Mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment

A surface treatment, mobile technology, used in grinding/polishing safety devices, grinding frames, metal processing equipment, etc., can solve the problem of not finding system equipment and polishing methods, operator muscle and nerve injury, grinding surface quality Influence and other problems, to achieve the effect of standardized production, simple and compact overall structure, and constant contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

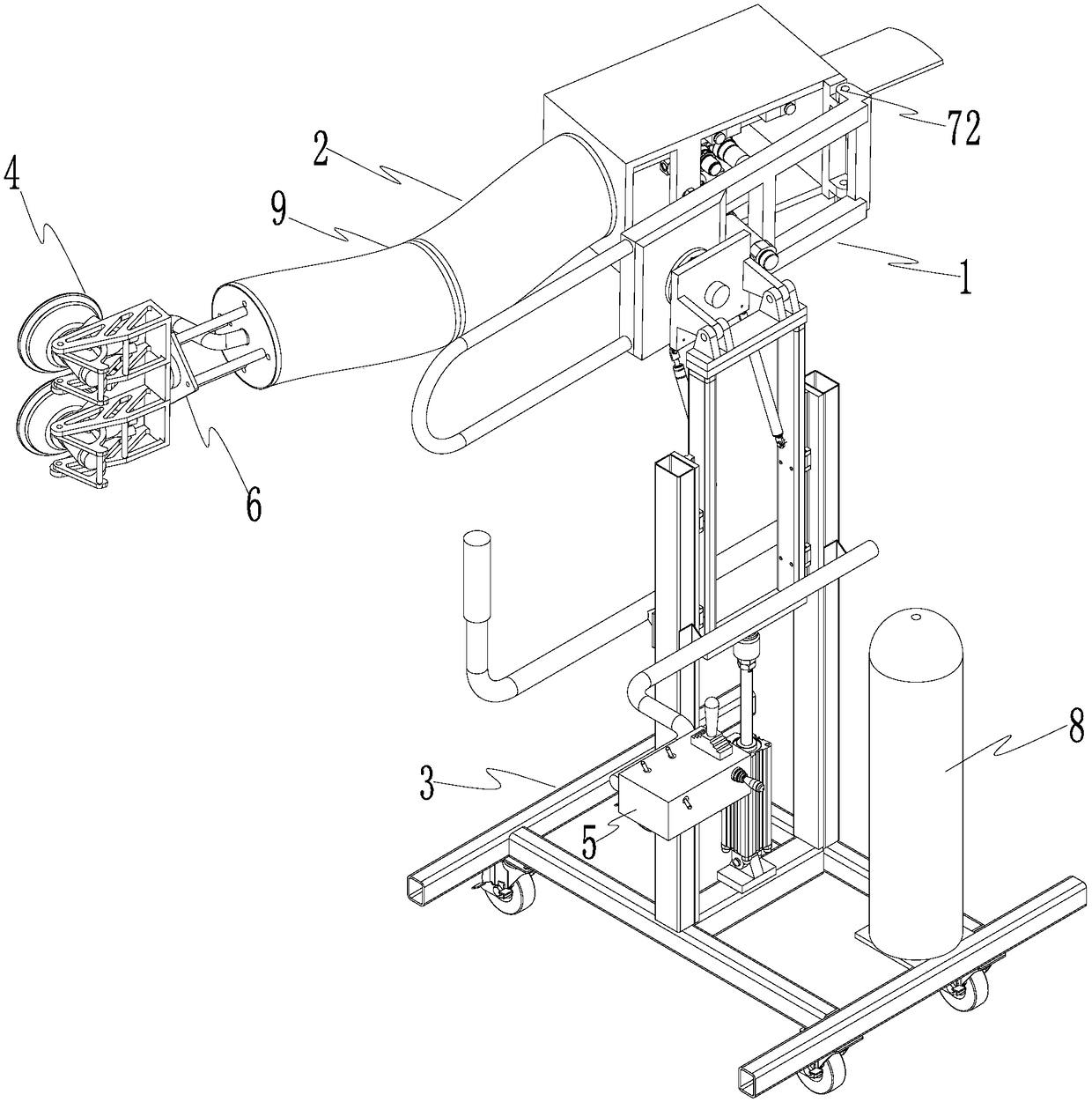

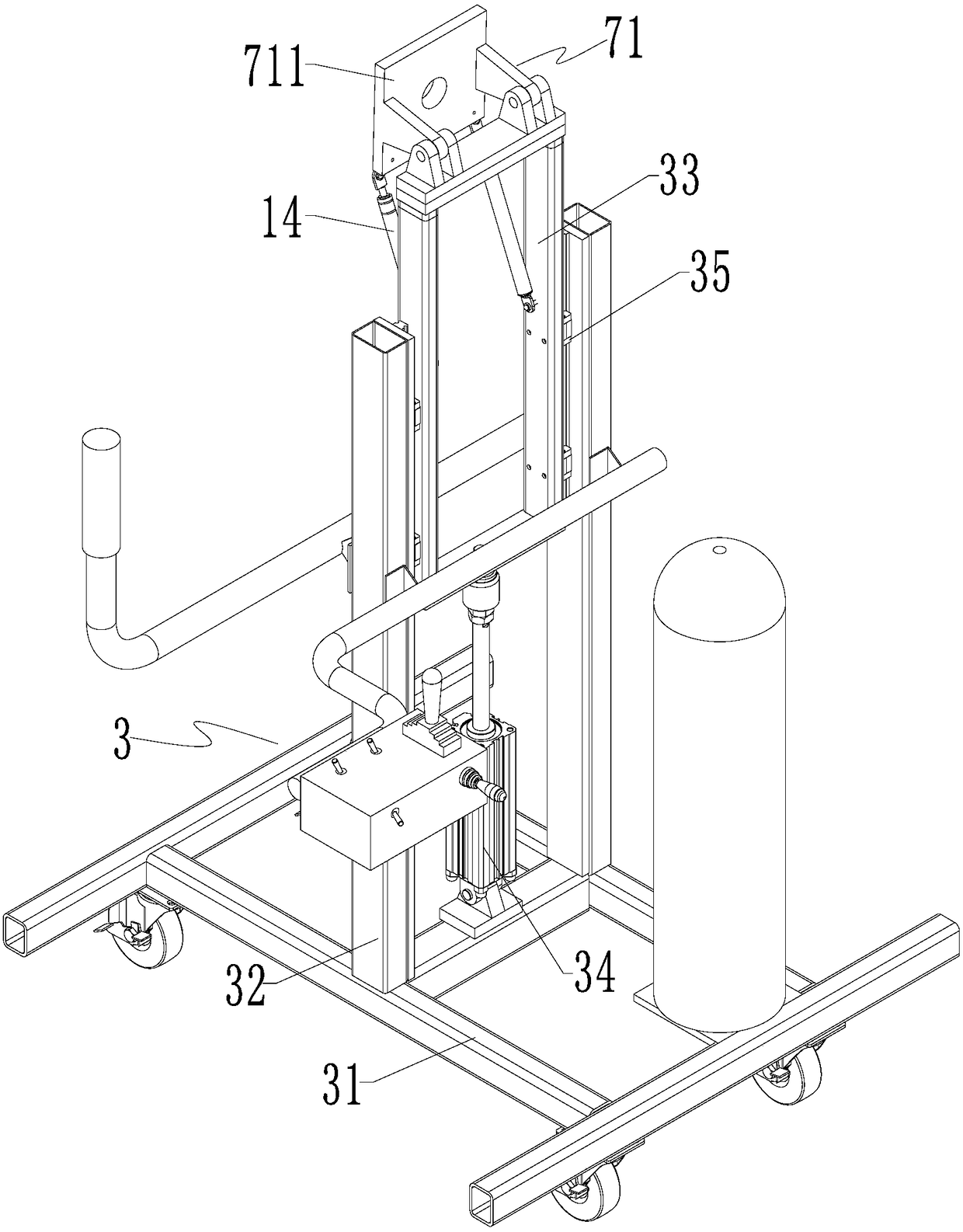

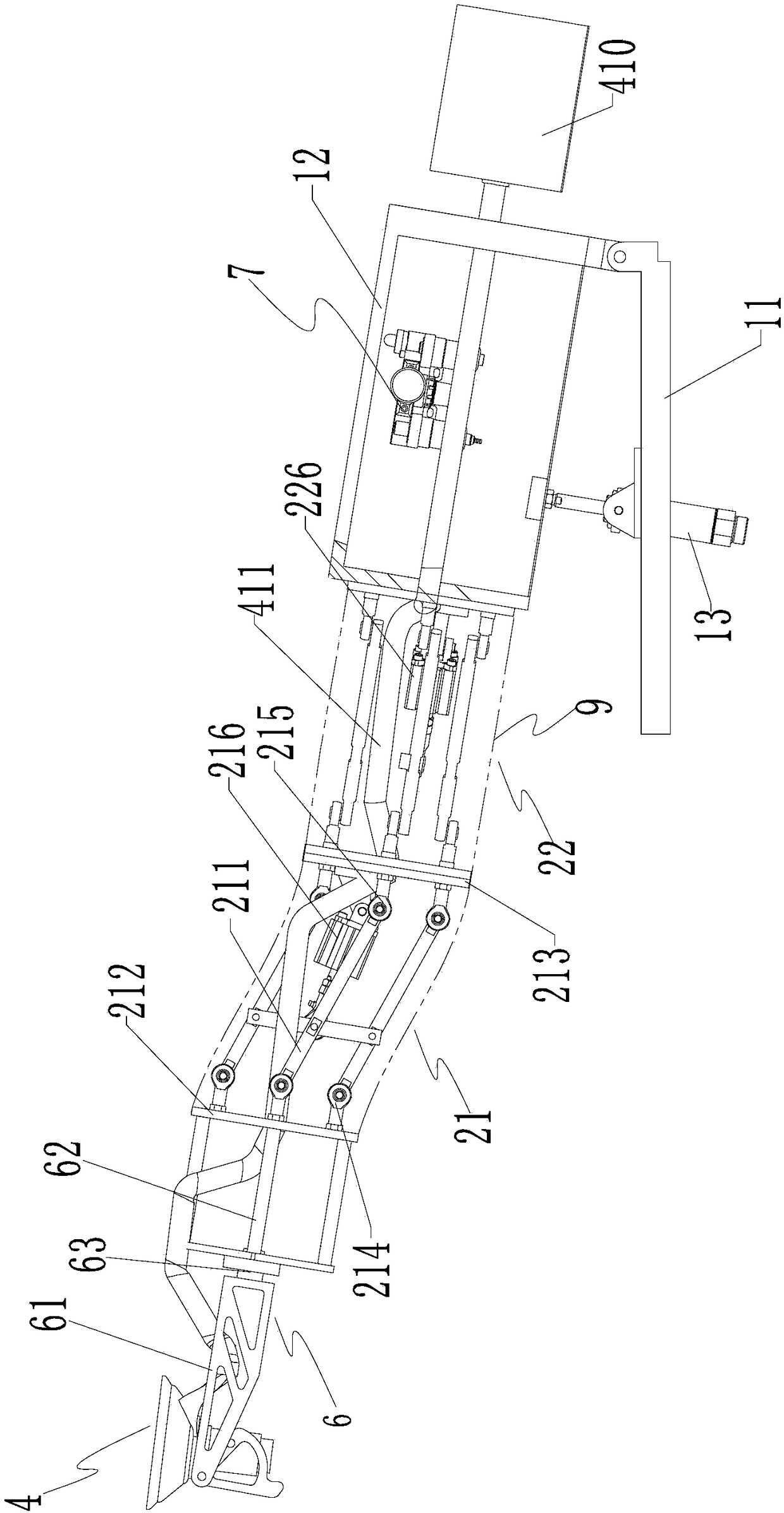

[0029] Such as Figures 1 to 3 As shown, the large equipment surface treatment mobile self-dusting continuous grinding and polishing machine of the present invention includes: a mobile base 3; a pneumatic mechanical arm, which is movably assembled on the mobile base 3, and includes an assembly positioning assembly 1 and a pneumatic swing arm assembly 2, wherein: the assembled positioning assembly 1 includes a hinged positioning support and a drive sealing box ( figure 1 It is a schematic diagram of the assembly structure of driving the sealing box to swing upward; however, it is not limited to this assembly method, and the driving sealing box can be assembled by swinging downward or sideways, which is not shown in the figure. ); the pneumatic swing arm assembly 2 is integrally installed on one end side of the above-mentioned drive sealing box, and it includes a four-bar linkage structure, a linear cylinder providing driving power for the four-bar linkage structure, and a four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com