Patents

Literature

93results about How to "To achieve the effect of one machine with multiple functions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

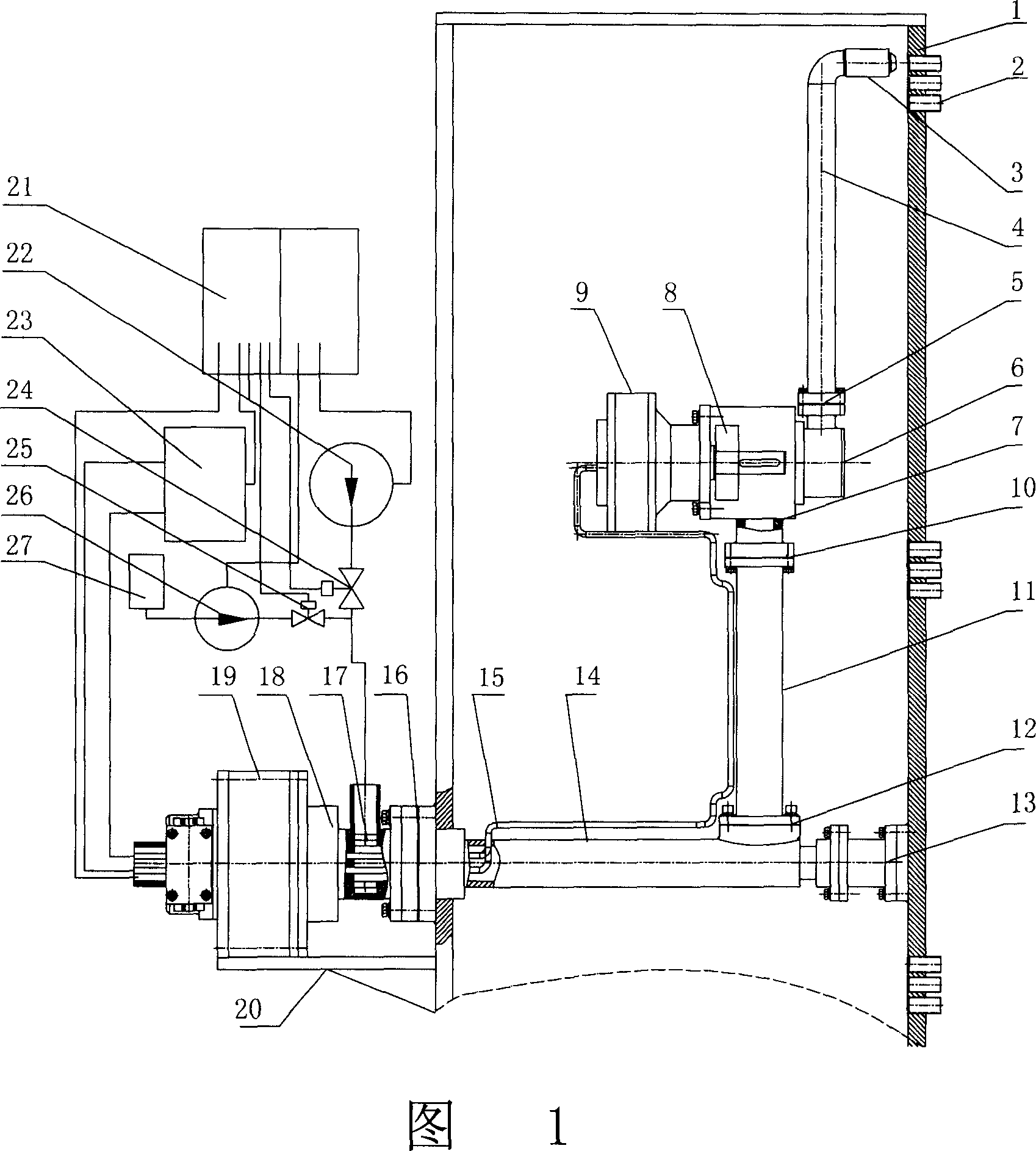

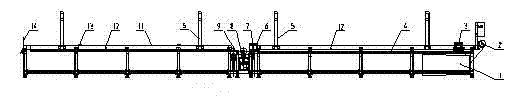

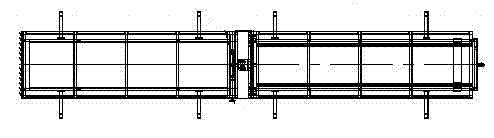

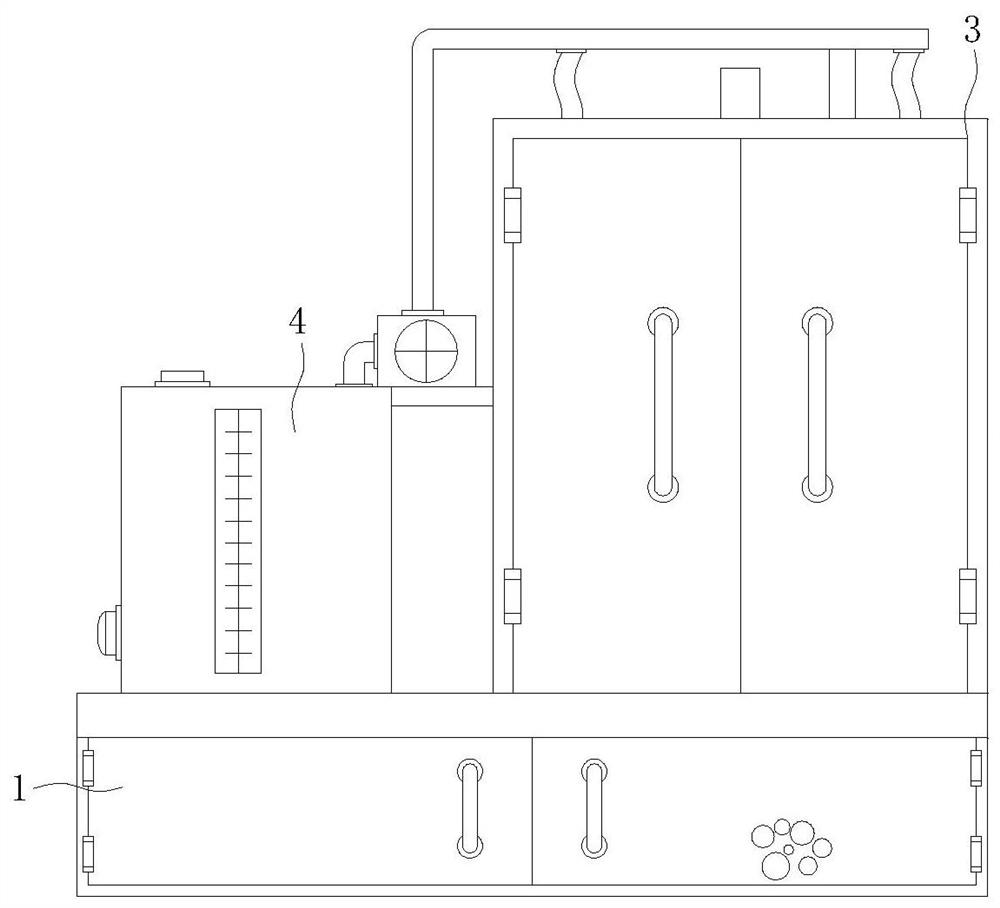

Automatic chip cleaner of full-functional machine tool

InactiveCN101786252ASolve the problem of optional chip conveyorWon't happen can'tConveyorsMaintainance and safety accessoriesNumerical controlTransmission belt

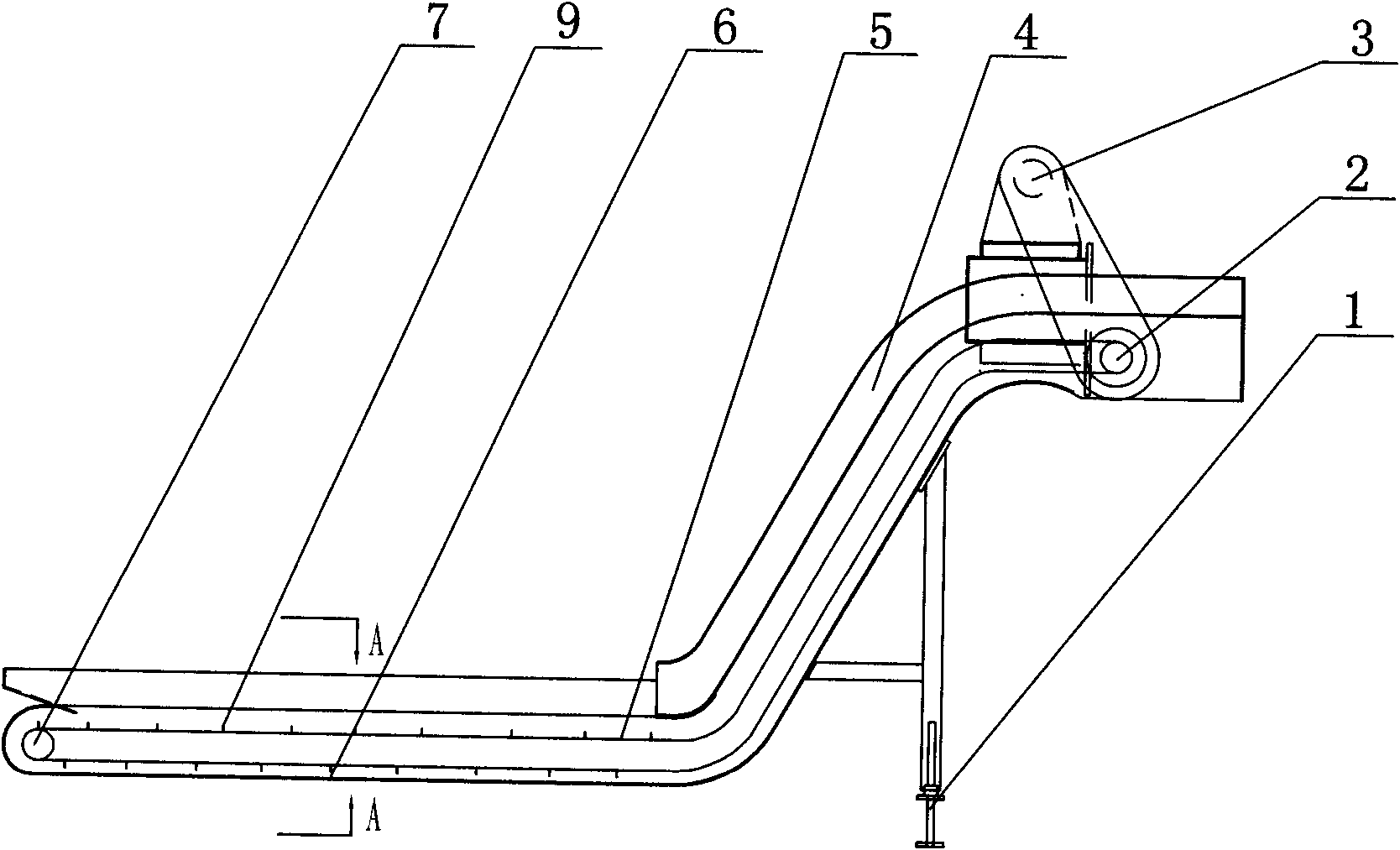

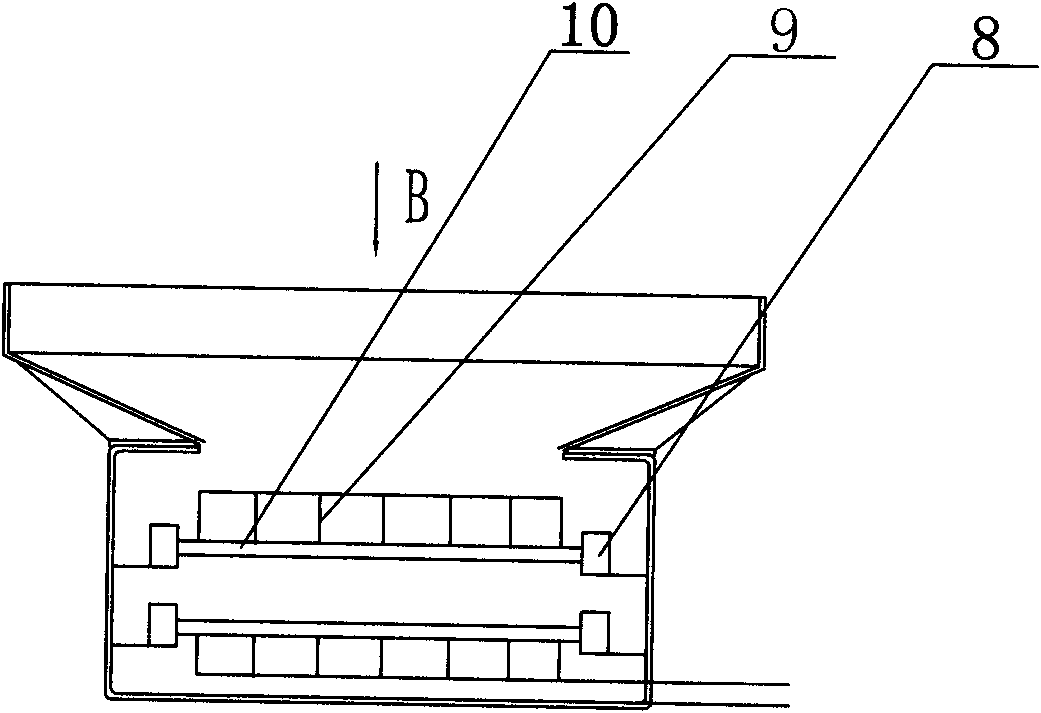

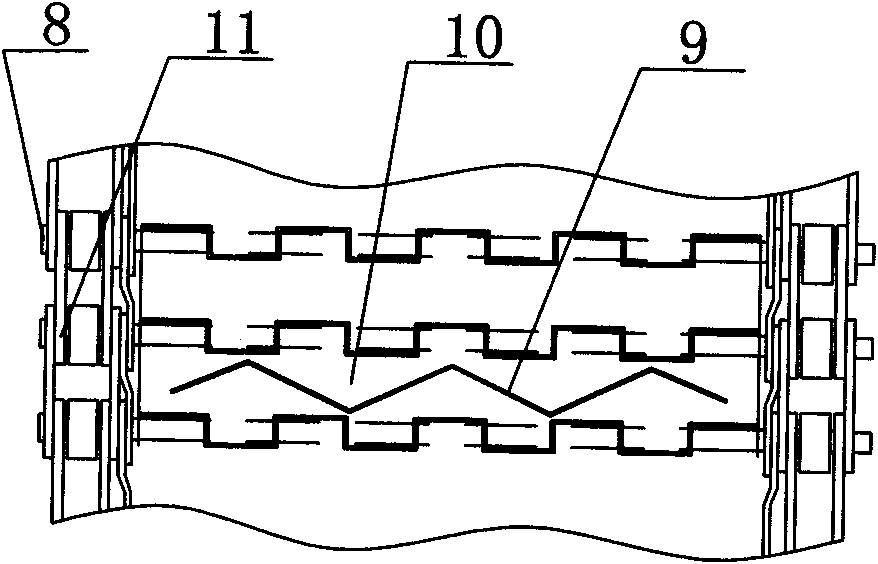

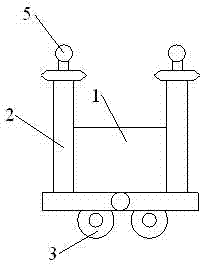

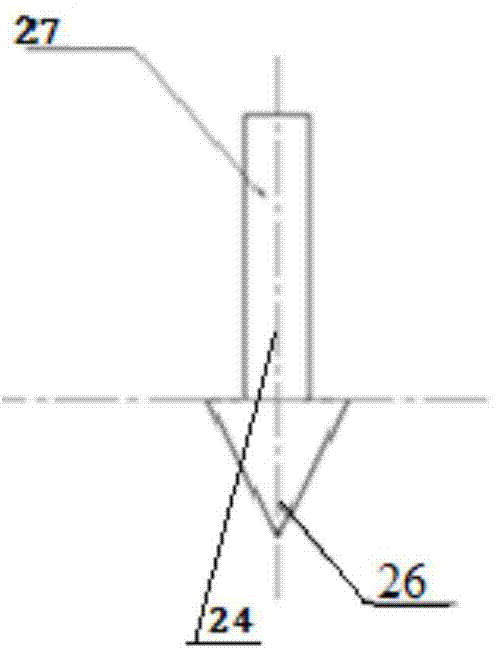

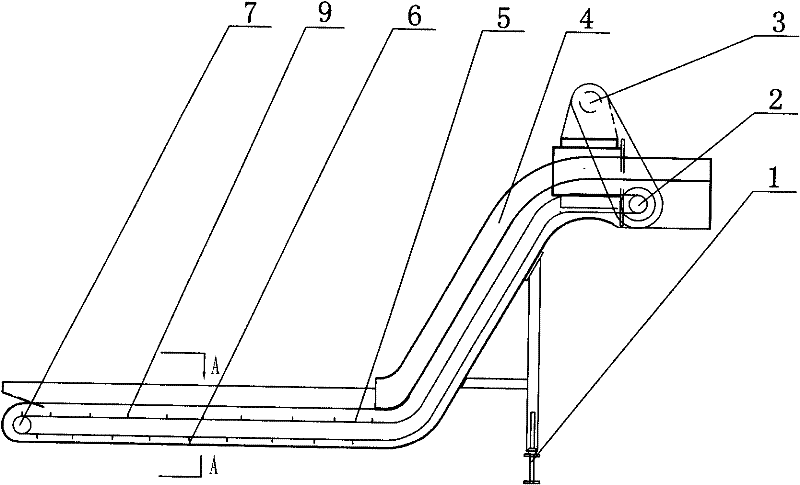

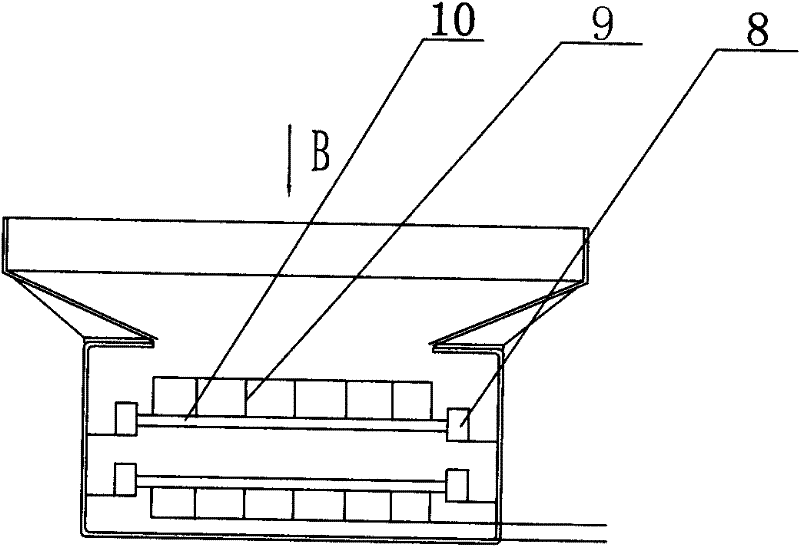

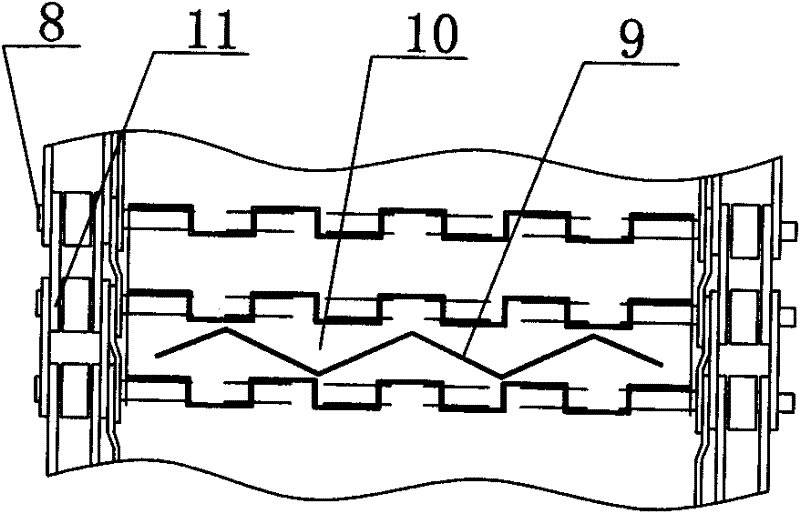

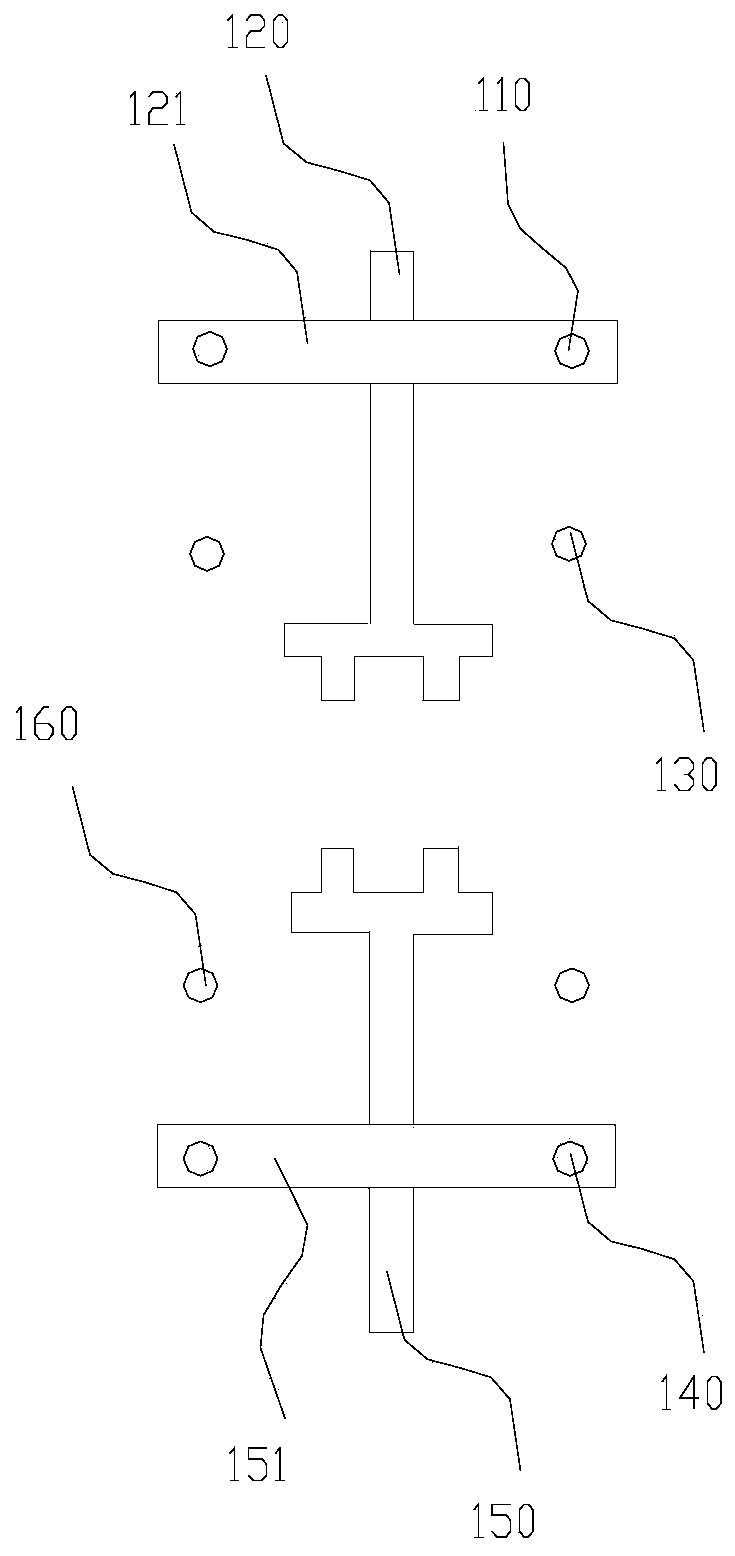

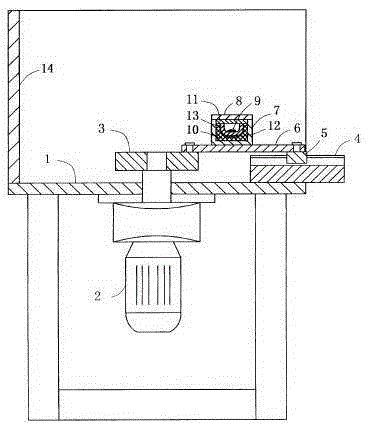

The invention discloses an automatic chip cleaner of a full-functional machine tool, which is complete equipment of various digital control machine tools, processing centers, specialized machine tools and assembly lines. The automatic chip cleaner of the full-functional machine tool provided by the invention can complete the chip delivery work in any state and has high efficiency and safe and reliable performance. The automatic chip cleaner of the full-functional machine tool comprises a machine frame, wherein a motor is connected with a driving shaft above the machine frame; a flight conveyor is arranged between the driving shaft and a support shaft below the machine frame; the flight conveyor consists of link joints, chains and hinge pins and the link joints are connected in a mode of folding plates; and adjusting stabilizers are arranged outside the machine frame. The automatic chip cleaner of the full-functional machine tool has a structural key point that the link joints are provided with W-shaped chip push plates vertical to the link joints.

Owner:沈阳华邦通用机械技术开发有限公司

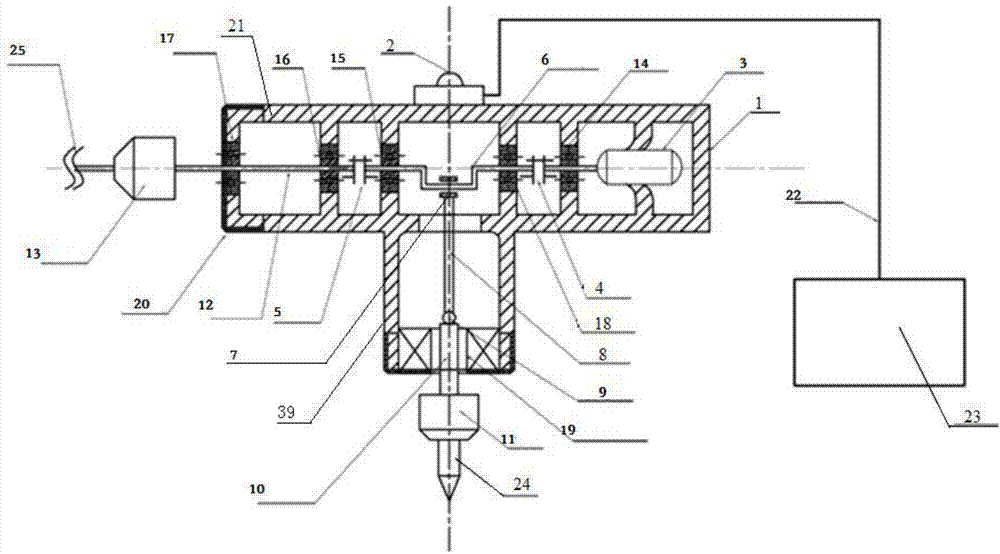

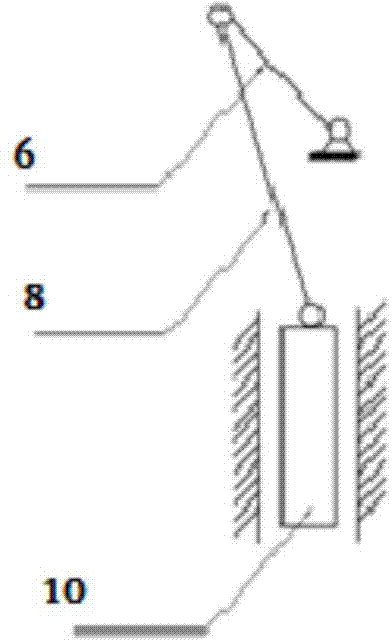

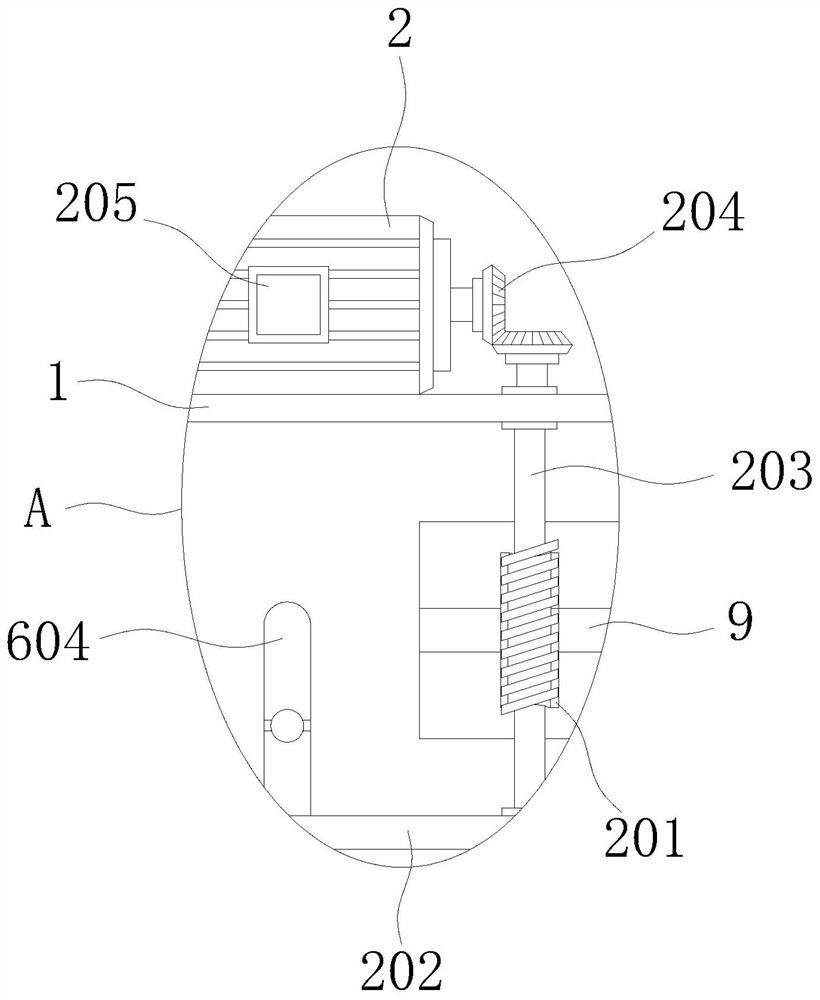

Wearable exoskeleton exercising and rehabilitating machine

InactiveCN102648884ARealize functionTo achieve the effect of one machine with multiple functionsChiropractic devicesMuscle exercising devicesThighDegrees of freedom

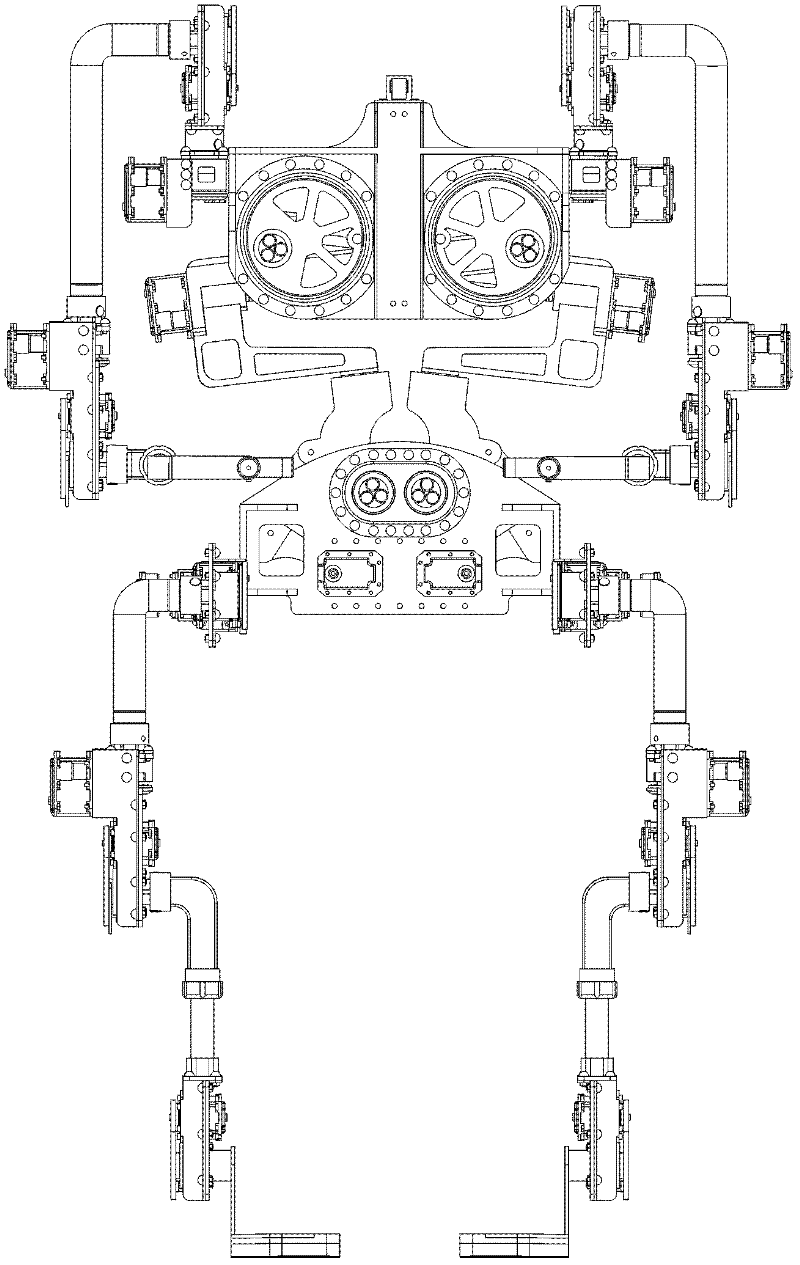

The invention discloses a wearable exoskeleton exercising and rehabilitating machine, which is designed according to the structure of a human skeleton, can exercise all parts of a human body and can perform rehabilitating traction on the human body. The wearable exoskeleton exercising and rehabilitating machine comprises two hand modules, two foot modules and a body module, wherein the two hand modules are in bilateral symmetry along the vertical central line of the body module; and the two foot modules are in bilateral symmetry along the vertical central line of the body module. In order to adapt to people with different heights, a hand extending component and a foot extending component are arranged and a screw rocker turnplate is arranged on the back to extend limbs. The whole wearable exoskeleton exercising and rehabilitating machine has 22 degrees of freedom, namely 4 degrees of freedom at the shoulders, 2 rotating degrees of freedom at the upper arm, 2 degrees of freedom at the elbows, 4 degrees of freedom at the hip, 2 rotating degrees of freedom at the upper legs, 2 degrees of freedom at the knees, 2 degrees of freedom at the ankles, 2 forward and backward degrees of freedom at the waist and 2 leftward and rightward degrees of freedom at the waist respectively. Through the 22 degrees of freedom, various motions of the limbs and the body can be realized, and through two different working modes, the exercising and rehabilitating functions can be realized.

Owner:赵欣驰

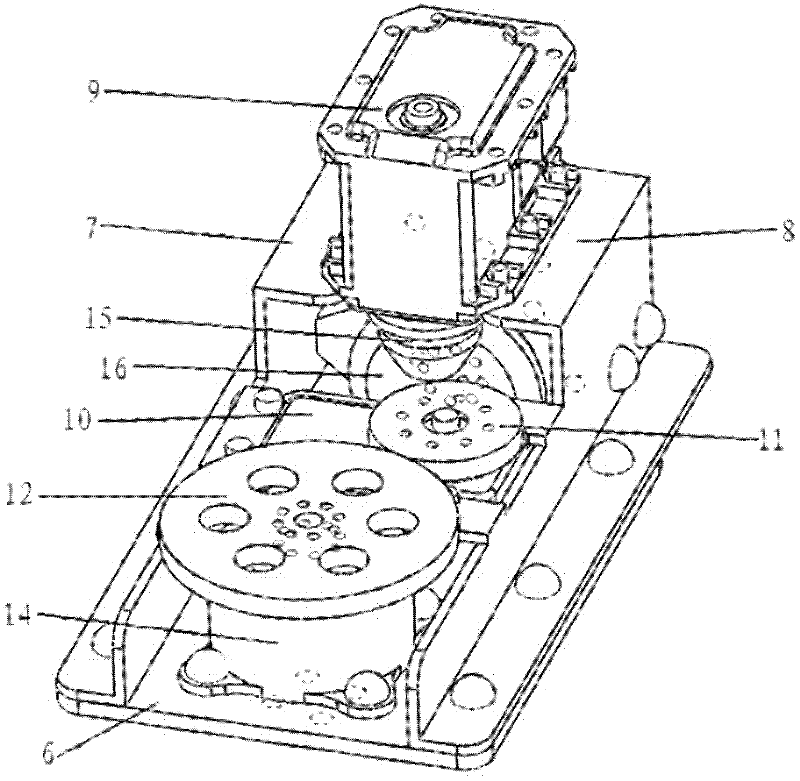

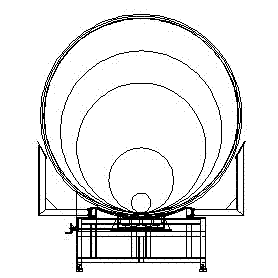

Rotary polishing device for household water purifier stainless steel cylinder

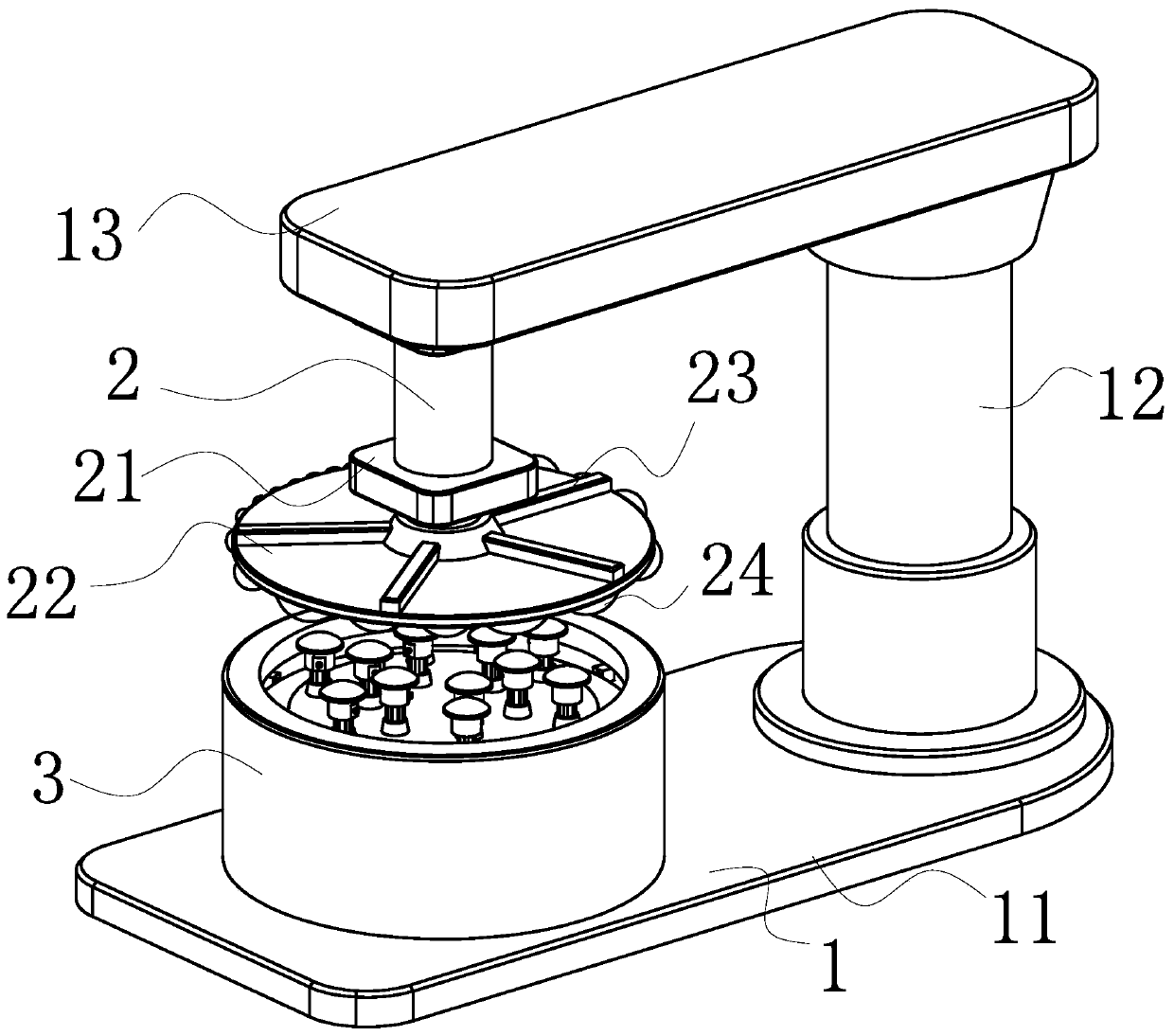

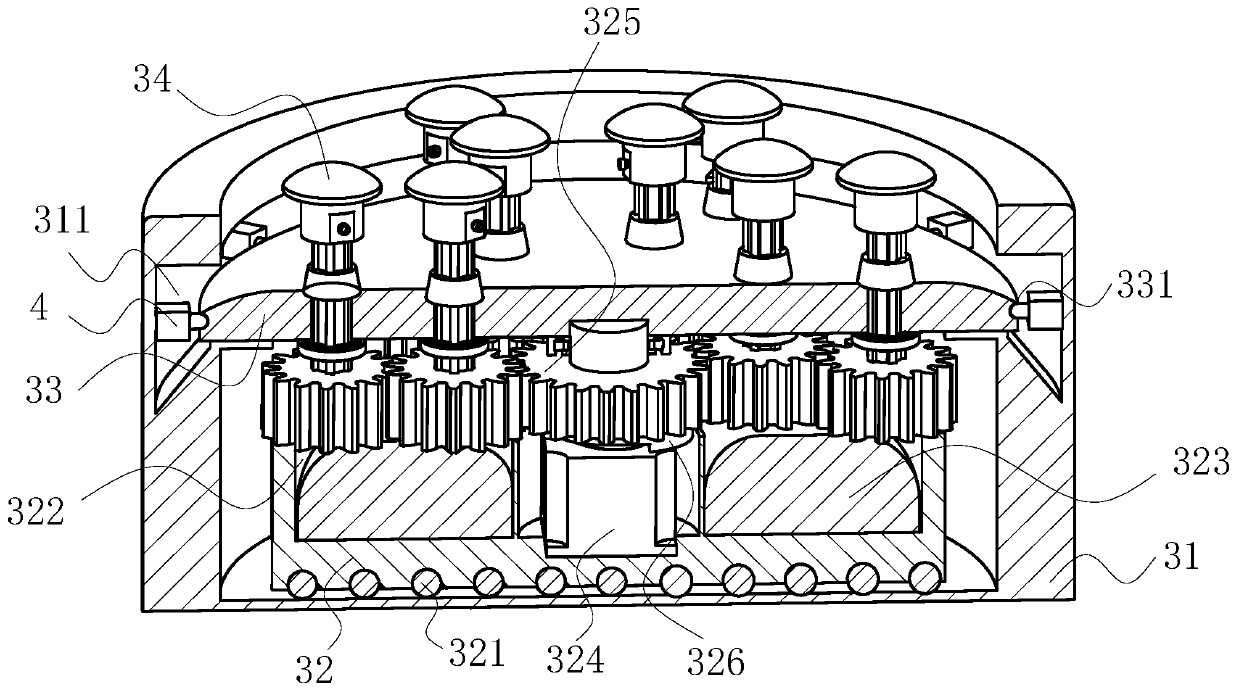

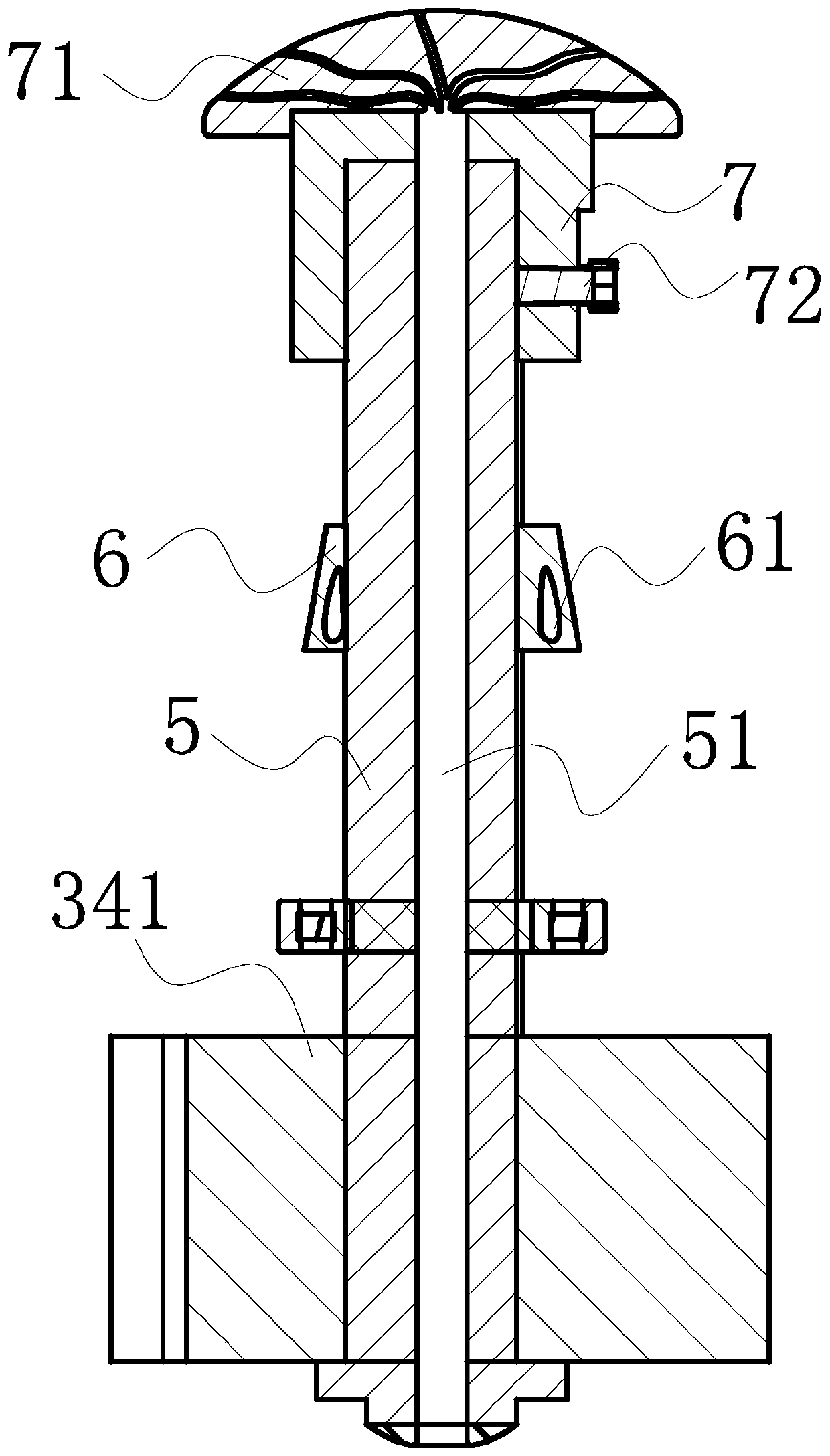

InactiveCN107042429AThoroughly polishedImprove polishing effectGrinding carriagesRevolution surface grinding machinesMaterials scienceSteel cylinder

The invention relates to a polishing device, in particular to a rotary polishing device for a household water purifier stainless steel cylinder. The technical problem to be solved by the present invention is to provide a rotary polishing device for stainless steel cylinders of household water purifiers that can be used for polishing various types of cylinders and has a good polishing effect. In order to solve the above technical problems, the present invention provides such a rotary polishing device for household water purifier stainless steel cylinder, which includes a support frame, a first motor, a clamping mechanism, a first fixing rod, a first bearing seat, etc.; The middle of the bottom of the frame is connected with a first motor, the top of the output shaft of the first motor is connected with a clamping mechanism, the back side of the top of the support frame is connected with a connecting plate, the connecting plate is located at the rear side of the first motor, and the top front of the connecting plate is connected with a support pole. In the present invention, the top of the cylinder body is driven by the pressing plate by rotating the first support rod, and then the handle is turned, thereby driving the grinding plate to move to the middle to clamp the cylinder body tightly, and then start the second motor.

Owner:郁海新

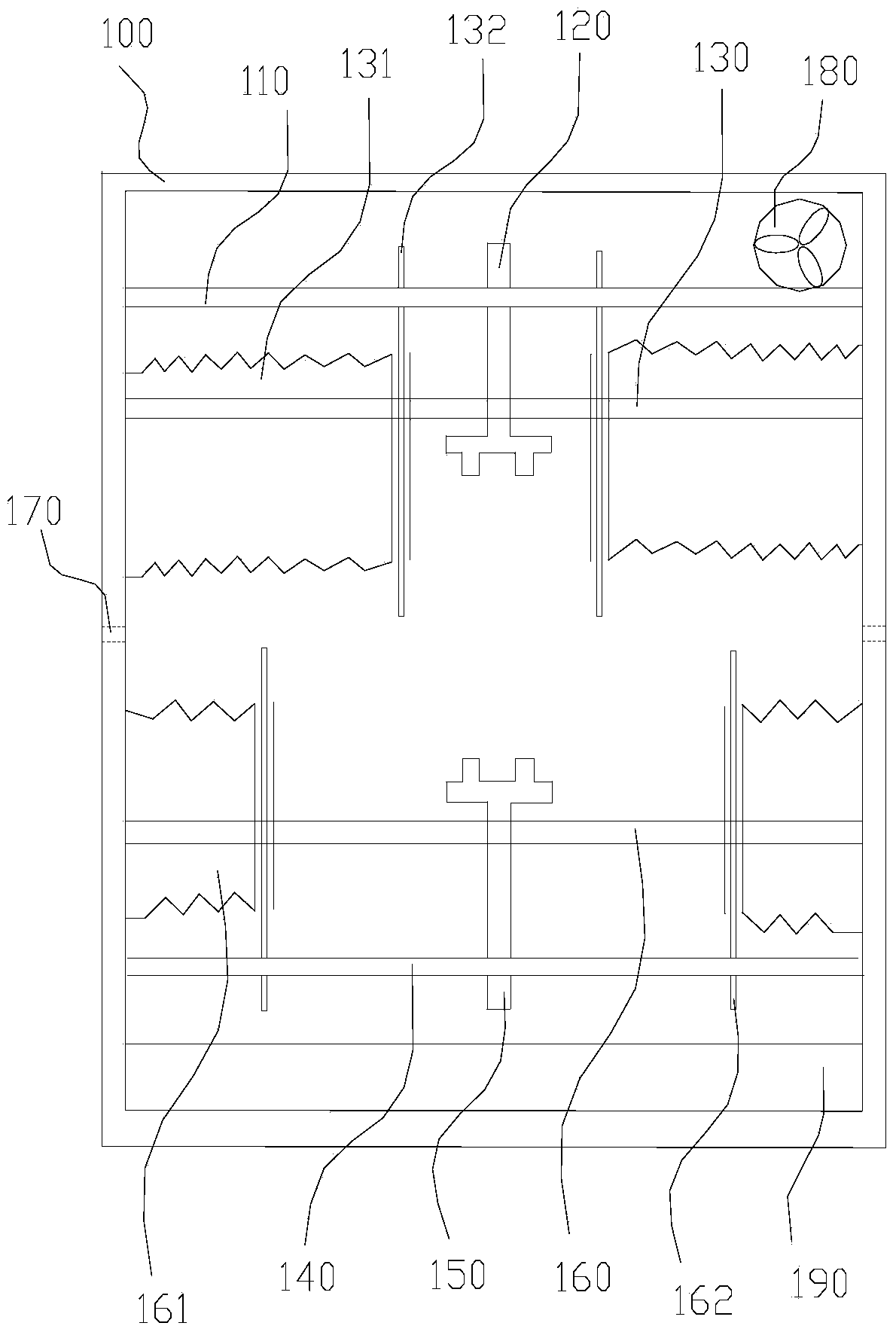

Multifunctional comprehensive ageing experiment box

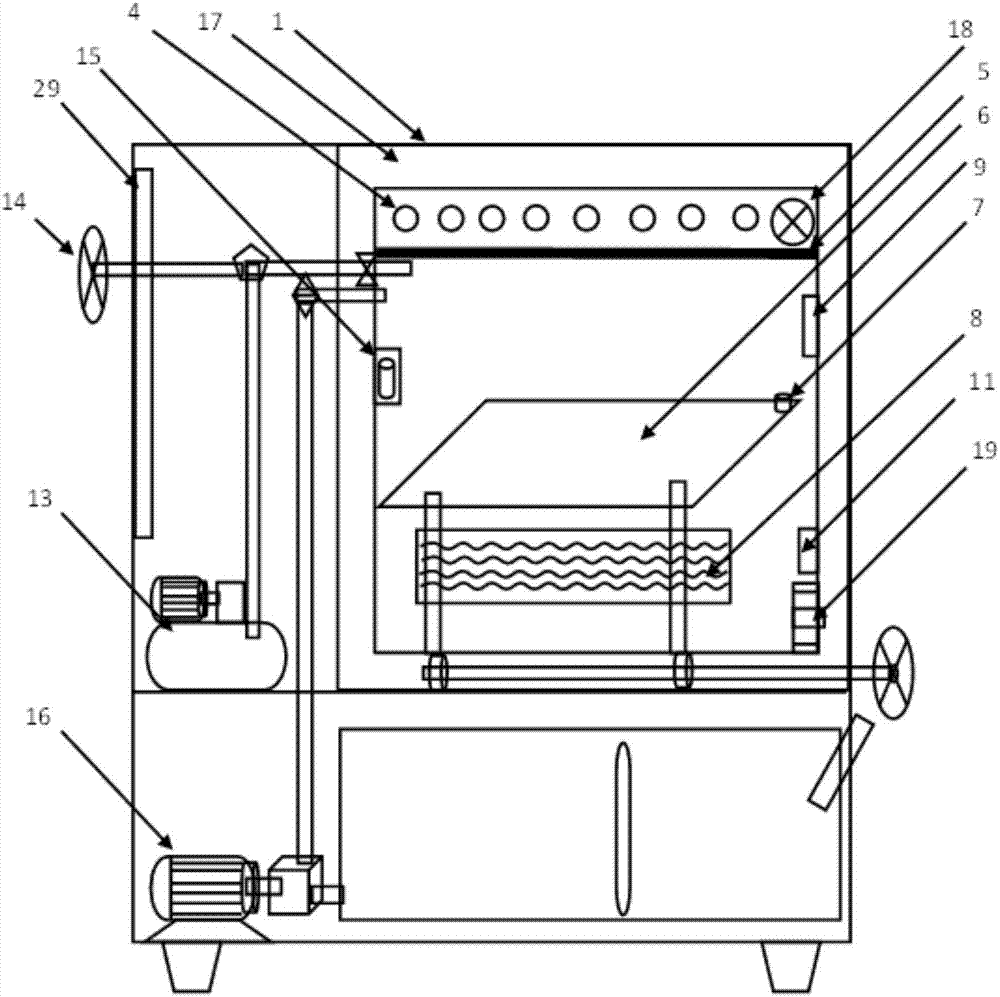

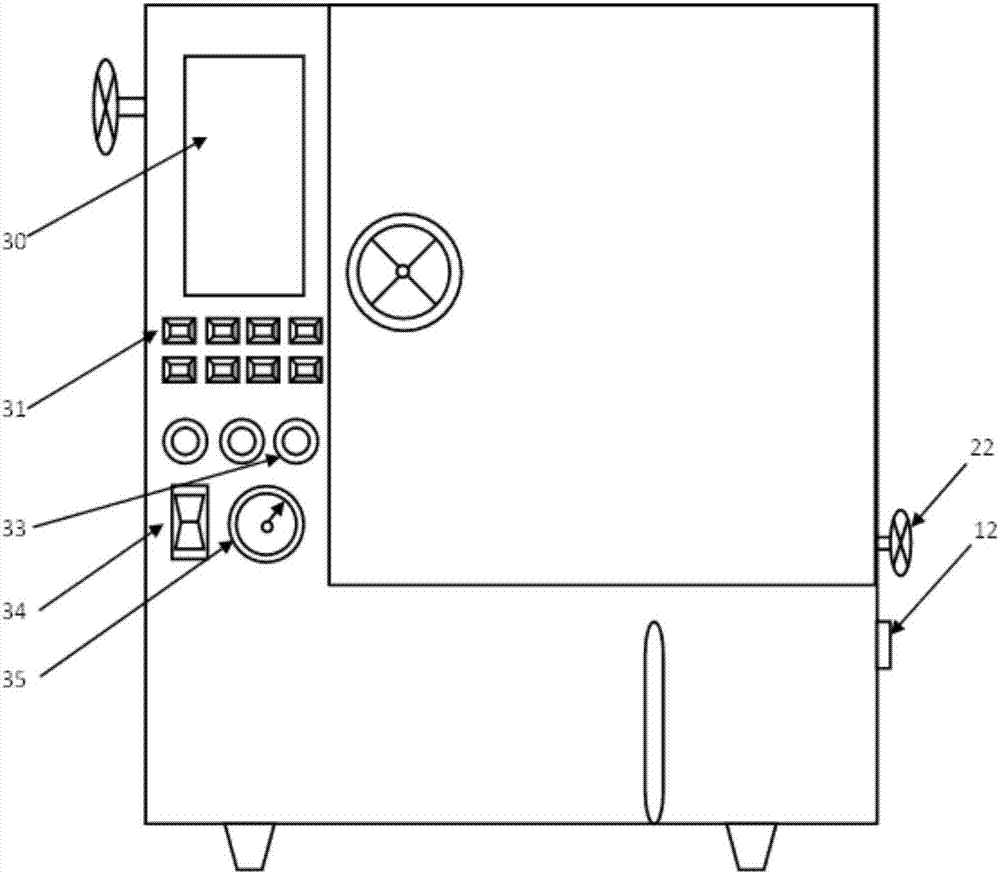

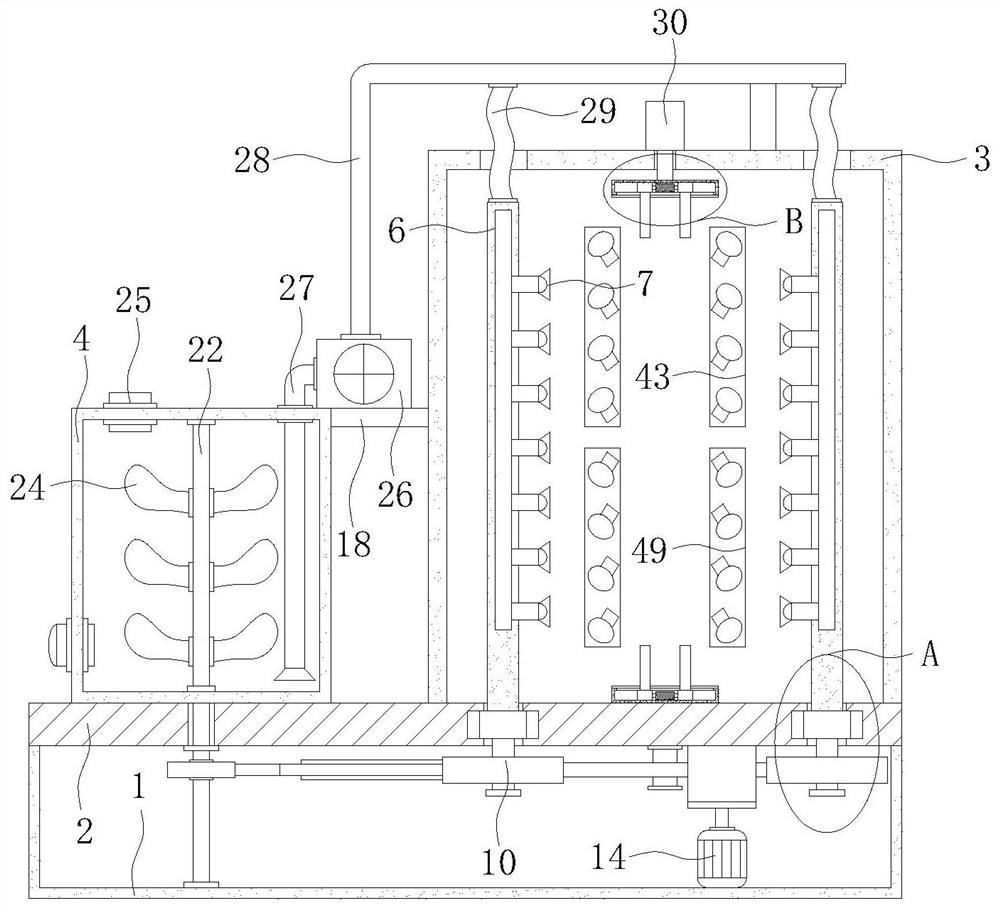

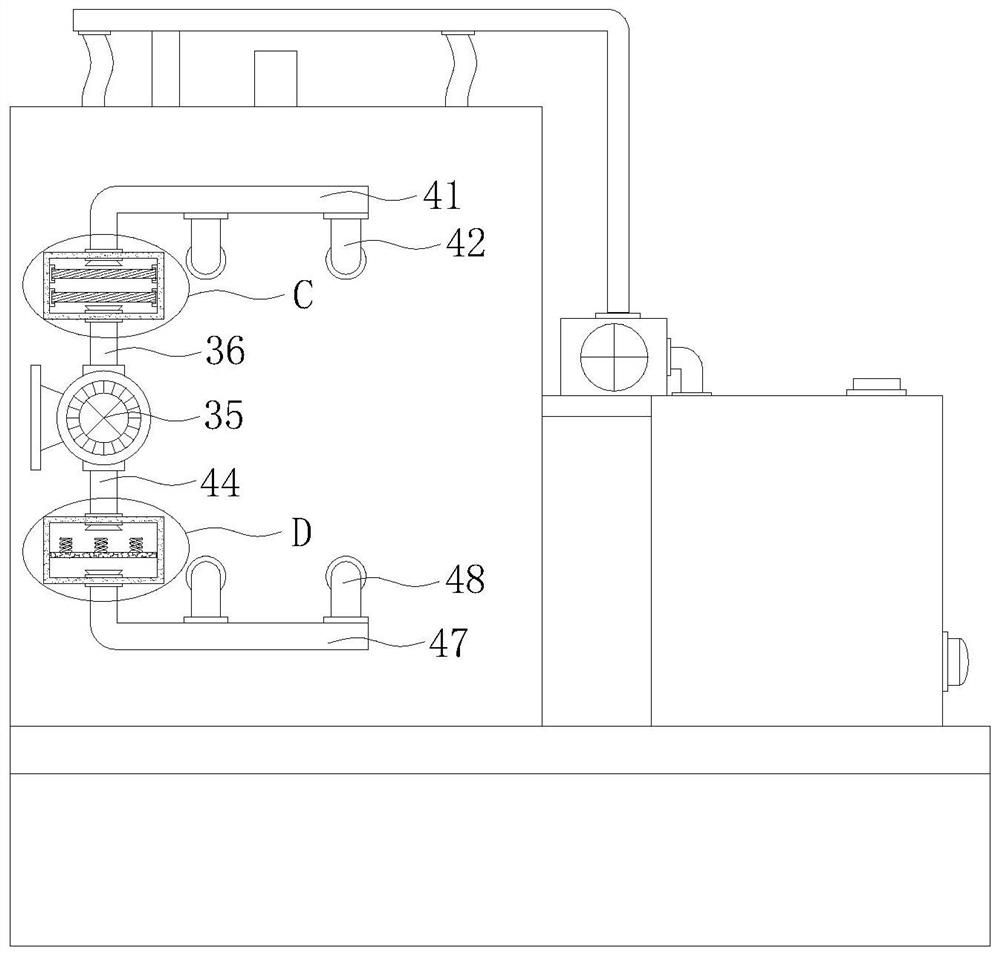

PendingCN107300938AShorten aging timeTo achieve the effect of one machine with multiple functionsWeather/light/corrosion resistanceSimultaneous control of multiple variablesControl systemUltraviolet lights

The invention relates to the field of ageing equipment and discloses a multifunctional comprehensive ageing experiment box. The multifunctional comprehensive ageing experiment box comprises a box body, an ageing chamber arranged in the box body and a sealing box door arranged at an opening of the ageing chamber; and an ultraviolet light system, a heating system, a humidifying system, an exhausting and pressure-reducing system, a pressurizing system and a control system are arranged in the box body. The multifunctional comprehensive ageing experiment box provided by the invention has multiple ageing functions and can obtain an ageing sample of a sample accurately and quickly, so as to effectively shorten the ageing time.

Owner:ZHEJIANG SCI-TECH UNIV

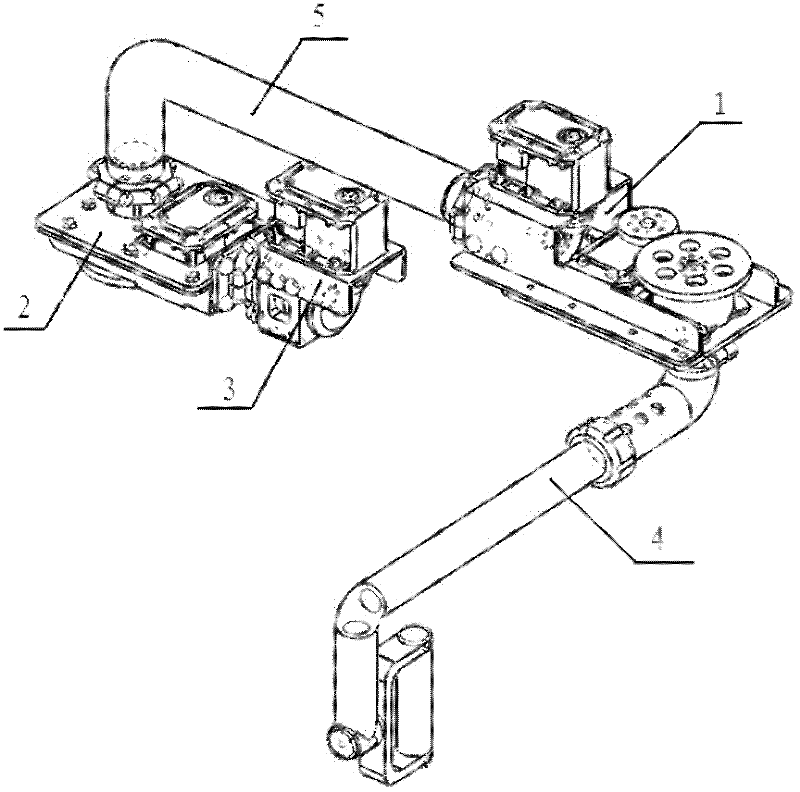

Two joint type online cleaning robot for condenser copper tube

InactiveCN1945196APrecise positioningHigh degree of automationProgramme-controlled manipulatorNon-rotary device cleaningJoints typesHigh pressure water

The two joint type robot for on-line cleaning of condenser copper tube includes a nozzle, a small arm, a rotary water chamber, a rotary coder, a hydraulic small arm driver, a large arm, a rotary connecting lever, a water inlet chamber, hydraulic large arm driver and a control mechanism. The rotary connecting lever set inside the condenser water chamber is connected to the hydraulic large arm driver outside the condenser water chamber with the water inlet chamber connected to the control mechanism in between; the large are is connected and communicated to the rotary connecting lever; the rotary water chamber in the top of the large arm is connected to the hydraulic small arm driver with the rotary coder in between; and the small arm is set on and communicated to the rotary water chamber and has the nozzle set on it. The present invention can operate in water to clean copper tubes of condenser with high pressure water as cleaning medium.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

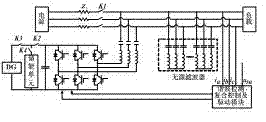

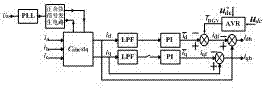

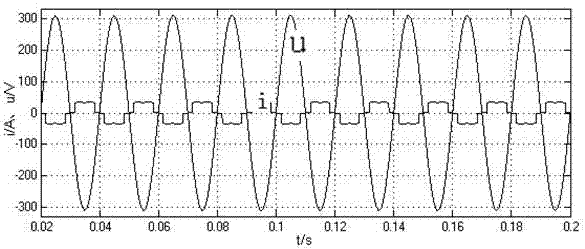

Novel power quality regulator on background of micro-grid

InactiveCN103117553ALow input costRealize reactive power compensationEnergy industrySingle network parallel feeding arrangementsPower qualityControl engineering

The invention provides a novel power quality regulator on the background of a micro-grid aiming at a power quality management problem in the micro-grid. According to the novel power quality regulator on the background of the micro-grid, a distributed power source and energy storage elements are added on the basis of an original parallel connection mixed type active electricity filter, an improved type id-iq compound directive current detection and combining implement method are adopted, and demand that one machine is provided with a plurality of functions is met. According to the novel power quality regulator on the background of the micro-grid, harmonic wave and reactive current compensation of the micro-grid are effectively solved, at the same time, grid-connection generating functions of distributed power source are well achieved, and governance cost of the power quality of the micro-grid is saved to the greatest extent. Simulation and experiment operating data show that the design scheme is effective and reliable.

Owner:HUNAN UNIV OF TECH

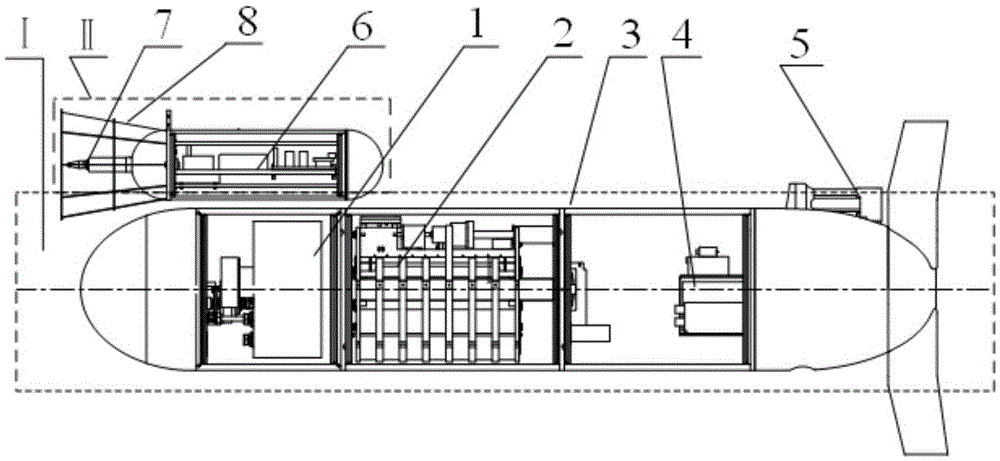

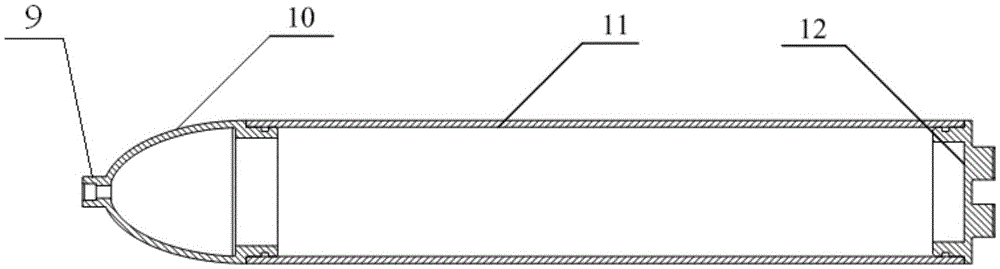

Underwater glider used for measuring marine microstructure

InactiveCN105526917AStrong control abilityEasy to operateOpen water surveyUnderwater equipmentAccelerometerMarine engineering

The invention provides an underwater glider used for measuring a marine microstructure. The underwater glider used for measuring the marine microstructure comprises an underwater glider; a pressure-resistant main body unit is arranged out of the underwater glider; the interior of the underwater glider is successively provided with a buoyancy driving unit, an attitude adjusting unit and a control unit, wherein an electronic compass is arranged in the control unit; a marine microstructure measuring system is detachably installed above the head of the underwater glider; and the external metal shell of the marine microstructure measuring system is composed of a front end housing, a middle shell and a rear end housing, wherein a signal processor equipped with an accelerometer is arranged in the middle shell, and a shear flow probe equipped with a protective cover is installed in the front end housing via a probe groove. According to the invention, the shear flow probe is integrated into the underwater glider, so the underwater glider used for measuring the marine microstructure is capable of measuring marine turbulent flow in a large scale for a long time.

Owner:TIANJIN UNIV

Multi-station paper product embossing molding integrated machine

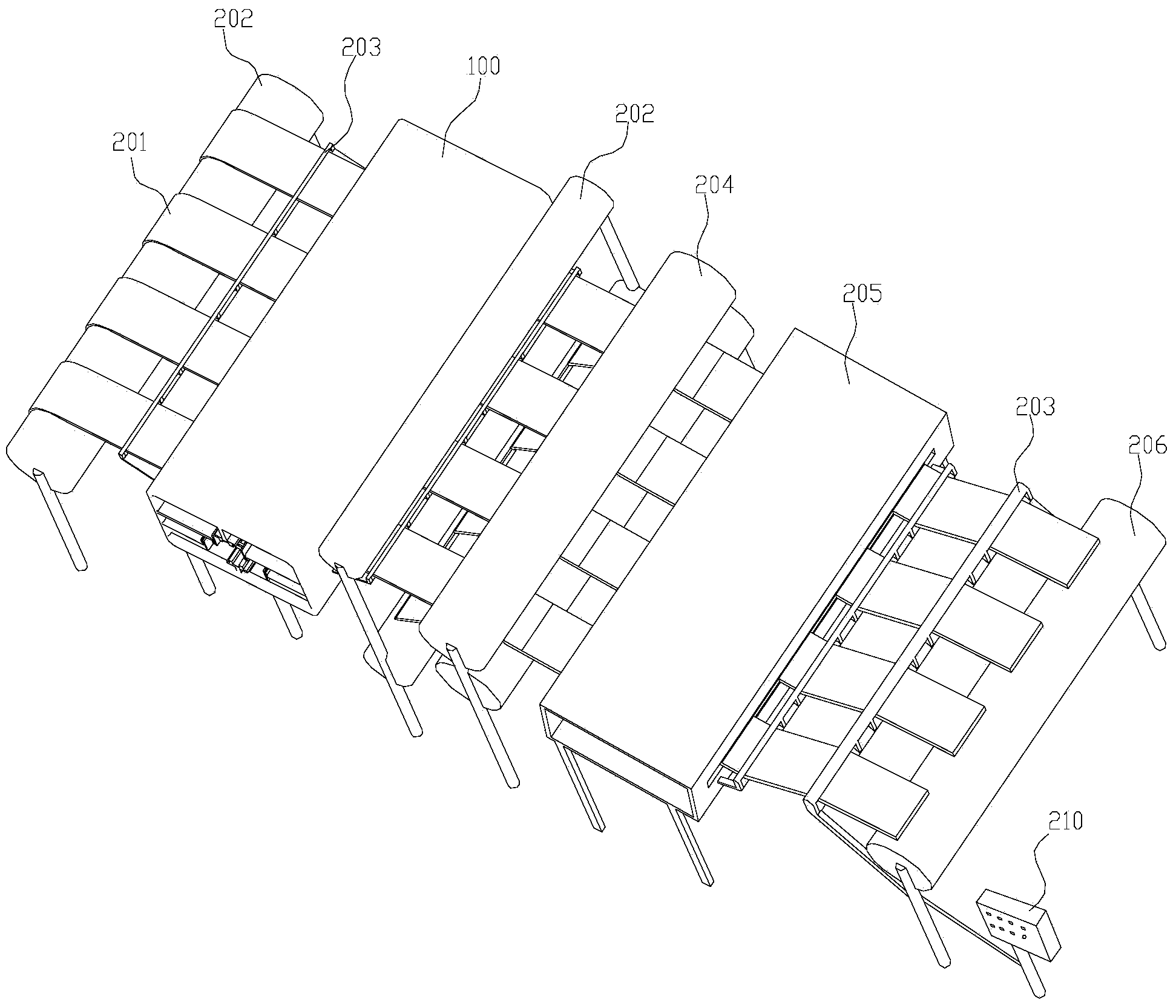

InactiveCN106346843AReduce workloadShorten the timeMechanical working/deformationArticle feedersPulp and paper industryWorkload

The invention discloses a multi-station paper product embossing and forming integrated machine, which comprises a first fixing frame, two supporting rods are fixedly connected between two first supporting plates of the first fixing frame, and the supporting rods A roller is movably connected between them through the shaft hole, a motor is installed on the top of the first fixed frame, the rotating shaft of the motor is connected to the roller through a belt, and a support frame is arranged on one side of the first fixed frame. A second fixed frame is fixedly connected to the support frame, an upper pressure roller and a lower pressure roller are respectively arranged between the two second support plates of the second fixed frame, and a driving device is arranged on one side of the second fixed frame . The invention facilitates the transportation of paper without manual control, which not only reduces the workload of workers, but also makes the processing more precise, reduces the waste of paper products, reduces costs, saves resources, and completes various processes at one time, resulting in higher work efficiency. High, can bring more benefits.

Owner:天津市越胜印刷有限责任公司

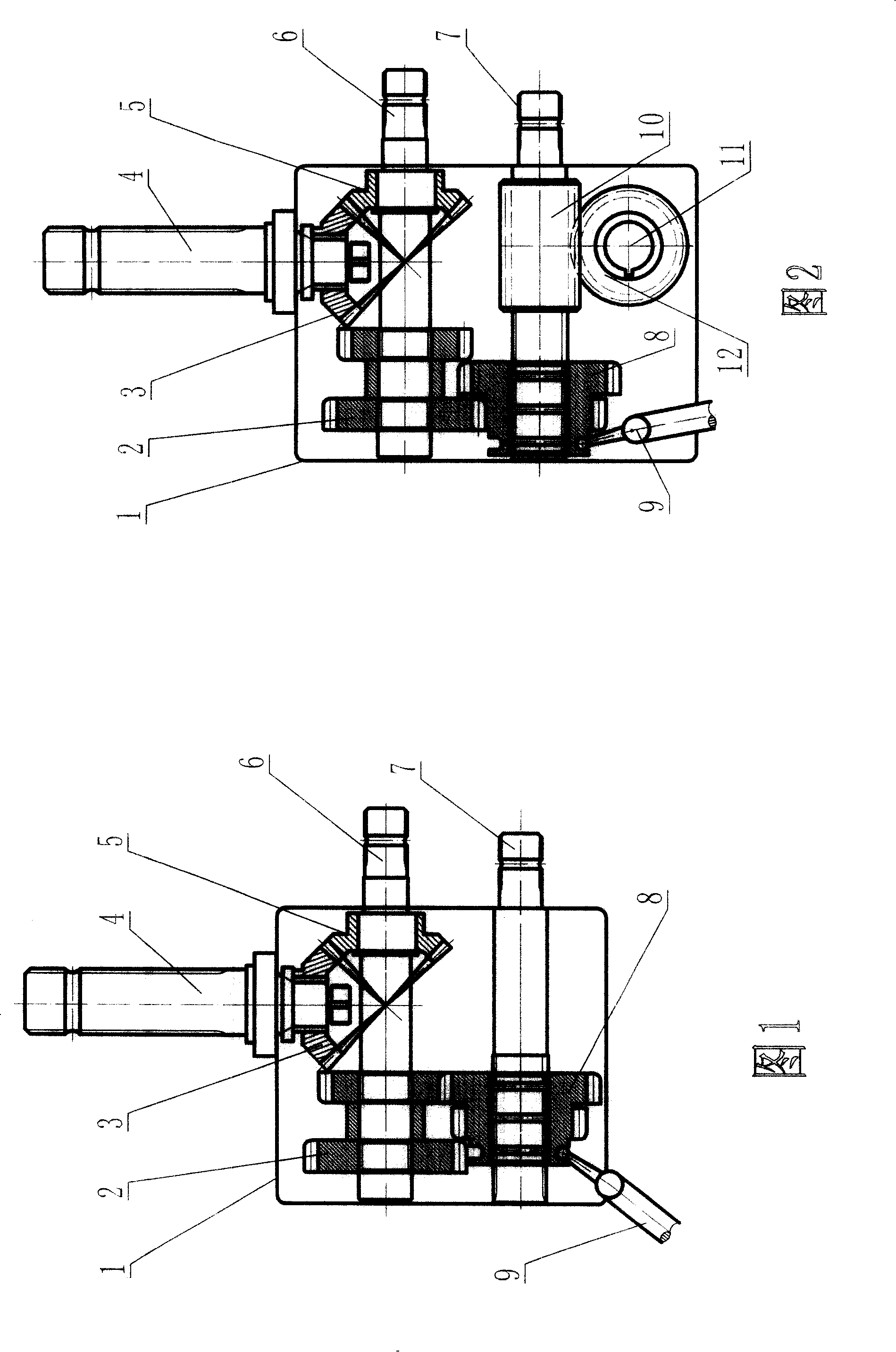

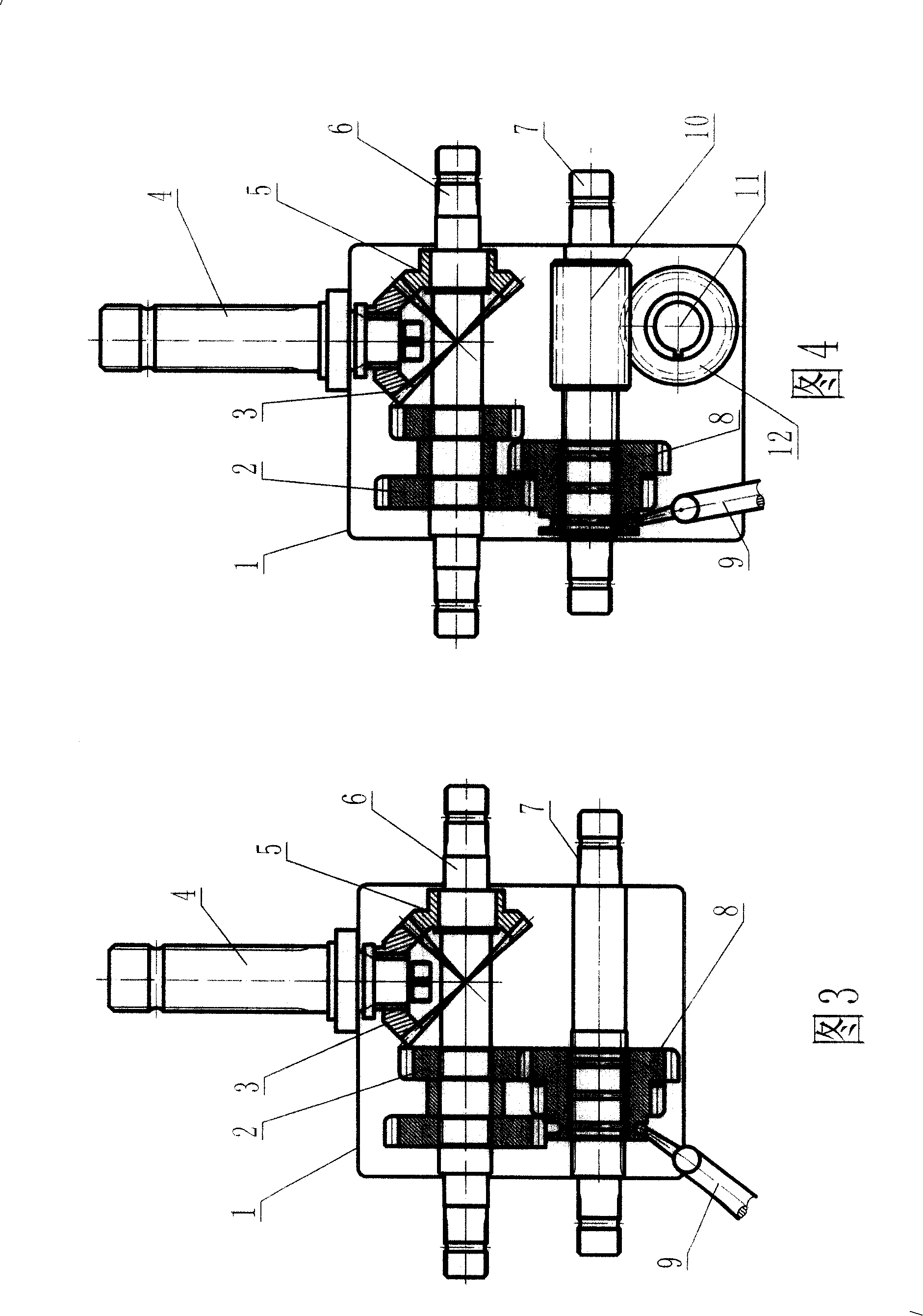

Transmission gear box for wheel type tractor

InactiveCN101210605ASimple structureReduce the use of partsToothed gearingsTractorWorking environment

The invention provides a transmission gear case for wheeled tractors and relates to a gear case working cooperatively with a wheeled tractor. The transmission gear case comprises a case body on which an input shaft, output shafts and a shifting member are arranged, and a bevel gear assembly, a transition gear and a double gear, which are arranged on the shafts. The invention is characterized in that the at least two output shafts are provided, including an output shaft I and an output shaft II, wherein the output shaft I and the output shaft II are arranged in parallel; the input shaft is arranged vertically to the output shafts; and the input shaft, the output shaft I and the output shaft II are in the same plane. In the invention, the output shaft I is used as both the output shaft and a shifting transition shaft, so that the structure is simplified greatly, the consumption of parts is minimized, both the cost and the power consumption are reduced, and the maintenance and repair of the machine is facilitated. The output directions of the two output shafts are different from each other, and the output speed of the output shafts is adjustable, so that the invention can meet the requirement for various agricultural operations under different working environments.

Owner:季顺中

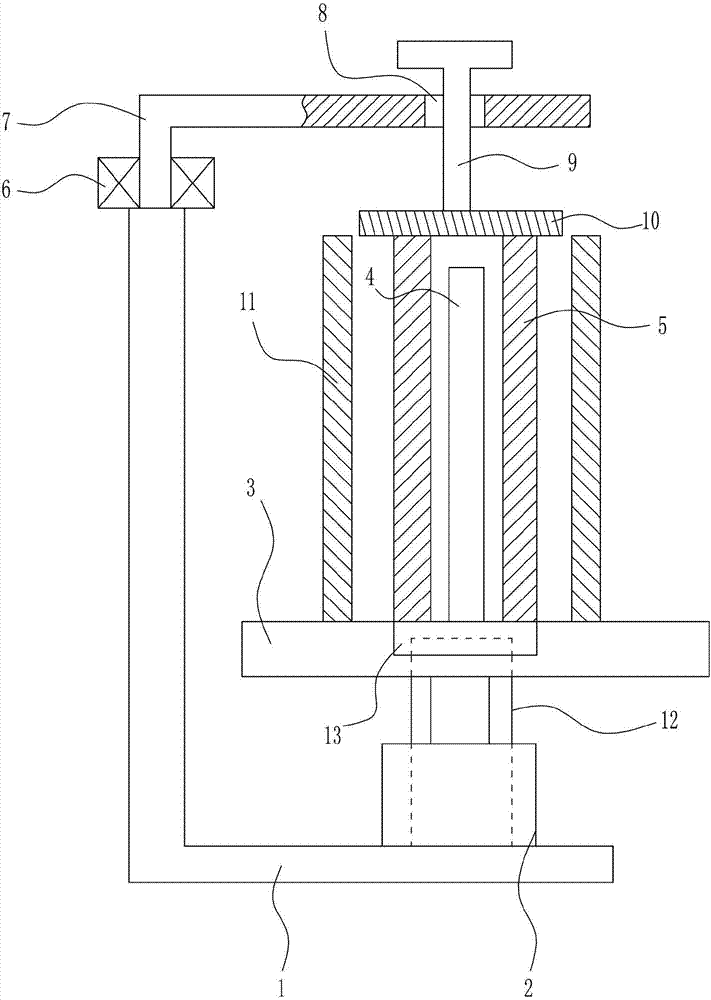

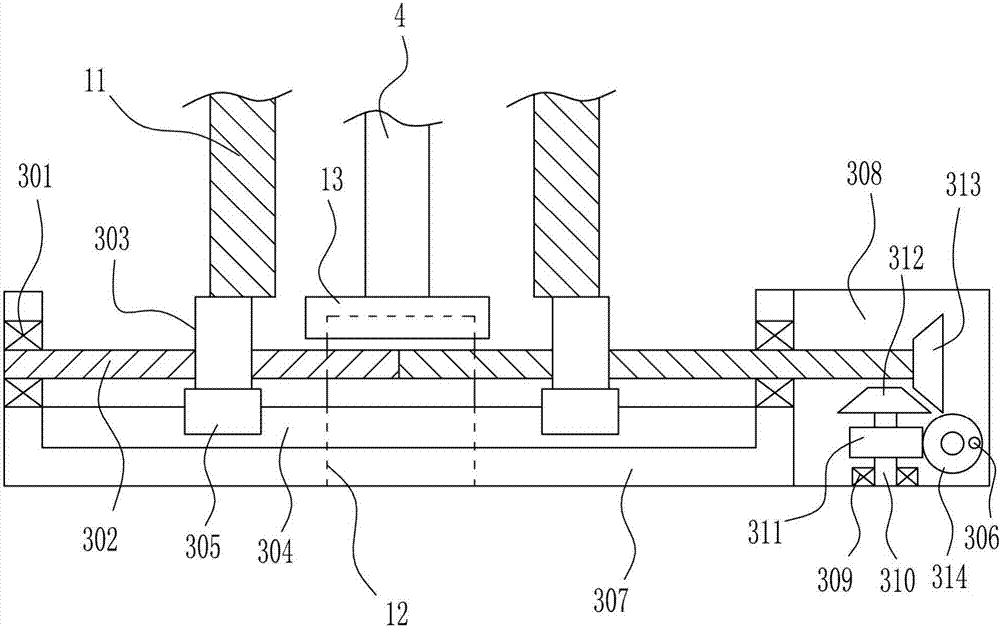

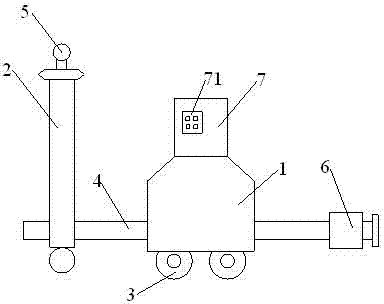

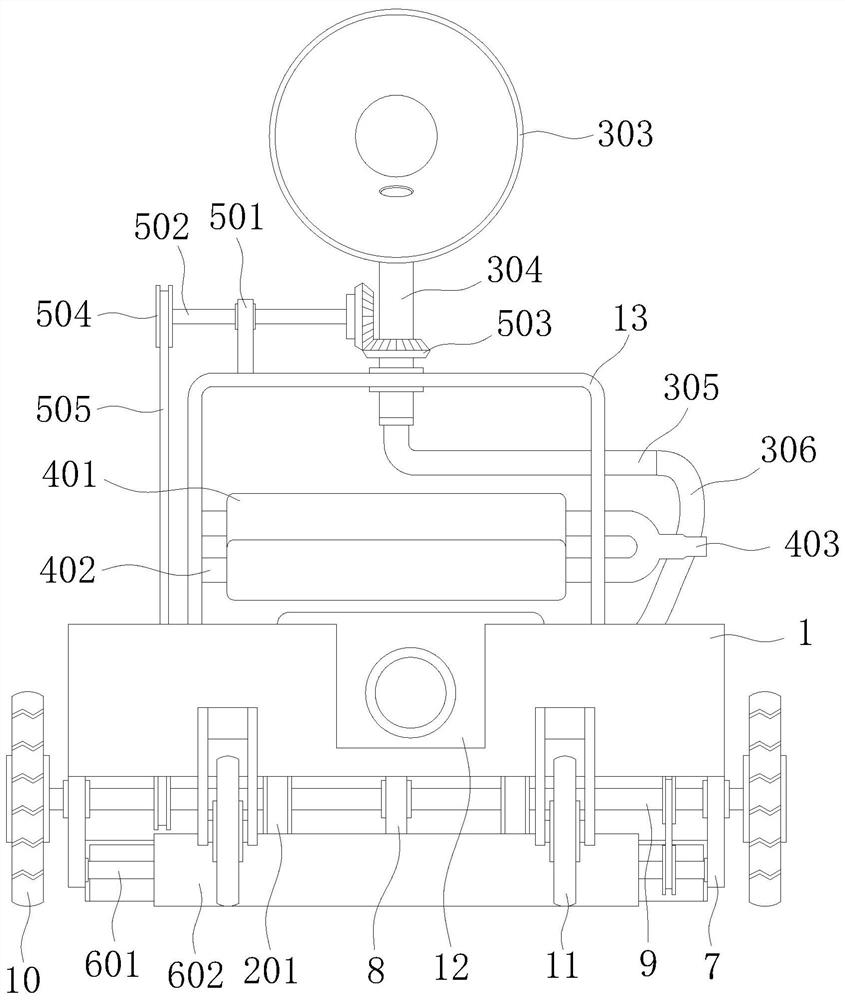

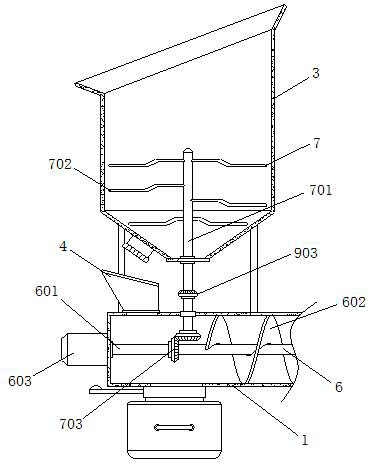

Automatic double-liquid grouting pump

InactiveCN102767511AStable temperature controlStable flow controlPump controlPositive-displacement liquid enginesTemperature controlAutomatic control

The invention discloses an automatic double-liquid grouting pump. The automatic double-liquid grouting pump comprises a pump body and grouting pipelines, wherein the pump body is fixedly arranged on supporting wheels; the bottom ends of the two grouting pipelines are fixedly connected on the bottom end of the pump body by a transmission pipeline; pressure meters are respectively arranged above the grouting pipelines; and a flow rate control valve is arranged on the transmission pipeline between the grouting pipelines and the pump body. Through the mode, the automatic double-liquid grouting pump disclosed by the invention can automatically control a slurry transmission process inside the pump body, and is simpler and more convenient to operate; and the temperature control and flow control of mortar are more stable, therefore, not only can double-liquid grouting be realized, but also single liquid grouping can be realized, the multi-purpose effects realized, and the application scope is expanded.

Owner:常州市众华建材科技有限公司

Curved surface polishing machine

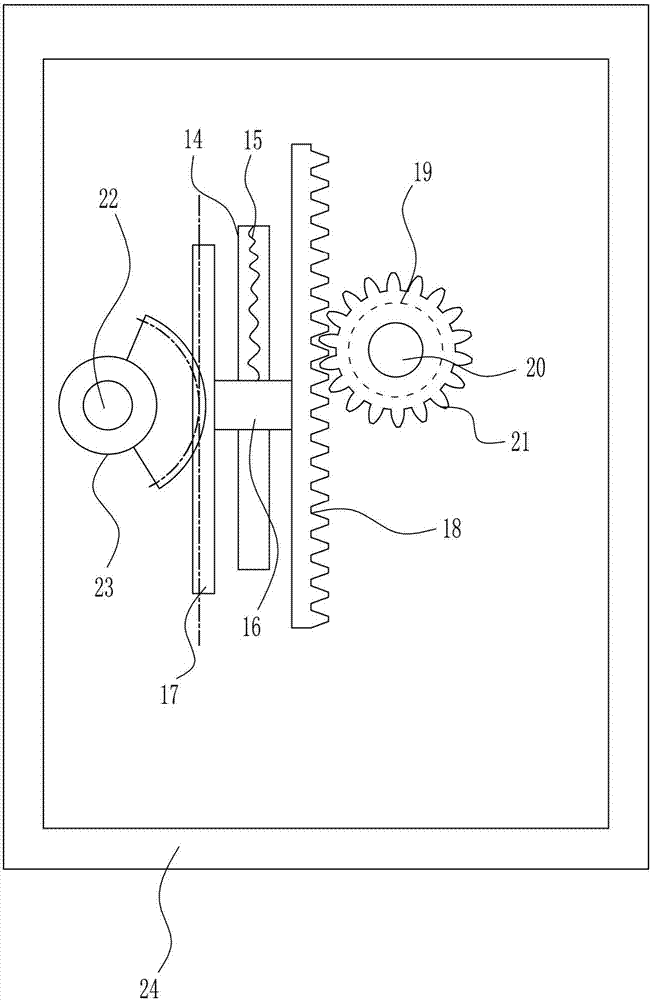

ActiveCN111168563AAct quicklyTo achieve the effect of one machine with multiple functionsLapping machinesLapping toolsPolishingGear wheel

The invention belongs to the technical field of polishing machines, and particularly relates to a curved surface polishing machine. The curved surface polishing machine comprises a body, a fixing device and a workbench; the machine body is provided with a bottom plate for mounting a supporting column, and a cantilever is mounted at the top end of the supporting column; an air cylinder in the fixing device is fixedly connected to the cantilever, a pressing plate is installed on the air cylinder, and reinforcing ribs and suckers are located on the two faces of the pressing plate; and a waste liquid collecting groove is formed in the workbench body, a sliding base is installed in the workbench body in a sliding mode, an annular air bag is located on the sliding base, a motor is fixedly connected to the center of the sliding base, a cam is installed on a motor shaft, a fixing plate is arranged above the inner side of the workbench body, clamping columns are evenly installed in the waste liquid collecting groove, and a grinding device is installed on the fixing plate in a sliding mode and connected with the motor through a first gear and a second gear. According to the curved surface polishing machine, the adaptability to a polishing surface can be improved, the polishing effect and efficiency are improved, the consumption of a polishing solution is reduced, and the cost is reduced.

Owner:佛山市中力金属有限公司

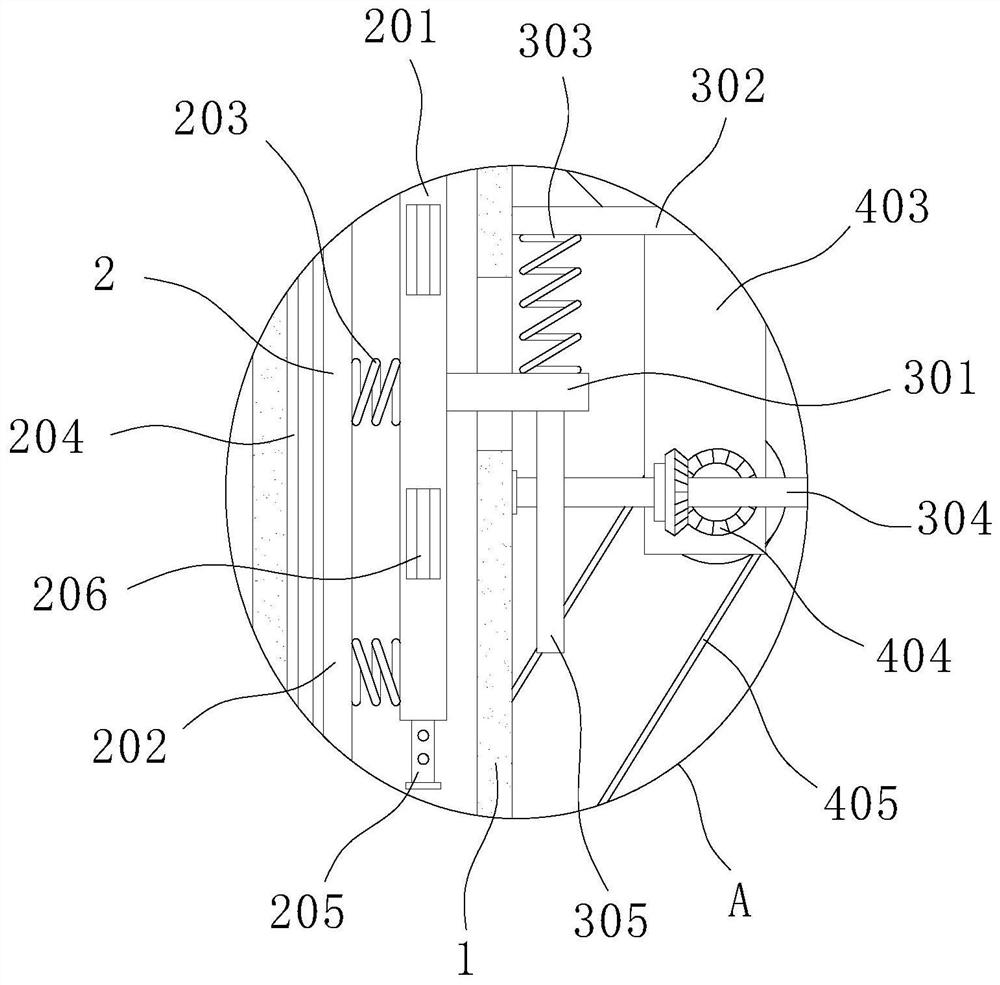

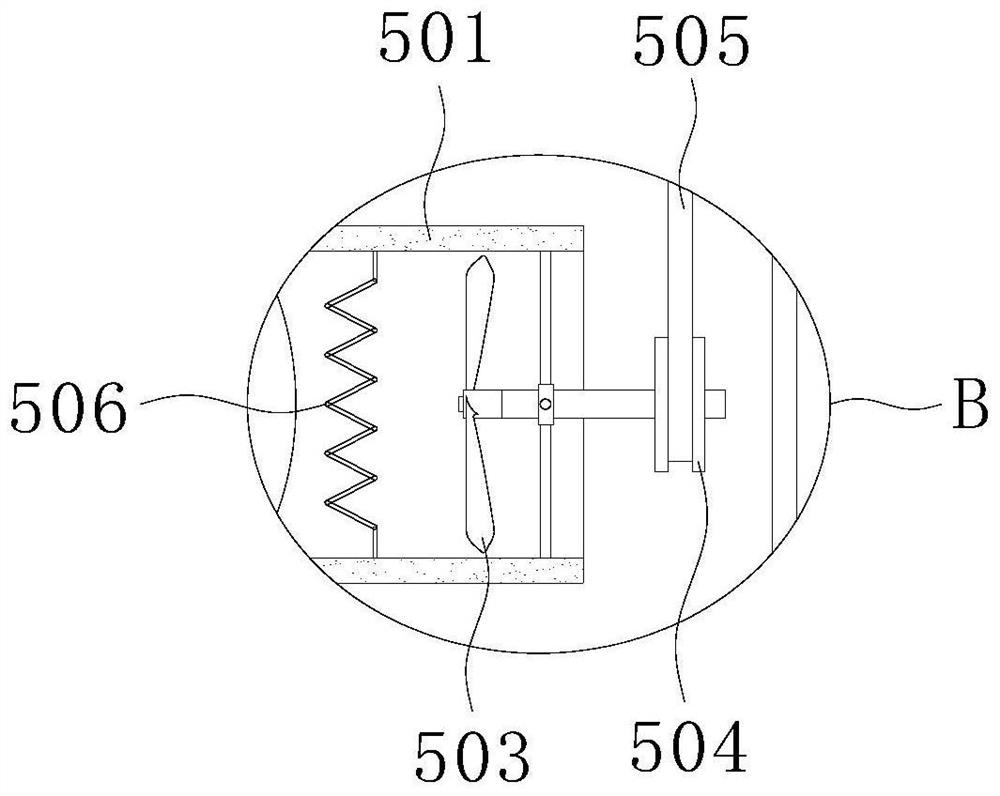

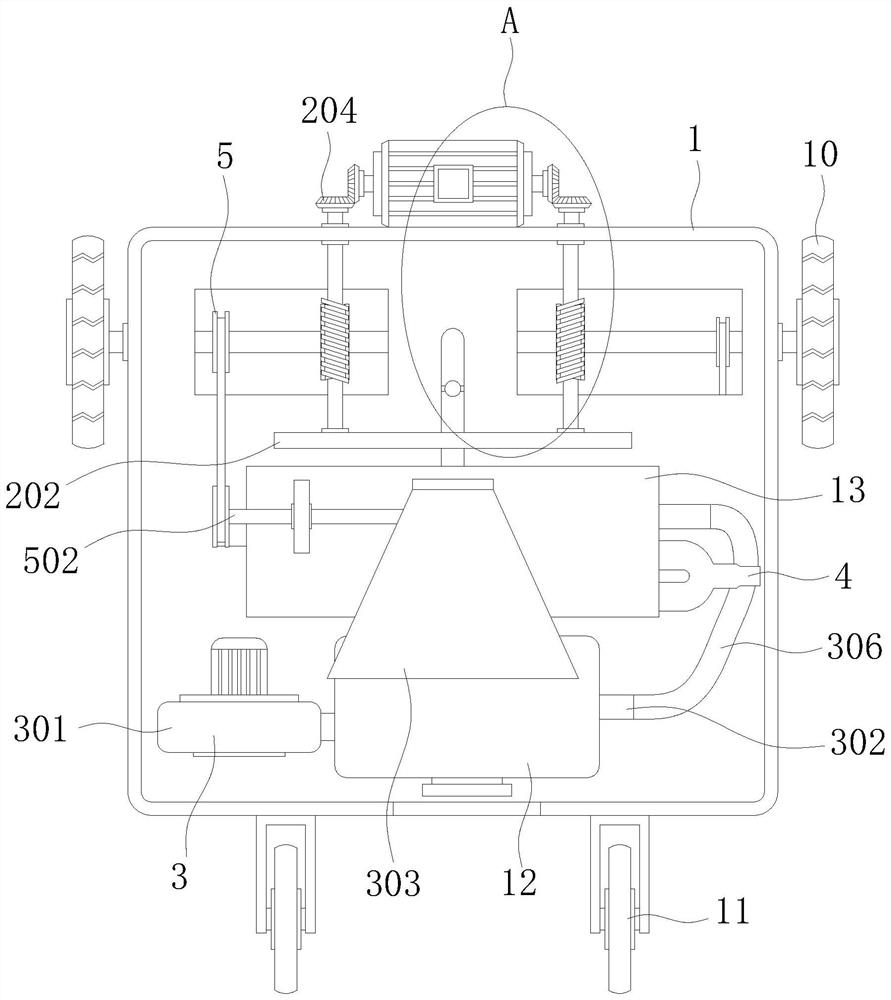

Bottle washing machine with draining and drying functions for rheumatalgia medicinal liquor packaging bottles

ActiveCN112570397AImprove cleaning efficiencyCleaning time is shortDrying solid materials without heatHollow article cleaningEngineeringProcess engineering

The invention discloses a bottle washing machine with draining and drying functions for rheumatalgia medicinal liquor packaging bottles, and relates to the technical field of medicinal liquor packaging. The bottle washing machine with the draining and drying functions for the rheumatalgia medicinal liquor packaging bottles comprises a washing box, a transmission mechanism, a fixing mechanism, a driving mechanism, a washing mechanism and a drying mechanism are arranged on the washing box, a processing box is fixedly installed at an opening in the top of the washing box, and a fixing plate is fixedly installed on the inner wall of the processing box; and a plurality of sets of sleeve rods are rotationally installed on the fixing plate, and cleaning brushes are fixedly installed on the outerwalls of the sections, located above the fixing plate, of the sleeve rods. According to the bottle washing machine with the draining and drying functions for the rheumatalgia medicinal liquor packaging bottles, the multiple sets of medicinal liquor bottles can be cleaned and brushed at the same time, the cleaning time is shortened, the cleaning efficiency of the machine is improved, it can be guaranteed that all sets of medicinal liquor bottles do not collide with one another during cleaning, and a user can conveniently take out the multiple sets of medicinal liquor bottles at the same time after cleaning.

Owner:江西众源药业有限公司

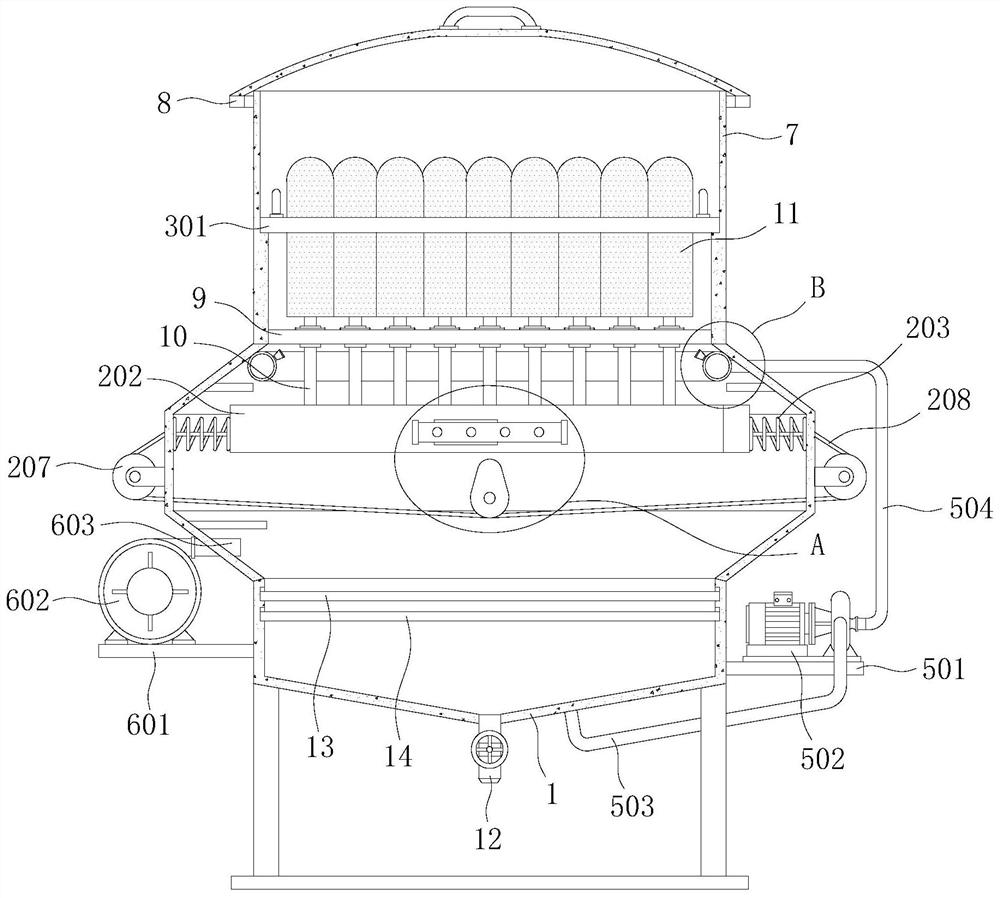

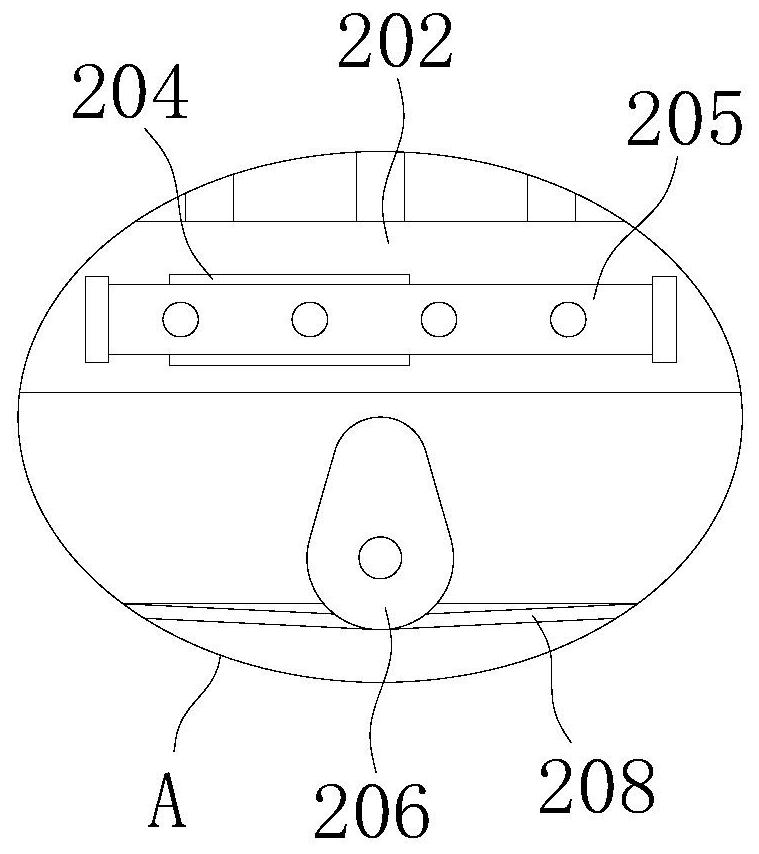

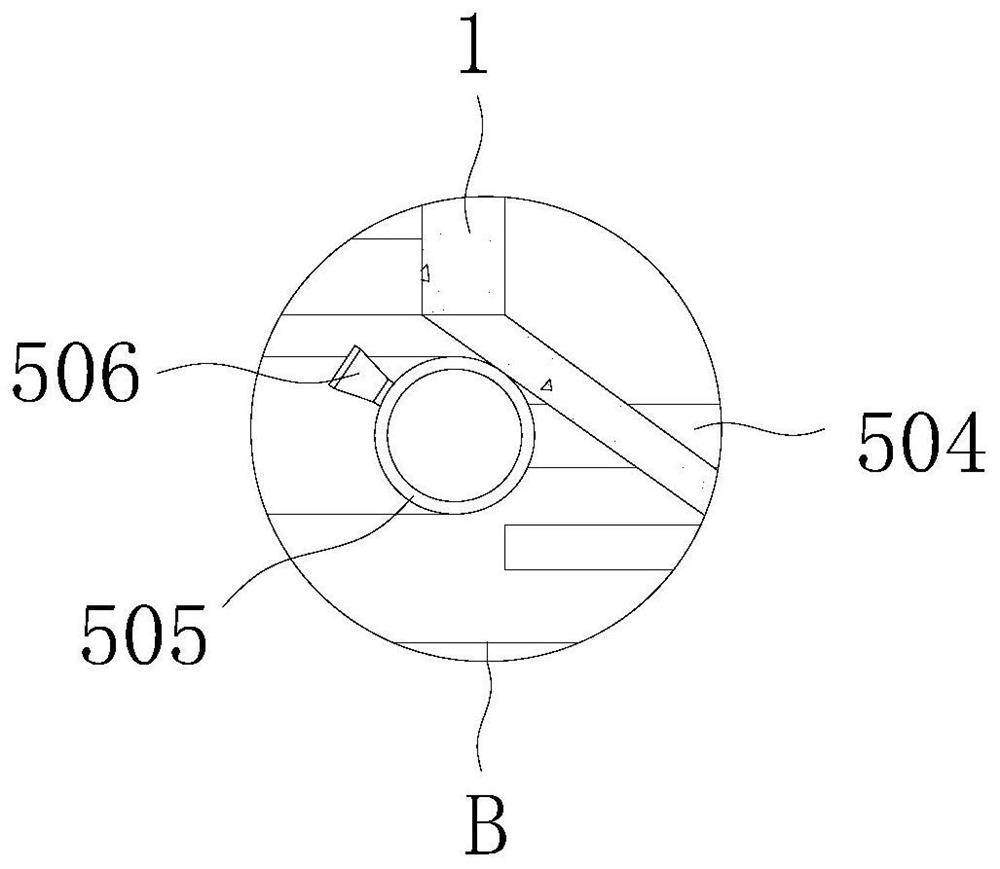

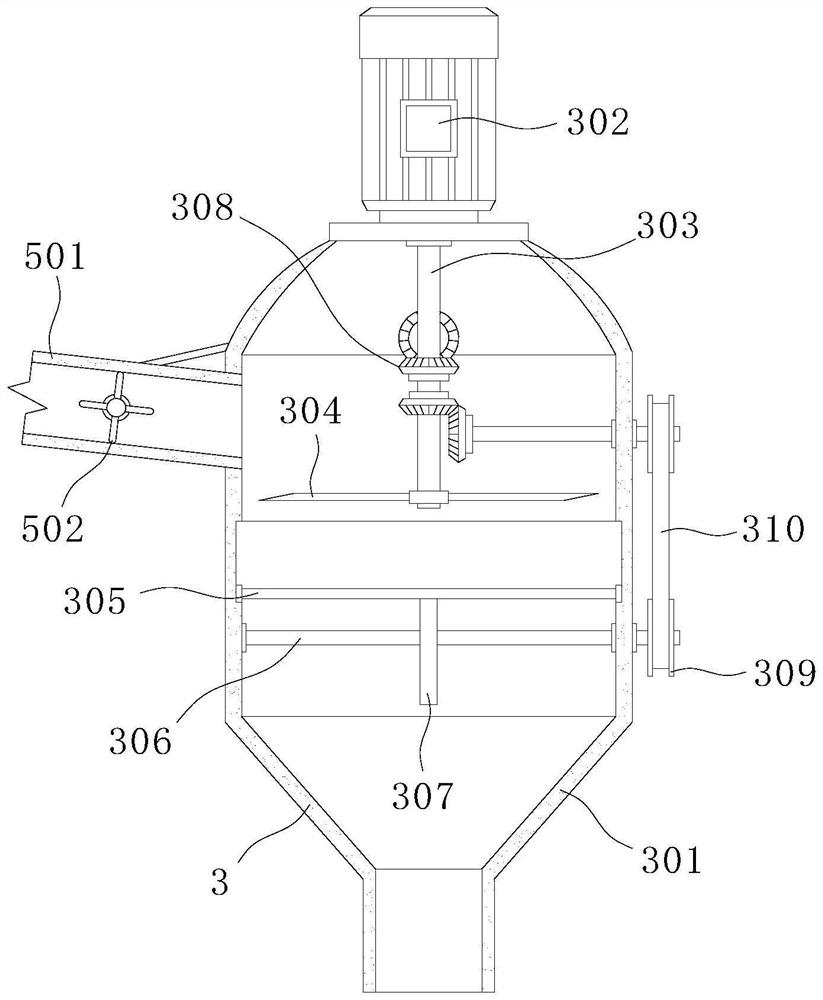

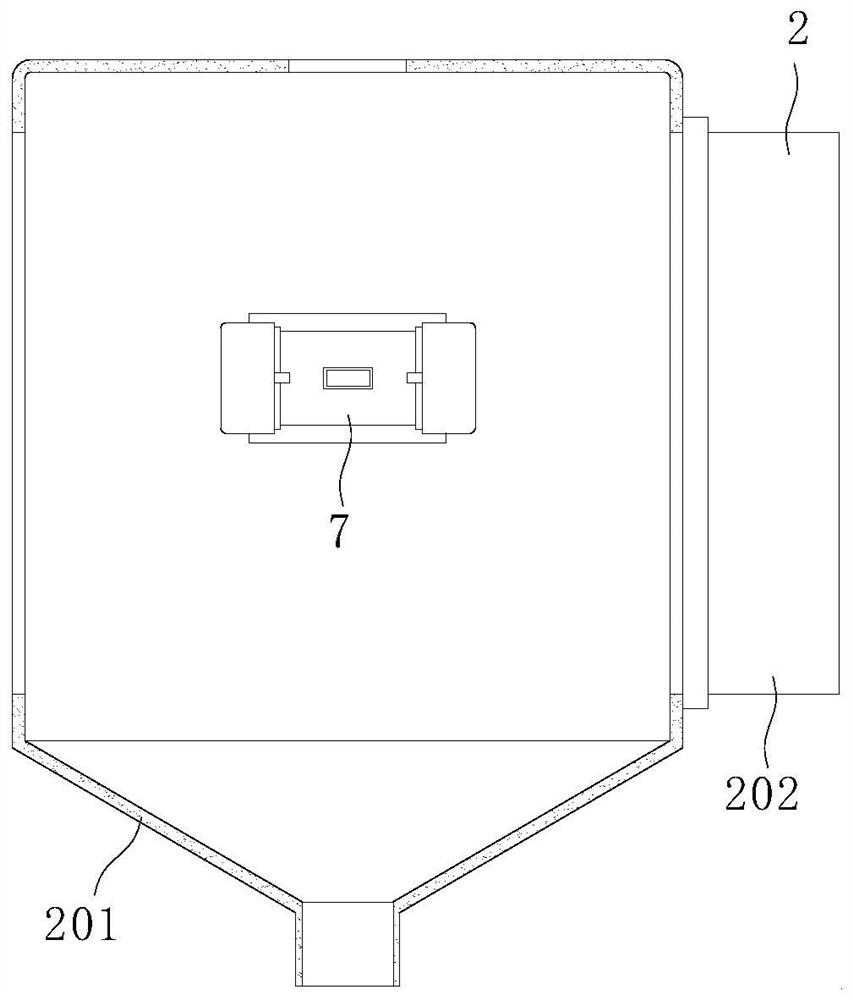

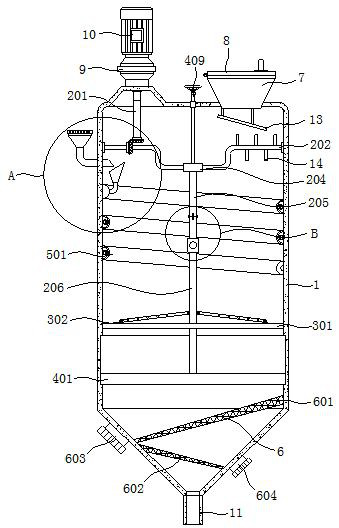

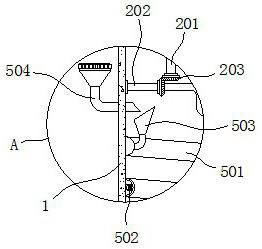

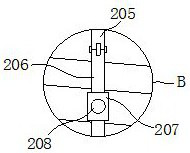

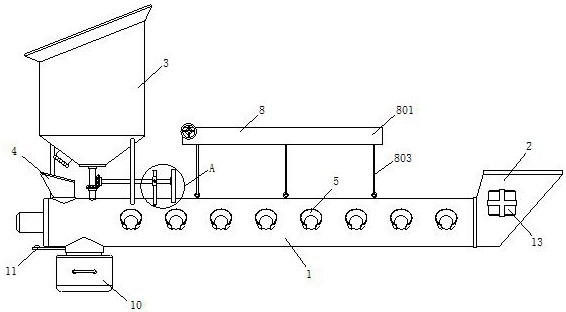

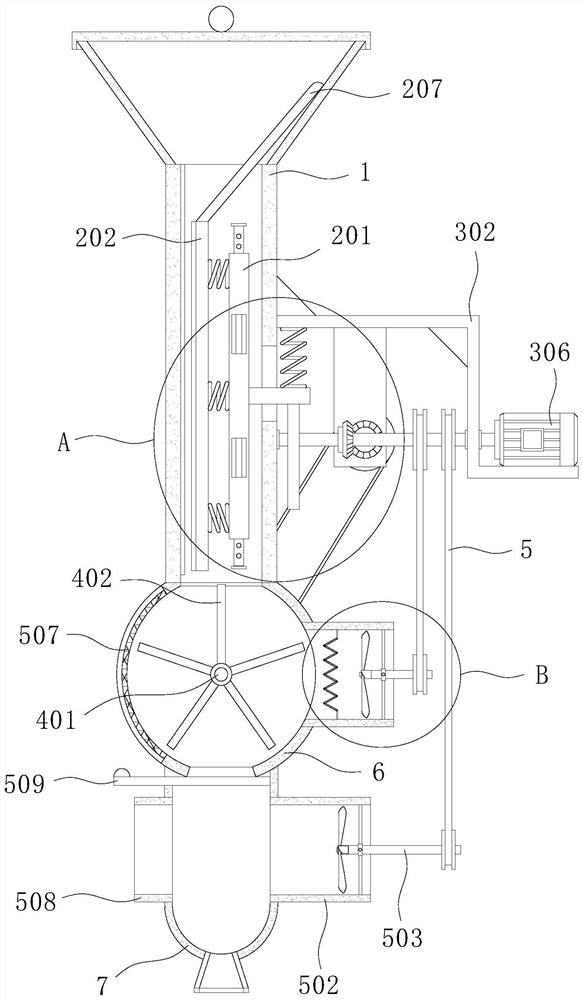

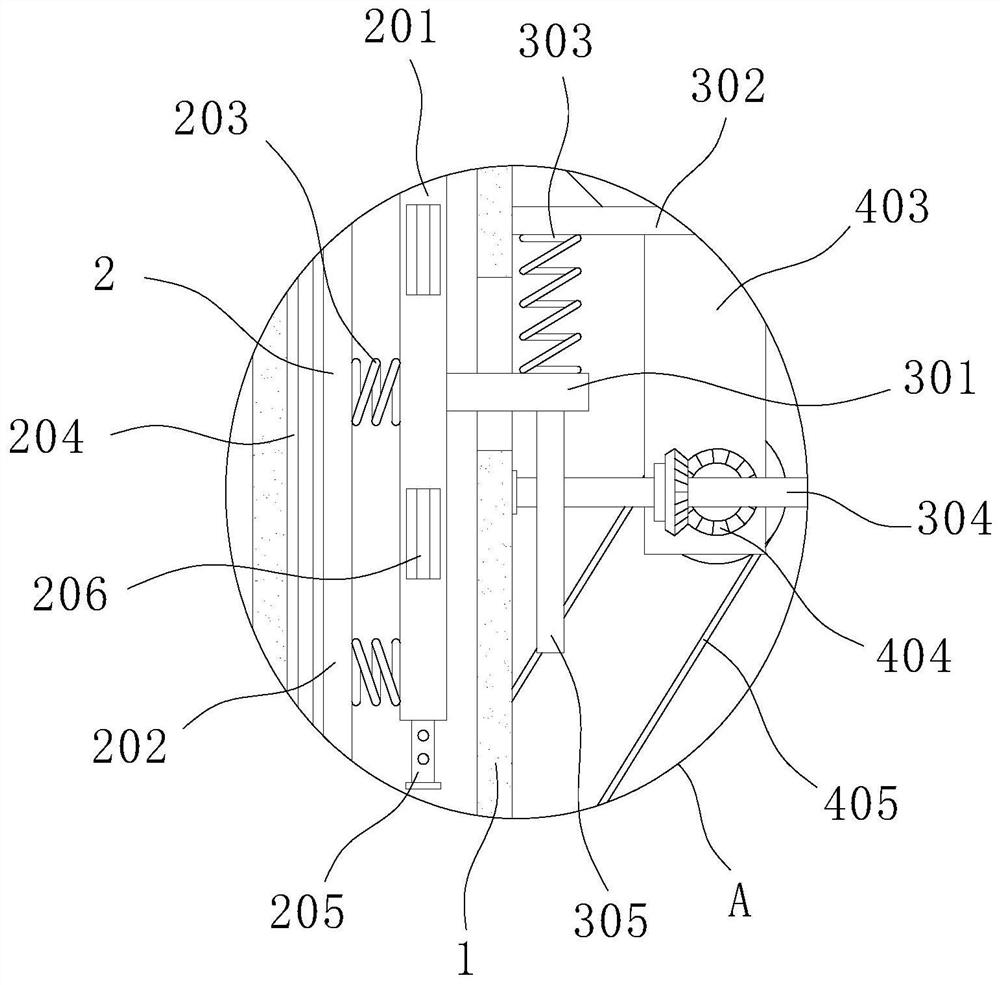

Production and processing technology and device of rice grains

ActiveCN113083402AImprove production and processing efficiencyAvoid mildew and spoilageGrain huskingGrain polishingAgricultural engineeringRice grain

The invention discloses a production and processing technology and device of rice grains, and relates to the technical field of rice processing. The production and processing technology of rice grains comprises three steps of steaming, pressurization and shelling. The production and processing technology of rice grains comprises a processing barrel, a shell grinding mechanism, a driving mechanism, a material turning mechanism and a pneumatic mechanism are arranged on the processing barrel, a drying box is fixedly arranged at an opening in a bottom part of the processing barrel, and an impurity removing box is fixedly arranged at a bottom part of the drying box. The production and processing technology of rice grains wets rice husks outside rice through steam, such that the rice husks are heated to expand, the rice grains are cooled immediately after being wetted through the steam, subsequent separation operation between the rice husks and the rice is facilitated, and a residual situation of the rice husks on the rice grains after husking is relieved. In the production and processing device of rice grains, a grinding and husking component adopts an elastic structure design, such that processing requirements of the rice grains with different grain sizes can be met, husking is thorough, and a breakage rate in a rice processing process is reduced.

Owner:重庆裕丰米业有限公司

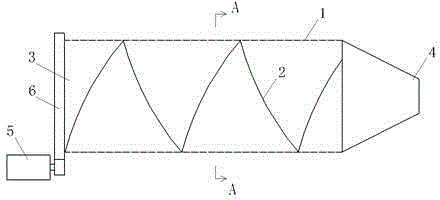

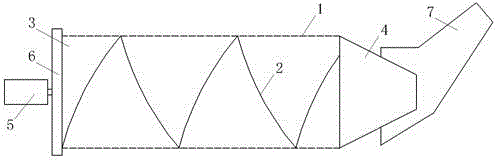

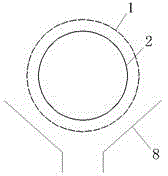

Stripper for pipe with diameter of 300-4000 mm

The invention relates to a stripper for pipes with a diameter of 300-4000 mm, which comprises a supporting mould assembly and a demoulding bench assembly. The supporting mould assembly comprises a limit stop in the front, an arc supporting plate in the middle, and a limit block at the back end; a supporting mould is arranged on a mould bracket; a long crosspiece is fixed on the mould bracket; a protective bracket is vertically fixed on the long crosspiece; tracks are disposed on a demoulding bracket of the demoulding bench assembly; a trolley is located on the tracks; a hoist is disposed at one end of a frame; a wire rope in the hoist pulls the trolley through a fixed pulley at the end part of the frame; a long crosspiece is fixed on the demoulding frame; a protective bracket is vertically fixed on the long crosspiece; and a cylinder assembly is located between the supporting mould assembly and the demoulding bench assembly. The advantages are that: firstly, the security and the rapid demoulding of the mould and the pipe are ensured; secondly, friction of the pipe winding pipe with other objects are ensured to be absent, and the qualified rate of the product is improved; thirdly, the operation is easy, convenient, quick, and safe; and fourthly, adaptation to external diameters without pipes with different sizes is realized, and a multipurpose machine is achieved.

Owner:ZHEJIANG SHUANGLIN ELECTROMECHANICAL TECH

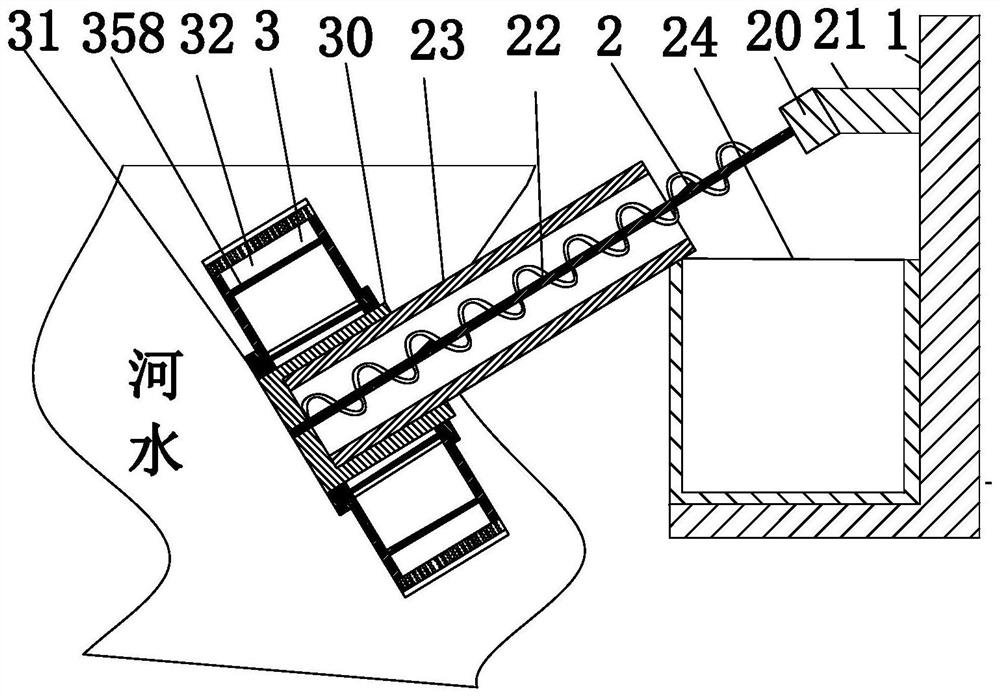

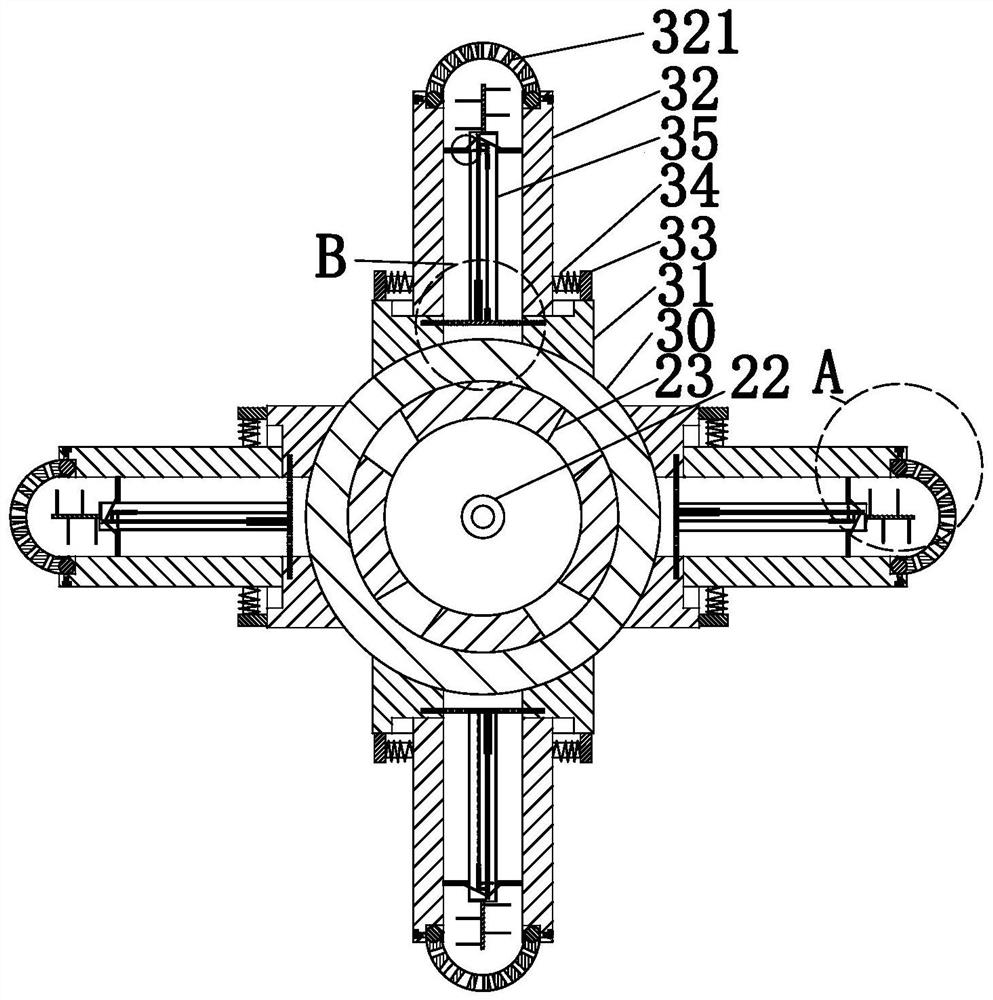

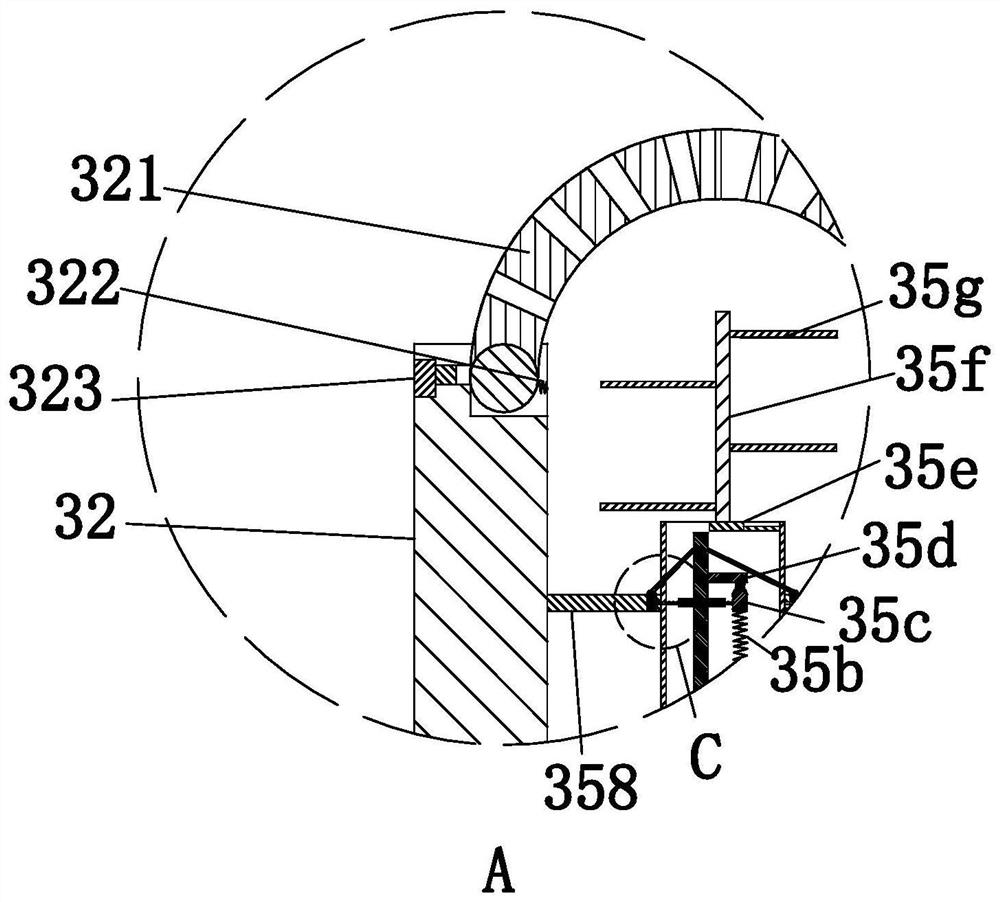

Environment-friendly treatment system for riverway sludge treatment

InactiveCN111762991AGood water flowExpand the scope of salvageSludge treatmentSoil-shifting machines/dredgersSludgeTreatment system

The invention relates to an environment-friendly treatment system for riverway sludge treatment. The system comprises an L-shaped plate, a feeding device and a sludge cleaning device, wherein the L-shaped plate is mounted on the existing working ground, the feeding device is arranged on the inner side wall of the L-shaped plate, and the sludge cleaning device is arranged on the feeding device. When the sludge cleaning device is used for claw fishing of sludge, water in the claw-fished sludge can be extruded, so that sludge cleaned ashore is prevented from being sludge mixed water, namely the sludge cleaning device achieves the effect of multiple purposes. Meanwhile, the sludge cleaning device is internally provided with a stirring rod for stirring, so that the water flow effect is better when water in the sludge is extruded.

Owner:张汀仁

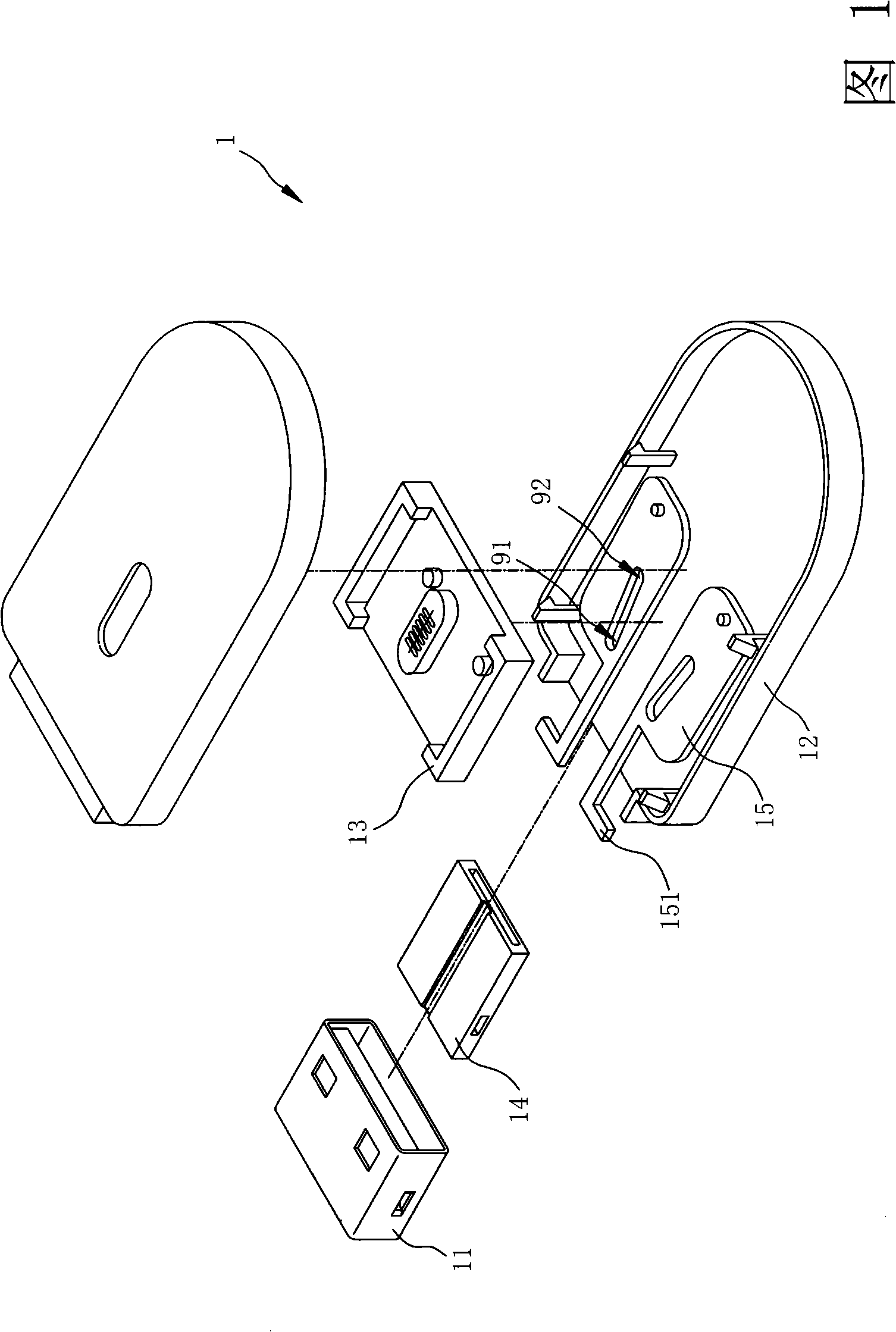

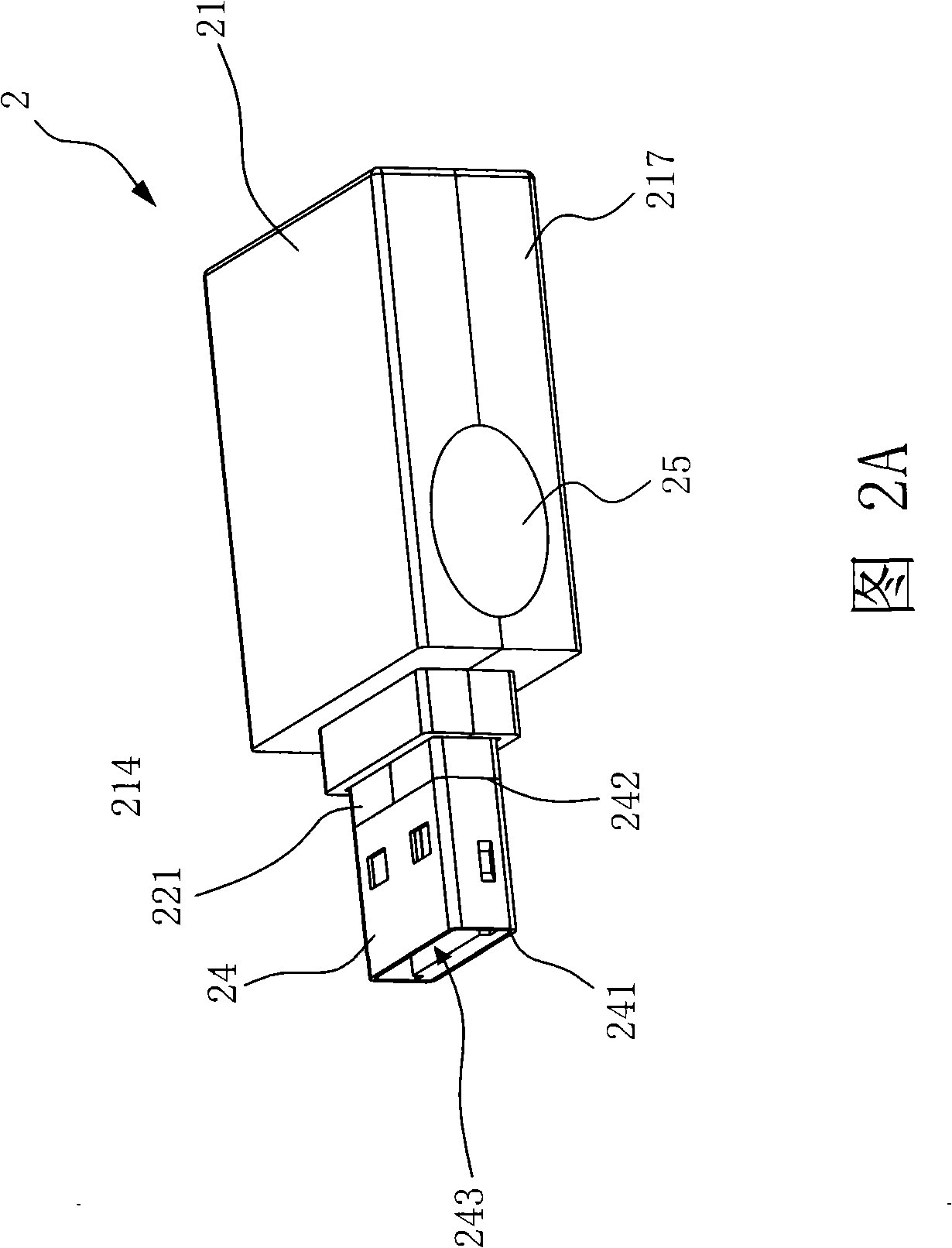

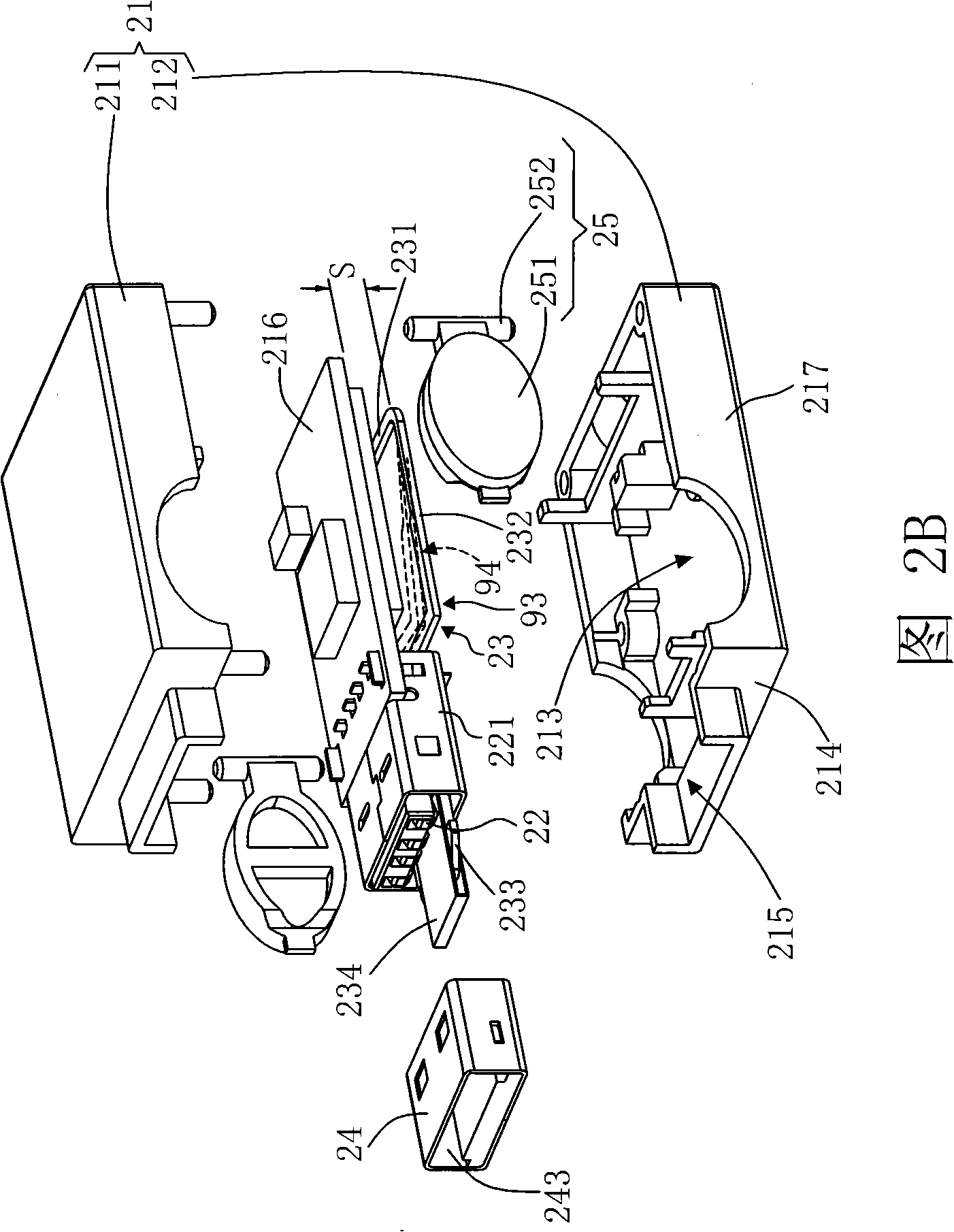

Anti-copy data device with duplexing joint

InactiveCN101316016ATo achieve the effect of one machine with multiple functionsReach a lockIncorrect coupling preventionBody contactUSB

The invention provides an anti-copy data device with a duplex joint, comprising a body, a plurality of telecommunication terminals, a connecting hook part and a connection-peg. The body is internally provided with a circuit substrate which can be used for memorizing and reading electronic data. A plurality of telecommunication terminals are connected with the substrate and arranged on one end surface of the body. The connecting hook part is arranged on the end surface. The connection-peg is internally provided with a plurality of conductive bodies of two telecommunication conductive end surfaces; furthermore, each conductive body is a certain distance away from a slot. When the connecting hook part is arranged on the first position, the connection-peg is connected with the body; furthermore, a plurality of conductive bodies contact with a plurality of telecommunication terminals one by one to form the telecommunication conduction; when the connecting hook part is arranged on the second position, the connection-peg is separated from the body; furthermore, the butting connection of the connection-peg and a USB port is carried out so as to seal the USB port.

Owner:GUANN TAU INT +1

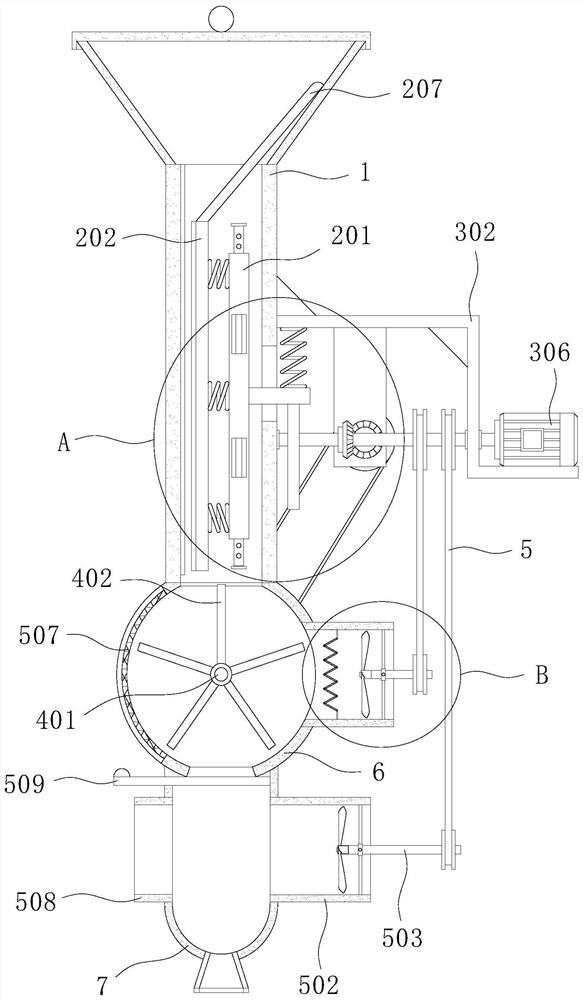

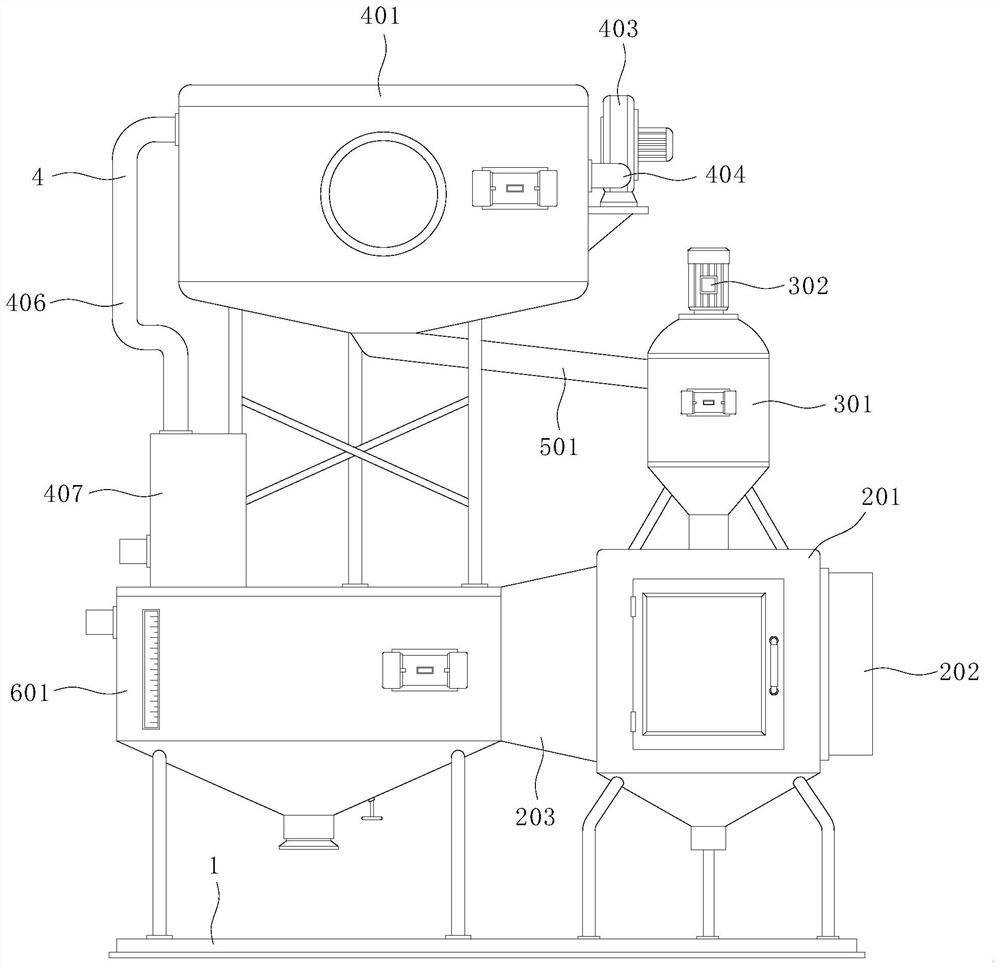

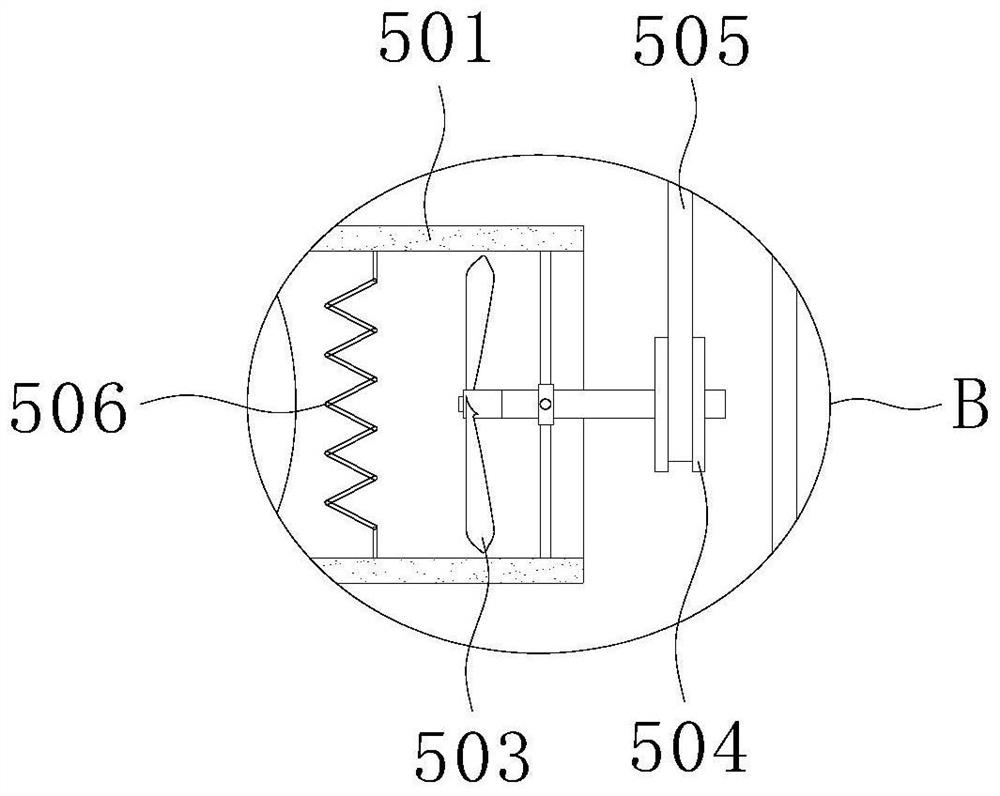

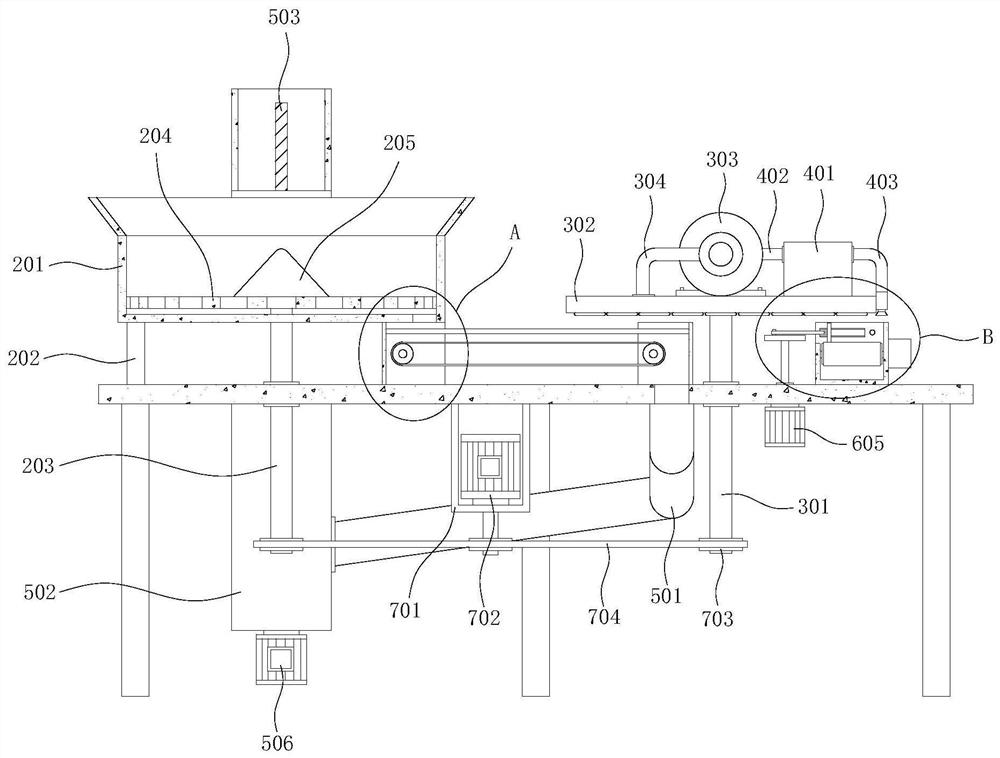

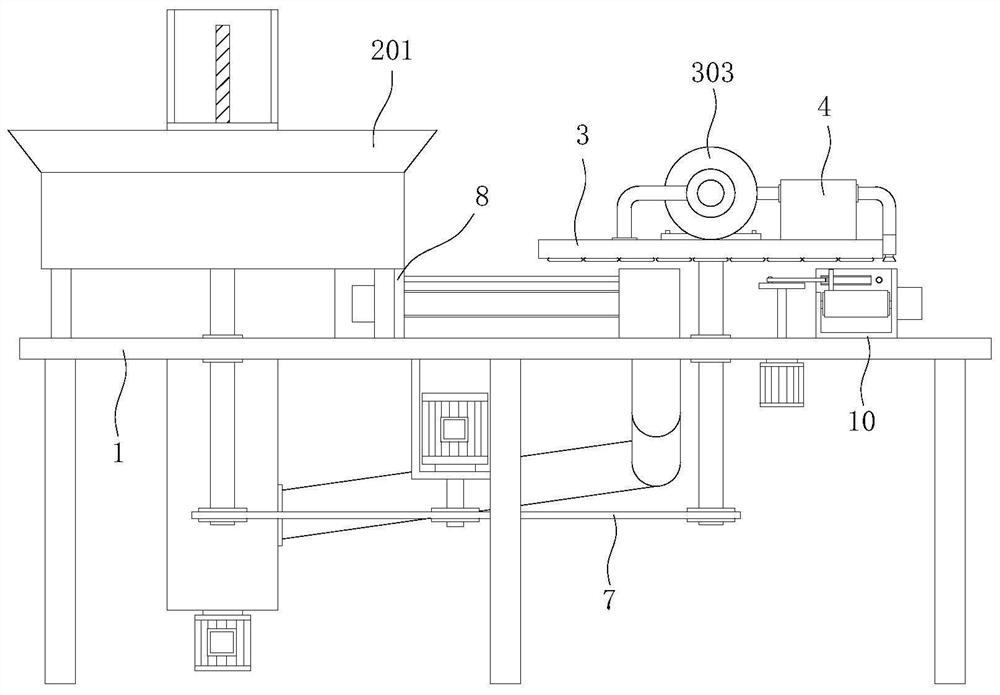

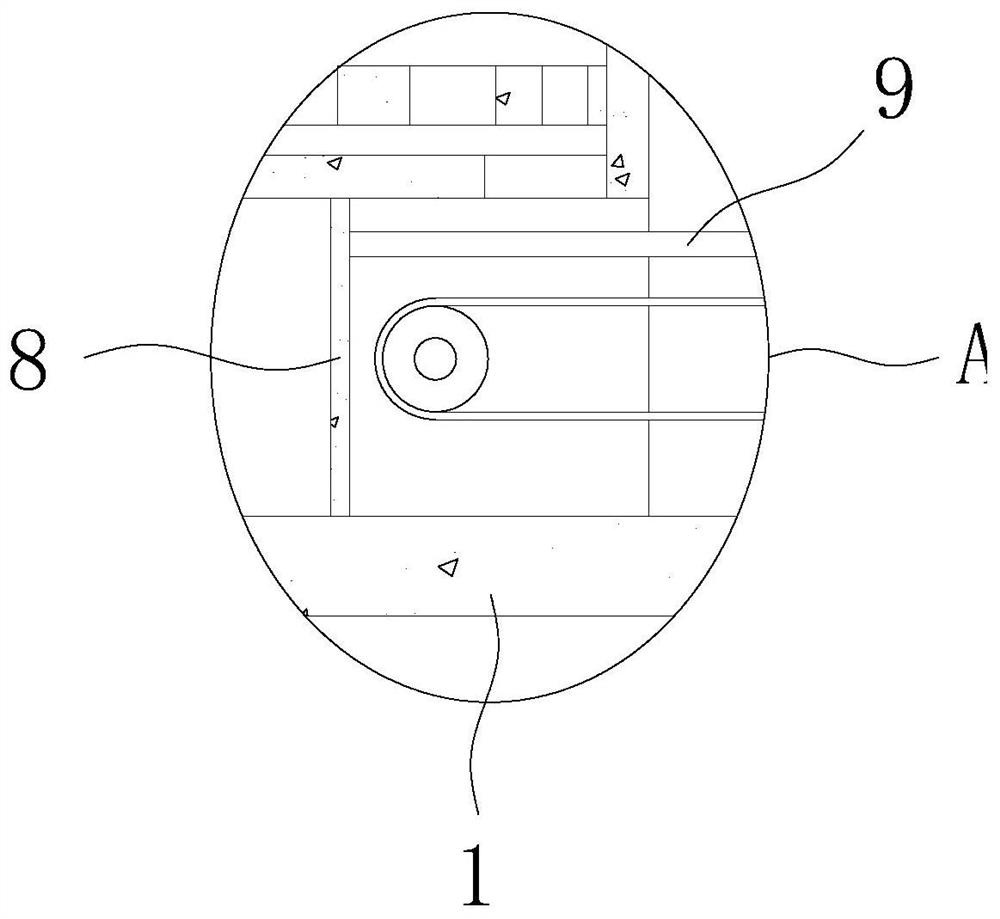

High-purity calcium hydroxide preparation process and equipment

InactiveCN113247934APrecise moisture controlQuality improvementCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideInorganic chemistry

The invention discloses a high-purity calcium hydroxide preparation process and equipment, and relates to the technical field of high-purity calcium hydroxide processing. The high-purity calcium hydroxide preparation process comprises the four steps of crushing, digesting, water distribution and winnowing. The high-purity calcium hydroxide preparation equipment comprises a base; a winnowing mechanism and an output mechanism are arranged at the top of the base; a processing mechanism is arranged at the top of the winnowing mechanism; a feeding mechanism is arranged at the top of the output mechanism; and a discharging mechanism is arranged between the processing mechanism and the feeding mechanism. According to the high-purity calcium hydroxide preparation equipment, calcium hydroxide can be crushed and screened before winnowing, so that blocky calcium hydroxide is pulverized, the blocky calcium hydroxide is prevented from being cleaned as impurities due to the gravity effect in the winnowing process, and unnecessary economic losses are reduced; and calcium hydroxide to be winnowed is fed in a negative pressure mode, and compared with a manual feeding mode, the operation is easy, high efficiency and practicability are achieved, and the production and processing efficiency is improved.

Owner:江西福得利碳酸钙业有限责任公司

T-shaped railway turnout maintenance tool

InactiveCN104120673ATo achieve the effect of one machine with multiple functionsEasy to operateRailway cleaningCouplingEngineering

The invention discloses a T-shaped railway turnout maintenance tool which comprises a maintenance tool body and a tool head. The maintenance tool body comprises a T-shaped split type casing. One end of a transverse part of the T-shaped split type casing is a transverse work end. A longitudinal part of the T-shaped split type casing is a longitudinal work end. Central lines of the two work ends are mutually perpendicular. A motor is installed in the T-shaped split type casing and connected with one ends of crankshafts through first couplers. The other ends of the crankshafts are connected with one ends of rotating shafts through second couplers. The other ends of the rotating shafts extend out of the transverse work end of the T-shaped casing and are connected with a second clamping head. The crankshafts are installed on a second bearing and a fifth bearing. The rotating shafts are installed on a third bearing and a fourth bearing. The power output end of the motor is installed on the first bearing in the T-shaped split type casing. The T-shaped railway turnout maintenance tool solves the problems that when an existing tool and an existing method are used for cleaning and maintaining a turnout, the efficiency is low and use is not safe.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Multifunctional portable power source

InactiveCN104836275AEffective protectionIncrease currentBatteries circuit arrangementsElectric powerVideo playerLiquid-crystal display

The invention relates to a multifunctional portable power source, and the main body of the multifunctional portable power source is a box. The multifunctional portable power source is characterized in that the box is provided with a lithium battery, a battery protection circuit, a switching circuit, a microprocessor and an indication lamp. The box is also provided with a touch screen, a liquid crystal display, an input interface, a USB interface and a Flash memory. The multifunctional portable power source is prevented from being overcharged and over discharged during the charging process, the circuit is effectively protected, the current and power of the lithium battery are prevented from being too high during the charge and discharge process, the multifunctional portable power source is combined with a video player and an audio player at the same time, a user can use the multifunctional portable power source conveniently, and the multifunctional portable power source can be used in many aspects, and is novel in design, and has diversified functions.

Owner:BENGBU HUIHONG ELECTRONICS TECH

Automatic chip cleaner of full-functional machine tool

InactiveCN101786252BSolve the problem of optional chip conveyorIncrease financial pressureConveyorsMaintainance and safety accessoriesNumerical controlDrive shaft

The invention discloses an automatic chip cleaner of a full-functional machine tool, which is complete equipment of various digital control machine tools, processing centers, specialized machine tools and assembly lines. The automatic chip cleaner of the full-functional machine tool provided by the invention can complete the chip delivery work in any state and has high efficiency and safe and reliable performance. The automatic chip cleaner of the full-functional machine tool comprises a machine frame, wherein a motor is connected with a driving shaft above the machine frame; a flight conveyor is arranged between the driving shaft and a support shaft below the machine frame; the flight conveyor consists of link joints, chains and hinge pins and the link joints are connected in a mode of folding plates; and adjusting stabilizers are arranged outside the machine frame. The automatic chip cleaner of the full-functional machine tool has a structural key point that the link joints are provided with W-shaped chip push plates vertical to the link joints.

Owner:沈阳华邦通用机械技术开发有限公司

Leftover material recycling device for textile production

InactiveCN112404039AExpand the scope of recyclingImprove recycling effectCarpet cleanersFloor cleanersWoven fabricYarn

The invention discloses a leftover material recycling device for textile production, and relates to the technical field of textiles. The leftover material recycling device for textile production comprises a box body, wherein a driving mechanism, an absorbing mechanism, a processing mechanism, a rotating mechanism and a sweeping and recycling mechanism are arranged on the box body; a connecting plate and two sets of bearing plates are welded and mounted on the outer surface of the bottom of the box body; a set of transmission rods are rotatably mounted on each of the two sets of bearing plates;one end of each transmission rod is rotatably mounted on the outer wall of the connecting plate; and a travelling wheel is welded and mounted at the other end of each transmission rod. The leftover material recycling device for textile production not only can recycle cotton fibers and silk threads floating in air and leftover materials such as rags and broken yarns accumulated on the ground in atextile workshop, but also can clean double surfaces of a textile penetrating through two sets of processing barrels, and recycles thread residues adhered to the textile into a collecting box, so thatthe using range and the using scene are expanded.

Owner:青岛爱婴坊商贸有限责任公司

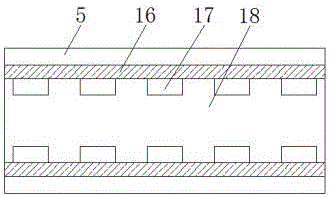

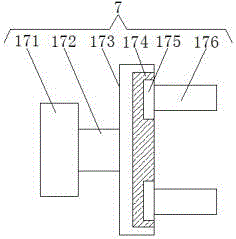

Glue spraying box and glue spraying device comprising same

ActiveCN104043565AImprove process precisionIncrease profitLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a glue spraying box and a glue spraying device comprising the same. The glue spraying box comprises a box body, a first glue spraying group and a second glue spraying group; the box body is provided with a through hole through which base cloth passes; the box body is internally provided with a first guide rail and a second guide rail respectively along the through hole up and down; the first guide rail is provided with the first glue spraying group capable of moving telescopically; the second guide rail is provided with the second glue spraying group capable of moving telescopically. The glue spraying box has the functions of positioning glue spraying functions on a single surface, double surfaces or local regions; the glue spraying device sequentially comprises a charging roller, a glue spraying box body, a fit press roller, a curing device, a material collecting roller and a control cabinet; the charging roller, the glue spraying box body, the fit press roller, the curing device and the material collecting roller are respectively and electrically connected with the control cabinet. The glue spraying box and the glue spraying device have the characteristics of automatic positioning glue spraying, high glue utilization ratio and stable performances, have multiple functions of coating beautifying coatings on the single surface or the double surfaces, fitting the single surface or the double surfaces, and the like, and can meet multiple production requirements for production of clothes and auxiliary materials for cloth, stripe trademarks, ropes and the like.

Owner:广东康派环创科技有限公司

Purifying and drying integrated spraying device for intelligent building materials

InactiveCN113369056AAesthetic issuesAvoid damageSpray boothsArchitectural engineeringStructural engineering

The invention discloses a purifying and drying integrated spraying device for intelligent building materials, and relates to the technical field of intelligent buildings. The purifying and drying integrated spraying device for the intelligent building materials comprises a working box, wherein a mounting plate is welded to the outer surface of the top of the working box; a paint spraying box and a paint box are welded to the outer surface of the top of the mounting plate; two sets of chutes are formed in the mounting plate; sliding blocks are slidably installed in the two sets of chutes; and two sets of paint spraying pipes are arranged in the paint spraying box. According to the device, paint raw materials can be driven to be stirred while uniform paint spraying is conducted, the situation that the paint raw materials are caked under the condition of static settlement is avoided, then the influence of caked paint spraying on the intelligent building materials during paint spraying is avoided, unforeseen circumstances are avoided, the effect that one machine has multiple purposes is achieved, and energy waste is effectively avoided, so that the device is more environment-friendly.

Owner:南京鹏玉工程设备有限公司

Frying machine for processing special-flavor lima beans

ActiveCN112616866ASolve the problem of deteriorating frying qualityReduce manufacturing costSievingScreeningProcess engineeringLima beans

The invention discloses a frying machine for processing special-flavor lima beans, and relates to the technical field of lima bean processing. The frying machine for processing special-flavor lima beans comprises a frying tank, wherein a transmission mechanism, a dispersing mechanism, a material containing mechanism, a heating mechanism and a material receiving mechanism are arranged on the frying tank; a feeding hopper is fixedly arranged on the top of the frying tank; one end of the feeding hopper extends into the frying tank; and a hopper cover is hinged to a top opening of the feeding hopper. The frying machine for processing special-flavor lima beans has the advantages that the lima beans bonded into balls can be dispersed; the problem of frying quality reduction due to lima bean bonding is solved; meanwhile, the lima beans can be in sufficient contact with oil; the frying efficiency is improved; the energy consumption is reduced; the contact area of the oil and an electric heating wire can also be increased; the preheating efficiency is improved; the preheating waiting time is further shortened; the manufacturing and operation cost of the frying machine is reduced; and the popularization and the use are facilitated.

Owner:重庆芝麻官实业股份有限公司

Bowl-shaped ornament polishing machine

InactiveCN105328558AReduce labor intensityPolished evenlyEdge grinding machinesPolishing machinesEngineeringUltimate tensile strength

The invention discloses a bowl-shaped ornament polishing machine, and belongs to the technical field of jewelry processing equipment. The bowl-shaped ornament polishing machine mainly comprises a rack, a rotating disc driven by a power device, a linear slideway, a connecting rod and an abrasive barrel body and a barrel cover, wherein the abrasive barrel body is connected with the barrel cover; the rotating disc is rotationally mounted on the rack; the linear slideway is fixedly mounted on the rack; one end of the connecting rod is hinged to the rotating disc; the other end of the connecting rod is constricted in the linear slideway; the abrasive barrel body is fixedly mounted on the connecting rod; and the abrasive barrel body is internally provided with an abrasive medium. The bowl-shaped ornament polishing machine is widely applied in the ornament processing industry, and solves the technical problems that the inner surface of a manually polished bowl-shaped ornament is not uniform, the labor intensity is high and the production efficiency is low.

Owner:南京豪达家居饰品厂

Screening device for producing organic bio-fertilizers

InactiveCN104438039AExtended stayHigh degree of automationSievingScreeningElectric machineryEngineering

The invention discloses a screening device for producing organic bio-fertilizers and belongs to the technical field of agricultural mechanical equipment. The screening device for producing organic bio-fertilizers comprises cylindrical screen cloth, wherein a spiral material guide plate is arranged on the inner wall of the screen cloth and extends in the axial direction of the screen cloth in a precession mode. A feeding port is formed in one end of the screen cloth, a discharging port is formed in the other end of the screen cloth, and a motor is arranged on the screen cloth in a matched mode and drives the screen cloth to rotate around the axis. According to the screening device for producing organic bio-fertilizers, the cylindrical screen cloth can screen organic fertilizer raw materials efficiently during operation to prolong duration of stay of screen efficiently by means of the cylindrical screen cloth and the spiral material guide plate. The screening device for producing organic bio-fertilizers can screen different raw materials or materials of different stages in the production, and has the advantages of being high in automation degree and good in device screen effect.

Owner:SICHUAN KAIERFENG AGRI TECH CO LTD

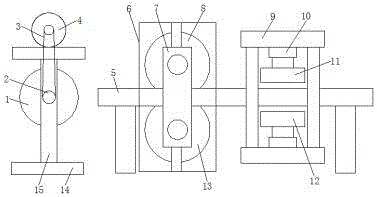

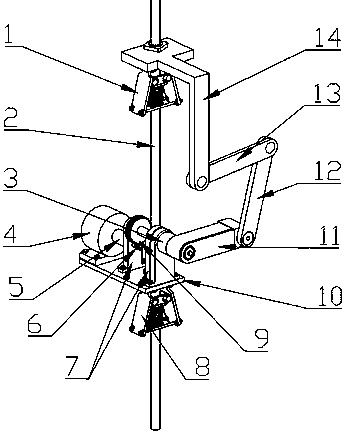

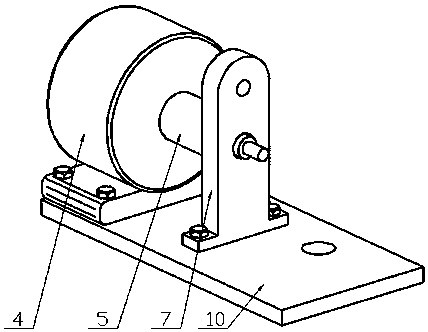

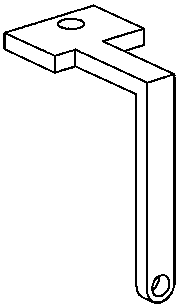

Comprehensive experiment teaching tool of hinge four-bar mechanism

InactiveCN108932898AInspire passion for learningImprove creativityEducational modelsTeaching toolEngineering

The invention relates to a comprehensive experiment teaching tool of a hinge four-bar mechanism. The comprehensive experiment teaching tool is characterized in that a crank rocker, double cranks, tworocker four-bar mechanisms and double slider-crank mechanisms (namely, two sets of slider-crank mechanisms) are ingeniously, perfectly and dynamically integrated, the whole teaching tool can randomlygallop upwards on a polished rod when in the double slider-crank state, and thus the practicability, interest and entertainment are realized. As a teaching tool, the device can lively and vividly demonstrate various changes of the four-bar mechanism to students, the effect of obtaining twofold results with half the effort is achieved, manual operation is available, automatic demonstration is alsoavailable, and the device is mainly used for classroom teaching, is novel, simple and diversified in structure, is strong in knowledge comprehensiveness, is easy to operate, and is low in fabricationcost.

Owner:HUBEI POLYTECHNIC INST

Poultry farming feed feeding device

The invention discloses a poultry farming feed feeding device, and relates to the technical field of poultry farming. The poultry farming feed feeding device comprises a feeding cylinder, a feeding assembly and an auxiliary assembly, multiple sets of feeding openings are formed in the outer wall of the feeding cylinder, multiple sets of blocking pieces are fixedly installed on the outer wall of the feeding cylinder, the feeding openings are located in the inner sides of the blocking pieces, and the blocking pieces are arranged obliquely upwards. According to the poultry farming feed feeding device, poultry can be separated during feed feeding, meanwhile, the feeding openings only allowing the heads of the poultry to stretch into are formed in the outer wall of the feeding cylinder, the poultry can eat only by stretching the heads into the feeding cylinder, the semi-closed opening type structural design is adopted, and the situation that the poultry grabs food is effectively prevented, so that the condition that the poultry waves wings to cause flying and splashing of the feed is avoided, the waste of the feed is reduced, the cleaning trouble of poultry feeders due to feed flying and splashing is reduced, and the actual use experience is improved.

Owner:重庆膳技庄养殖有限公司

A kind of rice grain production and processing technology and device

ActiveCN113083402BImprove production and processing efficiencyAvoid mildew and spoilageGrain huskingGrain polishingThermodynamicsProcess engineering

The invention discloses a process and device for producing and processing rice grains, and relates to the technical field of rice processing. The rice grain production and processing technology includes three steps of steaming, pressurizing and shelling. The rice grain production and processing device includes a processing cylinder, which is provided with a shell grinding mechanism, a driving mechanism, a material turning mechanism and a pneumatic mechanism, and a drying box is fixedly installed at the bottom opening of the processing cylinder, and the bottom of the drying box is There is a trash box for fixed installation. The rice grain production and processing process uses steam to moisten the rice husk outside the rice, so that the rice husk is heated and expanded, and then cooled immediately after steam wetting, which facilitates the subsequent separation between the rice husk and rice and reduces the peeling. The residue of rice husk on the rice grain. In the rice grain production and processing device, the rolling and shelling parts are designed with an elastic structure, which can meet the processing requirements of rice grains with different particle sizes, and the shelling is thorough, reducing the breakage rate in the rice processing process.

Owner:重庆裕丰米业有限公司

Automatic cap feeding device for cap screwing operation

ActiveCN112027989AIncrease productivityWide range of usabilityCapsThreaded caps applicationDust controlStructural engineering

The invention discloses an automatic cap feeding device for cap screwing operation, and relates to the technical field of packaging equipment. The automatic cap feeding device for the cap screwing operation comprises a workbench, wherein six supporting legs are welded and mounted on the outer surface of the bottom of the workbench; a sorting mechanism, a screening and feeding mechanism, a dust removing mechanism, a recycling mechanism, a pushing and alignment mechanism and a transmission mechanism are arranged on the workbench; two mounting frames are welded and mounted on the outer surface ofthe top of the workbench and distributed symmetrically; and two limiting rods are welded and mounted on the inner walls of the two mounting frames. According to the automatic cap feeding device for the cap screwing operation, the use scene and range of the device are wider, the use and the popularization of the device are facilitated, and it is guaranteed that the openings of arranged bottle capsall face downwards, so that compared with a part of devices with the openings of arranged bottle caps facing upwards, the practicability of the automatic cap feeding device is higher, the cap screwing operation requirement of most cap screwing machines in the market is met, the convenience is provided for subsequent processes, and the production efficiency of the whole packaging process is further improved.

Owner:东莞市新锋机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com