Automobile water-based two-component epoxy primer with excellent performance and preparation method thereof

A water-based two-component, epoxy primer technology, used in epoxy resin coatings, coatings, etc., can solve the problems of reducing construction solid content, adding more, and reducing filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

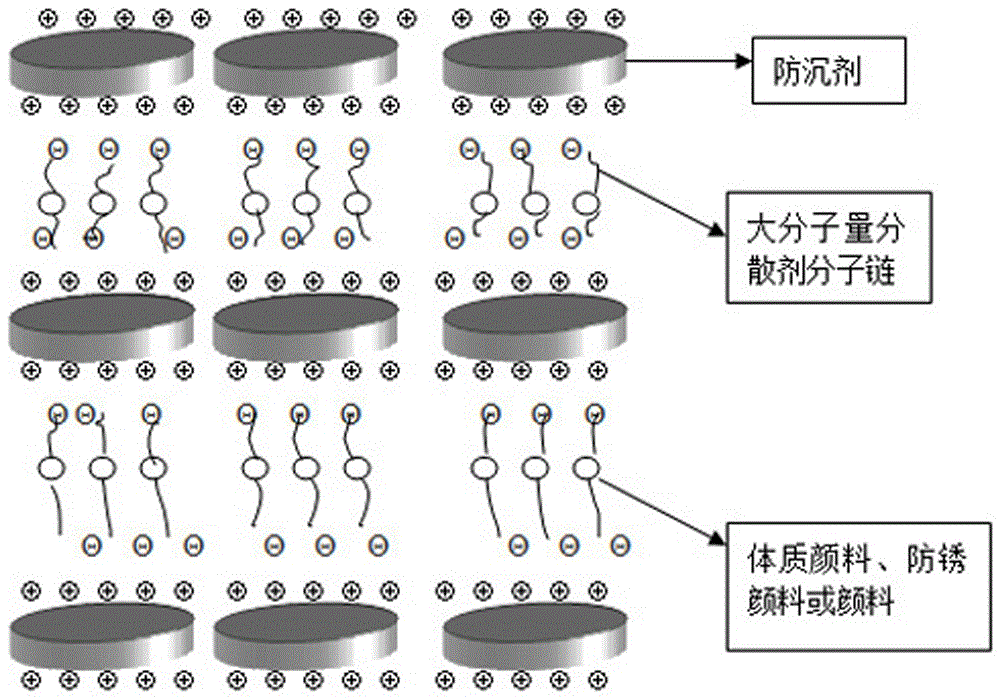

Method used

Image

Examples

Embodiment 1

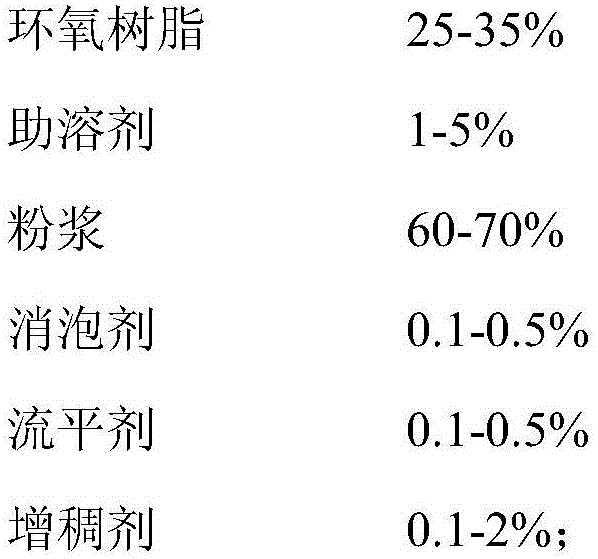

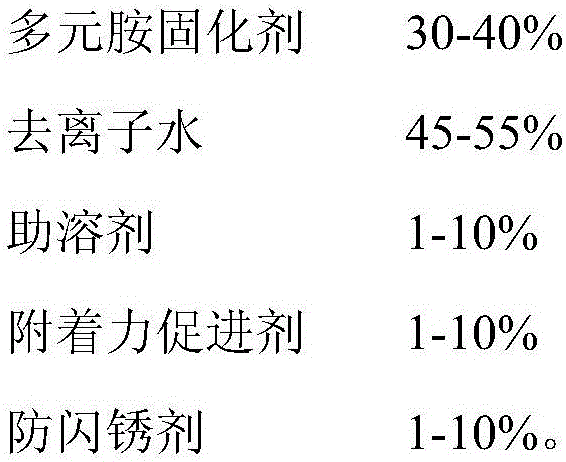

[0049] 1. Preparation of waterborne two-component epoxy primer component A

[0050]The formula of component A of the water-based two-component epoxy primer is shown in Table 1. The preparation process is as follows: ①Put deionized water into the stirring tank, then add BYK-190, FX600, TEGO-500 and TEGO-901w, after it is uniformly dispersed, continue to add DE and different types of extender pigments. After the extender pigments are fully dispersed, finally add aluminum tripolyphosphate, zinc iron phosphate, R-706 and Raven-3500, at 8-9m Stir at a linear speed of / s for 15 minutes; ②Pour the stirred slurry into a sand mill, grind for 45min-1h, and wait until the fineness is less than 30μm to obtain component A slurry; ③Put EP 386w, polyethylene glycol , n-hexanol mixed evenly, slowly add the ground slurry, after mixing evenly, add BYK-022, TEGO-240 and FX1070, stir evenly, stand and filter, and then get the component A of the water-based two-component epoxy primer .

[0051] ...

Embodiment 2

[0065] Table 3 is the feeding formula for preparing the water-based epoxy primer by changing the type of dispersant in Example 2 while keeping other materials unchanged, and the formula numbers are 5, 6, 7 and 8 in turn. 4 kinds of epoxy primers that are numbered as 5~8 shown in table 3 are prepared by the technical process of embodiment 1 to prepare water-based two-component epoxy primer, and prepare paint film according to the technical process of embodiment 1 to prepare epoxy primer film .

[0066] The properties of the waterborne two-component epoxy primers prepared by formula 5, formula 6, formula 7 and formula 8 are shown in table 4. It can be seen from the table that when the dispersant combination of (BYK-190+FX600) or (BYK-194N+OROTAN+BYK-151) is used in the formula, the water-based two-component epoxy primer has excellent storage stability, Grinding, filling, hiding power, adhesion, flexibility, water resistance and chemical resistance; when the dispersant combinati...

Embodiment 3

[0074] Table 5 is the feeding formula for preparing the water-based epoxy primer by changing the ratio of the dispersant in Example 3 while keeping other materials unchanged, and the formula numbers are 9, 10, 11 and 12 in turn. According to the technological process that embodiment 1 prepares water-based two-component epoxy primer, the numbering shown in table 5 is 4 kinds of epoxy primers that are 9~12, and the technological process that prepares epoxy primer film by embodiment 1 prepares paint film .

[0075] The properties of the water-borne two-component epoxy primers prepared by formula 9, formula 10, formula 11 and formula 12 are shown in Table 6. It can be seen from the table that when the ratio of dispersant BYK-190 and FX600 is 0.5:4.5, the water-based two-component epoxy primer has excellent sandability, filling, hiding power, adhesion, flexibility and chemical resistance. But its storage stability and water resistance are unqualified; when the ratio of dispersant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com