Polishing machine tool for machining metal plates

A metal sheet and machine tool technology, applied in the field of grinding machine tools for sheet metal processing, can solve the problems of inadvertent and ideal grinding efficiency, single movement mode, etc., and achieve the effect of ensuring tight fit, facilitating tight fit and improving grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

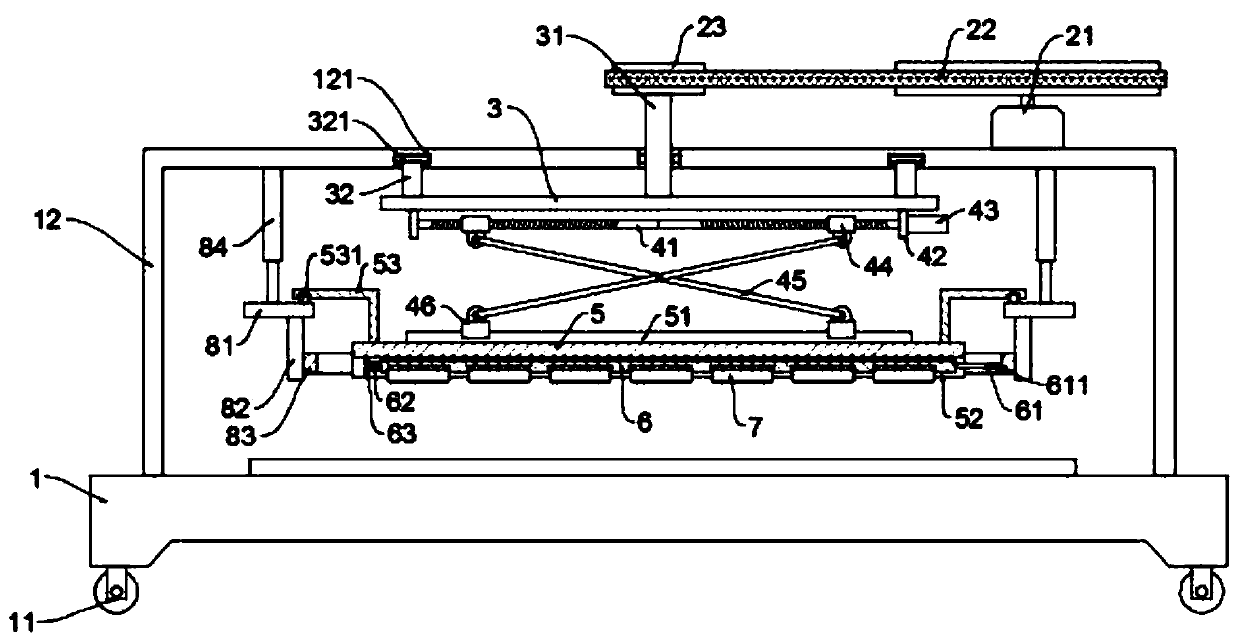

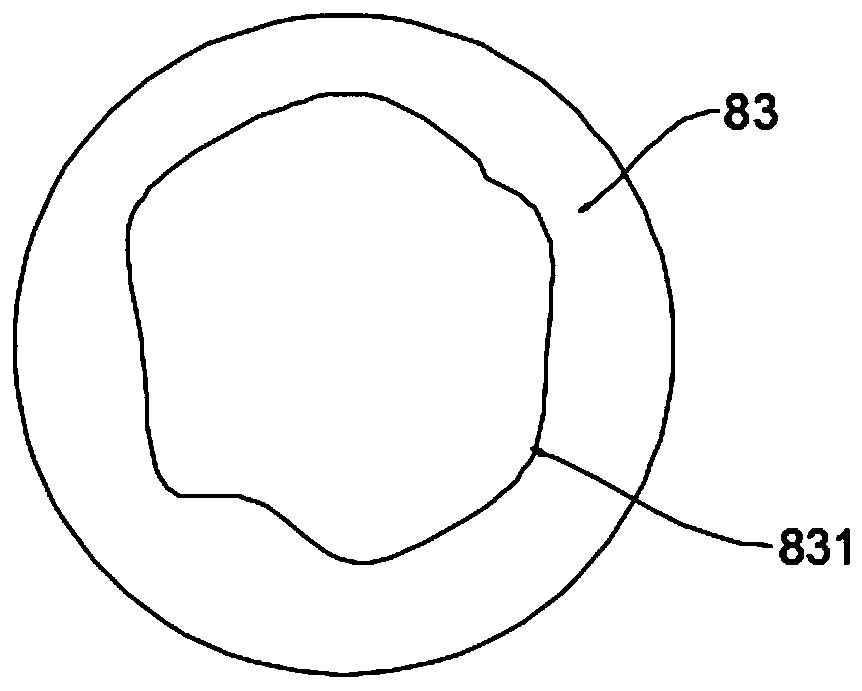

[0024] see Figure 1~4 , in an embodiment of the present invention, a grinding machine tool for sheet metal processing, comprising a bed body 1, a rotating seat 3, a mounting seat 5 and a connecting seat 6; Located below the gantry 12 and rotatably connected with the gantry 12 through the rotating shaft 31, the gantry 12 is provided with a driving mechanism for driving the rotating shaft 31; the mounting seat 5 is connected with the rotating seat 3 through a lifting mechanism, and the mounting seat 5 Both sides of the top are symmetrically fixed with a collision plate 53, the collision plate 53 is L-shaped and the balls 531 that are movable are embedded on the horizontal plate body; Corresponding to the elastic connector 84, the end of the elastic connector 84 is fixed with a horizontal plate 81, the horizontal plate 81 is located below the horizontal plate body of the collision plate 53 and conflicts with the ball 531, the bottom of the horizontal plate 81 is fixed with a ver...

Embodiment 2

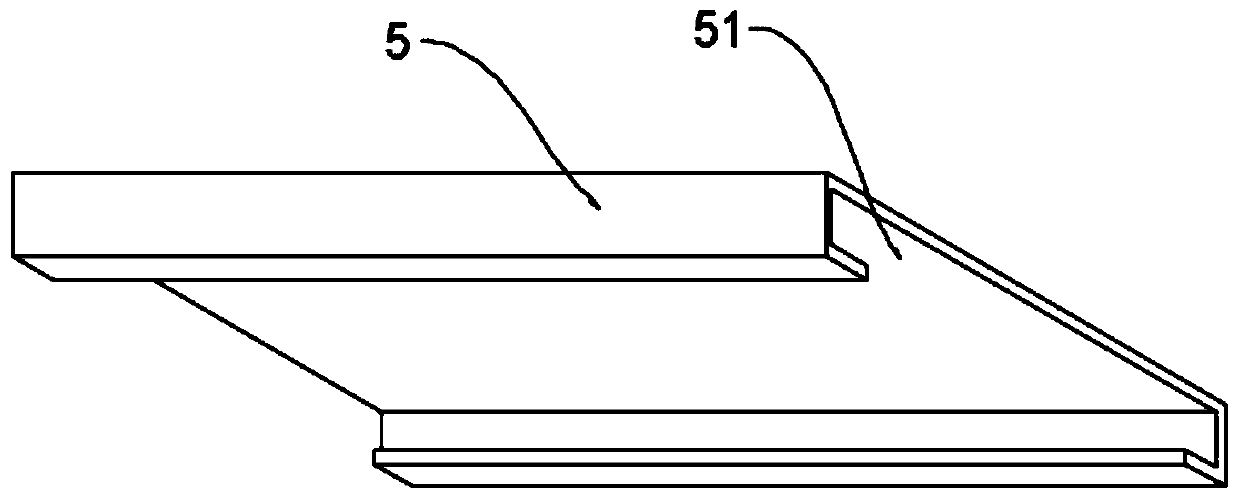

[0034] see Figure 5 , the embodiment of the present invention is optimized on the basis of embodiment 1, mainly for the improvement of the grinding parts, specifically:

[0035]In this embodiment, the grinding member includes a plurality of grinding units 7 evenly distributed on the bottom of the connecting base 6, and the connecting base 6 is provided with mounting grooves 54 corresponding to the grinding units 7 one by one. It is connected with the installation groove 54, so that it can be adaptively stretched according to the outer surface of the workpiece, so as to ensure the close fit between the grinding unit 7 and the workpiece. At the same time, a plurality of grinding units 7 are provided, and the expansion and contraction between adjacent grinding units 7 will not be mutual. The impact is more conducive to its close fit with the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com