Steel tube inner wall grinding device with water spraying dust removal function

A technology for the inner wall of steel pipes and water spray devices, which is applied to grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., and can solve problems such as halved efficiency, high energy consumption, and single-head grinding of fan dust suction filter devices , to achieve better grinding effect and save water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

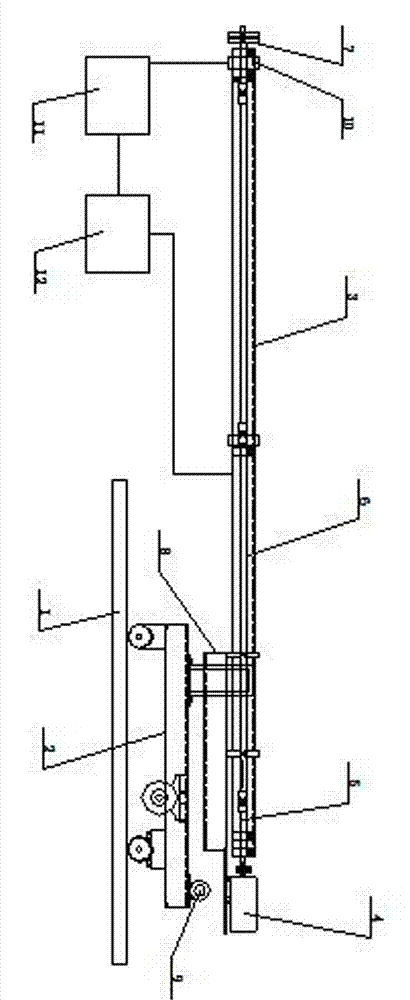

[0007] refer to figure 1 , the specific embodiment adopts the following technical solutions: a steel pipe inner wall grinding device with water spray and dust removal, including a track 1 installed on the ground, a mobile trolley 2 moving along the track, a mobile trolley installed on the mobile trolley 2 Steel pipe cleaning assembly 3, motor 4, water spray device 10, water tank 11 and circulating water pump 12, described steel pipe cleaning assembly 3 includes flexible shaft 5, outer casing 6, grinding head 7, support frame body 8, and described water spray device 10 Installed behind the grinding head 7, one end of the water spray device 10 is connected to one end of the circulating water pump 12 through a water pipe, and the other end of the circulating water pump 12 is connected to one end of the water tank 11 through a water pipe, and the water tank 11 The other end is connected to the other end of the water spraying device 10 through a water pipe.

[0008] refer to figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com