Edge polishing device for wind power generation blade

A wind power generation blade and edge technology, which is applied to grinding drive devices, machine tools suitable for grinding workpiece edges, grinding machines, etc. Long and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

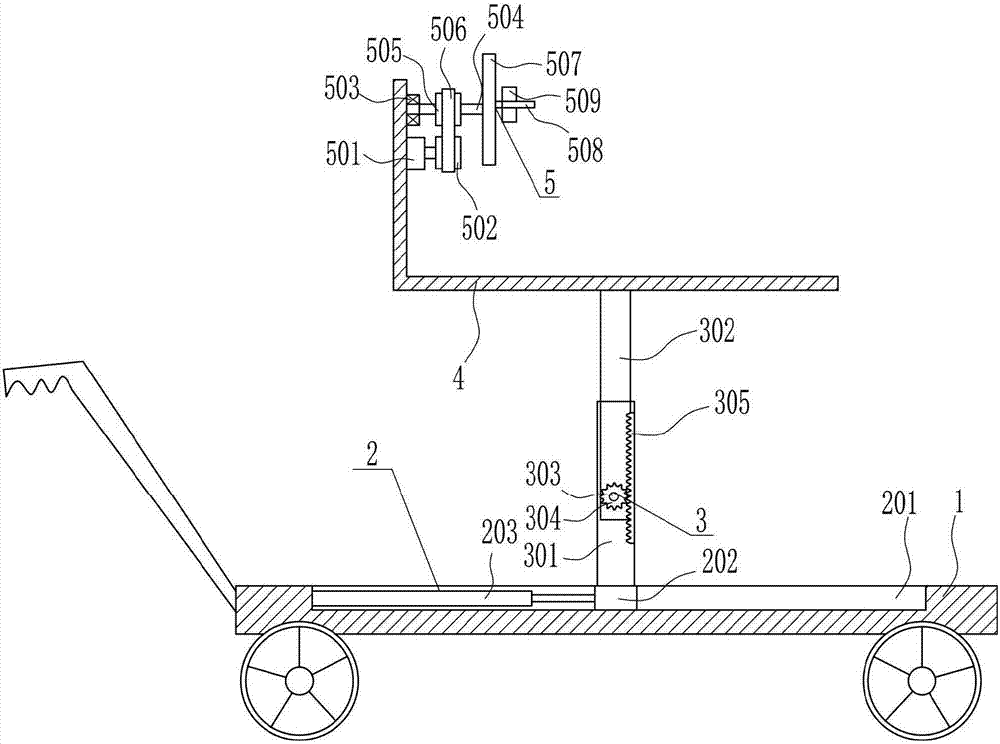

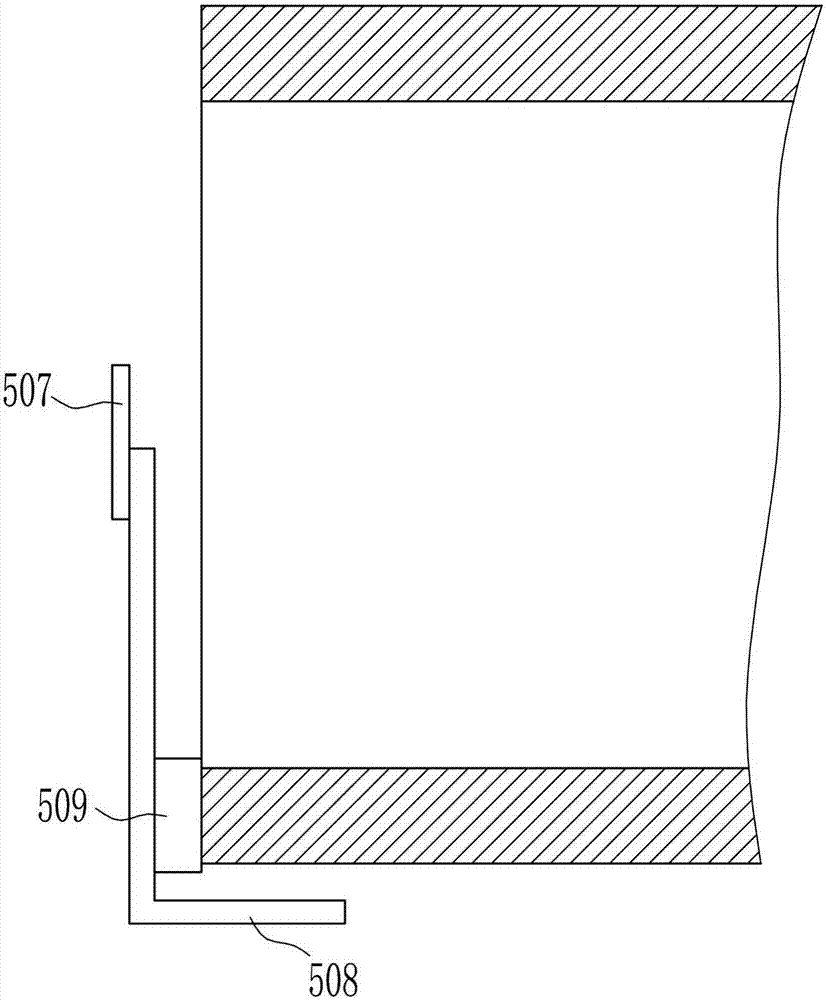

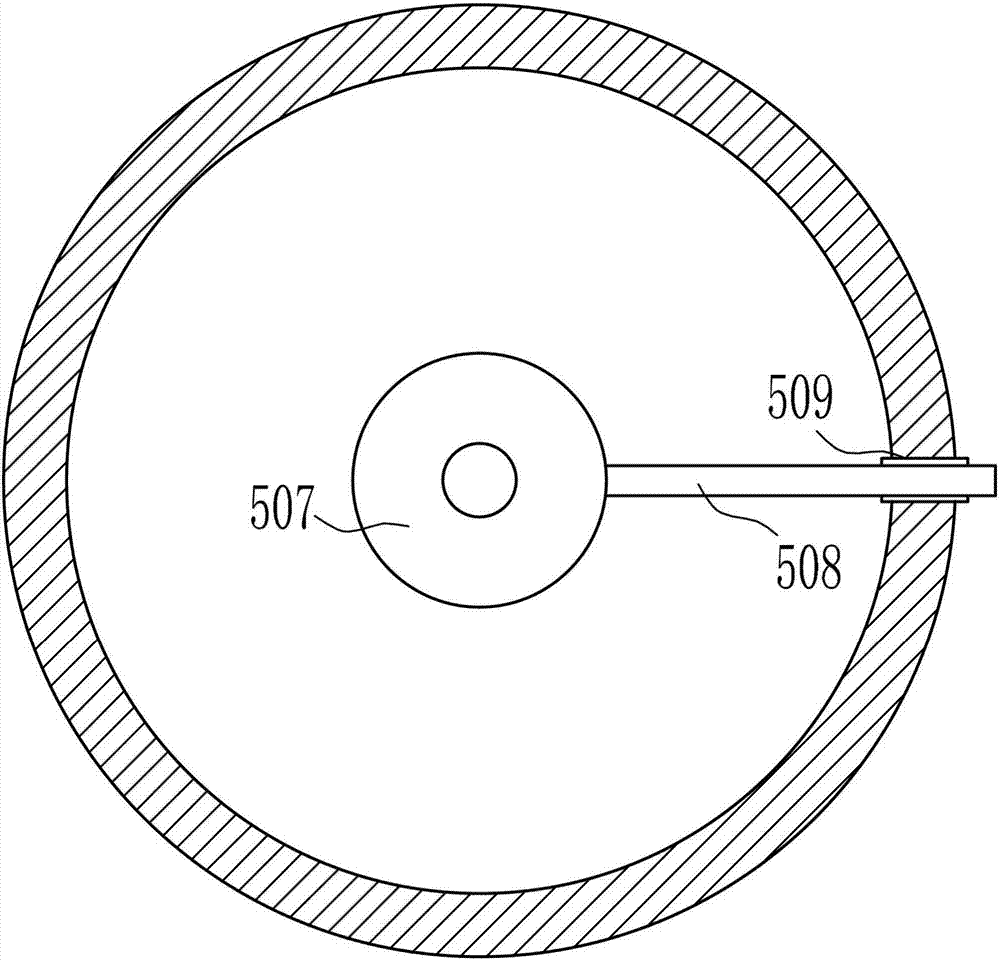

[0038] An edge grinding device for wind power blades, such as Figure 1-8 As shown, it includes a trolley 1, a left and right moving device 2, a height adjustment device 3, an L-shaped connecting plate 4 and a grinding device 5. The cart 1 is provided with a left and right movement device 2, and the top of the left and right movement device 2 is provided with a height adjustment device. 3. An L-shaped connecting plate 4 is welded on the top of the height adjusting device 3, and a grinding device 5 is provided on the upper right side of the L-shaped connecting plate 4.

Embodiment 2

[0040] An edge grinding device for wind power blades, such as Figure 1-8 As shown, it includes a trolley 1, a left and right moving device 2, a height adjustment device 3, an L-shaped connecting plate 4 and a grinding device 5. The cart 1 is provided with a left and right movement device 2, and the top of the left and right movement device 2 is provided with a height adjustment device. 3. An L-shaped connecting plate 4 is welded on the top of the height adjusting device 3, and a grinding device 5 is provided on the upper right side of the L-shaped connecting plate 4.

[0041] The height adjustment device 3 includes an outer telescopic rod 301, an inner telescopic rod 302, a first motor 303, a gear 304 and a rack 305, the outer telescopic rod 301 is connected with the bottom of the left and right moving device 2, and the outer telescopic rod 301 is provided with an inner telescopic rod 302, the front side of the inner telescopic rod 302 is connected with the first motor 303 by...

Embodiment 3

[0043] An edge grinding device for wind power blades, such as Figure 1-8 As shown, it includes a trolley 1, a left and right moving device 2, a height adjustment device 3, an L-shaped connecting plate 4 and a grinding device 5. The cart 1 is provided with a left and right movement device 2, and the top of the left and right movement device 2 is provided with a height adjustment device. 3. An L-shaped connecting plate 4 is welded on the top of the height adjusting device 3, and a grinding device 5 is provided on the upper right side of the L-shaped connecting plate 4.

[0044] The height adjustment device 3 includes an outer telescopic rod 301, an inner telescopic rod 302, a first motor 303, a gear 304 and a rack 305, the outer telescopic rod 301 is connected with the bottom of the left and right moving device 2, and the outer telescopic rod 301 is provided with an inner telescopic rod 302, the front side of the inner telescopic rod 302 is connected with the first motor 303 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com