Patents

Literature

131 results about "Gas retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

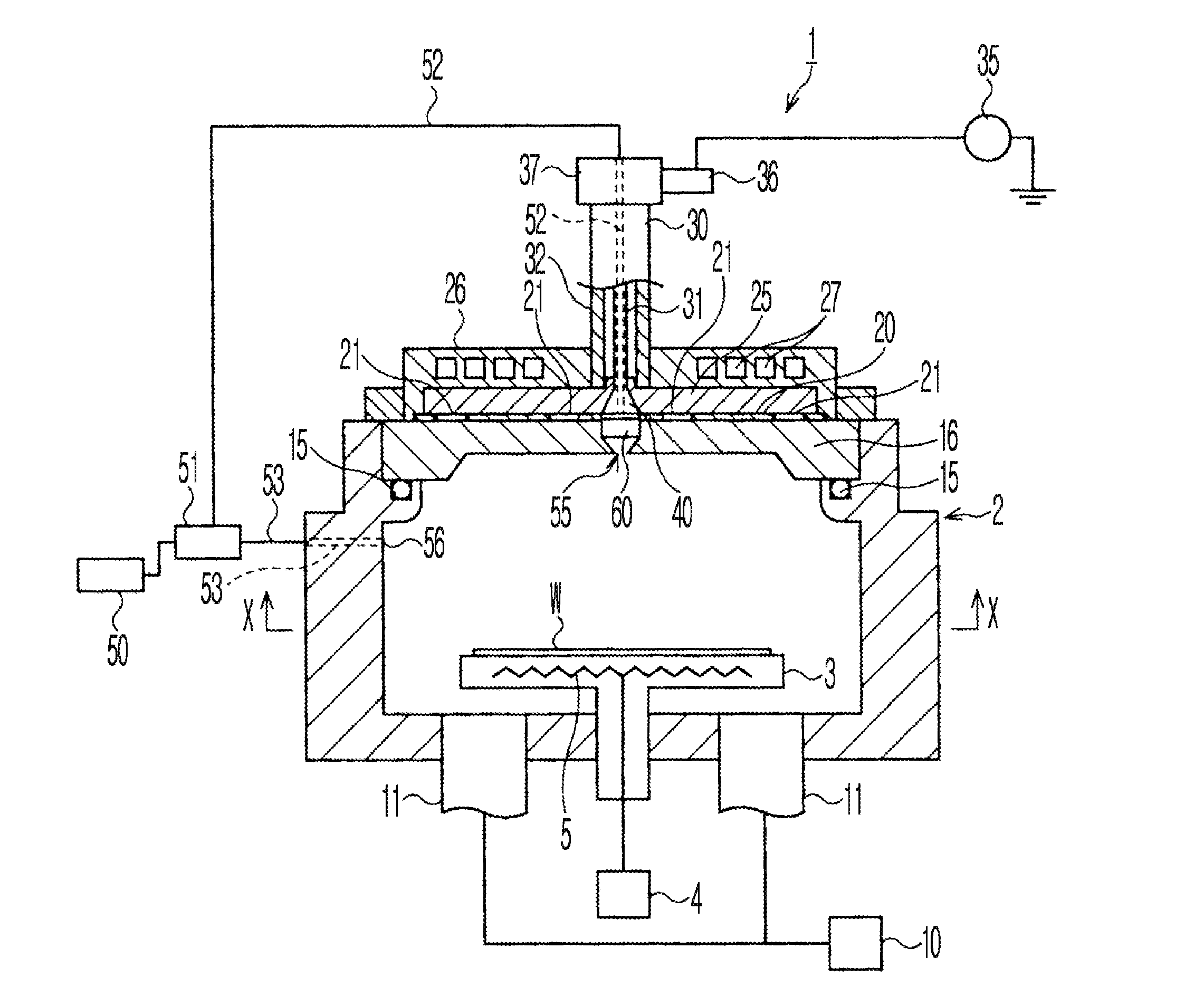

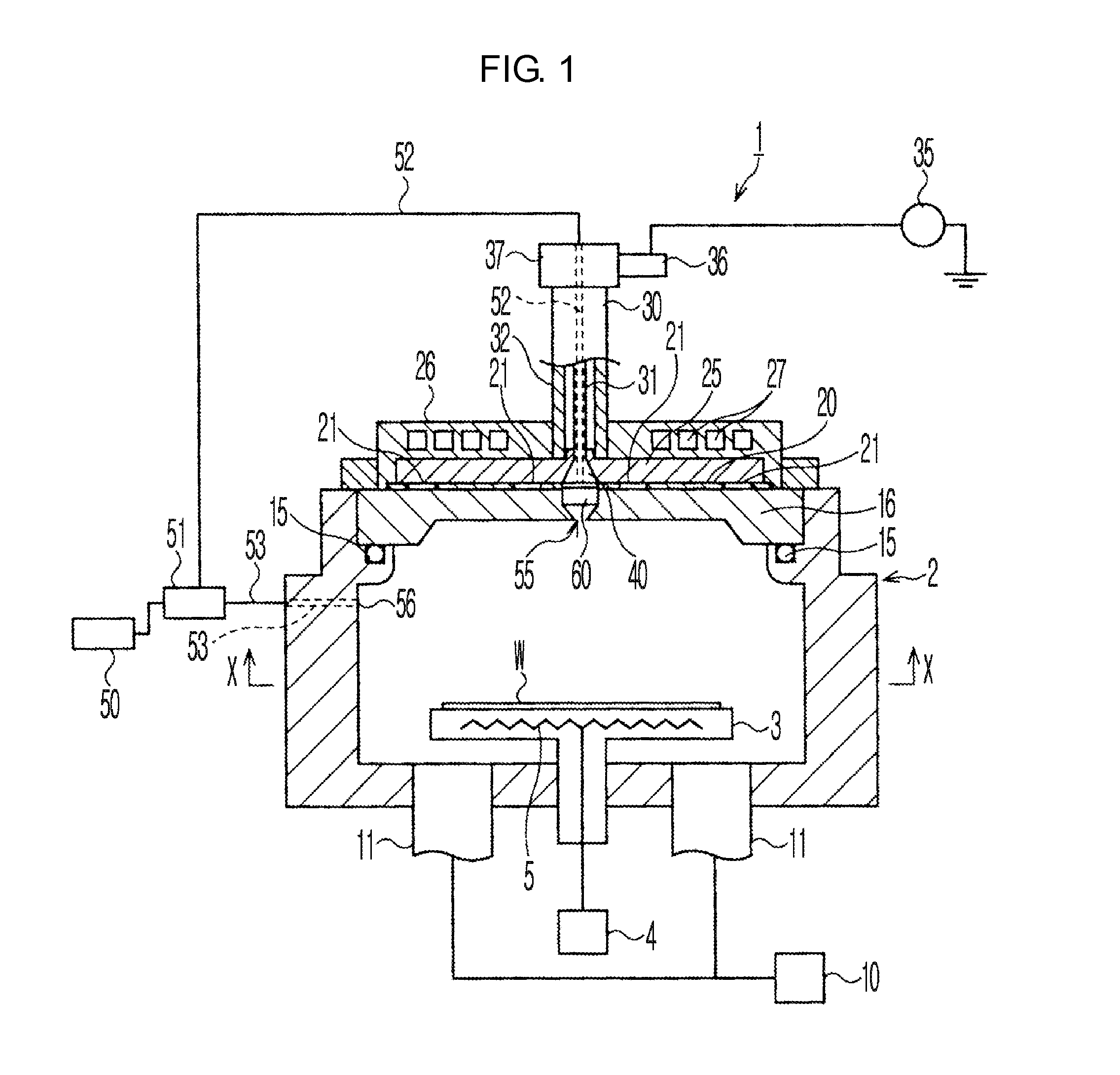

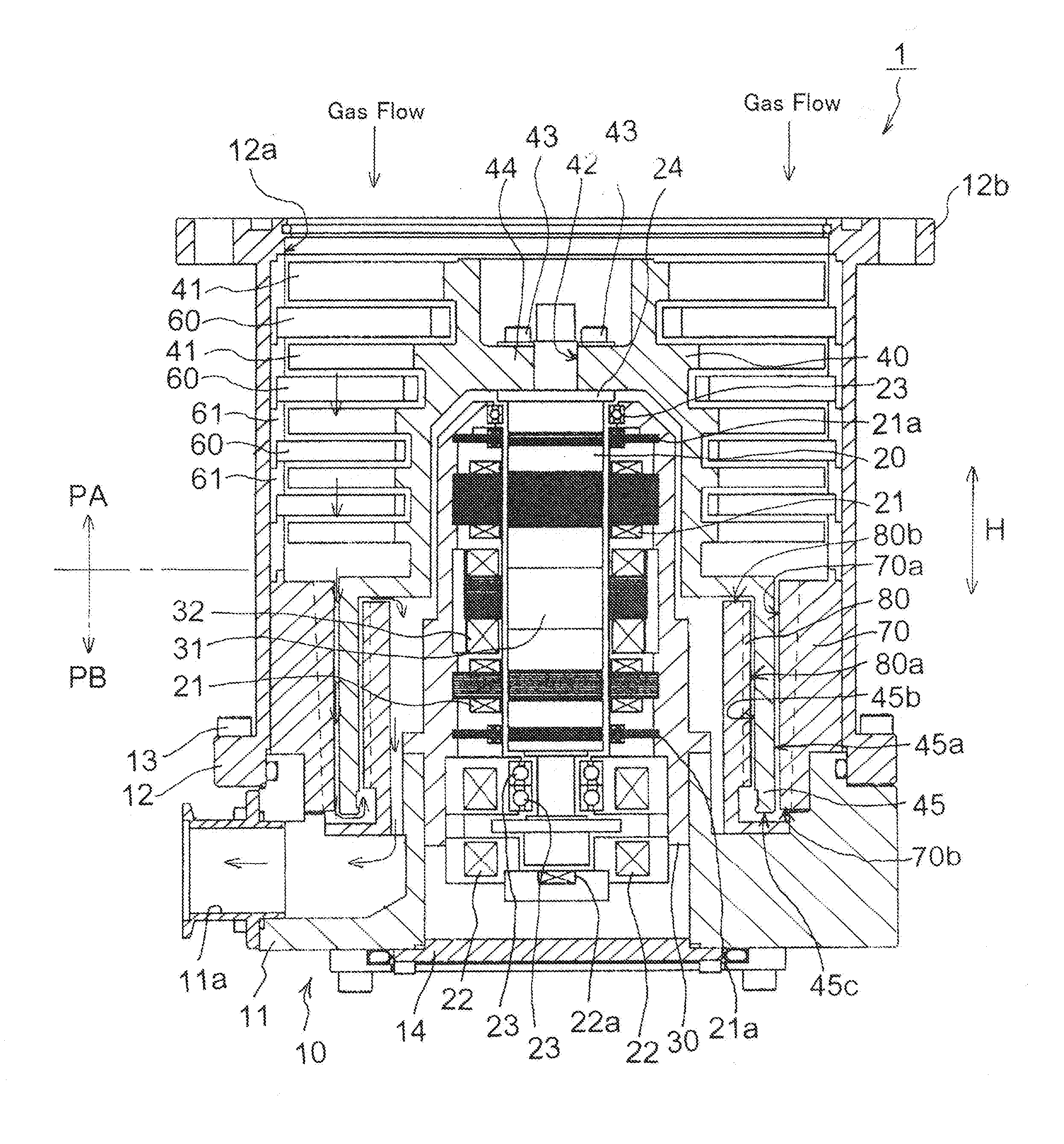

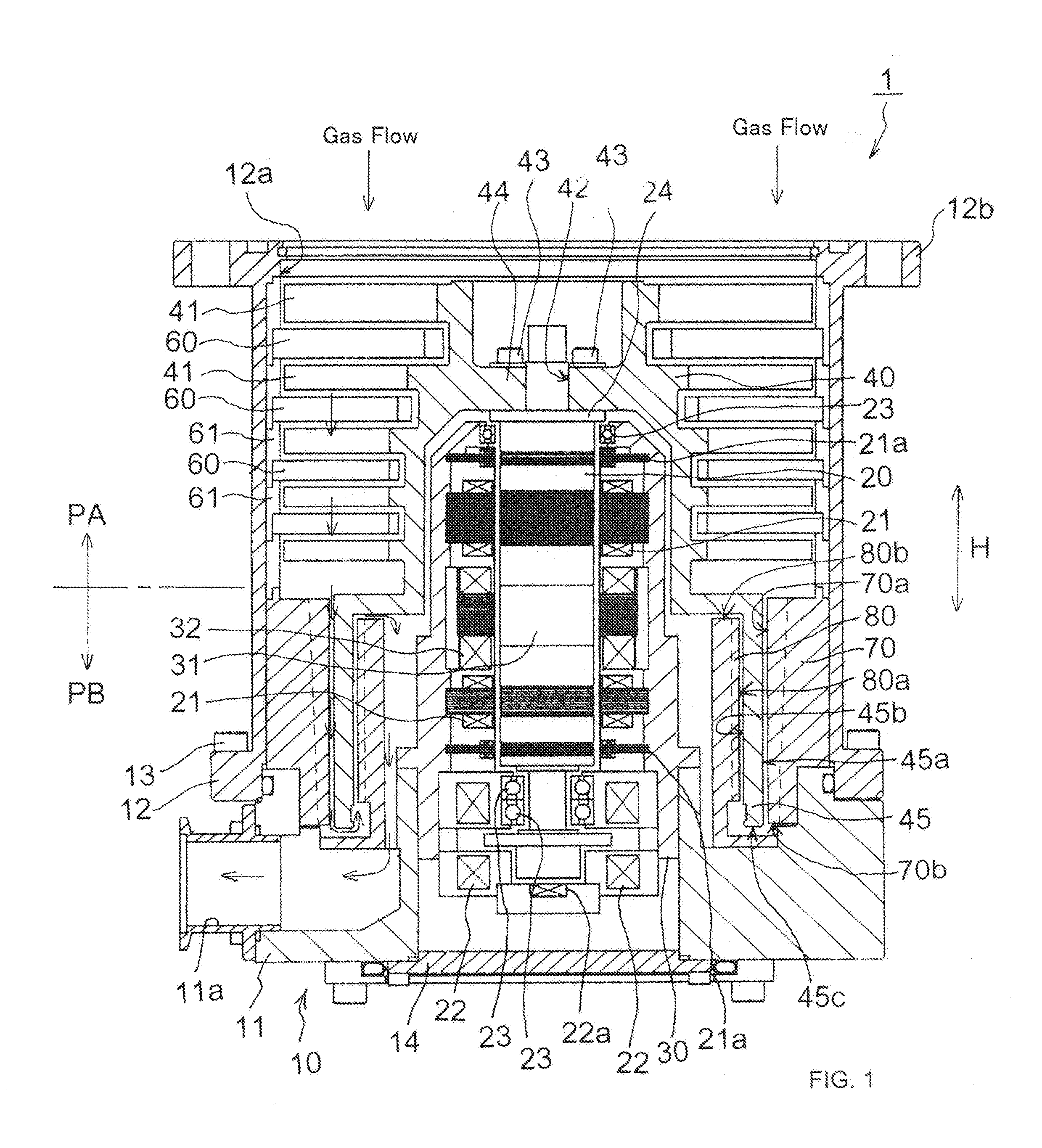

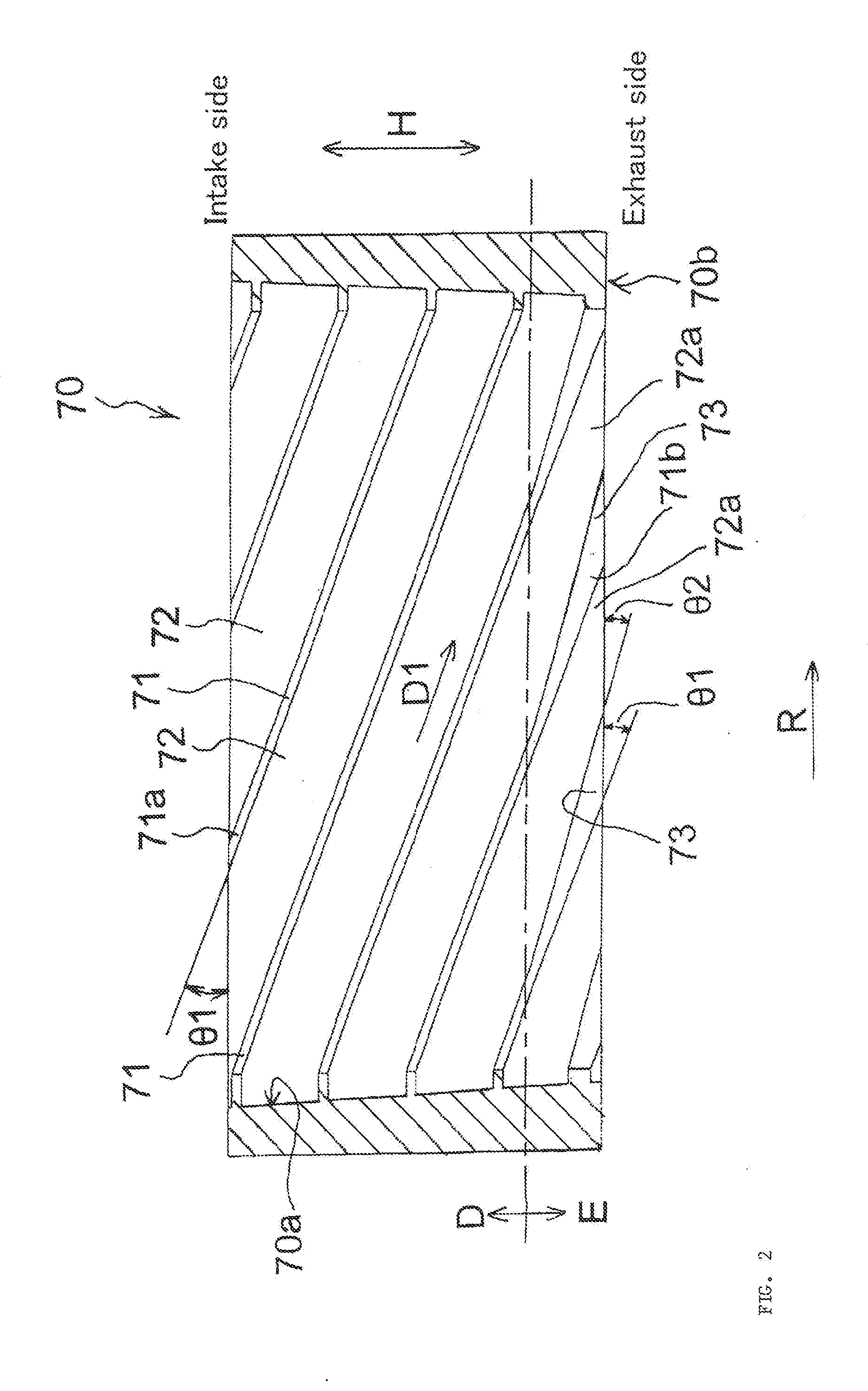

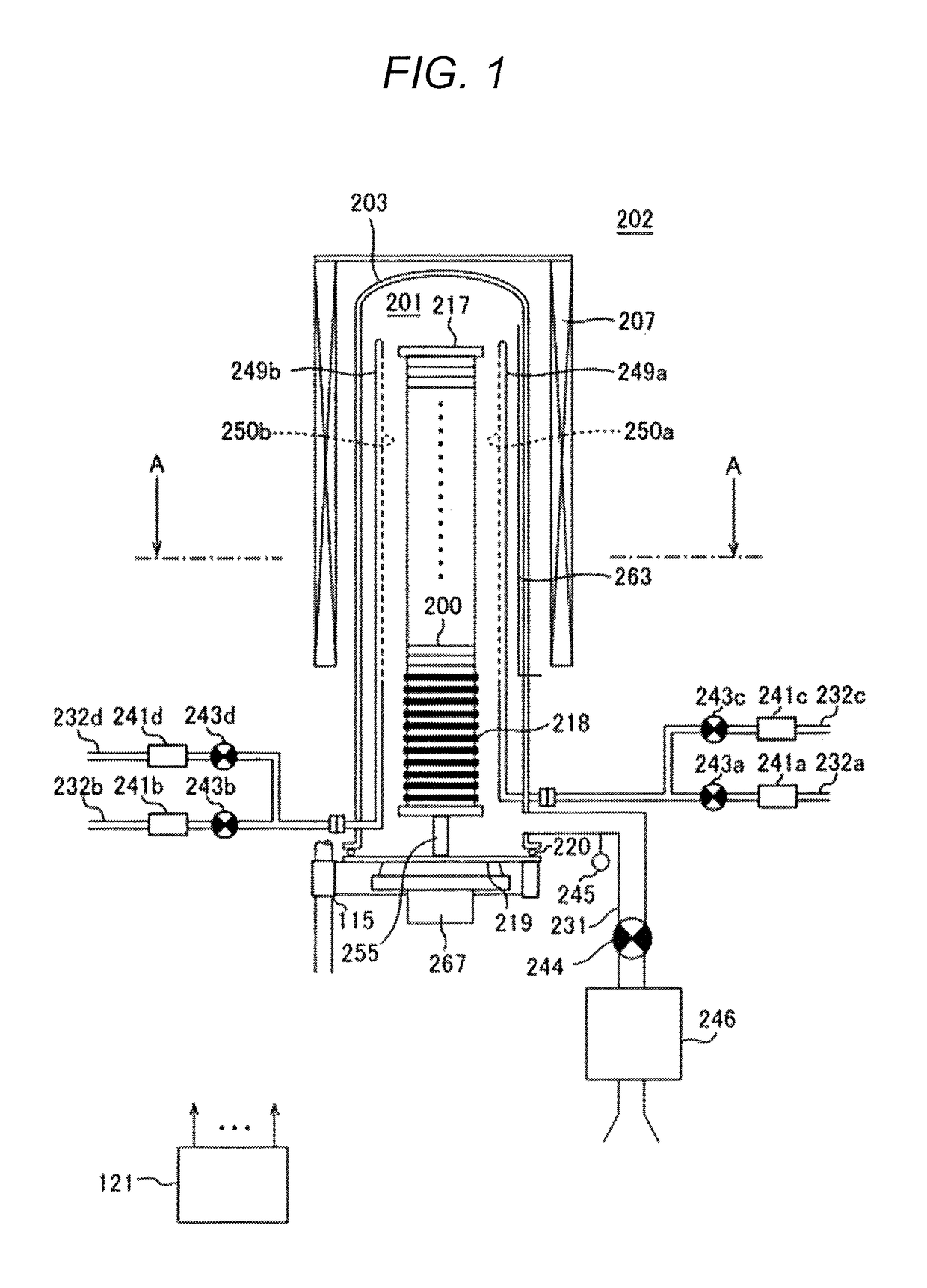

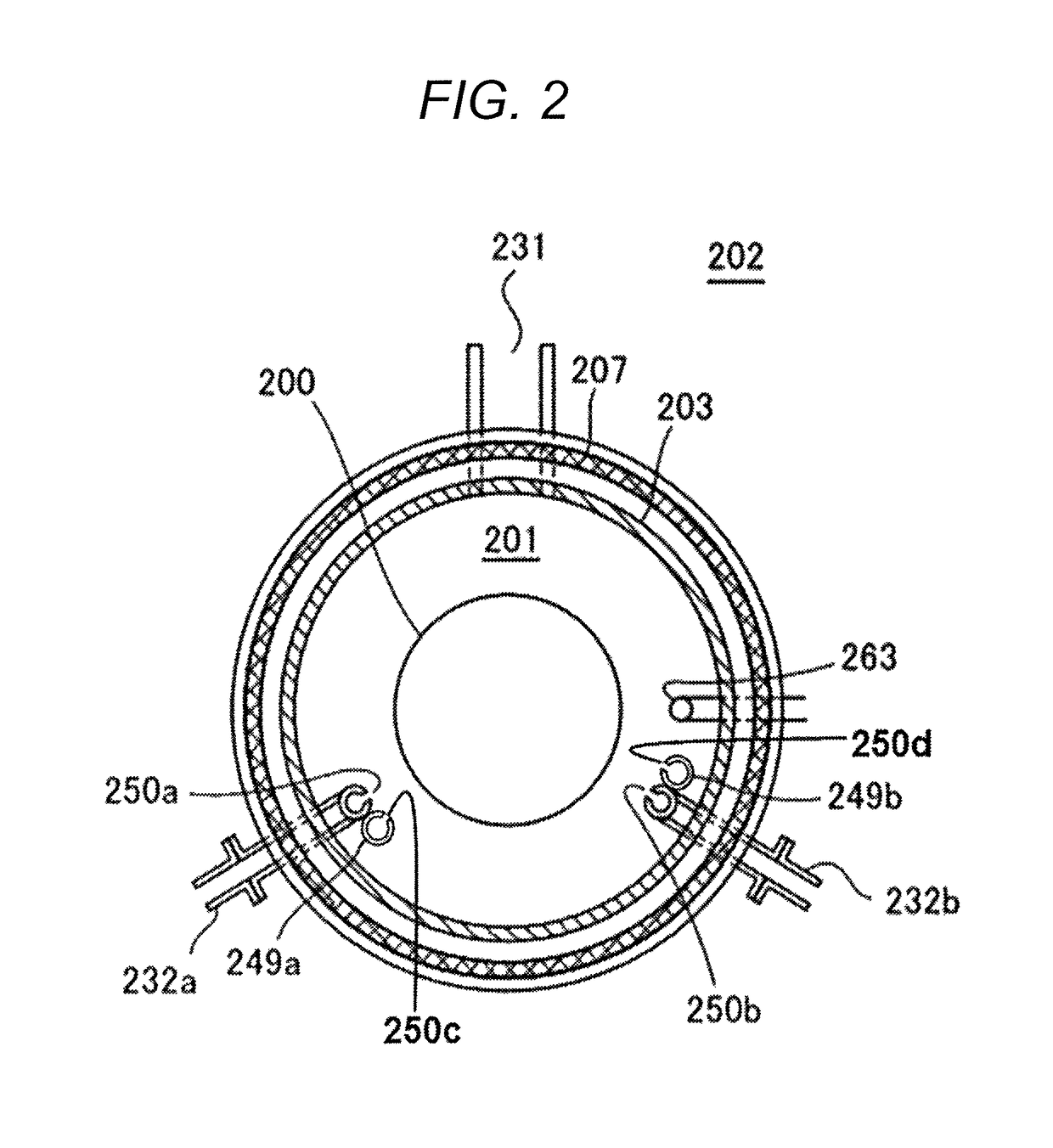

Plasma processing apparatus

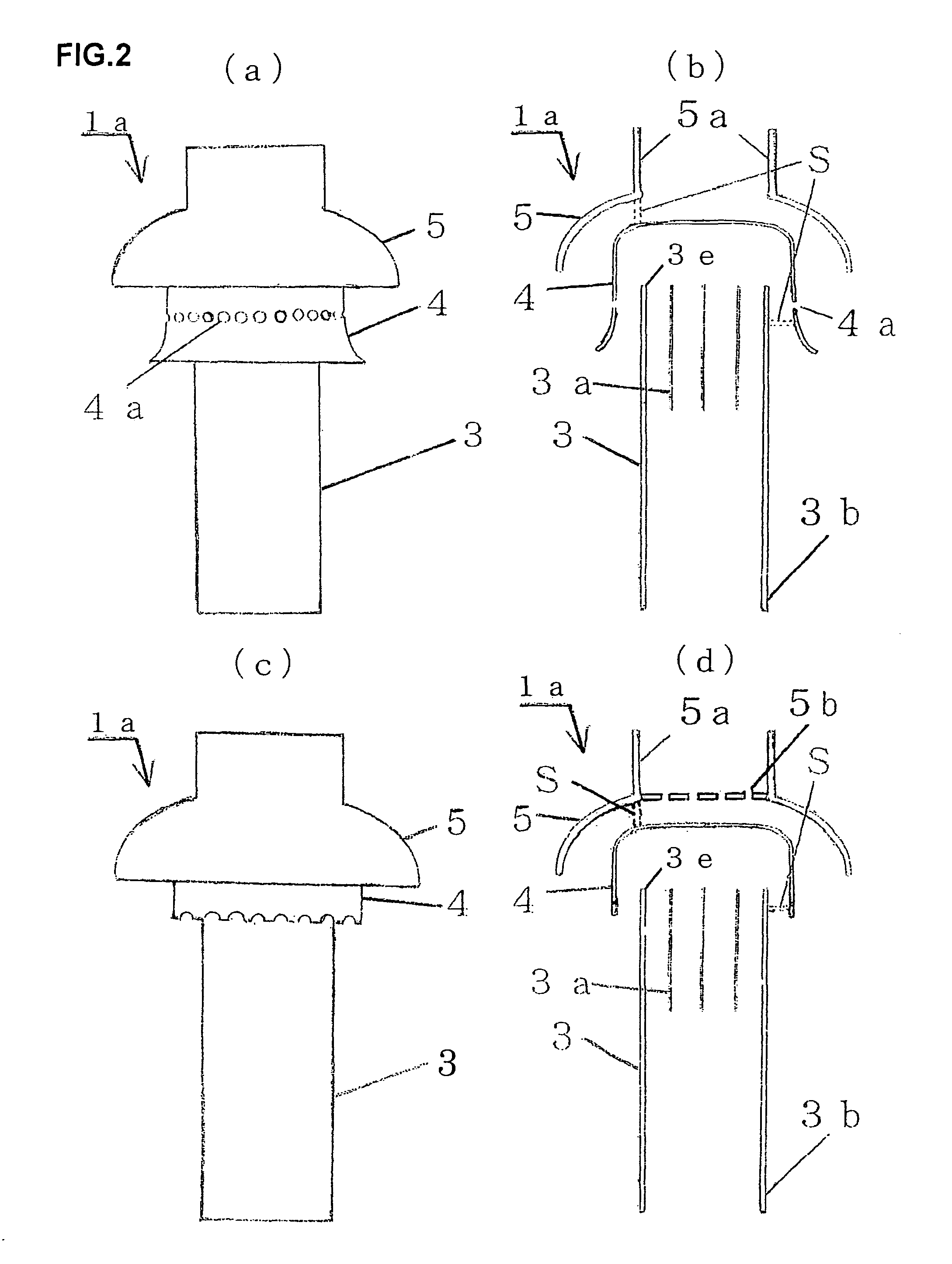

ActiveUS20110048642A1Improve removabilityElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringGas retention

In a plasma processing apparatus for processing a substrate by plasmatizing a process gas introduced into a processing container, an introducing unit which introduces the process gas is formed on a ceiling surface of the processing container; a gas retention portion which gathers the process gas supplied from the outside of the processing container through a supply passage, and a plurality of gas ejection holes which allow communication between the gas retention portion and the inside of the processing container are formed in the introducing unit; a gas ejection hole is not formed in a location of the gas retention portion that faces an opening of the supply passage; and a cross section of each of the gas ejection holes has a flat shape.

Owner:TOKYO ELECTRON LTD

Silicone-based low permeability airbag fabric coatings

InactiveUS6846004B2Highly cost-effectiveEasy to handlePreformed elementsThin material handlingHigh pressureGas retention

Owner:MILLIKEN & CO

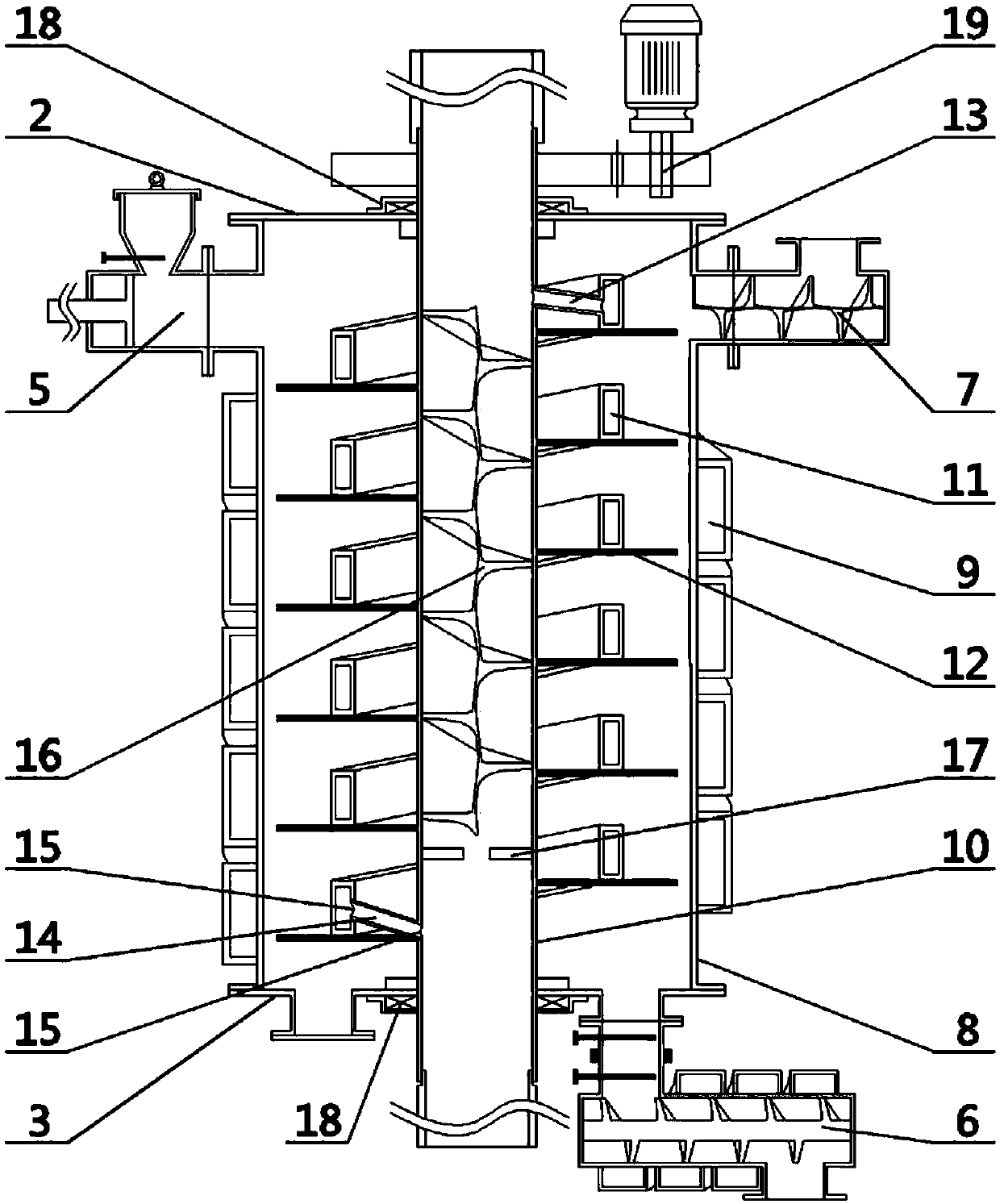

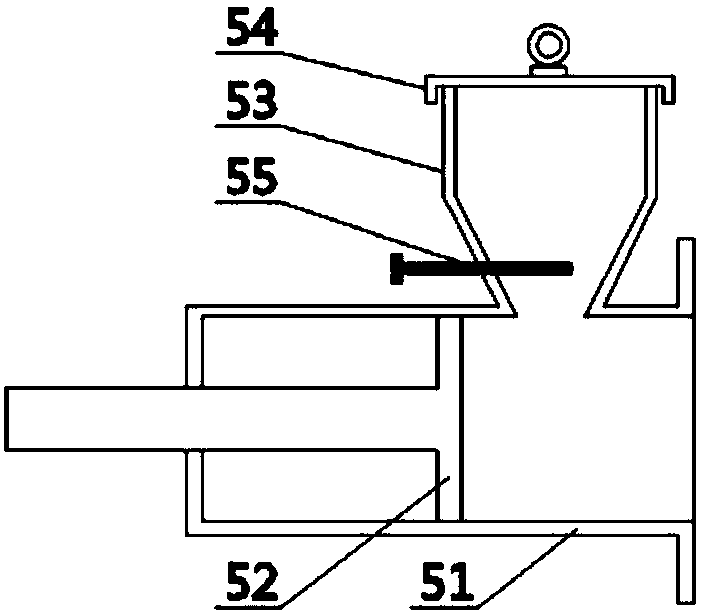

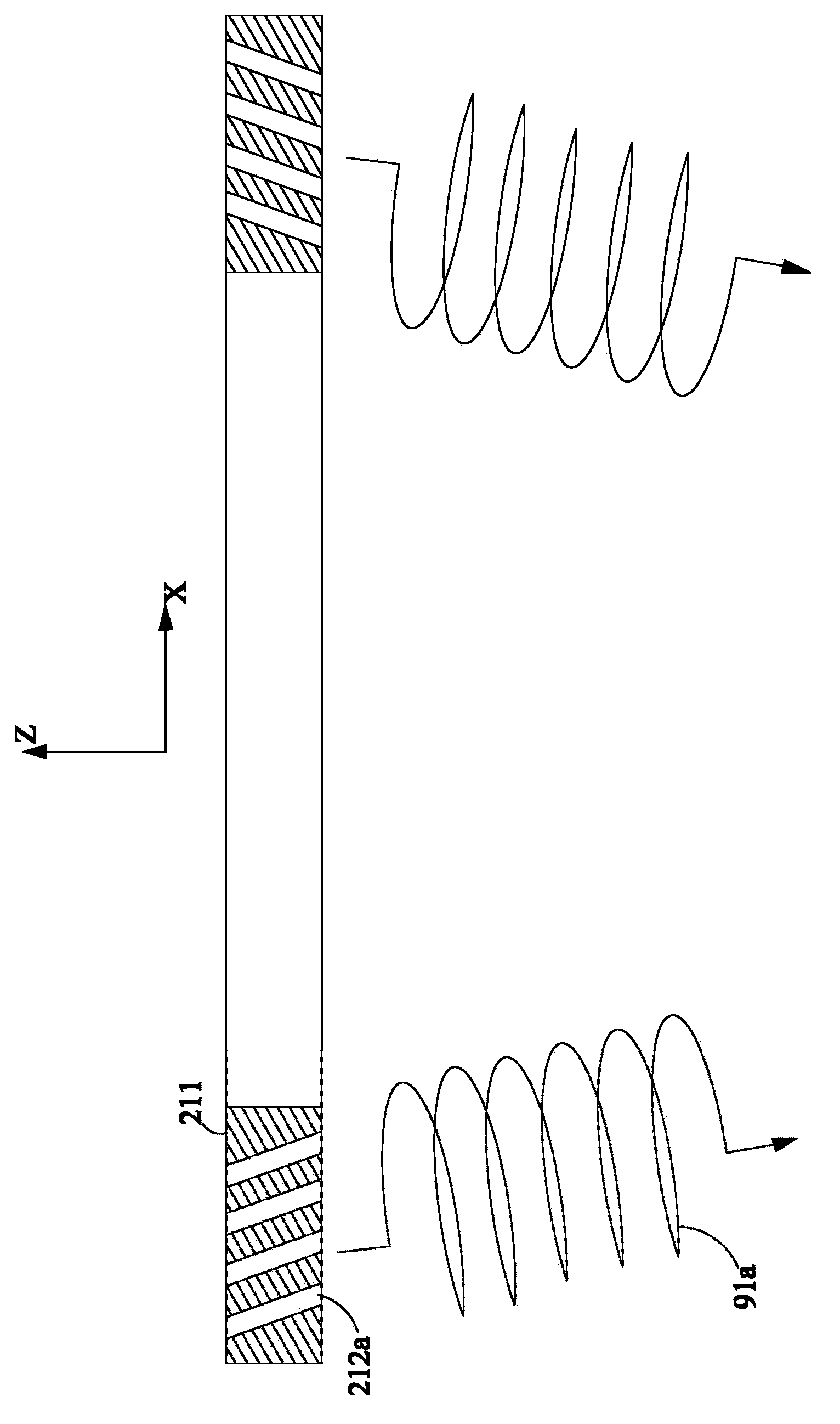

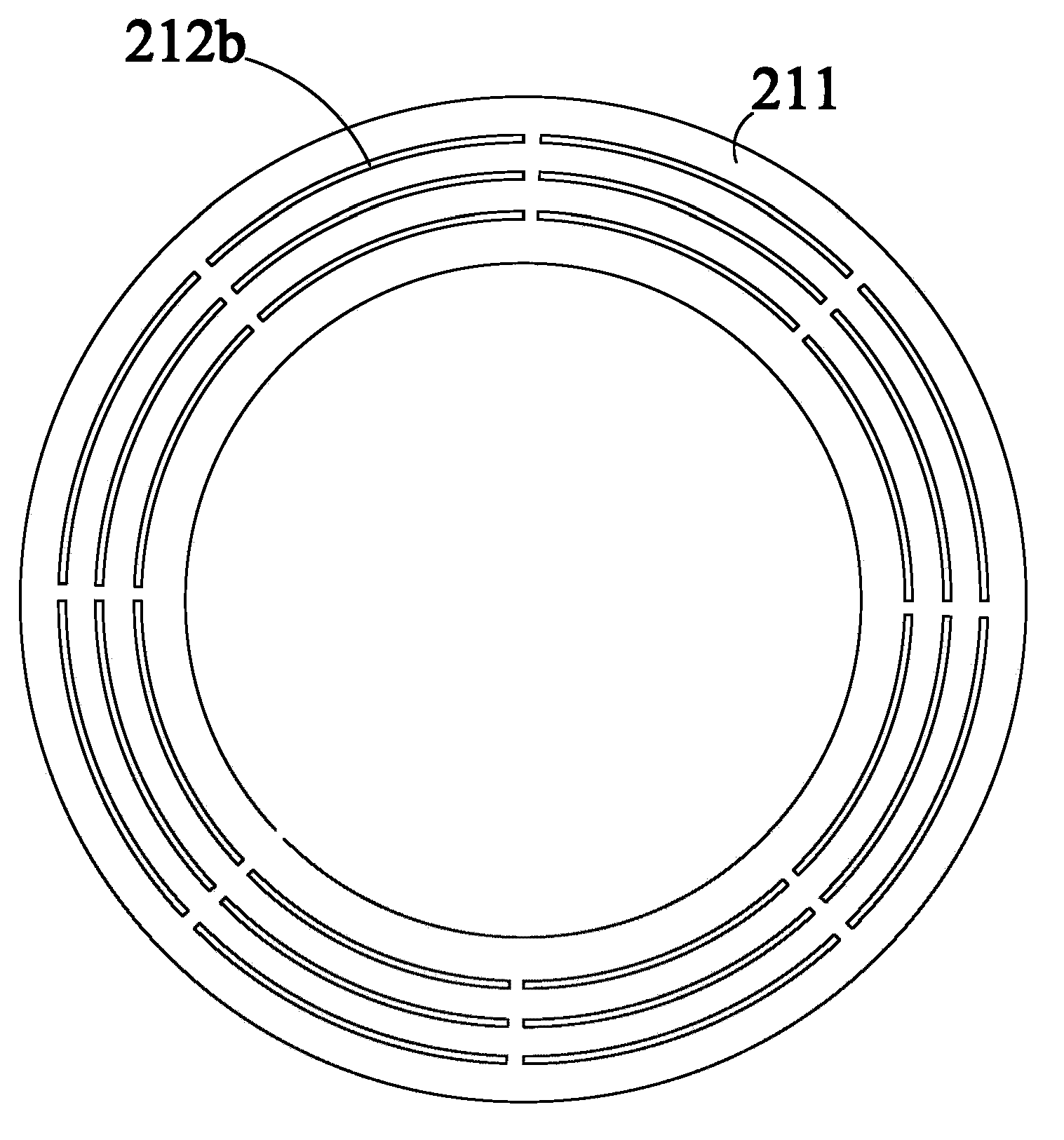

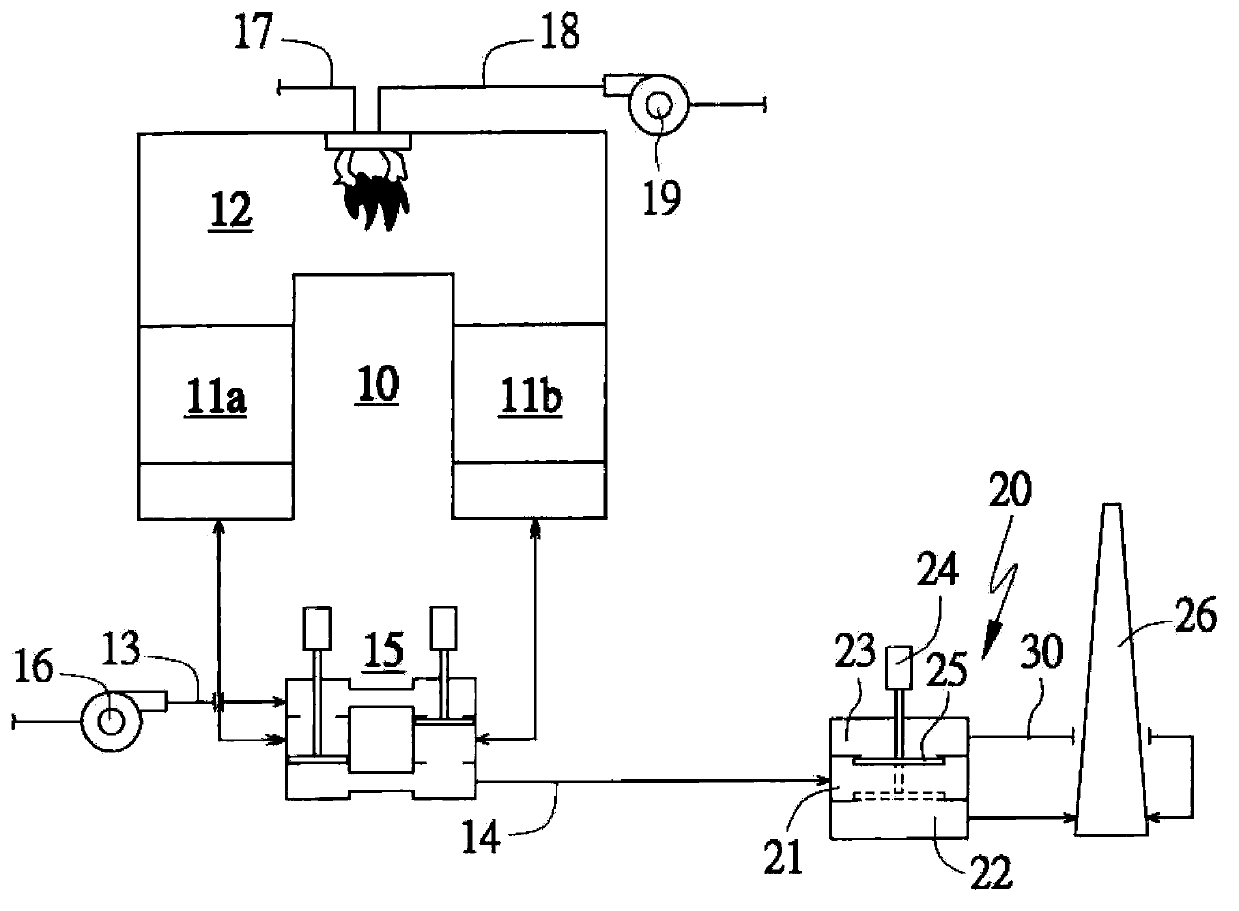

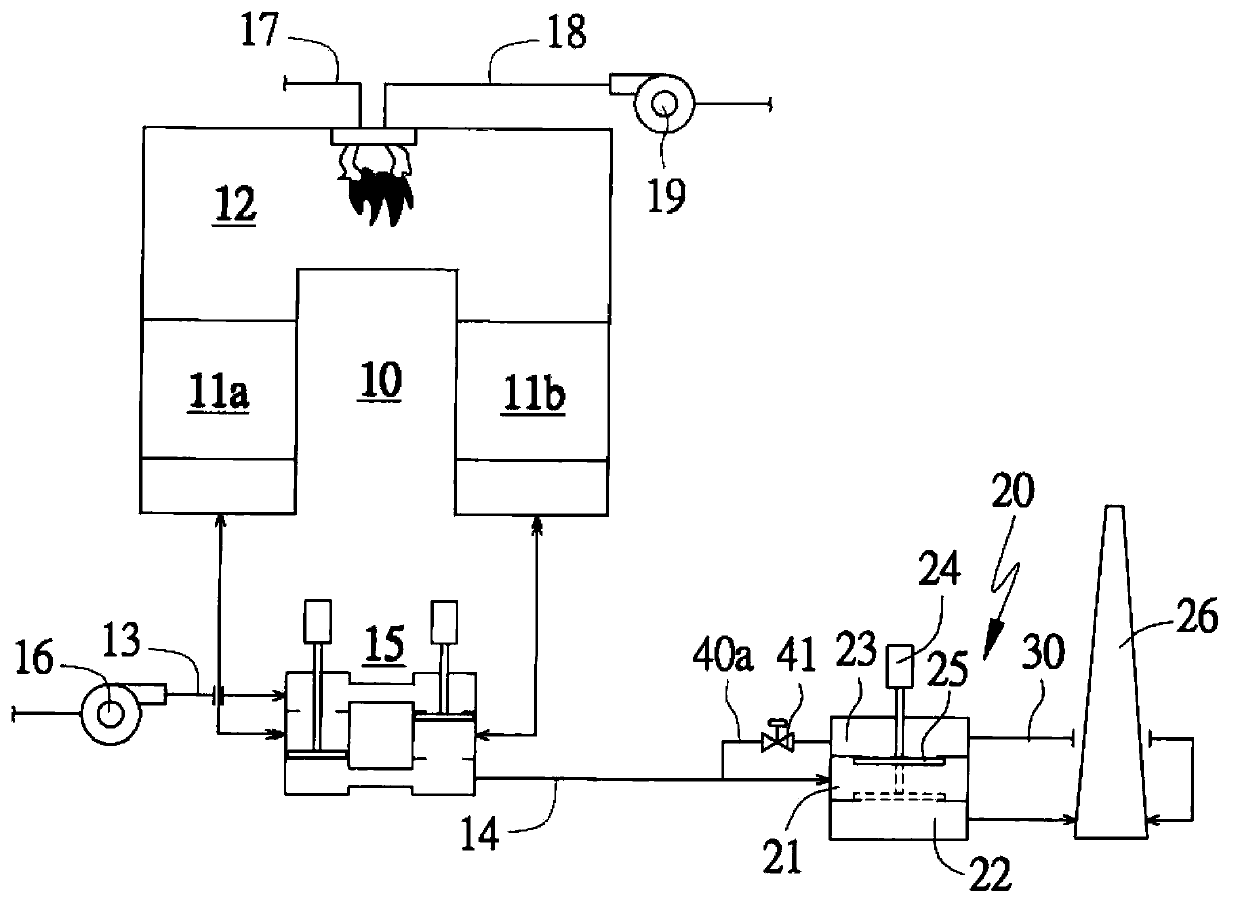

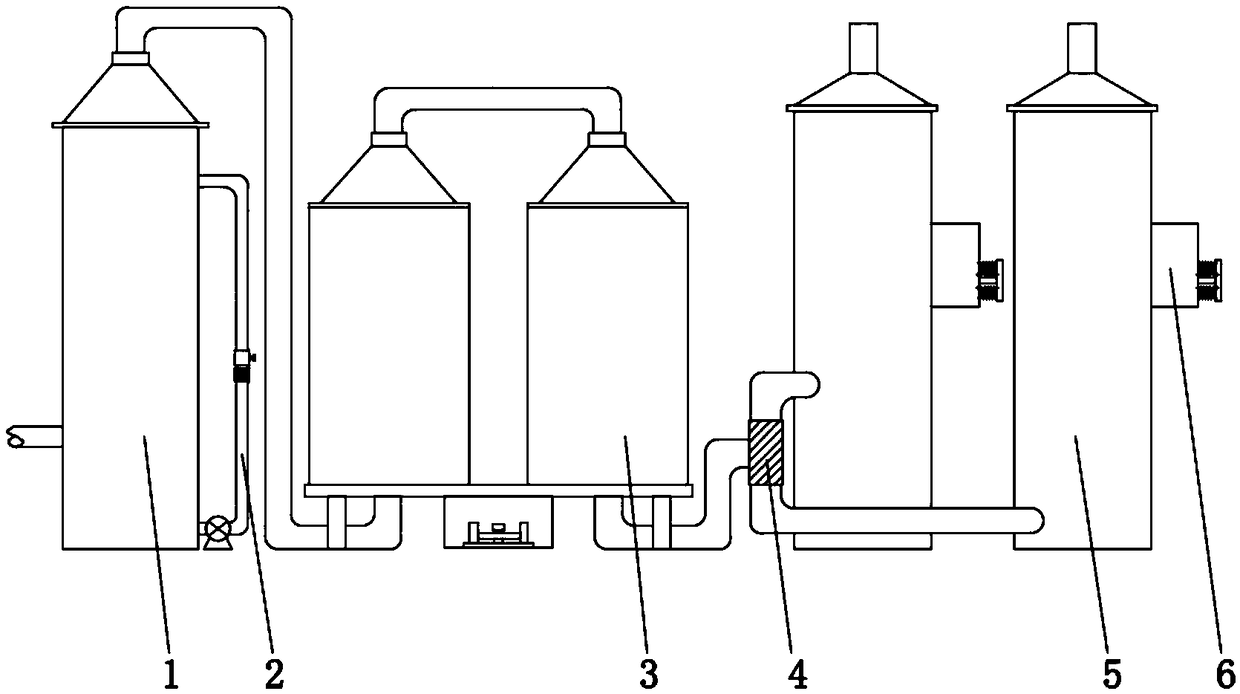

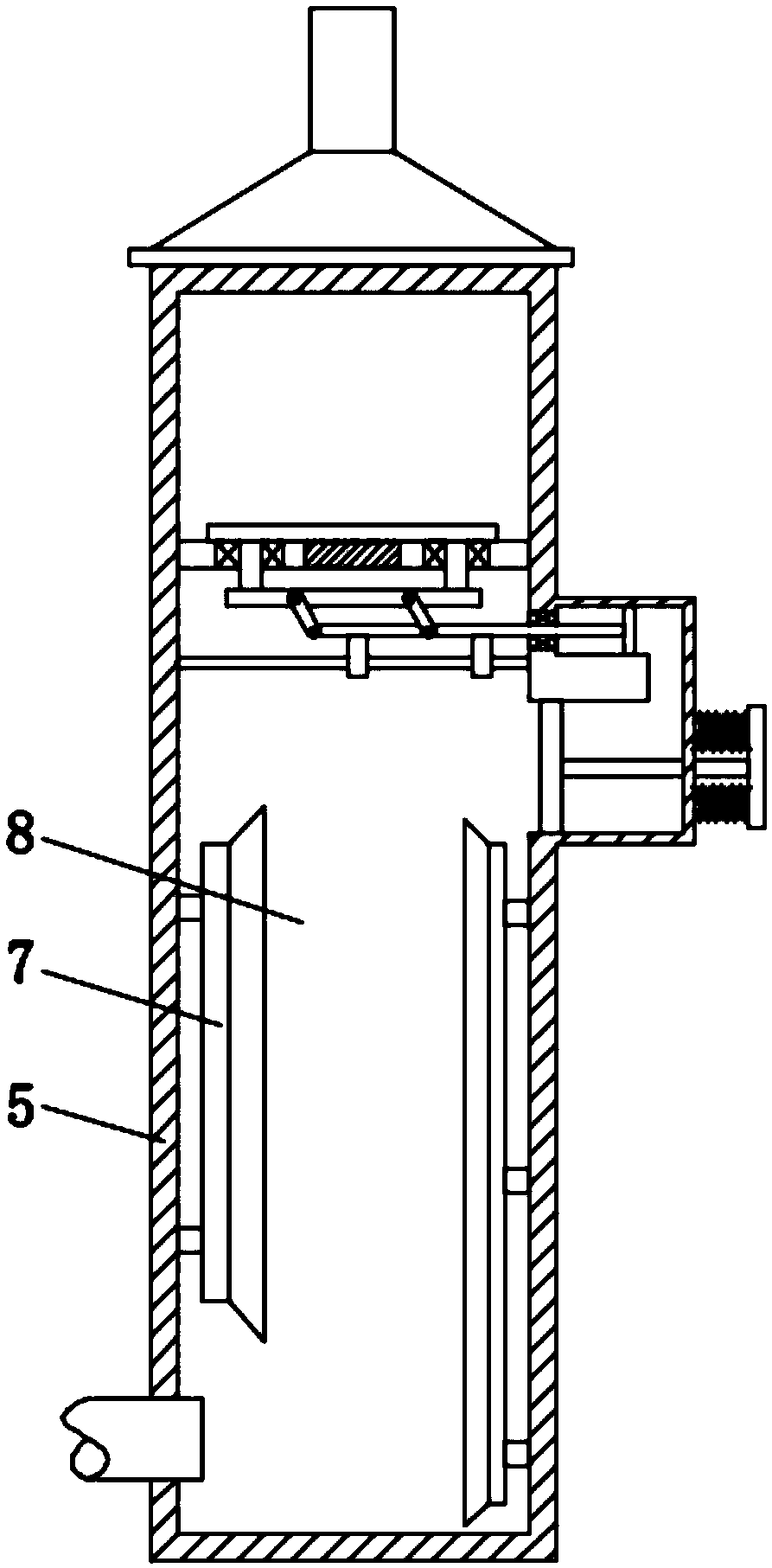

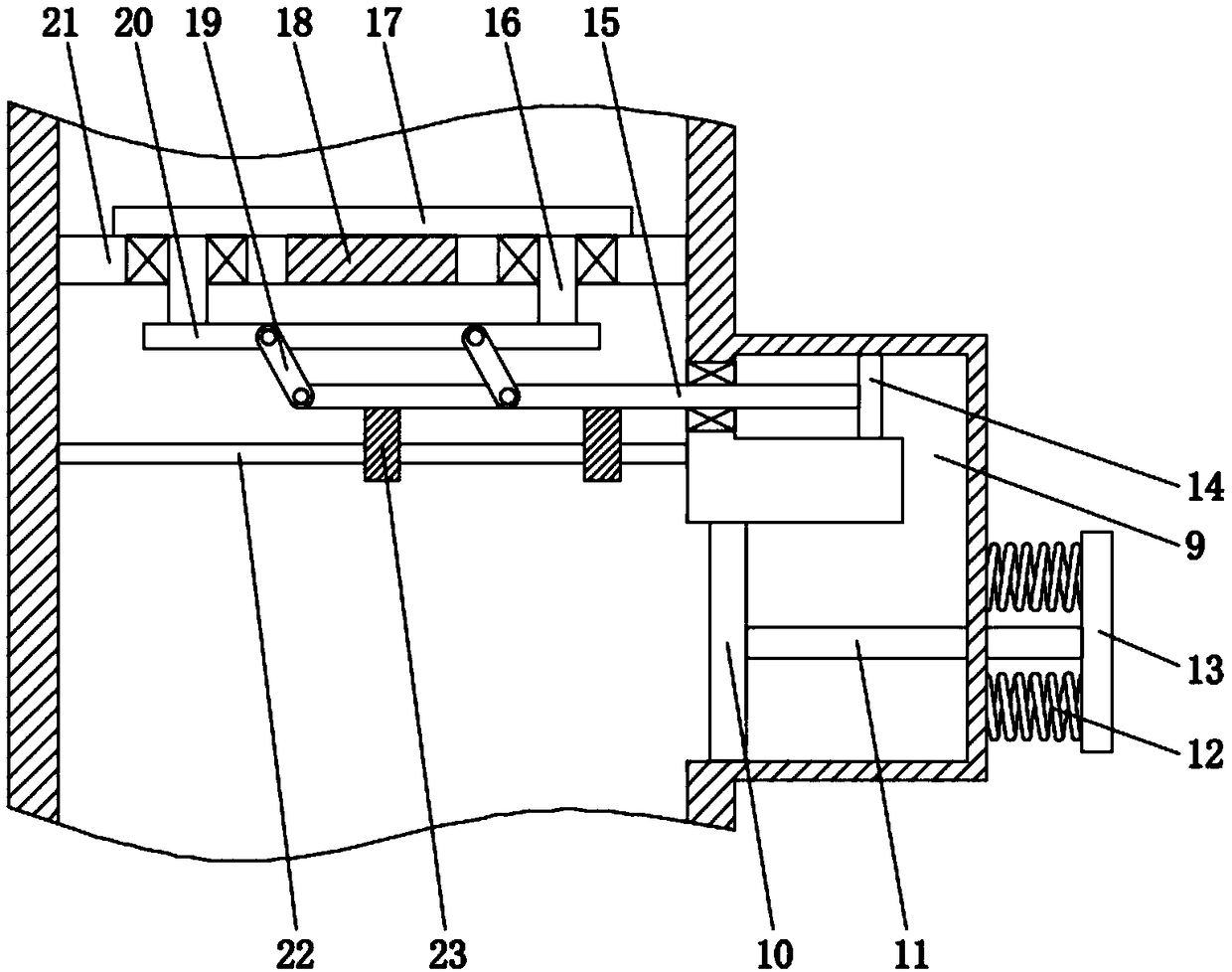

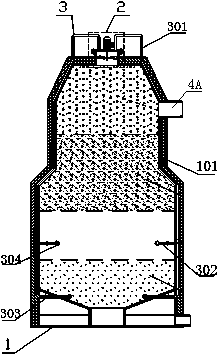

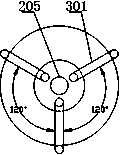

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

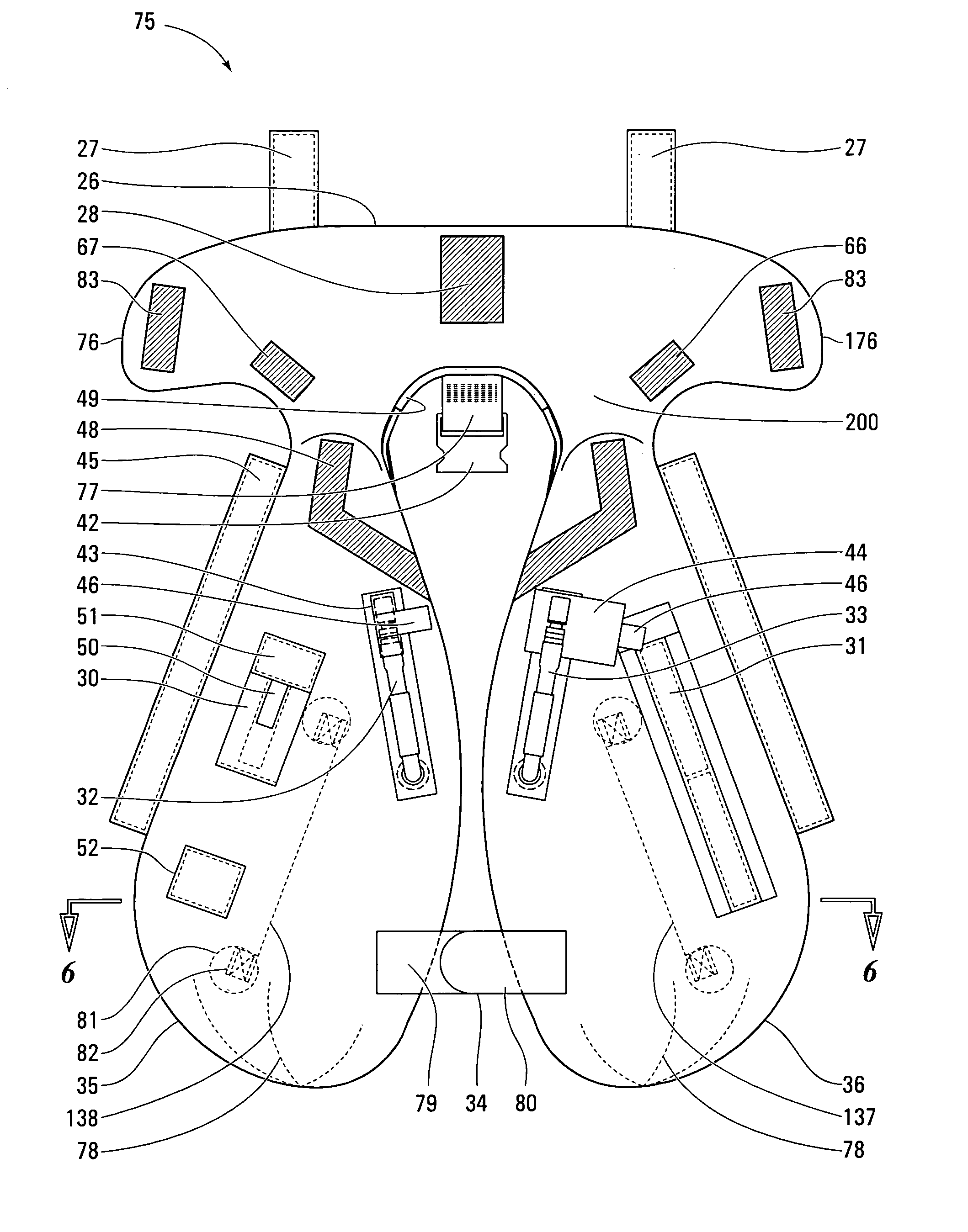

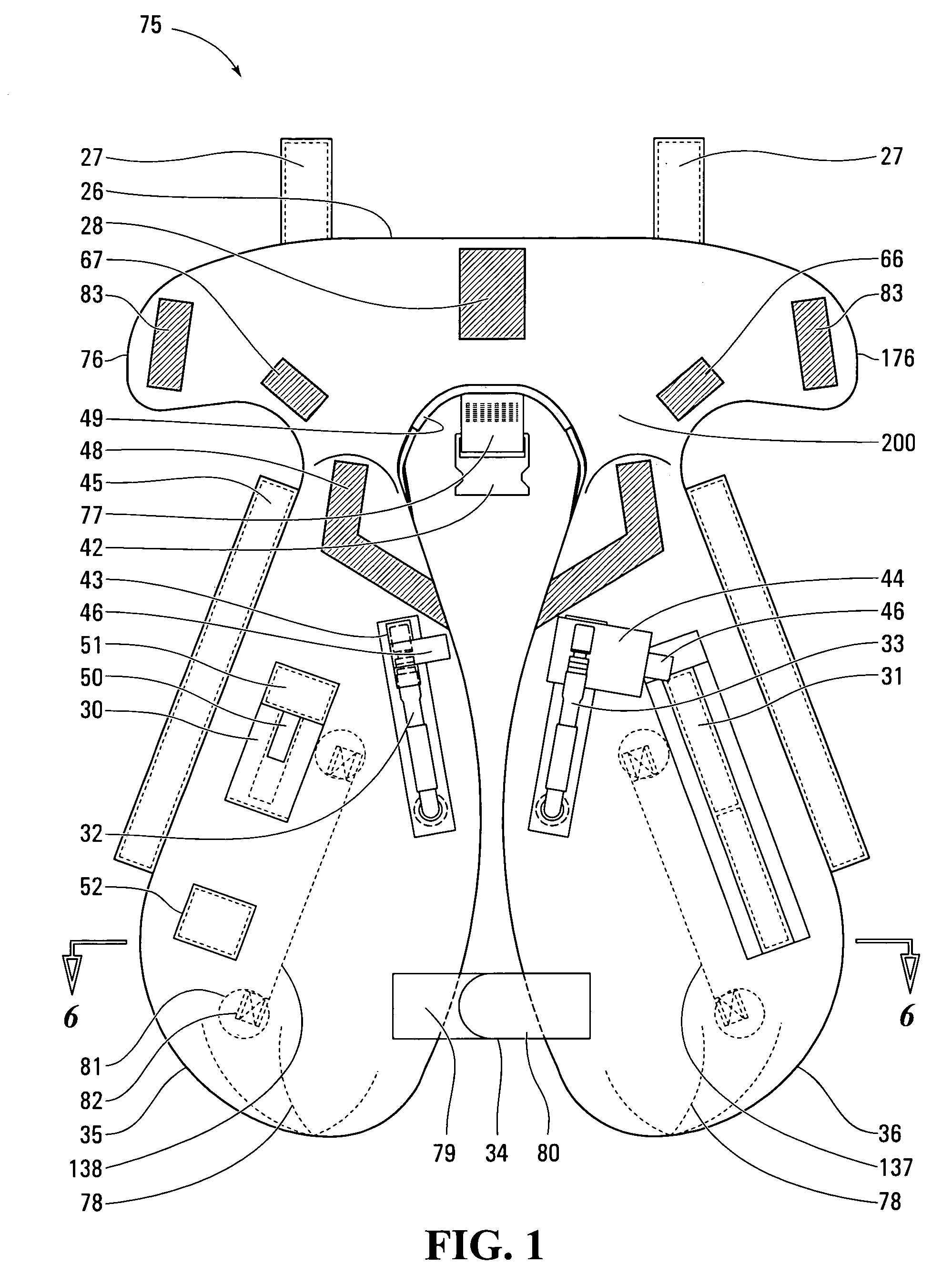

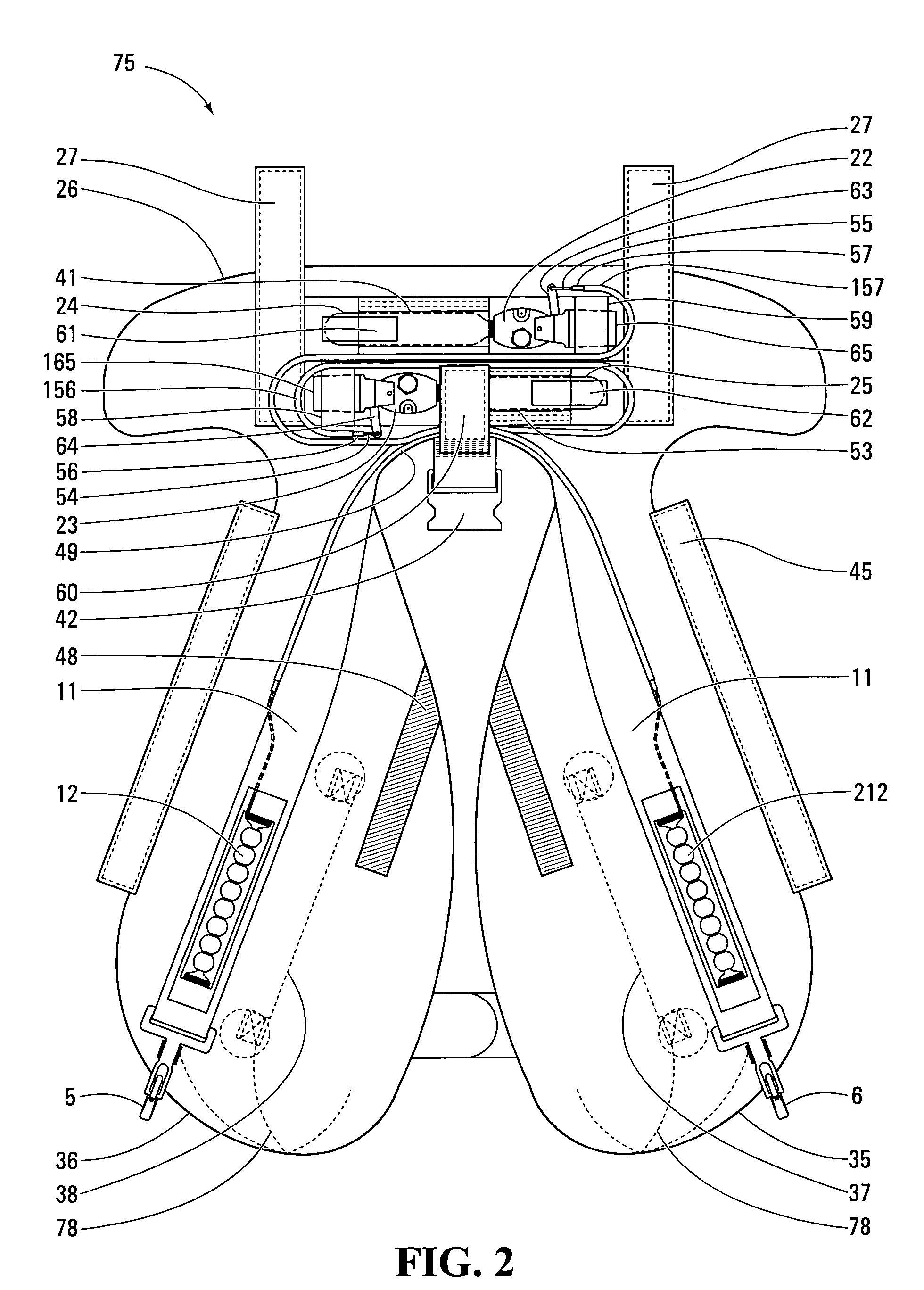

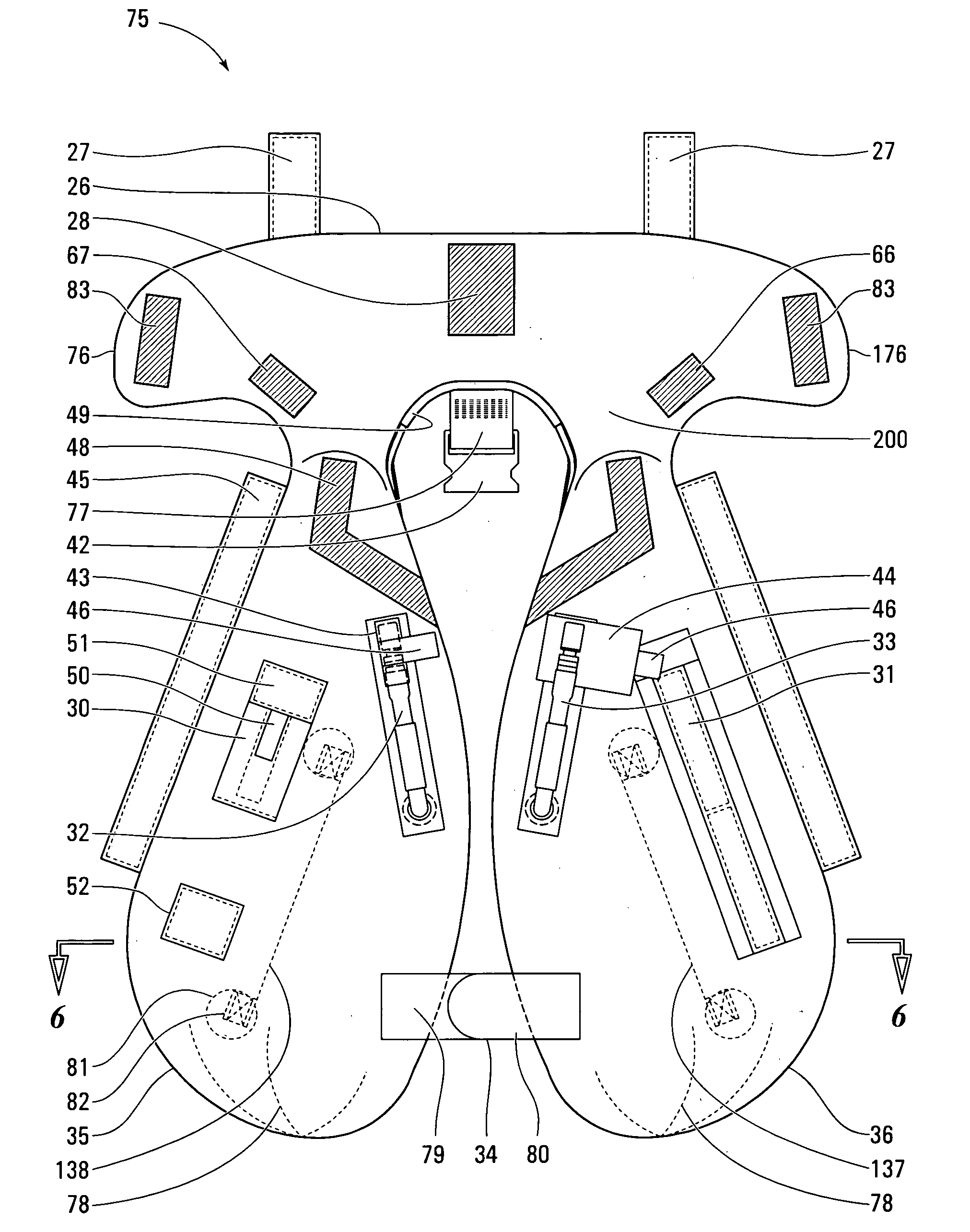

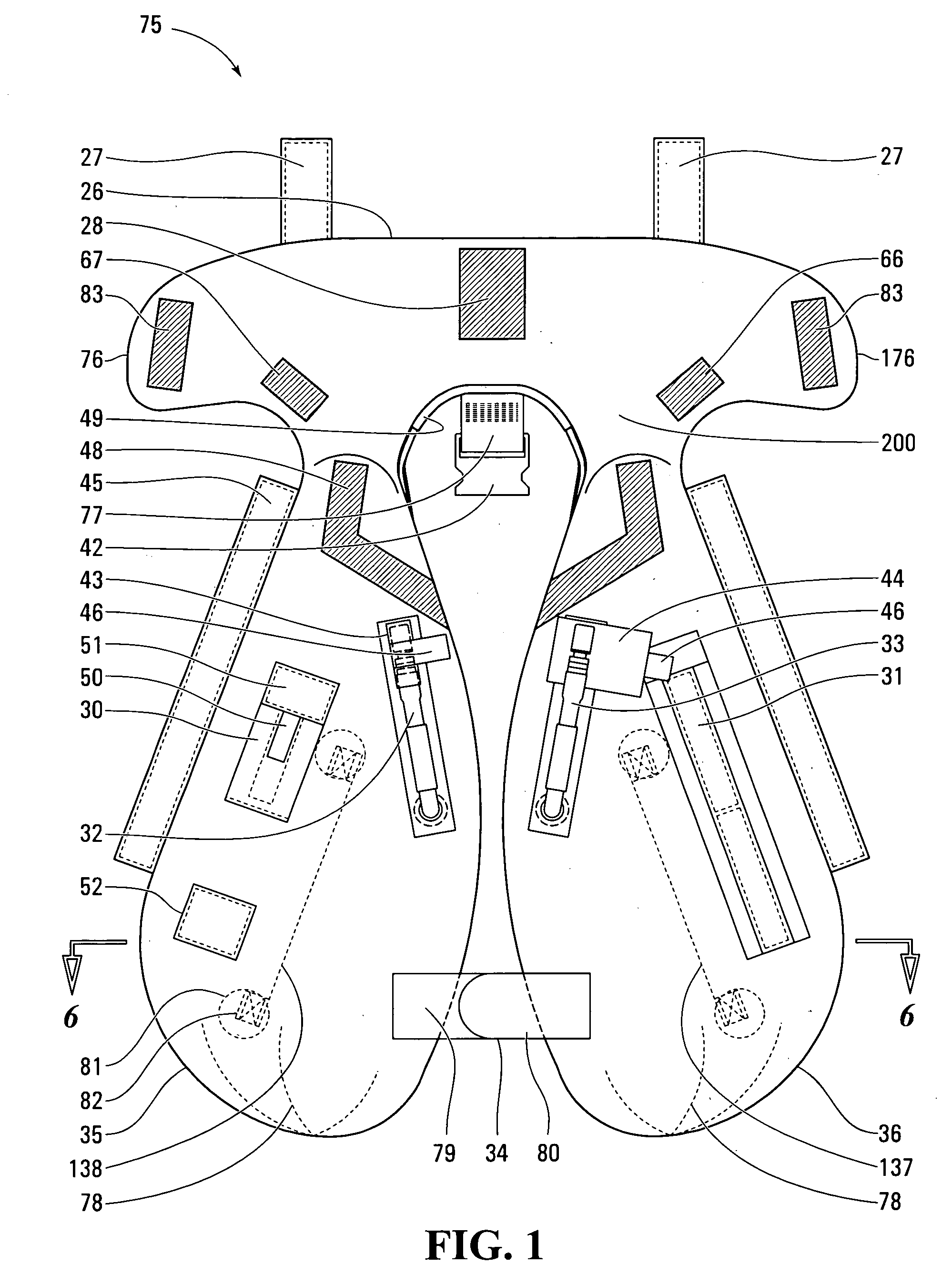

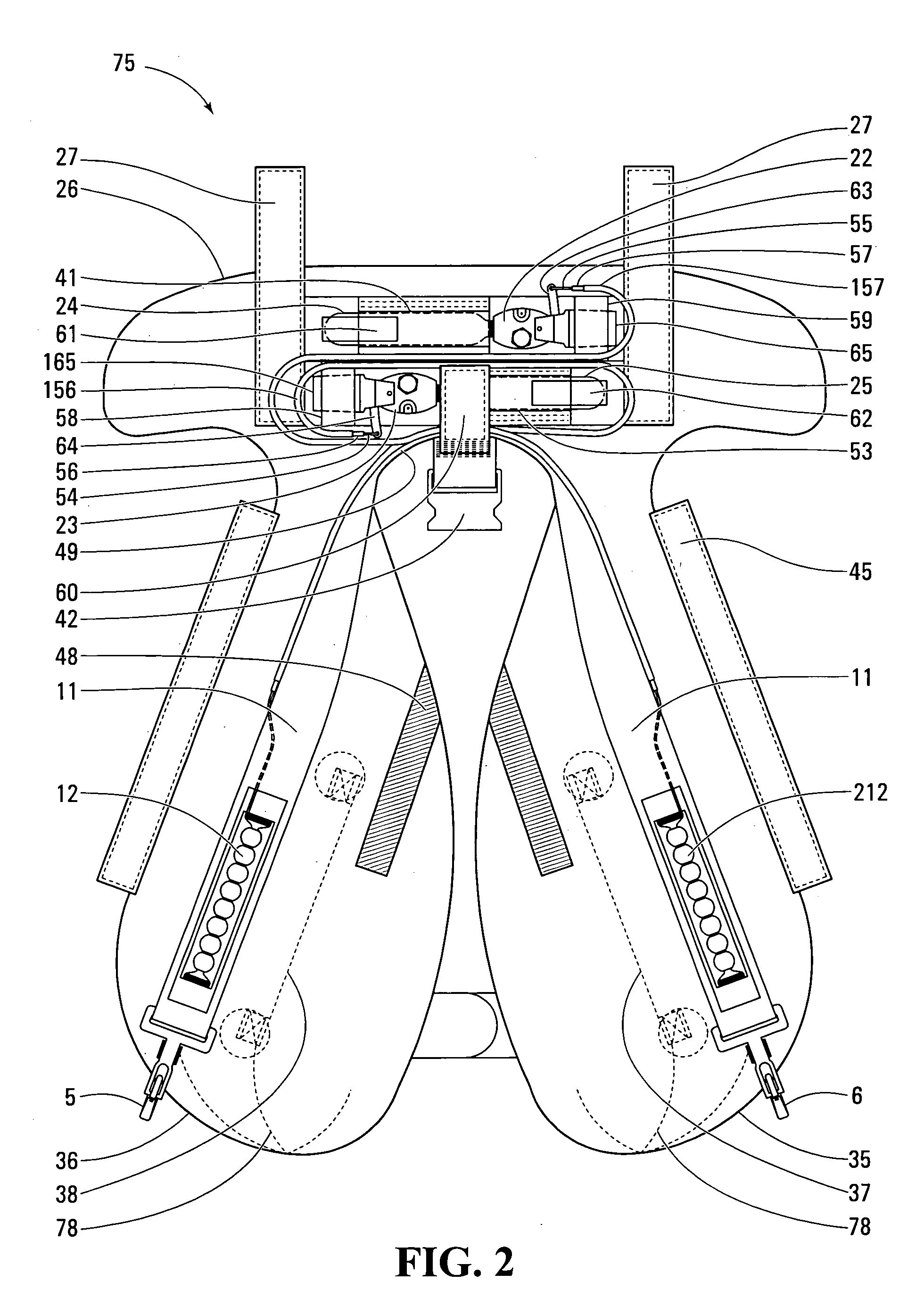

Life preserver system

An inflatable life preserver, capable of being in an inflated state and an uninflated state, is disclosed. The life preserver includes a structural overshell which defines the size and shape of the life preserver in the inflated state and a gas retention bladder fitted within the overshell. The overshell bears the expansion force of a gas within the bladder in the inflated state. The overshell defines inflatable side portions which are confined to sides of at least a portion of a chest area of a wearer, when the life preserver is in an uninflated state, and, which extend laterally over the chest area of the wearer, when the life preserver is in an inflated state.

Owner:TULMAR SAFETY SYST

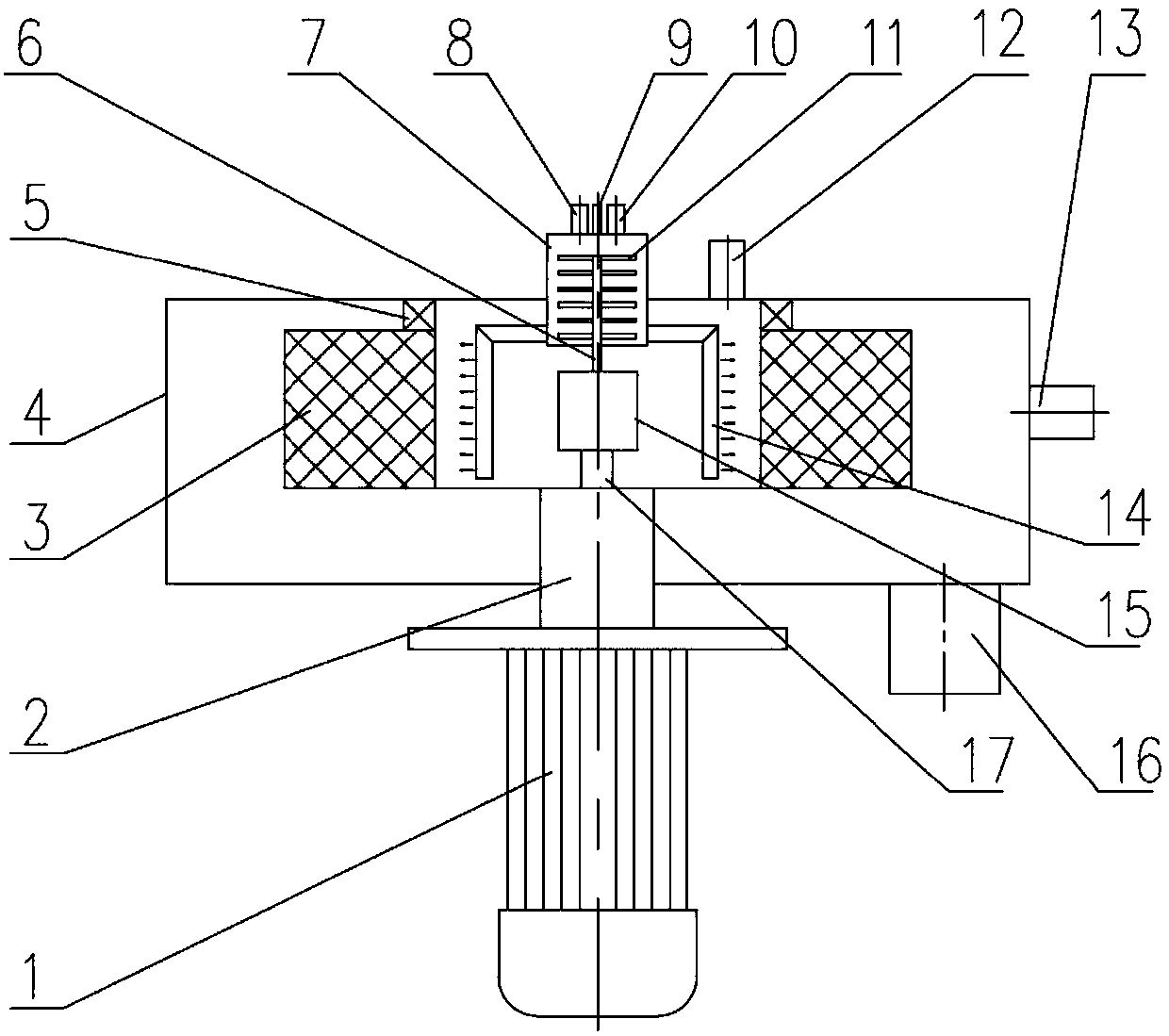

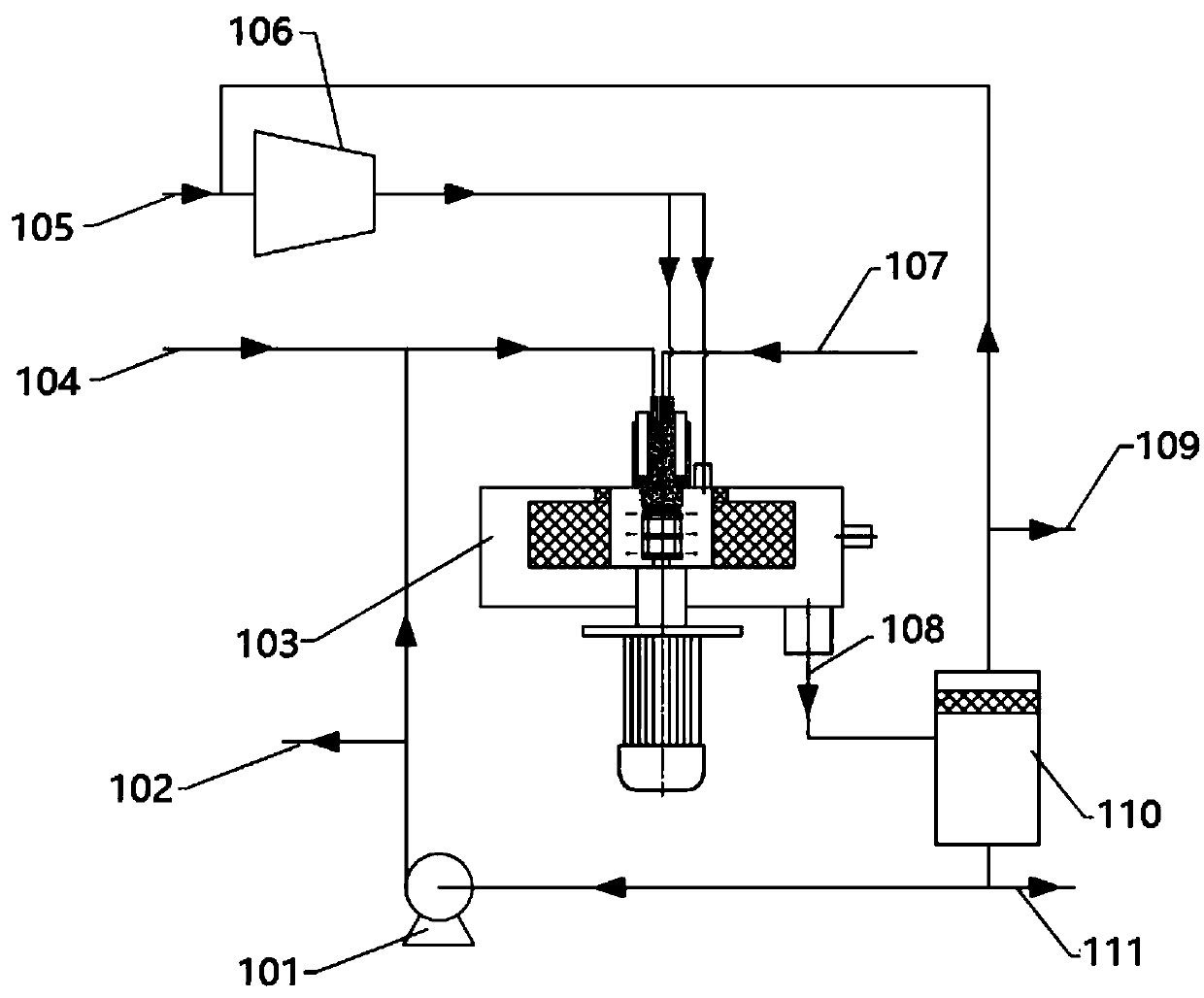

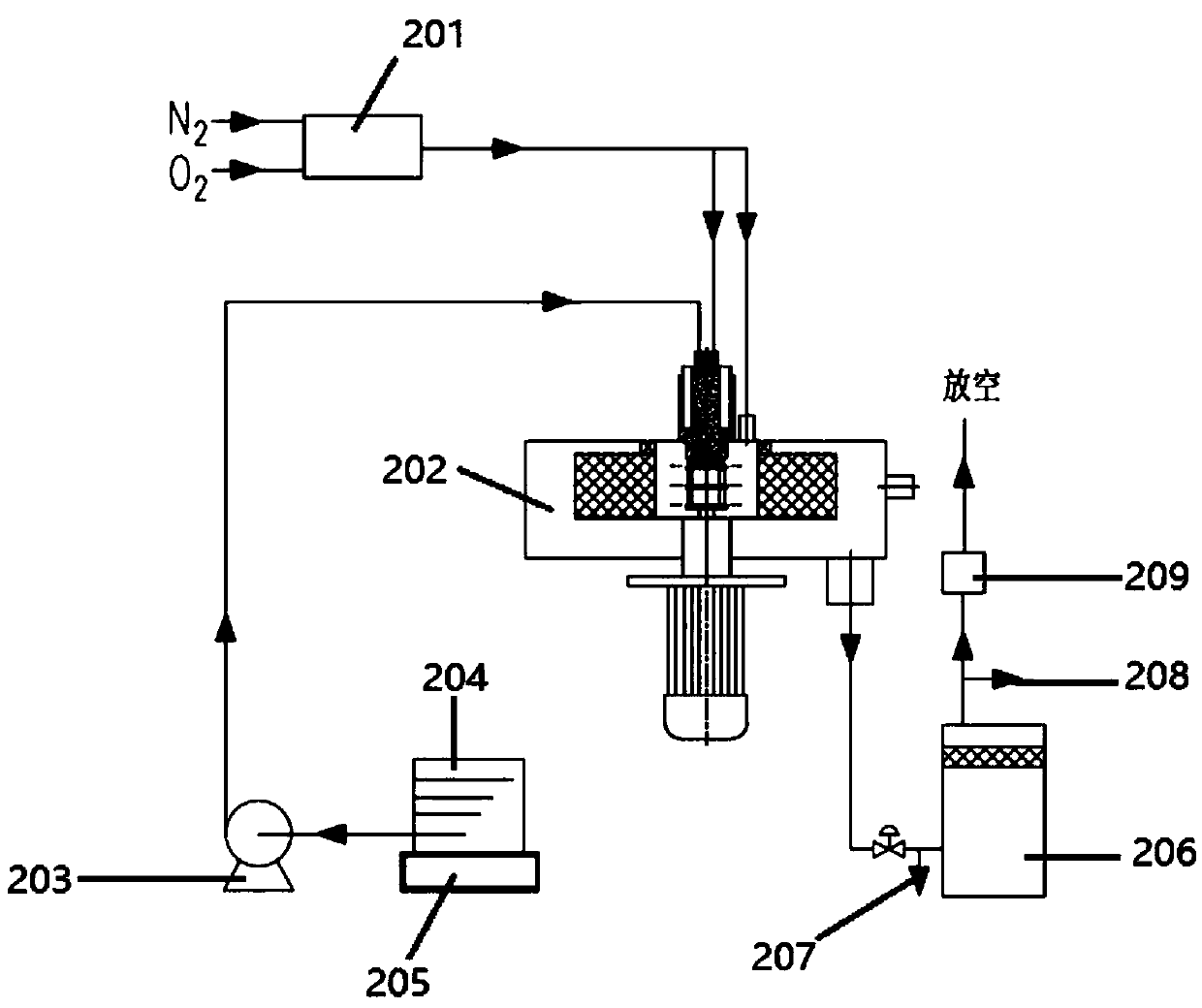

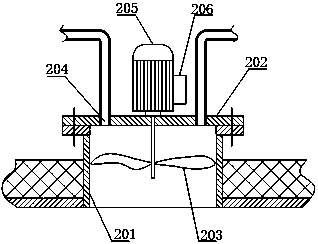

Hyper-gravity device for enhancing reaction by gas-liquid efficient premixing and application method thereof

ActiveCN107684880AImprove mass transfer efficiencyReduce partial pressureOrganic compound preparationTransportation and packagingReaction rateEngineering

The invention discloses a hyper-gravity device for enhancing a reaction by gas-liquid efficient premixing and an application method thereof. The hyper-gravity device comprises a motor, a main shaft, arotor, a shell, a liquid distributor, a secondary shaft, a speed-increasing gear, a speed-increasing gear output shaft and a charging cavity, wherein the main shaft at an output end of the motor passes through the bottom of the shell and extends into the shell; the rotor is fixed on an upper part of the main shaft; the charging cavity is arranged on an upper part of the shell; a lower part of thecharging cavity is connected with the liquid distributor; the main shaft is fixedly connected with the speed-increasing gear through the secondary shaft; the output shaft of the speed-increasing gearpasses through the bottom of the charging cavity and extends into the charging cavity; stirring wings are arranged on a part of the output shaft of the speed-increasing gear in the charging cavity. By adopting the hyper-gravity device, gas is distributed in a liquid phase in a nano-micron size, long gas retention period and high gas-liquid mass transfer efficiency are achieved, and the macro-reaction rate is increased effectively.

Owner:浙江中巨海锐科技有限公司

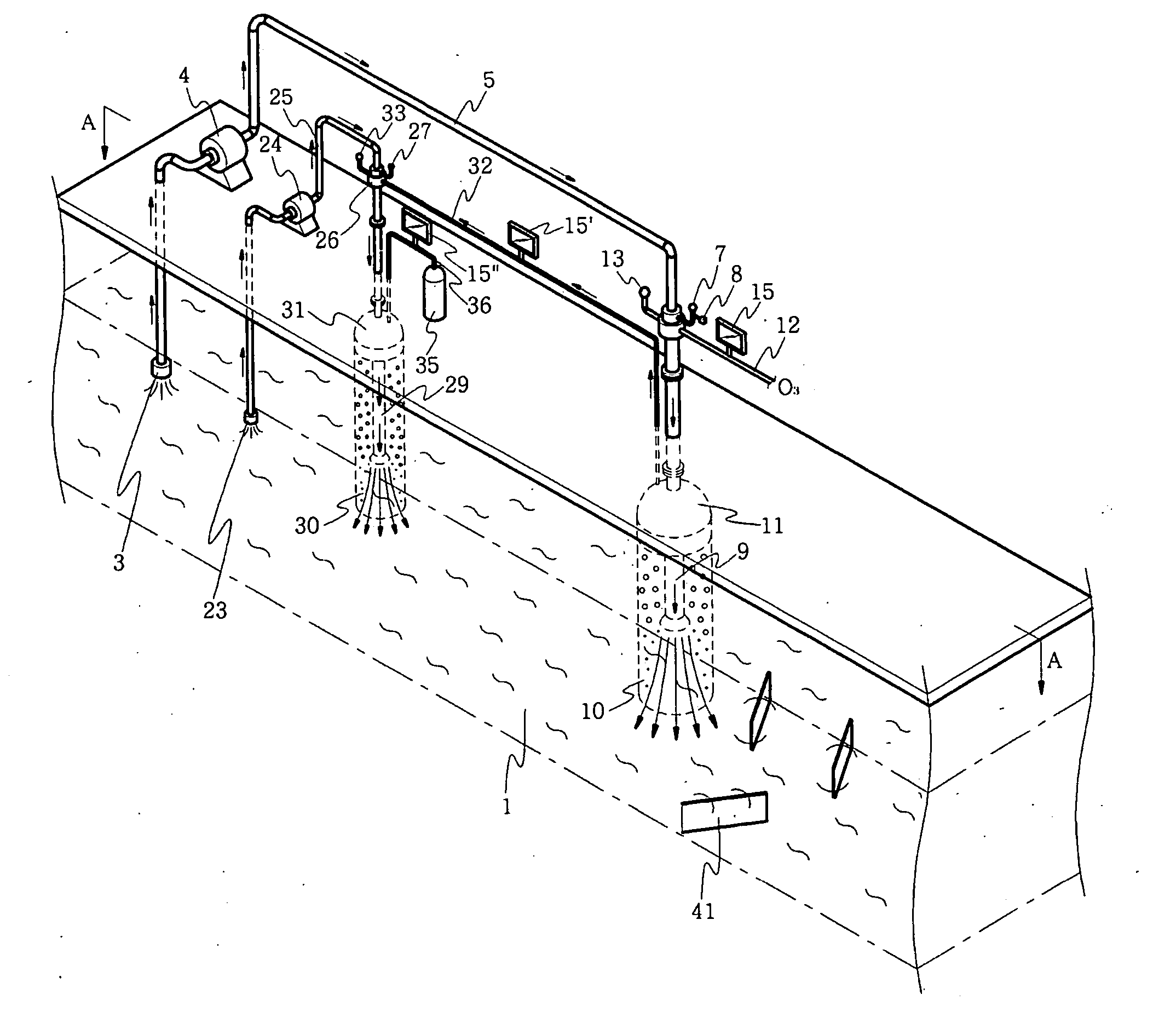

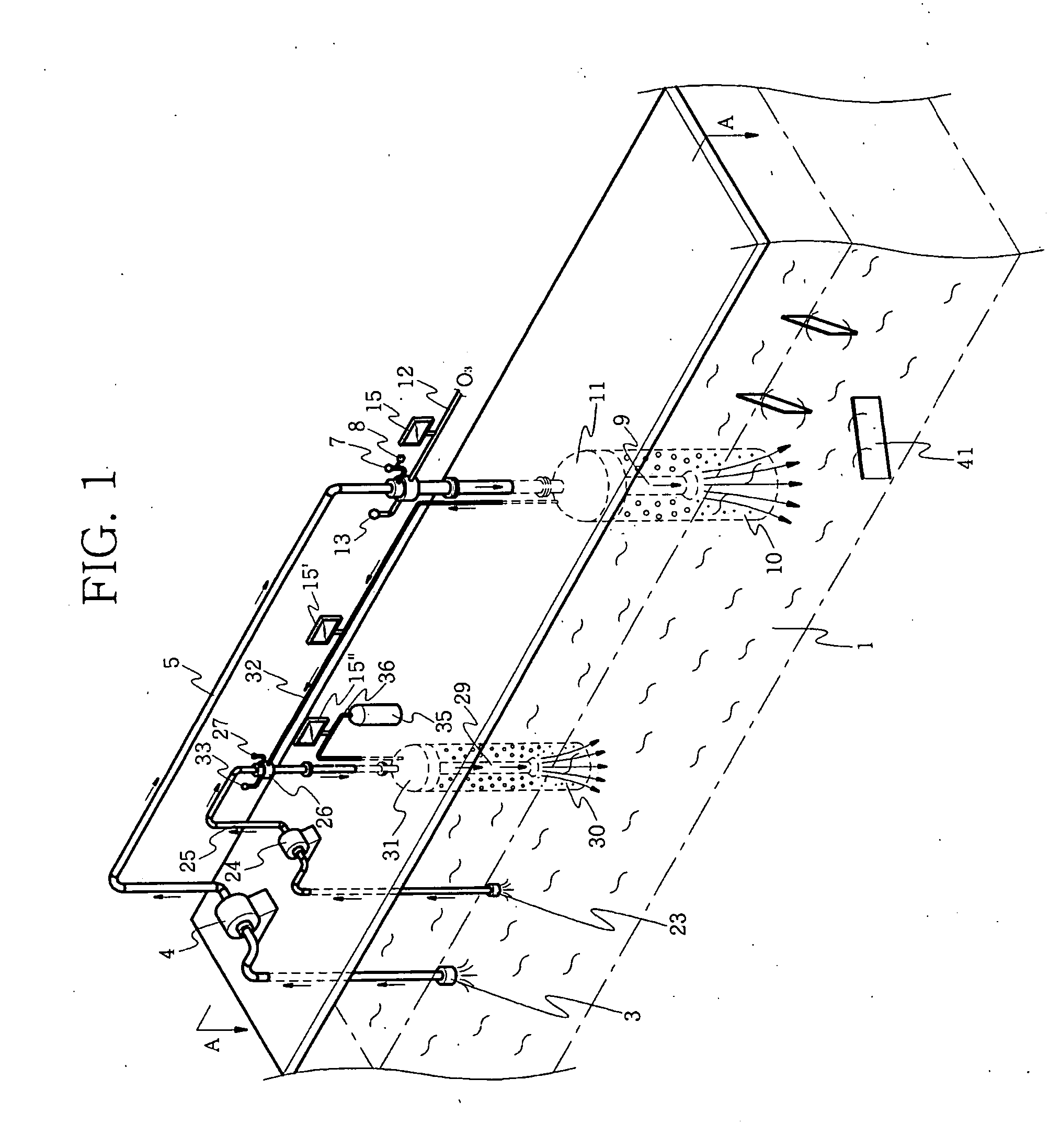

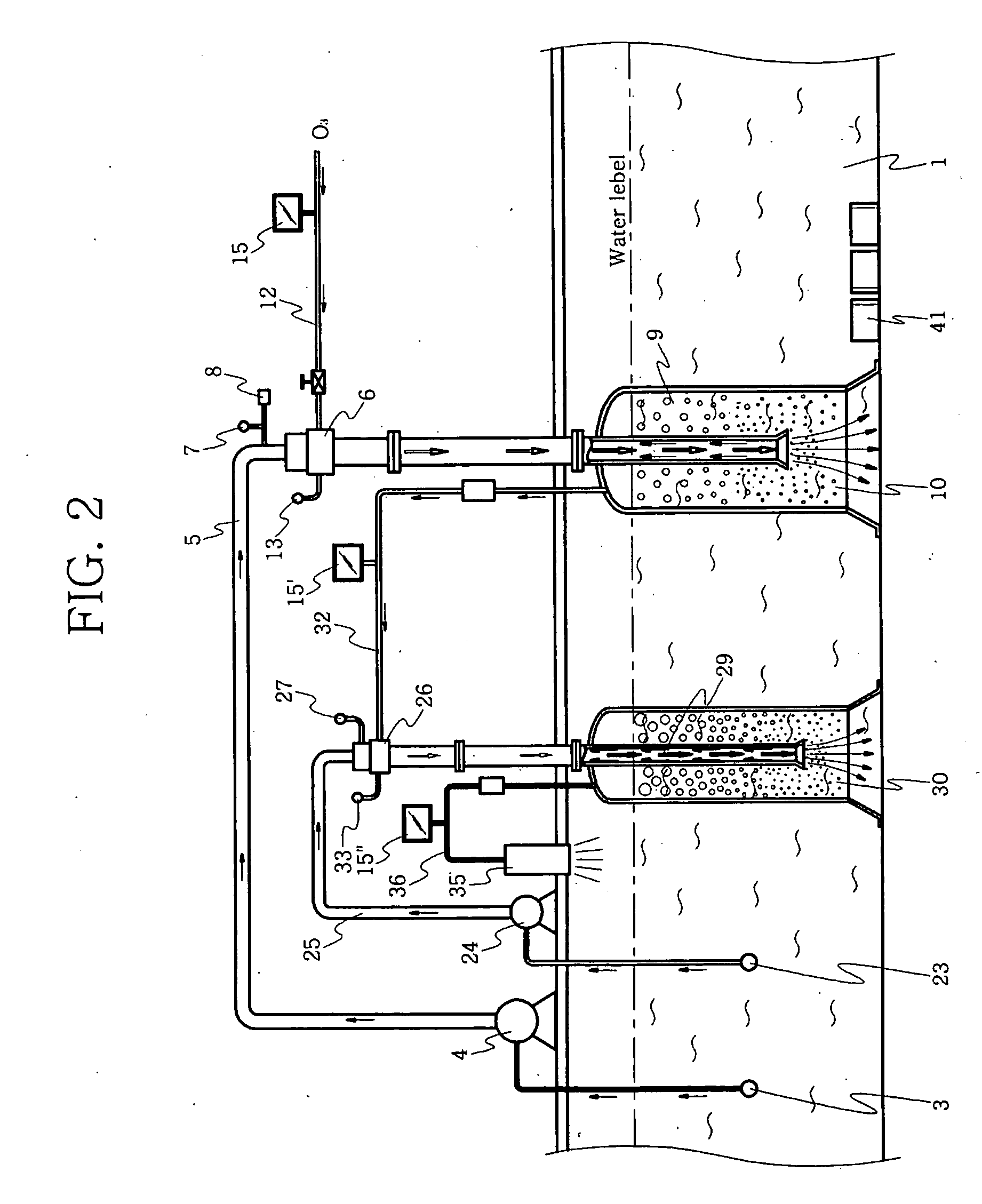

Ozone sterilization method and device for water supply drainage

InactiveUS20050218085A1Improve solubilityCost problemSpecial service provision for substationFlow mixersWater blockProduct gas

The present invention relates to an ozone sterilization device and method for sterilizing source water of water supply drainage using ozone generated in an ozone generator. The method includes a first process in which source water inputted to a first water block is sucked and discharged; a second process in which source water is sprayed onto ozone through the first ejector, wherein the above routine is repeatedly performed for thereby generating ozone water; a third process in which the ozone water which source water and ozone is mixed is discharged to the discharge unit separated by the first water block, and the ozone not dissolved is collected by a first gas staying tank; and a fourth process in which the source water of the inlet unit is sucked and passed through a second ejector, and the ozone from the first gas staying tank is sucked by a second vacuum pipe.

Owner:SHIN YOUNG CHUL +2

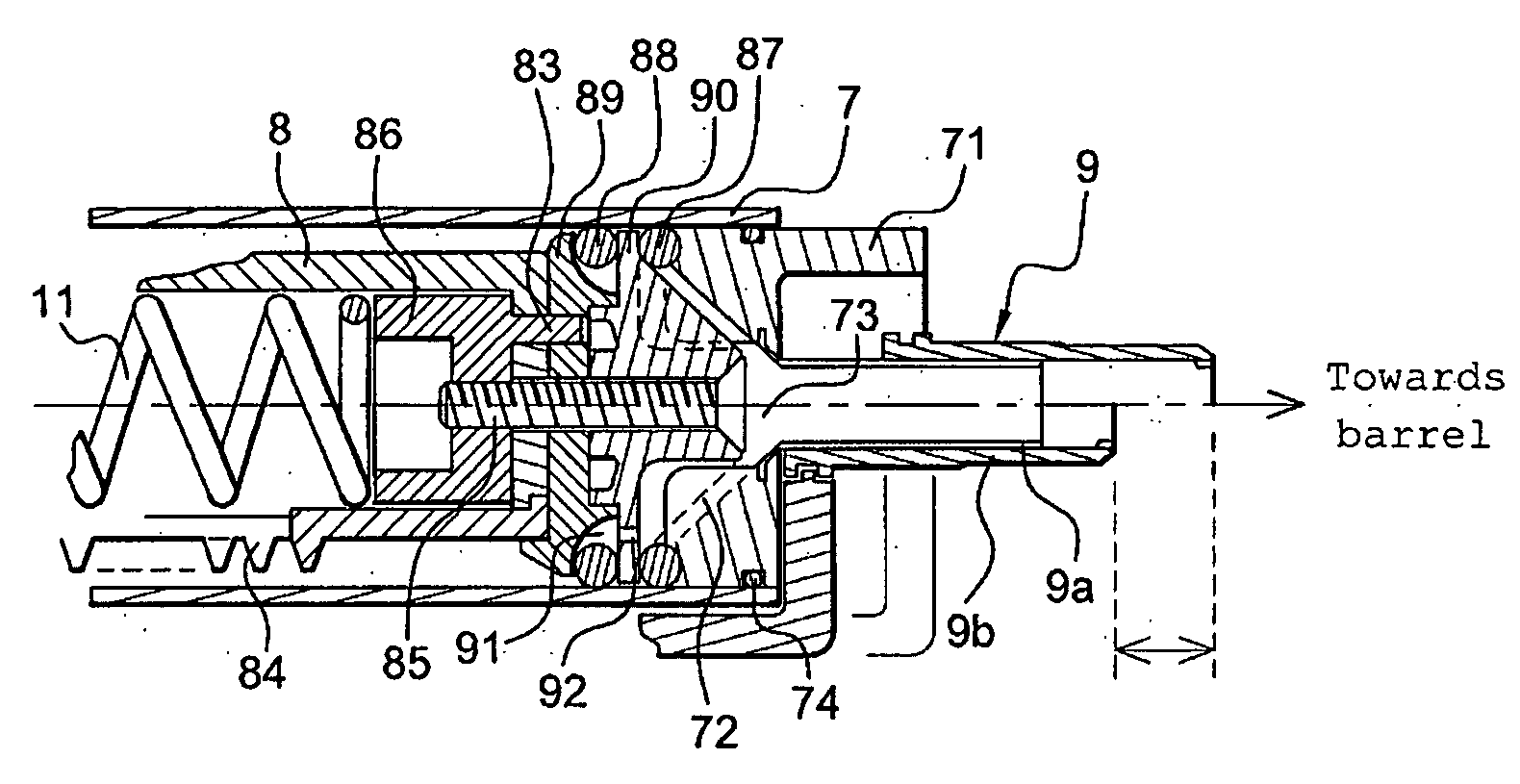

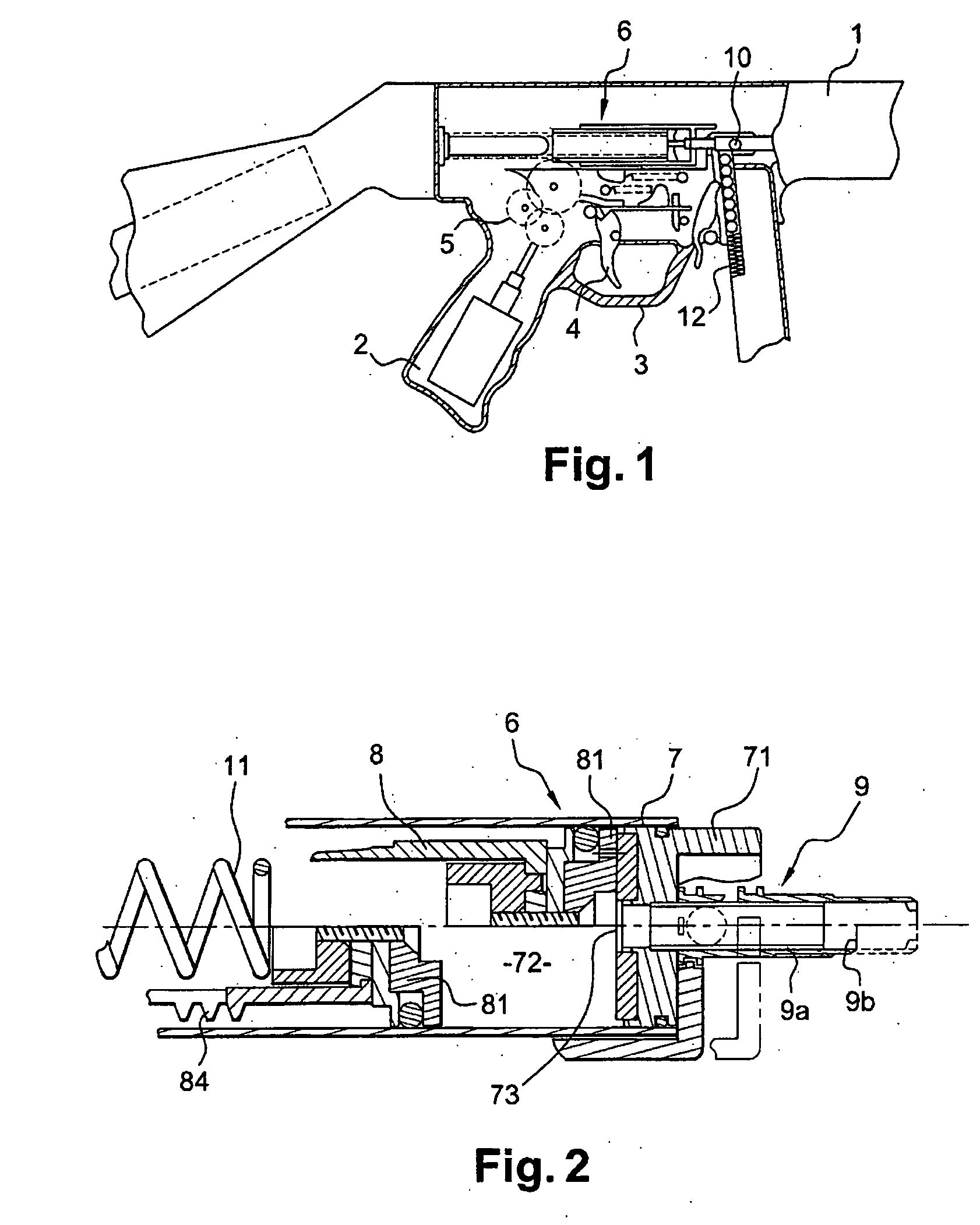

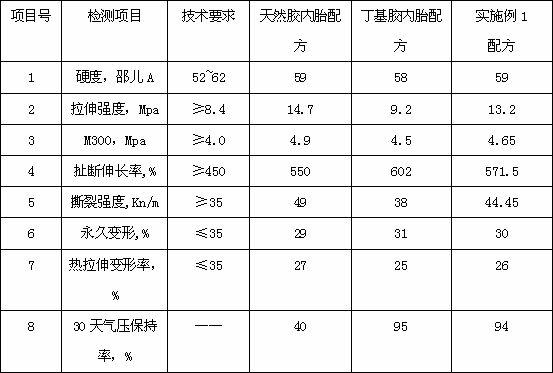

Compressed gas pump for replica weapon

InactiveUS20050183709A1Reduce resistancePositive displacement pump componentsCompressed gas gunsCylinder headAir pump

The invention concerns a pump for compressed gas for a replica weapon for the projection of balls, comprising: A cylinder (7) forming a gas retention compartment (72) and provided with a cylinder head (71) forming a lateral wall of the said retention compartment, said cylinder head comprising a central orifice (73) A gas ejection nozzle (9) having a first end opening into the retention compartment (72) and a second end opening into a barrel (1) of the replica weapon, and A piston (8) provided with a piston head (81) which is movable in the retention compartment and suitable for compressing the gas in the said compartment, in which, on the one hand, the piston head is conical in shape and, on the other, the cylinder head has the shape of a funnel, complementary to the conical shape of the piston head.

Owner:CYBERGUN

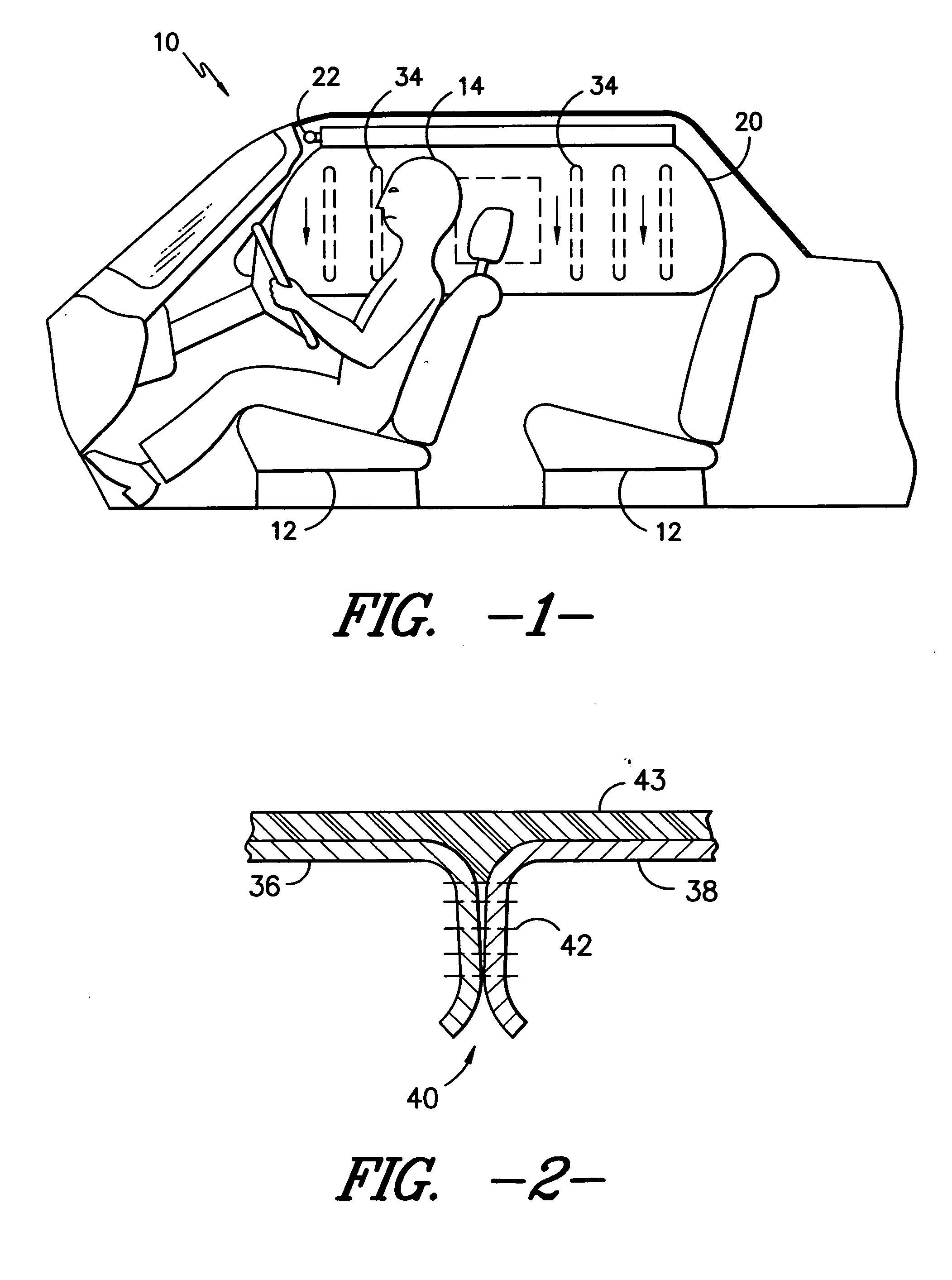

New silicone-based low permeability airbag fabric coatings

InactiveUS20040058601A1Highly cost-effectiveEasy to handlePreformed elementsThin material handlingHigh pressureGas retention

A new adhesive coating composition, particularly for use on airbag fabrics, which is composed of a silicone polymer and an appreciable level of a copolymer of ethylene and a polar monomer, is provided. This coating provides excellent adhesive properties to the coated fabric and provides a synergistic effect such that lower gas permeability upon inflation may be obtained with this coating than might be achieved with the silicone polymer alone. Additionally, such a coating allows maximization of the adhesion characteristics on one-piece woven airbag fabric such that blistering upon high-pressure inflation can be reduced, while retaining a high degree of inflation gas retention. Fabric treated with this material in the manner described herein permits reduction in the cost of the coating itself (by reducing the use of expensive silicone polymers). Airbag fabrics and cushions, as well as methods of making and using such a novel airbag coating material are also encompassed within this invention.

Owner:MILLIKEN & CO

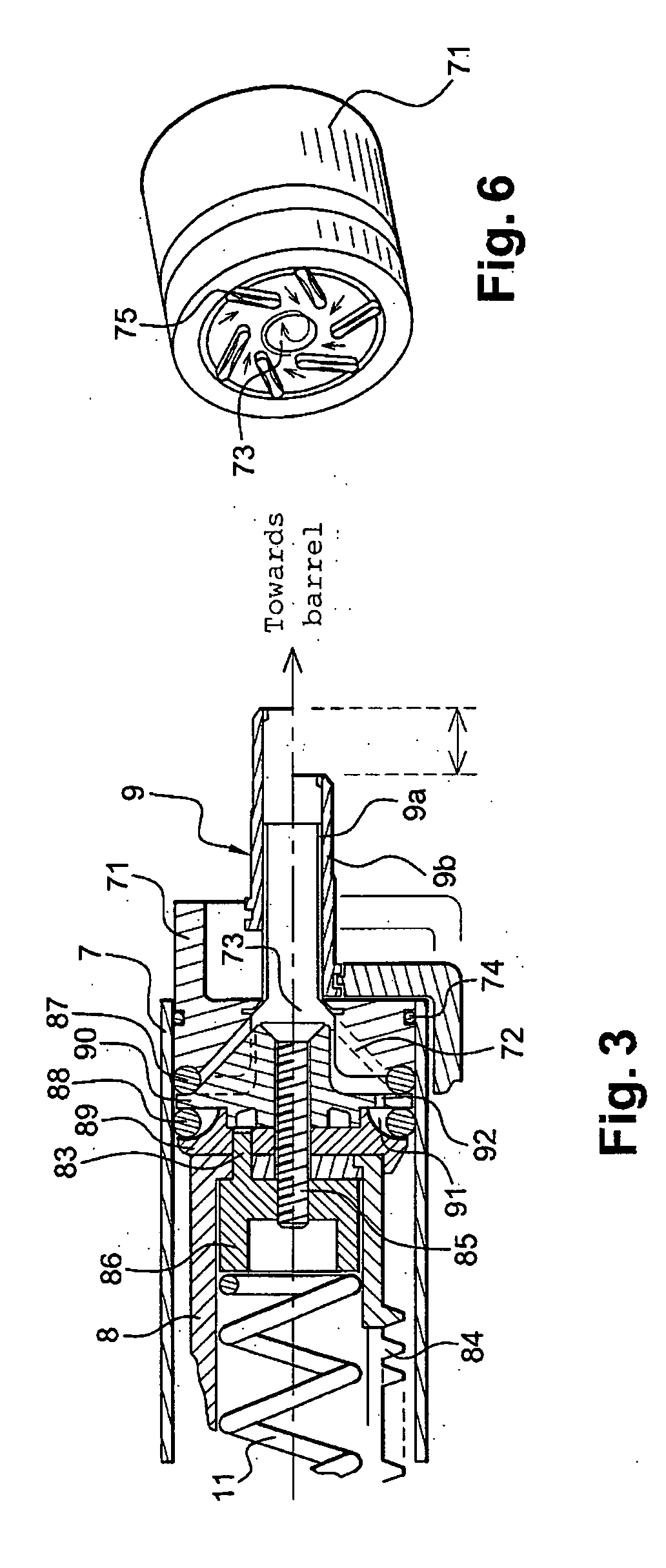

Tire inner tube rubber composition

The invention relates to the technical field of rubber, particularly a tire inner tube rubber composition which comprises the following components in parts by weight: 35-45 parts of natural rubber, 50-70 parts of outer tube regenerated rubber, 50-70 parts of brominated butyl regenerated rubber, 10-20 parts of carbon black N660, 10-20 parts of StronWiNTC, 1-2 parts of aromatic oil, 2-5 parts of stearic acid, 1-2 parts of anti-aging agent 4020, 1-2 parts of anti-aging agent RD, 1-2 parts of protective wax OK5194, 3-4 parts of rubber tackifying resin A-90, 5 parts of zinc oxide, 0.3-0.5 part of accelerator DM, 0.5-1.0 part of accelerator CZ and 2-3 parts of sulfur. The inner tube produced from the composition provided by the invention has the advantages of favorable gas retention performance, favorable aging resistance, high load carrying behavior, favorable processability and low cost.

Owner:TIUMSUN RUBBER TIRE WEIHAI

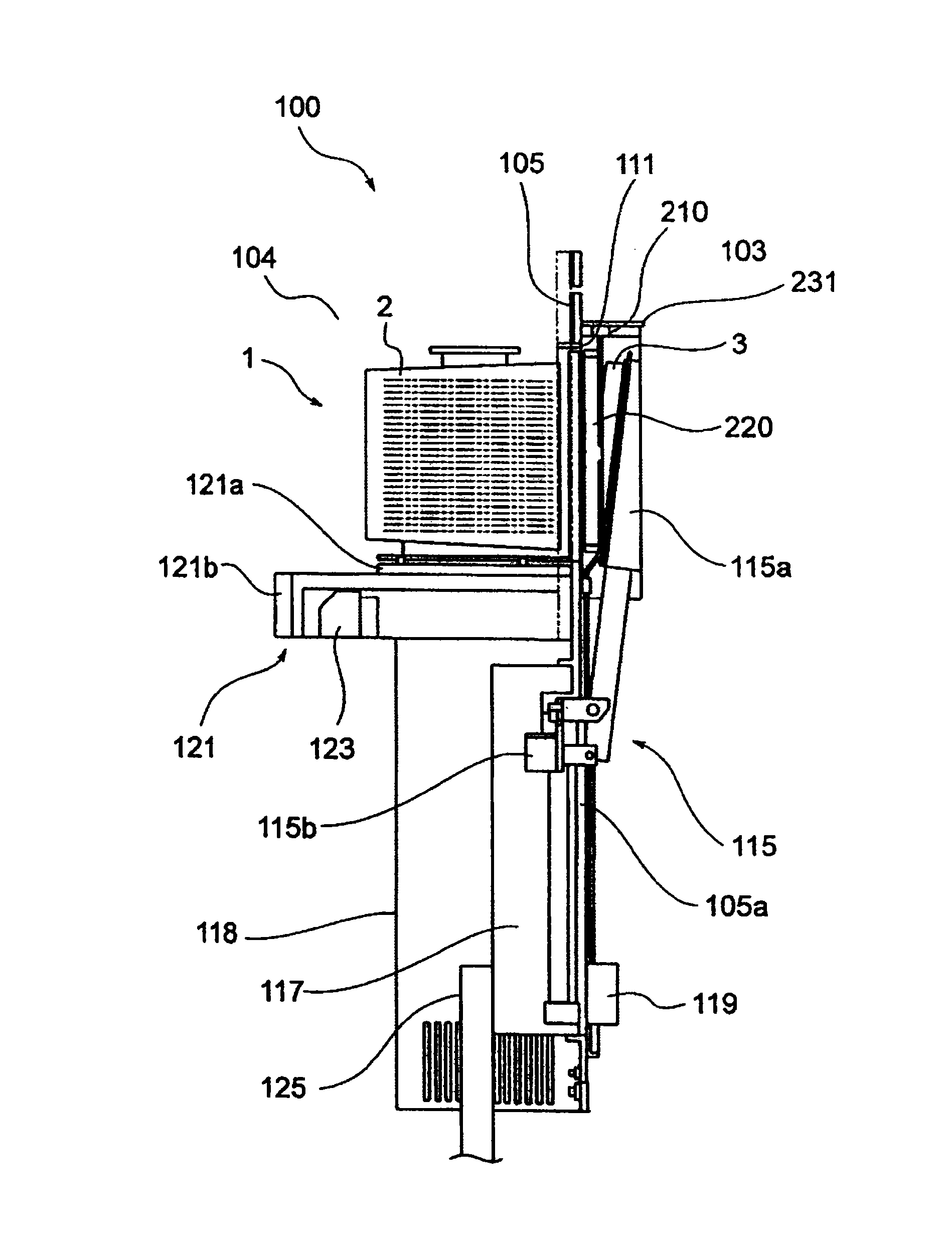

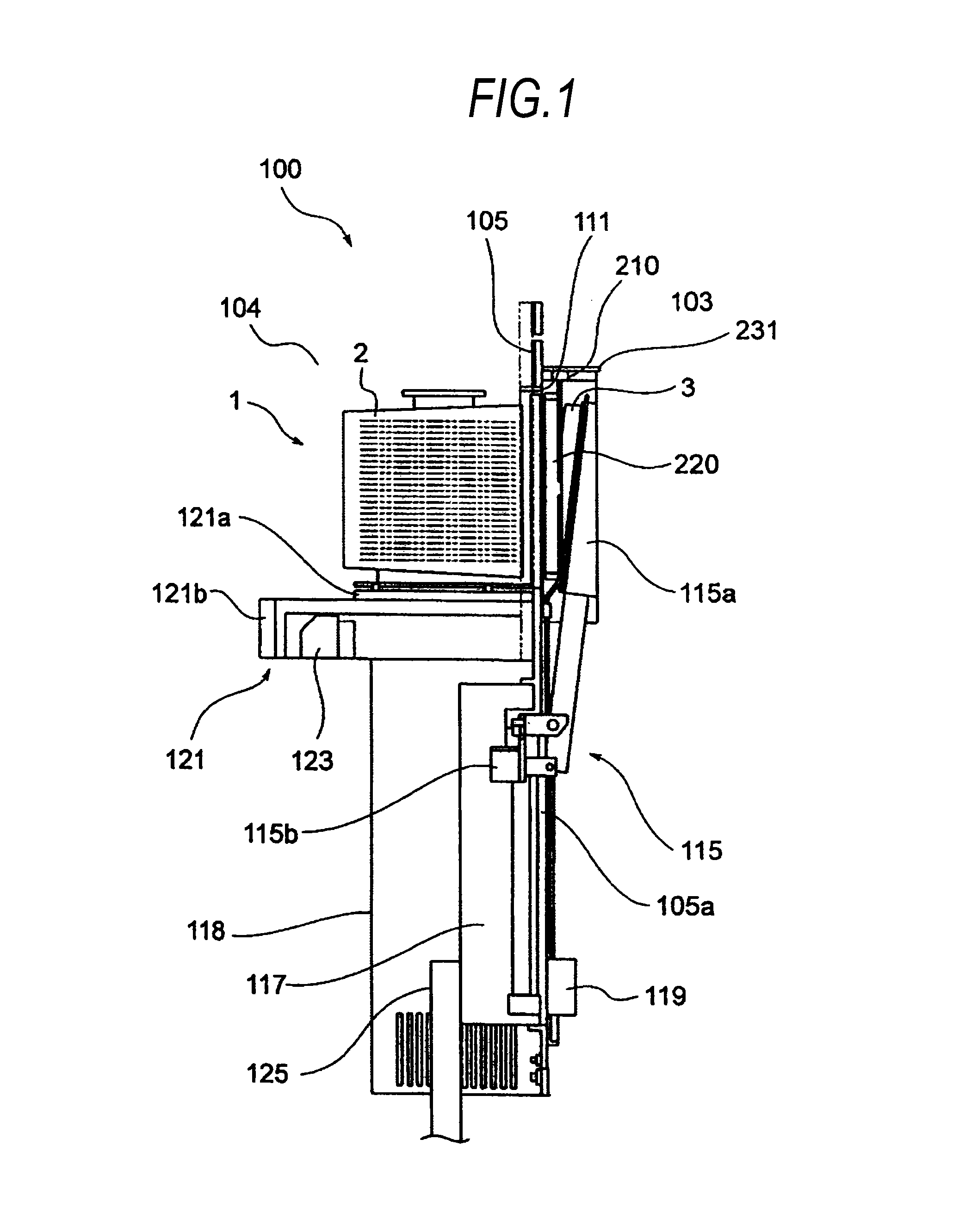

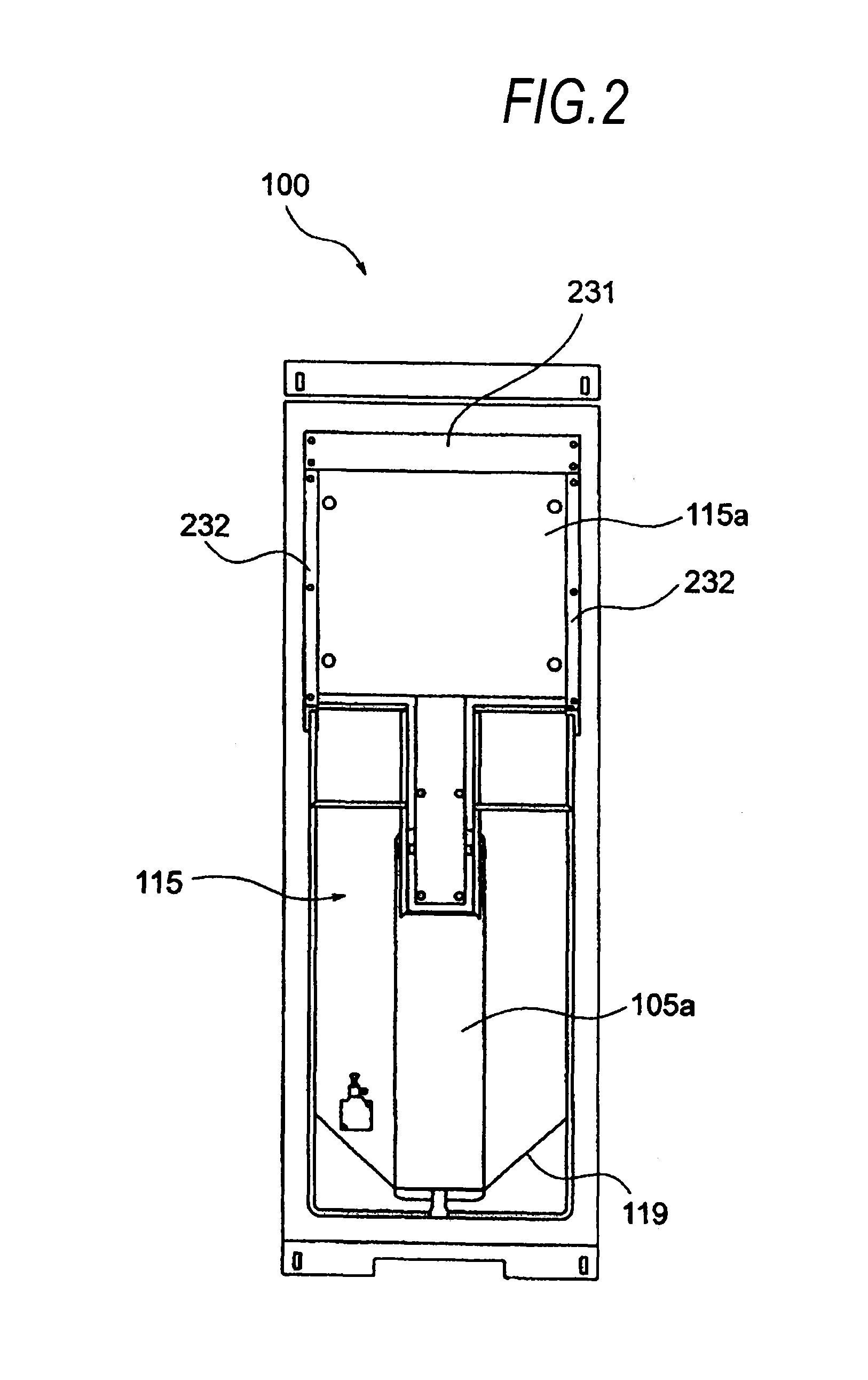

Load port apparatus

ActiveUS9153468B2Eliminate spaceEliminate riskSemiconductor/solid-state device manufacturingPackaging under special atmospheric conditionsInterior spaceEngineering

To prevent an inert gas from stagnating in an internal space of a mount base of a load port apparatus, the load port apparatus includes: an outside air supply device for introducing an air from an external space, in which an operator works, into the internal space of the mount base; a casing surrounding a space in which a drive mechanism for a door is arranged; and a duct through which a gas inside the internal space of the casing is dischargeable.

Owner:TDK CORPARATION

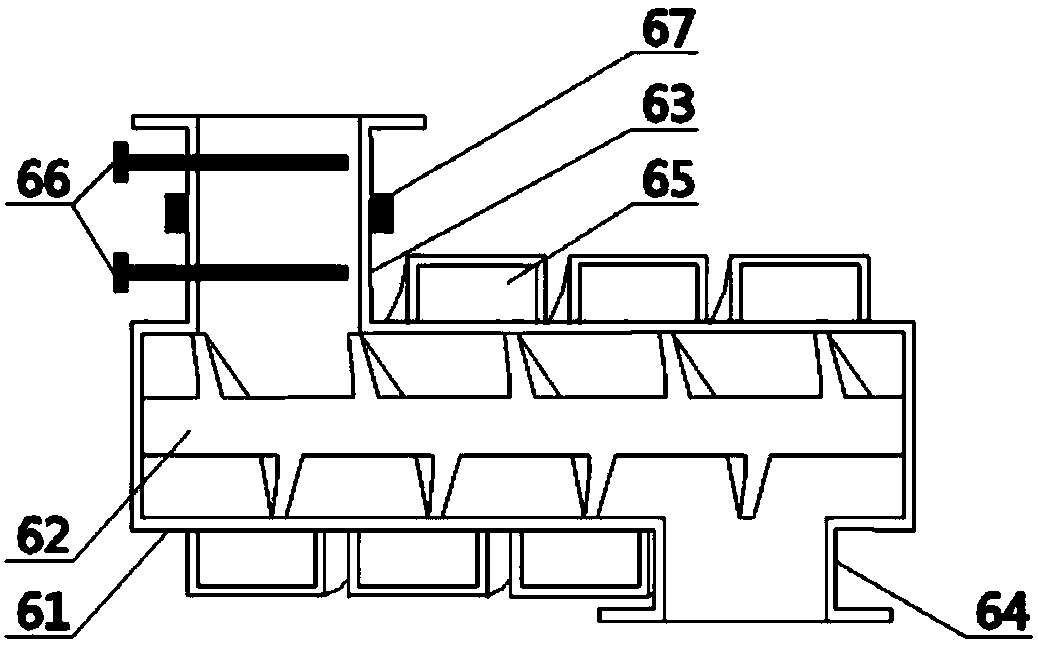

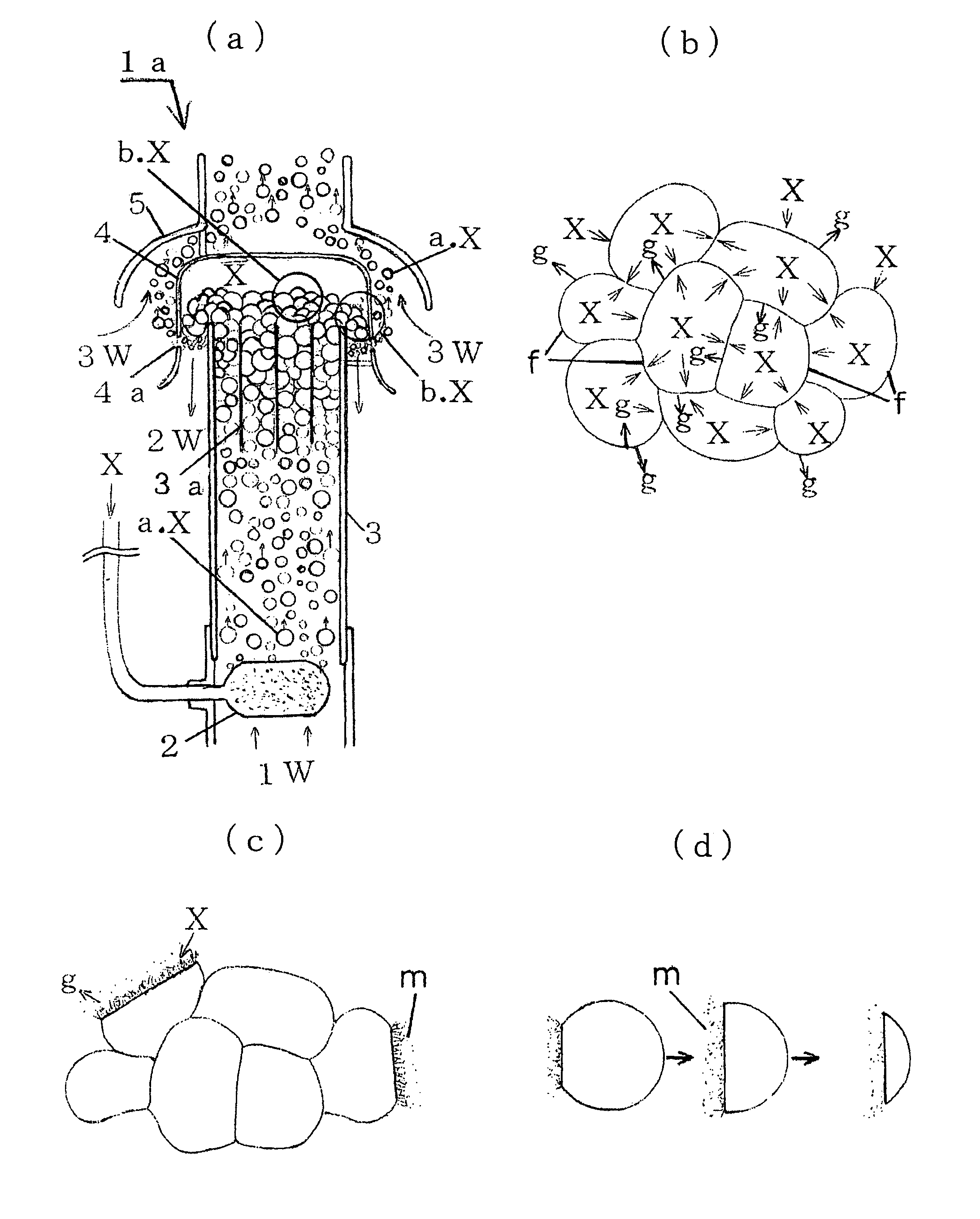

Aeration unit, aeration apparatus equipped therewith and method of aeration

ActiveUS8292271B2Improve energy savingEasy to useTreatment using aerobic processesFlow mixersSoap bubbleWater quality

An aeration unit, an aeration apparatus and a method of aeration are provided that can quickly realize water quality with gas dissolution balance appropriate for living creatures in water, and that can be utilized for treating polluted water at sewage treatment facilities and used in a gas-liquid contact step at chemical plants or others. A multiple stage aeration apparatus constituted with an air diffuser for producing bubbles in water, a liquid foam generating channel part for changing bubbles in water into liquid foam bodies (soap-bubble-like liquid foam aggregate), a gas retention chamber having a space capable of retaining gas in water and a bubble accumulating part for collecting bubbles newly released from below the gas retention chamber and feeding the bubbles to the liquid foam generating channel part connected to the upper part thereof is disclosed.

Owner:MA JUN +2

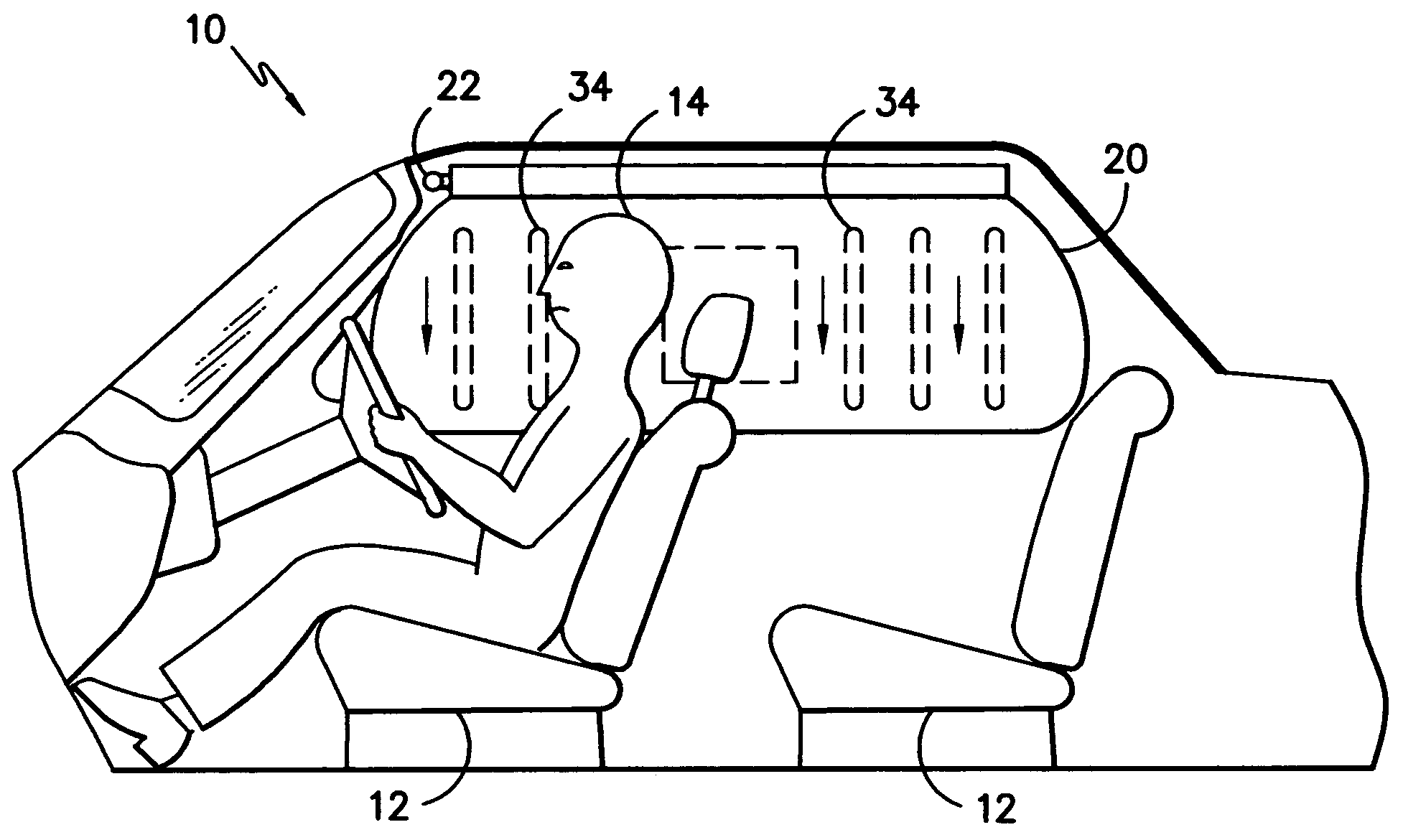

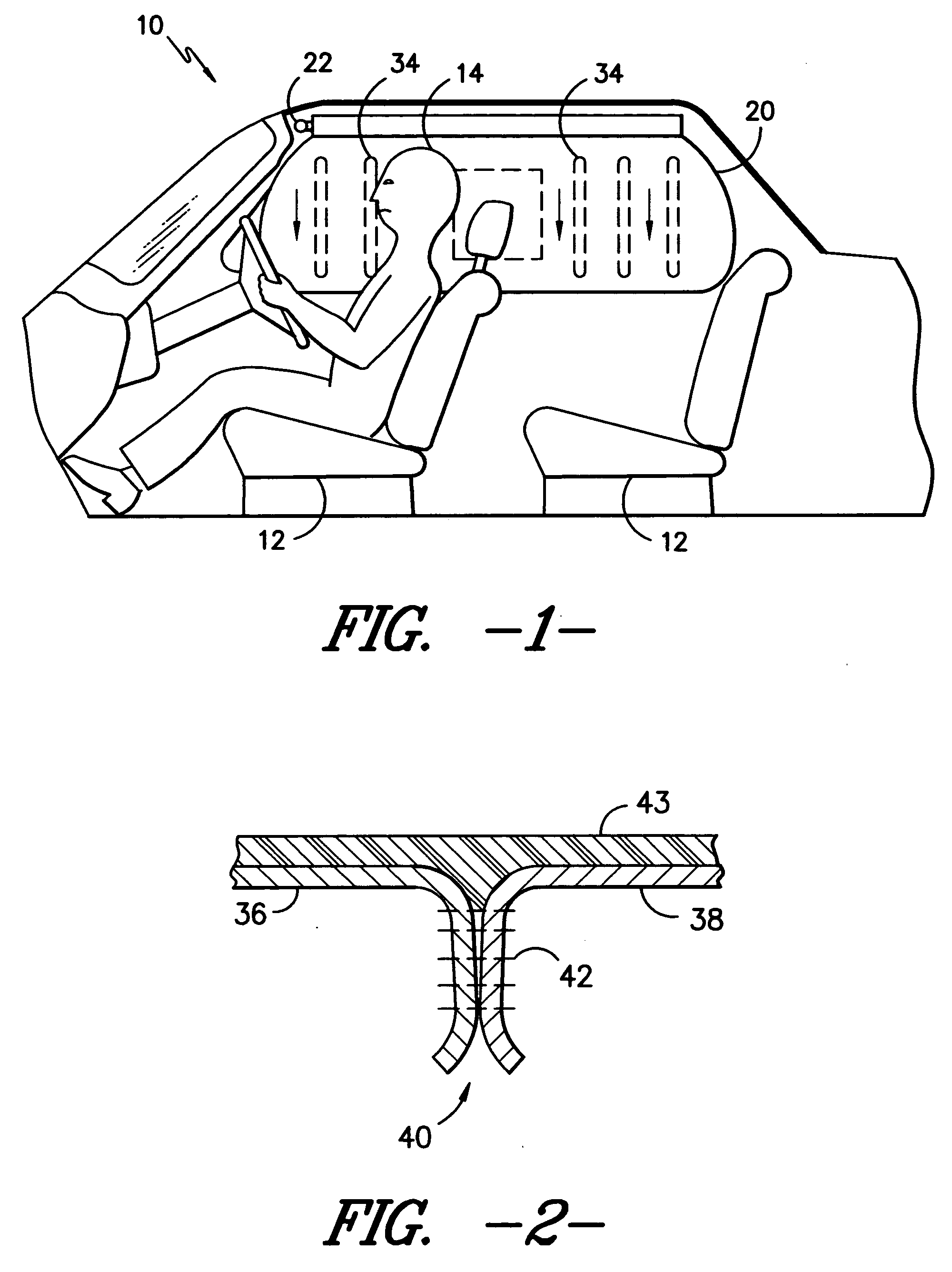

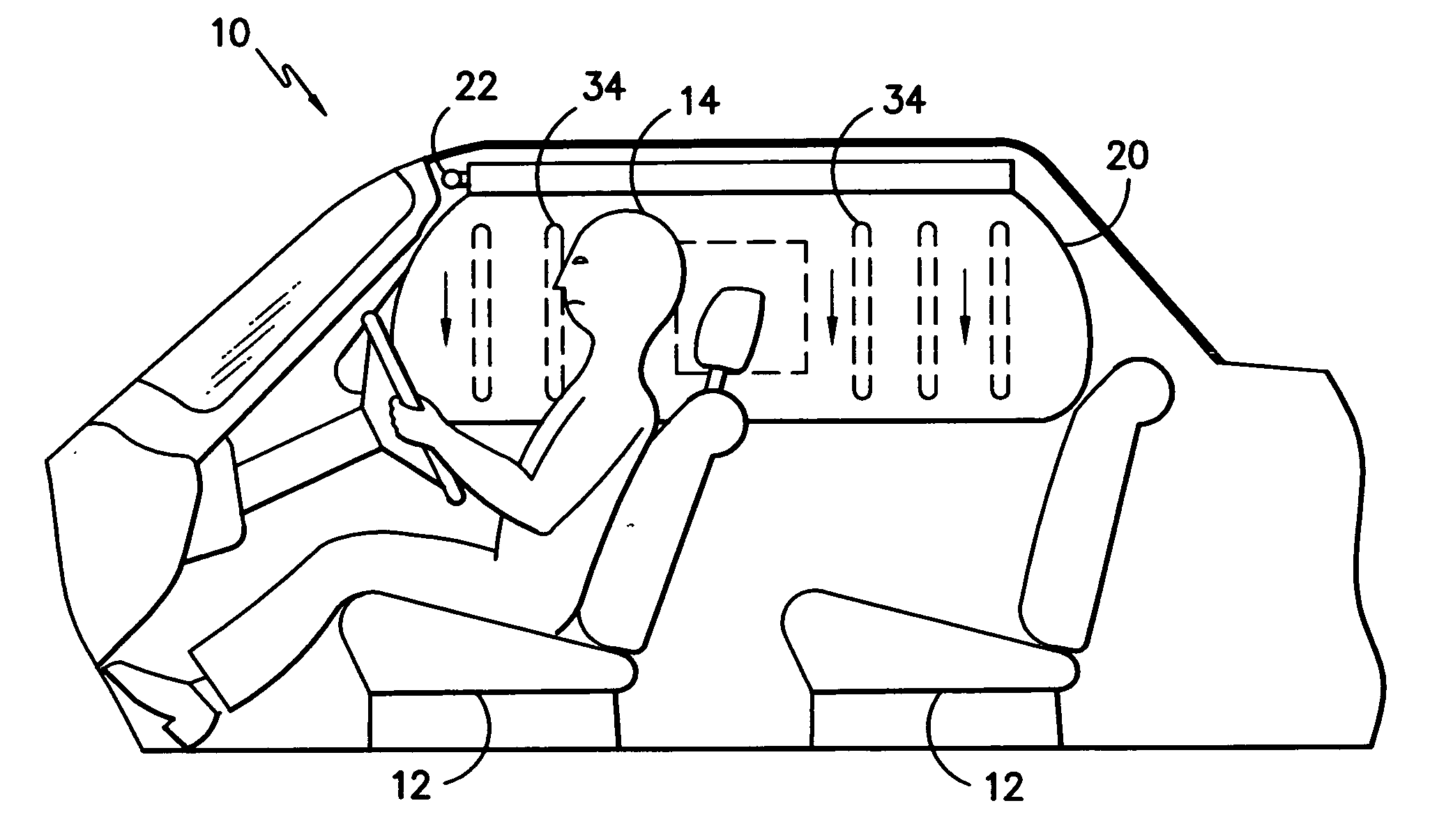

Side curtain air bag with polyurethane dispersion based coating

InactiveUS20080007029A1Reduction tendencyElectric discharge heatingPedestrian/occupant safety arrangementPolyurethane dispersionTime segment

A side curtain air bag treated with a film forming polyurethane coating that reduces the propensity for seam combing while simultaneously blocking permeability outboard of the seams to a sufficient degree to provide gas retention over an extended period of time following pressurization.

Owner:MILLIKEN & CO

Side curtain air bag with polyurethane dispersion based coating

InactiveUS20090297723A1Reduction tendencyPedestrian/occupant safety arrangementPretreated surfacesPolyurethane dispersionEngineering

A side curtain air bag treated with a film forming polyurethane coating that reduces the propensity for seam combing while simultaneously blocking permeability outboard of the seams to a sufficient degree to provide gas retention over an extended period of time following pressurization.

Owner:KESHAVARAJ RAMESH +1

Life preserver system

An inflatable life preserver, capable of being in an inflated state and an uninflated state, is disclosed. The life preserver includes a structural overshell which defines the size and shape of the life preserver in the inflated state and a gas retention bladder fitted within the overshell. The overshell bears the expansion force of a gas within the bladder in the inflated state. The overshell defines inflatable side portions which are confined to sides of at least a portion of a chest area of a wearer, when the life preserver is in an uninflated state, and, which extend laterally over the chest area of the wearer, when the life preserver is in an inflated state.

Owner:TULMAR SAFETY SYST

Making method of non-wheat bread flour

InactiveCN102614960AFacilitate cross-linkingIncrease elasticityDough treatmentPre-baking dough treatmentCross-linkHoneycomb

The invention provides a making method of a non-wheat bread flour. The method comprises the following steps of: carrying out dipping, grinding, crushing, screening, filter-pressing, crushing, drying and the like on rice products or grains so as to obtain a water milled flour, wherein a complex enzyme preparation is added to the rice products or the grains so that protein cross-linking in the rice and grains is improved, the elasticity and toughness of the protein are enhanced and gas retention properties of rice and grain green embryos are largely enhanced; therefore, a soft and delicious rice and grain bread is produced. The rice and flour bread, which is prepared by the non-wheat bread flour provided by the invention and the complex enzyme preparation used together with the non-wheat bread flour, has the advantages of uniform honeycomb, softness, looseness, good mouth feel and capability of preferably replacing the wheat breads.

Owner:高岚 +1

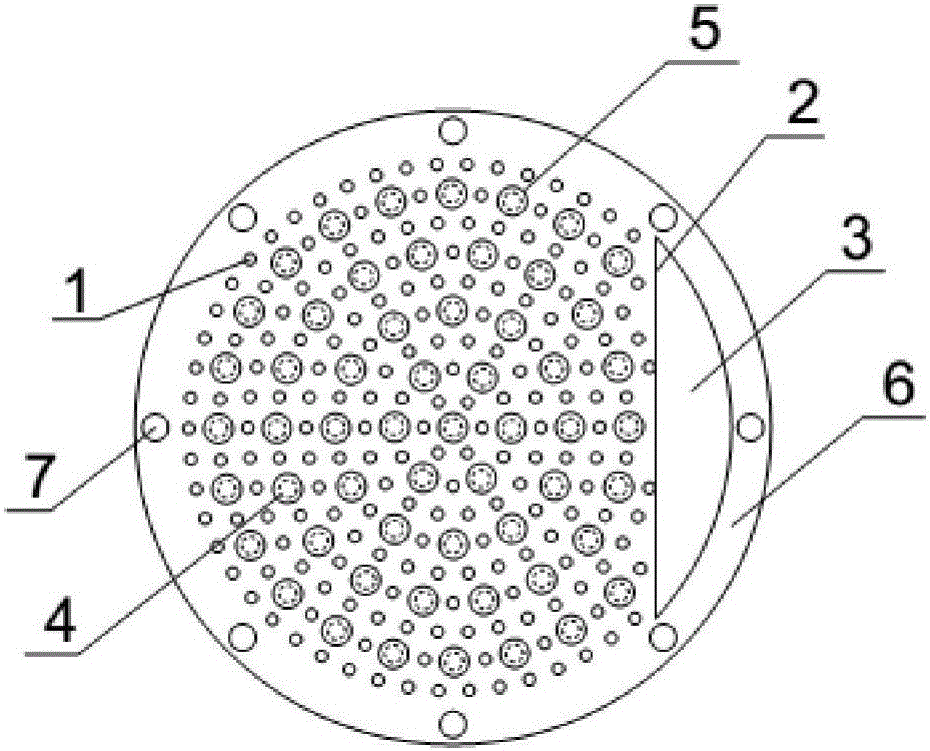

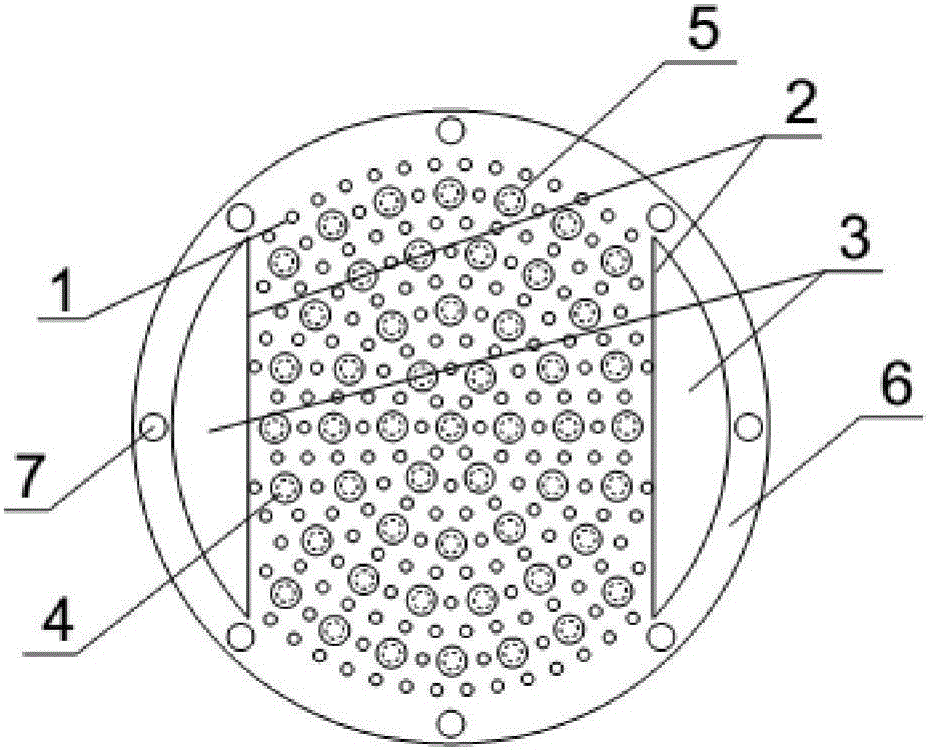

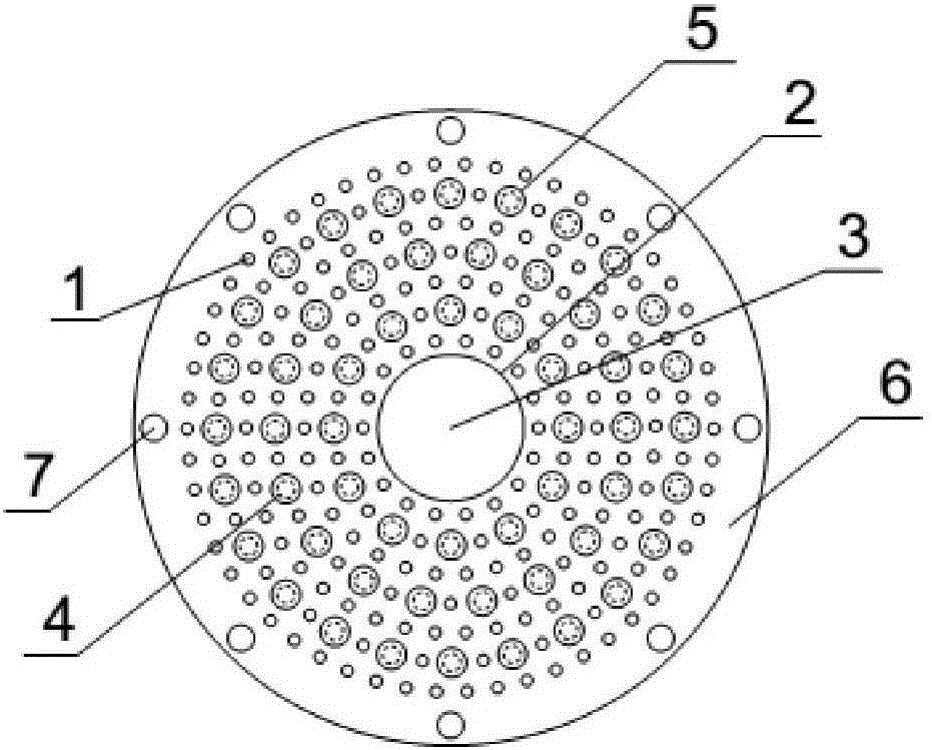

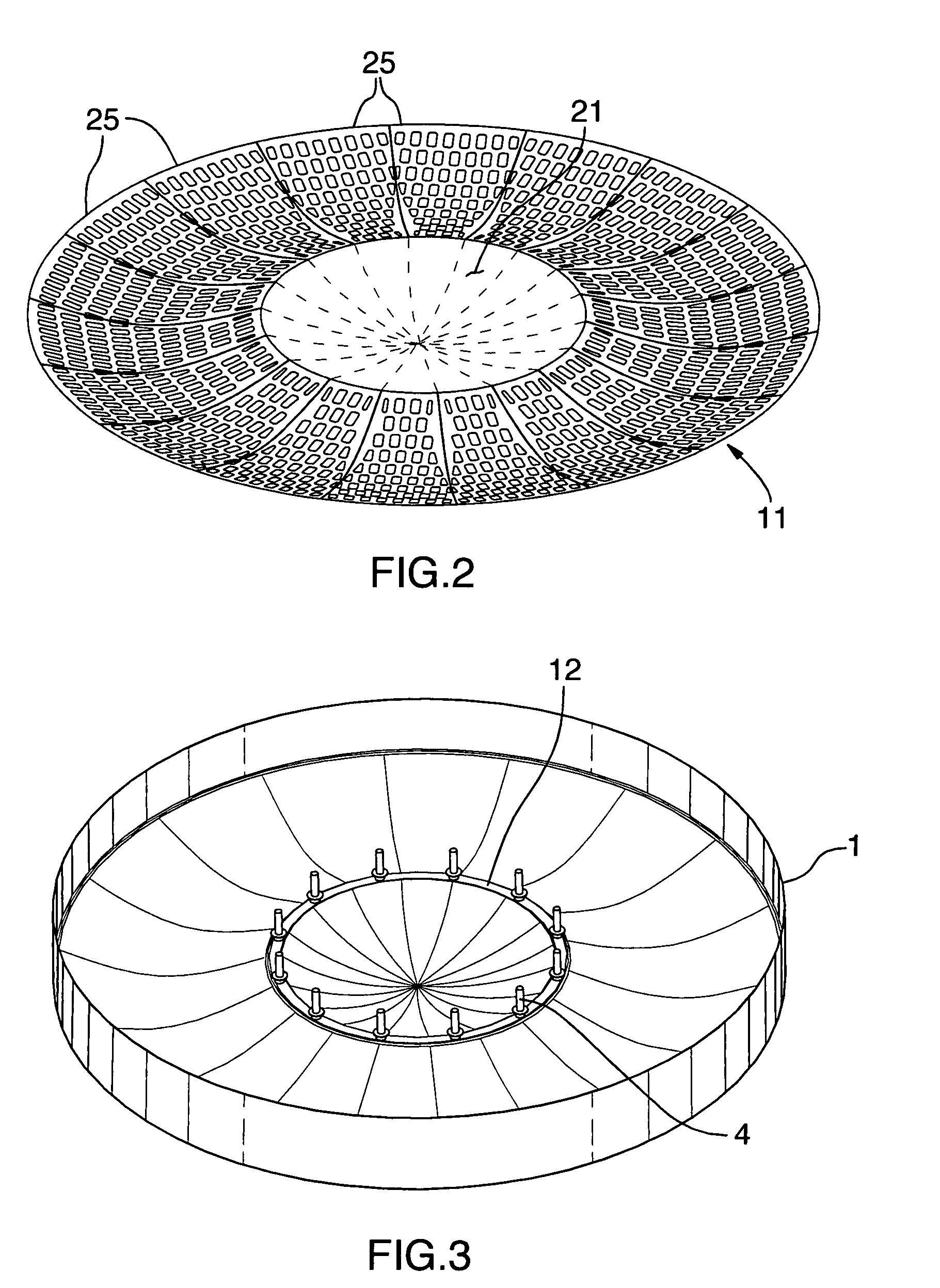

Novel lower-pressure-drop distribution plate applicable to multilayered bed

PendingCN105749819ASmall pressure dropMixed flowGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a novel lower-pressure-drop distribution plate applicable to a multilayered bed. The novel lower-pressure-drop distribution plate comprises sieve holes (1), an overflowing weir (2), a material dropping hole (3), large-hole nozzles (4) and matched air caps (5) thereof, a flange edge (6) and flange holes (7), wherein the distribution plate is an incomplete round plate and a notch is the material dropping hole (3); the overflowing weir (2) vertical to the distribution plate is arranged at the edge of the notch; the large-hole nozzles (4) are uniformly distributed on the plate and are matched with the air caps (5); air cap small holes (18) are uniformly distributed in the air caps (5); the sieve holes (1) are formed among the large-hole nozzles at intervals; and the edge of the distribution plate is the flange edge (6) and is provided with the flange holes (7). With the adoption of the novel lower-pressure-drop distribution plate, the pressure drop of the multilayered bed can be effectively reduced, and gas-liquid flowing is disordered; the contact area between flue gas and a solid purifying agent is large, and a gas flowing path is long, so that enough gas retention time is guaranteed; and the flue gas is in sufficient reaction with the solid purifying agent, and the novel lower-pressure-drop distribution plate has operational flexibility.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Gas Shower Device Having Gas Curtain And Apparatus For Depositing Film Using The Same

ActiveCN103805964AExtended dead timeIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVacuum pressureProcess engineering

A gas shower device having gas curtain comprises a first gas shower unit for injecting a reaction gas, thereby forming a reaction gas region, and a second gas shower unit. The second gas shower unit arranged around a periphery of the first gas shower unit comprises a buffer gas chamber for providing a buffer gas, and a curtain distribution plate. The curtain distribution plate further comprises a plurality through holes for injecting the buffer gas, thereby forming a gas curtain around a periphery of the reaction gas region. In another embodiment, an apparatus for depositing film is provided by utilizing the gas shower device having gas curtain, wherein the gas curtain prevents the reaction gas in the reaction gas region from being affected directly by a vacuum pressure so that a residence time of reaction gas can be extended thereby increasing the utilization of reaction gas and film-forming efficiency.

Owner:IND TECH RES INST

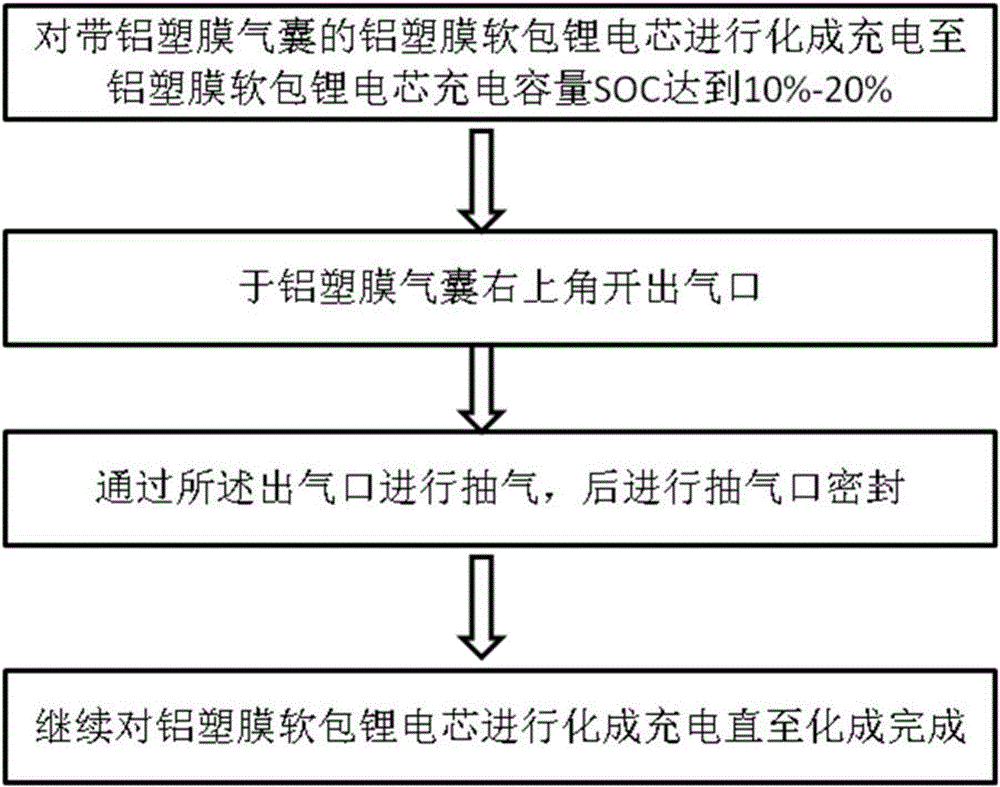

Formation method for reducing gas retention in formation process of flexibly-packaged lithium battery

InactiveCN106450531APhenomena that affect tight fitGuaranteed a tight fitSecondary cells charging/dischargingEngineeringGas retention

The invention discloses a formation method for reducing gas retention in a formation process of a flexibly-packaged lithium battery. The formation method is characterized by comprising the following steps of 1) performing formation charging on an aluminum plastic film flexibly-packaged lithium cell with an aluminum plastic film airbag until the charging capacity SOC of the aluminum plastic film flexibly-packaged lithium cell reaches 10-20%; 2) forming an exhausting opening in the right upper corner of the aluminum plastic film airbag; 3) performing exhausting from the exhausting opening, and then sealing the exhausting opening; and 4) continuing to perform formation charging on the aluminum plastic film flexibly-packaged lithium cell until the formation is completed. By adoption of the formation method for reducing gas retention in the formation process of the flexibly-packaged lithium battery, a phenomenon of influence to tight fitting among a positive plate, the negative plate and a diaphragm caused by retention of a large amount of gas, which is generated by an SEI produced on the surface of a negative plate, and other side reactions in the initial period of formation, in the interior of the cell, can be avoided; and therefore, the tight fitting among the positive plate, the negative plate and the diaphragm in the formation process is ensured.

Owner:GUOXUAN NEW ENERGY SUZHOU CO LTD

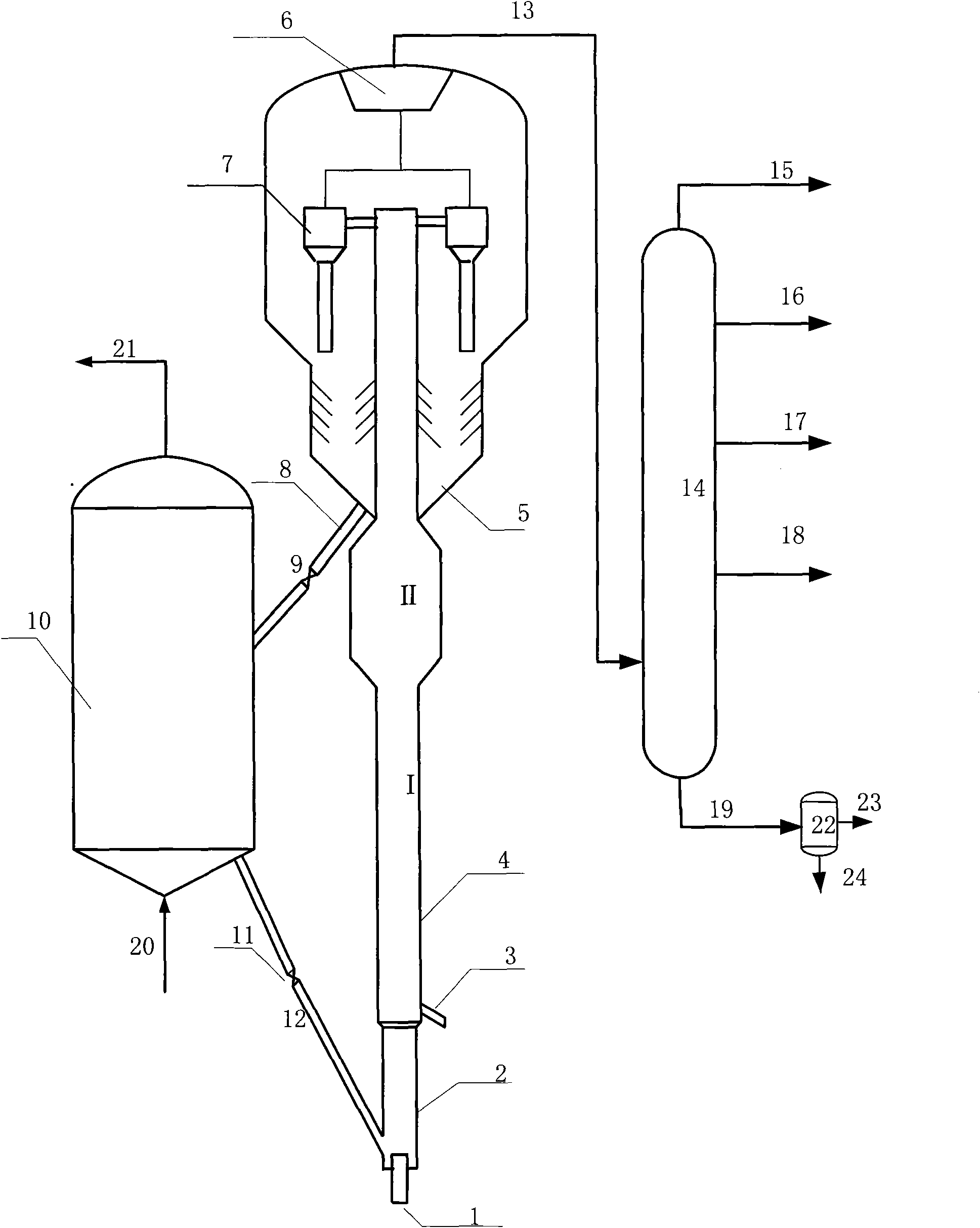

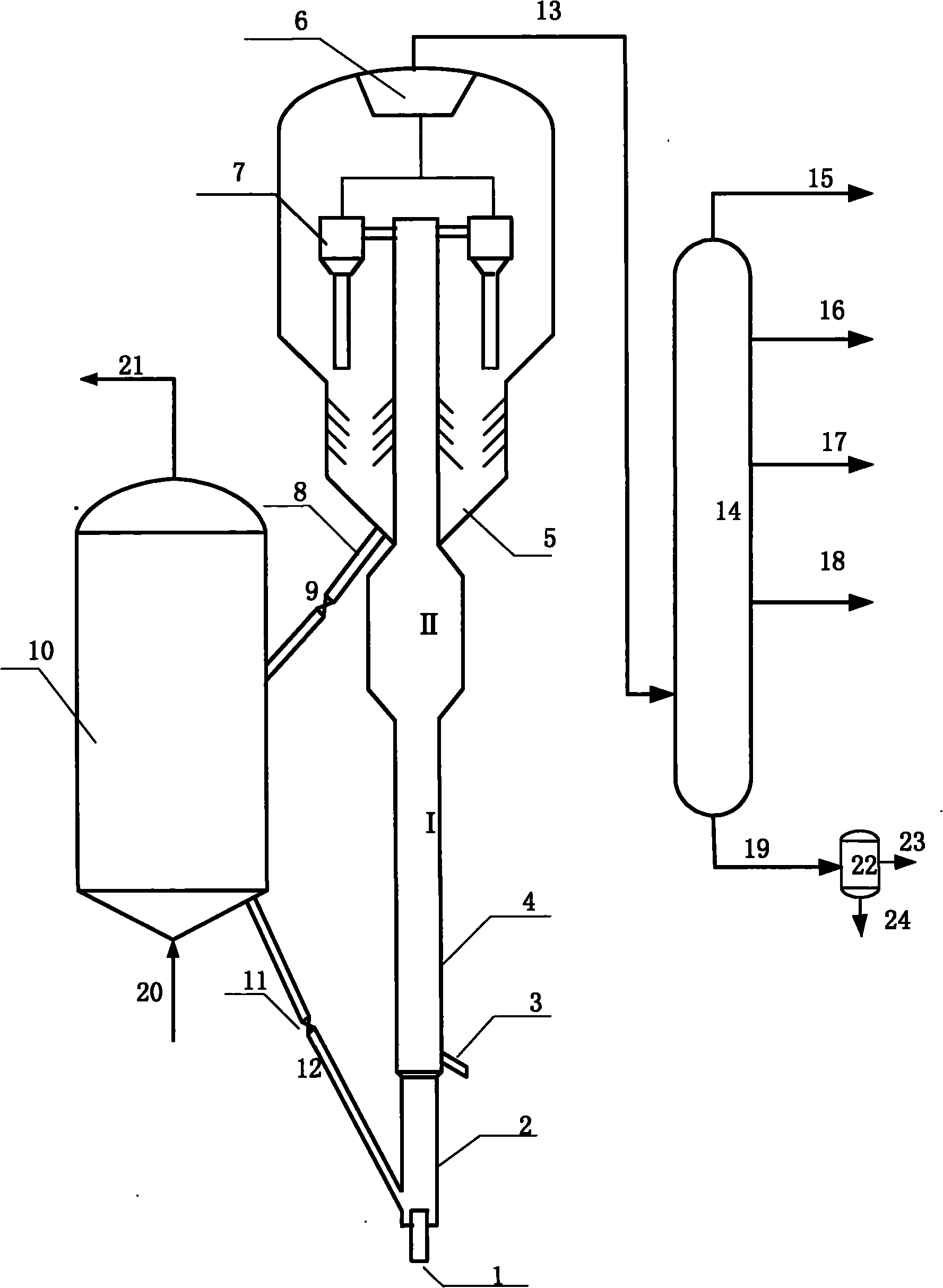

Catalytic conversion method for improving cetane number and yield of diesel

ActiveCN102041093AImprove performanceMaximize productionTreatment with hydrotreatment processesWaxReaction temperature

The invention discloses a catalytic conversion method for improving cetane number and yield of diesel. Raw oil is contacted with a catalyst containing large pore zeolite in a catalytic conversion reactor for reaction, and the reaction temperature, oil gas retention period, and the weight ratio of the catalyst to the raw oil sufficiently ensure that a reaction product containing catalytic wax oil which is 12 to 60 weight percent of the raw oil is obtained in the reaction, wherein the reaction temperature is 420 to 550DEG C, the oil gas retention period is 0.1 to 5 seconds and the weight ratio of the catalyst to the raw oil is 1-10; and the catalytic wax oil enters a hydrogenation unit, and the obtained hydrogenated catalytic wax oil returns to the catalytic conversion reactor. By the method, the diesel with high cetane number is produced maximally, the cracking catalyst with coarse particle size distribution can further improve the selectivity of dry gas and coke, and the catalyst breaking tendency and the catalyst consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

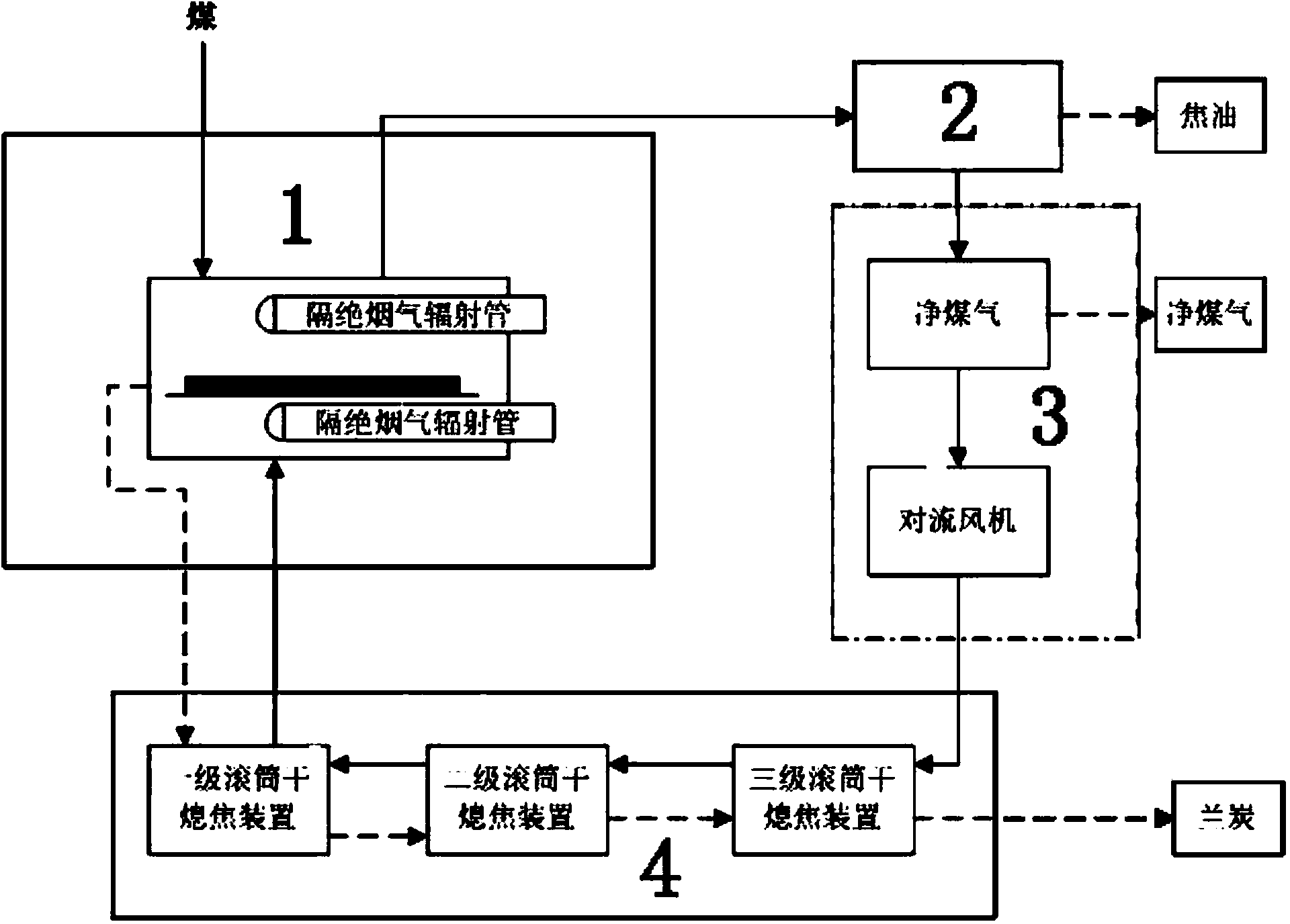

Coal low-temperature carbonization system and method

ActiveCN104178186AQuick take outShort staySpecial form destructive distillationTrappingCarbonization

The invention provides a coal low-temperature carbonization system and method. The system comprises a revolving bed carbonization unit, a raw gas washing unit, a tar trapping unit, a gas convection unit and a gas dry quenching unit, wherein the revolving bed carbonization unit is sequentially connected with the raw gas washing unit, tar trapping unit, gas convection unit and gas dry quenching unit. The system and method shorten the oil-gas retention time in the furnace, reduce the secondary cracking reaction and enhance the tar yield.

Owner:SHENWU TECH GRP CO LTD

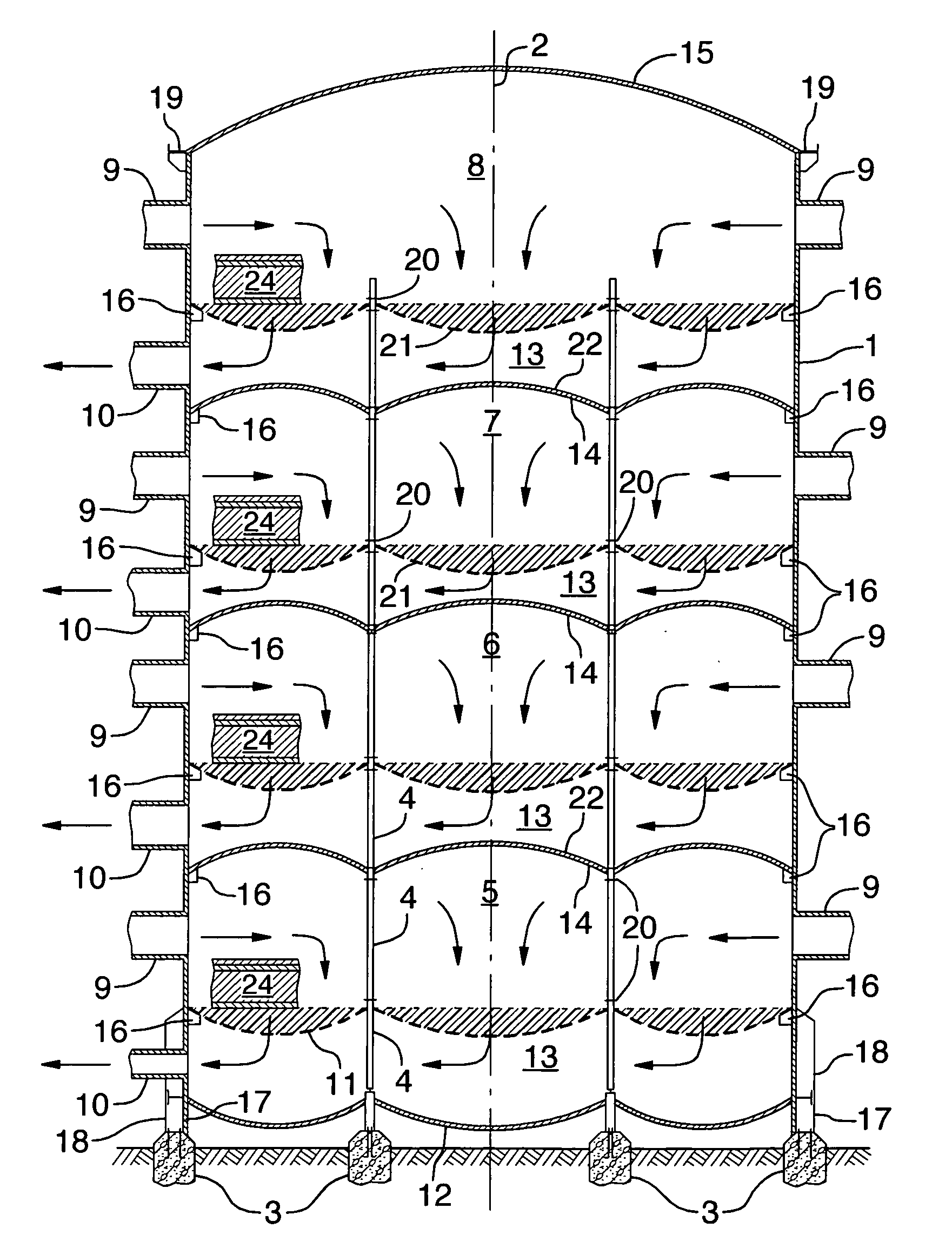

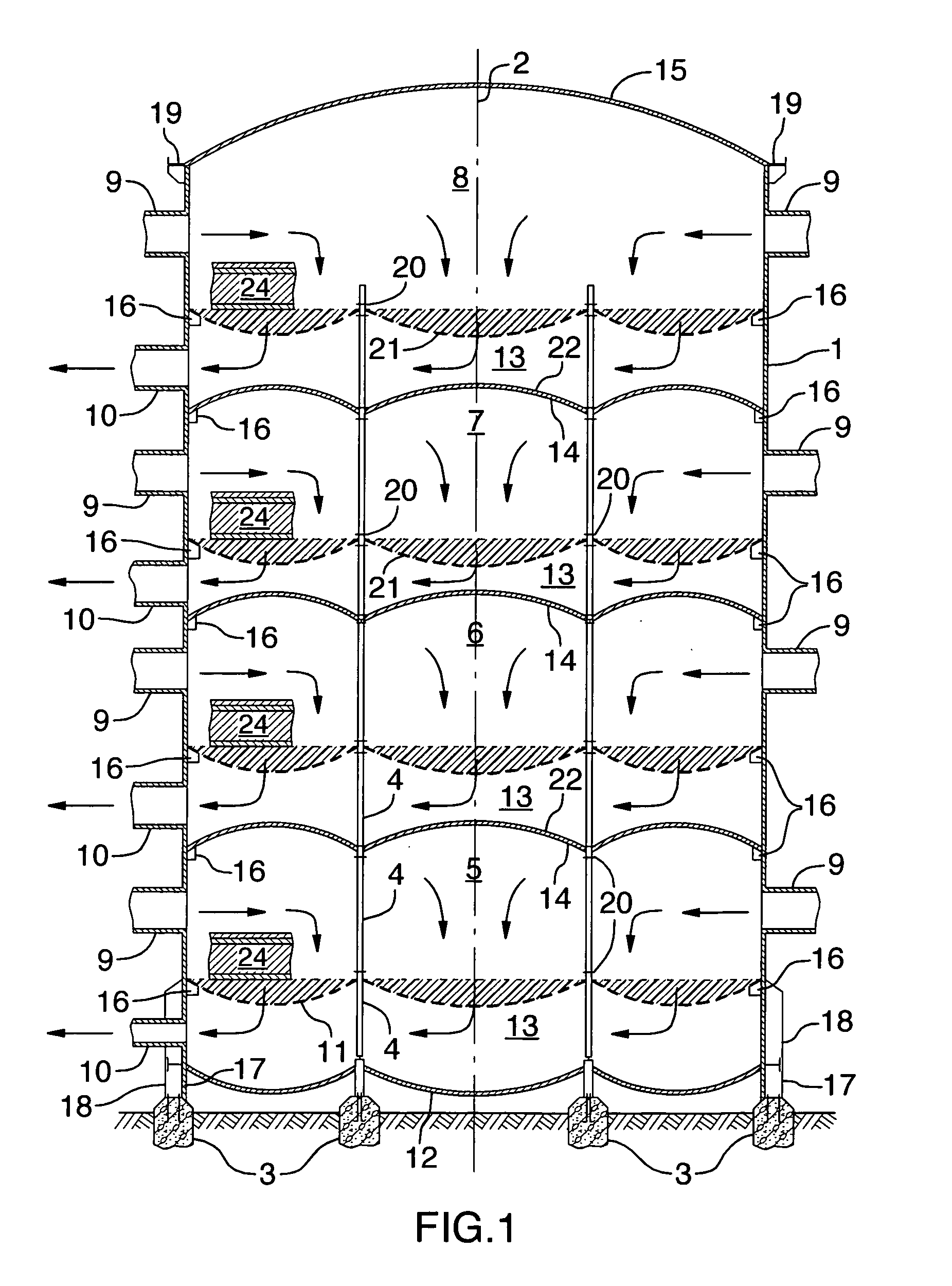

Gas converter

A converter having an exterior shell with a central axis, at least one gas inlet and at least one gas outlet. The exterior shell includes a base and an interior support structure. A number of vertically stacked catalytic chambers within the exterior shell are each in communication with one or more gas inlets and gas outlets. Each chamber is defined by an inner wall of the external shell, a permeable catalytic bed support platform, a lower division plate spaced below the platform defining a gas retention plenum and an upper division plate above the platform. At least one of: the platform; the upper division plate; and the lower division plate have a toroid surface symmetric about the central axis with an outer periphery supported by the inner wall of the exterior shell and an inner periphery supported by the interior support structure.

Owner:SNC-LAVALIN

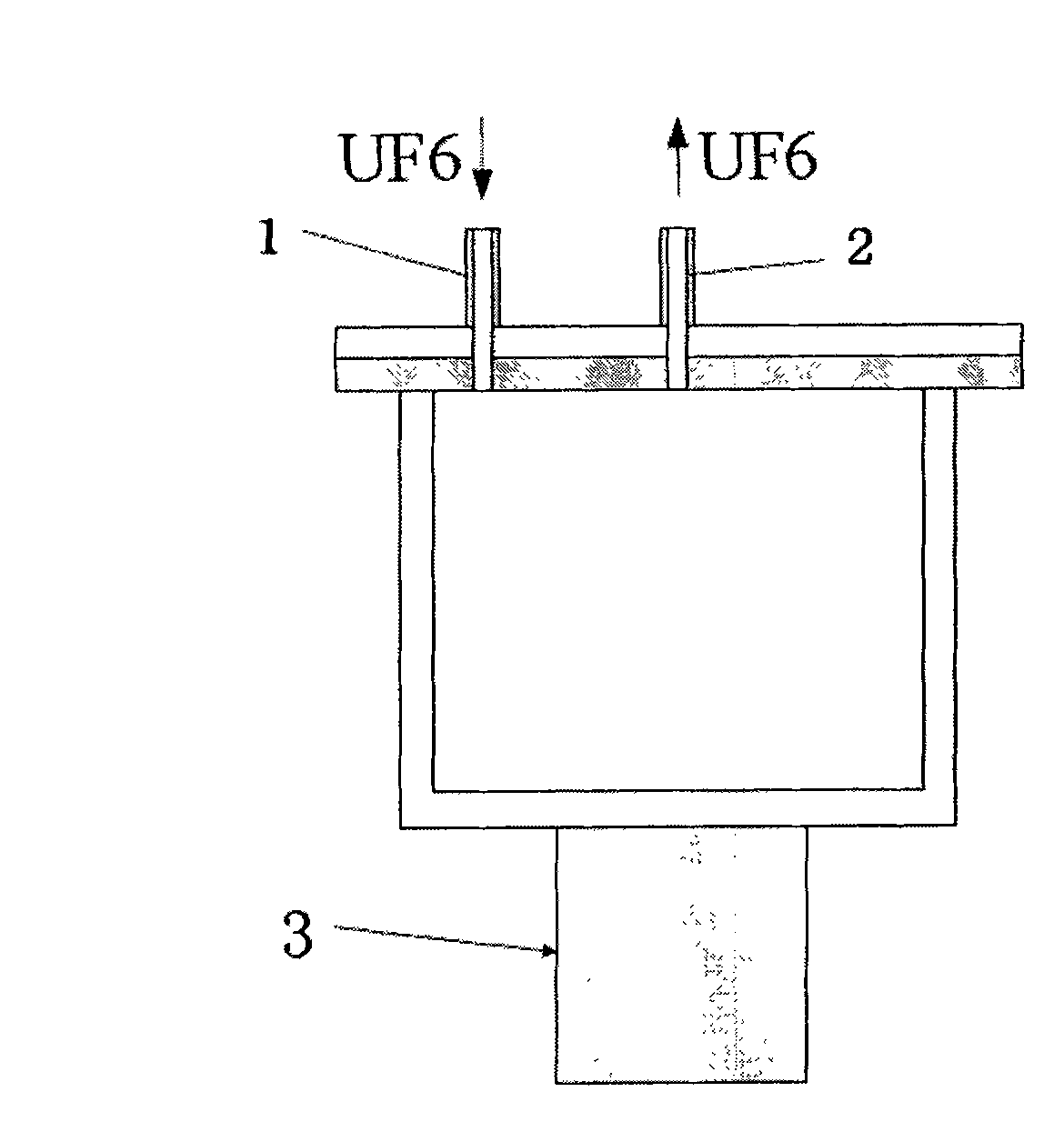

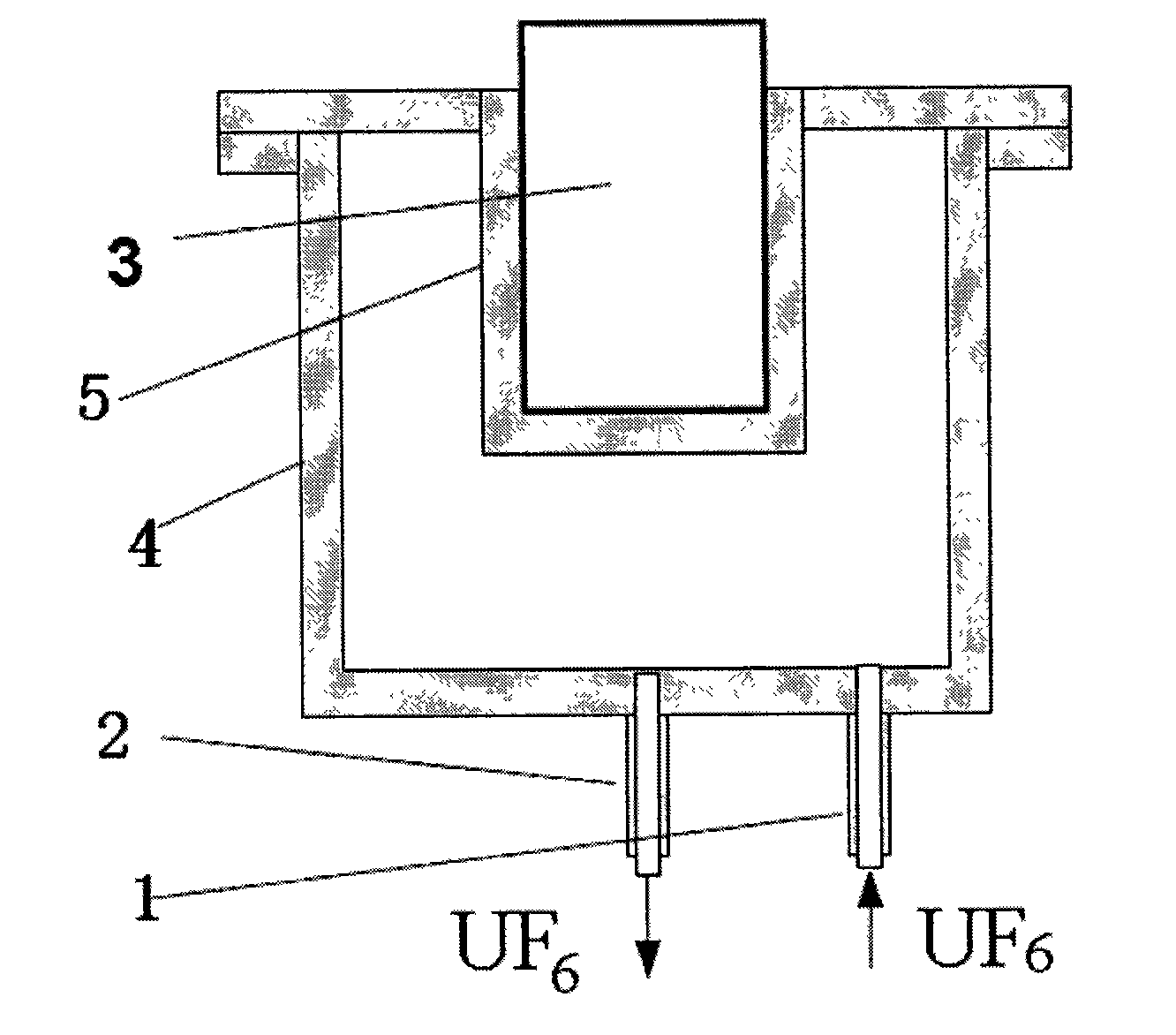

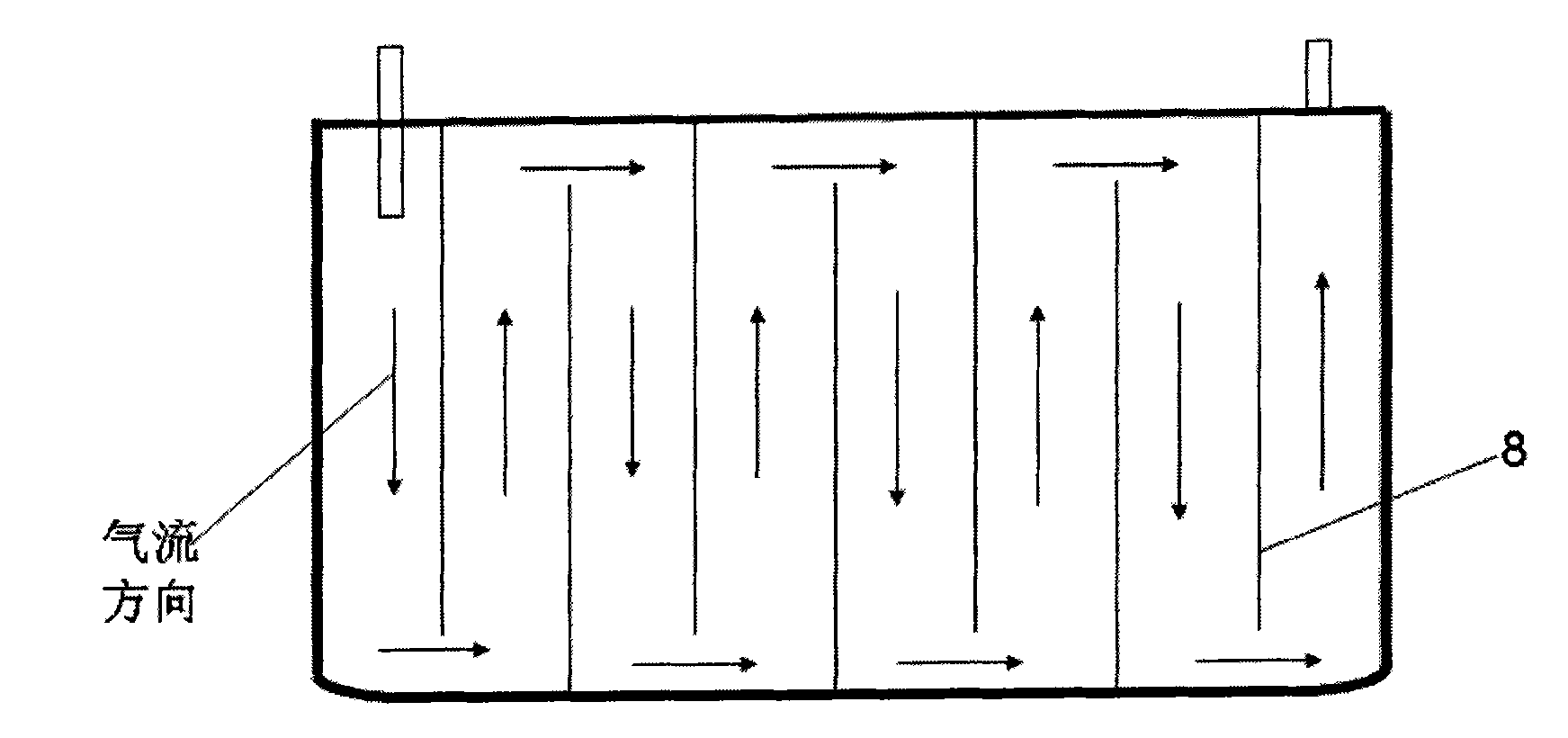

Measuring container of online detecting device for UF6 (uranium hexafluoride) gas uranium abundance

ActiveCN102175822AEnter without stayingReal-time monitoring of uranium abundanceMaterial analysisEngineeringContinuous flow

The invention discloses a measuring container of an online detecting device for UF6 gas uranium abundance, wherein the measuring container is of a cylindrical structure, and comprises a shell, an inlet pipe, an outlet pipe and a guide plate; the guide plate divides the container into a continuous flowing channel in the shell; and the inlet pipe is located at an inlet end, and the outlet pipe is located at an outlet end. The measuring container provided by the invention is capable of online and real-time detecting gas uranium abundance, and has the characteristics of simple structure, high probing efficiency and no gas retention.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

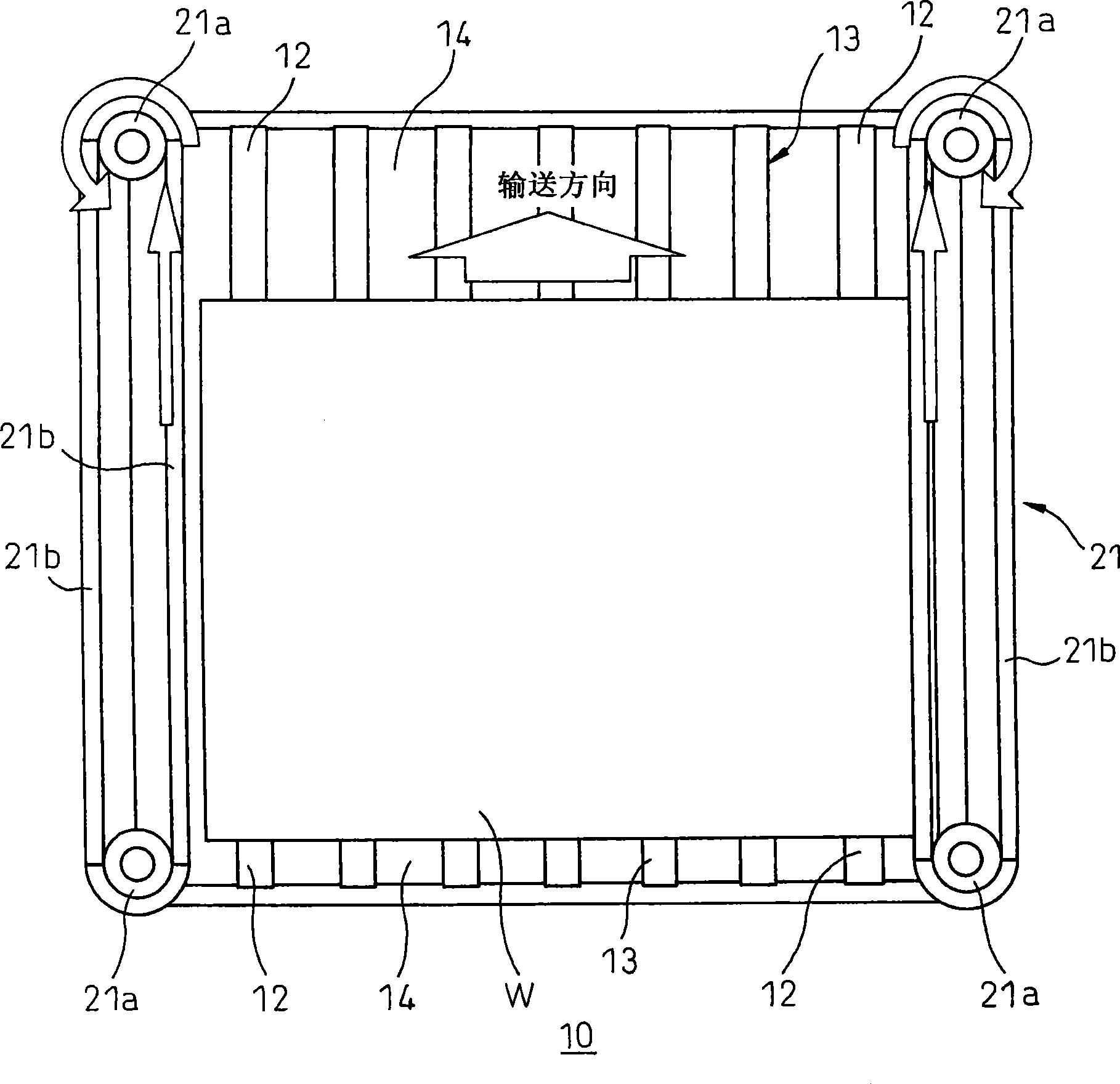

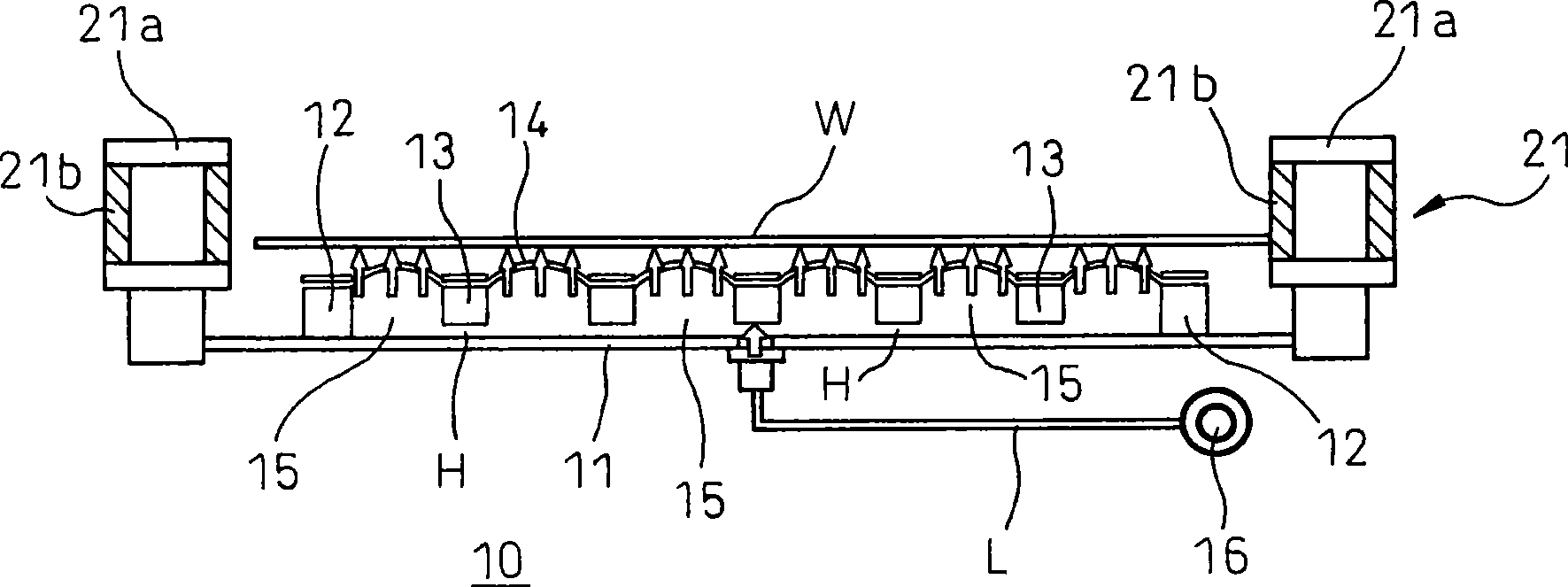

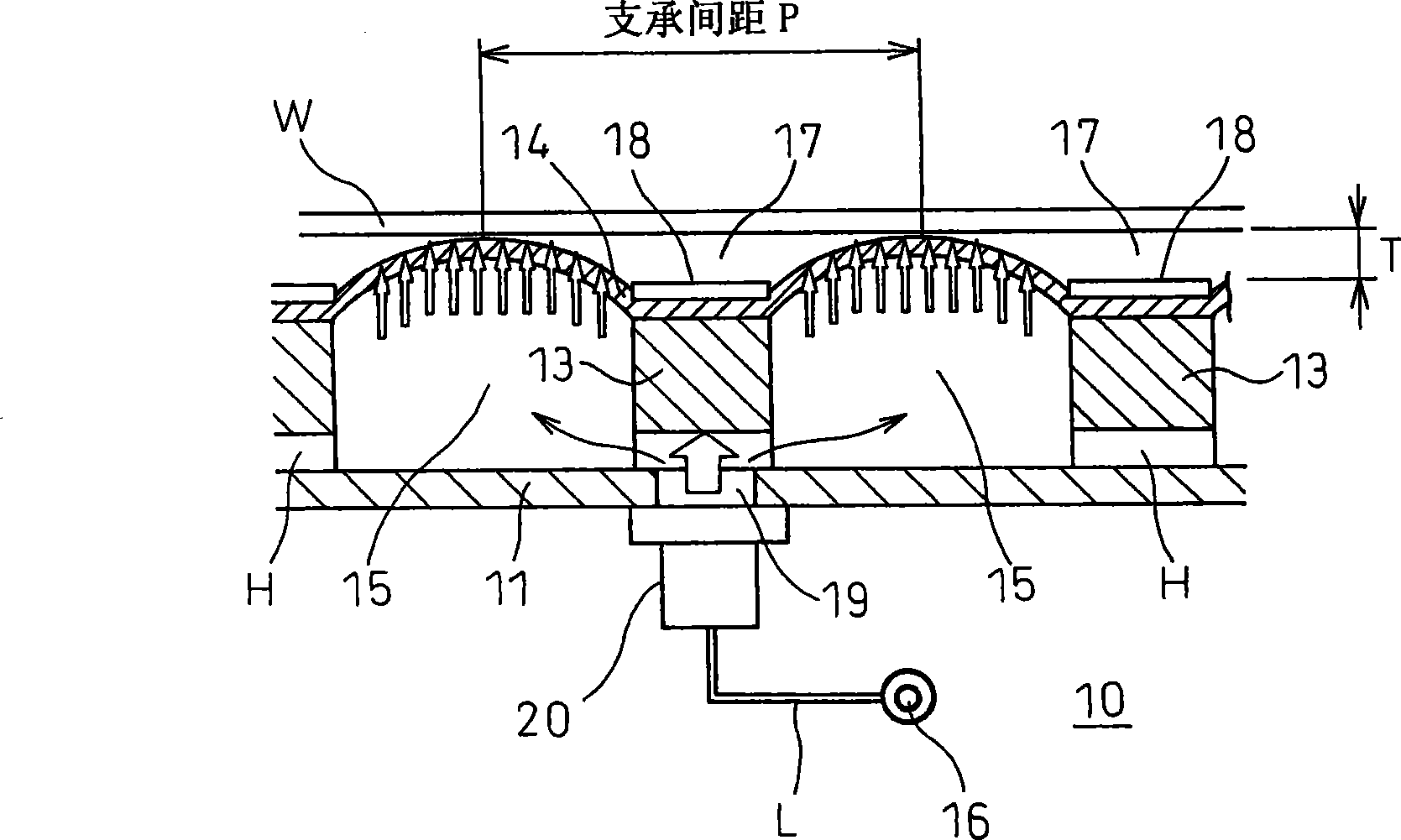

Workpiece supporting device

InactiveCN101447445AStable supportConveyorsSemiconductor/solid-state device manufacturingEngineeringGas retention

A workpiece supporting device is capable of transferring without damage and blemish through floating the workpiece using gas. An air permeability multihole sheet (14) is supported by mounting components (13) arranged at intervals of a prescribed distance, the bottom side of the air permeability multihole sheet (14) is divided to a close space (15) which is connected with a source (16) for supplying the pressure gas. The air permeability multihole sheet (14) is projected at each position mounting the mounting components (13) in convexity, and ensures gas holdup in a space (17) formed on the mounting components (13).

Owner:DENSO CORP

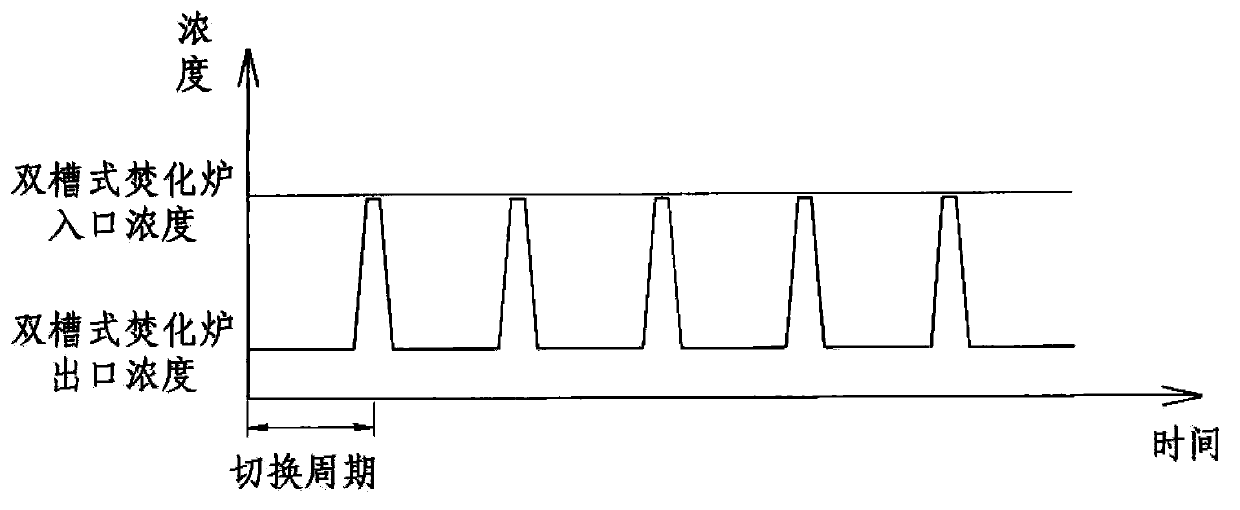

Tail gas switching peak value purification device with heat accumulating type incinerator

ActiveCN103968392ASmall pressure changeReduce odorIncinerator apparatusCombustion chamberExhaust fumes

The invention relates to a tail gas switching peak value purification device with a heat accumulating type incinerator, which comprises the heat accumulating type incinerator and a poppet valve, wherein the inside of the heat accumulating type incinerator is partitioned into a first heat accumulating chamber, a second heat accumulating chamber and a combustion chamber at least, the outside of the heat accumulating type incinerator is connected with a waste gas inlet pipe and an exhaust pipe, and both the inlet pipe and the exhaust pipe are provided with flow control valves; the poppet valve is partitioned into a gas inlet layer connected with the exhaust pipe, a purified gas outlet layer connected with an exhaust chimney and an unpurified gas outlet layer connected with a buffering pipe body, and the lifting of an internal disc is controlled by a drive part to switch airflow to flow out from the purified gas outlet layer or the unpurified gas outlet layer; the other end of the buffering pipe body is connected with the exhaust chimney; the total volume of the buffering pipe body and the unpurified gas outlet layer cannot be smaller than the volume of unpurified gas retained in the heat accumulating chambers and the flow control valve. The tail gas switching peak value purification device has the efficacies of small pressure variation, stable system, less odor, simple structure and space saving.

Owner:JG ENVIRONMENTAL TECH

Vacuum Pump

ActiveUS20160138602A1Suppress the deposit of the gas productEngine manufacturePump componentsGas retentionVacuum pump

A vacuum pump is provided, which suppresses occurrence of a gas product in an exhaust side outlet of a thread groove and maintains pump performance over a long period. The vacuum pump includes inflow suppressing walls formed by widening greater an exhaust side end portion of ridge portions, extended along a gas exhaust direction on an outer circumferential surface of an inner circumference side stator, forward in a rotor rotating direction than an intake side end portion, the inflow suppressing walls suppressing retention of gas in exhaust side outlets of thread grooves engraved among the ridge portions.

Owner:EDWARDS JAPAN

Automatic chemical waste gas purifying device

ActiveCN108619864AFlow is easy to controlHigh strengthDispersed particle separationDeodrantsCycloneTower

The invention discloses an automatic chemical waste gas purifying device, which comprises a cyclone absorption tower, cyclone plates, a water pipe, spray heads and plasma purification towers, whereina plurality of cyclone plates are arranged in the cyclone absorption tower; a stink absorbent is arranged at the inner bottom end of the cyclone absorption tower; the bottom end of the cyclone absorption tower is communicated with the water pipe; a water pump is arranged on the water pipe; a transparent pipe and a manual flow regulating valve are arranged on the water pipe; the water pipe penetrates through the inner wall of the top end of the cyclone absorption tower and is communicated with the spray heads; the cyclone absorption tower is communicated with the plasma purification towers through a pipeline. The automatic chemical waste gas purifying device has the advantages that the structure is stable; the operation is simple; the design is scientific and reasonable; the production period is short; the manufacturing cost is low; a sterilization tower is installed; the sterilization tower can further improve the waste gas treatment performance; the pollution on external environment is prevented; the sterilization tower is provided with a gas hold-up device, so that the detention time of gas can be further increased; when the gas in the sterilization tower excessively expands, thegas is automatically exhausted; the artificial participation is not needed in the process.

Owner:山东同创精细化工有限公司

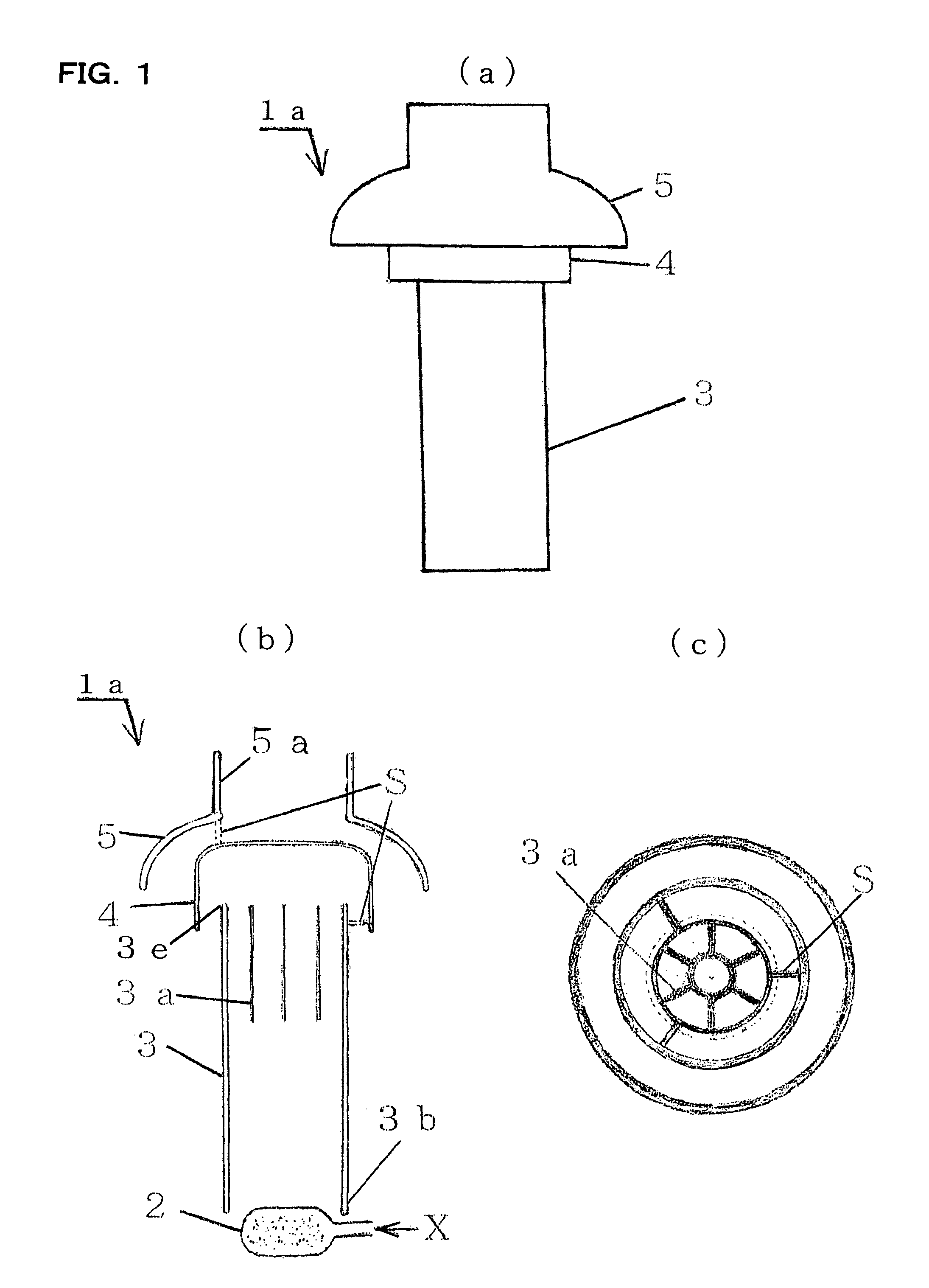

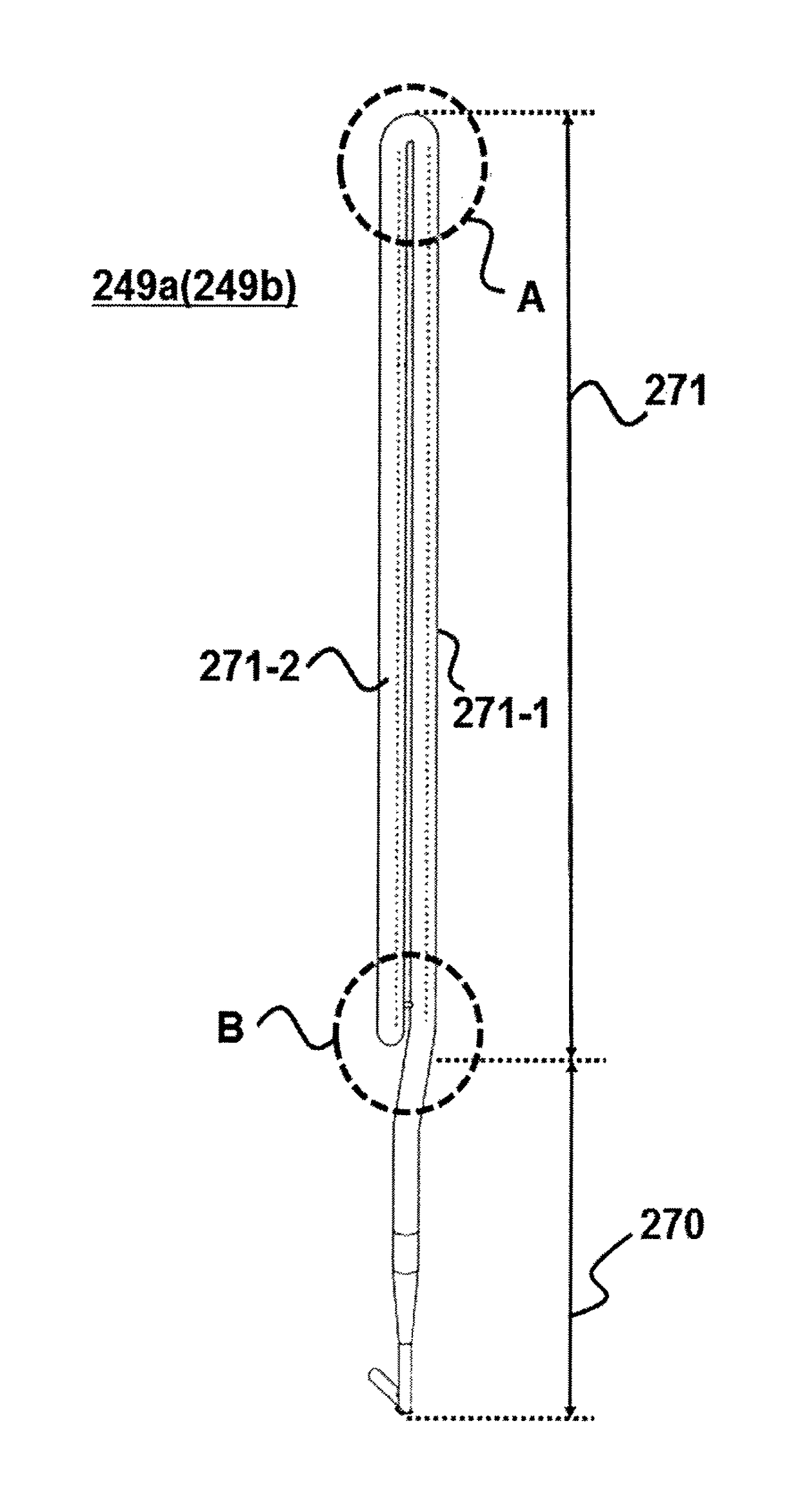

Gas supply nozzle, substrate processing apparatus, and non-transitory computer-readable recording medium

ActiveUS10081868B2Improve film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingResidenceProduct gas

Provided is a technology including a nozzle base end portion which is provided in a processing chamber processing a substrate to extend in a vertical direction and into which a processing gas processing the substrate is introduced, a nozzle distal end portion which is configured in a U shape and in which a gas supply hole supplying the processing gas is provided to a side surface of the substrate, and a gas residence suppressing hole which is provided in a downstream end of the nozzle distal end portion and has a diameter larger than that of the gas supply hole.

Owner:KOKUSA ELECTRIC CO LTD

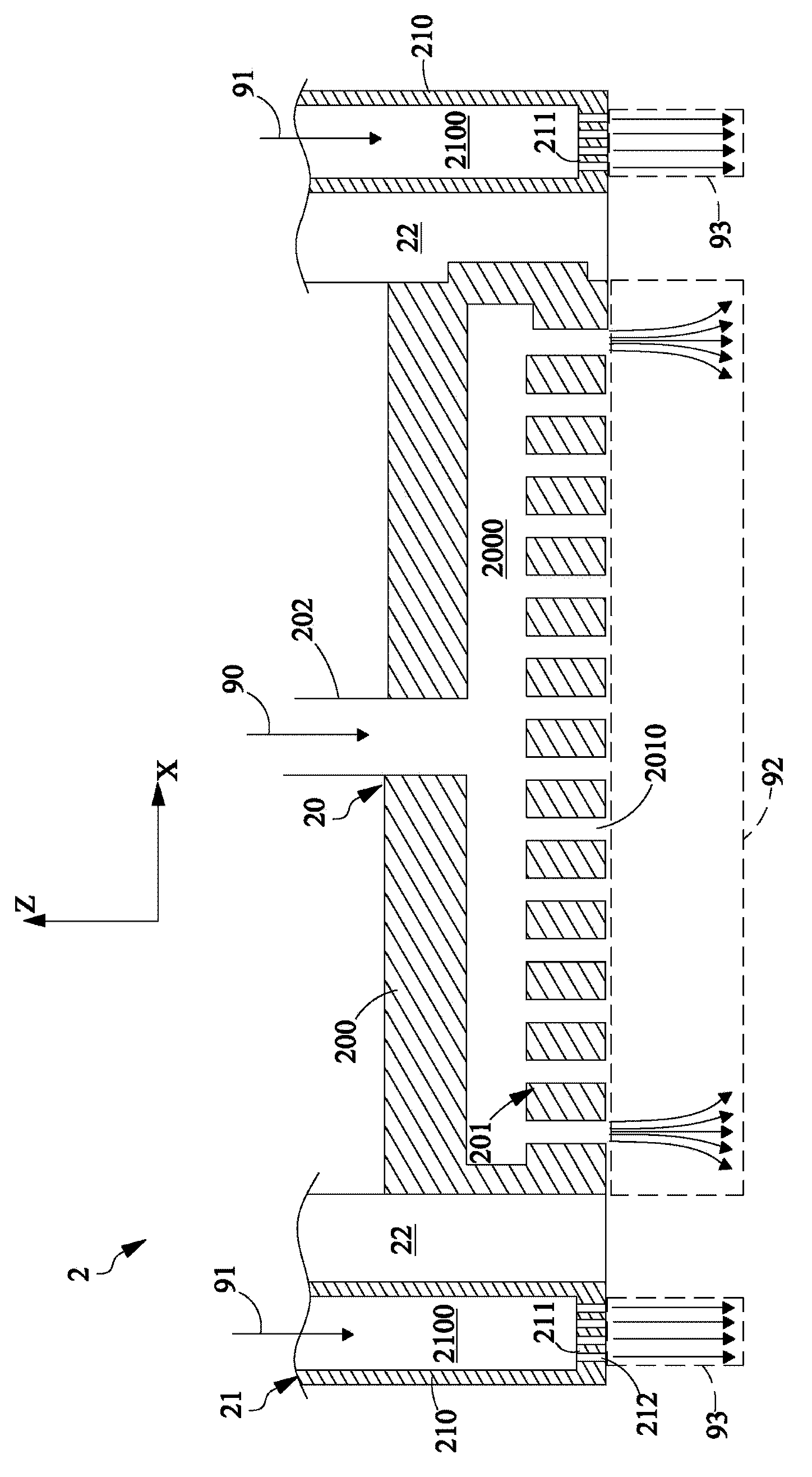

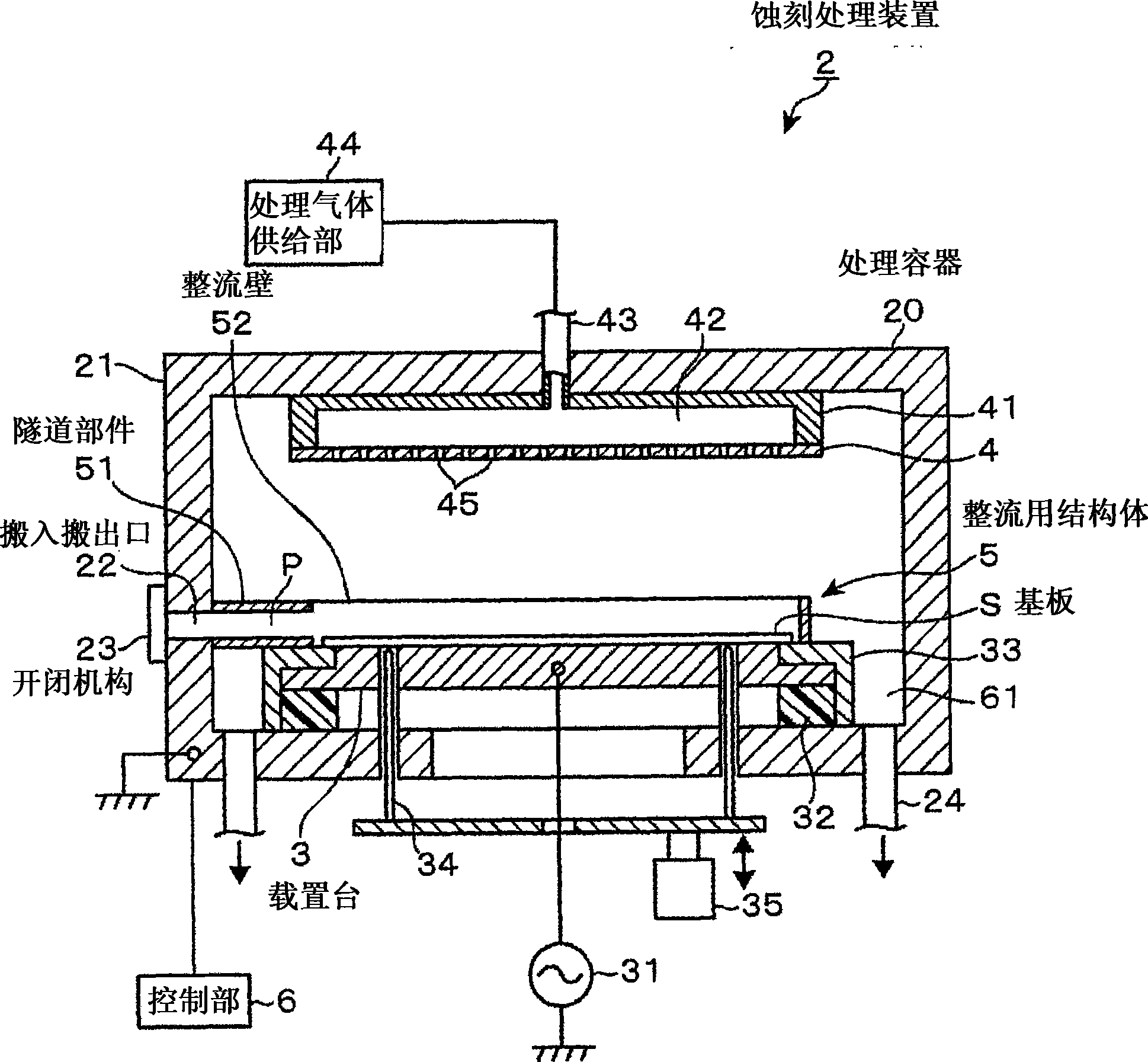

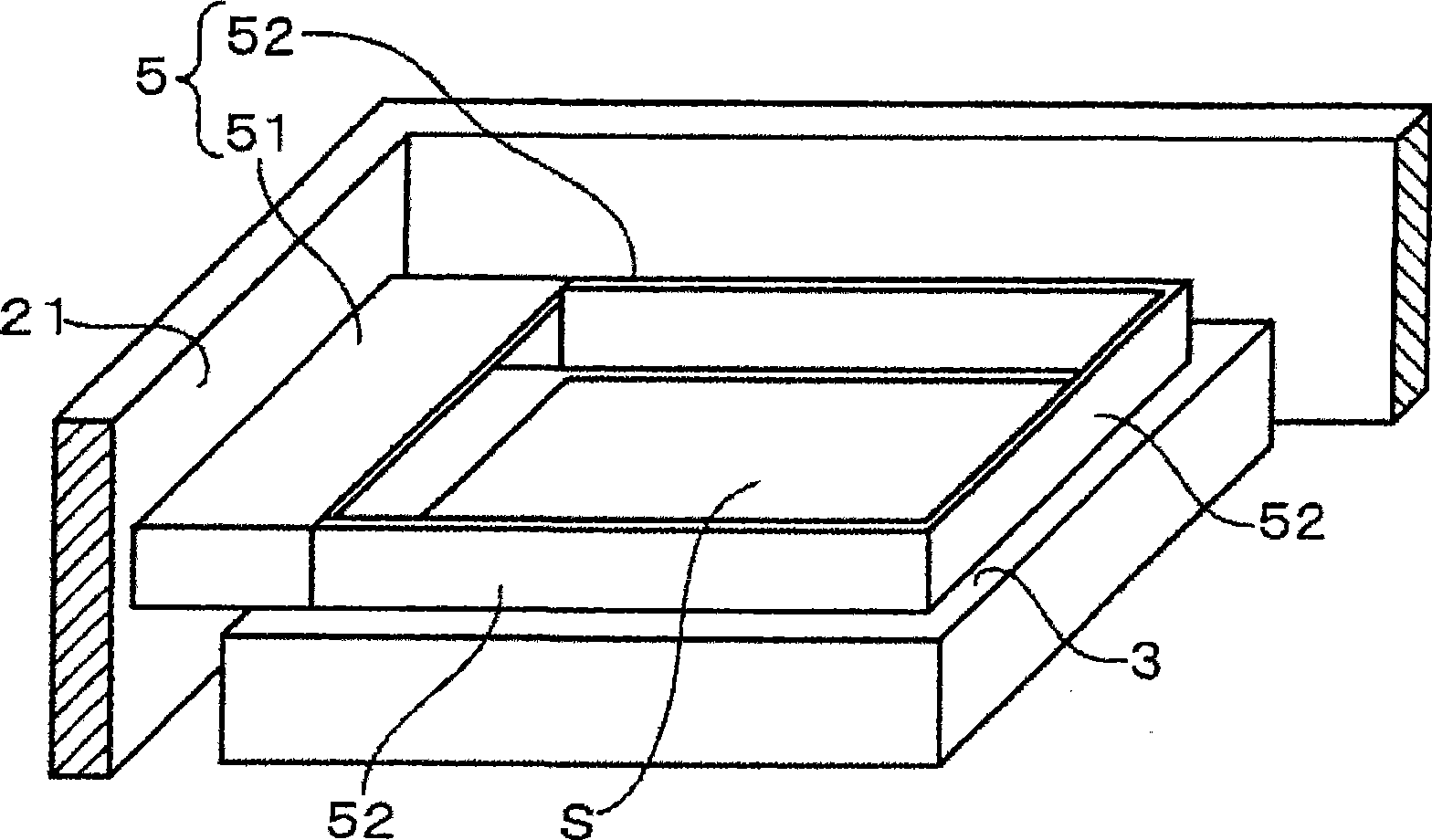

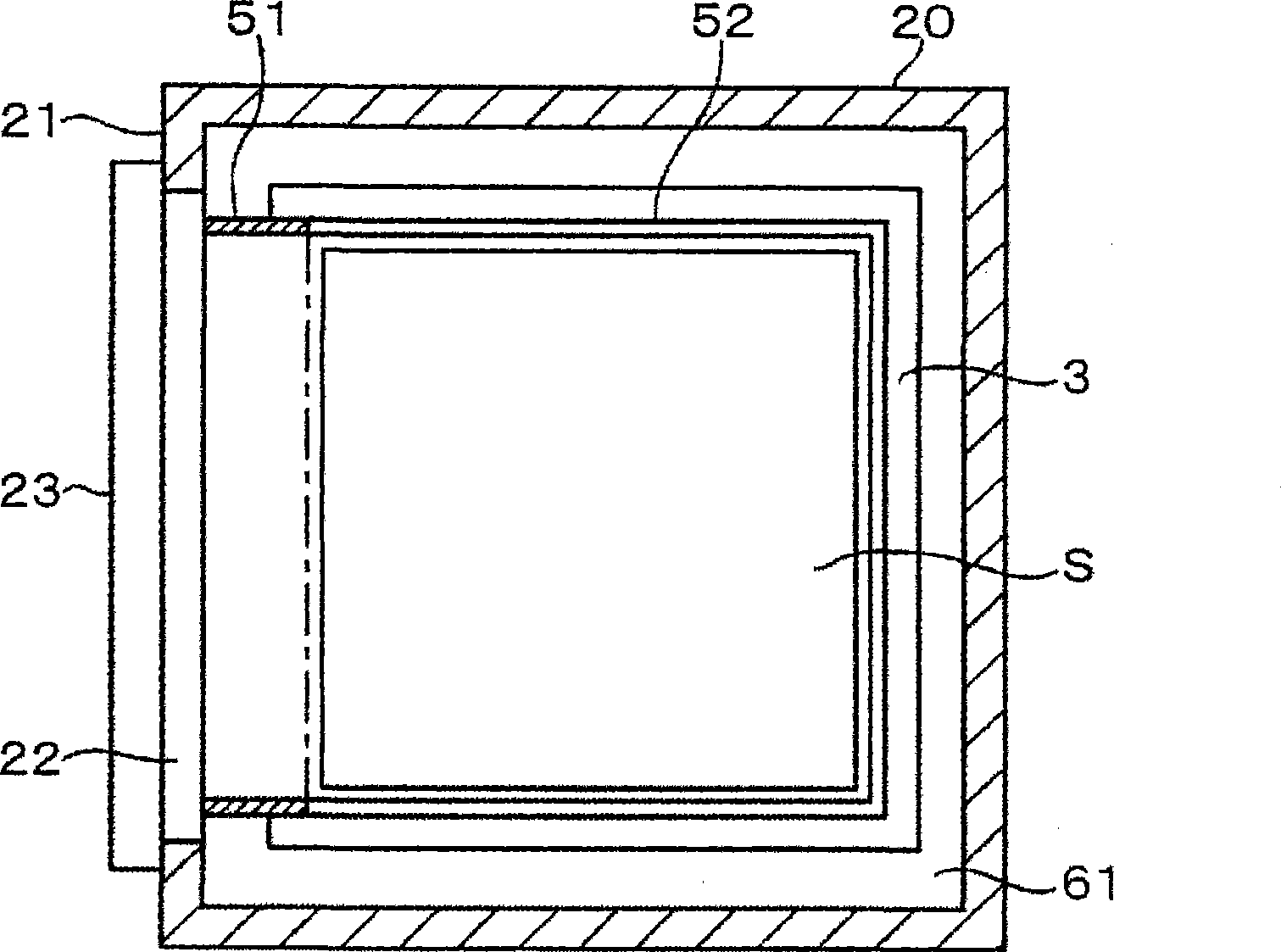

Processing device

InactiveCN101373707AReduce flow rateInhibition of attachmentElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeProduct gas

This invention provides a processing device for enhancing process in-plane homogeneity when processing gas flows into processing container to process the item to be processed, preventing particles from attaching on the item to be processed. In the processing container (20) having inlet / outlet (22) controlled by a switching mechanism (23) on side wall (21) thereof, a rectification structure (5) is disposed, wrapping bearing zone of bearing a stable (3) of a substrate (S), of which upper end has a transportation position higher than the substrate (S) to form a gas-hold zone for processing gas around the substrate (s) born on bearing table (3) in order to reduce flow speed of the processing gas around of the substrate (S). A tunnel element (51) is disposed on inlet / outlet (22) of the structure (5), this tunnel element (51) is used for forming transportation passage (P) of the substrate (S) between the inlet / outlet (22) and the bearing zone.

Owner:TOKYO ELECTRON LTD

Pressurizing reverse-flow type organic garbage gasification furnace

PendingCN108117889AFast dryingHigh calorific valueGasification processes detailsCombustible gas productionCombustionHydrogen

The invention relates to the technical field of garbage treatment devices and provides a pressurizing reverse-flow type organic garbage gasification furnace. The pressurizing reverse-flow type organicgarbage gasification furnace comprises a gasification furnace body, a smoke refluxing device, a porous gas fetching device and an umbrella-type heat guiding device, and also comprises a smoke refluxing and cooling device. The gas refluxing and cooling device is arranged on t he top of the gasification furnace body, so that the drying speed of the garbage is accelerated, more carbon monoxide and hydrogen are generated, and the heat value of gasified gas is improved effectively. In addition, a plurality of gas fetching pipes are also arranged, so that gas is uniformly distributed in the furnacebody, and purity of discharged gas is prevented from being affected as the generated gas is left in the gasification furnace. The umbrella-type heat guiding device is arranged above the hearth of thegasification furnace, so that the temperature of a combustion layer can be kept in a high-temperature state. By refluxing the smoke in the organic garbage gasification furnace to a cooling and dehydrating device to remove water vapor in the smoke, the combustion value of the smoke is increased effectively.

Owner:玉溪市圣力环保科技有限公司

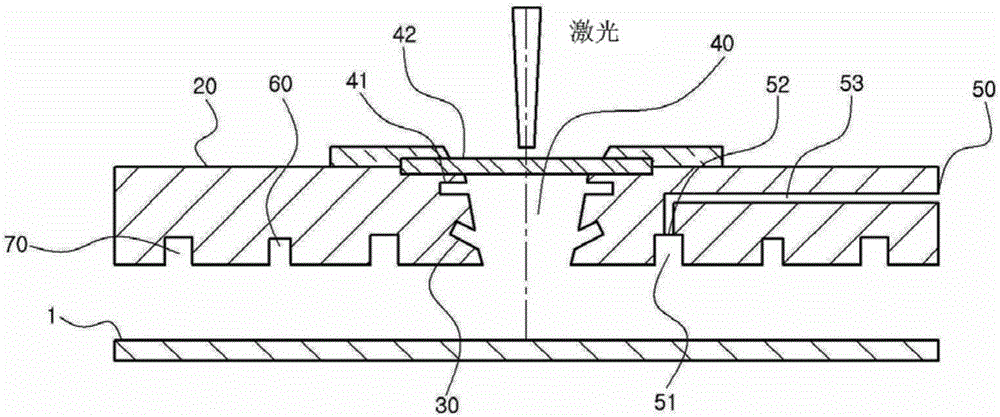

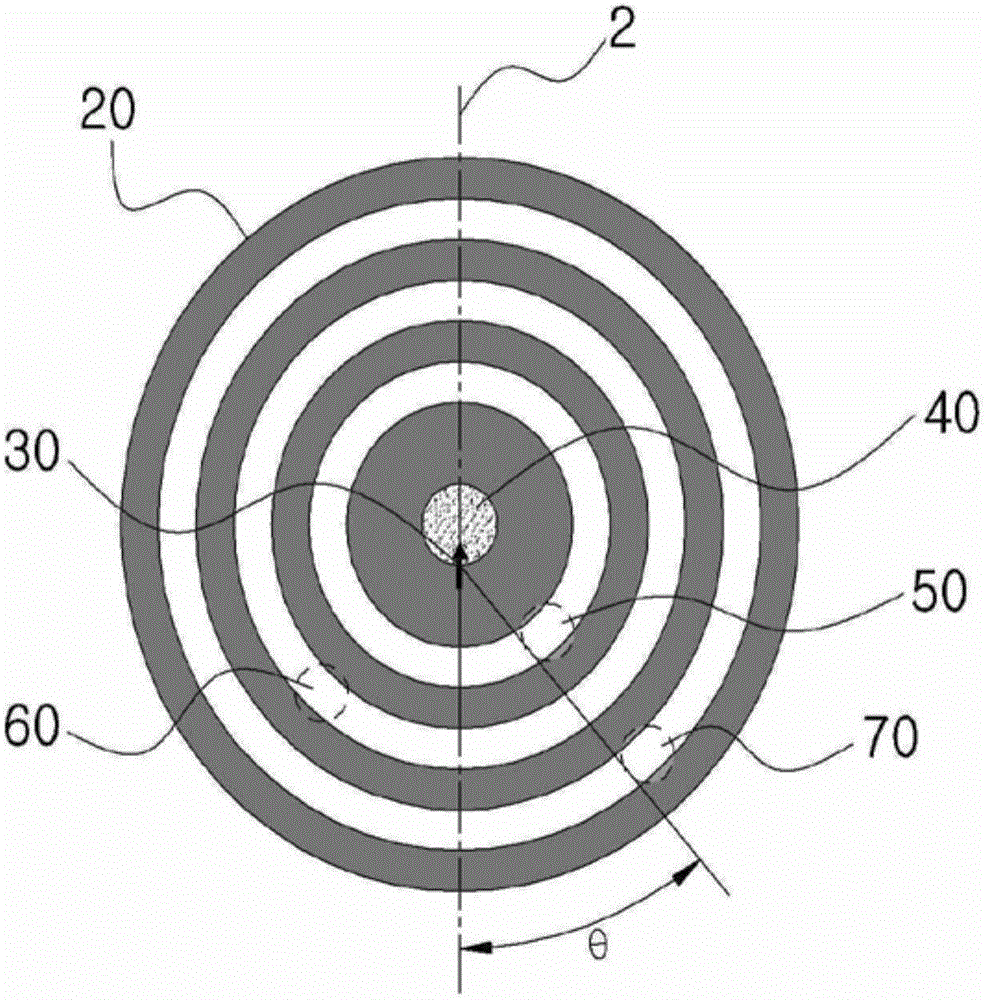

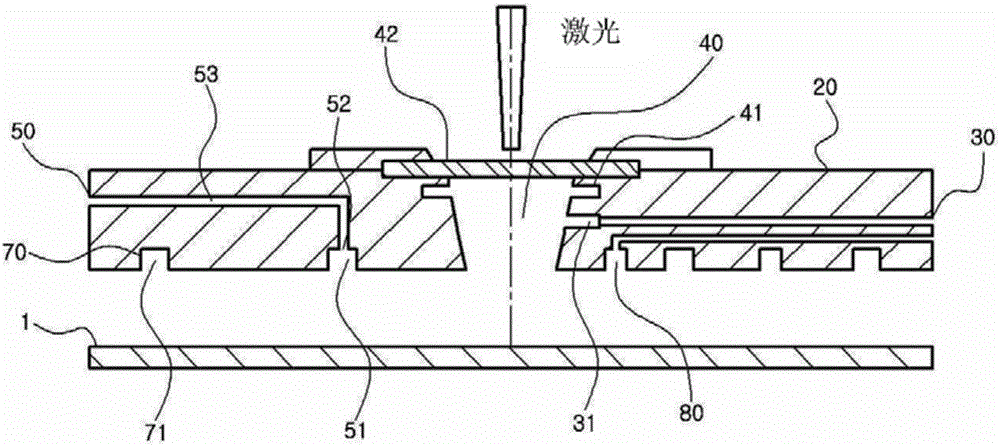

Thin film forming apparatus

ActiveCN107523803AImprove responseReduce generationChemical vapor deposition coatingGas phaseProcess engineering

According to an aspect of the present invention, there is provided a method of manufacturing a semiconductor device, including: supplying a CVD (Chemical Vapor Deposition) raw material gas onto a surface of a substrate, irradiating the supplied raw material gas with laser light, A thin film forming apparatus for forming a thin film on a substrate, comprising: a chamber unit provided on the substrate; a chamber supply unit for supplying a source gas to the chamber unit; a gas supplying unit and a second exhaust unit for exhausting a gas and a raw material gas, wherein a gas flow in the gas retention chamber is formed in a gas retention chamber, a first exhaust unit for exhausting a raw material gas discharged from the gas retention chamber, forming means for forming a uniform pressure in all directions of the gas retention chamber is formed in order to make the gas retention chamber uniform It is a ball.

Owner:HB TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com