Formation method for reducing gas retention in formation process of flexibly-packaged lithium battery

A technology of soft-pack lithium battery and formation method, which is applied in the direction of electrical components, secondary batteries, electrochemical generators, etc., can solve the problems of unfavorable positive and negative electrodes and separators closely fitting, lithium separation, etc., and achieves the improvement of formation production Gas, to ensure a tight fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

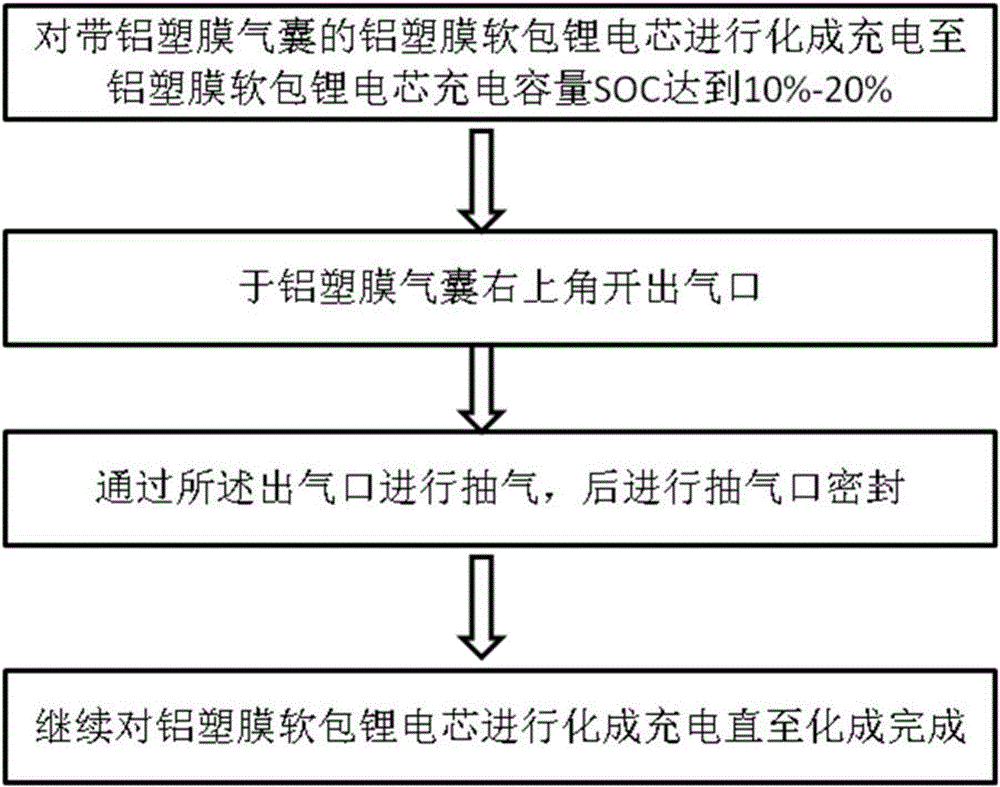

[0017] see figure 1 , which demonstrates a method for improving the formation and gas production of pouch lithium batteries;

[0018] Including the following steps:

[0019] 1) The positive and negative poles of the aluminum-plastic film soft-covered lithium battery with aluminum-plastic film airbags are clamped on the positive and negative poles of the formation cabinet;

[0020] 2) Write the formation charging system according to the formation process requirements, and then the formation cabinet performs formation charging on the aluminum-plastic film soft-packed lithium battery cell with aluminum-plastic film airbag according to the formation charging system until the SOC of the aluminum-plastic film soft-pack lithium battery cell reaches 15%;

[0021] 3) Put the aluminum-plastic film soft-packed lithium battery into the cabinet, and transfer it to a workshop with constant temperature and humidity control;

[0022] 4) Use scissors to open a suction port on the aluminum-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com