Sealing device of rotating cylinder equipment

A sealing device and cylinder technology, which is applied in the direction of mechanical equipment, engine sealing, engine components, etc., can solve the problems of sealing structure failure leakage, poor sealing performance, and sealing failure, so as to reduce equipment failure rate and improve sealing performance , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

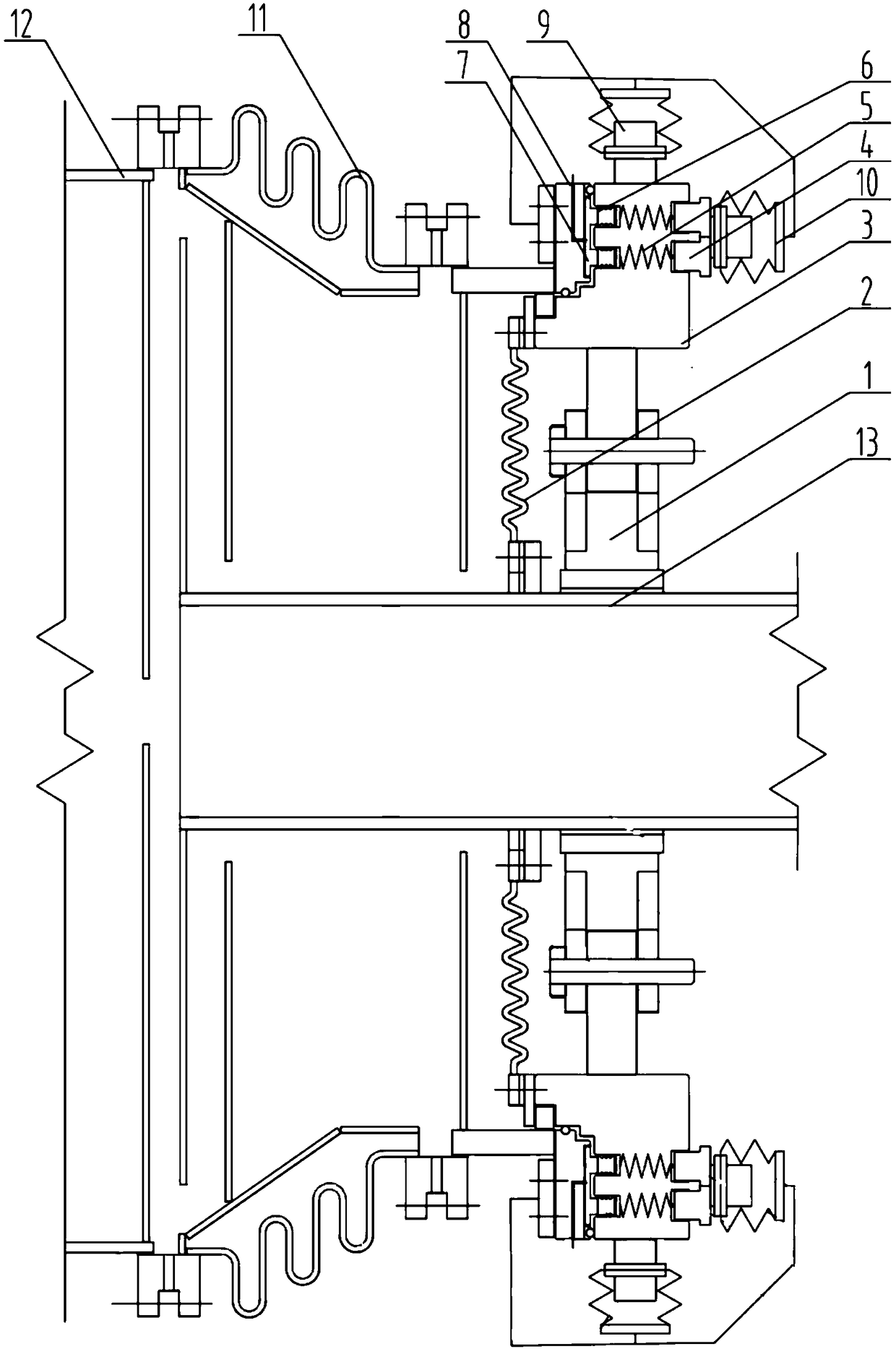

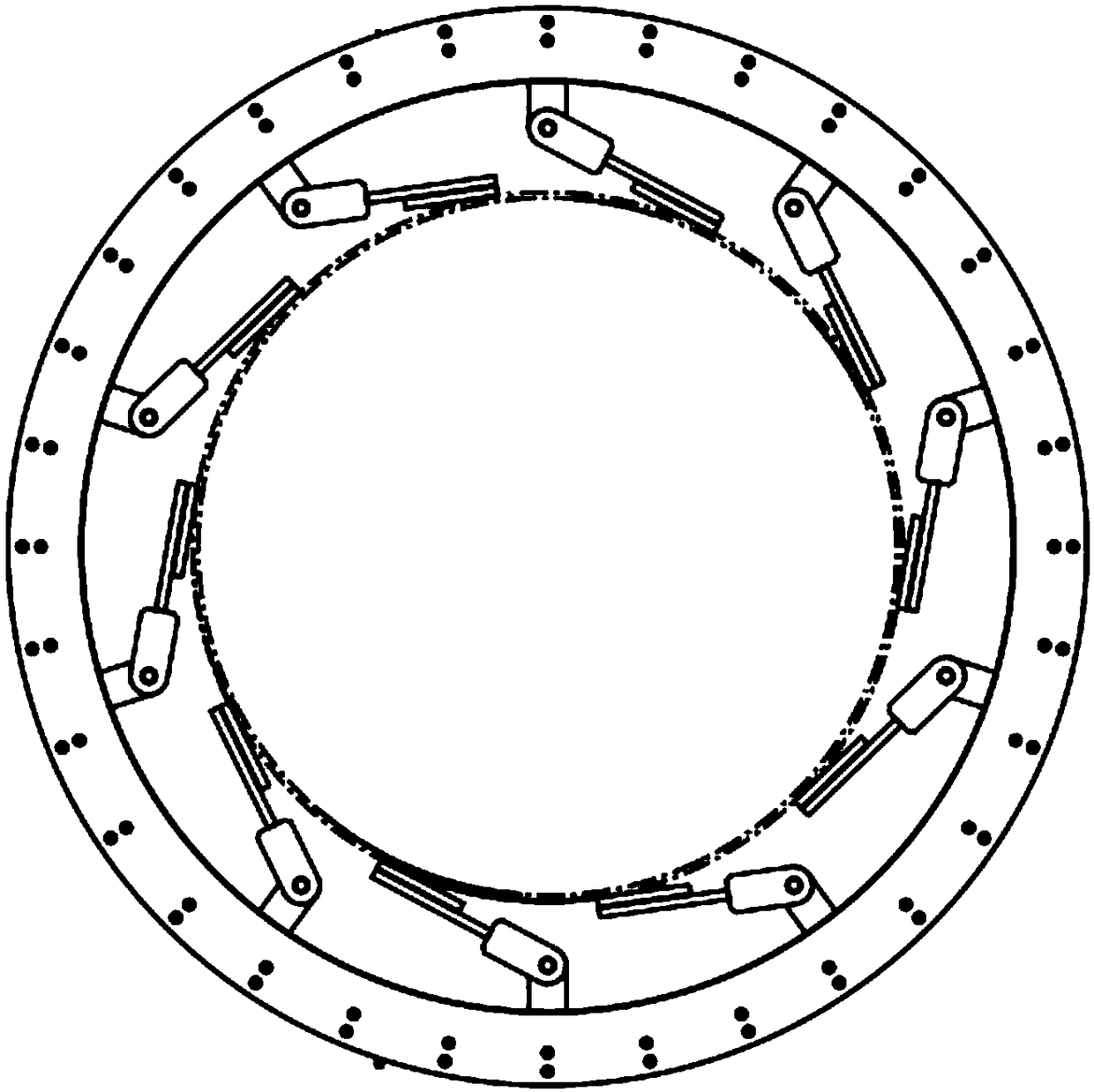

[0030] The flexible support assembly 1 is a support assembly of the same type evenly distributed along the circumference, which can play the role of connecting the rotating cylinder body and the moving ring assembly 3, and can offset the movement between the rotating cylinder body 13 and the moving ring assembly 3. Dynamic and thermal deformation; the above support components are made of leaf spring hinges and / or spring columns.

Embodiment 2

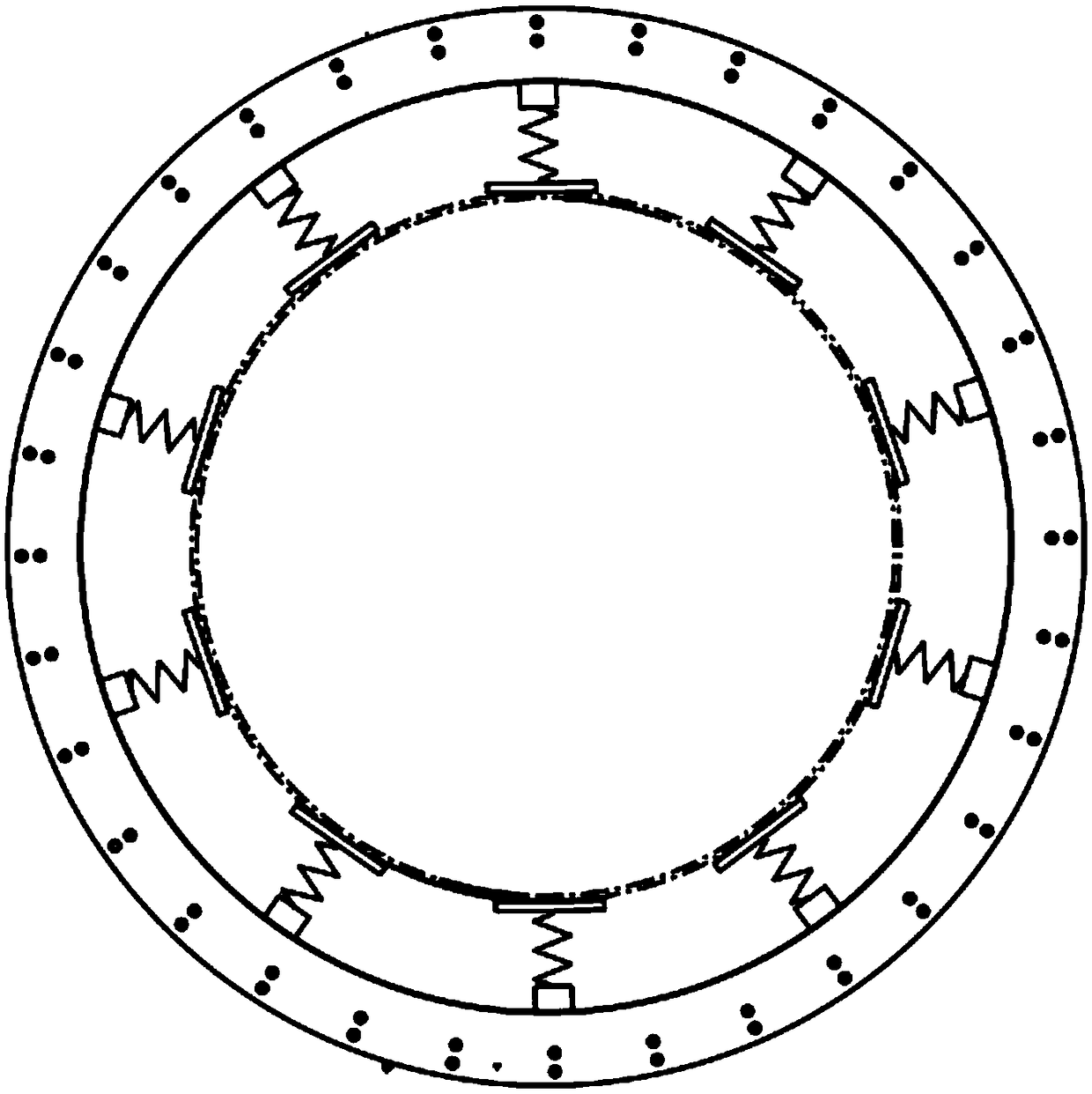

[0032] The ripple ring 2 is a special circular thin plate, and the inner and outer sides of the ripple ring 2 are respectively provided with connecting components, and the inner side of the ripple ring 2 is made into ripples; the ripple ring 2 is manufactured by integral stamping and / or welded Z-shaped plates.

Embodiment 3

[0034] The threaded holes on the moving ring assembly 3 are evenly distributed on the circumference, and the spring column assembly 5 installed in the threaded holes of the moving ring assembly 3 can automatically compensate the wear amount of the sealing block 6, and the front static ring 7 and the seal are connected by the set screw 4. The pressing force between blocks 6 is adjusted; the moving ring assembly 3 is provided with a grease lubrication injection channel, which can inject high temperature resistant grease through the external interface, which not only enhances its sealing performance, but also effectively reduces rolling resistance. The axial end surface of the sealing block 6 ensures that it has a small roughness, so that the sealing block 6 and the end surface of the front stationary ring 7 maintain a stable and uniform end surface contact seal; the radial cylindrical surface of the sealing block 6 is provided with O-ring grooves , and a special O-ring is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com