Patents

Literature

109results about How to "Achieve sanding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

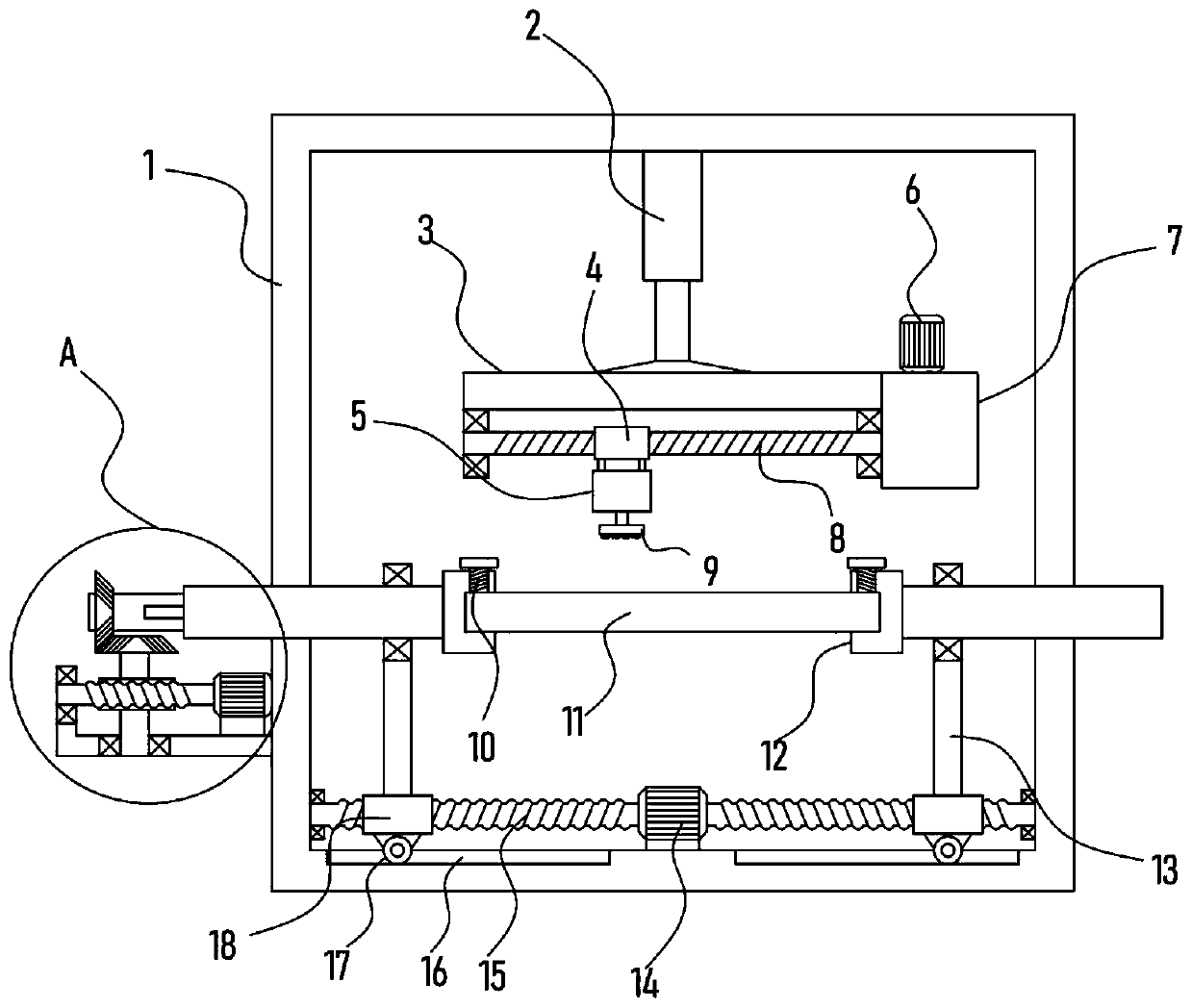

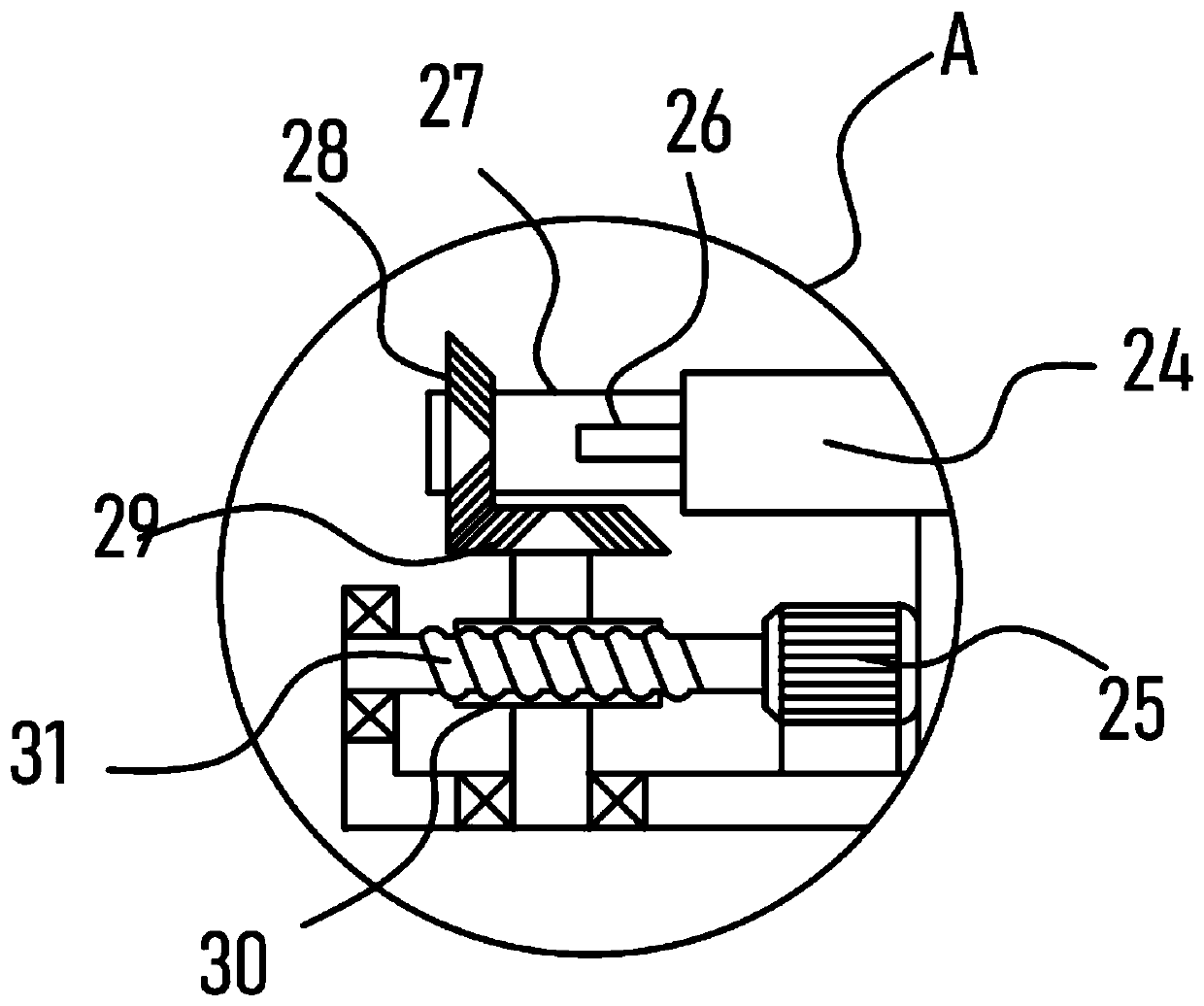

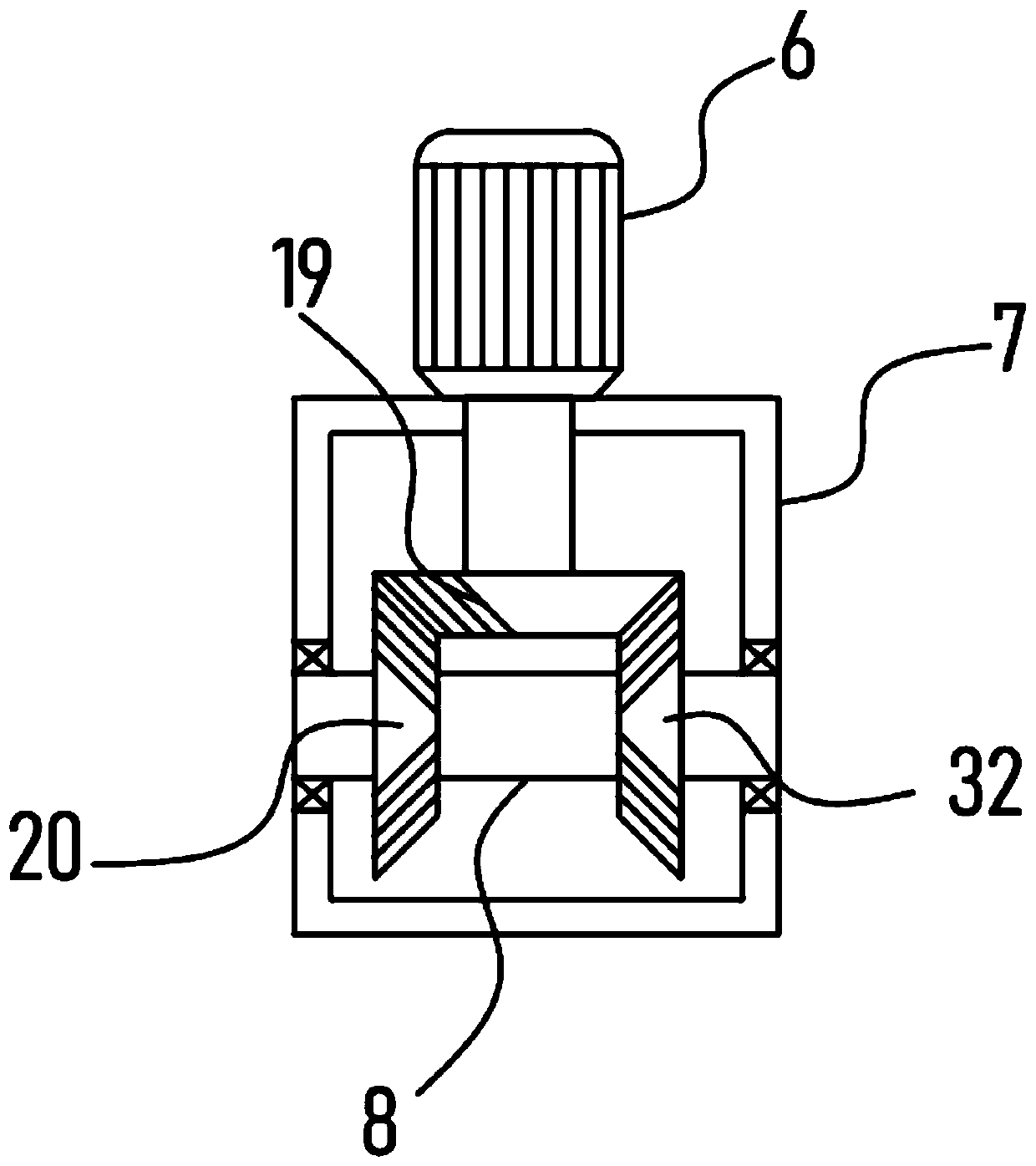

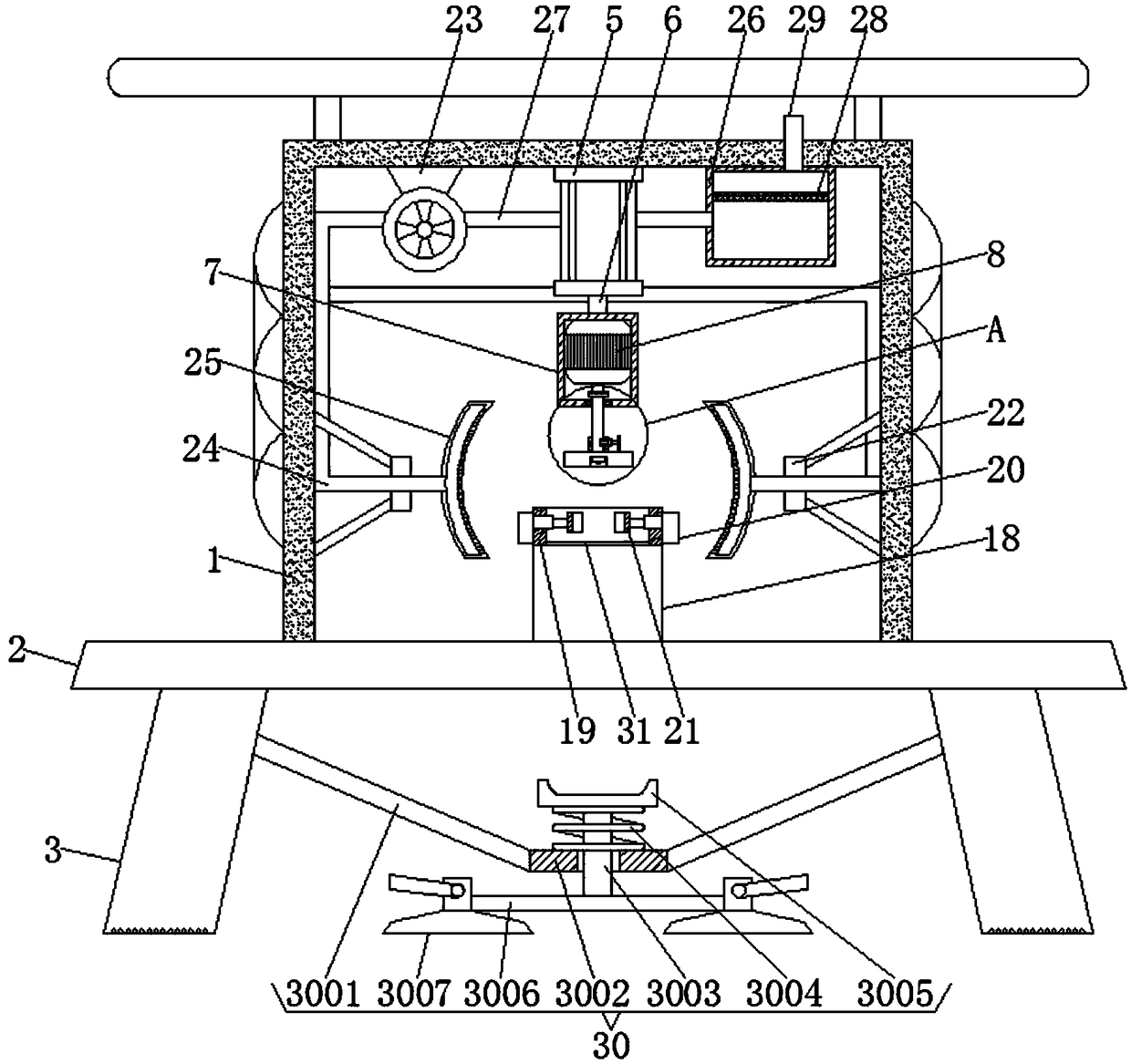

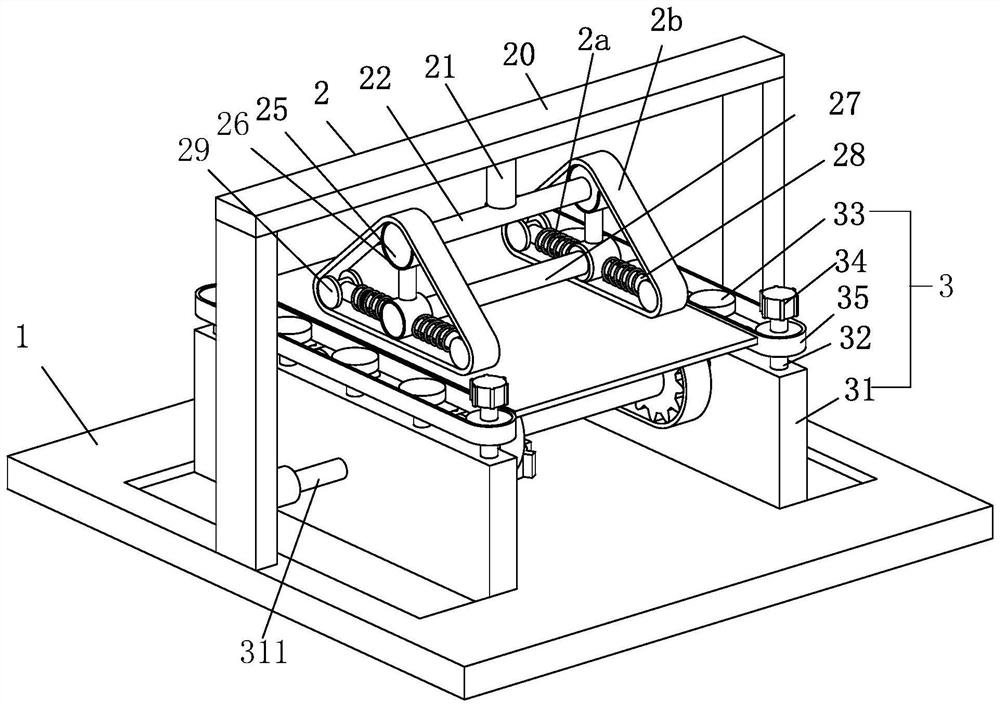

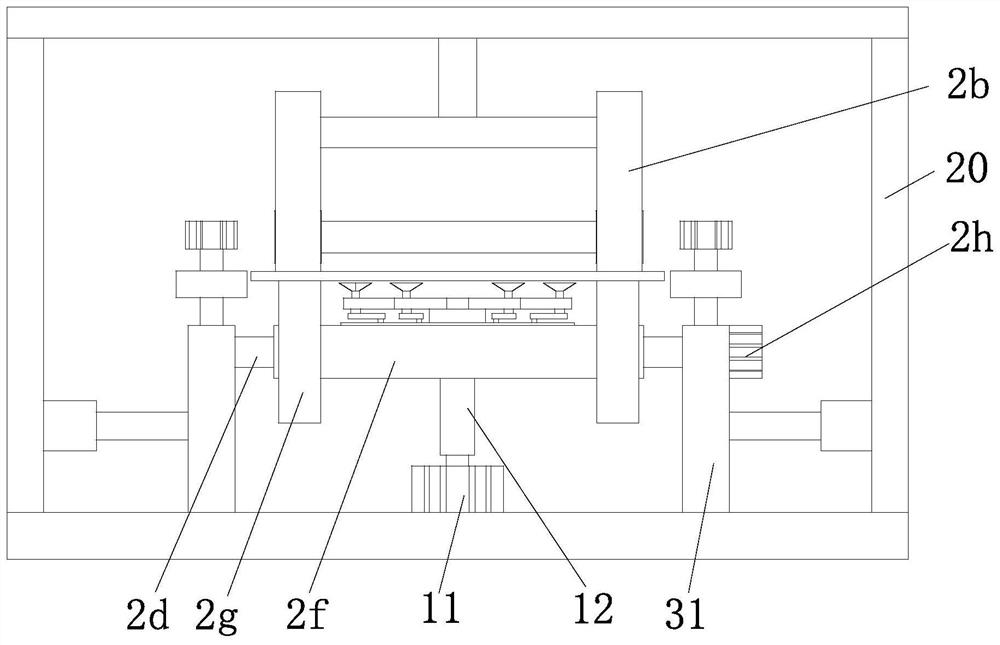

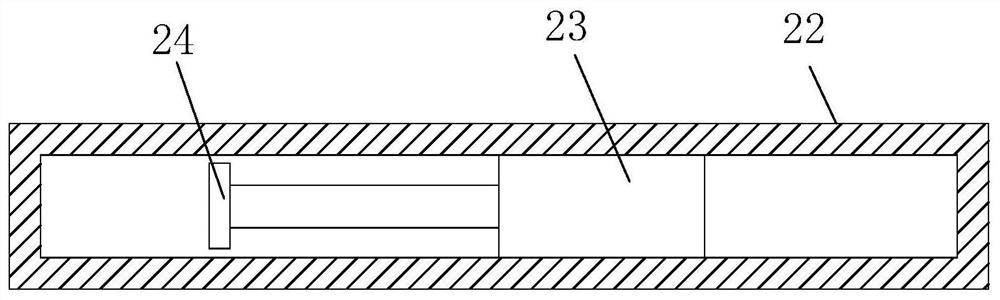

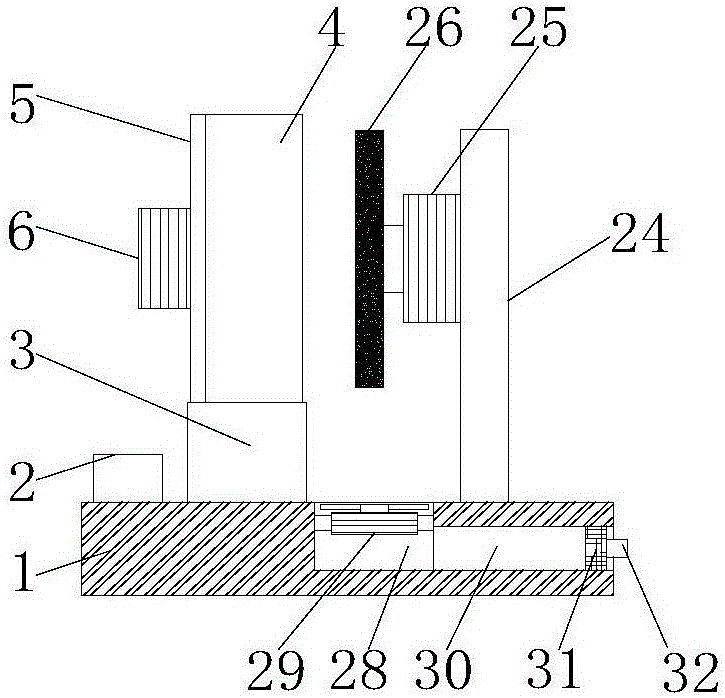

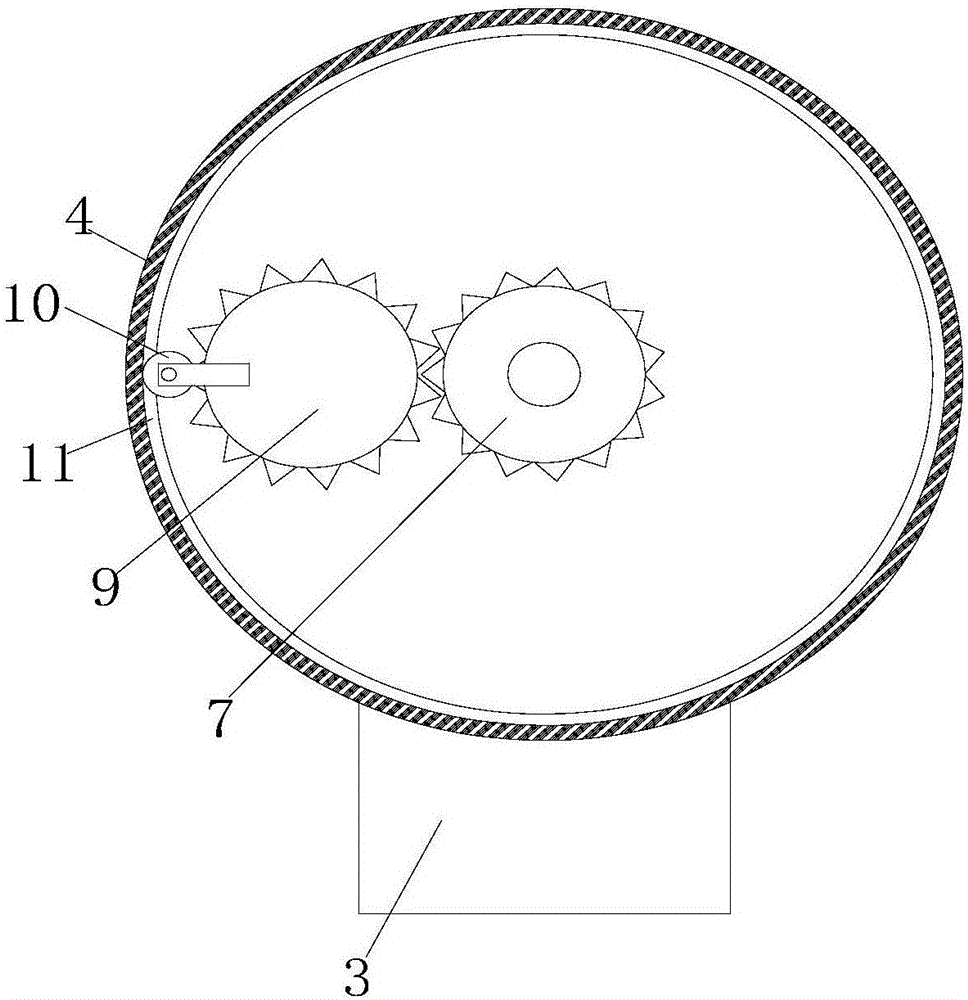

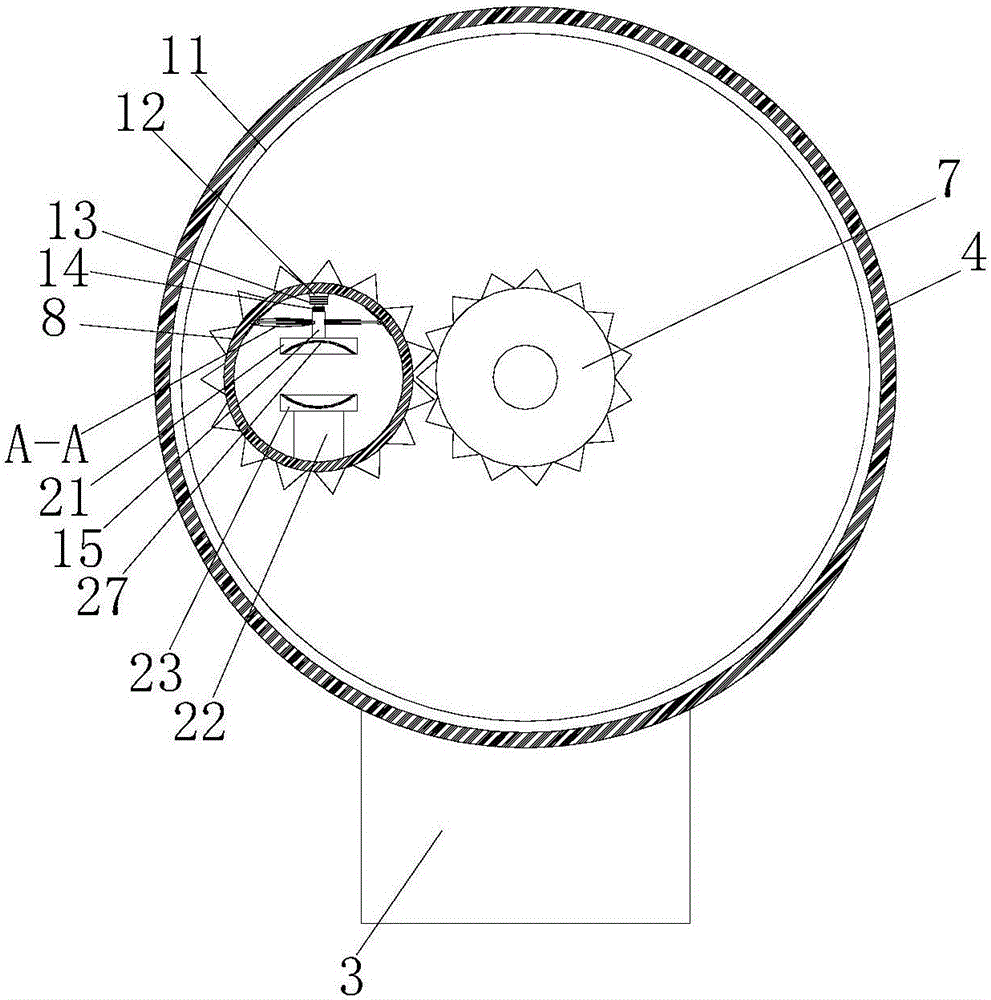

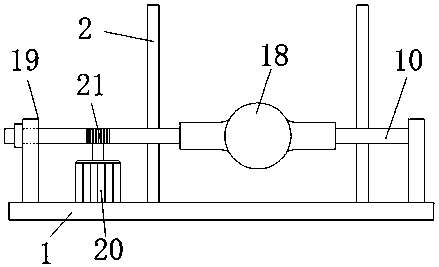

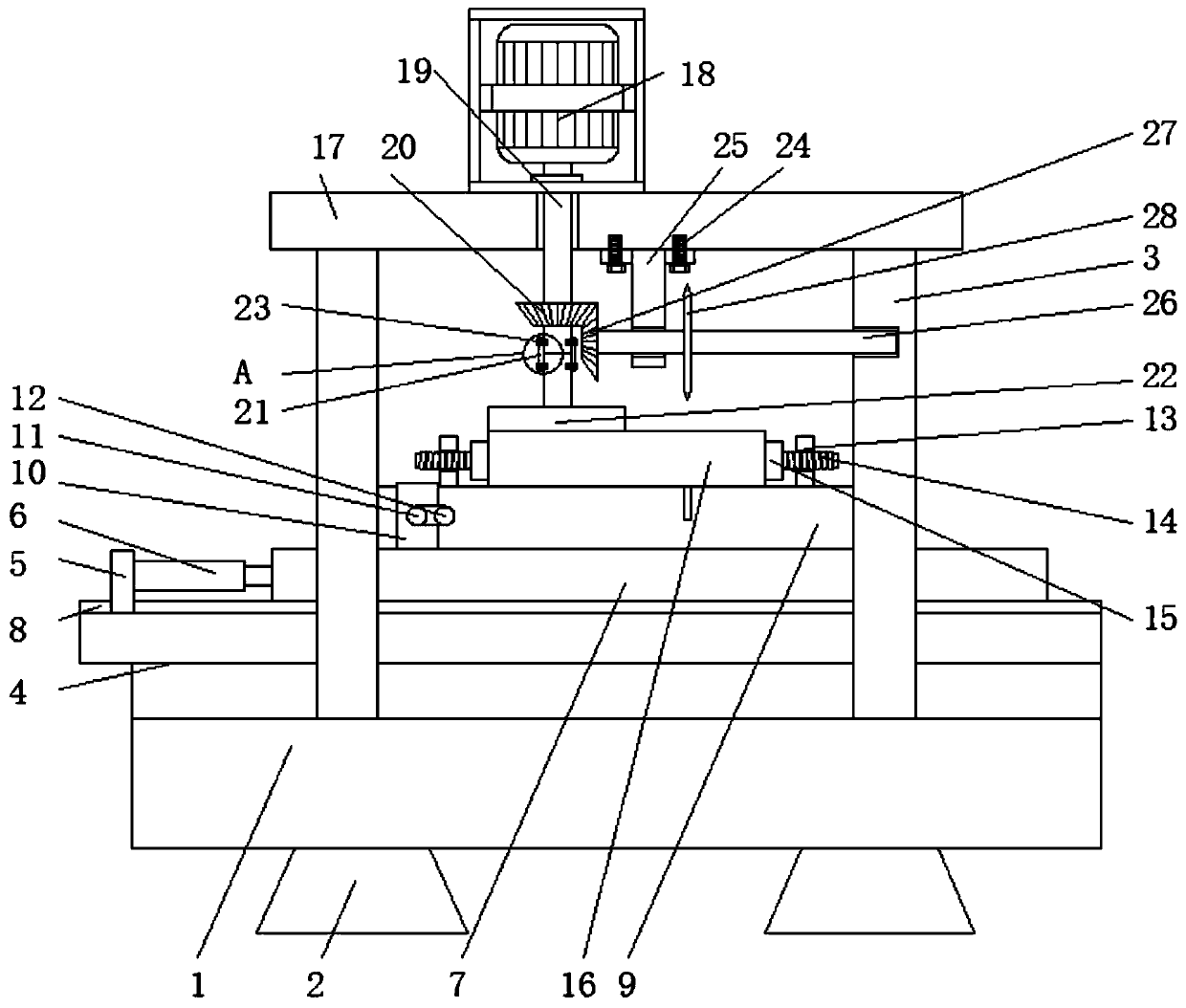

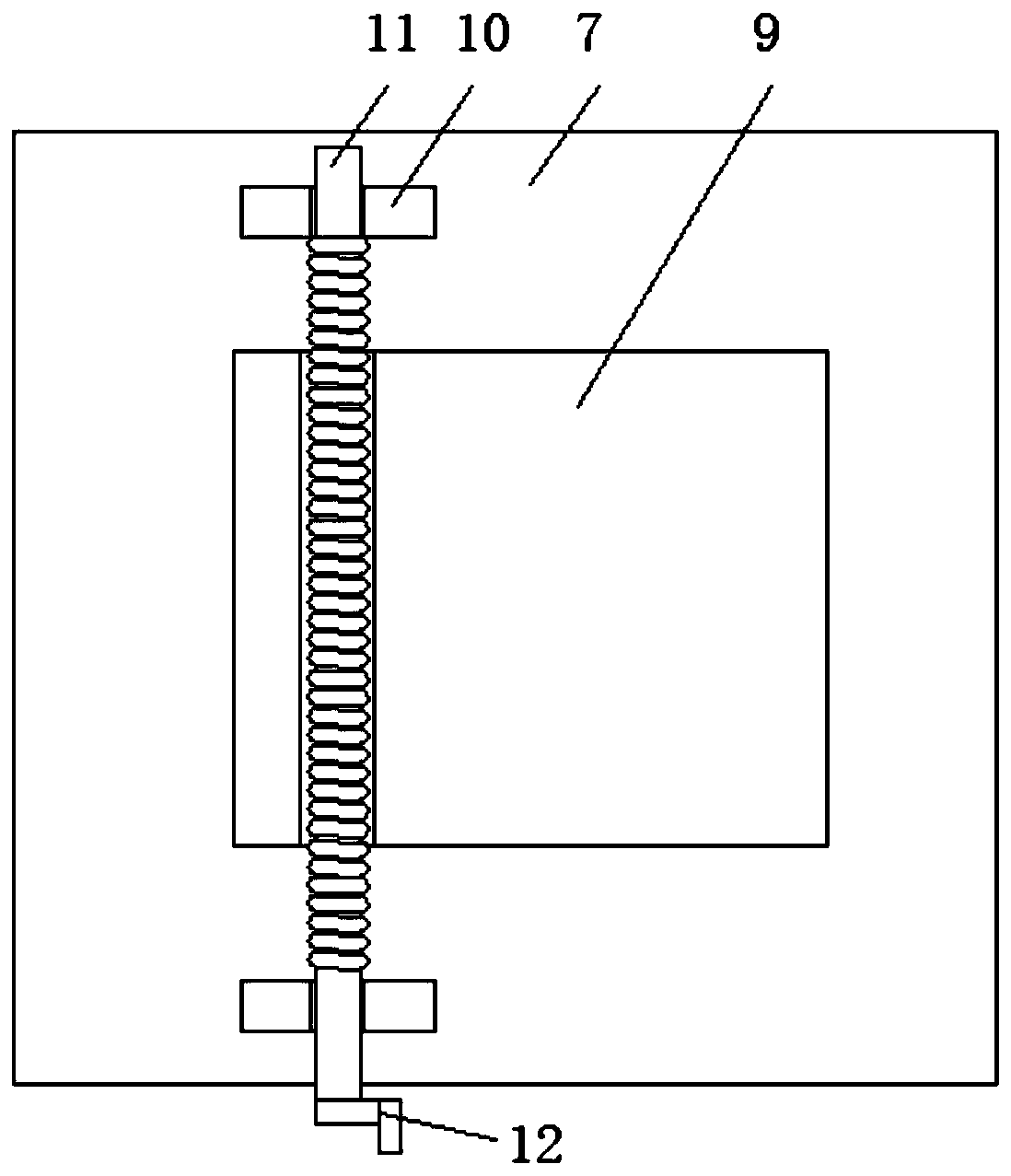

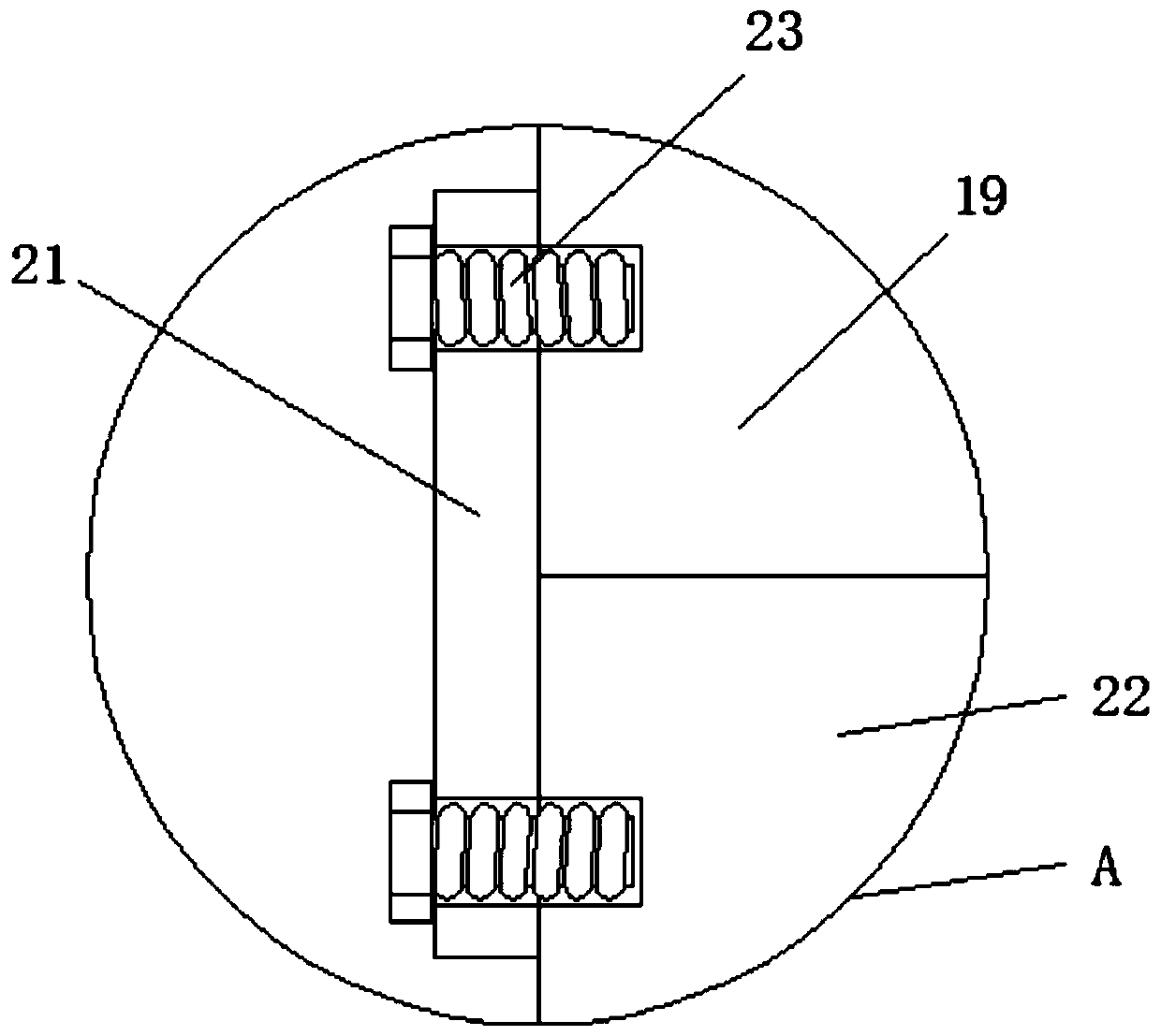

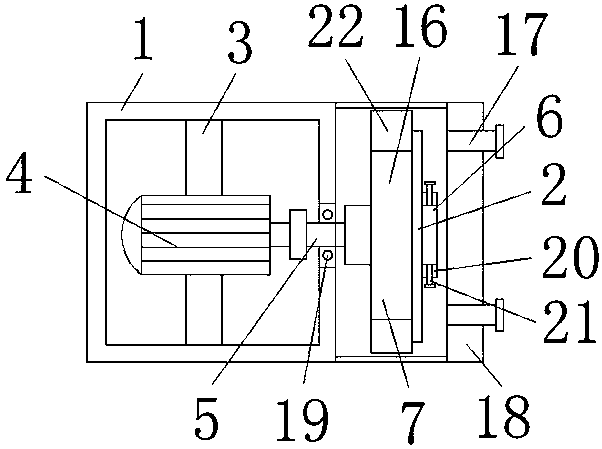

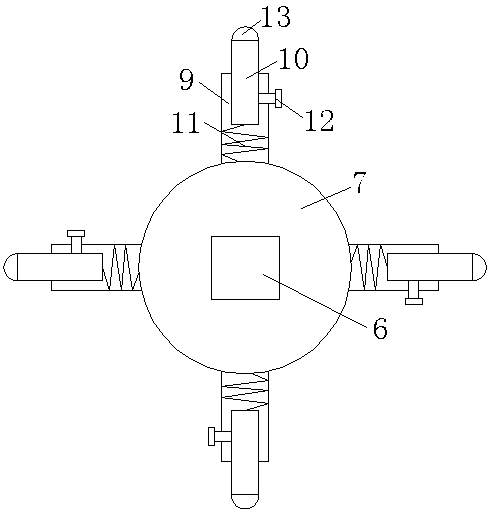

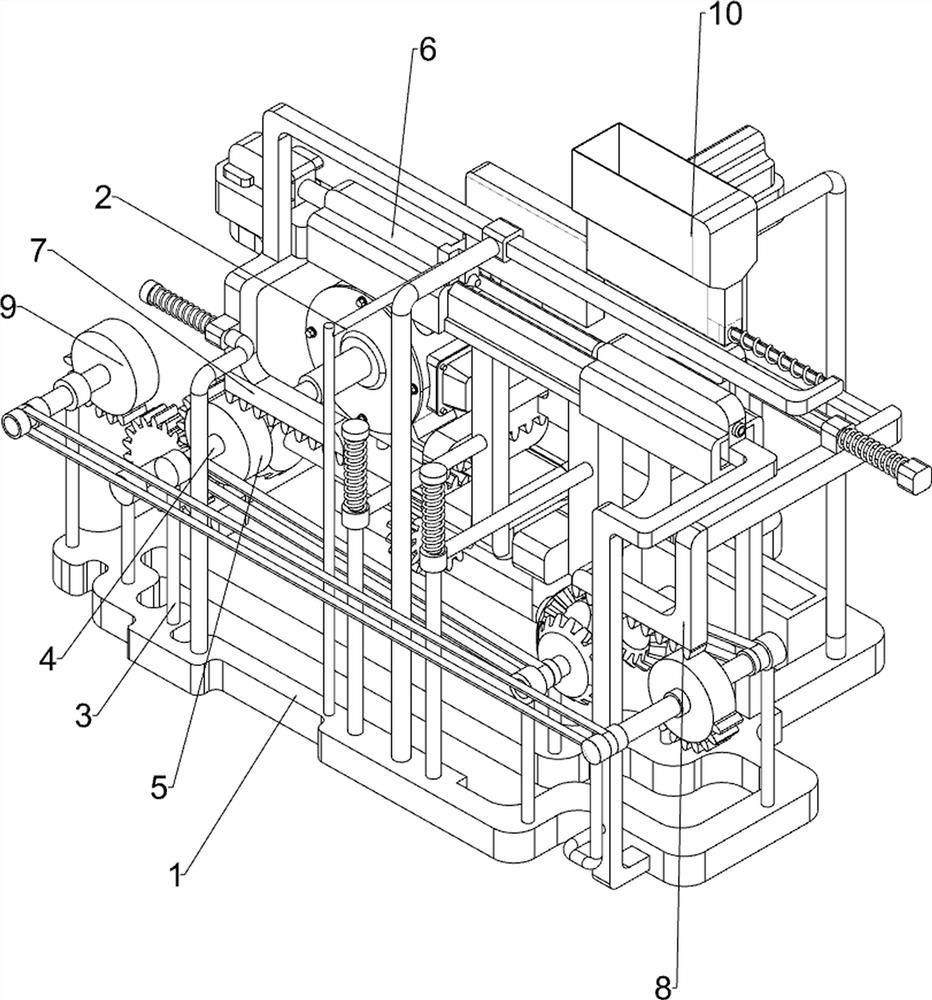

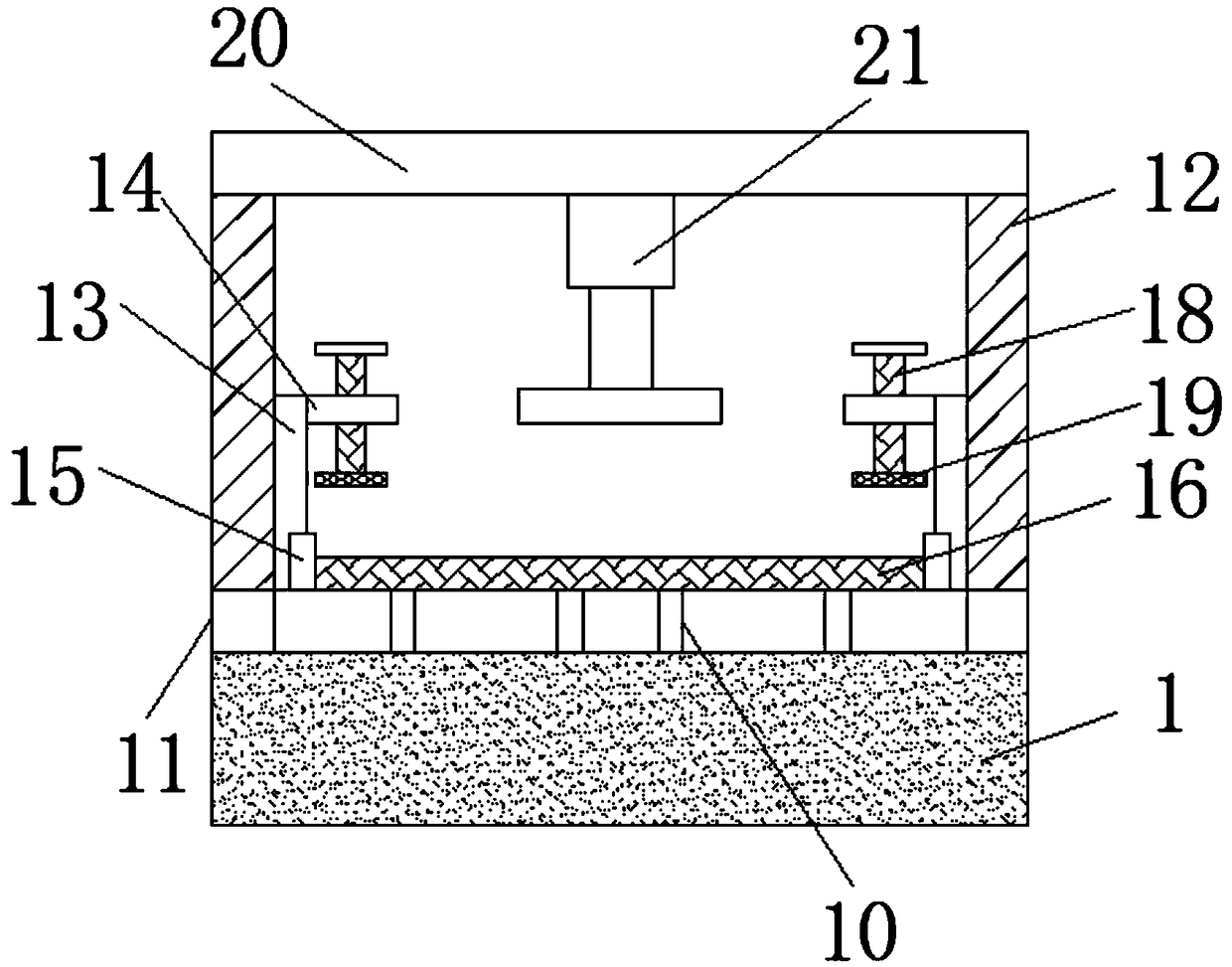

Mechanical plate grinding device with overturning function

InactiveCN111300185ARealize clamping and fixingRealize the grinding effectGrinding drivesGrinding feedersEngineeringMachining

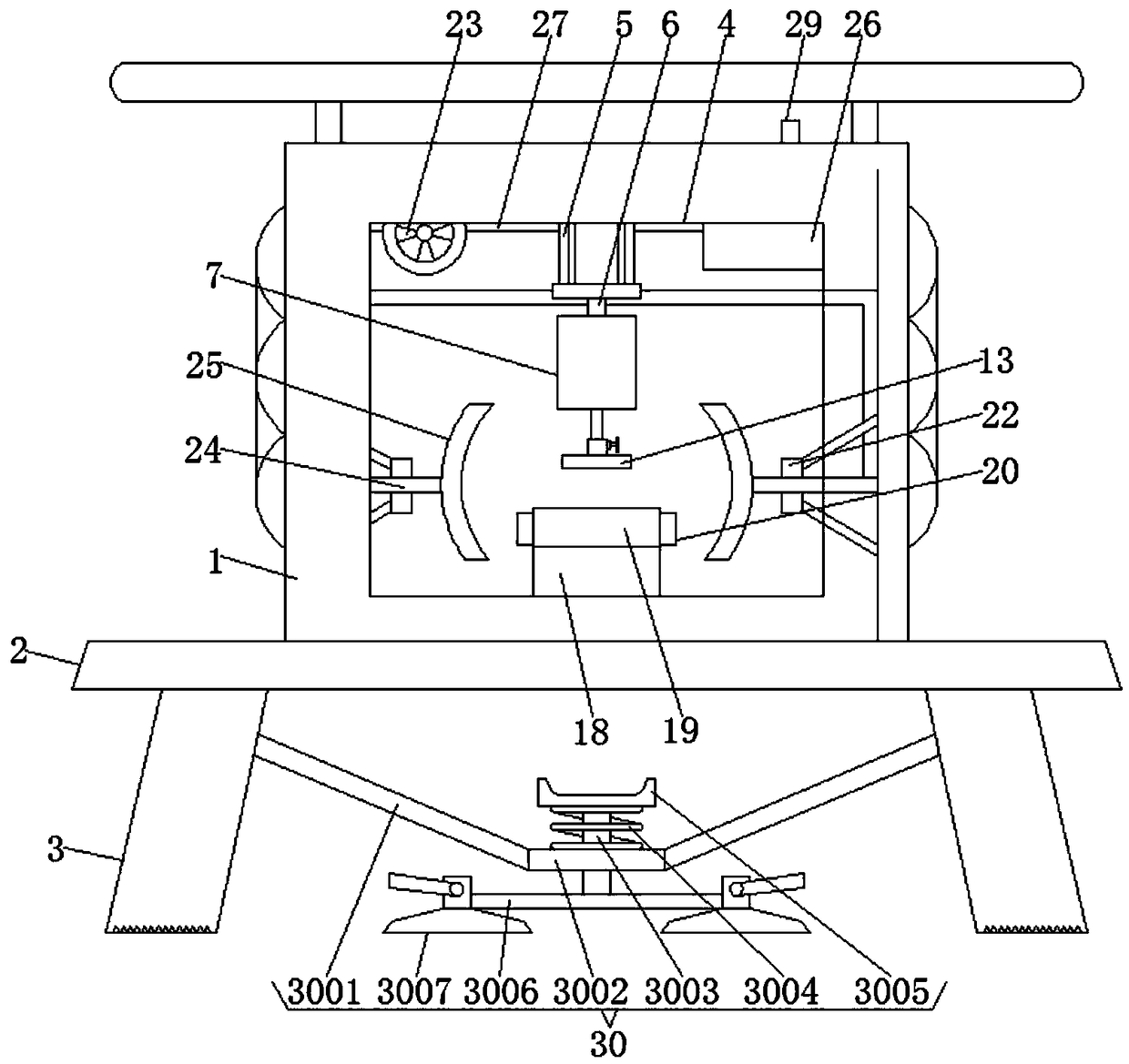

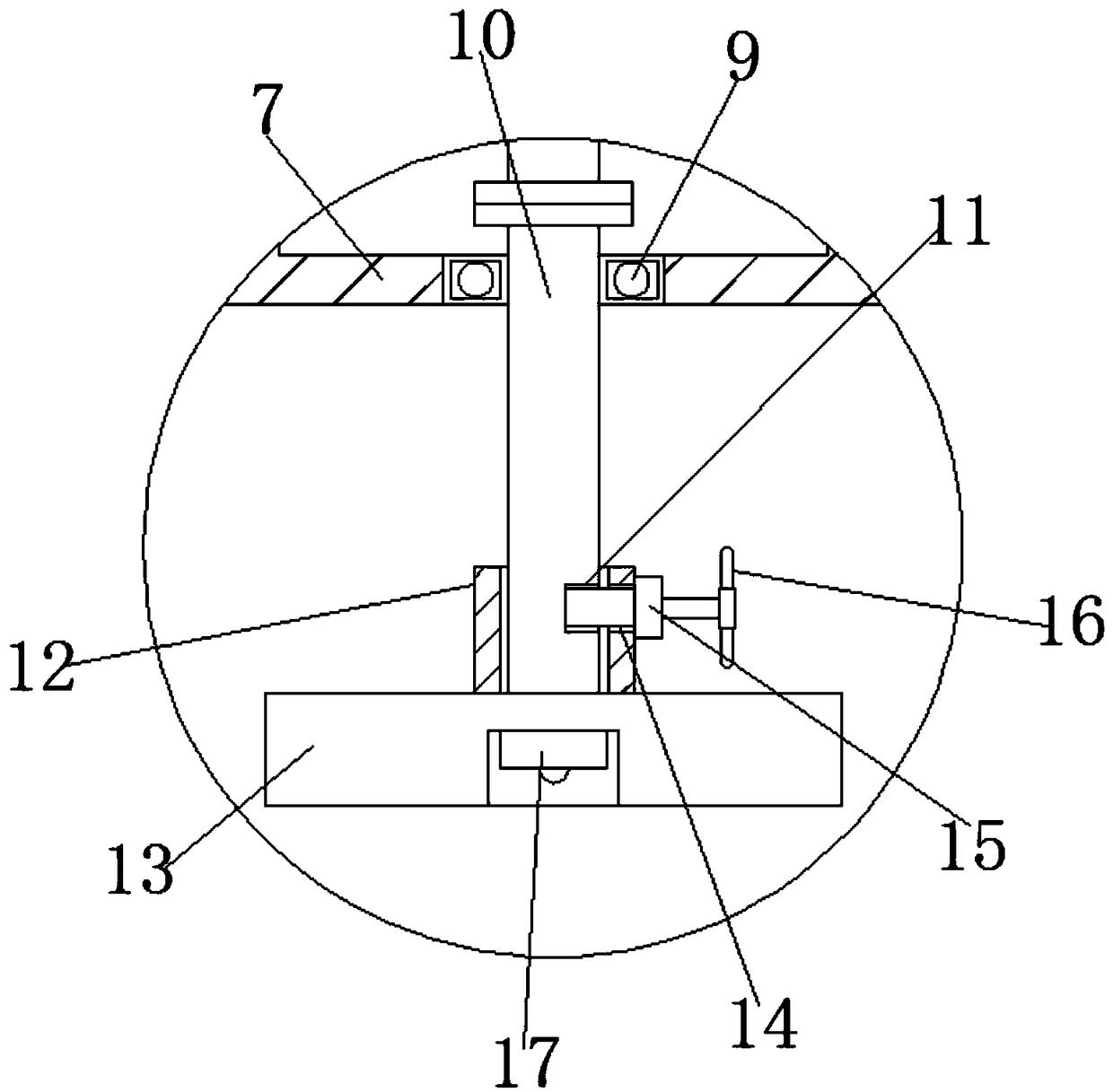

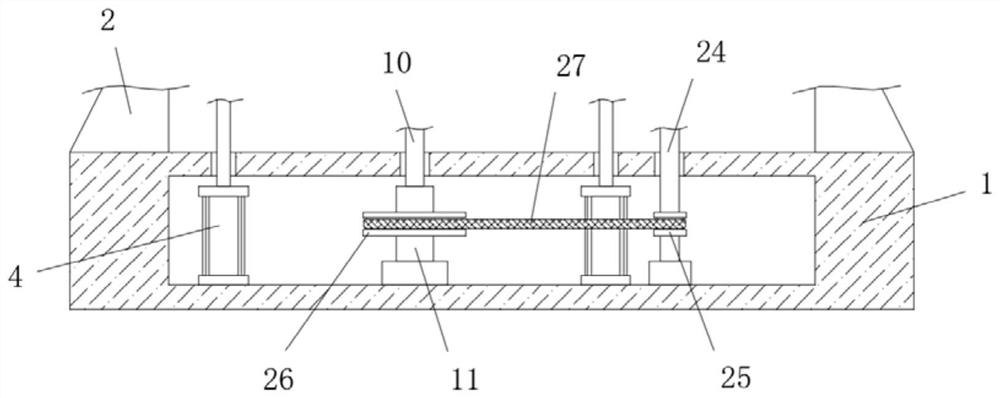

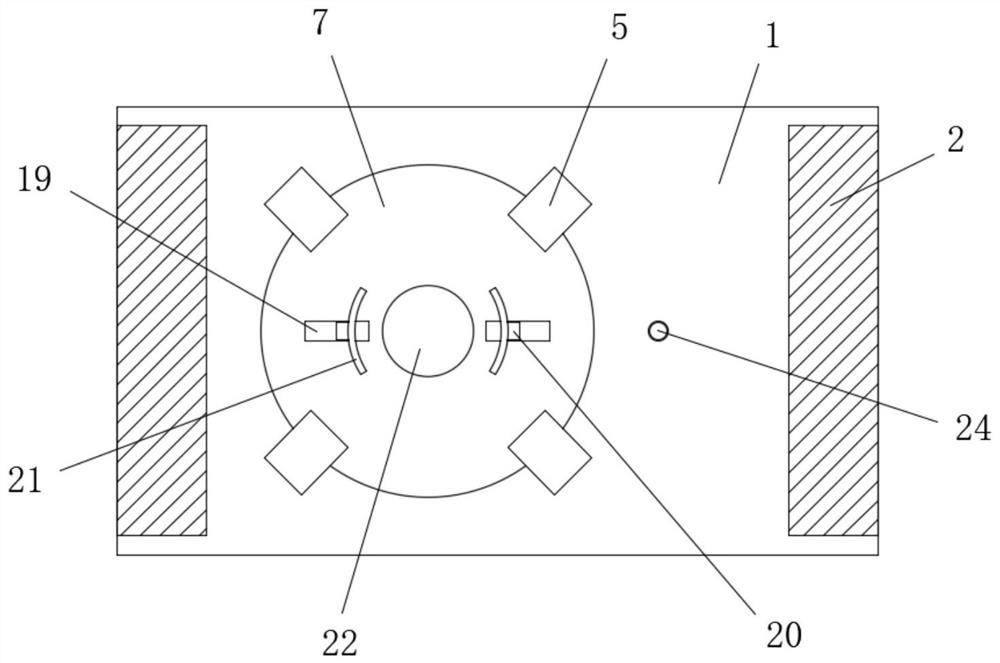

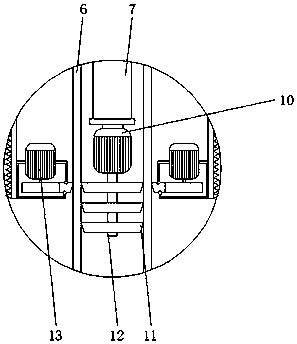

The invention discloses a mechanical plate grinding device with an overturning function, and relates to the technical field of machining. The mechanical plate grinding device comprises a supporting frame, wherein an electric push rod is vertically fixed at the inner top of the supporting frame; a translation mechanism for driving a grinding mechanism to move transversely is arranged in a steeringbox; an adjusting mechanism for driving two clamping plates to move oppositely is arranged on the supporting frame; and the supporting frame is provided with an overturning mechanism used for drivingthe clamping plates to rotate. According to the mechanical plate grinding device with the overturning function, the two clamping plates are driven by the arranged adjusting mechanism to move oppositely to clamp and fix a plate, so that stability of the plate in the grinding process is guaranteed, and a grinding effect is guaranteed; a grinding plate in the arranged grinding mechanism rotates to achieve grinding effects on the surface of the plate, and the translation mechanism can drive the grinding plate to transversely move relative to the plate, so that the grinding range of the plate is greatly widened, and the working efficiency is improved; and the arranged overturning mechanism can overturn the plate, so that sufficient double-face grinding effects of the grinding plate are achievedon the surface of the plate.

Owner:武文家

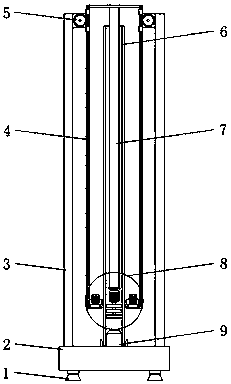

Polishing device with high safety for industrial design

ActiveCN108838771AImprove securityEasy height adjustmentGrinding carriagesGrinding work supportsFiltrationPiston rod

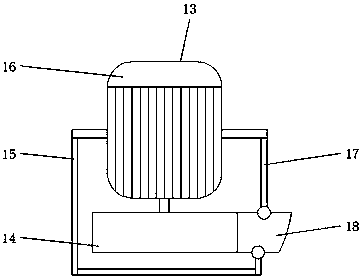

The invention discloses a polishing device with high safety for industrial design, and relates to the technical field of industrial design. The polishing device with high safety for industrial designcomprises a box; a support table is fixedly connected to the bottom of the box; two support legs are fixedly mounted at two ends of the bottom surface of the support table; an inlet is formed in the center of the front surface of the box; a cylinder is fixedly mounted in the center of the top surface of an inner cavity of the box; and a piston rod is mounted at the bottom end of the cylinder. In the polishing device with high safety for industrial design, through improvement of an element polishing device, the cylinder and a speed reducing motor are cooperatively used to conveniently polish elements, so that the labor intensity of workers can be reduced to a greater extent; and an exhaust fan and a filter box are cooperatively used to finish filtration of element polishing dust, so that the harm to workers by the dust is reduced to a greater extent, and the personal safety of the workers is improved.

Owner:芜湖文青机械设备设计有限公司

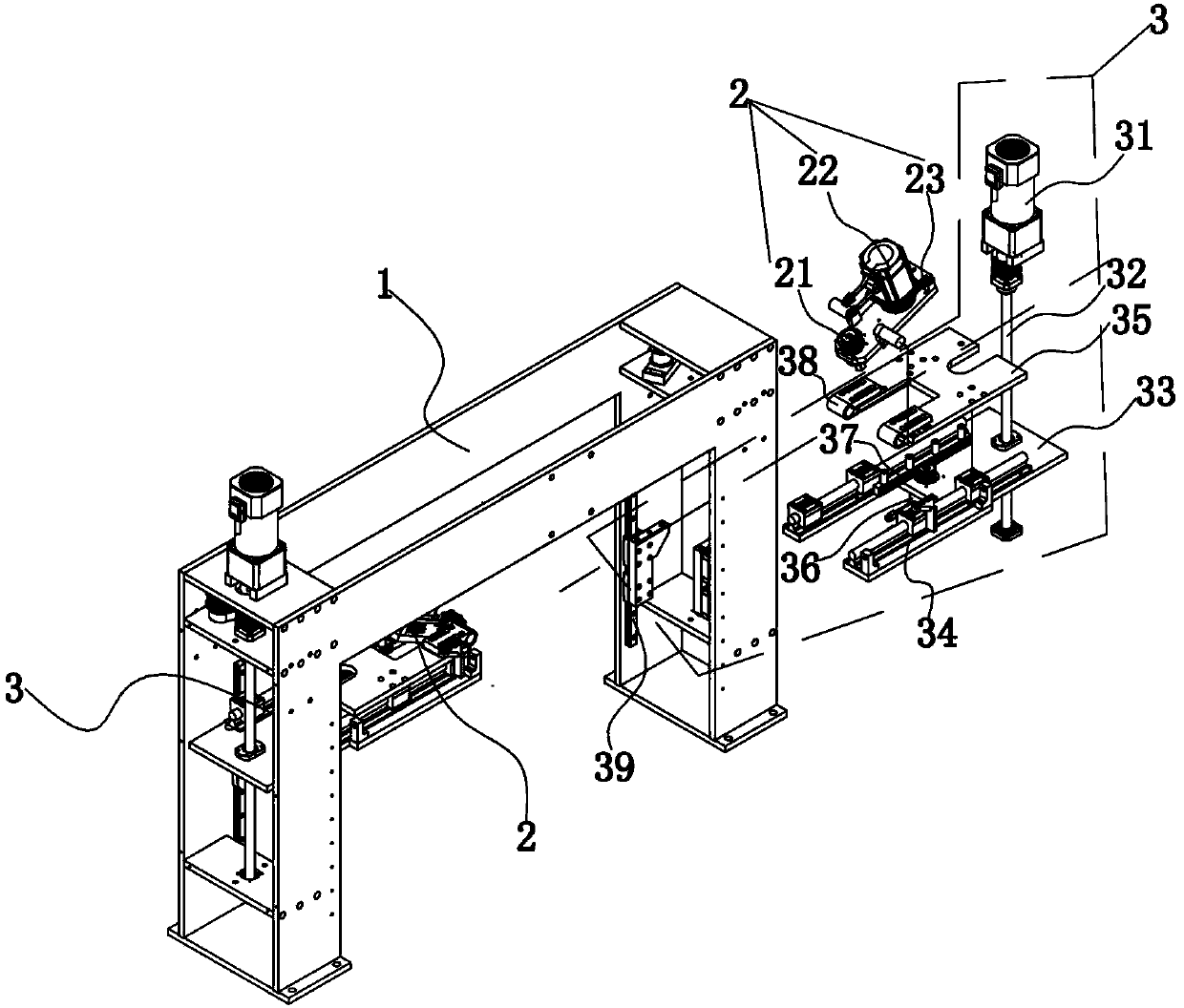

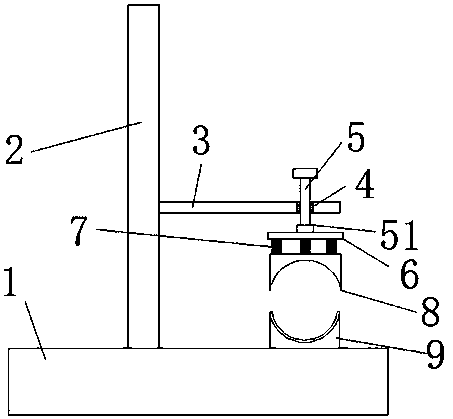

Novel grinding machine

InactiveCN104175188AWide range of applicationsReduce air pollutionEdge grinding machinesGrinding machine componentsMechanical engineeringEngineering

The invention discloses a novel grinding machine and relates to the technical field of a grinding apparatus. The novel grinding machine comprises a grinding mechanism, a clamping mechanism and a rotating mechanism, wherein the grinding mechanism consists of a grinding head, a grinding head motor and a grinding head driving device; the grinding head driving device can enable the grinding head to move up and down and left and right; the rotating mechanism comprises a rotating motor and an extension shaft fixed on an output shaft of the rotating motor; the rotating motor is fixed on a rotating mechanism fixed seat; the clamping mechanism comprises a clamping cylinder and two clamping bases; one clamping base is arranged below the extension shaft and the other clamping base is arranged on a cylinder rod of the clamping cylinder. The novel grinding machine has the beneficial effects that due to adoption of a grinding mode, no matter what shape a product is of, the grinding head can be attached to the surface of the product to move; the products with any shapes can be ground; the novel grinding machine has a very wide application range.

Owner:东莞市捷利康自动化机械有限公司

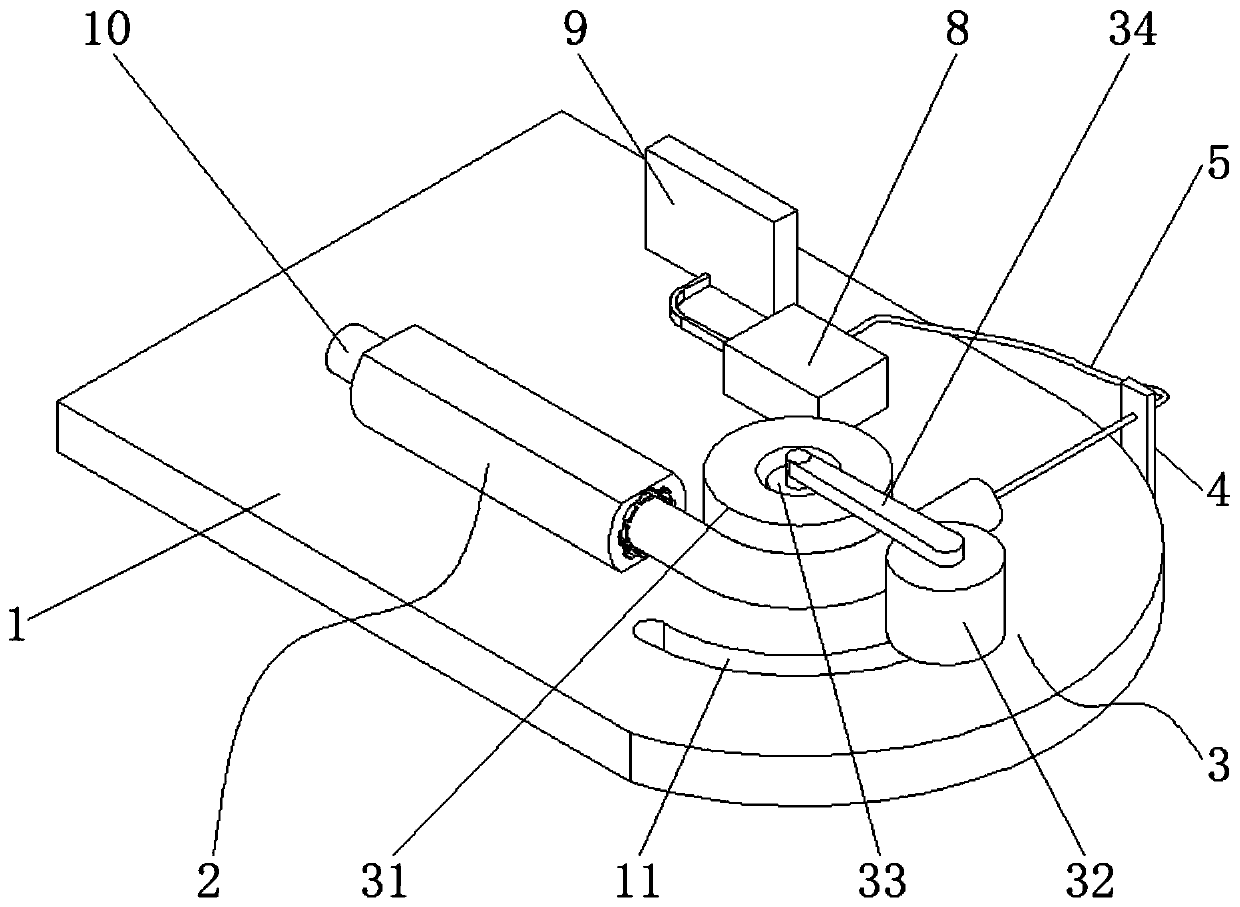

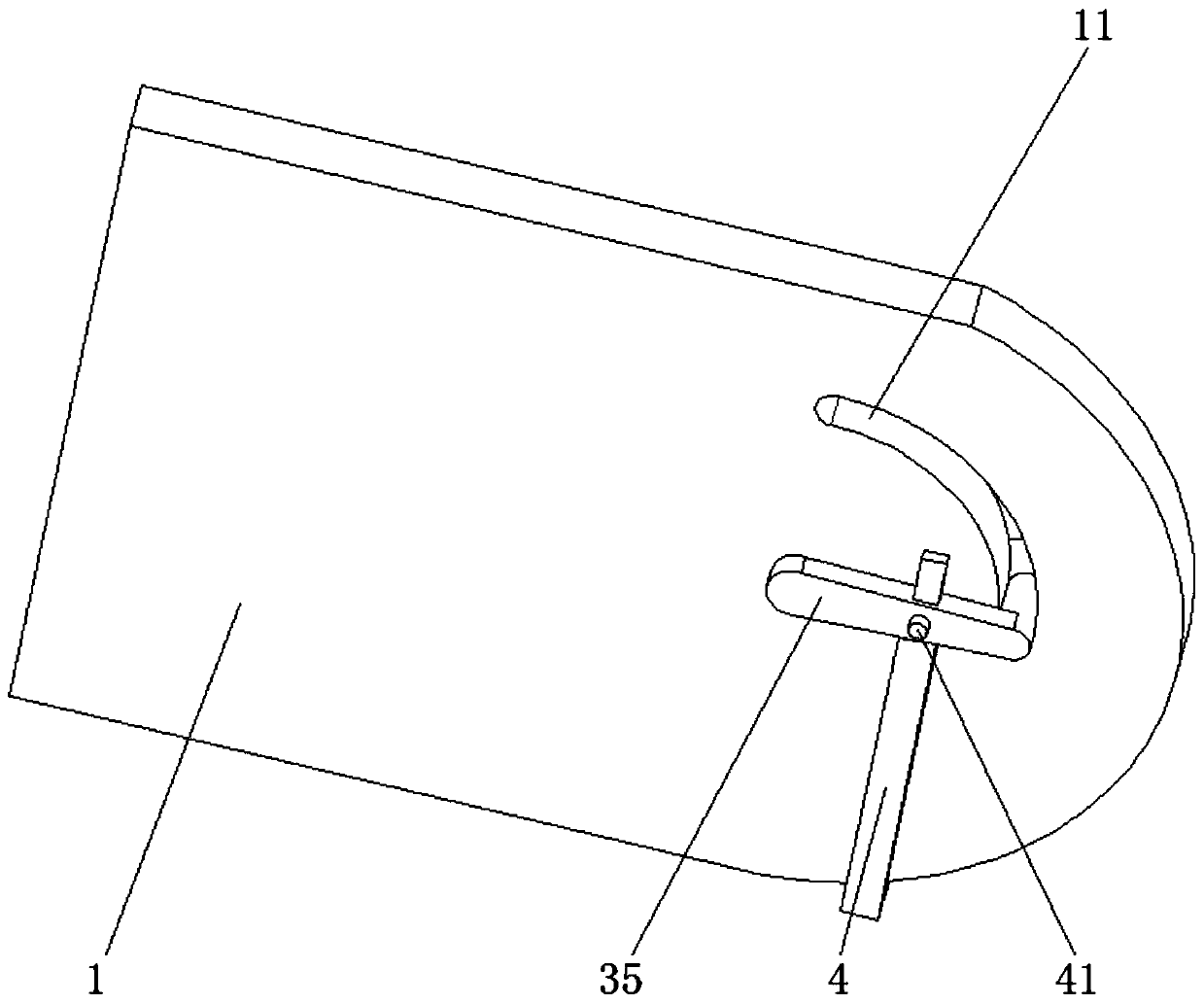

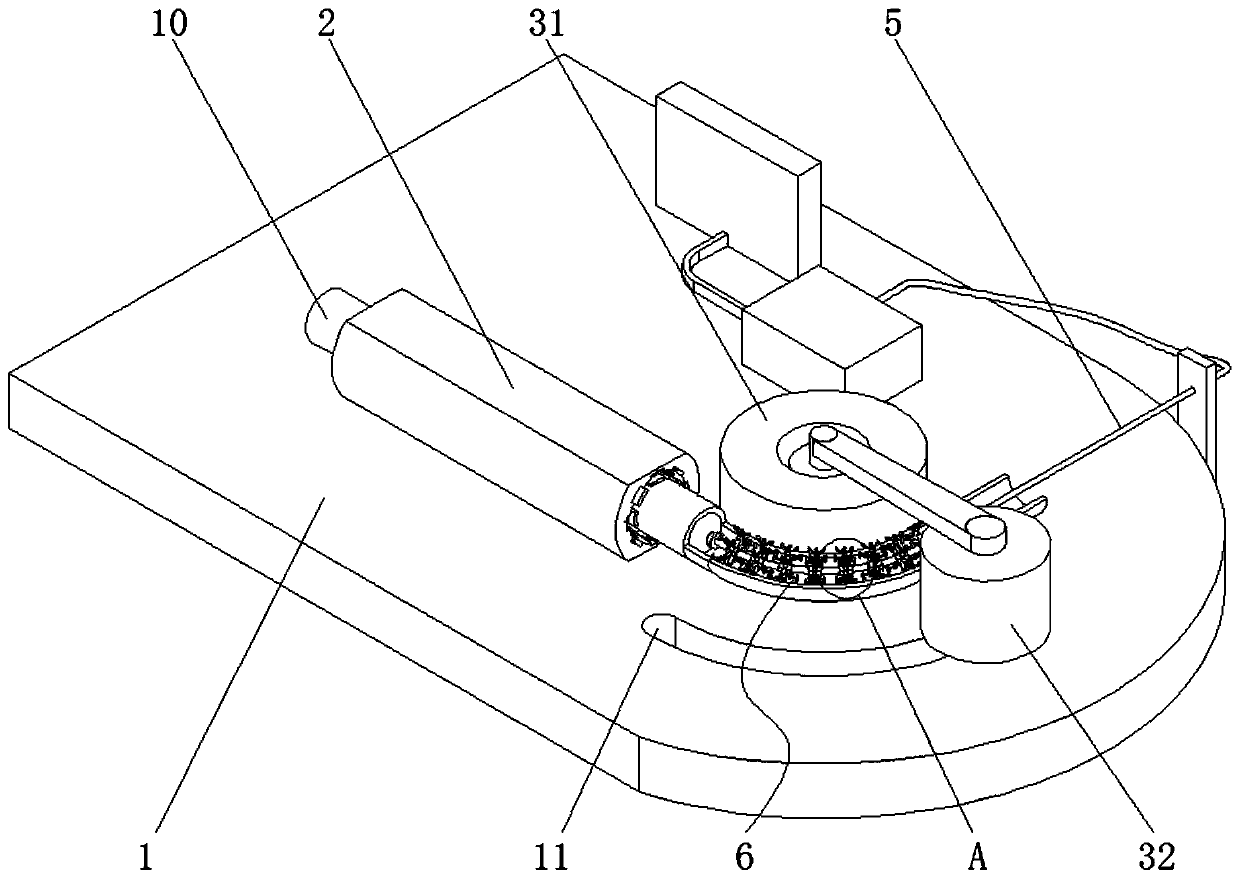

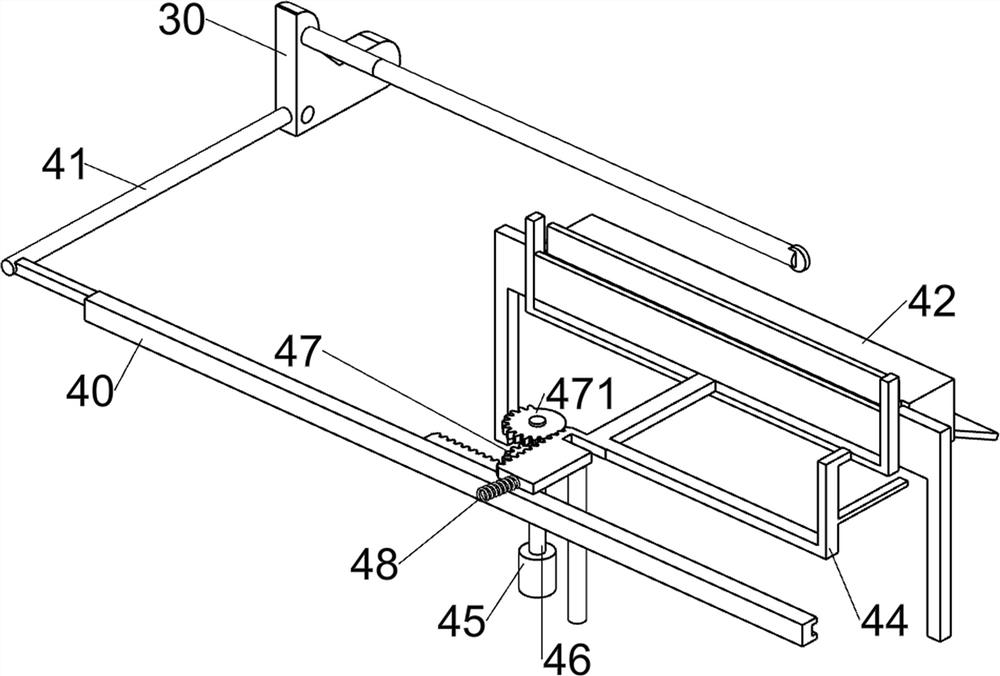

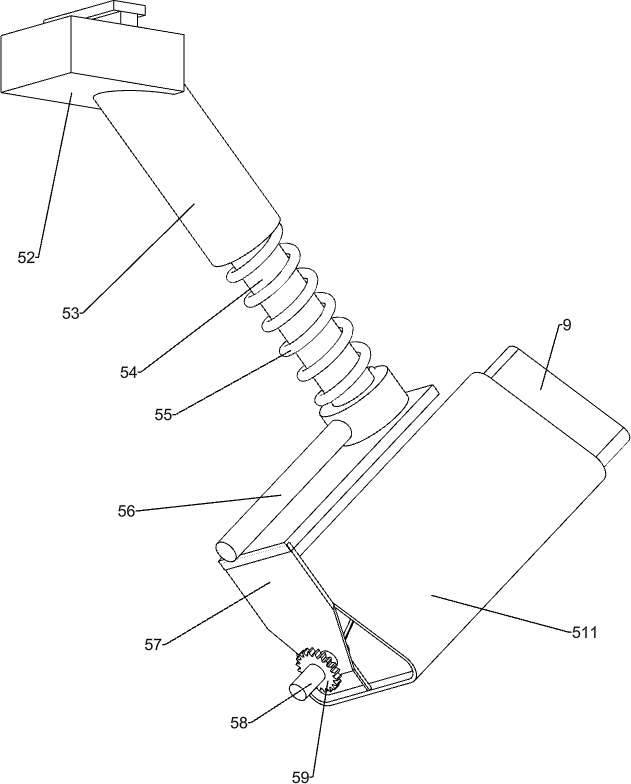

Surface machining device and method aiming at bending metal pipes of small specifications

ActiveCN111346955AAffect the use effectAchieve sanding effectEdge grinding machinesRevolution surface grinding machinesPolishingStructural engineering

The invention provides a surface machining device and method aiming at bending metal pipes of small specifications and relates to the field of metal pipes. The surface machining device aiming at bending the metal pipes of the small specifications is used for bending pipe bodies and comprises a working table, a placing groove, a bending mechanism, a supporting rod, a cable and multiple polishing mechanisms. The placing groove is formed in the working table. The bending mechanism is arranged on one side of the placing groove. According to the surface machining device aiming at bending the metalpipes of the small specifications, by means of cooperation of the cable, a fixing sleeve, a tiny electric pushing rod and a scraper, the whole polishing mechanism extends into the metal pipes to be bent. The function of filler is achieved, and the interiors can be stressed uniformly when the pipes are bent. After the pipes are bent, the cable is pulled to drive the scraper on the polishing mechanism to move while the scraper makes contact with pipe walls. Thus wrinkles generated on the inner walls of bent portions of the pipes are milled flatly, the effect of polishing the inner walls of the metal pipes of the small specifications is achieved, and the situation that due to existence of the wrinkles, the use effect of the pipes is influenced.

Owner:绍兴市菲尔乐管业有限公司

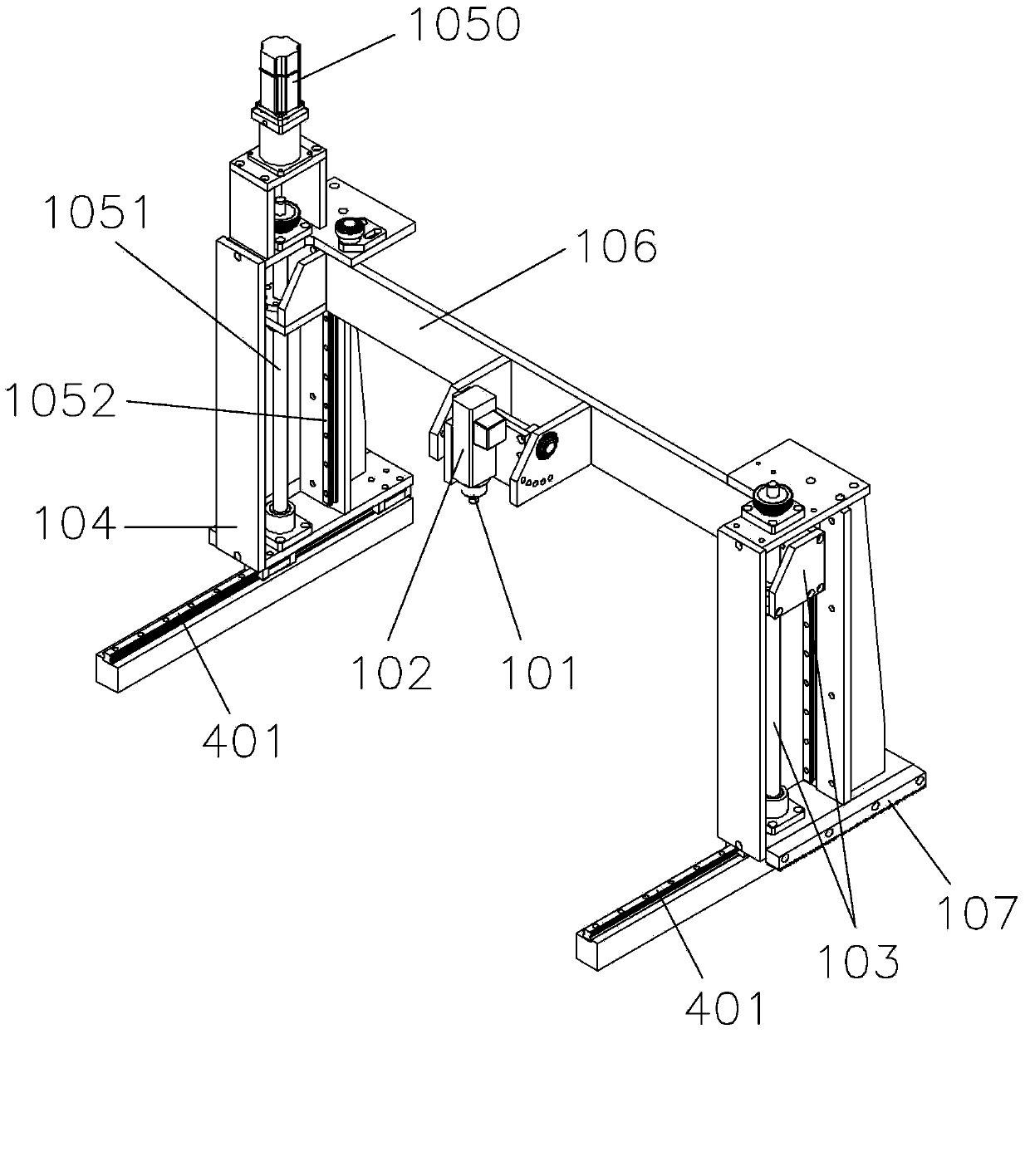

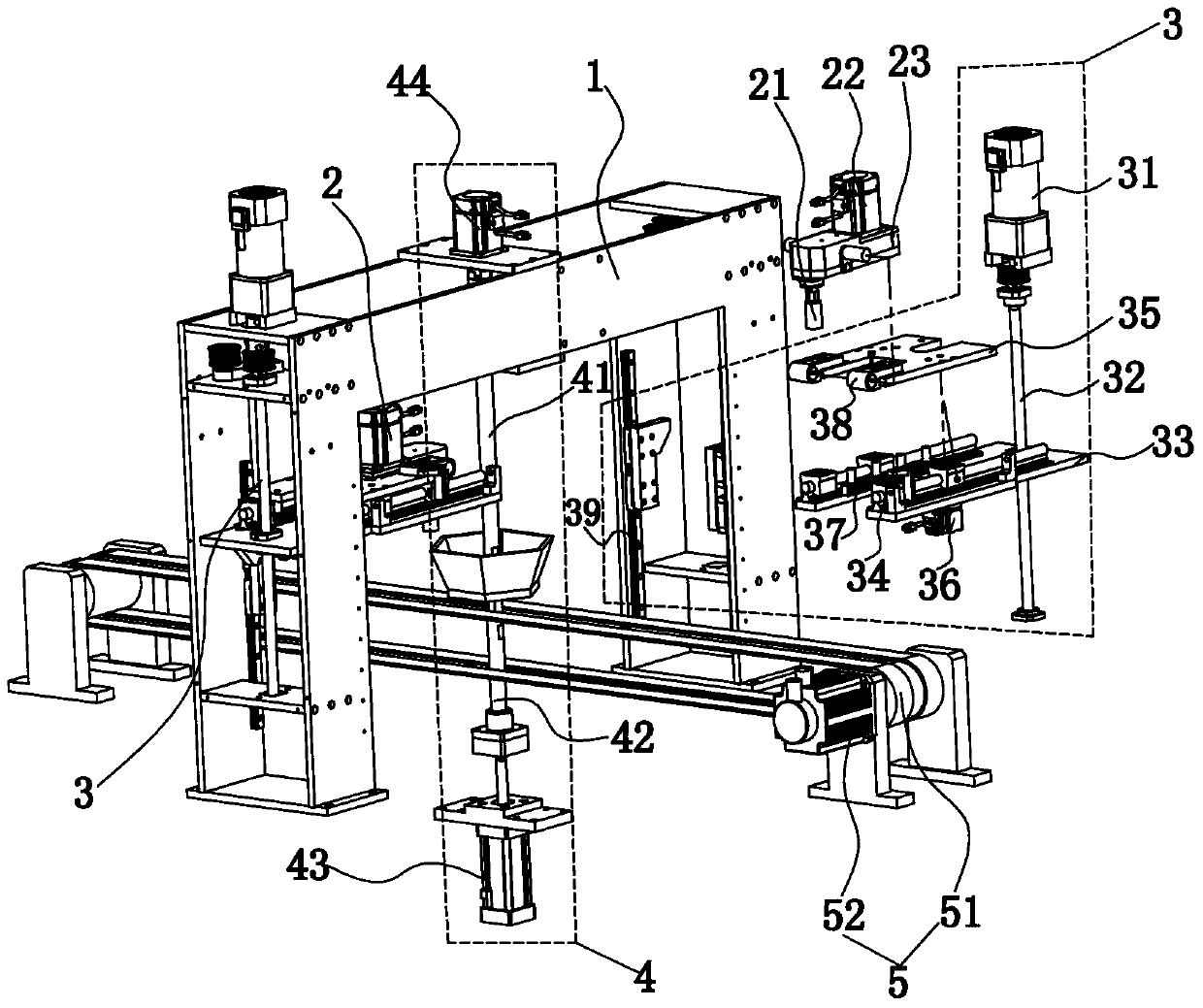

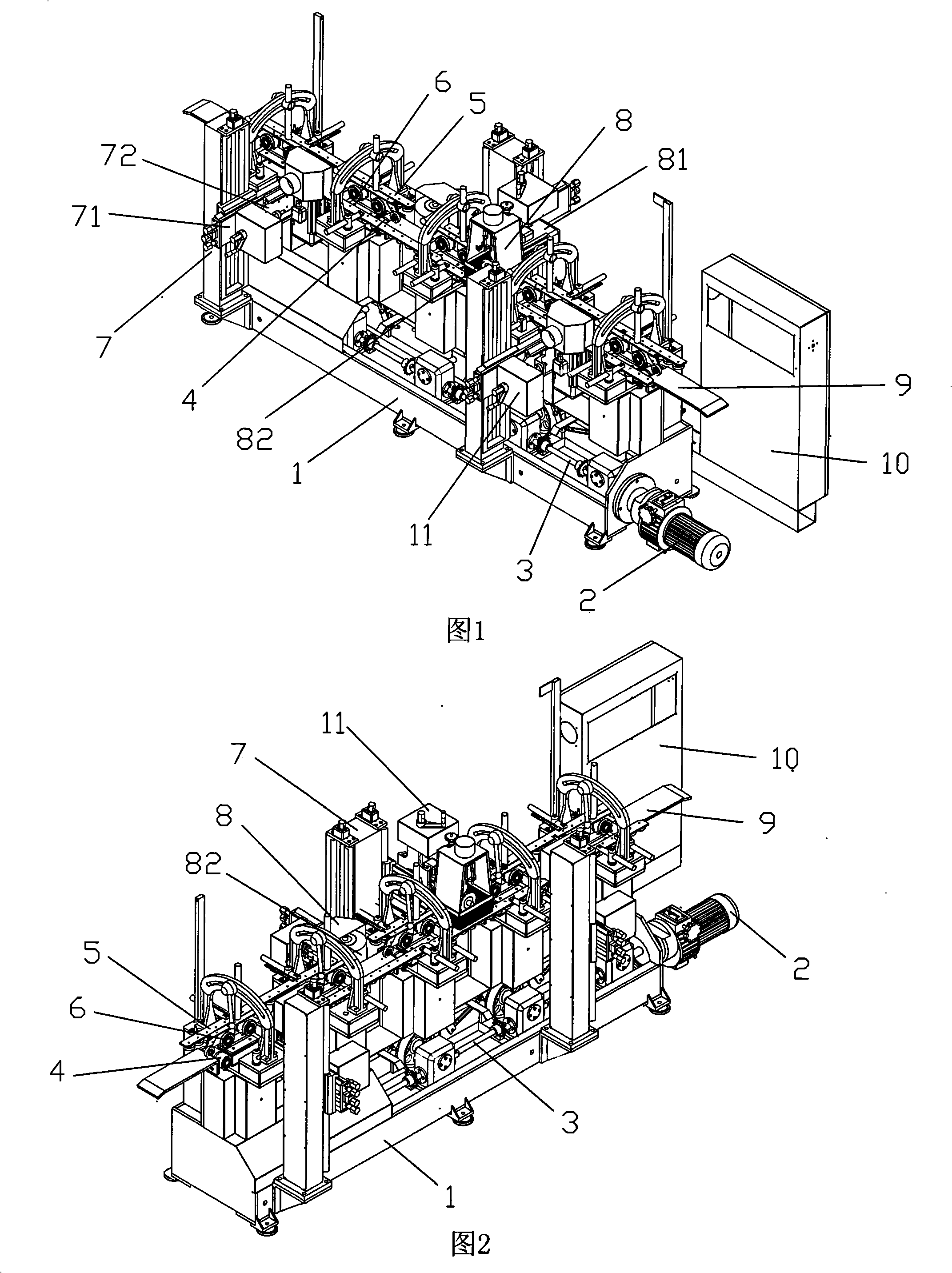

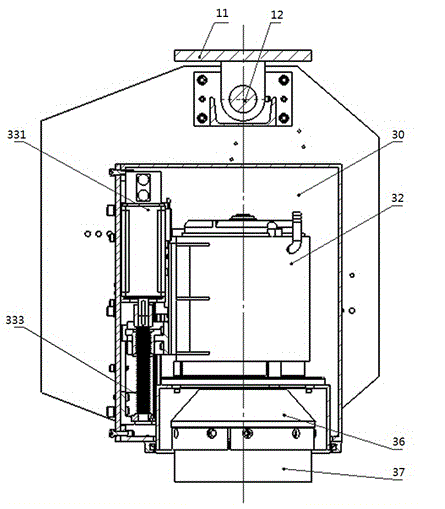

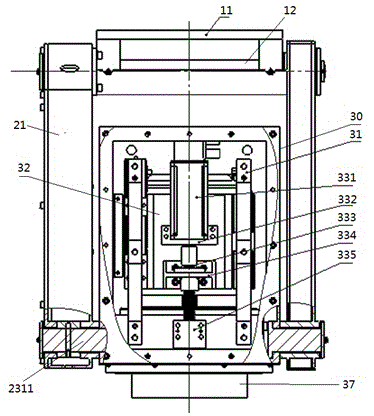

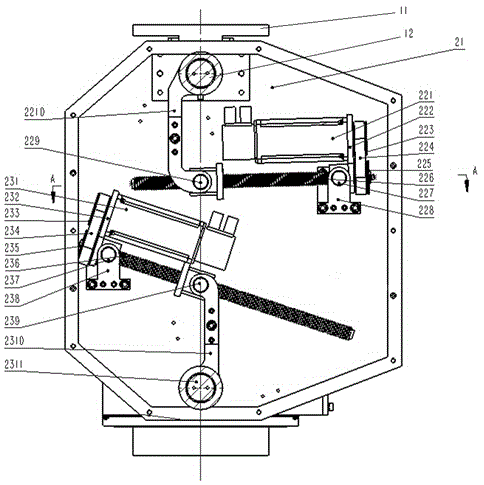

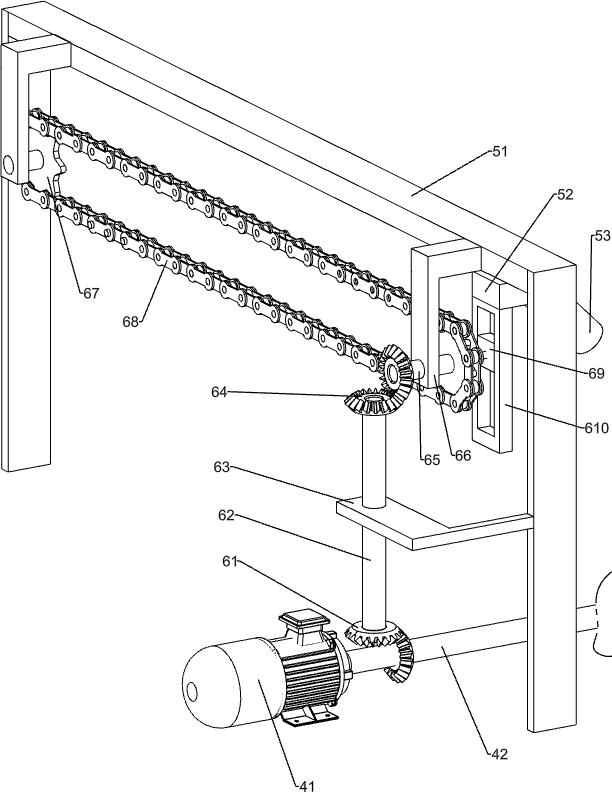

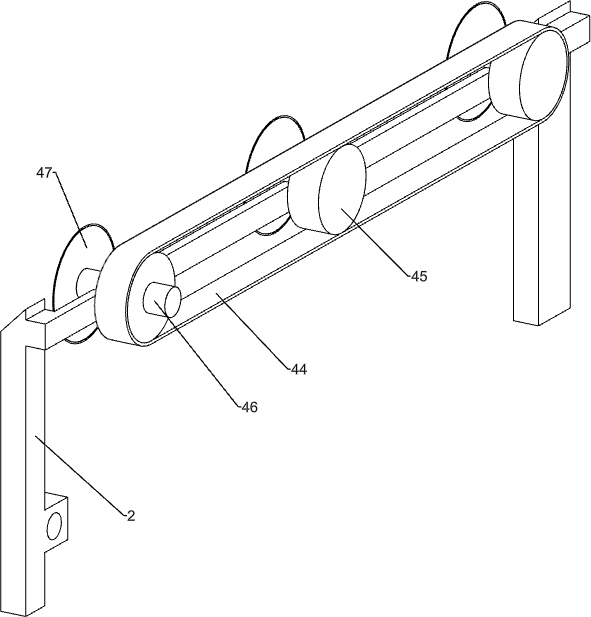

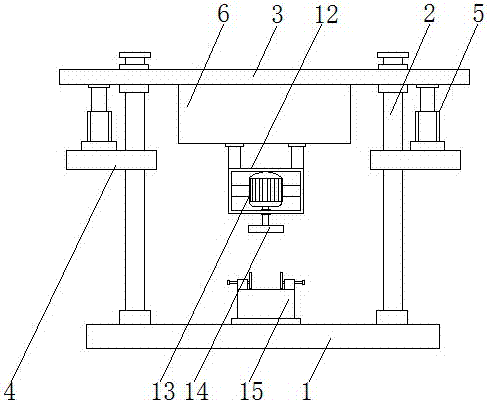

Gantry edging mechanism and automatic polisher using same

InactiveCN103692312AChange the rotation speed at willAdjust the tilt angleEdge grinding machinesGrinding work supportsEngineeringMechanical engineering

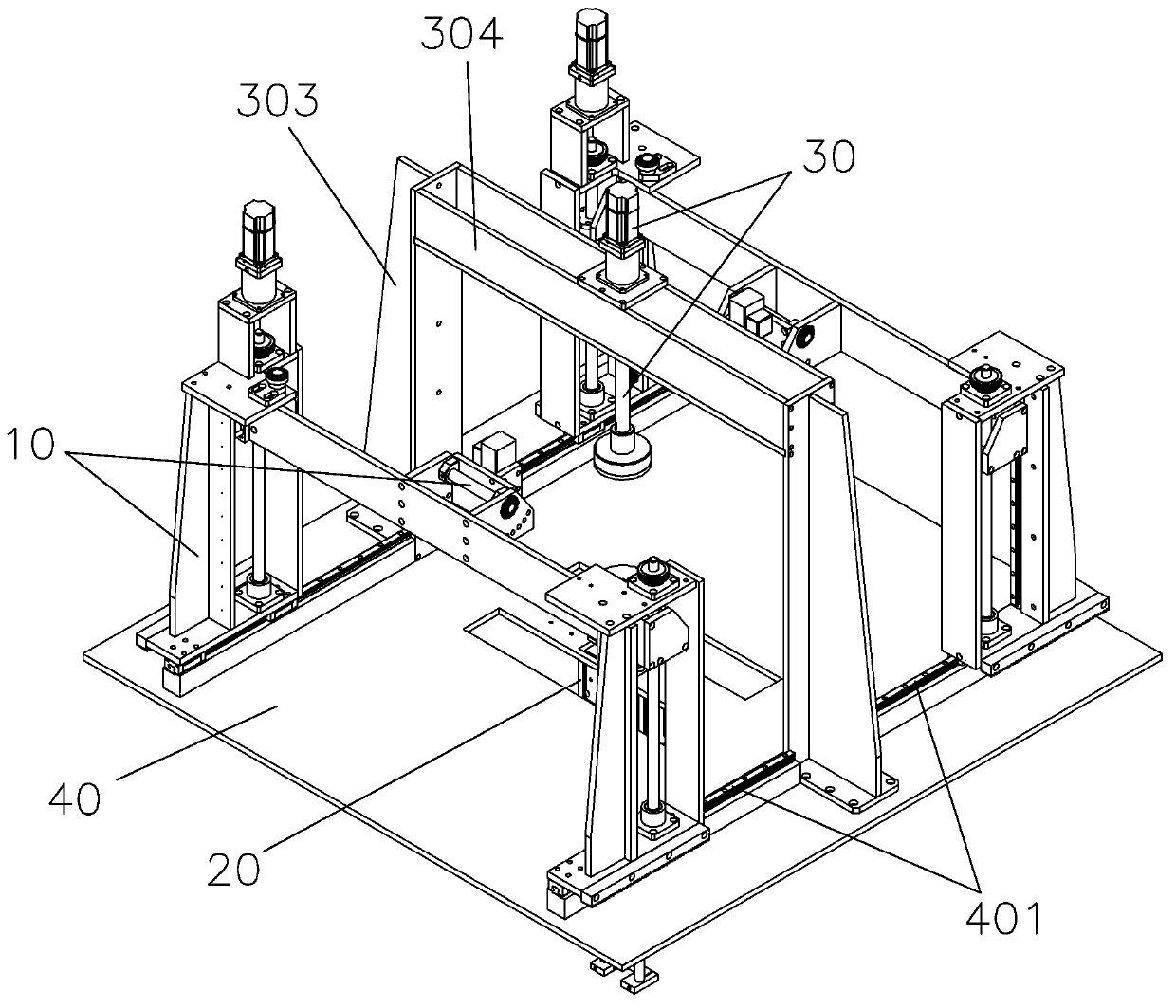

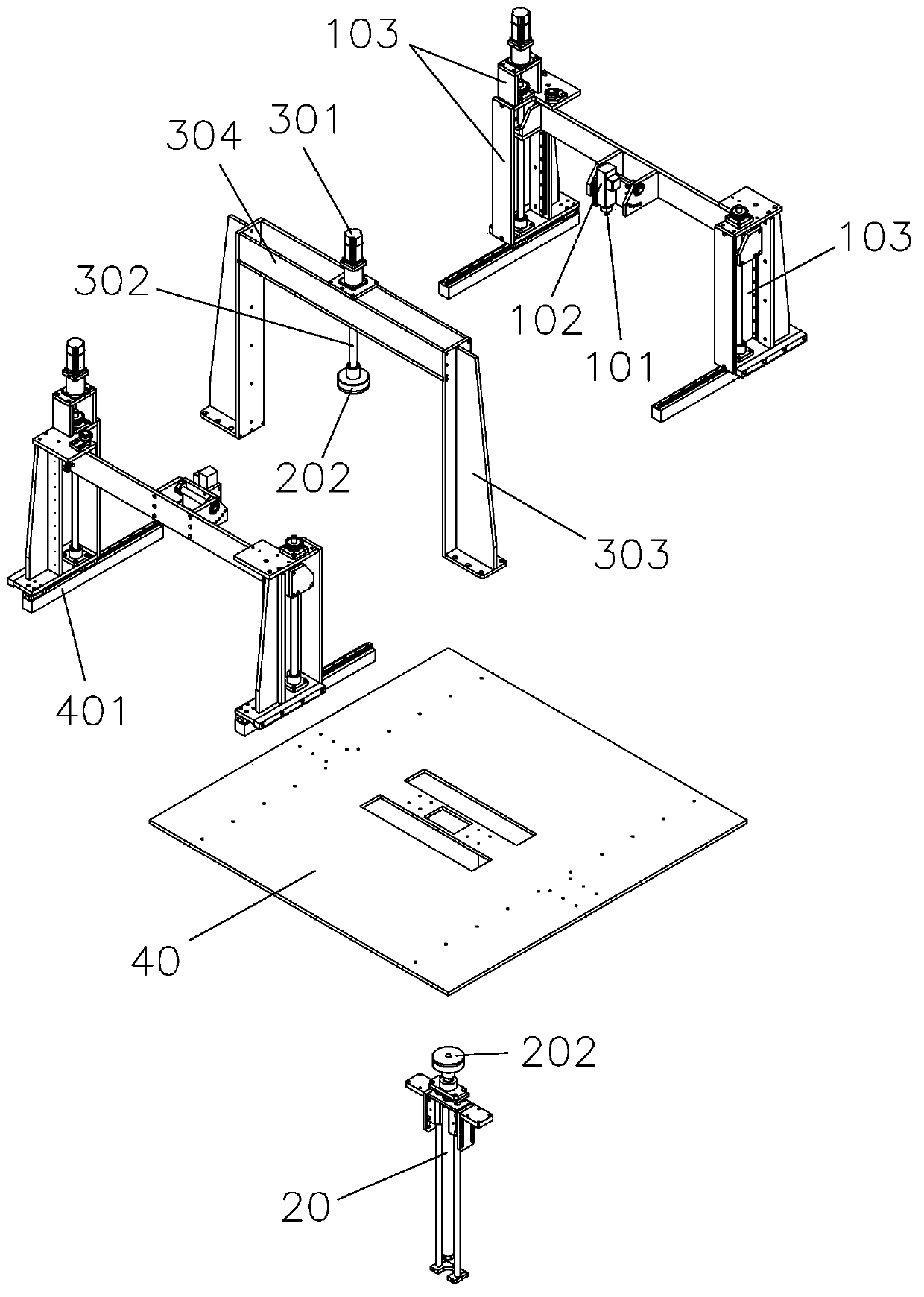

The invention discloses a gantry edging mechanism and an automatic polisher using the same, and belongs to the field of polishing instruments. The gantry edging mechanism comprises a gantry frame, a polishing assembly and a driving assembly, wherein both the polishing assembly and the driving assembly are arranged on a side frame of the gantry frame, and the polishing assembly moves upwards, downwards, frontwards and backwards for edging through the driving of the driving assembly; the automatic polisher comprises the gantry edging mechanism and a material clamping mechanism. The gantry edging mechanism and the automatic polisher applying the same can automatically edge products for substituting a manual polishing mode, thereby improving the production efficiency of the products and reducing the damage of dust generated by polishing to an operator; in addition, the structure is stable, and the edging effect is good.

Owner:DONGGUAN CHUANJIN MECHANICAL

Eyeglass corner polishing equipment for manufacturing eyeglasses

ActiveCN111958387AAchieve sanding effectSave human effortEdge grinding machinesGrinding carriagesEyewearStructural engineering

The invention relates to polishing equipment, in particular to eyeglass corner polishing equipment for manufacturing eyeglasses. The eyeglass corner polishing equipment for manufacturing the eyeglasses is simple in operation, and capable of improving working efficiency and saving manpower. The eyeglass corner polishing equipment comprises a bottom plate, a storage plate, a frame, a bracket and a transmission assembly, wherein one side of the top of the bottom plate is connected with a leaking frame; the storage plate is connected to one side of the top of the leaking frame and is obliquely arranged; the frame is connected in the middle of the top of the bottom plate; the bracket is connected to the upper part of one side of the frame; and the transmission assembly is arranged on the bottomplate. According to the eyeglass corner polishing equipment, the eyeglasses are polished through the matched operation of the transmission assembly, a clamping assembly and a polishing assembly, so that the effect of polishing the eyeglasses is achieved.

Owner:浙江维真医疗科技有限公司

Tempered glass forming processing system

InactiveCN112171464AIncrease contact areaGrinding stabilityGrinding drivesBelt grinding machinesStructural engineeringToughened glass

The invention provides a tempered glass forming processing system. The tempered glass forming processing system comprises a bottom plate, a fixing device and a grinding device. The lower end face of the bottom plate is fixed to the existing ground, the fixing device is arranged on the upper end face of the bottom plate, and the grinding device is arranged below the fixing device. According to thetempered glass forming processing system, through mutual cooperation of a cylinder, a piston, I-shaped air bags and a ventilation pipe, the I-shaped air bags can deform; and through mutual cooperationof the I-shaped air bags, movable rods, I-shaped wheels and rubber belts, the I-shaped air bags can drive the I-shaped wheels and the rubber belts to expand and deform towards the two ends when expanding, so that the contact area between the rubber belts and the surface of glass is increased, the friction force between the rubber belts and the surface of the glass is increased, the glass is morestable in the grinding process, and the tempered glass forming processing system can adapt to glass of various specifications by changing the expansion degree of the I-shaped air bags.

Owner:李阳

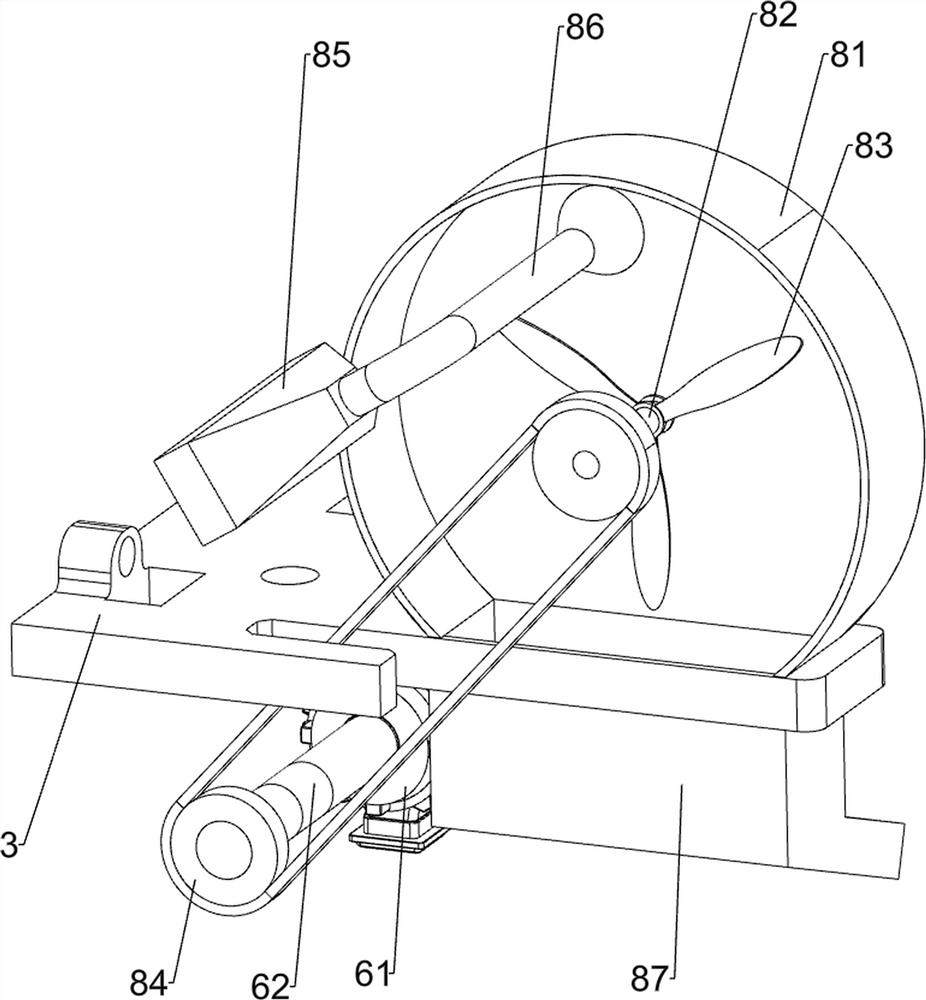

Special-shaped wooden strip sanding grinder

InactiveCN101318305AAchieve sanding effectReplace heavy laborGrinding machinesDrive wheelEngineering

The invention discloses a special-shaped wooden wire sanding machine, comprising a frame, the lower end of which is provided with a turbine shaft driven by a motor, and a pulley on the turbine shaft is respectively connected with a driving wheel which is arranged in the lower part of a worktable via a belt; the frame is provided with a pressing frame which is provided with a driven wheel corresponding to the driving wheel; the frame is provided with a vertical slide rail which is provided with a horizontal slide rail, and the horizontal slide rail is connected with a compensating slide rail via a turntable; the compensating slide rail is provided with a buffing device which comprises a motor seat, and the motor seat is provided with a grinding wheel which is driven by the motor; the buffing surface of the grinding wheel inosculates with the shape of the buffing surface of the special-shaped wooden wire. Owing to high automation degree, the product of the invention completely replaces heavy labor of workers and greatly reduces manufacturing cost, thus the sanding machine can be widely applied to precise buffing of various special-shaped line materials.

Owner:谢亚勇

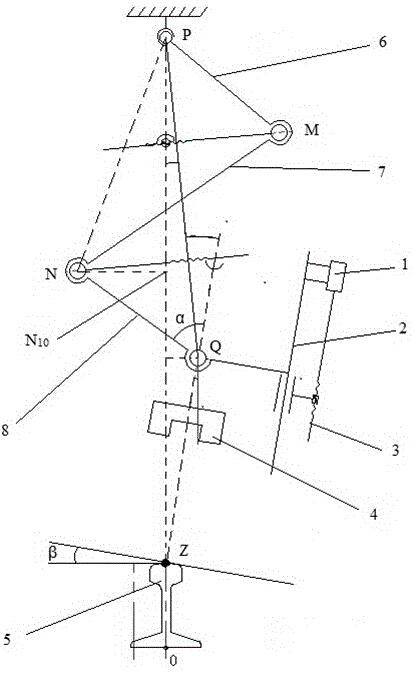

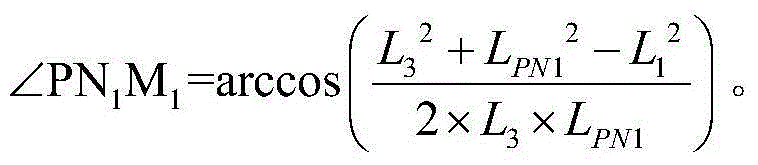

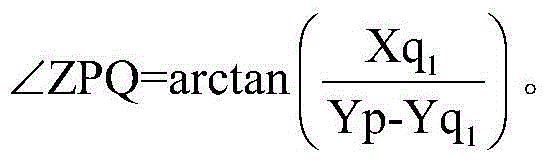

Track profiling grinding method

ActiveCN104452500AAchieve sanding effectReduce the amount of feedRailway track constructionRectangular coordinatesEngineering

The invention relates to the technical field of railway track maintenance, in particular to a track profiling grinding method. A track profiling grinder is arranged at the initial position, the track transverse section where the rotary axis of a grinding head of the grinder is located serves as a datum plane, a rectangular coordinate system is built, coordinate parameters of track profiles and the initial position parameters of the grinder are obtained by measurement, a track profile to be grinded is determined, the straight line, crossed with the datum plane, of the track profile to be grinded serves as a grinding tangent line, the grinding head of the grinder is moved until the rotary axis of the grinding head is perpendicular to the grinding tangent line, the grinding head of the grinder is driven to move in the radial direction of the rotary axis of the grinding head until the lower end face of the grinding head coincides with the grinding tangent line, and the grinding head of the grinder is driven to move along the track profile to be grinded to finish grinding of the track profile to be grinded. According to the track profiling grinding method, the grinding head of the grinder is moved according to the coordinate parameters until the rotary axis of the grinding head is perpendicular to the grinding tangent line, and the effect of adopting the end face of the grinding head for grinding when grinding of any angle is performed is achieved.

Owner:南京宏典轨道装备有限公司

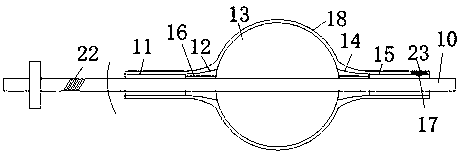

Rail grinding machine

ActiveCN104404846AImprove repair effectRealize multi-degree-of-freedom motionRailway track constructionElectric machineryStructural engineering

The invention relates to the field of mechanical equipment for use in rail maintenance, in particular to a rail grinding machine. The rail grinding machine comprises a fixed base, a grinding motor, a grinding head, a horizontal driving unit, a grinding head swinging driving unit, a frame and a feeding driving unit, wherein the feeding driving unit can be used for driving the grinding motor to move along the axis of the motor; the feeding driving unit is arranged on the frame through a shaft; the grinding head swinging driving unit can be used for driving the feeding driving unit to swing axially on the frame; the frame is connected to the horizontal driving unit; the horizontal driving unit is connected with the fixed base; the horizontal driving unit can be used for driving the frame to move horizontally. By adopting the rail grinding machine disclosed by the invention, multi-degree-of-freedom motion of the grinding head is realized, profile grinding can be realized on a steel rail during grinding, and the grinding effect is enhanced; a linear guide rail on which the motor is arranged is fixed on a driving box, and meanwhile the linear guide rail is arranged on the side face of a feeding servo motor to form an eccentric structure, so that the problems of mechane failure and poor grinding effect caused by vibration are solved.

Owner:南京宏典轨道装备有限公司

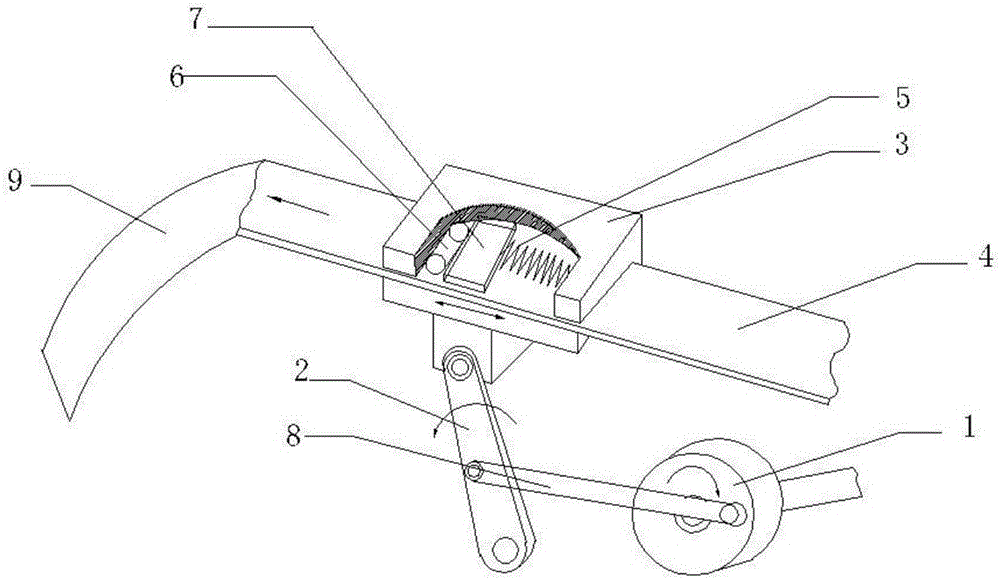

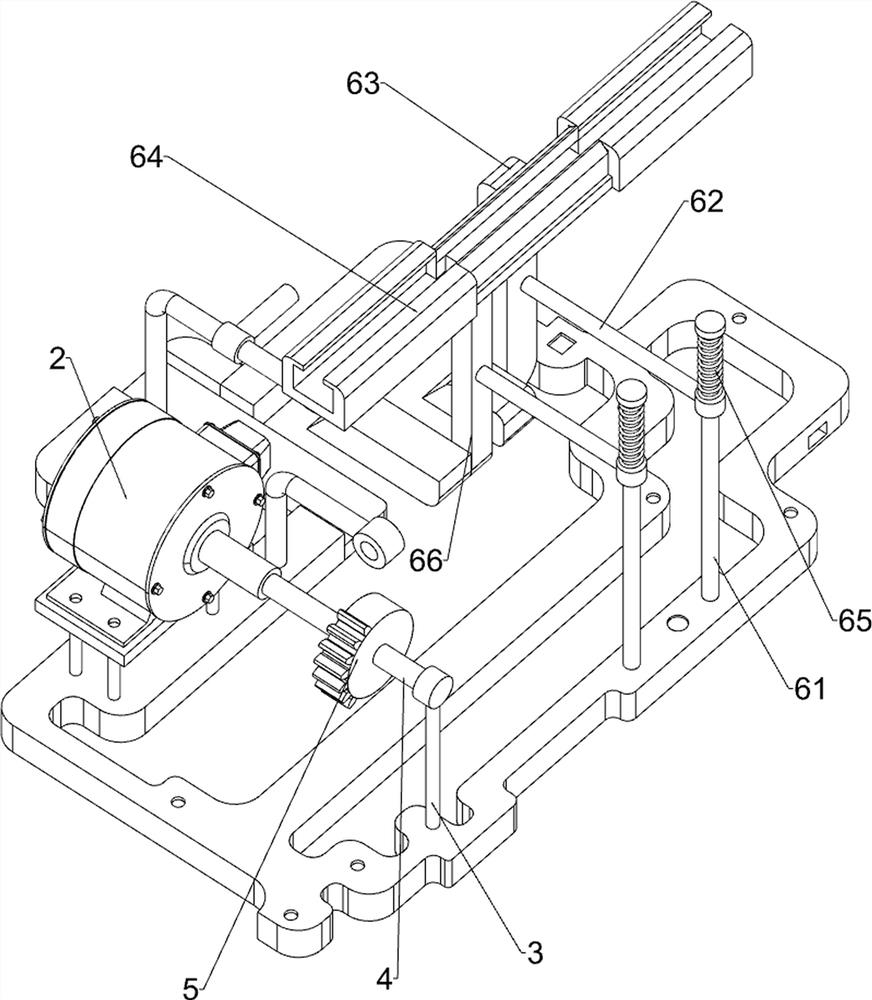

Intermittent feeding device of continuous belts

InactiveCN106629185AImprove feeding efficiencyAchieve grindingPlane surface grinding machinesWebs handlingEngineering

The invention relates to the technical field of machinery, and discloses an intermittent feeding device of continuous belts; and compared with the prior art, the device is simple in structure, high in feeding efficiency, safe and reliable, and has proper polishing function. The device comprises a crank wheel, a rocker rod, a reciprocating box and a rolling column; the crank wheel and the rocker rod are fixedly linked through a connecting rod; the upper end of the rocker rod is movably hinged with the bottom of the reciprocating box; the rolling column is arranged on the inner wall of one end of the reciprocating box; a spring is arranged on the inner wall of the other end of the reciprocating box; and the spring is fixedly connected with a pressing block.

Owner:GUANGXI UNIV FOR NATITIES

Plastic valve end port grinding device

ActiveCN106695493AReduce riskAchieve the effect of rotationEdge grinding machinesRevolution surface grinding machinesEngineering

The invention discloses a plastic valve end port grinding device which comprises a base. A controller is fixedly installed on the left side of the top of the base. A fixed base is fixedly connected to the top of the base and located on the right side of the controller. The top of the fixed base is fixedly connected with a fixed ring. A fixed plate is fixedly connected to the left side of the fixed ring. A first motor is fixedly installed on the left side of the fixed plate. The output end of the first motor penetrates through the fixed plate, extends into the fixed ring and is fixedly connected with a first gear. A second gear used in cooperation with the first gear is arranged inside the fixed ring. A stabilizing plate is fixedly connected to the left side of the second gear. A first roller is movably installed on the left side of the stabilizing plate through a support. A first sliding rail is fixedly connected to the inner wall of the fixed ring, and the first roller is in sliding connection with the first sliding rail. According to the plastic valve end port grinding device, operation is easy, the effect of even grinding can be achieved by automatically rotating a plastic valve, and risks during work are reduced for workers.

Owner:吴江市强塑阀门管件厂

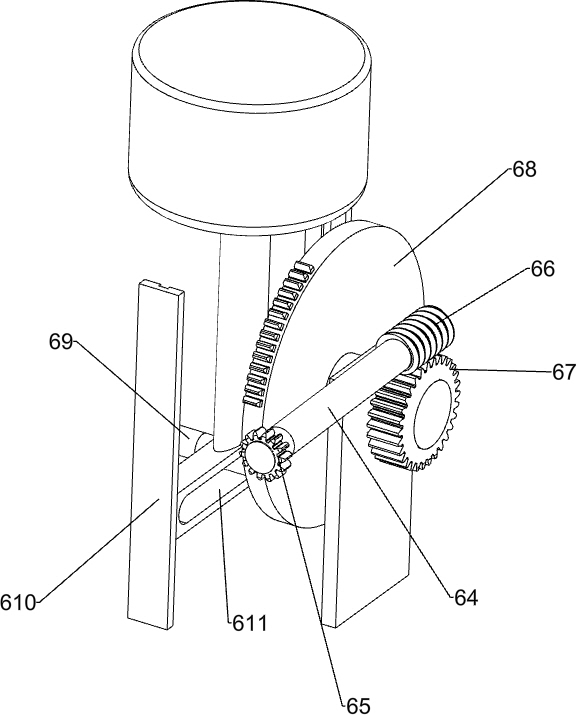

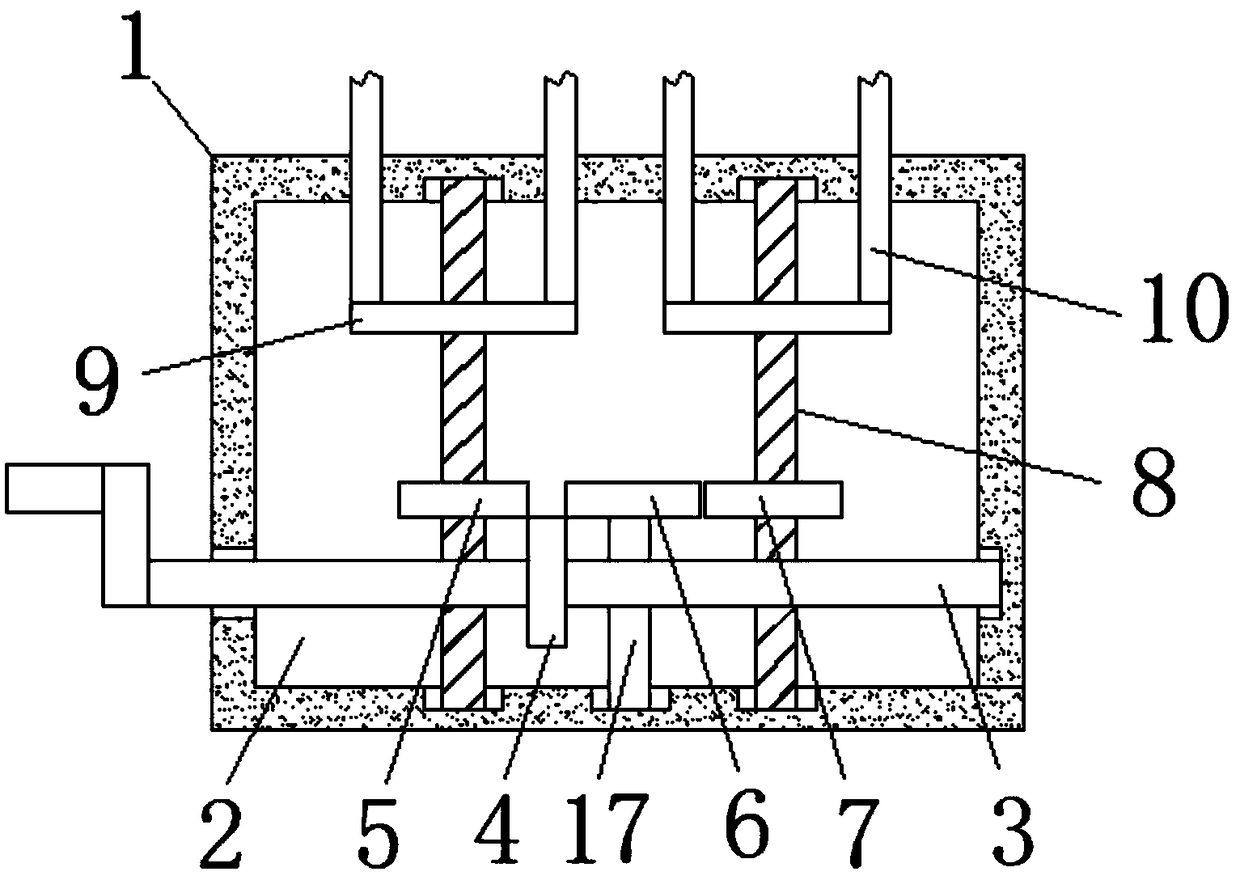

Rotatable gear machining and polishing device

ActiveCN111890144APlay a fixed effectExactly atGrinding carriagesRevolution surface grinding machinesGear wheelPolishing

The invention belongs to the technical field of gear machining, particularly discloses a rotatable gear machining and polishing device, and puts forward the following scheme so as to solve the problemof gear machining and polishing devices are very inconvenient to use due to the fact that the gear machining and polishing devices are poor in adjustment flexibility, are troublesome to operate and cannot meet polishing requirements of gears in different hole diameters in the prior art. The rotatable gear machining and polishing device comprises a base; the base is of a hollow structure; two vertical plates are symmetrically and fixedly connected on the two sides of the outer wall of the top of the base; and the tops of the two vertical plates are fixedly connected with a same top plate. According to the rotatable gear machining and polishing device, the height of a round plate can be adjusted by the aid of lifting air cylinders, the clamping effect on machining gears can be achieved through starting of a first servo motor, the machining gears and a polishing roller can be driven simultaneously to perform synchronous operation through starting of a driving motor, the requirement for polishing the machining gears in different hole diameters can be realized under the condition that normal work of the polishing roller is not affected through starting of a second servo motor, and thusthe machining and polishing efficiency is improved.

Owner:WENZHOU UNIVERSITY

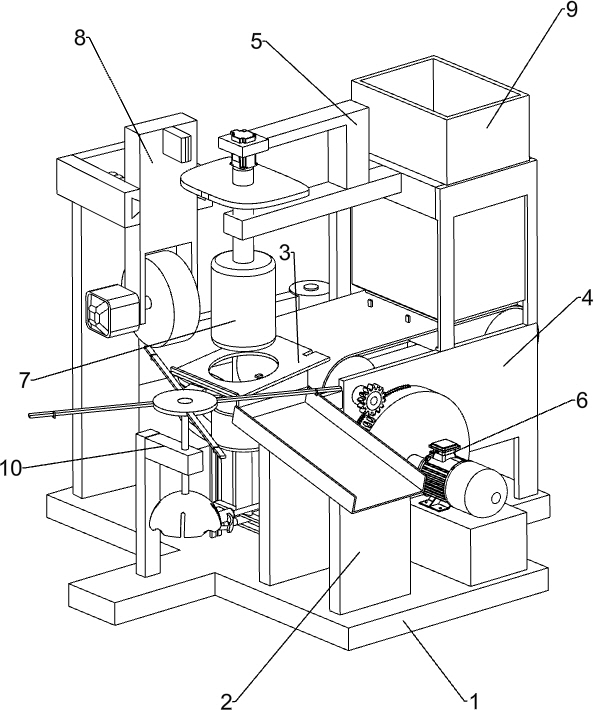

Bamboo straw manufacturing equipment for beverage shop

ActiveCN112621964AAchieve sanding effectStationary drilling machinesGrinding drivesMechanical engineeringIndustrial engineering

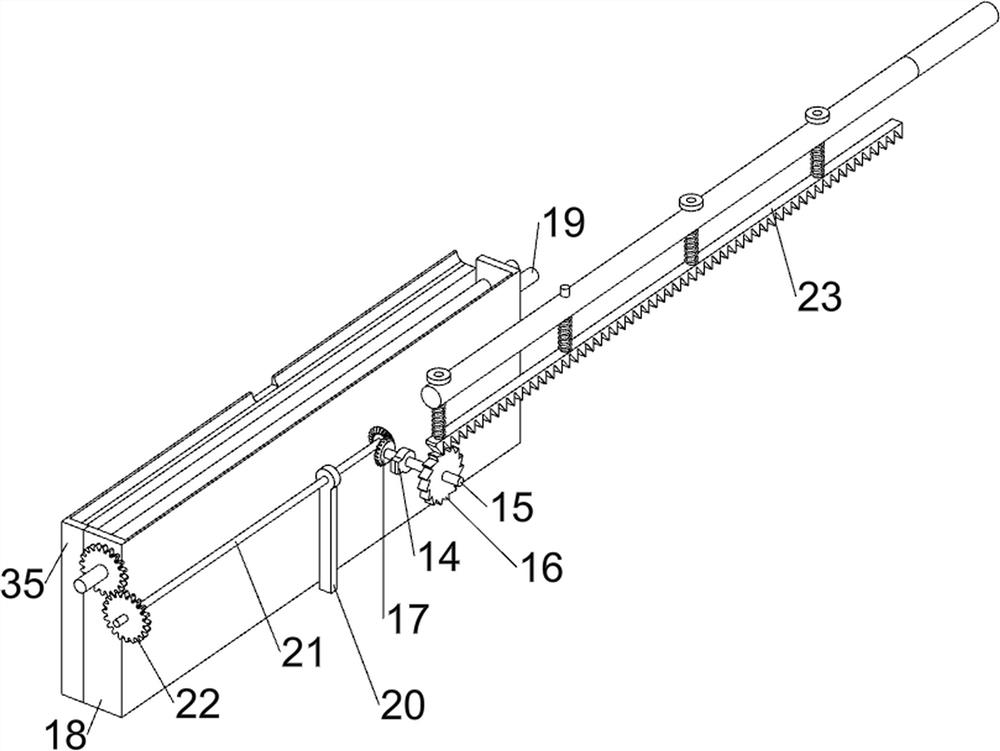

The invention relates to manufacturing equipment, in particular to bamboo straw manufacturing equipment for a beverage shop. The invention aims to provide the bamboo straw manufacturing equipment for the beverage shop, which can realize automatic feeding and can polish the bamboo straws after drilling is completed. The bamboo straw manufacturing equipment for the beverage shop comprises a base, an air cylinder, a drilling mechanism and a propelling mechanism, and the base is used for mounting the entire equipment; the air cylinder is arranged on one side of the upper part of the base; the drilling mechanism is arranged on the side, close to the air cylinder, of the upper portion of the base; and the propelling mechanism is arranged on the other side of the upper part of the base. The effects that automatic feeding can be achieved, and the bamboo straw can be polished after drilling is completed are achieved. Bamboo canes are placed in a first material box, the bamboo canes are continuously moved into a feeding frame in sequence through rotation of feeding teeth, then the bamboo canes are pushed out in sequence through a second rack, and therefore the effect of sequential discharging can be achieved.

Owner:郭英英

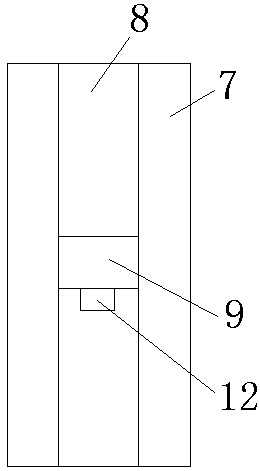

Device for grinding burrs in inner cavities of driving axles of new energy automobiles

PendingCN108274334APrevent spinningAvoid damageEdge grinding machinesGrinding work supportsNew energyEngineering

The invention discloses a device for grinding burrs in inner cavities of driving axles of new energy automobiles. The device comprises a bottom plate and a grinding rod, wherein height support rods are fixedly mounted on the upper surface of the bottom plate; two height support rods are arranged; a driving axle clamping rod is fixedly mounted on the front side wall of each height support rod; a threaded hole is formed in the inner wall of each driving axle clamping rod; the inner wall of the threaded hole is in threaded connection with a screw; a fixing part of a rotating shaft is fixedly mounted on the lower wall of each screw; a lower plate is fixedly mounted on a rotating part of each rotating shaft. According to the device for grinding burrs in inner cavities of driving axles of new energy automobiles, driving axle clamping structures with springs are arranged, so that two ends of the driving axles are clamped; meanwhile, the possible occurrence of the situation that the outer structures of the two ends of the driving axles are damaged due to excessively strong clamping force is also avoided; the occurrence of the situation that the driving axles rotate together with the grinding rods when grinding the inner cavities of the driving axles is avoided; the effect of enhancing the grinding effect is achieved.

Owner:LINYI LUYU MACHINERY

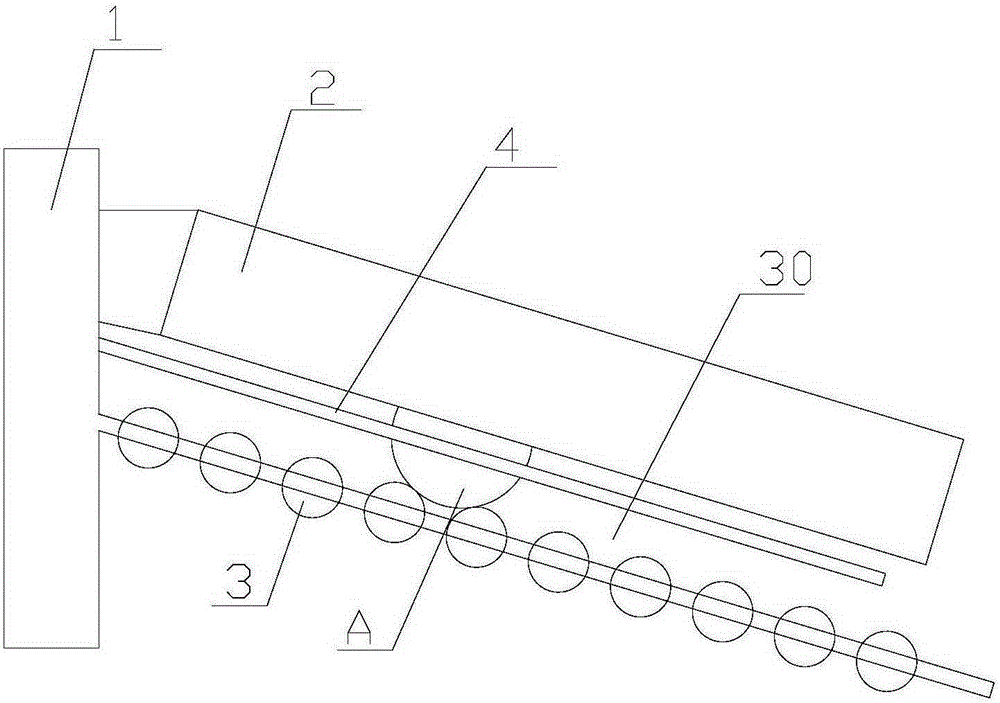

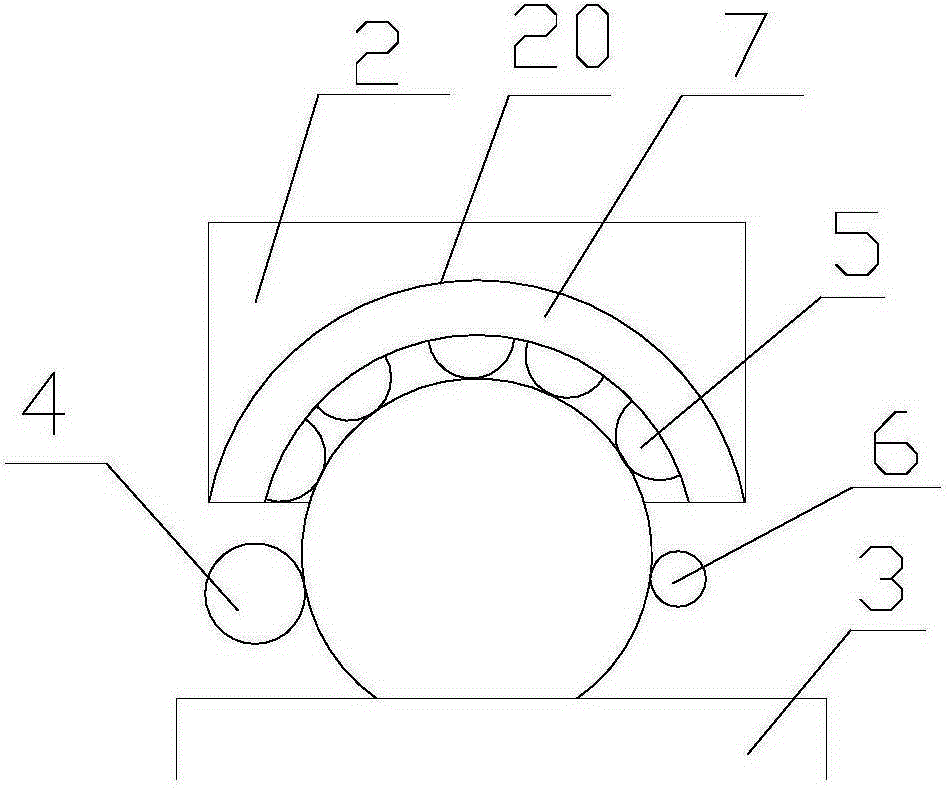

Wear-resisting ball surface treating device

InactiveCN105215824AReasonable structureEnergy savingSpherical surface grinding machinesSurface finishingEngineering

The invention discloses a wear-resisting ball surface treating device. The wear-resisting ball surface treating device comprises a support, a rust removing structure, a plurality of first rollers, a second roller, a first driving mechanism and a second driving mechanism. The multiple first rollers are installed on the support and arranged on an inclined plane in parallel to form a conveying rail. The first driving mechanism is connected with the first rollers and drives the first rollers to rotate around a central shaft. A wear-resisting ball on the conveying rail rolls from the higher end to the lower end. The rotation direction of the first rollers is opposite to the movement direction of the wear-resisting ball. According to the wear-resisting ball surface treating device, all-dimensional rotation of the wear-resisting ball can be achieved under the action of self-weight and the friction force by means of the conveying rail and the second roller which are arranged obliquely, so that during rolling, relative friction is achieved between the whole ball surface and the grinding structure, and the grinding effect is achieved. The wear-resisting ball surface treating device is reasonable in structure, the gravity action is utilized sufficiently, energy sources are saved easily, and the working efficiency is improved.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

Grinding device for rim of red wine glass

InactiveCN111408995ASave human effortSave manual effortGrinding drivesGrinding machinesGrindingEngineering

The invention relates to a grinding device, in particular to a grinding device for a rim of a red wine glass, and solves the technical problem of how to design the grinding device, which does not needto manually and directly hold the red wine glass during grinding and is capable of saving the labor consumed by workers and is used for the rim of the red wine glass. The grinding device for the rimof the red wine glass comprises a workbench, a first rotating shaft and a second rotating shaft, wherein a cylindrical tank body is connected to one side of the top of the workbench, a weeping pipe isconnected to the top of the workbench on one side of the cylindrical tank body, a grinding disc is rotationally connected in the cylindrical tank body, and a water outlet end of the weeping pipe is aligned with the grinding disc; the first rotating shaft is rotationally connected to the middle of the bottom of the grinding disc and is rotationally matched with the workbench; and the second rotating shaft is rotationally connected to one side, close to the first rotating shaft, of the top of the workbench. According to the grinding device, the rim part of the red wine glass can be pressed on the grinding disc for grinding through the cooperation of a clamping mechanism and a swing pressure plate, so that an effect of grinding the rim part of the red wine glass is achieved.

Owner:佘小梅

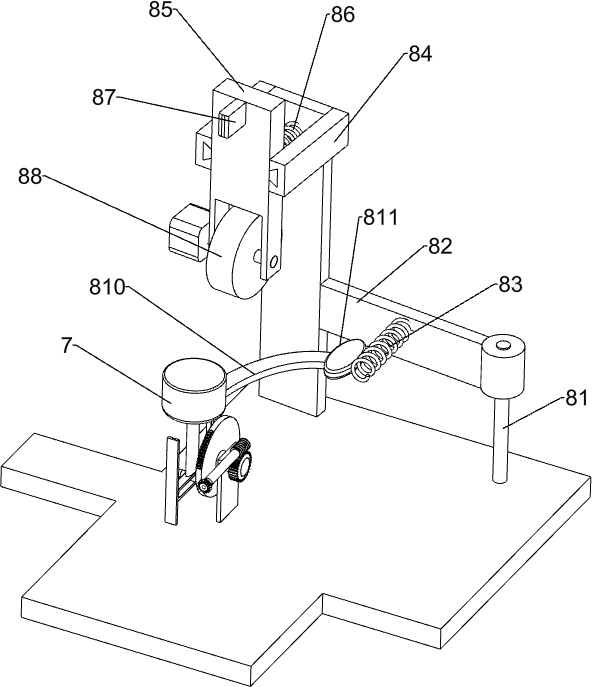

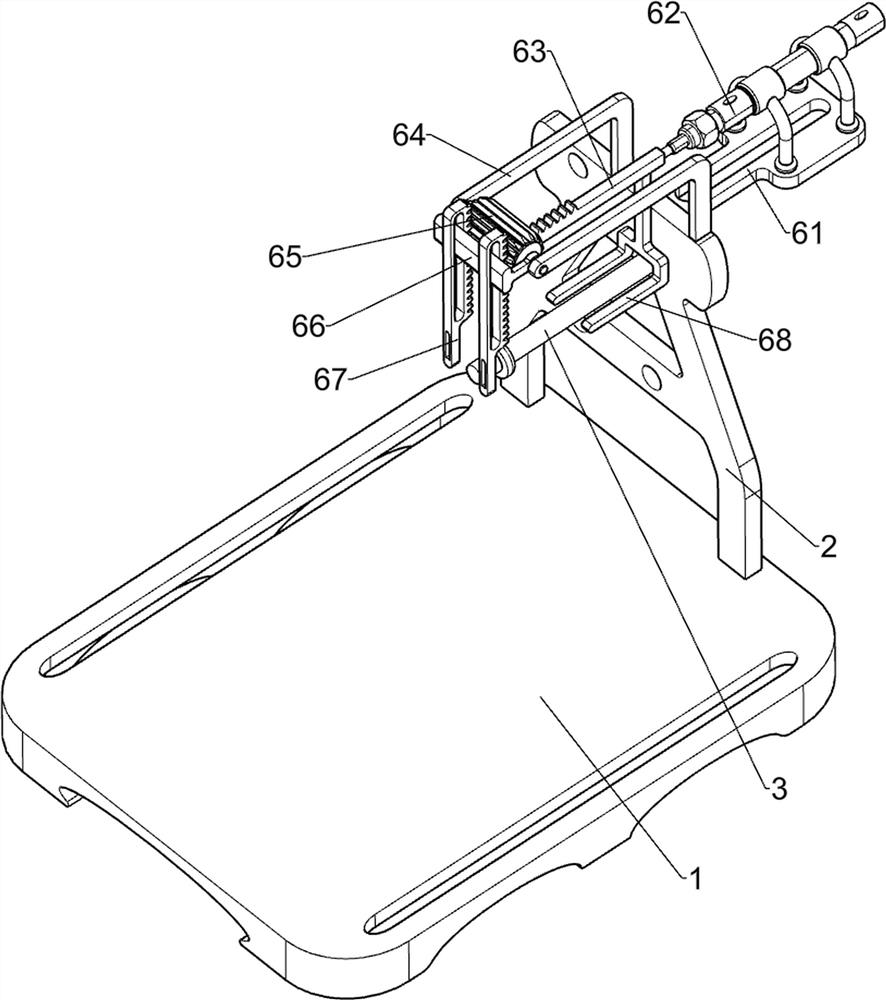

Rotary wood spoon polishing device

PendingCN112428077AQuick sandingRealize the clamping effectEdge grinding machinesGrinding carriagesPolishingManufacturing engineering

The invention relates to a wood spoon polishing device, in particular to a rotary wood spoon polishing device. The rotary wood spoon polishing device can automatically clamp a wood spoon, rotates a polishing tool to polish the wood spoon, and is safe, efficient, time-saving and labor-saving. The rotary wood spoon polishing device comprises a base, a first support frame, a cylinder, a clamping mechanism and a polishing mechanism, wherein the first support frame is arranged on the base; the cylinder is arranged at the lower part of one side of the first support frame; the clamping mechanism is arranged on the first support frame; and the polishing mechanism is arranged on the base. The rotary wood spoon polishing device is provided with the clamping mechanism; a first pressing block in the clamping mechanism is downwards pressed, so that a first connecting rod moves downwards to achieve the effect of clamping the wood spoon by replacing manual holding of the wood spoon for machining; andthe rotary wood spoon polishing device is provided with the polishing mechanism, and a polisher in the polishing mechanism polishes the edge of the wood spoon to achieve the effect of quickly polishing the edge of the wood spoon.

Owner:张世勇

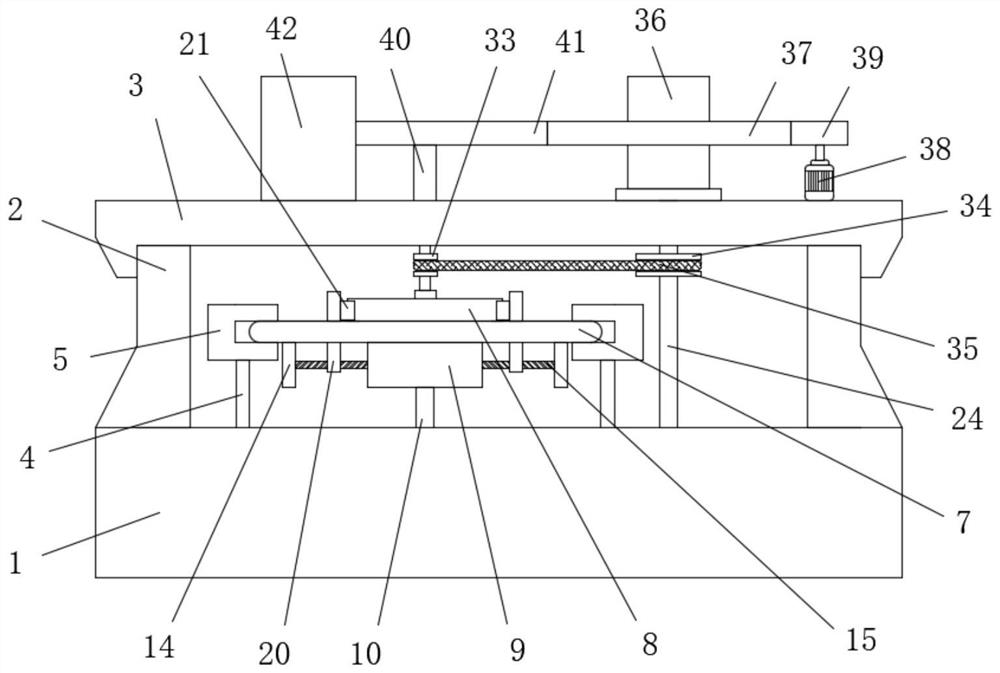

Steel plate manufacturing equipment manufactured by high-end equipment

ActiveCN110014339AAchieve reductionAchieve sanding effectGrinding drivesShearing machinesArchitectural engineeringSteel plates

The invention relates to the technical field of steel plate manufacturing equipment, and discloses steel plate manufacturing equipment manufactured by high-end equipment. The steel plate manufacturingequipment comprises a bottom plate, wherein supporting legs are fixedly arranged on the two sides of the bottom of the bottom plate, vertical rods are fixedly installed on the two sides of the top ofthe bottom plate, the top of the bottom plate is fixedly provided with a lifting platform, one side of the top of the lifting platform is fixedly provided with a vertical plate, one side of the vertical plate is fixedly connected to a telescopic rod, the right end of the telescopic rod is fixedly connected to a first movable plate, and the top of the lifting platform is fixedly provided with a guide rail. According to the steel plate manufacturing equipment manufactured by the high-end equipment, though the cooperation of a motor, a circular shaft and a grinding plate, the grinding effect canbe achieved through electric rotation; and meanwhile, a first gear, a second gear, a long rod and a cutting plate are arranged in a matched mode, cutting of the steel plate can be realized so that the two purposes of grinding and cutting can be realized by the device, the grinding and cutting integration is realized, the problems that two devices need to be used when the existing steel plate is manufactured are solved, and the manufacturing cost is reduced.

Owner:广西盛隆钢铁材料研究院有限公司

Triangular prism chamfering and grinding equipment for toy building blocks

ActiveCN111843705ASave human effortEasy to operateEdge grinding machinesGrinding carriagesGrindingTriangular prism

The invention relates to grinding equipment, in particular to triangular prism chamfering and grinding equipment for toy building blocks. The technical problem to be solved by the invention is to provide the triangular prism chamfering and grinding equipment for the toy building blocks, which can save manpower during operation and ensure the safety of an operator during operation. In order to achieve the technical purpose, the triangular prism chamfering and grinding equipment for the toy building blocks comprises a bottom plate, a grinding device and a self-rotating assembly, wherein the bottom plate is connected to one side of the top of the bottom plate, and a cutting frame is connected to the supporting frame; the grinding assembly is arranged between the bottom plate and the supporting frame; and the self-rotating assembly is arranged between the bottom plate and the cutting frame. According to the triangular prism chamfering and grinding equipment, the triangular-prism-shaped building blocks are ground through cooperative operation of the grinding assembly and the self-rotating assembly, and therefore the effect of grinding the triangular-prism-shaped building blocks is achieved.

Owner:GUANGDONG KAIYU SCI & EDUCATION CULTURE CO LTD

Grinding wheel machine convenient to adjust

PendingCN107855882AEasy to adjustAchieve sanding effectGrinding machine componentsGrinding machinesCouplingArchitectural engineering

The invention discloses a grinding wheel machine convenient to adjust, which comprises a case and a mounting plate, wherein the inner wall of the case is fixedly connected with a supporting rod; the surface of the supporting rod is fixedly connected with a motor; the output end of the motor is fixedly connected with a rotating shaft through a coupling; one end of the rotating shaft penetrates through and extends out of the case; the surface of the rotating shaft is fixedly connected with a connecting block; the surface of the connecting block is fixedly connected with a mounting ring; the surface of the mounting ring is provided with a sliding groove; the inner wall of the sliding groove is fixedly connected with a telescopic pipe; and the inner wall of the telescopic pipe is slidably connected with a telescopic rod. According to the grinding wheel machine convenient to adjust, the telescopic rod is adjusted to slidably ascend and descend on the inner wall of the telescopic pipe through a lifting bolt, the telescopic rod drives the mounting block to ascend and descend, and after the mounting block ascends to a proper position, the telescopic rod is in threaded connection with the lifting bolt, so that the effect that the grinding wheel machine convenient to adjust is suitable for grinding wheels with different hole diameters is achieved, and consequently the problem that a common grinding wheel machine is relatively fixed in mounting model, so that the inconvenient is brought to grinding operation in a certain degree is effectively solved.

Owner:FORTURE TOOLS CO LTD

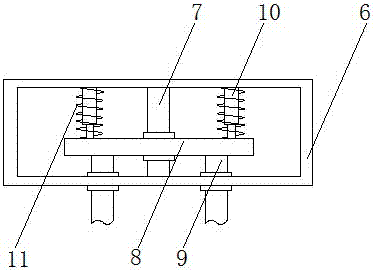

Edge grinding device for glass processing

The invention discloses an edge grinding device for glass processing, and relates to the technical field of glass processing. The edge grinding device for glass processing comprises a base. Vertical rods are fixedly mounted on the two sides of the upper surface of the base. The upper portions of the surfaces of the vertical rods are in sliding connection with a transverse plate. A supporting plate is fixedly mounted at the position, located below the transverse plate, of the surface of each vertical rod. A hydraulic air cylinder is fixedly mounted on the upper surface of each supporting plate. The output end of each hydraulic air cylinder is fixedly connected with the lower surface of the transverse plate. A shock absorption box is fixedly mounted on the lower surface of the transverse plate. A sliding rod is fixedly mounted between the top and the bottom of an inner cavity of the shock absorption box. The surface of the sliding rod is in sliding connection with a lifting plate. Lifting rods are fixedly mounted at the positions, located on the two sides of the sliding rod, of the lower surface of the lifting plate. The ends, away from the lifting plate, of the lifting rods penetrate a bottom plate of the shock absorption box and extend to the position below the shock absorption box. A grinding wheel is in contact with glass. The lifting rods and the lifting plate press springs to achieve the function of shock absorption. Generated defective goods are reduced.

Owner:FOSHAN SHENYAN INFORMATION TECH CO LTD

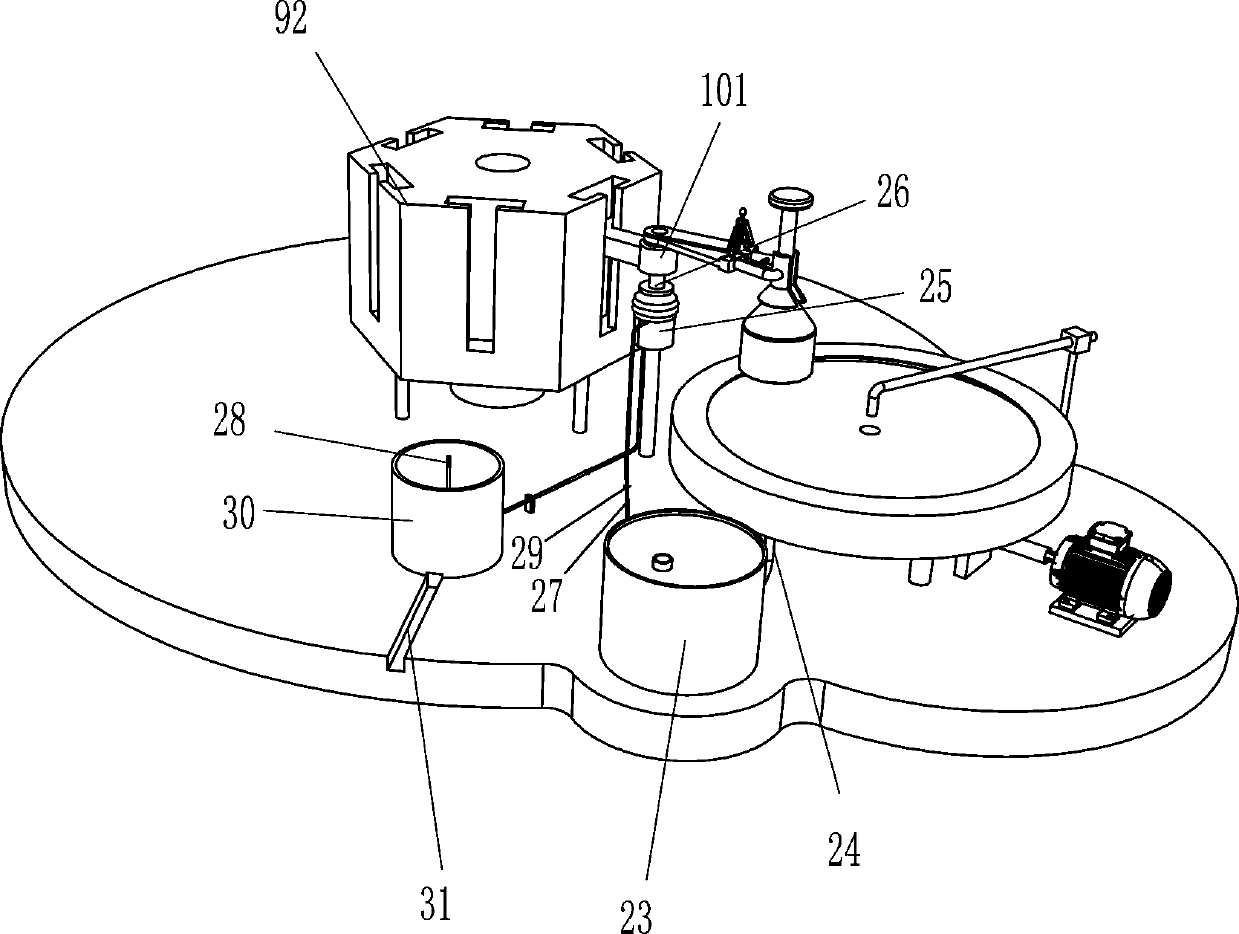

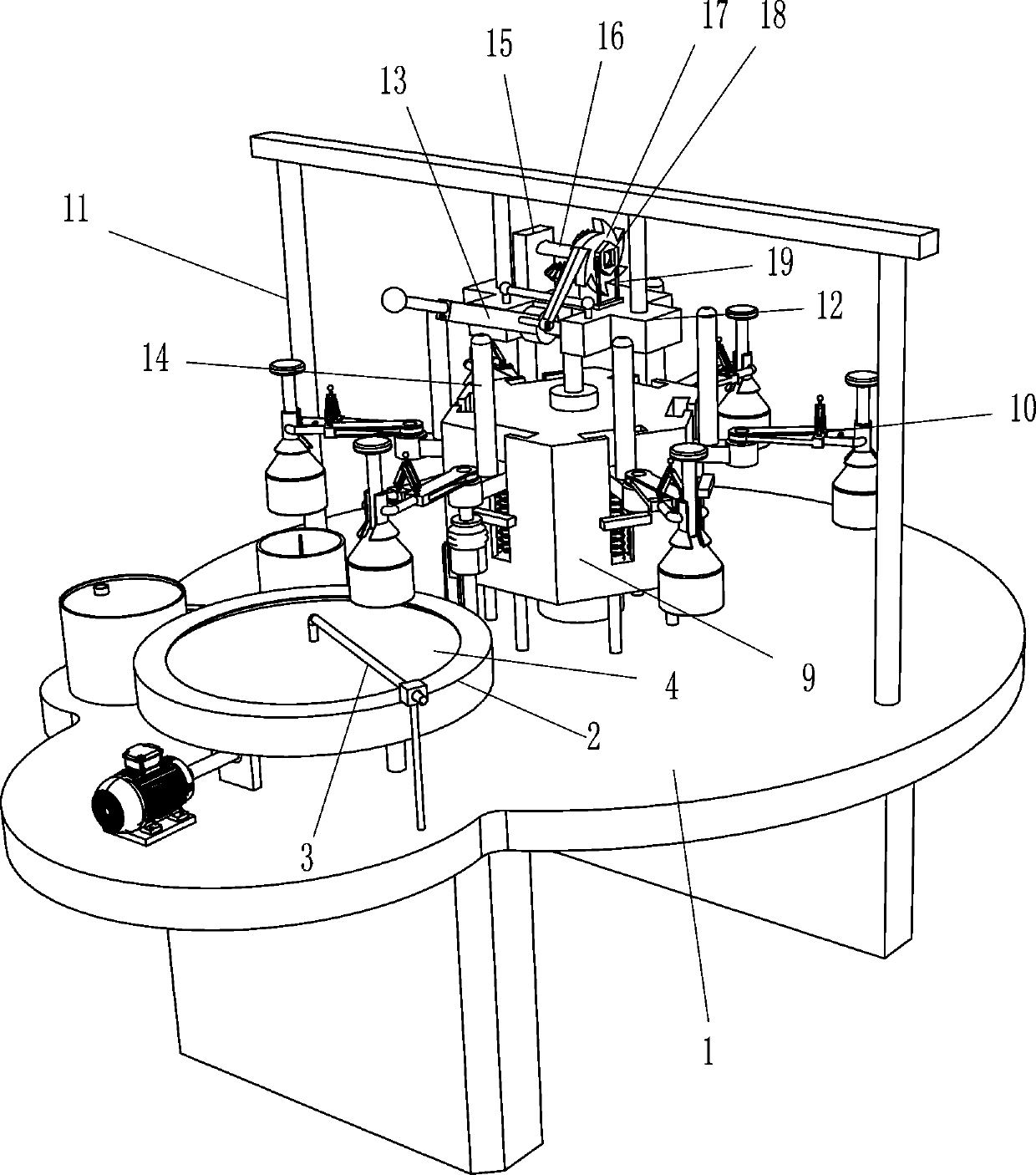

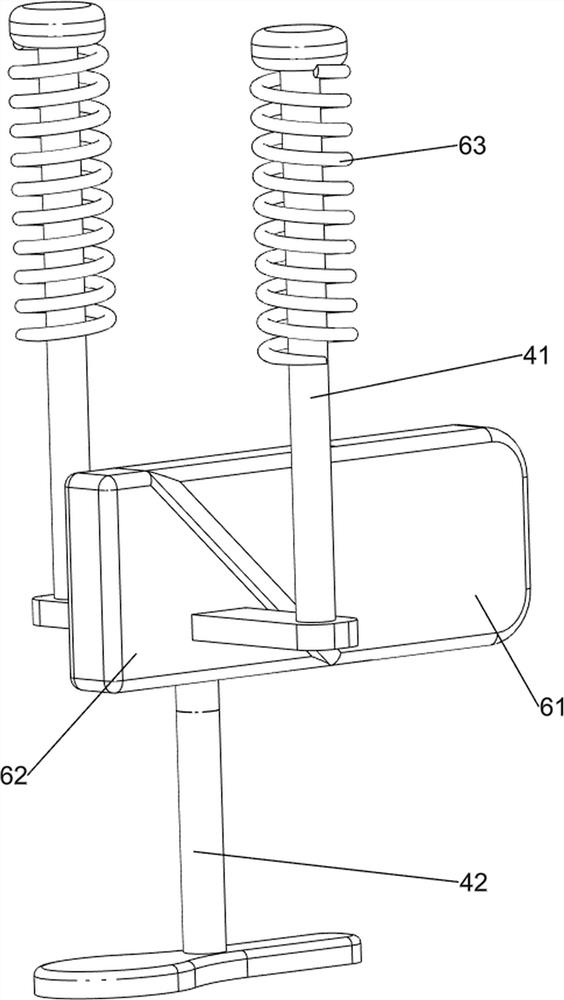

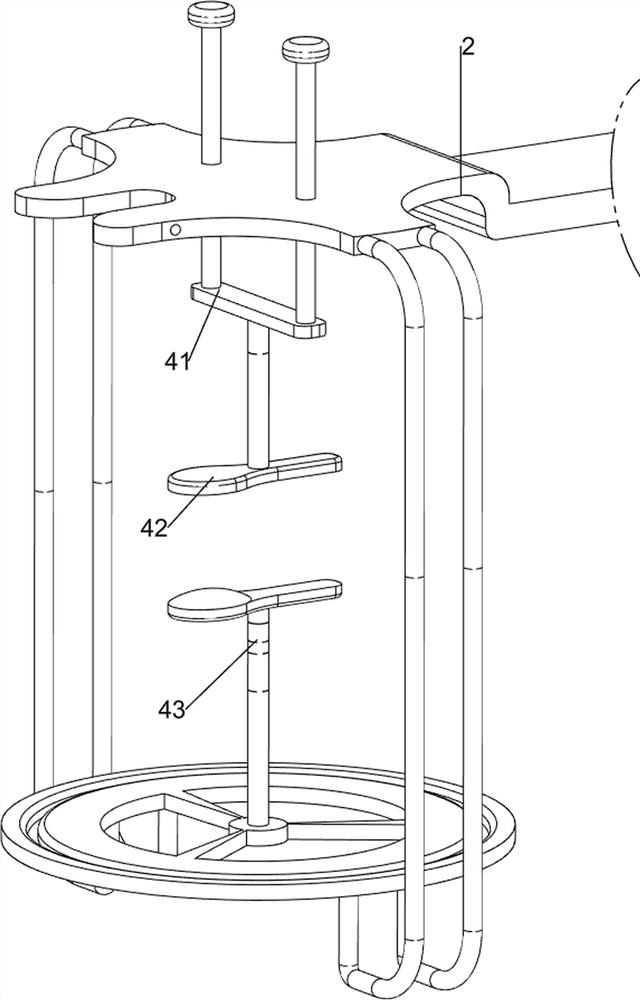

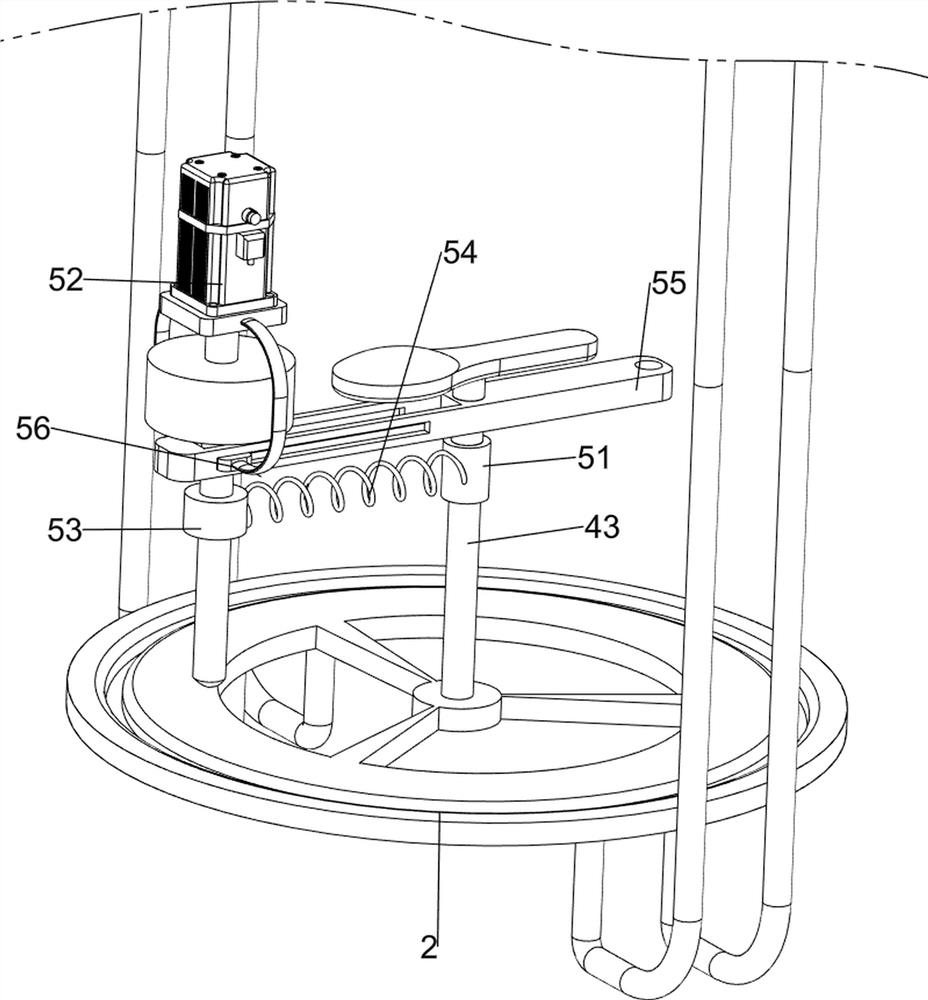

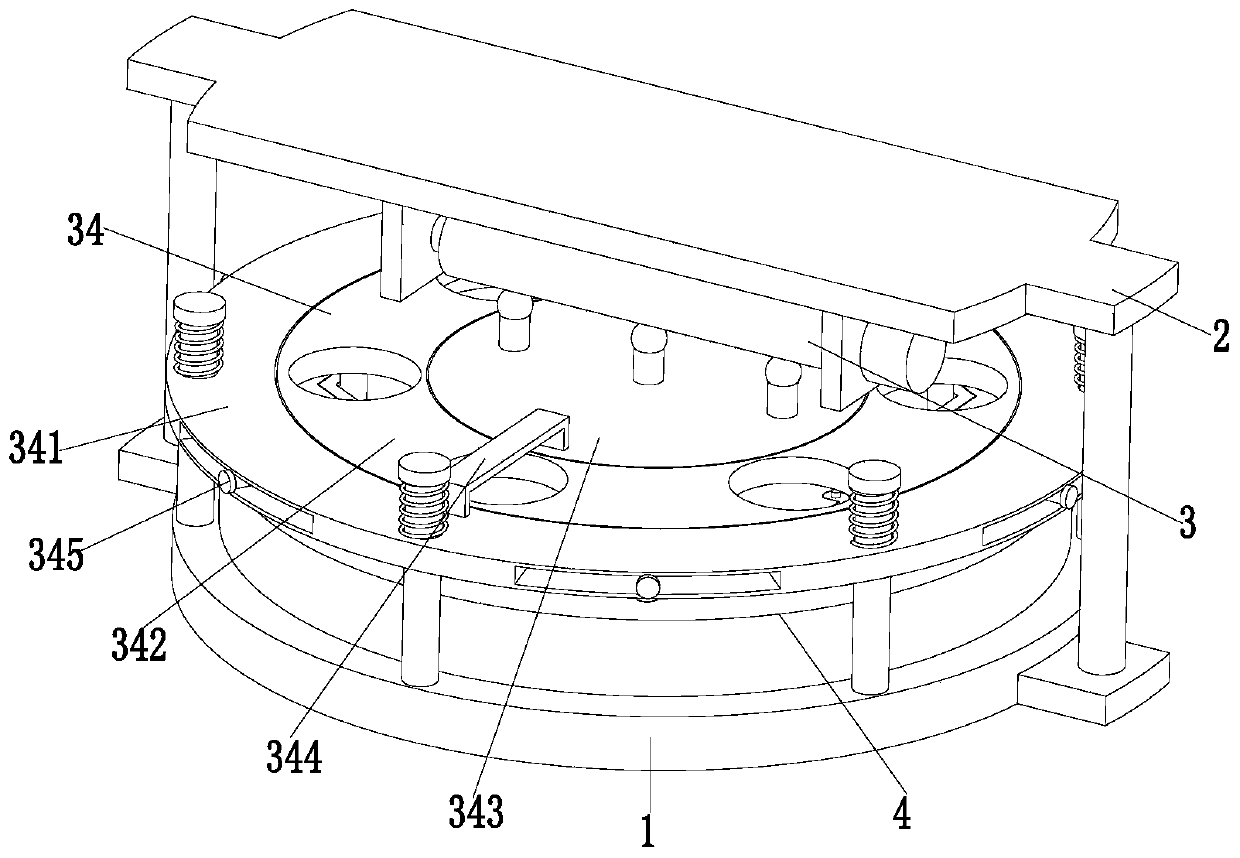

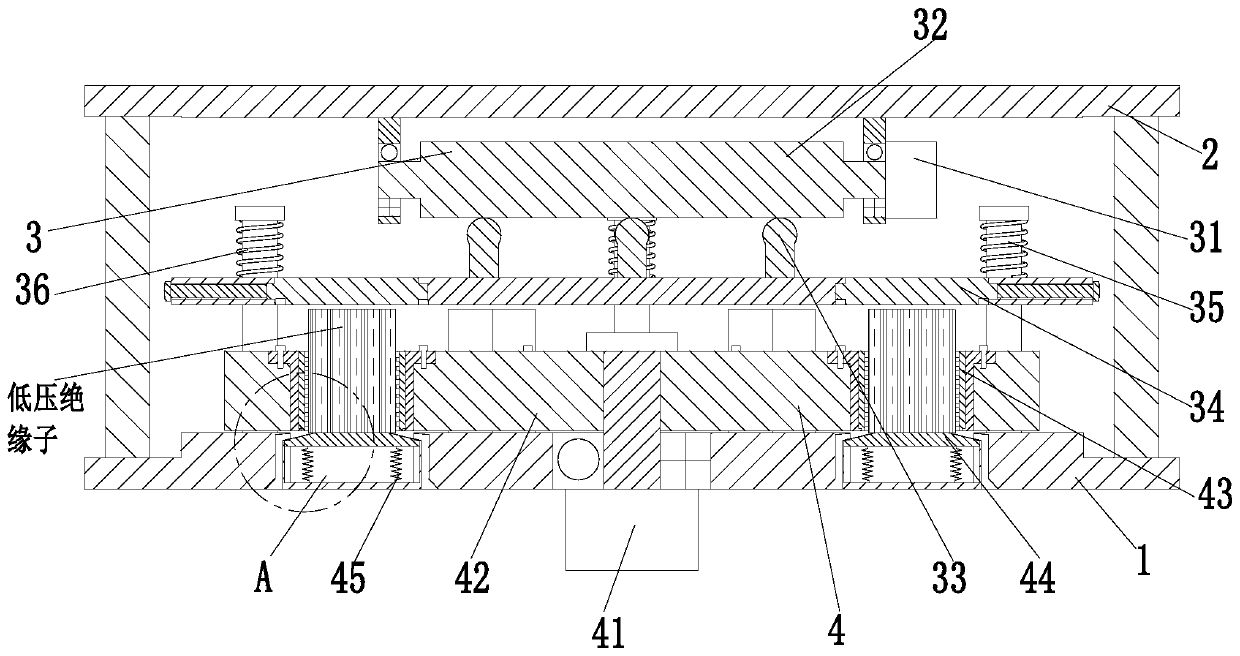

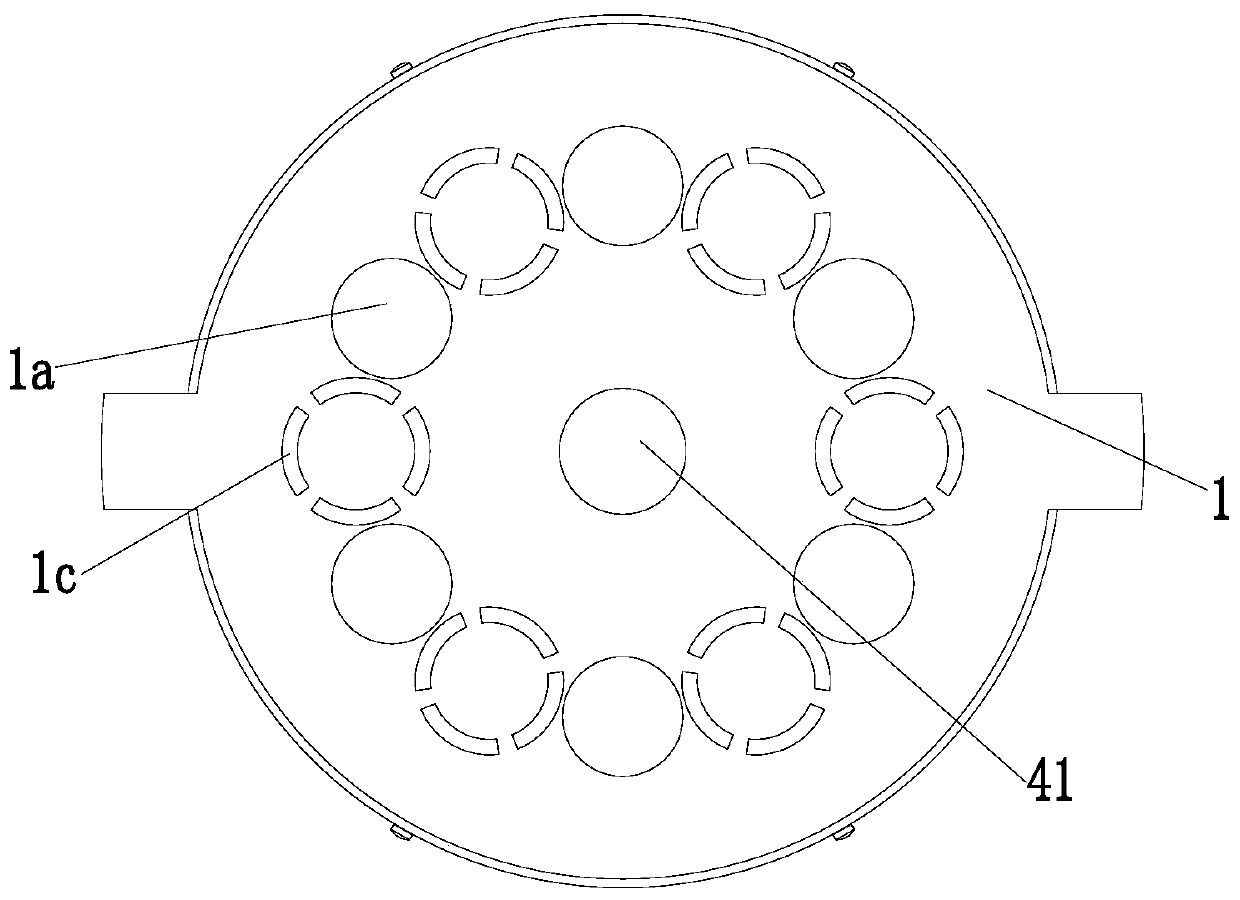

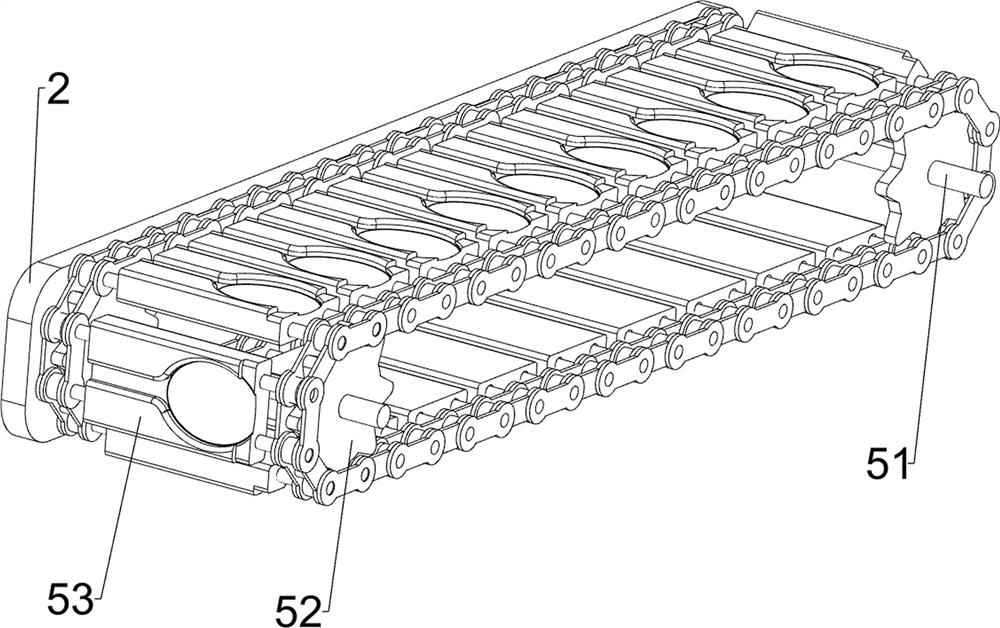

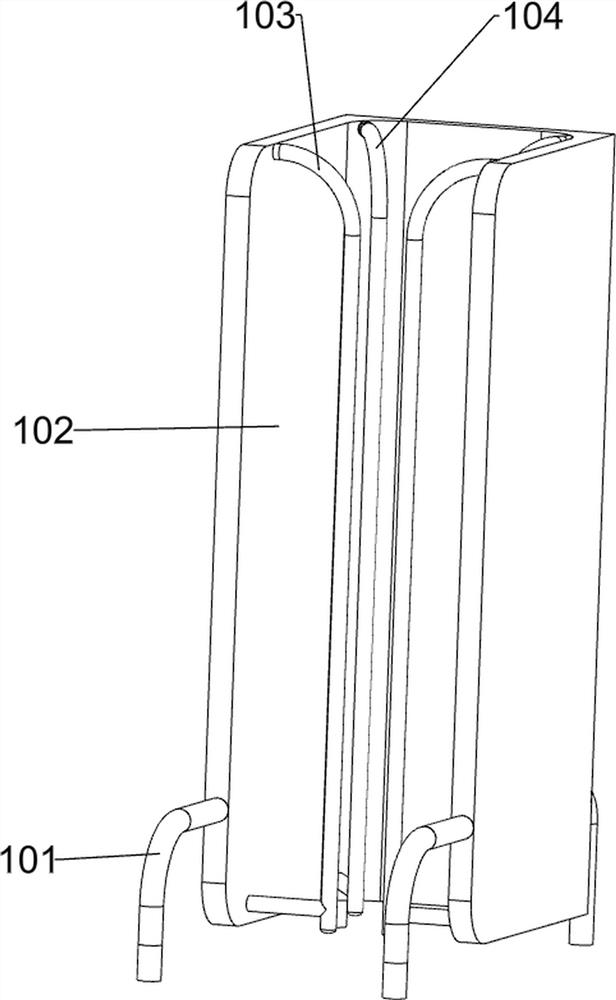

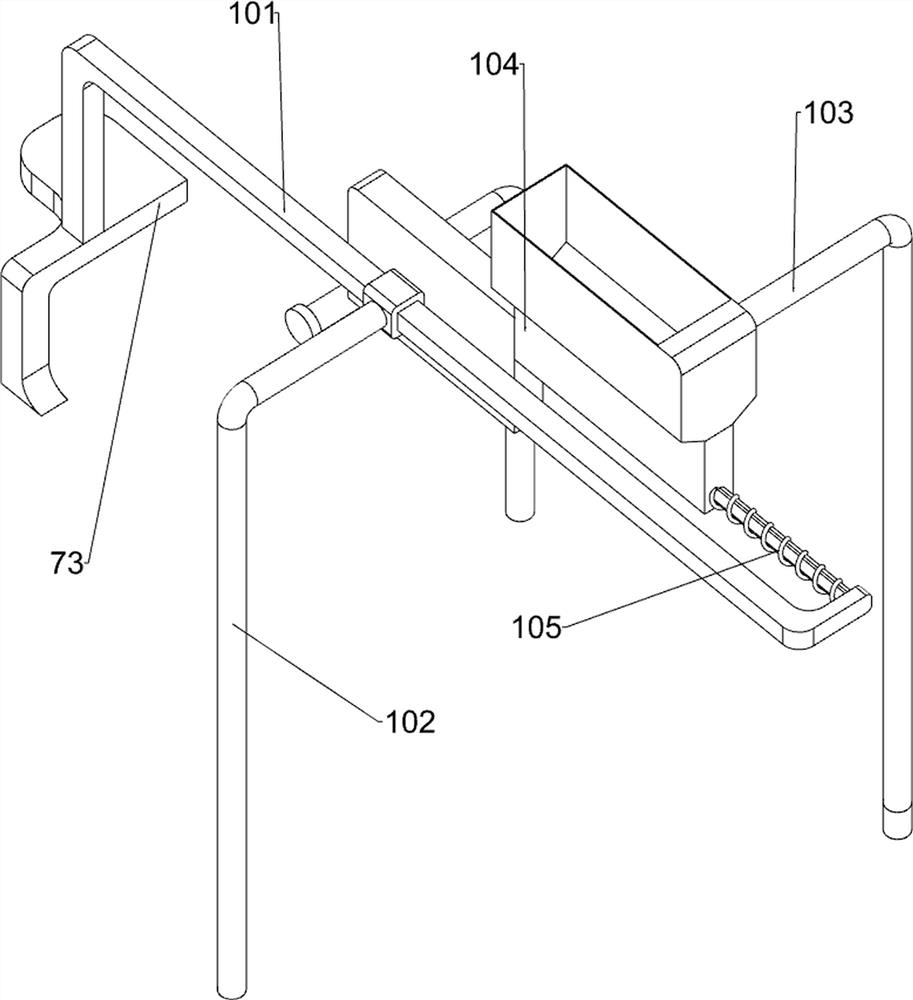

Forming manufacturing machining machine and machining method for low-voltage insulator

ActiveCN111531444AReduce fixation stepsImprove grinding efficiencyGrinding machinesGrinding work supportsStructural engineeringManufacturing engineering

The invention relates to a forming manufacturing machining machine and a machining method for a low-voltage insulator. The forming manufacturing machining machine comprises a fixing table board, a mounting frame, a pushing pressing mechanism and a material placing mechanism, wherein the upper end of the fixing table board is provided with the mounting frame, the lower end of the mounting frame isprovided with the pushing pressing mechanism, the lower end of the pushing pressing mechanism is tightly attached to the upper end of the material placing mechanism, the material placing mechanism ismounted on the fixing table board, blanking openings and material placing grooves are uniformly formed in the fixing table board in the circumferential direction of the fixing table board, the blanking openings and the material placing grooves are arranged at intervals, and the blanking openings and the material placing grooves each are of a circular structure. According to the forming manufacturing machining machine, through the common cooperation of the pushing pressing mechanism and the material placing mechanism, the operation of grinding the outer surface of the hexagonal low-voltage insulator is completed; and a grinding frame matched with the shape of the low-voltage insulator is arranged on the material placing mechanism in advance, so that it is guaranteed that the grinding frameis attached to the surface of the low-voltage insulator without repeated position adjustment of the material placing mechanism before grinding, the grinding efficiency is effectively improved, and thegrinding effect is guaranteed.

Owner:永州捷宝电讯塑胶五金有限公司

Polishing device for wooden spoon production

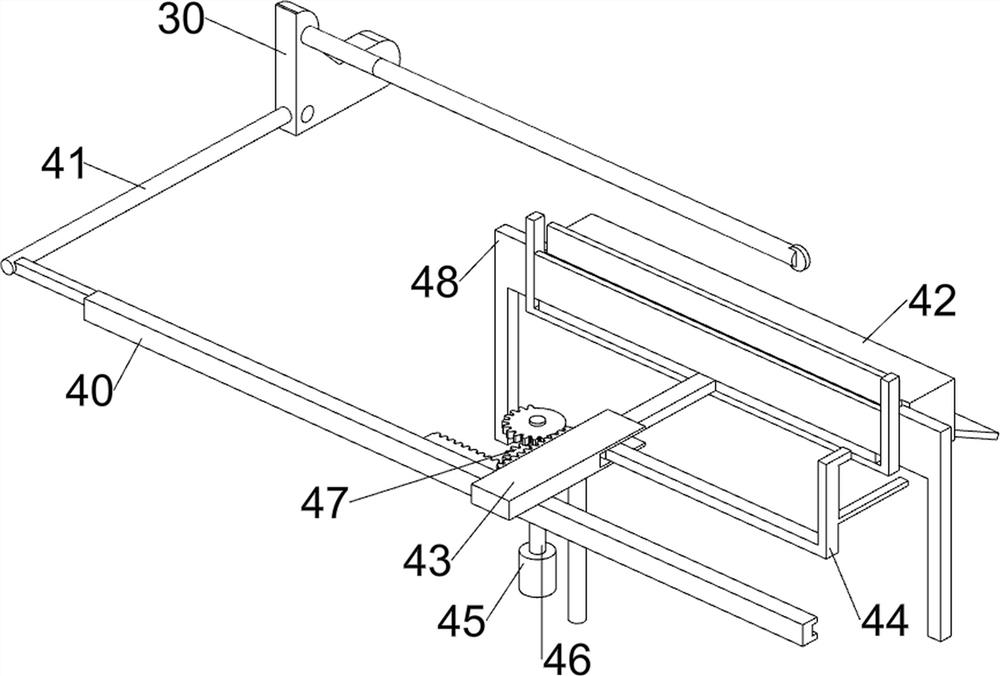

PendingCN112518517AAchieve sanding effectSave human effortGrinding drivesGrinding machinesMechanical engineeringIndustrial engineering

The invention relates to a polishing device, in particular to a polishing device for wooden spoon production. The technical aim to be achieved by the invention is how to design the polishing device for wooden spoon production. The device is simple to operate, can improve the working efficiency and saves manpower. In order to achieve the technical aim, the polishing device for wooden spoon production comprises a plurality of supporting legs, a storage plate, a feeding mechanism and a transmission mechanism. Protective plates are connected between the tops of the supporting legs at the two sides, one of the protective plates is connected with the storage plate, and the top of the storage plate is connected with a supporting frame; the feeding mechanism is arranged on the protective plates; and the transmission mechanism is arranged between the storage plate and the supporting frame. The feeding mechanism, the transmission mechanism, a polishing mechanism and a dust collection mechanism are matched to grind wooden spoons, and therefore the effect of polishing the wooden spoons is achieved.

Owner:朱光荣

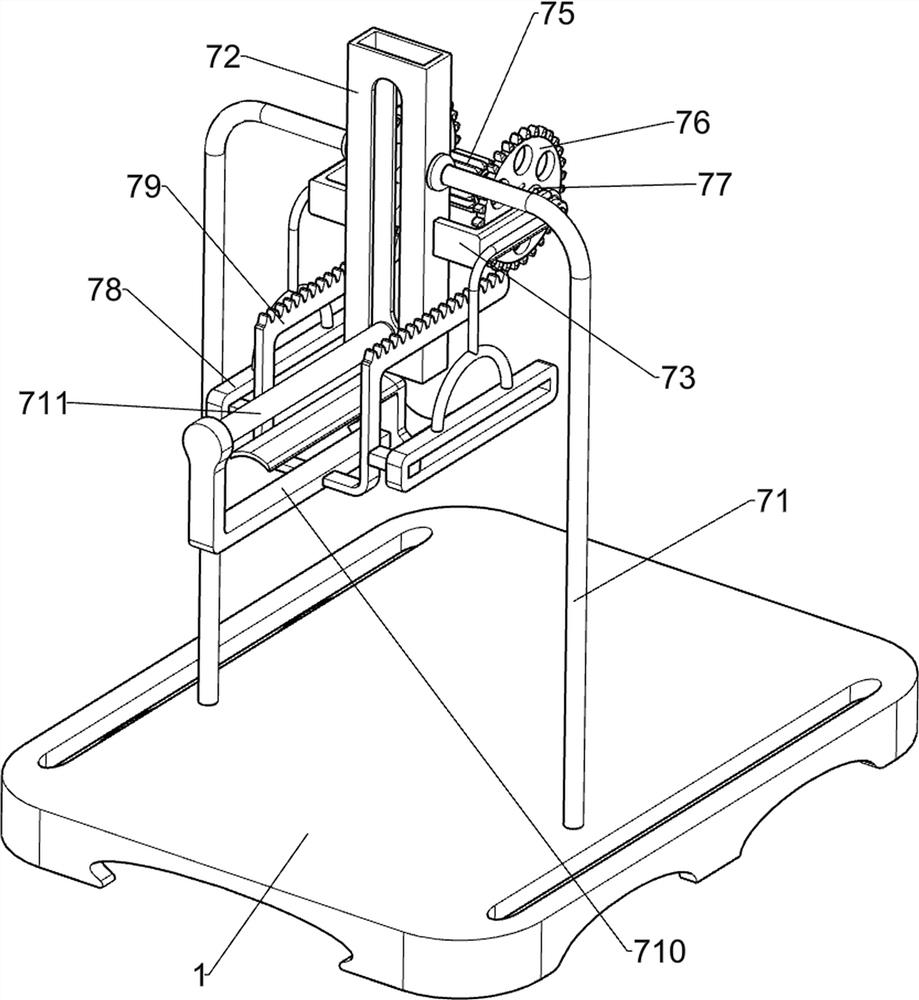

Wooden stick rotary grinding machine for manufacturing shovels

PendingCN112355747ASave human effortAchieve sanding effectGrinding carriagesRevolution surface grinding machinesGrindingElectric machinery

The invention relates to a grinding machine, in particular to a wooden stick rotary grinding machine for manufacturing shovels. The wooden stick rotary grinding machine for manufacturing the shovels is quite smooth in grinding and capable of achieving automatic feeding and discharging. The wooden stick rotary grinding machine for manufacturing the shovels comprises a base, first fixed rods, firstrotating shafts and first one-third gears. A motor is mounted on the base. The first fixed rods are arranged on the base. The first rotating shafts are rotationally arranged on the first fixed rods, and the first rotating shafts are connected with an output shaft of the motor. The first one-third gears are arranged on the first rotating shafts. Through arrangement of a bearing, containing and discharging mechanism, the bearing, containing and discharging mechanism cooperates with a translation grinding mechanism, so that the effect of automatically grinding wooden sticks is achieved, and moremanpower is saved; and through arrangement of a recovery mechanism, the recovery mechanism can enable a grinding knife to move backwards to reset, and people can conduct the next wooden stick grindingoperation conveniently.

Owner:李统

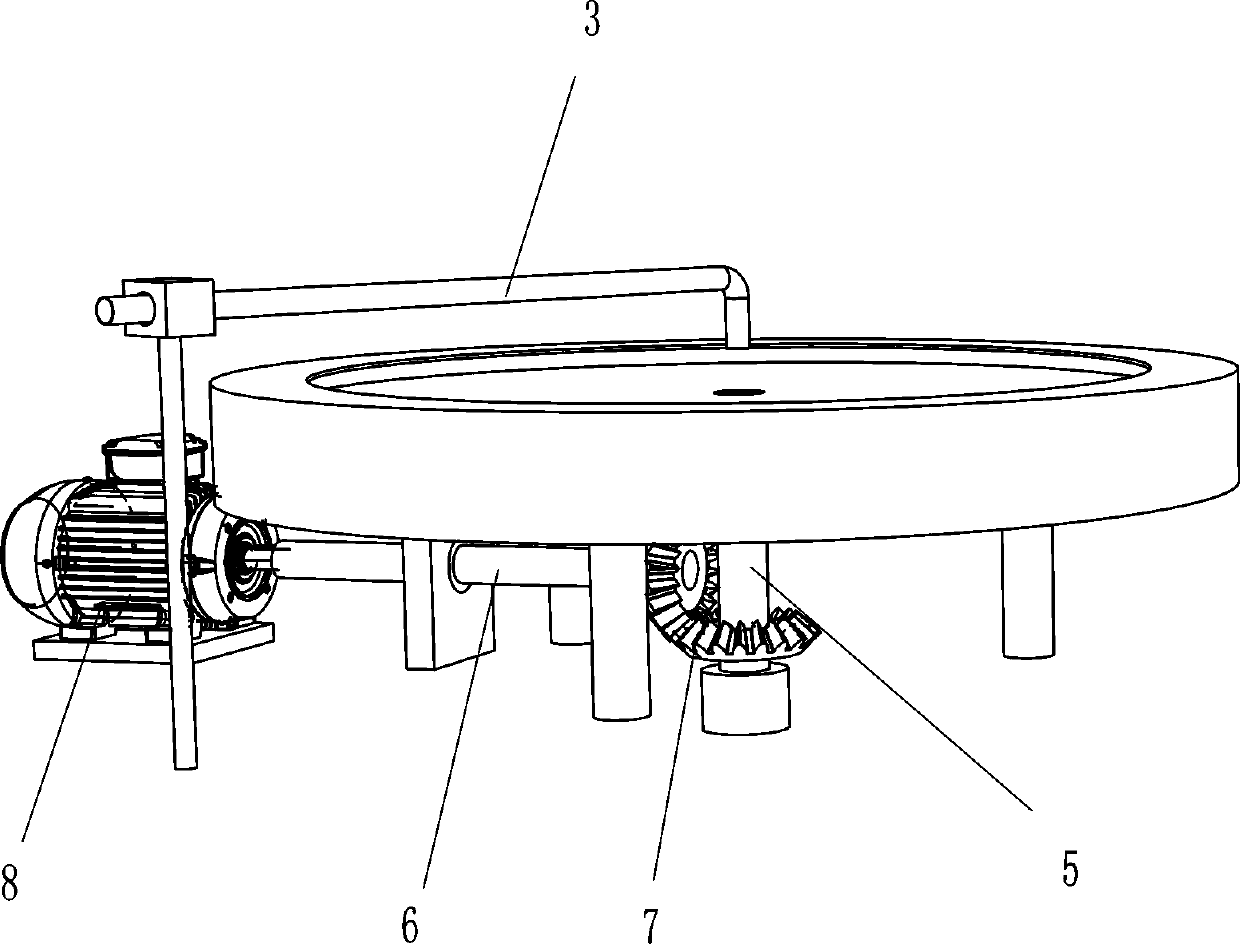

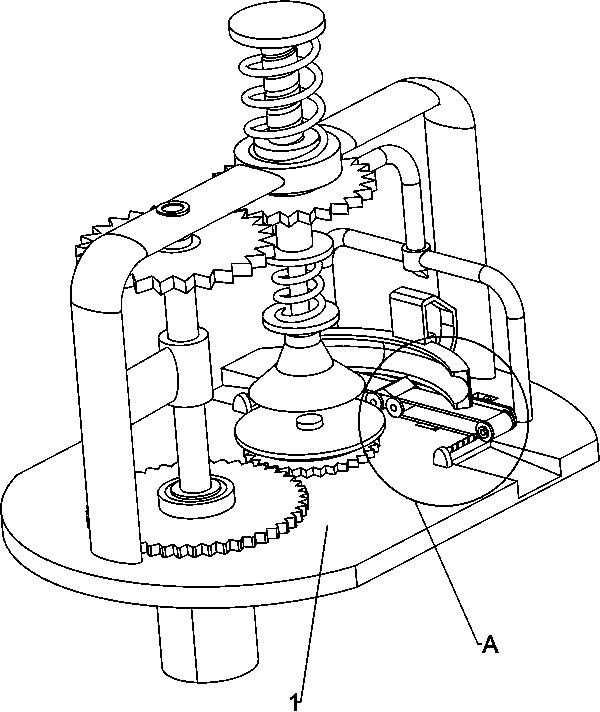

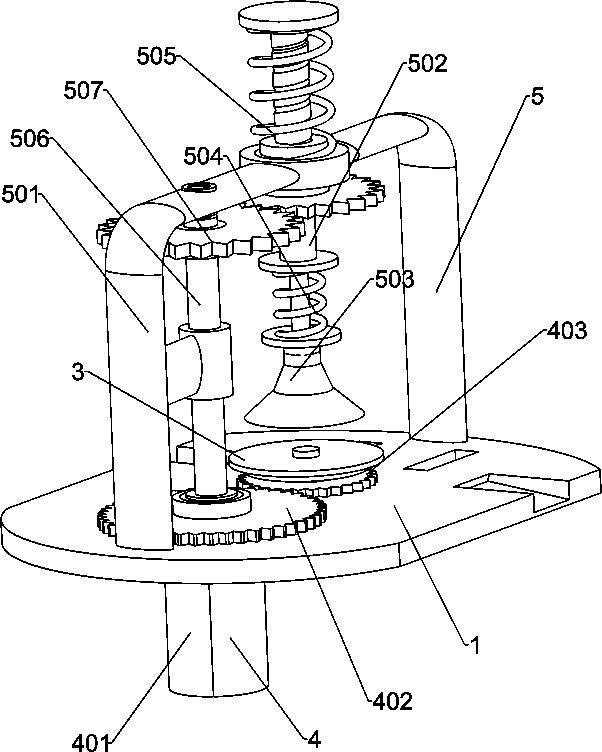

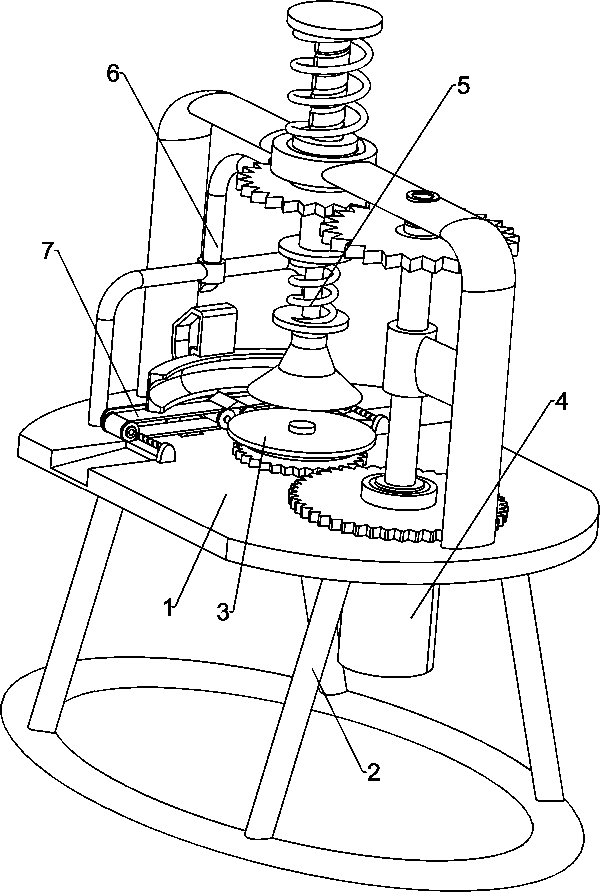

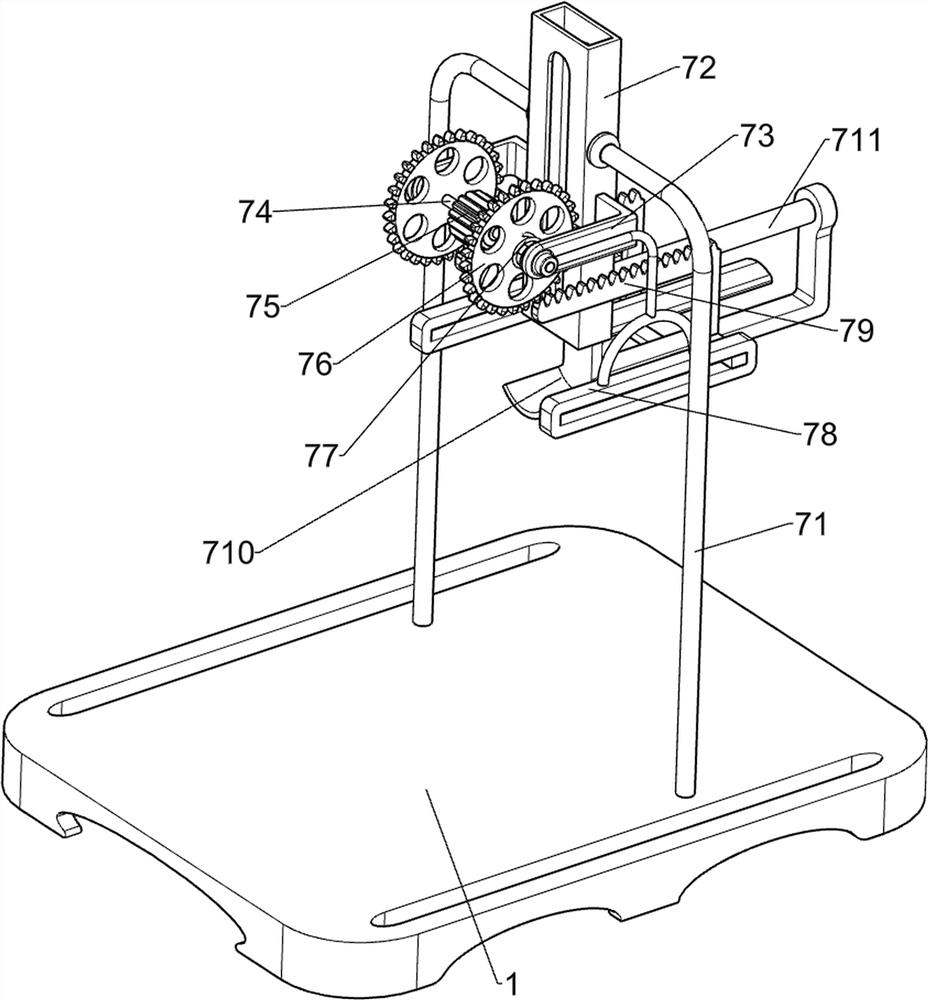

Polishing device for hat and coat stand chassis

ActiveCN111571373AAchieve sanding effectSave human effortGrinding carriagesGrinding drivesEngineeringPhysics

The invention relates to a polishing device, in particular to a polishing device for a hat and coat stand chassis. According to the polishing device for the hat and coat stand chassis, the operation is simple, the working efficiency can be improved, and manpower can be saved during operation. The polishing device for the hat and coat stand chassis comprises supporting legs, a rotary disc, a driving mechanism and a fixing mechanism, wherein the supporting legs are connected with the bottom of a base; the rotary disc is rotationally connected with the middle of the top of the base; the driving mechanism is arranged between the base and the rotary disc; and the fixing mechanism is arranged on the base. According to the polishing device for the hat and coat stand chassis, through cooperative operation of the driving mechanism and the fixing mechanism, polishing paper is manually held by hand to polish the hat and coat stand chassis, and therefore the effect of polishing the hat and coat stand chassis is achieved.

Owner:永康市巨豪家居用品股份有限公司

Grinding and polishing device for window rubber roller

ActiveCN113290469AAchieve sanding effectSave human effortGrinding carriagesGrinding drivesPolishingPulley

The invention relates to a polishing device, in particular to a grinding and polishing device for a window rubber roller. The grinding and polishing device for the window rubber roller aims to achieve the technical effects of being easy to operate and capable of improving the working efficiency and saving manpower. In order to achieve the technical effects, the grinding and polishing device for the window rubber roller comprises a bottom plate frame, a limiting shaft, a rotating mechanism, and a grinding mechanism, wherein a mounting frame is connected to one side of the top of the bottom plate frame, the limiting shaft is connected to the mounting frame, the rotating mechanism is arranged on the mounting frame, and the grinding mechanism is arranged on the mounting frame. The rubber roller is ground through cooperative operation of the rotating mechanism, the grinding mechanism and the limiting shaft, so that the effect of grinding the rubber roller is achieved.

Owner:河南科饶恩门窗有限公司

Polishing device for bamboo product production processing

InactiveCN109048590AAchieve sanding effectWith fixed effectGrinding carriagesGrinding work supportsEngineeringSlide plate

The invention discloses a polishing device for bamboo product production processing and relates to the technical field of bamboo product production processing. The polishing device comprises a workbench; the workbench is internally provided with a cavity; the lower end of the cavity is provided with a rotary shaft; the middle part of the rotary shaft is provided with a first gear; a second gear isengaged and connected to one side of the upper end of the first gear; a third gear is engaged and connected to the other side of the upper end of the first gear; a fourth gear is engaged and connected to the one side of the third gear; the middle part of the second gear and the middle part of the fourth gear are provided with screw rods respectively; the middle part of each screw rod is providedwith a sliding plate; and the two sides of the upper surface of each sliding plate are provided with push rods respectively. Through the rotary shaft, the first gear, the second gear, the third gear,the fourth gear, the screw rods, the sliding plates, the push rods, sliding rails, sliding blocks and a placement plate, the polishing device for bamboo product production processing achieves the effect of polishing plates in different thicknesses.

Owner:安吉华杰竹木制品厂

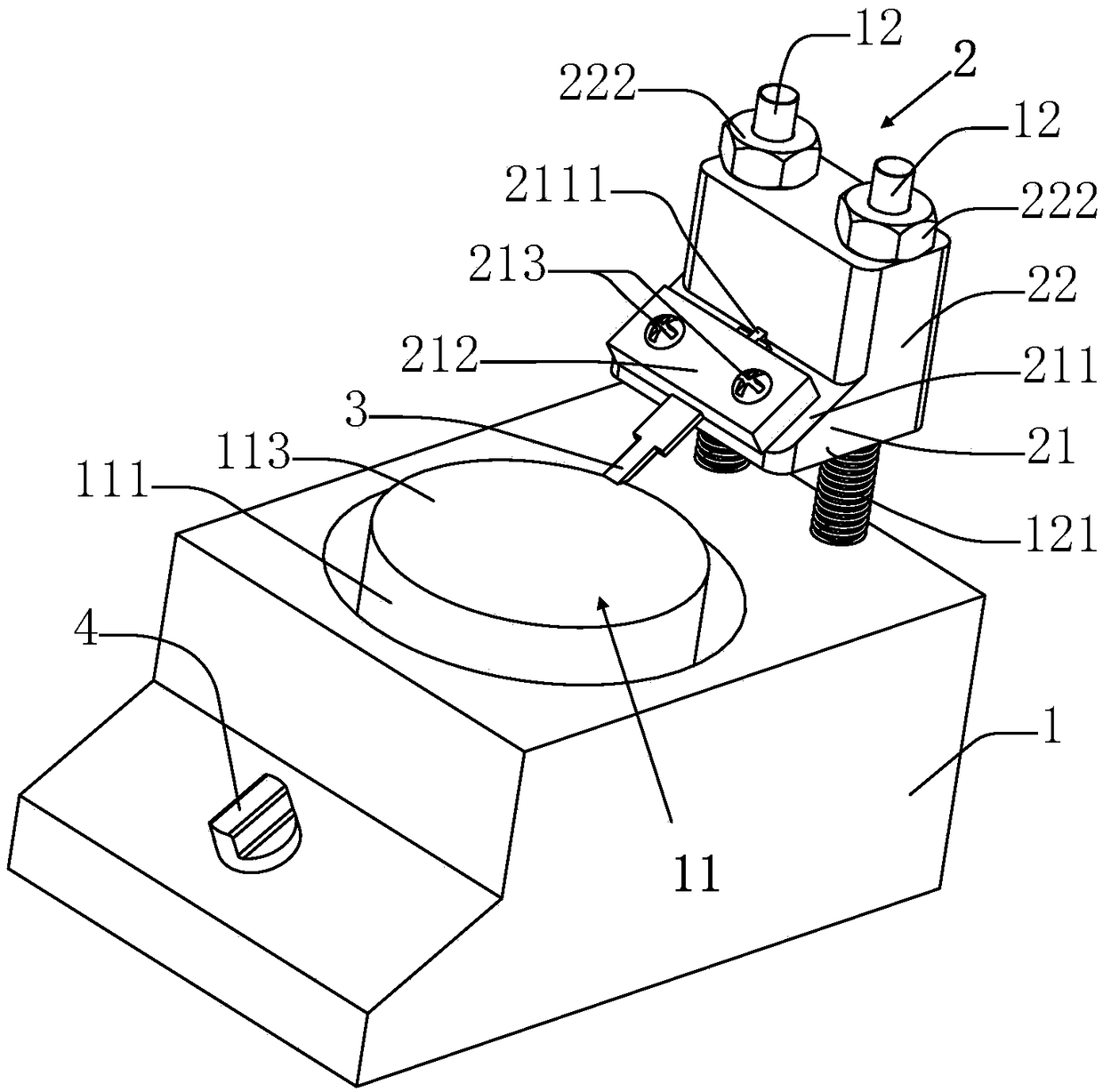

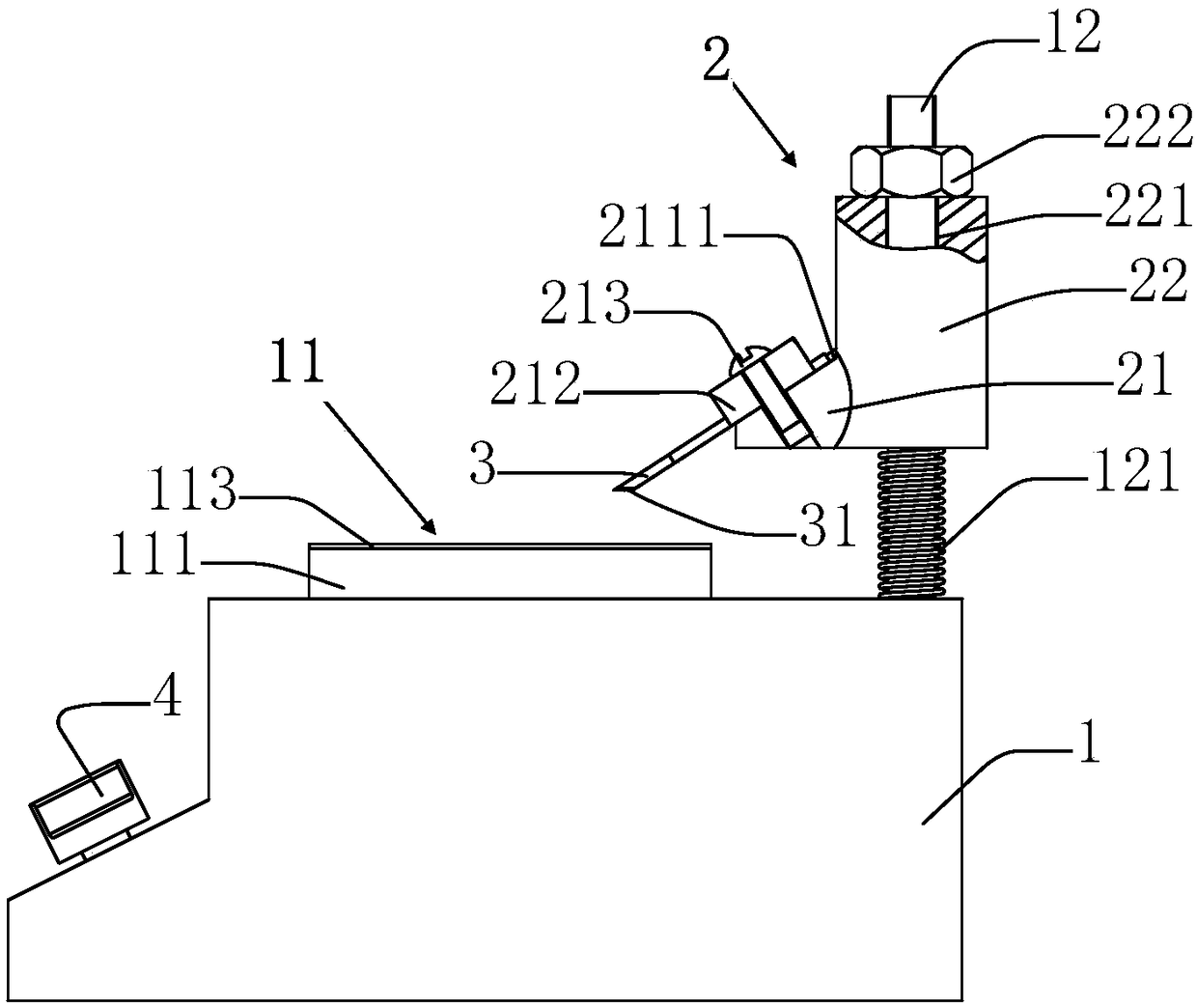

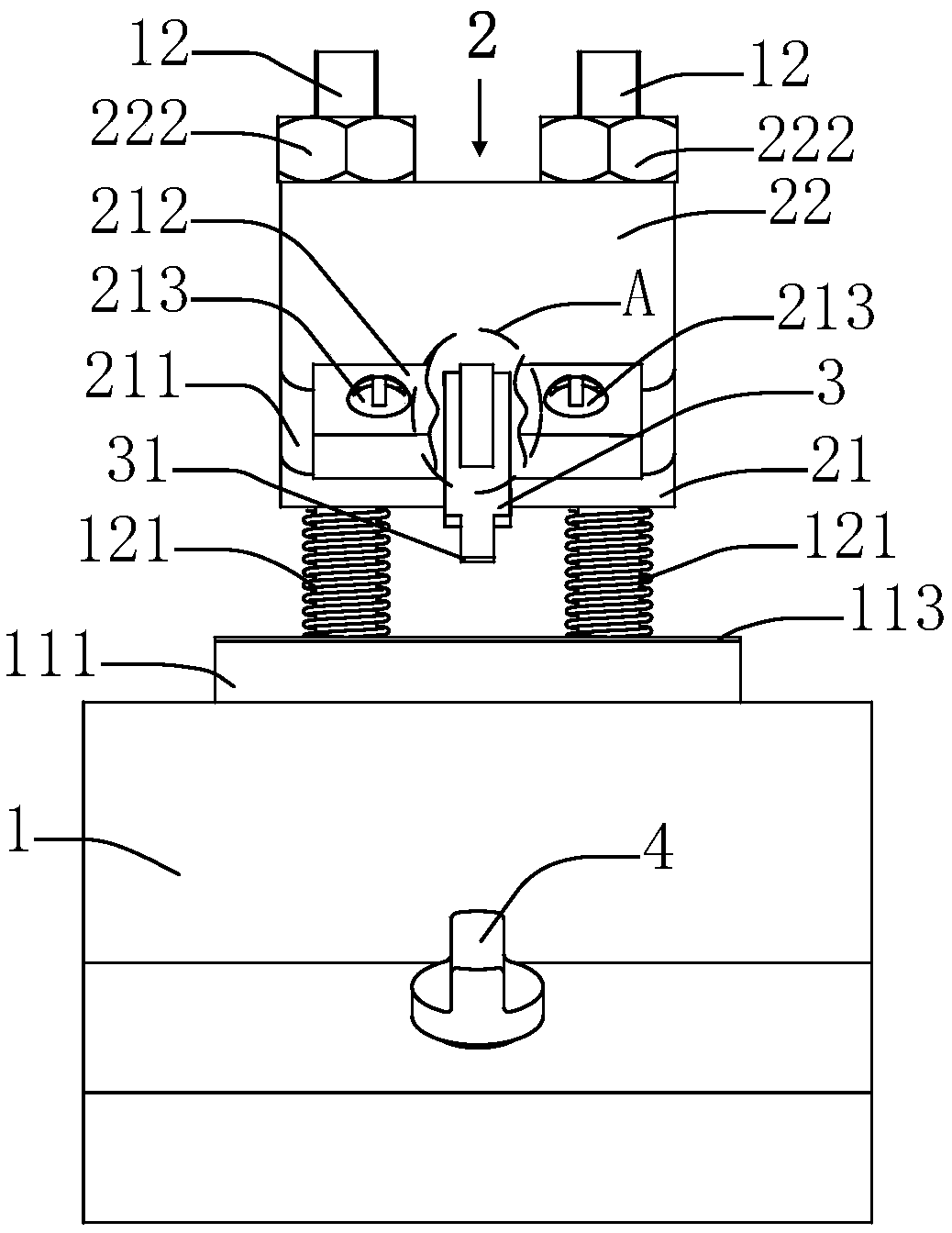

Grinding device

PendingCN109366328AImprove securityImprove use reliabilityGrinding machinesGrinding work supportsEngineeringElectrode

The invention discloses a grinding device. The grinding device comprises a base and a clamping structure arranged on the base. The clamping structure is used for fixing an electrode and provided withan inclined clamping part. The electrode is fixed to the clamping structure through the clamping part. The base is provided with a grinding structure, and a to-be-ground part of the electrode can makecontact with the grinding structure. Through the arrangement of the clamping structure, accurate fixing of the electrode can be achieved, accordingly, the to-be-ground part of the electrode is accurately ground, and the precision and the usage reliability of the grinding device are improved.

Owner:YINLONG ENERGY CO LTD

Stainless steel tube interior finishing device

InactiveCN107553250ATo achieve the effect of placementGood sandingEdge grinding machinesGrinding drivesSteel tubeArchitectural engineering

The invention discloses a stainless steel tube internal finishing device, which comprises a support foot, a base, a support plate, a lifting motor, a connecting column, a grinding device and an outer grinding ring. The support foot is welded on the lower surface of the base, and both sides of the upper end of the base are installed There is a support plate, a lifting motor is installed on the opposite surface of the support plate, a lifting rack is installed on the opposite surface of the lifting motor, the top of the lifting rack is connected through a connecting column, and a lifting rack is installed at the end of the connecting column. Grinding device, an inner grinding motor is installed at the end of the connecting column, an inner grinding rotating shaft is installed at the output end of the inner grinding motor, an inner grinding wheel is installed on the inner grinding rotating shaft, and the lower end of the elevating rack is oppositely installed There is an external grinding device, and the upper end of the external grinding device is provided with an external grinding motor. The invention can grind the inner and outer surfaces of the stainless steel pipe through the inner grinding motor and the outer grinding motor, so that the surface of the pipe fitting is smoother and the use effect is better.

Owner:浙江久德不锈钢型材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com