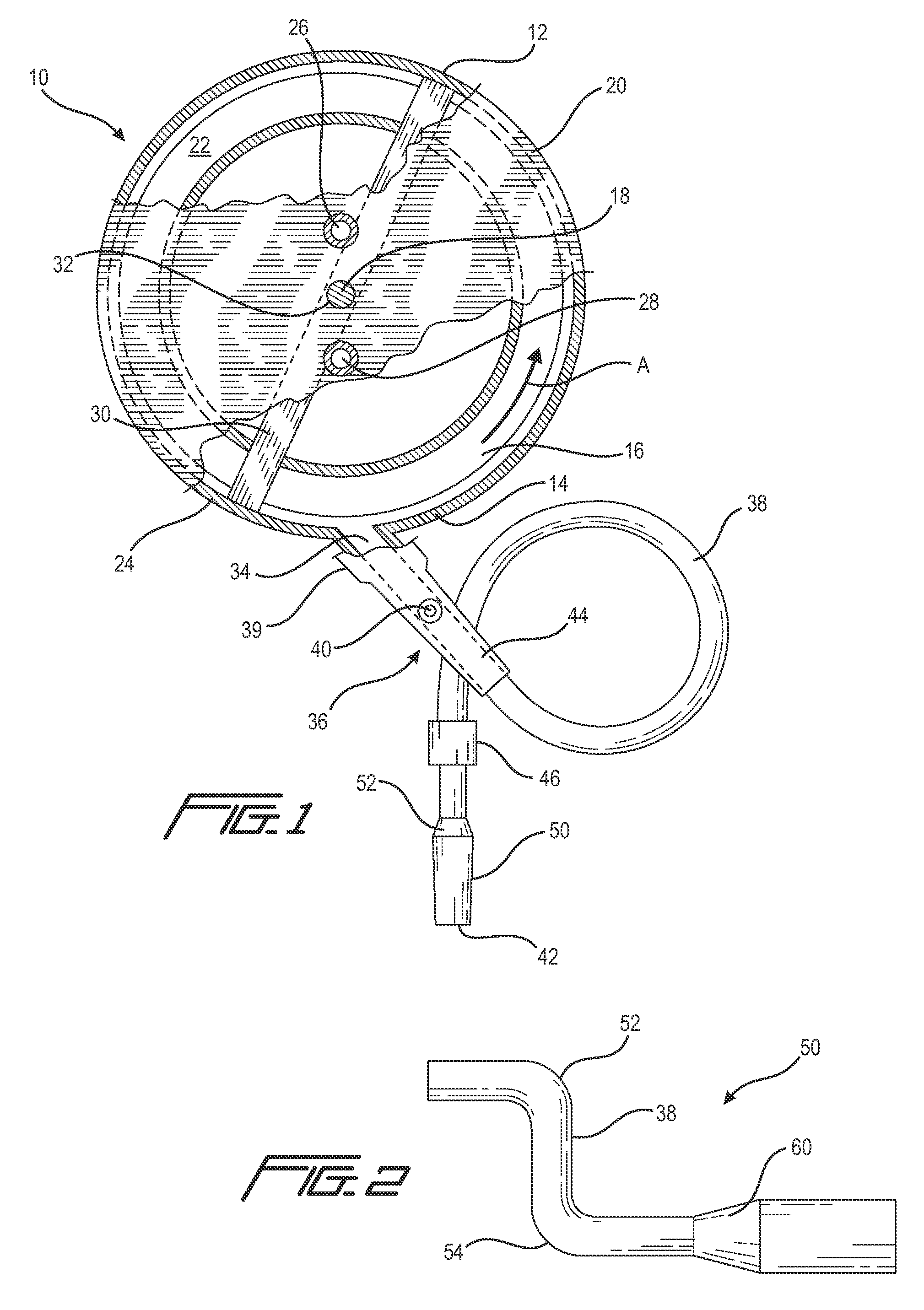

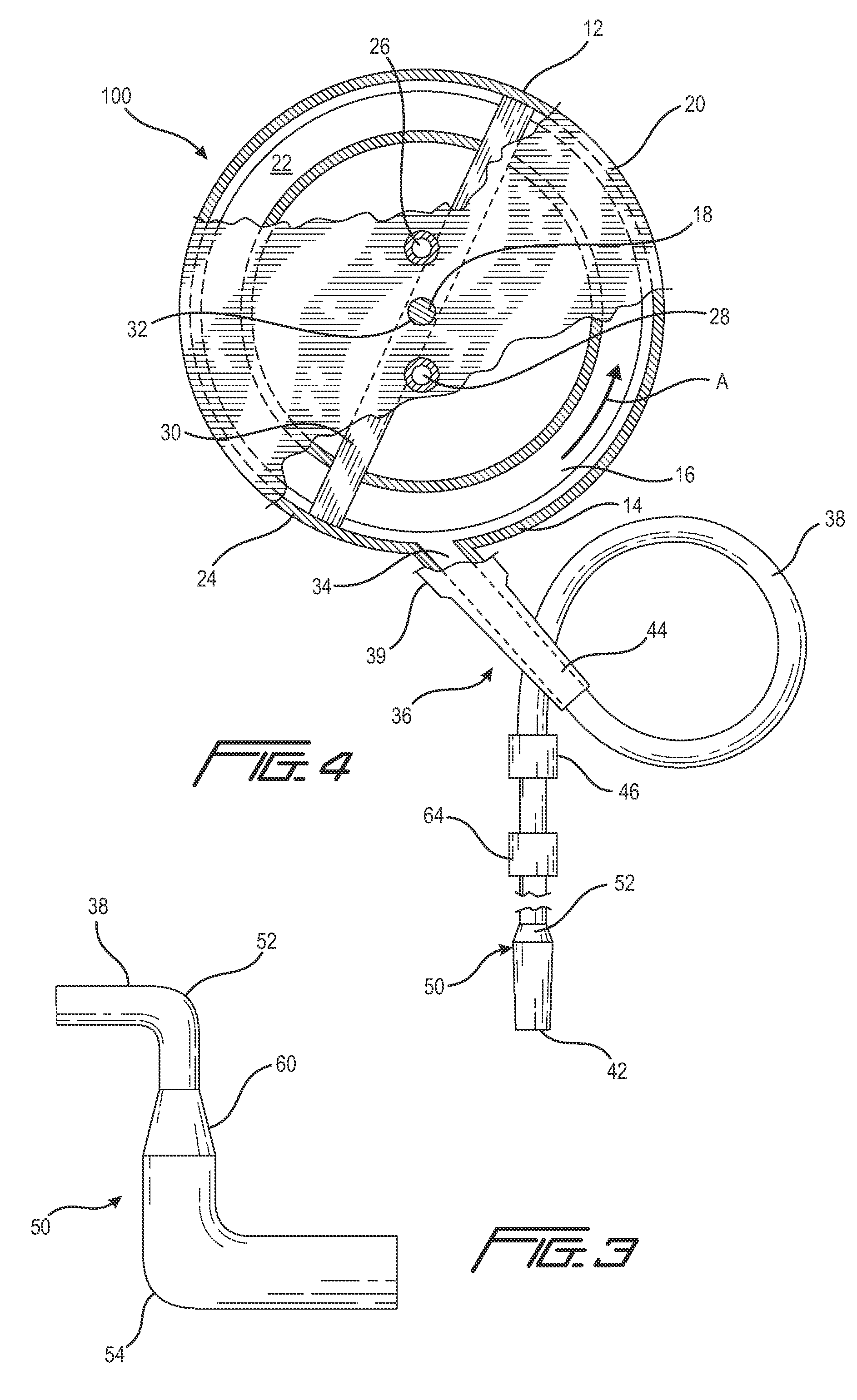

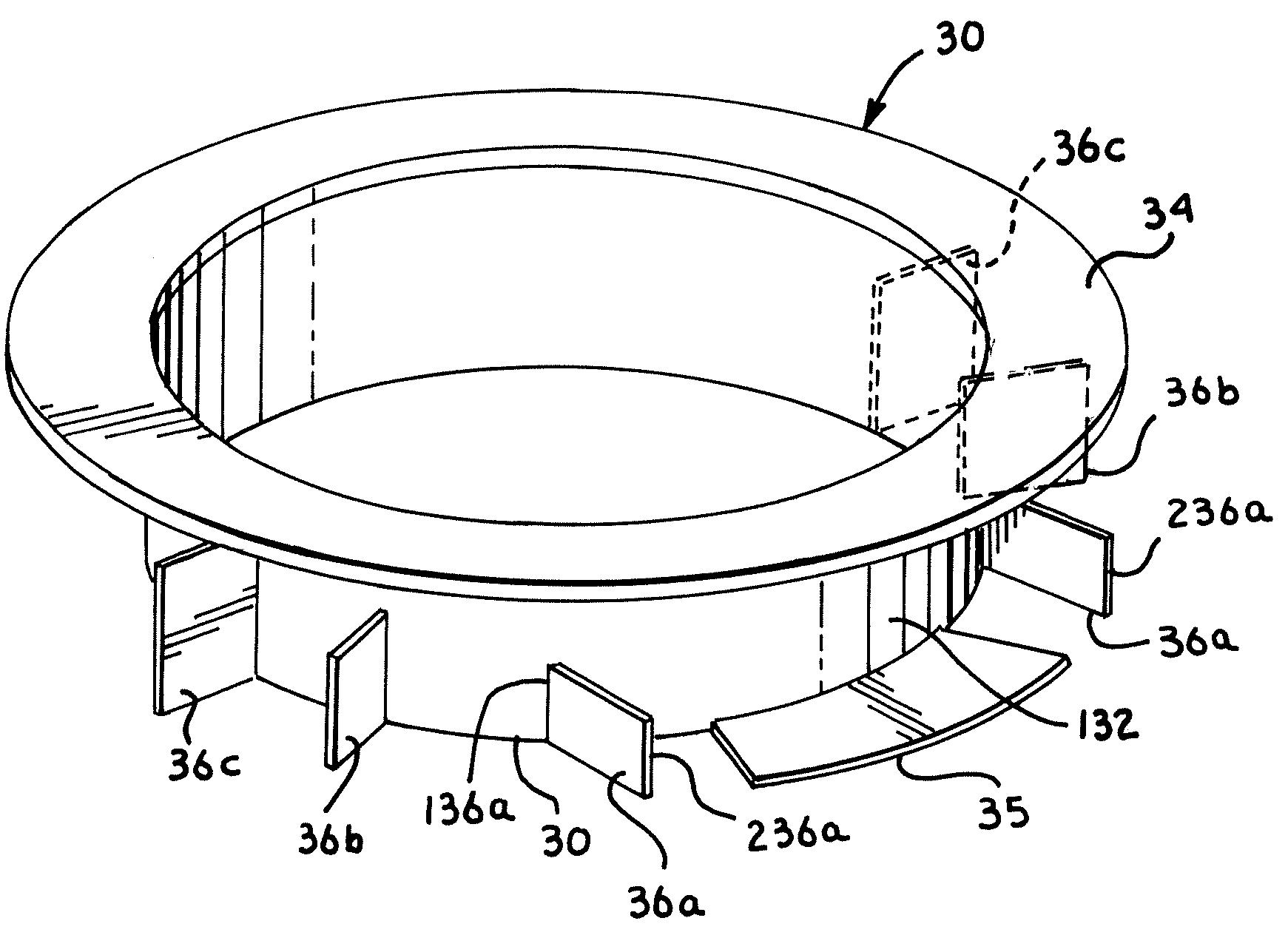

Method and apparatus for facilitating more uniform vapor distribution in mass transfer and heat exchange columns

ActiveUS7104529B2Transportation and packagingUsing liquid separation agentEngineeringCircular segment

A vapor horn device for use in an elongated, generally upright mass transfer and / or heat exchange column having an internal region comprises an elongated, generally arcuate wall arranged to be located within the internal region and disposed to extend around a longitudinal axis of the column. The arcuate wall includes an inlet area positioned for being contacted by a vapor or mixed phase stream entering the column and causing the stream to flow along an outer surface of the arcuate wall and generally around the axis. The device also includes a primary elongated vane extending outwardly from the outer surface of the arcuate wall. This primary vane has an inner end located adjacent the outer surface of the inner wall and an outer end disposed in spaced relationship relative to the outer surface of the wall. The vane is disposed at a tangential angle relative to the direction of flow of the stream such that the inner end of the vane is further downstream than the outer end thereof whereby any portion of the stream impinging on the primary vane is redirected toward the outer surface of the arcuate wall. The device also desirably includes one or more vanes that extend radially outwardly from the inner wall.

Owner:KOCH GLITSCH INC

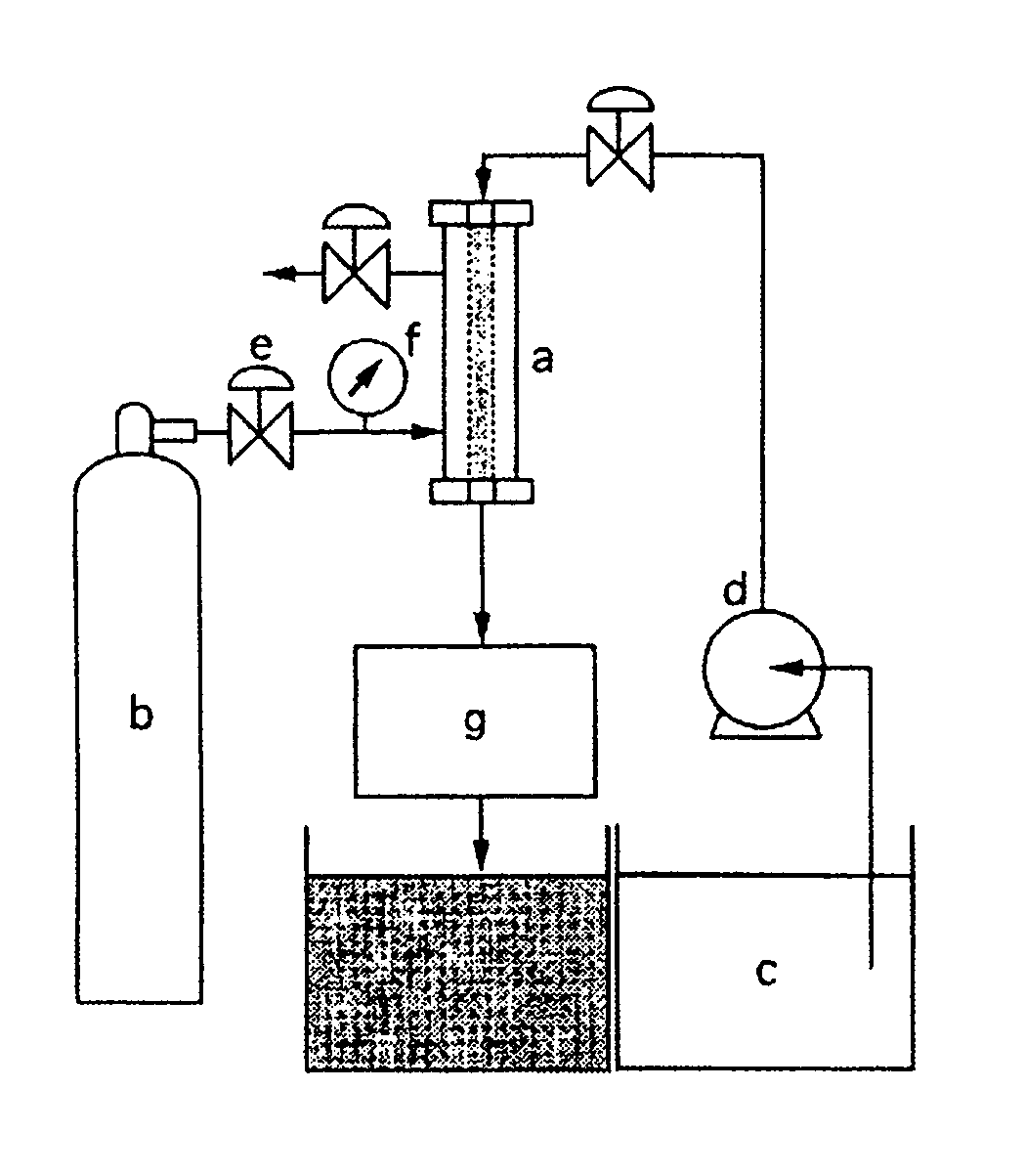

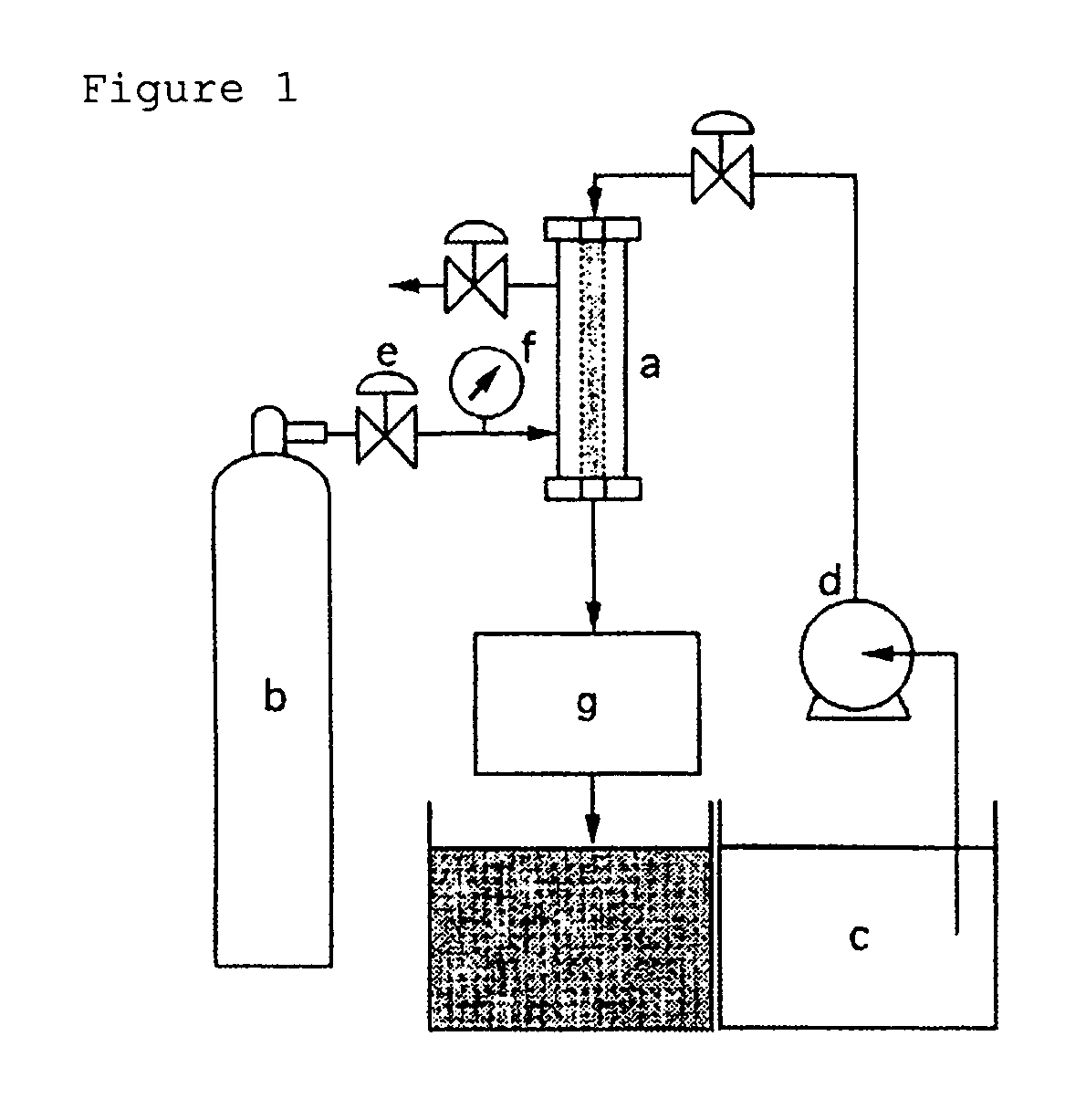

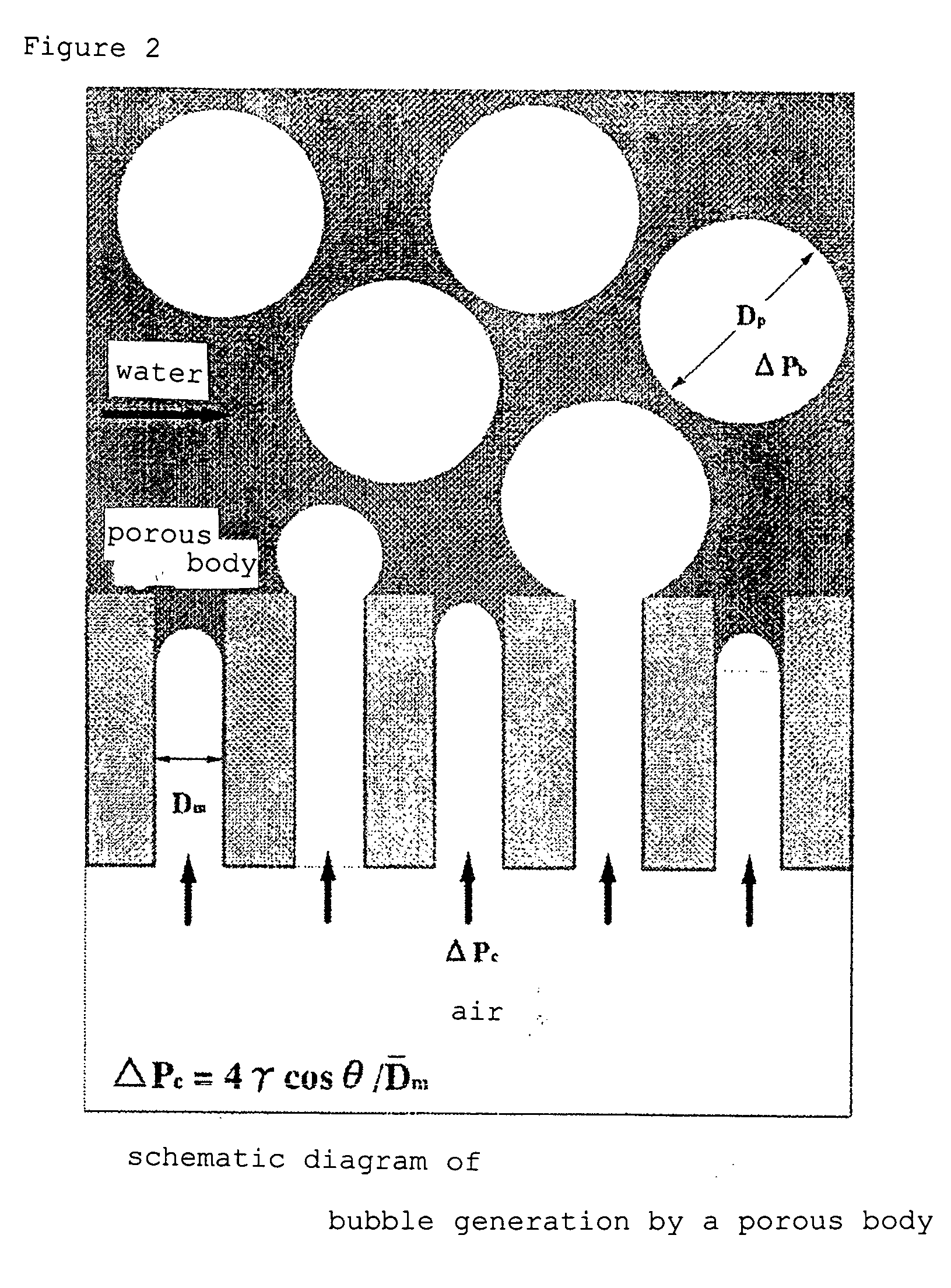

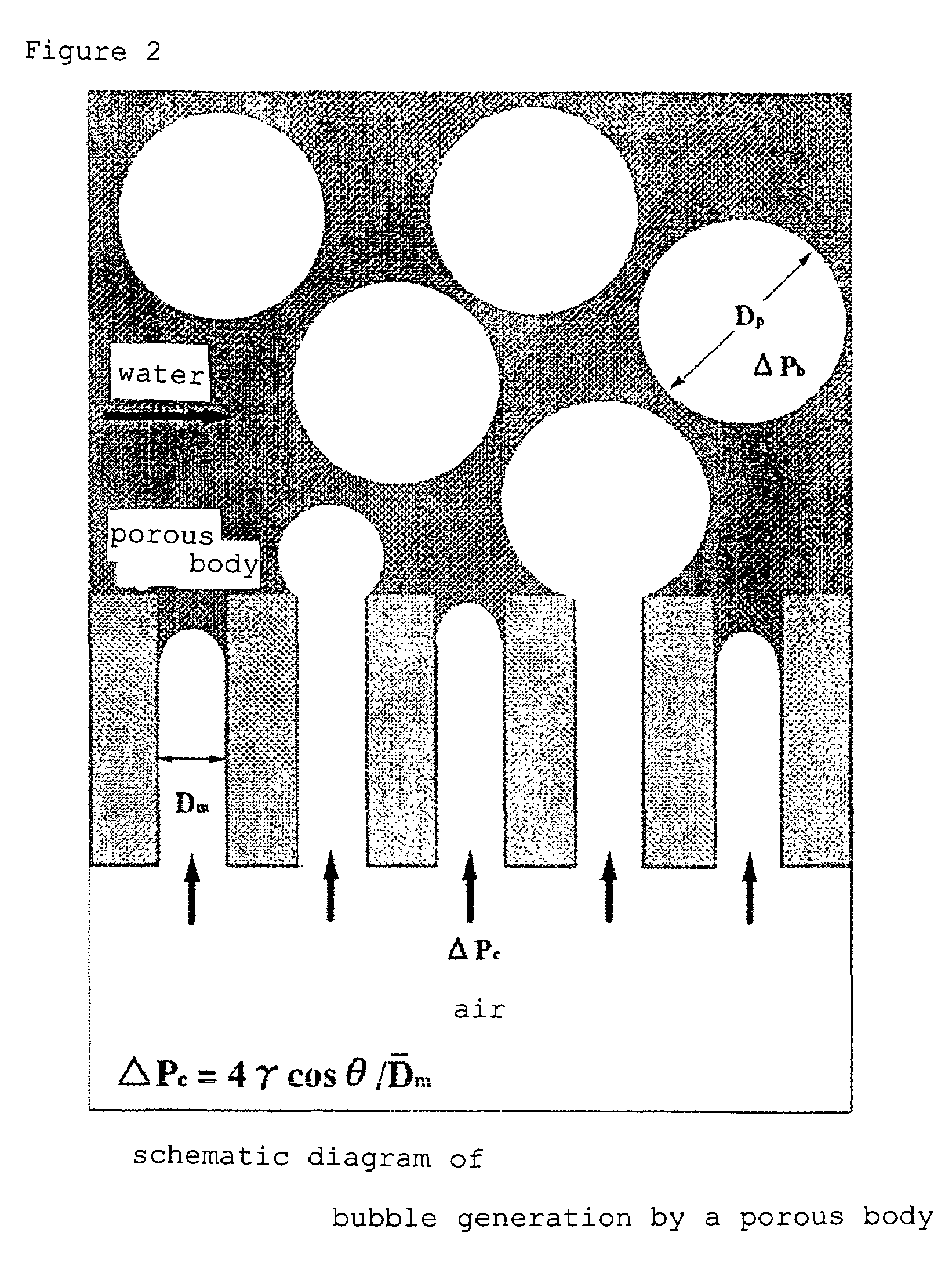

Method for producing monodisperse bubbles

InactiveUS7591452B2Reliably producedCarburetting airLighting and heating apparatusPore distributionPore diameter

The invention provides a method for producing bubbles that exhibit an excellent monodispersity. The invention relates to a method for generating bubbles by the injection and dispersion of a gas through a porous body into a liquid, wherein the value produced by dividing the pore diameter that accounts for 10% of the total pore volume in the relative cumulative pore distribution curve of the porous body by the pore diameter that accounts for 90% of the total pore volume in the relative cumulative pore dismeter distribution curve of the porous body is 1 to 1.5.

Owner:MIYAZAKI PREFECTURE +1

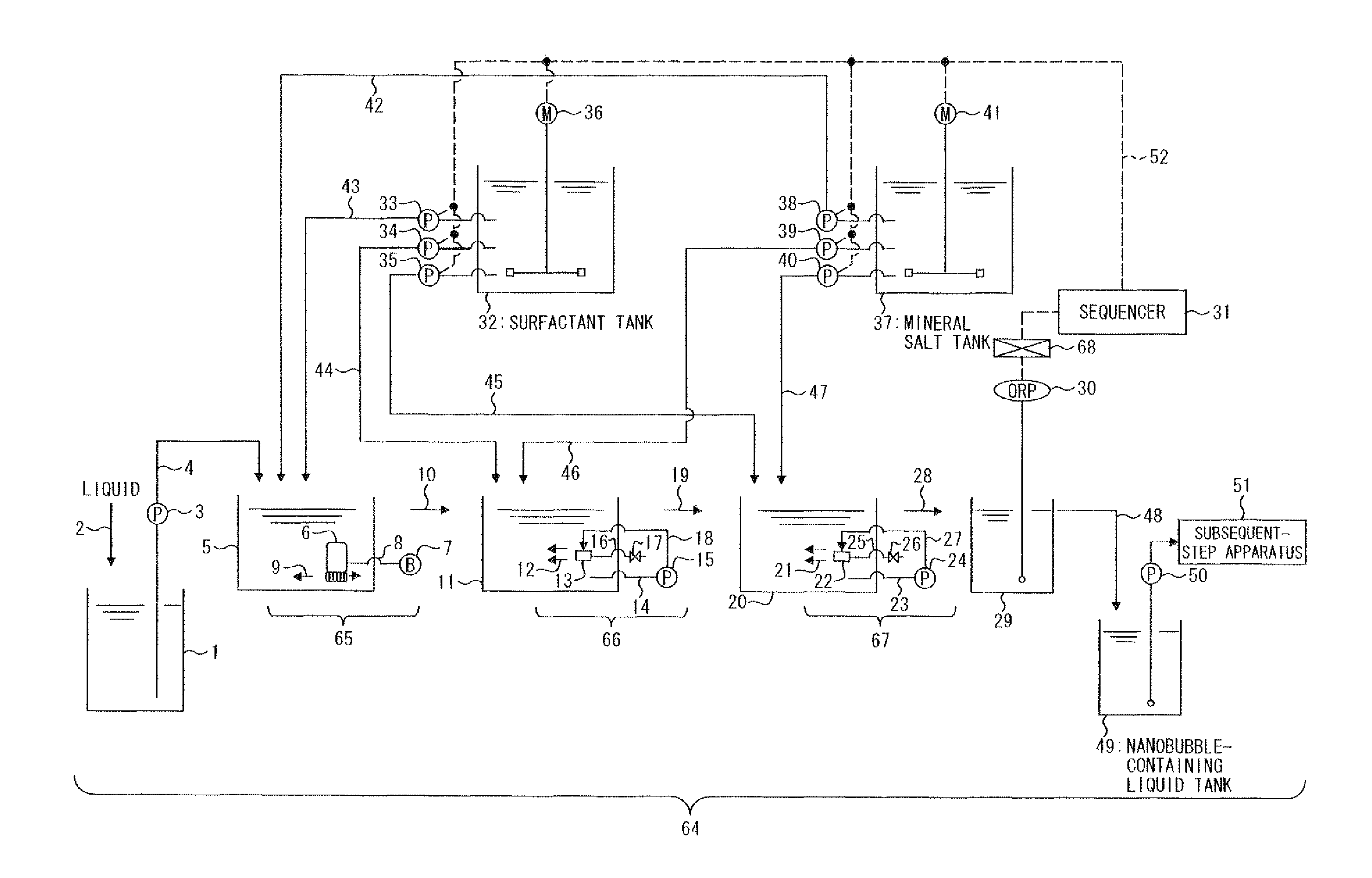

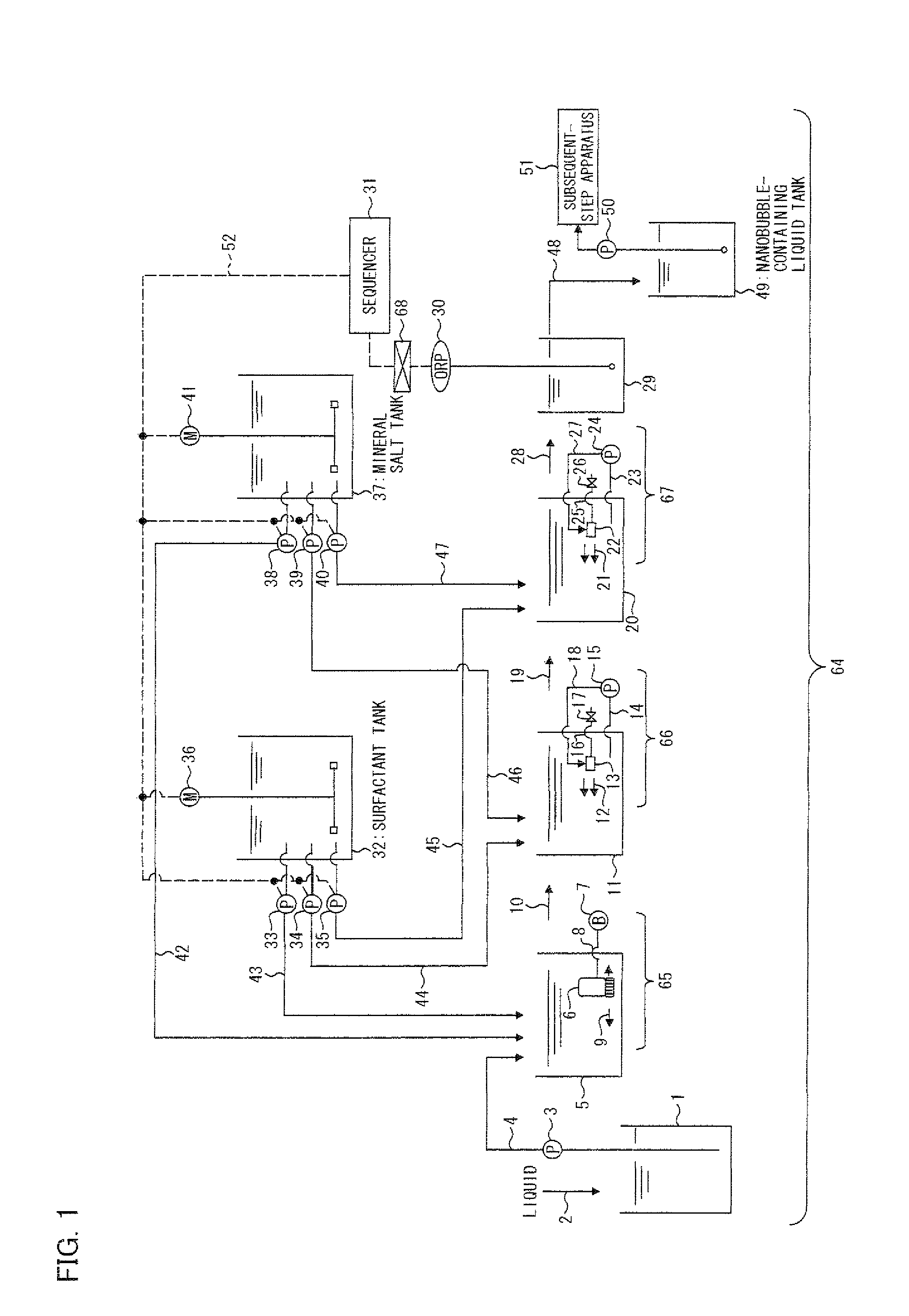

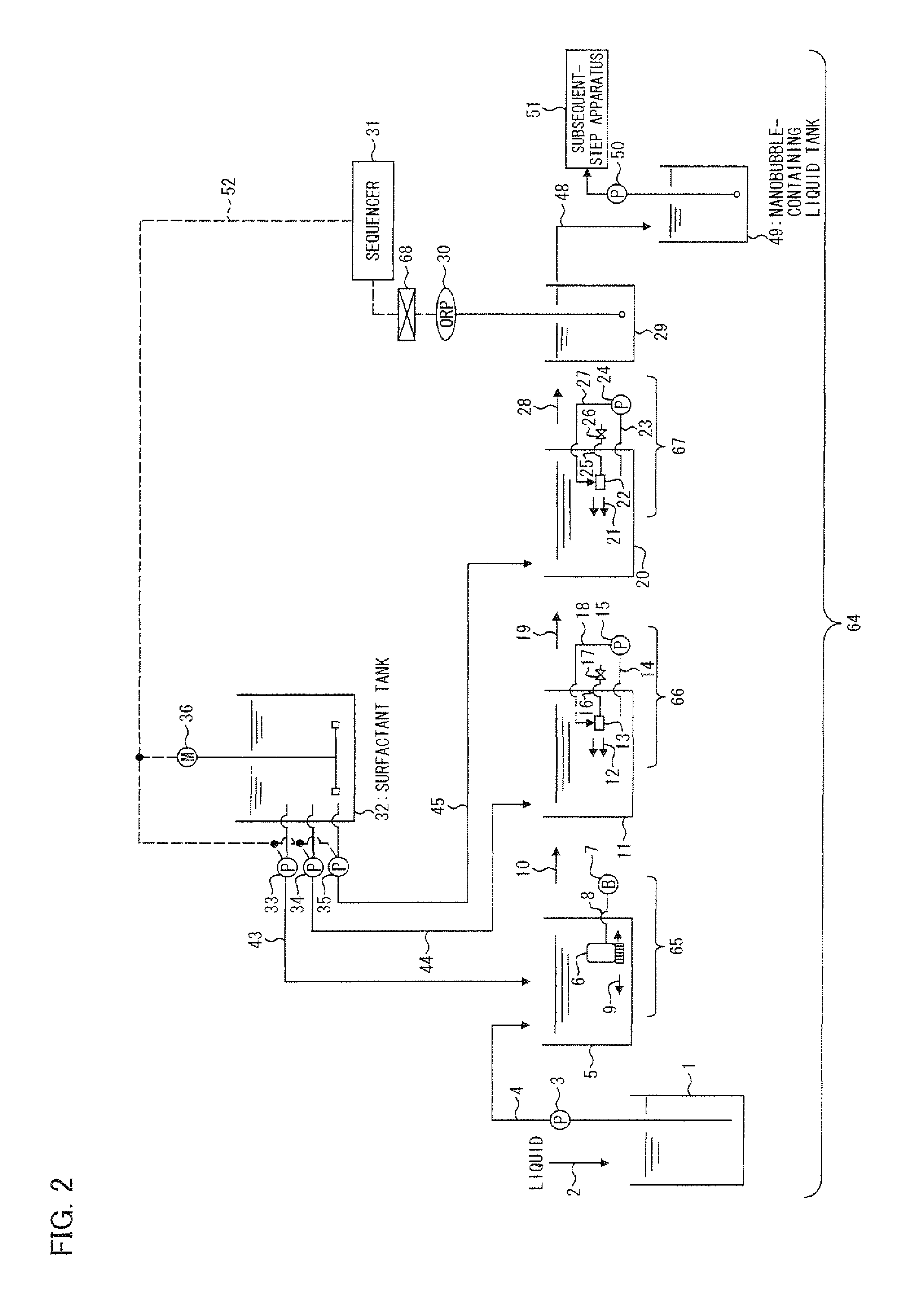

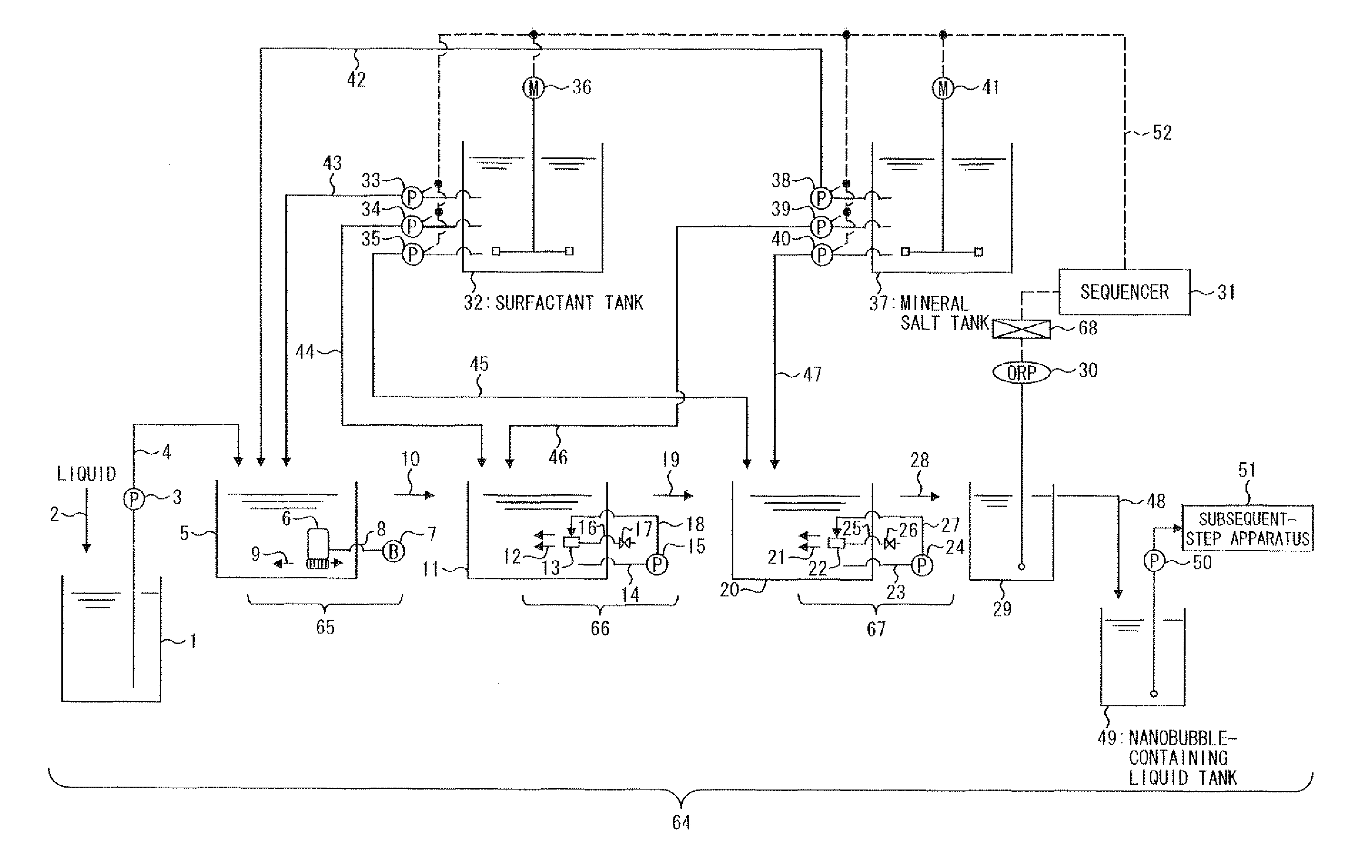

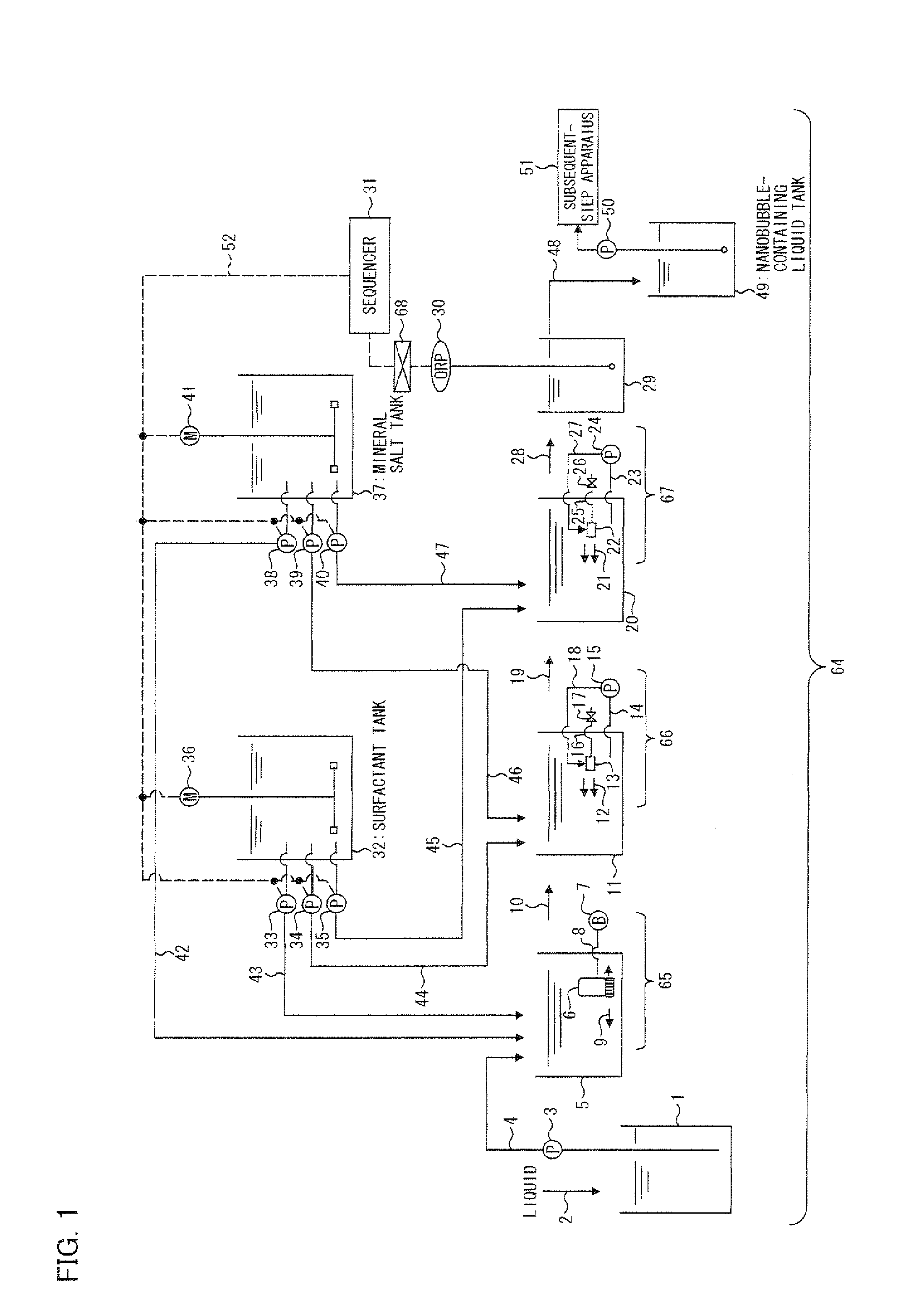

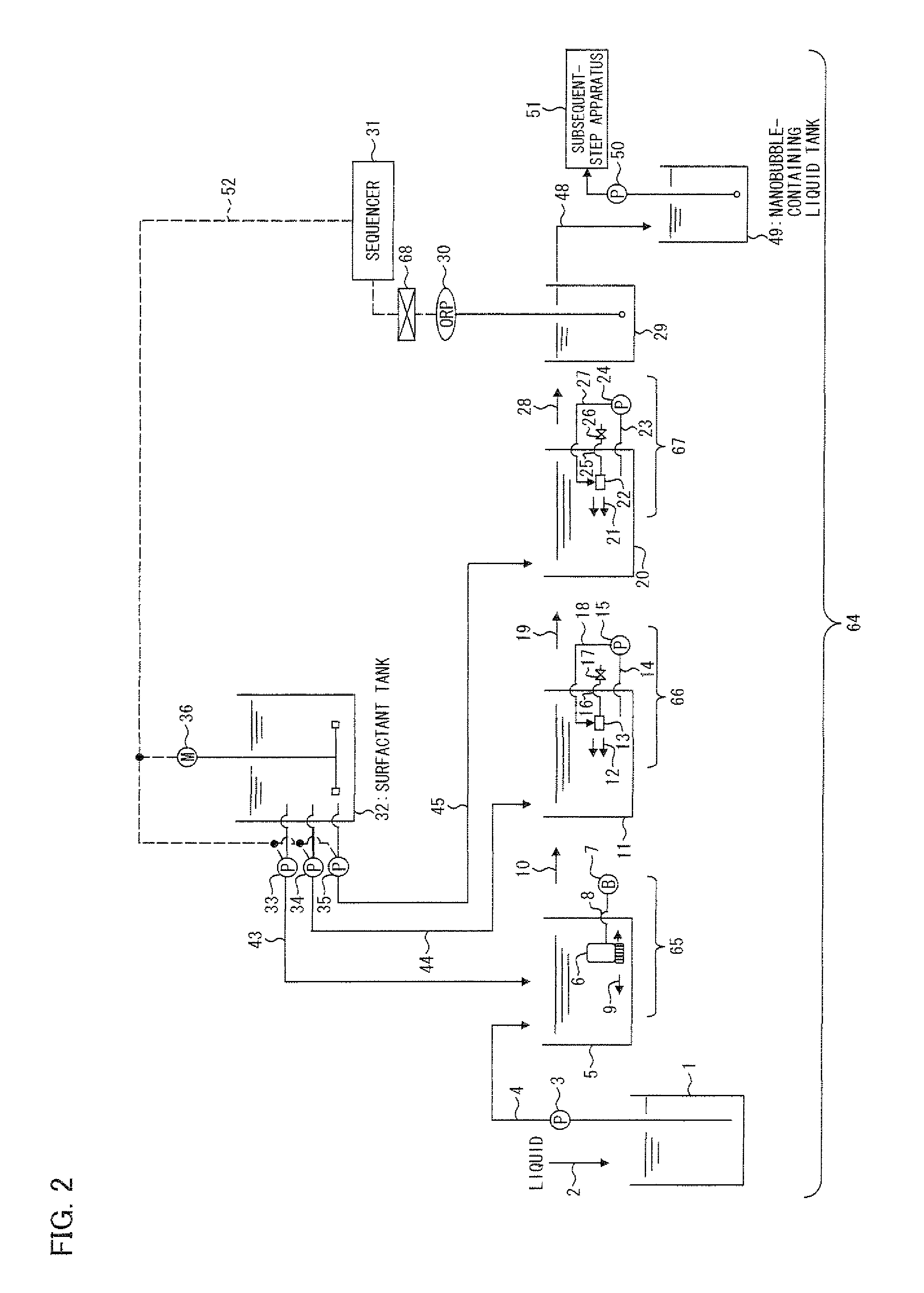

Nanobubble-containing liquid producing apparatus and nanobubble-containing liquid producing method

ActiveUS8317165B2Reduce manufacturing costShort timeUsing liquid separation agentTransportation and packagingGeneral purposeEngineering

Owner:SHARP KK

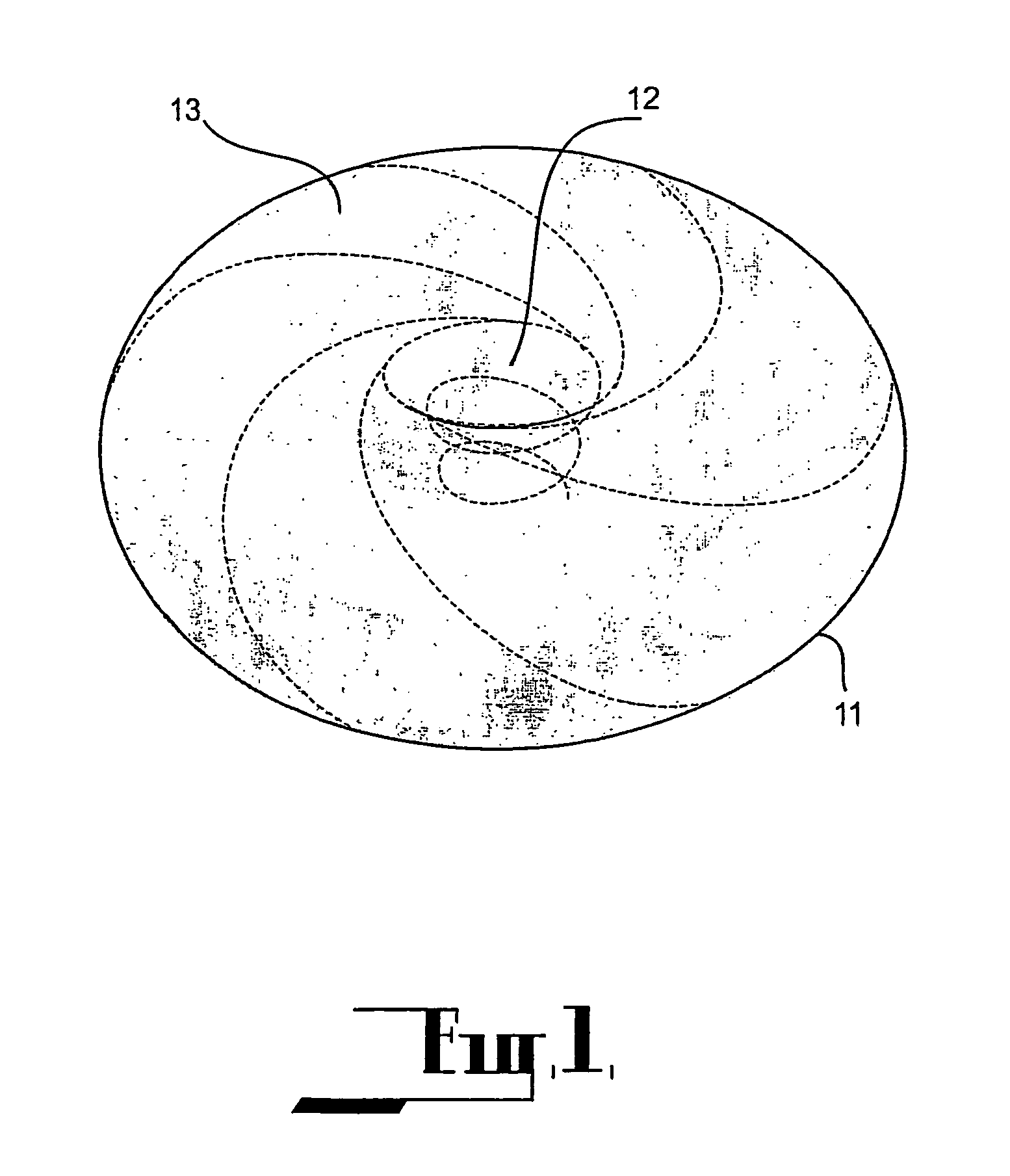

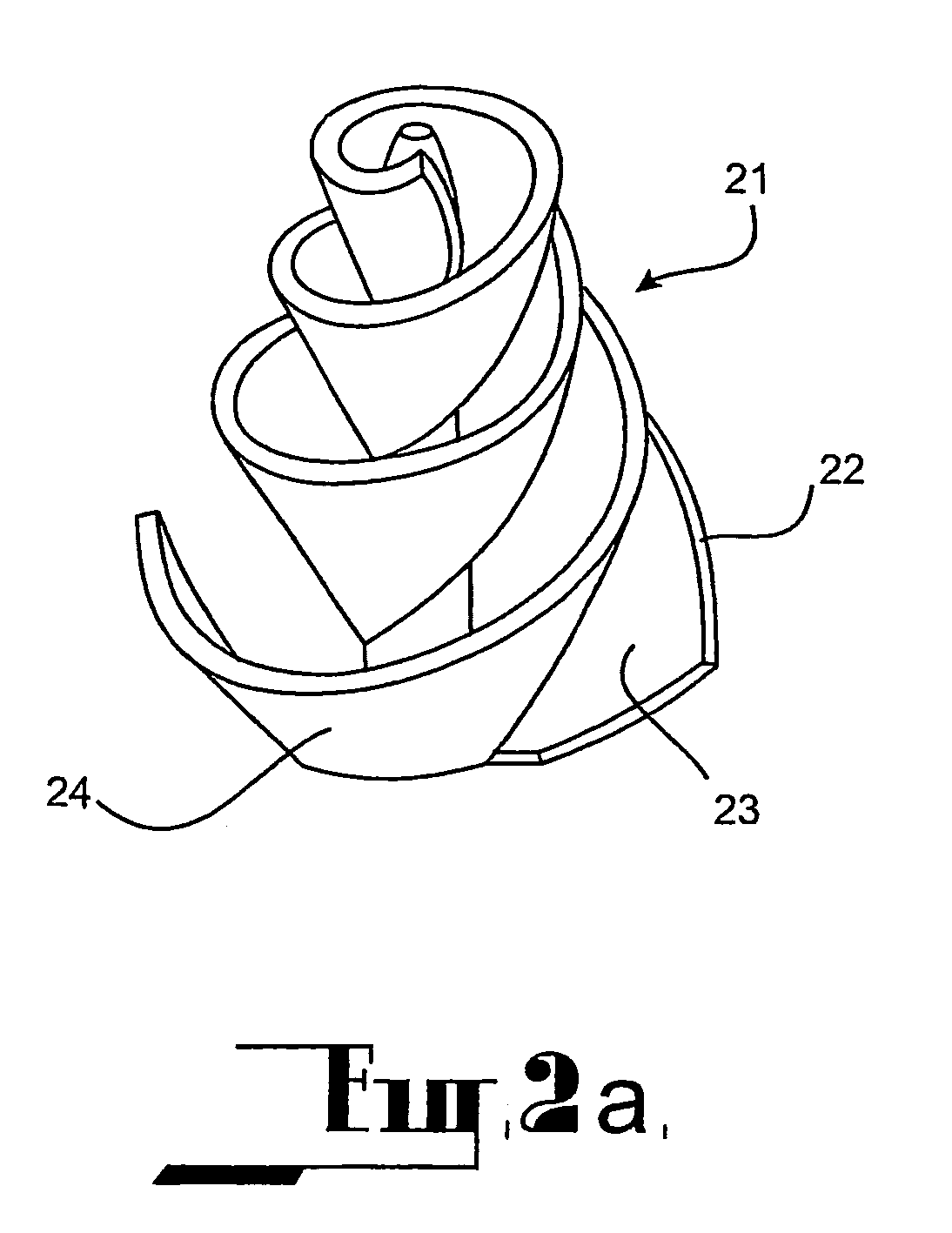

Fluid circulation system

A fluid circulation system wherein circulation is caused within a body by establishing a ring vortex within the fluid caused by an impeller designed in accordance with the Golden Section or Phi Geometry.

Owner:PAX SCI

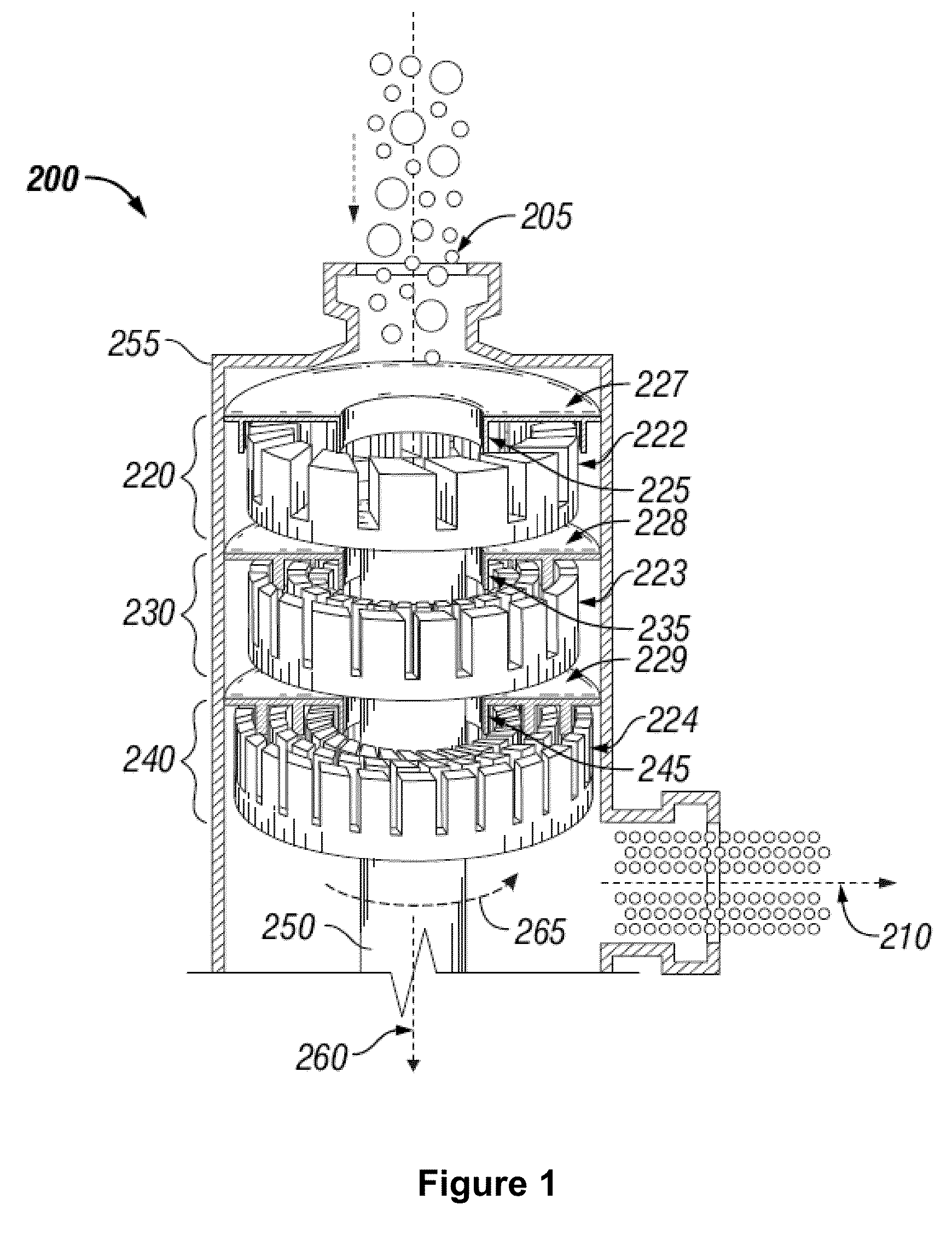

High shear application in processing oils

InactiveUS20130266703A1Fatty acid hydrogenationSeed preservation using chemicalsReactive gasProduct gas

Herein disclosed is a method of processing oil, comprising providing a high shear device comprising at least one rotor and at least one complementarily-shaped stator configured to mix a gas with a liquid; contacting a gas with an oil in the high shear device, wherein the gas is an inert gas or a reactive gas; and forming a product, wherein the product is a solution, a dispersion, or combination thereof. Herein also disclosed is a high shear system for processing oil, comprising; at least one high shear device, having an inlet and at least one rotor and at least one complementarily-shaped stator configured to mix a gas with a liquid; a gas source fluidly connected to the inlet; an oil source fluidly connected to the inlet; and a pump positioned upstream of a high shear device, the pump in fluid connection with the inlet and the oil source.

Owner:HRD CORP

Nanobubble-containing liquid producing apparatus and nanobubble-containing liquid producing method

ActiveUS20100089133A1Reduce manufacturing costShort timeLighting and heating apparatusUsing liquid separation agentGeneral purposeMicrobubbles

Owner:SHARP KK

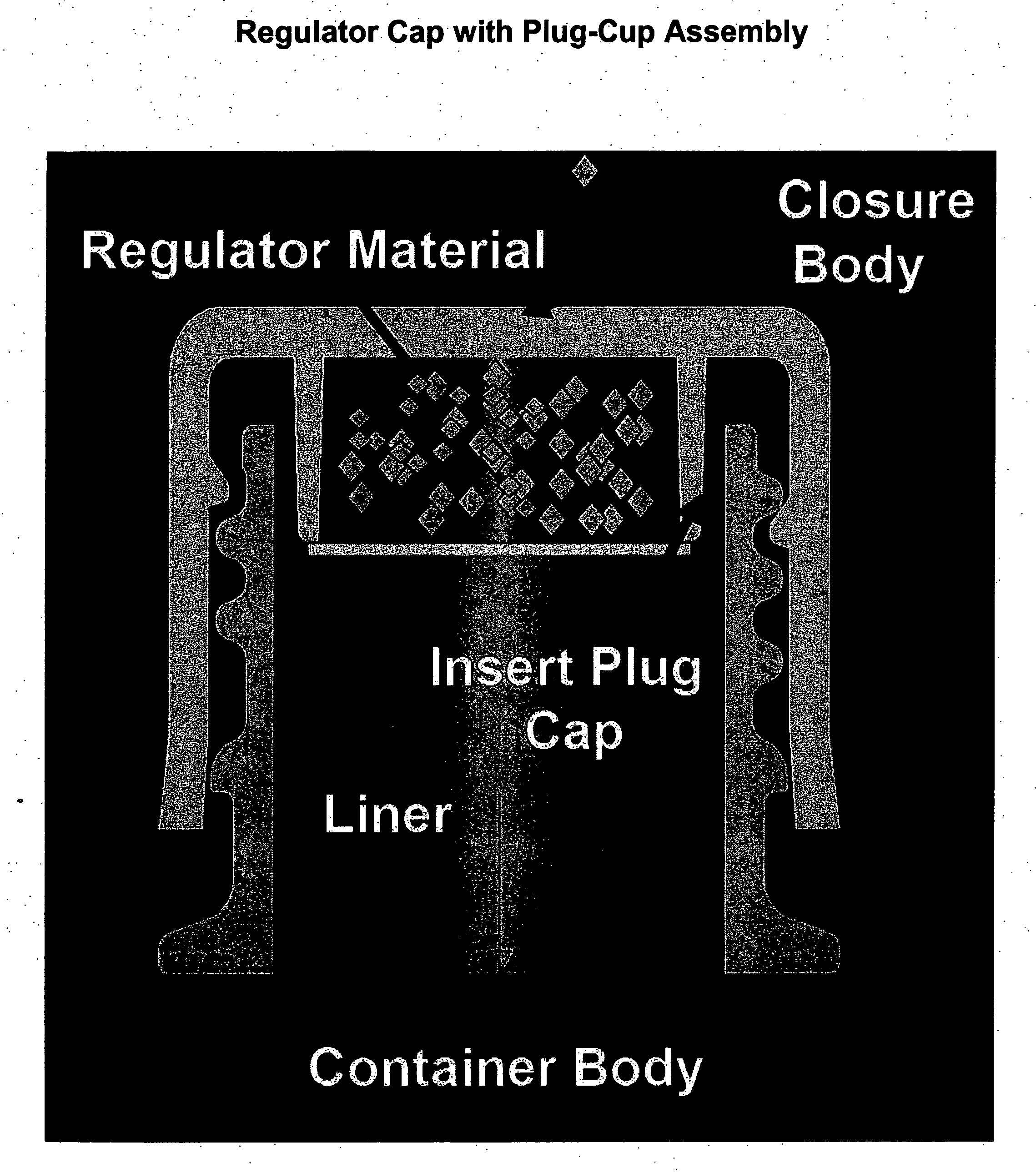

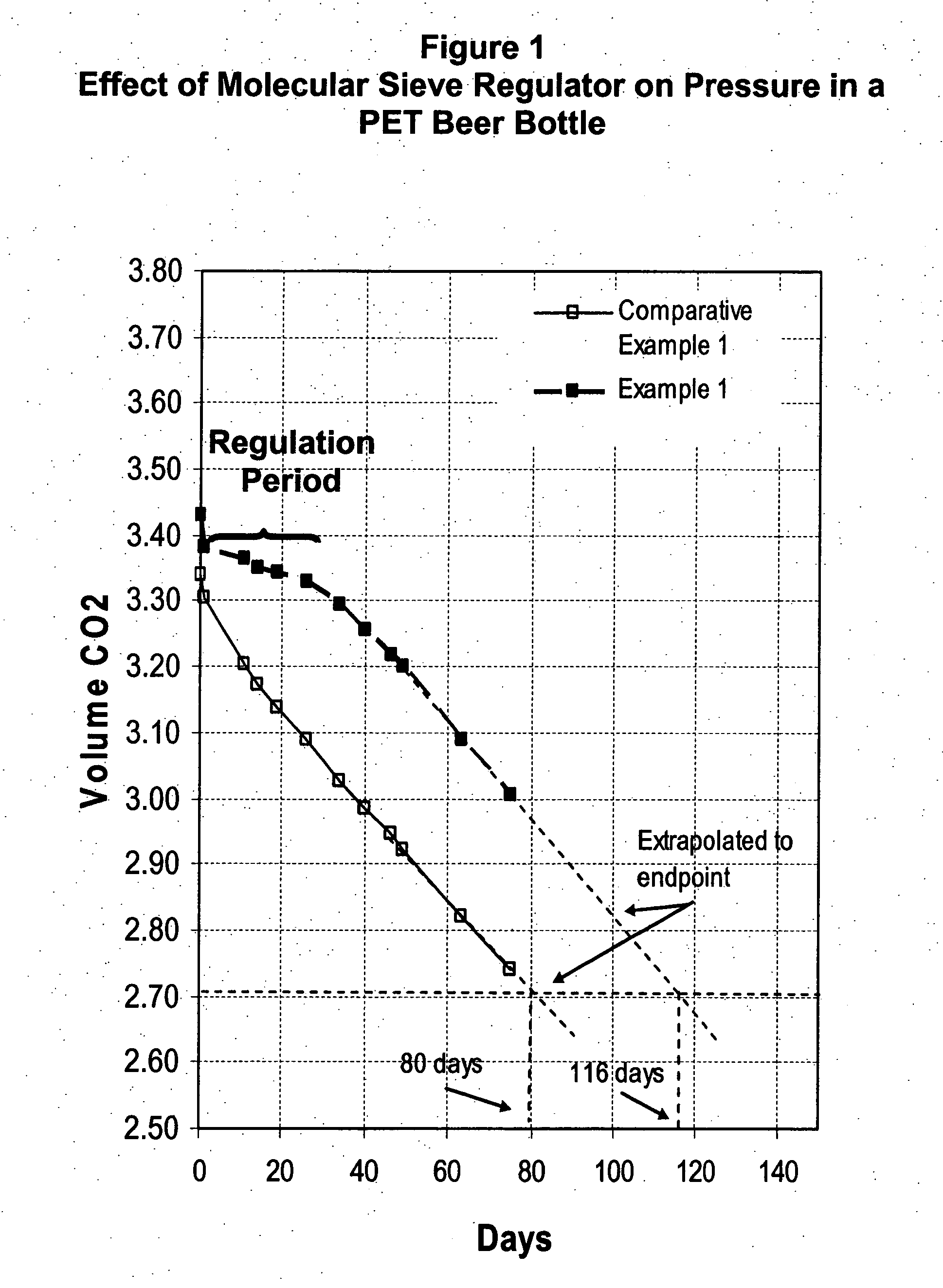

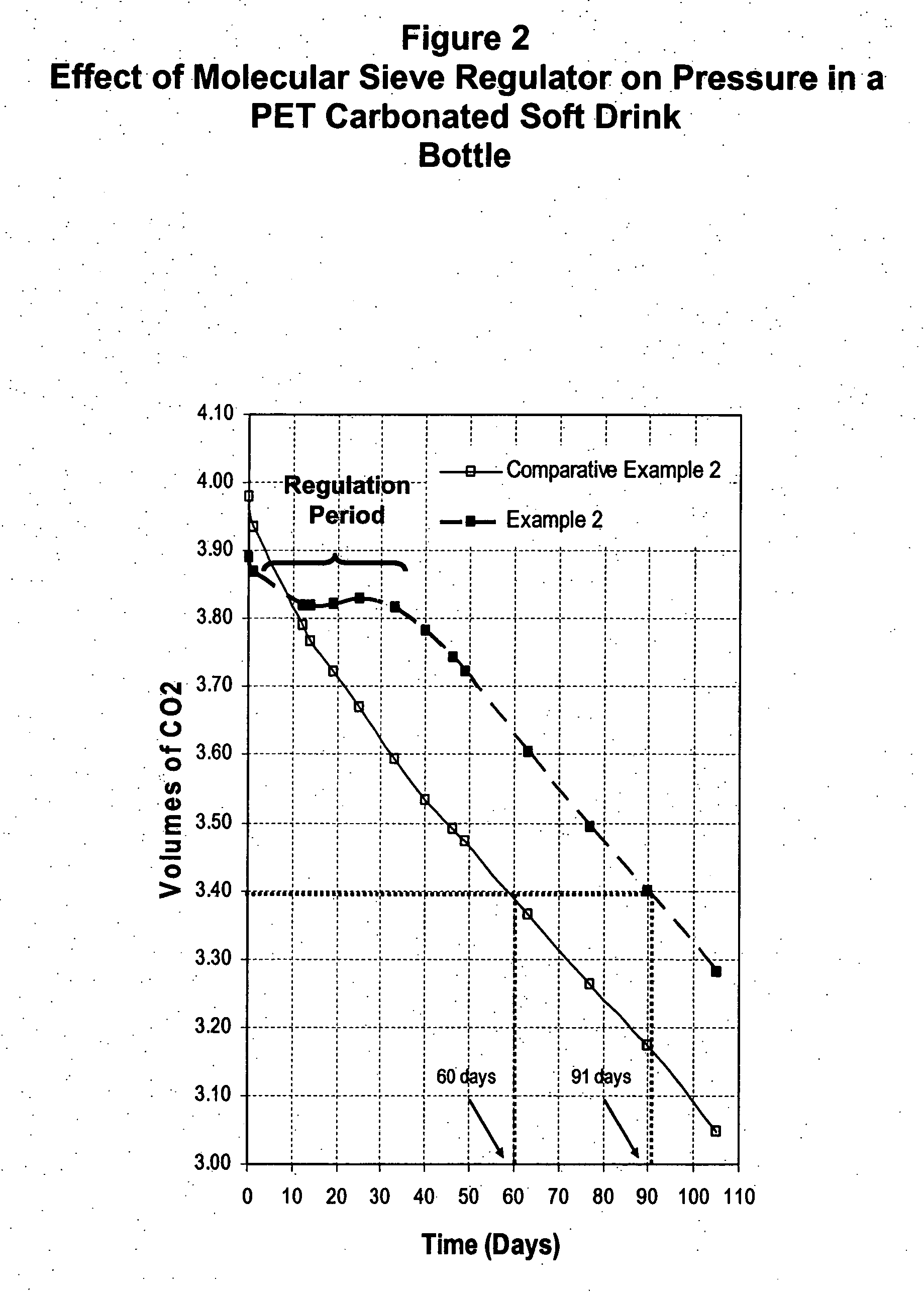

Using carbon dioxide regulators to extend the shelf life of plastic packaging

InactiveUS20050230415A1Keep the pressurePower operated devicesDispensing apparatusPlastic packagingPlastic materials

A method for replenishing carbon dioxide gas in a carbonated beverage container where a carbon dioxide regulator releases carbon dioxide at a rate approximately equal to the rate of carbon dioxide loss from said container. Also disclosed is packaging system for maintaining a consistent pressure of a carbonated beverage comprising a closure, a plastic container, and a carbon dioxide regulator. Also disclosed is a method for making a packaging system for maintaining a consistent pressure in a carbonated beverage comprising overmolding a preform around an assembly for a carbon dioxide regulator, or blending a carbon dioxide regulator into the plastic material used to form the body of a container for said carbonated beverage. Also disclosed is carbon dioxide regulator composition for replenishing carbon dioxide gas in a carbonated beverage container comprising polymeric carbonates, organic carbonates, or materials that absorb and subsequently release carbon dioxide.

Owner:BP CORP NORTH AMERICA INC

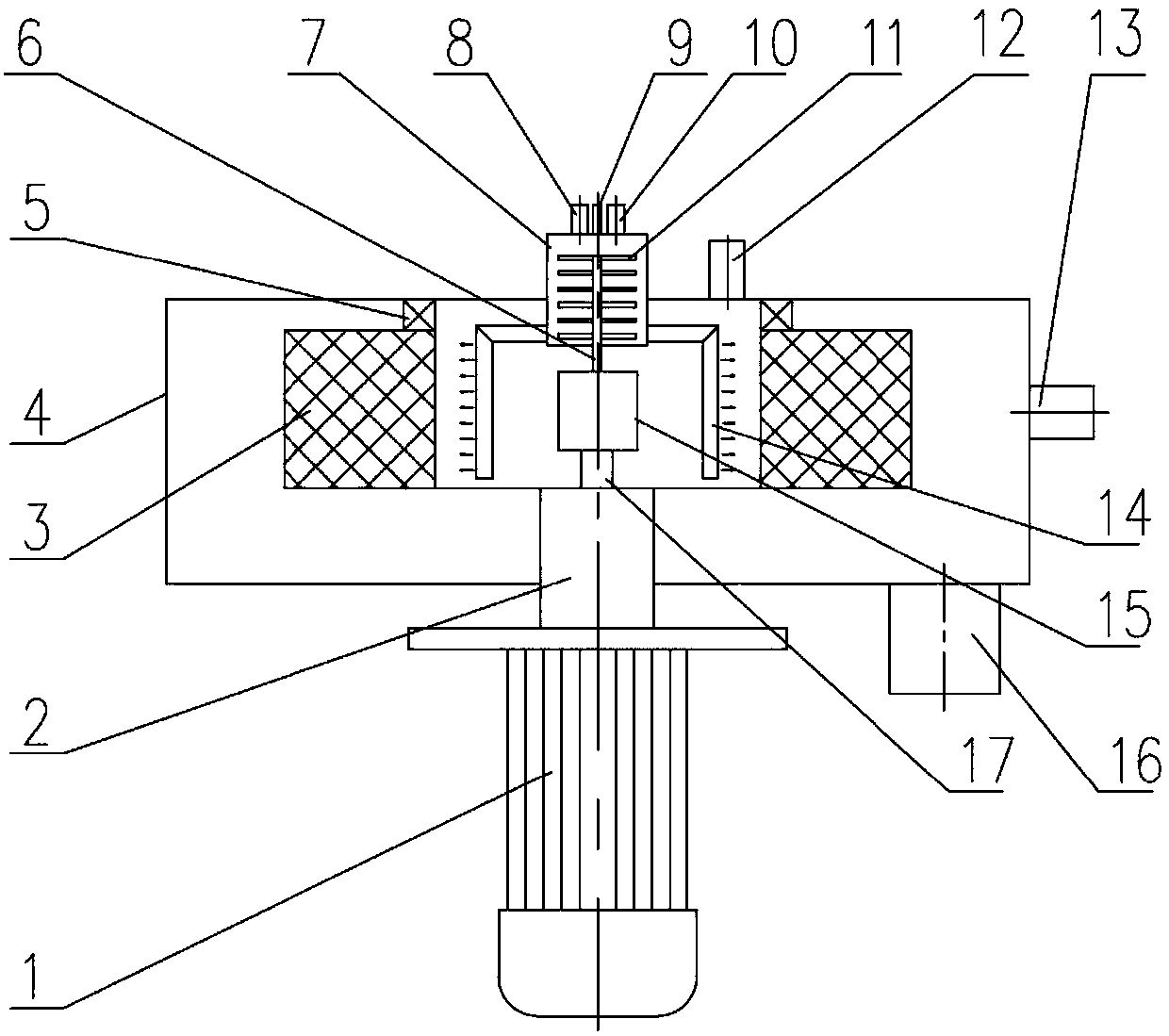

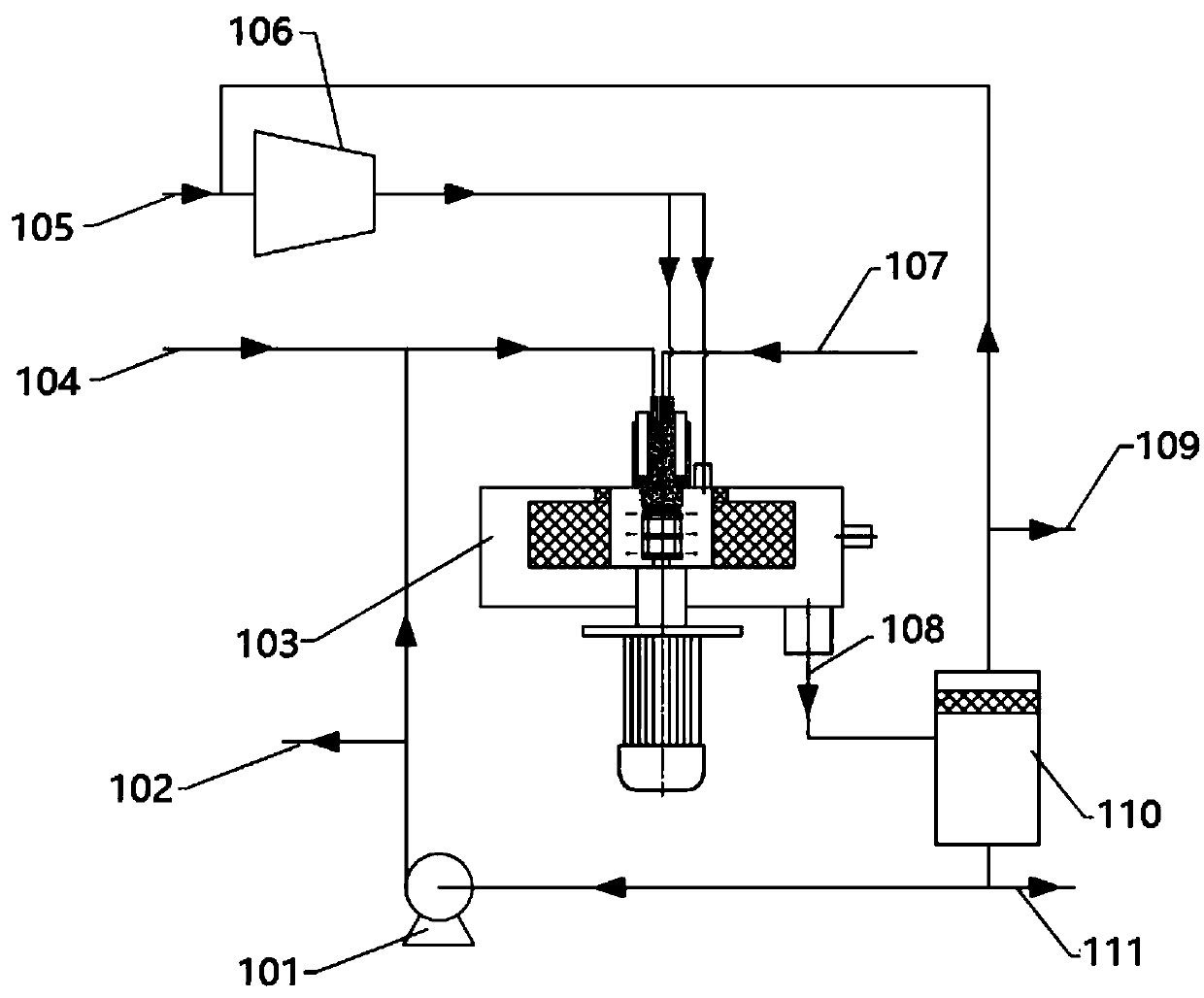

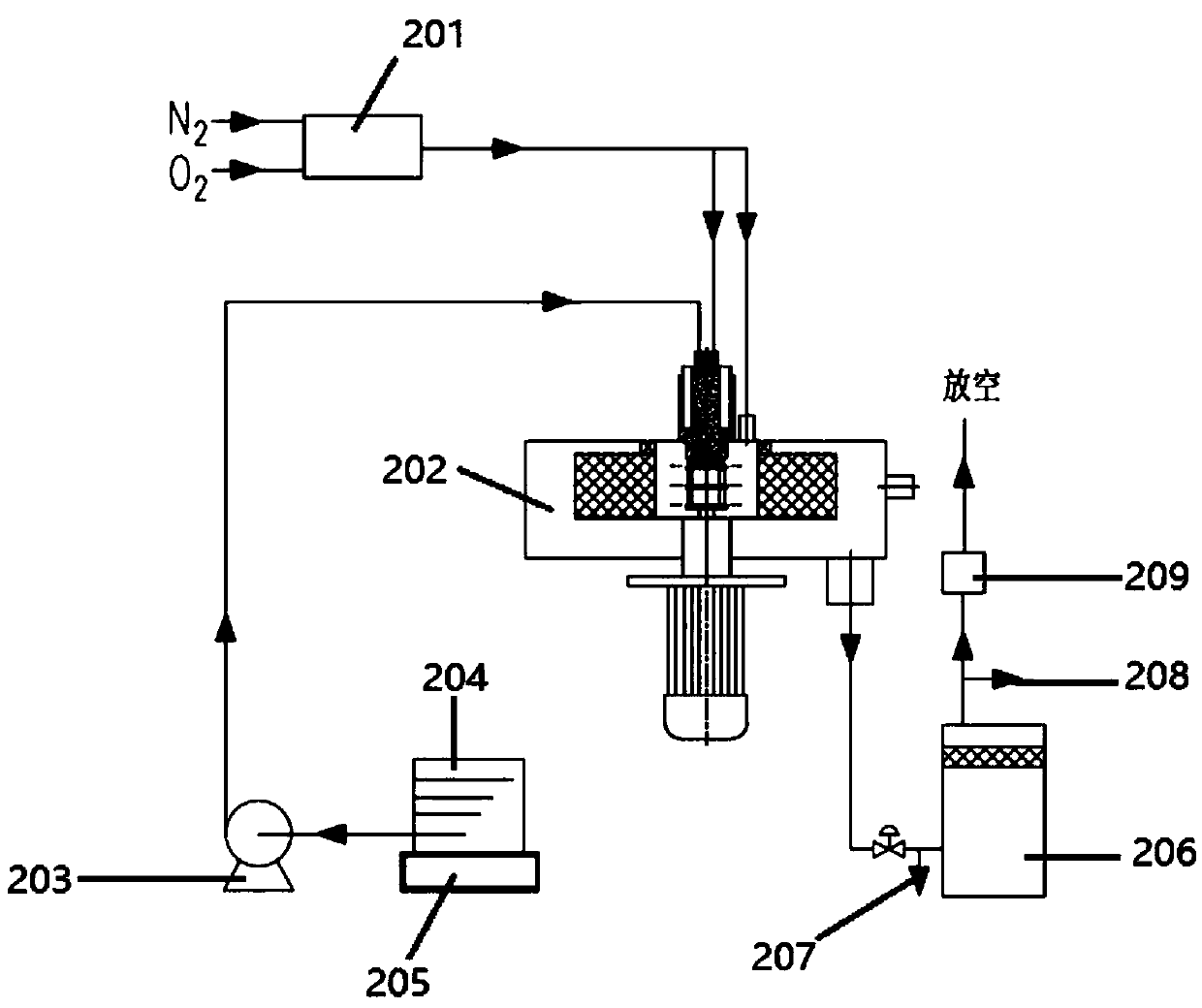

Hyper-gravity device for enhancing reaction by gas-liquid efficient premixing and application method thereof

ActiveCN107684880AImprove mass transfer efficiencyReduce partial pressureOrganic compound preparationTransportation and packagingReaction rateEngineering

The invention discloses a hyper-gravity device for enhancing a reaction by gas-liquid efficient premixing and an application method thereof. The hyper-gravity device comprises a motor, a main shaft, arotor, a shell, a liquid distributor, a secondary shaft, a speed-increasing gear, a speed-increasing gear output shaft and a charging cavity, wherein the main shaft at an output end of the motor passes through the bottom of the shell and extends into the shell; the rotor is fixed on an upper part of the main shaft; the charging cavity is arranged on an upper part of the shell; a lower part of thecharging cavity is connected with the liquid distributor; the main shaft is fixedly connected with the speed-increasing gear through the secondary shaft; the output shaft of the speed-increasing gearpasses through the bottom of the charging cavity and extends into the charging cavity; stirring wings are arranged on a part of the output shaft of the speed-increasing gear in the charging cavity. By adopting the hyper-gravity device, gas is distributed in a liquid phase in a nano-micron size, long gas retention period and high gas-liquid mass transfer efficiency are achieved, and the macro-reaction rate is increased effectively.

Owner:浙江中巨海锐科技有限公司

Method and apparatus for facilitating more uniform vapor distribution in mass transfer and heat exchange columns

ActiveUS20050146062A1Evenly distributedReduction in ascending vapor velocityUsing liquid separation agentTransportation and packagingEngineeringCircular segment

A vapor horn device for use in an elongated, generally upright mass transfer and / or heat exchange column having an internal region comprises an elongated, generally arcuate wall arranged to be located within the internal region and disposed to extend around a longitudinal axis of the column. The arcuate wall includes an inlet area positioned for being contacted by a vapor or mixed phase stream entering the column and causing the stream to flow along an outer surface of the arcuate wall and generally around the axis. The device also includes a primary elongated vane extending outwardly from the outer surface of the arcuate wall. This primary vane has an inner end located adjacent the outer surface of the inner wall and an outer end disposed in spaced relationship relative to the outer surface of the wall. The vane is disposed at a tangential angle relative to the direction of flow of the stream such that the inner end of the vane is further downstream than the outer end thereof whereby any portion of the stream impinging on the primary vane is redirected toward the outer surface of the arcuate wall. The device also desirably includes one or more vanes that extend radially outwardly from the inner wall.

Owner:KOCH GLITSCH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com