Eyeglass corner polishing equipment for manufacturing eyeglasses

A lens and edge technology, which is applied in the field of lens edge grinding equipment for glasses manufacturing, can solve the problems of cumbersome, labor-intensive, and low work efficiency, and achieve the effects of improving work efficiency, simple operation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

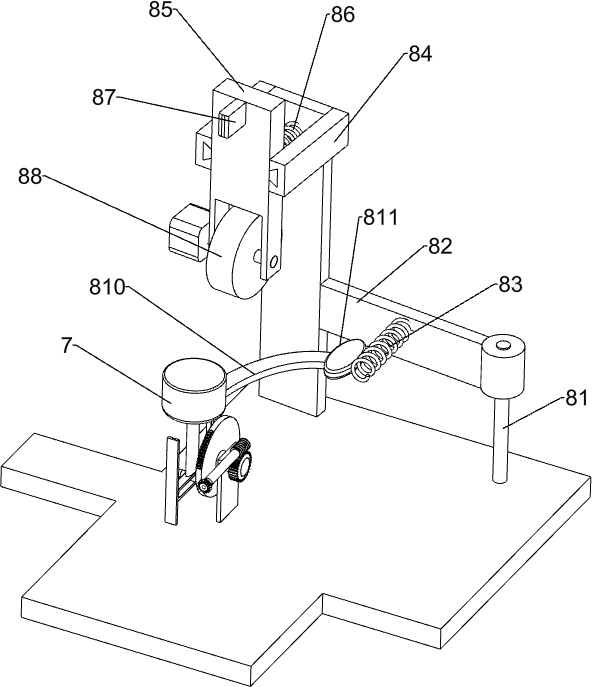

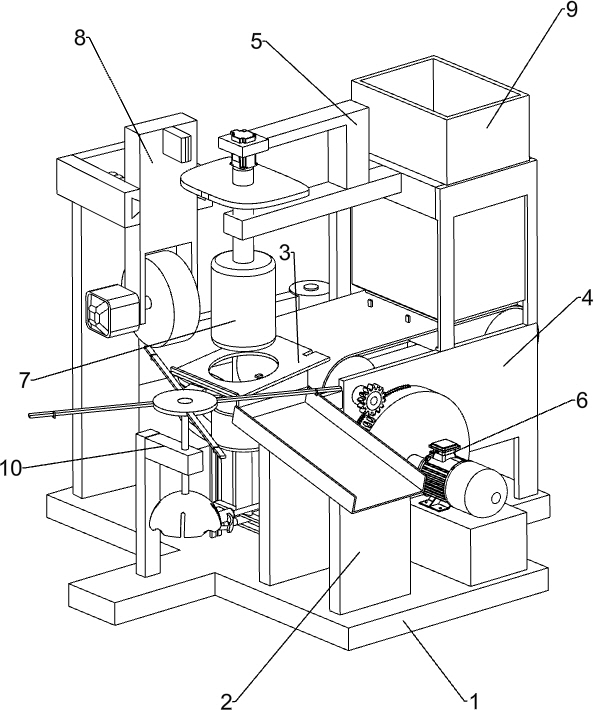

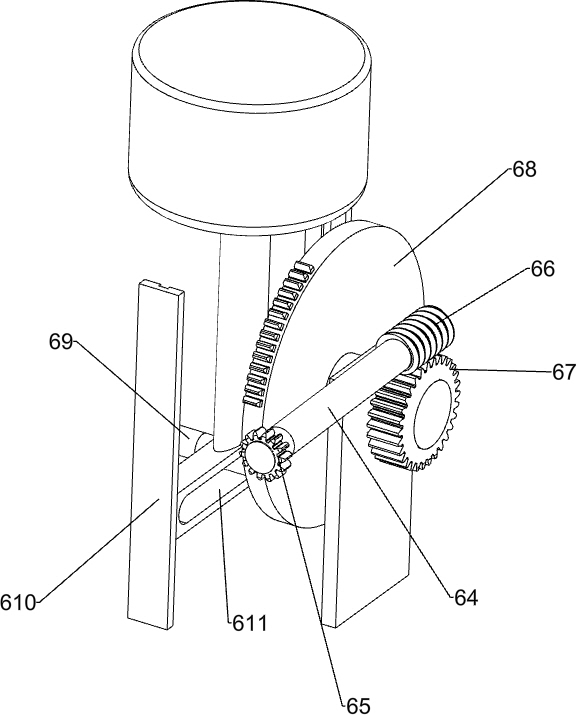

[0028] A lens edge grinding equipment for glasses manufacturing, such as Figure 1-5 As shown, it includes a bottom plate 1, a leakage rack 2, a placement plate 3, a frame 4 and a bracket 5, the front side of the top of the bottom plate 1 is connected with a leakage rack 2, and the rear side of the top of the leakage rack 2 is connected with a placement plate 3. The board 3 is set at an inclination, the top of the bottom plate 1 is connected with a frame 4 in the middle, the upper left side of the frame 4 is connected with a bracket 5, and also includes a transmission component 6, a clamping component 7 and a grinding component 8, and the bottom plate 1 is provided with a transmission component 6. A clamping component 7 is provided between the bracket 5 and the transmission component 6 , and the clamping component 7 is connected to the transmission component 6 , and a grinding component 8 is provided between the bottom plate 1 and the clamping component 7 .

[0029] The transm...

Embodiment 2

[0034] On the basis of Example 1, such as Figure 6 As shown, a feed assembly 9 is also included, and the feed assembly 9 includes a barrel 91, a roller 92, a connecting gear 93, a conveyor belt 94, a dial 95 and a second arc rack 96, and the upper part of the right side of the frame 4 is connected with the barrel 91, the left and right sides of the frame 4 are rotatably connected with a drum 92, the drive shaft of the left drum 92 is connected with a connecting gear 93, a conveyor belt 94 is wound between the drums 92 on both sides, and the discharge end of the barrel 91 is located at On the top of the conveyor belt 94 , multiple groups of shifting blocks 95 are evenly spaced connected to the conveyor belt 94 , and a second arc-shaped rack 96 is connected to the first turntable 62 , and the second arc-shaped rack 96 will mesh with the connecting gear 93 .

[0035] When placing the lenses, the lenses can be stacked in the barrel 91, and the bottom lens will contact the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com