Patents

Literature

67results about How to "Guaranteed a tight fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

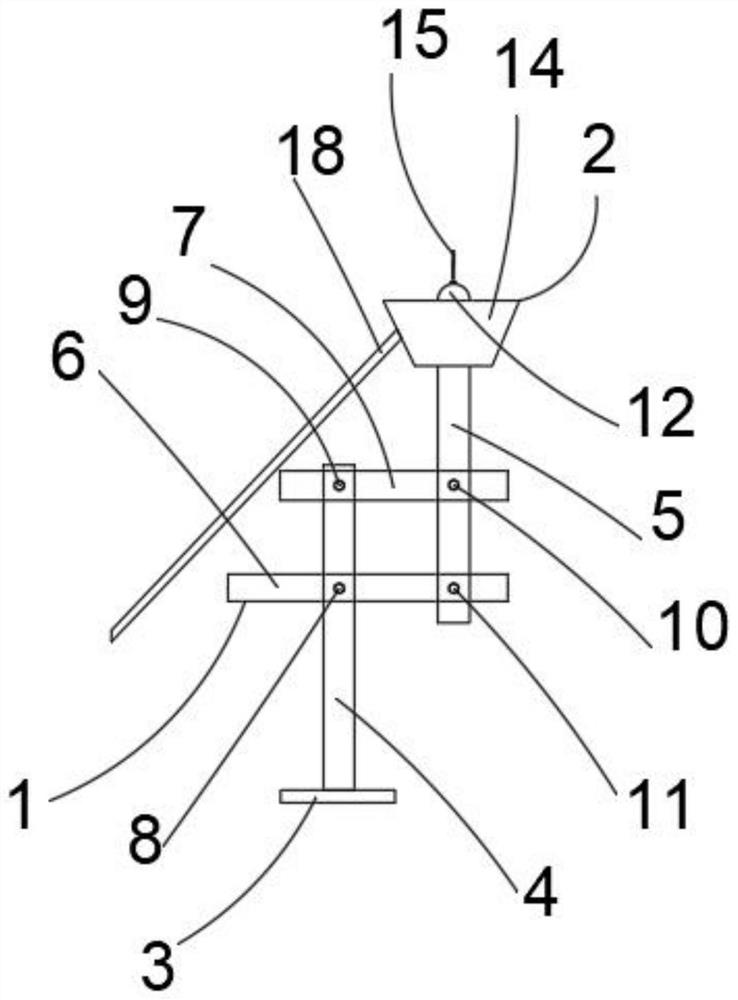

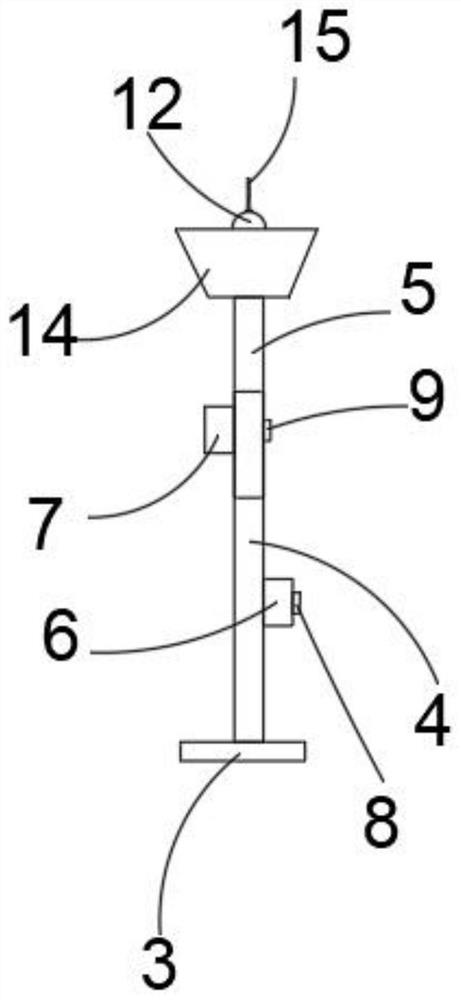

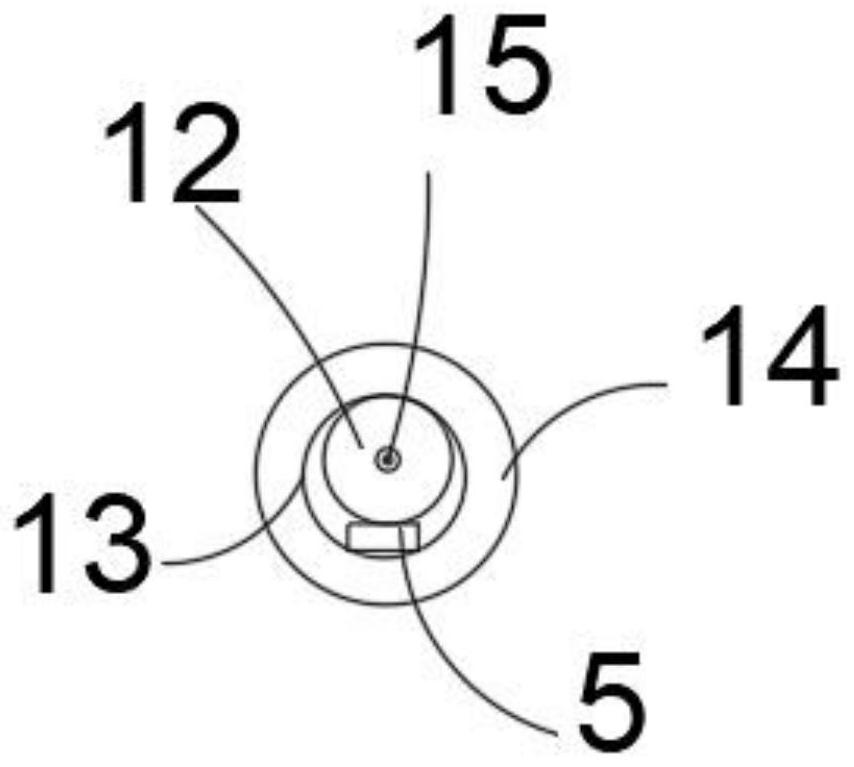

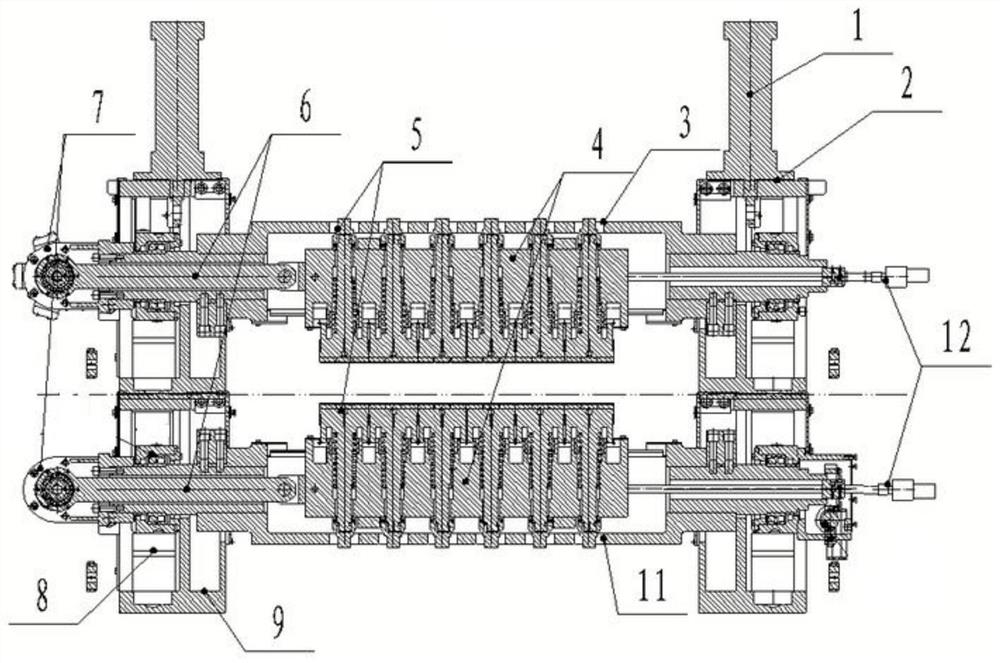

Electrochemical machining method for auxiliary anode tube electrode

ActiveCN103317196AInhibition of stray corrosionReduce sensitivityElectrochemical machining apparatusElectrolysisElectronic load

The invention relates to an electrochemical machining method for an auxiliary anode tube electrode and belongs to the technical field of electrochemical machining. The electrochemical machining method includes the following processes: 1, manufacturing a perforated plate (5); 2, positioning and clamping a workpiece anode (4), the perforated plate (5) and an auxiliary anode (6); 3, connecting the positive pole of a power source (2) with one end of a substrate clamp (7) and one end of the workpiece anode (4), connecting the negative pole of the power source (2) with a tube electrode (1), and connecting the other end of the electronic load (3) with the workpiece anode (4); 4, leading in electrolyte, setting a constant voltage working mode of the electronic load (3) to achieve voltage drop, starting the power source, and performing electromechanical machining on the tube electrode when the potential of the workpiece anode (4) is lower than that of the auxiliary anode; 5, separating and cleaning the workpiece anode (4), the perforated plate (5) and the auxiliary anode (6). The electrochemical machining method for the auxiliary anode tube electrode has important meaning in improving aperture outlet accuracy of tube electrode electrochemical machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

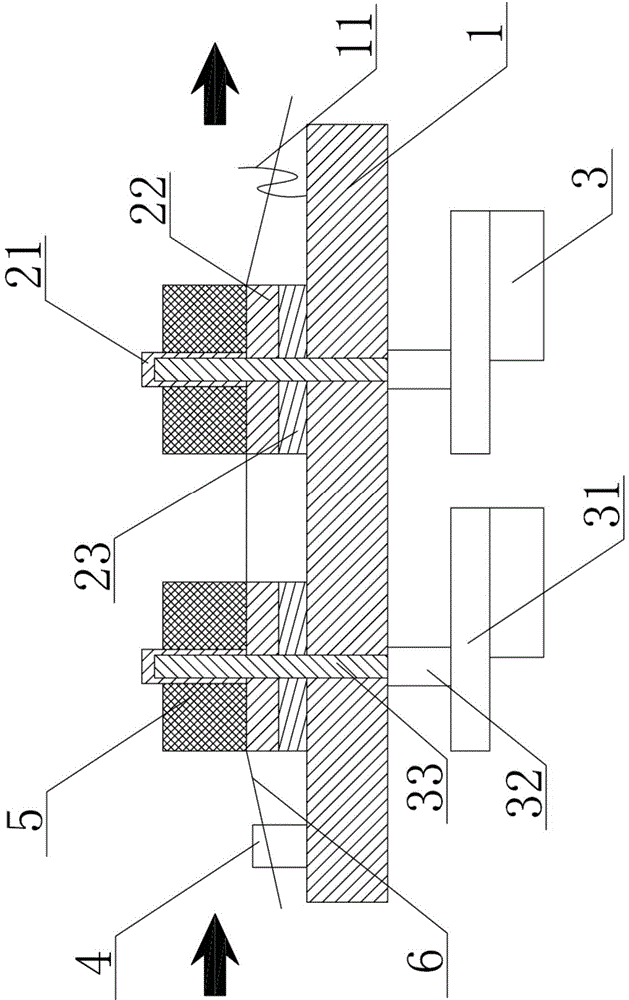

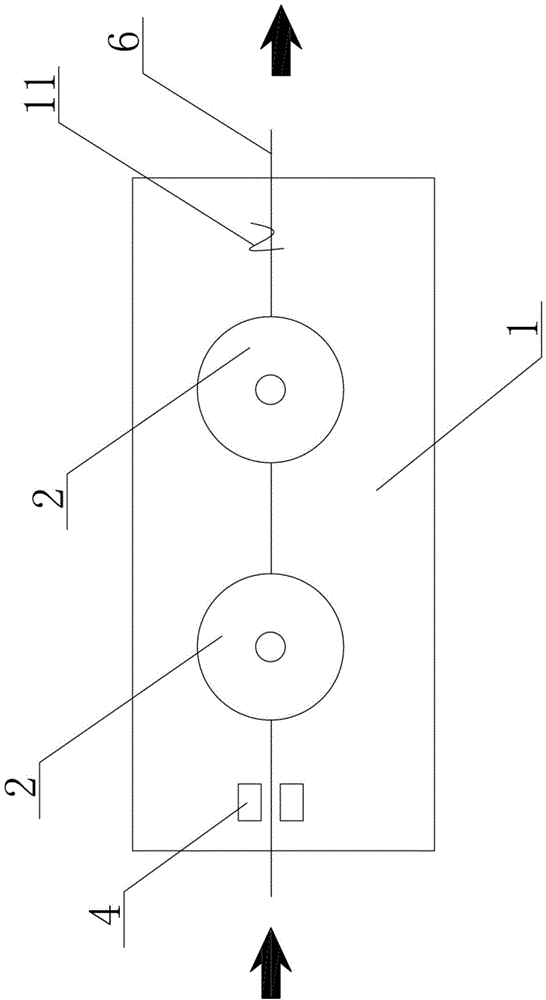

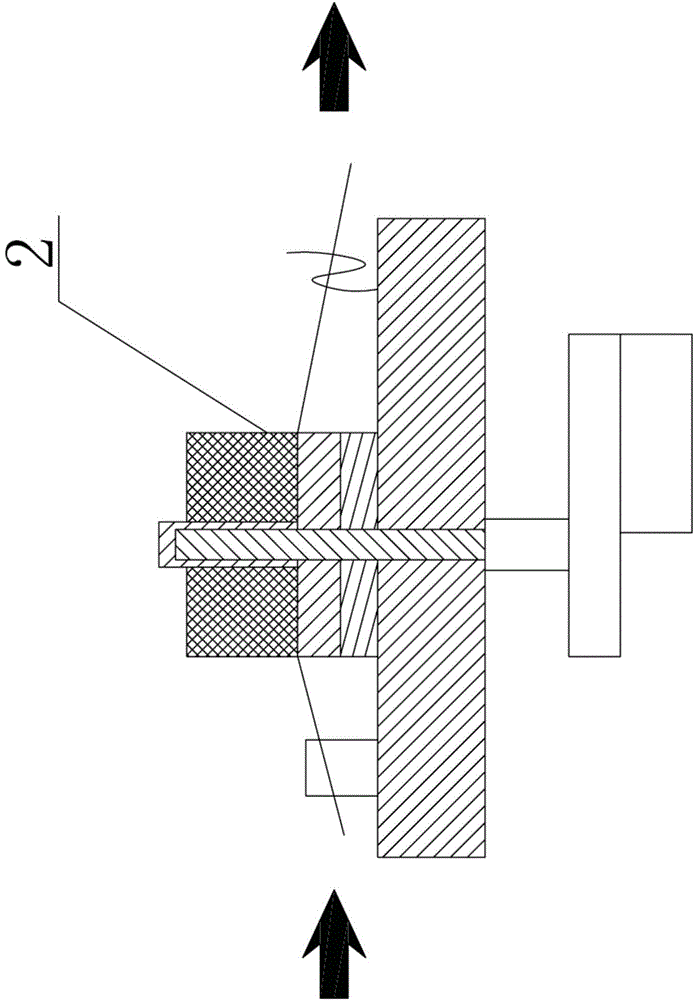

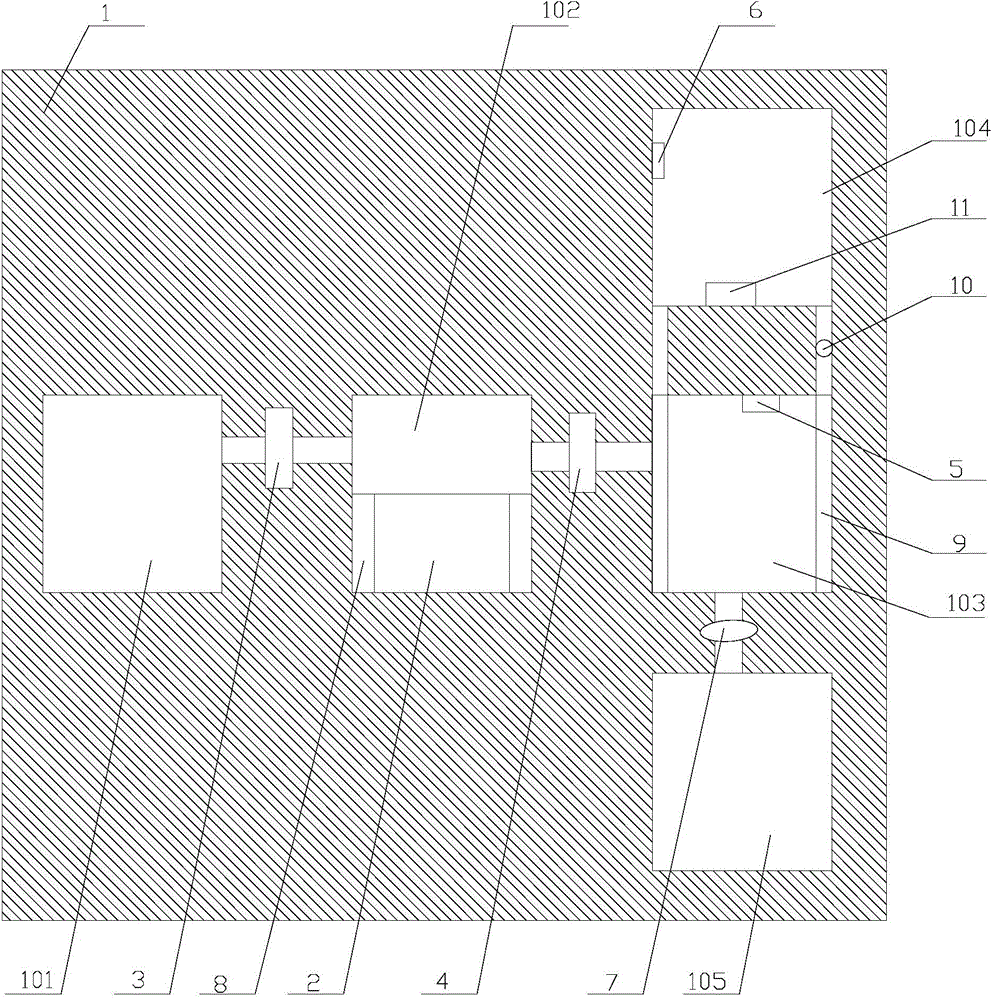

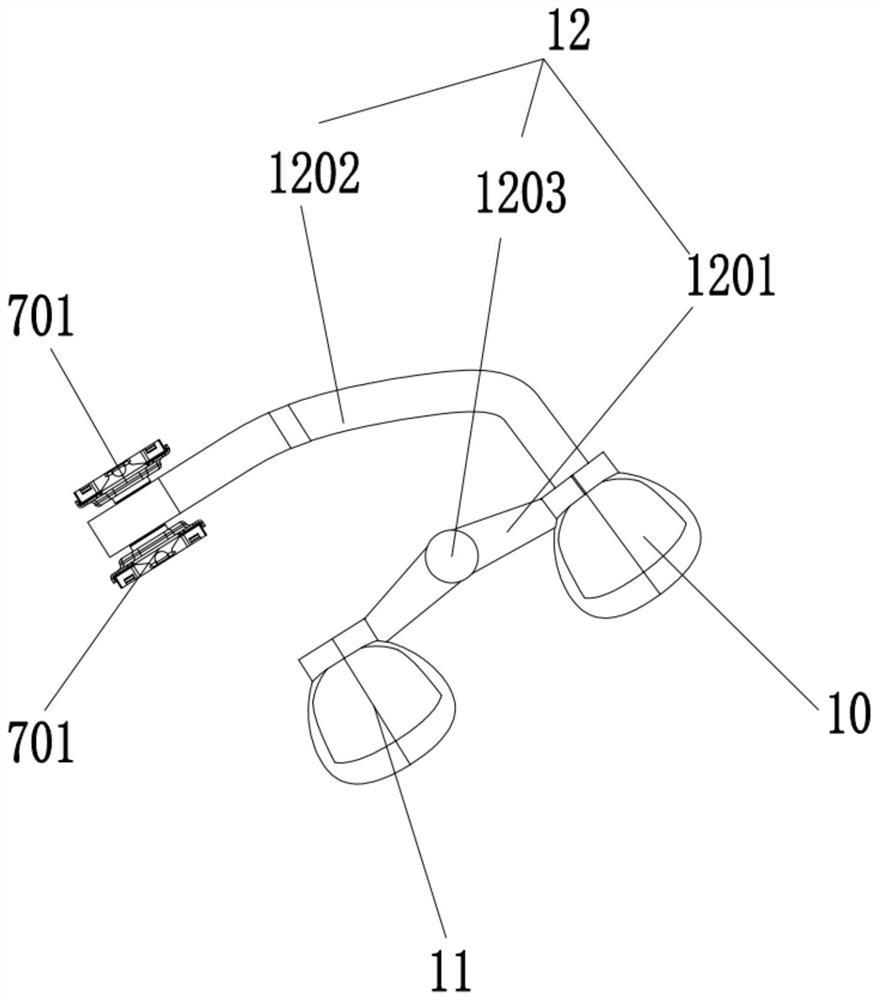

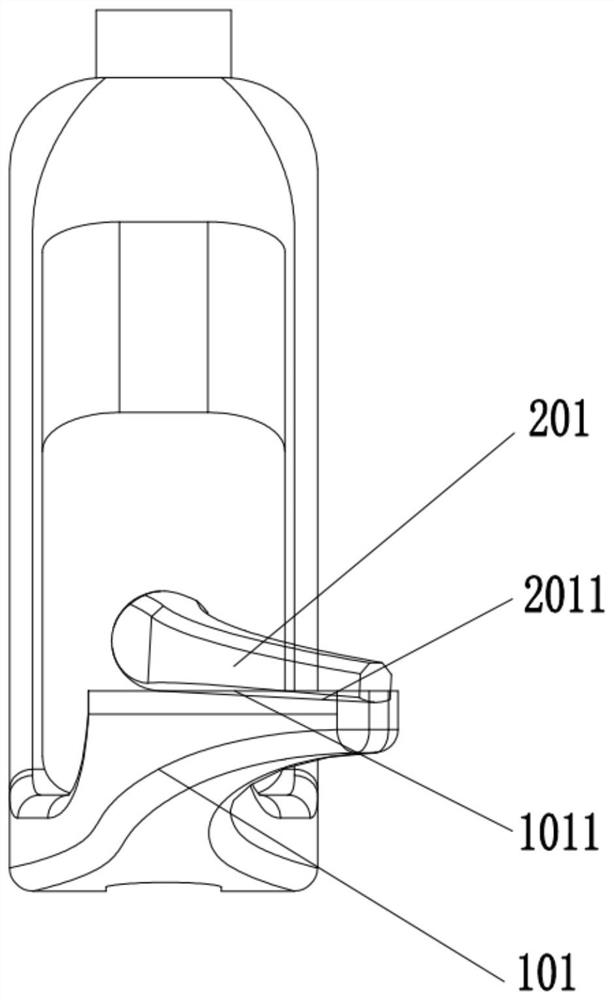

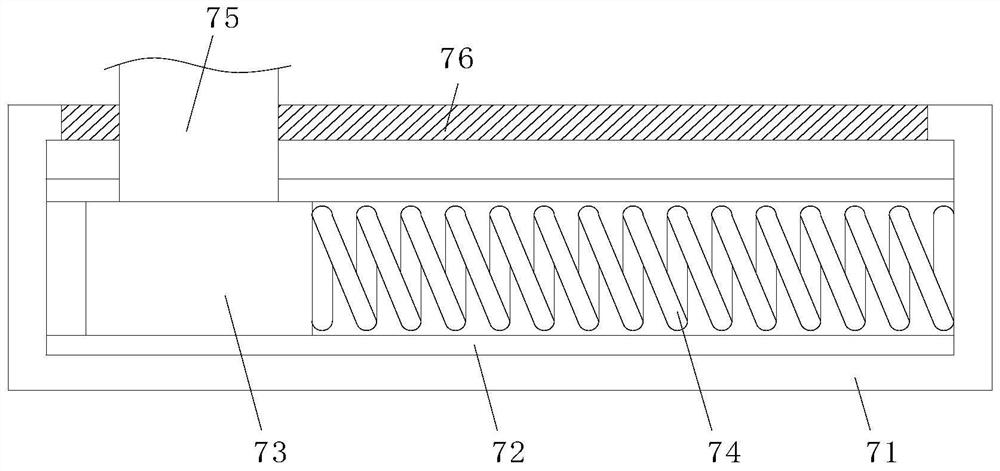

Pulse sensor capable of calibrating static force and pulse collection device

PendingCN106108865APromote the standardization processAll-round collectionCatheterDiagnostic recording/measuringMechanical engineeringForce sensor

The invention discloses a pulse sensor capable of calibrating static force and a pulse collection device equipped with the pulse sensor. The pulse sensor capable of calibrating static force comprises a static force sensor, a dynamic force sensor and a buffer module, wherein the static force sensor is used for measuring pressure applied to a human to-be-detected part by the pulse sensor in the pulse-taking process; the dynamic force sensor is used for measuring dynamic force during pulse beating in the pulse-taking process; and the buffer module is connected with the dynamic force sensor and / or the static force sensor and is used for reducing interference of external jitter on pulse-taking measurement and preventing offset of the measuring position. According to the invention, the pulse information can be acquired in an all-around manner, and capabilities of performing high-sensitivity dynamic force detection, performing accurate static force measurement and acquiring three-dimensional haptical information are guaranteed.

Owner:BEIJING BAIMAIZHILIAN TECH CO LTD

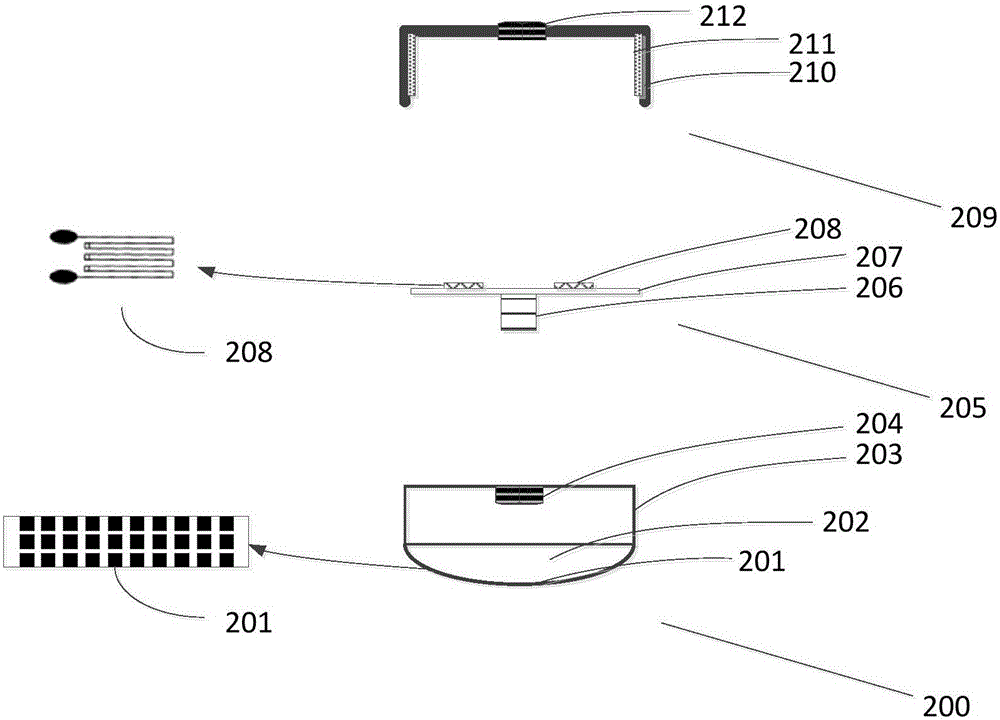

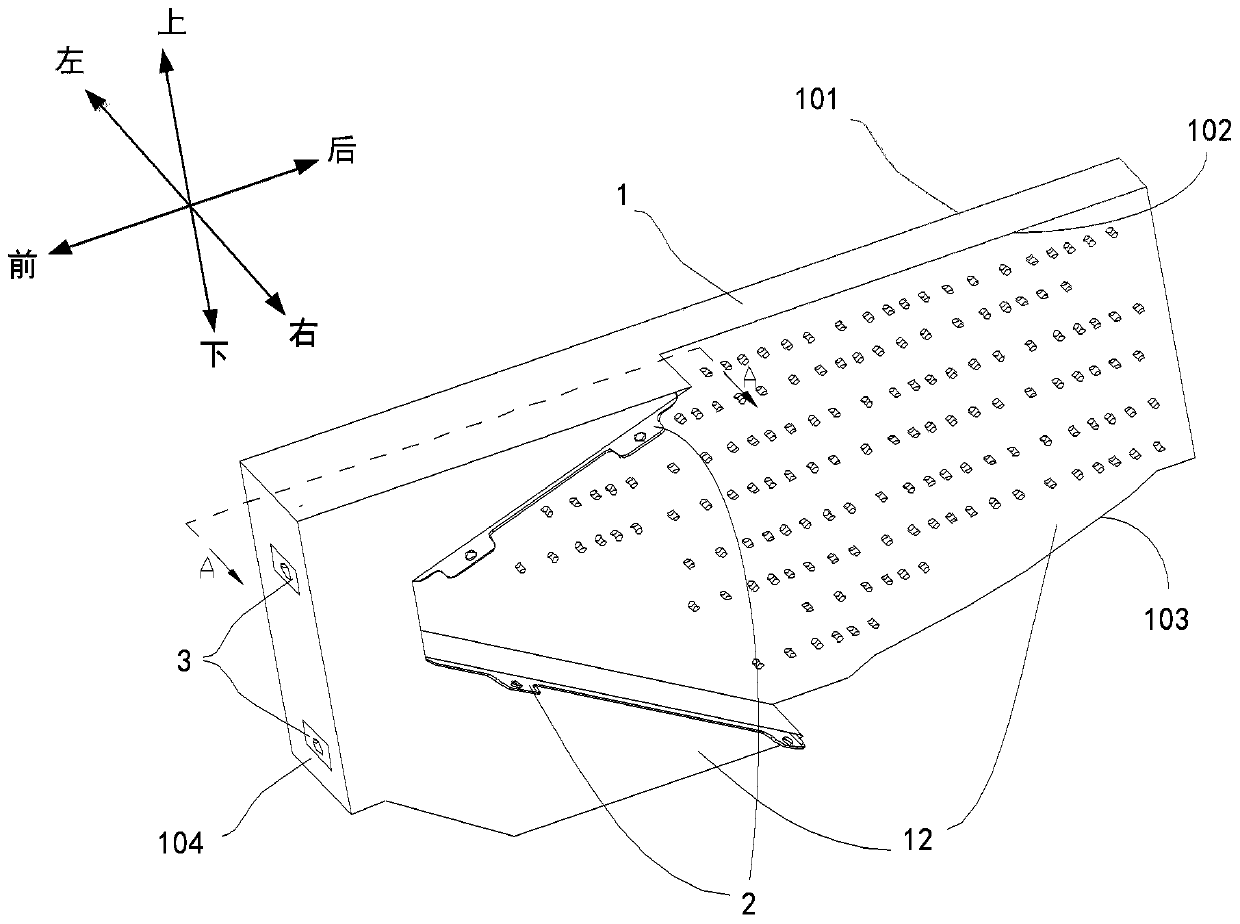

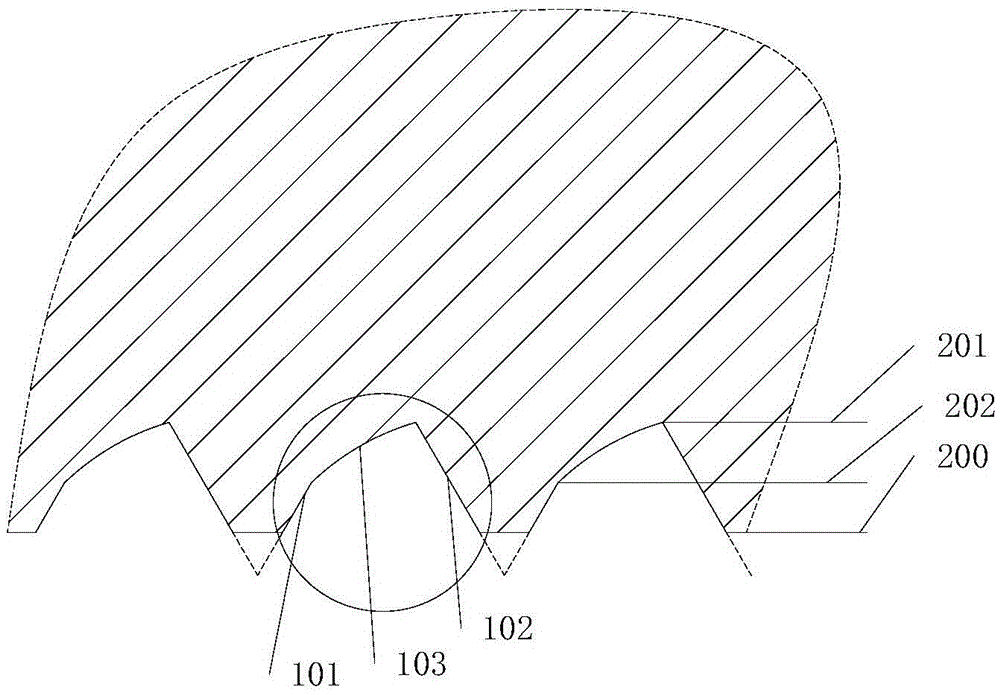

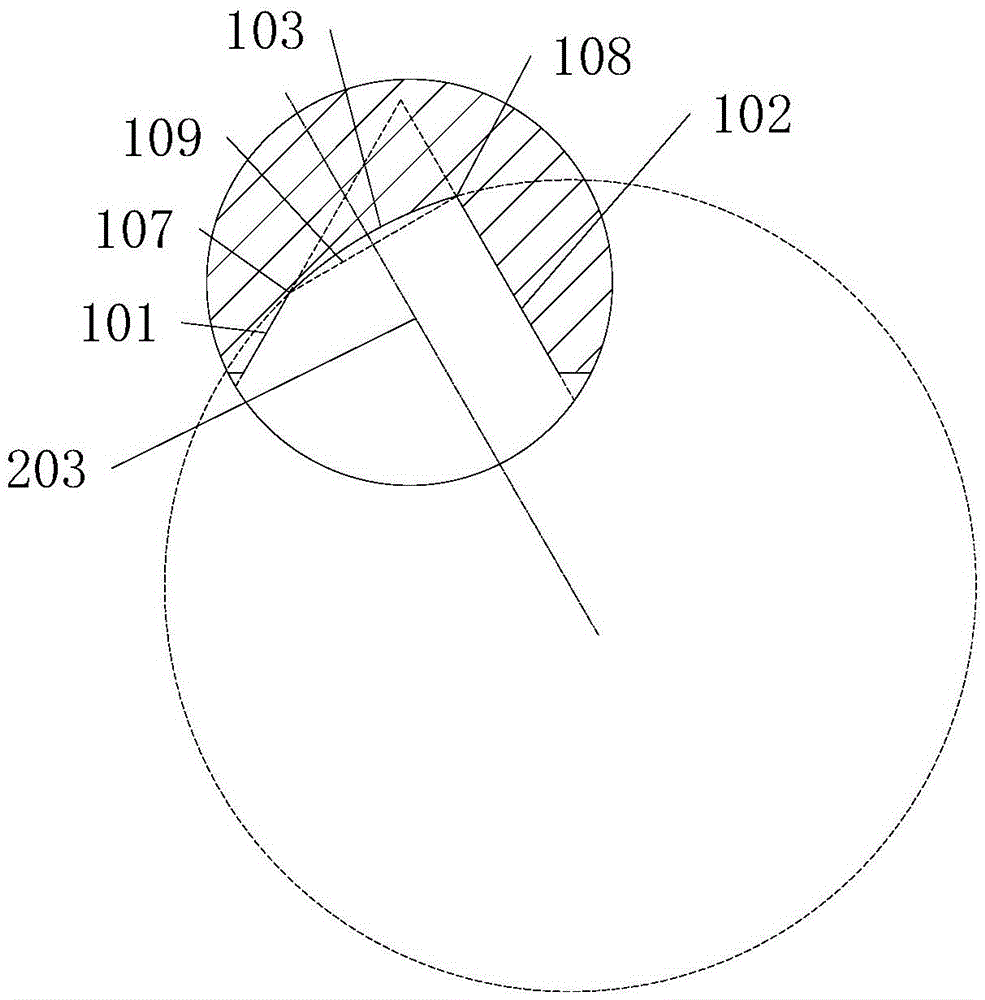

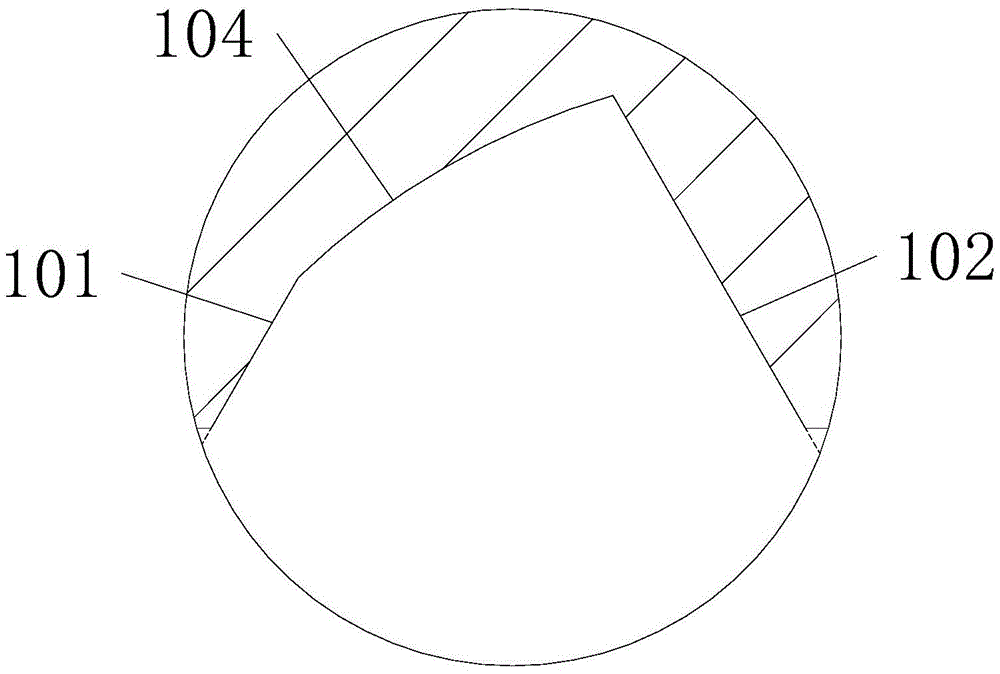

Manufacturing method for satellite borne antenna reflecting surface

The invention relates to a manufacturing method for a satellite borne antenna reflecting surface, particularly relates to a manufacturing method for a high-precision satellite borne antenna reflecting surface adopting a carbon fiber composite panel aluminium honeycomb sandwich structure, and belongs to the technical field of satellite communication and deep space detection. The reflecting surface is shaped like a 'cap with a brim', the periphery of a panel adopts a symmetrical laying layer, and is enabled to form a local thickened symmetrical laying layer, the maintenance of the shape surface precision during the panel forming process and the follow-up operation is facilitated, and the condition that the inboard shrinkage produced due to the differential pressure change during the honeycomb sandwich structure forming process influences the precision of the center reflecting area is prevented.

Owner:BEIJING SATELLITE MFG FACTORY

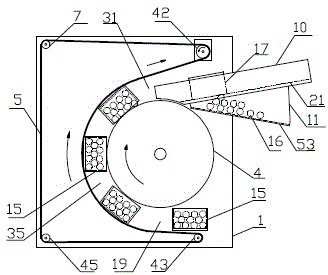

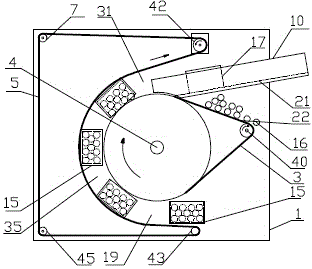

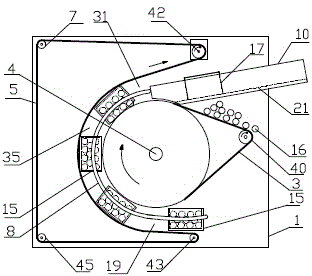

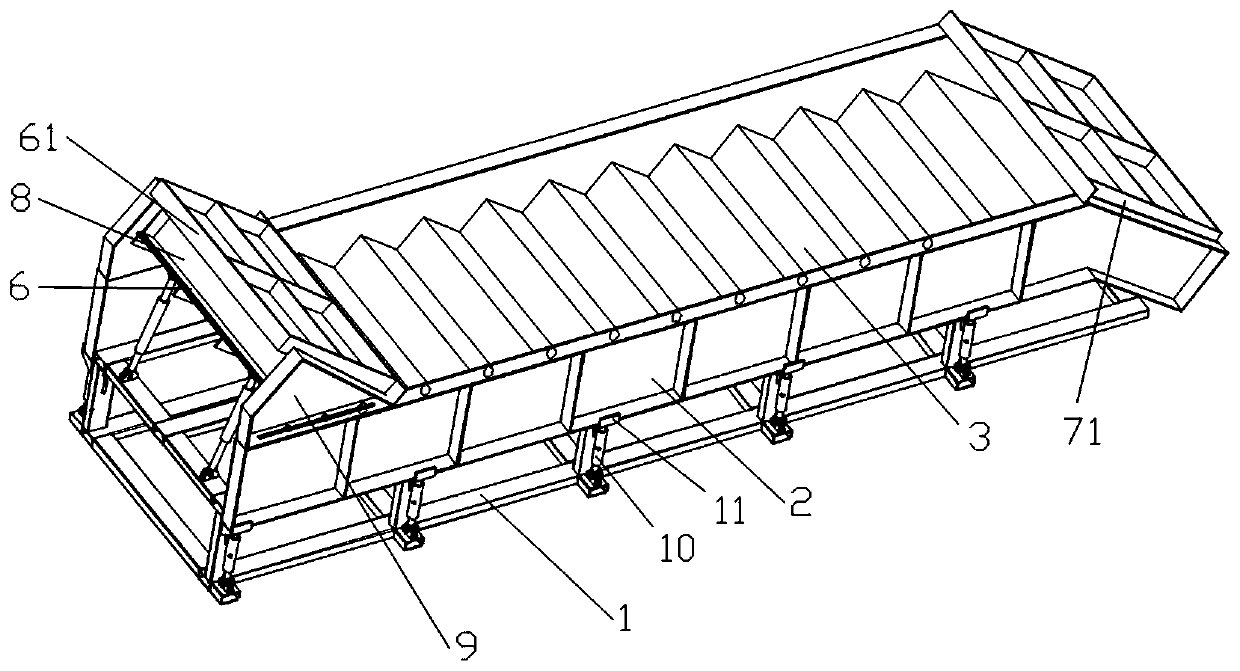

Machine for pouring fruits and vegetables out of boxes

InactiveCN104828568AInhibit sheddingPrevents movement from skewingBottle emptyingLoading/unloadingEngineeringMechanical engineering

The invention discloses a machine for pouring fruits and vegetables out of boxes. The machine comprises a machine frame. A drum wheel, a second driving roll, a driven roll, a third guide roll and a fourth guide roll are arranged on the machine frame, the second driving roll is located above the drum wheel, the driven roll is located below the drum wheel, the third guide roll is located on the upper left of the drum wheel, the fourth guide roll is located on the lower left of the drum wheel, an external pressing belt is wound around the second driving roll, the driven roll, the third guide roll and the fourth guide roll, the drum wheel and the second driving roll both have power input, the drum wheel rotates clockwise, the second driving roll rotates anticlockwise, the external pressing belt is located on the left side of the drum wheel, and the external circumference surface of the drum wheel and the external pressing belt are kept operating synchronously; a conveying channel is formed between the external pressing belt and the drum wheel, a full box entrance is formed between the driven roll and the drum wheel, a full box exit is formed between the second driving wheel and the drum wheel, and a box and fruit separation device is arranged at the full box exit. The machine is capable of pouring the fruits and vegetables out of the boxes continuously and efficiently and low in fruit and vegetable damage rate.

Owner:MAF RODA MACHINERY YANTAI CO LTD

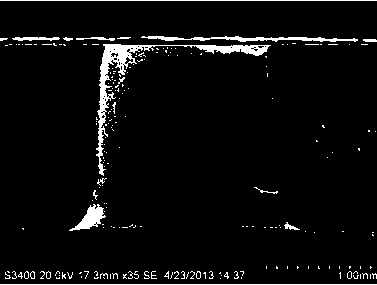

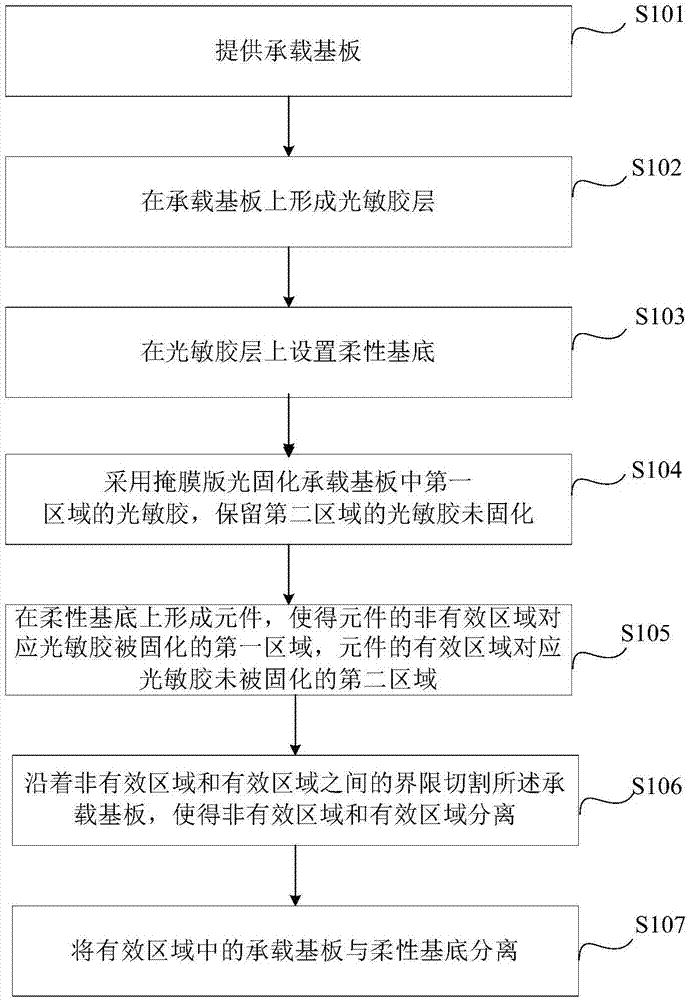

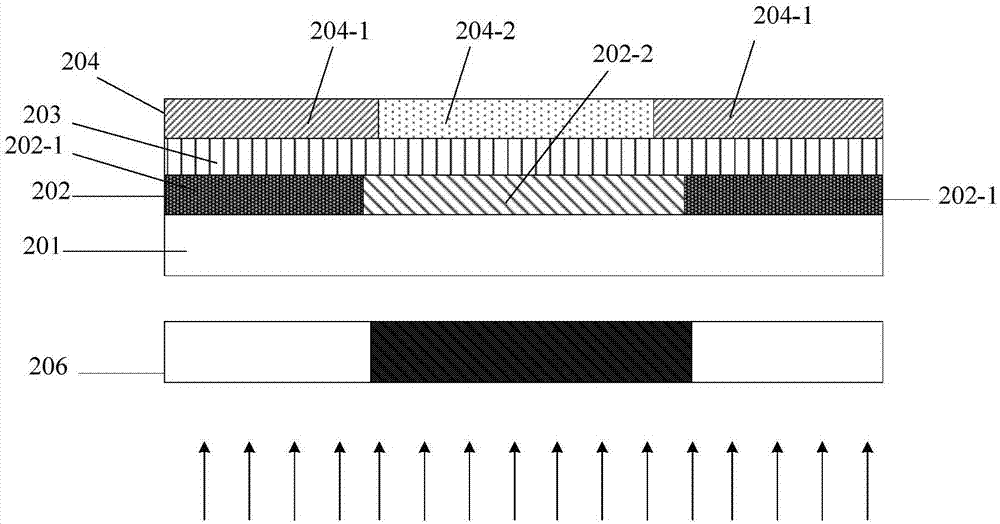

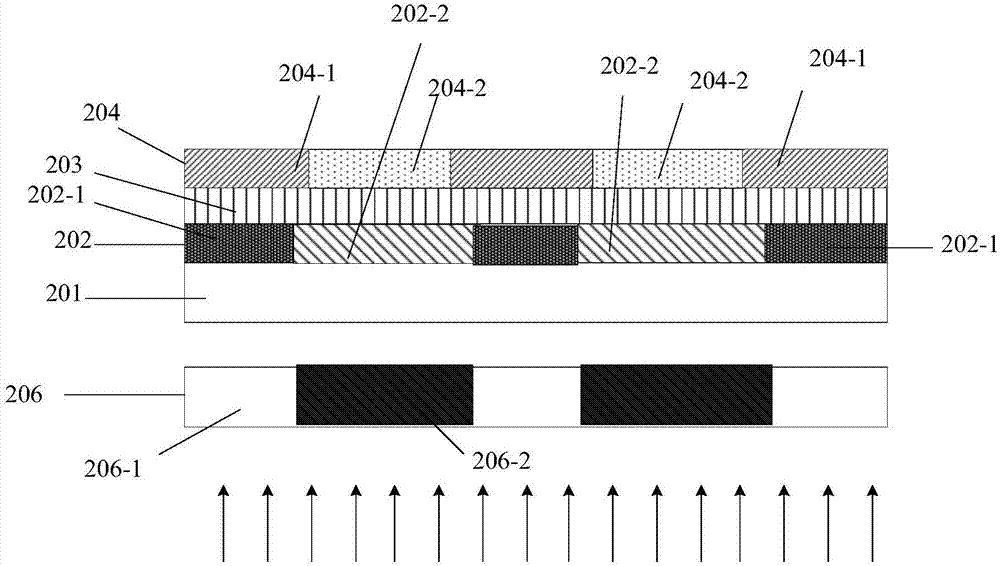

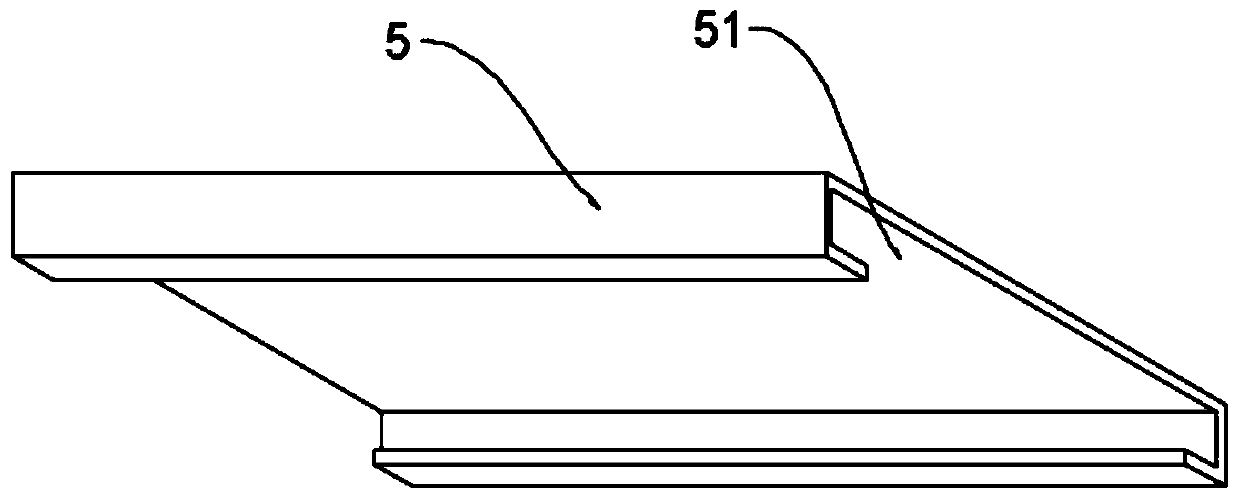

Flexible substrate and method for manufacturing the same, flexible display device and flexible display apparatus

InactiveCN107482022AGuaranteed a tight fitPrevent falling offFinal product manufactureSolid-state devicesEngineeringLight cure

Owner:BOE TECH GRP CO LTD +1

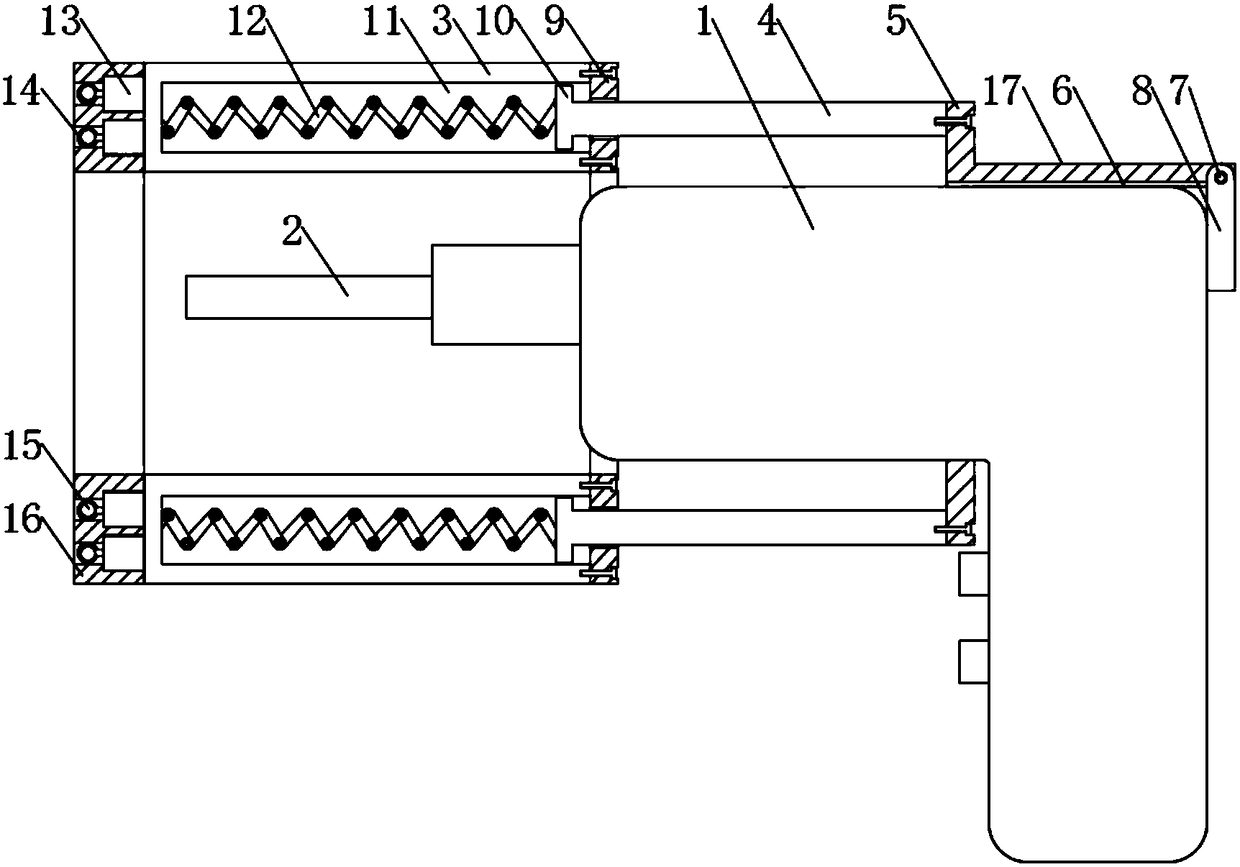

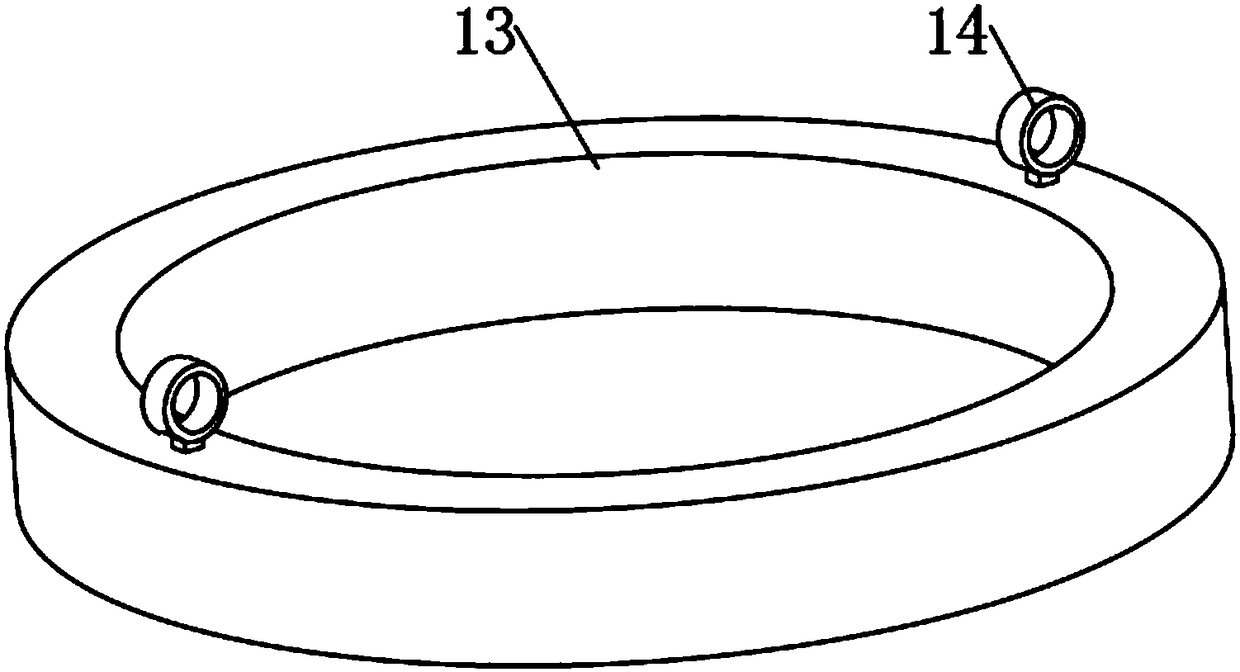

Dustproof electric hand drill

InactiveCN108405929AReasonable structureFunctionalPortable power-driven toolsPortable drilling machinesDrill bitPetroleum engineering

The invention discloses a dustproof electric hand drill. The dustproof electric hand drill comprises an electric hand drill body, a drill bit, a transparent dustproof cover ring and a fixed observingring; the drill bit is arranged on the left side of the electric hand drill body; the transparent dustproof cover ring is arranged on one circle of the outer side of the drill bit, and is internally provided with a telescopic groove; and a limiting plate is movably arranged in the telescopic groove. In the device, the electric hand drill body is reasonable in external structure design, the dustproof performance is good, and using is convenient; in the using process of the electric hand drill, dust is sealed in the transparent dustproof cover ring and cannot leak out, the dustproof performanceis high, and the protecting performance for human body health is good; in the using process of the electric hand drill, a rubber sealing ring guarantees tight attaching with a wall or an object, the dust is completely sealed in the transparent dustproof cover ring, the dust-free effect is guaranteed, and the dustproof electric hand drill is suitable for popularization.

Owner:陈永强

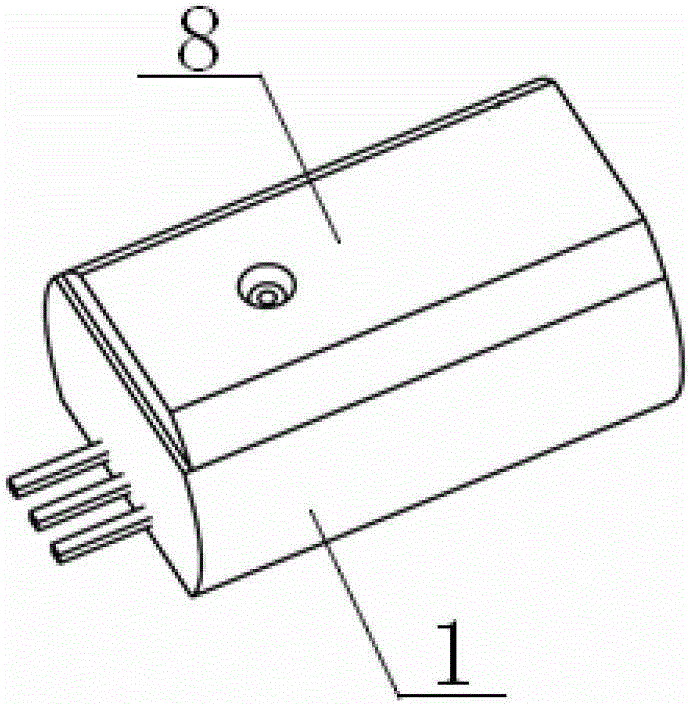

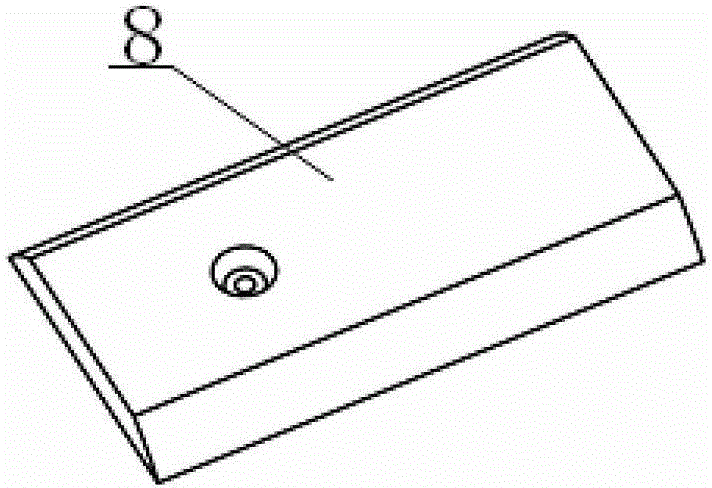

Modular sensor and manufacturing technique thereof

ActiveCN103336139AAccurate and stable positioningPrecise positioningSpeed/acceleration/shock instrument detailsDevices using electric/magnetic meansPins needlesComputer module

The invention discloses a modular sensor and a manufacturing technique thereof. The modular sensor comprises a cavity module, a framework module, a circuit board, a Hall chip and a cover plate, the top of the cavity module is opened, a positioning groove is formed in the bottom of the cavity module, and the cavity is integrally injected and molded with PIN needle module; strip through holes are formed in the rear end of the framework module, two position spacing tables are arranged on the upper end surface of the framework module, a positioning lug boss is arranged on the lower end surface of the framework module, and a clamp groove comprising two buckles and one support table and used for accommodating the hall chip is formed in the outer part of the front end of the framework module. The buckle adopts an inner side interference pointed hook part and an end surface hot riveting spur, so as to enable the hall chip to be fixed and confined in the space; the elasticity of the metal PIN needle and the matching structure of the cavity module and the framework module guarantee the framework module to be accurately positioned and fixedly connected in the cavity body module, and prevent the electric element from being damaged after glue flowing uncontrolled cover the electronic element temperature shock; the front end surface of the hall chip and the front cavity surface of the cavity module are closely pressed, but the compression force is not so large as to cause deformation and damage of the cavity module front end, so as to effectively guarantee sensor information.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

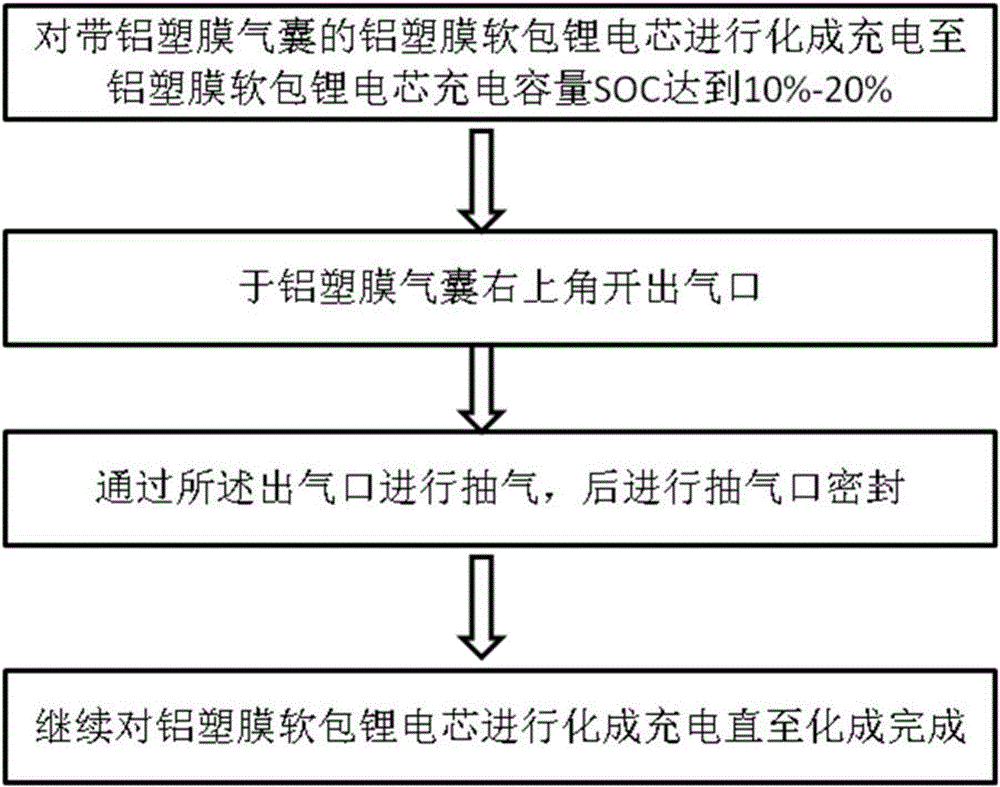

Formation method for reducing gas retention in formation process of flexibly-packaged lithium battery

InactiveCN106450531APhenomena that affect tight fitGuaranteed a tight fitSecondary cells charging/dischargingEngineeringGas retention

The invention discloses a formation method for reducing gas retention in a formation process of a flexibly-packaged lithium battery. The formation method is characterized by comprising the following steps of 1) performing formation charging on an aluminum plastic film flexibly-packaged lithium cell with an aluminum plastic film airbag until the charging capacity SOC of the aluminum plastic film flexibly-packaged lithium cell reaches 10-20%; 2) forming an exhausting opening in the right upper corner of the aluminum plastic film airbag; 3) performing exhausting from the exhausting opening, and then sealing the exhausting opening; and 4) continuing to perform formation charging on the aluminum plastic film flexibly-packaged lithium cell until the formation is completed. By adoption of the formation method for reducing gas retention in the formation process of the flexibly-packaged lithium battery, a phenomenon of influence to tight fitting among a positive plate, the negative plate and a diaphragm caused by retention of a large amount of gas, which is generated by an SEI produced on the surface of a negative plate, and other side reactions in the initial period of formation, in the interior of the cell, can be avoided; and therefore, the tight fitting among the positive plate, the negative plate and the diaphragm in the formation process is ensured.

Owner:GUOXUAN NEW ENERGY SUZHOU CO LTD

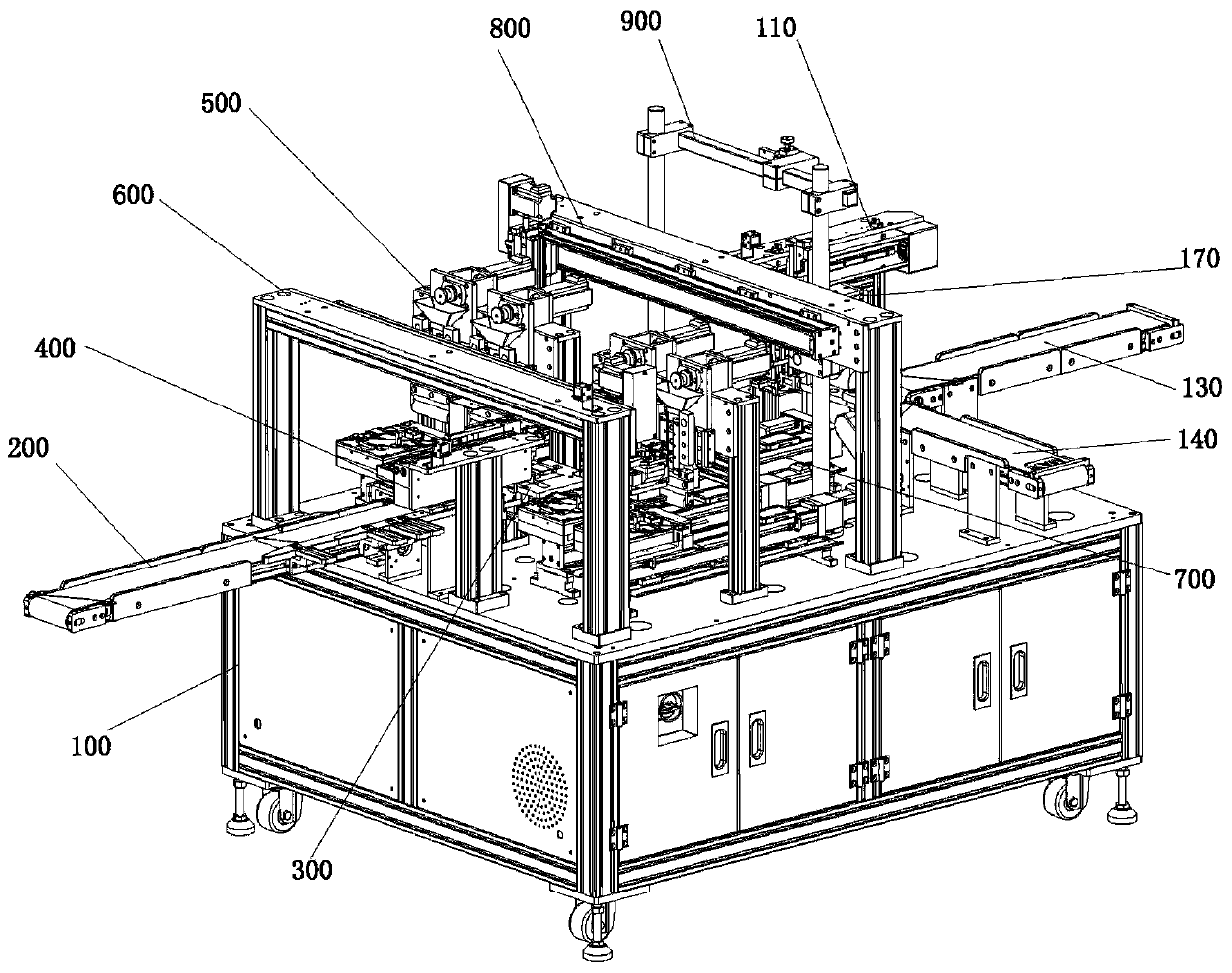

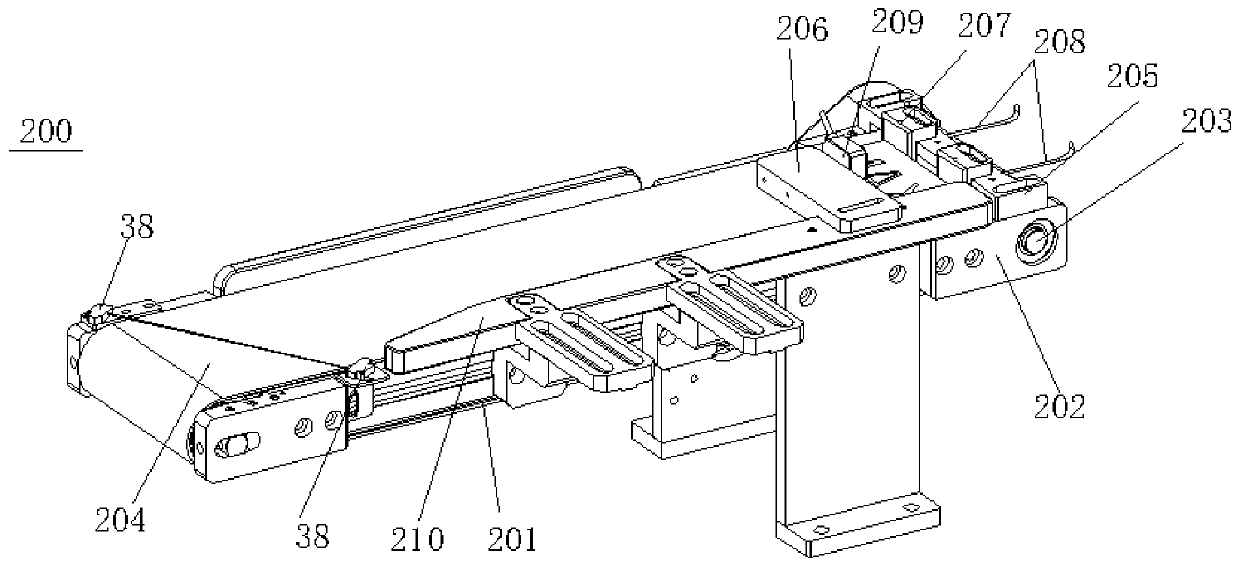

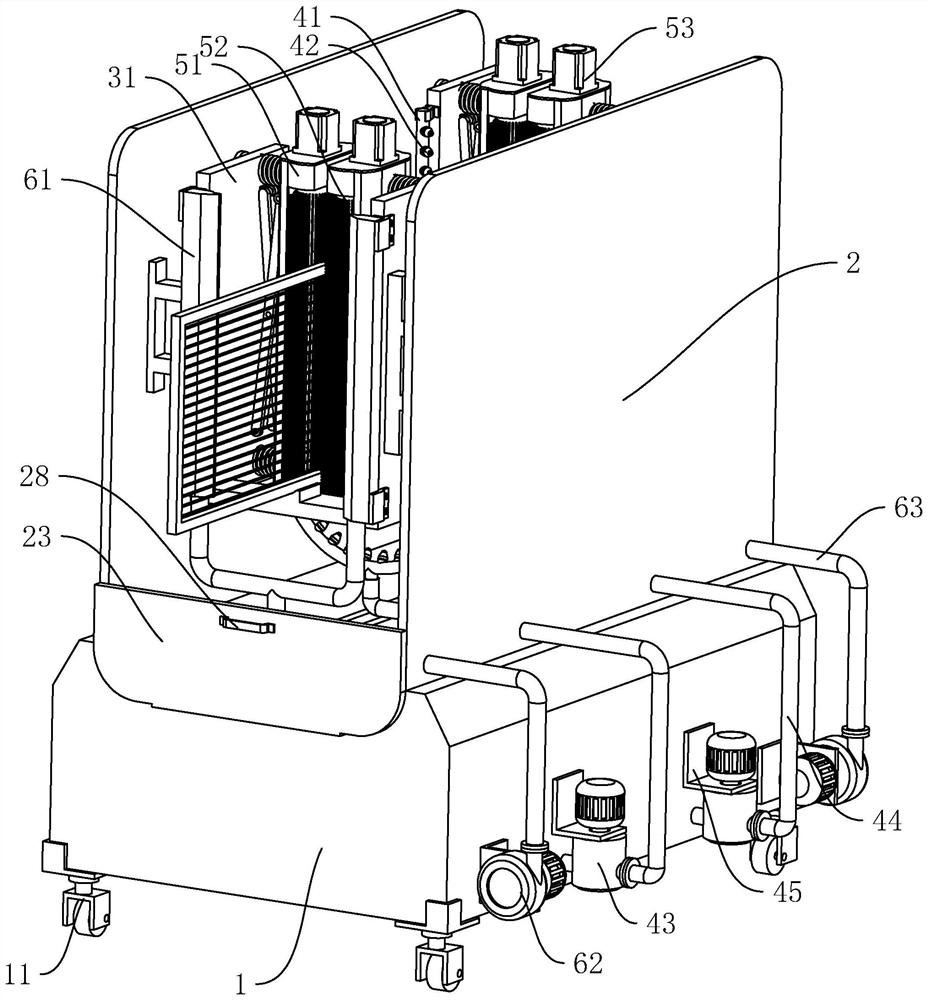

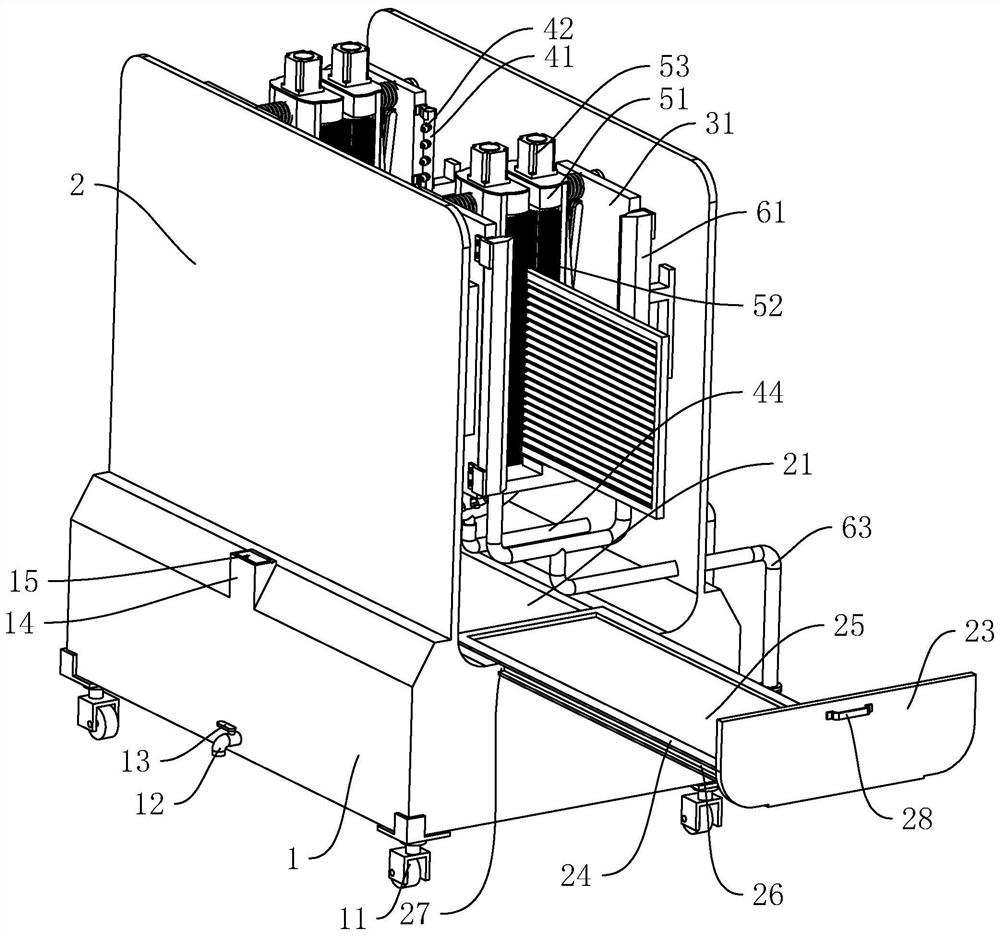

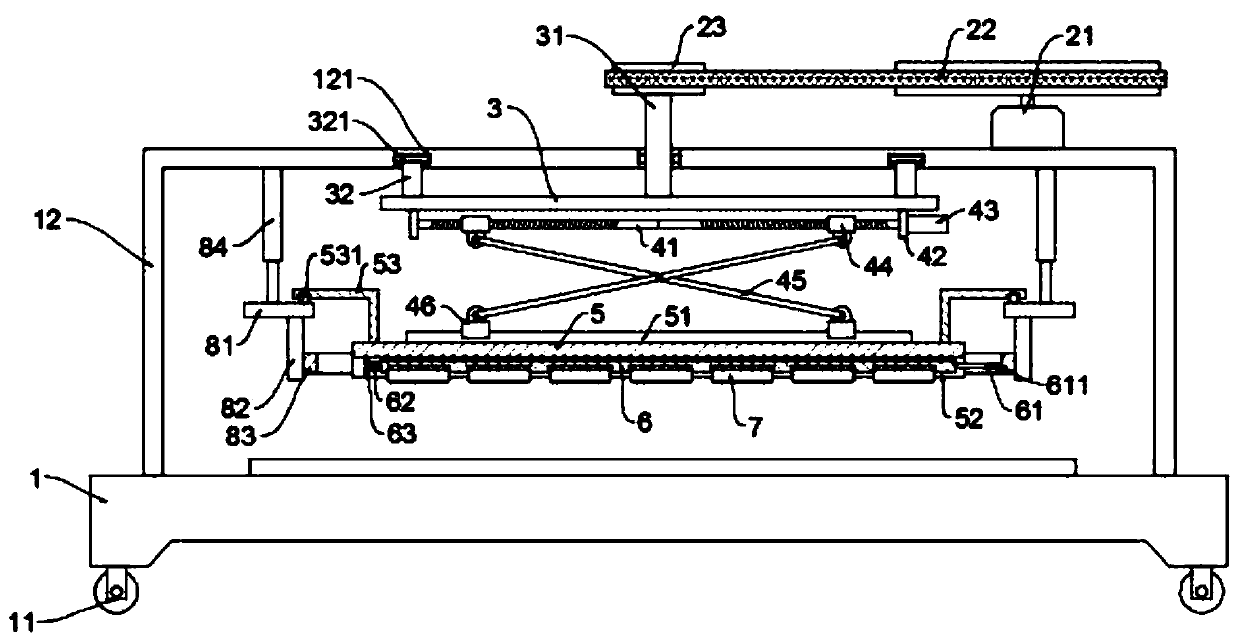

Battery membrane laminator

ActiveCN110137558AGuaranteed a tight fitEliminate air bubblesPrimary cell manufactureAssembling battery machinesManipulatorFixed time

The invention discloses a battery membrane laminator comprising a lower rack which is provided with a feeding line, a feeding manipulator for conveying a battery on the feeding line to a secondary positioning device, a membrane laminating feeding manipulator for conveying the battery on the secondary positioning device to a membrane laminating air pressure device for pressing a membrane, and a membrane laminating discharging manipulator for conveying the battery after membrane lamination of the membrane laminating air pressure device to a discharging air pressure module, wherein the secondarypositioning device is arranged between two groups of membrane laminating air pressure devices, and the discharging air pressure module conveys the membrane laminated battery to the position of a CCD detection device for quality detection. The battery with the laminated membrane can be rolled at the fixed time, and then the lamination state of the laminated membrane after rolling of the battery isdetected. The photoelectric sensor is aligned in secondary positioning to detect the height of the battery, and a rolling module is arranged to set the fixed time and the number of rolls back and forth in the rolling process of the battery so that the close contact of the membrane rolling of the battery can be ensured.

Owner:GUANGDONG DONGBO AUTOMATION EQUIP CO LTD

Prefabricated stair mold

Owner:内蒙古中朵远大建筑工业有限公司

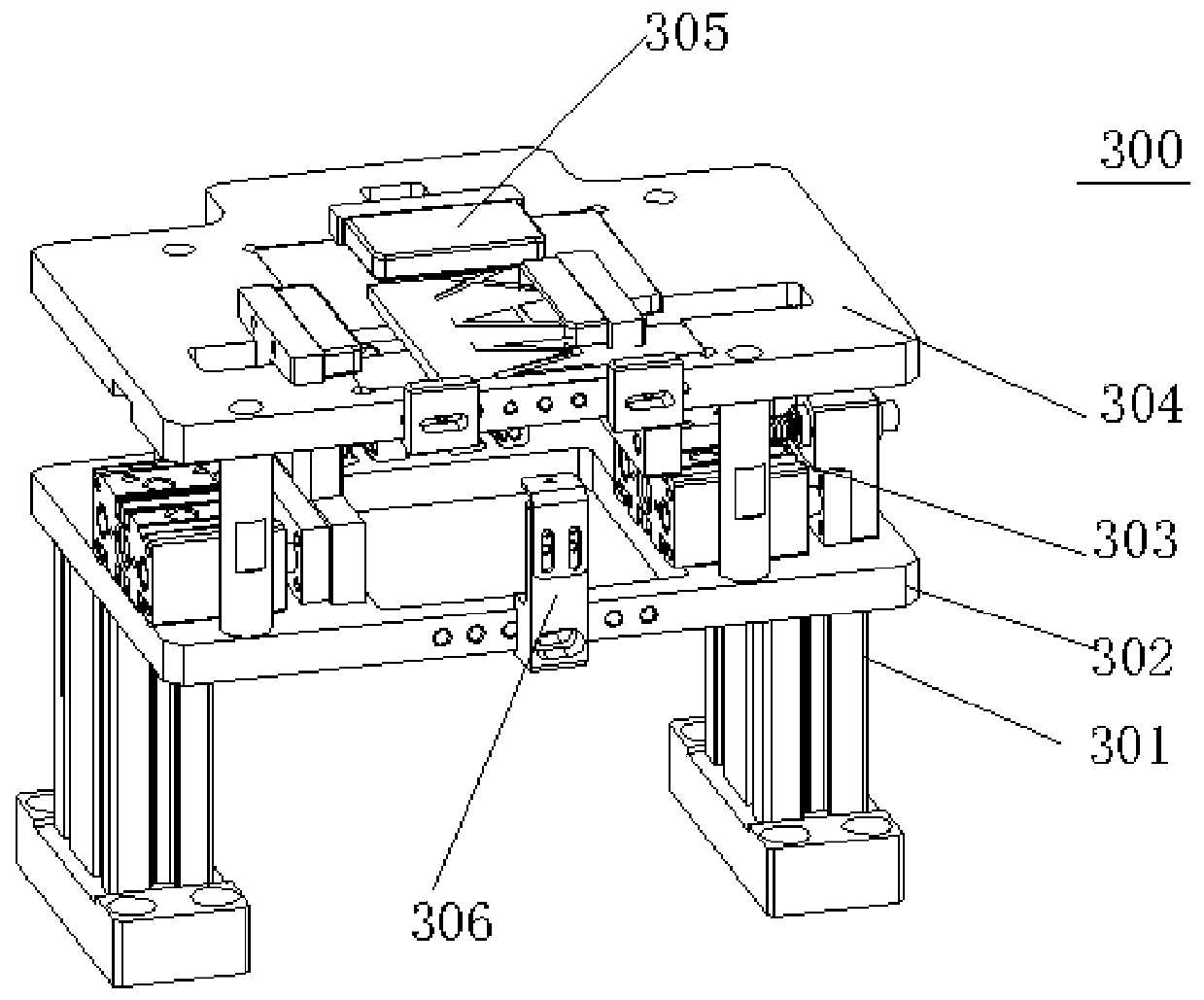

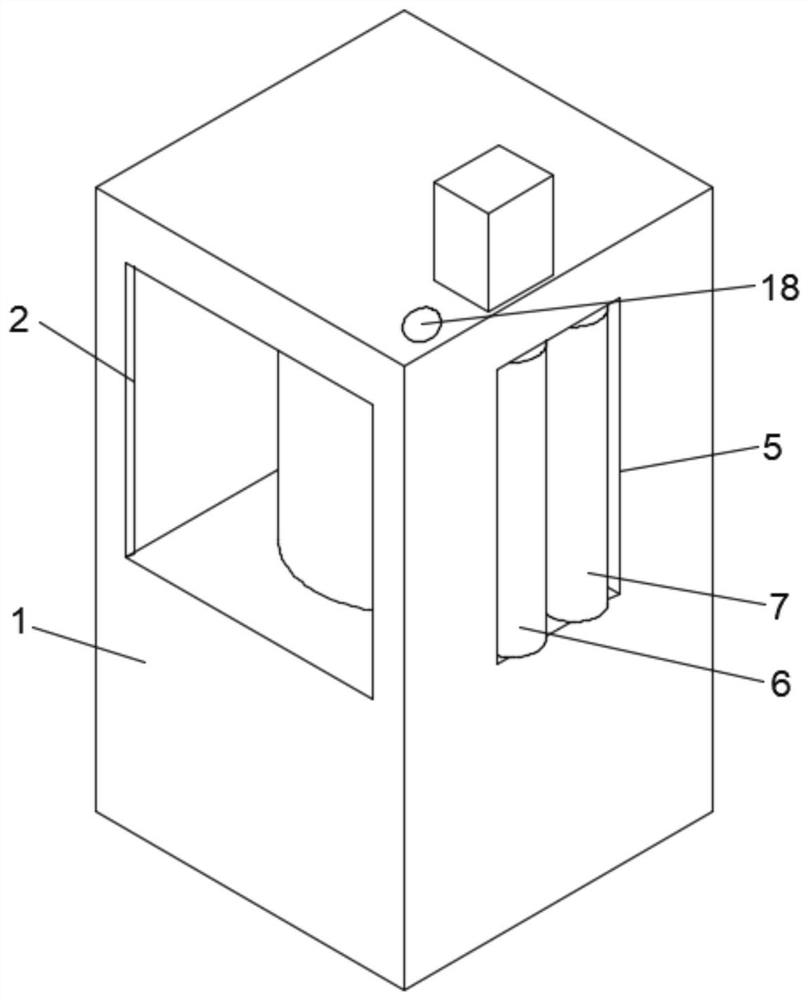

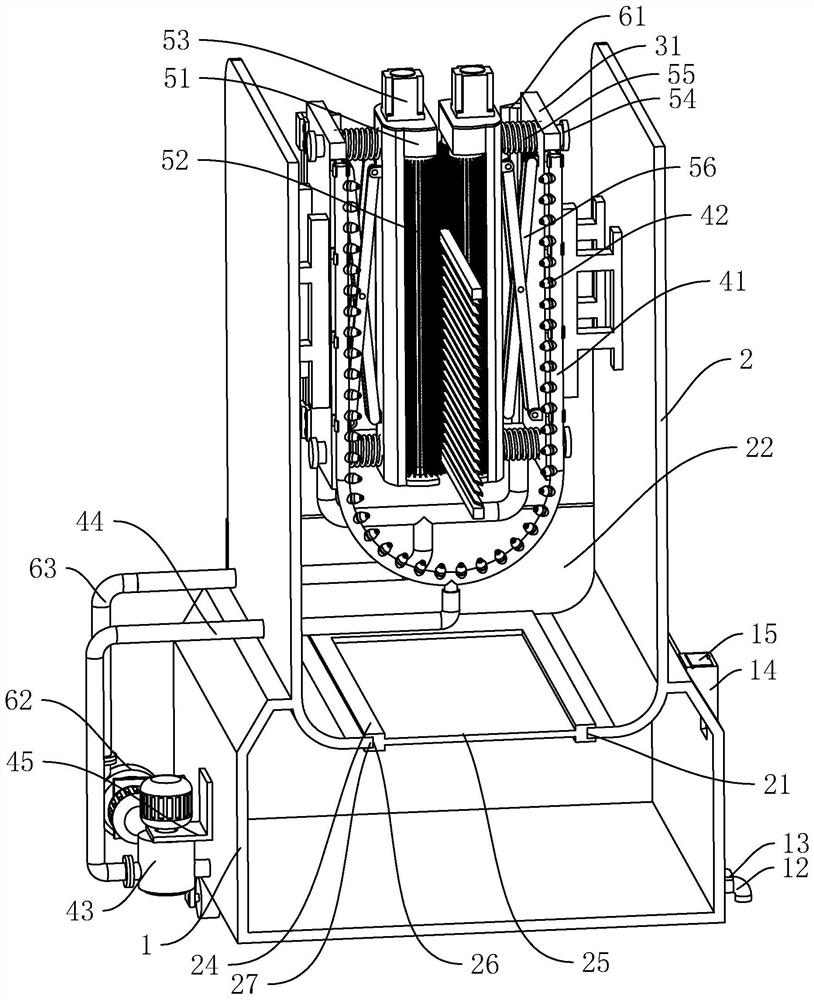

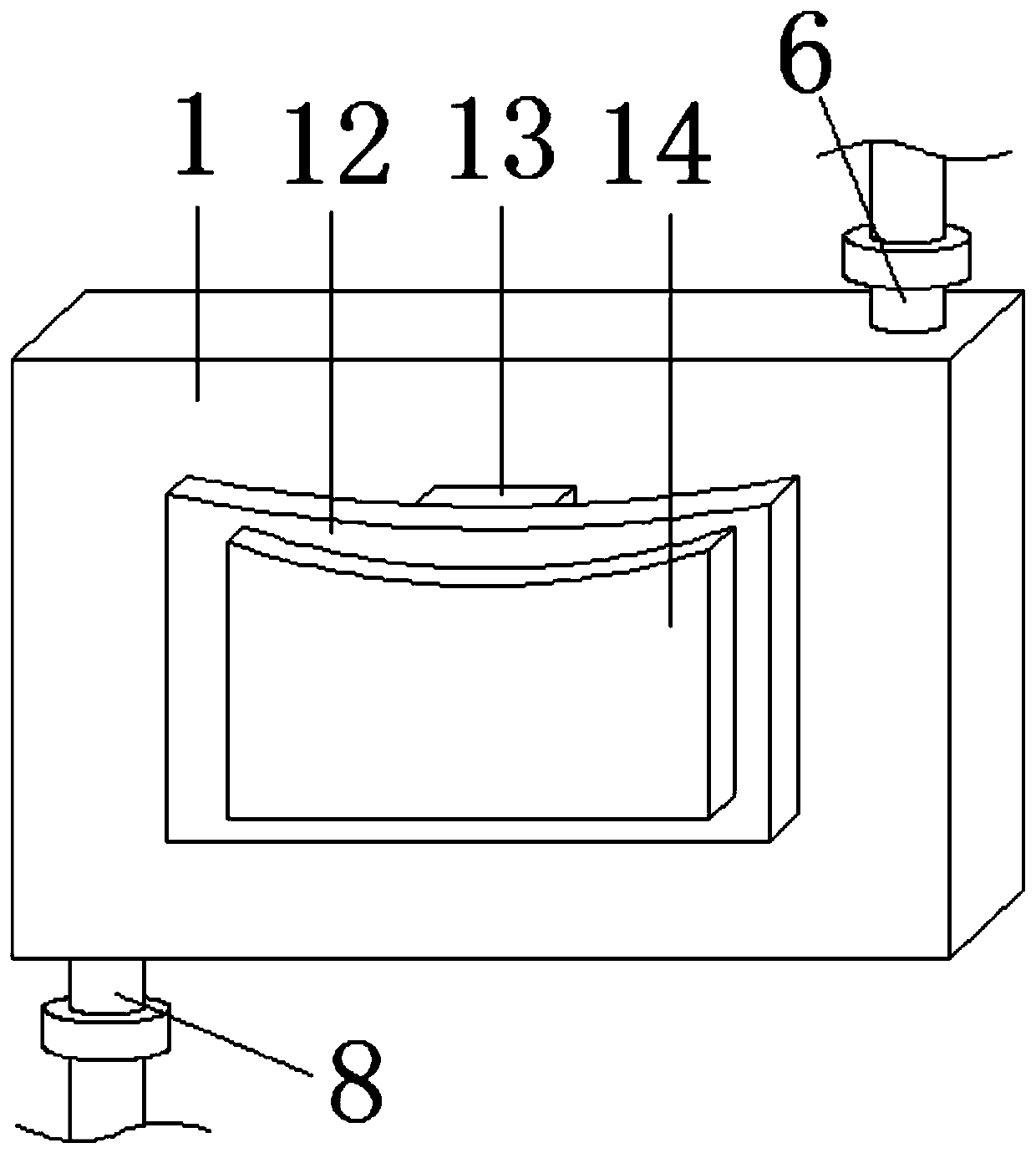

Oil-immersed transformer end insulation automatic bonding machine

PendingCN112201473AGuaranteed a tight fitImprove adhesionLiquid surface applicatorsCoatingsElectric machineTransformer

The present invention discloses an oil-immersed transformer end insulation automatic bonding machine. The oil-immersed transformer end insulation automatic bonding machine comprises a main body, a bonding cavity is formed in the front side wall of the main body, the lower side wall of the bonding cavity is rotationally connected with a rotating table, the lower side wall of the rotating table is fixedly connected with a first motor, the first motor is fixedly installed in an inner cavity of the main body, and an insulation paper input groove is formed in the right side wall of the bonding cavity; the first gear and the second gear are located in the driving cavity, the first motor drives the rotating table to rotate, the second motor drives the first roller to rotate so that insulation paper can enter the bonding cavity, then the first roller is glued through the gluing device so that the insulation paper can be bonded to the side wall of the iron core, and then the insulation paper isextruded through the extrusion roller. By means of the iron core insulation paper pasting device, pasting of the iron core insulation paper can be simpler and more convenient, and manpower and material resources are saved.

Owner:康利源科技(天津)股份有限公司

Composite method of composite BOPP film of art paper

InactiveCN103042805AGuaranteed a tight fitLess prone to glitchesSynthetic resin layered productsLaminationEngineeringCopper

The invention relates to a composite method of a composite BOPP film of an art paper. The method comprises (1) mounting the BOPP film coils and the art paper coils on a compositing machine; (2) injecting a dry coating glue into the compositing machine and starting a heating system of a dryer; (3) starting a transmission motor when a set temperature is achieved and beginning production; (4) drawing the BOPP film coils to pass through an anilox roller through an anti-coiling device, coating the glue and drying; and (5) applying the BOPP film coils and the art paper coils to finish the composite technology. According to the invention, by adjusting different parameters during a production process of the compositing machine, the special technological parameters cooperate with each other, thereby ensuring tight applying between the thin film and the art paper, hardly occurring burr and cracked skin whether during cutting time or using in the future, shortening production period, improving production efficiency and reducing production cost.

Owner:TIANJIN GUANGMING PRINTING

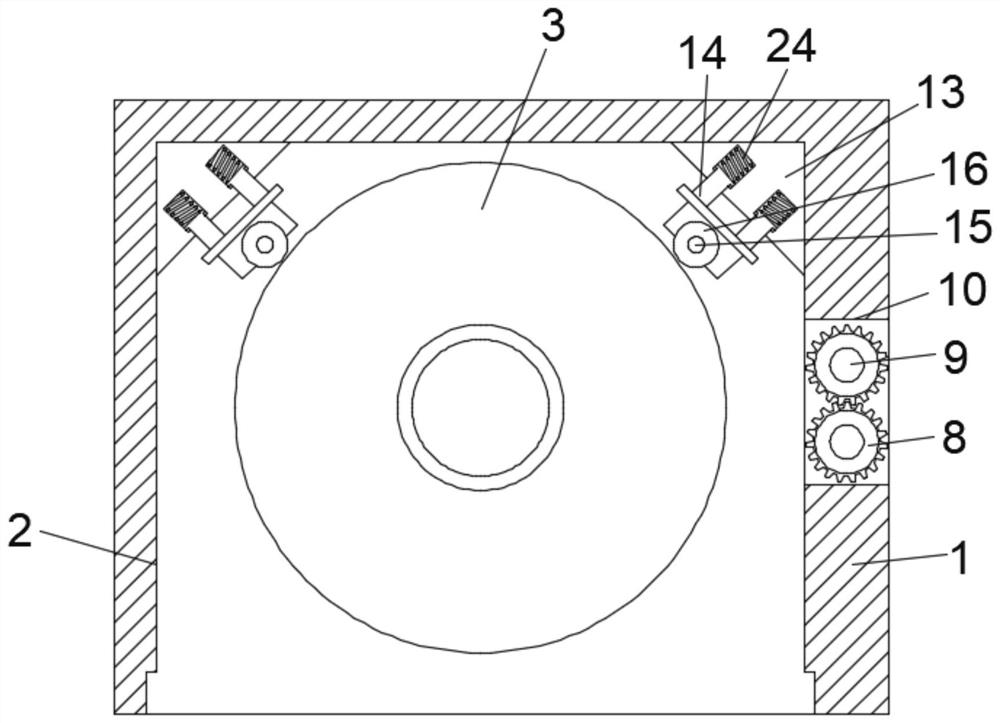

Yarn waxing device

The invention discloses a yarn waxing device which comprises a machine frame. The device further comprises a wax block fixing unit and a drive unit, and the wax block fixing unit is installed on the machine frame and provided with a positioning part used for fixing a wax block. An output shaft of the drive unit is fixedly connected with the positioning part and drives the positioning part to rotate, and the positioning part drives the wax block to rotate. Compared with the prior art, the yarn waxing device can be directly matched with a flat knitting machine or other similar kinds of knitting machines in use, an original waxing mode of a groove drum machine or a winding machine can be completely replaced, and accordingly yarn waxing and knitting efficiency is improved. Besides, due to independent operation, influences on yarn tension are reduced, accordingly waxing stability is guaranteed, and yarn waxing uniformity is improved.

Owner:JIANGSU JINGMENG KNITTING

Oil-free constant-temperature compressor

InactiveCN104696196AGuaranteed a tight fitPrevent leakagePositive displacement pump componentsPositive-displacement liquid enginesWater storageHigh temperature storage

The invention provides an oil-free constant-temperature compressor. The oil-free constant-temperature compressor comprises a body, a turbine, a piston, a first exhaust valve, a second exhaust valve, a first temperature sensor, a second temperature sensor, a first suction pump and a control module, wherein a compressing chamber, an exhausting chamber, a cooling chamber, a cooling water storage chamber and a gas storage chamber are arranged inside the body. An elastic cushion is arranged inside the oil-free constant-temperature compressor to ensure tight adhesion of the piston to the exhausting chamber so as to prevent leakage of compressed gas; the elastic cushion also can protect the piston, so that abrasion and oiling lubrication during the motion of the piston are avoided, and further oil strains are prevented from entering the compressed gas and completely oil-free gas compression can be achieved. In the oil-free constant-temperature compressor, the compressed gas is cooled in the cooling chamber through cold exchange of a cooling coil, and is then pumped into the gas storage chamber and stored, so that high-temperature storage risks of the gas can be avoided; through arrangement of the cooling water storage chamber, circulating replacement of cooling water can be achieved, so that the cooling effect of the cooling coil is ensured and the cyclic utilization of cooling water is achieved.

Owner:安徽寅时压缩机制造有限公司

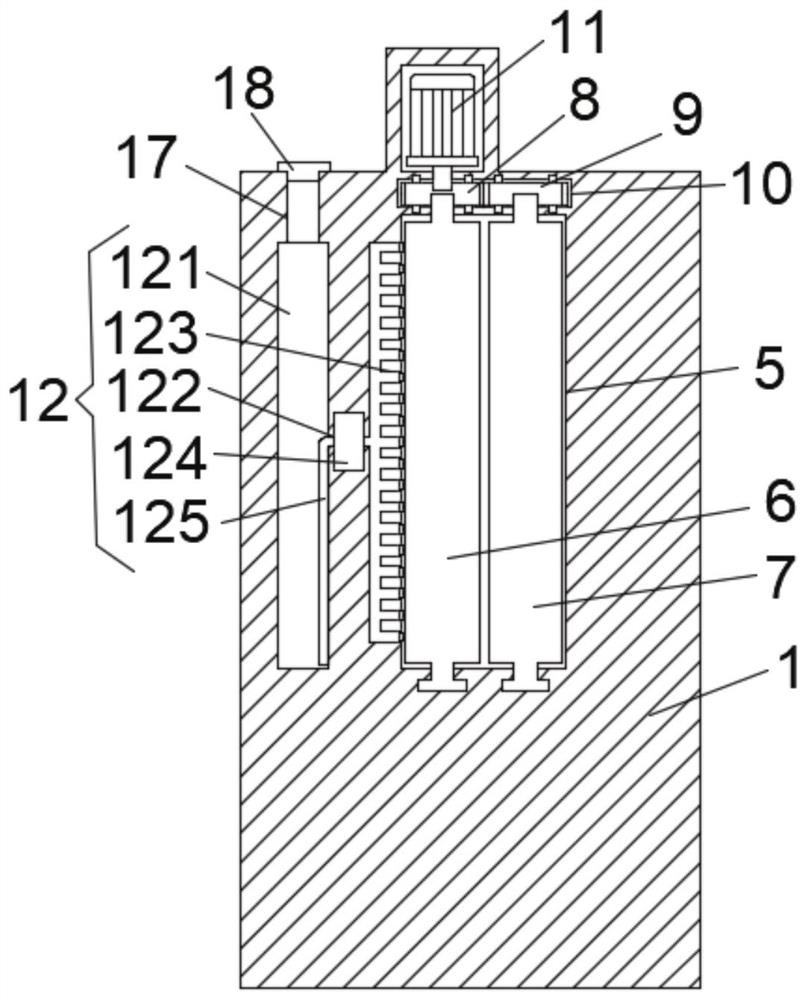

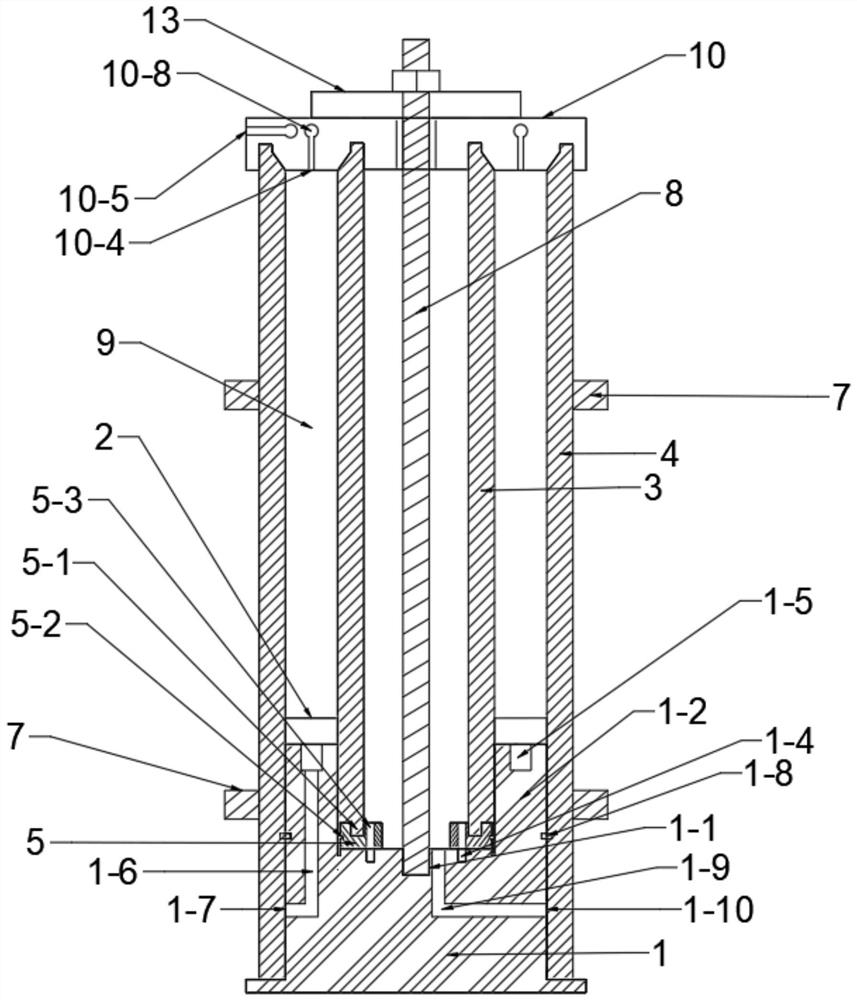

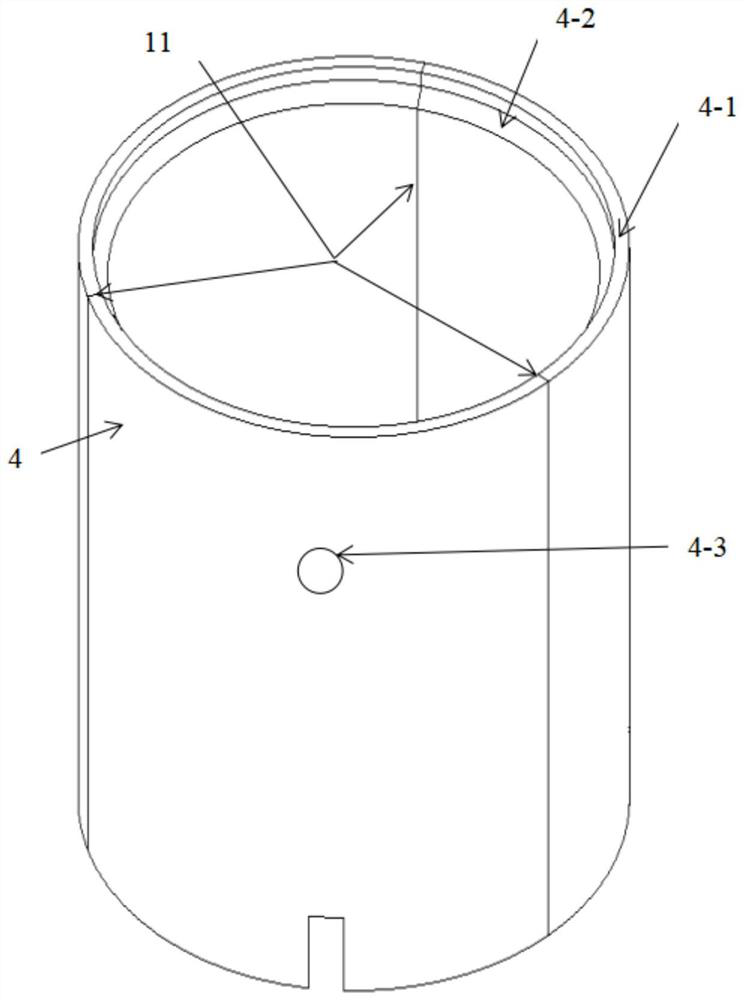

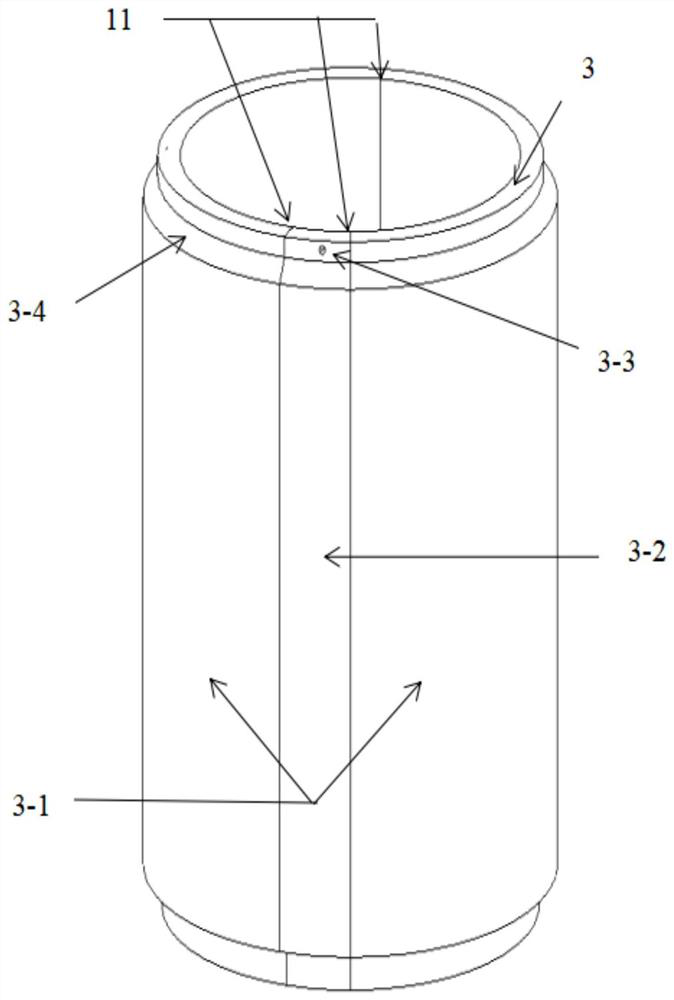

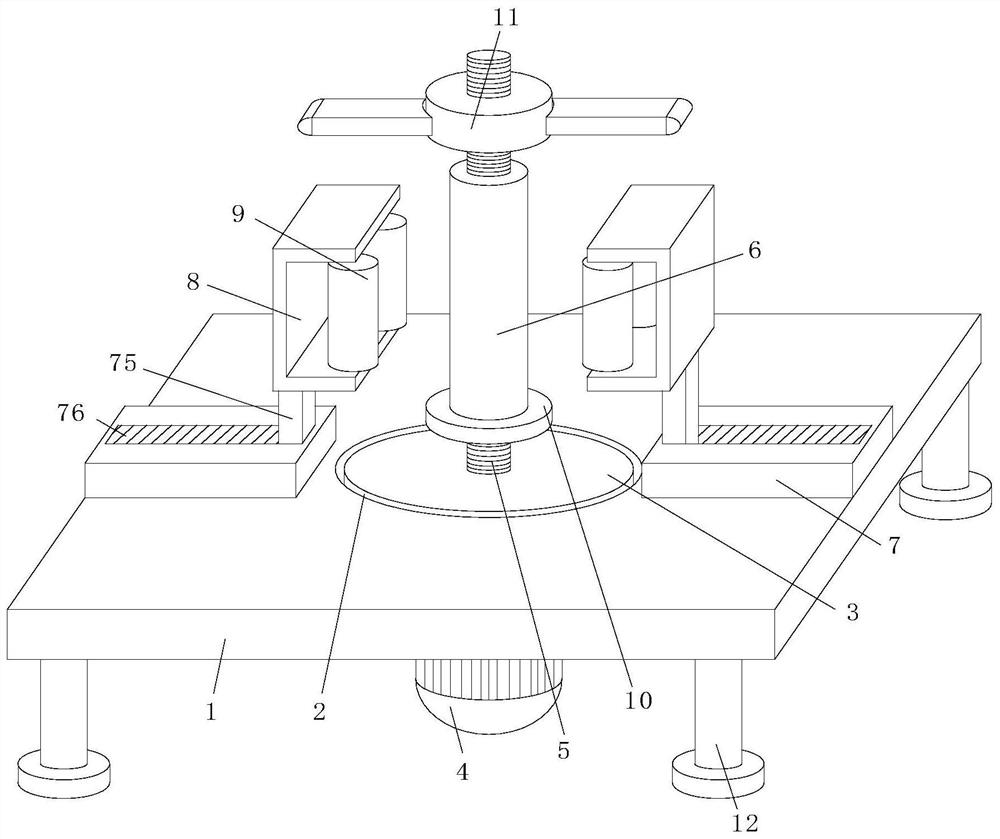

Hollow cylindrical sample preparation device for microorganism solidified sandy soil and use method

ActiveCN112747983AGuaranteed fillingEnsure normal dischargePreparing sample for investigationMaterial strength using steady torsional forcesMicroorganismSoil science

The invention discloses a hollow cylindrical sample preparation device for microorganism solidified sandy soil and a use method thereof. The device comprises a base, an inner cylinder, an outer cylinder and an injection cap, the inner cylinder, the outer cylinder and an annular support seat are utilized to form a sample bin, and an injection channel and a liquid discharge groove are utilized to ensure injection and discharge of a liquid; mould cylinders used by the inner cylinder and the outer cylinder are spliced by adopting ''V''-shaped bayonets, and iron rods penetrate through traction holes in small petals of the inner cylinder so that disturbance to a hollow cylindrical sample is effectively avoided, and the standard size of the hollow cylindrical sample and the reliability of the test are ensured; and the technical problems that a bacterial liquid and a reaction liquid cannot be discharged in the preparation process of the hollow cylindrical microorganism solidified sample and disturbance is large during sampling are effectively solved, the integrity of the sample is guaranteed, and the reliability of an experimental result is improved.

Owner:NANJING UNIV OF TECH +1

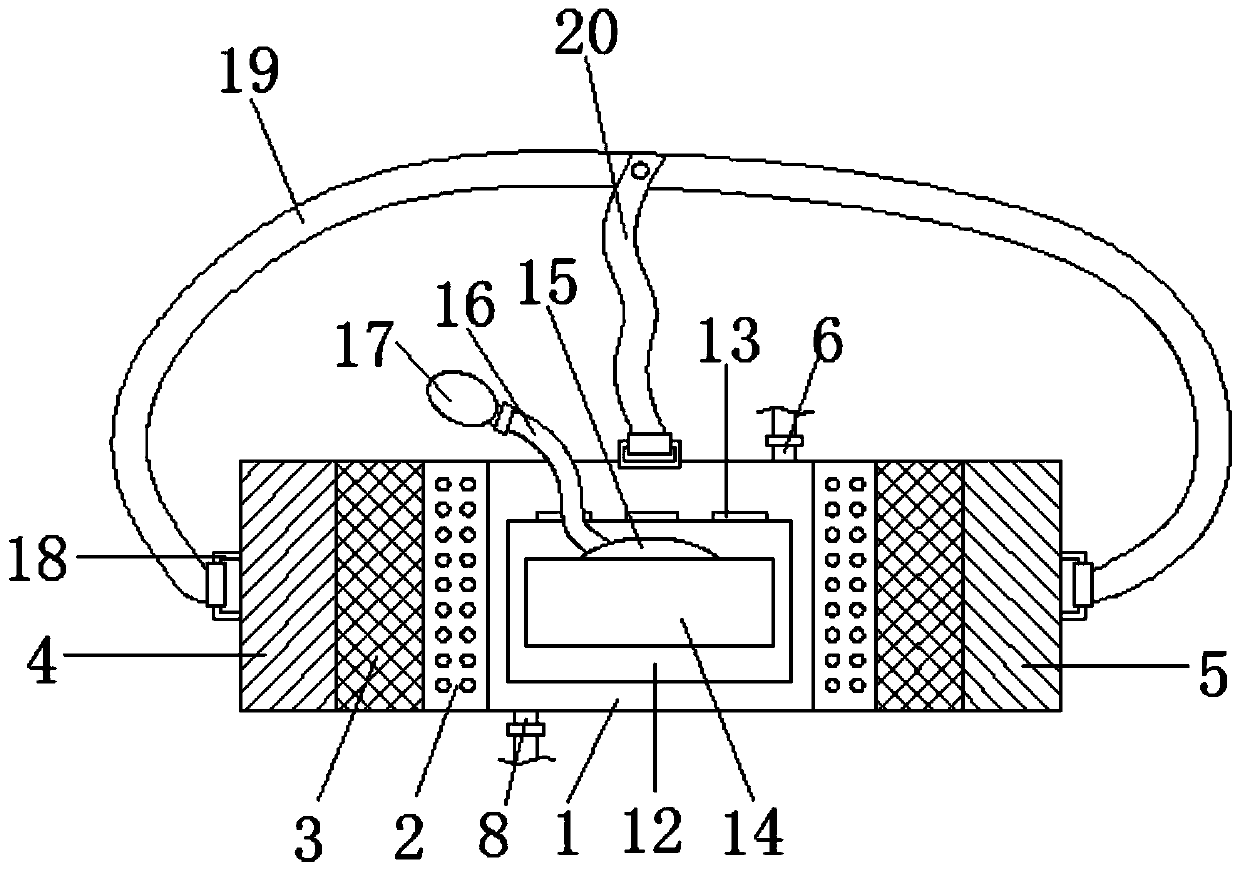

Cleaning device for air deflector of central air conditioner

PendingCN111842308AReduce dependenceAchieve cycleDrying gas arrangementsCleaning using toolsPublic placeWater source

The invention discloses a cleaning device for an air deflector of a central air conditioner, relates to the central air conditioner, and aims to solve the problems that a cleaning device depends on awater source to be not suitable for large-scale public areas and the labor requirement of workers is too large. According to key points of the technical scheme, the cleaning device for the air deflector of the central air conditioner comprises a water tank base, an anti-sputtering plate and two cleaning mechanisms, wherein the two cleaning mechanisms comprise supporting frames, spraying structures, wiping structures and air blowing structures correspondingly, the spraying structures comprise U-shaped water pipes, high-pressure nozzles and high-pressure water pumps, the wiping structures comprise hairbrush seats, hairbrush cylinders and driving motors, and the air blowing structures comprise air knifes and high-pressure air pumps. According to the cleaning device for the air deflector of the central air conditioner, dependence on the water source is reduced, the cleaning device is suitable for the large-scale public areas, the workers can clean a large number of air deflectors more easily, and the cleaning effect is improved.

Owner:浙江九辰环境工程有限公司

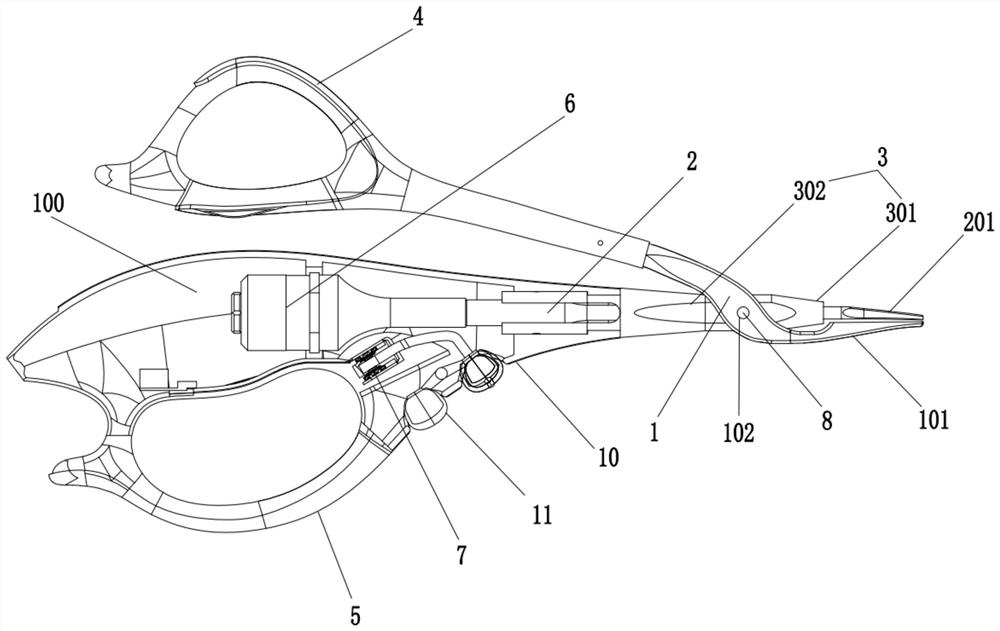

Single-time long-distance ultrasonic scissors with roll shearing function

The invention discloses a pair of single-time long-distance ultrasonic scissors with a roll shearing function. The ultrasonic scissors comprise a first shaft member and a second shaft member, the first shaft member comprises a first handheld part and an elbow, the second shaft member comprises a second handheld part, a pipe sleeve and a waveguide rod, a transducer and a circuit board switch which are connected with a waveguide rod are arranged in the second handheld part. The pipe sleeve penetrates through the bent part of the elbow and is in pivot connection with the elbow. A tool bit of the waveguide rod extends out of the port of the pipe sleeve, extends forwards in an arc shape and is arranged in the pipe sleeve in a deflection mode, and the far end of the elbow is a working section which is consistent with the tool bit in radian and can be tightly attached to the tool bit. The length of the tool bit is increased, the tool bit extends in an arc shape, the overall strength of the tool bit is improved, the waveguide rod is arranged in a deflection mode, the inner cutting face forms an inclined structure, tight contact between the tool bit and the far end of the working section is guaranteed, and shearing smoothness and integrity are guaranteed.

Owner:INNOLCON MEDICAL TECH SUZHOU

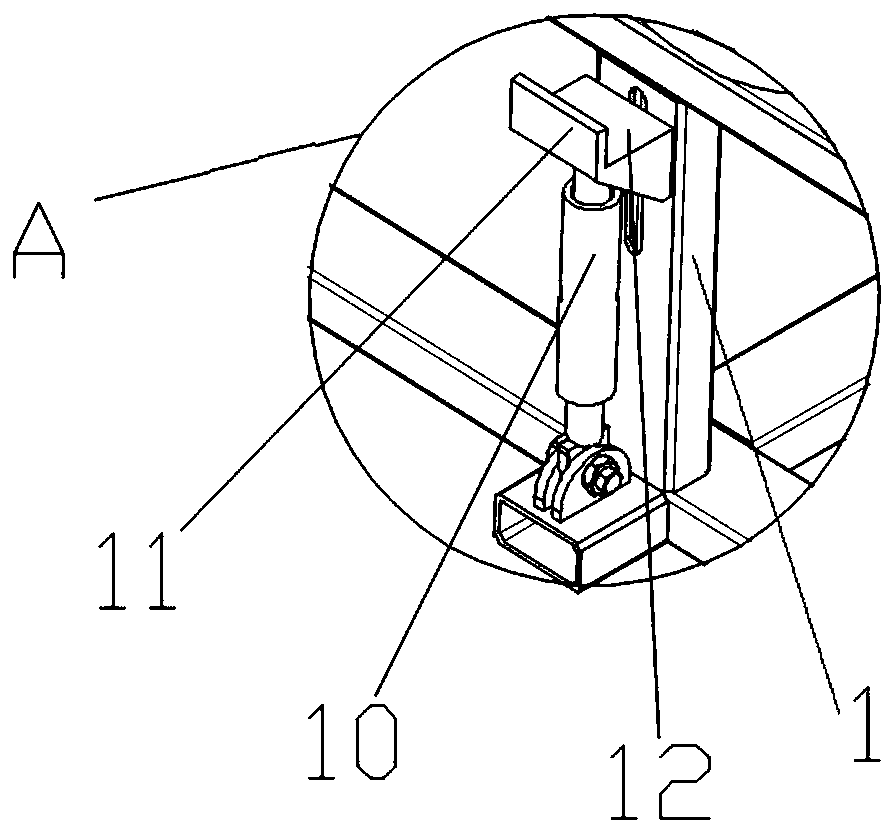

Secondary structure embedded steel bar drilling device

InactiveCN112571633AEasy and flexible drillingNo pollution in the processWorking accessoriesStone-like material working toolsSupporting systemMortise and tenon

The invention discloses a secondary structure embedded steel bar drilling device. The secondary structure embedded steel bar drilling device comprises a mortise and tenon joint structure and a drilling mechanism which are fixedly connected. The mortise and tenon joint structure comprises a stable tray, a first vertical rod supporting square pipe, a second vertical rod supporting square pipe, a first operation handle square pipe and a second operation handle square pipe, the stable tray is fixed to the lower portion of the first vertical rod supporting square pipe, and the front end face of thefirst vertical rod supporting square pipe is connected with one end of the first operation handle square pipe. The first vertical rod supporting square pipe, the second vertical rod supporting squarepipe, the first operation handle square pipe and the second operation handle square pipe form a movable supporting system of the whole device, the square pipes are connected through rotating shafts,the square pipes are kept in a connected and movable state, and workers can conveniently, easily and flexibly conduct drilling operation.

Owner:CHINA CONSTR FOURTH ENG DIV

Polishing machine tool for machining metal plates

ActiveCN111069992AImprove sanding effectGuaranteed a tight fitGrinding carriagesGrinding drivesPolishingEngineering

The invention discloses a polishing machine tool for machining metal plates. The polishing machine tool comprises a machine tool body, a rotating seat, a mounting seat and a connecting seat; the mounting seat is provided with a clamping groove, the connecting seat is slidably clamped in the clamping groove, and a polishing member is arranged at the bottom of the connecting seat; and one end of theconnecting seat is connected with a fixed plate fixed at the clamping groove through a return spring, and a rotating rod is fixed at the other end of the connecting seat. According to the polishing machine tool for machining metal plates, due to the fact that the connecting seat is sliably arranged in the mounting seat, in combination with the arrangement of abutting rods, elastic telescopic pieces, transverse plates, vertical plates, fixed rings and the rotating rod, the connecting seat can move on the horizontal plane while rotating around the axis, and accordingly the polishing effect of the polishing member on a workpiece is improved.

Owner:徐州亦维制造有限公司

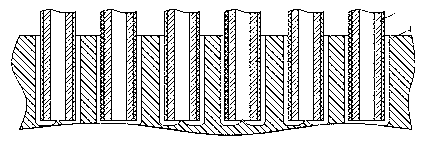

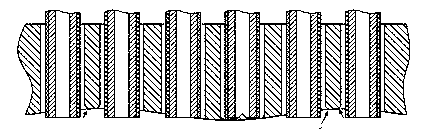

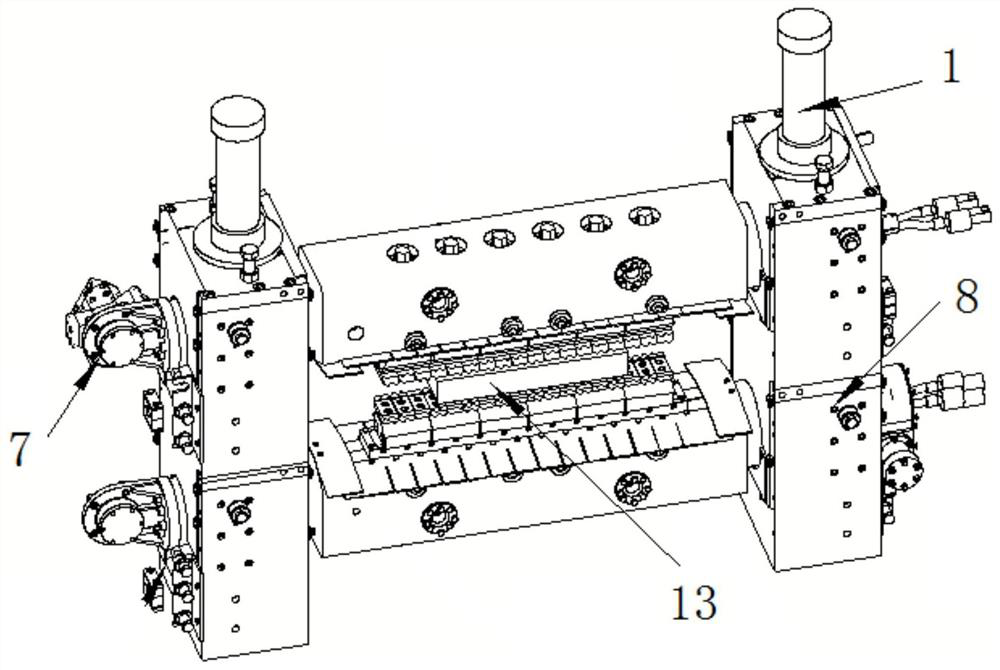

Tooth-shaped deburring machine for upper surface and lower surface of continuous casting stainless steel plate blank

The invention relates to mechanical equipment, in particular to a tooth-shaped deburring machine for the upper surface and the lower surface of a continuous casting stainless steel plate blank. According to the technical scheme, the tooth-shaped deburring machine for the upper surface and the lower surface of the continuous casting stainless steel plate blank comprises an upper deburring device and a lower deburring device, and the upper deburring device and the lower deburring device are combined and connected into a whole. According to the tooth-shaped deburring machine for the upper surface and the lower surface of the continuous casting stainless steel plate blank, the online deburring rate can be increased, the product quality can be improved, and the later deburring cost can be reduced.

Owner:TAIHE CONTINUOUS CASTING APP

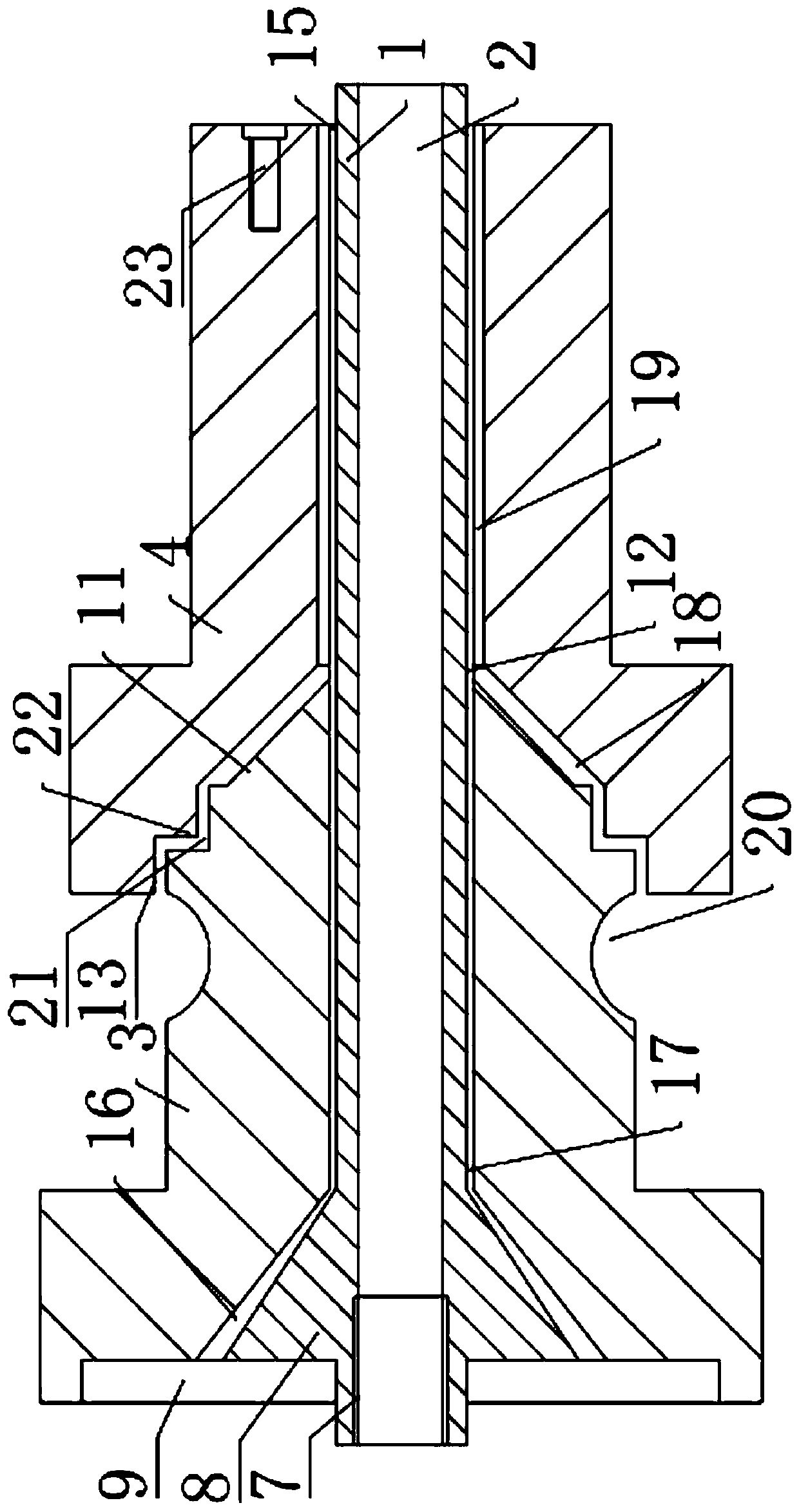

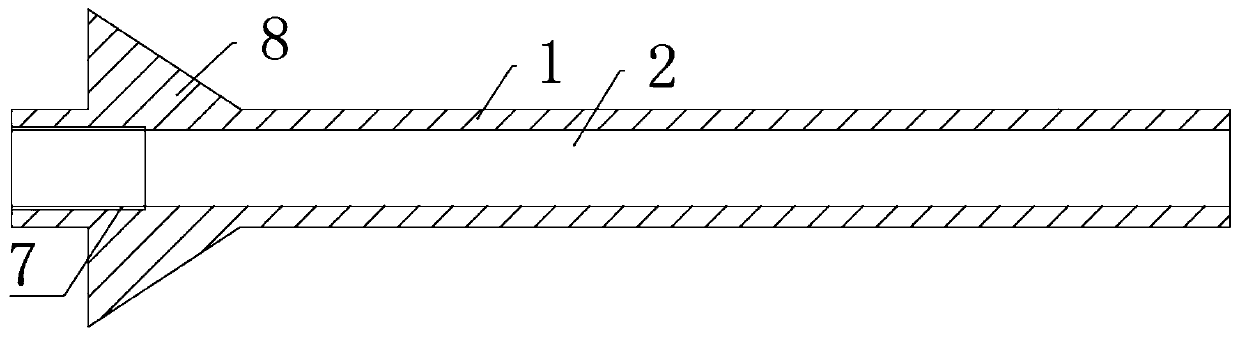

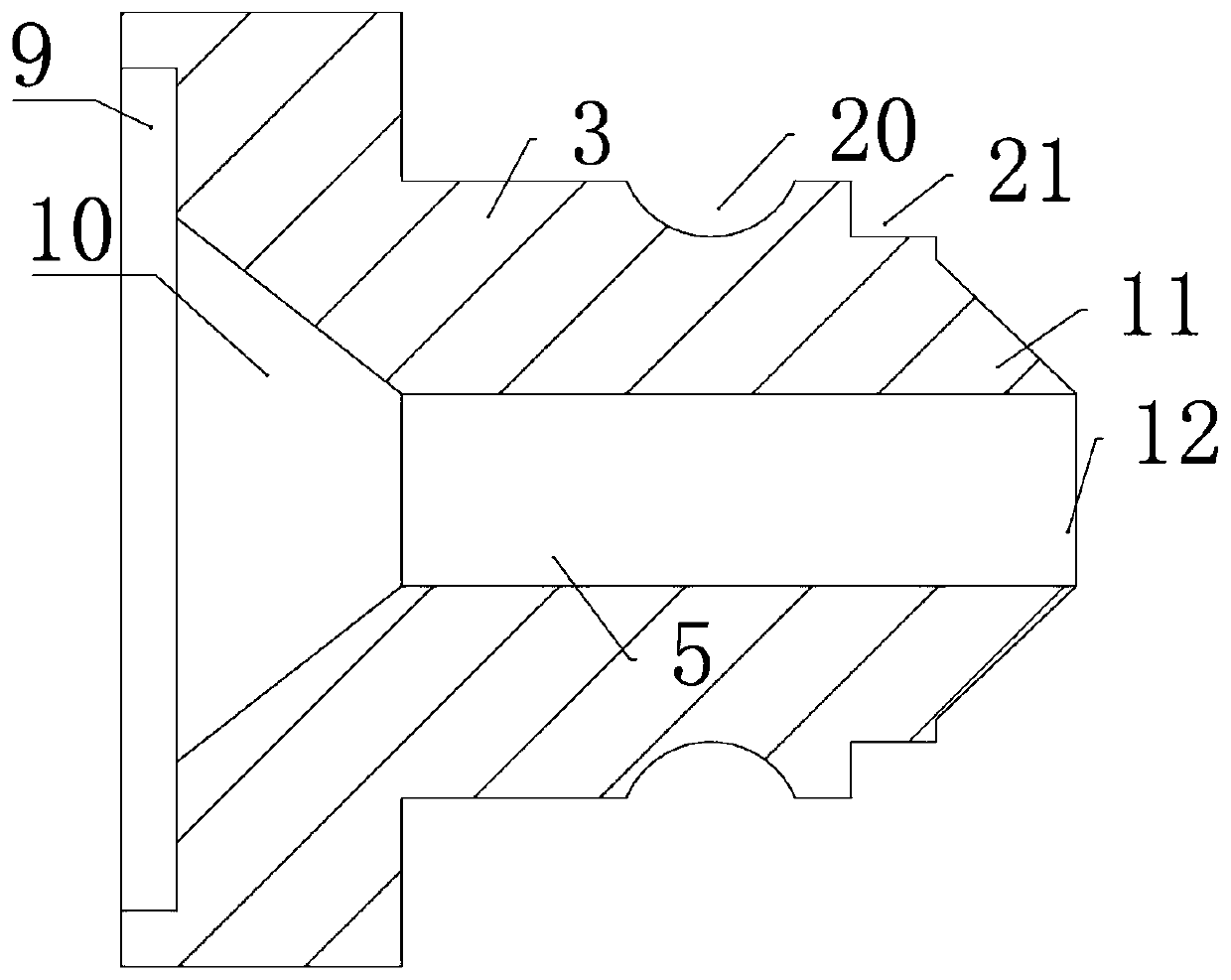

Rubber and plastic pipe double-layer co-extrusion mold

PendingCN109968628AHigh mechanical strengthImproved resistance to twistingTubular articlesEngineeringCo extrusion

The invention provides a rubber and plastic pipe double-layer co-extrusion mold. The rubber and plastic pipe double-layer co-extrusion mold comprises a mold tube. The mold tube is internally providedwith a blowing cavity. The outer side of the mold tube is sleeved with a first extrusion part and a second extrusion. The first extrusion part is internally provided with a first mold cavity. The second extrusion part is internally provided with a second mold cavity. The inner wall of the front end of the mold tube is provided with an internal thread. The outer sidewall of the front end of the mold tube is provided with a first conical boss. The front end of the first extrusion part is provided with a first groove. The bottom of the first groove is provided with a first conical groove. The first conical groove communicates with the first mold cavity. The rear end of the first extrusion part is provided with a second conical boss. The second conical boss is provided with a first outlet communicating with the first mold cavity. The front end of the second extrusion part is provided with a second groove. The bottom of the second groove is provided with a second conical groove. The rear end of the second extrusion part is provided with a second outlet communicating with the second mold cavity. The rubber and plastic pipe double-layer co-extrusion mold has the characteristics that an inner layer and a filling layer are bonded closely, and the rubber and plastic pipe double-layer co-extrusion mold is high in overall structure mechanical strength and distortion resistance and easy toinstall.

Owner:CHANGLE COUNTY YOUYI PLASTICS CO LTD

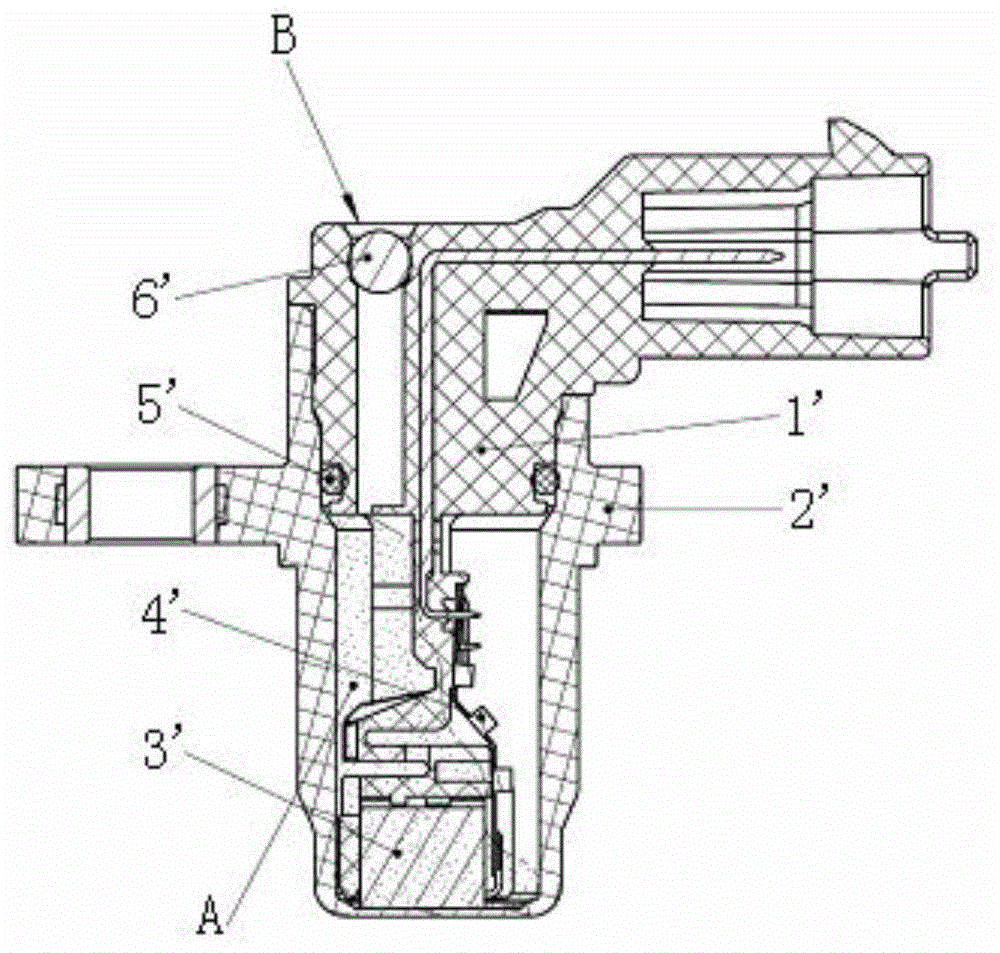

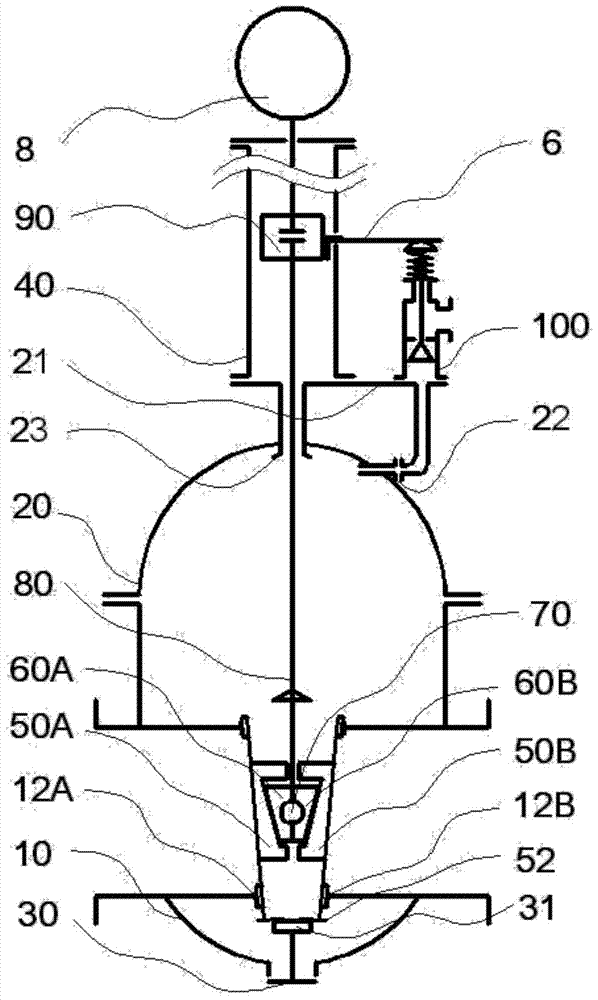

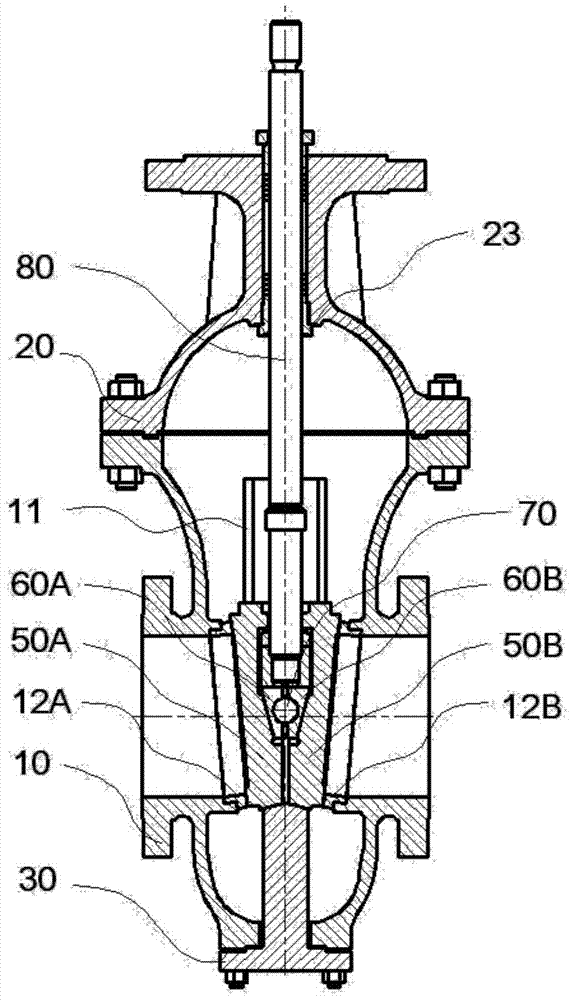

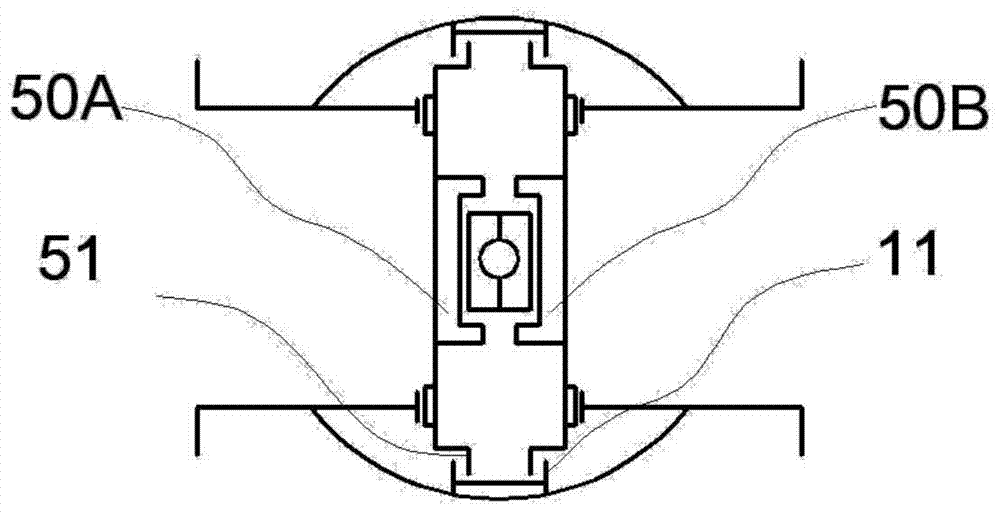

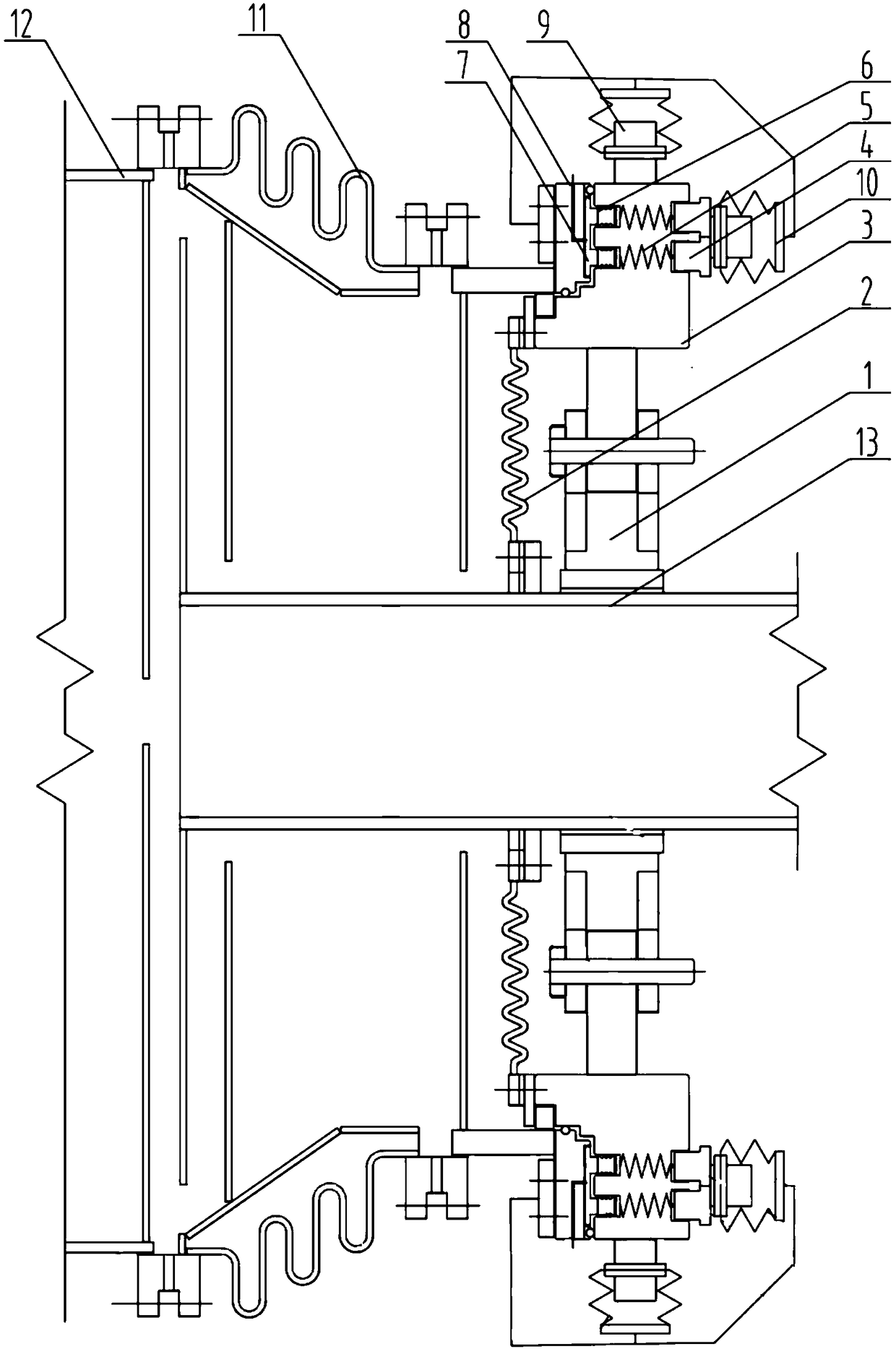

A double-wedge gate valve with external air-added auxiliary valve

ActiveCN104806777BFlexible moving processGuaranteed a tight fitSlide valveTemperature differenceDouble gate

The invention aims to provide a double wedge-type gate valve with an additional auxiliary air valve. The double wedge-type gate valve comprises a valve body, wherein the valve body is provided with a valve seat hole and a flow channel; the upper part of the valve body is connected with a valve cover through a flange; the lower part of the valve body is connected with a bottom cover through a flange; an additional auxiliary air valve base is arranged above the valve cover; the additional auxiliary air valve base is connected with one or more additional auxiliary air valves. The double wedge-type gate valve disclosed by the invention is provided with a double-gate plate structure; bidirectional forced sealing can be realized; only the friction force at the inclined surface of a wedge block is required to be overcome when the valve is opened; after the wedge block is moved, the gate plate can also move flexibly. The double wedge-type gate valve with the additional auxiliary air valve meets the cutting requirement of a reactor, is unique in structure, reliable in sealing, flexible in action and long in service life, and is particularly suitable for the working conditions with a high temperature or a great temperature difference.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Modified epoxy-phenolic high-temperature thermal recovery surface pipeline

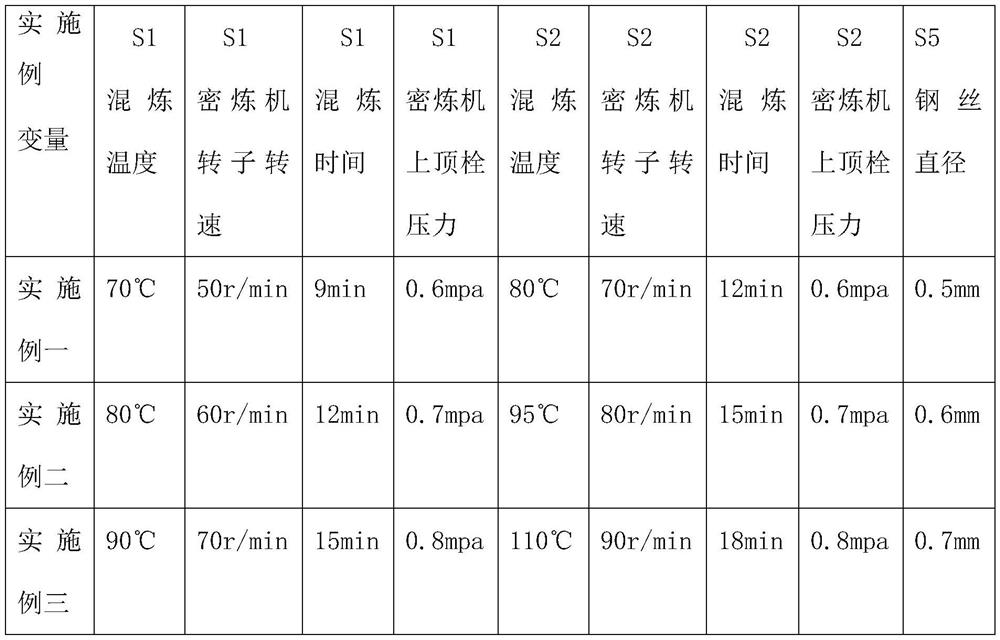

ActiveCN112283461AEasy to operateSimple stepsRigid pipesPipe protection against damage/wearVulcanizationPhysical chemistry

The invention discloses a modified epoxy-phenolic high-temperature thermal recovery surface pipeline, and relates to the technical field of petroleum thermal recovery pipelines. The pipeline is composed of an outer coating, an outer rubber layer, a skeleton layer, an inner rubber layer and an inner coating, and the outer coating and the inner coating have the same composition. The pipeline is prepared through the steps of primary mixing, vulcanization, secondary mixing, primary extrusion molding, knitting winding, secondary extrusion molding, impregnation and spraying. According to the modified epoxy-phenolic high-temperature thermal recovery surface pipeline, epoxy resin and phenolic resin in coating raw materials are subjected to modification treatment, the epoxy-modified phenolic resinobtained through modification has excellent heat resistance and abrasion resistance, and thus the pipeline can meet the challenges of sand storm invasion and large day and night temperature differenceand is suitable for being vigorously used and popularized in various oil fields in China. In the process, a cold vulcanization method is used for impregnating an extrusion-molded pipe blank during rubber vulcanization treatment, the two effects of cooling and vulcanization are achieved at the same time, and thus the production efficiency of the process is improved.

Owner:胜利油田金岛工程安装有限责任公司

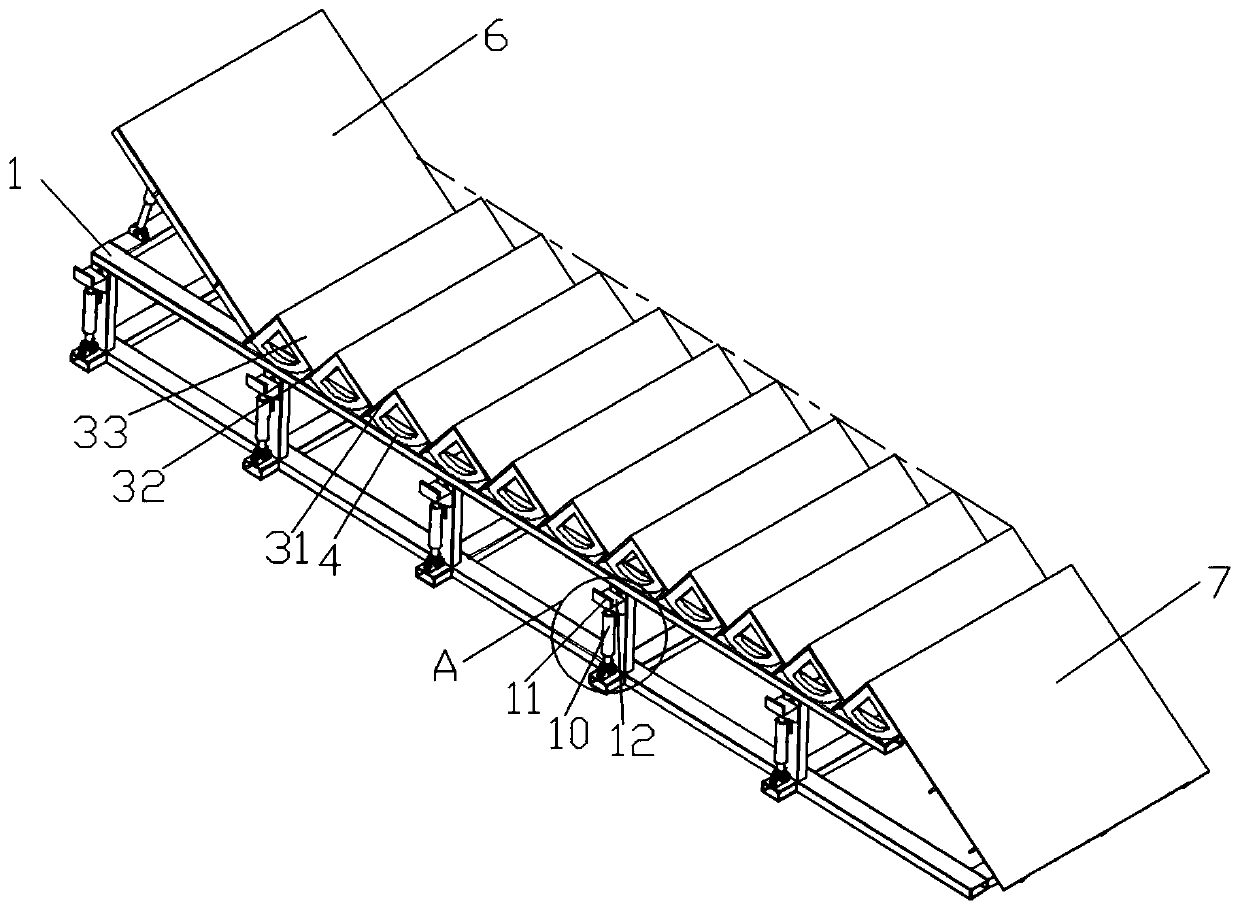

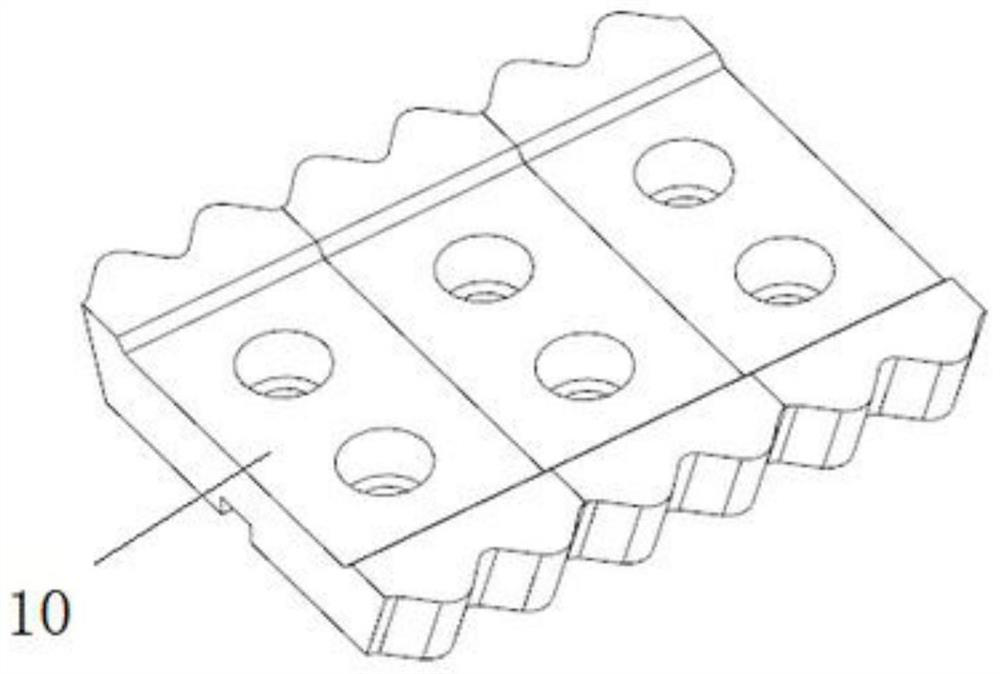

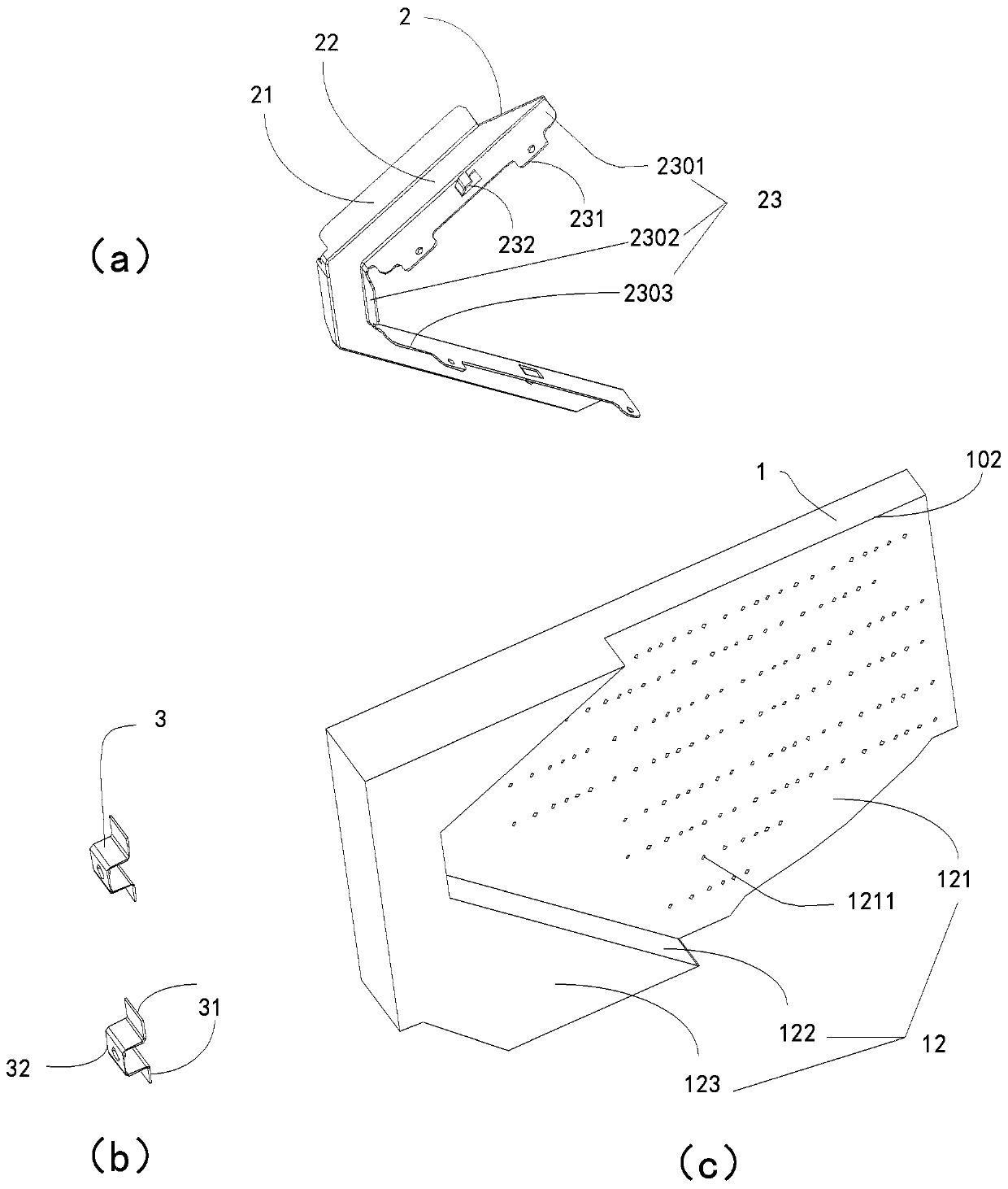

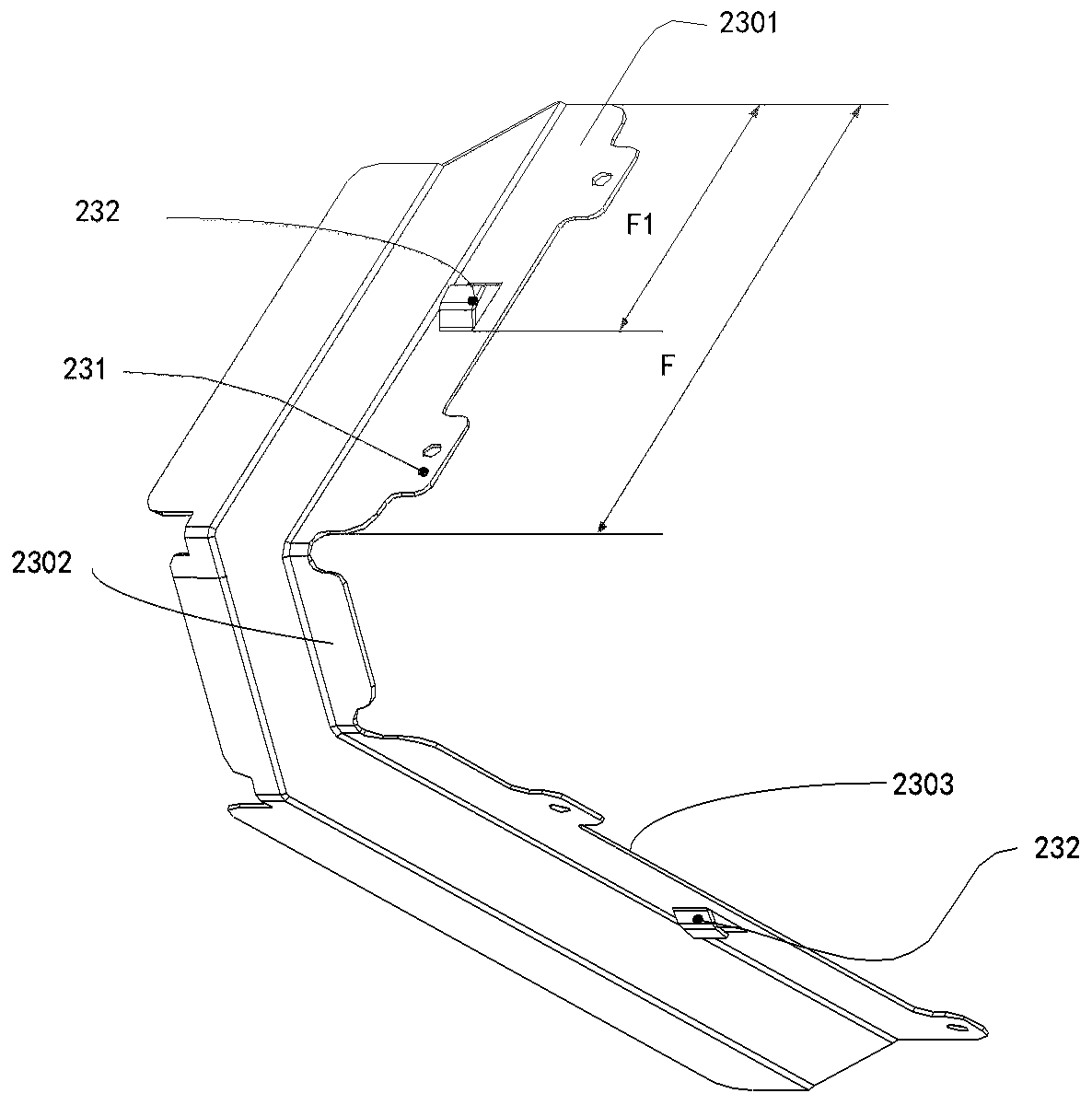

Upper tool mounting structure for fin transecting die

The invention discloses an upper tool mounting structure for a fin transecting die; the upper tool mounting structure comprises an upper tool holder; one end of the upper tool holder is provided with a sliding plate and a limiting post, the sliding plate is vertically movably disposed on the upper tool holder, an upper tool is connected to the lower end of the sliding plate, the sliding plate is provided with an elongated hole, one end of the limiting post is abutted to the upper tool holder, the other end of the limiting post is passed through the elongated hole and is provided with a non-lubricating slider, one side of the non-lubricating slider is attached to the sliding plate, the other side of the non-lubricating slider is provided with a first fitting end face and is provided with a cover plate, the area of a part of the cover plate fitting the first fitting end face is not less than 80% of that of the first fitting end face, and the cover plate is fixedly connected with the upper tool holder. The area of the part of the cover plate fitting the first fitting end face of the non-lubricating slider is not less than 80% of that of the first fitting end face, tight fit between the non-lubricating slider and the sliding plate is effectively guaranteed, loosening is avoided occurring just after using for a period of time, and transecting quality is guaranteed accordingly.

Owner:WUXI HI TECH PRECISION MOLD

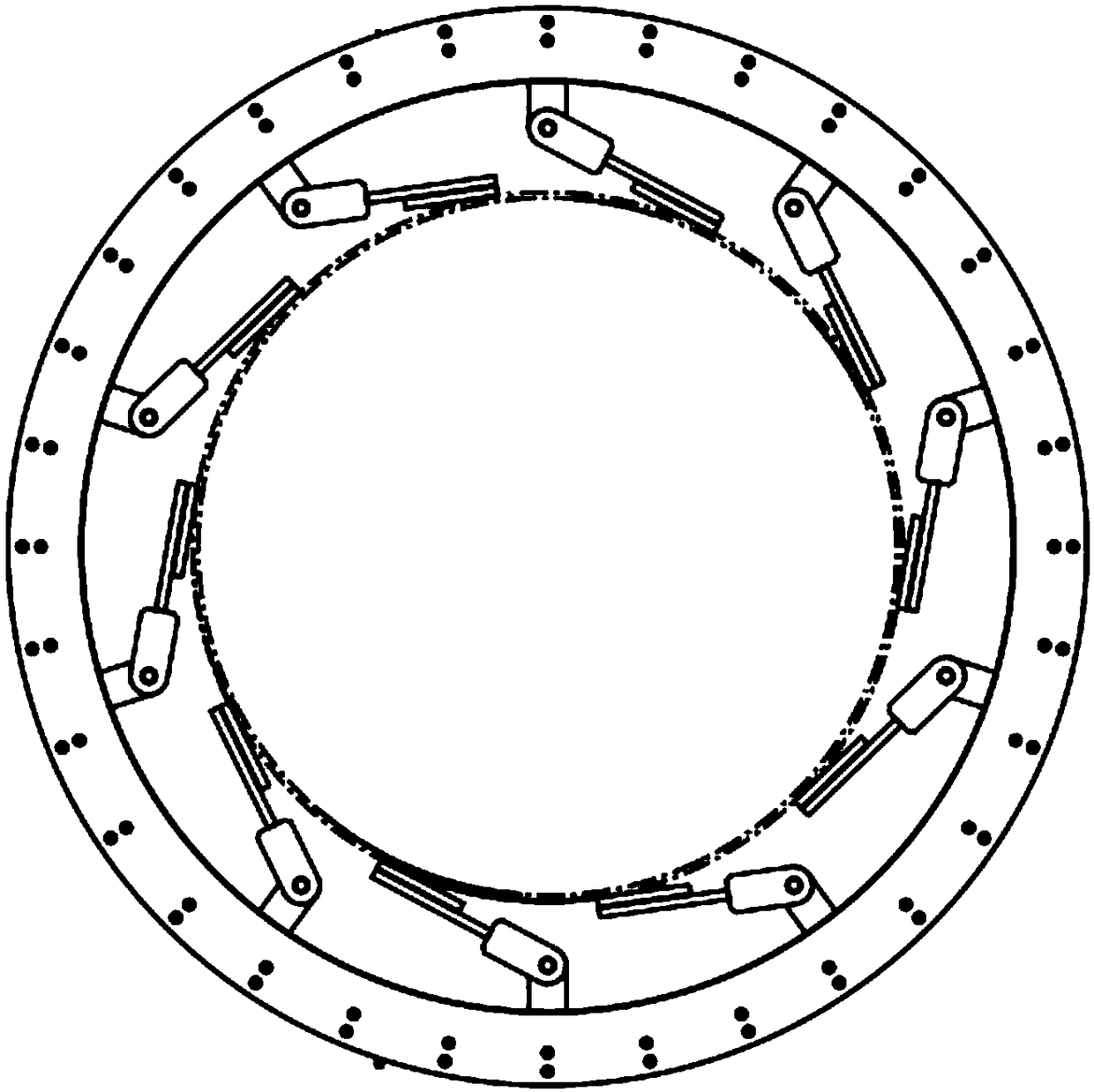

Cotton roll compacting device of lapper for spinning

The invention relates to the technical field of spinning, in particular to a cotton roll compacting device of a lapper for spinning. The cotton roll compacting device comprises a base plate, a turntable, a driving motor, a positioning screw rod, a winding drum, propelling mechanisms, installation frames, pressing rollers, a limiting plate, a fastener and bottom feet, wherein an installation grooveis formed at the middle position of the base plate; the bottom of the turntable is rotatably connected with the base plate through a bearing; the turntable is positioned in the interior of the installation groove; the driving motor is fixedly installed at the middle position of the bottom of the base plate; the output end of the driving motor is in transmission connection with the bottom of the turntable; and one end of the positioning screw rod is fixedly connected with the middle position of the top of the turntable. According to the cotton roll compacting device of the lapper for spinning,the purposes of avoiding the phenomena of loosening and expansion among winding layers of a cotton roll are achieved, the compact state of the cotton roll in the winding process is improved, and thetight fit among the cotton layers is ensured, so that the winding length of each cotton roll is increased, and the attractiveness of the cotton roll and the quality of the finished product are improved.

Owner:YANCHENG INST OF IND TECH

Anti-condensation structure and air conditioner

PendingCN110836530AGuaranteed a tight fitConvenience guaranteedDucting arrangementsCondensate preventionAir volumeHeat conservation

The invention discloses an anti-condensation structure and an air conditioner. The anti-condensation structure comprises a heat preservation assembly, wherein the heat preservation assembly is of a heat insulation and connection integrated structure and is arranged on the inner side of a side plate of an air conditioner inner machine, the left side face of the heat preservation assembly is used for being assembled with the inner surface of the side plate, and the right side face of the heat preservation assembly is used for being assembled and connected with an evaporator. Based on the heat preservation assembly, two functions of heat insulation and connecting the evaporator are realized at the same time, the heat insulation and connection functions are integrated, the air conditioning airbetween the side plate and the heat preservation assembly serving as the evaporator connecting structure is isolated, so that on one hand, the condensation generated by blowing air between the side plate and the heat preservation assembly is avoided, and on the other hand, the air volume loss caused by air conditioner air flowing between the side plate and the heat preservation assembly is avoided or reduced, thus improving the air outlet amount of an air outlet; and in addition, due to the fact that the heat preservation assembly is arranged inside the side plate, the cleanliness and the attractiveness of the appearance of the side plate are improved.

Owner:NINGBO AUX ELECTRIC

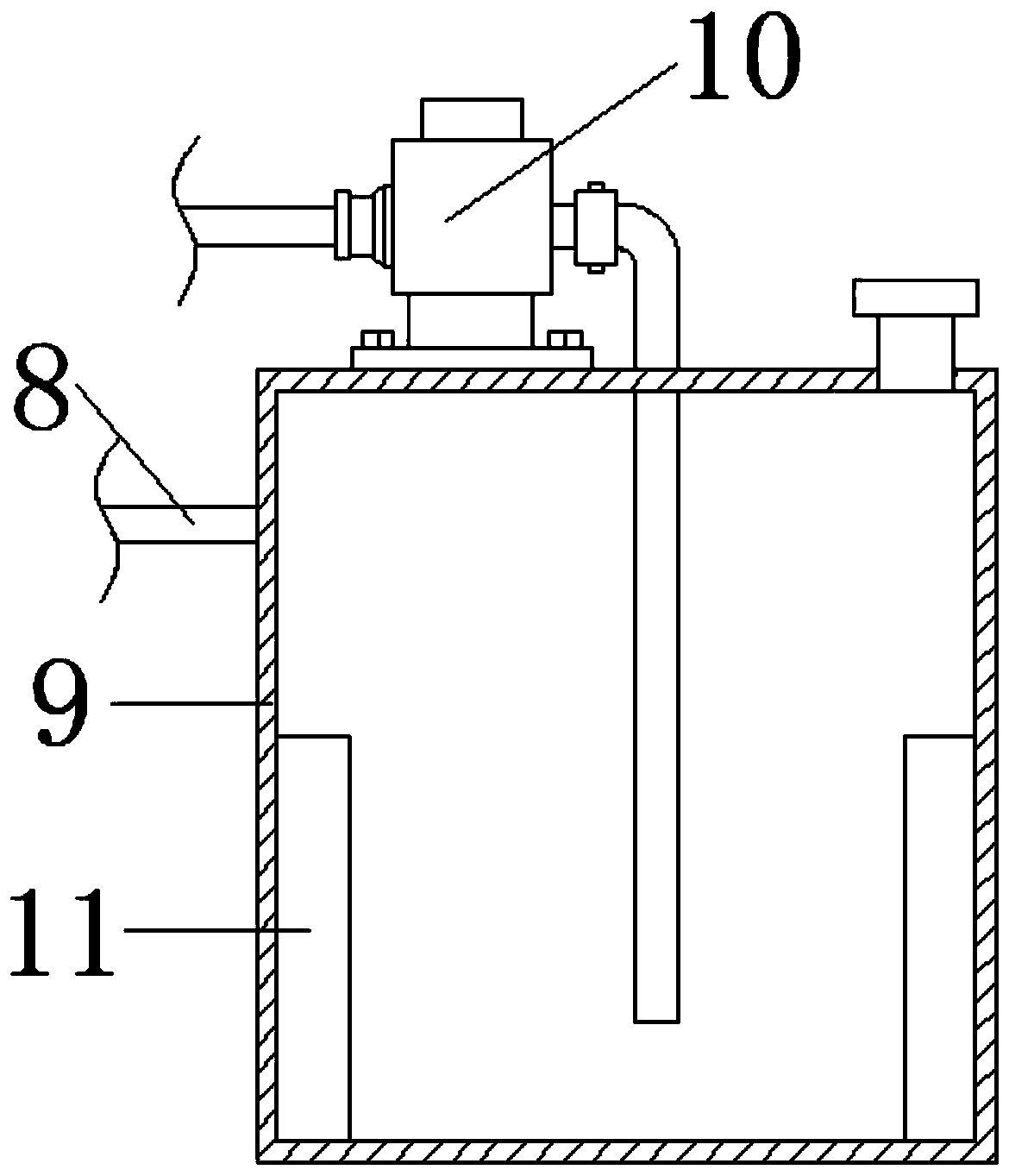

Cold compress device for obstetrics and gynecology nursing

InactiveCN110811973AImprove cold compress efficiencyIncrease contact areaSurgeryTherapeutic coolingCold compressesNursing care

The invention discloses a cold compress device for obstetrics and gynecology nursing. The device includes a nursing pad, two sides of the nursing pad are respectively fixedly connected with air-permeable cloth bags, two sides of the air-permeable cloth bags are respectively fixedly connected with elastic bands, and two sides of the elastic bands are respectively connected with a sticking sub bandand a sticking mother band; a water inlet pipe is arranged on one side of the nursing pad, a water flow pipe is arranged in the nursing pad, and one end of the water flow pipe is connected to the water inlet pipe; one end, far away from the water inlet pipe, of the water flow pipe is connected to a water outlet pipe, one end, far away from the water flow pipe, of the water outlet pipe is connectedto a cold water tank, a water pump is arranged on the top outer wall of the cold water tank, and one end of the water pump is connected to the water inlet pipe; cooling sheets are arranged on the inner wall of the cold water tank; the water flow pipe is S-shaped; and a first cloth bag is arranged on the outer wall of one side of the nursing pad, a cold compress bag is placed between the nursing pad and the first cloth bag, and a second cloth bag is arranged on the outer wall of one side of the cold compress bag.

Owner:李静

R-shaped thread

The invention provides an R-shaped thread, and belongs to the field of fasteners. A first guiding-in side angle line and a second guiding-in side angle line are arranged on the two side edges of a thread profile respectively and are connected through a transition line. The transition line is concaved in the direction away from a crest. According to the technical scheme, the defect that an existing thread is prone to loosening after being assembled is overcome, and the R-shaped thread with the seismic preventing and loosening preventing functions is provided.

Owner:阳江市贯虹五金科技有限公司

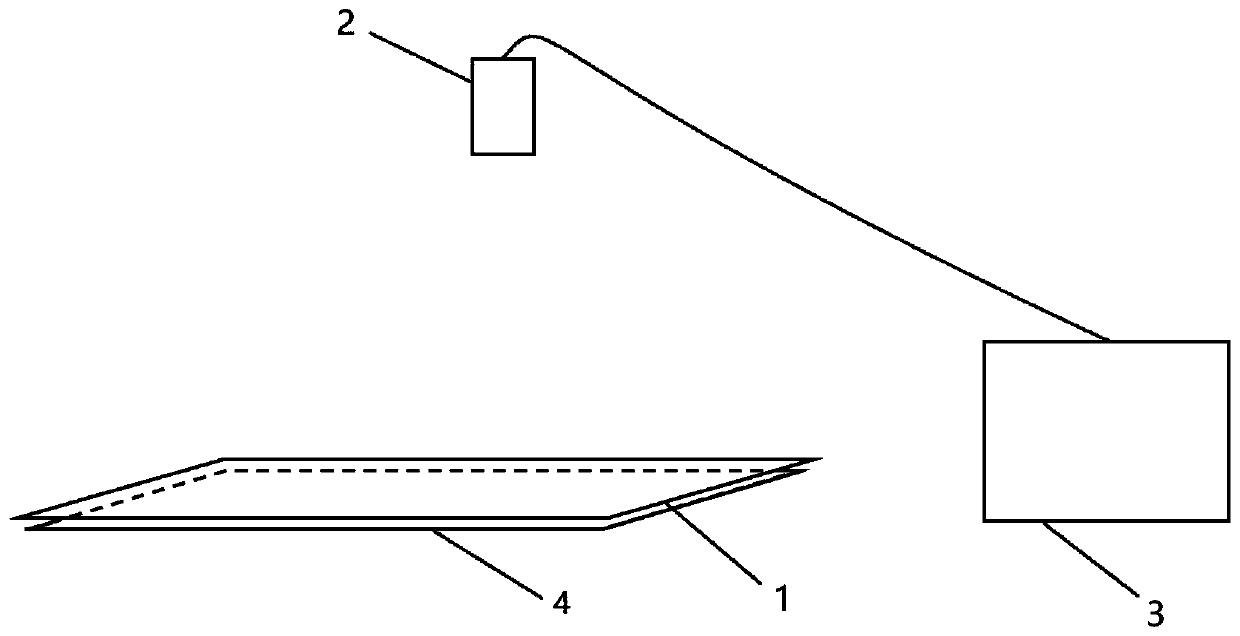

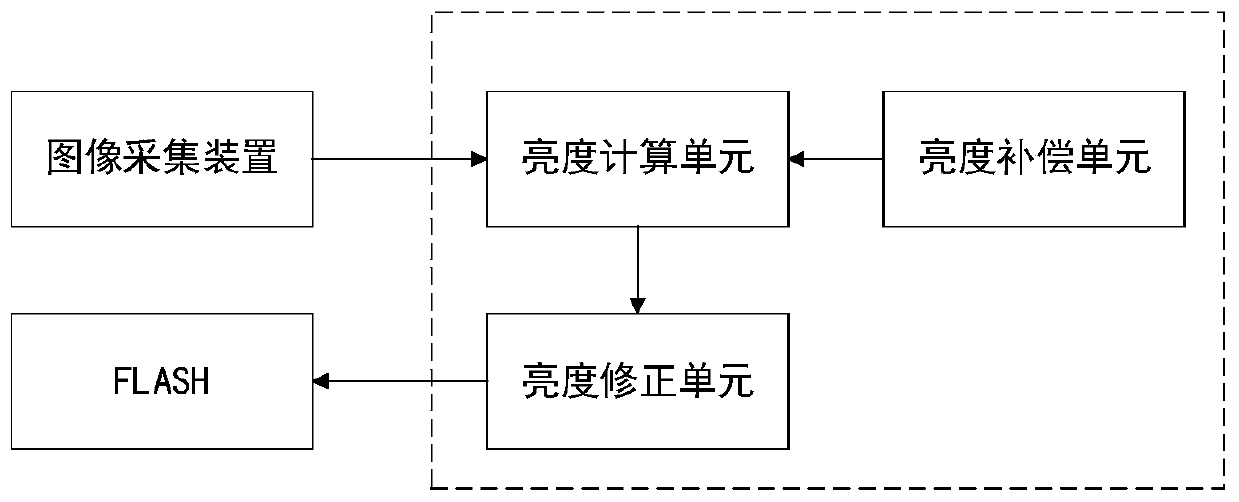

Brightness correction system and method

ActiveCN110428793AIncrease the number of raysImprove accuracyCathode-ray tube indicatorsComputer scienceCorrection method

The invention discloses a brightness correction system and a brightness correction method, and relates to the technical field of display. The system comprises a scattering film layer, an image acquisition unit and a brightness calculation unit. The scattering film layer is placed between a to-be-tested display screen and an image acquisition device. The size of the scattering film layer is not smaller than that of the to-be-tested display screen. The scattering film layer is used for dispersing light with a single emitting direction emitted by the to-be-tested display screen into a plurality of emitting directions. The image acquisition device is used for shooting a display screen image containing a scattering film layer. The brightness calculation unit is used for extracting an area wherethe display screen is located from the display screen image and calculating a brightness value of each pixel point in the area where the display screen is located. Starting from the light-emitting angle of the display screen, the light which is emitted by the display screen and has a single emitting direction is dispersed into a plurality of emitting angles through the scattering film layer. Therefore, the quantity of the light entering the view field of the camera is increased as much as possible. The influence of the view field angle is reduced. The accuracy of subsequent brightness measurement and color spot repair is improved.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

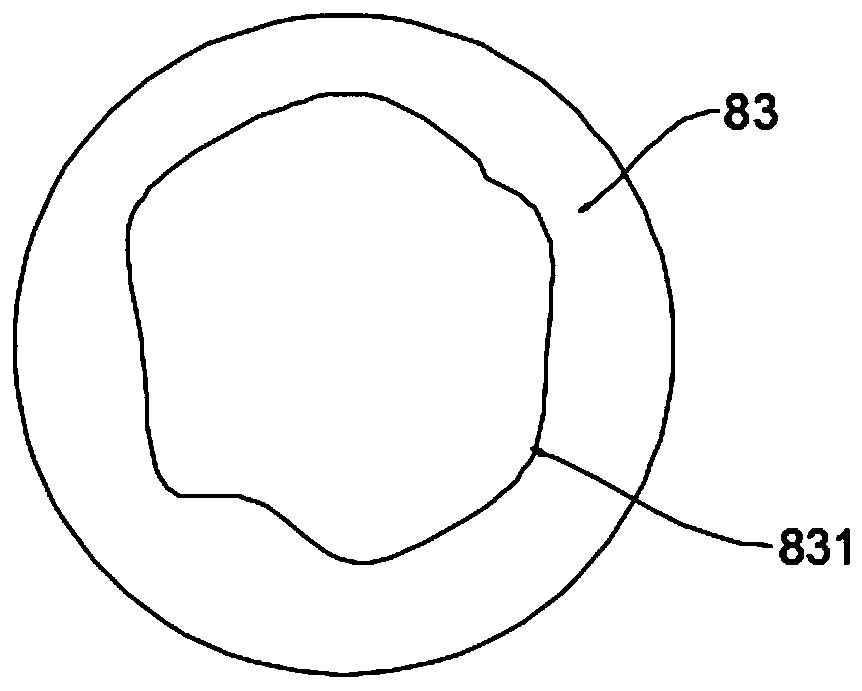

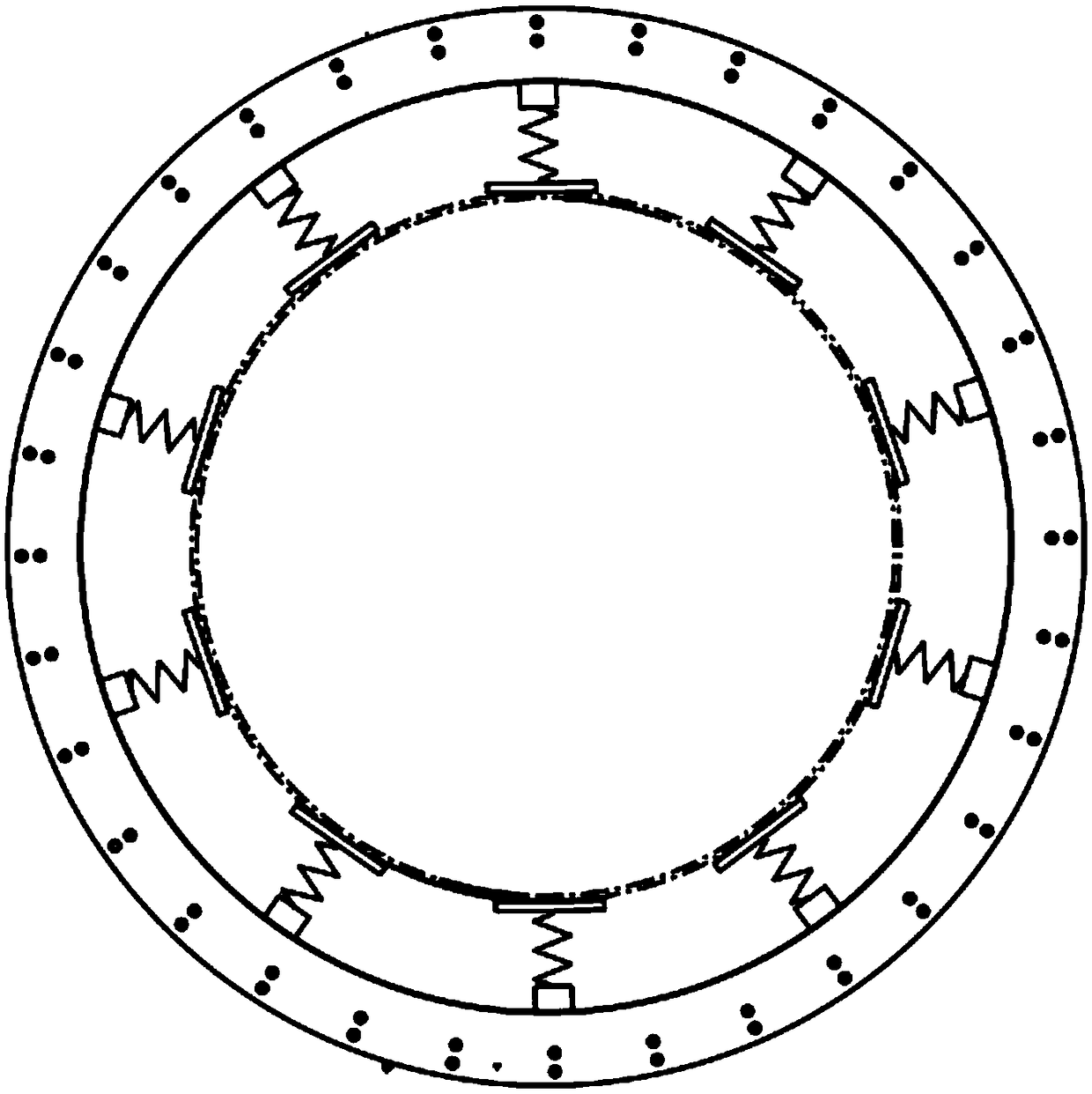

Sealing device of rotating cylinder equipment

PendingCN109296752AGuaranteed tight fit and concentricitySmooth and reliable low rolling resistance operationEngine sealsThermal deformationEngineering

The invention discloses a sealing device of rotating cylinder equipment. The sealing device of the rotating cylinder equipment comprises a flexible bearing assembly and spring column assemblies. The flexible bearing assembly is installed on a rotating cylinder body in a clearance fit manner. The flexible bearing assembly is fixed to a rotating seal ring assembly through bolts and / or hinges, the rotating seal ring assembly is fixedly provided with a ripple ring through bolts, the inner side of the ripple ring is tightly attached to the rotating cylinder body, threaded holes in an outer ring ofthe rotating seal ring assembly are provided with the spring column assemblies through set screws. A sealing block is arranged between one side of each spring column assembly and the rotating seal ring assembly in a sleeving manner. The outer side of the sealing block is provided with a front stationary seal ring, the front stationary seal ring is tightly attached to the sealing block to form a mechanical end face seal, and the front stationary seal ring is installed in an embedding groove of a rear stationary seal ring assembly. The sealing device has the beneficial effects that the error deformation generated in the rotating cylinder equipment production and manufacture process can be effectively offset, thermal deformation, axial bouncing and radial bouncing generated in the running process are resisted, the tight attaching and coaxiality of the mechanical seal end face are guaranteed, and stable mechanical end face seal is maintained.

Owner:GUANGZHOU WEIGANG ENVIRONMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com