Efficient polishing equipment for wood plate processing

A high-efficiency, wood-based technology, used in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problems of complicated operation, inconvenient operation and poor polishing uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

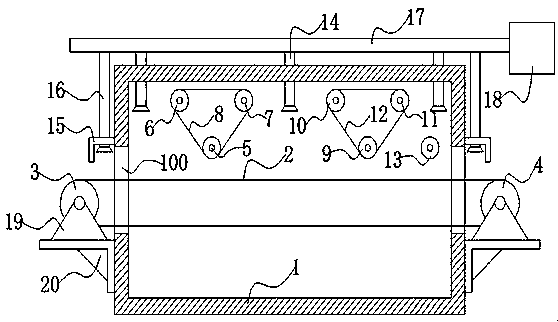

[0012] Such as figure 1 As shown, the present invention discloses a high-efficiency polishing equipment for processing wood boards, comprising: a polishing box 1 and a transmission through hole 100. The two side walls of the polishing box 1 are symmetrically opened with transmission through holes 100, and the A transmission belt 2 is installed in the transmission through hole 100 provided, and the two ends of the transmission belt 2 are connected by a driving wheel 3 and a driven wheel 4 which are arranged on the outside of the polishing box 1 both sides. The driven wheels 4 are respectively rotatably mounted on a turret 19 , and the turret 19 is fixedly mounted on a support frame 20 , and the support frame 20 is fixedly welded to the outer wall of the polishing box 1 .

[0013] Directly above the conveyor belt 2 and positioned at both sides of the interior of the polishing box 1, a rough grinding mechanism and a fine grinding mechanism are respectively installed, and the roug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com