Dust collection type putty grinding device

A putty and dust collection technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding racks, etc., can solve the problems of surrounding pollution, high labor intensity, large quantity, etc., and achieve adjustable grinding intensity and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

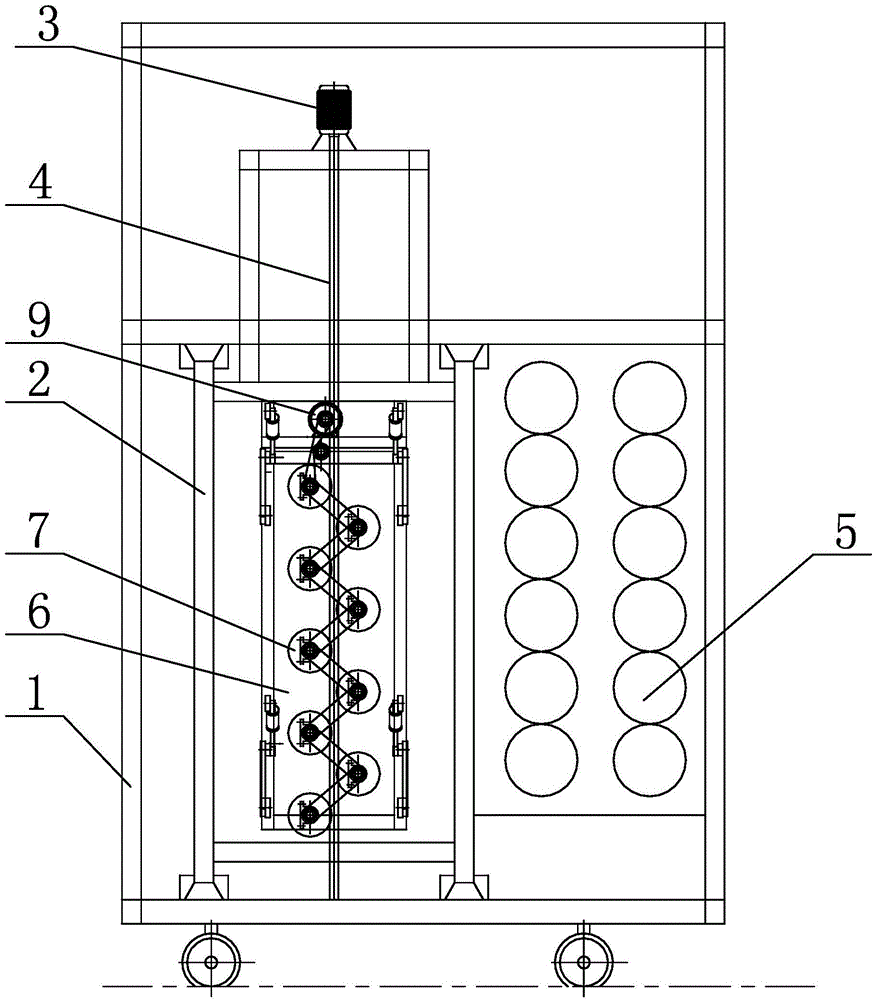

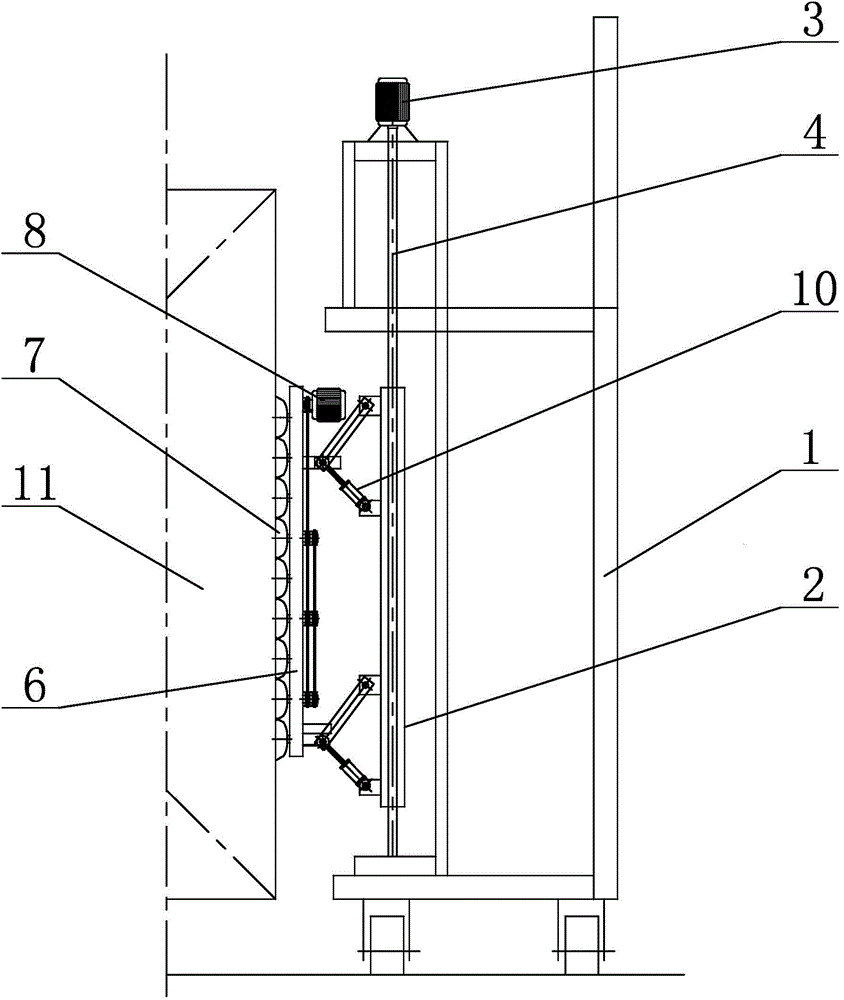

[0022] Such as Figure 1-Figure 2 As shown, the dust-collecting putty grinding device according to the embodiment of the present invention is characterized in that it comprises: a horizontally movable trolley 1, the trolley 1 is provided with a vertical moving frame 2, and a first drive mechanism for driving the vertical moving frame 2 to move up and down (the first drive mechanism includes: the first motor 3, the screw rod 4 connected with the output head of the first motor 3, the vertical moving frame 2 is provided with an internal thread that cooperates with the screw rod 4), and the vertical moving frame 2 is equipped with a grinding assembly, a blowing mechanism located on one side of the grinding assembly (the blowing mechanism includes several nozzles 5 arranged vertically, and the rear end of the nozzles 5 is connected to an air pump through a blowing pipe), and a dust collector that covers the grinding assembly and the blowing mechanism together. Cover (not shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com