Square wood block edge chamfering equipment for furniture production

A chamfering and square technology, which is applied in the field of chamfering equipment for the edge of square wooden blocks, can solve the problems of easy cutting hands and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

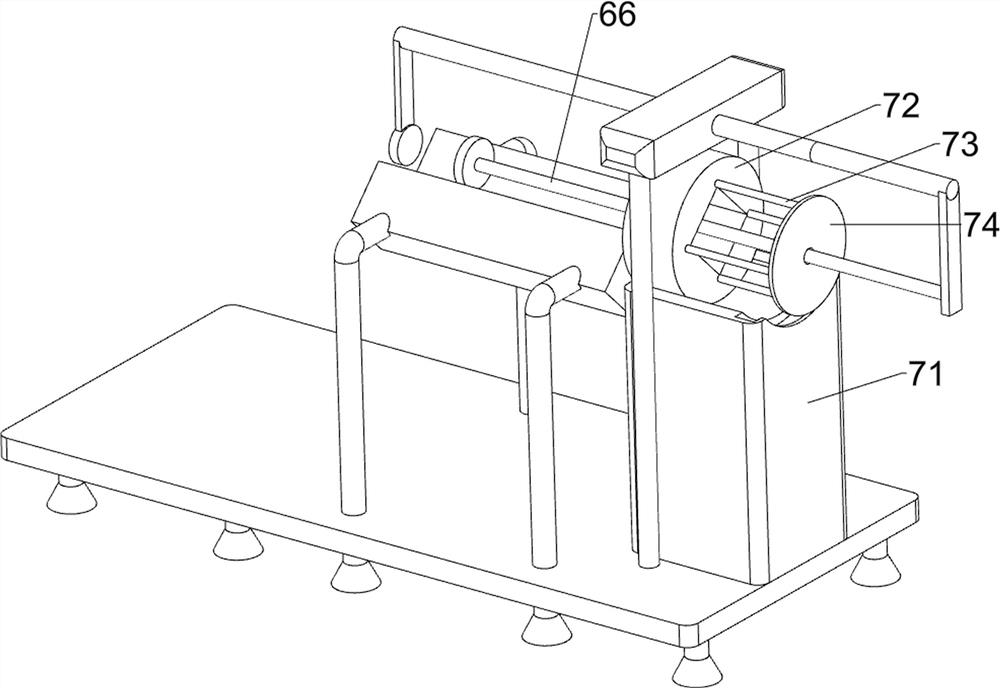

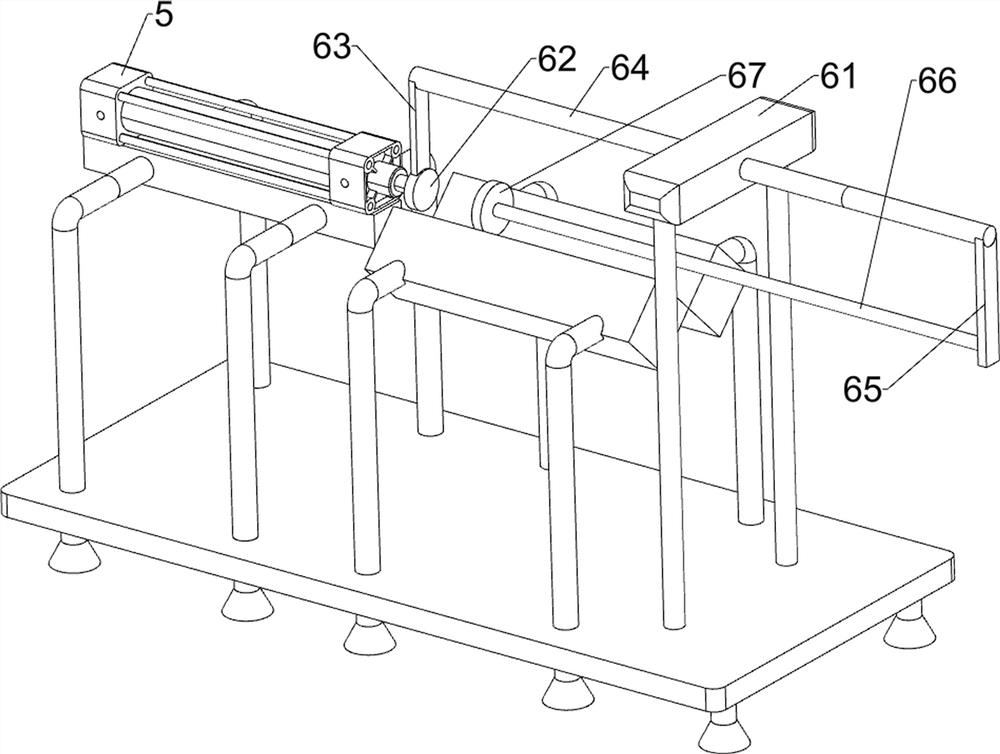

[0025] A device for chamfering the edges of square wooden blocks for furniture production, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a support frame 1, a motor frame 2, a reduction motor 3, a chamfering assembly 4, a cylinder 5, and a feeding assembly 6. The support frame 1 is provided with a motor frame 2, and the motor frame 2 is provided with a reduction motor 3. The output shaft of the motor 3 is provided with a chamfering assembly 4 , the upper left side of the support frame 1 is provided with a cylinder 5 , the chamfering assembly 4 is provided with a feeding assembly 6 , and the feeding assembly 6 is connected with the cylinder 5 .

[0026] Put the square wooden block that needs to be chamfered on the chamfering assembly 4, turn on the reduction motor 3, the reduction motor 3 drives the chamfering assembly 4 to move, so that the square wooden block is polished, open the cylinder 5, and the output shaft of the cylinder 5 drives the fee...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, a manual rotation assembly 7 is also included. The manual rotation assembly 7 includes a support column 71, a rotation block 72, a fifth connecting rod 73 and a rotating disk 74. The support frame 1 is provided with a support column 71, and the fourth connecting rod 66 The sliding type is provided with a turntable 74 on which a fifth connecting rod 73 is arranged. The left side of the fifth connecting rod 73 is connected with a rotating block 72 , and the rotating block 72 is located at the top of the support column 71 .

[0033] When the square block was pushed onto the rotating block 72, the turntable 74 was rotated, and the turntable 74 drove the fifth connecting rod 73 to rotate, thereby driving the rotation block 72 to rotate, and then the square block was rotated to polish the edge that was not polished.

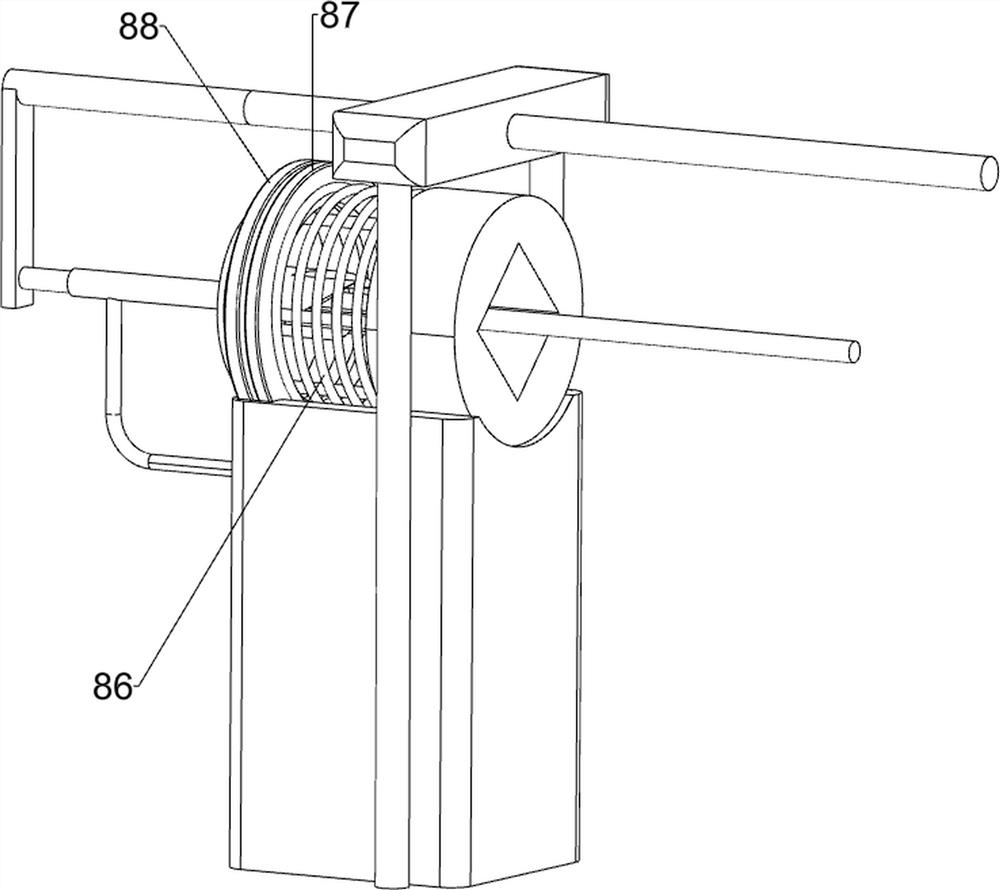

[0034] Also includes an automatic rotation assembly 8, the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com