Patents

Literature

343results about How to "Good sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

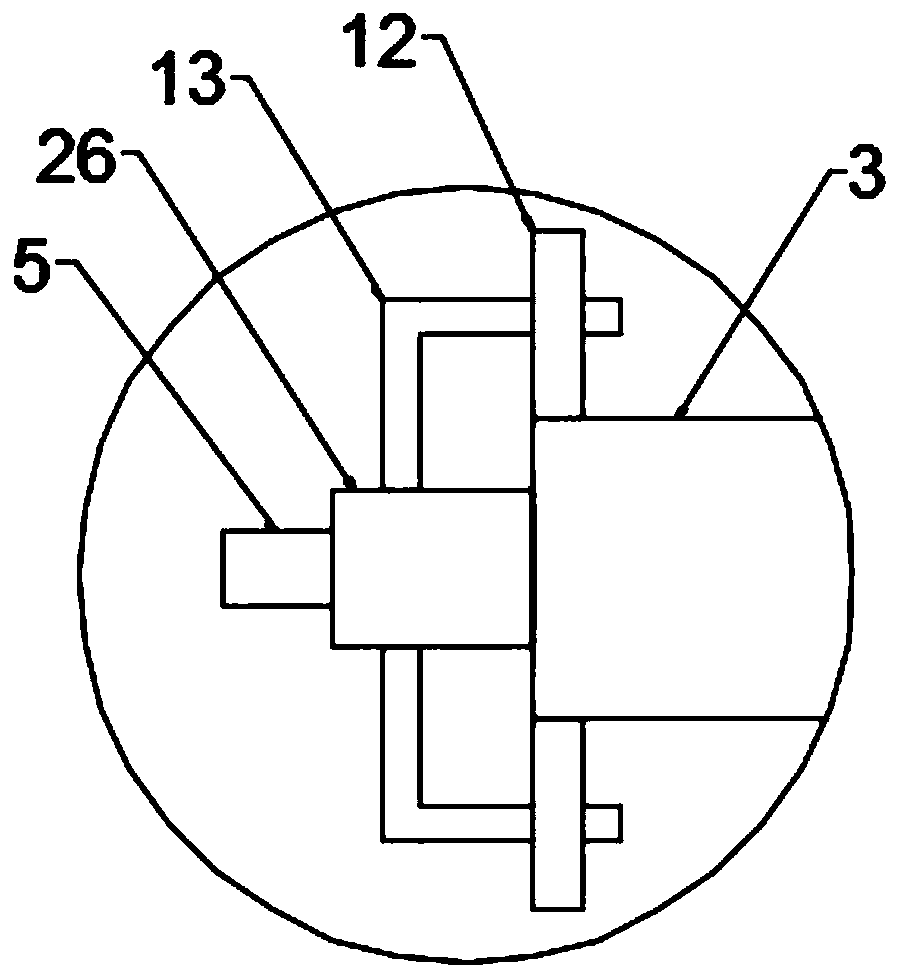

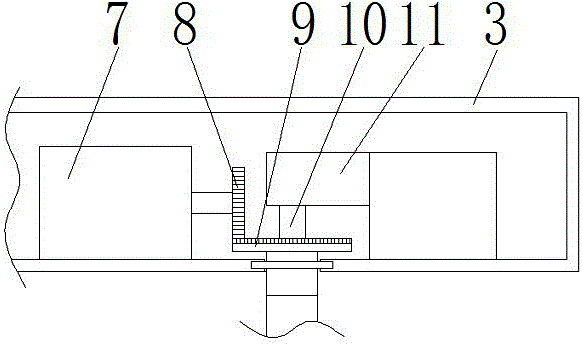

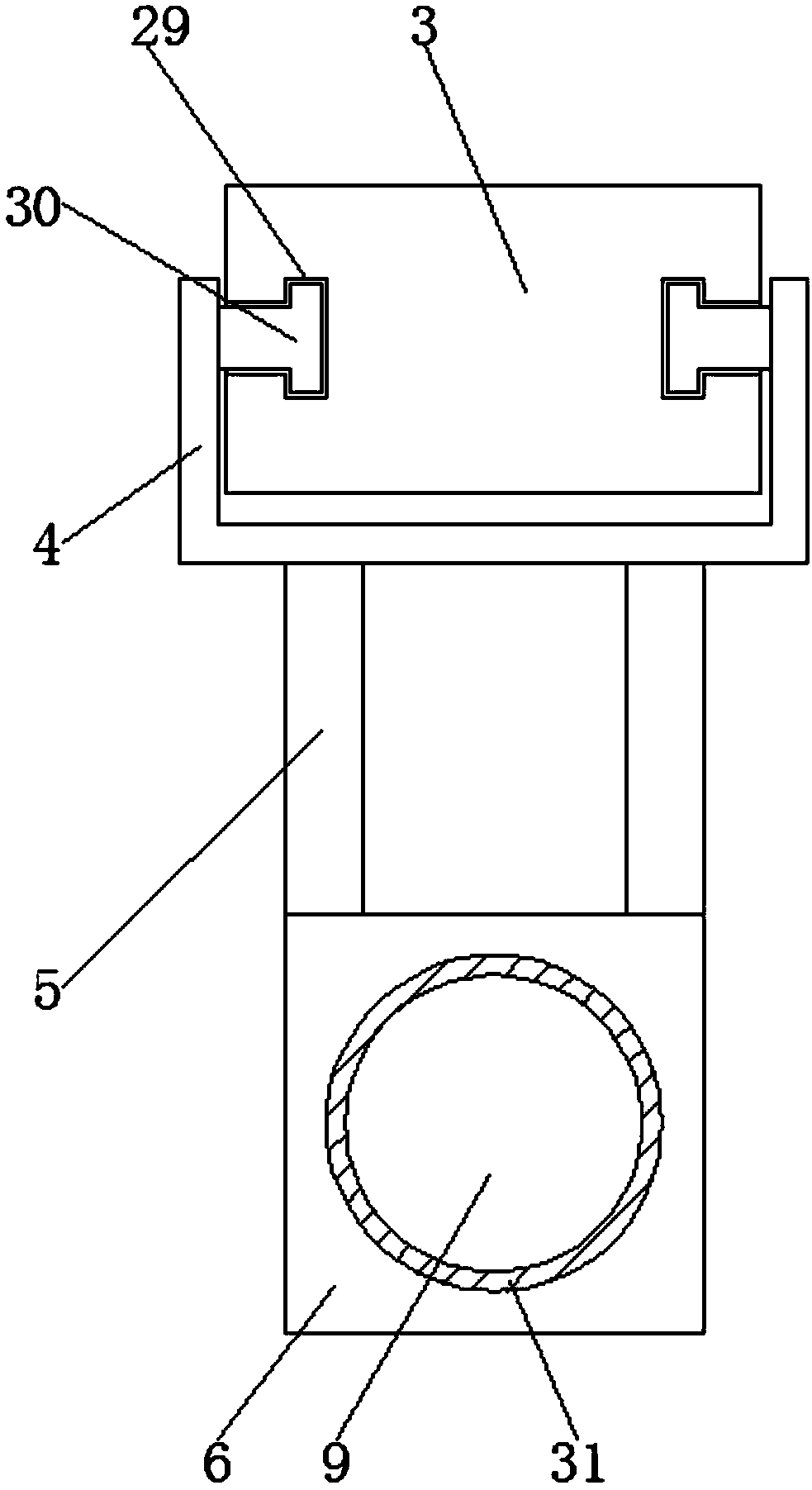

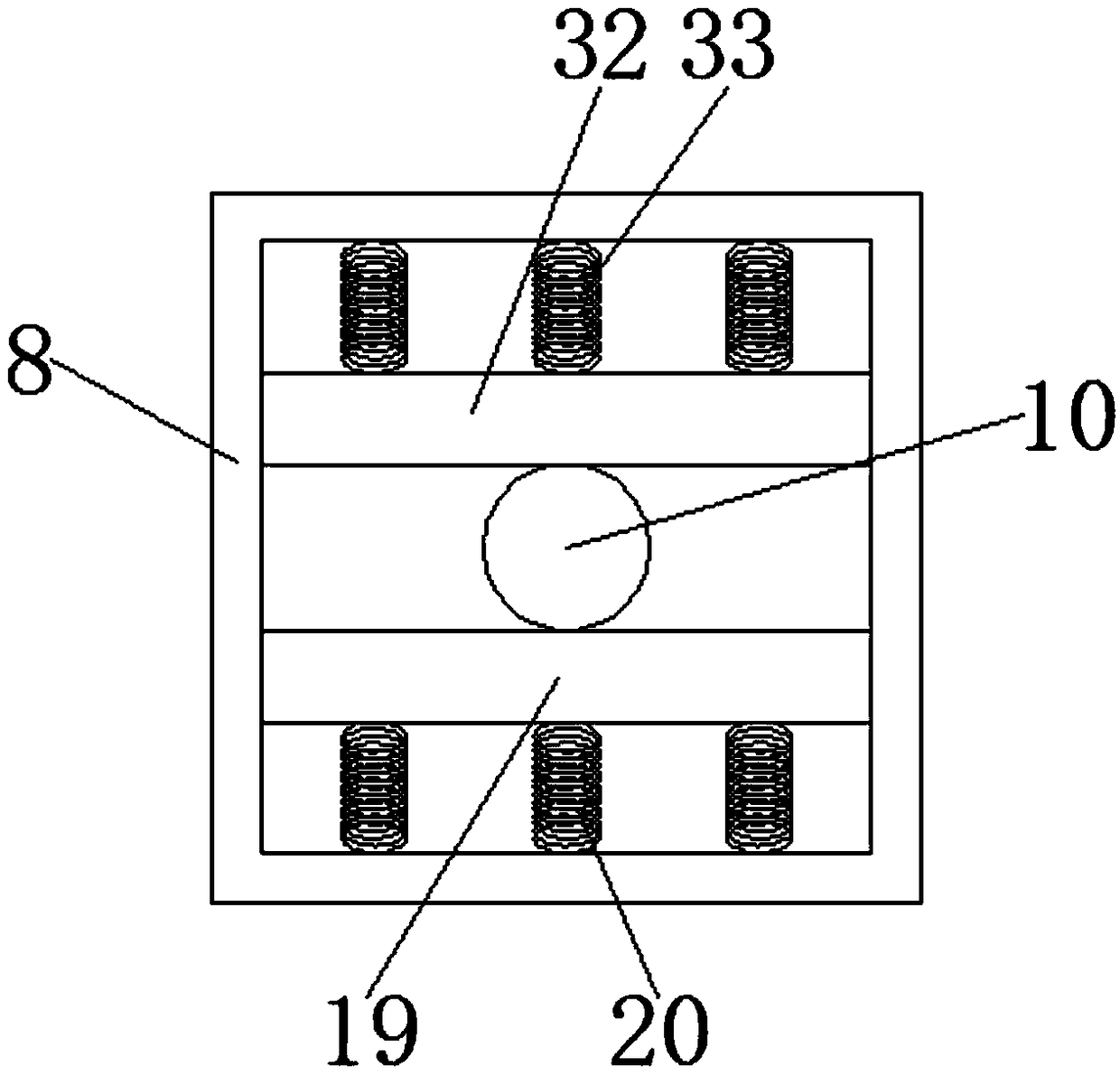

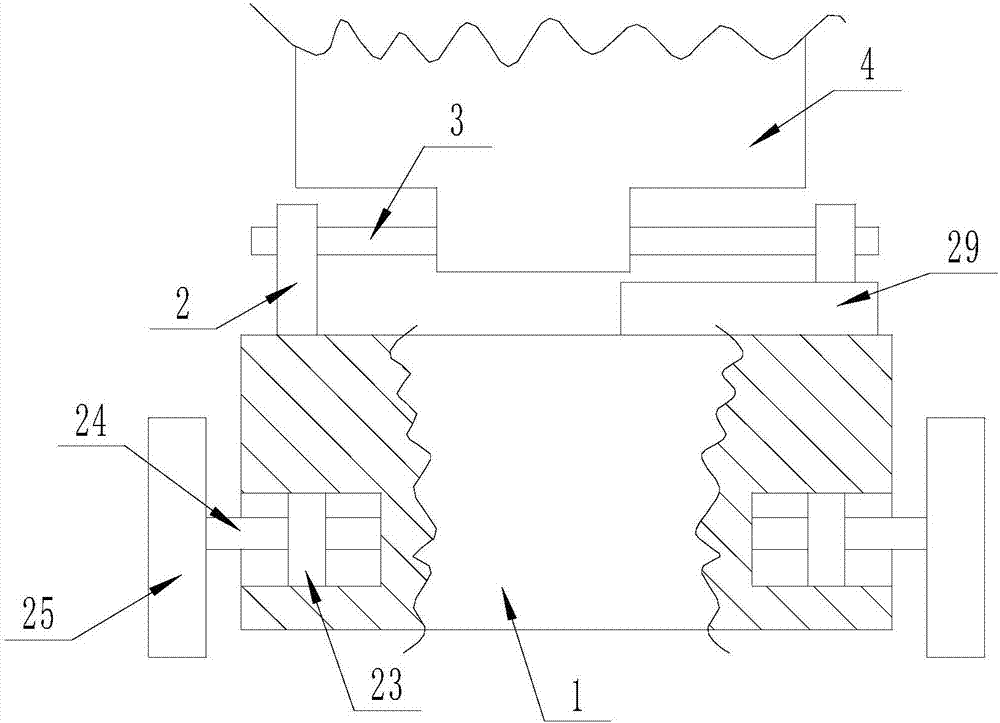

Short steel pipe outer wall polishing device for building engineering

InactiveCN108788952AAffect Fixed GrindingFixed grinding is firm and stableRevolution surface grinding machinesGrinding work supportsHydraulic cylinderArchitectural engineering

The invention discloses a short steel pipe outer wall polishing device for building engineering. The short steel pipe outer wall polishing device comprises a bottom base plate, a supporting rod frameis arranged on the upper end face of the bottom base plate, the upper ends of four connecting rods and the lower sides of four corresponding arc-shaped jacking plates are hinged, the left end of an adjusting transverse shaft penetrates out of a supporting transverse pipe, and a rotating transverse lead screw is provided with a driving spiral sleeve matched with the rotating transverse lead screw;the outer side wall of the driving spiral sleeve is provided with a connecting sleeve, and the upper side of the supporting rod frame is provided with a hydraulic cylinder, wherein the bottom of the hydraulic cylinder is slidably connected with the supporting rod frame; the side end of the supporting rod frame is provided with a double-output-shaft motor, one end of the double-output-shaft motor is connected with the outer side wall of the supporting transverse pipe through a transmission mechanism, and the other end of the double-output-shaft motor is provided with an incomplete bevel gear; and one end of the rotating transverse lead screw is provided with two rotating bevel gears, and the two rotating bevel gears are engaged with the incomplete bevel gear alternately. The short steel pipe outer wall polishing device is simple in structure and convenient to operate, a steel pipe is fixed stably, the polishing effect is obvious, the efficiency is high, and the short steel pipe outer wall polishing device is worth popularizing.

Owner:郑州荣献新材料技术有限公司

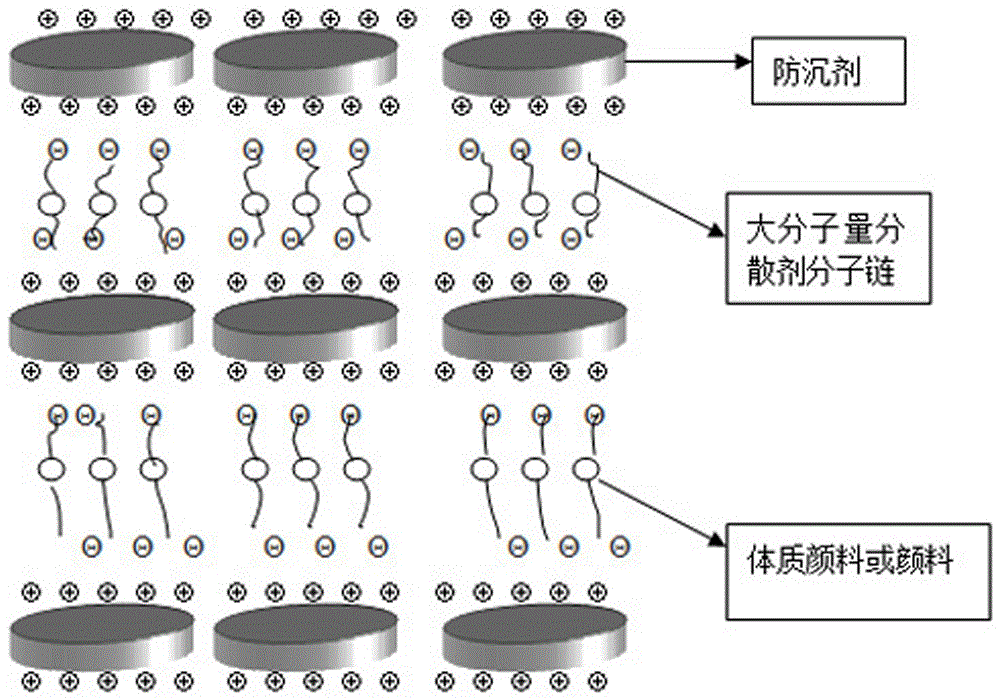

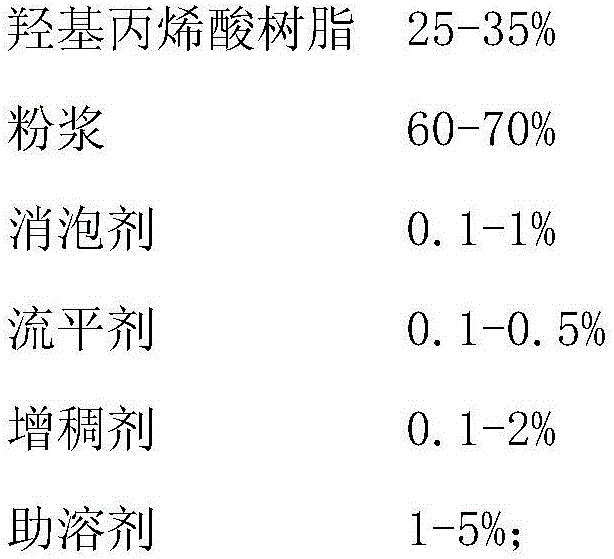

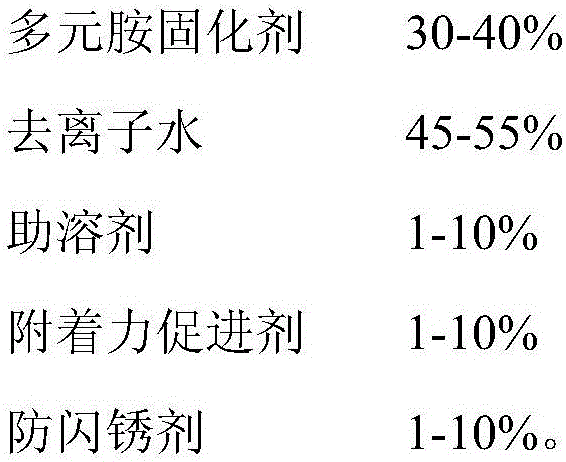

Automobile water-based dual-component middle coating excellent in performance and preparation method thereof

The invention discloses an automobile water-based dual-component middle coating excellent in performance and a preparation method thereof. The water-based middle coating is composed of a component A and a component B. The component A is composed of hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent, wherein powder syrup contains deionized water, amine neutralizer, auxiliaries, extender pigment and pigment. The component B is composed of a curing agent, auxiliaries and cosolvent. After being put in according to the formula of the powder syrup of the component A, materials are dispersed at a high speed for 15 min and then enter a grinding machine to be ground till the granularity is smaller than 30 micron, then powder syrup is obtained, and hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent are evenly mixed to obtain the component A. The component A and the component B are mixed in certain proportion, viscosity is adjusted by adding deionized water, and a middle coating film is obtained through spraying construction. By means of the water-based middle coating, the water-based performance of the automobile middle coating is achieved, the VOC content is greatly decreased, and excellent comprehensive performance is achieved.

Owner:GUANGDONG YATU CHEM

Architectural ornament equipment capable of automatically polishing and whitewashing arc-shaped wall space

InactiveCN107795108AGood securityImprove cleanlinessBuilding constructionsPlane surface grinding machinesHydraulic cylinderPetroleum engineering

The invention relates to a building decoration equipment capable of automatically grinding and painting arc-shaped walls. The lower end is installed with a brushing device and a grinding device in sequence from front to back. A receiving trough is installed at the lower end of the grinding device. The side wall of the receiving trough is an arc structure. Cylinders, steering motors, steering plates, push cylinders, adjustment hydraulic cylinders, brush holders, rotating motors and brushes. The invention can solve the problems of high risk, poor cleanliness, low work efficiency, high labor intensity and incomplete grinding in the process of painting the outer wall of the curved wall, and can realize automatic grinding of the curved wall, The function of painting has the advantages of good safety, high cleanliness, high work efficiency, better grinding effect and low labor intensity.

Owner:范满香

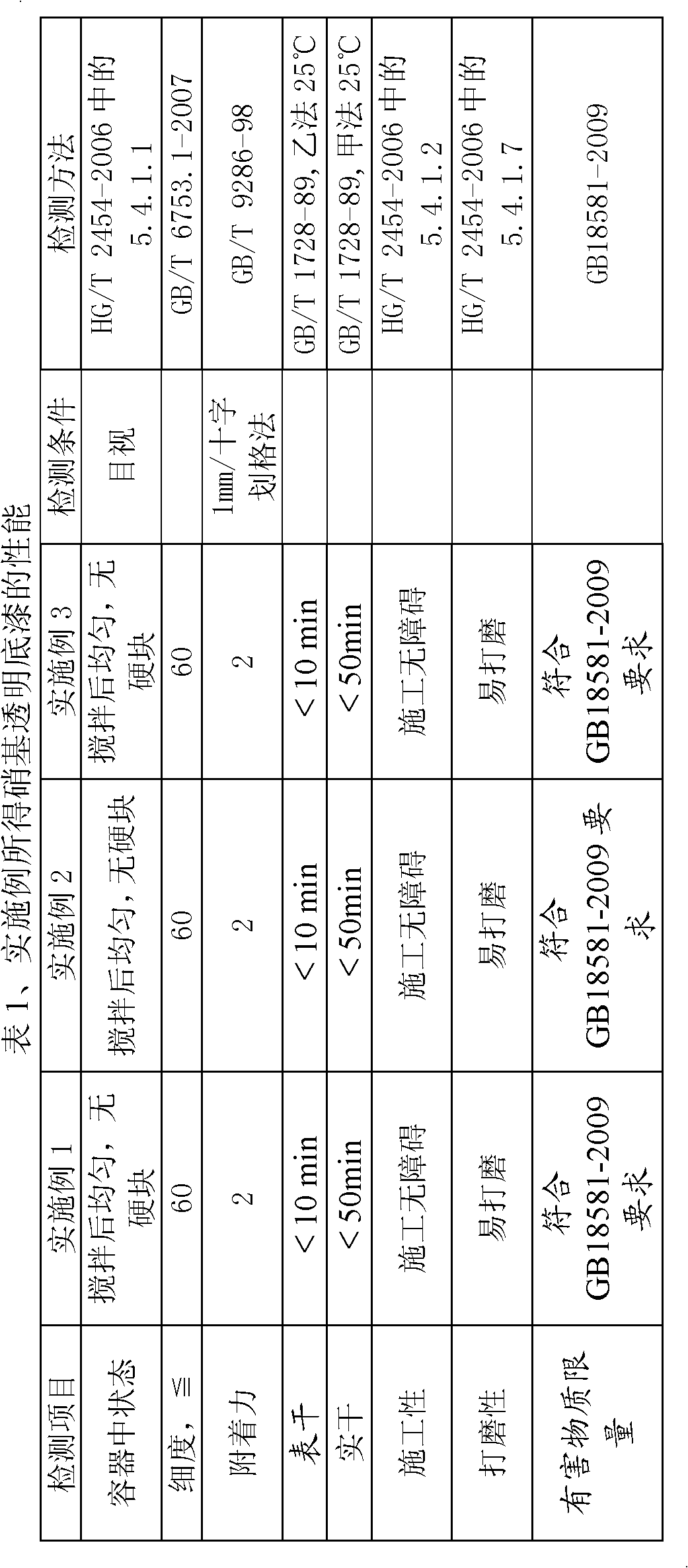

Nitrocellulose transparent primer and application thereof

ActiveCN102618126AQuick dryingEasy constructionNatural resin coatingsPolyester coatingsBenzenePolymer science

The invention discloses a nitrocellulose transparent primer and an application thereof. The primer is prepared by mixing main lacquers and diluents based on a mass ratio of 1: (0.4-0.6), the main lacquers are obtained by evenly mixing 21.0-25.0% of alkyd resins, 6.0-8.0% of inflexible resins, 0.2% of dispersing agents, 45.0-50.0% of nitrocotton liquids, 3.0-5.0% of plasticizers, 8.0-10.0% of extender pigments, 4.0-6.0% of grinding aids, 0.5% of anti-setting agents, 0.2% of defoaming agents, 0.1% of anti-yellowing agents and 5.5% of main lacquer solvents, the extender pigments are mixtures of more than two of a talcum powder, a transparent powder or a silica micropowder, and the diluents are prepared by mixing and uniformly stirring 42% of ester solvents, 33% of aromatic hydrocarbon solvents, 13% of solvent oil and 12% of alcohol ether solvents. According to the nitrocellulose transparent primer, the repainting transparency is high, the drying is quick, the film filling capability is good, the grinding capability is good, the fullness degree is high, construction times are effectively reduced, and each of the components has not any benzene-containing solvent, thereby the health of a constructor is greatly guaranteed, the environmental pollution is effectively reduced, and the nitrocellulose transparent primer can be widely applied to aspects of home decoration, furniture and the like.

Owner:NIPPON PAINT GUANGZHOU

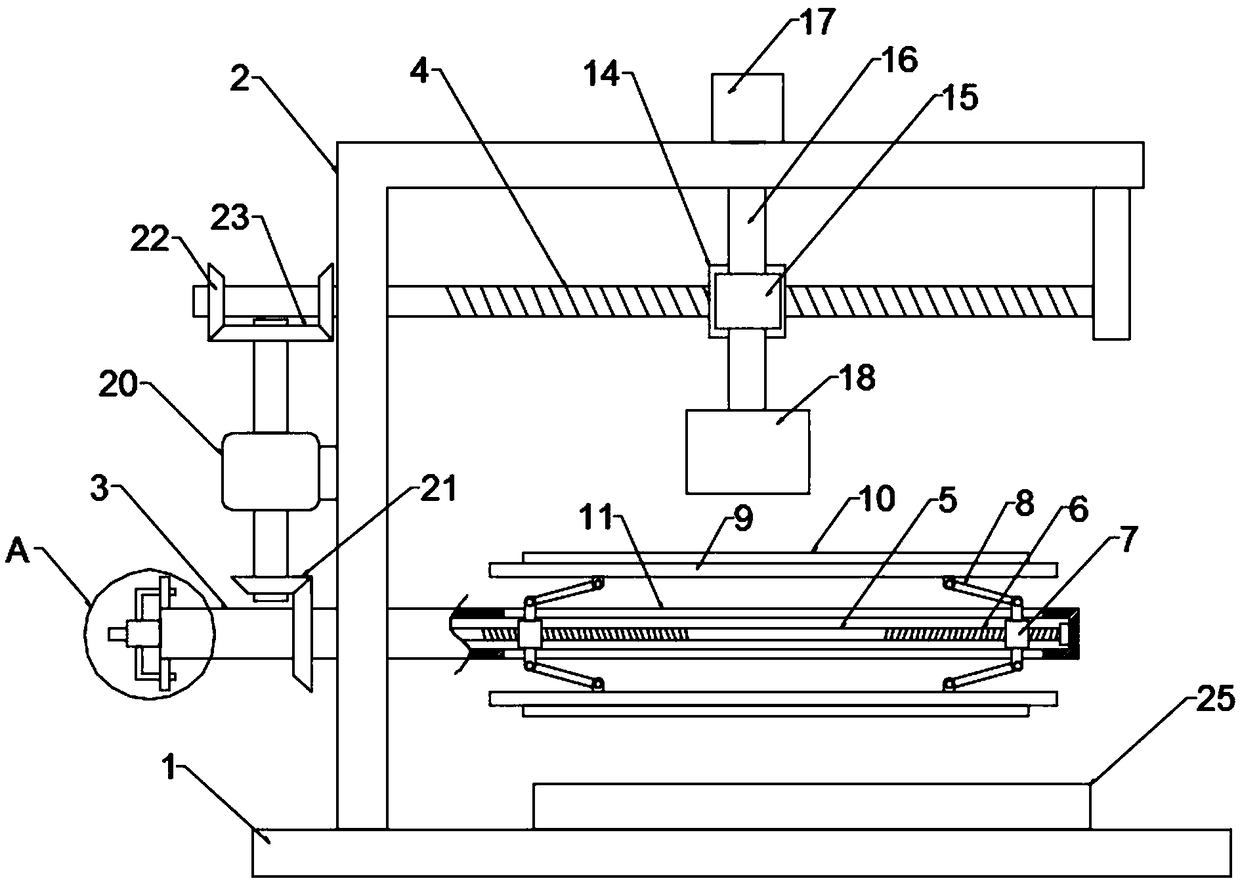

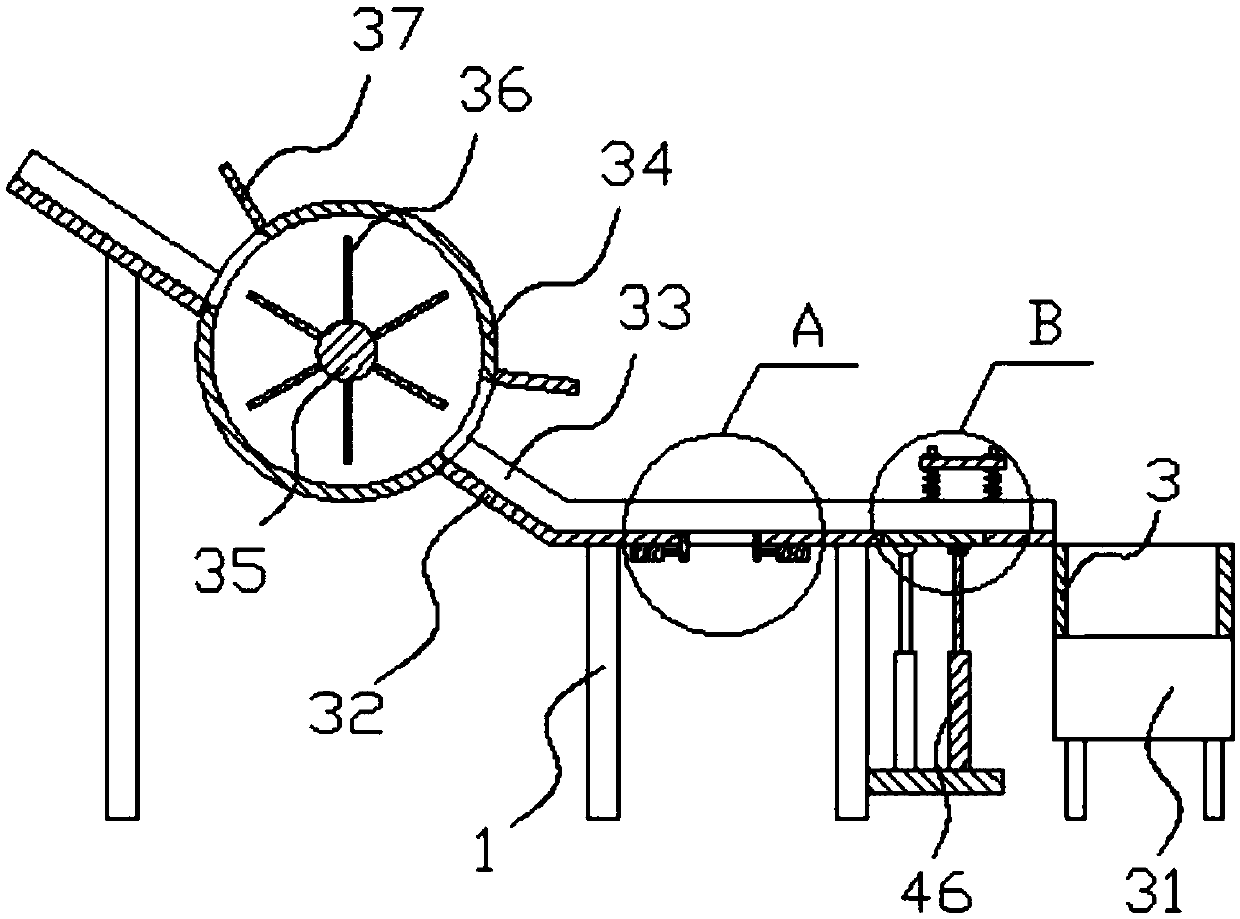

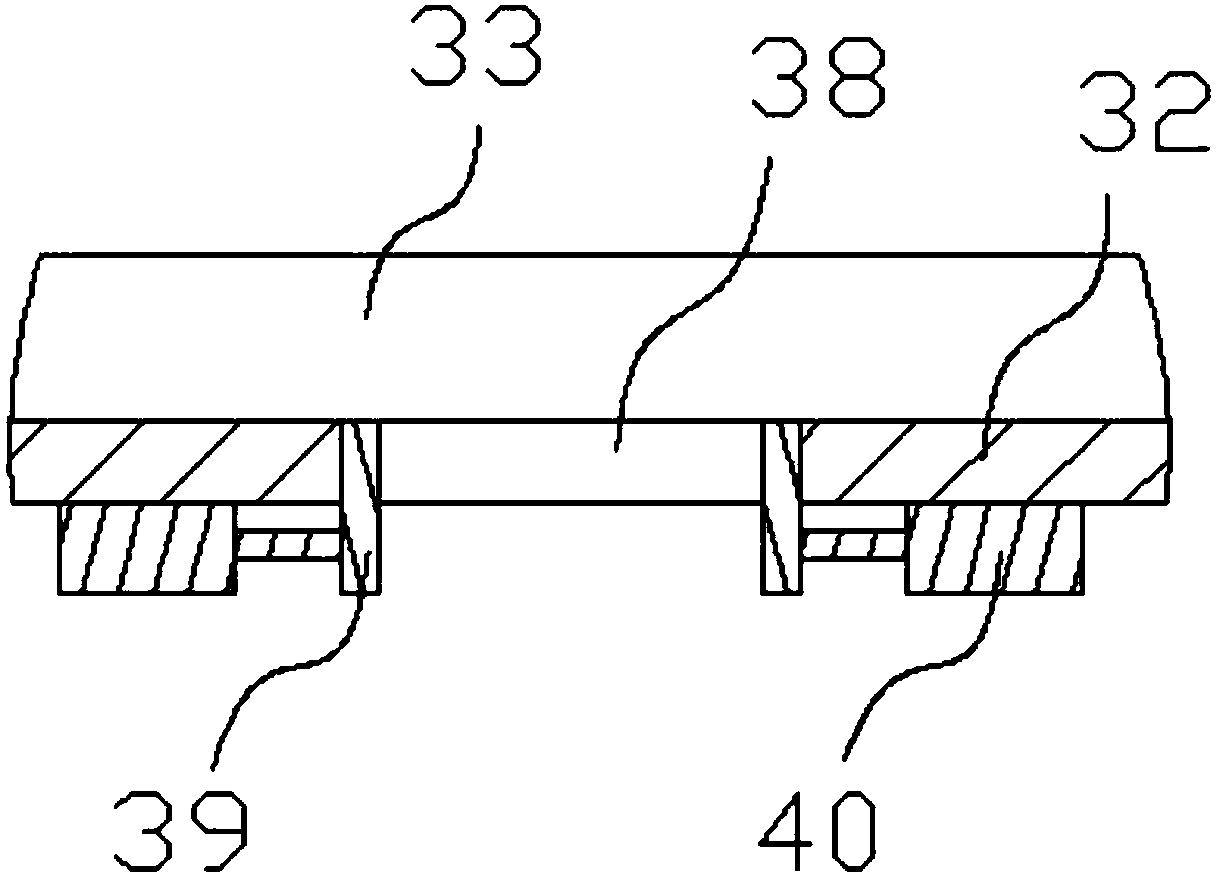

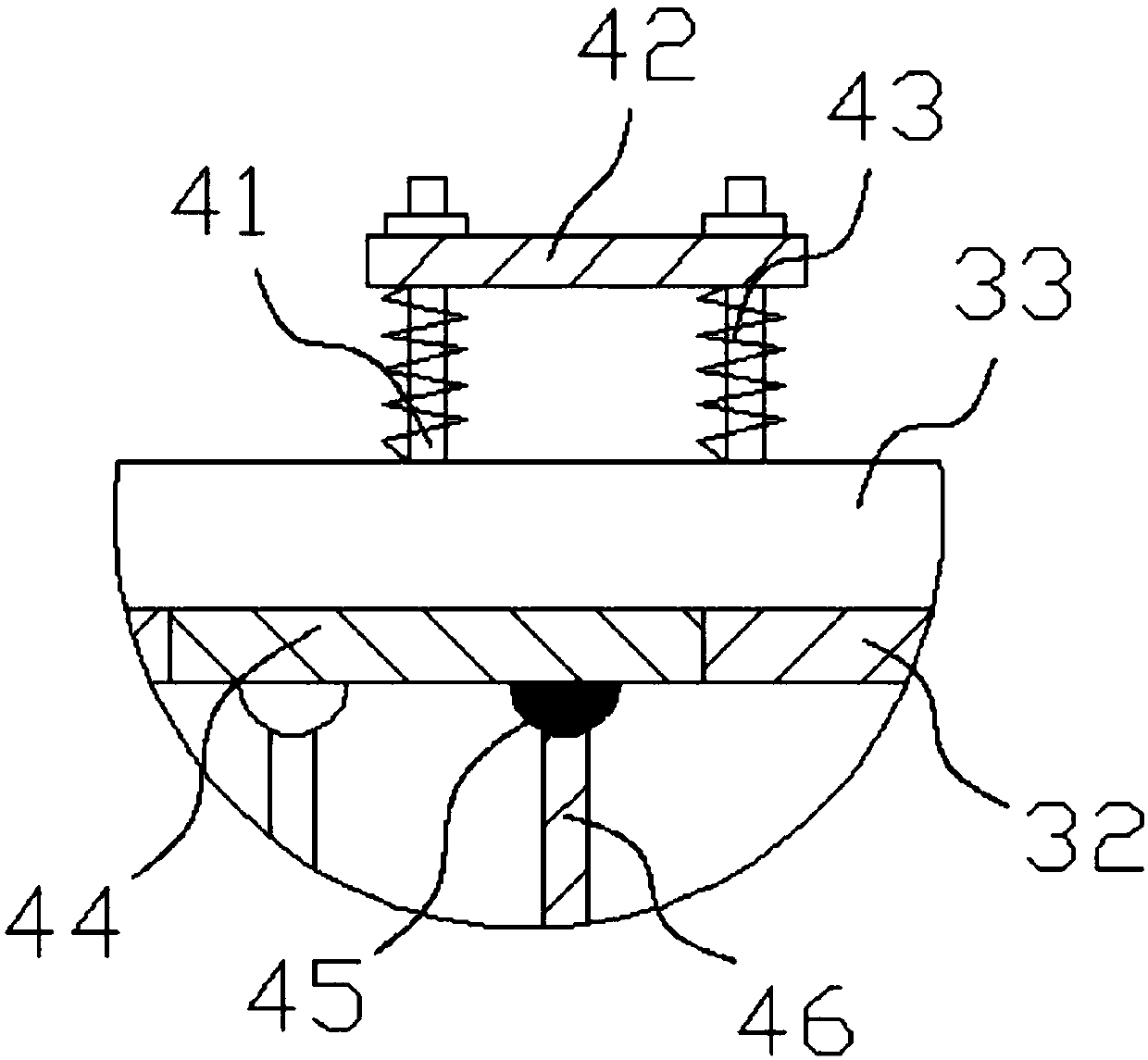

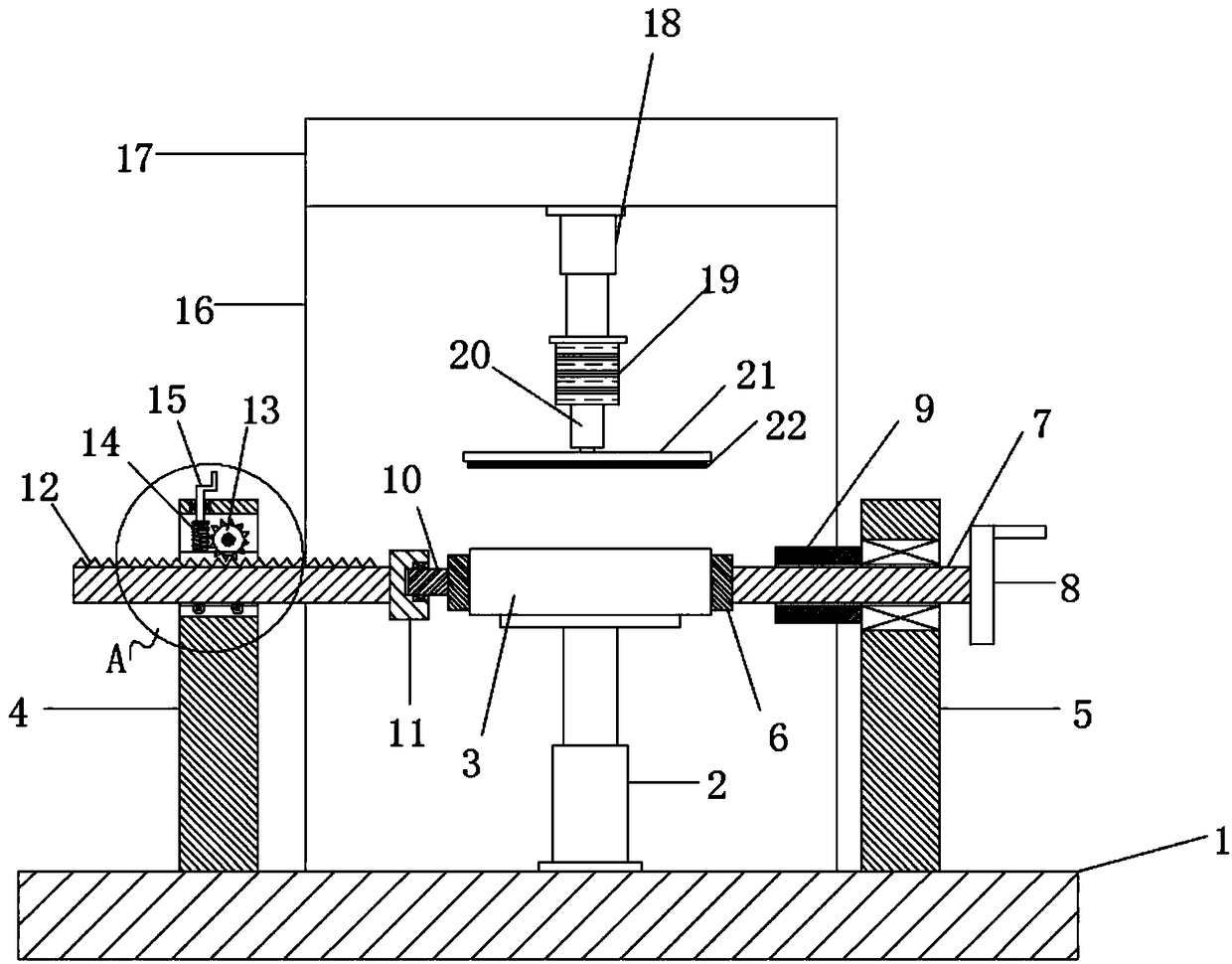

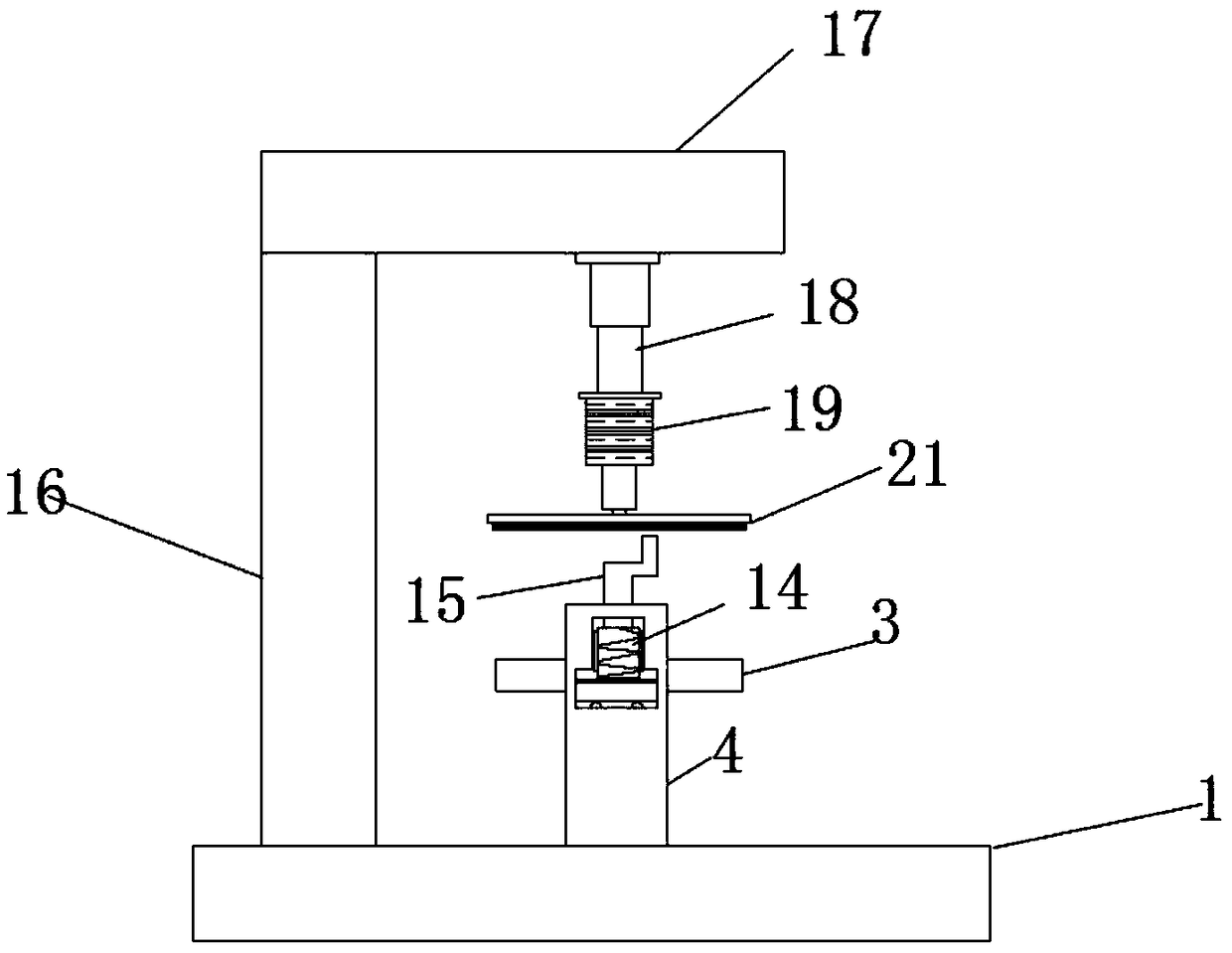

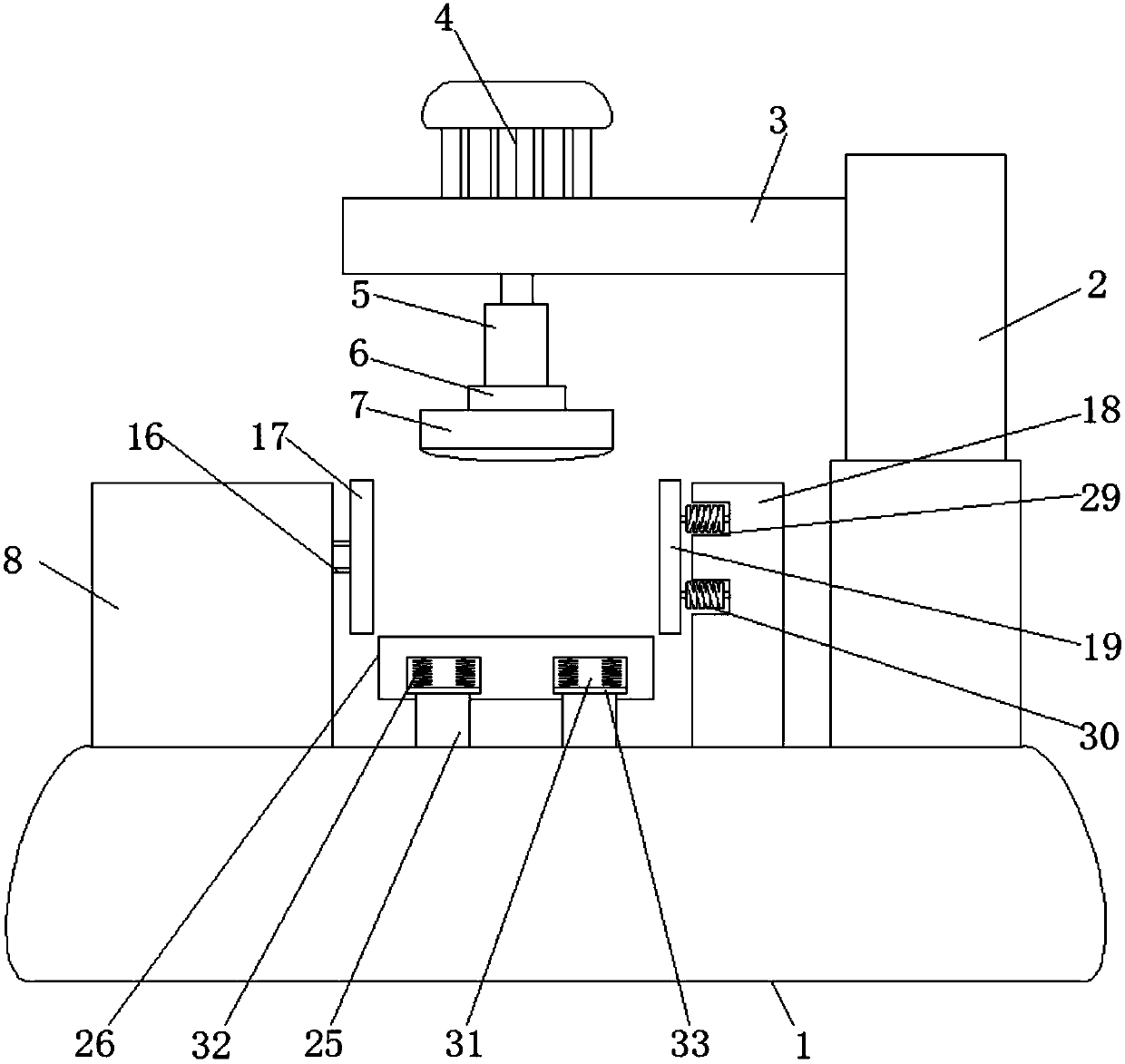

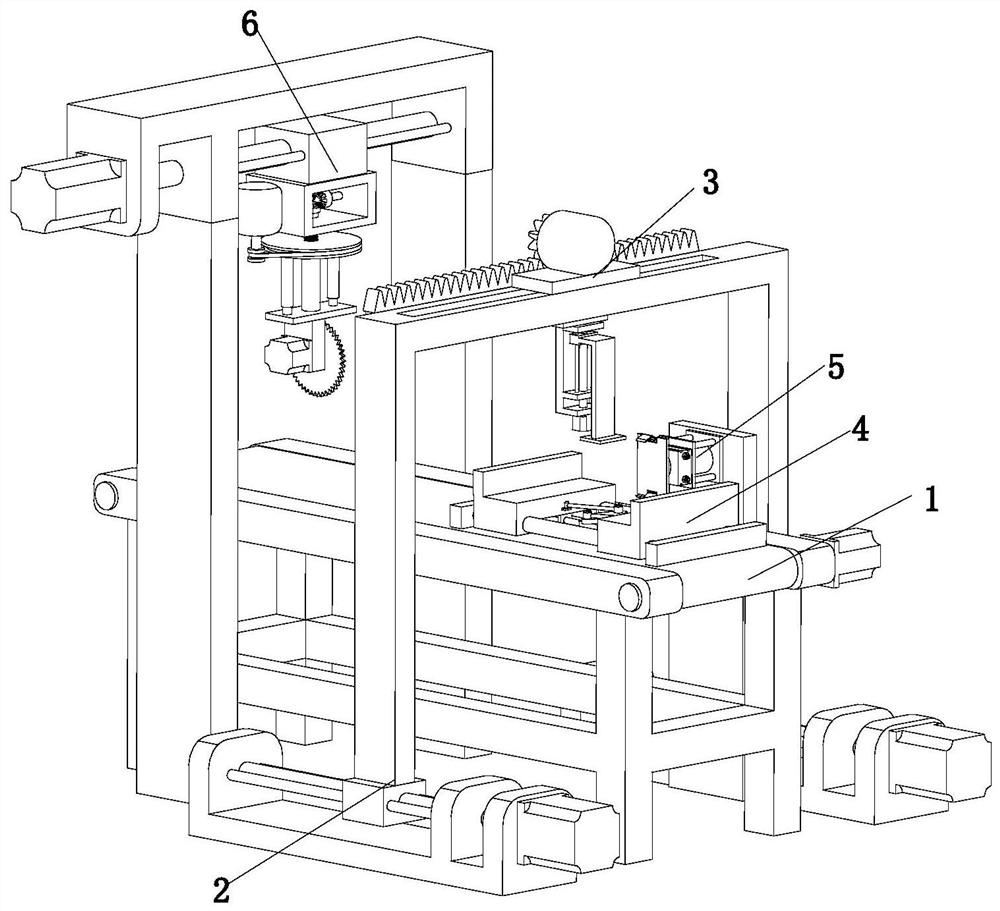

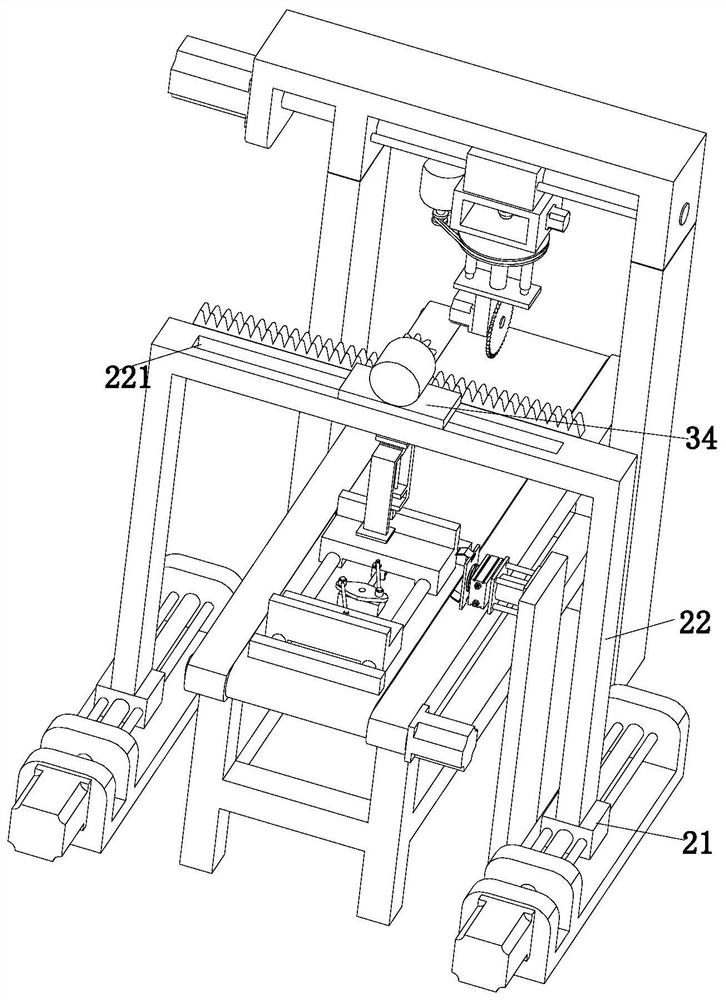

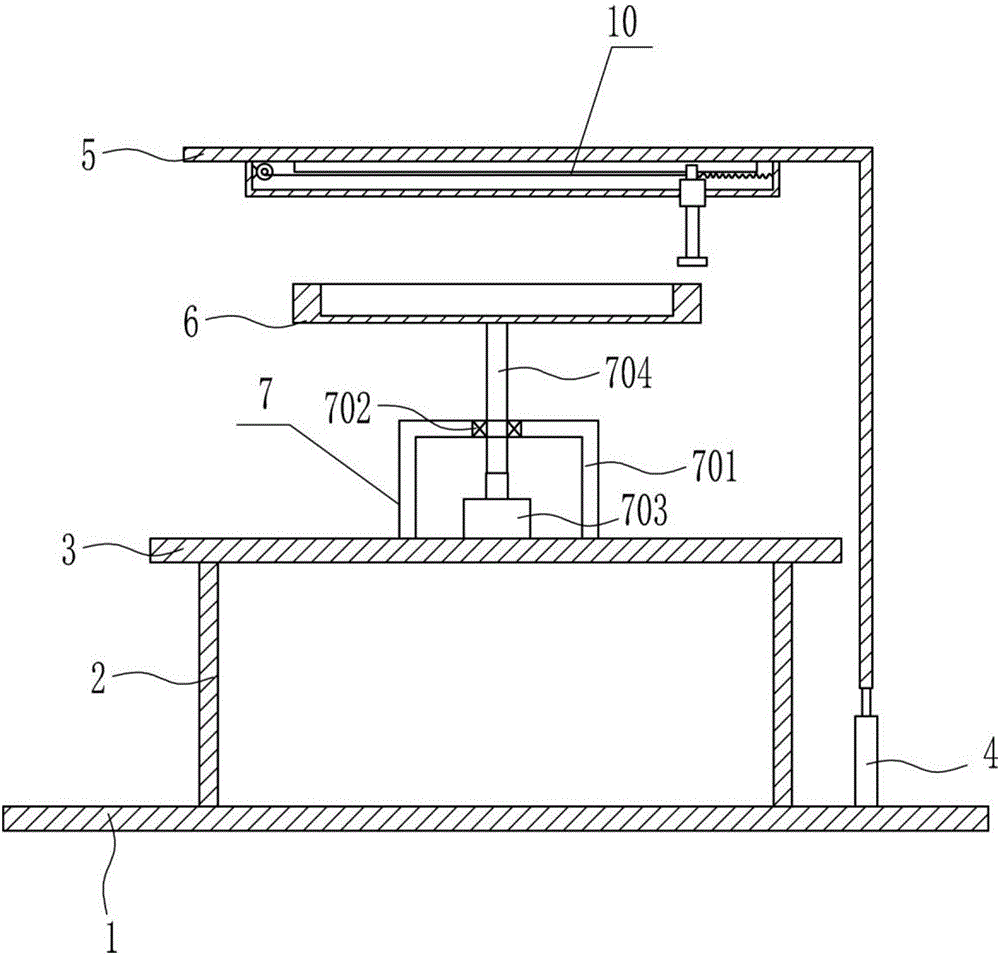

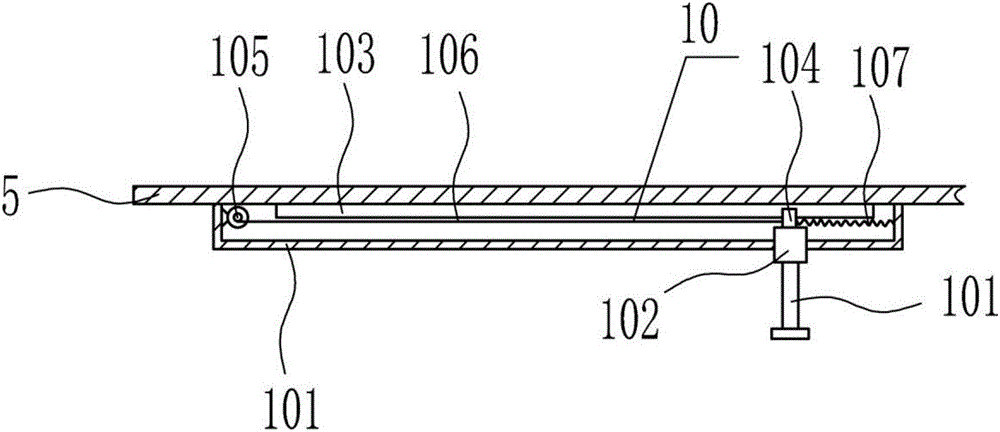

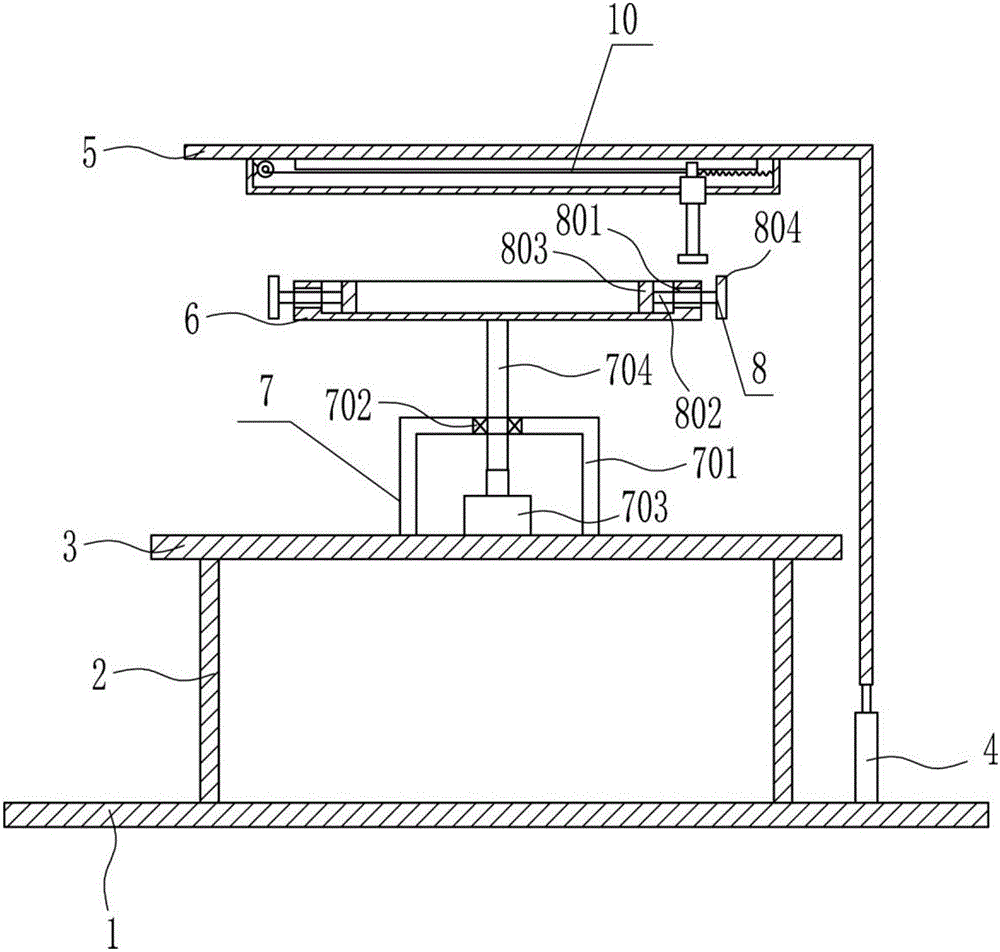

Arc-shaped part polishing equipment for construction machinery

ActiveCN107984336APolished evenlyImprove grinding efficiencyGrinding machinesGrinding/polishing safety devicesArchitectural engineeringBuilding construction

The invention relates to arc-shaped part polishing equipment, in particular to arc-shaped part polishing equipment for construction machinery. The arc-shaped part polishing equipment for constructionmachinery has the technical effects of being high in polishing efficiency, even in polishing and excellent in polishing effect. To achieve the technical effects, the arc-shaped part polishing equipment for construction machinery comprises a base plate and the like. An n-shaped frame is arranged at the top of the base plate. A polishing mechanism is arranged at the top of the interior of the n-shaped frame. A moving mechanism is arranged above the polishing mechanism. A rotation mechanism is arranged on the left side of the top of the base plate. An arc-shaped storage plate is arranged at the top of the rotation mechanism. According to the arc-shaped part polishing equipment for construction machinery, the polishing mechanism is used for polishing ac-shaped parts, the moving mechanism drives the rotation mechanism to work, then the arc-shaped storage plate is driven to rotate, the parts are evenly polished, and the effects of high polishing efficiency, even polishing and excellent polishing effect are achieved.

Owner:尚古智造(山东)智能装备有限公司

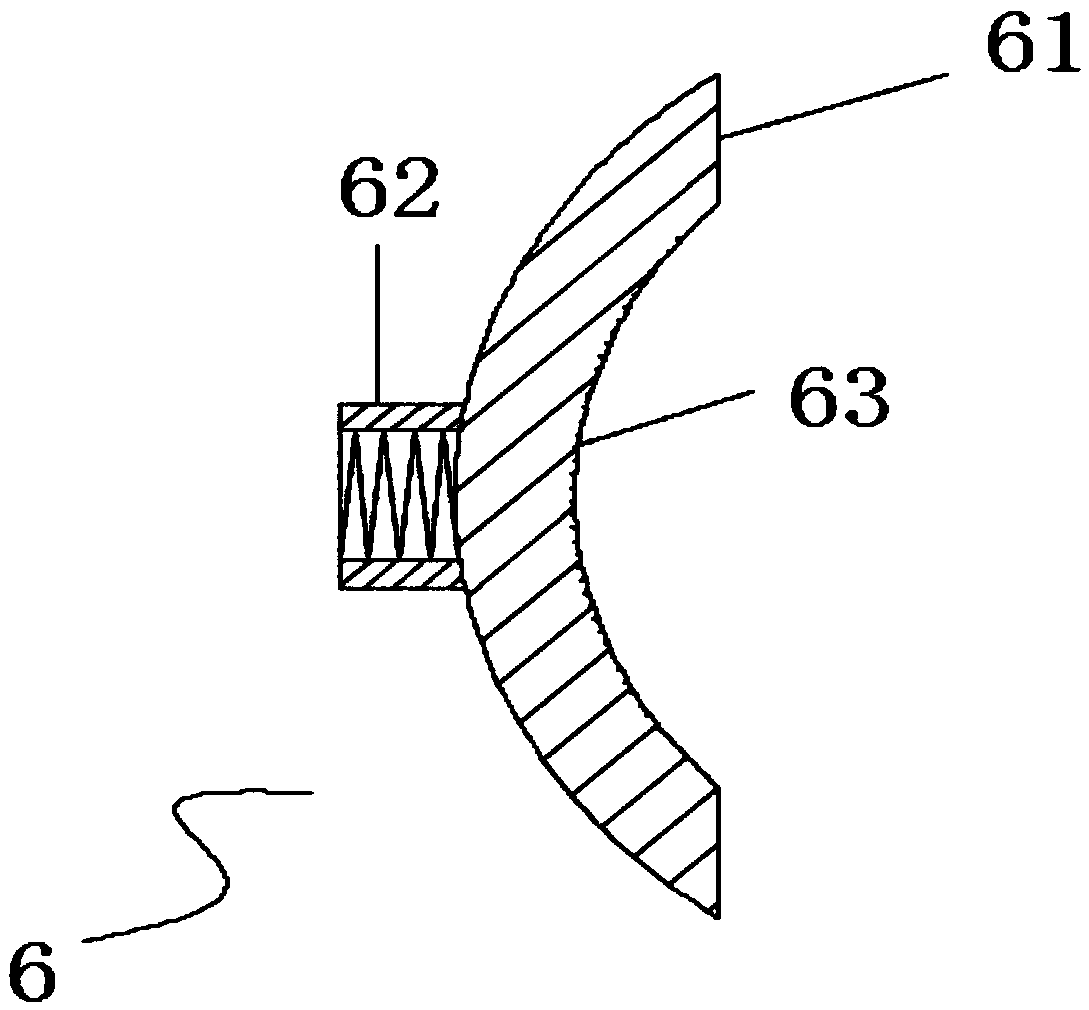

Bamboo splitting machine capable of automatically screening bamboo barrel specification

InactiveCN107803344AGuaranteed accuracyImprove efficiencyWood splittingIrregularity removal devicesHinge angleEngineering

The invention relates to a bamboo breaking machine capable of automatically screening bamboo tube specifications, comprising a frame, a screening device, a bamboo tube blanking device and a bamboo breaking mechanism. The screening device includes a screening conveying plate and a conveying guard plate. The horizontal part of the screening conveying plate is provided with a screening slot and a feeding slot for defective products. The feeding slot for defective products is equipped with a lifting block for feeding defective products. The lower part of the unloading lifting block is provided with a triangular distribution of defective product blanking hinge seats, and the defective product blanking hinge seat is hingedly matched with the cylinder push rod of the defective product blanking lifting cylinder; the present invention adopts a screening groove to match a screening intercepting block Realize a bamboo tube screening with a diameter specification, which can intercept oval and bent bamboo tubes, and set a lowering block for defective products under the screening block to remove the intercepted defective products, ensure the accuracy of screening, and improve the screening and conveying. s efficiency.

Owner:DONGGUAN UNIV OF TECH

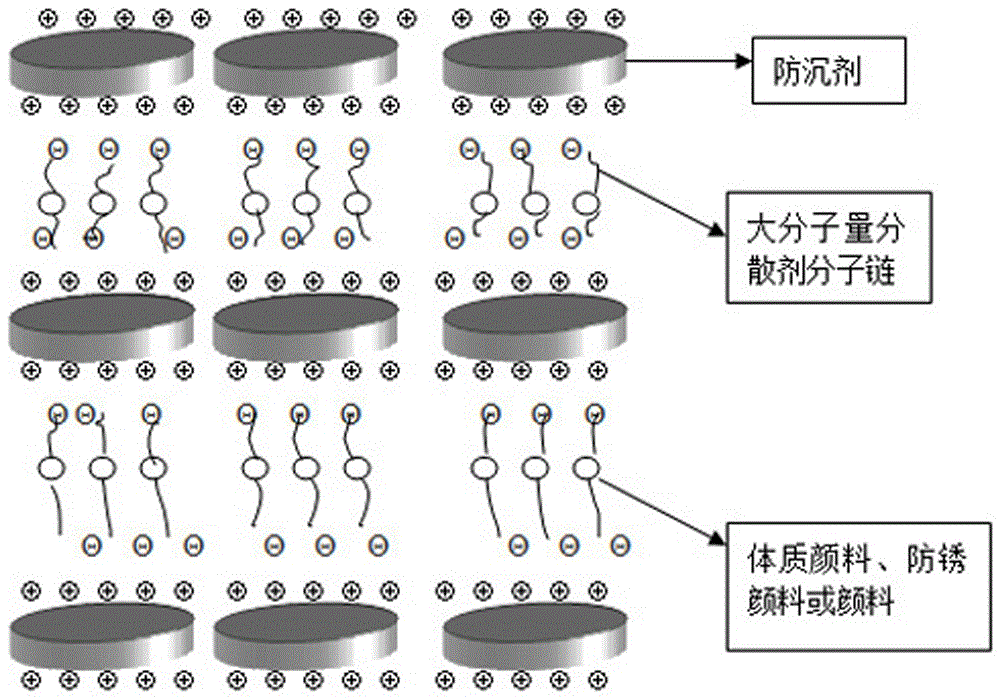

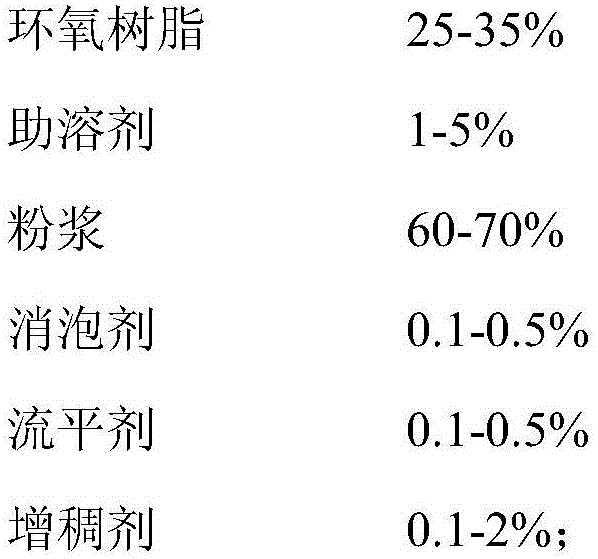

Automobile water-based two-component epoxy primer with excellent performance and preparation method thereof

The invention discloses an automobile water-based two-component epoxy primer with excellent performance and a preparation method thereof. The water-based epoxy primer involved in the invention is composed of a component A and a component B. The component A is composed of epoxy resin, a cosolvent, powder slurry and assistants, wherein the powder slurry includes deionized water, additives, extender pigment, anti-rust pigment and pigment. The component B contains a polyamine curing agent, deionized water, a cosolvent and assistants. The preparation method includes: conducting charging according to the powder slurry formula of the component A, then performing high speed dispersion for 15min, then bringing the materials into a sand mill to conduct grinding to fineness of less than 30 micrometers to obtain the powder slurry, mixing epoxy resin, the cosolvent, the powder slurry and the assistants evenly to obtain the component A, mixing the component A with the components B in certain proportion, adding deionized water to adjust viscosity, and carrying out spray coating to obtain an epoxy primer film. The water-based epoxy primer provided by the invention not only realizes aquation of automobile epoxy primer and great reduction of the VOC content, but also has excellent comprehensive performance.

Owner:GUANGDONG YATU CHEM

Machining and polishing device for die

InactiveCN105881152AIncrease usageSimple structureEdge grinding machinesGrinding carriagesEngineeringMachining process

The invention discloses a mould processing and grinding device, comprising a workbench, a lifting device is arranged on the left side of the workbench, a work box is arranged on the right side of the lifting device and above the workbench, and the work box is A motor and an electric telescopic device are respectively arranged inside, the electric telescopic device is located on the right side of the motor, the output shaft of the motor is sleeved with a first gear, the first gear is meshed with a second gear, and the first gear is engaged with the first gear. The inner ring of the second gear is sleeved with a rotating rod. The rotating rod penetrates the working box and extends to the outside of the working box. Two grinding blocks are arranged inside the protective shell. The grinding blocks penetrate through the protective shell and are fixed with the grinding plate arranged outside the protective shell. connect. The mold processing and grinding device of the invention has simple structure and convenient use, can grind the mold holes or grinding tool grooves during processing, and has better grinding effect on the burrs in the holes or grooves, so that the utilization rate of the mold is higher when it is put into use. .

Owner:CHANGZHOU JINCHENGYU HARDWARE

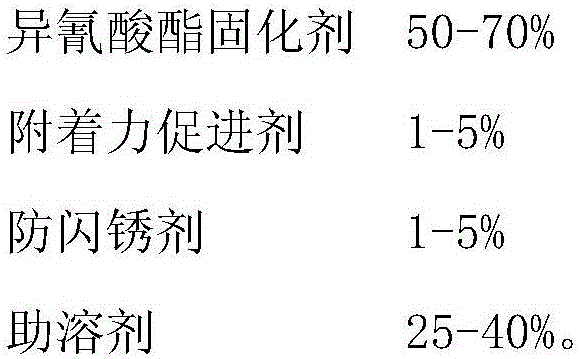

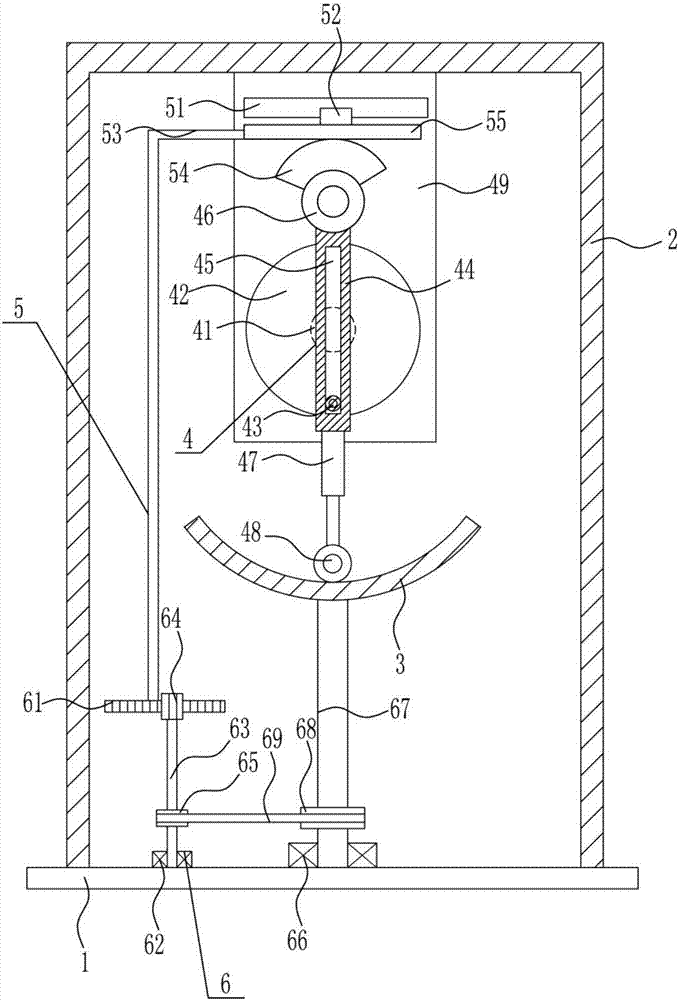

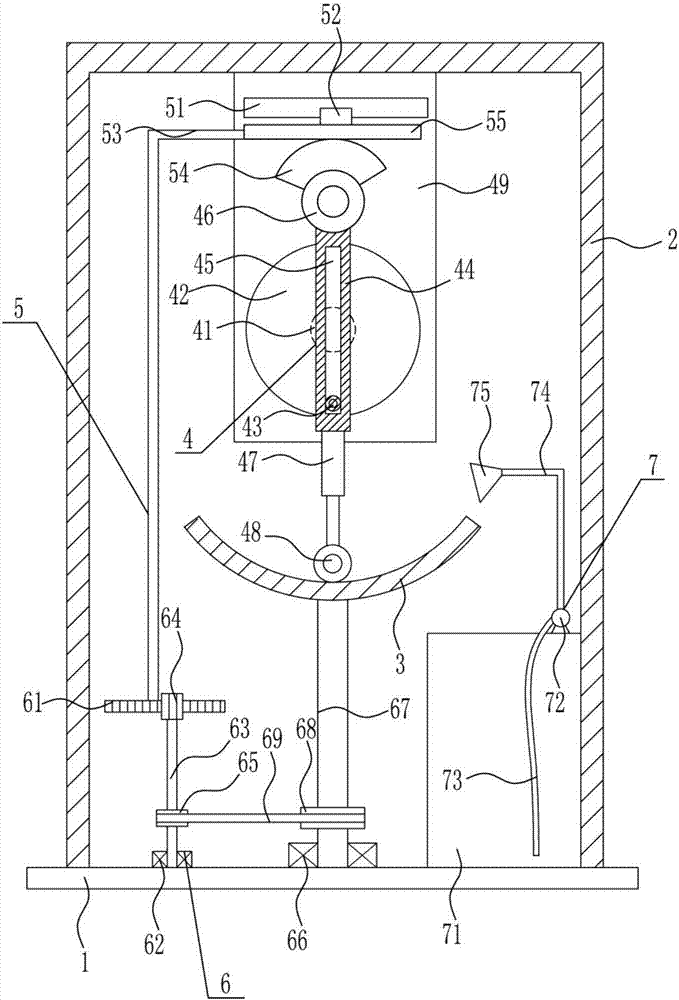

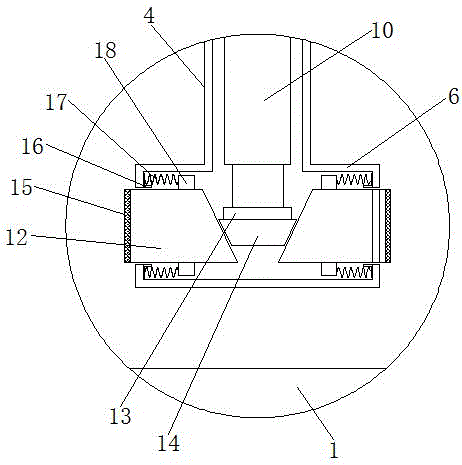

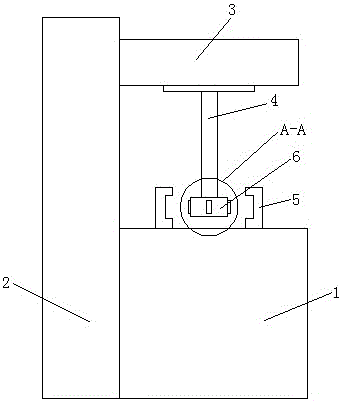

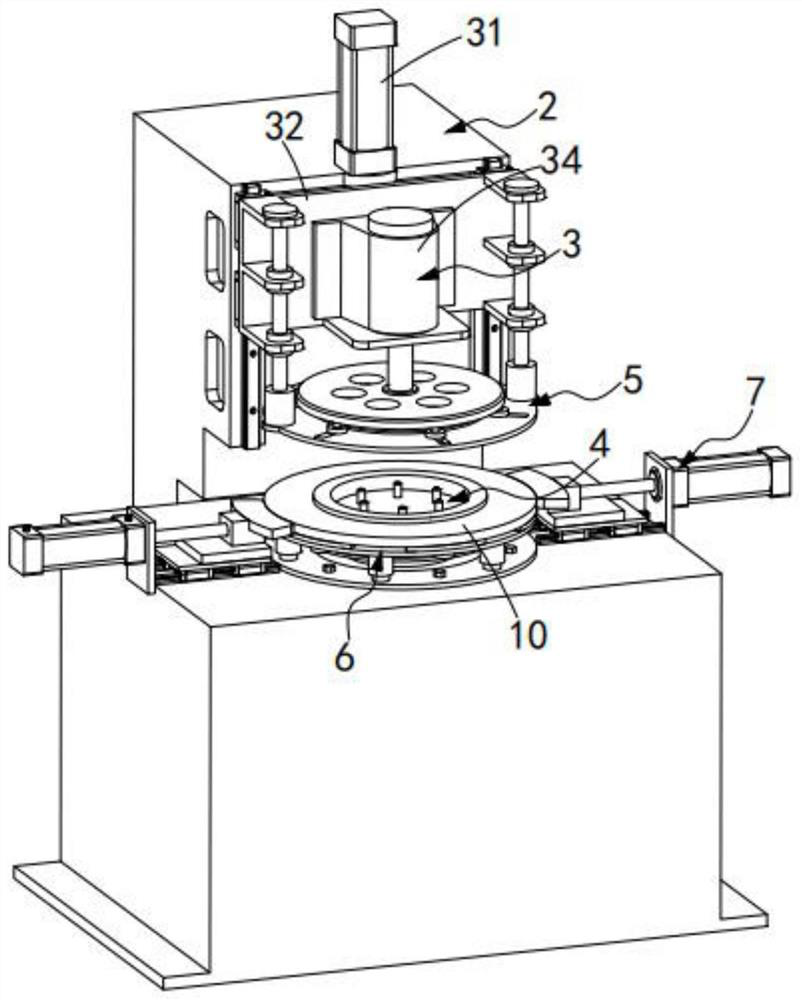

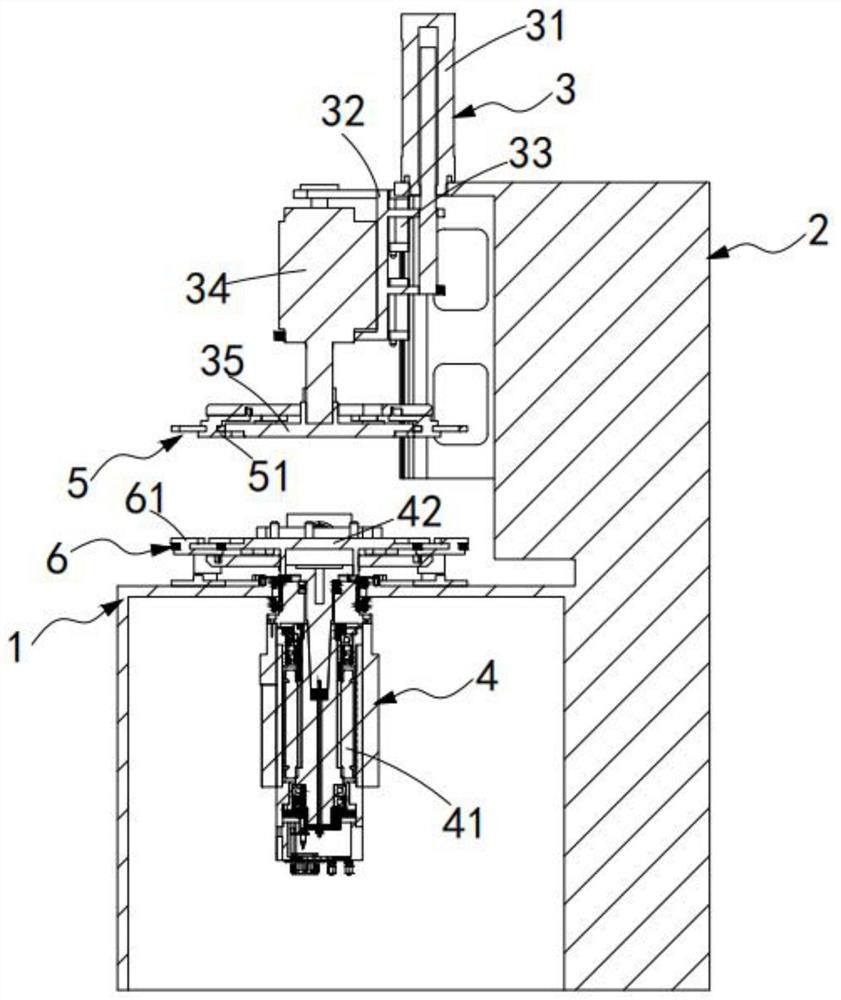

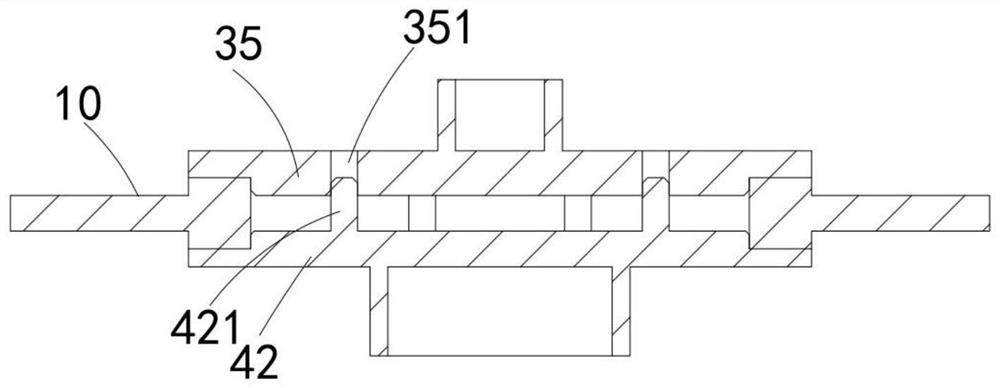

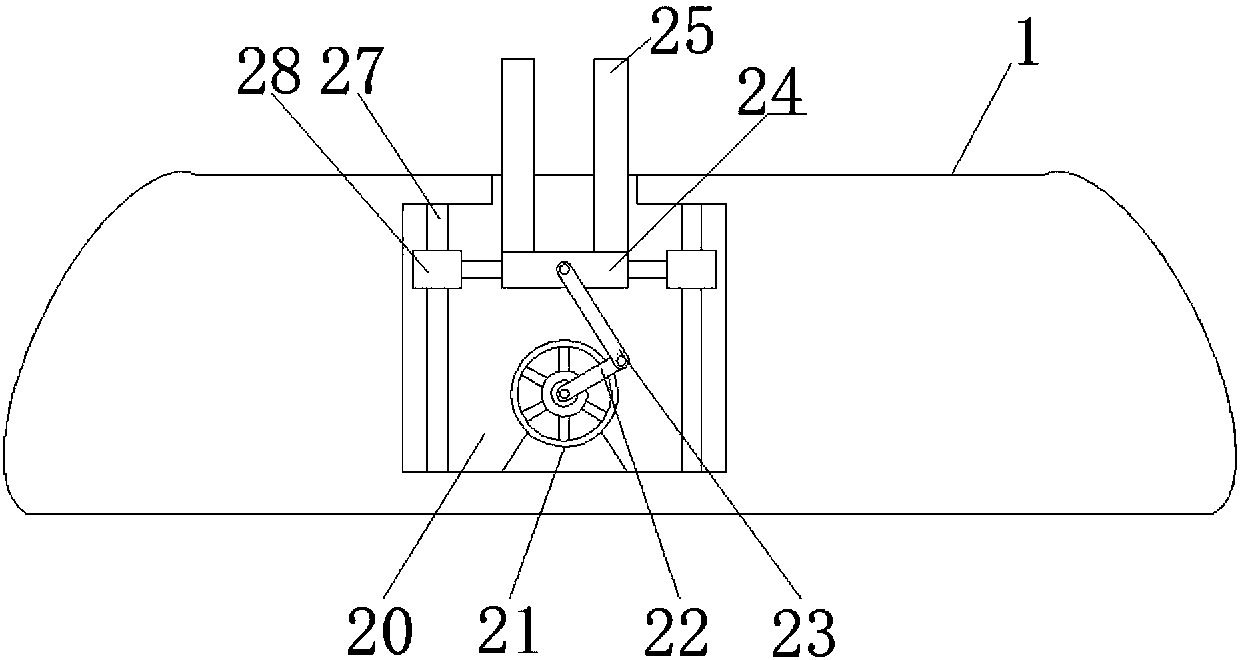

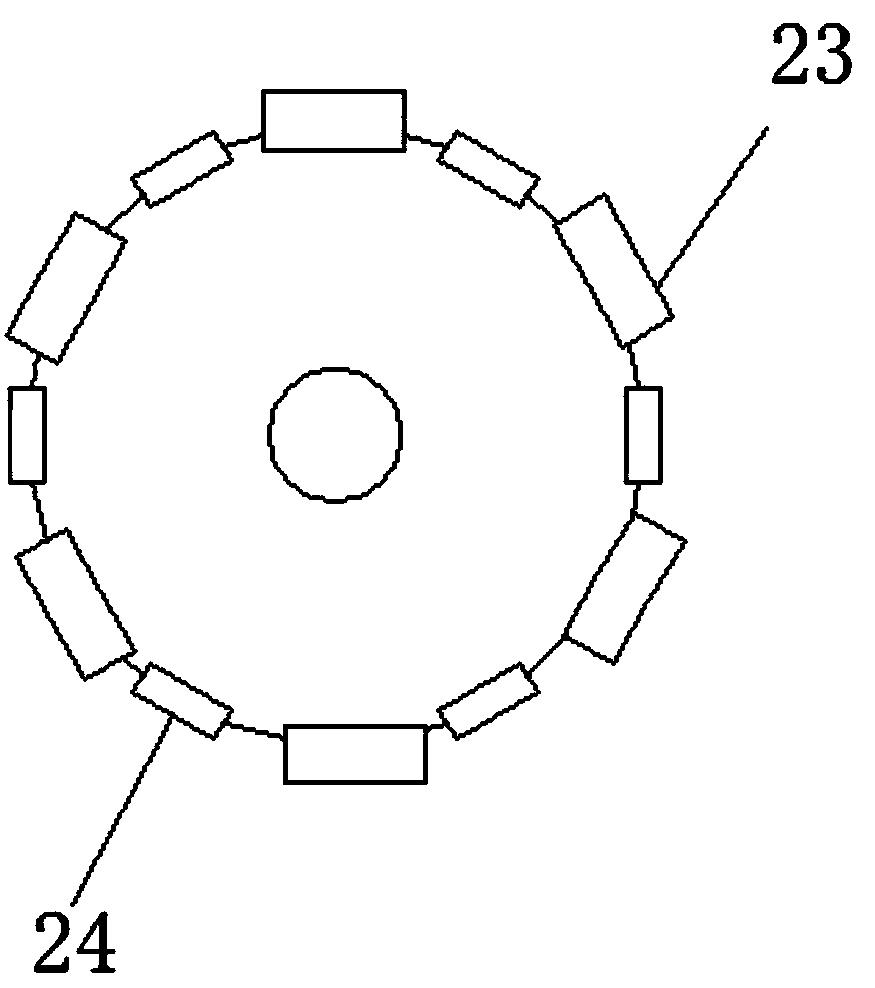

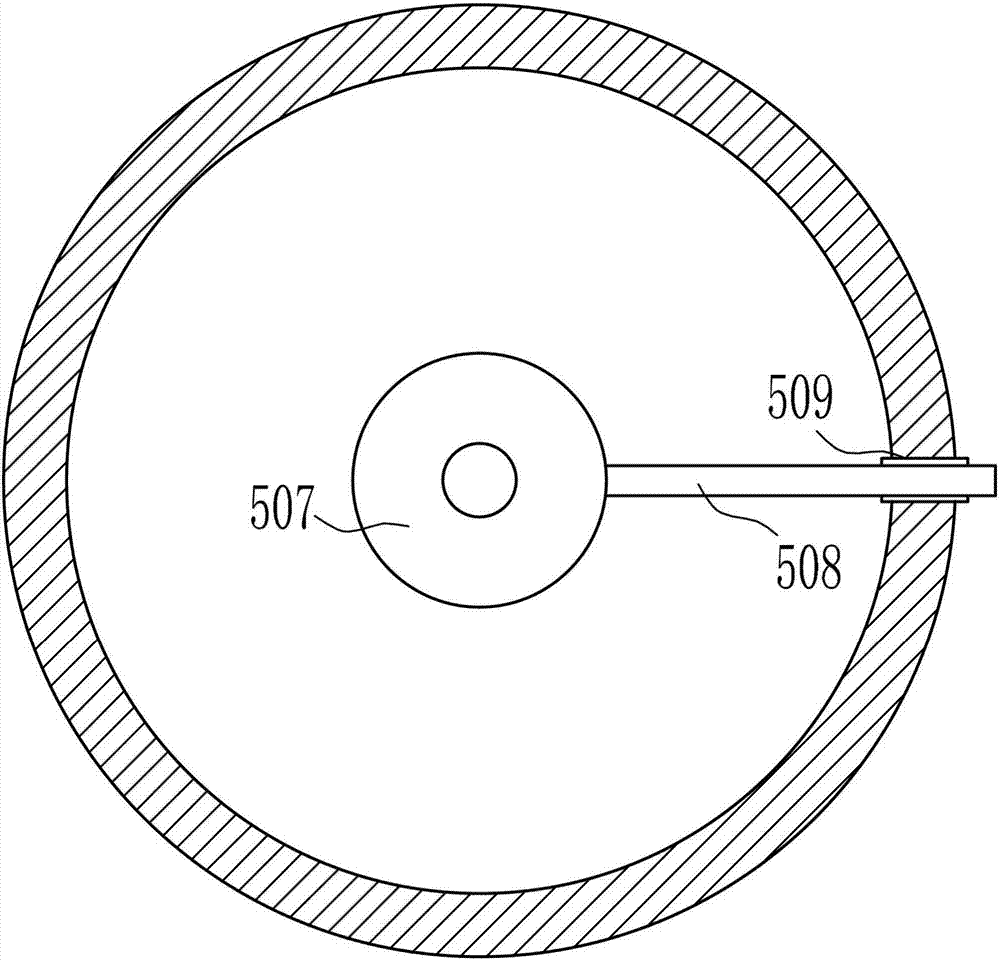

Flywheel polishing device with clamping function

InactiveCN109352463AAchieve clampingEasy clampingGrinding carriagesGrinding drivesEngineeringFlywheel

The invention discloses a flywheel polishing device with a clamping function, and belongs to the technical field of flywheel machining. The flywheel polishing device comprises a base, a telescopic supporting device is arranged in the middle of the top end of the base, a flywheel is placed at the top end of the telescopic supporting device, a first supporting base and a second supporting base are arranged on the left side and the right side of the telescopic supporting device correspondingly, and arc clamping blocks are symmetrically connected to the left side and the right side of the flywheel. By arranging a gear and rack structure, flywheels with different sizes can be clamped, flywheel overturning can be achieved by means of an arranged rotating shaft structure, the polishing device canpolish the two faces of the flywheel, flywheel secondary installation is not needed, installation time is saved, labor of users is saved, auxiliary supporting can be achieved for the flywheel by means of the arranged telescopic supporting device, installation and clamping are facilitated, the flywheel ground can be stably supported during polishing, the polishing effect is better, and polishing precision is improved.

Owner:郭志斌

Nanometer waterborne woodware paint

The invention discloses a nanometer waterborne woodware paint. The paint is prepared by stirring the following raw materials in parts by weight: 65-70 parts of polyacrylate emulsion, 10-15 parts of linseed oil, 5 parts of talcum powder, 10-15 parts of candelilla wax, 6 parts of sodium hexametaphosphate, 20 parts of propylene glycol, 16 parts of alkali lignin, 2 parts of zircon isocaprylate, 13 parts of nano-TiO2 slurry, 5 parts of defoaming agent and 4 parts of wetting agent. Experiments prove that the product of the invention has good wetting property, flexibility and weather resistance, excellent sealing property and grindability and simpler material and technology and can be widely used in the surface finishings of solid wood furniture and panel type furniture.

Owner:WUJIANG LONGJING HONGBEI INTERIOR DECORATION

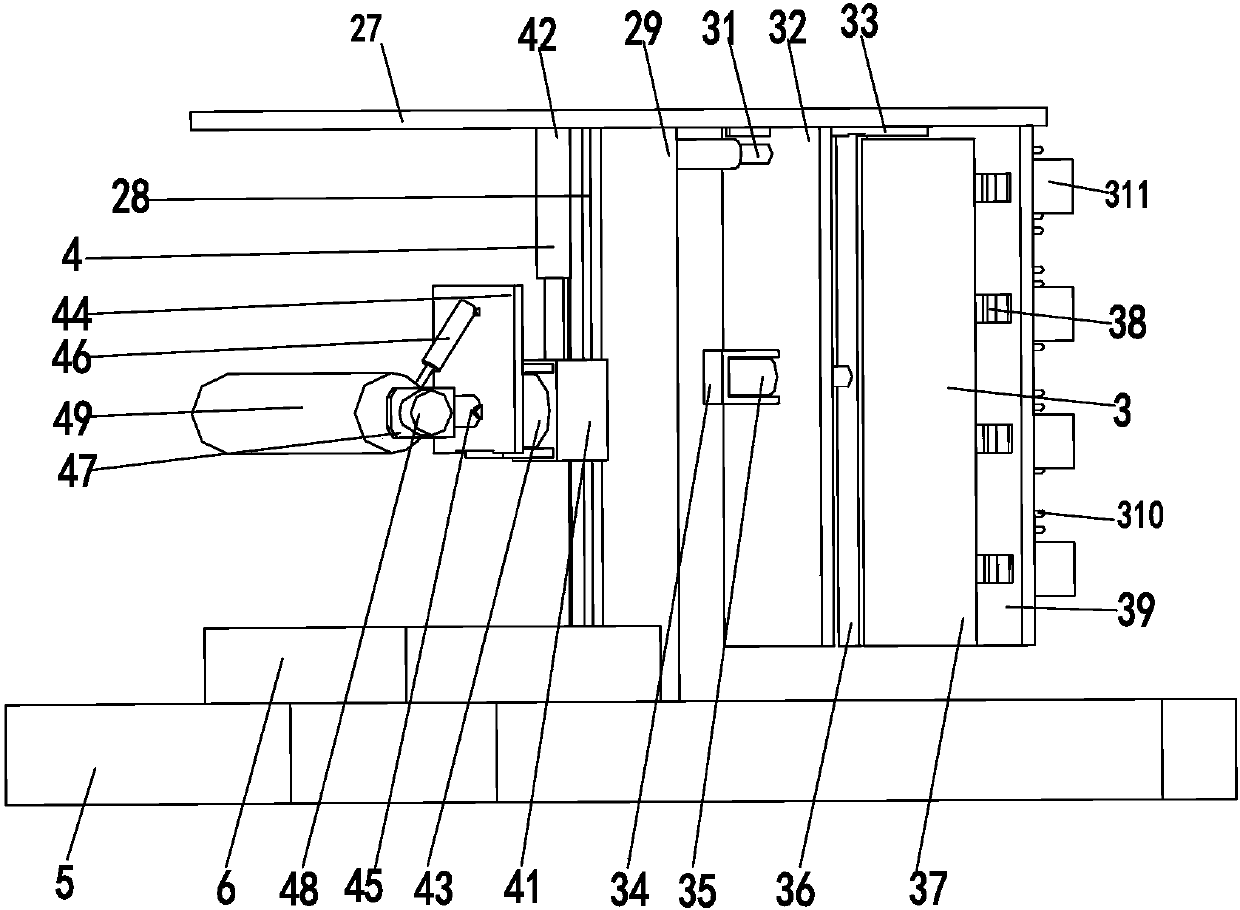

Multifunctional mechanical working table capable of working in multi-angle mode

ActiveCN108067886AVersatileFunctionalOther manufacturing equipments/toolsPneumatic cylinderEngineering

The invention discloses a multifunctional mechanical working table capable of working in multi-angle mode. The working table comprises a machine tool, a mounting plate is arranged on one side of the machine tool, and first electromagnetic sliding rails are arranged on the two sides above the mounting plate; the top of the first electromagnetic sliding rail is provided with two sets of first electromagnetic sliding blocks, and a first installation base is arranged above the first electromagnetic sliding block; an installation groove is formed in the top of the first installation base, and foursets of lifting pneumatic cylinders are arranged in the installation grooves, the top of the lifting pneumatic cylinder is provided with a piston rod, and the top of the piston rod is provided with afixing block; and a second installation base is arranged at the top of the fixed block, and an installation hole is formed in the inner side of the second installation base. The workbench is providedwith a cutting table and a grinding table, a cutting structure and a grinding structure on the mechanical table cooperate, so that the function of the working table is more comprehensive, the polishing operation of the hardware can be realized, the cutting operation of the hardware can be realized, and the functionality is stronger.

Owner:肇庆市高要区博斯五金制品有限公司

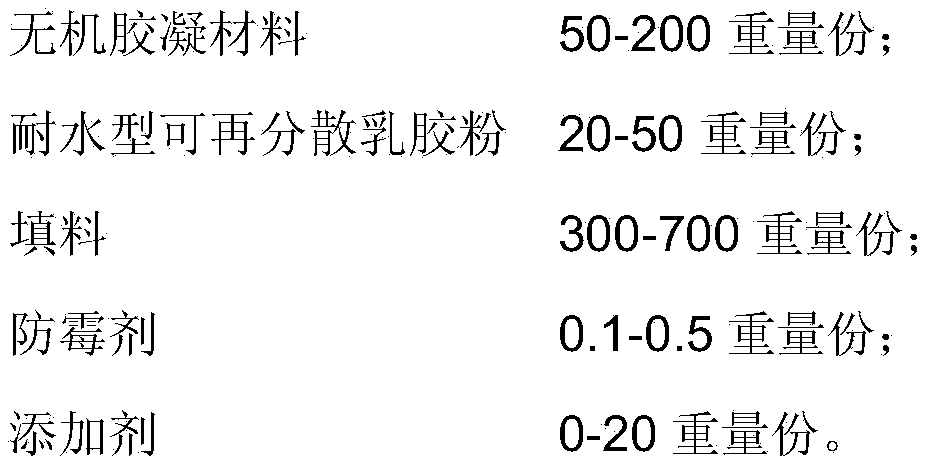

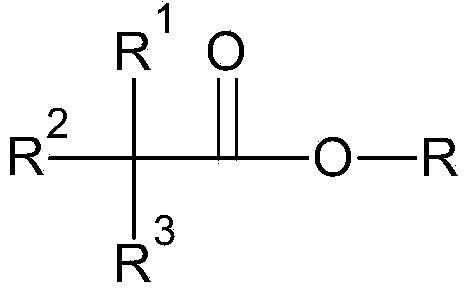

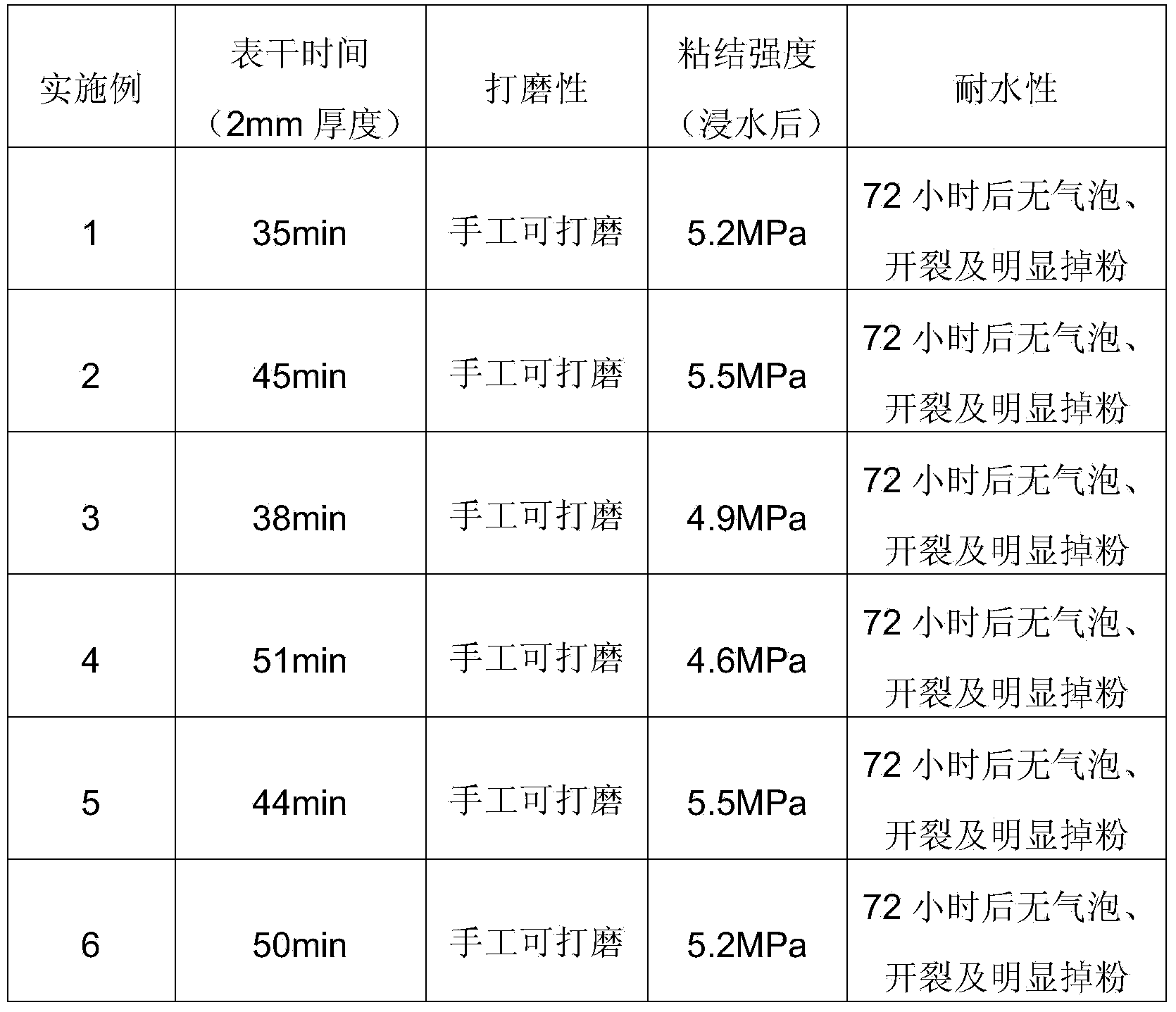

Ultra-strong water-resistant mildew-resistant inorganic dry powder putty

The invention provides ultra-strong water-resistant mildew-resistant inorganic dry powder putty. The ultra-strong water-resistant mildew-resistant inorganic dry powder putty comprises, by weight, 50-200 parts of an inorganic gel material, 20-50 parts of water-resistant redispersible latex powder, 300-700 parts of a filling material, 0.1-0.5 parts of a mildew inhibitor and 0-20 parts of an additive. The ultra-strong water-resistant mildew-resistant inorganic dry powder putty satisfies water-resistant (N) putty requirements of the standard JG / T298-2010, reaches to the mildew-resistant level 0 of the standard GB / T1741-2007, has the advantages of good polishability, good cohesiveness and storage stability, does not produce harmful substances such as VOC, benzene, formaldehyde and heavy metals, and is especially suitable for indoor wet environments such as toilets, underground spaces and kitchens. The invention also provides an object such as a building containing the ultra-strong water-resistant mildew-resistant inorganic dry powder putty.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

Water-based woodenware seal primer and preparing method thereof

Water-based woodenware seal primer and a preparing method thereof are disclosed. The seal primer comprises components in a certain ratio. The method includes adding an acrylic emulsion, a silane coupling agent, a nanometer enhancer, a coalescing agent, a defoaming agent, a leveling agent, a thickening agent and a pH conditioner in order, stirring, filtering and packaging. The seal primer is high in permeability and excellent in sealing performance, and is capable of penetrating into the inside of wood, blocking capillary pores on the surfaces of the wood, allowing the amount of open pores on the surfaces of the wood to be reduced, and making the sealed pores increased, thus inhibiting penetration of water in top paint into a base material so as to achieve excellent anti-expansion effects. A unique paint film enhancing technology is adopted, so that paint film is dried rapidly to achieve film formation. Compact honeycombed paint film is formed on the base material, and tannic acid and grease in the wood are prevented from penetrating to the surface of the paint film, thus achieving anti-expansion and grease-sealing effects.

Owner:漳州水之采环保科技有限公司

Iron rod polishing device for hardware processing

InactiveCN108527136AEasy to polishImprove grinding effectPolishing machinesGrinding drivesEngineeringMechanical equipment

The invention provides an iron rod polishing device for hardware processing, and relates to the field of mechanical equipment. The iron rod polishing device includes a base, supporting legs are fixedly connected to four corners of the top of the base, and a shell is fixedly connected to the tops of the supporting legs. An attle recycling device is fixedly connected to the right side of the bottomof the shell, and a transmission device is fixedly connected to the left side of the shell. A driving device is fixedly connected to the left side of the transmission device, and a first rotating shaft is arranged in the shell. According to the iron rod polishing device for hardware processing, through the arrangement of the attle recycling device, generated attle can fall onto a collecting bottomplate in the attle recycling device while grinding, and then falls into a collecting tank through a second collecting opening and a first collecting opening; a recycling door is opened, the collecting tank can be easily drawn out, and the attle in the collecting tank can be recycled; and cleaning, recycling and reusing of the attle are effectively facilitated, and the cleaning efficiency is improved.

Owner:新昌县盛南建材有限公司

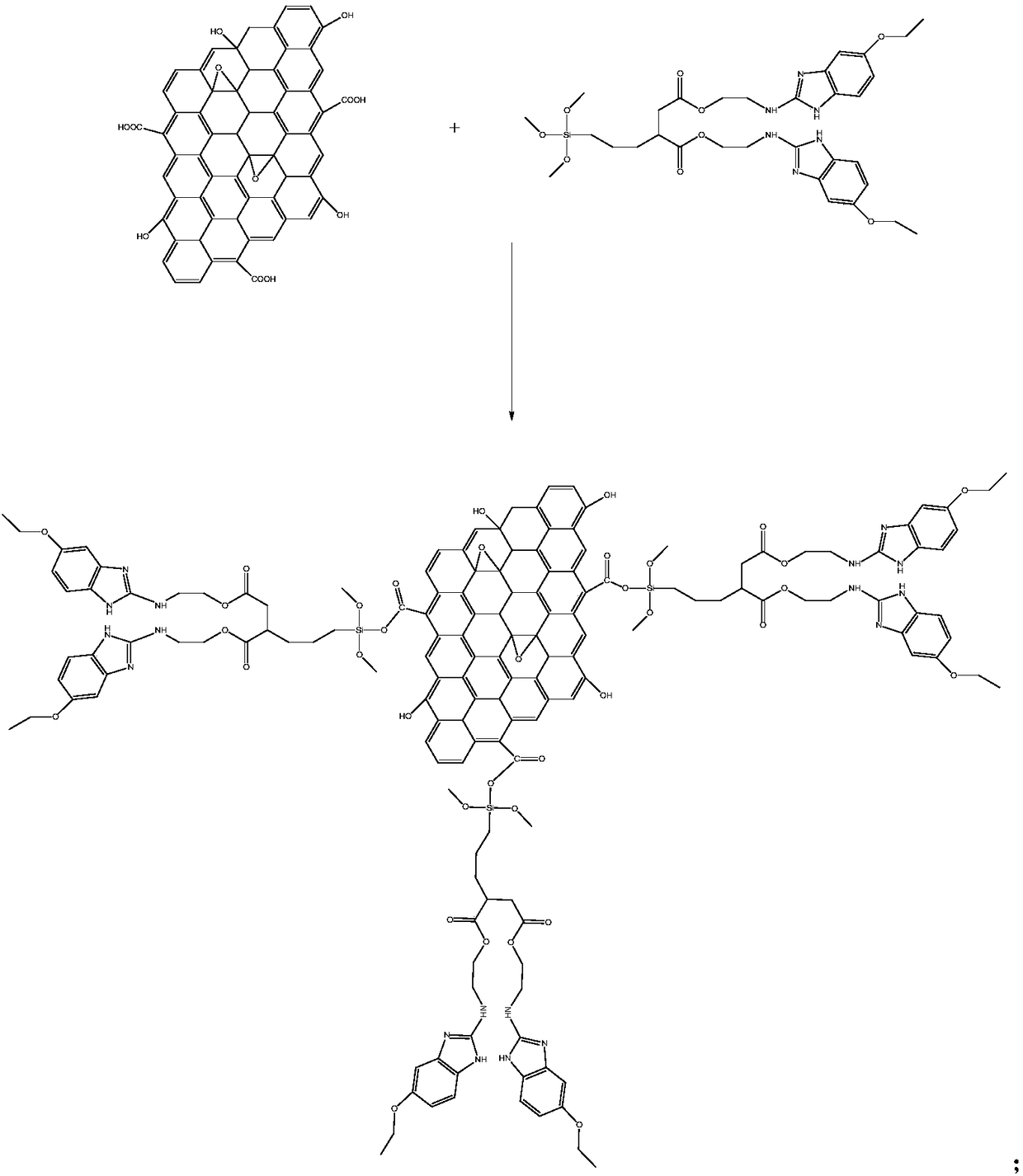

Metal substrate long-lasting anticorrosive inter-coat and preparation method thereof

ActiveCN108997916AHigh mechanical strengthImprove dispersion uniformityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention belongs to the technical field of anticorrosive coating, and in particular, relates to a metal substrate long-lasting anticorrosive inter-coat and a preparation method thereof, wherein the inter-coat is composed of a component A and a component B, and the component A is composed of the following raw materials in parts by weight: 50-60 parts of an epoxy-organosilicone resin modified acrylic resin emulsion, 12-18 parts of functionalized modified graphene, 10-20 parts of a filler, 8-15 parts of a cosolvent, 0.1-0.5 part of a defoamer, 0.5-1 part of a leveling agent, 0.3-0.8 part ofa water-based drier, 0.3-0.8 part of a thickener, 0.5-1 part of a wetting agent, and 30-35 parts of deionized water; the component B is composed of the components in parts by weight: 40-50 parts of anisocyanate curing agent, and 10-20 parts of a cosolvent. The inter-coat has the advantages of long-term excellent anticorrosive performance, strong adhesion force of the substrate, high mechanical strength, excellent friction resistance, excellent salt spray resistance, good water resistance, chemical resistance, oil resistance and impact resistance, high construction adaptability and the like.

Owner:惠州市湾厦表面处理技术有限公司

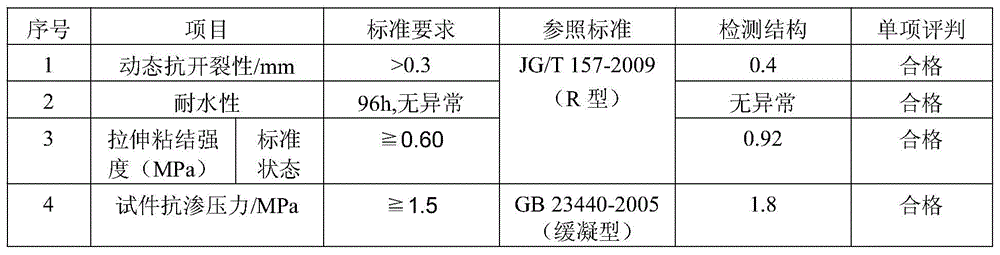

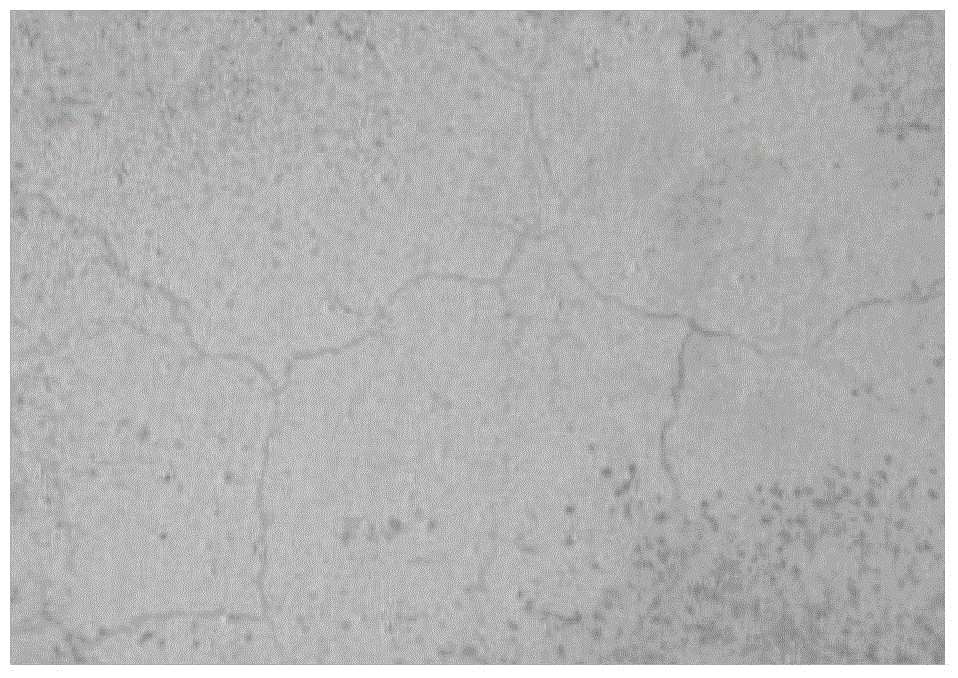

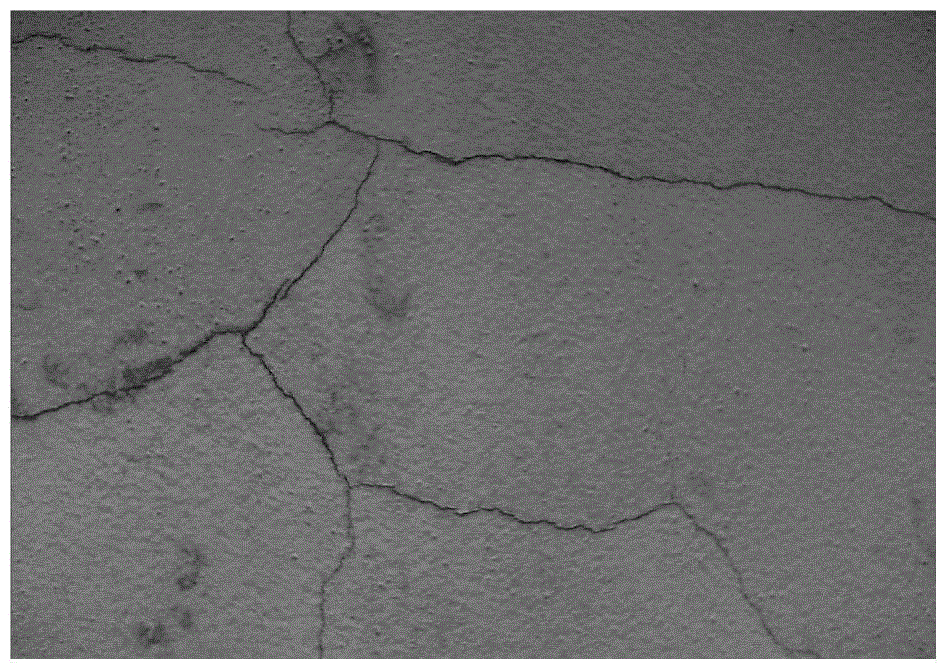

Two-component elastic anti-cracking waterproof putty for exterior walls

InactiveCN104559414AOvercome the defects of cracking, poor water resistance and low aging resistanceHigh bonding strengthFilling pastesEmulsionAging resistance

The invention provides two-component elastic anti-cracking waterproof putty for exterior walls, which comprises the following components: cement, fine quartz sand, HPMC (hydroxy propyl methyl cellulose), a UEA expanding agent, limestone flour, dispersible latex powder, and elastic acrylic emulsion. In case that the two-component elastic anti-cracking waterproof putty for exterior walls is used as a putty layer, the putty layer has certain elastic deformation, and due to the elastic action of the putty, the cracking of the putty layer caused by the micro-cracking of a mortar layer can be reduced; and the putty has water repellency, so that the putty can increase the waterproof level of a building exterior wall, thereby greatly increasing the water repellency and aging resistance of the wall surface.

Owner:广州协堡建材有限公司

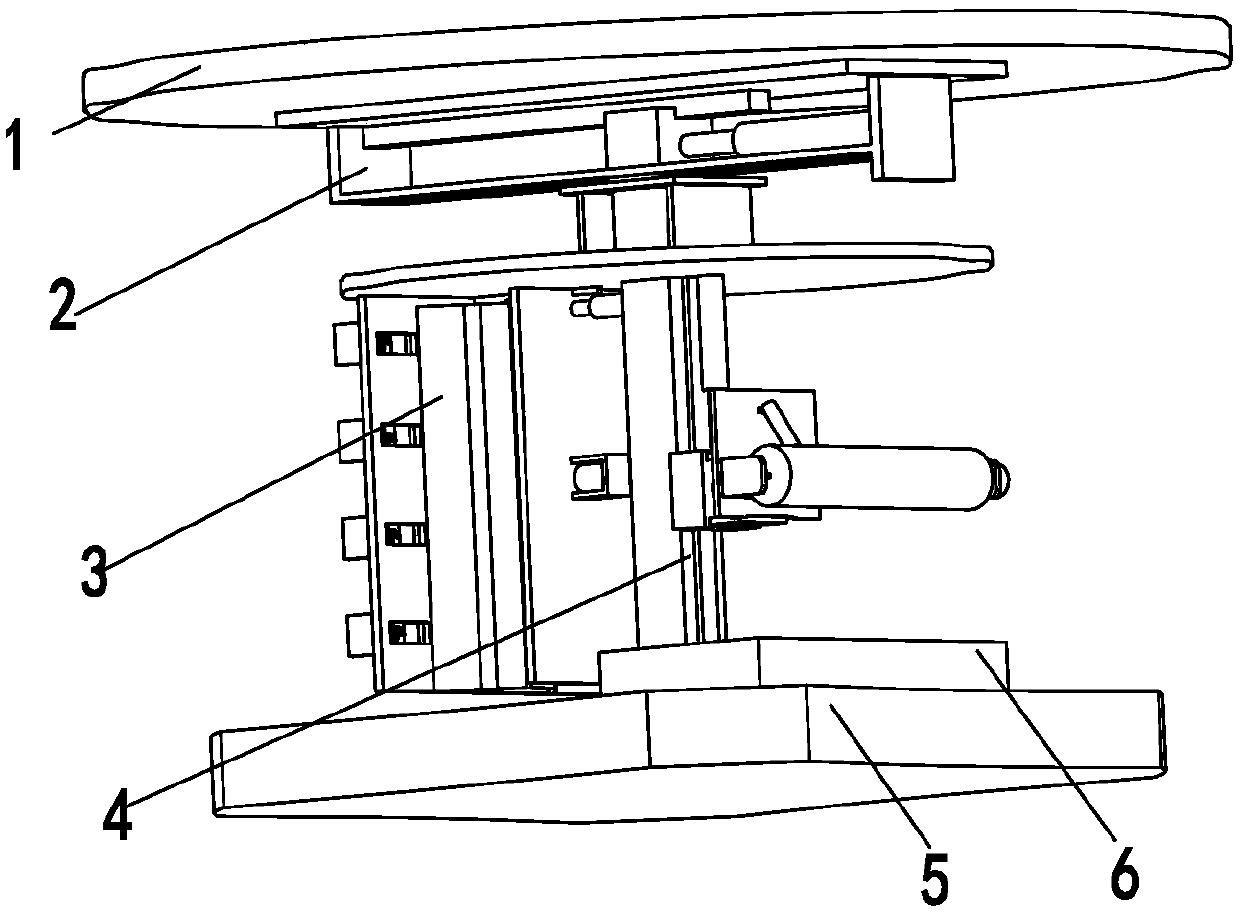

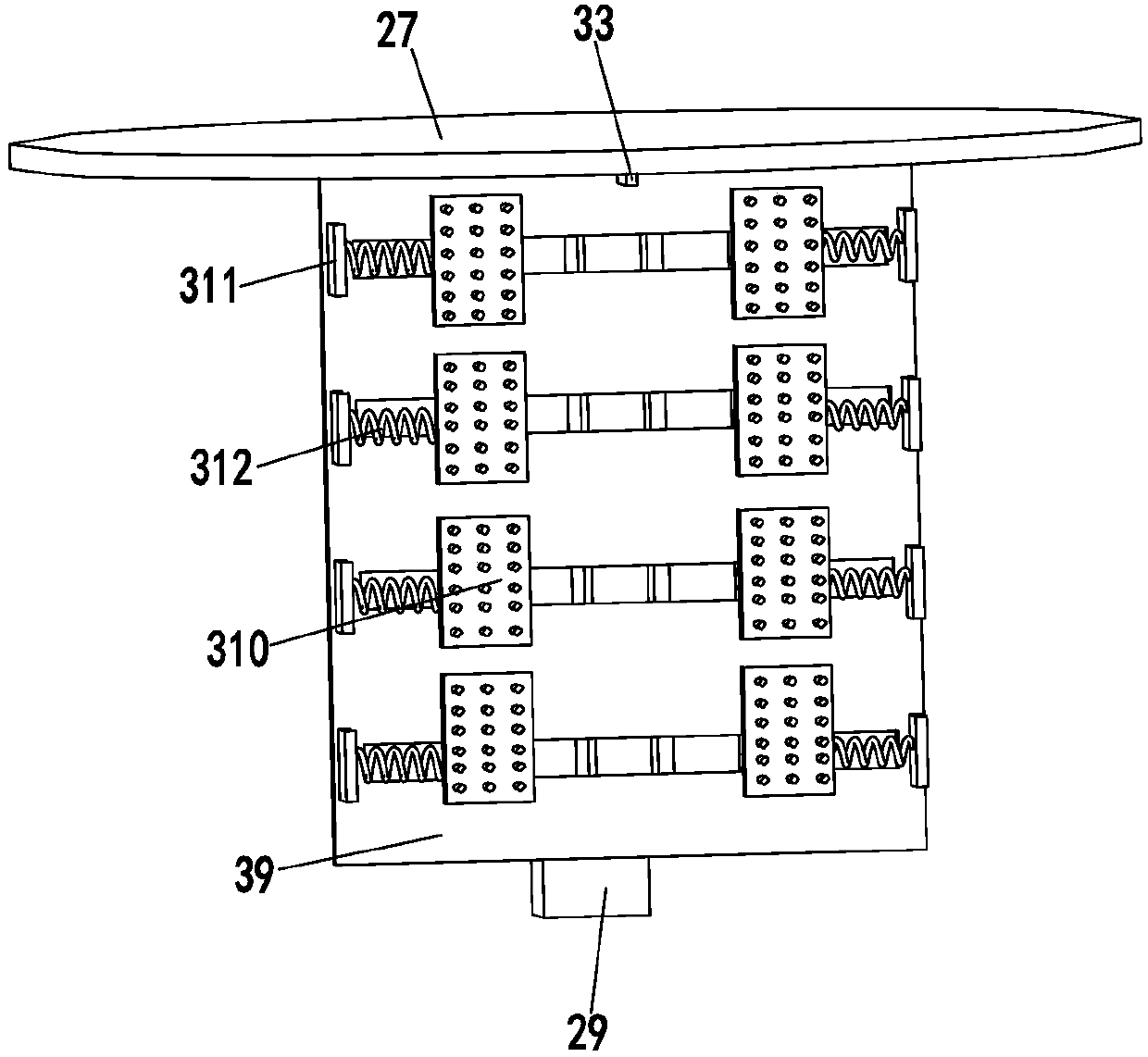

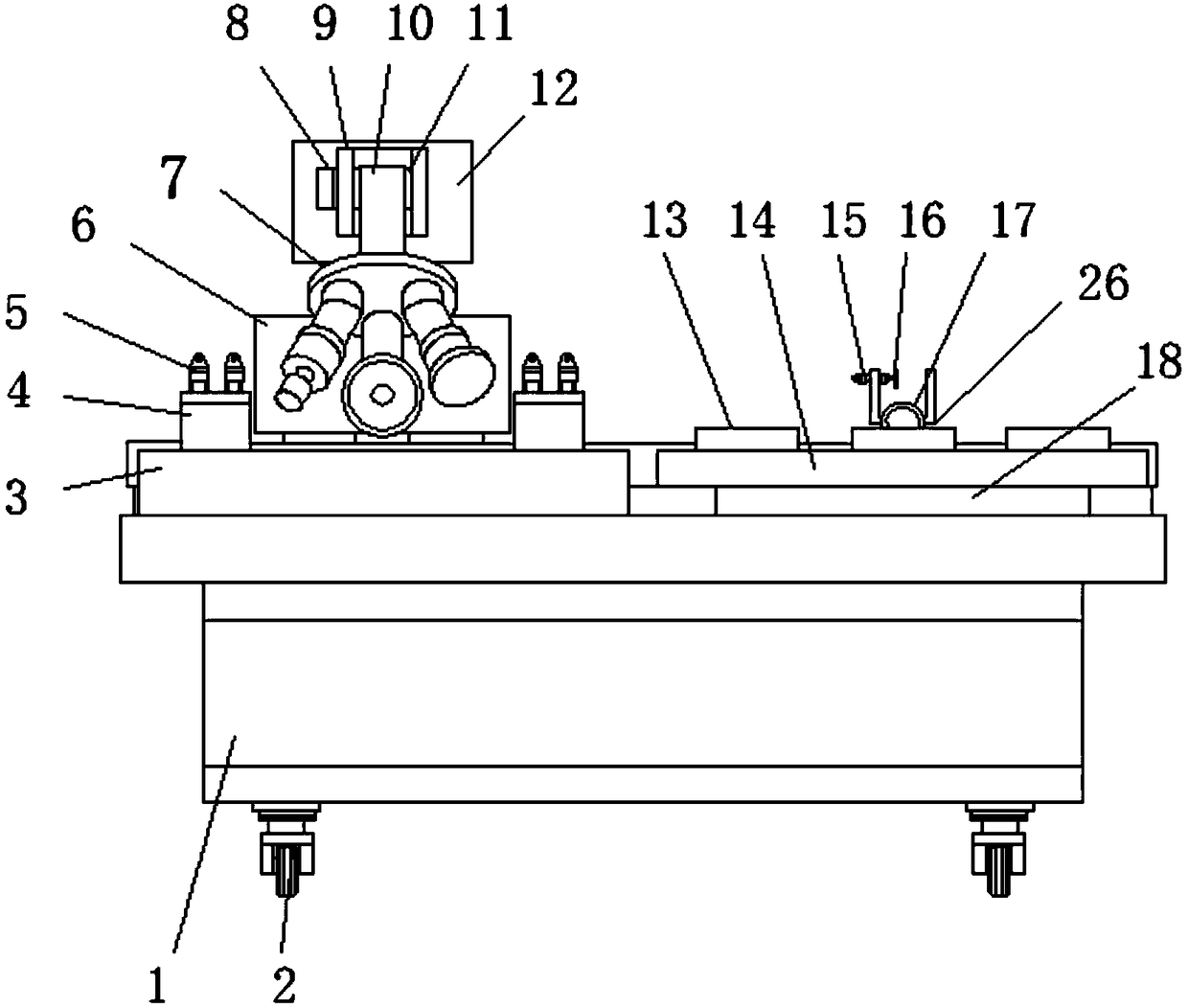

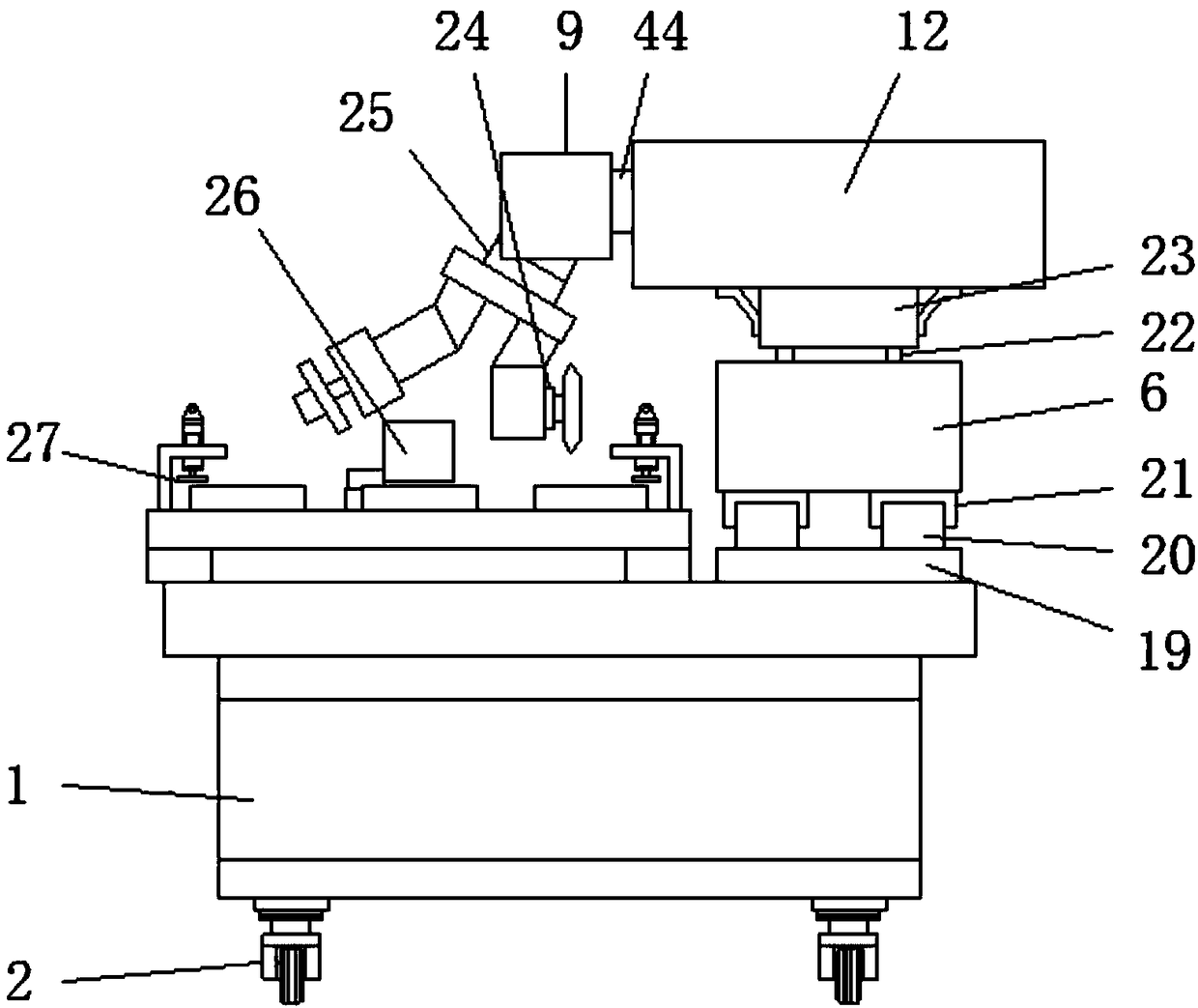

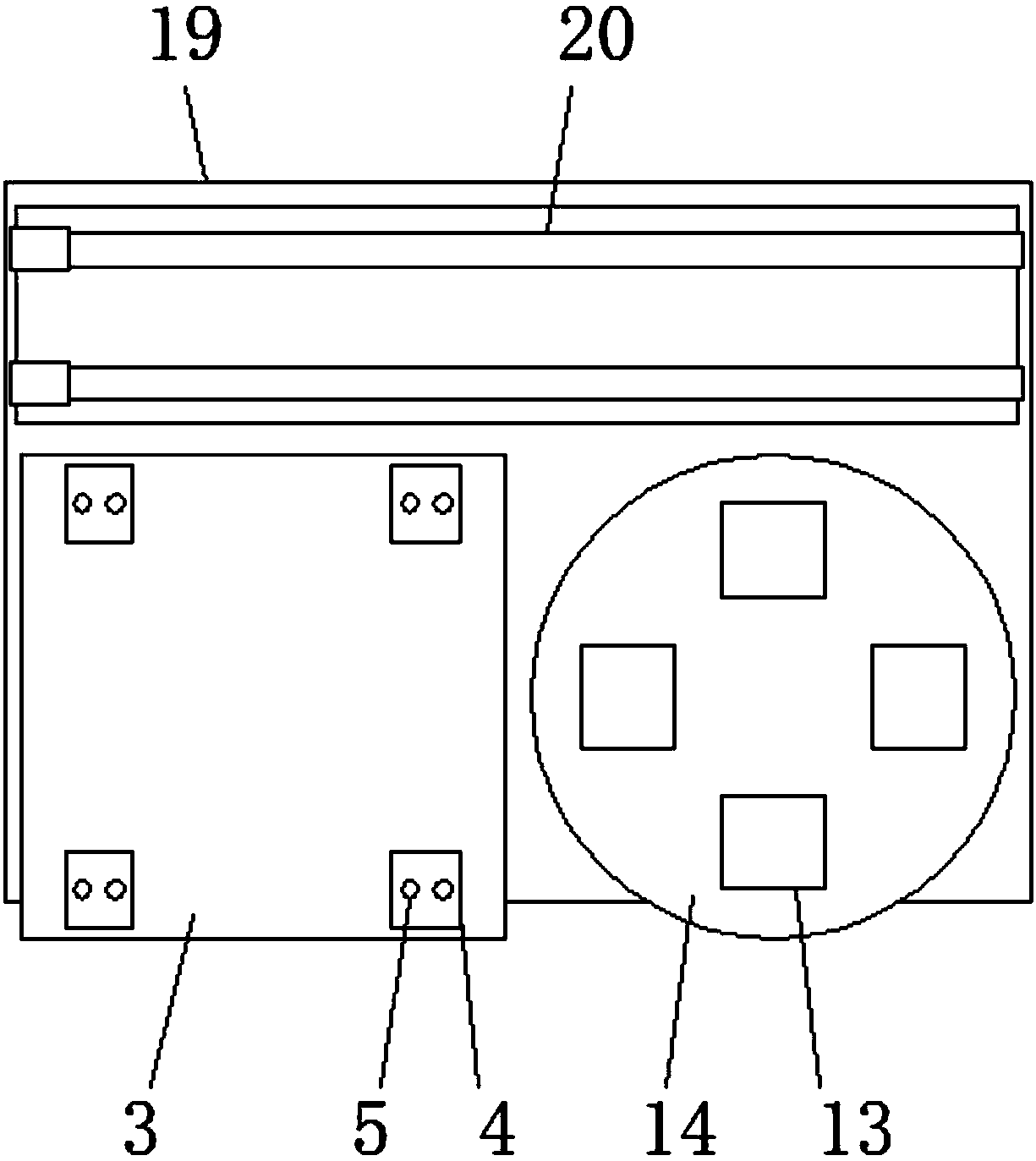

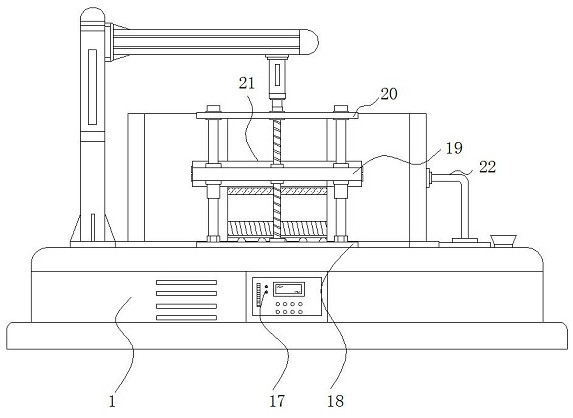

Double-sided grinding machine tool

ActiveCN113319668AImprove grinding accuracySolve the technical problem of low grinding precisionEdge grinding machinesGrinding carriagesMachine toolBrake pad

The invention relates to the technical field of brake disc double-sided grinding, in particular to a double-sided grinding machine tool, which comprises a machining table, a mounting stand column, a hydraulic mechanism, a carrying mechanism, an upper grinding mechanism, a lower grinding mechanism and a side grinding mechanism, wherein the upper grinding mechanism comprises an upper grinding piece arranged in the radial direction of a brake pad in a sliding mode; and the lower grinding mechanism comprises a lower grinding piece arranged in the radial direction of the brake pad in a sliding mode. The upper grinding piece and the lower grinding piece which are arranged on the upper end face and the lower end face of the brake pad and used for grinding can slide in the radial direction of the brake pad to be matched with rotation of the brake pad, and the upper grinding piece and the lower grinding piece move and grind on the grinding end face of the brake pad in an 8-shaped track on the brake pad, so that the grinding precision of the brake pad is improved, and the technical problem that an existing double-sided grinding machine tool is low in grinding precision of the brake pad is solved.

Owner:周吉

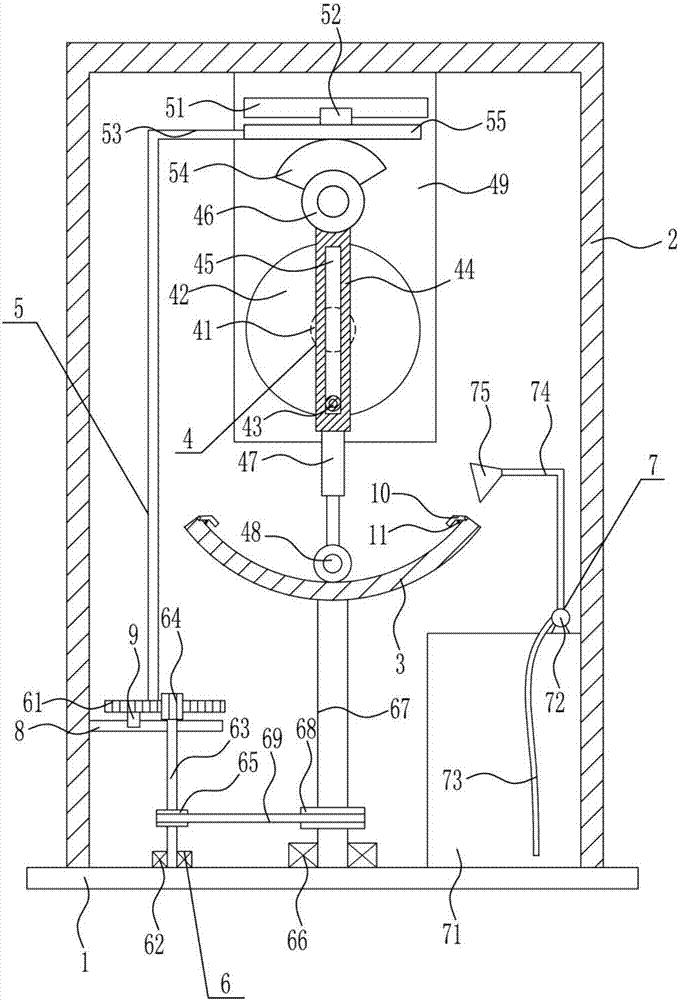

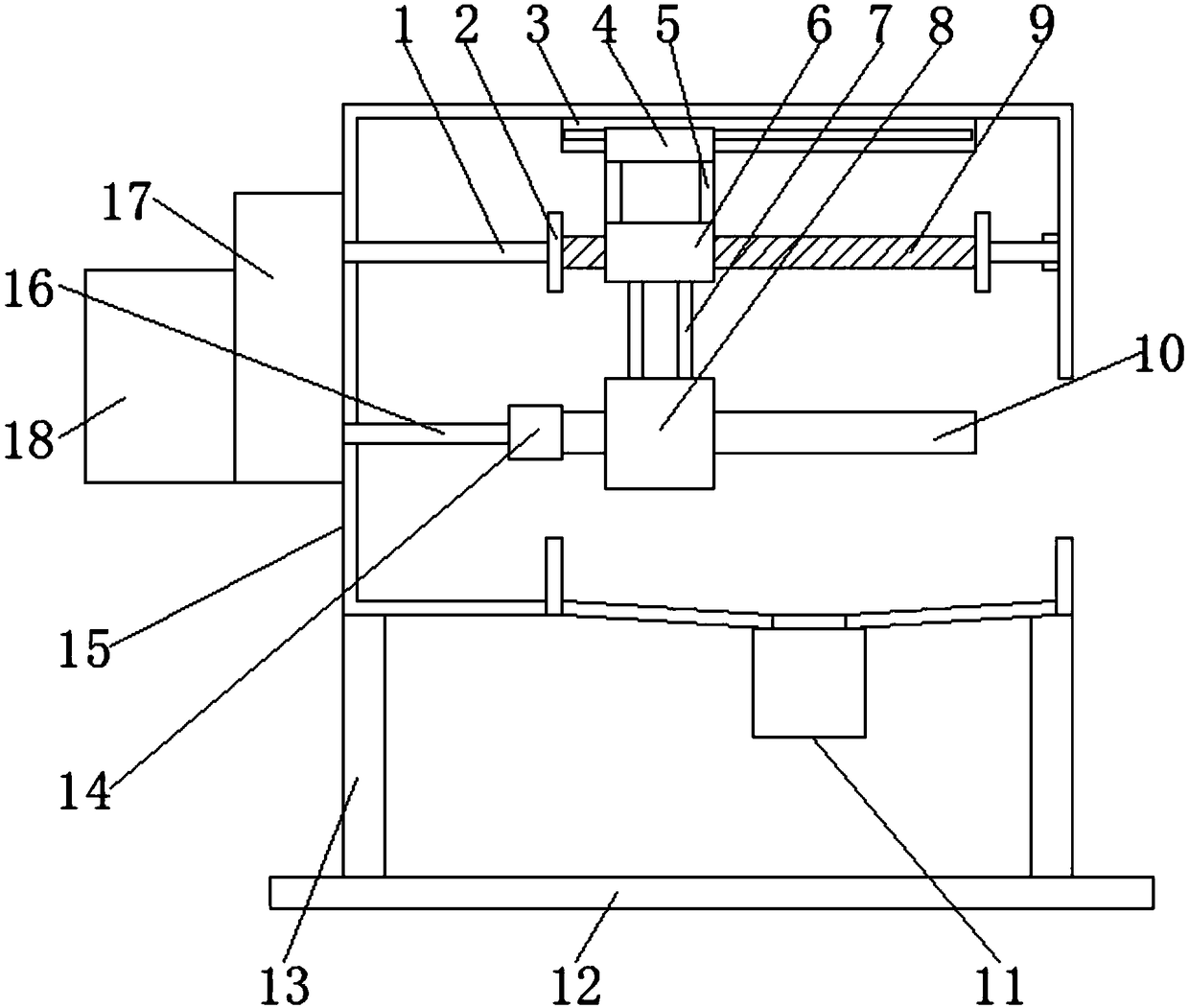

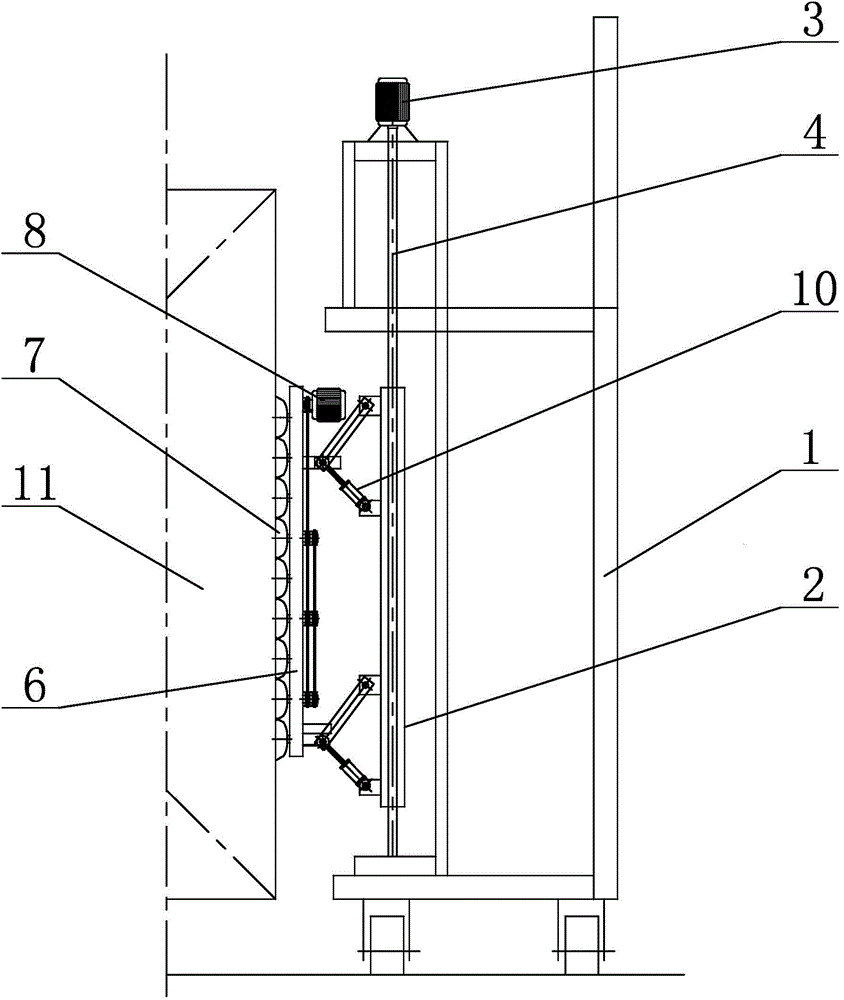

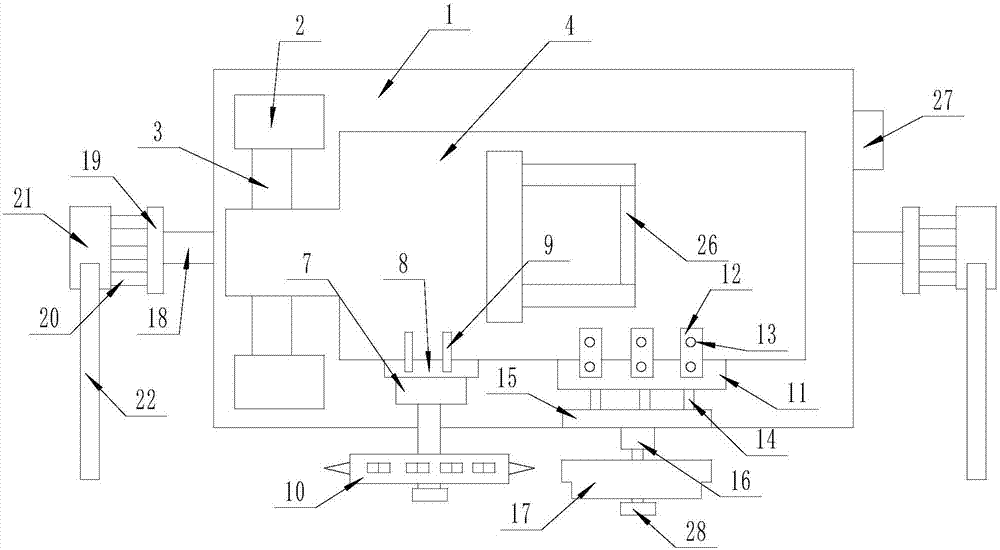

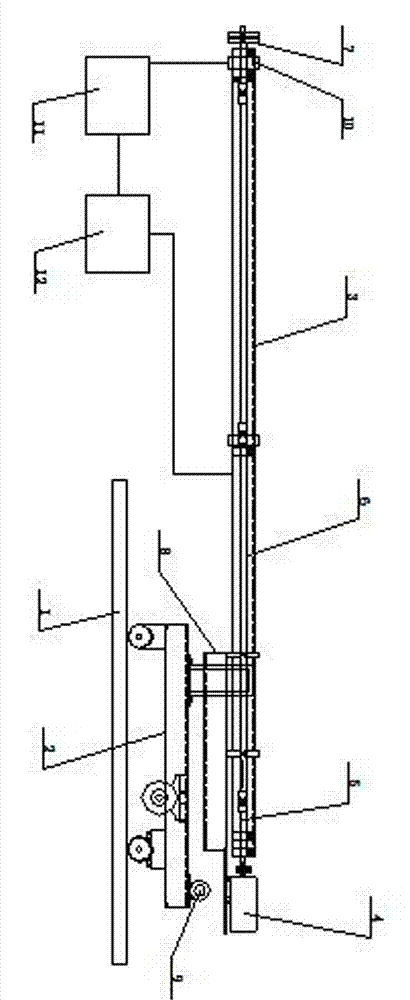

Dust collection type putty grinding device

ActiveCN104084858ARealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

Polishing machine convenient for clamping for automobile parts

PendingCN107671671AEasy to holdEasy height adjustmentGrinding machinesGrinding work supportsElectric machineryEngineering

The invention provides a polishing machine convenient for clamping for automobile parts. The polishing machine comprises a machine base, wherein a lifting table is fixedly installed on the right sideof the top of the machine base, a cross plate is fixedly connected to the top of the left side of the lifting table, a first motor is inlaid into the top of the cross plate, the output end of the first motor penetrates through the top of the cross plate and extends to the lower portion of the cross plate, and a fixing base is fixedly connected to the end, located on the lower portion of the crossplate, of the output end of the first motor. According to the polishing machine convenient for clamping for the automobile parts, a second motor, a belt, a screw, a threaded block, a limiting rod, a ball and a movable rod are arranged, so that the output end of the second motor drives the screw to clockwise rotate through the belt, the threaded block moves on the screw in a horizontally leftward manner, the ball is driven by the threaded block to move on the limiting rod in a horizontally leftward manner, and the moving rod is driven by the threaded block to move leftwards; and the automobileparts are clamped through a first clamp and a second clamp, and the convenient clamping effect is achieved.

Owner:绍兴柯桥韩玉电子科技有限公司

Cutting and edge polishing integrated equipment for color steel tiles

The invention discloses cutting and edge polishing integrated equipment for color steel tiles. The cutting and edge polishing integrated equipment for color steel tiles comprises a strip-shaped supporting base, wherein one end of the upper surface of the strip-shaped supporting base is fixedly connected with a group of fixed projections; carrying circular shafts are arranged among the group of fixed projections; a strip-shaped oscillating plate sleeves the carrying circular shafts; a cutting mechanism is arranged at one end of a side surface of the strip-shaped oscillating plate; a polishing mechanism is arranged at the other end of the side surface of the strip-shaped oscillating plate; the upper surfaces of the group of fixed projections are fixedly connected with an L-shaped fixed plate; a plurality of electronic control pushing rods are arranged between the lower surface of the L-shaped fixed plate and the upper surface of the strip-shaped oscillating plate; moving mechanisms are arranged on the front surface and the rear surface of the strip-shaped supporting base; and protecting mechanisms are arranged on a left surface and a right surface of the strip-shaped supporting base. The cutting and edge polishing integrated equipment for color steel tiles has the beneficial effects that the equipment is relatively convenient to operate and good in cutting effect, the polishing effect on a cutting end surface is good, workers can be protected, polishing depth is convenient to control, the labor intensity is reduced, and therefore, the equipment is a device suitable for cutting the color steel tiles in batches.

Owner:佛山市金泽科金属制品有限公司

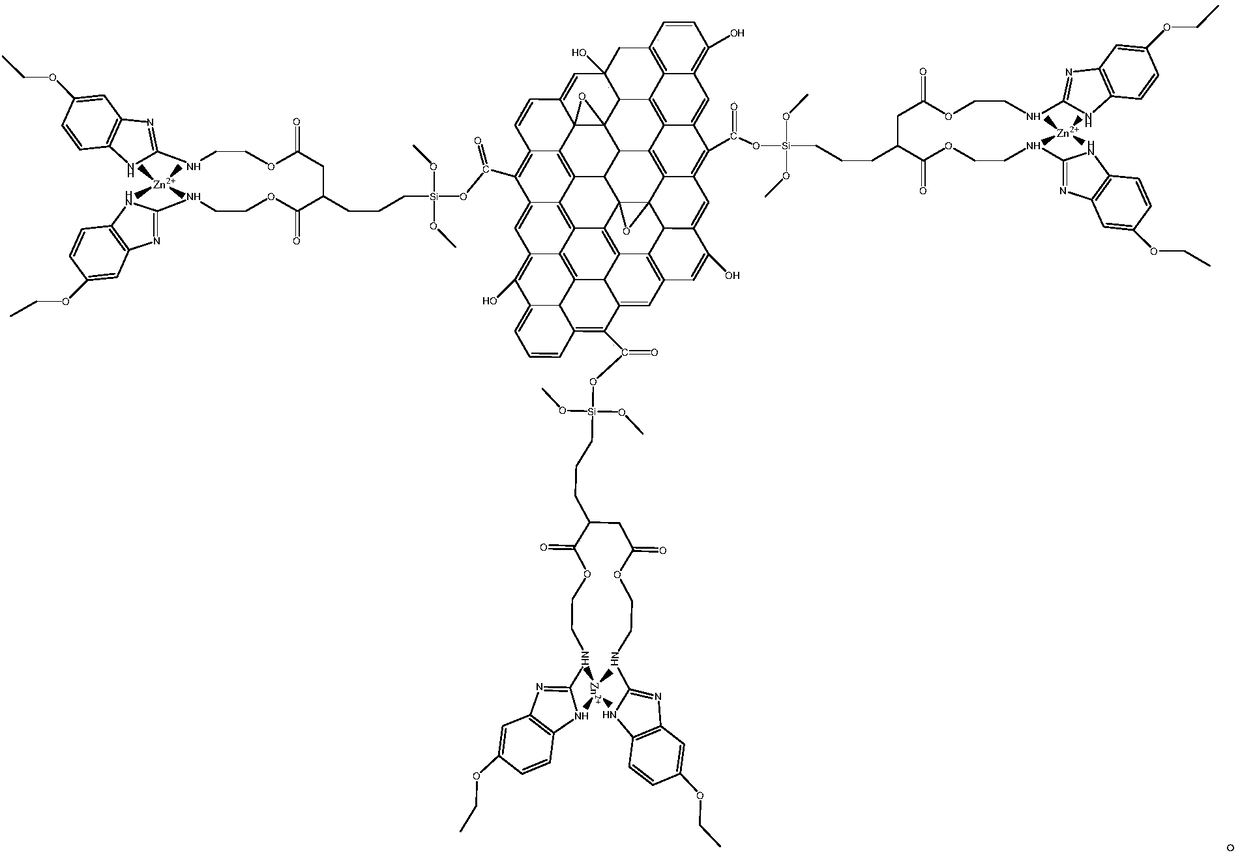

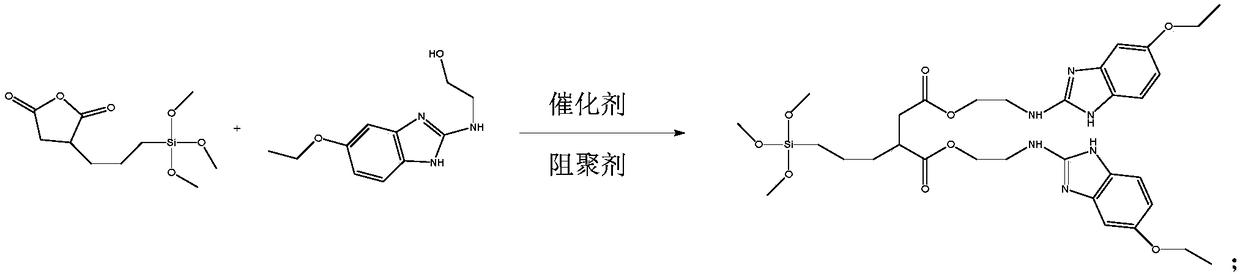

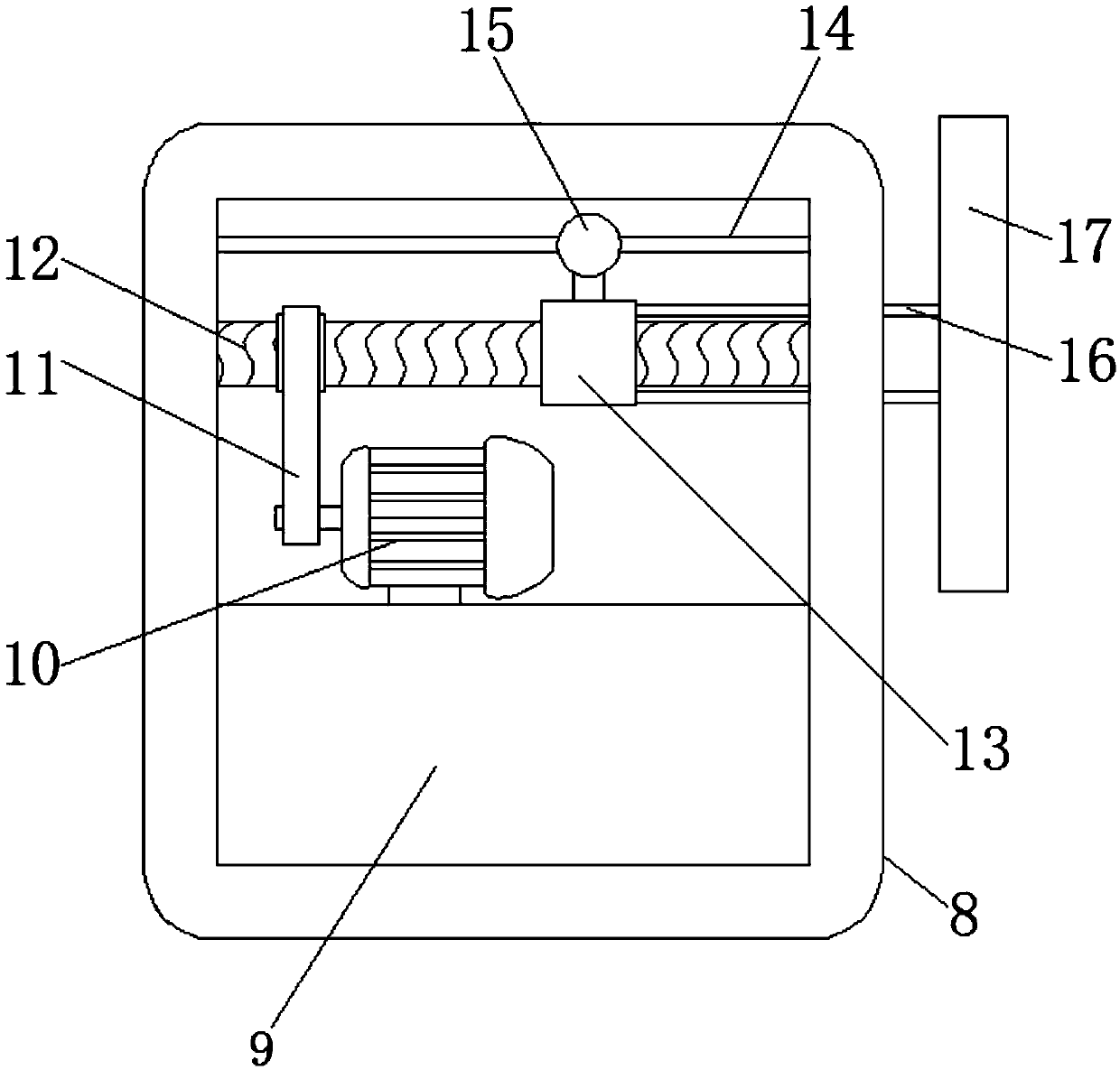

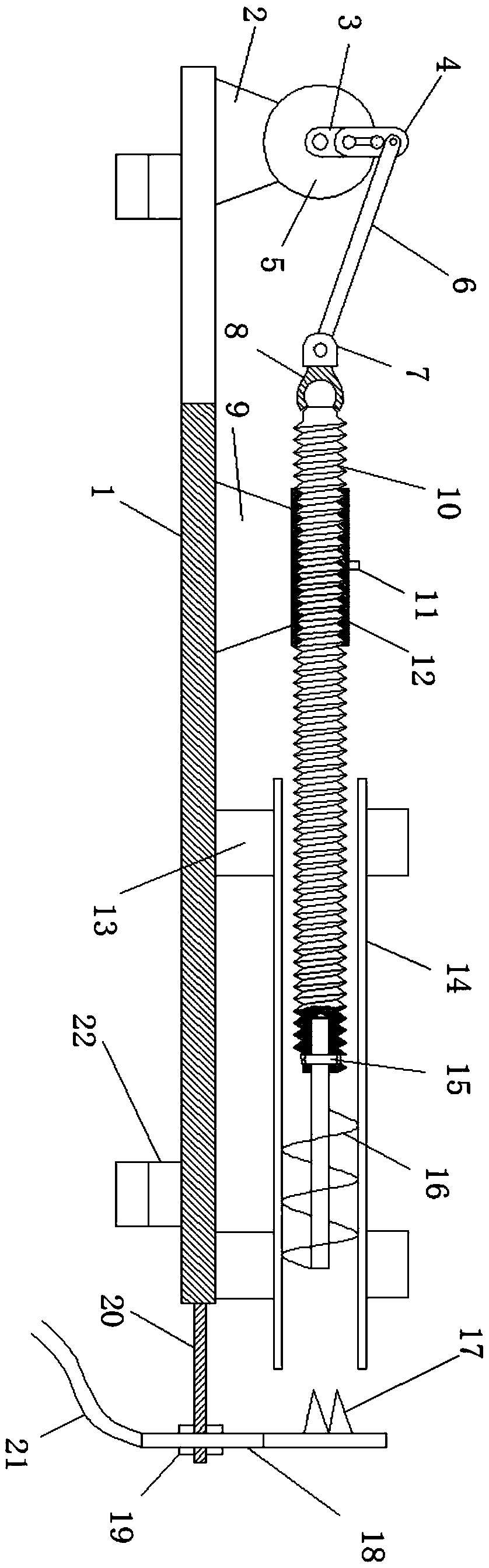

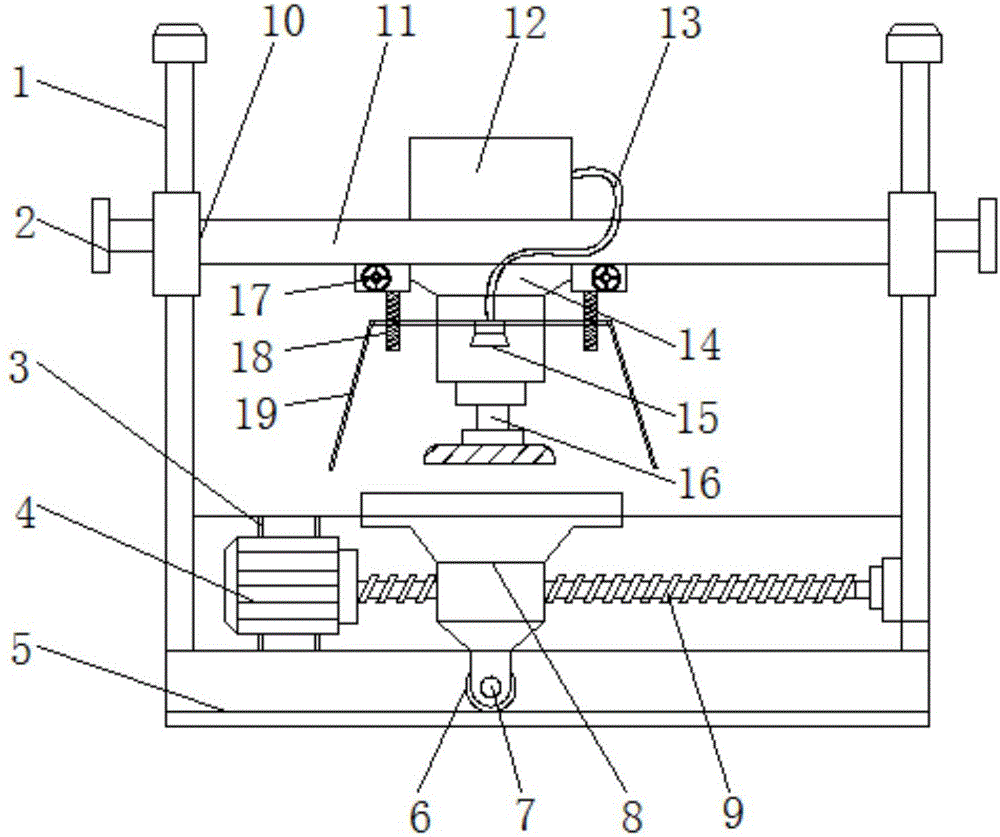

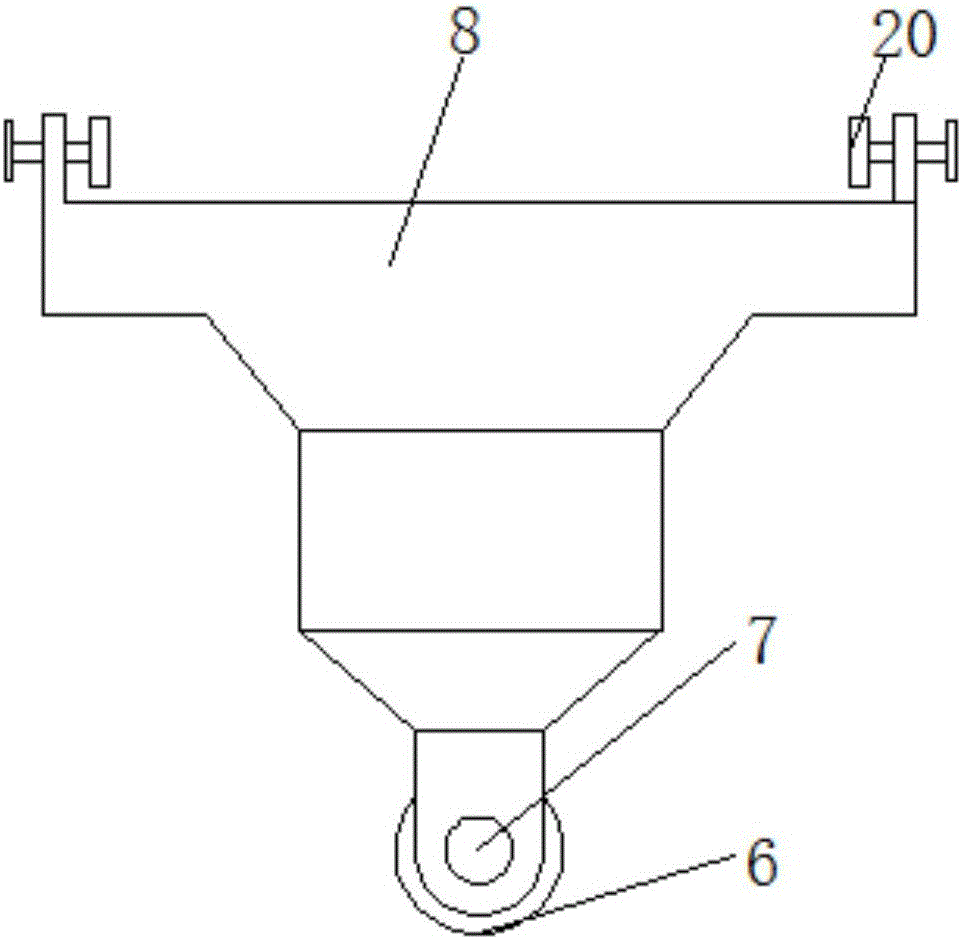

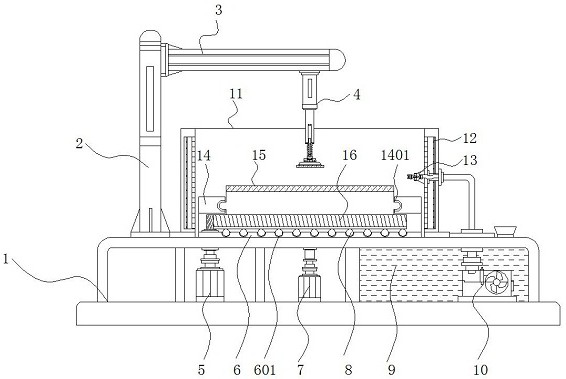

Polishing and grinding device for inner wall of glass pipeline

InactiveCN108044492AGood sandingImprove grinding effectPolishing machinesGrinding drivesWire gauzeReciprocating motion

The invention discloses a polishing and grinding device for the inner wall of a glass pipeline. The device comprises a bottom plate and a lead screw, wherein the lead screw is arranged above the bottom plate in parallel; four mounting legs are rectangularly distributed at the lower end of the bottom plate and are fixedly connected to the bottom plate; a sleeve sleeves the column surface of the lead screw; an inner thread corresponding to an outer thread of the lead screw is arranged on the inner wall of the sleeve; the sleeve is fixedly connected to the bottom plate through a sleeve support; the end, close to the sleeve, of the lead screw is fixedly connected to a joint bearing; the end, far from the lead screw, of the joint bearing is fixedly connected to a connecting block; and a connecting rod is hinged to the connecting block. The device disclosed by the invention is simpler in structure, small in power input and strong in co-movement, and is stronger in co-movement compared with that of an existing device in structure while solving the problem that the manual grinding cost is high. A grinding head also reciprocates in the glass pipeline while rotating. In addition to the action of oilstones and an asbestosed wire gauze, the grinding and polishing effect is better.

Owner:合肥挺泰环保科技有限公司

Rapid automatic grinding machine

InactiveCN107433503AEasy to moveReduce gravityGrinding machine componentsGrinding machinesReducerEngineering

The invention discloses a fast automatic grinder, which comprises a grinder main body frame. A moving motor is fixed at one end of the bottom of the grinder main body frame through a motor fixing frame, and the moving motor is connected to a screw through a reducer. A grinding table is connected, and the bottom of the grinding table is rotatably connected to the rotating wheel through the rotating shaft, and the rotating wheel is embedded in the chute at the bottom of the main frame of the grinding machine, and the top of the main frame of the grinding machine is welded with a cross bar through a sleeve. In the present invention, firstly, the rotating wheel is connected to the bottom of the grinding table. When the screw acts on the grinding table to move the grinding table, the rotating wheel at the bottom of the grinding table can carry out auxiliary movement, thereby making the grinding table move more smoothly and reducing shaking , so that the grinding effect is better, and at the same time reduce the gravity of the screw, so as to protect the mobile motor and prolong the service life of the fast automatic grinding machine.

Owner:成都尚智恒达科技有限公司

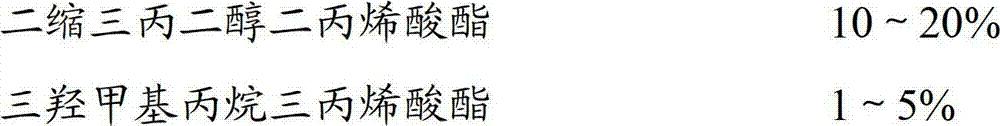

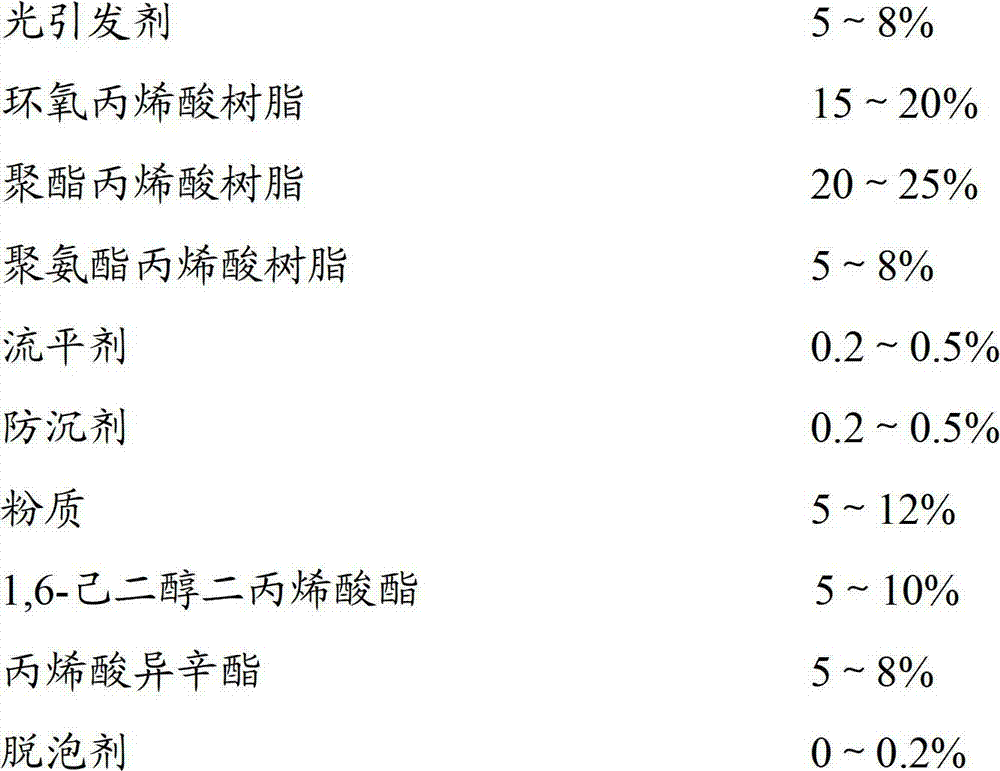

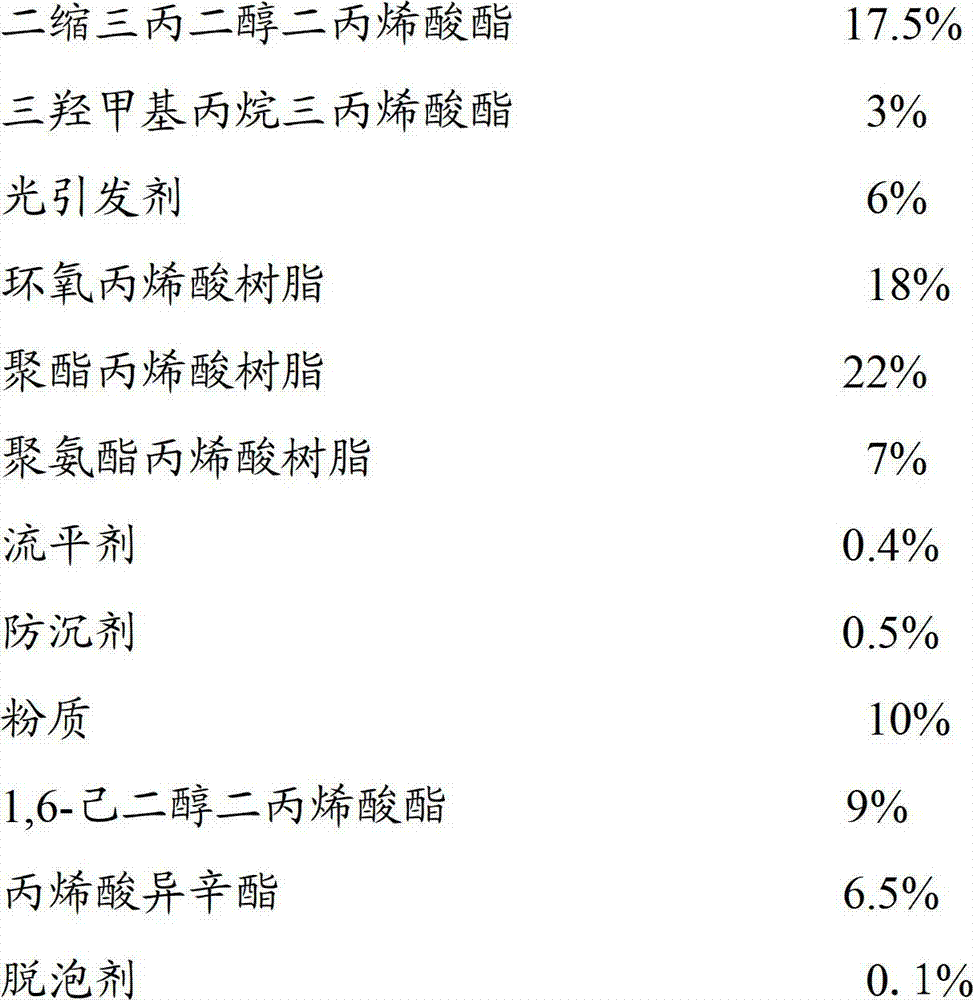

Environment-friendly light-curing electrostatic spraying primer

InactiveCN102732137ALow viscosityIncrease moisturePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

The invention provides an environment-friendly light-curing electrostatic spraying primer, comprising the following components in percentage by weight: 10-20% of 2-Propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]] ester, 1-5% of trimethylolpropane triacrylate, 5-8% of a photo-initiator, 15-20% of epoxy acrylate, 20-25% of polyester acrylic resin, 5-8% of polyurethane acrylic resin, 0.2-0.5% of a flatting agent, 0.2-0.5% of an anti-settling agent, 5-12% of flour, 5-10% of 1,6-hexanediol diacrylate, 5-8% of 2-ethylhexyl acrylate and 0-0.2% of a defoaming agent. The light-curing electrostatic spraying primer adopts a UV monomer with low viscosity and strong dilution capacity to replace an original solvent, contains no VOC (Volatile Organic Compounds), can be recycled and belongs to green and environment-friendly paints; UV resin with low viscosity and good wettability is used as main resin so that the content of solid paint is high; and the light-curing electrostatic spraying primer can be directly applied to electrostatic spraying without being diluted by the organic solvent and has the advantages of good atomization effect, good package to devices, excellent adherence and good rubbing property.

Owner:东莞大宝化工制品有限公司 +1

Cutting and grinding device for GRC plate machining

InactiveCN112339132APrecise Control DepthPrecise position controlWorking accessoriesStone-like material working toolsMechanical engineeringIndustrial engineering

The invention discloses a cutting and grinding device for GRC plate machining, and belongs to the technical field of GRC plate machining. The cutting and grinding device comprises a conveying table, asliding assembly, a moving assembly, a fixing assembly, an overturning assembly and a cutting assembly, wherein the sliding assembly is arranged beside the conveying table, the working end of the sliding assembly is arranged above the conveying table, the moving assembly is arranged on the sliding assembly, the fixing assembly is arranged on the conveying table, the overturning assembly is arranged between the conveying table and the sliding assembly, the cutting assembly is arranged beside one end of the conveying table, and the working end of the cutting assembly is arranged above the conveying table. Through cooperation of all the assemblies, all the faces of a GRC plate can be ground, the cutting depth and position can be accurately controlled during cutting, the machining efficiencyis higher, and the effect is better.

Owner:安徽地豪科技环保材料有限公司

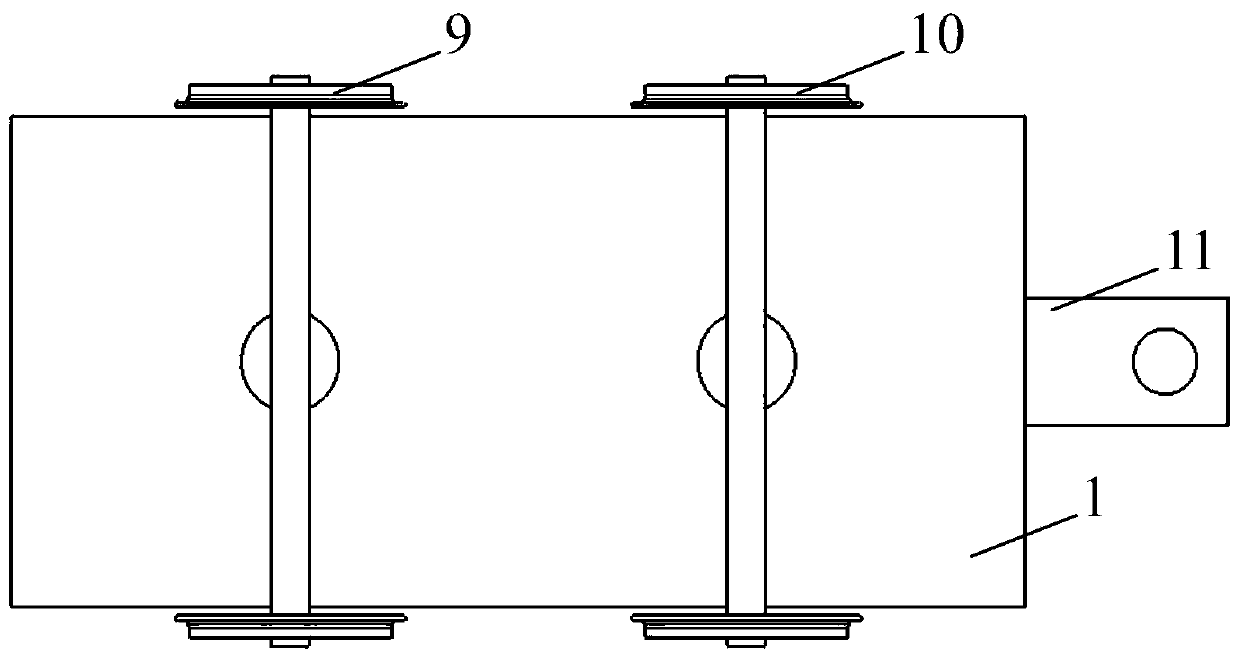

Steel tube inner wall grinding device with water spraying dust removal function

InactiveCN102765021AWill not polluteGood sandingRevolution surface grinding machinesGrinding/polishing safety devicesWater savingSprayer

The invention discloses a steel tube inner wall grinding device with a water spraying dust removal function, and relates to the field of steel tube inner wall grinding devices used after cold drawing of precision seamless steel tubes. A water sprayer is mounted behind a polishing head, one end of the water sprayer is connected with one end of a circulating water pump by a water pipe, the other end of the circulating water pump is connected with one end of a water tank by a water pipe, and the other end of the water tank is connected to the other end of the water sprayer by a water pipe. The water sprayer is mounted behind the polishing head, so that water is sprayed during polishing, dust generated by polishing is removed, environmental pollution is avoided, a better polishing effect is achieved, impurities such as oxide-scales on the inner wall of a steel tube is flushed away with water so as to keep the inner wall clean, and water can be recycled for the water sprayer by the aid of the water pump, and accordingly is saved.

Owner:中材科技(南通)有限公司

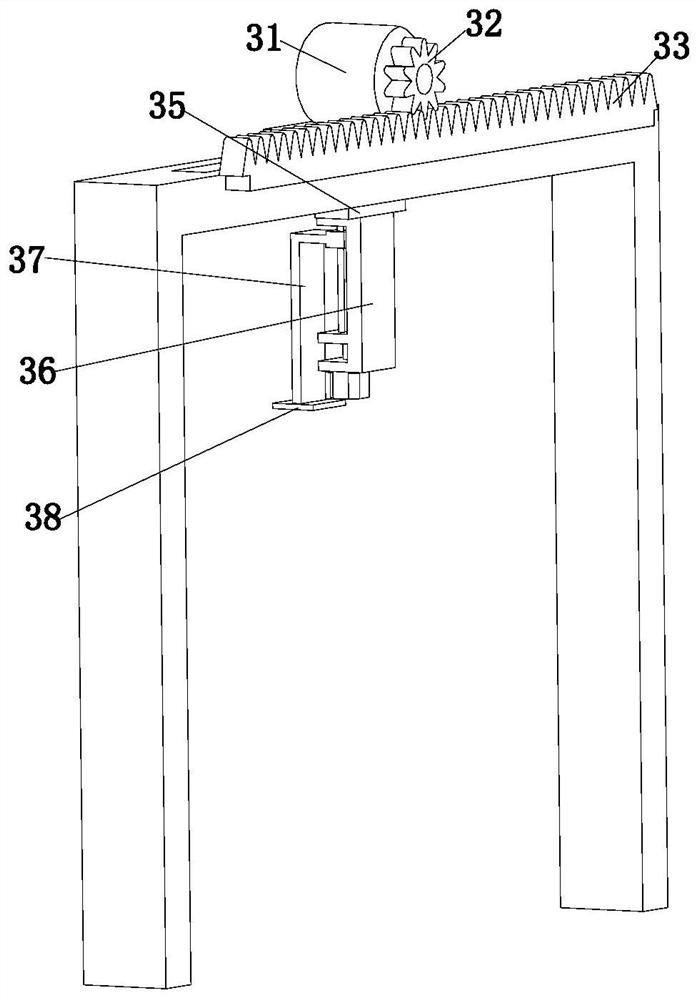

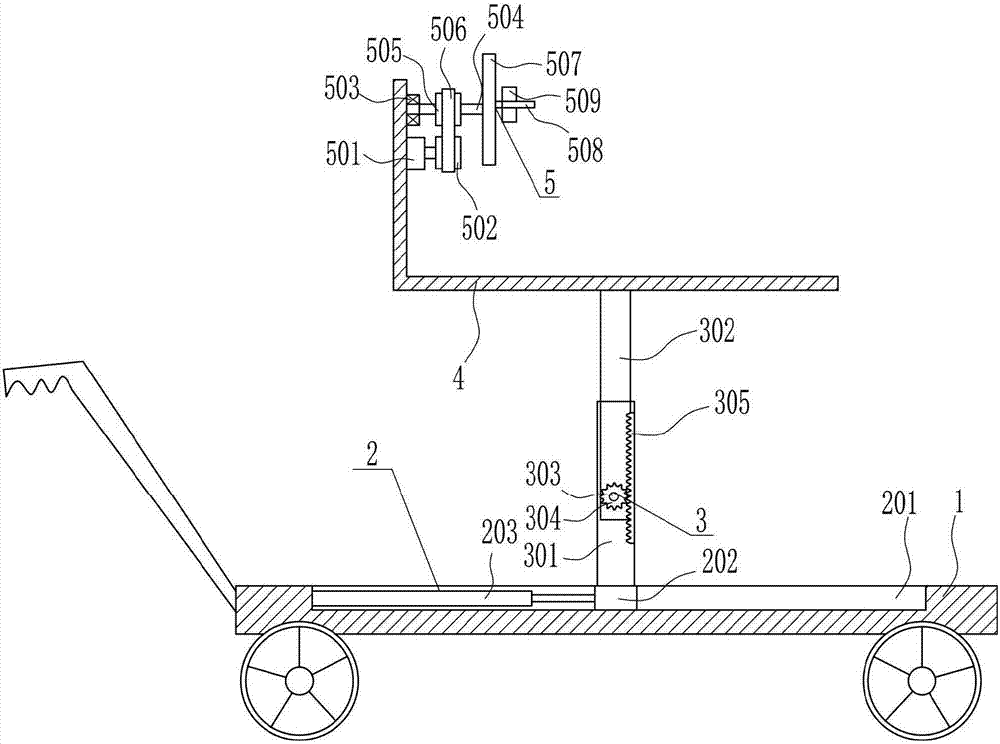

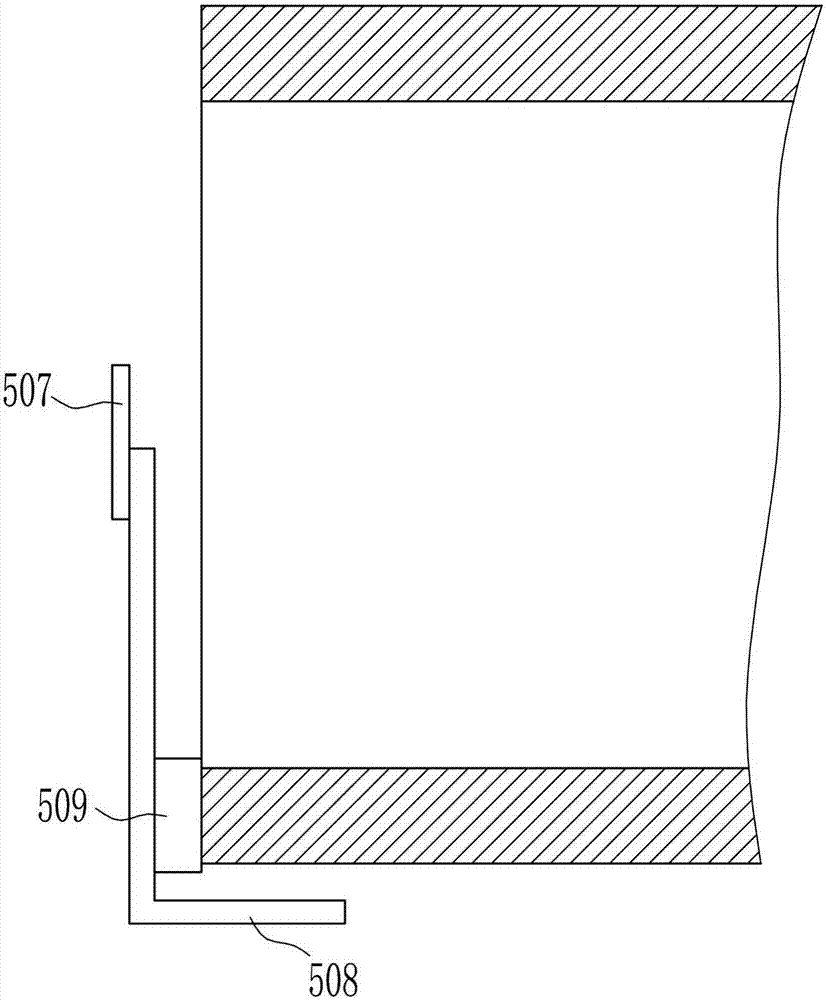

Edge polishing device for wind power generation blade

PendingCN107225460APrevent movementHigh strengthEdge grinding machinesGrinding carriagesEngineeringWind force

The invention relates to a wind power generation blade edge polishing device, in particular to an edge polishing device for a wind power generation blade. According to the edge polishing device for the wind power generation blade, time and labor are saved, the polishing speed is high, the polishing effect is good, and a height adjusting function is achieved. The edge polishing device for the wind power generation blade comprises a cart and the like. The cart is provided with a left-right moving device. A height adjusting device is arranged at the top of the left-right moving device. An L-shaped connecting plate is welded to the top of the height adjusting device. A polishing unit is arranged on the upper portion of the right side face of the L-shaped connecting plate. According to the edge polishing device for the wind power generation blade, the distance between the polishing unit and the wind power generation blade is adjusted through the height adjusting device, and the wind power generation blade is polished through the polishing unit.

Owner:来安县华鹏摩擦材料厂

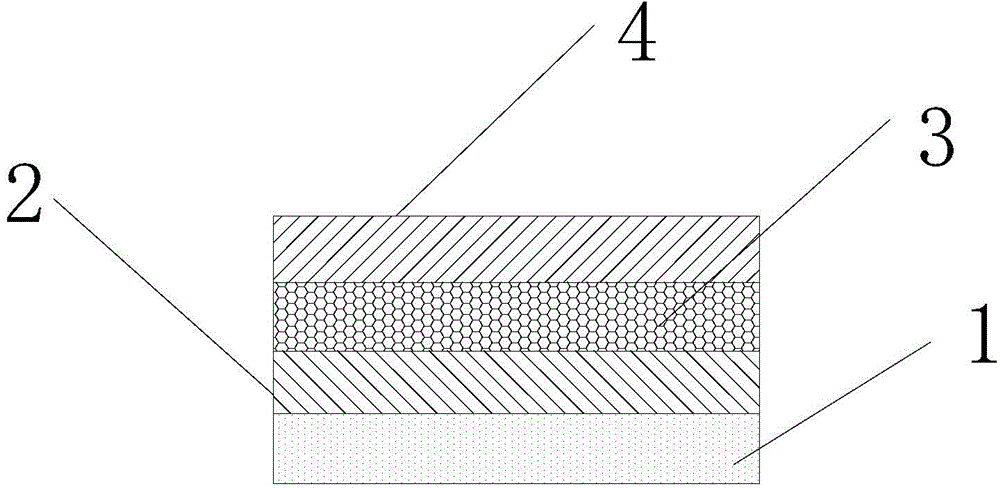

Abrasive paper

The invention relates to abrasive paper. An abrasive material layer is adhered to a base material layer through an adhesive and is coated with a coating. The abrasive paper has the advantages of simple structure, convenience in use, excellent polishing performance, long service life and less dust. The production cost is reduced, the labor conditions are good, and the working efficiency is improved.

Owner:孙金福

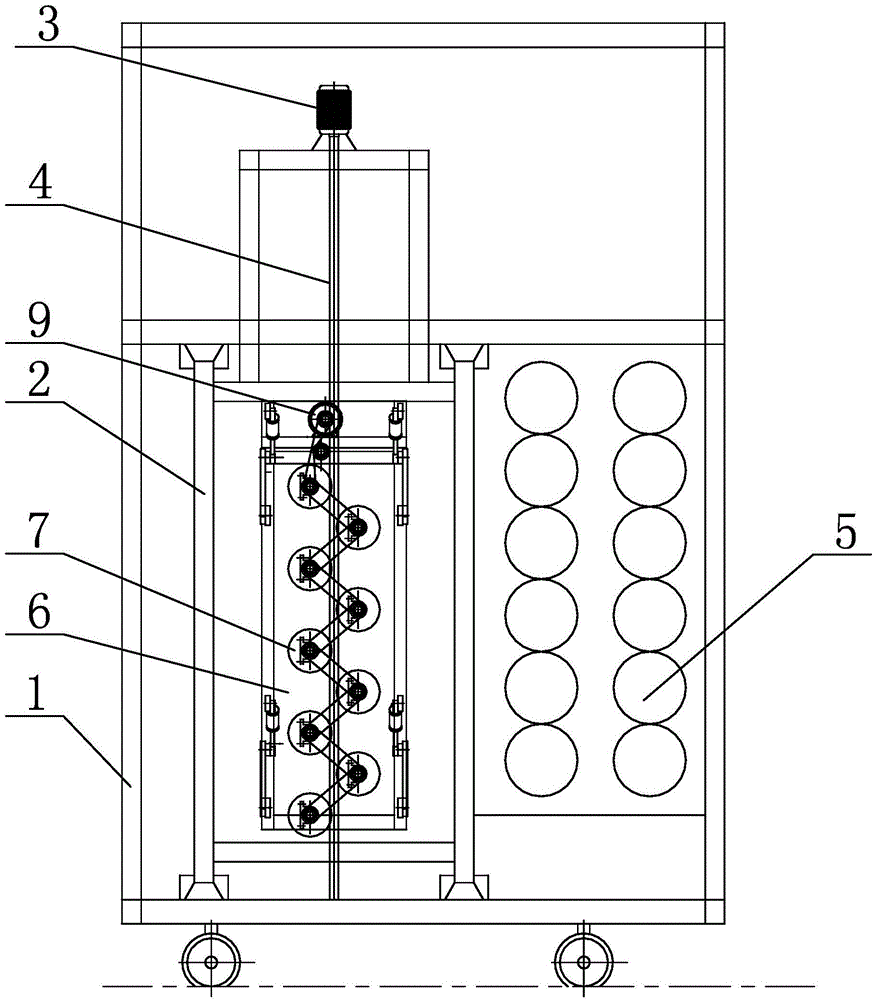

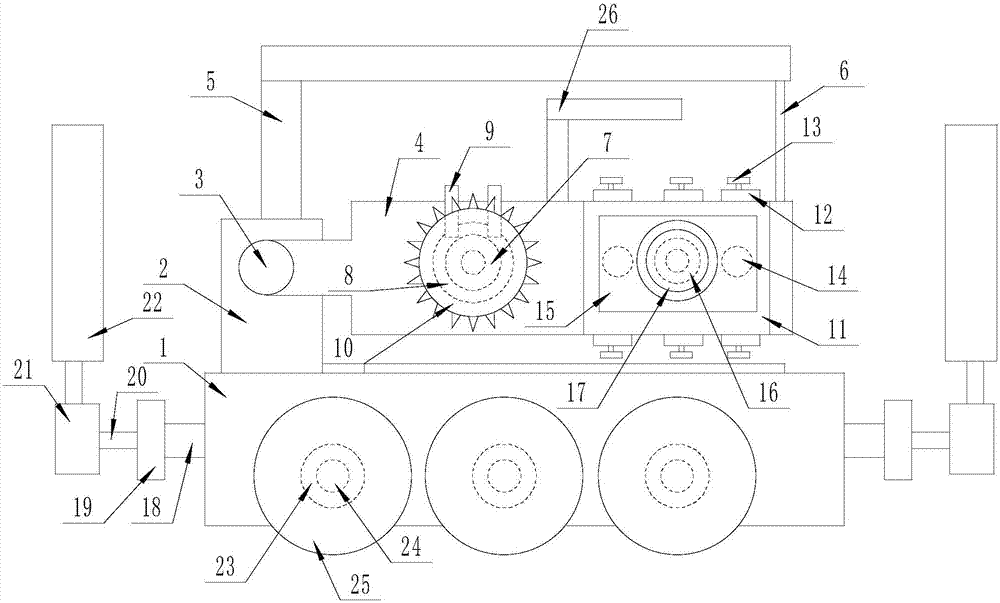

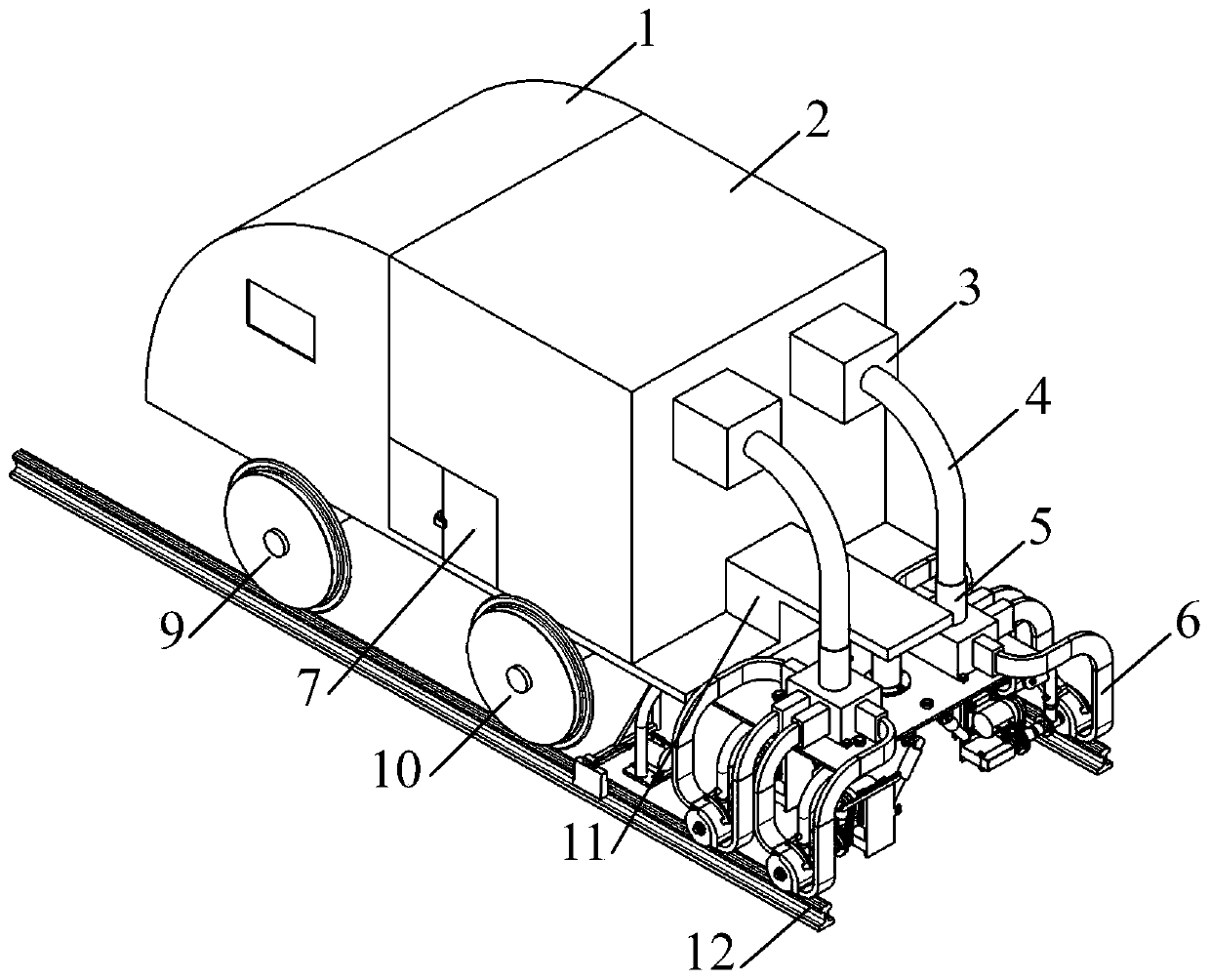

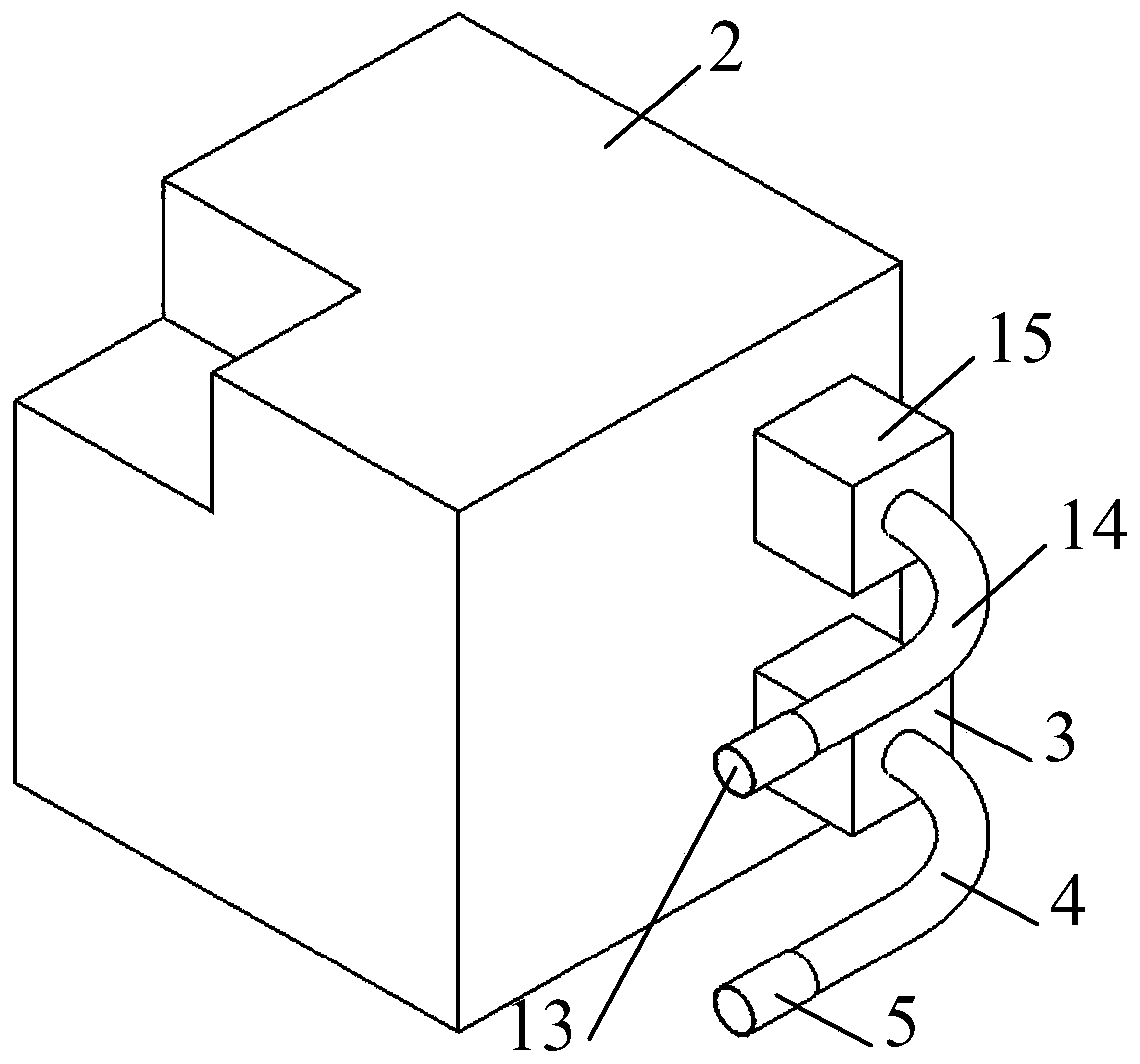

Multifunctional rail grinding wagon

PendingCN109914167AHigh recovery rateReduce pollutionRailway track constructionCar drivingEngineering

The invention belongs to the technical field of rail grinding, in particular to a multifunctional rail grinding wagon. The multifunctional rail grinding wagon comprises a motor car, an iron filing recovery device and a multifunctional grinding trolly; a first wheel set and a second wheel set are arranged below the motor car; the iron filing recovery device and the multifunctional grinding trolly are both connected to the motor car; the motor car drives the iron filing recovery device and the multifunctional grinding trolly to move; the multifunctional grinding trolly is used for grinding rails; the iron filing recovery device is used for recovering iron filings generated during the grinding process. The multifunctional rail grinding wagon provided by the invention has the advantages of high automation degree, high grinding efficiency, good grinding effect, low grinding cost, environmental protection, wide application range and the like.

Owner:LANZHOU JIAOTONG UNIV

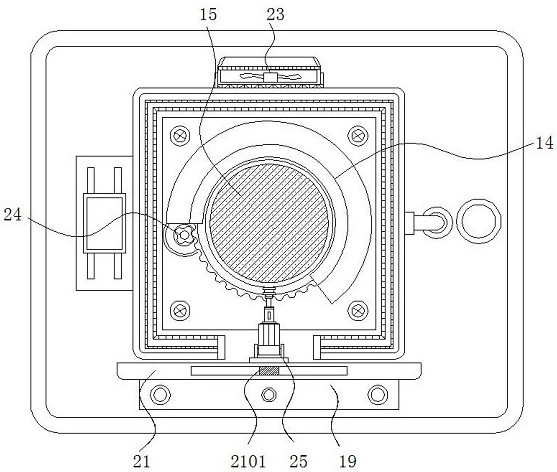

Shell grinding equipment with dustproof structure for motor production

InactiveCN111805330AReduce occlusionAdjustable grinding angleEdge grinding machinesGrinding drivesGear wheelElectric machinery

The invention discloses shell grinding equipment with a dustproof structure for motor production. The shell grinding equipment includes a base, a dustproof cover, a turntable and a movable plate. A control panel is installed at the middle position of one end of the base, a water tank is formed in one side of the inner part of the base, a water pump is fixed inside the water tank, a water pipe is installed at the output end of the water pump, a bottom plate is installed at the middle position of the top of the base, a fluted disc is fixed to the top end of the bottom plate, and the turntable isinstalled at the top of the fluted disc. A rotating seat is installed at the top end, outside of the fluted disc, of the bottom plate, a transmission gear is installed at the end, away from the waterpump, of the top of the bottom plate, and a driving motor is installed in the base under the transmission gear. According to the shell grinding equipment with the dustproof structure for motor production, by arranging a pressure plate, pressing can be carried out under the action of a hydraulic lifting rod to compact a motor shell, and compared with a traditional clamping fixture, an upper-lowerclamping and fixing method can reduce the shielding on the outer wall of the motor shell.

Owner:东莞市奇趣机器人科技有限公司

Polishing device for wind power generation blade

InactiveCN107520717AHigh strengthEasy to useGrinding machinesGrinding/polishing safety devicesEngineeringWind power generation

The invention relates to polishing devices, in particular to a polishing device for a wind power generation blade. The polishing device for the wind power generation blade is easy to operate, convenient to use and good in polishing effect and comprises a bottom plate, supporting rods, a transverse plate, an air cylinder, a 7-shaped plate, a U-shaped storage plate and the like. The supporting rods are welded to the top of the bottom plate. The transverse plate is welded to the tops of the supporting rods. A rotating device is mounted on the top of the transverse plate. A rotating part on the rotating device is connected with the U-shaped storage plate. The right side of the top of the bottom plate is connected with the air cylinder through a bolt. A telescopic rod of the air cylinder is connected with the 7-shaped plate. The generation blade is polished through a polishing part on a horizontal moving device, chips are swept through a sweeping device, and accordingly the effects of good polishing effect, easy operation and convenient use are achieved.

Owner:王臻

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com