Plastic polishing device for plastic product processing

A technology for plastic products and plastics, applied in the field of plastic grinding devices, can solve the problems of limited grinding position, inability to grind the surface of plastic products, rough surface of plastic products, etc., and achieve the effect of increasing the grinding range and improving the grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

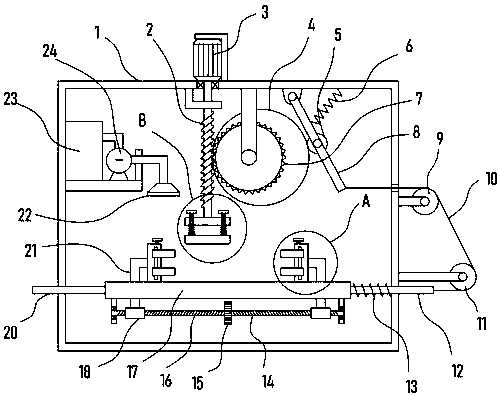

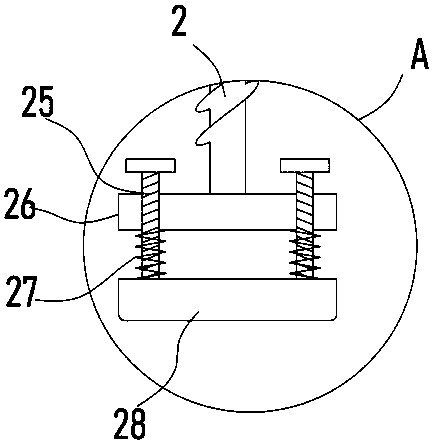

[0026] see Figure 1-7 , a plastic grinding device for processing plastic products, comprising a grinding chamber 1, a support plate 17 for supporting plastic products is horizontally slidably installed in the grinding chamber 1, and a clamping mechanism for clamping plastic products is provided on the support plate 17, so The top of the grinding chamber 1 is fixed with a driving motor 3, the output shaft of the driving motor 3 is coaxially fixed with a worm 2, the bottom of the worm 2 is fixed with a fixed disc 26, and the bottom of the fixed disc 26 is connected with a grinding disc 28 for grinding plastic products.

[0027] The plastic product to be polished is clamped and fixed on the support plate 17 by the clamping mechanism provided to ensure the fixation of the plastic product when it is polished. The drive motor 3 drives the worm 2 to rotate, and the worm 2 drives the fixed disk 26 to rotate, and the fixed disk 26 Drive the grinding disc 28 to rotate, and then realize...

Embodiment 2

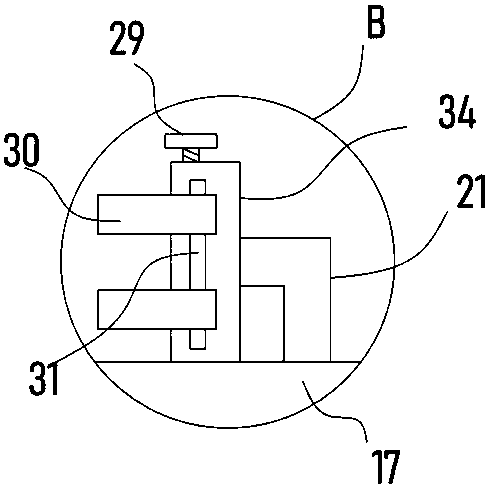

[0033] In order to further improve the firmness of the clamping mechanism for clamping plastic products and ensure the smooth progress of the grinding operation, on the basis of Embodiment 1, in addition, a clamping threaded rod 29 arranged vertically is threaded on the translation clamping block 34, On the clamping threaded rod 29, external thread I36 and external thread II37 with opposite rotation direction are provided on the upper tap, and the external thread I36 and external thread II37 are threadedly connected and fixed with snap-in sleeves 32 respectively, and snap-in sleeves 32 are fixed with clamping plate 30 .

[0034] Rotate the clamping threaded rod 29 to rotate, and the clamping threaded rod 29 drives the two clamping sleeves 32 to move towards each other through the external thread I36 and external thread II37 on it. The block 32 slides to fit the card slot 35, and the card joint block 32 slides along the card slot 35 to finally realize the clamping of the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com