Patents

Literature

89results about How to "Thoroughly polished" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional robot polishing equipment

ActiveCN108655911ATimely collectionAdd collection functionGrinding carriagesGrinding machinesCouplingEngineering

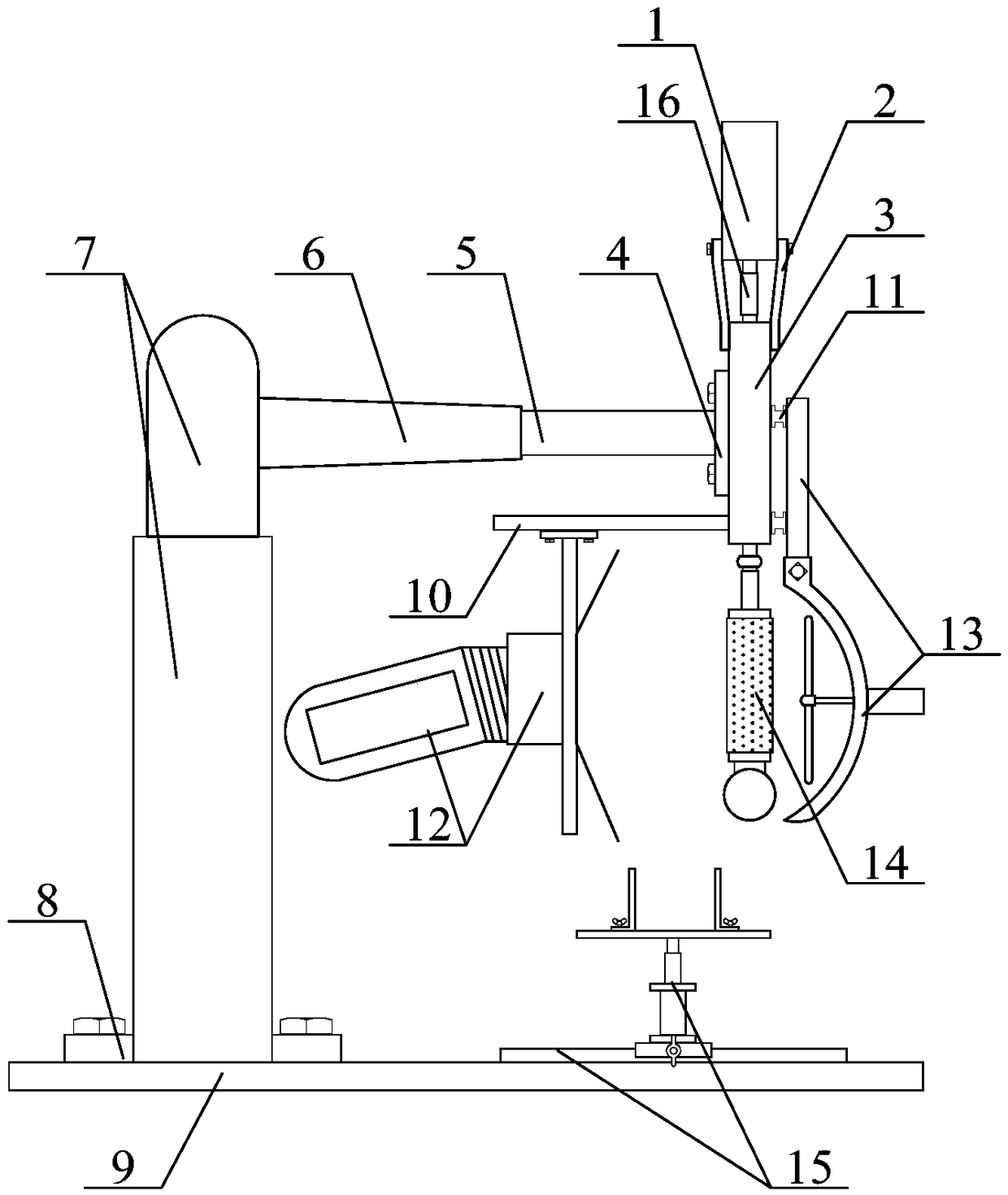

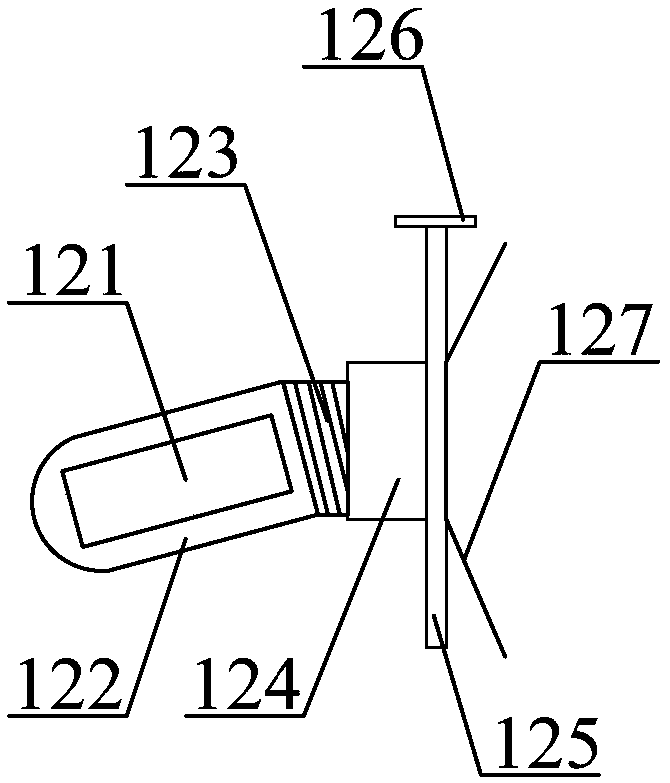

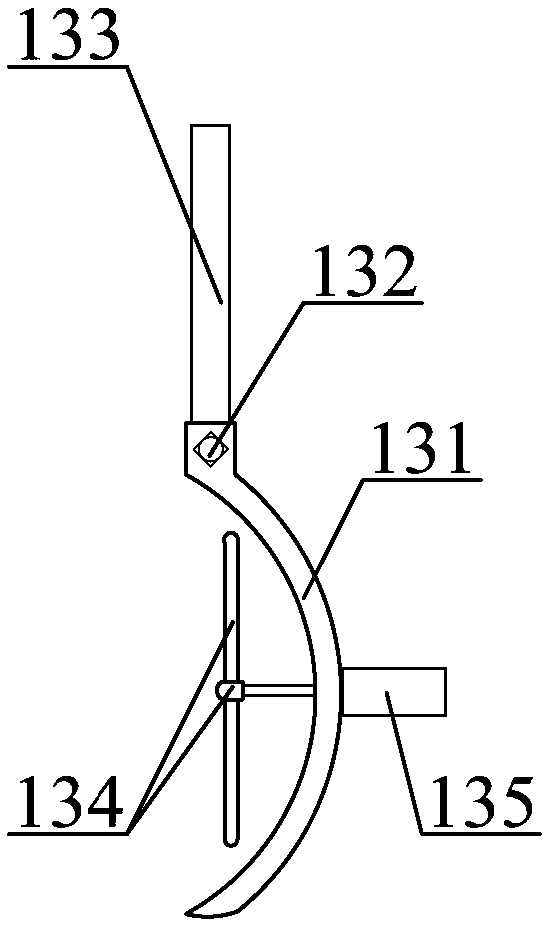

The invention provides multifunctional robot polishing equipment. The multifunctional robot polishing equipment comprises a polishing motor, a fixed plate, a fixed sleeve, a connecting plate, a robotpower arm, a robot extension arm, an ER50-3200 six-axle robot, a fixed clamping base, a base, a support plate, an I-shaped frame, a waste chip and dust collecting environmental-protection barrel structure, an adjustable dust and waste chip blowing machine structure, a quick polishing replacement rod structure, a height-adjustable clamping plate structure and a sleeve coupling. Through arrangementof a collecting barrel, a metal hose, a dust guide pipe, a joint base, a support lining base and a dust guide hopper, dust and waste chips generated by polishing are timely collected, the collecting function is added, the pollution is prevented, and the environment is protected; through arrangement of a transparent piece, the collecting condition of the dust and the waste chips in the collecting barrel can be timely determined to achieve replacement or cleaning; and through arrangement of fan blades and a blowing motor, the waste chips and the dust generated by polishing are timely blown out to guarantee the polishing efficiency.

Owner:柳州中科机器人自动化股份有限公司

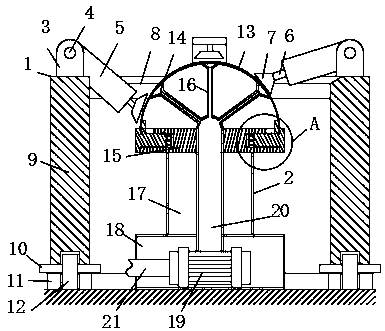

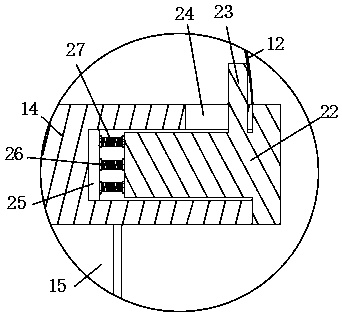

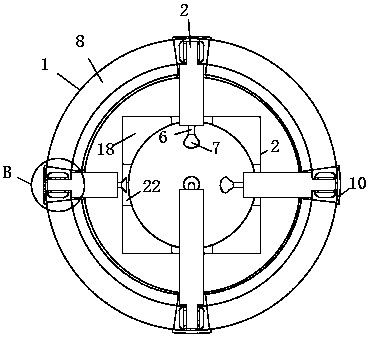

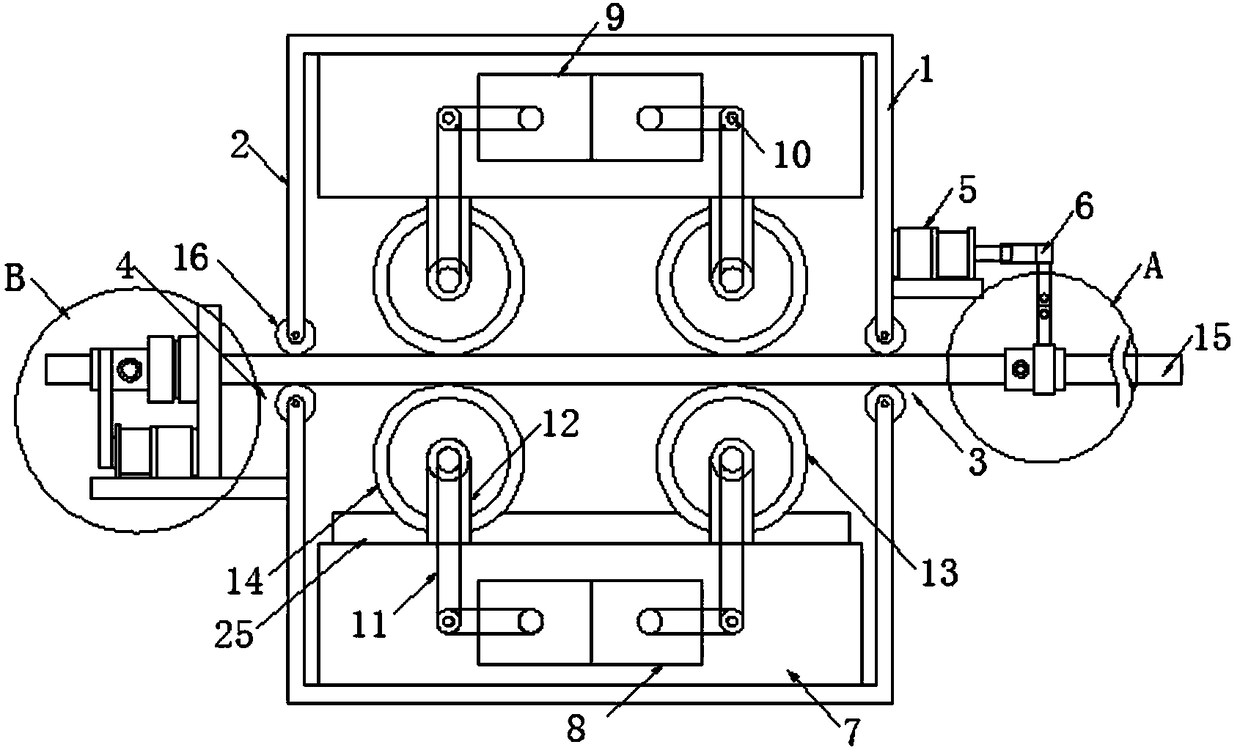

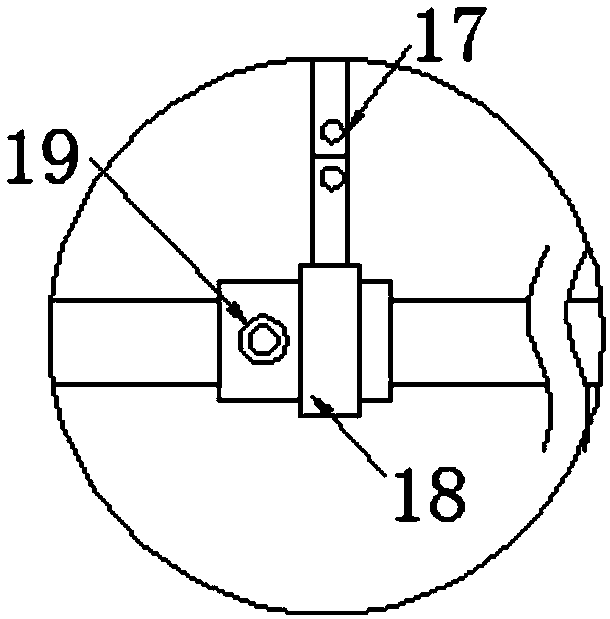

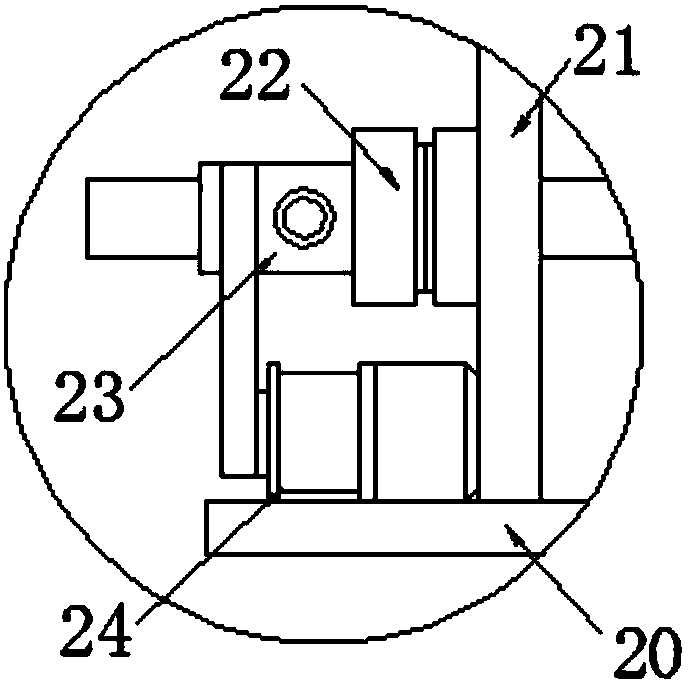

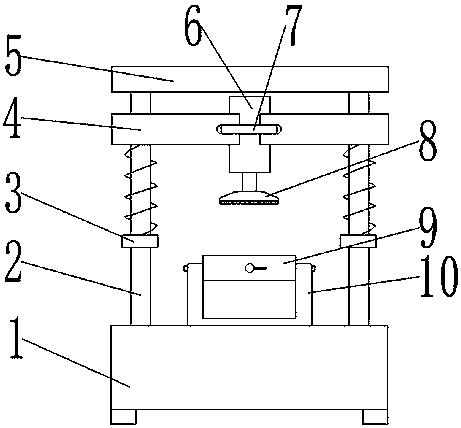

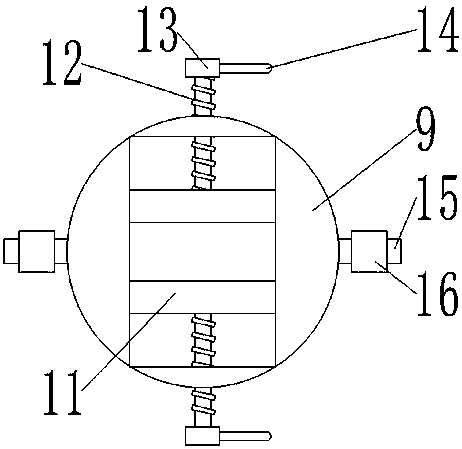

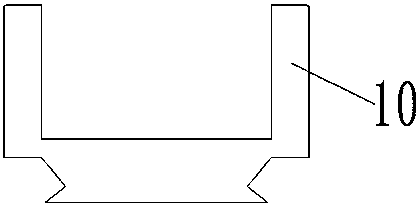

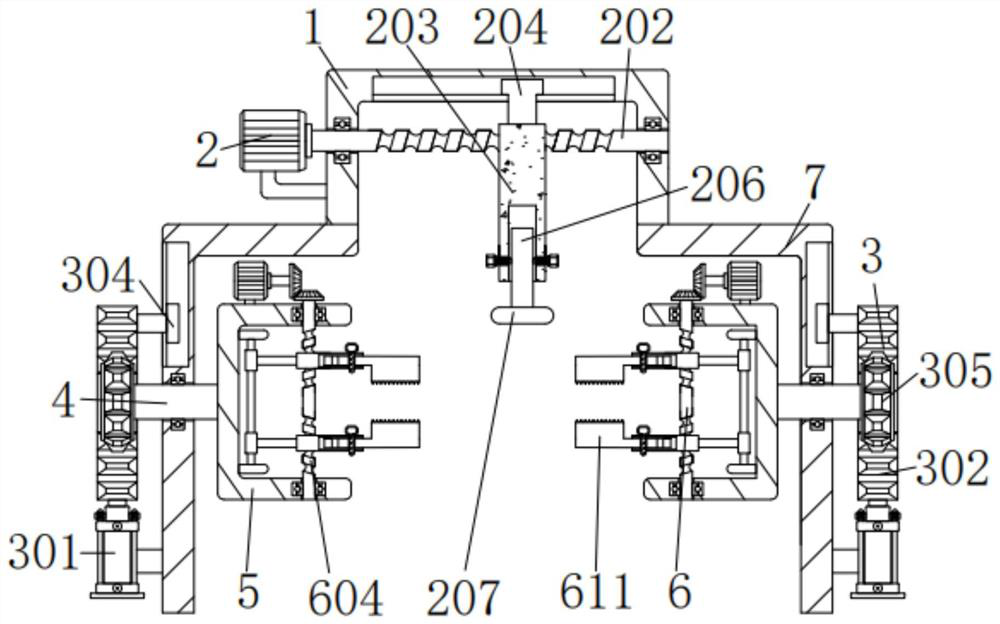

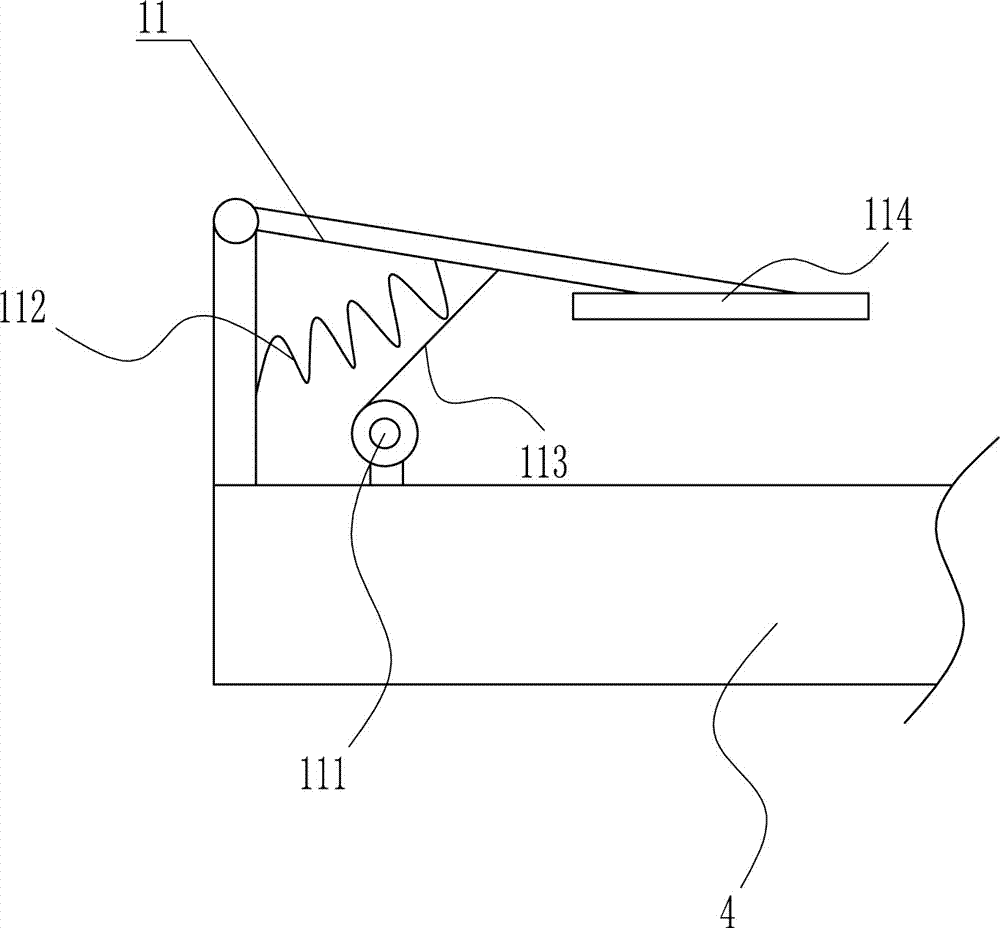

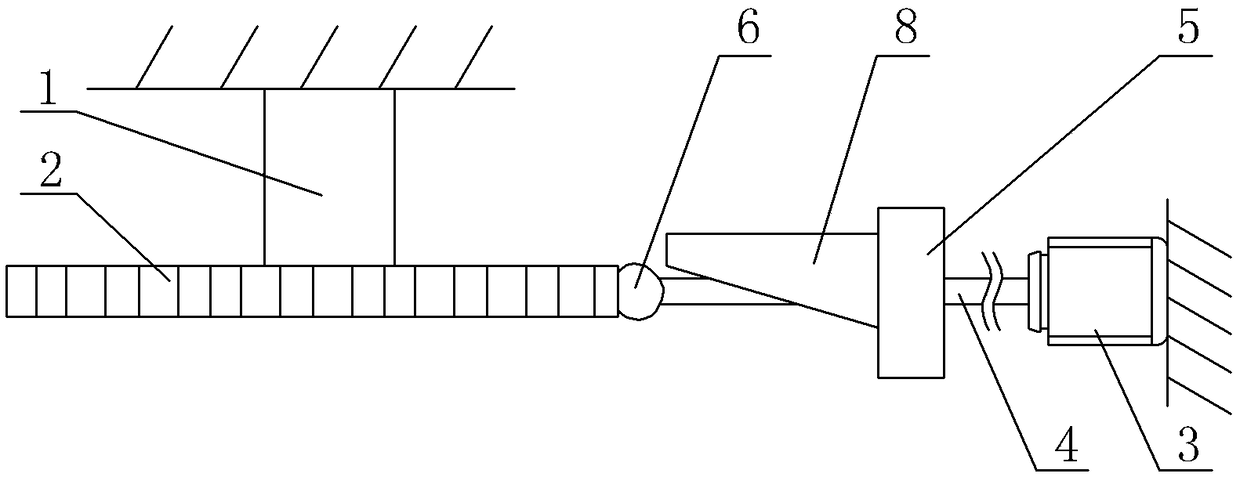

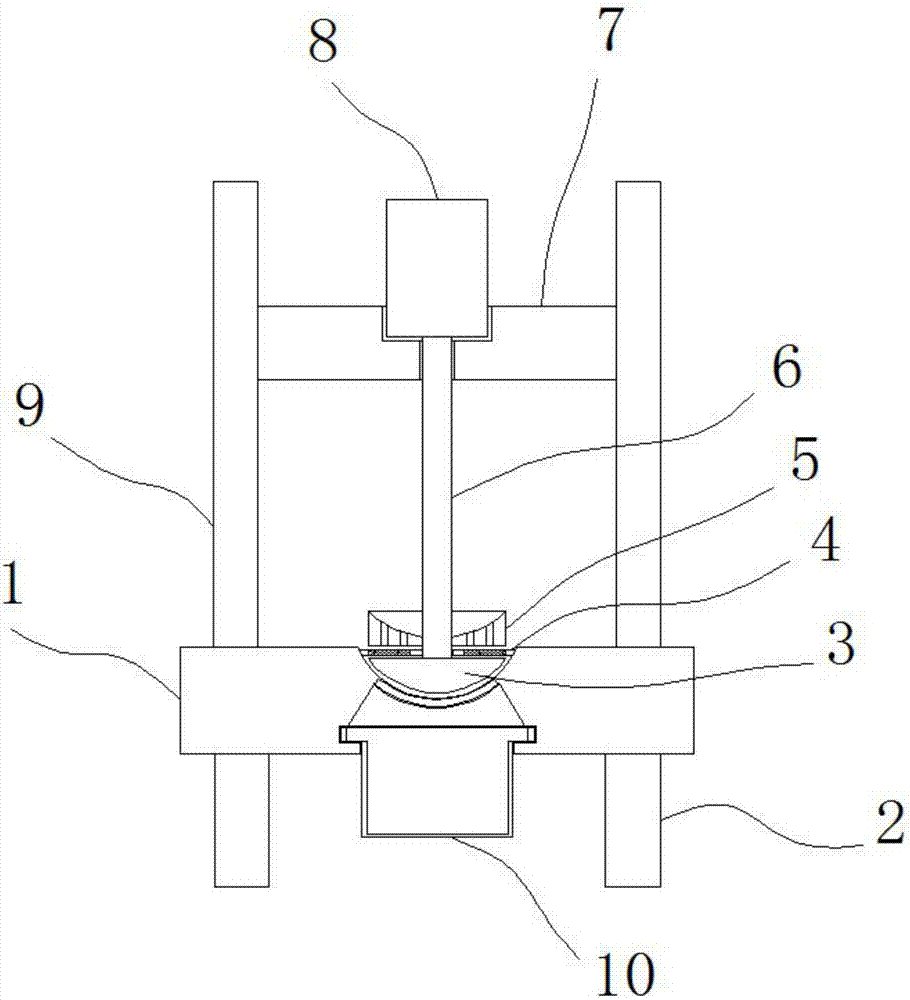

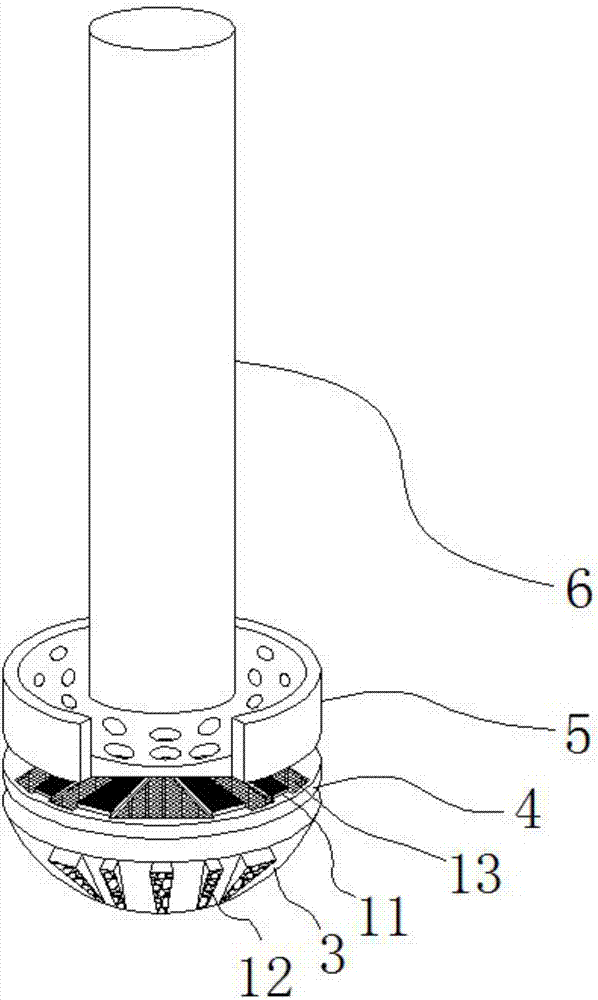

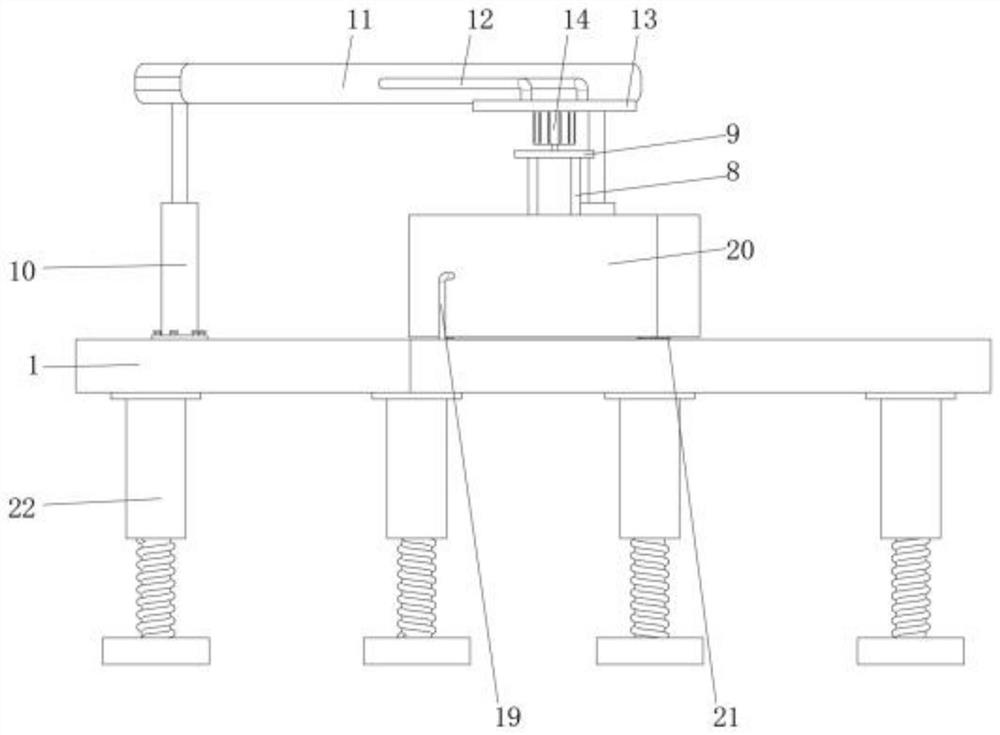

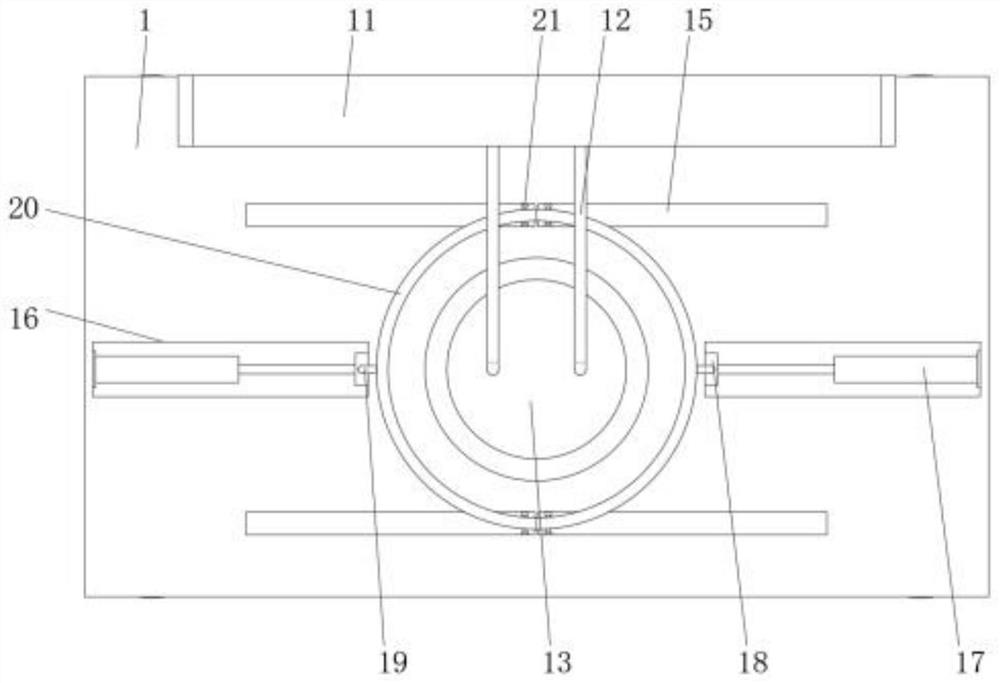

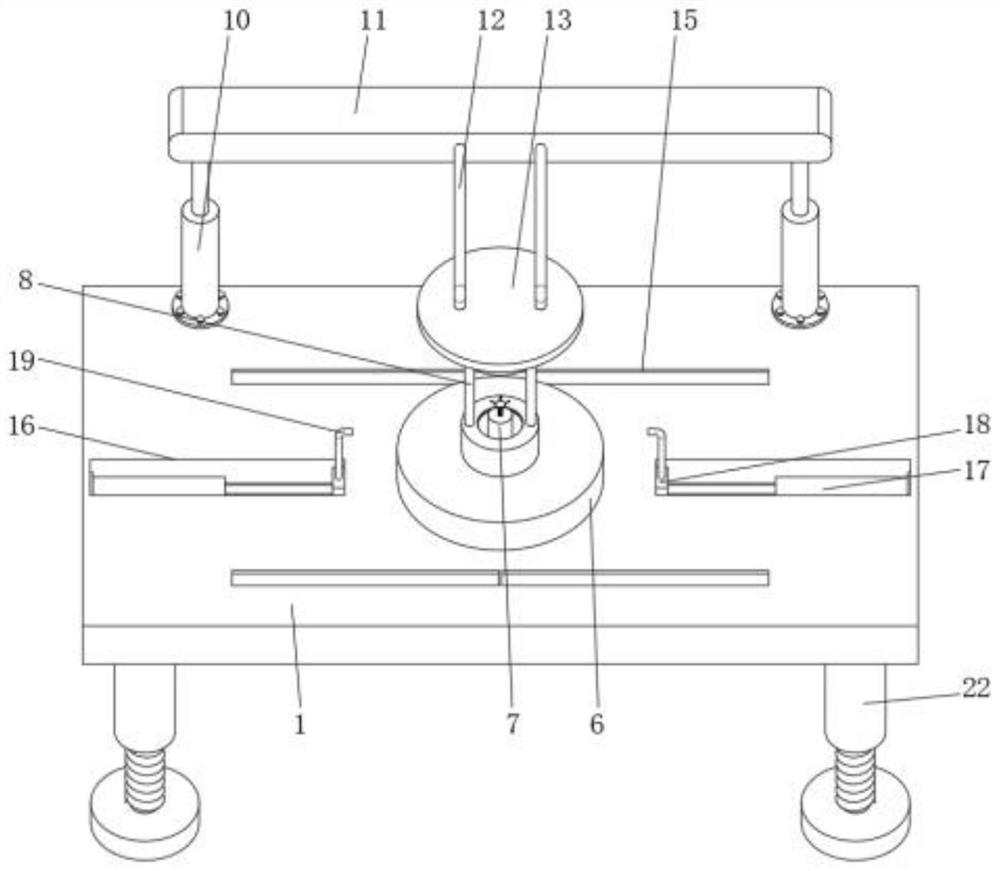

Rotary polishing device for household water purifier stainless steel cylinder

InactiveCN107042429AThoroughly polishedImprove polishing effectGrinding carriagesRevolution surface grinding machinesMaterials scienceSteel cylinder

The invention relates to a polishing device, in particular to a rotary polishing device for a household water purifier stainless steel cylinder. The technical problem to be solved by the present invention is to provide a rotary polishing device for stainless steel cylinders of household water purifiers that can be used for polishing various types of cylinders and has a good polishing effect. In order to solve the above technical problems, the present invention provides such a rotary polishing device for household water purifier stainless steel cylinder, which includes a support frame, a first motor, a clamping mechanism, a first fixing rod, a first bearing seat, etc.; The middle of the bottom of the frame is connected with a first motor, the top of the output shaft of the first motor is connected with a clamping mechanism, the back side of the top of the support frame is connected with a connecting plate, the connecting plate is located at the rear side of the first motor, and the top front of the connecting plate is connected with a support pole. In the present invention, the top of the cylinder body is driven by the pressing plate by rotating the first support rod, and then the handle is turned, thereby driving the grinding plate to move to the middle to clamp the cylinder body tightly, and then start the second motor.

Owner:郁海新

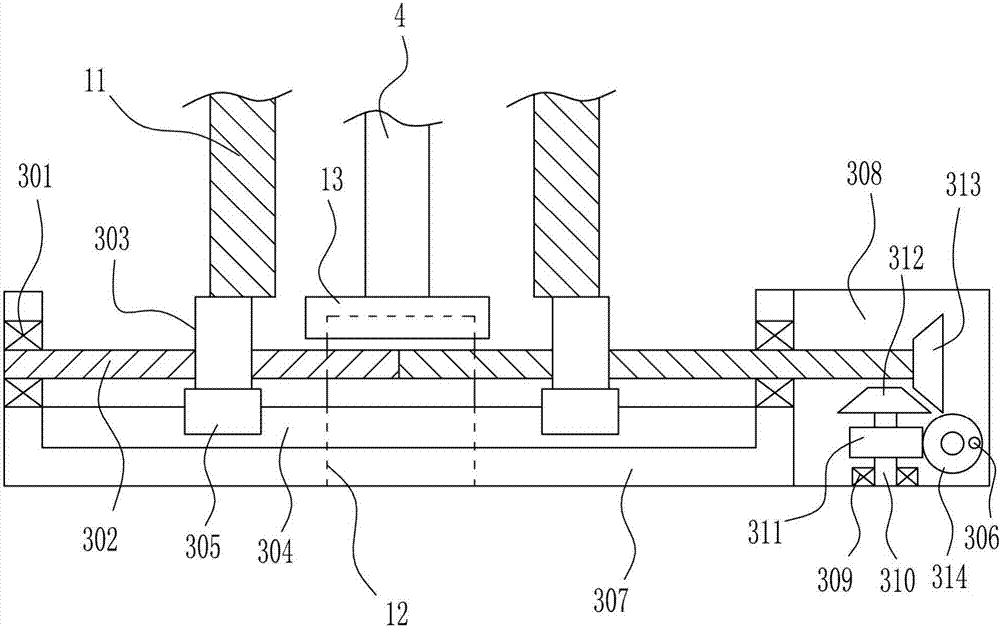

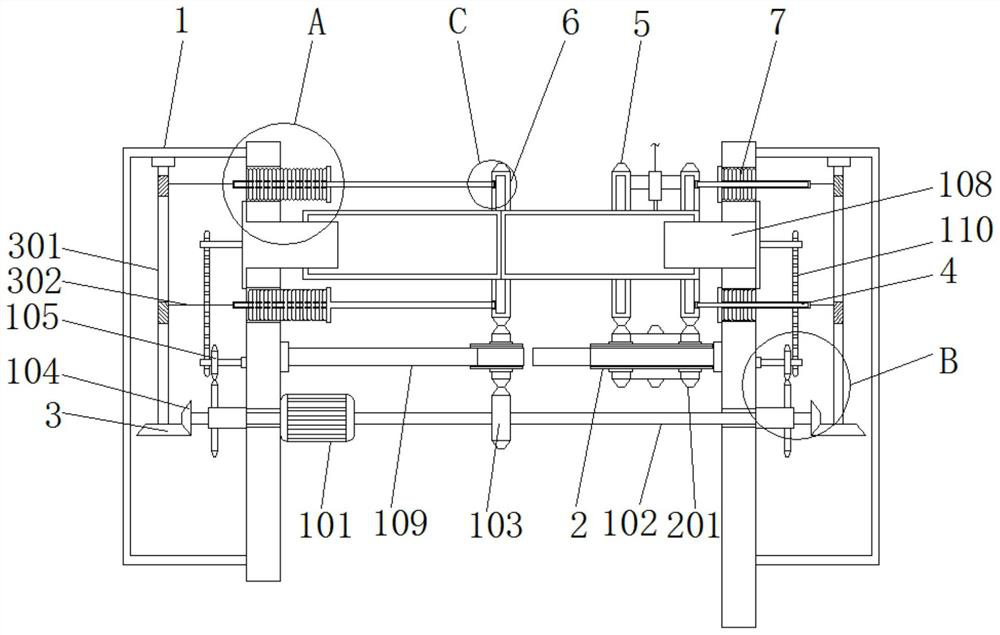

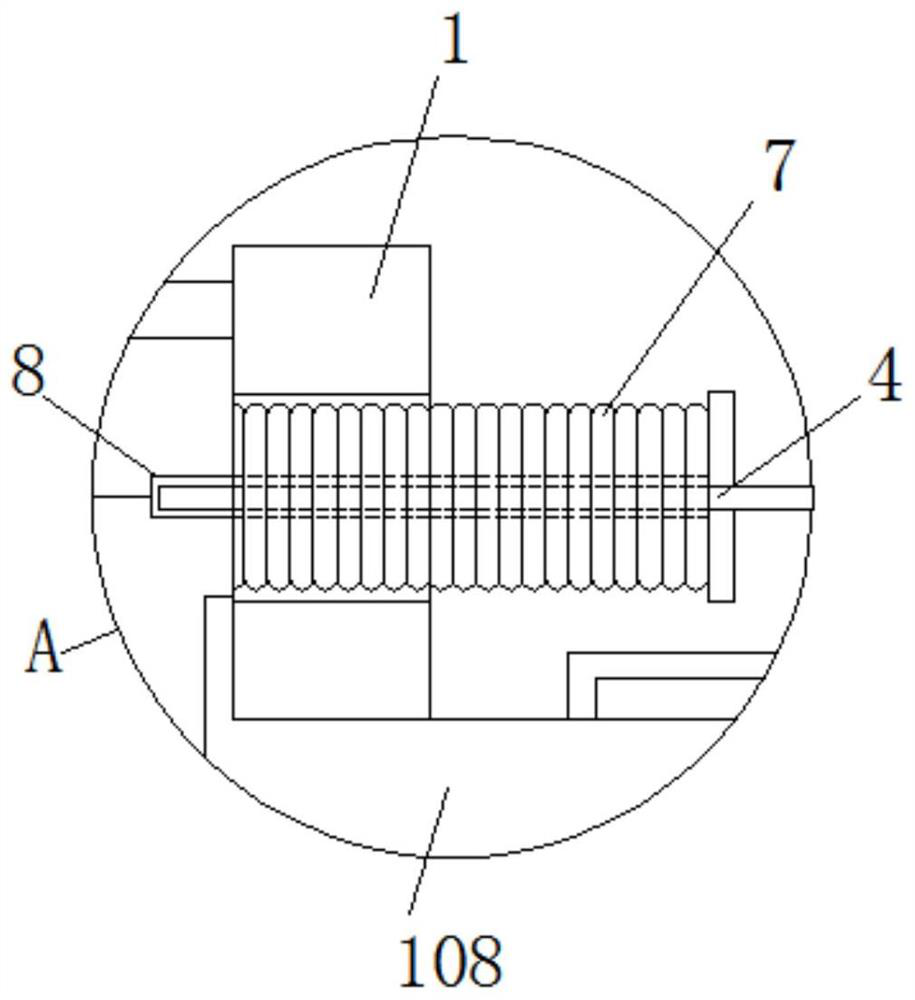

Anti-slippage composite base material boiler body outer surface polishing and grinding machine

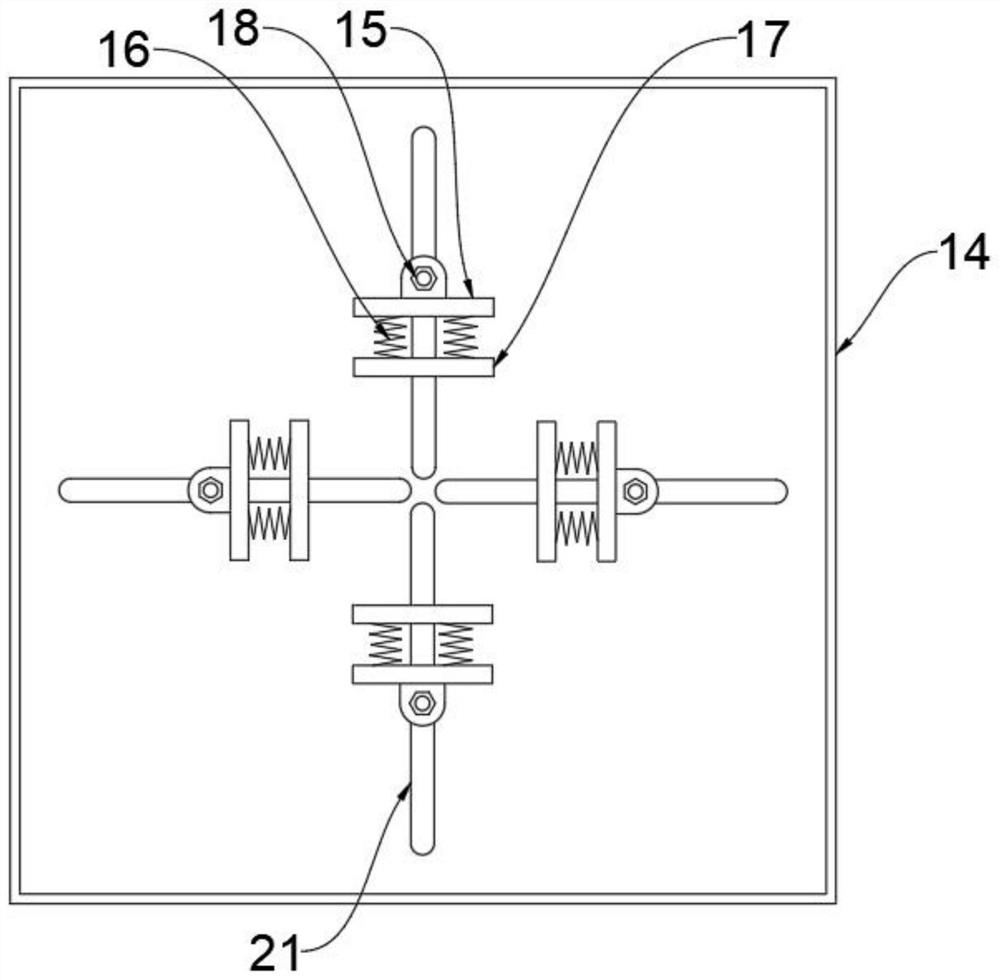

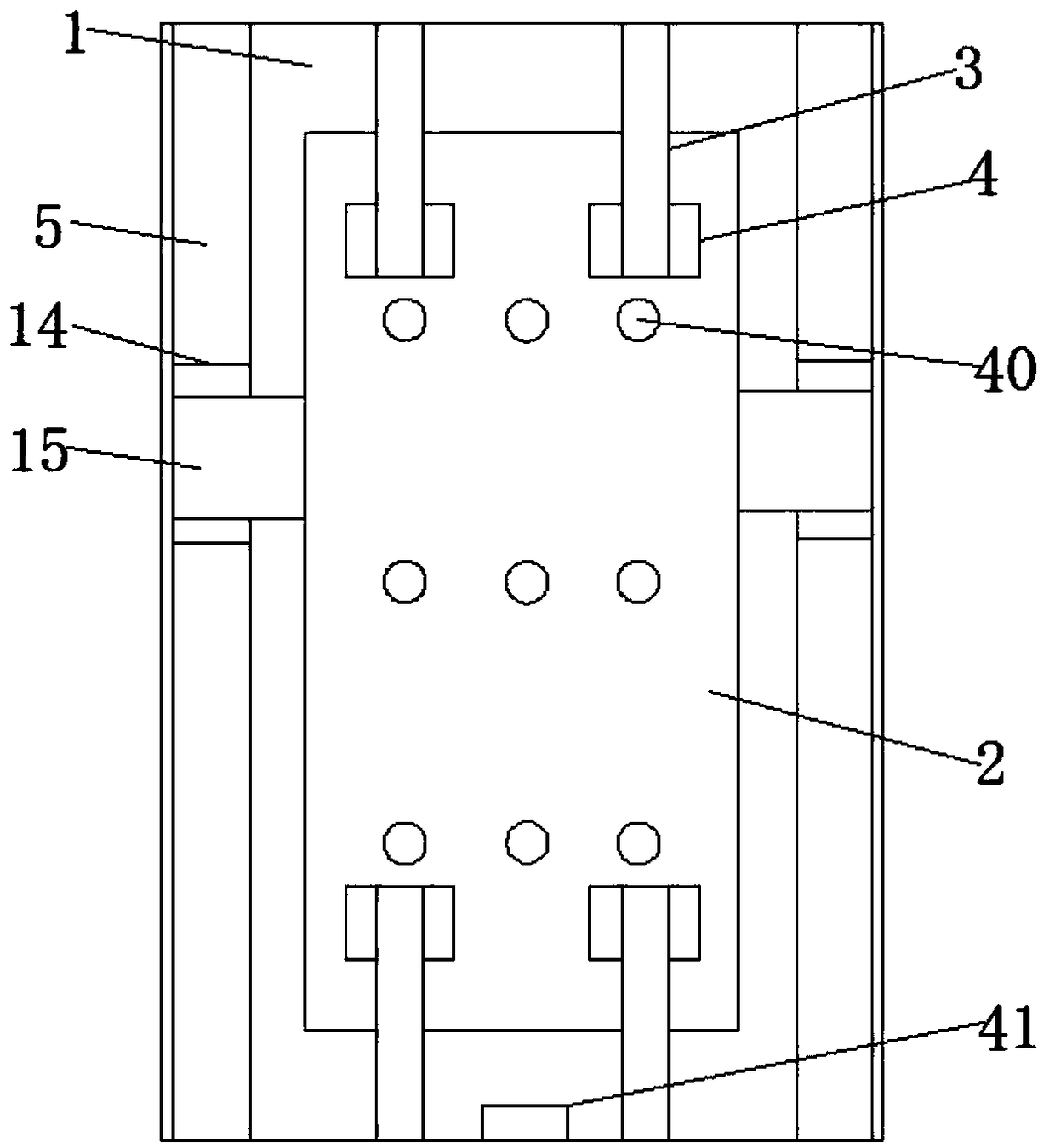

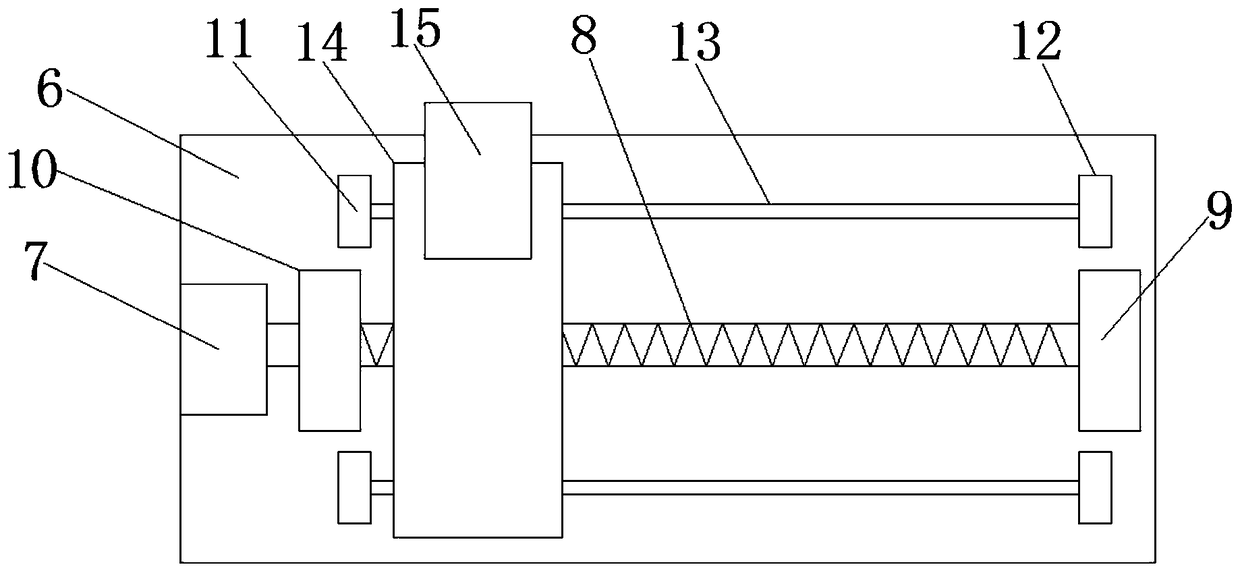

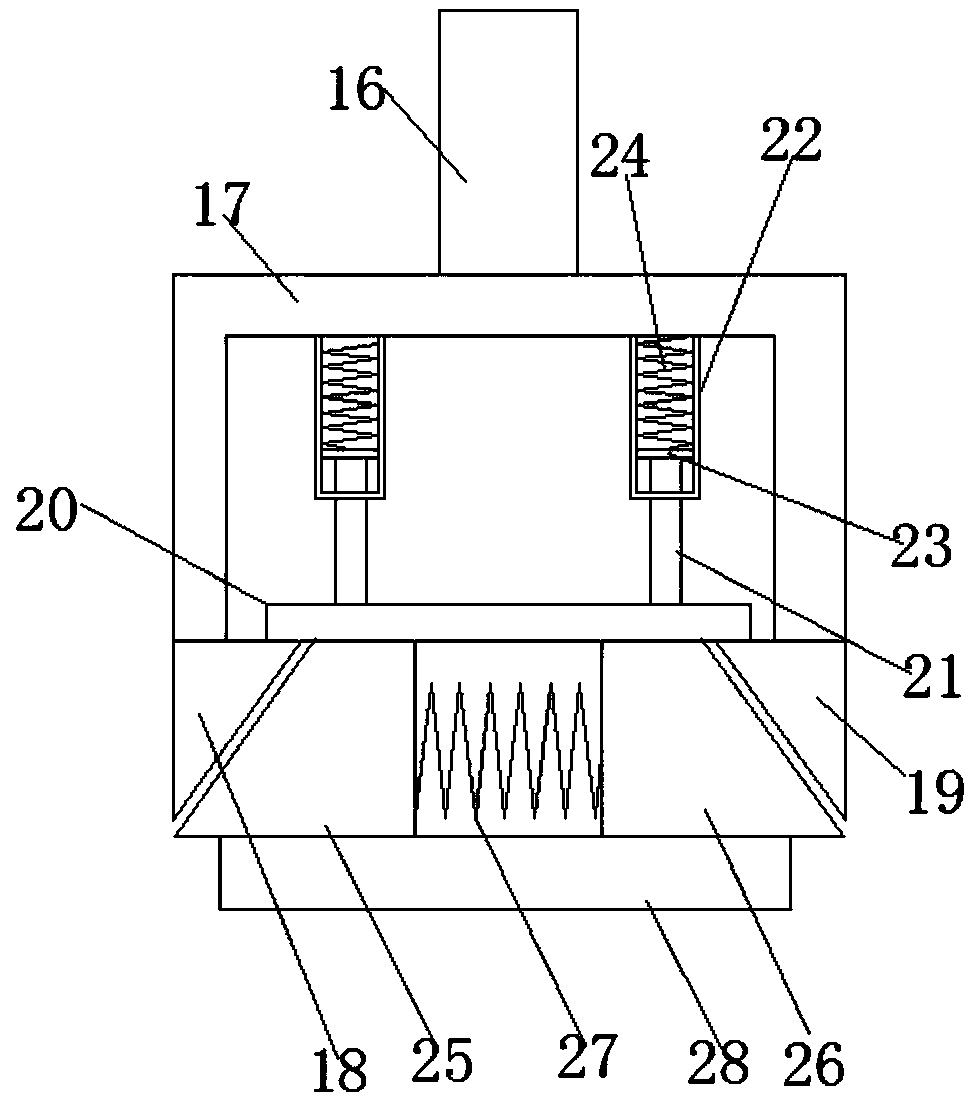

PendingCN108544360AImprove the degree of adsorptionImprove stabilityGrinding carriagesPolishing machinesPulp and paper industryBolt connection

The invention provides an anti-slippage composite base material boiler body outer surface polishing and grinding machine. The anti-slippage composite base material boiler body outer surface polishingand grinding machine comprises a polishing mechanism and a clamping mechanism. Supporting columns are arranged on the outer side of the polishing mechanism. Polishing rack fixing bases are arranged atthe upper ends of the supporting columns an integral forming manner. The polishing rack fixing bases are in bolt connection to the tail ends of polishing racks through fastening bolts. Polishing wheel shafts are fixedly connected to the front ends of the polishing racks. The front ends of the polishing wheel shafts are fixedly connected with polishing wheels. Stable plates are arranged at the lower ends of the supporting columns and internally fixedly connected with sliding wheels. The sliding wheels are in sliding connection into sliding grooves, and the sliding grooves are in a circular ring shape and are fixedly formed outside the clamping mechanism. A containing plate is arranged at the upper end of the clamping mechanism, each of the four side edges of the containing plate is fixedlyconnected with a spring buckle, and a vacuum suction pipe is arranged in the middle of the containing plate. According to the anti-slippage composite base material boiler body outer surface polishingand grinding machine, the angle of the polishing racks can be adjusted, the polishing wheels can face the surfaces of boiler bodies different in height for grinding along the surfaces of the boiler bodies, polishing is more comprehensive and more thorough, the anti-slippage composite base material boiler body outer surface polishing and grinding machine can adapt to polishing of the boiler bodiesdifferent in height, and usage is more convenient.

Owner:PINGDINGSHAN MEIYI METAL PROD

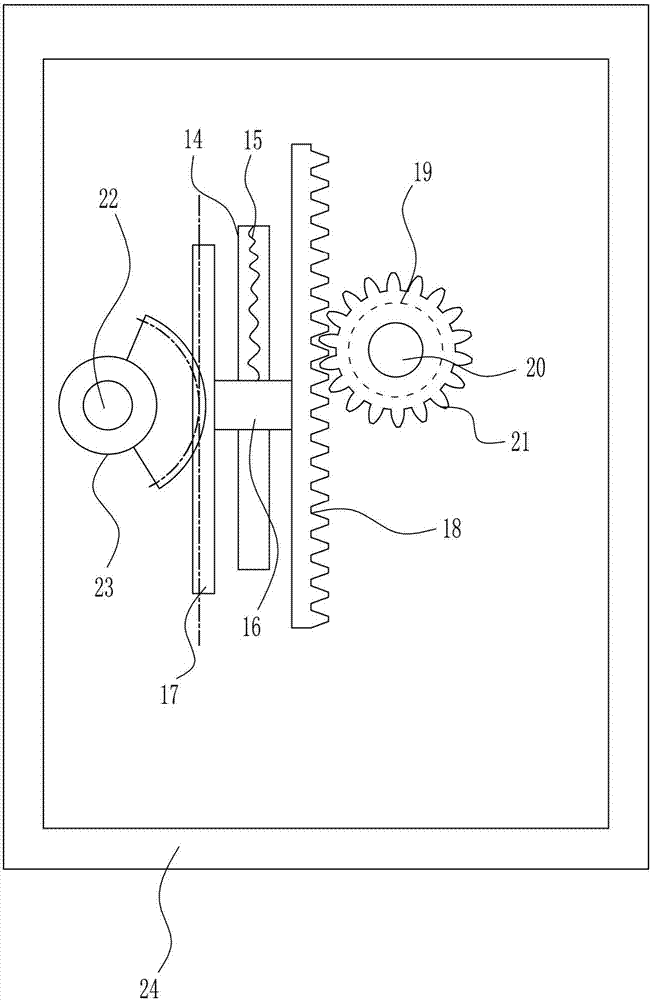

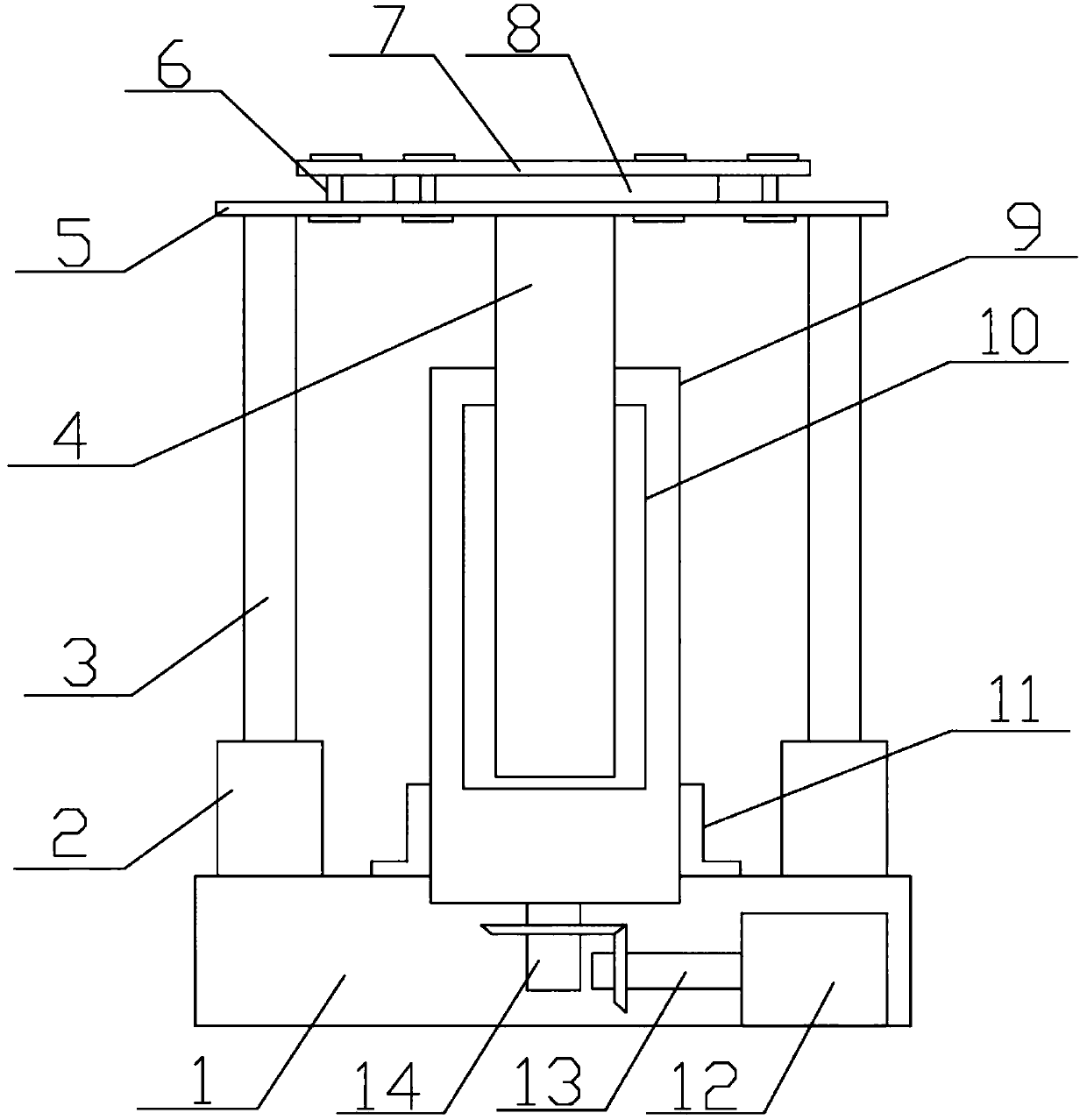

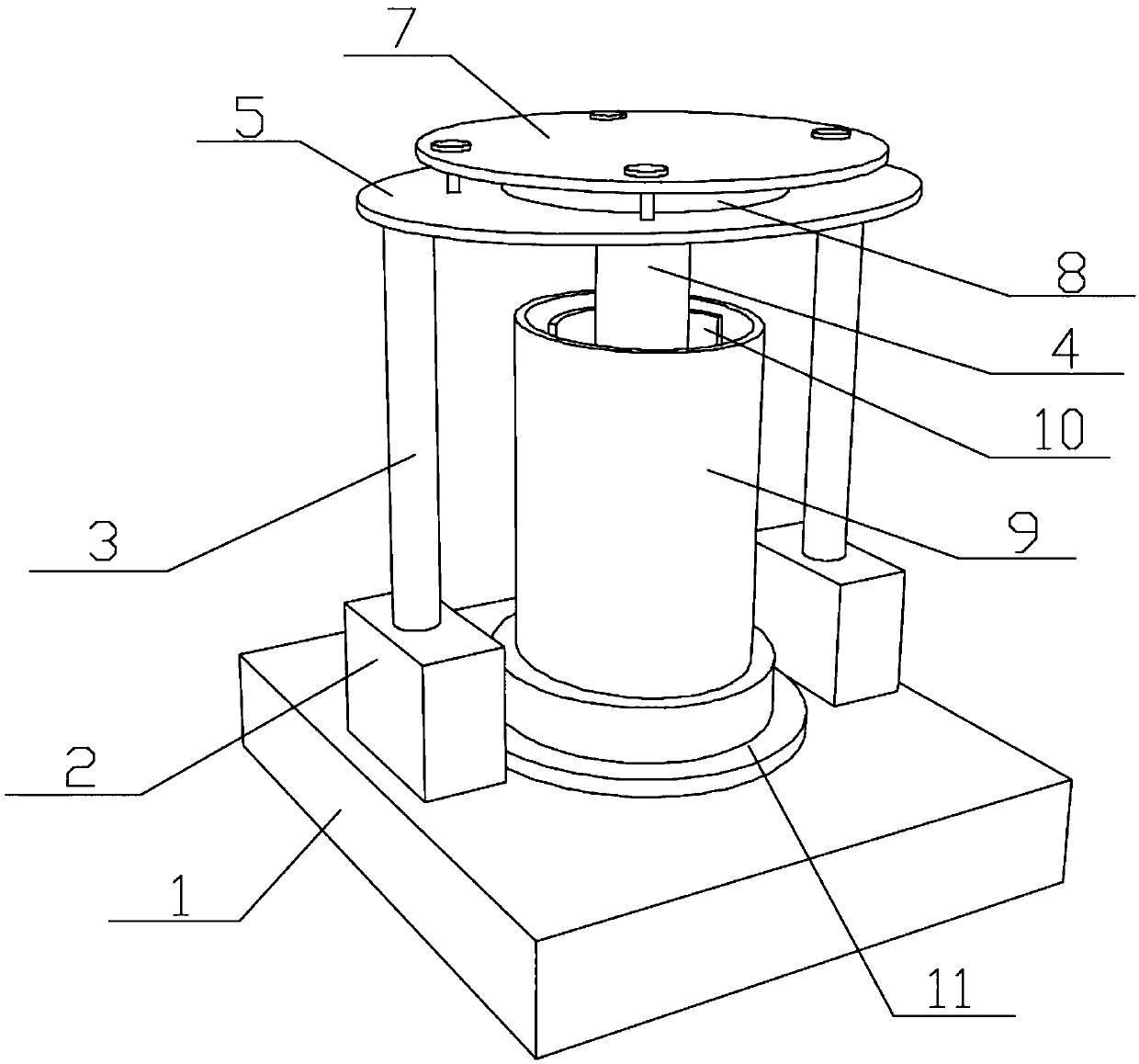

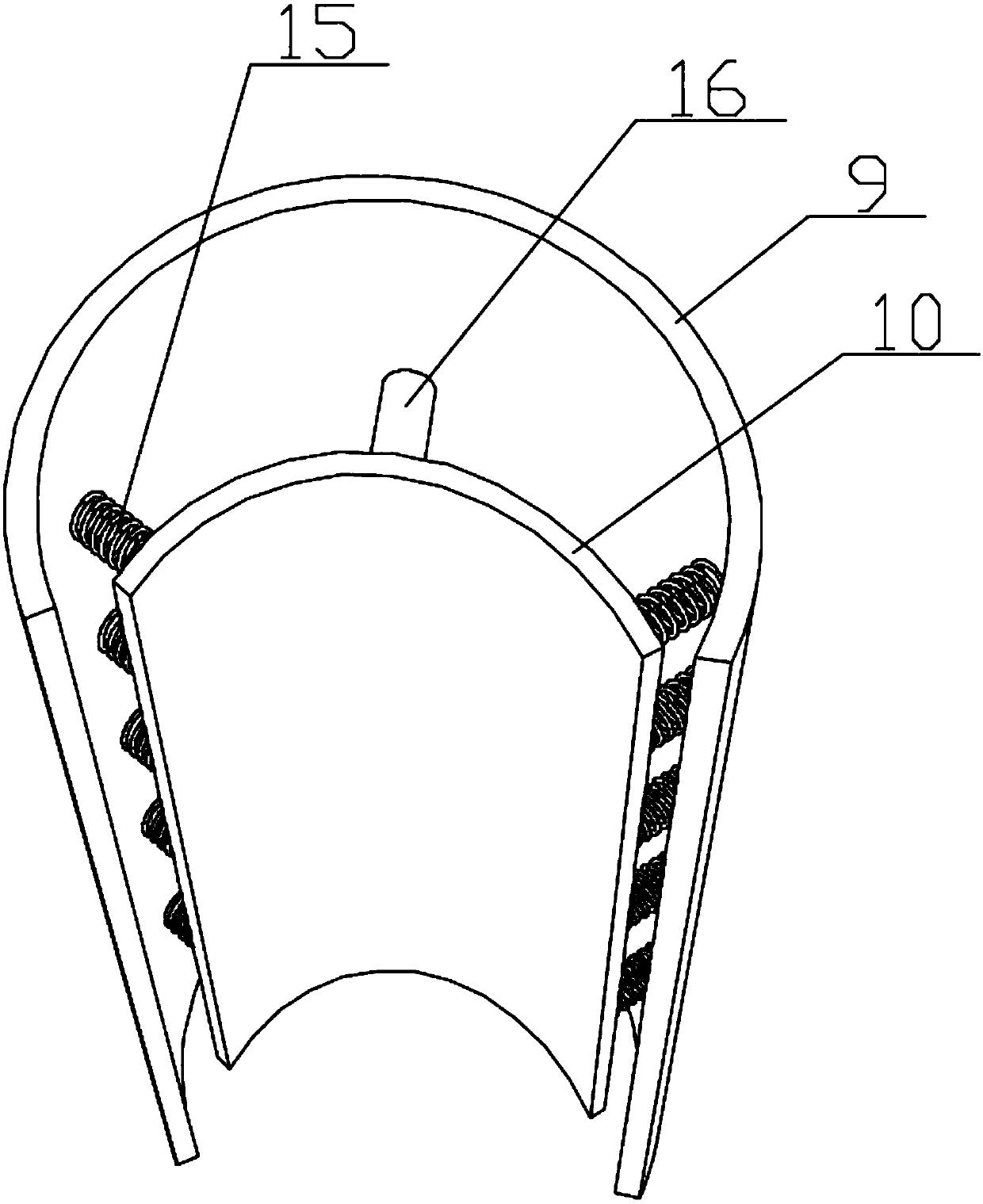

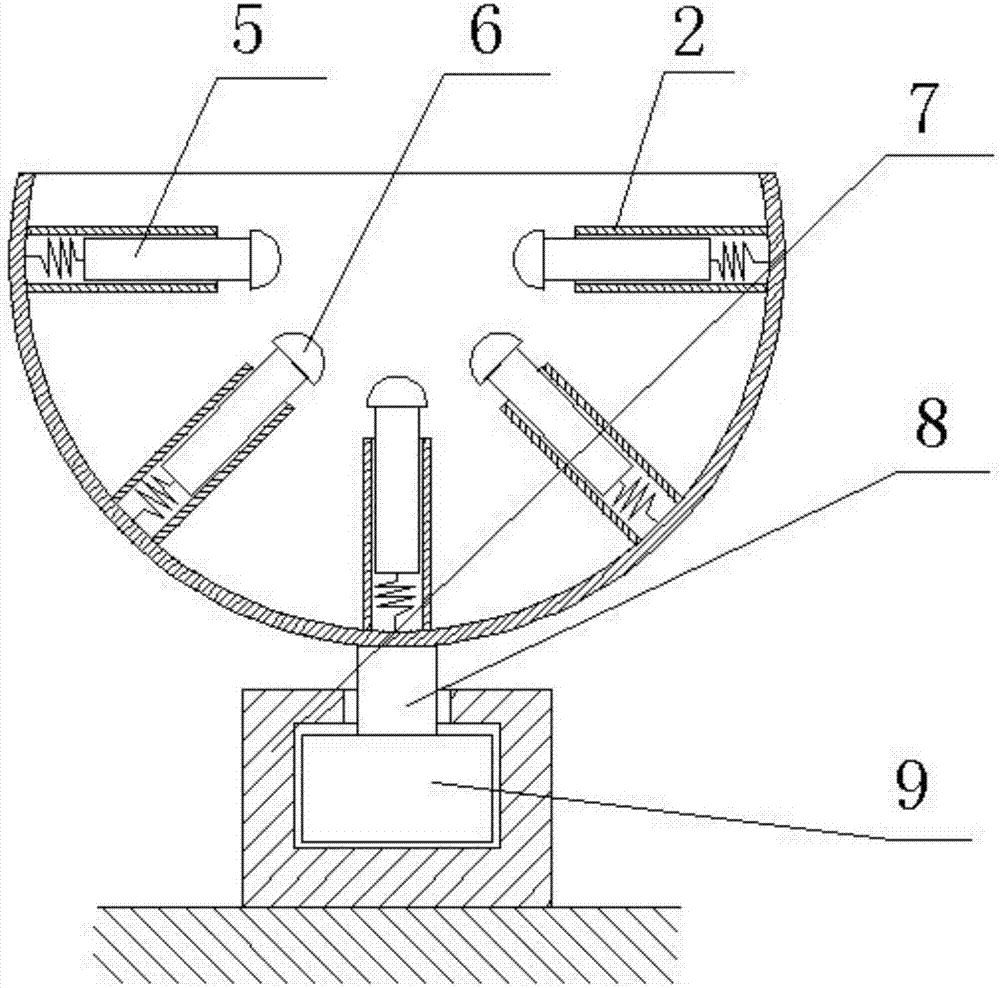

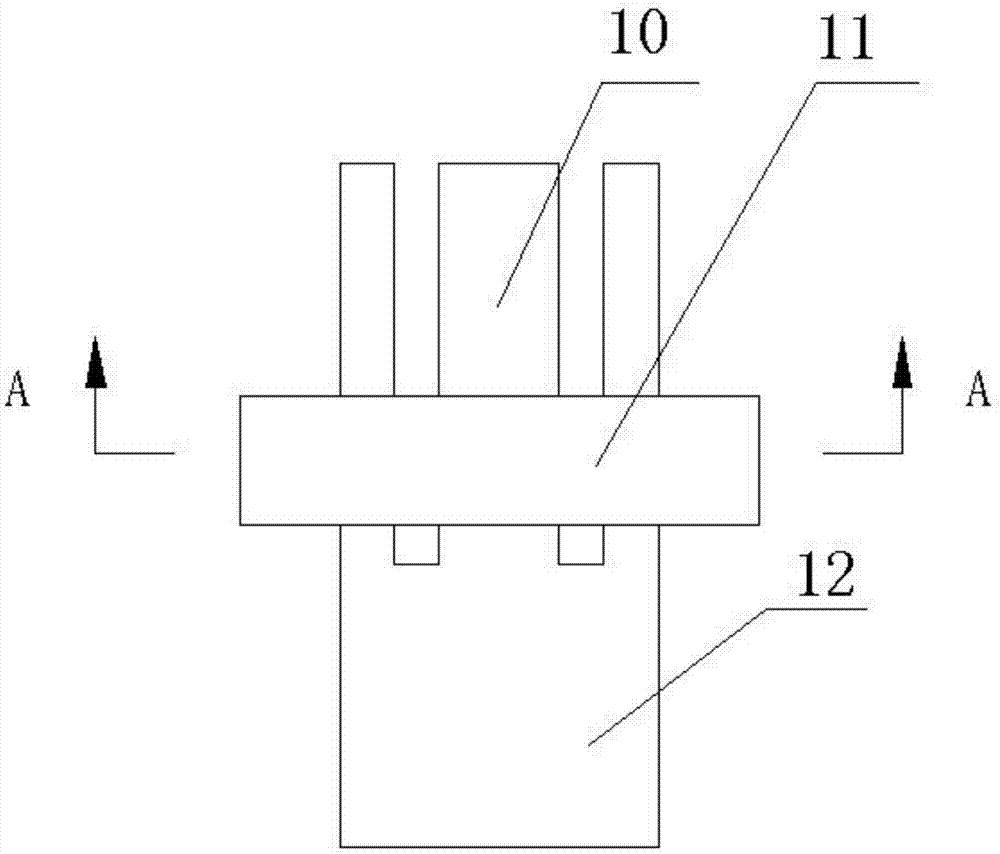

Grinding device capable of following steel nails in self-adaptive mode

InactiveCN107695829AExpand the scope of useEasy to install and removeEdge grinding machinesGrinding drivesSelf adaptiveCylindrical grinding

The invention discloses a polishing device capable of self-adaptively following steel nails, comprising a steel nail fixing device, a base is arranged under the steel nail fixing device, and a rotatable grinding cylinder with an opening at the top is fixed on the base, the grinding cylinder There is an arc-shaped piece made of elastic material inside. The outer side of the arc-shaped piece is fixed to the inner wall of the grinding cylinder through a fixing rod. The outer side of the arc-shaped piece near the side is connected to the inner wall of the grinding cylinder through a spring. Steel wire bristles for grinding nail body. The radian of the arc-shaped part of the present invention can follow the change of the diameter of the steel nail, that is, the present invention can self-adaptively follow the change of the size of the steel nail, which significantly expands the scope of application. In addition, the invention controls the steel nails to move up and down through the air cylinder, so that the grinding is thorough, and it is also applicable to steel nails of different lengths, which further expands the scope of use.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

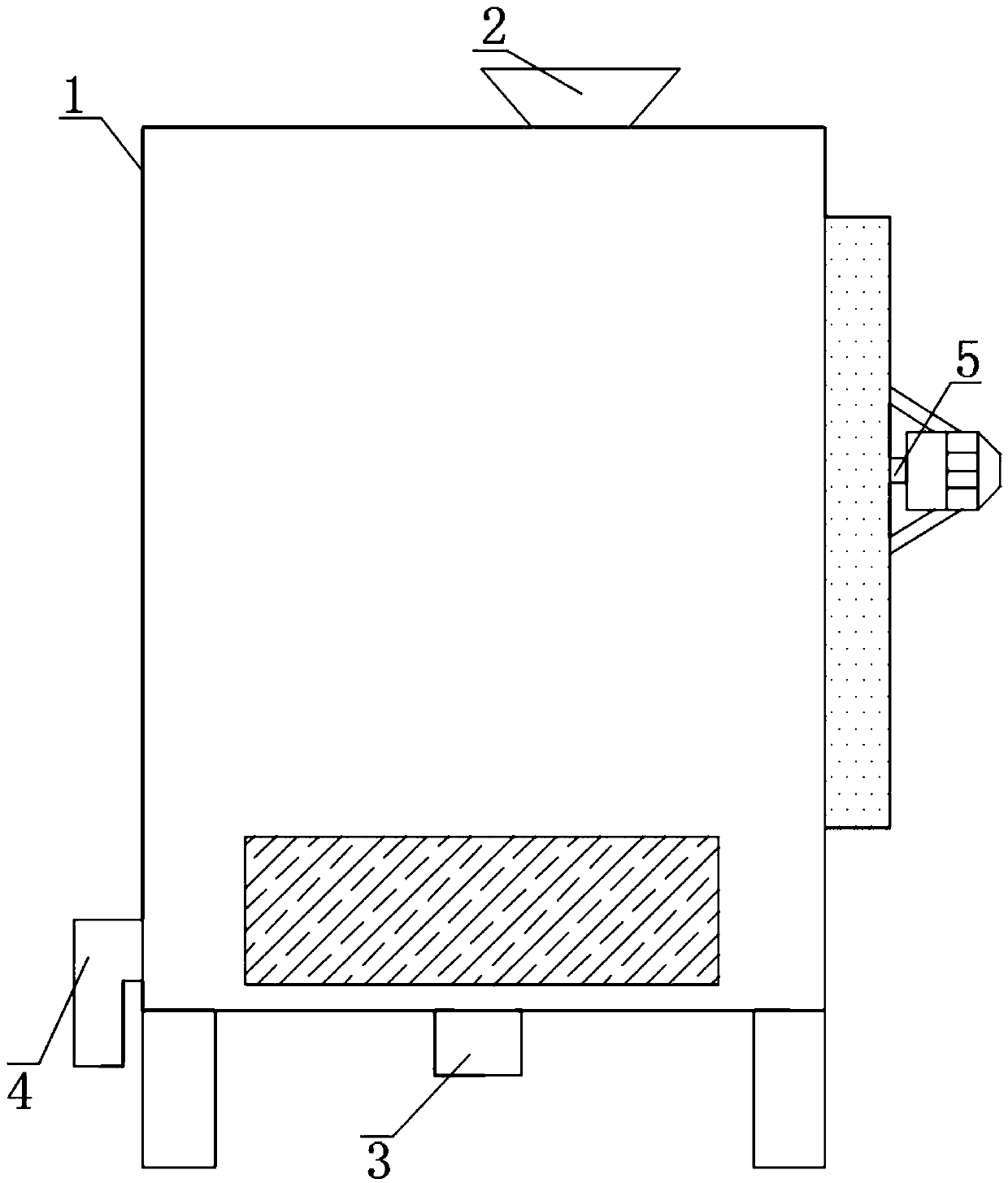

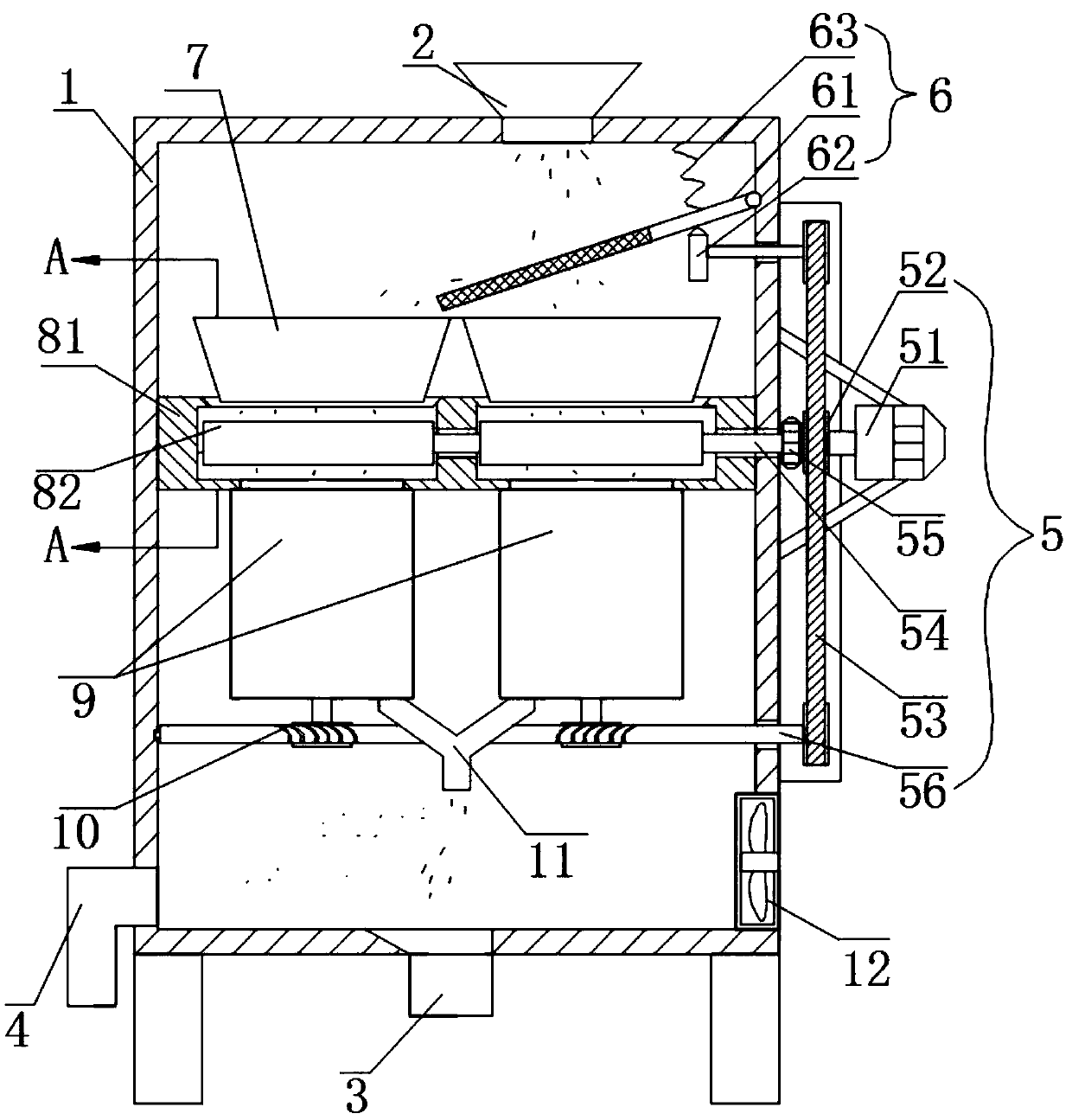

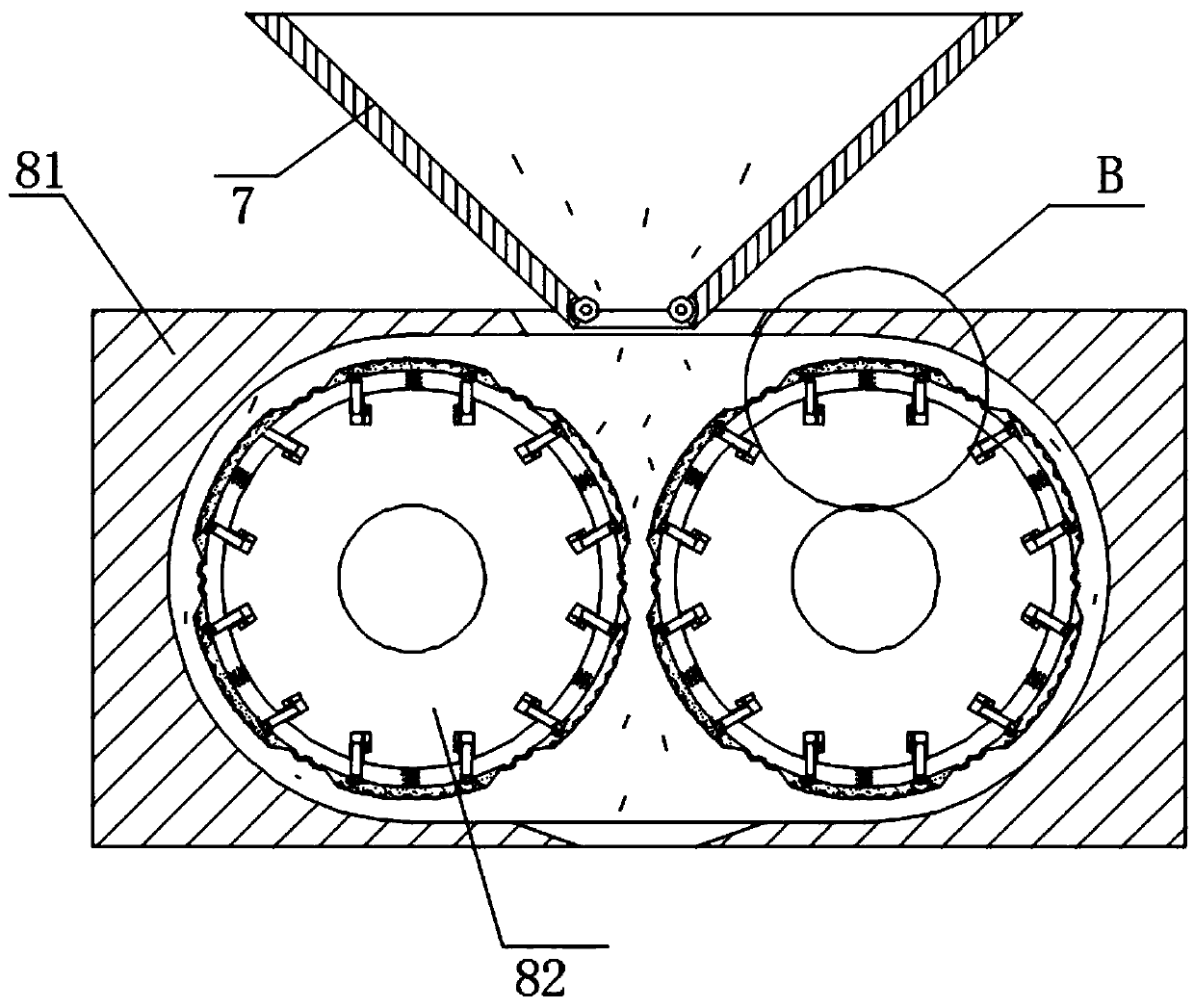

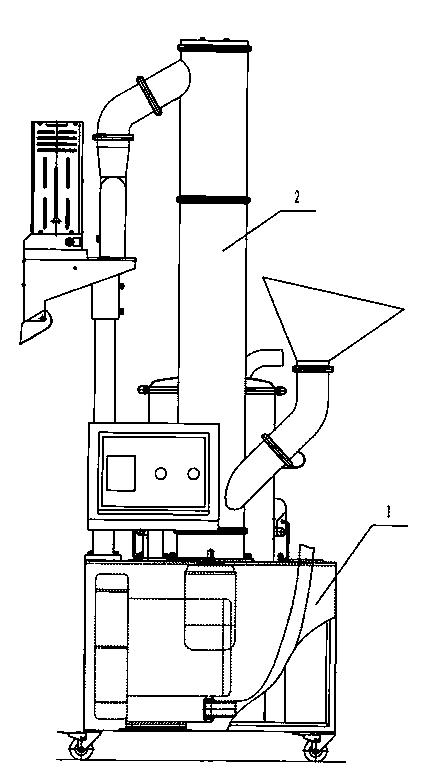

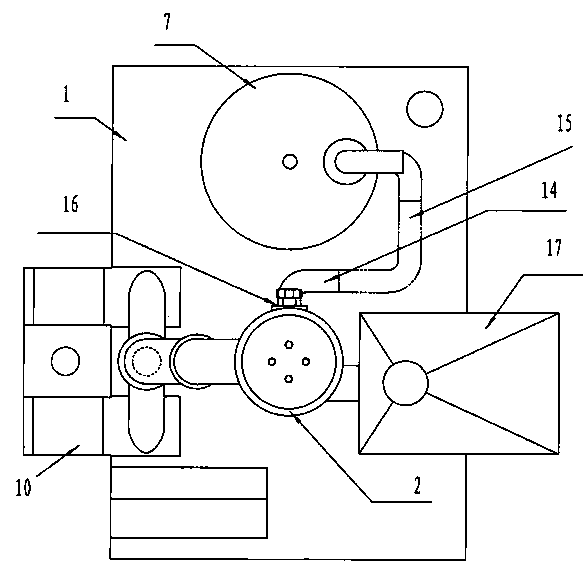

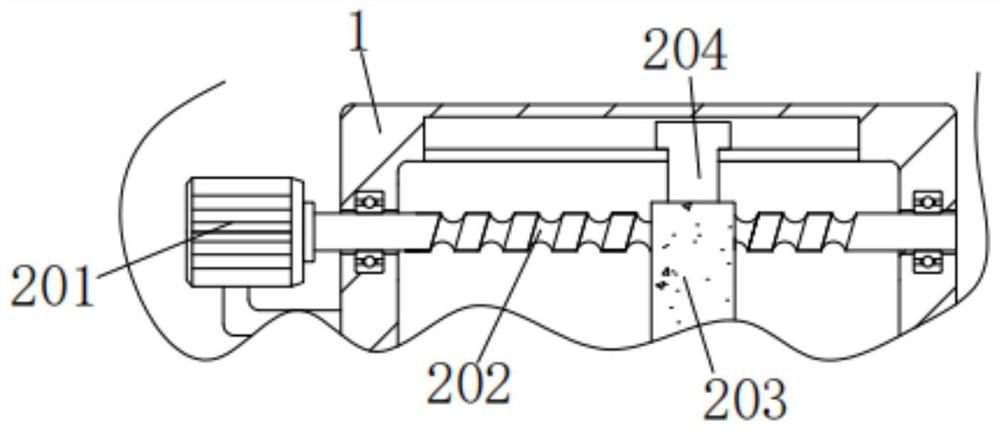

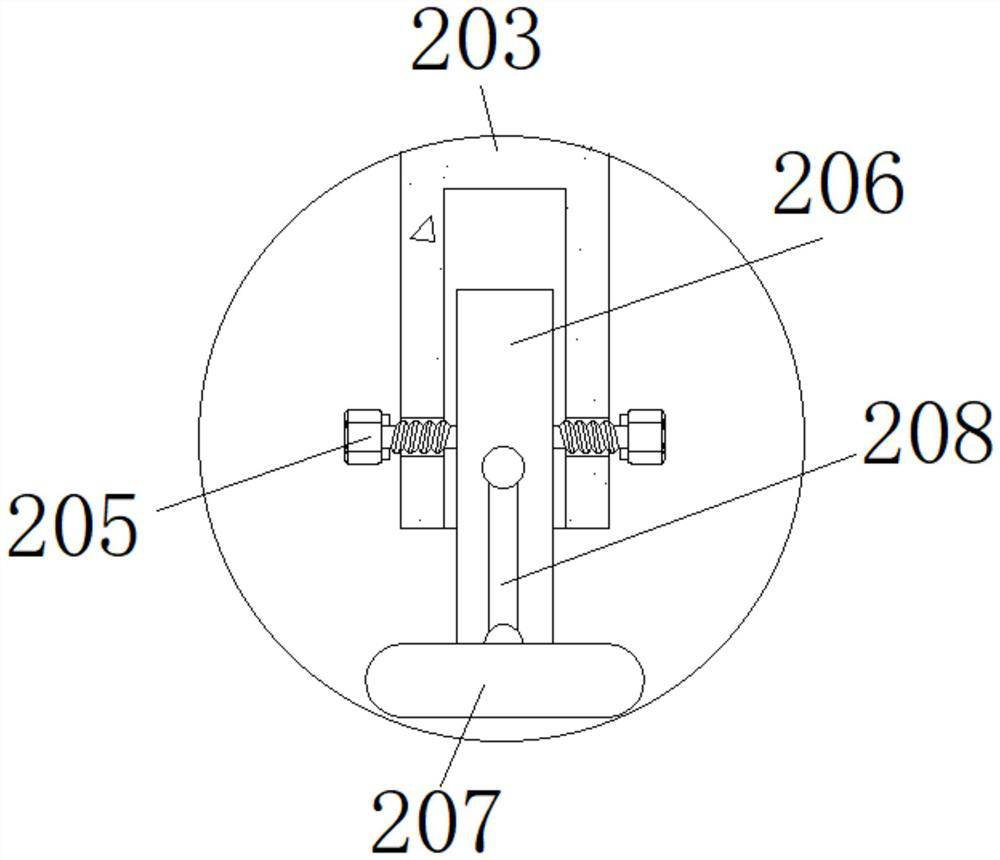

Rice processing and polishing device with polishing improving efficiency

ActiveCN109569768AImprove polishing efficiencyPrevent crushingGrain huskingGrain polishingPulp and paper industryImpurity

The invention provides a rice processing and polishing device with polishing improving efficiency. The rice processing and polishing device comprises a machine body, a draught fan penetrating throughand connected with the side wall of the machine body, a feed port running through and connected with the upper end of the machine body, a discharge port running through and connected with the lower end of the machine body, an impurity outlet running through and connected with the lower end of the side wall of the machine body, and a motor connected to the outer side wall of the machine body through a support. The motor, the draught fan and an external power supply form a series-connection circuit through wires. A driving device is connected with the outer side wall of the machine body. The defects in the prior art are overcome, the design is reasonable, the structure is compact, the problem that an existing rice polishing effect is not ideal is solved, rice is polished through various methods, the rice is screened through a rice screening device first, then primarily polished through a polishing roller and secondarily polished through the polishing device, finally impurities are removed through the draught fan, and the polishing efficiency is improved through a series of measures.

Owner:WEST ANHUI UNIV

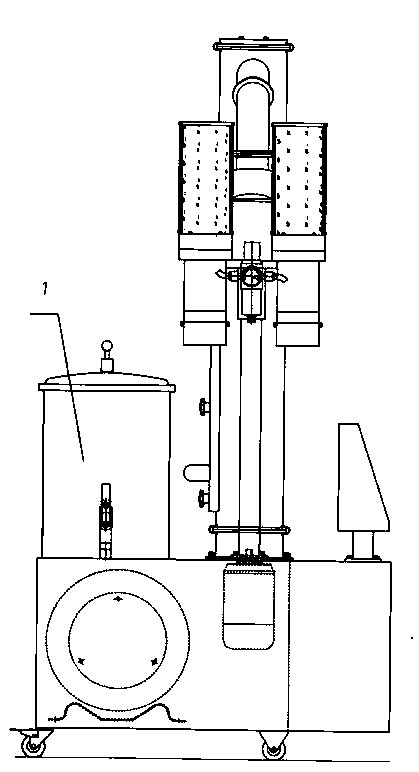

Vertical capsule polisher

ActiveCN103692333AUse a small footprintEasy accessEdge grinding machinesPolishing machinesElectrical and Electronics engineeringEngineering

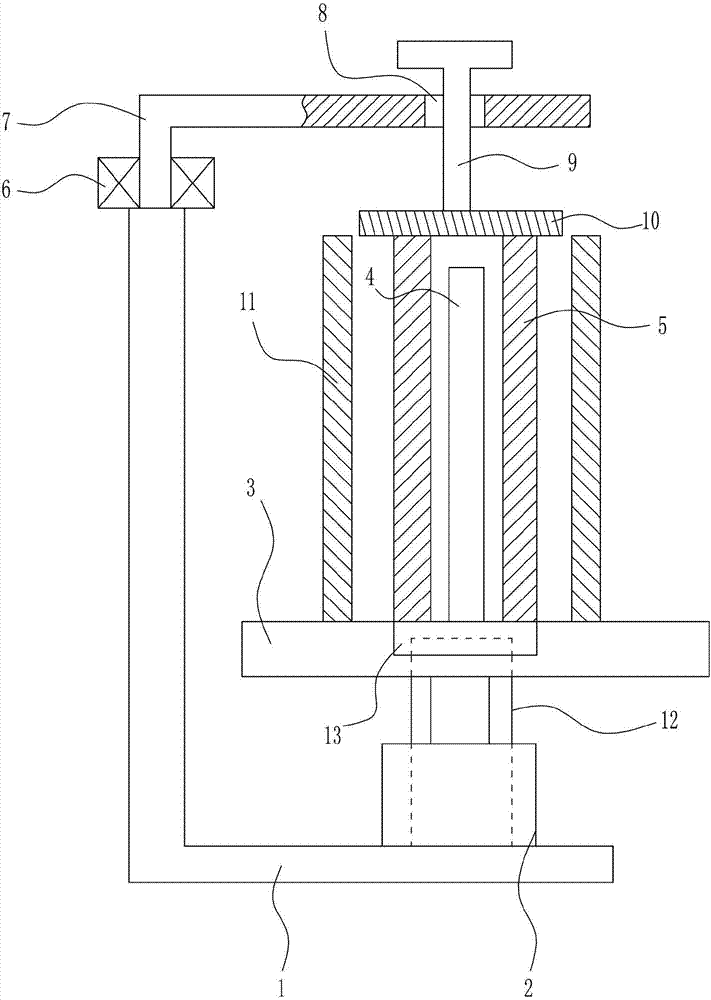

The invention relates to a vertical capsule polisher. A capsule polishing passage is arranged on a base vertically, a feed port and a discharge port are formed in the capsule polishing passage, a helical guide grail and a rotating brush which are matched with each other to convey capsules from the feed port to the discharge port are arranged in the capsule polishing passage, and through holes are formed in the side wall of the capsule polishing passage and connected with a dust suction device. By the vertical structure, used occupied area of the vertical capsule polisher is effectively decreased. The dust suction device and the polisher are arranged on one base, so that the used occupied area is further decreased, and the vertical capsule polisher is more practical and convenient, and is integrally moved more simply and conveniently.

Owner:ZHEJIANG FUCHANG MACHINERY

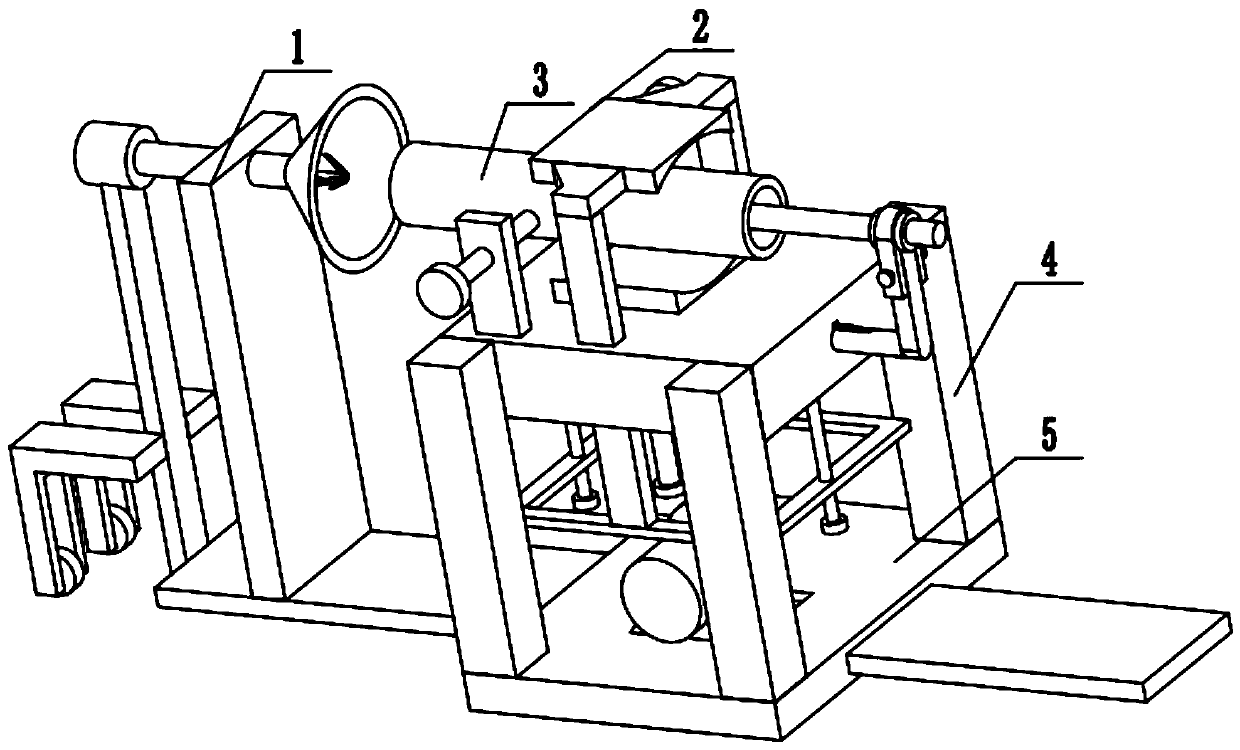

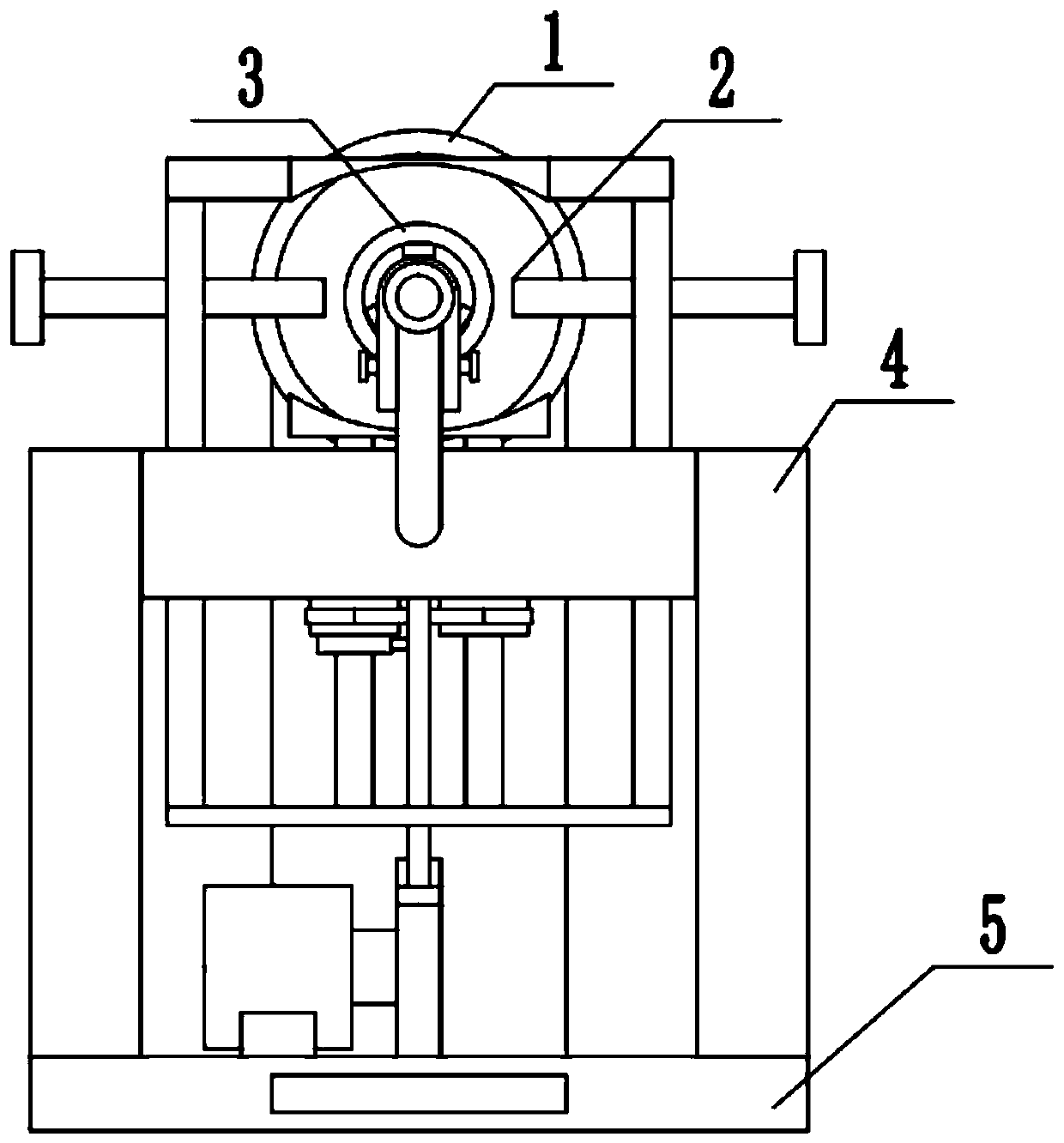

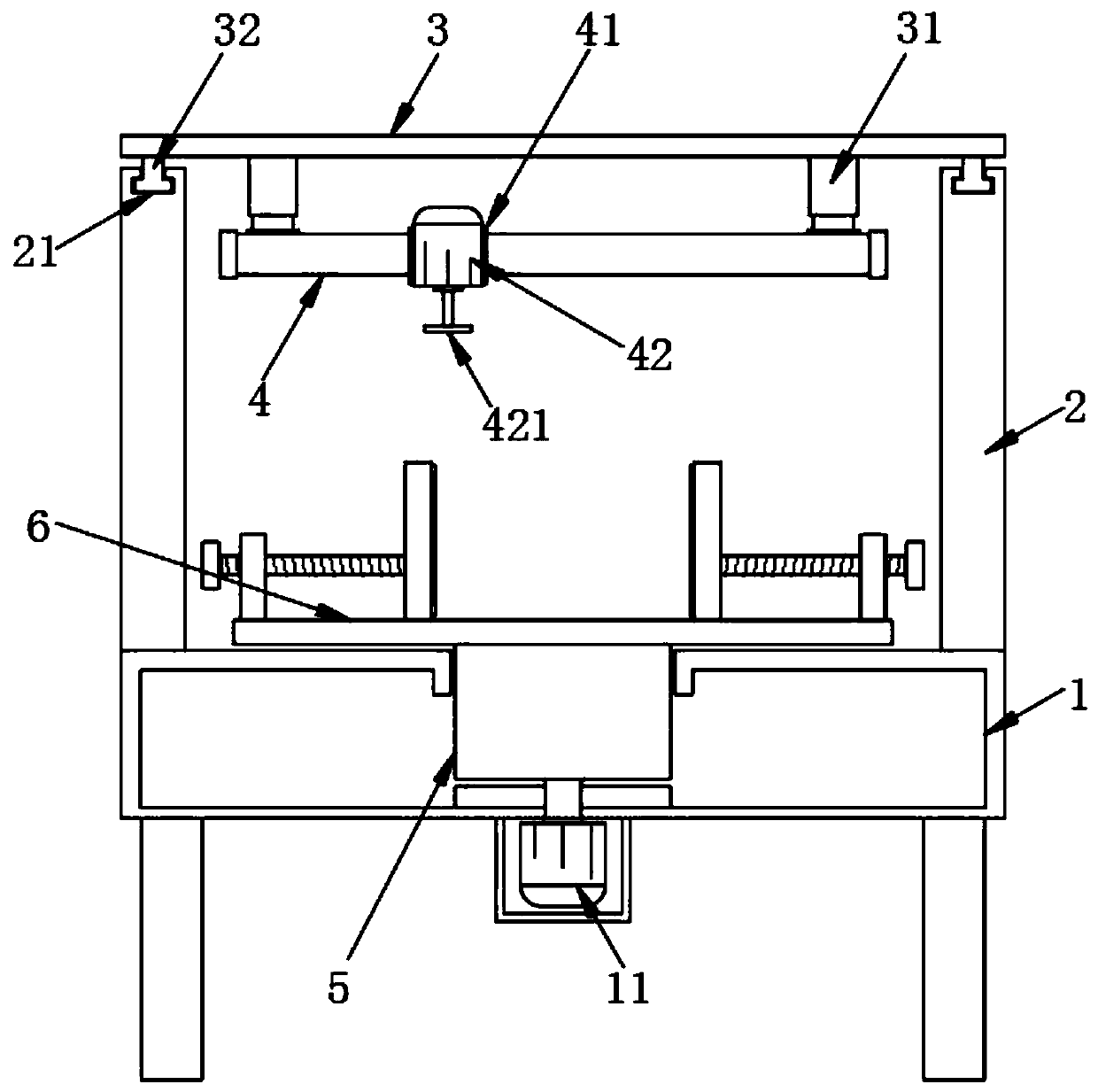

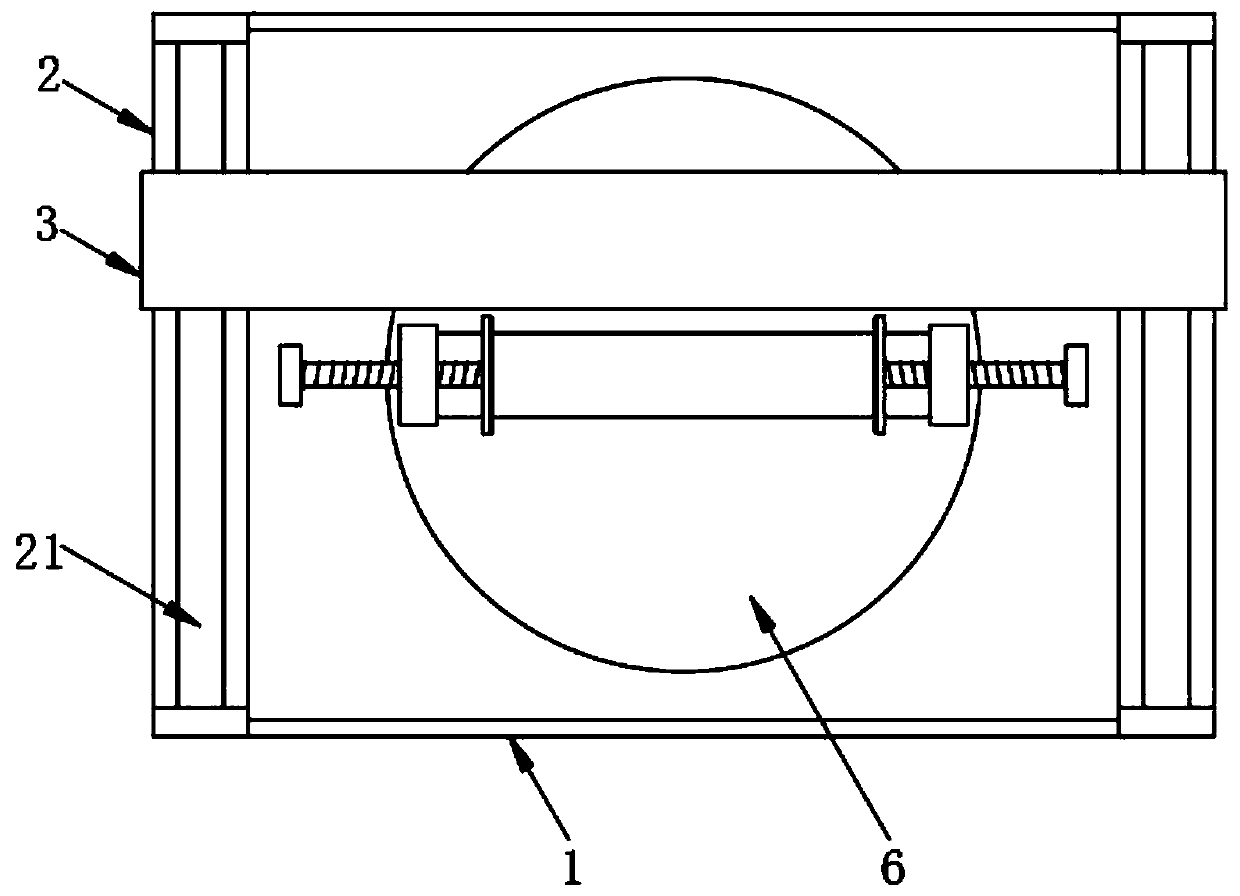

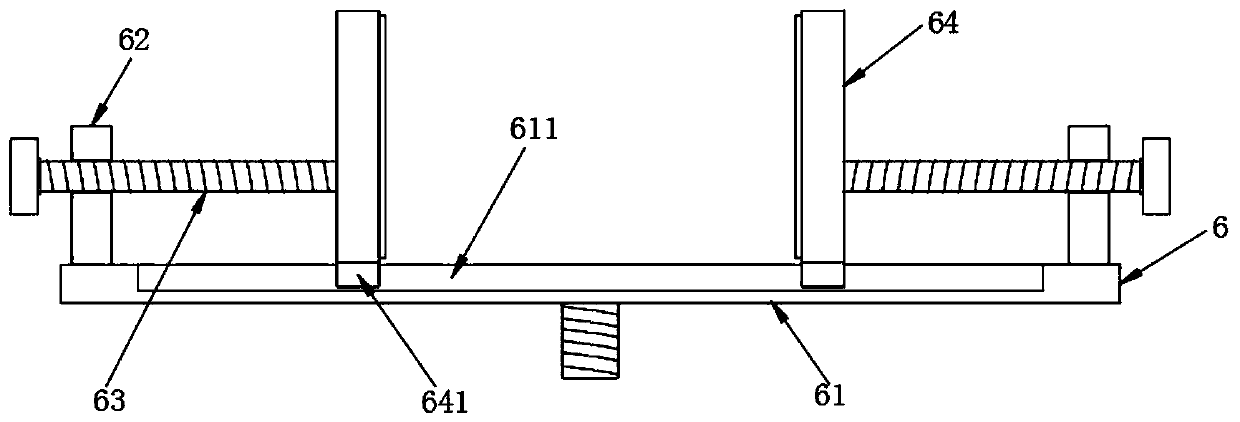

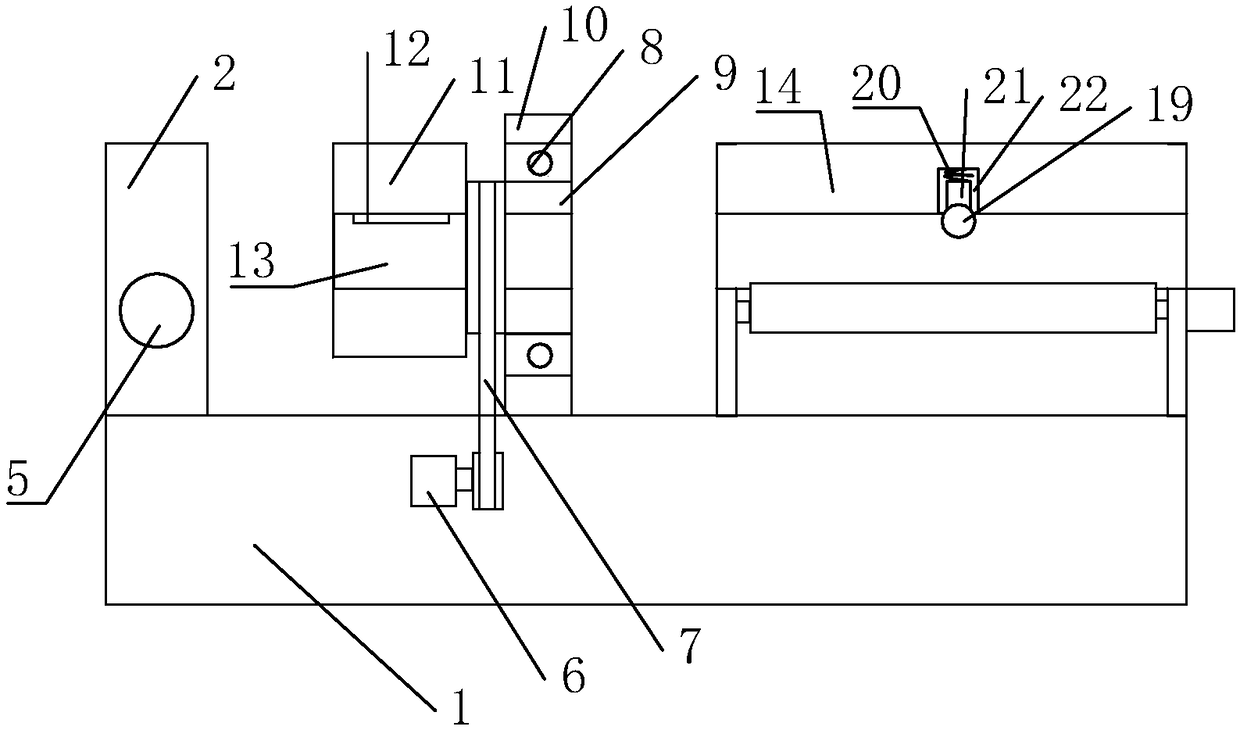

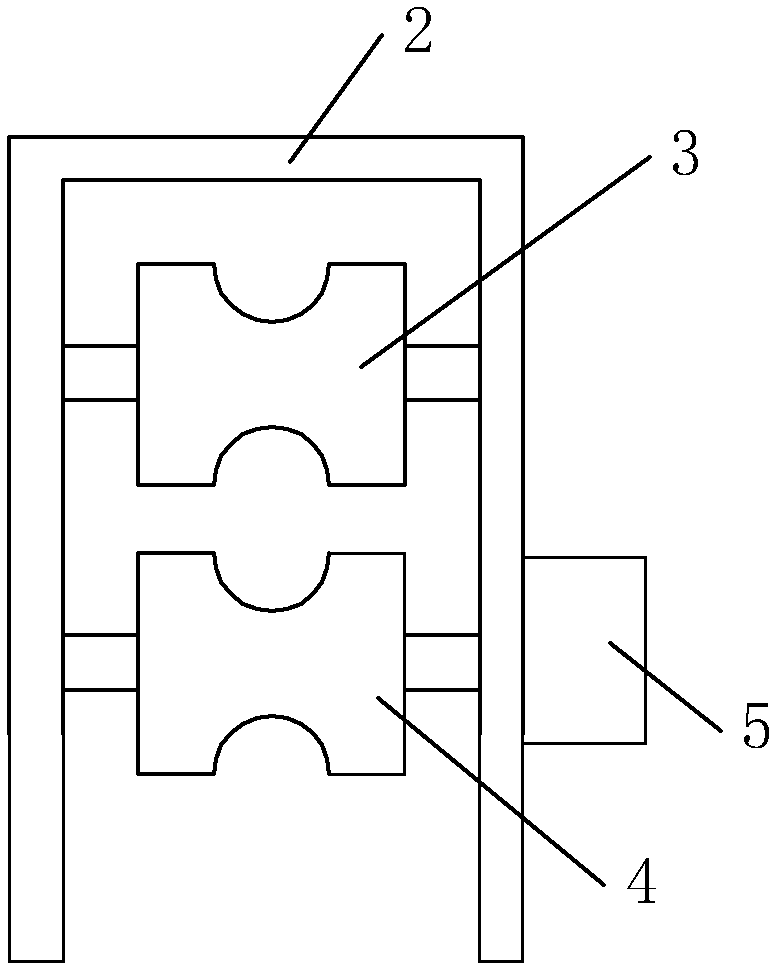

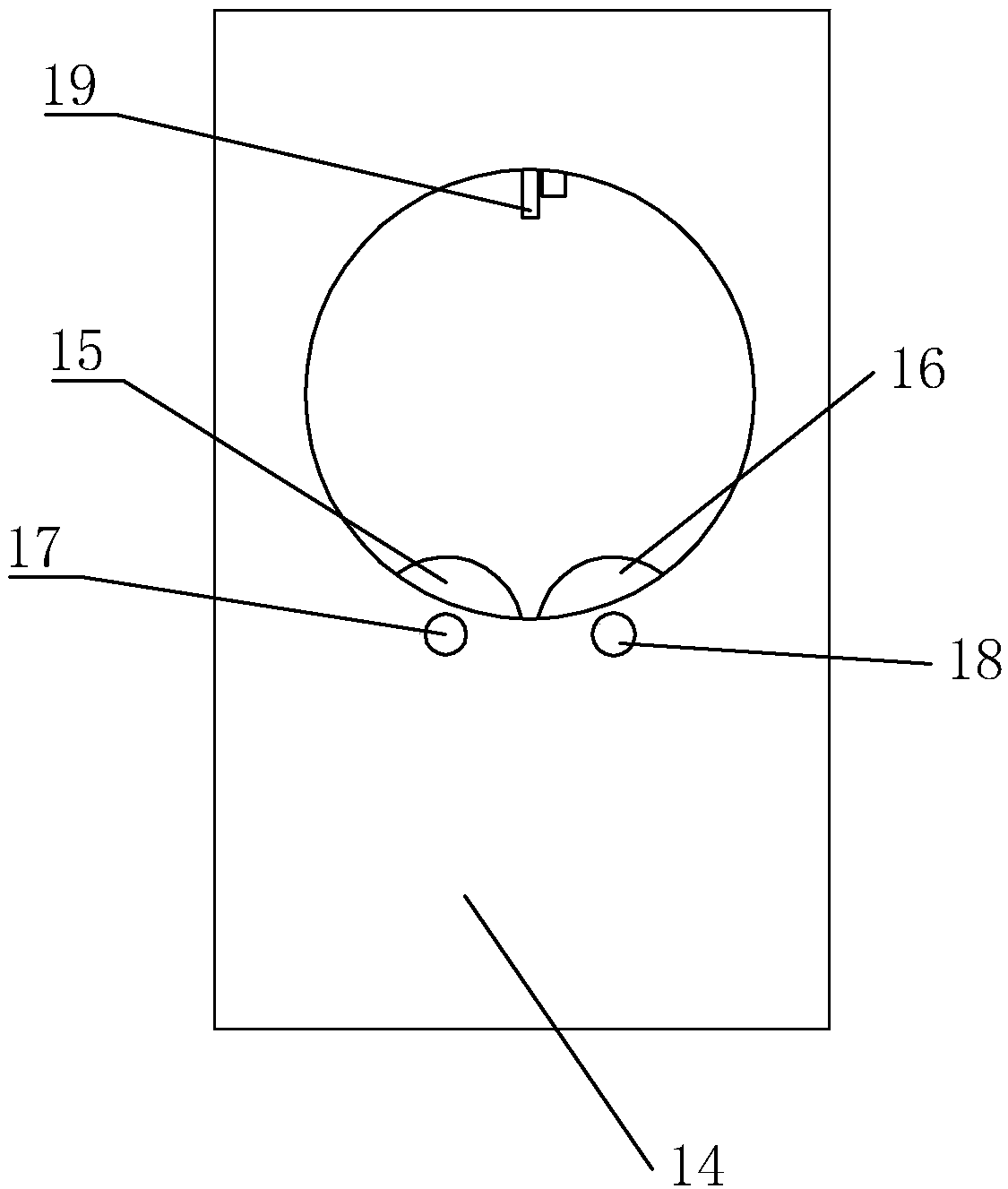

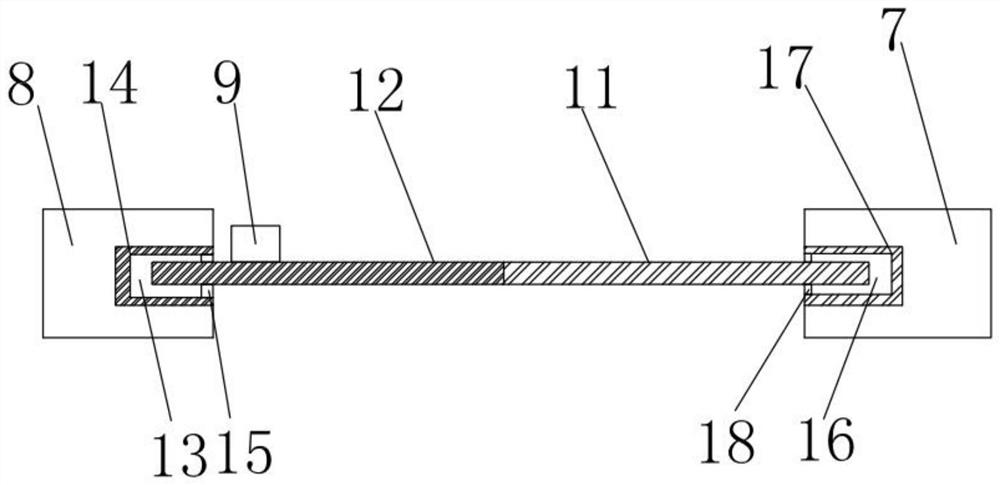

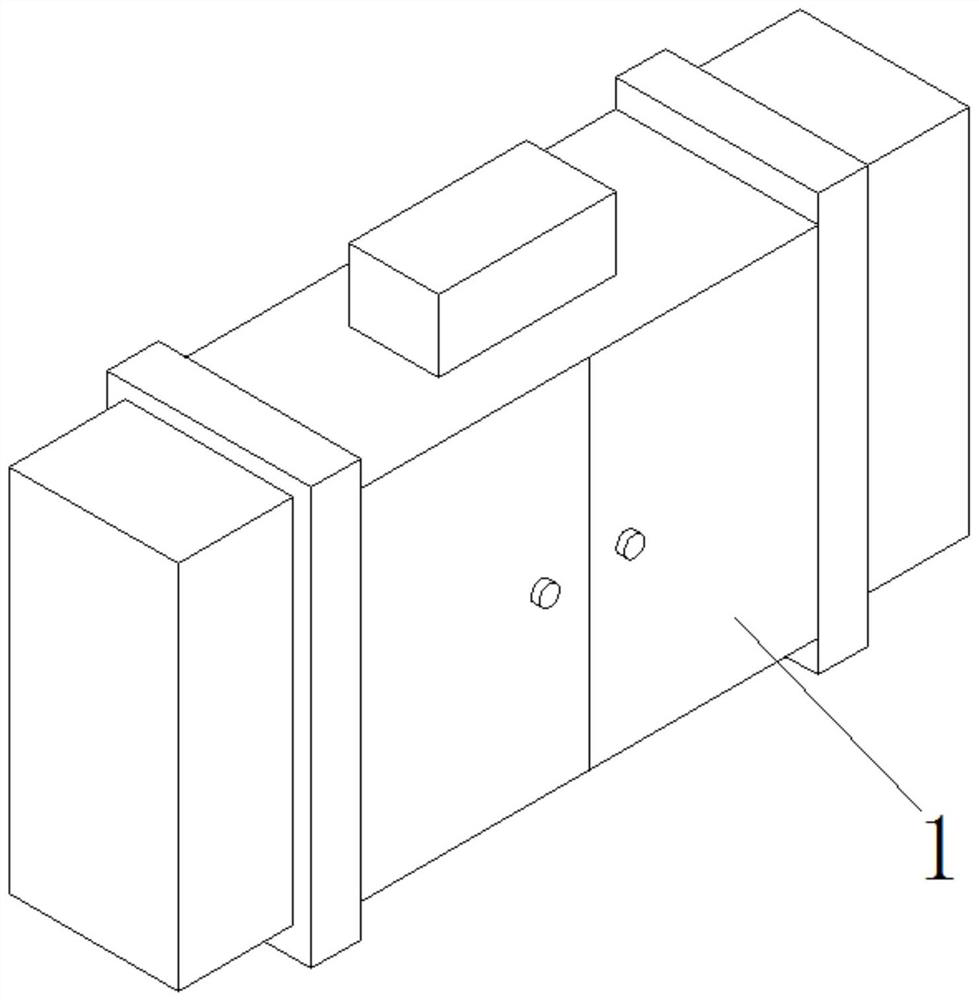

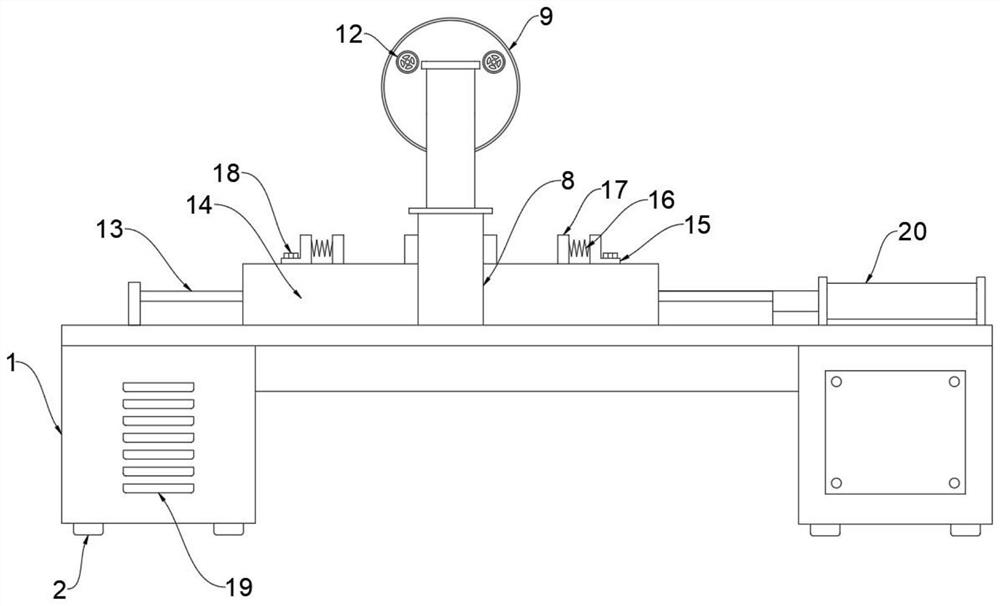

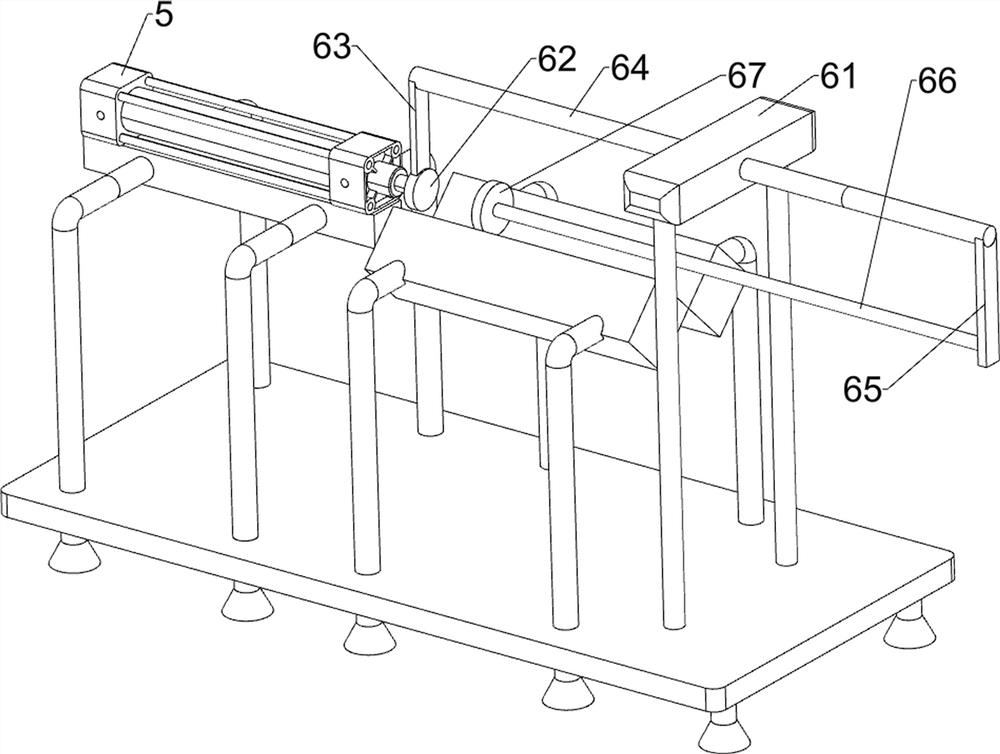

Steel pipe cutting surface polishing processing device

ActiveCN110788692APrevent slippingImprove work efficiencyEdge grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to a steel pipe polishing processing device, in particular to a steel pipe cutting surface polishing processing device. The steel pipe cutting surface polishing processing devicecomprises a steel pipe polishing device, a steel pipe clamping device, a steel pipe body, a support fixing frame and a feeding device, wherein the steel pipe polishing device is fixedly installed onthe feeding device, the steel pipe body is placed on the steel pipe clamping device, the steel pipe clamping device is fixedly installed on the support fixing frame, and the support fixing frame is fixedly installed on the feeding device. According to the device, the steel pipe clamping device is arranged, and the steel pipe clamping device is fixed at multiple points, so that a steel pipe is morestable and is prevented from slipping; the device is used for automatically polishing, people only need to control a motor, and the device polishes an inner hole and an outer circle of the steel pipeat the same time, so that the working efficiency is greatly improved and the polishing time is saved; and the steel pipe clamping device is provided with a circle center aligning device, and burrs are polished in a circumferential polishing mode, so that the burrs are polished more thoroughly and uniformly.

Owner:CHANGZHOU TENGFEI STAINLESS STEEL

Multifunction machining device of pipe fittings

InactiveCN108127529AAvoid influenceCompact structureGrinding carriagesGrinding drivesPipe fittingMachining process

The invention discloses a multifunctional machining device of pipe fittings. The multifunctional machining device comprises a body, a supporting plate, a feeding opening, a discharging opening, a translation air cylinder, a piston rod, a workbench, a grinding motor, a polishing motor, a driving wheel, a driving belt, a mounting shelf, sand wheels, polishing wheels, the pipe fittings, a press wheel, a suspension rod, a limiting connector, a locking part, a mounting plate, an end plate, a movable connecting part, a rotary cylinder, a rotary motor and a material collecting tank. The multifunctional machining device is compact in structure and convenient to use, grinding and polishing of workpieces are integrated, in the machining process, rough parts of the pipe fittings can be ground according to machining requirements, polishing work is facilitated, the time and labor are effectively saved, the machining procedures are reduced, and the production efficiency is improved; meanwhile, in the machining process, the material collecting tank can collect machining waste chippings, the waste chippings can also be collected and recycled while the waste chippings are prevented from influencingthe machining environment, resources are effectively saved, and the multifunctional machining device adapts to different working modes.

Owner:钱姝雅

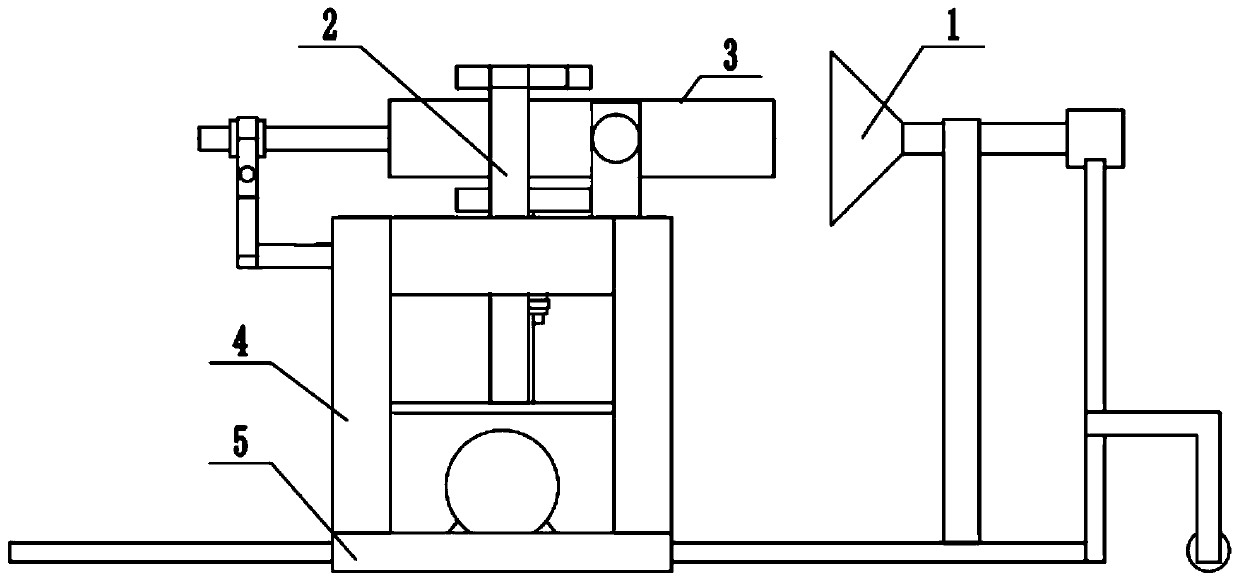

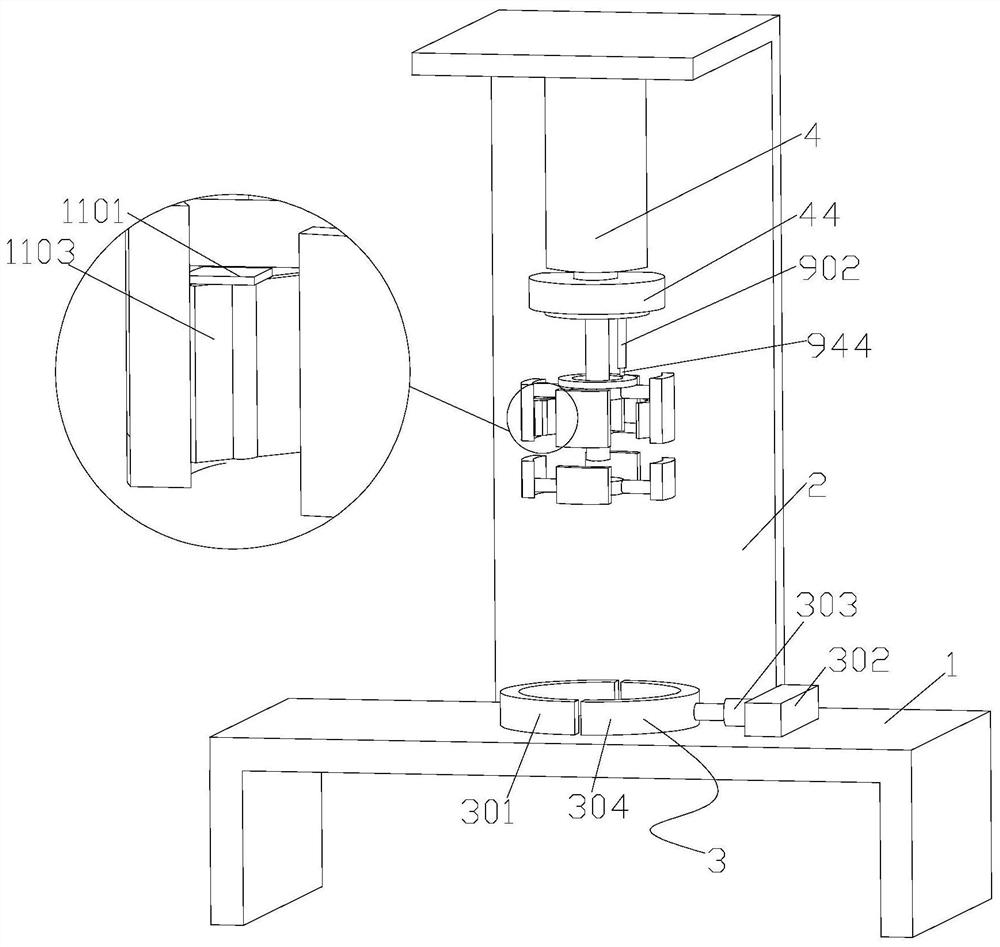

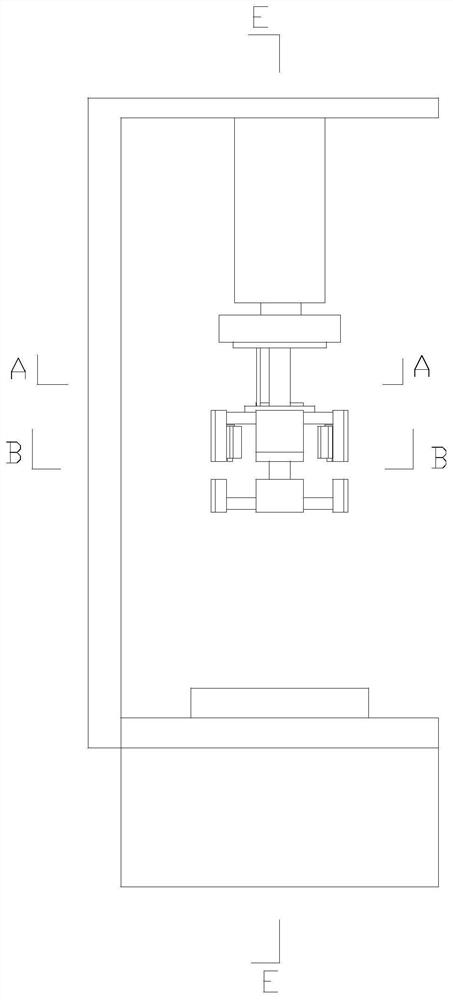

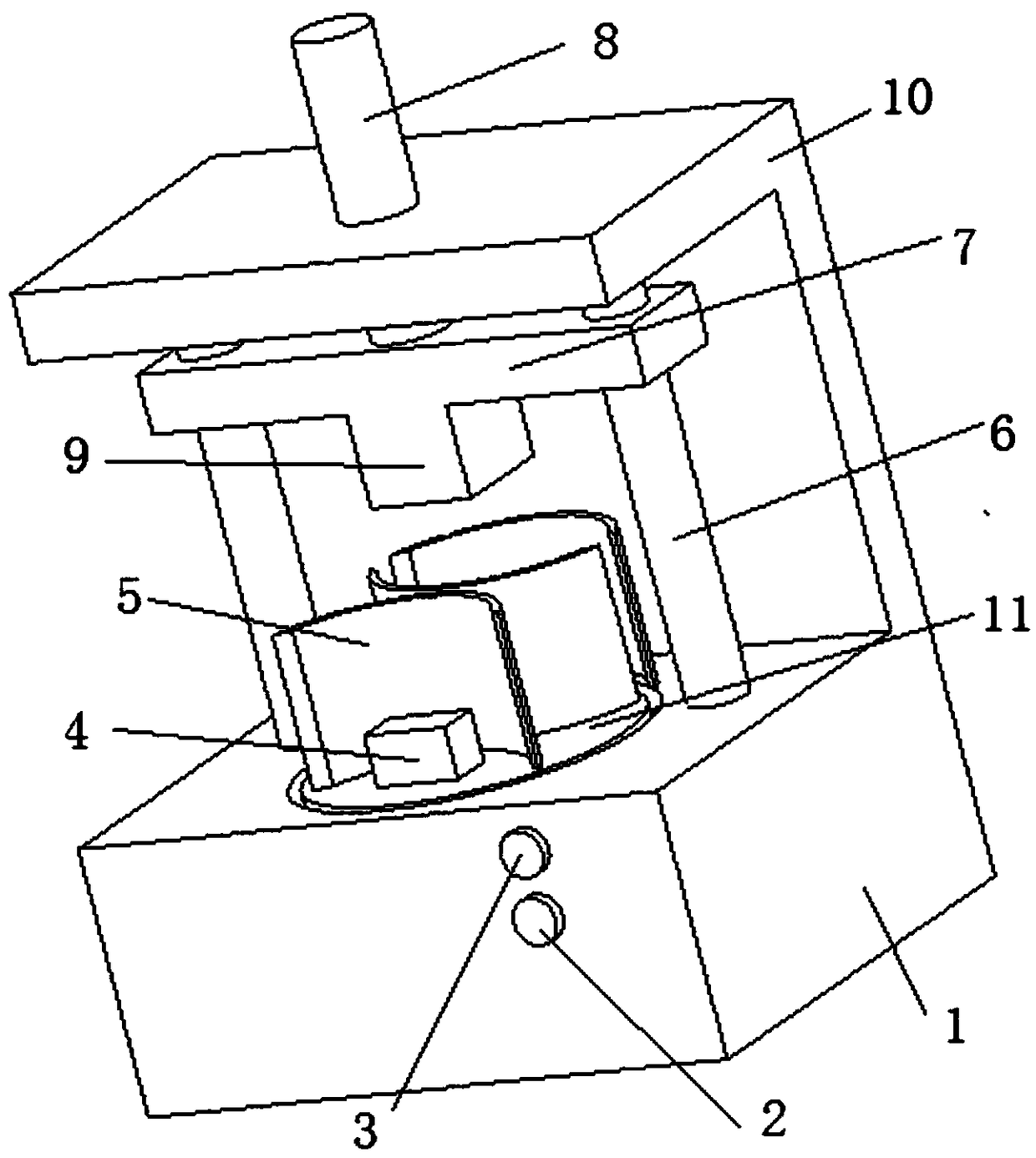

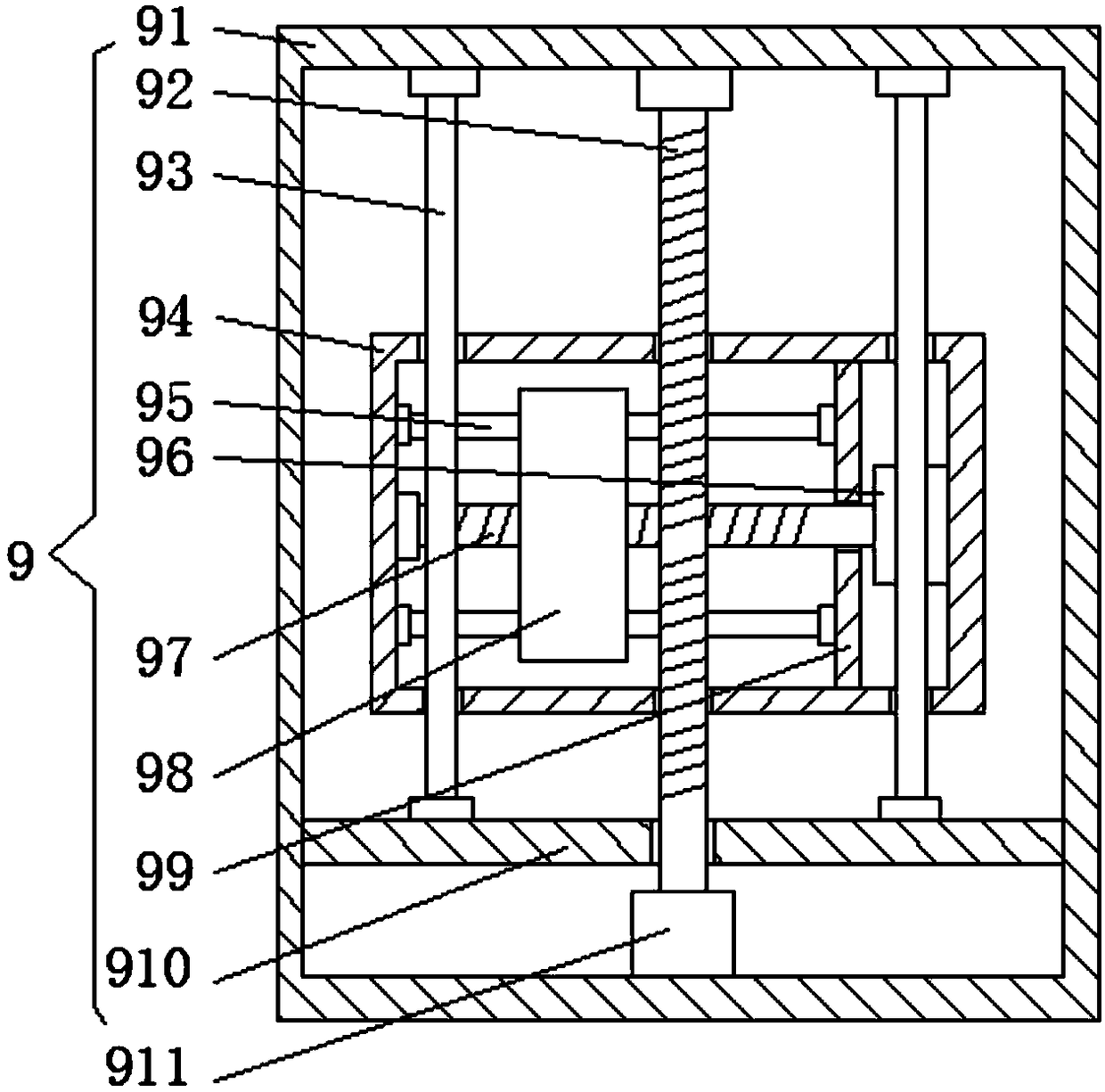

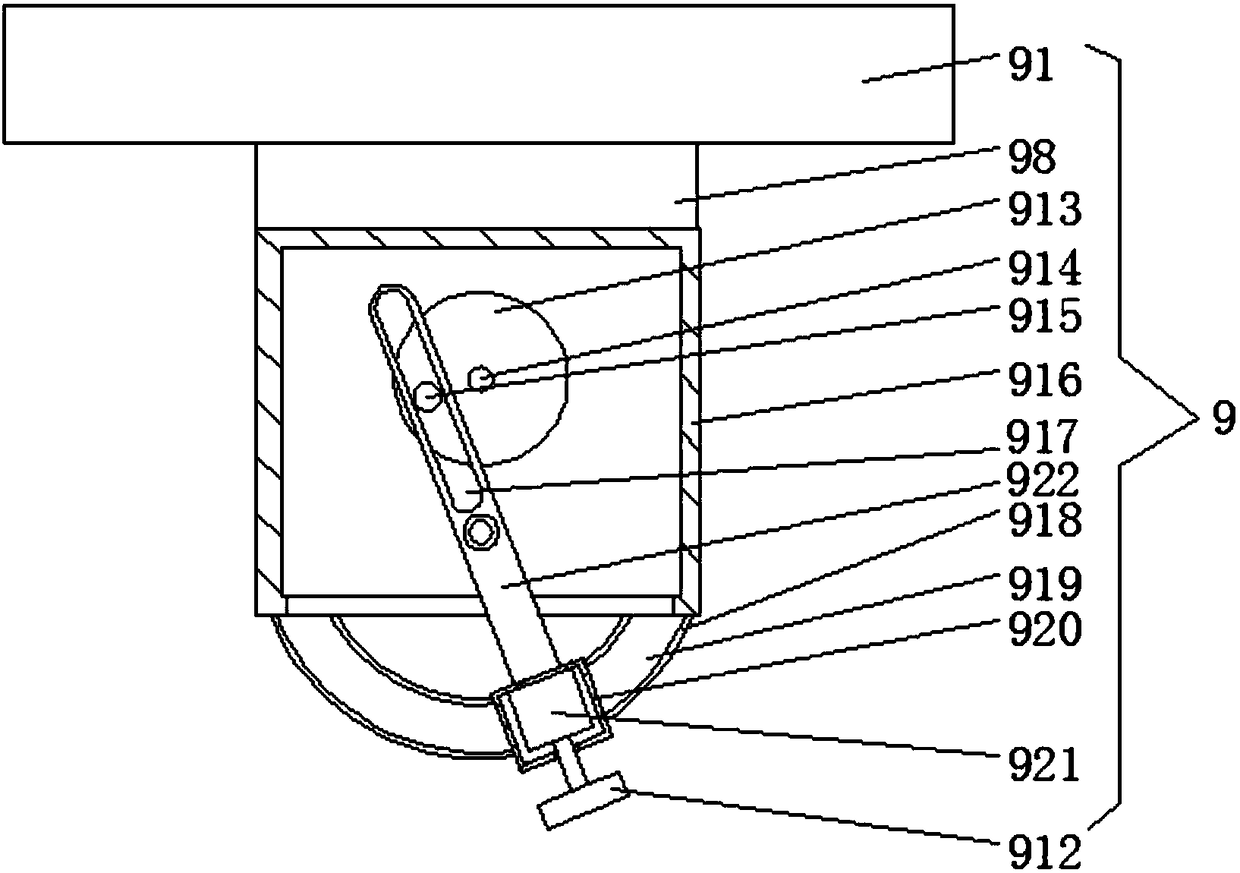

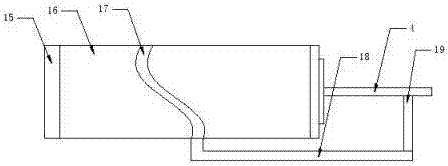

Hydraulic oil cylinder barrel inner wall deburring equipment

InactiveCN112355768AThoroughly polishedSimple structureEdge grinding machinesRevolution surface grinding machinesElectric machineryStructural engineering

The invention discloses hydraulic oil cylinder barrel inner wall deburring equipment. The hydraulic oil cylinder barrel inner wall deburring equipment comprises a base. An L-shaped plate is fixedly arranged on the side face of the base. A clamping mechanism is arranged on the base. An air cylinder is fixedly arranged on the top of the L-shaped plate. An electric shell is fixedly arranged on a piston rod of the air cylinder. A motor is fixedly arranged in the motor shell. A polishing mechanism is arranged at the output end of the motor.

Owner:杭州佑滨科技有限公司

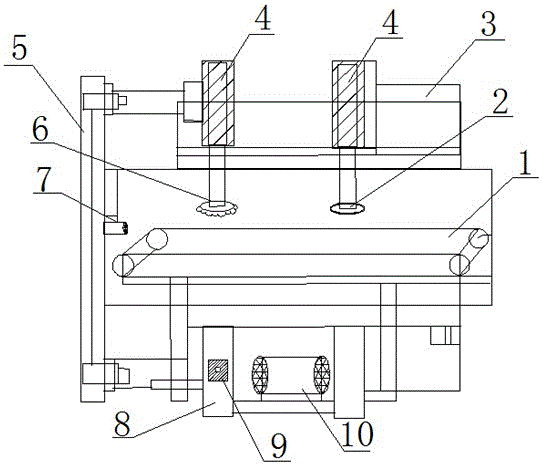

Efficient polishing equipment for wood plate processing

InactiveCN109333265AThoroughly polishedSimple structureBelt grinding machinesGrinding/polishing safety devicesDrive wheelWood plank

The invention discloses efficient polishing equipment for wood plate processing. Conveying through holes are symmetrically formed in the two side walls of a polishing box, a conveying belt is mountedin the formed conveying through holes, and the two ends of the conveying belt are in transmission connection through a driving wheel and a driven wheel which are arranged outside the two sides of thepolishing box; a coarse grinding mechanism and a fine grinding mechanism are mounted at the positions, on the two sides inside the polishing box, over the conveying belt correspondingly; the coarse grinding mechanism is composed of a first grinding roller, a first guiding roller, a second guiding roller and a coarse grinding belt which are in transmission connection; and the fine grinding mechanism is composed of a second grinding roller, a third guiding roller, a fourth guiding roller and a fine grinding belt which are in transmission connection, and a sweeping roller is mounted on the rightside of the fine grinding mechanism. By adopting the efficient polishing equipment, the structure is simple, assembly and mounting are convenient, coarse grinding operation and fine grinding operationare conducted through a coarse grinding belt and a fine grinding belt correspondingly, the plate surface of a wood plate is ground and polished thoroughly, and the grinding and polishing effects aregood.

Owner:安徽建联木业有限公司

Special polishing device for jade engraved products

ActiveCN107900885AAchieve vertical movementAchieve tilt rotationGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses a special polishing device for jade engraved products. The special polishing device comprises a base, a mounting base and a fixed base; two metal slide rods, vertically placed,are welded at the top end of the base; limiting rings are welded on the side walls of the two metal slide rods; spring pieces sleeve the side walls, near the top ends of the limiting rings, of the two metal slide rods; the same slide base sleeves the side walls, near the top ends of the spring pieces, of the two metal slide rods; a motor is clamped in the middle position of the side wall of the slide base; a polishing brush is fixed on an output shaft of the motor through a bolt; the same metal plate is fixed at the top ends of the two metal slide rods through bolts; a slide block is arrangedat the bottom end of the mounting base; a chute matched with the slide block in specification is formed in the outer wall of the top end of the base; the slide block is inserted in the chute; and thefixed base is of a disc structure. The special polishing device can be convenient to operate, improves the operation comfort, is more thorough in polishing, improves the product quality, improves theefficiency, and reduces the reject ratio.

Owner:滨州高新高端装备制造产业园有限公司

Adjustable industrial robot suitable for being used in mechanical production workshop

InactiveCN112139943AAdjustable rotation angleRealize multi-angle grindingGrinding carriagesGrinding drivesThick plateIndustrial robotics

The invention discloses an adjustable industrial robot suitable for being used in a mechanical production workshop. The adjustable industrial robot comprises a first shell and a second shell, a movingdevice is arranged on the upper portion of the interior of the first shell, a first sliding block is fixedly connected to the top of a thick plate, and the outer wall of the first sliding block is connected with a groove in the top of the inner wall of the first shell in a sliding and clamping mode. A vertical plate is in clearance fit with a groove in the bottom of the thick plate, a grinding wheel is fixedly connected to the bottom of the vertical plate, first bolts are arranged on both the two sides of the vertical plate, and the outer walls of the two first bolts are in threaded connection with the lower portions of the left side and the right side of the thick plate and abut against the left side and the right side of the vertical plate. A grinding piece is rotatably connected with the vertical plate, one side of the vertical plate is provided with an electric push rod which is rotatably connected, the extending end of the electric push rod is rotatably connected with the end ofone side of the grinding piece, the rotating angle of the grinding piece can be adjusted through stretching and retracting of the electric push rod, therefore multi-angle grinding is achieved, and theoverall grinding efficiency is improved.

Owner:黎锦华

Polishing machine

InactiveCN105127868AThoroughly polishedGuaranteed cleanlinessPolishing machinesGrinding machinesEngineeringMechanical engineering

The invention discloses a polishing machine. The polishing machine comprises a driving device and a polishing device, the polishing device is located at the uppermost position and connected with the driving device through a rack, the polishing device comprises polishing revolving shaft components, a rough polishing disc and a fine polishing disc, the rough polishing disc and the fine polishing disc are each connected with the corresponding polishing revolving shaft component, a conveying belt is arranged under the polishing device, the driving device is installed under the conveying belt and located on a base, a driving switch is arranged on the base, a blower is arranged at the position, in parallel with the conveying belt, of the interior of the rack, and the polishing revolving shaft components, the conveying belt and the blower are all driven by the driving device. The polishing machine has the advantages that the structure is simple, the polishing machine provided with the rough polishing disc and the fine polishing disc is provided, so that a workpiece in need of polishing is subjected to two procedures, namely the rough polishing and the fine polishing, through the conveying belt, the workpiece is polished thoroughly, through the blower which is arranged additionally, unnecessary dust can be blown off in the polishing process of the workpiece, the cleanliness of the workpiece after the polishing is guaranteed, and thereby labor and time are saved.

Owner:TAICANG WENGUANGHUI CLEANING EQUIP CO LTD

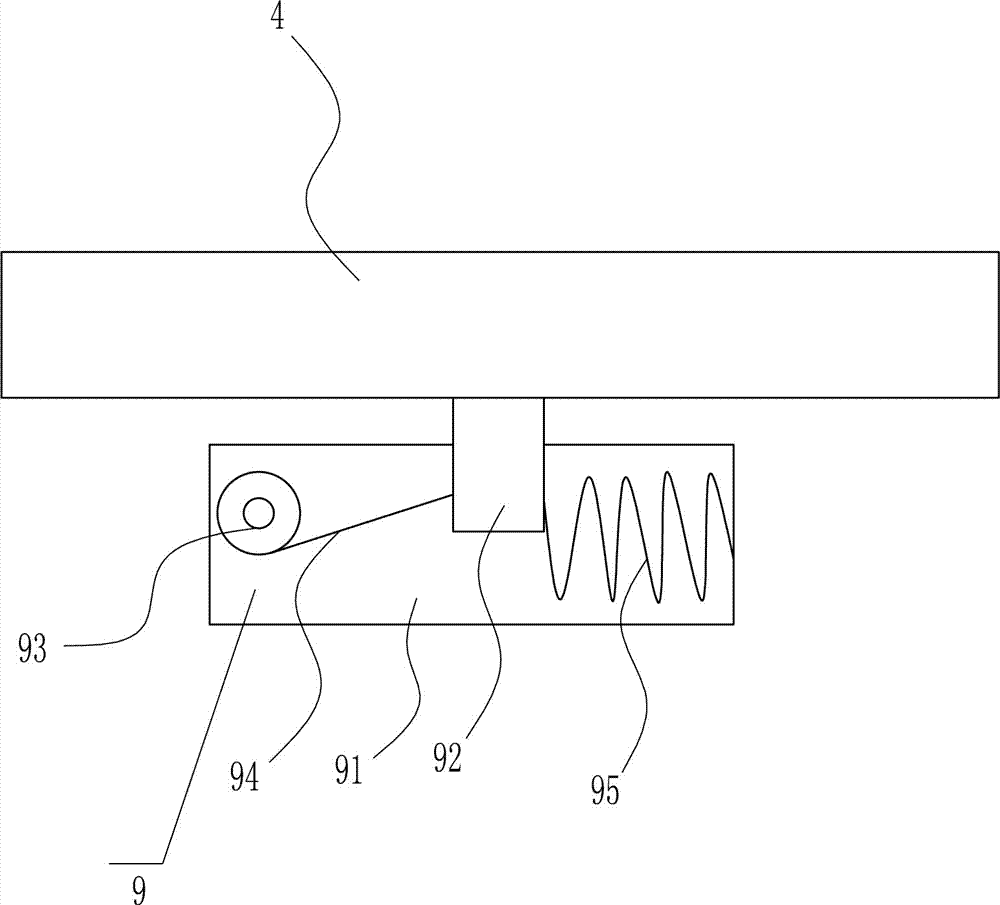

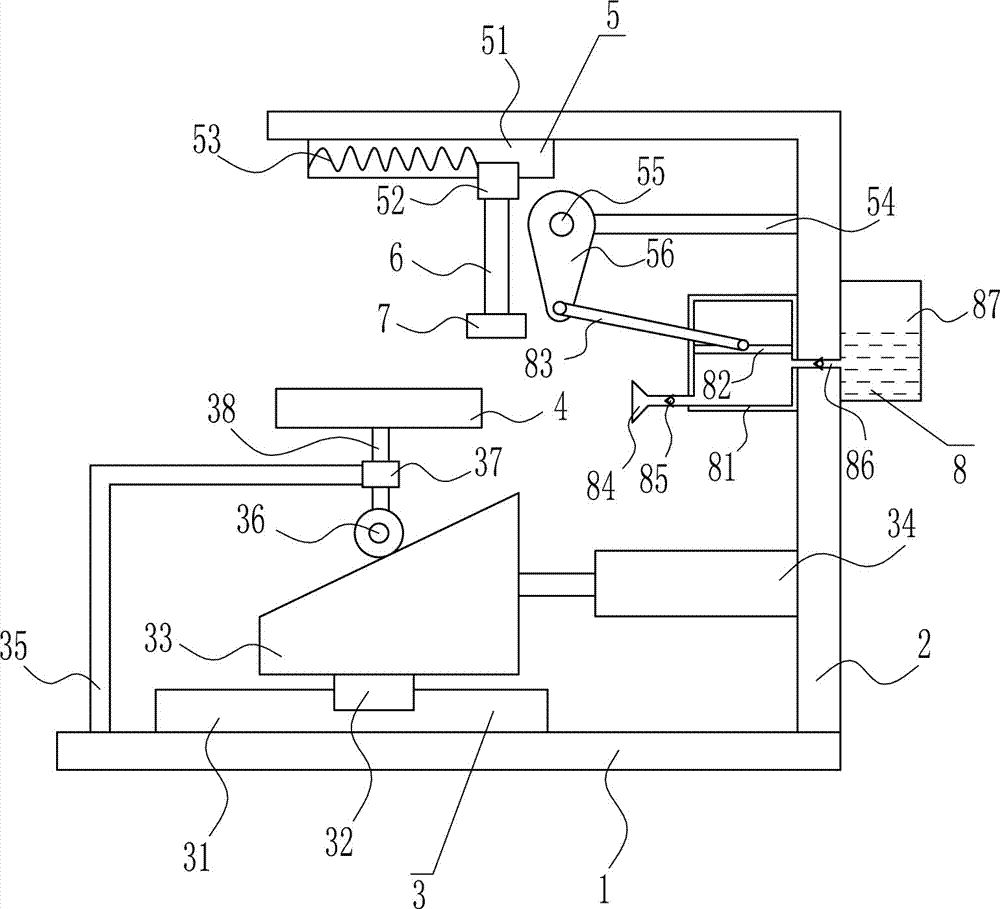

Work method of polishing device for automobile spare part production

InactiveCN108436706AQuick positioning clampingThoroughly polishedGrinding carriagesGrinding machinesHydraulic cylinderProduction schedule

The invention relates to the technical field of polishing devices, in particular to a work method of a polishing device for automobile spare part production. The polishing device comprises a box body,one side of the upper end of the box body is provided with an L-shaped plate, the middle of the upper end of the L-shaped plate is provided with a hydraulic cylinder, the lower end of the hydraulic cylinder penetrates through the L-shaped plate and is connected with a grinding device, one side of the outer wall of the box body is provided with a first switch and a second switch, and the two sidesof the upper end of a first rotary plate are both provided with fixtures. By means of the polishing device, a grinding wheel can move randomly on the plane, and polishing can be more thorough; the arranged fixtures can rapidly position and clamp a workpiece, and time and labor are saved; an arranged motor drives the first rotary plate to rotate, and the two fixtures can be used alternatively; loading and unloading can be performed on the other fixture while the workpiece is polished; and the production schedule is accelerated, time is saved, work efficiency is improved, and the production cost is lowered.

Owner:朱明德

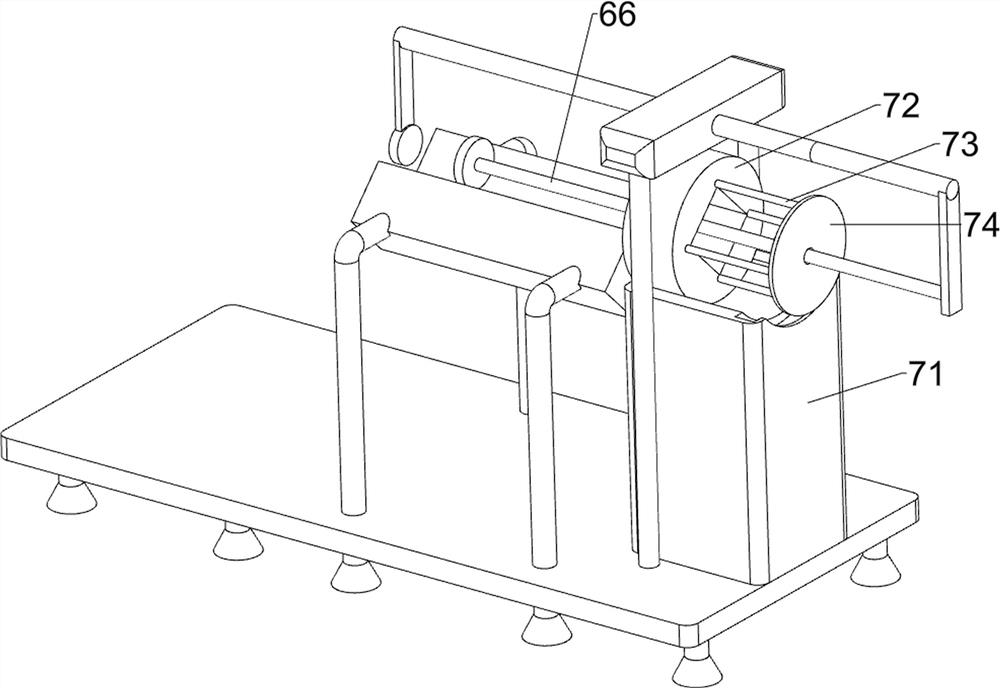

Leather polishing device for production of leather shoes

The invention relates to a leather polishing device, in particular to a leather polishing device for production of leather shoes. The leather polishing device for production of the leather shoes solves the technical problems that polishing is uneven, polishing is not thorough and the polishing quality is poor. In order to solve the problems, the leather polishing device for production of the leather shoes comprises a bottom plate, a right support, a moving device, a placement plate, a driving device and the like; the right support is arranged on the right of the top of the bottom plate, the moving device is arranged on the left of the top of the bottom plate, the placement plate is arranged at the top of the moving device, the driving device is arranged at the top inside the right support, a fixing rod is arranged at the bottom of the driving device, and the bottom of the fixing rod is connected with a polishing block. The leather polishing device for production of the leather shoes achieves the effects of even polishing, thorough polishing and excellent polishing quality, stress uniformity is achieved, omnibearing polishing is realized, and leather can also be fixed without moving and is prevented from wrinkling.

Owner:郑世珍

Grinding device for magnesium alloy part production

InactiveCN110153856AReduce labor intensityHigh degree of automationGrinding carriagesGrinding drivesPulp and paper industryUltimate tensile strength

The invention belongs to the technical field of part production and machining and particularly relates to a grinding device for magnesium alloy part production. The grinding device comprises a base. Amotor is fixedly connected to the bottom end of the base. The motor is electrically connected with an external power supply. The output end of the motor is fixedly connected with a rotary seat. The top end of the rotary seat extends to the outer side of the base. The top end of the rotary seat is detachably connected with a fixing assembly. The two sides of the top end of the base are both fixedly connected with supports. The top ends of the supports are slidably connected with a top plate. The two ends of the lower end face of the top plate are both fixedly connected with electric push rods.The position of a grinding disk is adjusted by moving the top plate and a movable block. The grinding disk is moved to the location over a part. The grinding disk is moved to the surface of the partthrough the electric push rods. An electromotor and the motor are started to conduct grinding on the part. Workers do not need to hold abrasive paper or a grinder to conduct grinding on the part. Thegrinding device for magnesium alloy part production is high in automation degree, relieves the labor intensity of the workers and improves the grinding efficiency.

Owner:巢湖云海镁业有限公司

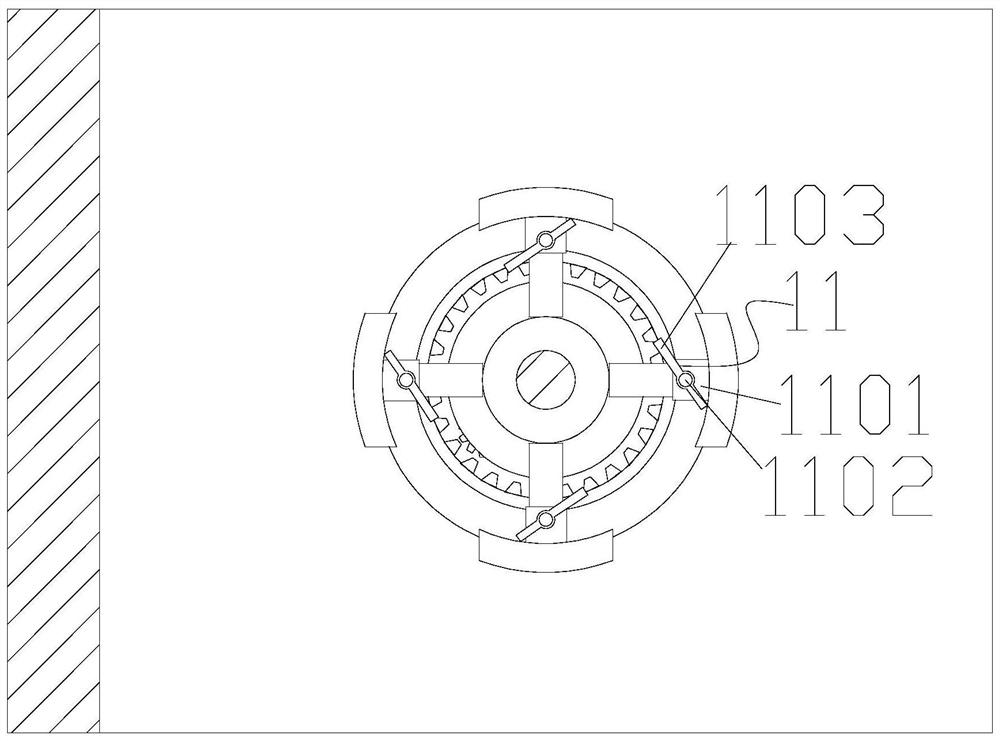

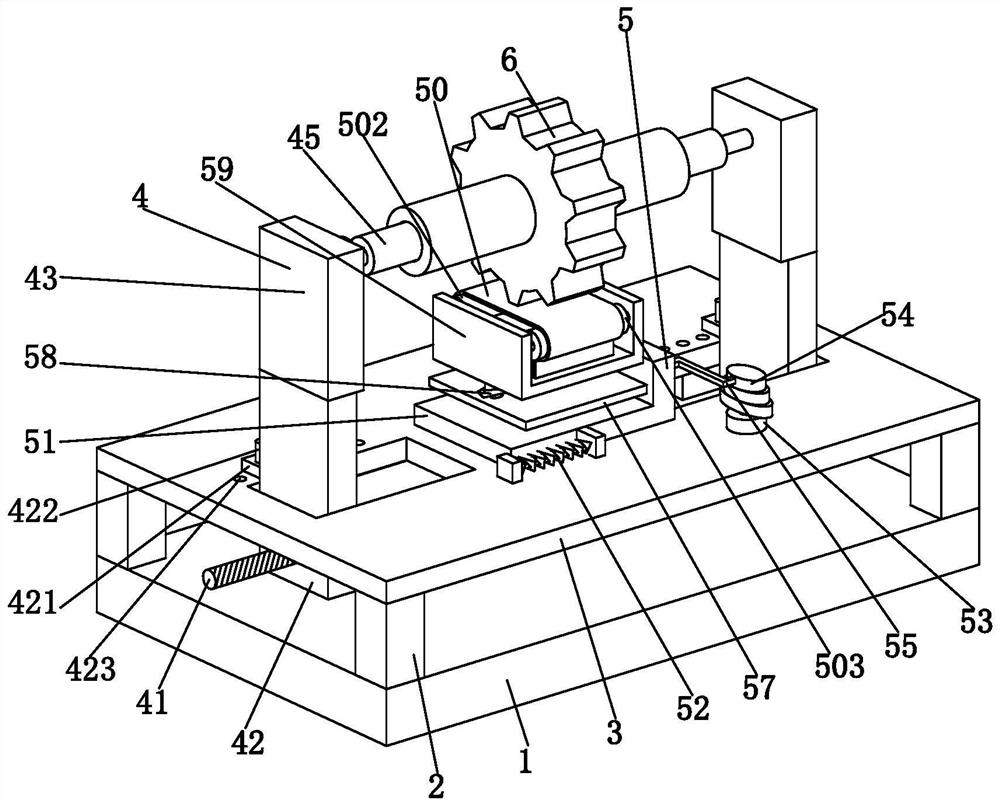

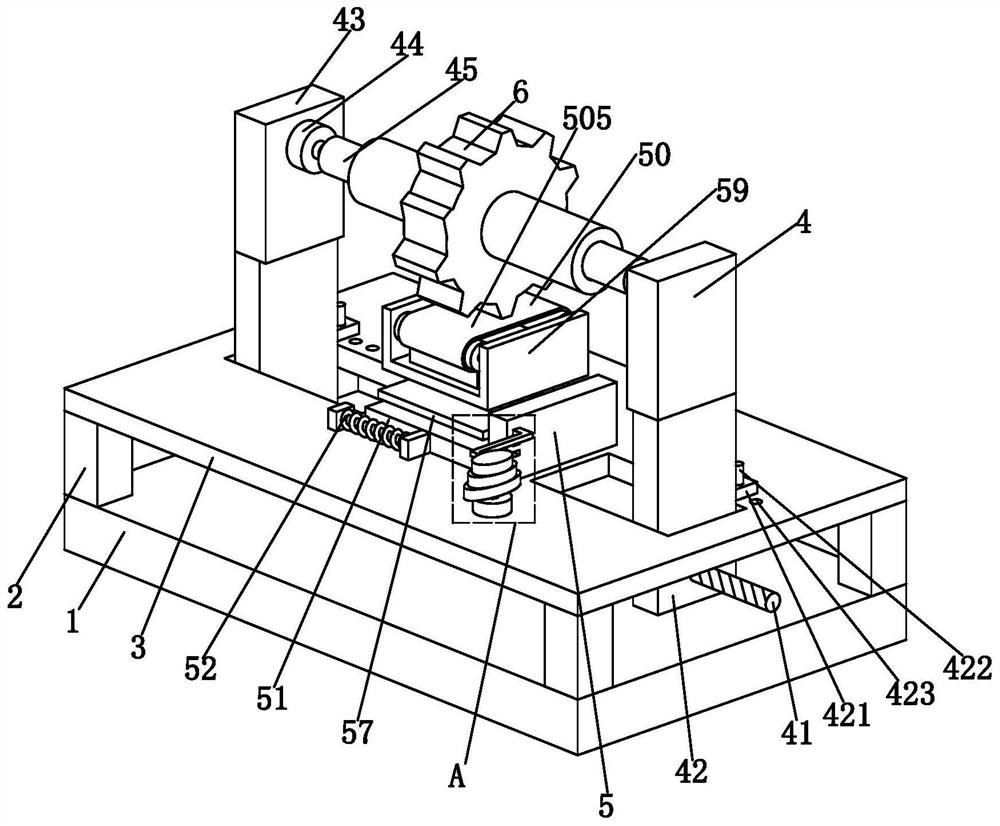

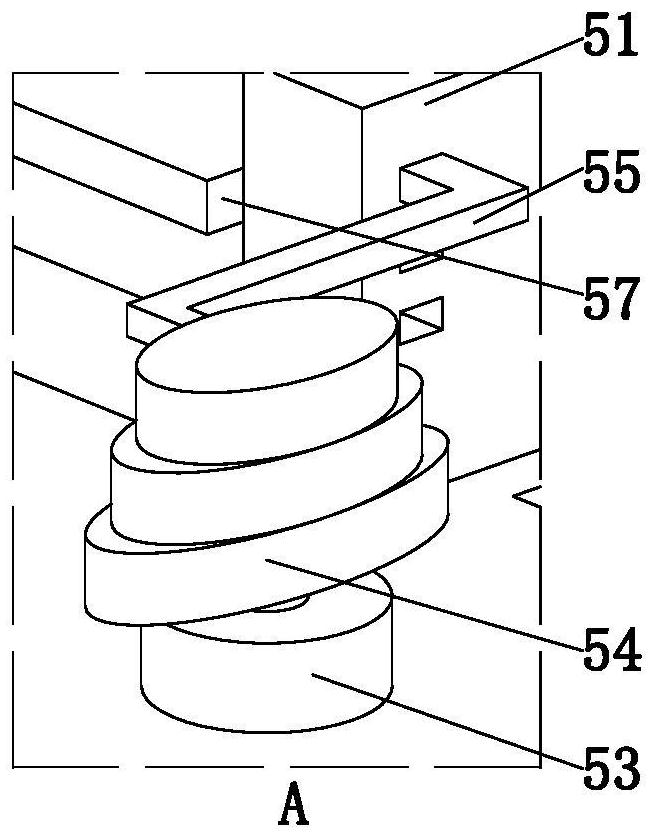

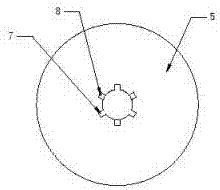

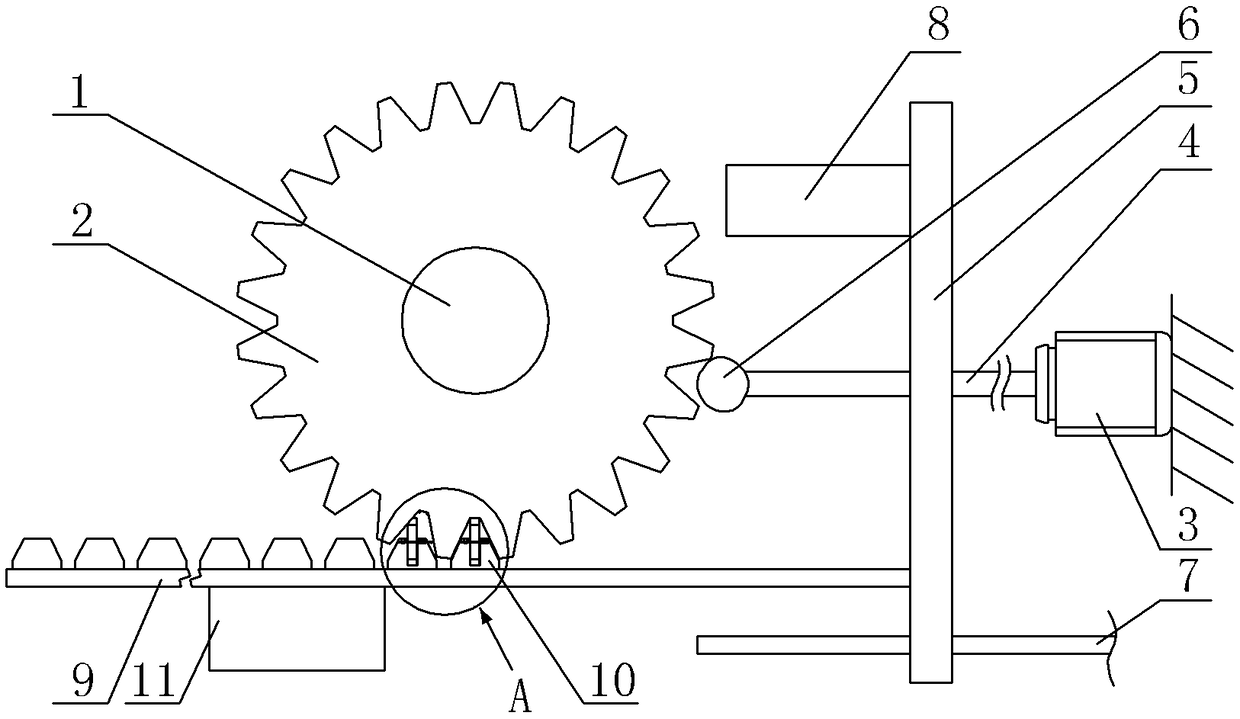

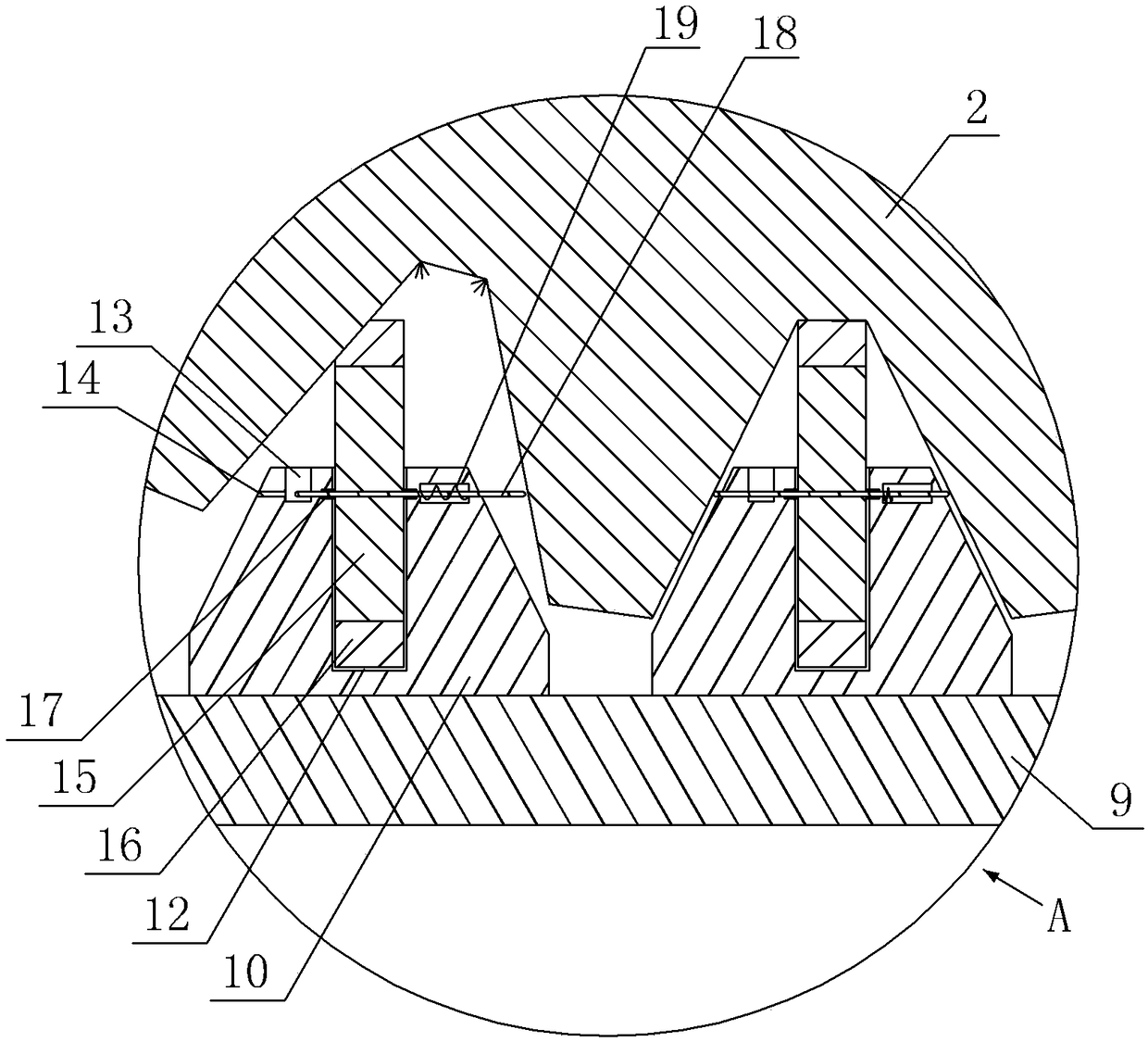

Planet gear machining system and machining process

ActiveCN113829196AAffect the transmission effectPrevent rotationGrinding drivesBelt grinding machinesMachining systemMachining process

The invention relates to the technical field of planet gear machining, in particular to a planet gear machining system and a machining process. The planet gear machining system comprises a bottom rack, supporting columns, a supporting plate, a limiting clamping mechanism and a grinding mechanism. According to the planet gear machining system and the machining process, in a designed grinding belt, an air bag can drive grinding abrasive paper to be tightly attached to planet gear teeth through the good deformation capacity of an air bag in the expansion process, so that the grinding abrasive paper grinds the planet gear teeth more thoroughly, and the situation that burrs left on the planet gear teeth affect the transmission effect of a planet gear in the follow-up using process is avoided. According to the planet gear machining system and the machining process, arc-shaped plates are formed by hinging a plurality of sets of arc-shaped strips through hinges, so that the contact area between inner supporting frames and the planet gear is increased when the planet gear is internally supported by the inner supporting frame, the planet gear is prevented from relatively rotating in the rotating process, and it is ensured that the planet gear more stably clamped by the supporting plate.

Owner:泰州市东方传动技术有限公司

Automobile socket wrench polishing device

ActiveCN106903582APracticalReduce manufacturing costPlastic recyclingGrinding machinesElectric machineryWrench

The invention discloses an automobile socket wrench polishing device which comprises a machine base, wherein an internal grinding mechanism and an external grinding mechanism are arranged on the machine base; the internal grinding mechanism comprises an elastic iron sheet and a sliding rod; a baffle is arranged at one end of the elastic iron sheet; a through hole is formed in the baffle; three slide openings are formed in the inner wall of the through hole; a limiting groove is formed between every two adjacent slide openings; an annular hole is formed in the side wall of the elastic iron sheet; an iron ball is connected to the annular hole in a sliding manner; three bulges are arranged on the sliding rod; six first tension springs are arranged on the inner wall of the elastic iron sheet; the six first tension springs are fixedly connected with the sliding rod; a plurality of elastic parts are arranged between the elastic iron sheet and the sliding rod; the external grinding mechanism comprises a motor and an external grinding barrel fixedly connected with the motor; an electromagnet is arranged on the outer wall of the external grinding barrel; a curved annular groove is formed in the outer wall of the external grinding barrel; an L-shaped rod is connected to the annular groove in a sliding manner; the L-shaped rod is fixedly connected with an auxiliary rod; the auxiliary rod is detachably connected with the sliding rod. The automobile socket wrench polishing device mainly solves the problem that the conventional polishing method for the inner wall of the socket wrench is high in cost.

Owner:杭州伟图科技开发有限公司

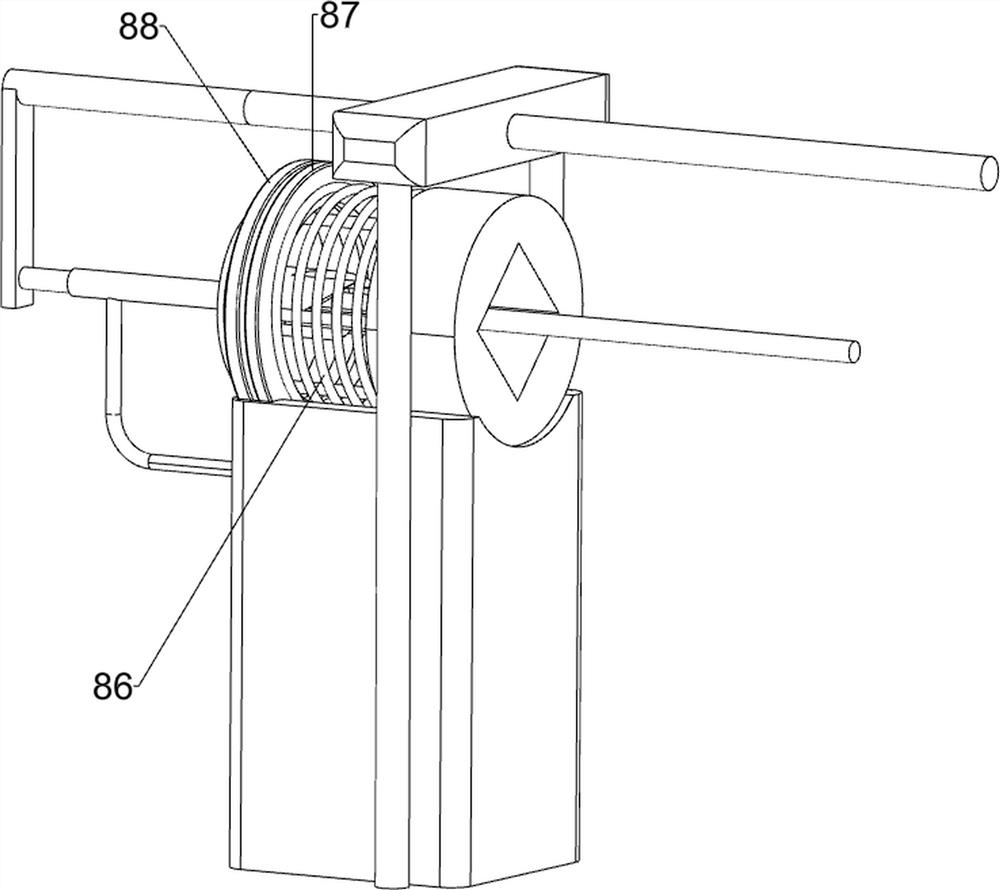

Detection device for measuring spacing precision of teeth of transmission gear

The invention relates to the field of detection of gear tooth spacing, in particular to a detection device for measuring the spacing precision of teeth of a transmission gear. The device comprises a rack, a support rod used for supporting the transmission gear and a detection mechanism, the detection mechanism comprises a push-pull unit and a detection unit, the detection unit comprises a supportplate and a plurality of detection heads, and the push-pull unit can push and pull the support plate to move; the detection heads are uniformly and fixedly disposed on the support plate, and each detection head is provided with a groove, a storage slot and a through groove running through the groove and the storage slot; a nut is rotatably arranged in each groove and provided with a polishing sleeve; a screw rod is slidably arranged in each through hole and is in threaded connection with the corresponding nut, and an elastic member sleeves the end, close to the push-pull unit, of each screw rod. When the technical scheme is adopted, the spacing of the teeth of the transmission gear can be detected, and meanwhile burrs in tooth slots of the transmission gear can be polished.

Owner:CHONGQING RUNYUE MACHINERY CO LTD

Mechanism for bamboo integral treatment

PendingCN108582342AReduce manufacturing costLabor savingCane mechanical workingIrregularity removal devicesEngineeringMechanical engineering

The invention discloses a mechanism for bamboo integral treatment. The mechanism for bamboo integral treatment comprises a machine body; a feeding module, a cutting module and a polishing module are mounted on the machine body; the cutting module is positioned between the feeding module and the polishing module; the cutting module comprises a bracket, a cutting disc, a blade, and a driving devicefor driving the cutting disc to rotate; a cutting hole is formed in the cutting disc; the blade is axially arranged on the side wall of the cutting hole; the cutting disc and the bracket are rotationally connected; the polishing module comprises a polishing box, a polishing shaft and a rotating device for driving the polishing shaft; the polishing box is provided with a polishing channel corresponding to the cutting hole; the polishing shaft is positioned at the bottom of the polishing channel, and is axially arranged with the polishing channel; and the two ends of the polishing shaft are rotationally connected with the polishing box. The mechanism can quickly process bamboos to achieve high efficiency, and can greatly relieve the manpower.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

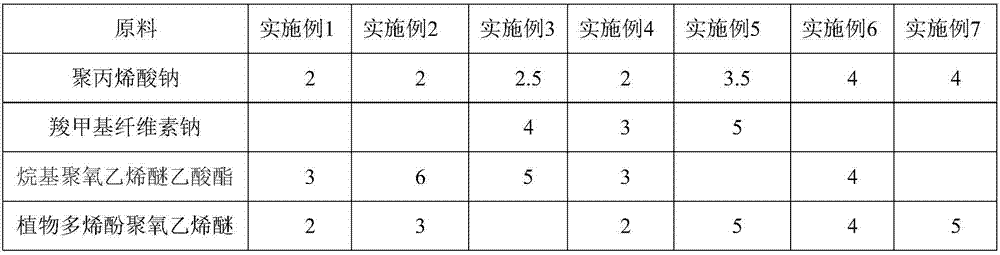

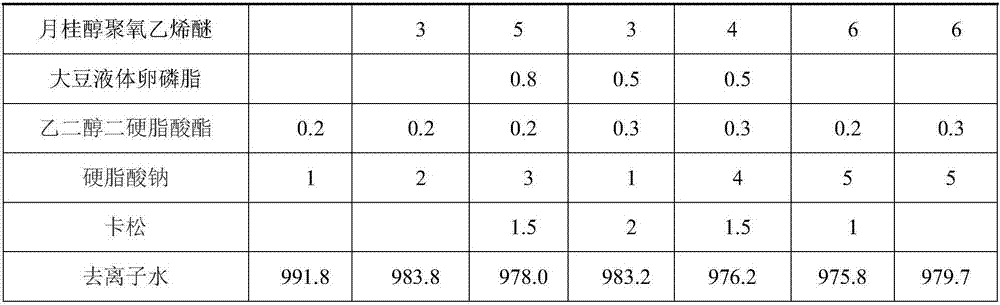

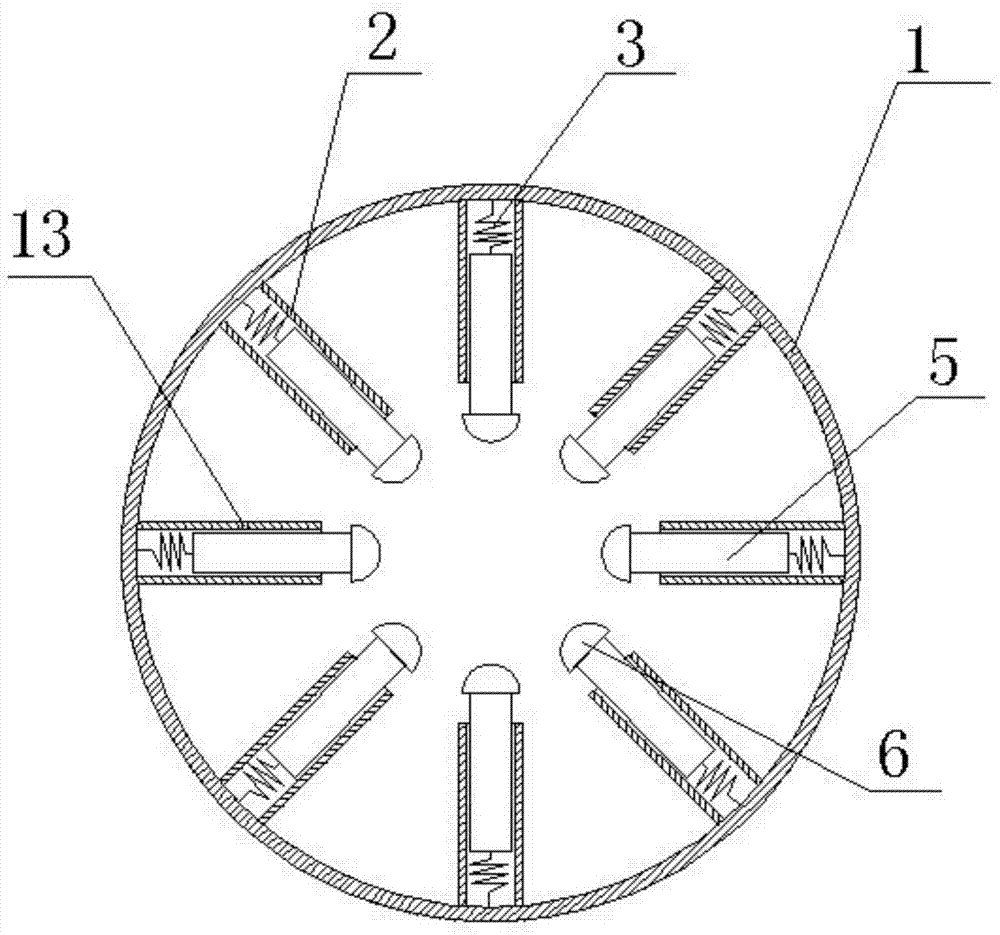

Car wash cleaning solution and preparation method thereof

ActiveCN106398886BEasy to useSave waterOrganic detergent compounding agentsSurface-active detergent compositionsSodium stearateSURFACTANT BLEND

A car-wash cleaning solution and a preparation method therefor. The car-wash cleaning solution contains sodium polyacrylate, a surfactant, sodium stearate, ethylene glycol distearate and deionized water, in which the surfactant is any two or three of alkyl polyoxyethylene ether acetate, phytocene polyoxyethylene ether and lauryl alcohol polyoxyethylene ether.

Owner:LINKAGE AUTOMOBILE SERVICES CO LTD

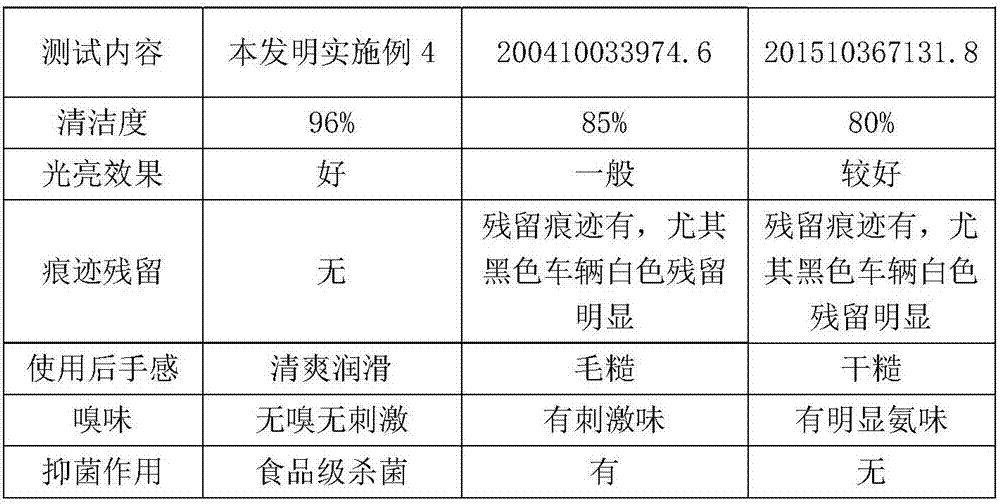

Grinding device of hexagon socket bolt

InactiveCN107263287ASimple structureEasy to operateGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses a grinding device of a hexagon socket bolt, which relates to the field of bolt grinding devices. The grinding device comprises a grinding tool and a clamping tool, wherein the grinding tool comprises a housing, a plurality of limiting barrels are fixedly connected to the inner surface of the housing, guide rods are connected to the interiors of the limiting barrels in a sliding mode, grinding wheels are connected to the outer ends of the guide rods, the inner ends of the guide rods are connected with the inner walls of the limiting barrels by virtue of springs, a rotating shaft is fixedly connected to the bottom of the housing, the rotating shaft is connected with a motor, a motor box is arranged outside the motor, the clamping tool comprises a sleeve, a clamping plate is arranged on the upper part of the sleeve, threads are formed on the outer side of the clamping plate, and a nut which is matched with the clamping plate is arranged on the outer side of the clamping plate. The rusty bolt is ground by virtue of rotation, the guide rods are matched with the springs, so that the bolt can be ground all around with dead angles, the grinding is complete, and the grinding is performed directly by virtue of the motor, so that manpower and time are saved.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

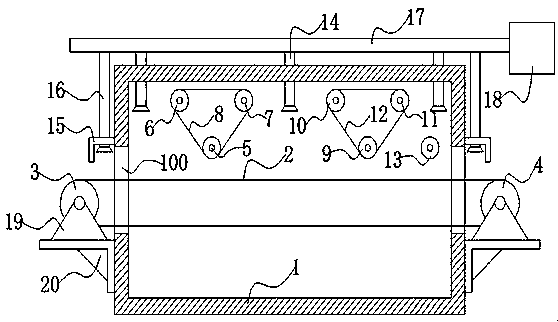

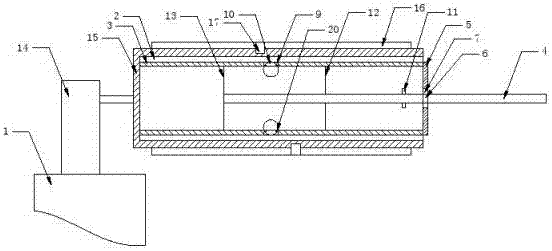

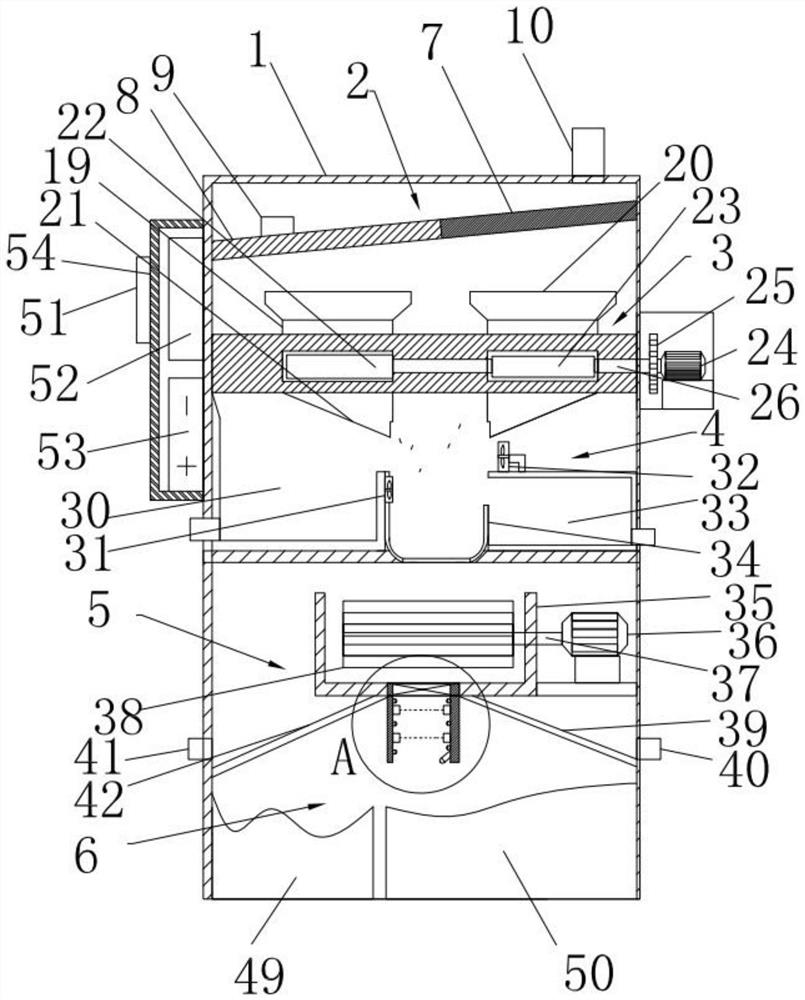

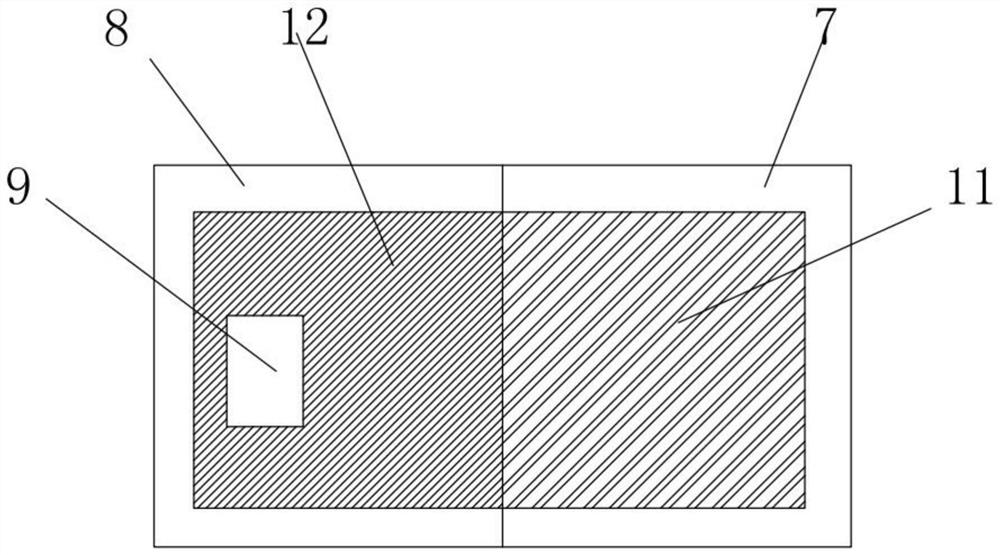

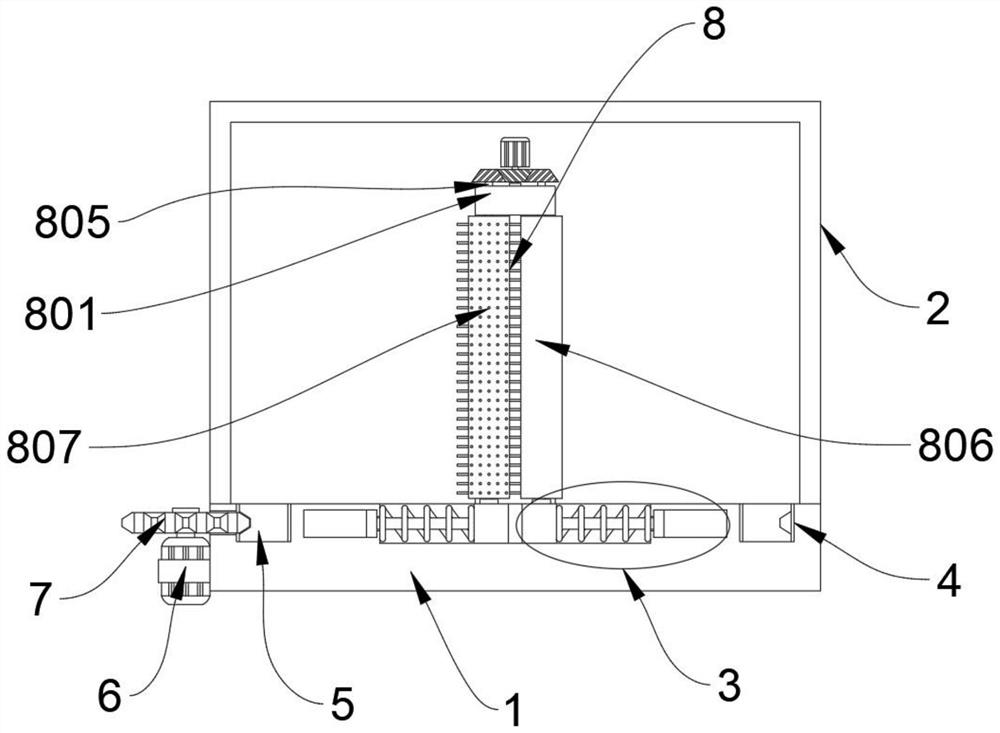

Selenium-enriched rice finish machining equipment

InactiveCN112237952AHigh densityThoroughly polishedGrain huskingSievingAir velocityAgricultural engineering

The invention discloses selenium-enriched rice finish machining equipment. The equipment comprises a shell and a feeding pipe, the shell comprises a sieving plate, a polishing mechanism, a bran removing mechanism, a dust removing mechanism, a screening mechanism and a control box, the sieving plate and the polishing mechanism are arranged, rice grains cannot be crushed when polished, and polishingis more thorough; and the broken rice rate is effectively reduced. The bran removing mechanism is arranged, a first fan and a second fan which are different in air speed are arranged, and the good removing effect on bran of different sizes is achieved; and the screening mechanism and the control box are arranged, a central processing unit controls a first servo motor, a second servo motor, the first fan, the second fan, a valve, an illuminating lamp and an air blowing pipe to be started and processes rice screening signals through a photoelectric sensor, manual operation is reduced, automation and intellectualization of the equipment are achieved, and repeated screening of rice is reduced.

Owner:衡南世源农业发展有限公司

Pulverizer for ceramic production

InactiveCN107214846AThoroughly polishedEasy to operateClay processing apparatusGrain treatmentsEngineeringPulverizer

The invention discloses a powder mill for ceramic production, which comprises a bottom plate, support rods are symmetrically and vertically arranged on both sides above the bottom plate, a cross bar is arranged between the two support rods, and a cross bar is installed on the cross bar. A driving device, the driving end of the driving device is connected with a connecting rod, the connecting rod passes through the cross bar and extends toward the bottom plate, one end of the connecting rod is provided with a hemispherical roller, and the connecting rod is sequentially sleeved from top to bottom A placing body and a grinding plate are connected, the placing body and the connecting rod are fixedly connected, the grinding plate and the connecting rod are connected in rotation, and one side of the grinding plate is offset against the placing body. The invention is easy to operate and simple in structure. After the first stage of grinding between the placement body and the grinding plate, the second stage of grinding is carried out between the polishing plate and the hemispherical mill, and finally the third stage is performed between the hemispherical roller and the inner wall of the grinding tank. Grinding makes the grinding of ceramic raw materials more thorough and achieves fast and efficient grinding effects.

Owner:CHONGQING YONGHENG BOTAO TECH

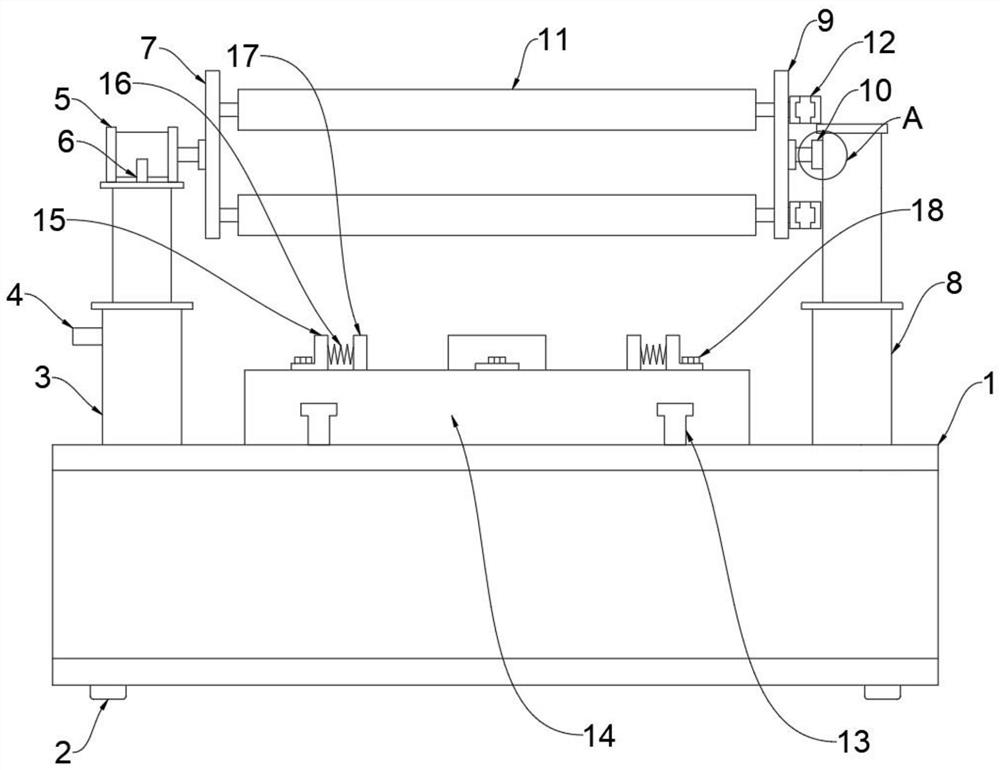

Pipeline welding and grinding all-in-one machine

PendingCN114700732AReduce up and down handlingReduce clamping alignmentOther manufacturing equipments/toolsManufacturing engineeringBevel gear

The invention belongs to the field of pipeline machining, and particularly discloses a pipeline welding and grinding all-in-one machine which comprises a machining machine, a connecting frame is arranged on the inner side of the machining machine, a first bevel gear is arranged in the machining machine, and a reset spring is fixedly connected to the inner side of the machining machine through a bolt. And the tail end of the reset spring is fixedly connected with an extension rod through a bolt, the interior of the extension rod is slidably connected with a connecting rod, the tail end of the connecting rod is provided with a first gear set, and the tail end of the connecting rod is provided with a second gear. The existing grinding and welding all-in-one machine is poor in efficiency when the whole device is used for machining a pipeline, meanwhile, when some grinding and welding all-in-one machines are used and grinding and welding modes are switched, multiple sets of servo motors and automatic telescopic rods need to be switched through placement of threaded rods, the rotating time of the threaded rods is long, and the switching efficiency of the whole device is reduced.

Owner:ZHEJIANG ZHONGGONG PETROCHEMICAL EQUIP CO LTD

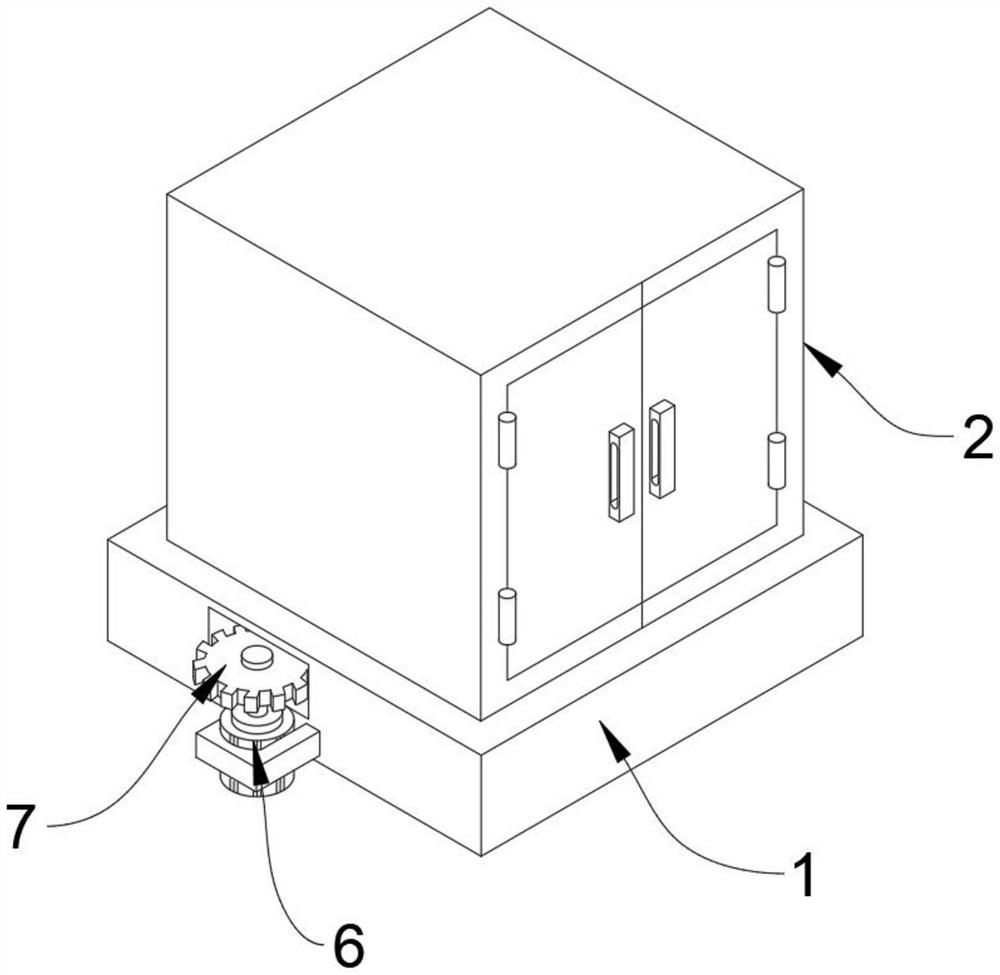

Die end face machining device and machining method thereof

InactiveCN112388456AImprove stabilityMeet fixed needsGrinding machinesGrinding work supportsElectric machineryEngineering

The invention discloses a die end face machining device and a machining method thereof, and relates to the technical field of die machining. The device and the method aim at solving the problems thatan existing die end face machining device can only machine dies of the same size and is poor in universality. The device is characterized in that heat dissipation shutters are arranged at the front end of a cabinet body, seven heat dissipation shutters are arranged, guide rails are arranged on the upper surface of the cabinet body, two guide rails are arranged, a workbench is installed above the guide rails, a linkage column is installed at the front end of the upper portion of the workbench, a second rotating disc is installed above the linkage column, a hydraulic column is installed at the rear end of the upper portion of the workbench, a liquid inlet is formed in the outer wall of the hydraulic column, a stepping motor is installed above the hydraulic column, the stepping motor is fixedly connected with the hydraulic column through a motor support, and a first rotating disc is installed at the output end of the stepping motor.

Owner:苏州锦坤模塑有限公司

Polishing device for glass working

ActiveCN109159026ASimple structureEasy to processEdge grinding machinesGrinding carriagesEngineering

The invention discloses a polishing device for glass working. The polishing device for glass working comprises a base; a workbench is arranged at the upper end of the base; two sets of fixing supportsare arranged at the positions, at the upper end and the lower end of the workbench, of the base; clamping devices are arranged at the positions, above the workbench, of the lower ends of one sides ofthe fixing supports; sliding devices are arranged at the positions, on two sides of the workbench, of the upper end of the base and comprise fixing boards; the lower ends of the fixing boards are connected with the base; first motors are arranged on one sides of the upper ends of the fixing boards; lead screws are arranged at one ends of the first motors; output shafts of the first motors are connected with the lead screws; first fixing blocks are arranged at the positions, at the ends, away from the first motors, of the lead screws, of the fixing boards; second fixing blocks are arranged onthe lead screws and located between the first motors and the first fixing blocks; third fixing blocks are arranged on two sides of the second fixing blocks and located on the fixing boards; fourth fixing blocks are arranged on two sides of the first fixing blocks and on the fixing boards; and slide rods are arranged between the third fixing blocks and the fourth fixing blocks.

Owner:嘉善铂汉塑胶五金有限公司

Grinding device for machining car brake disc

ActiveCN111673562AThoroughly polishedSmall structureEdge grinding machinesGrinding carriagesBrakeElectric machinery

A grinding device for machining car brake disc includes a workbench. A placement groove is formed in the middle of the workbench. A pad is placed in the placement groove. A workpiece is placed on thetop of the pad. The outer surface of the workpiece is sleeved with a shell. The inner wall of the shell is provided with a sandpan, the sandpan is in connection with the outer surface of a part to beprocessed. A fixing mechanism is installed in the middle of the placing groove, the top of the fixing mechanism sequentially penetrates the part to be processed, the sandpan and the shell and extendsto the outside of the shell, and the fixing mechanism is movably connected with the inner wall of the part to be processed. Two hydraulic rods are fixed on the back side of the workbench. A back plateis fixedly installed between the two hydraulic rods. The front side of the back plate is connected to a passive plate through a connecting rod. The bottom of the passive plate is installed with a drive motor. The output shaft of the drive motor is connected to the connecting plate. The bottom end of a ejector rod is connected with the top of the shell. The grinding device uses the rotation of thehousing and the sandpan to polish the workpiece to be processed, and has the advantages of good polishing effect, non-damaging fixation of the brake disc, and can avoid injury to workers.

Owner:XIJING UNIV

Square wood block edge chamfering equipment for furniture production

ActiveCN112847658AQuick sandingThoroughly polishedEdge grinding machinesGrinding carriagesAgricultural engineeringElectric machinery

The invention relates to square wood block edge chamfering equipment, in particular to square wood block edge chamfering equipment for furniture production. According to the square wood block edge chamfering equipment for furniture production which is provided by the invention, square wood blocks can be automatically pushed and ground, the square wood blocks can further be rotated to unpolished edges for polishing, and safety and high efficiency are achieved. In order to solve the technical problem, the square wood block edge chamfering equipment for furniture production comprises a supporting frame, a motor frame, a gear motor, a chamfering assembly, an air cylinder and a feeding assembly, the motor frame is arranged on the supporting frame, the gear motor is arranged on the motor frame, the chamfering assembly is arranged on an output shaft of the gear motor, the air cylinder is arranged on the upper portion of the left side of the supporting frame, and the feeding assembly is arranged on the chamfering assembly and connected with the air cylinder. According to the square wood block edge chamfering equipment for furniture production, the chamfering assembly is arranged, and a saw blade in the chamfering assembly rotates, so that the effect of rapidly polishing square wood blocks is achieved.

Owner:福建华森家具有限公司

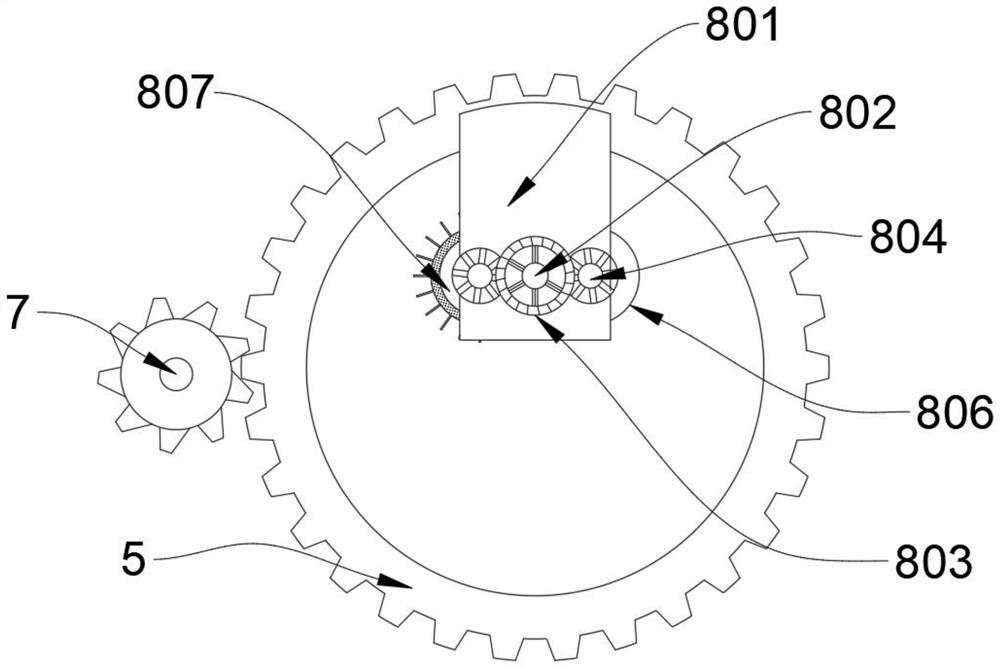

Polymer injection molding part surface polishing device

InactiveCN114147614AFull sanding operationReduce labor intensityGrinding carriagesPolishing machinesGear wheelPolishing

The invention discloses a polymer injection molding part surface polishing device, and relates to the field of automobile injection molding part machining equipment. The polishing device comprises a workbench, a shell and a clamping unit, an annular gear ring is installed in a tooth groove, a polishing structure is arranged at the top of the annular gear ring, and a polishing roller is driven to rotate at a high speed through meshing force generated by meshing transmission of a gear and the annular gear ring, so that the whole polishing structure does circular motion, and meanwhile the polishing effect is improved. The outer side surface of the injection molding part is fully ground, more time and labor are saved, the labor intensity of operation of workers is reduced, efficiency is higher, polishing is more thorough, in the polishing process, the arranged cleaning barrel can synchronously rotate, chippings attached to the surface of the injection molding part are comprehensively swept, and the polishing efficiency is improved. And the polishing quality of the injection molding part is greatly improved, meanwhile, the flatness of the injection molding part is guaranteed, and the practicability is good.

Owner:江西莲雄实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com