Patents

Literature

137results about How to "Expand the grinding range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

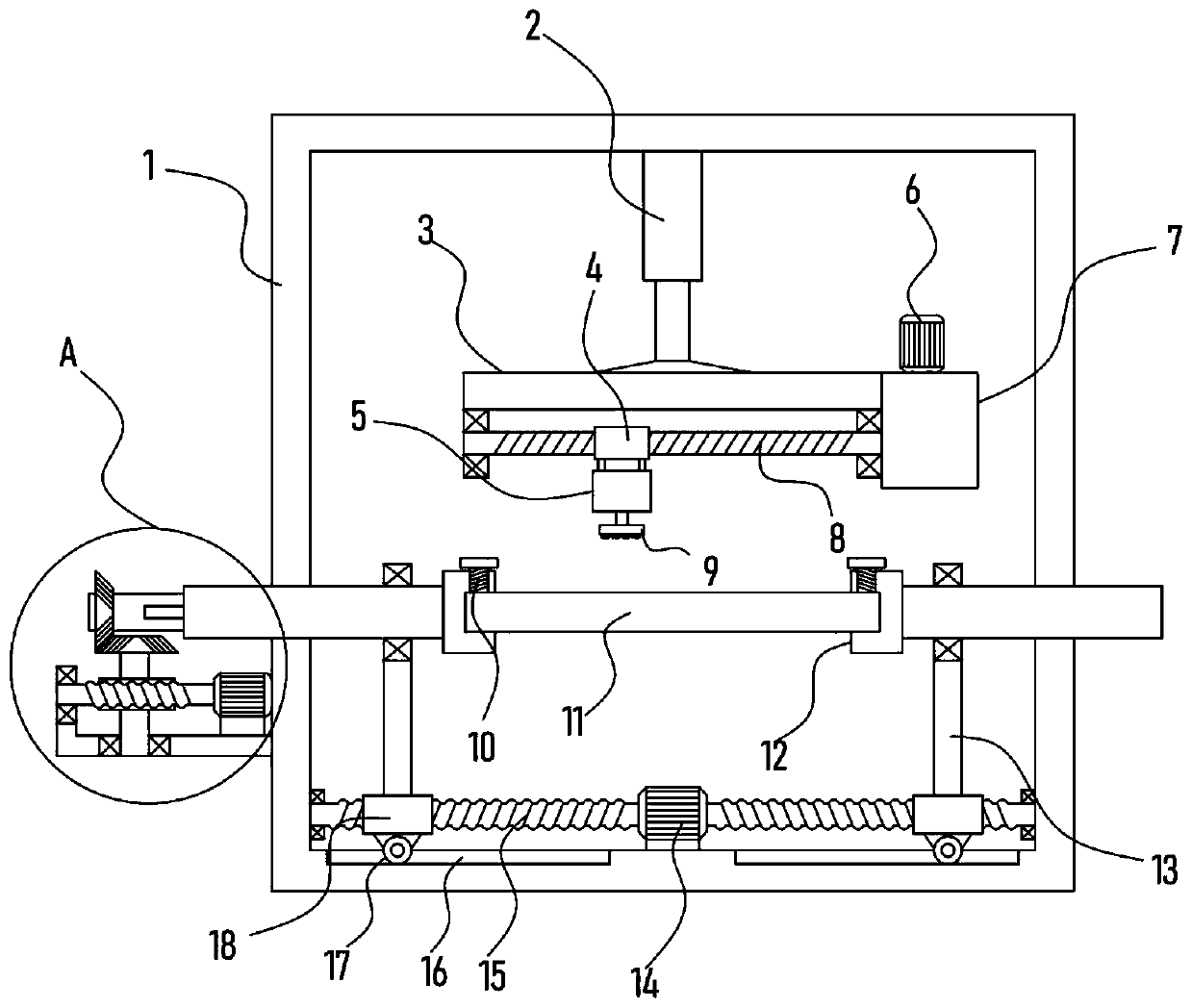

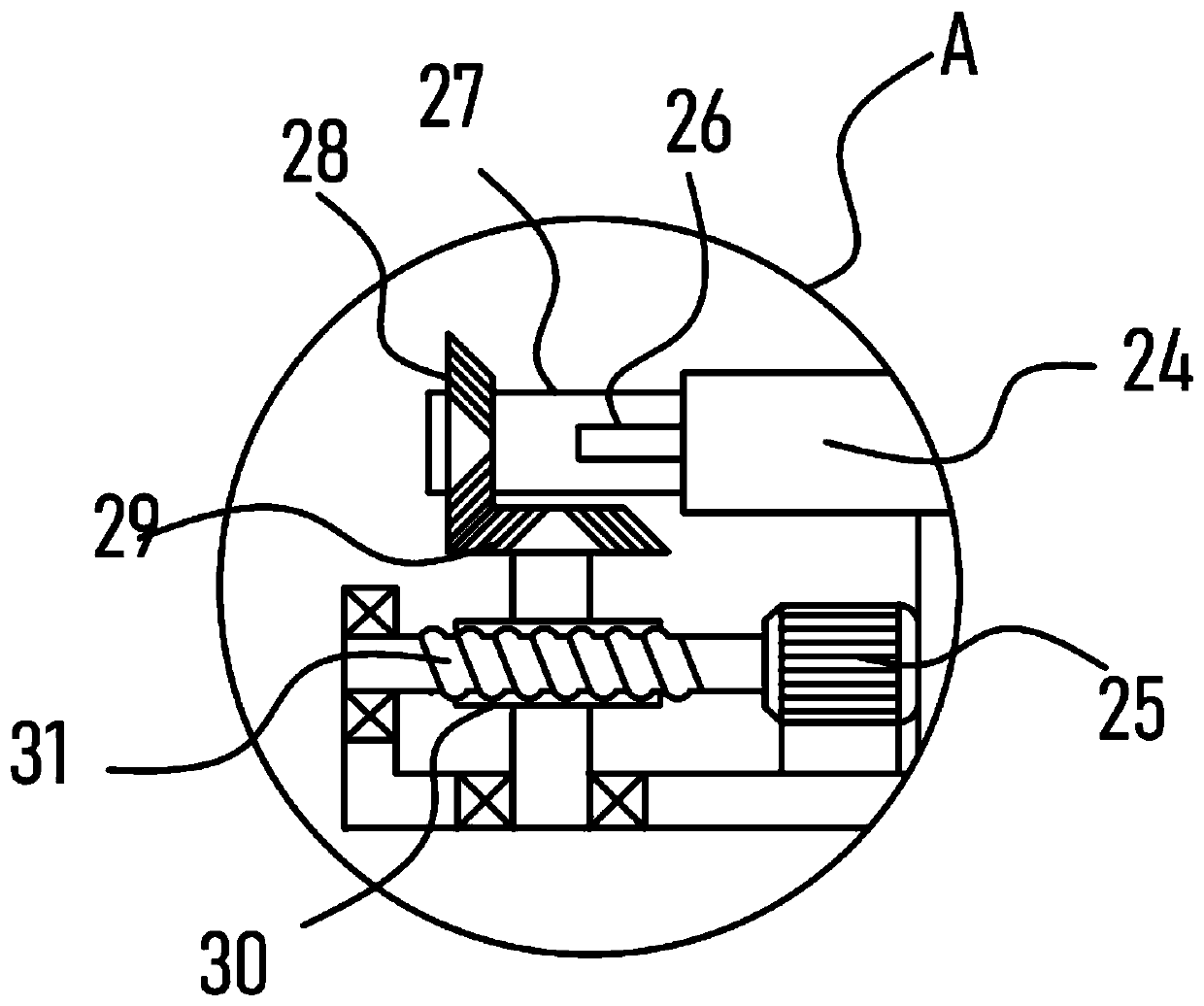

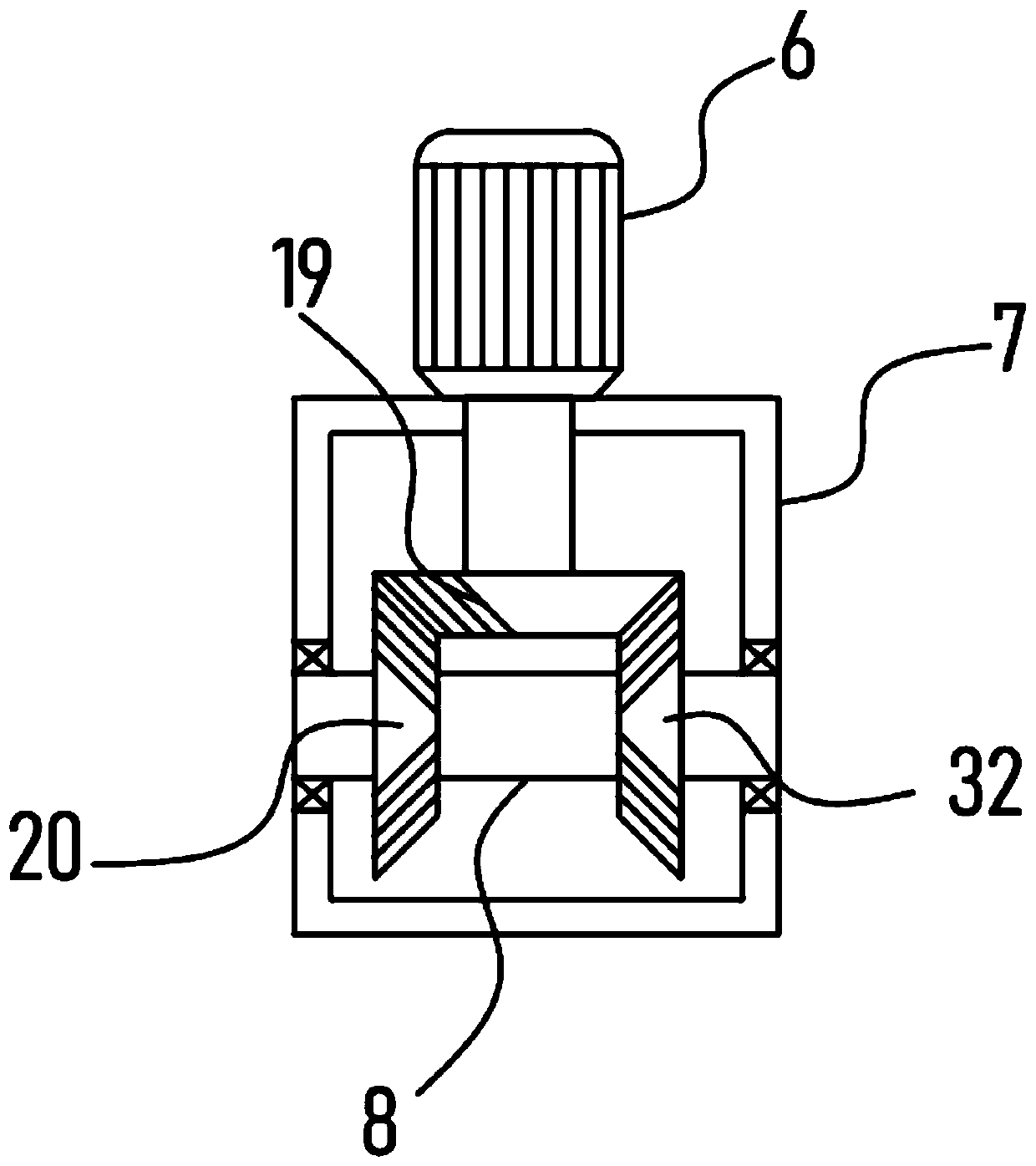

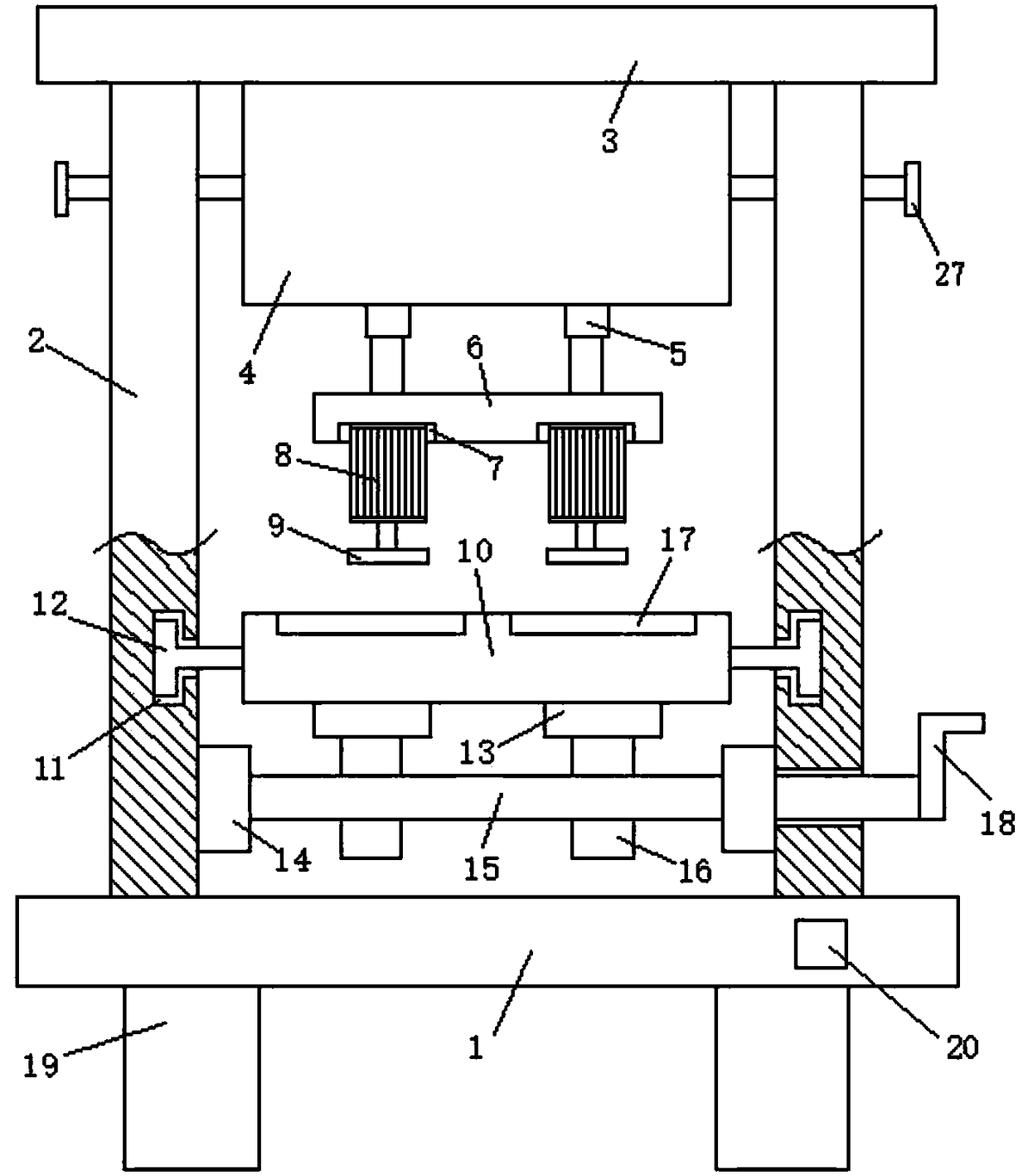

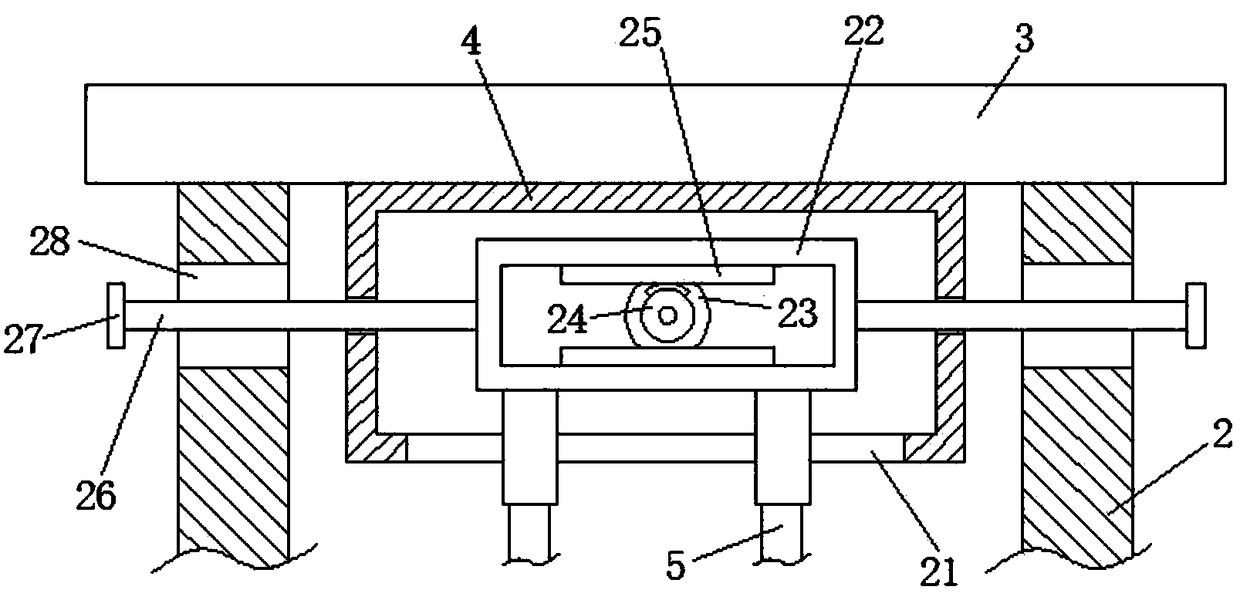

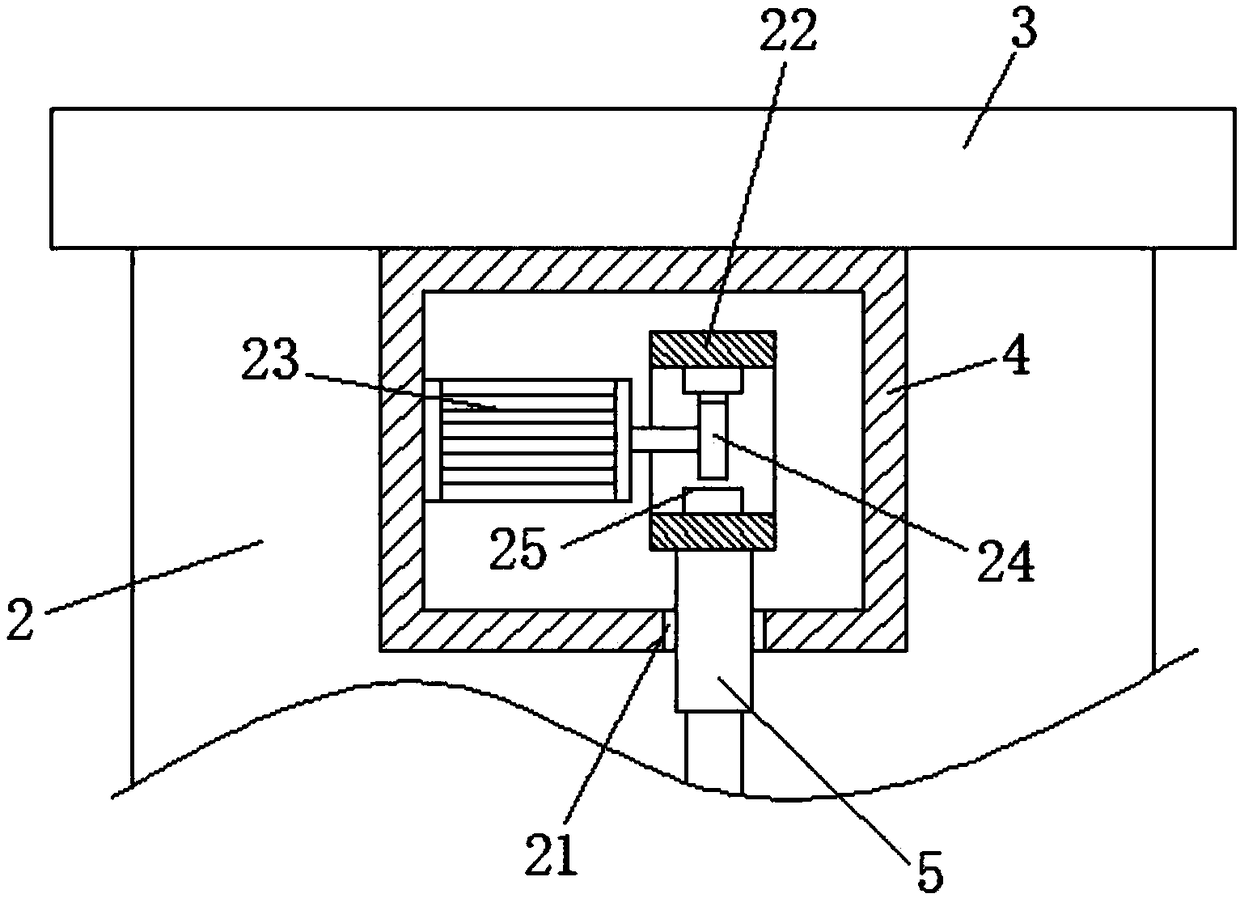

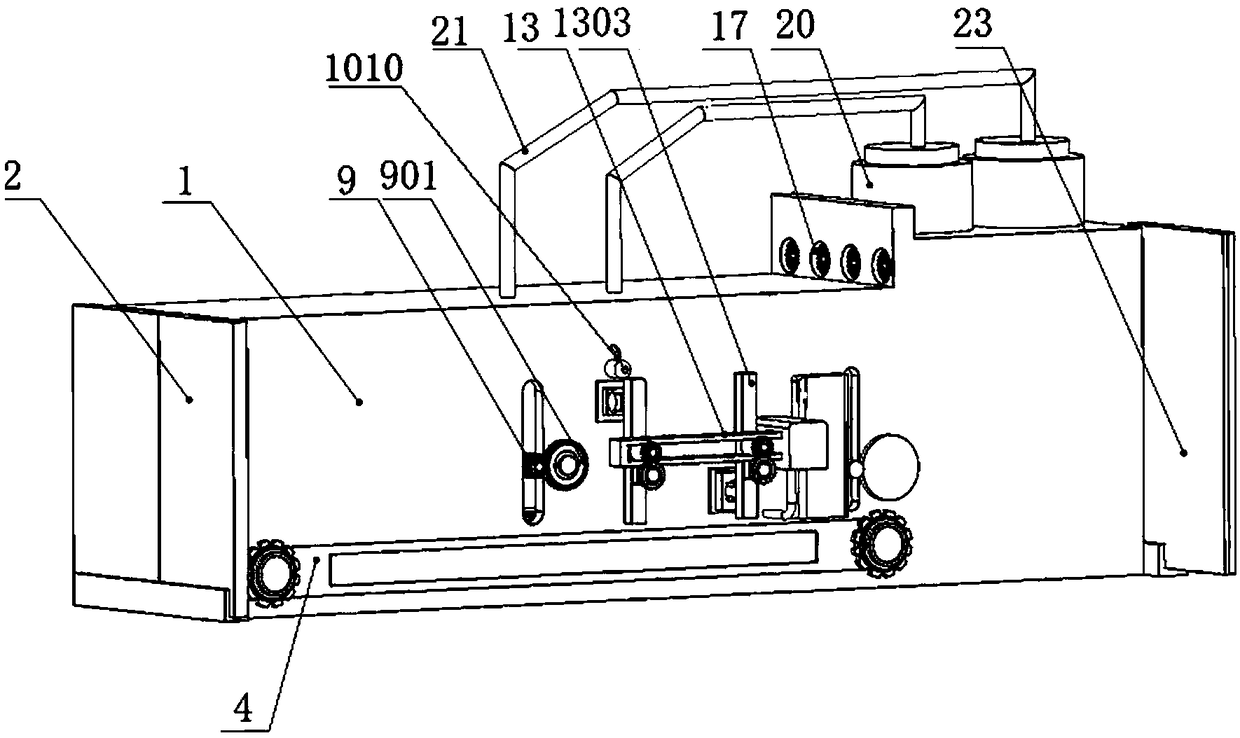

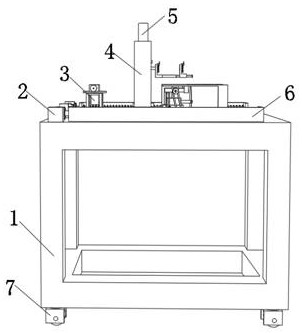

Mechanical plate grinding device with overturning function

InactiveCN111300185ARealize clamping and fixingRealize the grinding effectGrinding drivesGrinding feedersEngineeringMachining

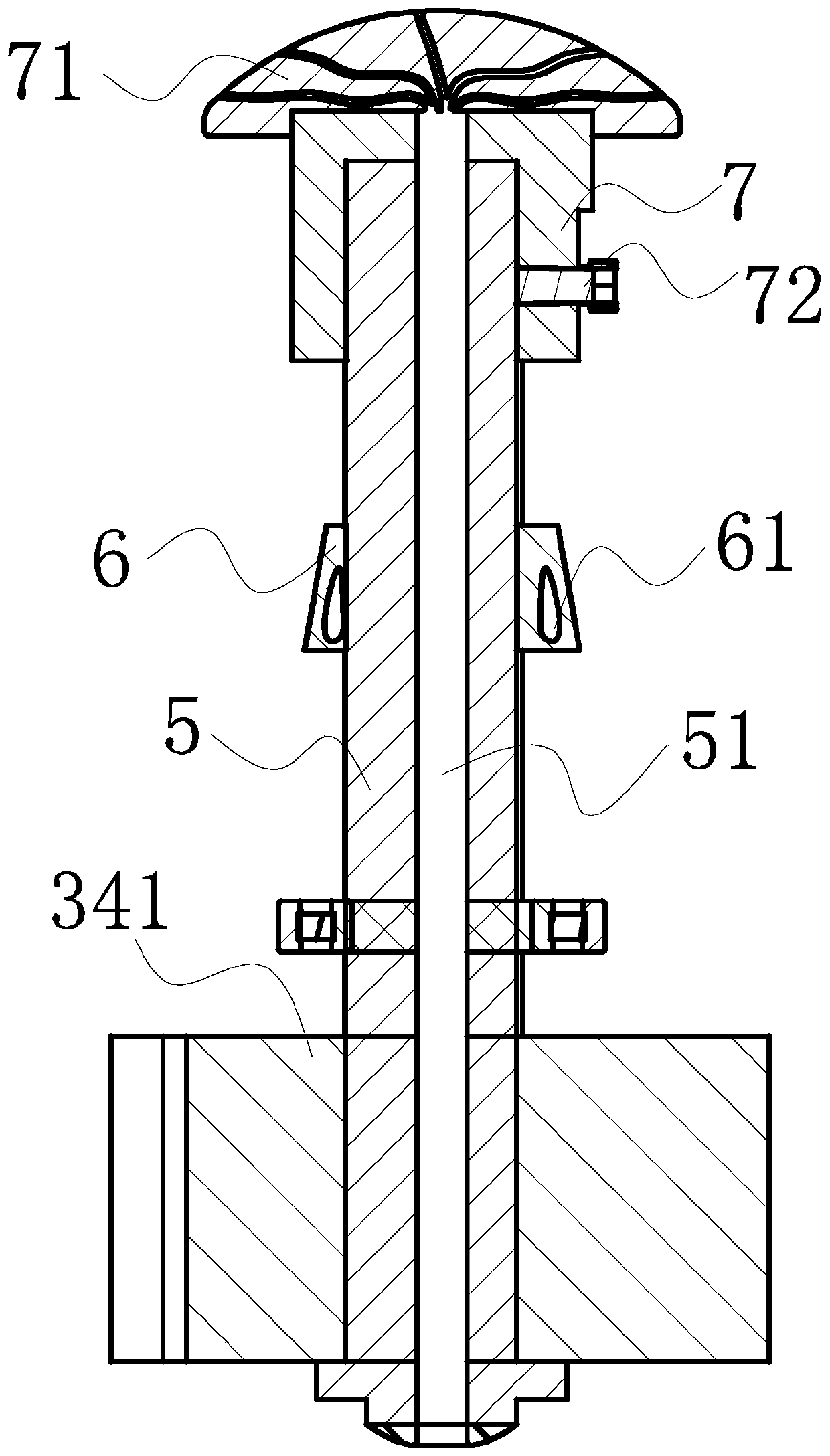

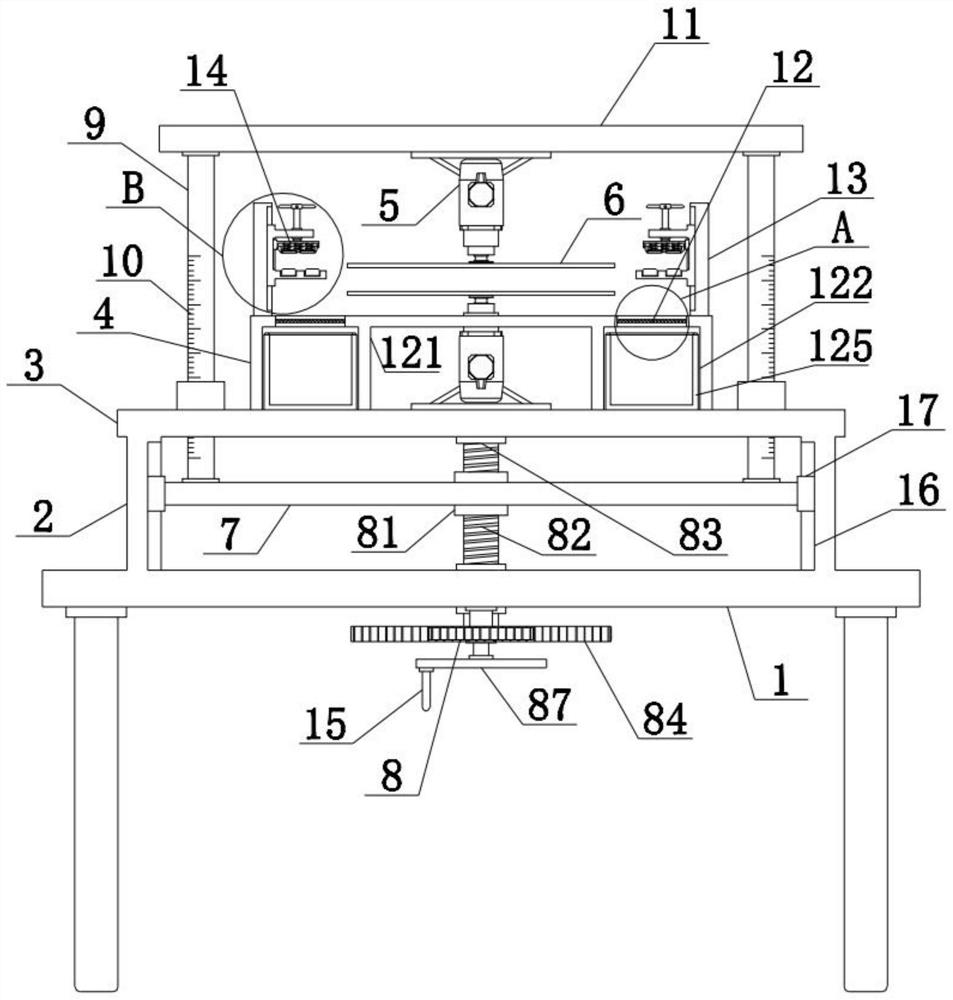

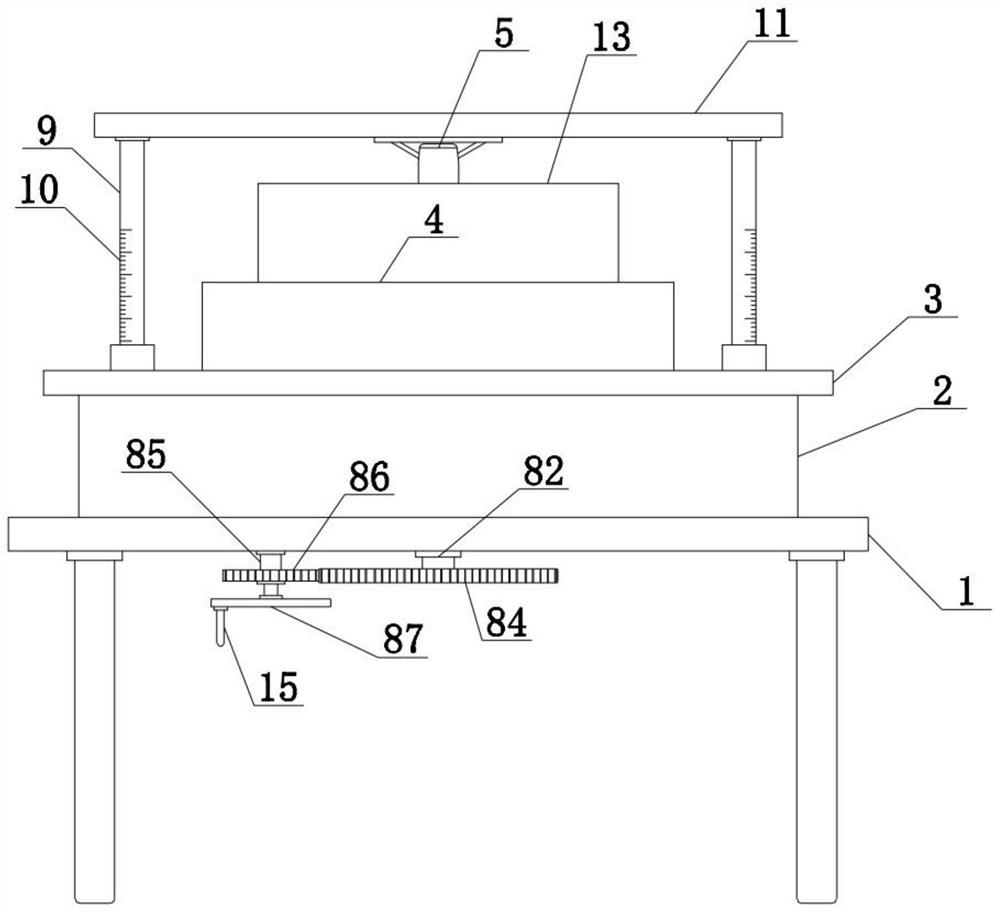

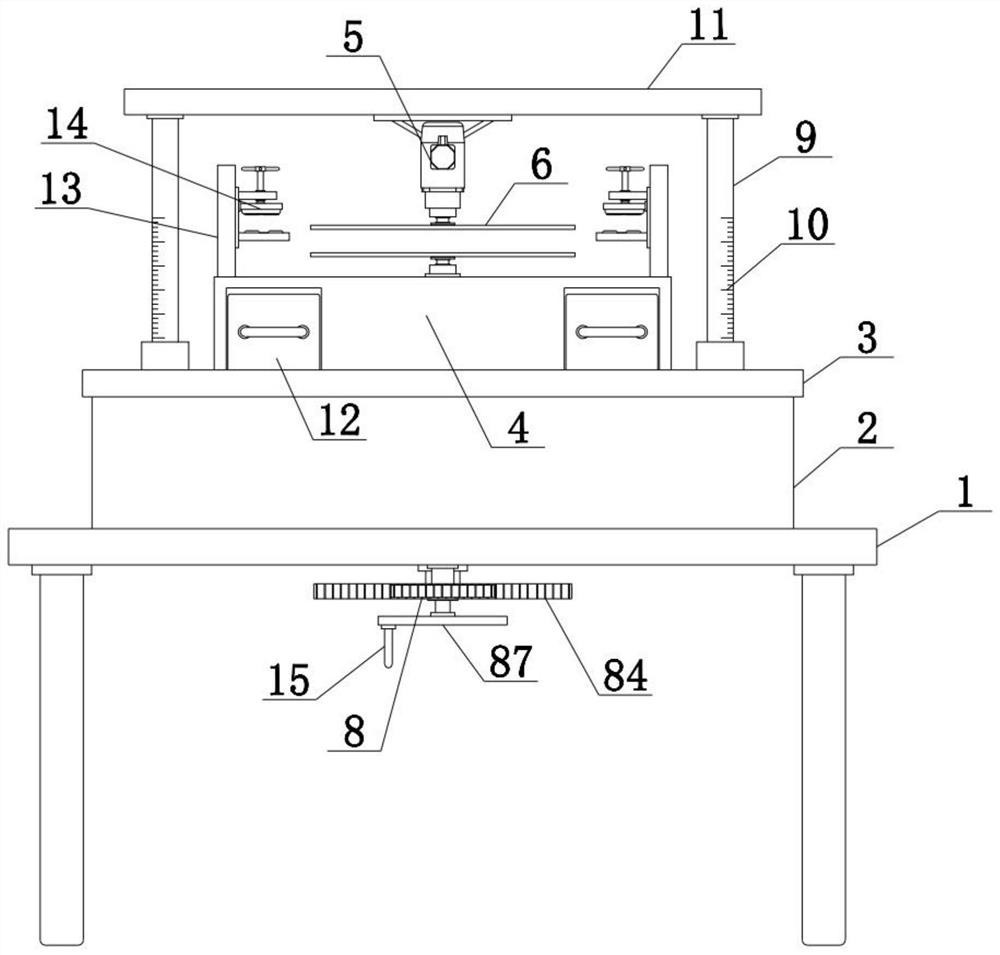

The invention discloses a mechanical plate grinding device with an overturning function, and relates to the technical field of machining. The mechanical plate grinding device comprises a supporting frame, wherein an electric push rod is vertically fixed at the inner top of the supporting frame; a translation mechanism for driving a grinding mechanism to move transversely is arranged in a steeringbox; an adjusting mechanism for driving two clamping plates to move oppositely is arranged on the supporting frame; and the supporting frame is provided with an overturning mechanism used for drivingthe clamping plates to rotate. According to the mechanical plate grinding device with the overturning function, the two clamping plates are driven by the arranged adjusting mechanism to move oppositely to clamp and fix a plate, so that stability of the plate in the grinding process is guaranteed, and a grinding effect is guaranteed; a grinding plate in the arranged grinding mechanism rotates to achieve grinding effects on the surface of the plate, and the translation mechanism can drive the grinding plate to transversely move relative to the plate, so that the grinding range of the plate is greatly widened, and the working efficiency is improved; and the arranged overturning mechanism can overturn the plate, so that sufficient double-face grinding effects of the grinding plate are achievedon the surface of the plate.

Owner:武文家

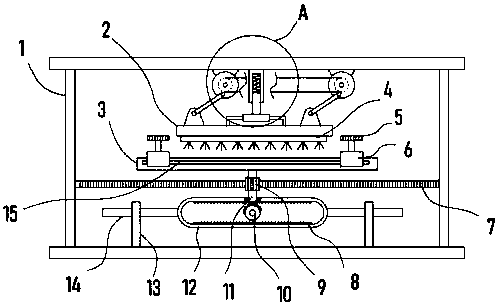

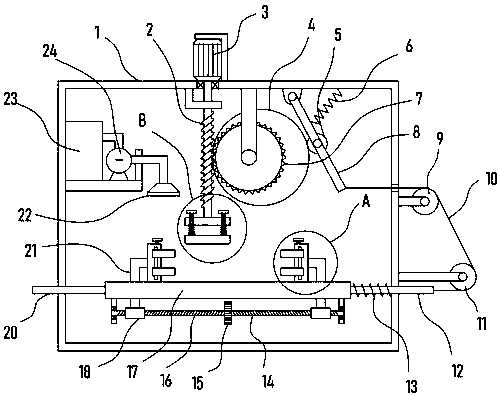

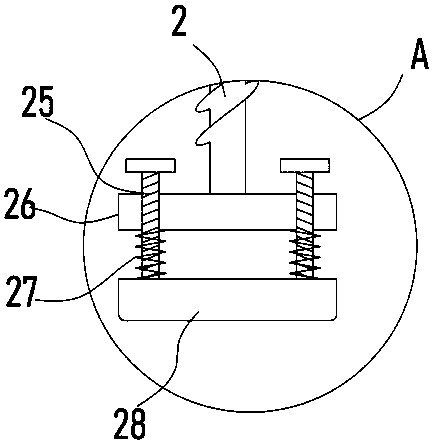

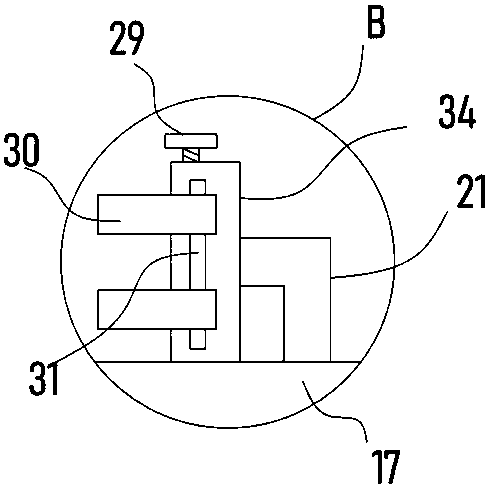

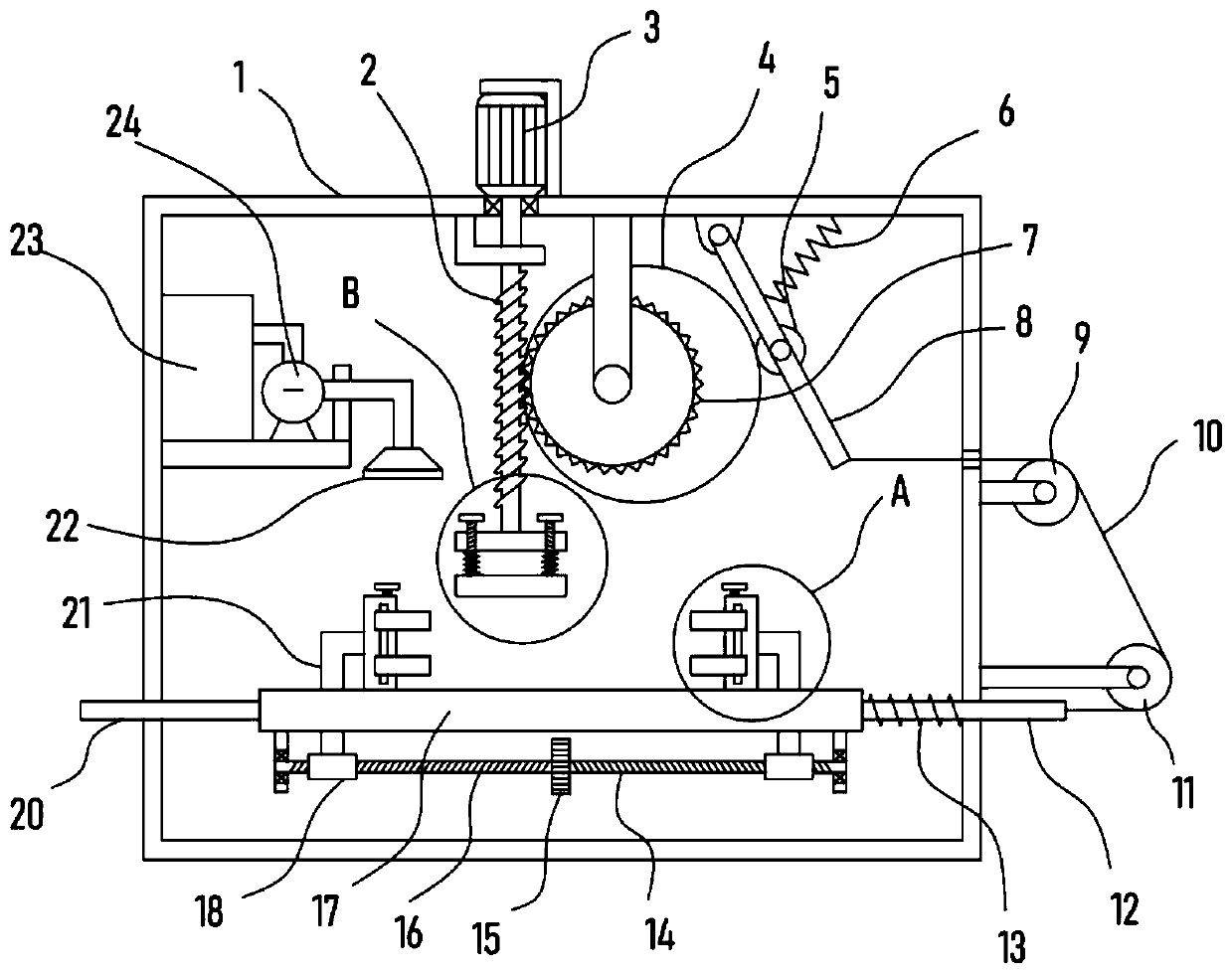

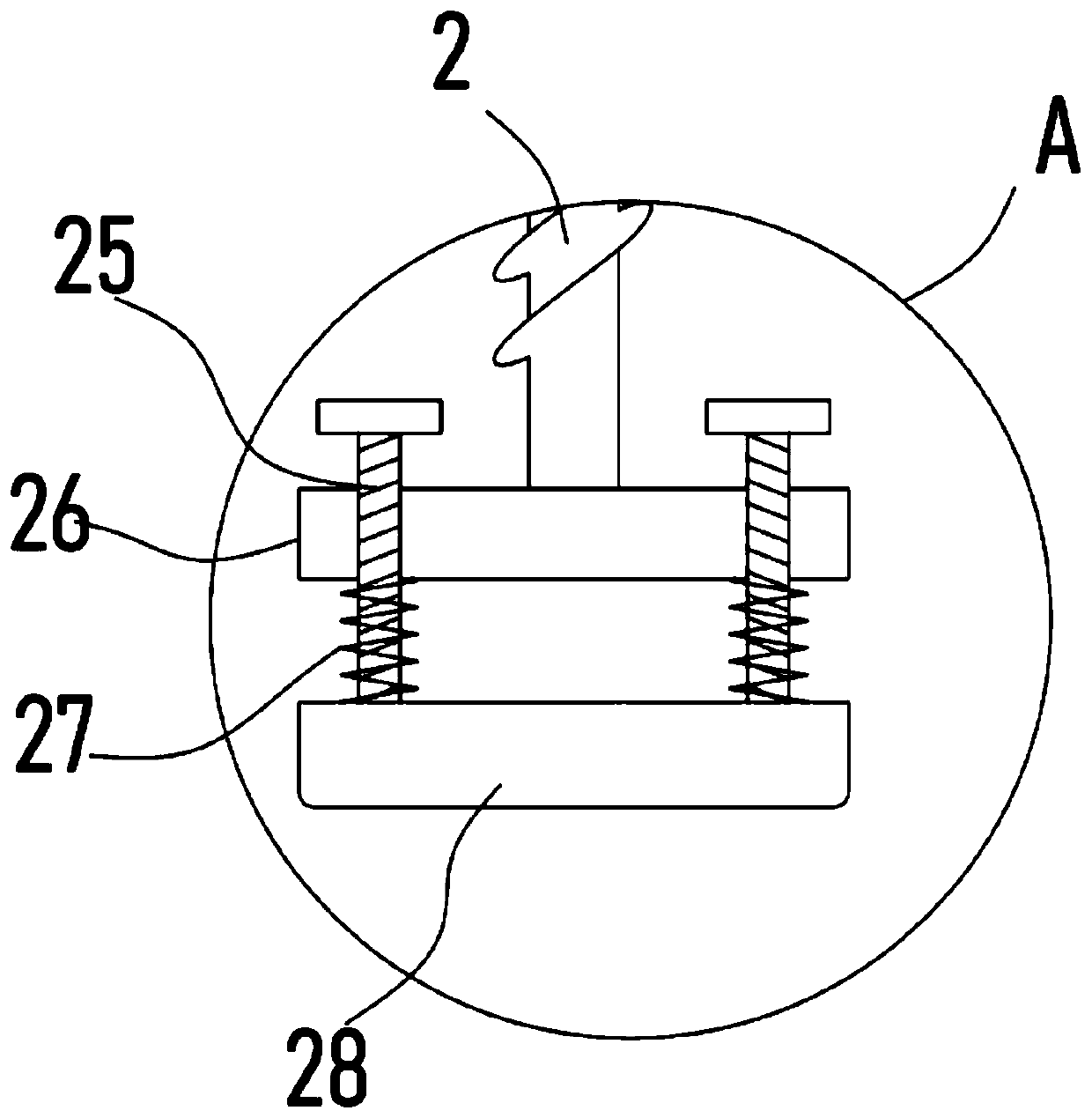

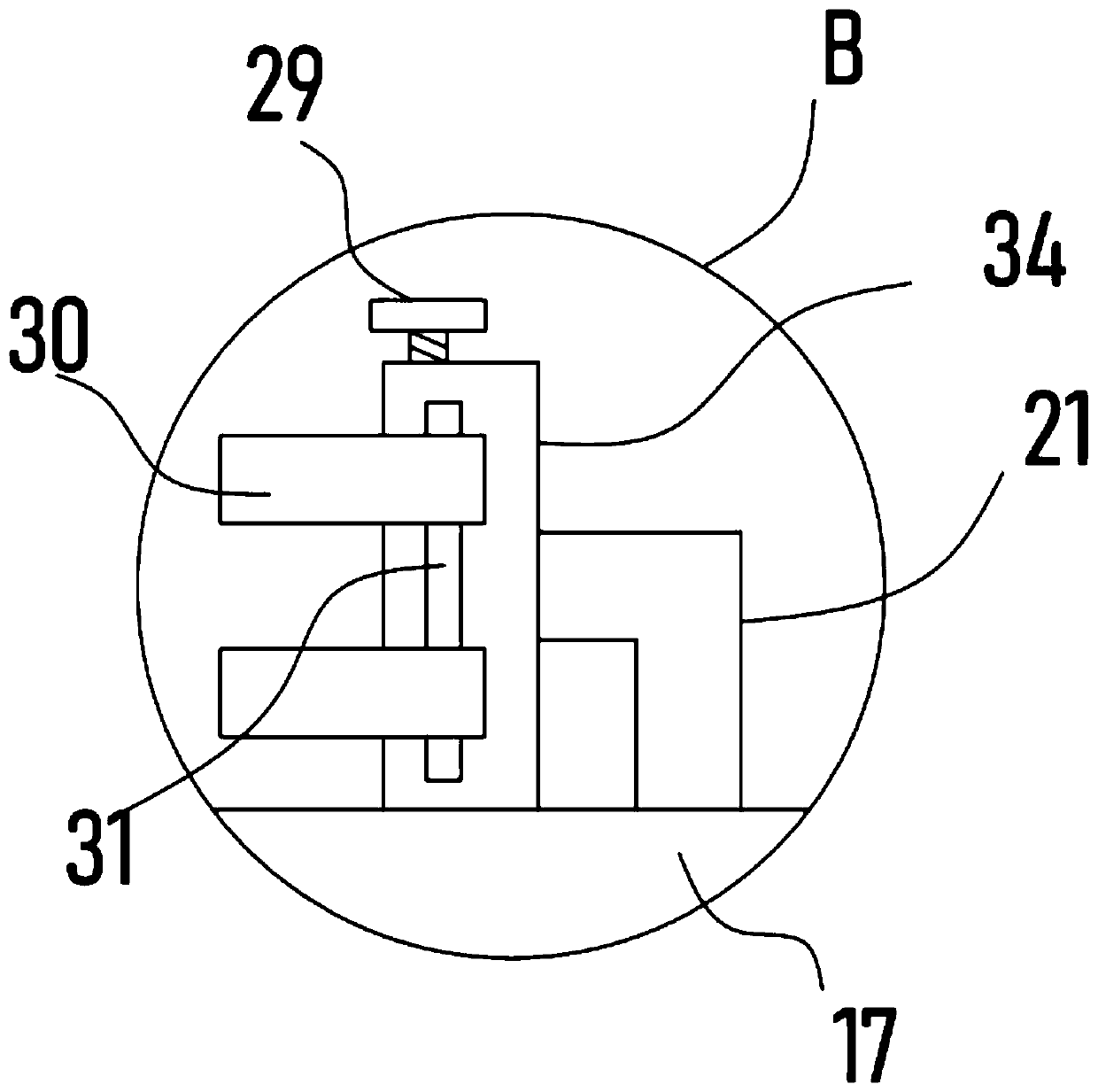

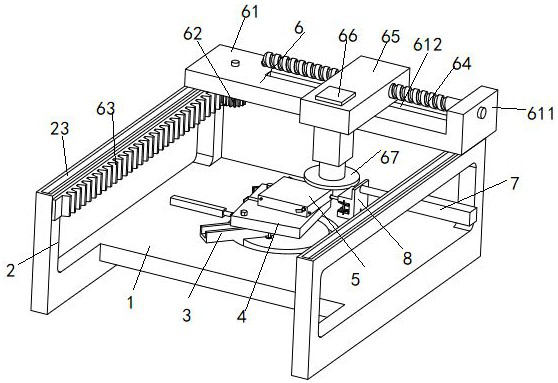

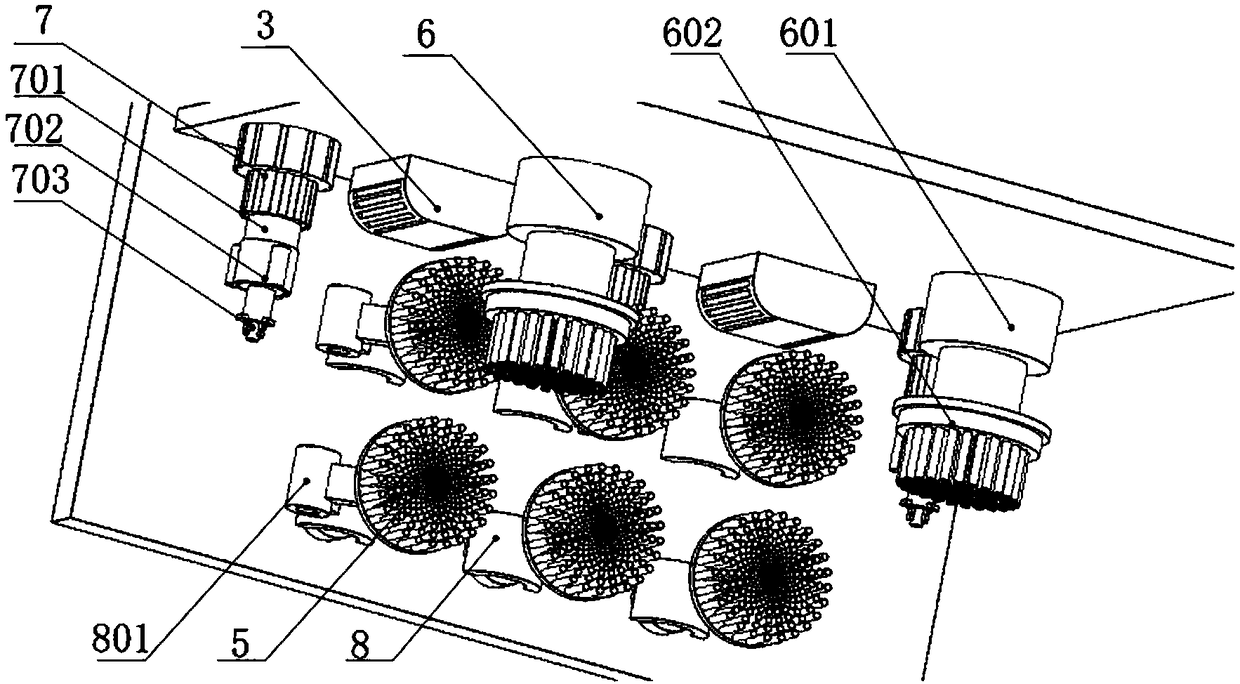

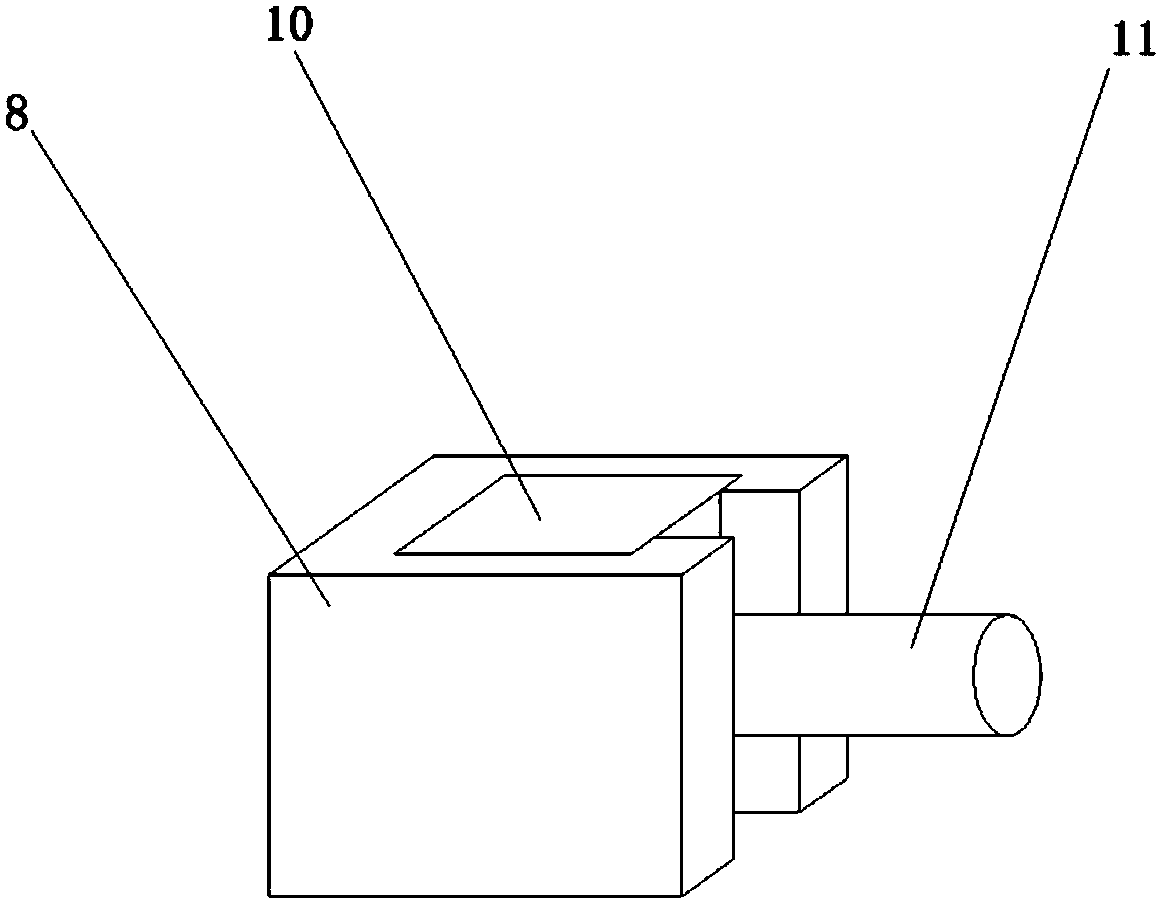

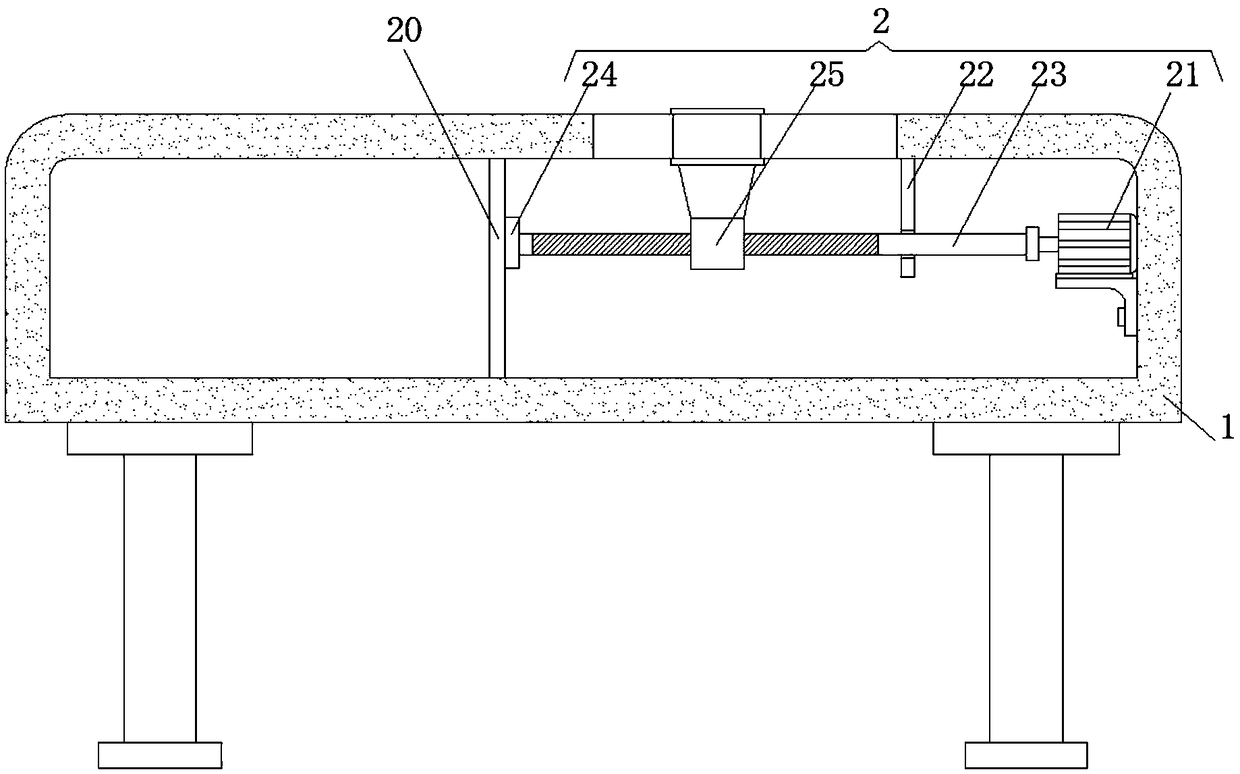

Leather polishing device for leather bag processing

InactiveCN109108774AGrind fully and thoroughlyExpand the grinding rangeGrinding carriagesGrinding drivesChinese charactersReciprocating motion

The invention discloses a leather polishing device for leather bag processing, and relates to the technical field of leather product processing machines. The leather polishing device for leather bag processing comprises a supporting frame; a frame shaped like a Chinese character 'hui' is horizontally arranged in the supporting frame; the left end and the right end of the frame are fixedly providedwith guide rods penetrating through a limiting board in a sliding mode; a rotary shaft is rotationally arranged on the frame; a limiting sleeve is vertically and fixedly installed on the top in the supporting frame; a slide shaft is vertically arranged inside the limiting sleeve in a sliding mode; a horizontal limiting rod is fixedly installed on the upper surface of a transmission board and movably sleeved with a casing pipe fixed to the lower end of the slide shaft; and a polishing board is fixedly installed at the bottom of the transmission board. The polishing board is driven to polish leather in a rubbing mode through swinging of the transmission board, enough polishing force is ensured, leather polishing is more sufficient and complete, the supporting board drives the leather to move left and right in a reciprocated mode and rotate at the same time, the polishing range of the polishing board on the leather is greatly enlarged, and the leather polishing efficiency is effectivelyimproved.

Owner:温州天炽包装有限公司

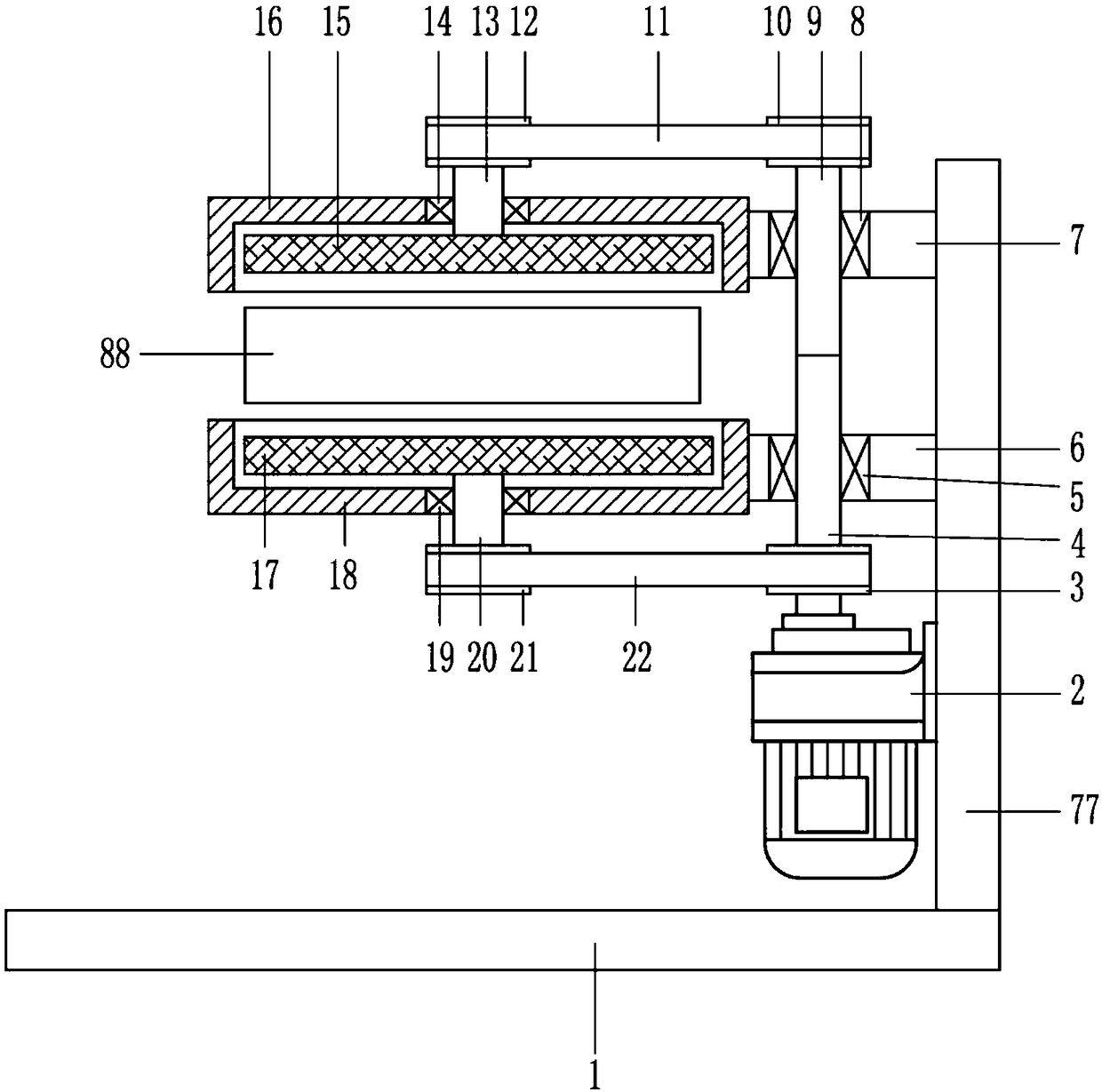

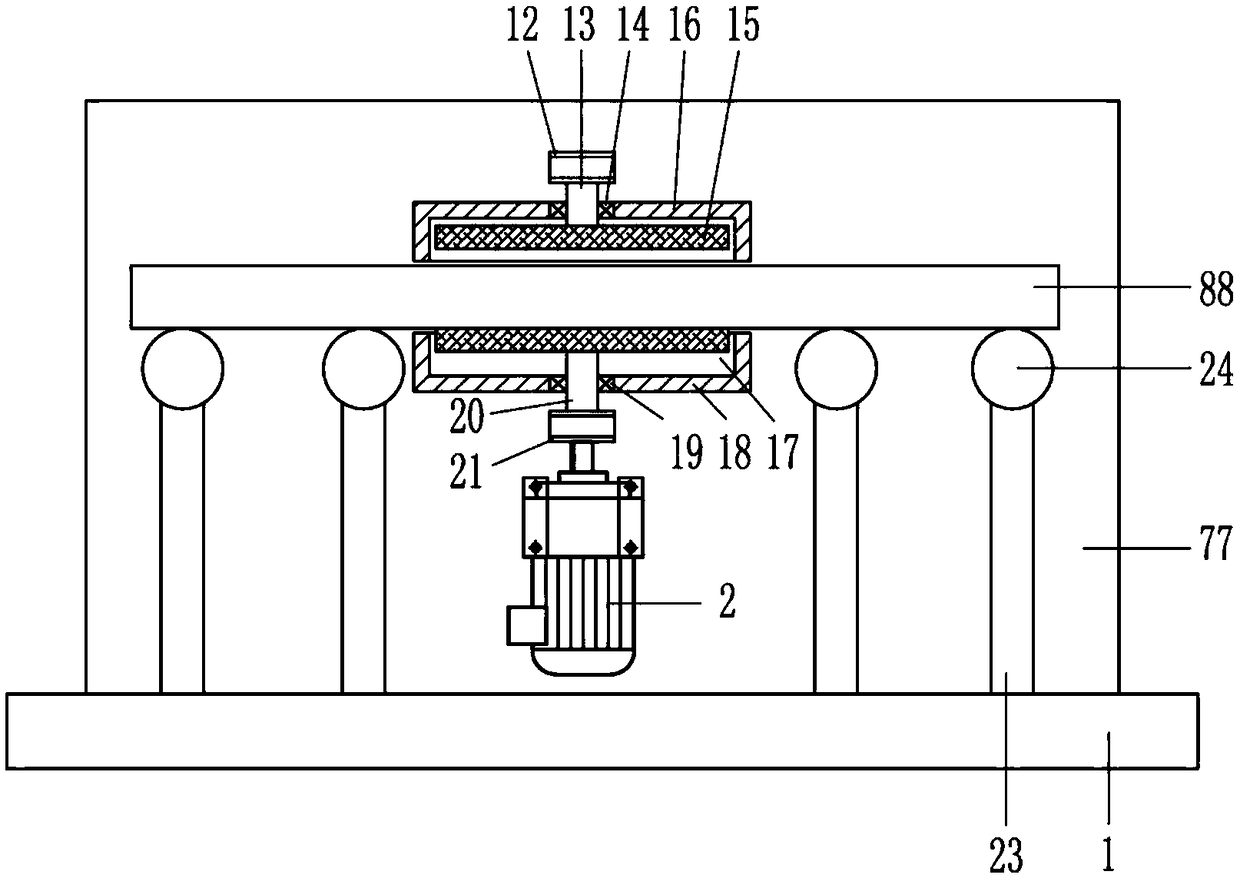

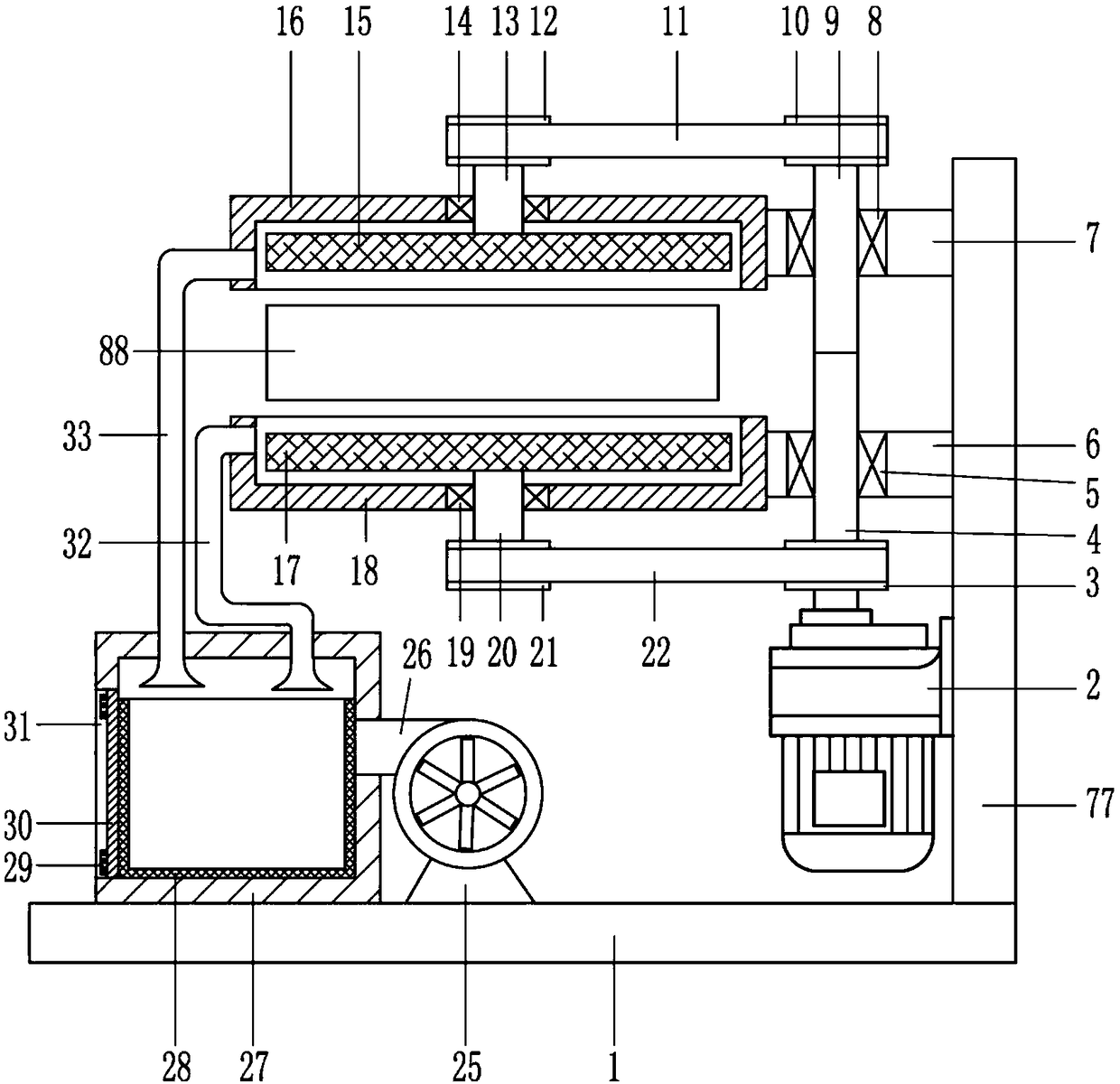

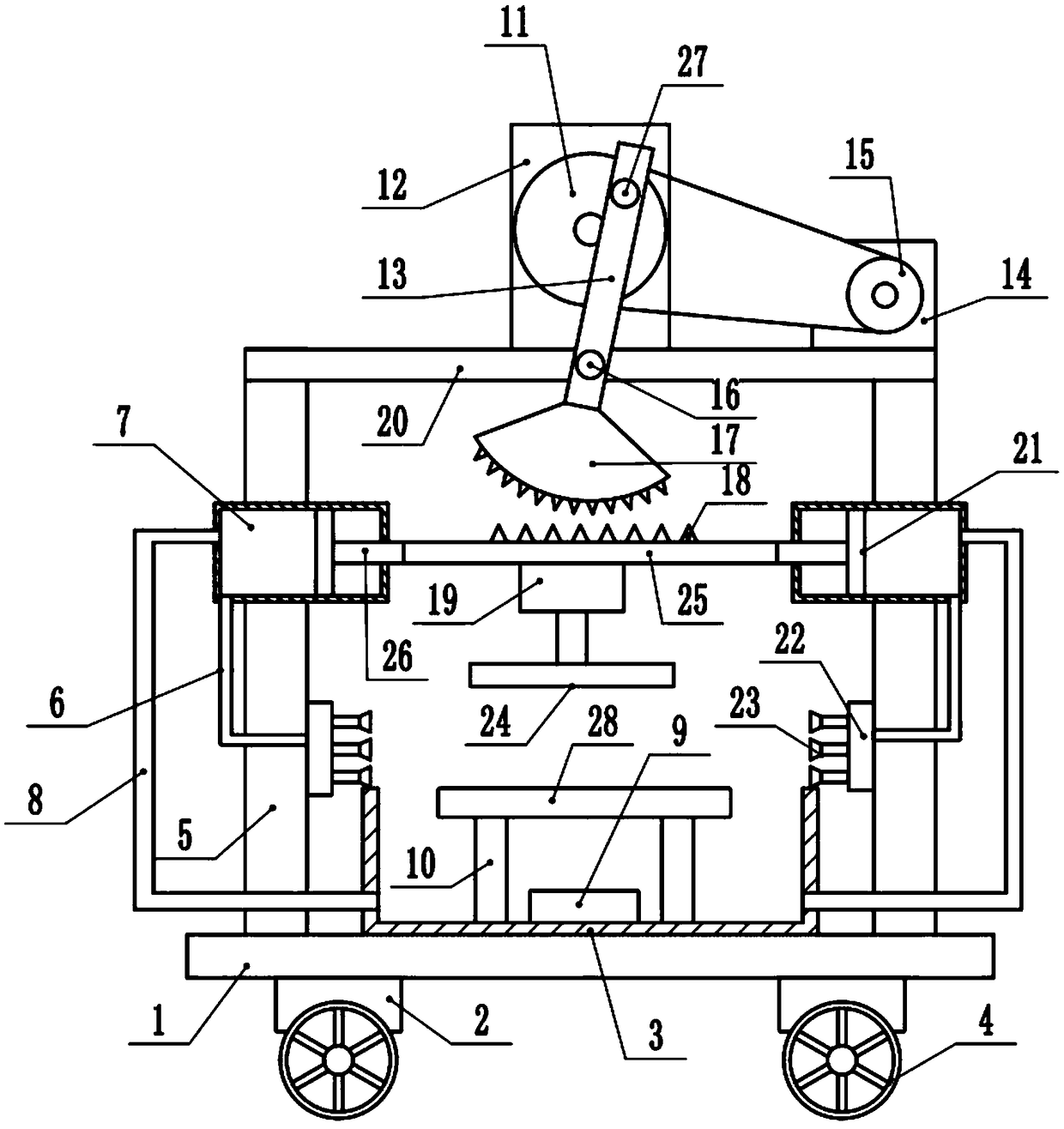

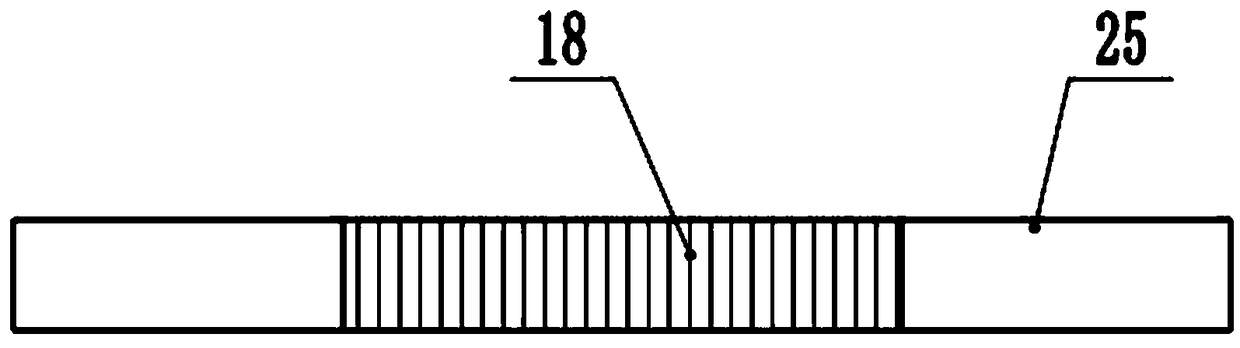

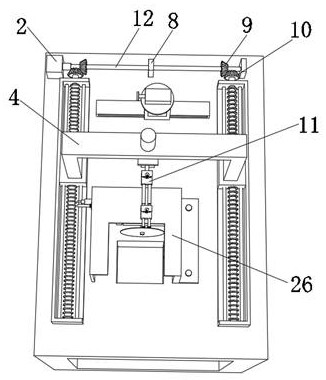

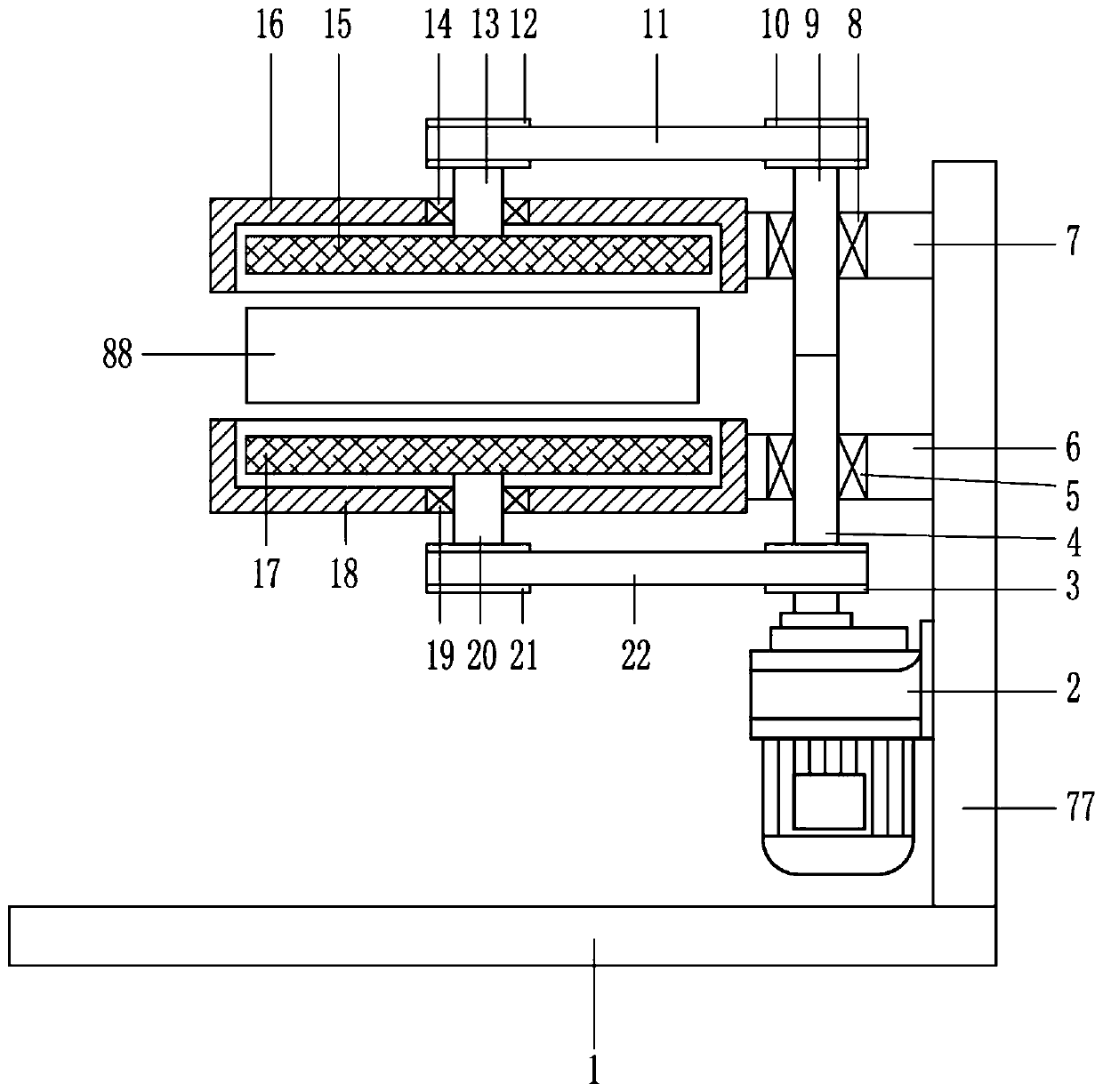

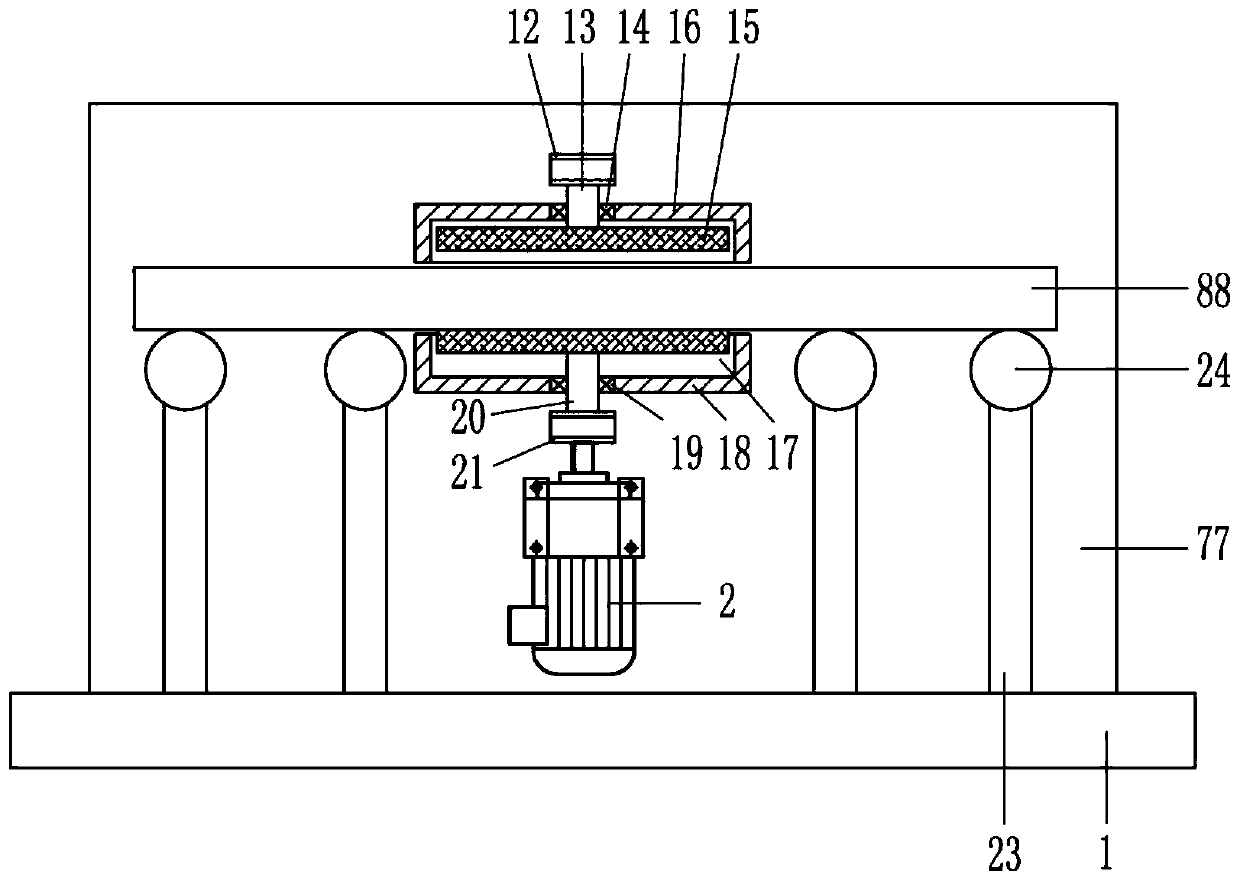

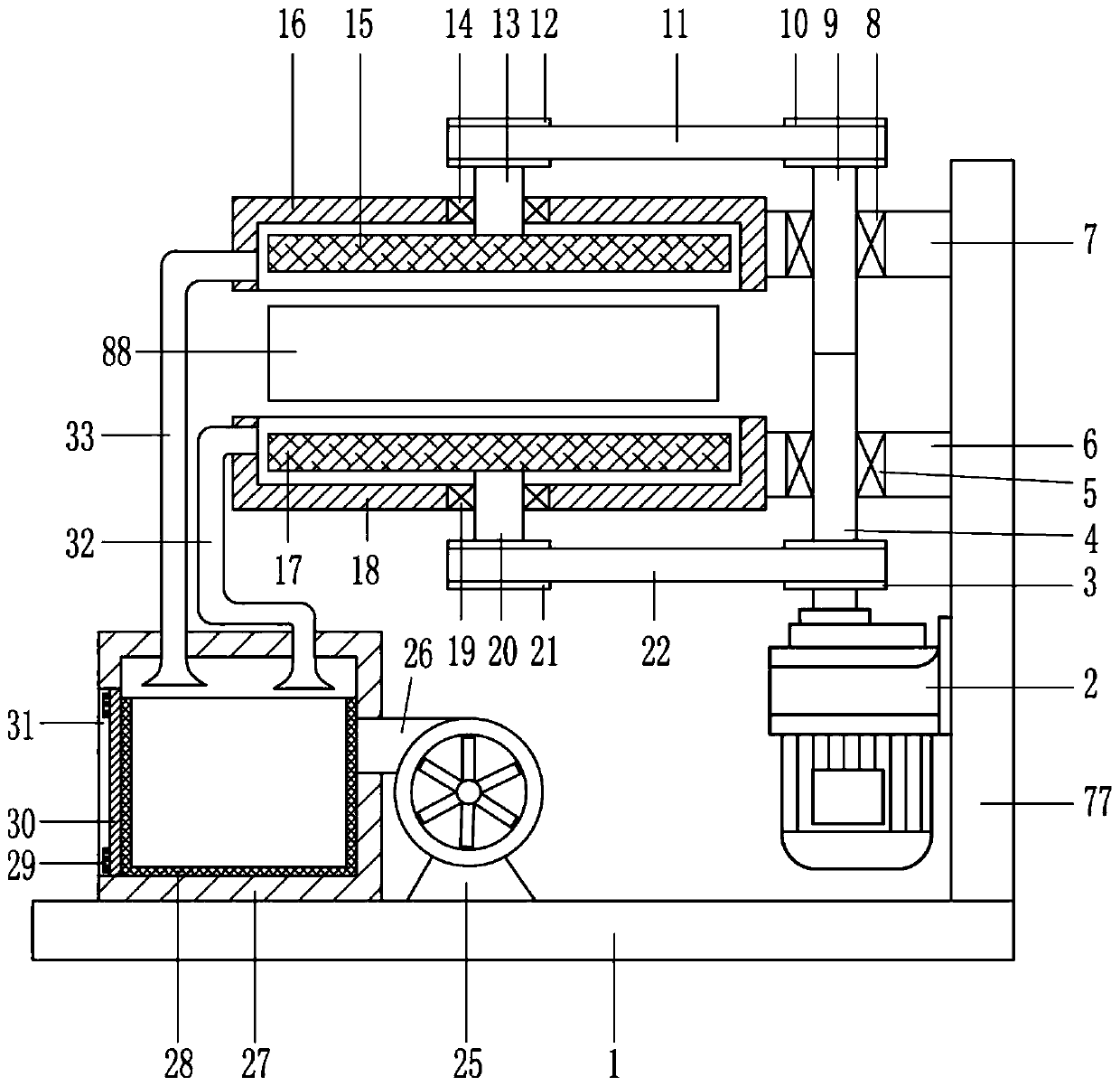

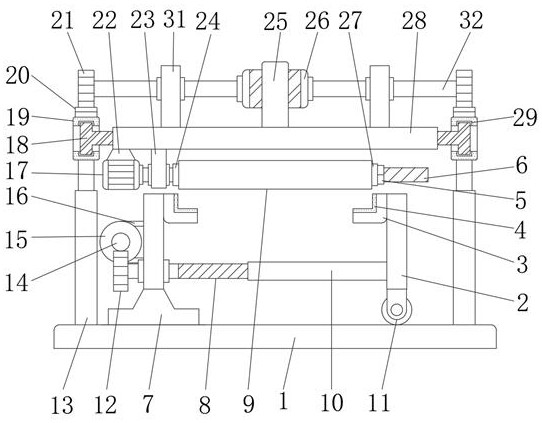

Double-sided polishing machine for wood used for manufacturing furniture

InactiveCN108907936AImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesWood machiningFurniture manufacturing

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

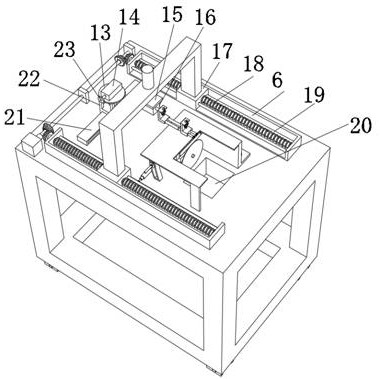

Plastic polishing device for plastic product processing

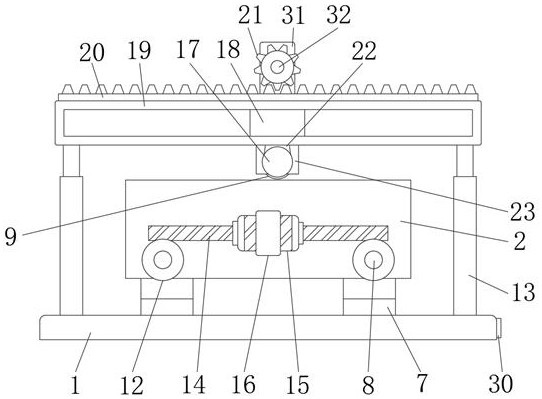

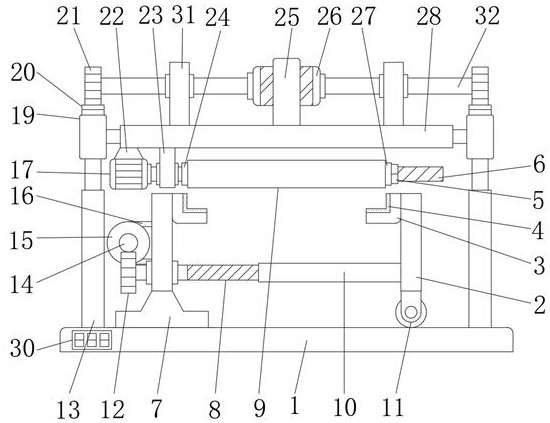

InactiveCN110000664AExpand the grinding rangeSufficient sanding strengthGrinding machinesGrinding/polishing safety devicesGear wheelReciprocating motion

The invention discloses a plastic polishing device for plastic product processing, and relates to the technical field of plastic product processing. The plastic polishing device comprises a paint spraying chamber, a lifting frame is arranged in the paint spraying chamber, a transverse spur rack is slidably mounted in the paint spraying chamber, a gear I and a gear II which are engaged with each other are rotatably arranged in the paint spraying chamber, an incomplete gear I and an incomplete gear II are coaxially and fixedly mounted on the gear I and the gear II correspondingly, and the incomplete gear I and the incomplete gear II are alternately engaged with the transverse spur rack. Through engagement transmission of the gear I and the gear II, the transverse spur rack drives a paint spraying head at the bottom to reciprocate leftwards and rightwards to carry out repeated paint spraying treatment on the plate, the paint spraying range of the plate is greatly increased, paint sprayingis uniform and efficient, after paint spraying of the plate is finished, the plate can rotate and heat and dry towards the electric heating wire through the driving of a steering motor, the paint drying time is greatly shortened, the paint spraying and drying processes are in place in one step, work efficiency is remarkably improved.

Owner:温州誉诚包装有限公司

Plastic polishing device for plastic product machining

InactiveCN110103106AExpand the grinding rangeSufficient sanding strengthGrinding drivesGrinding machinesReciprocating motionEngineering

The invention discloses a plastic polishing device for plastic product machining, and relates to the technical field of plastic product machining. The device comprises a paint spraying chamber; a lifting frame is arranged in the paint spraying chamber; a transverse straight rack is slidingly mounted in the paint spraying chamber; a gear I and a gear II engaged with each other are rotationally arranged in the paint spraying chamber; and an incomplete gear I and an incomplete gear II are coaxially and fixedly mounted on the gear I and the gear II, and are alternately engaged with the transversestraight rack. Through engaged transmission of the gear I and the gear II, the transverse straight rack drives a paint spraying head at the bottom to perform a left-right reciprocating motion to repeatedly spray paint to plates, so that the paint spraying range of the plates is greatly widened, and the paint spraying is uniform and efficient; and after paint spraying of the plates, through drivingby a steering motor, the rotation of the plates can be realized, and the plates face the electric heating wires for being heated and dried by the electric heating wires, so that the paint drying timeis greatly shortened, and meanwhile, the paint spraying and drying processes are synchronously performed to prominently improve the working efficiency.

Owner:温州誉诚包装有限公司

Automobile firmware surface polishing treatment device

InactiveCN108972268ASatisfy grinding needsReasonable structureGrinding carriagesGrinding drivesEngineeringPiston rod

The invention discloses an automobile firmware surface polishing treatment device. The automobile firmware surface polishing treatment device comprises a base, both sides of the upper end of the baseare provided with a support frame, the top end of the support frame is provided with a horizontal frame, the middle of the upper end of the horizontal frame is provided with a fixing plate, the middleof the front end of the fixing plate is provided with a driven belt pulley, the front end of the driven belt pulley is provided with a rotary column, the middle of the horizontal frame is provided with a fixing column, the front end of the fixing column is connected in a hinged mode with a swing frame, and the lower end of the swing frame is provided with a swing wheel; the middle of the supportframe is provided with a drainage cylinder inside which pistons are arranged, piston rods are arranged between the pistons, a guide plate is arranged between the piston rods, the lower end of the guide plate is provided with a polishing motor, and the lower end of the polishing motor is connected with a polishing head; the inside of the lower end of the support frame is provided with a diversion cavity outside which a spray pipe is connected. The automobile firmware surface polishing treatment device achieves swinging of the polishing head to expand the polishing range, and meanwhile, by blow-cooling the polishing head through the drainage cavity, prolongs the service life of the polishing head, thereby meeting the polishing requirement of automobile firmware.

Owner:合肥岑遥新材料科技有限公司

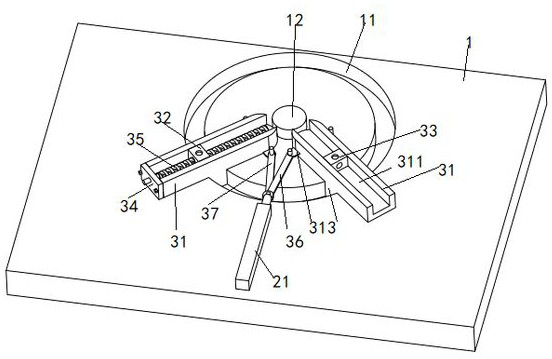

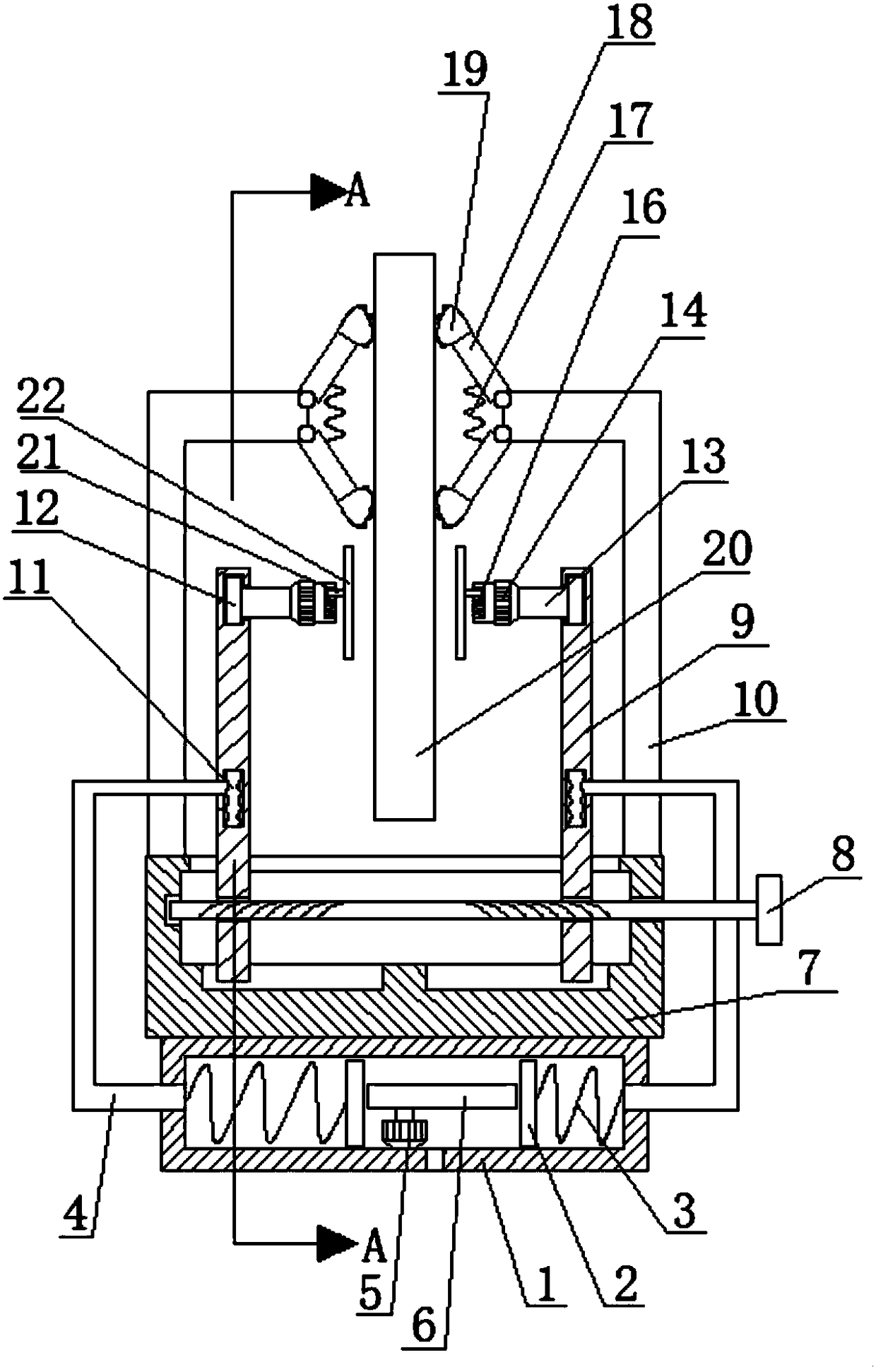

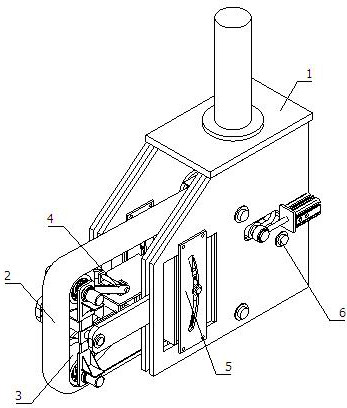

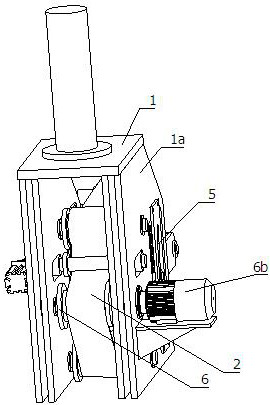

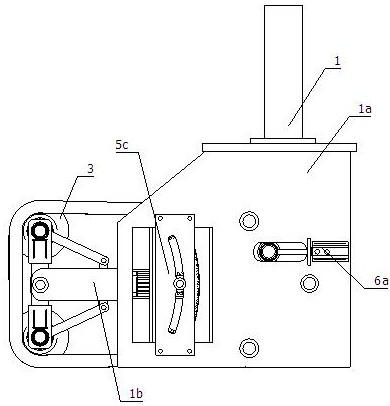

Linkage dustproof plate arc edge and flat edge integrated grinding device

ActiveCN112405181AChange angleImprove grinding efficiencyEdge grinding machinesGrinding work supportsHydraulic cylinderElectric machinery

The invention discloses a linkage dustproof type plate arc edge and flat edge integrated grinding device. The linkage dustproof type plate arc edge and flat edge integrated grinding device comprises agrinding platform, an angle adjusting mechanism is installed in the middle of the surface of the grinding platform in a sliding fit mode, a supporting plate is installed on the angle adjusting mechanism in a sliding fit mode, a first gear motor is installed in the middle of the surface of the supporting plate, a fixed position changing mechanism is installed at the power output end of the first gear motor, and a to-be-ground plate is fixed to the fixed position changing mechanism. When a first hydraulic cylinder works, a first push rod and a second push rod synchronously drive the ends, awayfrom a blocking column, of two angle limiting supporting strips to get away from or get close to each other, and then the included angle between the two angle limiting supporting strips is changed; and the rotating radian of the supporting plate is changed by changing the included angle to adapt to rotation of different radians, after being adjusted according to the grinding angle, the grinding device can adapt to automatic grinding of the concave arc edge, the convex arc edge and the straight edge, and the grinding efficiency is improved.

Owner:江阴泰舜机械设备有限公司

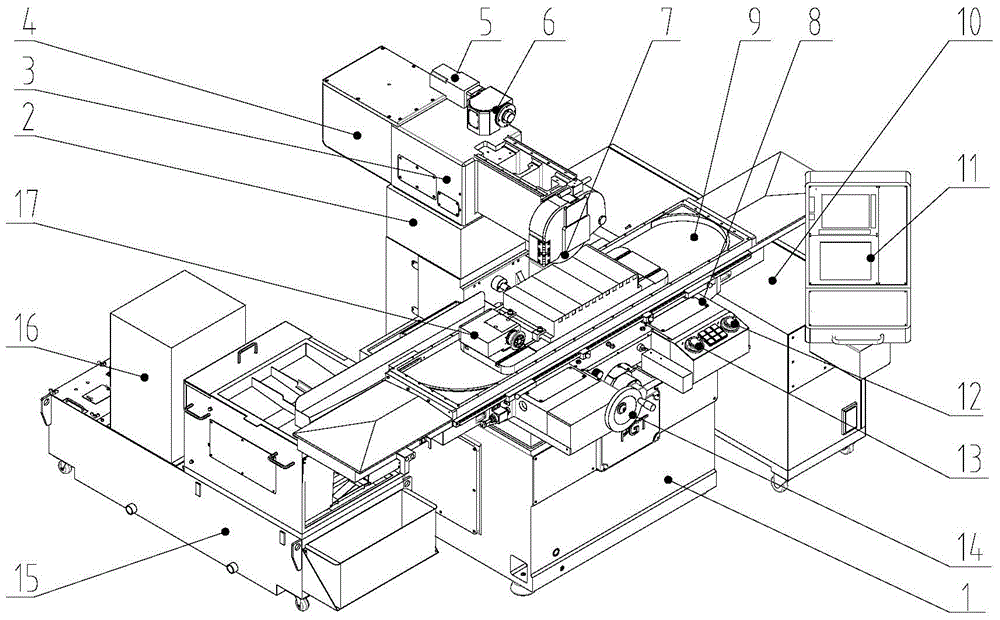

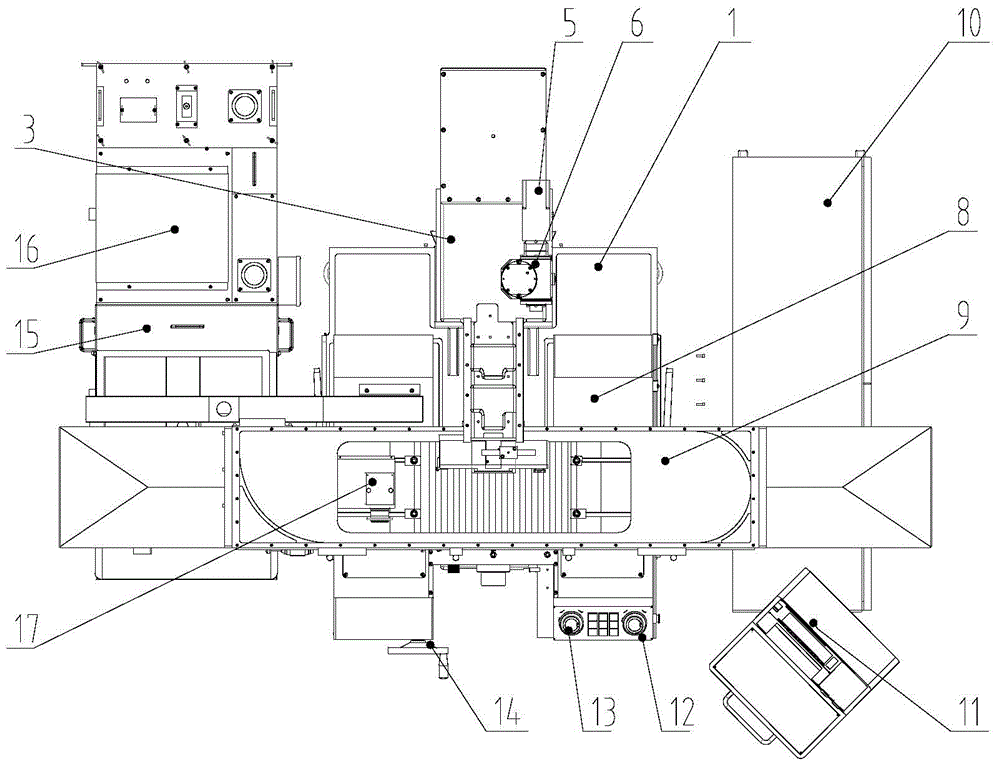

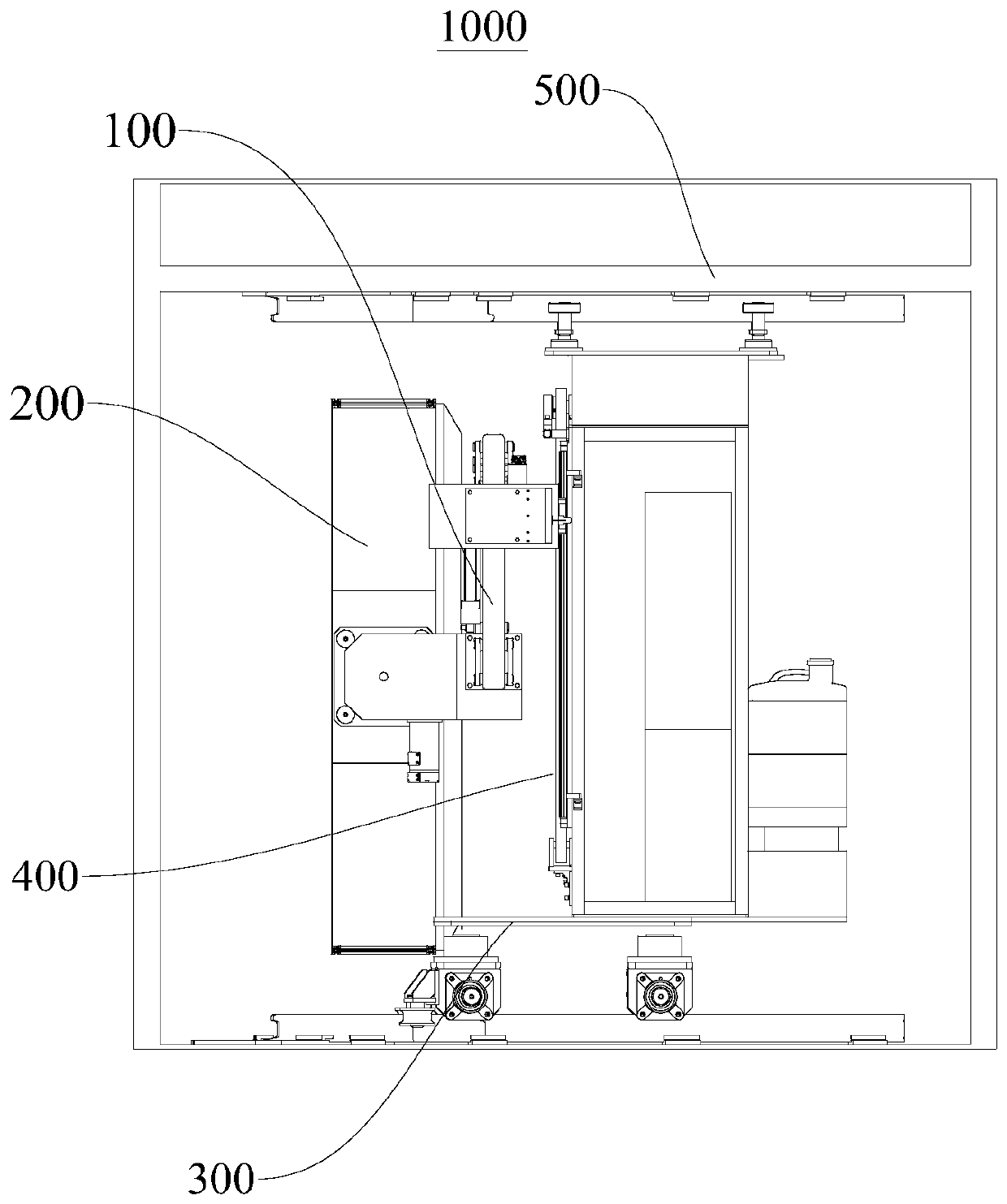

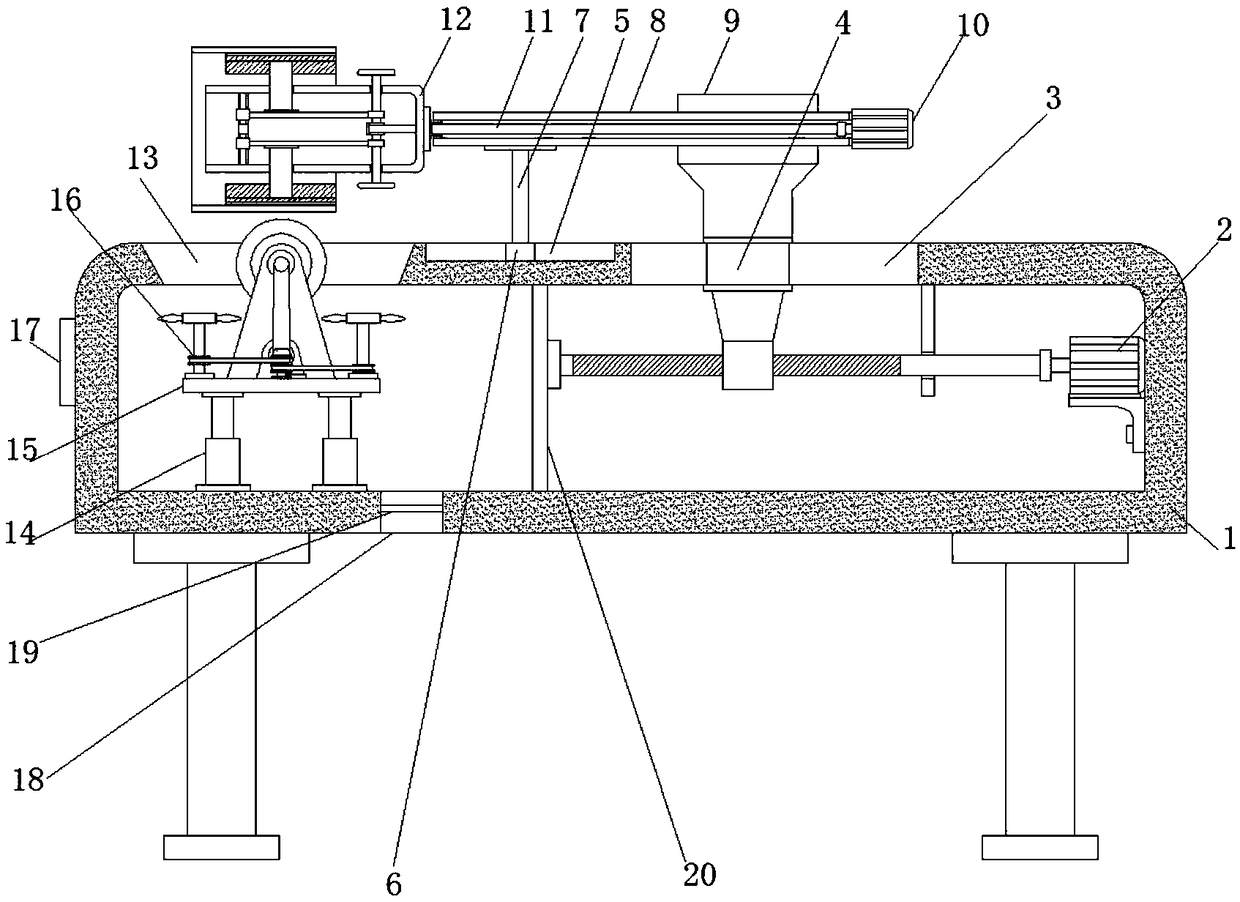

Small and medium-sized plane form grinding machine tool

InactiveCN104476345AImprove rigidityImprove stabilityGrinding drivesAbrasive surface conditioning devicesDisplay deviceReducer

The invention discloses a small and medium-sized plane form grinding machine tool. A vertical shaft upright column is mounted at the rear part of a tool body; a water cooler is mounted behind a water tank; a display is mounted in front of the upper part of an electric cabinet; a grinding head is mounted at the upper end of the vertical shaft upright column; a Y-axis lead screw is mounted inside the vertical shaft upright column; a spindle motor is mounted inside the grinding head; a counter weight is mounted at the rear end of the grinding head; a Y-axis speed reducer matched with the Y-axis lead screw is mounted at the upper part of the grinding head; a Y-axis servo motor matched with the Y-axis speed reducer is mounted at the front end of the Y-axis speed reducer; an abrasive wheel is mounted at the front end of the grinding head; a Z-axis lead screw, a Z-axis servo motor and a Z-axis speed reducer are mounted inside the tool body; according to the grinding head and the vertical shaft upright column of the machine tool, overall vertical movement feeding is realized, and the rigidity and the accuracy stability are high; the grinding capacity of the plane form grinding machine tool is greatly improved, the grinding amount is large, and the accuracy retention is high; the machining stability of a plane grinder is improved. The grinding range of the plane grinder is expanded, and the machine tool is high in accuracy, high in steady mobility and long in service life.

Owner:XIAN PGT PRECISION MACHINERY

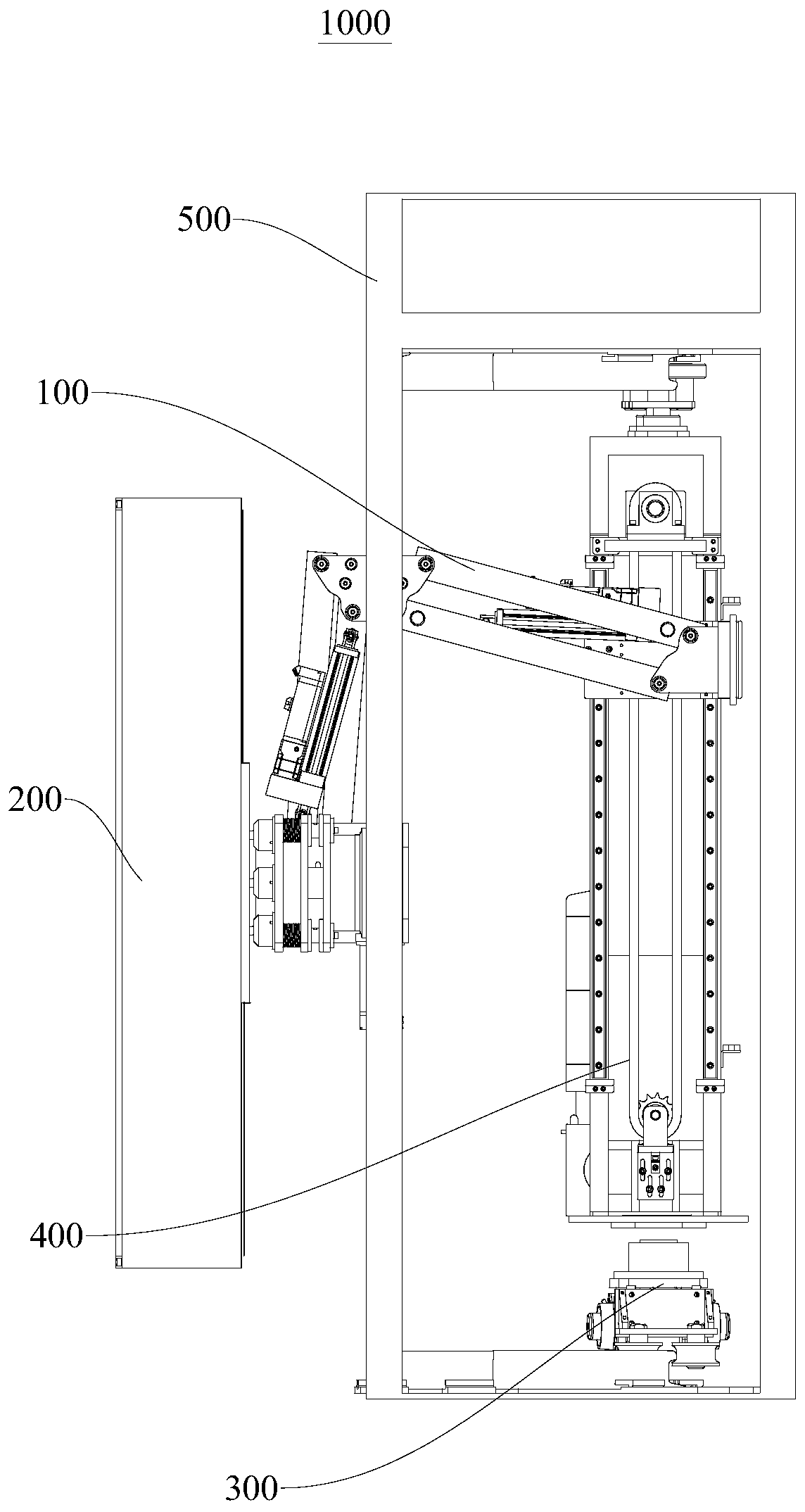

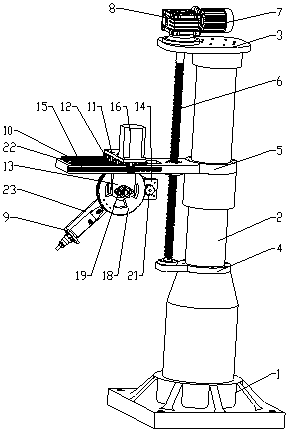

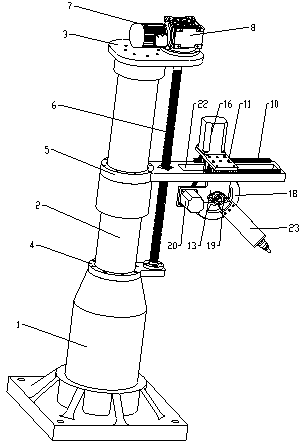

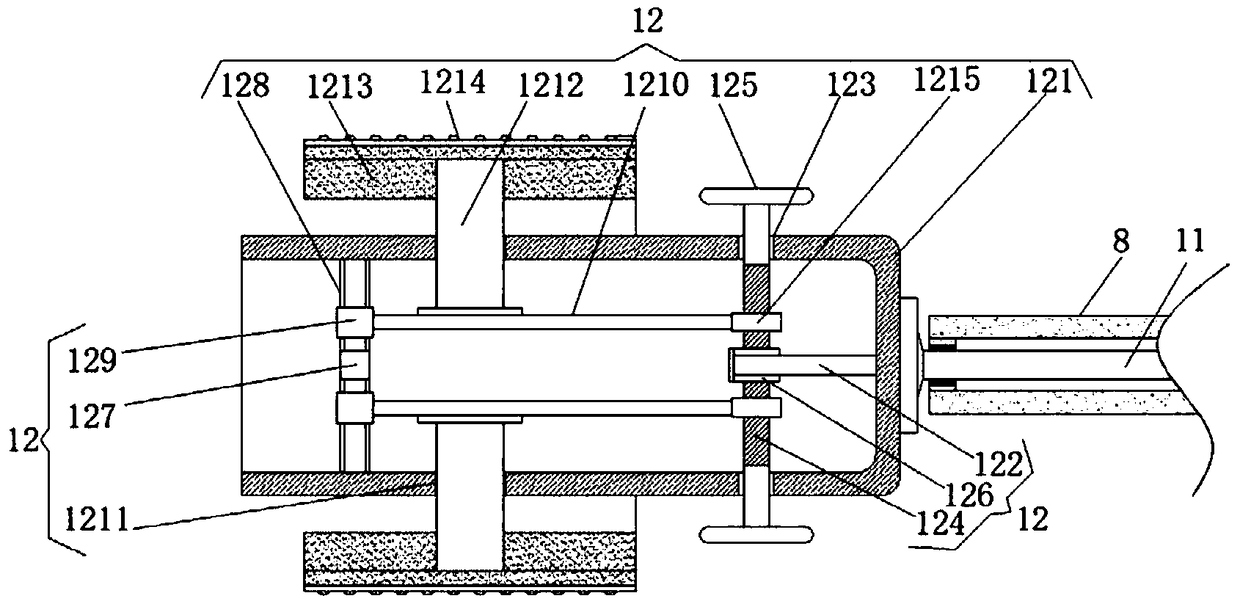

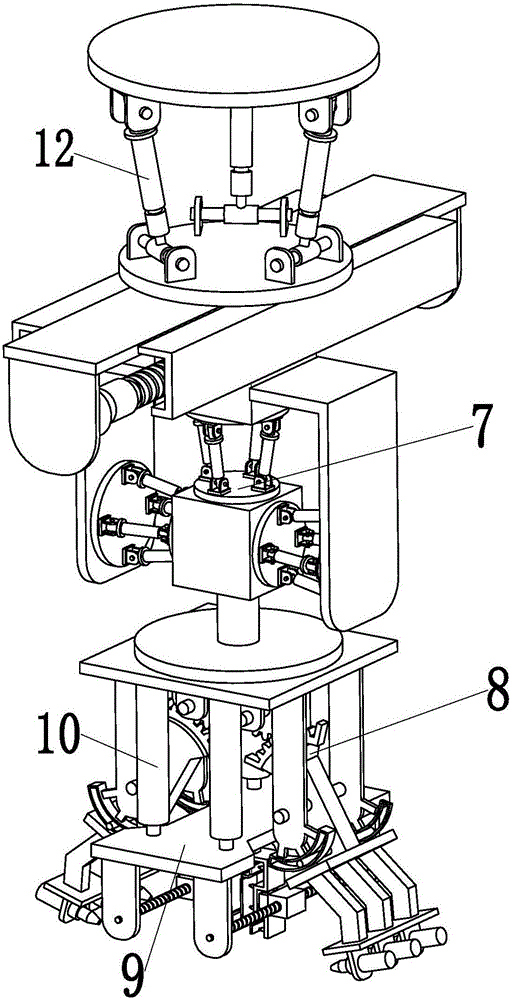

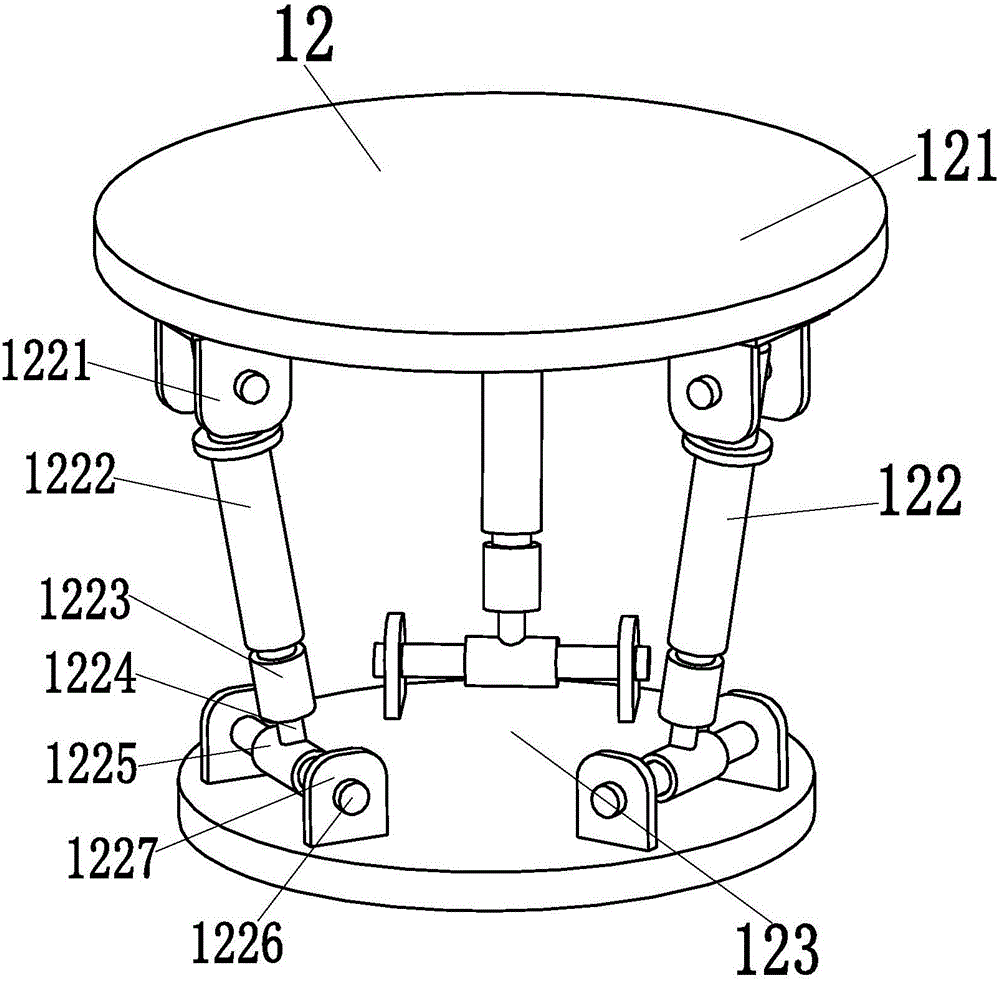

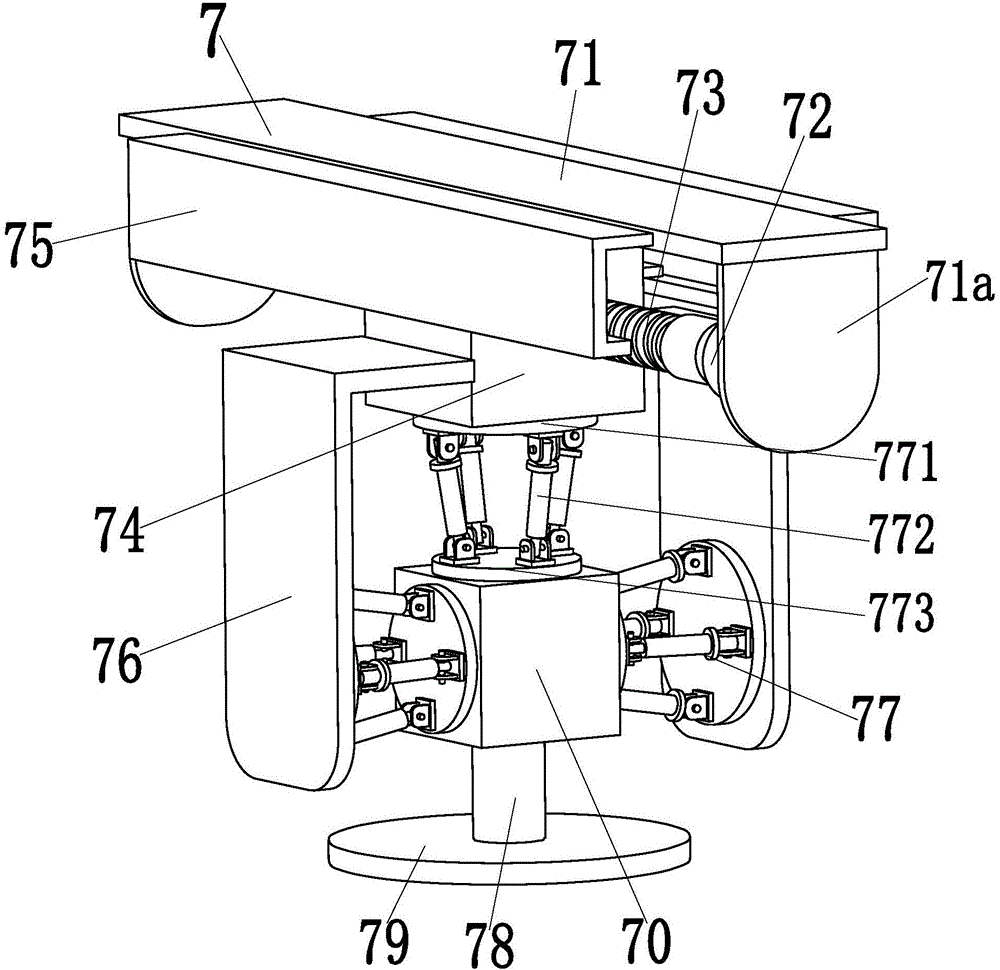

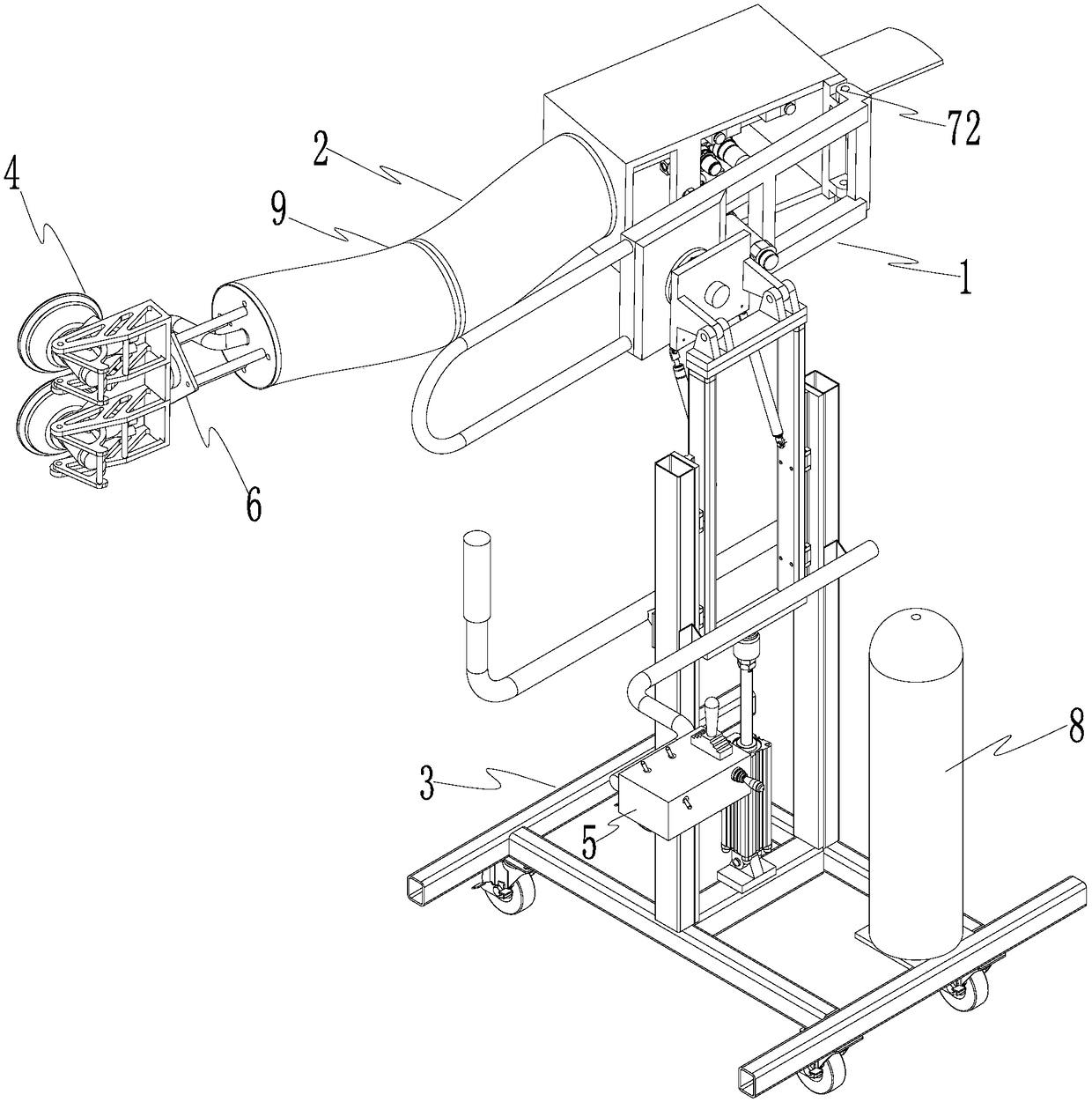

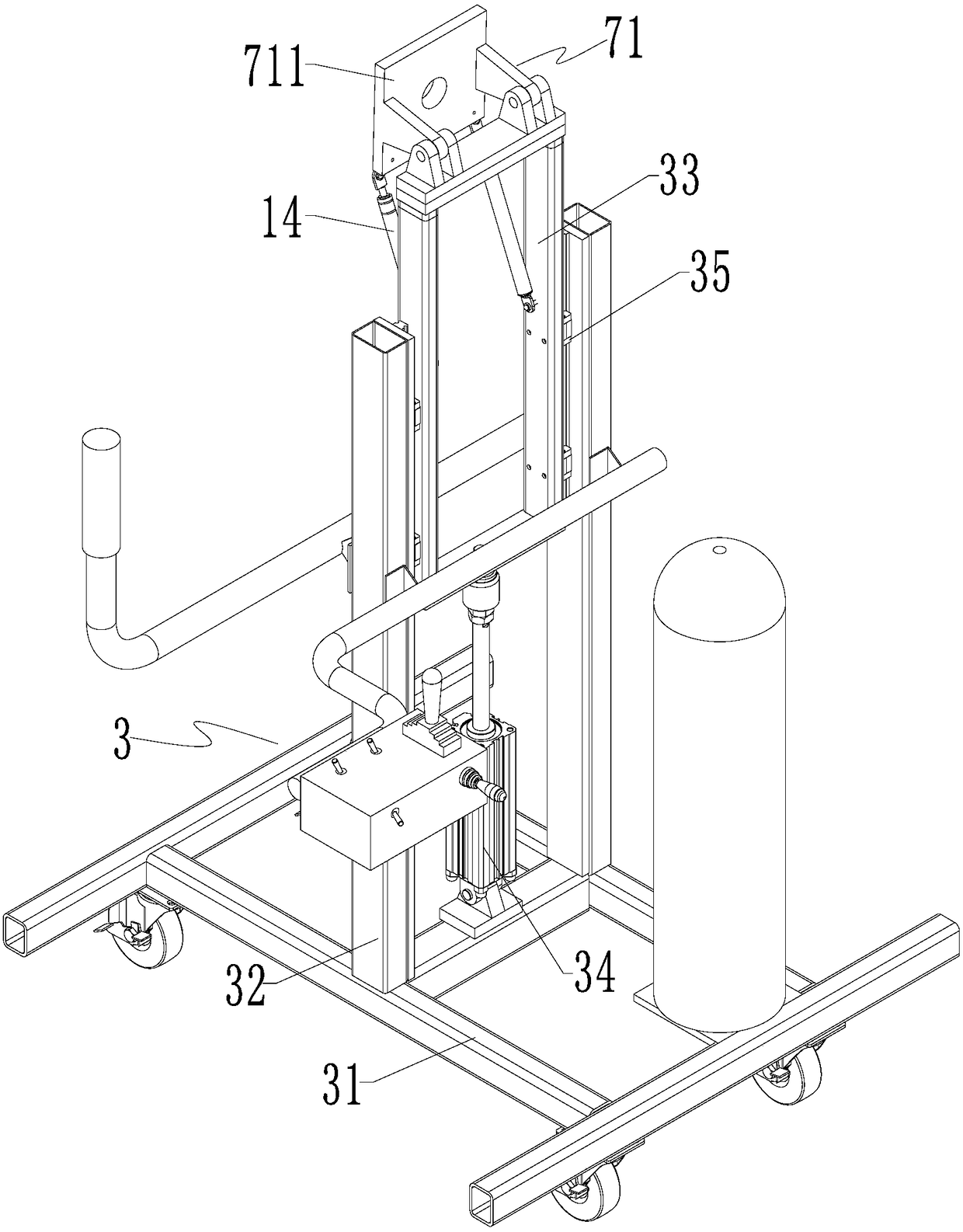

Polishing robot

InactiveCN110814897AIncrease flexibilityRealize automatic grinding processGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a polishing robot. The polishing robot comprises a moving device, a lifting device and a mechanical arm, wherein the moving device can move along a preset path, the lifting device is arranged on the moving device in a liftable mode in the vertical direction, one end of the mechanical arm is connected with the lifting device, and the mechanical arm is provided with a mounting surface parallel to a base surface to be polished. According to the polishing robot, the moving device, the lifting device, the mechanical arm and a polishing device are arranged in the polishing robot, the effect that the polishing robot can control the mechanical arm to rise and fall in the vertical direction when the polishing robot moves on the preset path can be realized, meanwhile the mechanical arm can further control the polishing device to perform automatic polishing on the base surface to be polished, thereby enabling the polishing robot to have high flexibility, and meanwhile enables the polishing robot to realize large range polishing through small distance movement, and furthermore under cooperation of all the devices, the polishing robot can realize automatic polishing forthe base surface to be polished and achieve the high automatic degree.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

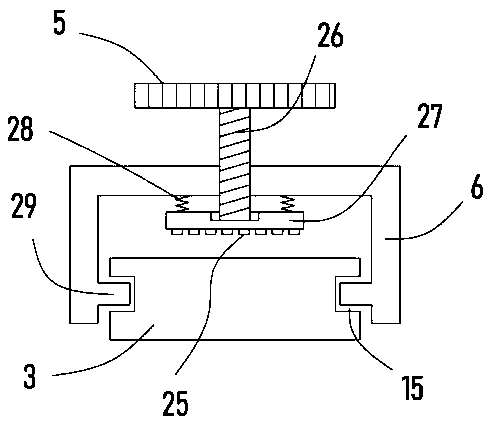

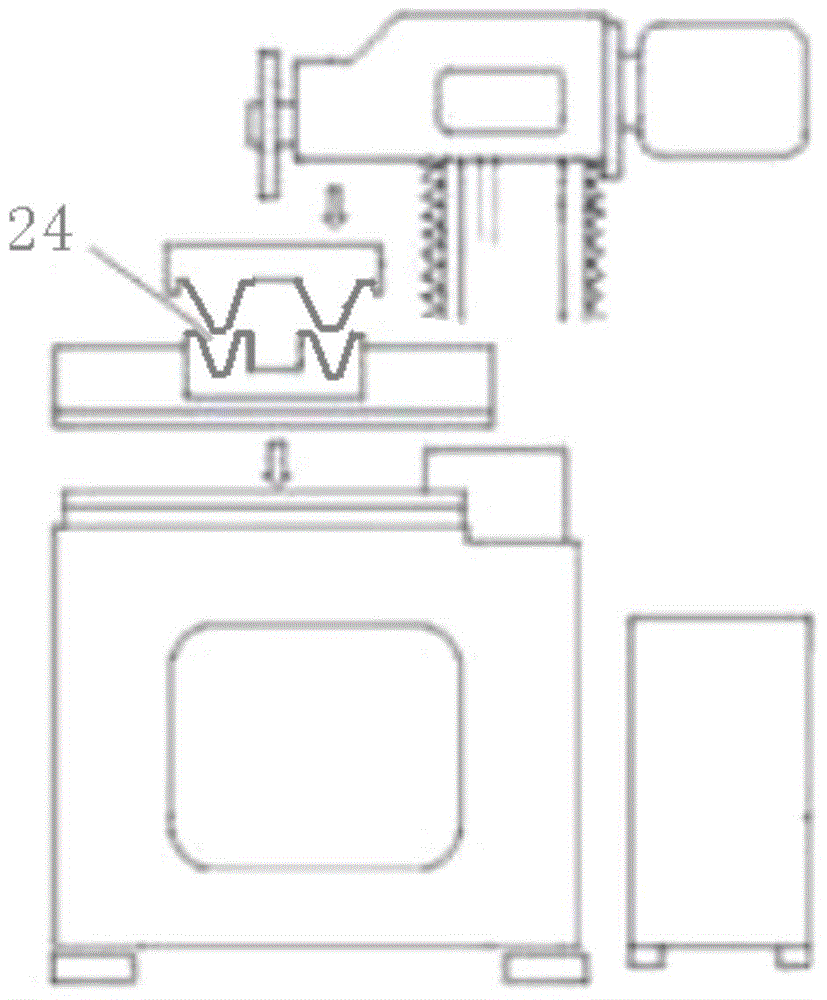

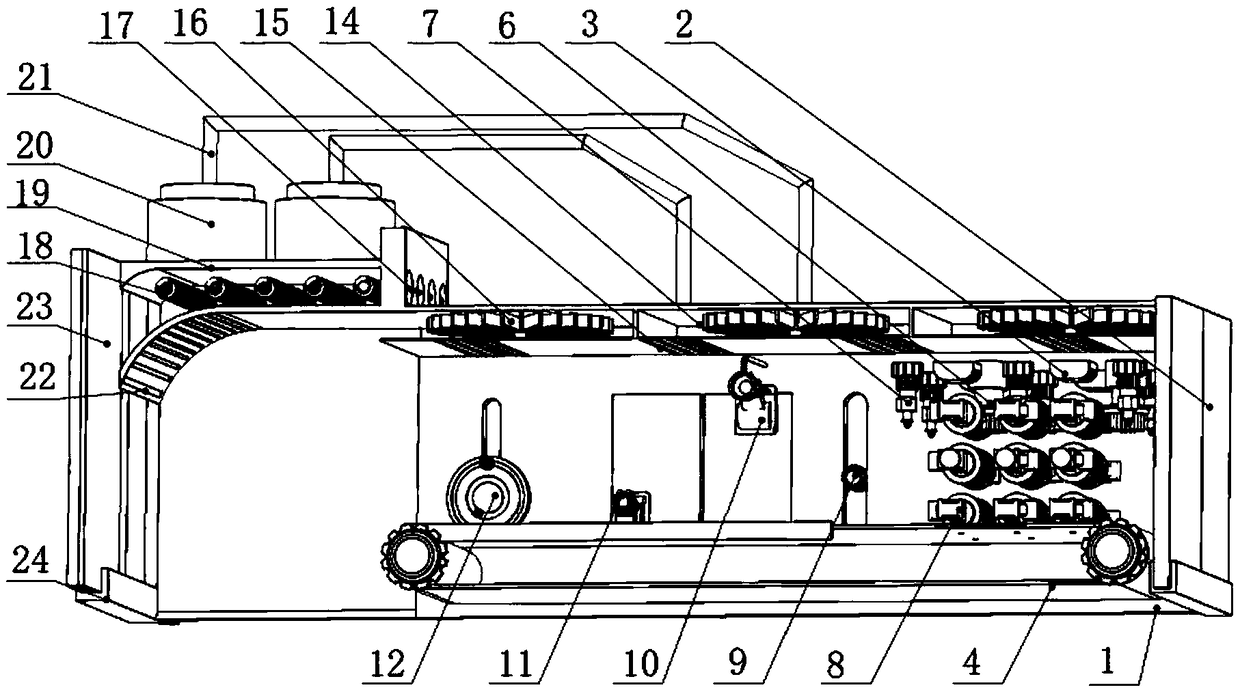

Efficient and comprehensive double-sided rapid grinding machine for dustproof steel plates

InactiveCN108436636APrevent slippingSimple structureGrinding work supportsPlane surface grinding machinesEngineeringPiston

The invention discloses an efficient and comprehensive double-sided rapid grinding machine for dustproof steel plates. The efficient and comprehensive double-sided rapid grinding machine comprises a first air cylinder, and the inner bottom wall of the first air cylinder is fixedly connected with a first motor. The efficient and comprehensive double-sided rapid grinding machine for dustproof steelplates is simple in structure, the steel plate is placed between four extrusion pads, under the action of the third spring, the steel plate is clamped, a protruding structure can prevent the steel plate from sliding down, a screw rod is manually rotated, at the moment, an external power supply is connected, the second motor is powered on, so as to drive a grinding piece to rotate; due to the action of a second spring, the grinding piece can also vibrate when the grinding piece is rotationally abrased, and the grinding area of the grinding piece is enlarged; the first motor is started to drivea cam to rotate, and the two pistons move back and forth under the action of a first spring, so that air bags expand and contract, the first sliding blocks can slide, and then the grinding pieces canmove; and the grinding range of the grinding piece is further increased, the steel plate is ground more comprehensively, and the working efficiency is improved.

Owner:陈永强

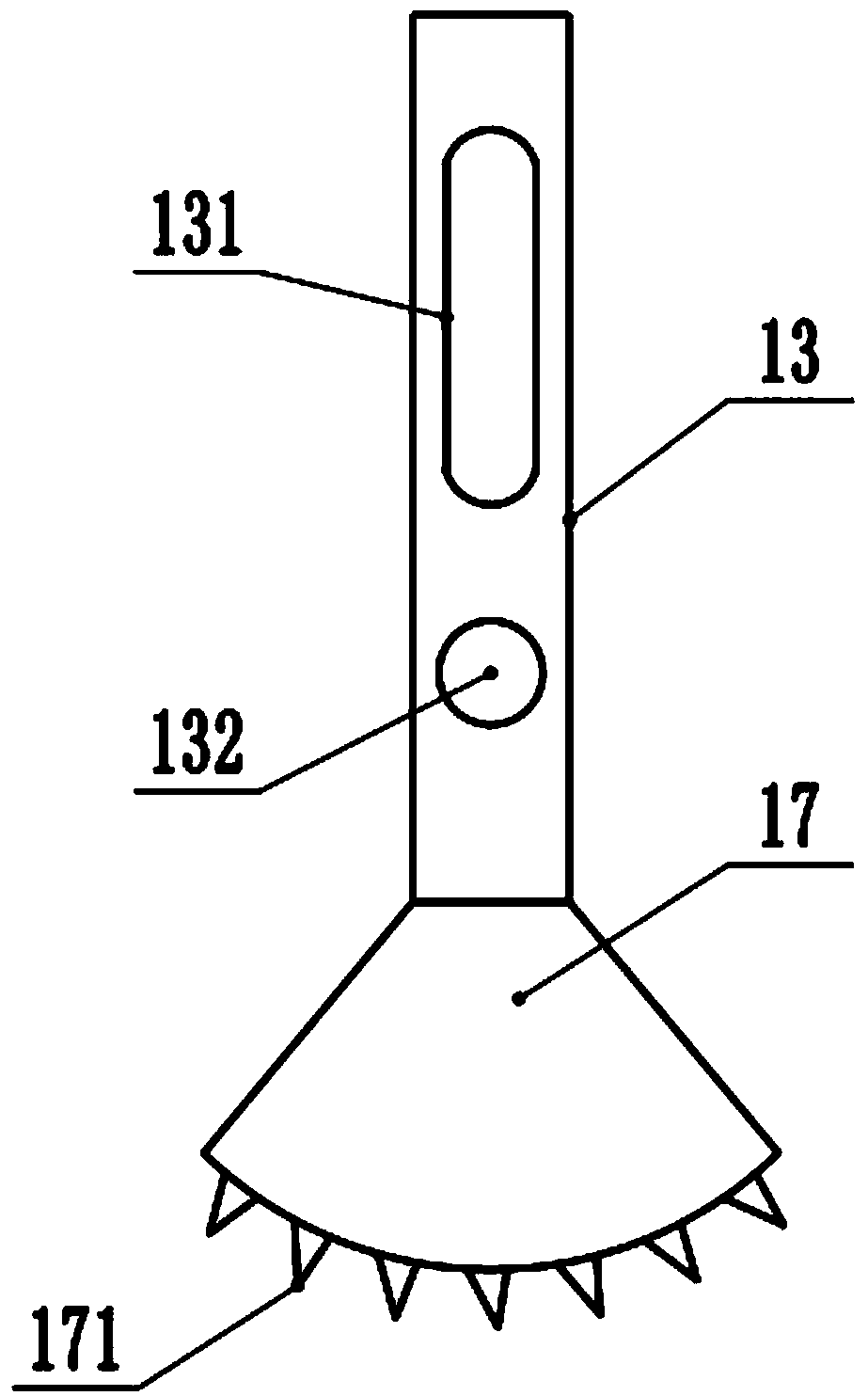

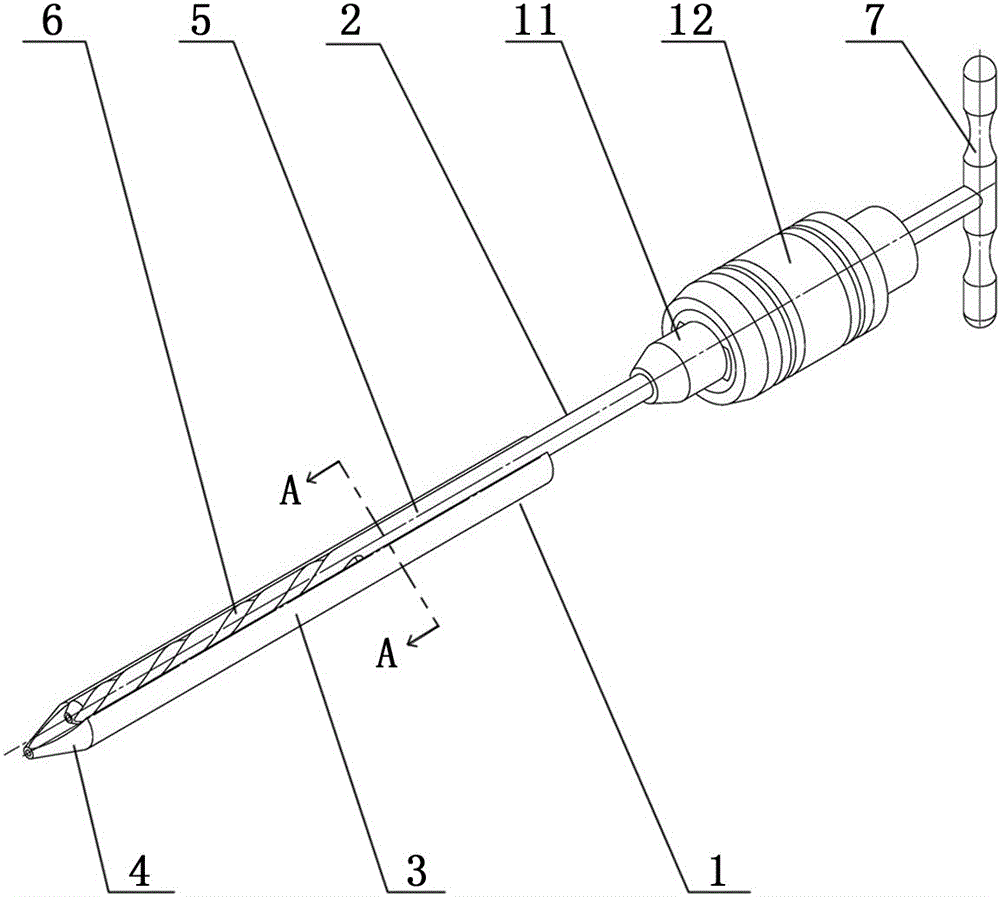

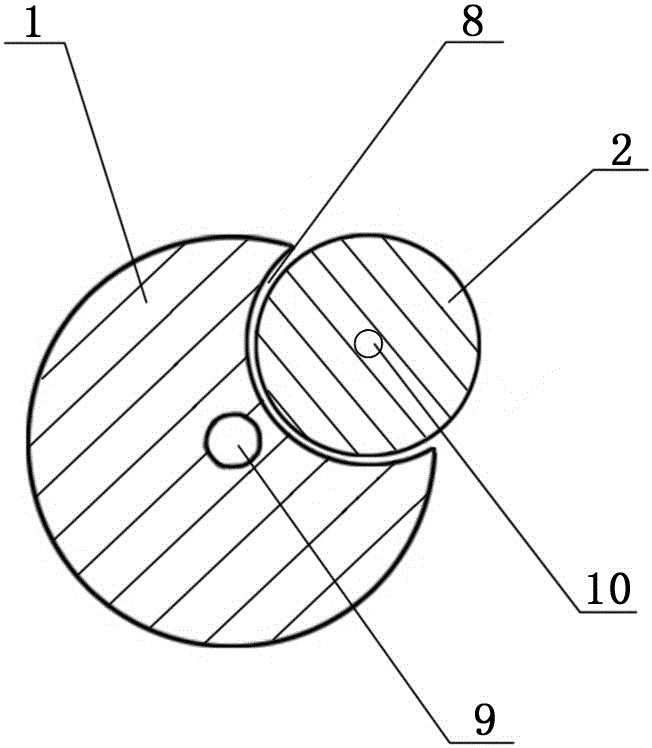

Bone drill capable of directionally drilling bone on articular process

ActiveCN105011983APrecision grindingWide implant spaceBone drill guidesEngineeringArticular processes

The invention relates to a bone drill capable of directionally drilling bone on an articular process. The bone drill structurally comprises a directional guide bar and a bone grinding drill. The side wall of the directional guide bar is provided with an axial eccentric through groove, the inner groove face of the eccentric through groove is an equal-diameter arc face, and an axial wire guide threading hole penetrating through the bar body is formed in the directional guide bar. The bone grinding drill is provided with a threaded drill bit at the front end of a drill pipe. The length of the drill pipe is larger than that of the directional guide bar. The diameter of the drill pipe is slightly smaller than that of the eccentric through groove. When the drill pipe is placed in the eccentric through groove of the directional guide bar, the edge of the threaded drill bit at the front end protrudes out of the groove edge of the eccentric through groove. By means of the bone drill, the operative route direction can be accurately positioned, on the premise that safety and stability are achieved, bone blocking the operative route direction is accurately ground, the grinding range is enlarged by rotating the directional guide bar in the bone grinding process, an accurate and wide implant space is provided for a work sleeve, and an enough visual angle is provided for an endoscope.

Owner:HEBEI RUIHE MEDICAL DEVICES CO LTD

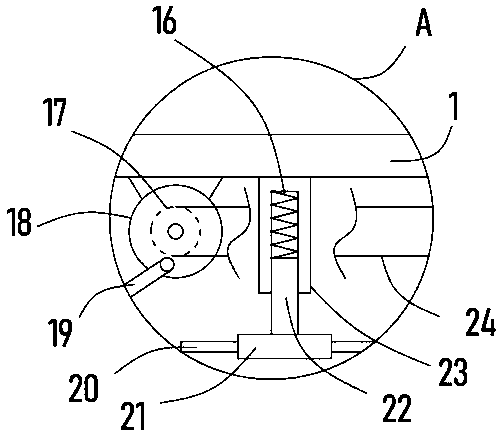

Novel mechanical part grinding device

InactiveCN109500696AIncrease flexibilityExpand the grinding rangeGrinding machinesGrinding/polishing safety devicesCold airMechanical components

The invention discloses a novel mechanical part grinding device. The device structurally comprises a device body, a motor, a grinding table, a dust collector, a micro fan and a power supply; the top of the grinding table is fixedly connected to the device body, and the motor is fixedly connected to the top of the device body. According to the device, the dust collector is installed inside the grinding table, the dust collector is in communication with dust collecting holes through a connecting pipe in a penetrating mode, so that waste chips in the grinding process can be sucked into a scrap collecting drawer through the dust collector, then the grinding table is cleaner, and the work of workers is facilitated; and a fixed seat is fixedly connected to the right side of the inner side of thedevice body, the left side of the fixed seat is in communication with an air inlet pipe in a penetrating mode, the micro fan is installed on the left side of the air inlet pipe, the bottom of the fixed seat is connected to a miniature water tank through a sliding groove in a sliding mode, water and ice blocks can be added into the miniature water tank, so that the micro fan blows out cold air, then the grinding device is cooled, the design is reasonable, and the structure is simple.

Owner:扬州华测光电技术有限公司

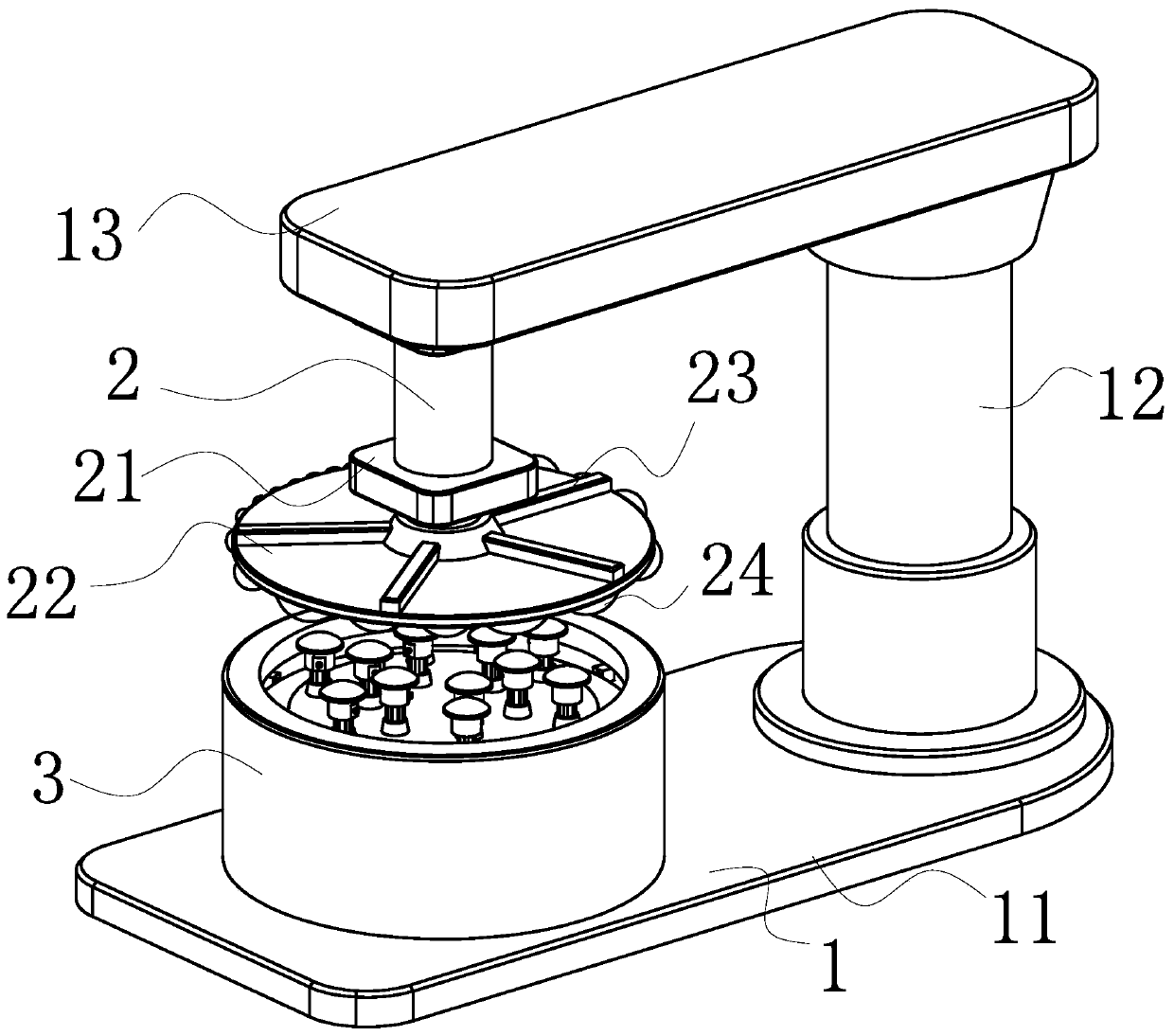

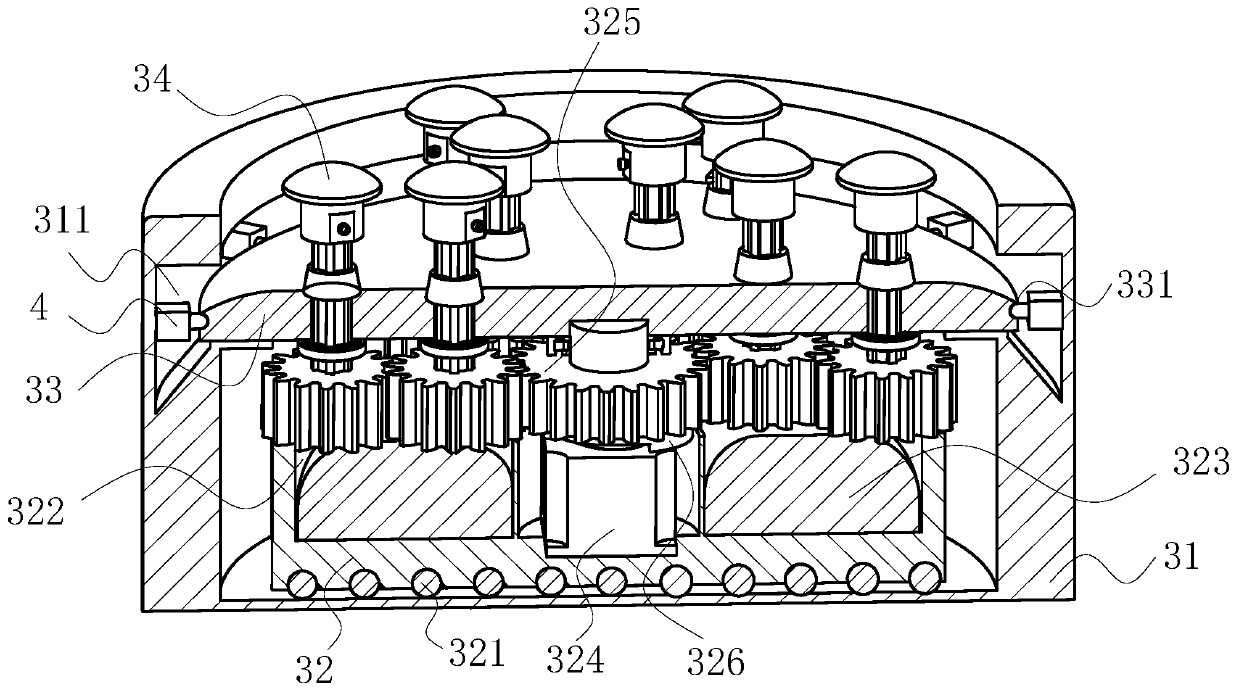

Curved surface polishing machine

ActiveCN111168563AAct quicklyTo achieve the effect of one machine with multiple functionsLapping machinesLapping toolsPolishingGear wheel

The invention belongs to the technical field of polishing machines, and particularly relates to a curved surface polishing machine. The curved surface polishing machine comprises a body, a fixing device and a workbench; the machine body is provided with a bottom plate for mounting a supporting column, and a cantilever is mounted at the top end of the supporting column; an air cylinder in the fixing device is fixedly connected to the cantilever, a pressing plate is installed on the air cylinder, and reinforcing ribs and suckers are located on the two faces of the pressing plate; and a waste liquid collecting groove is formed in the workbench body, a sliding base is installed in the workbench body in a sliding mode, an annular air bag is located on the sliding base, a motor is fixedly connected to the center of the sliding base, a cam is installed on a motor shaft, a fixing plate is arranged above the inner side of the workbench body, clamping columns are evenly installed in the waste liquid collecting groove, and a grinding device is installed on the fixing plate in a sliding mode and connected with the motor through a first gear and a second gear. According to the curved surface polishing machine, the adaptability to a polishing surface can be improved, the polishing effect and efficiency are improved, the consumption of a polishing solution is reduced, and the cost is reduced.

Owner:佛山市中力金属有限公司

Double-sided polishing machine for wood board processing

ActiveCN112894520AEasy to polishExpand the grinding rangeGrinding carriagesGrinding drivesGear wheelPolishing

The invention discloses a double-sided polishing machine for wood board processing. The double-sided polishing machine comprises a base, wherein the upper end of the base is fixedly connected with a supporting frame, the upper end of the supporting frame is fixedly connected with a processing table, the upper end of the processing table is fixedly connected with a motor box, a driving motor is fixedly installed inside the motor box, the bottom end of the driving motor is fixedly connected with the processing table, and the output end of the driving motor penetrates through the motor box to be fixedly provided with a polishing sheet. A rotating disc in an adjusting mechanism is used for driving a driving gear disc to rotate, the driving gear disc drives a driven gear disc to rotate, the driven gear disc drives a stud to rotate, the stud is in threaded connection with an adjusting plate, the adjusting plate is lifted or lowered, the adjusting plate moves up and down to drive a top plate to move, the polishing sheet on the upper half portion and the driving motor can be adjusted, so that wood boards with different thicknesses can be polished, and the polishing range of the wood boards is widened.

Owner:南京超图中小企业信息服务有限公司

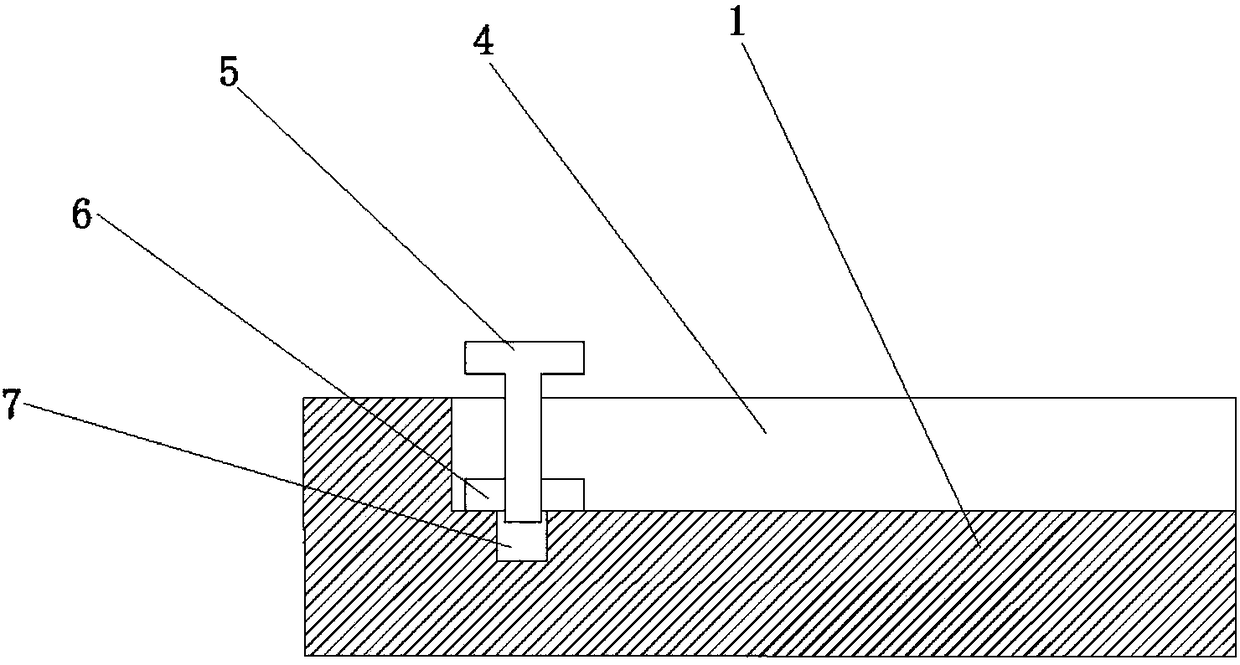

Precise polishing device for auto parts processing

InactiveCN108115510AEasy to operateEasy to useGrinding carriagesGrinding drivesPulp and paper industryGrinding wheel

The invention relates to the technical field of polishing devices, in particular to a precise polishing device for auto parts processing. The precise polishing device comprises a supporting plate in horizontal arrangement, a supporting leg is arranged at each of four corners of the undersurface of the supporting plate, a side plate is vertically arranged at each of two ends of the top face of thesupporting plate, a top plate is horizontally arranged at the top ends of the two side plates, a shell is arranged in the middle of the undersurface of the top plate, a mounting plate is arranged right below the shell, a power mechanism is arranged inside the shell, an extensible rod is arranged at each of two ends of the top face of the mounting plate, the top end of each extensible rod is connected with the power mechanism, a mounting groove is formed in each of two ends of the undersurface of the mounting plate, a first motor is vertically arranged in each mounting groove, an abrasive wheelis arranged on an output shaft of each first motor, a T-shaped sliding groove is formed in the bottom end of the inner side of each of the two side plates, a T-shaped slider is arranged in each T-shaped sliding groove, and a mounting platform is horizontally arranged between the two T-shaped sliders. The precise polishing device is simple to operate and convenient to use, polishing range is widened, and operation efficiency is improved.

Owner:重庆友拓汽车零部件有限公司

Vehicle paint surface spraying and repairing device

InactiveCN108906459AImprove repair effectRestore the effect of car paintPretreated surfacesCoatingsElectrophoresisEngineering

The invention discloses a vehicle paint surface spraying and repairing device, and belongs to the technical field of vehicle paint repairing technologies. The vehicle paint surface spraying and repairing device comprises a shell and sealing doors, and the sealing doors are arranged at the two ends of the shell to form a closed shell with a mounting space inside. A conveying device used for conveying a vehicle is arranged at the bottom of the inner side of the shell, and the inner part of the shell is sequentially provided with a grinding area, a phosphorization area, an electrophoresis area, aspraying area and a drying area in the conveying direction of the conveying device. The grinding area is provided with a grinding mechanism, the phosphorization area is provided with a phosphorization mechanism, an electrophoresis part is arranged in the electrophoresis area, a spraying part is arranged in the spraying area, and a drying mechanism is arranged in the drying area. By arranging multiple repairing mechanisms, car paint repairing can be carried out in a sealed dust-free environment, and the paint spraying and repairing effects of a vehicle paint surface are enhanced so that the vehicle can recover the paint spraying effect obtained when the vehicle leaves a factory. The conveying device and the like are arranged, so that the repairing work is more intelligent, and the work efficiency is improved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

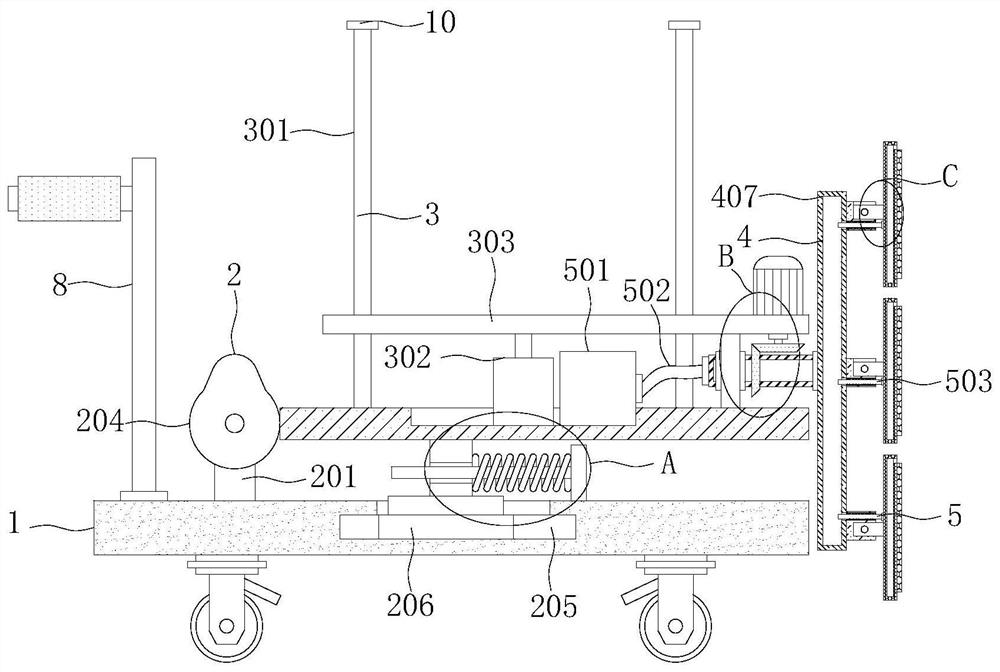

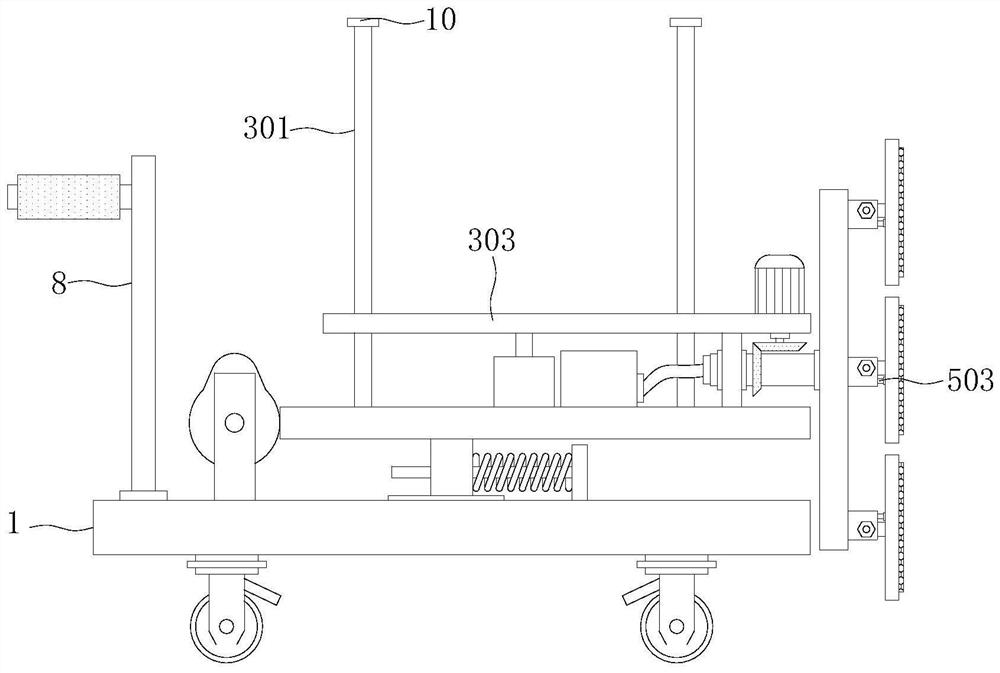

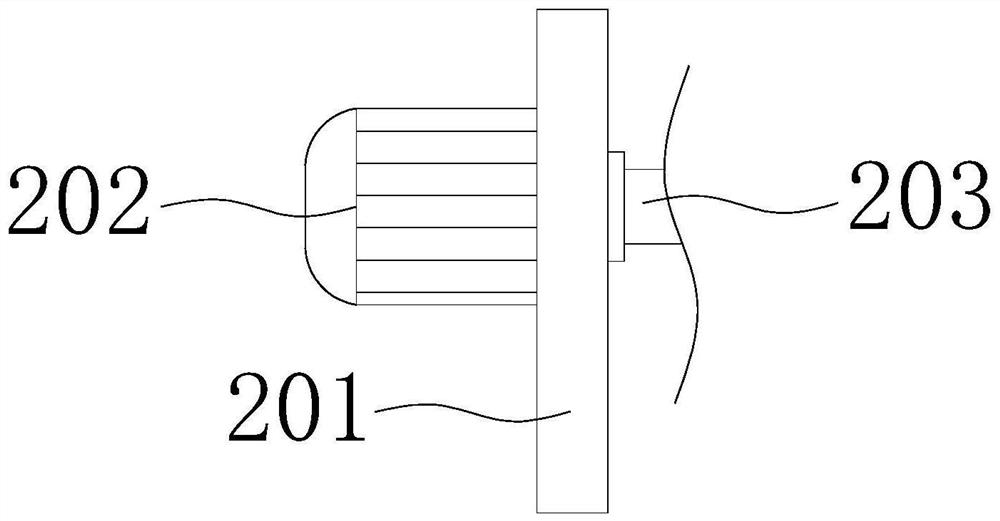

Automatic wall grinding machine

InactiveCN108326660AShock cushioning weakenedImprove stabilityGrinding carriagesGrinding drivesMotor driveEngineering

The invention provides an automatic wall grinding machine. The automatic wall grinding machine comprises a car body, wherein rollers are arranged on the bottom of the car body; one end of the car bodyis equipped with a trolley; grooves are symmetrically formed in the two sides of the upper surface of the car body; the grooves are of long-strip-shaped structures, length of the grooves is not greater than that of the car body; the bottoms at the two sides of each groove are equipped with horizontal regulating bases; and each horizontal regulating base comprises a regulating screw and a fixed nut, wherein the fixed nut is fixedly arranged on the bottom of the corresponding groove. A linear motor drives a grinding mechanism to abut against a wall, a rotary motor drives a grinding disc to rotate for grinding a wall body, and the grinding mechanism can perform curve sliding along a curve guide rail; meanwhile, the grinding mechanism can horizontally slide along a lead screw, and can grind avertical wall body and a top wall body, is great in grinding range, does not need manual holding in a grinding process, is high in automatic and intelligent degree, reduces manual labor intensity, and improves grinding efficiency and grinding quality.

Owner:湖州高锐教育科技有限公司

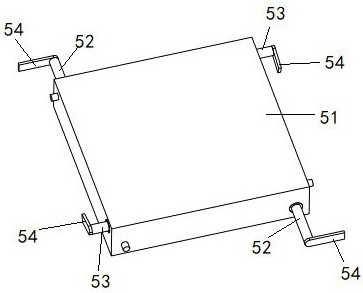

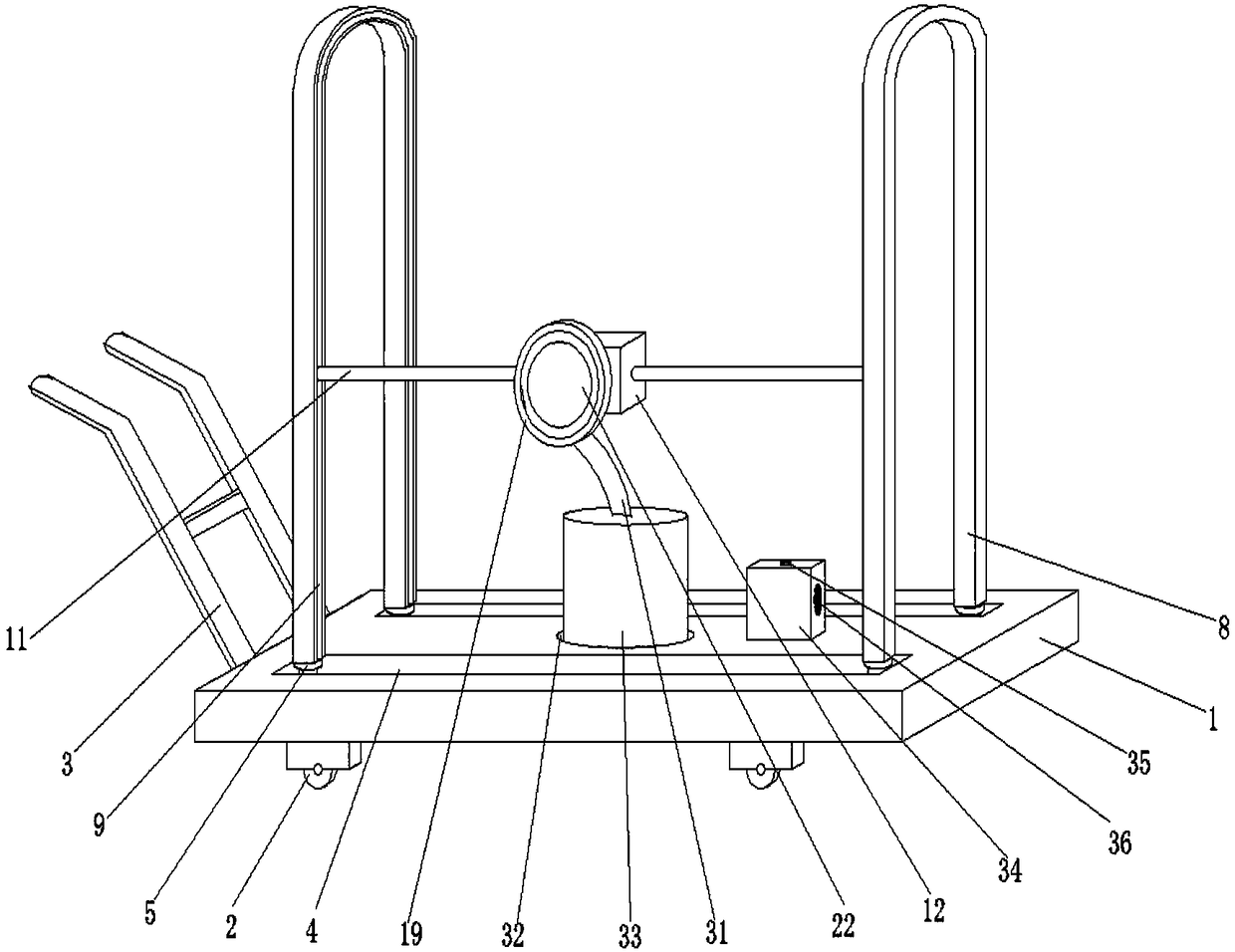

Pipe cutting and polishing device for building engineering guardrail

ActiveCN112045425AGood for fallingAchieve miterMetal sawing devicesGrinding carriagesPolishingConstruction engineering

The invention discloses a pipe cutting and polishing device for a building engineering guardrail, and relates to the technical field of pipe cutting and polishing devices. The invention aims to adjusta cutting angle of a saw blade so as to achieve the multi-angle cutting of the saw blade. The pipe cutting and polishing device for the building engineering guardrail specifically comprises a supporting base and a pipe clamping mechanism, wherein four universal wheels are rotatably connected to the outer wall of the bottom of the supporting base through rotating shafts; a supporting frame is fixed to the outer wall of the top of the supporting base through bolts; a rotating frame is connected to the inner wall of the top of the supporting frame through a hinge; an adjusting frame is welded tothe inner wall of the top of the supporting frame; an adjusting rod is welded to the outer wall of one side of the rotating frame; and the circumferential outer wall of the adjusting rod is fixed tothe outer wall of one side of the adjusting frame through a nut. According to the pipe cutting and polishing device for the building engineering guardrail provided by the invention, the top of the supporting frame is arranged to be of a plane structure, so that a clamp fixed with a pipe can be conveniently supported when the pipe is subsequently cut; meanwhile, a notch is formed in the top of thesupporting frame, so that cut waste can conveniently fall off; and meanwhile, an arc-shaped frame can be used for supporting a holding rod.

Owner:广东华海建设集团有限公司

Polishing machine

InactiveCN108098483AExpand the scope ofPolishing flexibleEdge grinding machinesGrinding carriagesMechanical engineeringTransverse beam

The invention relates to the technical field of polishing equipment, in particular to a polishing machine. The polishing machine is characterized in that the polishing machine comprises a base, a seatshaft, a top plate, a bottom plate, a transverse beam used for fixing a polishing mechanism, a lead screw, a third driving device and the polishing mechanism; the polishing mechanism comprises multiple guide rails, a transverse plate, a sliding block, a left support plate, a right support plate, a rack, a first driving motor, a first gear, a second large gear, a second large gear shaft sleeve, asecond driving motor, a second small gear and a fixing device; through a third driving device, the lead screw is driven to rotate so that the polishing machine is adjusted to move upwards or downwards; through a first driving motor, the first gear is driven to rotate; the polishing machine is adjusted to move forward and backward through engagement between the first the first gear and the rack; the second small gear is driven by the second driving motor; and the polishing machine is adjusted to move along a circumferential direction of the second large gear through engagement between the second small gear and the second large gear; therefore, the position of the polishing machine is conveniently adjusted; an adjustment is adjusted more flexibly; and the adjustment range of the polishing machine is greatly broadened.

Owner:丹阳市俊腾五金有限公司

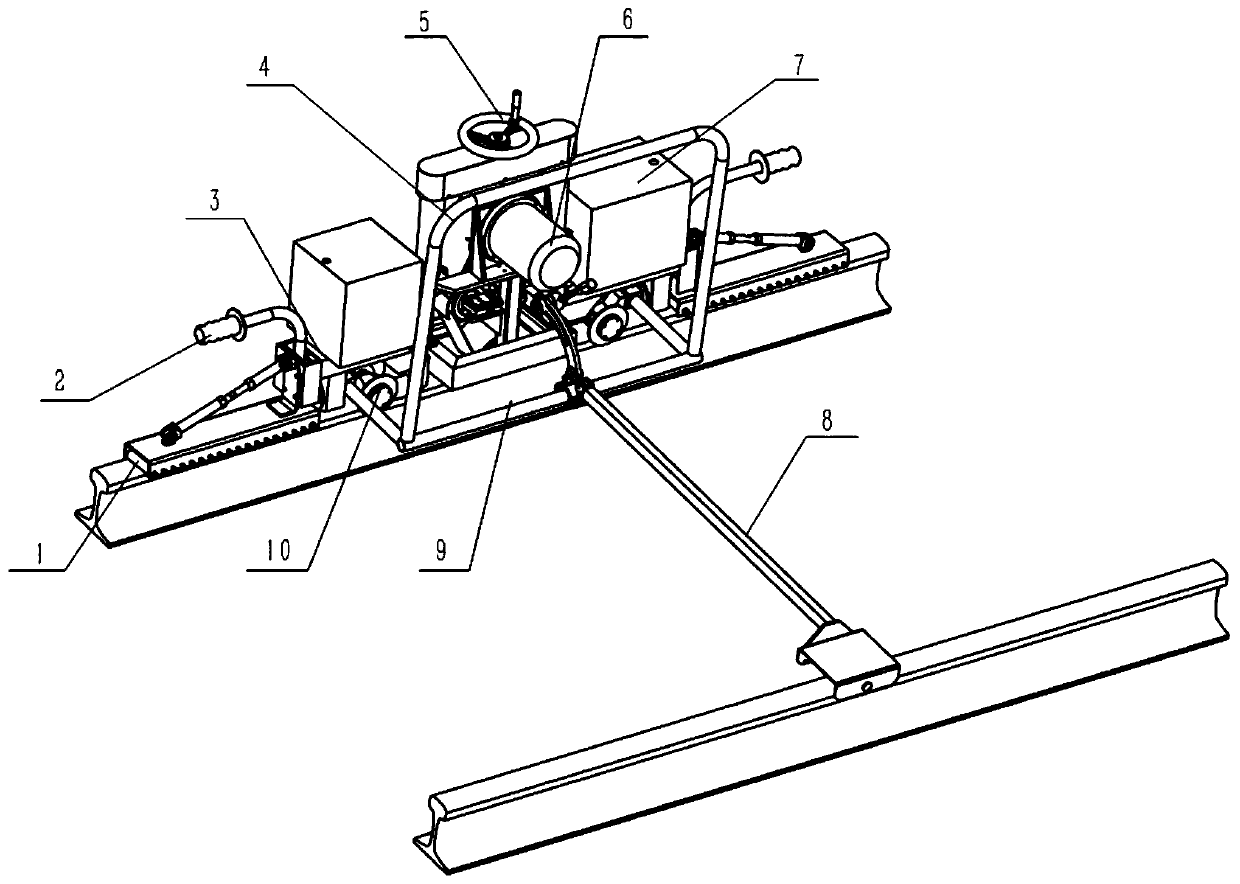

Steel rail grinding equipment

PendingCN111088735AEffective regulationImprove grinding efficiencyRailway track constructionMaterials scienceBelt grinding

The invention provides steel rail grinding equipment. The steel rail grinding equipment comprises a rack, a power supply device, an abrasive belt grinding device and a power providing device. According to the steel rail grinding equipment, the abrasive belt is adopted as a grinding tool, the actual contact area between the abrasive belt and the surface of the steel rail is large during grinding, and grinding efficiency is improved; due to the characteristics of the contact wheel rubber layer and the abrasive belt, the abrasive belt and the steel rail are in flexible contact during grinding operation, the influence of vibration of grinding equipment on the grinding quality can be reduced, and the grinding quality is improved; a corrugation roller structure is adopted, so that corrugation ofthe steel rail can be further effectively eliminated during grinding; deflection of the grinding device is completed through a swing guide groove and a guide groove nut, the structure is compact, andoperation is easy and convenient. Meanwhile, grinding is conducted in an electric mode, and operation is environmentally friendly and free of pollution.

Owner:山东博砺思轨道交通装备科技有限公司

Lifting type dust-free wall surface grinding machine for decoration engineering

ActiveCN113070757APolished evenlyAdjust the clearanceGrinding wheel securing apparatusGrinding carriagesGear wheelDust control

The invention discloses a lifting type dust-free wall surface grinding machine for decoration engineering, and relates to the technical field of decoration engineering machinery. The lifting type dust-free wall surface grinding machine for decoration engineering comprises a working bottom plate, wherein an adjusting structure, a lifting mechanism, a grinding mechanism and a dust removal mechanism are arranged above the working bottom plate. According to the lifting type dust-free wall surface grinding machine for decoration engineering, a second motor, a rotating shaft, a first umbrella-shaped gear, a fixing plate, a hollow rotating rod, a second umbrella-shaped gear, a mounting vertical plate, a mounting block, a bolt, a nut, a grinding plate, a grinding disc and a connecting rod are used in cooperation, a wall surface is ground, a grinding area of the device is large, the wall surface grinding efficiency is improved, meanwhile, a grinding disc is convenient to mount and dismount, then the grinding disc is convenient to replace, the situation that the grinding effect of the grinding disc is reduced due to long-time use of the grinding disc is prevented, the grinding effect is guaranteed, and popularization and use are facilitated.

Owner:重庆瀚方装饰工程有限公司

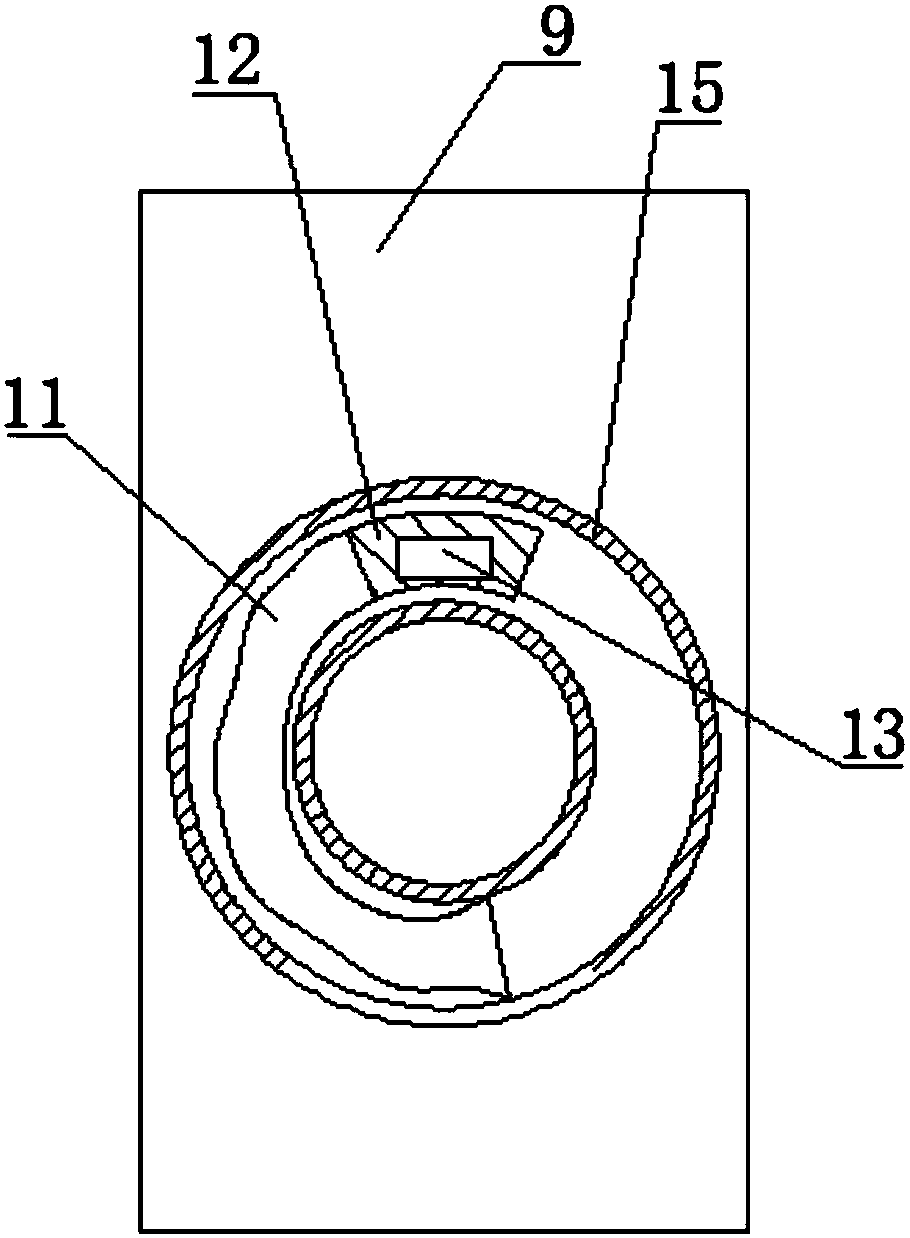

Precise grinding equipment for inner ring of steering wheel casting

ActiveCN114670098AAutomatic width adjustmentEasy to GrindBelt grinding machinesGrinding/polishing safety devicesSteering wheelControl theory

The invention relates to the technical field of automobile part polishing, in particular to precise polishing equipment for an inner ring of a steering wheel casting. Comprising a five-axis robot and further comprises a first mounting frame, a grinding belt, two adjustable grinding wheels, a grinding adjusting mechanism and a grinding driving mechanism, the first mounting frame is mounted at the output end of the five-axis robot, mounting plates and a second mounting frame are further arranged on the first mounting frame, the second mounting frame is arranged between the two mounting plates, and the two adjustable grinding wheels are arranged on the first mounting frame. The two adjustable grinding wheels are symmetrically arranged along the center face of the second mounting frame, the grinding adjusting mechanism comprises a width adjusting assembly and a distance adjusting assembly, each adjustable grinding wheel comprises an adjusting framework and an elastic rubber outer ring, and the elastic rubber outer rings are arranged on the outer sides of the adjusting frameworks in a sleeving mode. The width of the framework can be changed through the adjustable grinding wheel, so that the corners of the inner ring of the steering wheel can be ground more finely, and the grinding device can adapt to the in-place grinding function of different width parts of the inner ring of the steering wheel.

Owner:南通安信机械科技有限公司

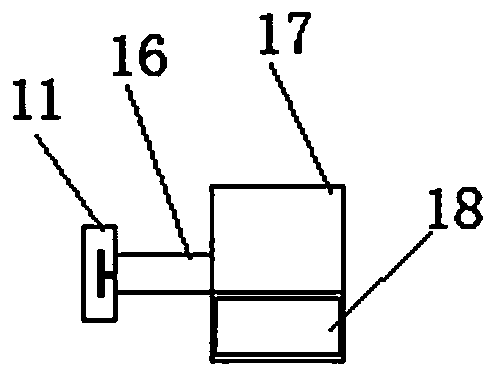

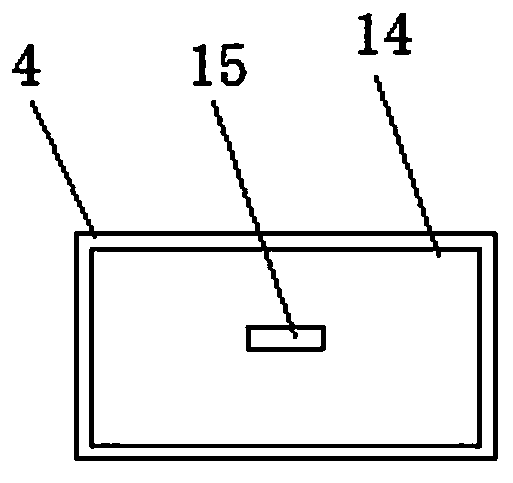

Rough machining deburring device for steering motor shell

InactiveCN108747677AIncomplete removalPrevent activityEdge grinding machinesGrinding drivesControl theoryMachining

The invention relates to the technical field of steering motor shell machining and discloses a rough machining deburring device for a steering motor shell. The rough machining deburring device for thesteering motor shell comprises a machine body with a transverse movable through groove; the inner side of the transverse movable through groove is movably connected with a transverse movable connection block; the bottom of the transverse movable connection block is connected with a transverse circular drive mechanism; a transverse auxiliary slide groove is formed in the middle of the top of the machine body; the inner side of the transverse auxiliary slide groove is movably connected with a transverse auxiliary connection block; the top of the transverse auxiliary connection block is fixedlyconnected with an auxiliary supporting rod; and a fixed rotary barrel is fixedly connected with the top of the auxiliary supporting rod. Through mutual cooperation of the machine body, the transversecircular drive mechanism, the fixed rotary barrel, a low-speed motor, a torque rotary shaft, an inner direction clamp mechanism, an electric lifting rod, a drive machining mechanism and a control panel, the problem that an existing machining deburring device for the steering motor shell cannot remove burrs on the surface of the motor shell thoroughly is solved.

Owner:芜湖市智行天下工业设计有限公司

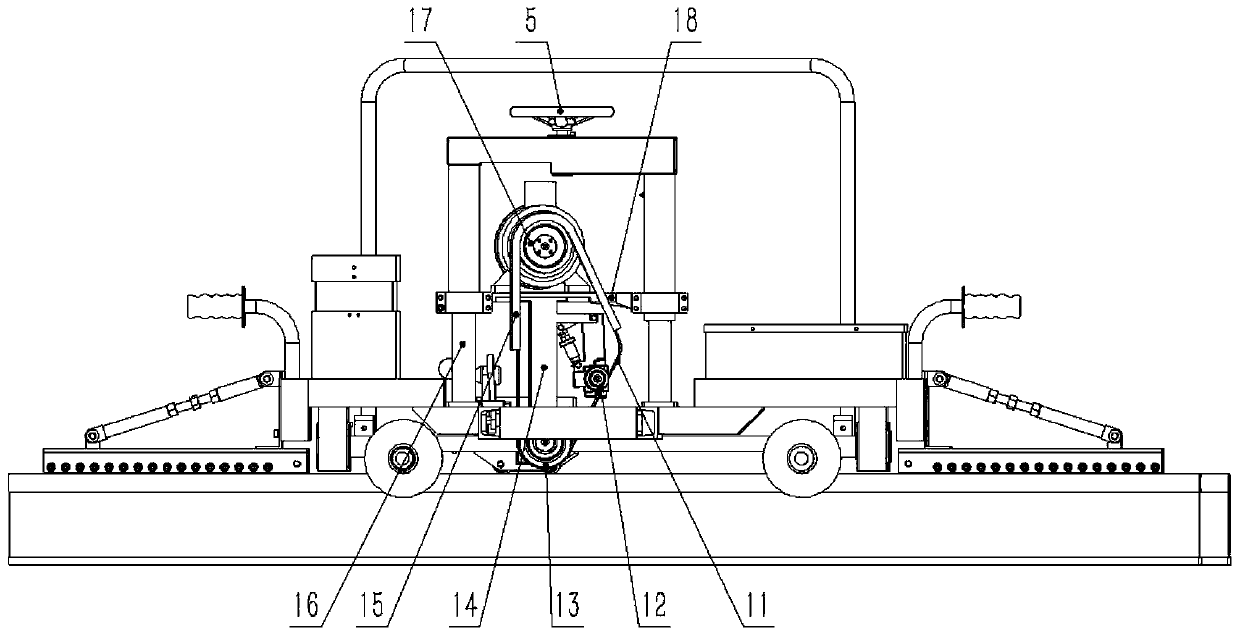

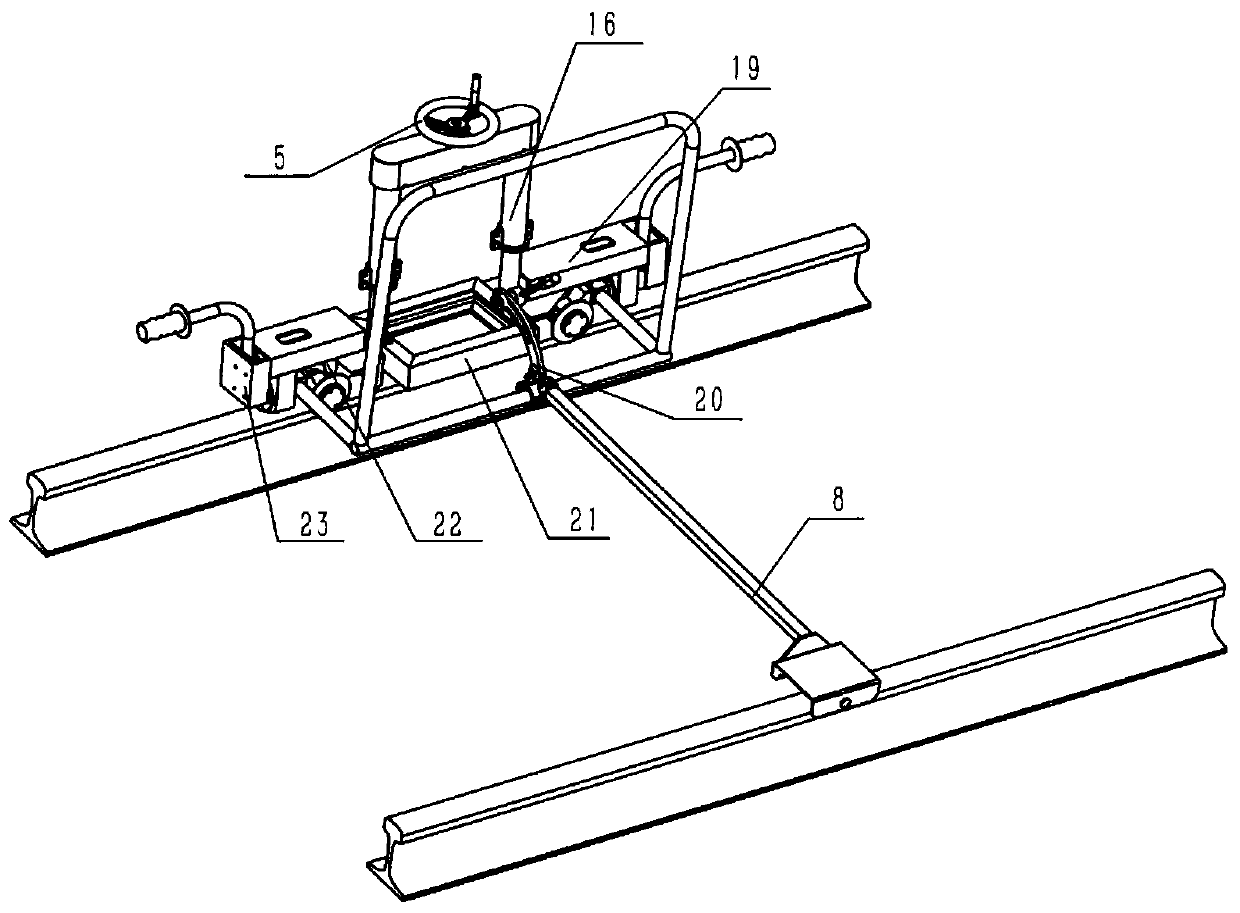

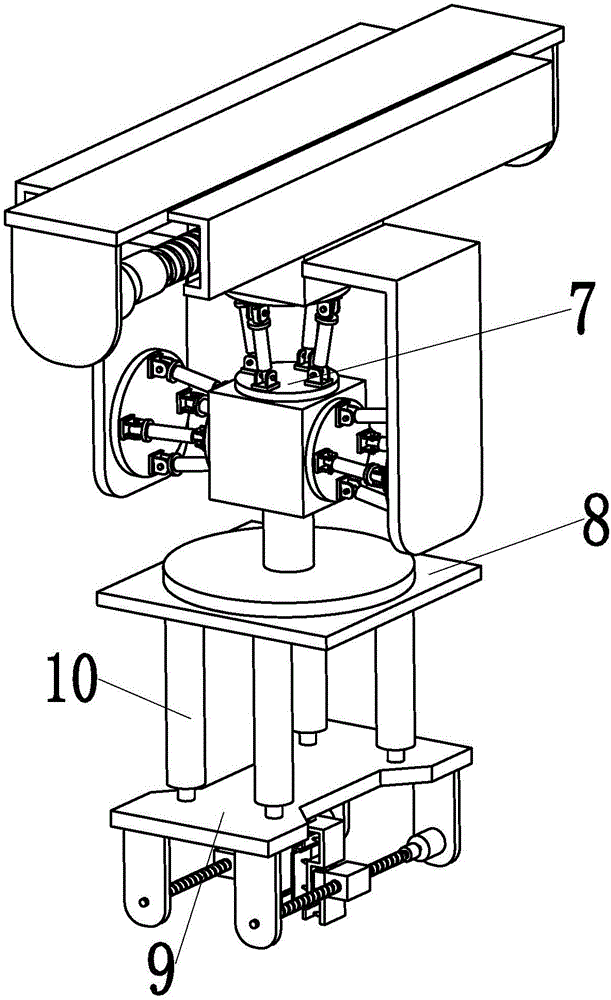

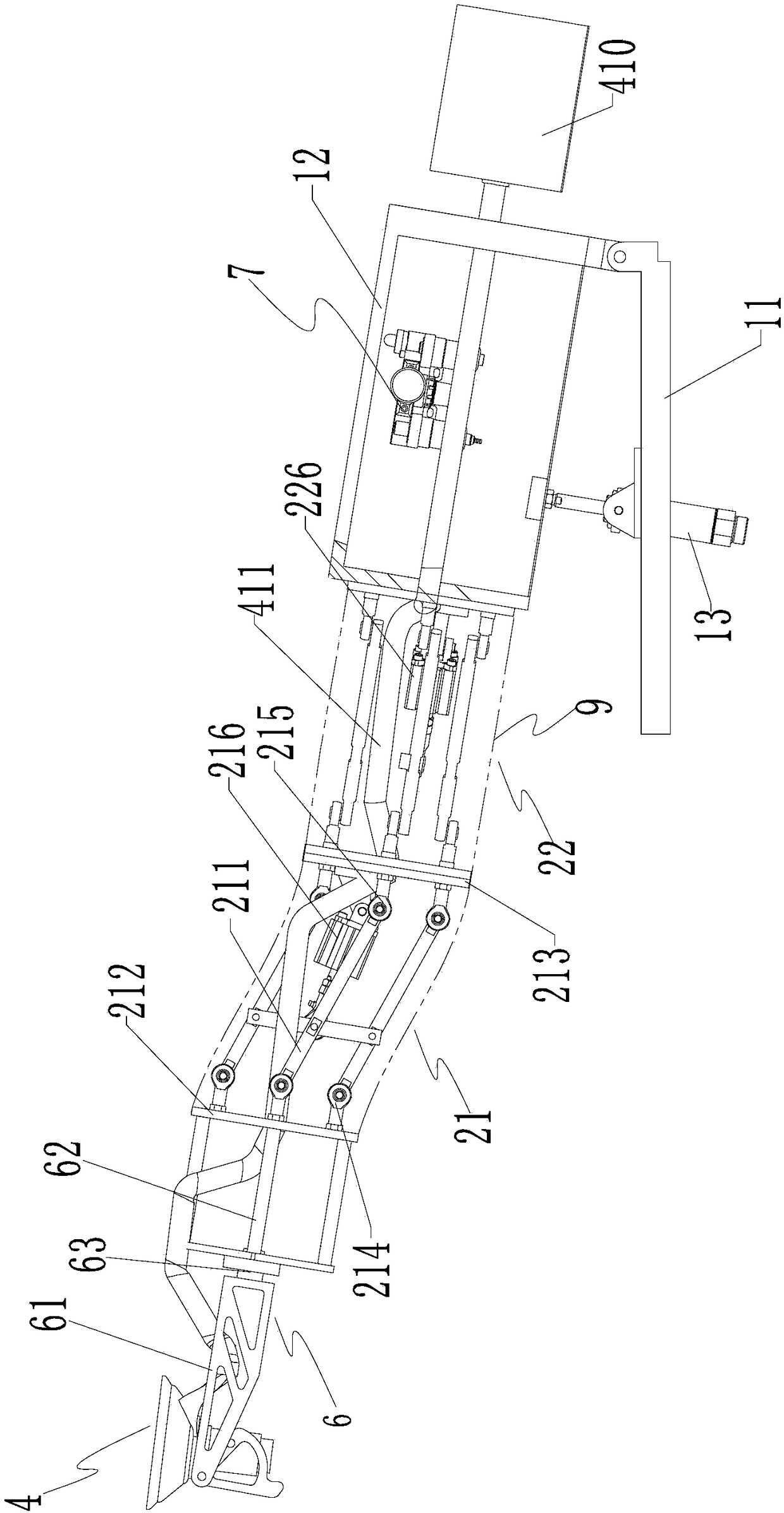

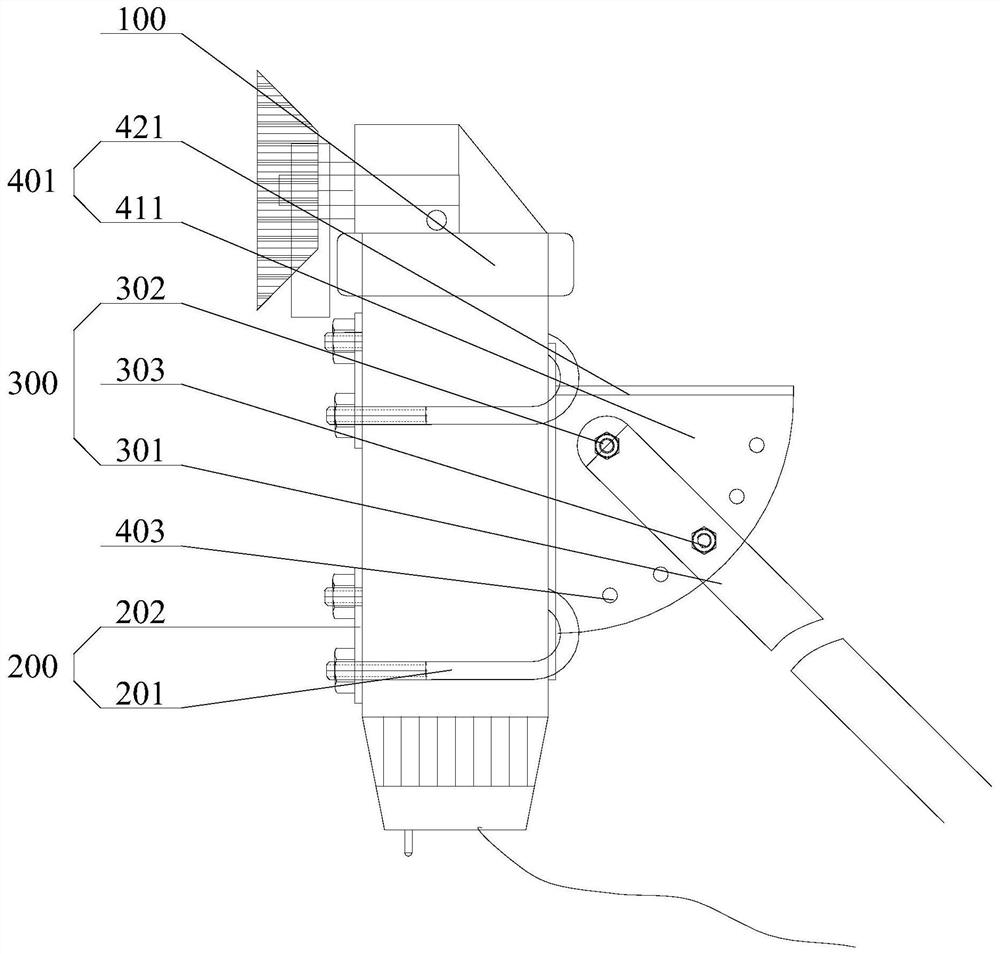

Intelligent grinding apparatus for high-speed rail

ActiveCN106002546AStable self-adjusting grinding directionExpand the grinding rangeGrinding machinesGrinding headsHydraulic cylinderEngineering

The invention relates to an intelligent grinding apparatus for a high-speed rail. The intelligent grinding apparatus comprises a self-stabilized moving device capable of stable self-adjustment of a grinding direction according to a bend shape of a rail such that the intelligent grinding apparatus is applicable to grinding rails of different trajectory shapes, and wide in range of application. A grinding baseplate is mounted on a lower end face of the self-stabilized moving device. Four 4# hydraulic cylinders are symmetrically mounted on a lower end of the grinding baseplate. Adjustable grinding devices are mounted on top ends of the four 4# hydraulic cylinders. The four 4# hydraulic cylinders are capable of adjusting a grinding height of the intelligent grinding apparatus for a high-speed rail such that the intelligent grinding apparatus is suitable for grinding rails at different terrain elevations. The adjustable grinding devices are capable of completely and closely fitting with the surfaces of rails for grinding back and forth, allowing for large grinding range, good grinding effect and high working efficiency. The intelligent grinding apparatus for a high-speed rail is capable of realizing full-automatic grinding function for rails without manual operation, and high in automation degree.

Owner:唐山宏正机械设备有限公司

Wood double-sided grinding machine for furniture manufacturing

InactiveCN108907936BImprove grinding efficiencyWon't flyGrinding machine componentsPlane surface grinding machinesSanderPolishing

The invention belongs to the field of a wood machining, and particularly relates to a double-sided polishing machine for a wood used for manufacturing furniture. The invention aims to solve a technical problem that polishing efficiency can be improved and a large amount of dust generated in the polishing process can be avoided by providing the double-sided polishing machine for the wood used for manufacturing the furniture and in order to solve the technical problem, the invention provides the double-sided polishing machine for the wood used for manufacturing the furniture. The double-sided polishing machine comprises a mounting plate, a bottom plate, a motor, a first belt wheel, a first rotating shaft, a first bearing seat, a first connecting plate, the second connecting plate, the secondbearing seat, the second rotating shaft, the second belt wheel, a first flat belt, a supporting seat and a guide roller and the like. The mounting plate is fixedly connected with one side part of thebottom plate, a first dustproof frame is fixedly connected with the mounting plate through the second connecting plate, and the second dustproof frame is fixedly connected with the mounting plate through the first connecting plate. According to the double-sided polishing machine, the wood polishing efficiency is improved, and an effect that not too much dust is generated in the polishing processis ensured.

Owner:佛山市新铭思家具有限公司

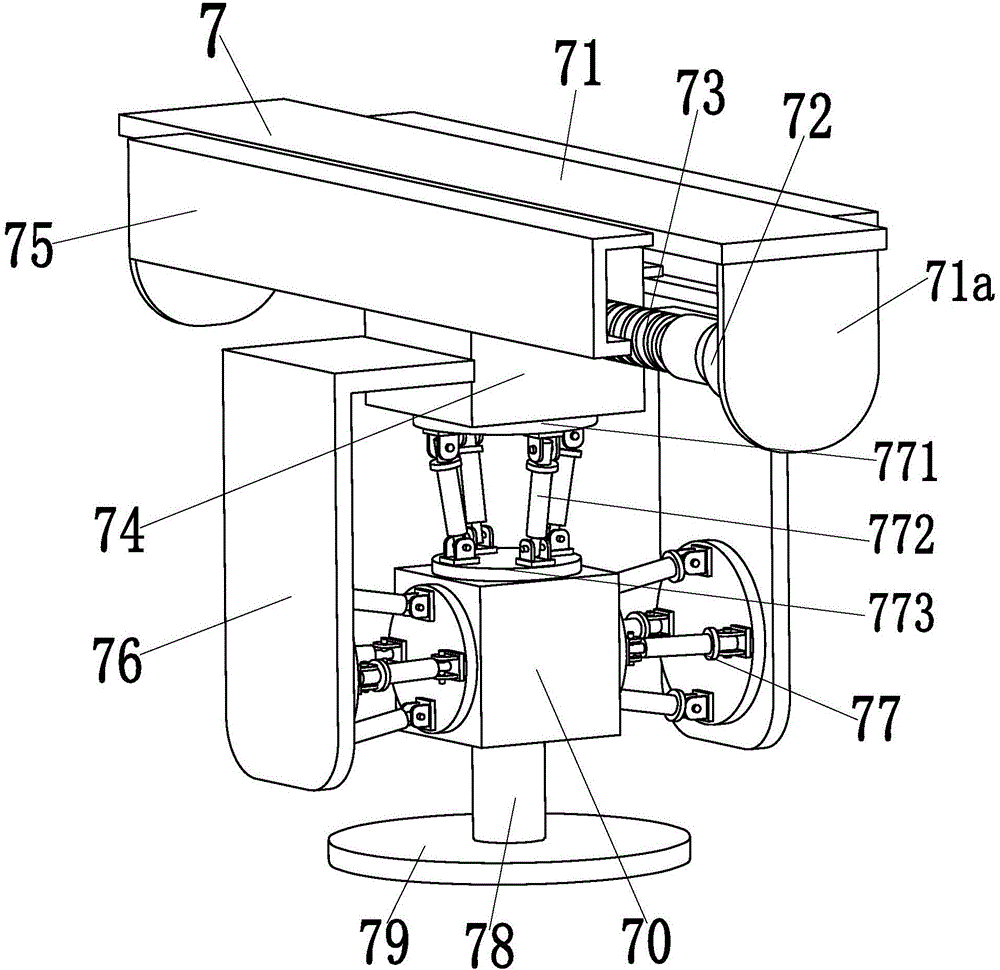

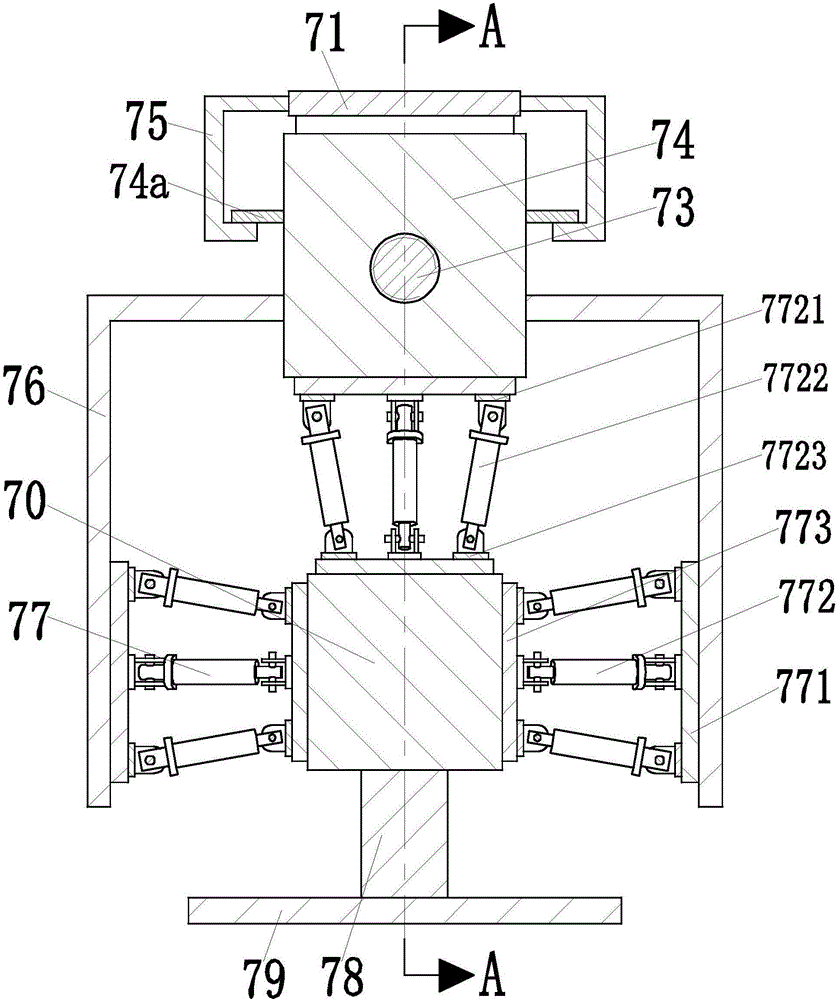

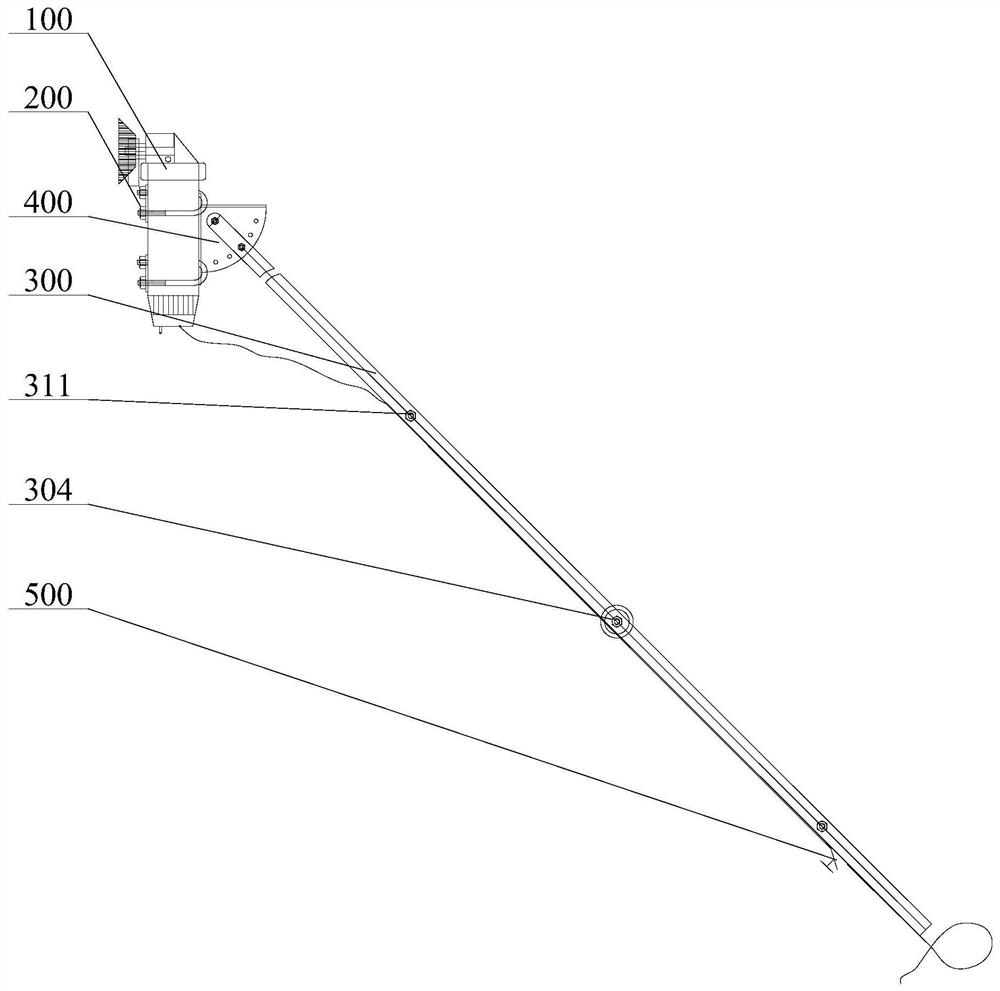

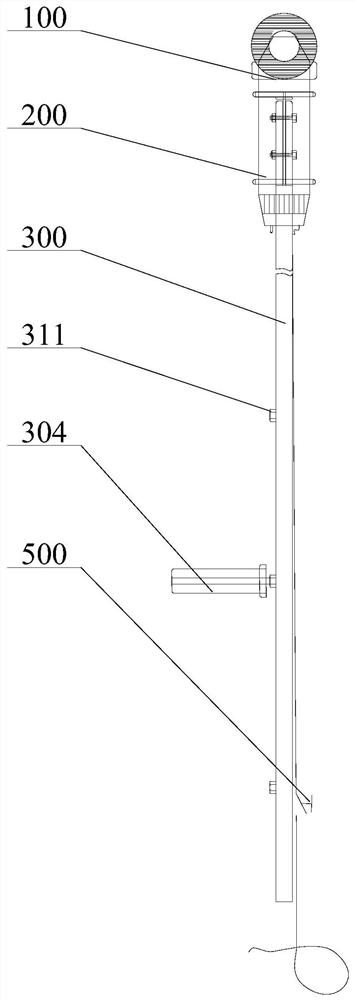

Intelligent polishing and cleaning integrated machine special for railway track

ActiveCN106120495AGood dynamic responseIncrease stiffnessRailway track constructionRailway cleaningHydraulic cylinderEngineering

The invention relates to an intelligent polishing and cleaning integrated machine special for a railway track. The intelligent polishing and cleaning integrated machine comprises a parallel-connection supporting mechanism, and the parallel-connection supporting mechanism comprises a fixed platform. Three parallel-connection branch chains are evenly installed on the lower end face of the fixed platform in the axis direction. The top ends of the three parallel-connection branch chains are all installed on a movable platform. A self-stabilizing mobile device is welded to the lower end face of the movable platform, and the self-stabilizing mobile device can achieve stable self-adjustment of the polishing direction according to the bending shape of the railway track. A variable high-pressure cleaning device is installed on the lower end face of the self-stabilizing mobile device, can quickly remove residual polishing scrap iron and unremoved dust adhering to the railway track based on the working principle of high-pressure water jetting, and has a good high-pressure cleaning effect. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the variable high-pressure cleaning device. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The adjustable polishing device can carry out polishing back and forth by being completely attached to the surface of the railway track. The intelligent polishing and cleaning integrated machine can achieve the full-automatic railway track polishing and cleaning functions, is free of manual operation and is high in degree of automation.

Owner:盐城华依鑫机械科技有限公司

Processing technology of aluminum veneer for curtain wall

ActiveCN112338664AEasy to placeEasy to polishGrinding wheel securing apparatusGrinding drivesElectric machinerySingle plate

The invention discloses a processing technology of an aluminum veneer for a curtain wall, and relates to the technical field of aluminum veneer processing. The aluminum veneer comprises a bottom plate, wherein two vertical plates are arranged above the bottom plate, L-shaped supporting plates are fixedly connected to the upper positions of the opposite faces of the two vertical plates, and two supporting blocks are fixedly connected to the lower surface of the vertical plate on the left side. According to the processing technology of the aluminum veneer for the curtain wall, two worms are driven to rotate through rotation of a first double-shaft motor, the worms are meshed with a transmission turbine, then a second screw rod rotates, the second screw rod enables a threaded cylinder to moveleft and right in the rotating process, then the vertical plate on the right side stably moves under the action of a pulley, the distance between the two vertical plates is adjusted, so that a workercan adjust the distance between the two L-shaped supporting plates according to the width of the aluminum veneer, the aluminum veneer can be conveniently placed on a protective pad, the aluminum veneers with different widths are ground, the adjustment is simple and convenient, convenience is brought to the work of workers, and the use requirements of users are met.

Owner:湖南昕泰装饰材料有限公司

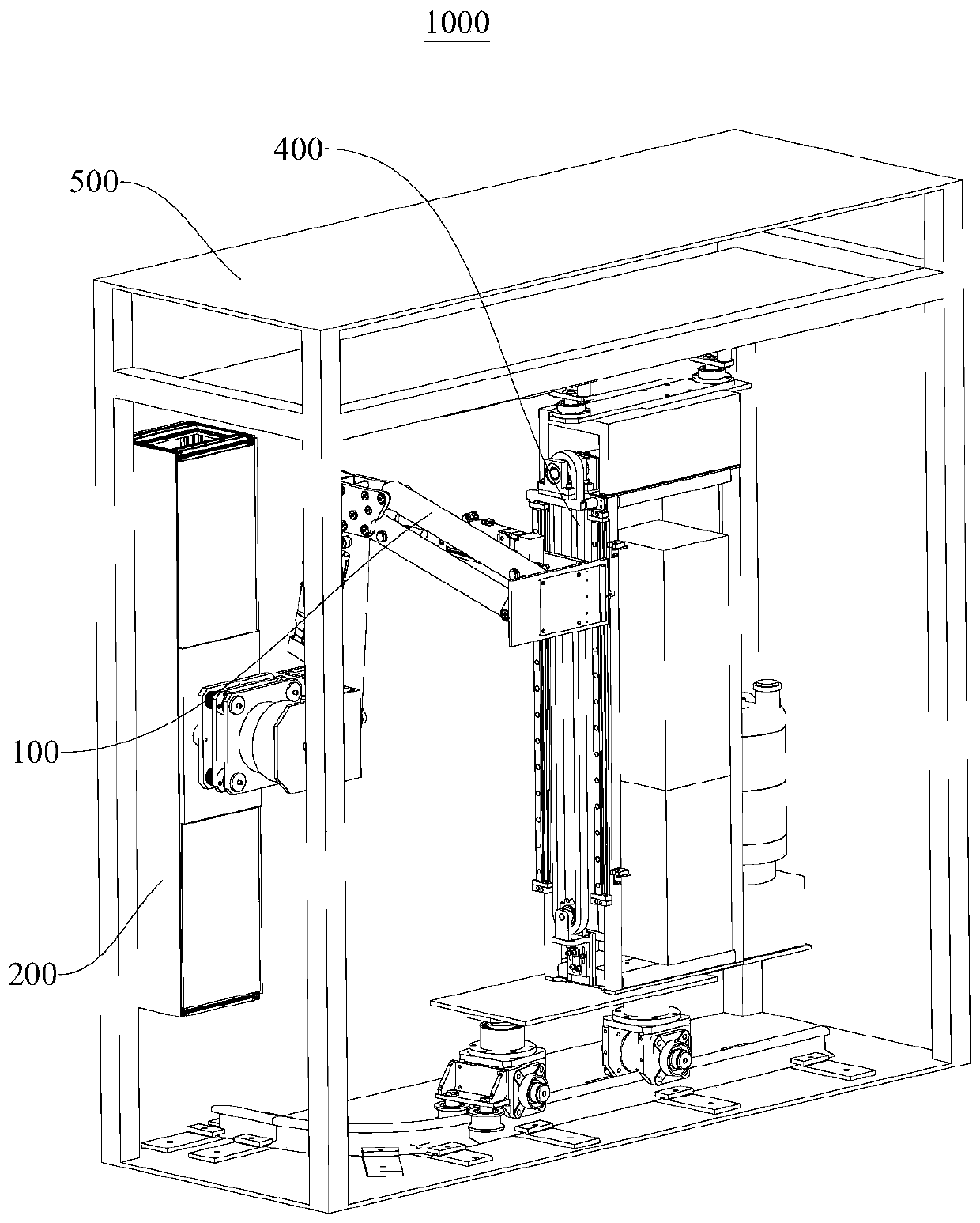

Mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment

ActiveCN108544375AAvoid permanent damageCompact structureGrinding carriagesGrinding drivesEngineeringFuselage

The invention discloses a mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment. The mobile self-dust-suction continuous grinding and polishing machine comprises a mobile base, a pneumatic mechanical arm and a self-dust-suction eccentric grinding machine; the pneumatic mechanical arm is movably assembled on the mobile base and comprises an assembling and positioning assembly and a pneumatic swinging arm assembly; and the self-dust-suction eccentric grinding machine is installed at one end of the pneumatic mechanical arm through a connecting rack structure. According to the mobile self-dust-suction continuous grinding and polishing machine for large equipment surface treatment, the pneumatic swinging arm and the self-dust-suction eccentricgrinding machine are installed on the mobile base, one person operates the machine to enable the machine to move along the outer contour of a machine body, the grinding process of various shape and hook face coherent portions of the machine body is continuously completed, the structure is simple and compact, programming is not needed, operation is flexible and convenient, standardized production is facilitated, the production efficiency and the machine body grinding surface quality are improved, environmental pollution is reduced to the maximum limit, and sufficient technical guarantees are provided for grinding and polishing of complex and irregular hook faces of the large machine body.

Owner:广东博科数控机械有限公司

Adjusting device for polishing equipment, and polishing equipment

PendingCN111922863AExpand the grinding rangeLimited sanding rangePortable grinding machinesPolishingFixed position

The invention provides an adjusting device for polishing equipment, and the polishing equipment, and relates to the technical field of polishing devices. The adjusting device comprises a fixing mechanism, a lengthening mechanism and an angle adjusting disc; and the angle adjusting disc is connected with the polishing equipment through the fixing mechanism, and the lengthening mechanism can be fixed along multiple positions of a fan-shaped face of the angle adjusting disc to enable the lengthening mechanism and the polishing equipment to be provided with fixed positions of multiple angles. By handholding the end of the lengthening mechanism and through multi-direction-and-angle adjusting and fixing of the lengthening mechanism and the angle adjusting disc, the polishing range of the polishing equipment is enlarged, an operator can stand on a platform and the ground to polish a high position within the range at a distance of 3.5 m from the datum plane and a position with a narrow space,the technical problems that in the prior art, the polishing range of an angle grinder handholding polishing method is limited, scaffold setting-up wastes the time and labor, the working efficiency islow, the polishing distance is short, and dust harms human bodies are relieved, the working efficiency is improved, and the construction cost is saved.

Owner:SHANDONG ELECTRIC POWER CONSTR NO 2

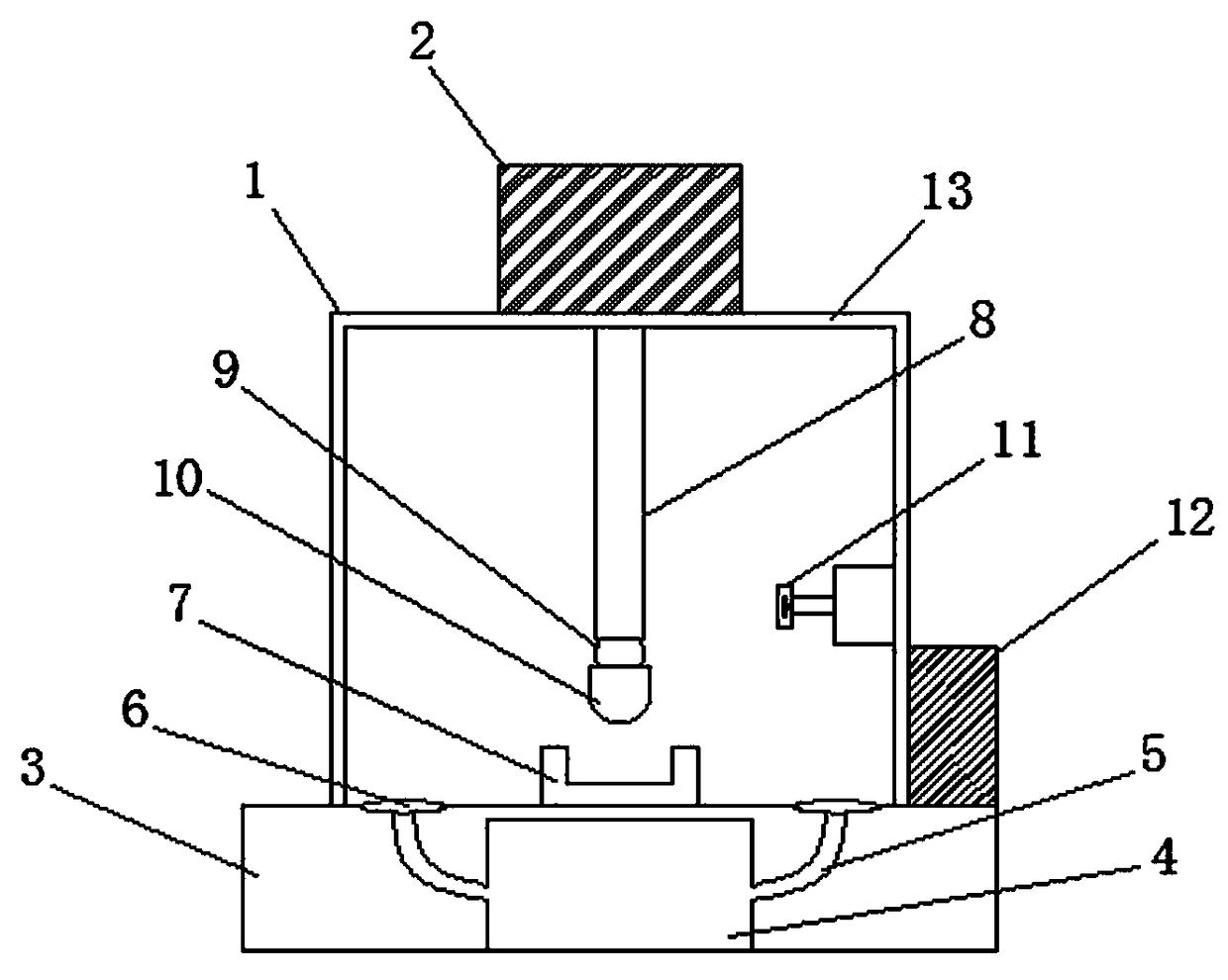

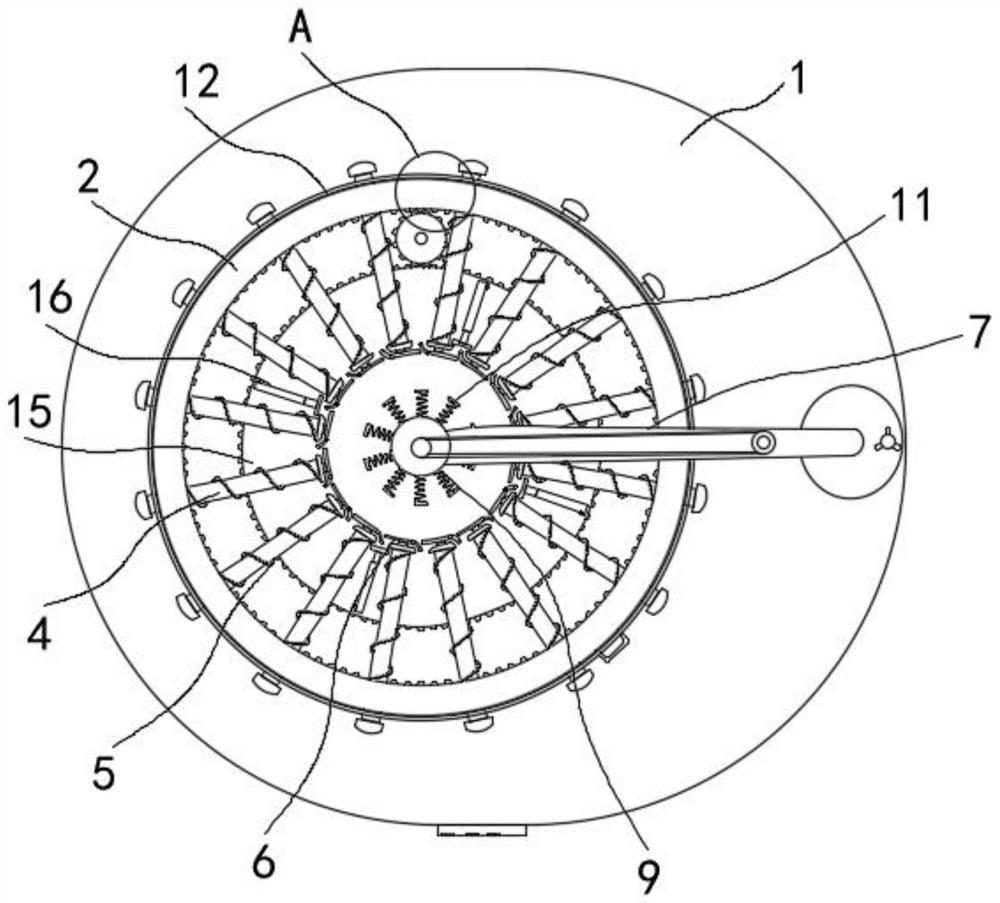

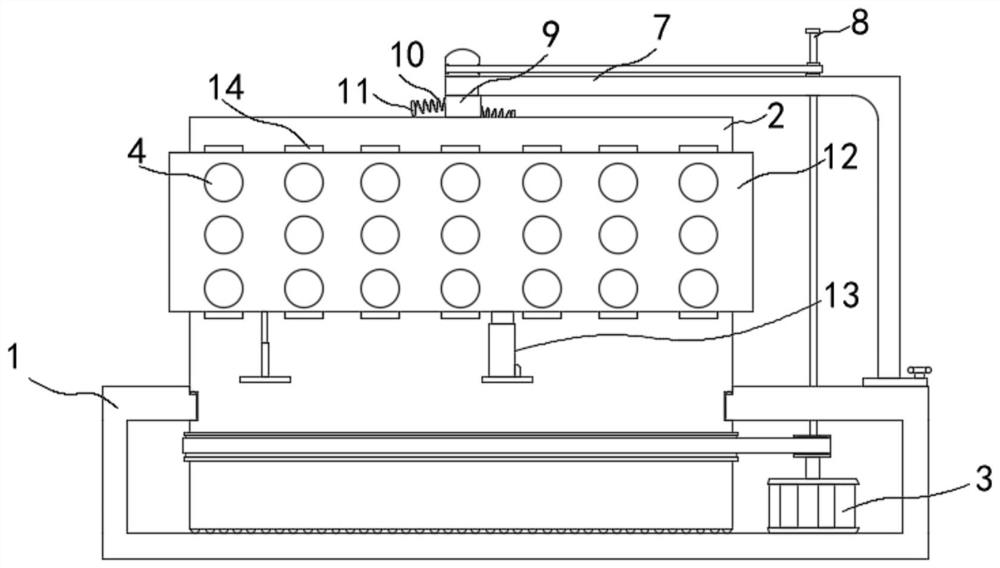

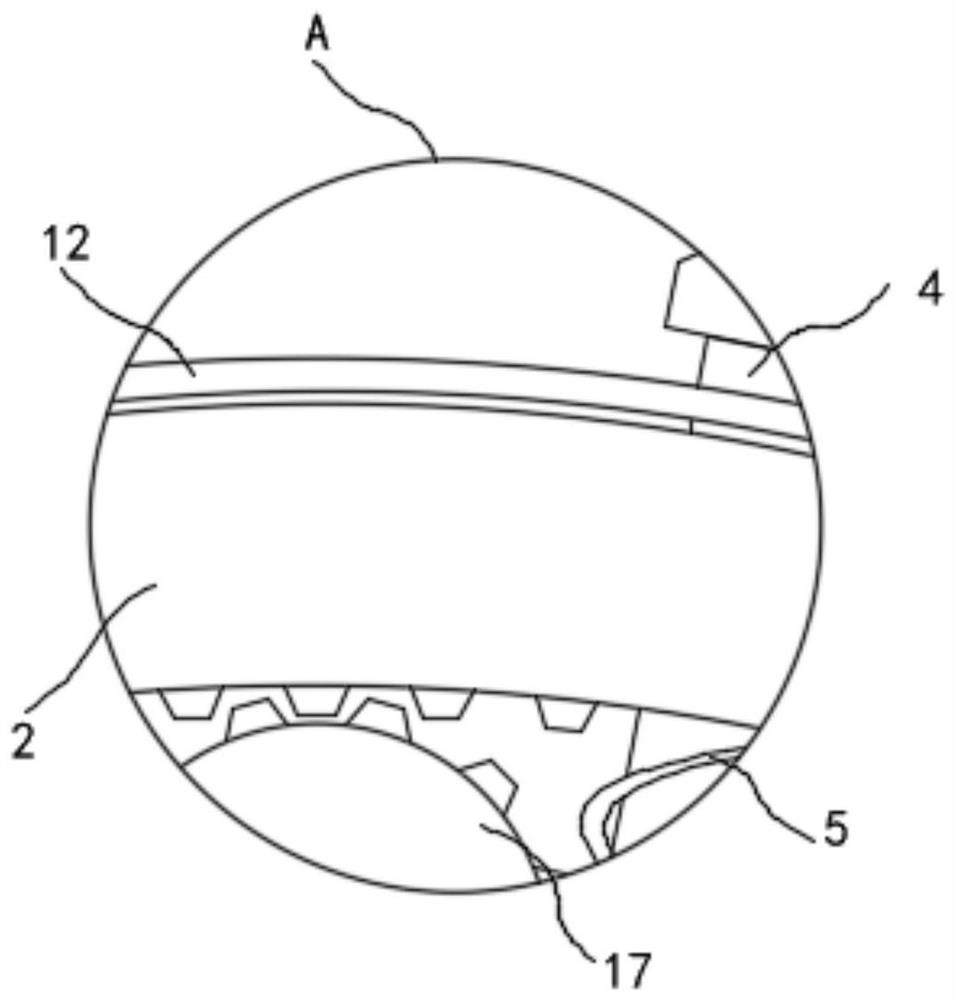

Efficient circular casting inside and outside synchronous grinding equipment

InactiveCN114260762AControllable contact pressureEasy to polishRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention provides efficient circular casting inside and outside synchronous grinding equipment, and relates to the technical field of casting machining equipment.The efficient circular casting inside and outside synchronous grinding equipment comprises a base, a motor is bolted to the bottom of the inner wall of the base, and a belt pulley is mounted at the end of an output shaft of the motor; the efficient round casting inner and outer synchronous grinding equipment comprises a base, a belt wheel is arranged on the top of the base, a rotating outer barrel rotationally connected with the base penetrates through the top of the base, a belt is connected between the rotating outer barrel and the belt wheel, and densely-distributed movable abutting rods penetrate through the outer wall of the rotating outer barrel. A movable abutting rod overcomes the force applied by an outer spring under the action of centrifugal force to move towards the outside of a rotary outer cylinder, so that the contact pressure between an outer wall grinding block and a workpiece can be controlled, the workpieces of various sizes can be ground conveniently, and rotation of the rotary outer cylinder can drive an inner rotary rod and an inner wall grinding block on the outer wall of the inner rotary rod to rotate; and the inner wall and the outer wall can be synchronously polished, and the machining efficiency is improved.

Owner:徐州申工金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com