Patents

Literature

30results about How to "Help inhalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-atomization capturing electrostatic paint spray booth

InactiveCN104437949AImprove capture abilityLarge specific surface areaLiquid surface applicatorsSpraying apparatusSpray nozzleWater curtain

The invention relates to a double-atomization capturing electrostatic paint spray booth which comprises an electrostatic paint spray booth. An electrostatic spray nozzle is mounted in the electrostatic paint spray booth, a main water curtain plate and side water curtain plates are arranged on the inner wall of the electrostatic paint spray booth, a steam-water separation chamber is connected to the back of the main water curtain plate of the electrostatic paint spray booth, a bevel flushing plate is arranged on the lower portion of the main water curtain plate, the electrostatic paint spray booth is communicated with the steam-water separation chamber via a double-atomization paint mist capturing structure which is connected with the lower end of the bevel flushing plate, and a bottom plate flow guide structure is arranged at the bottom of the electrostatic paint spray booth. The double-atomization capturing electrostatic paint spray booth has the advantages that the double-atomization capturing electrostatic paint spray booth is simple in structure, scientific and reasonable in design, low in cost and high in paint mist capturing efficiency, and follow-up environmental protection treatment load can be effectively reduced.

Owner:赛智环保科技(天津)有限公司

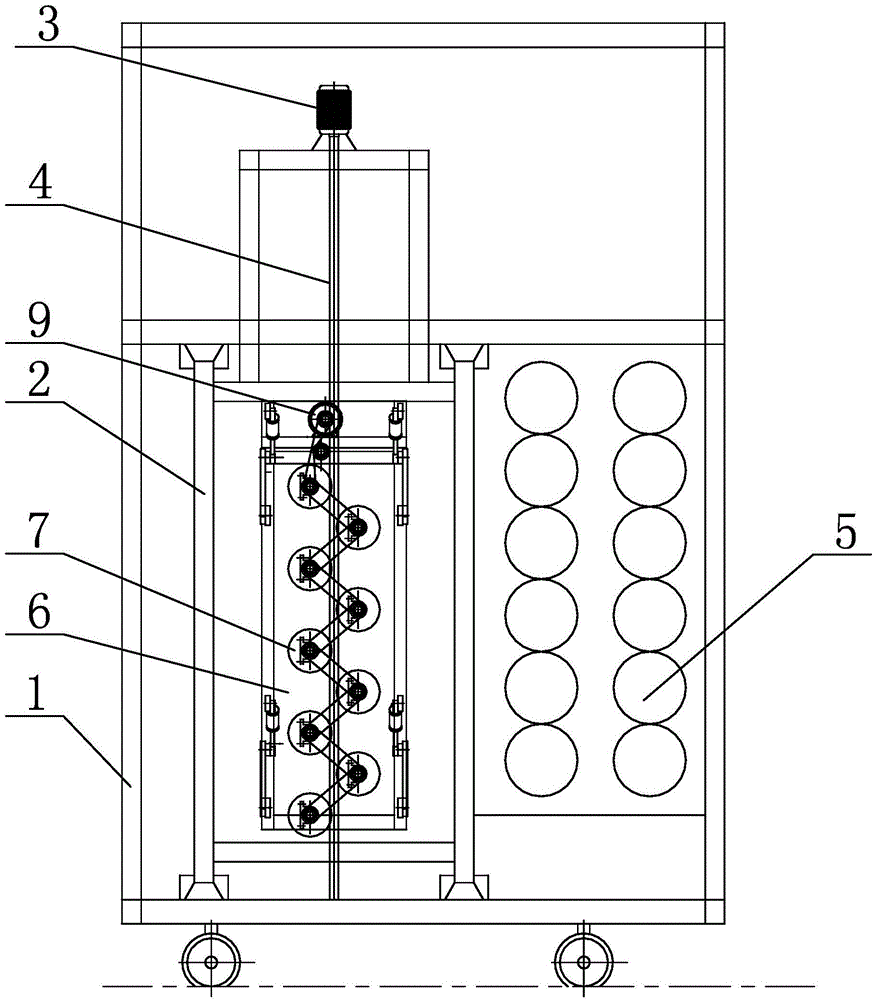

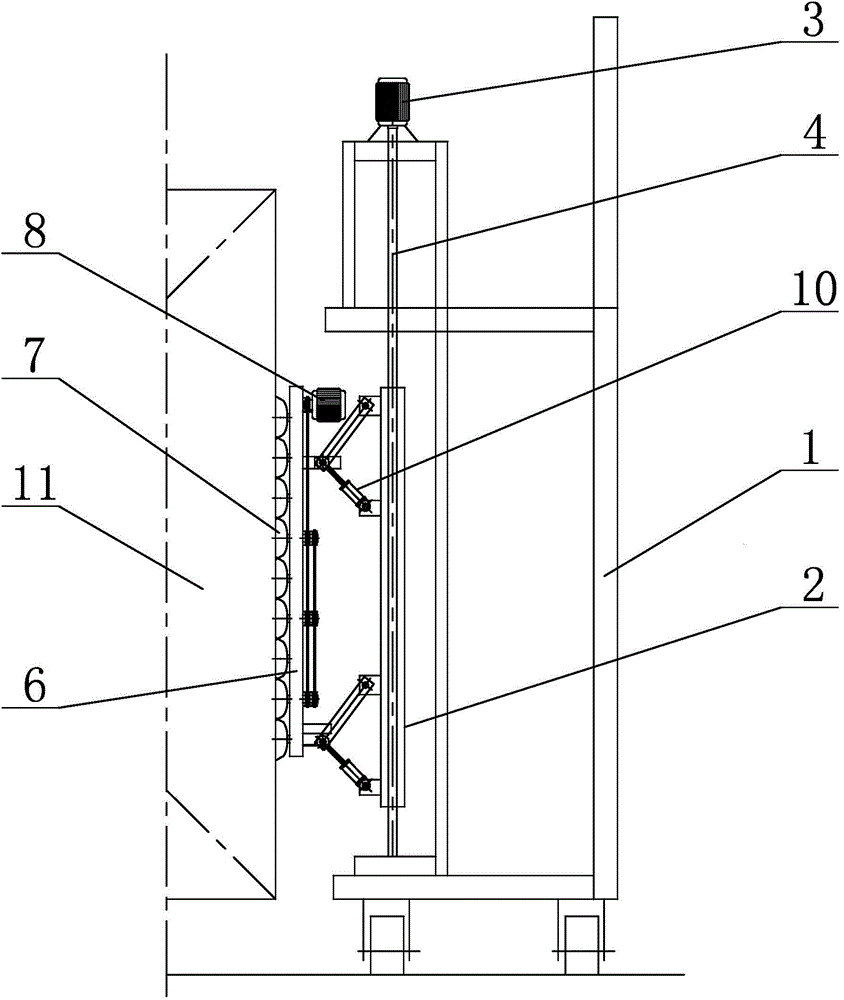

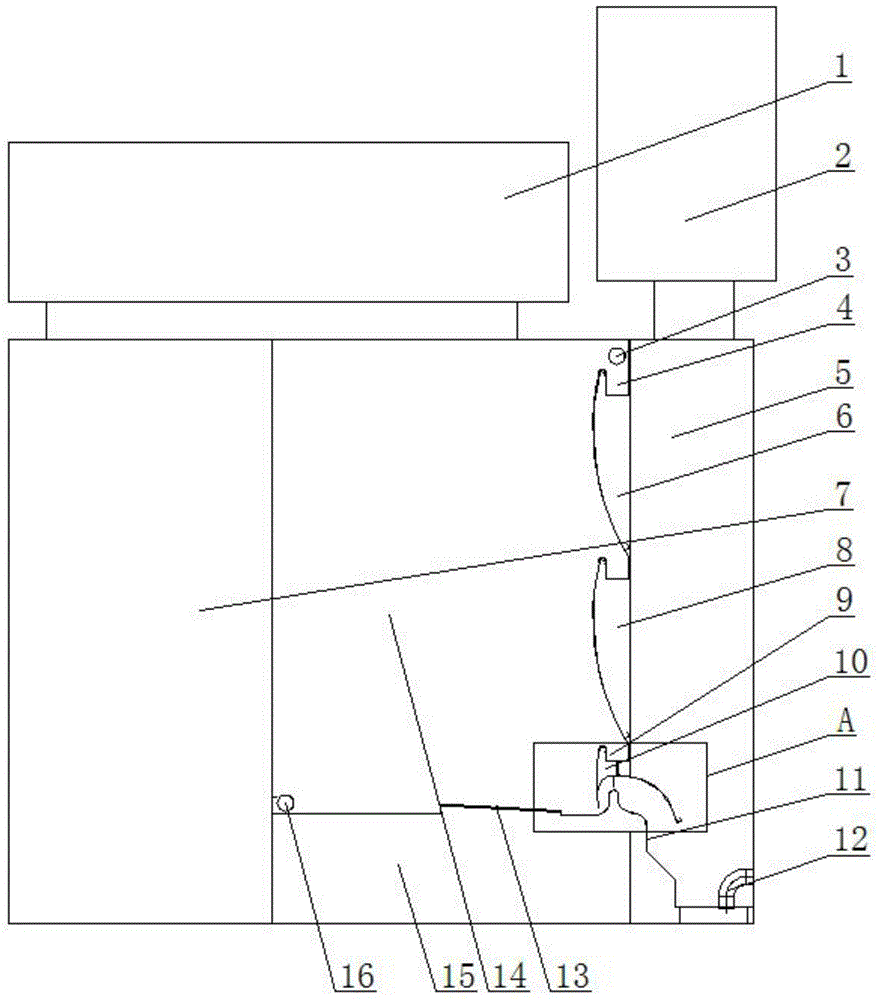

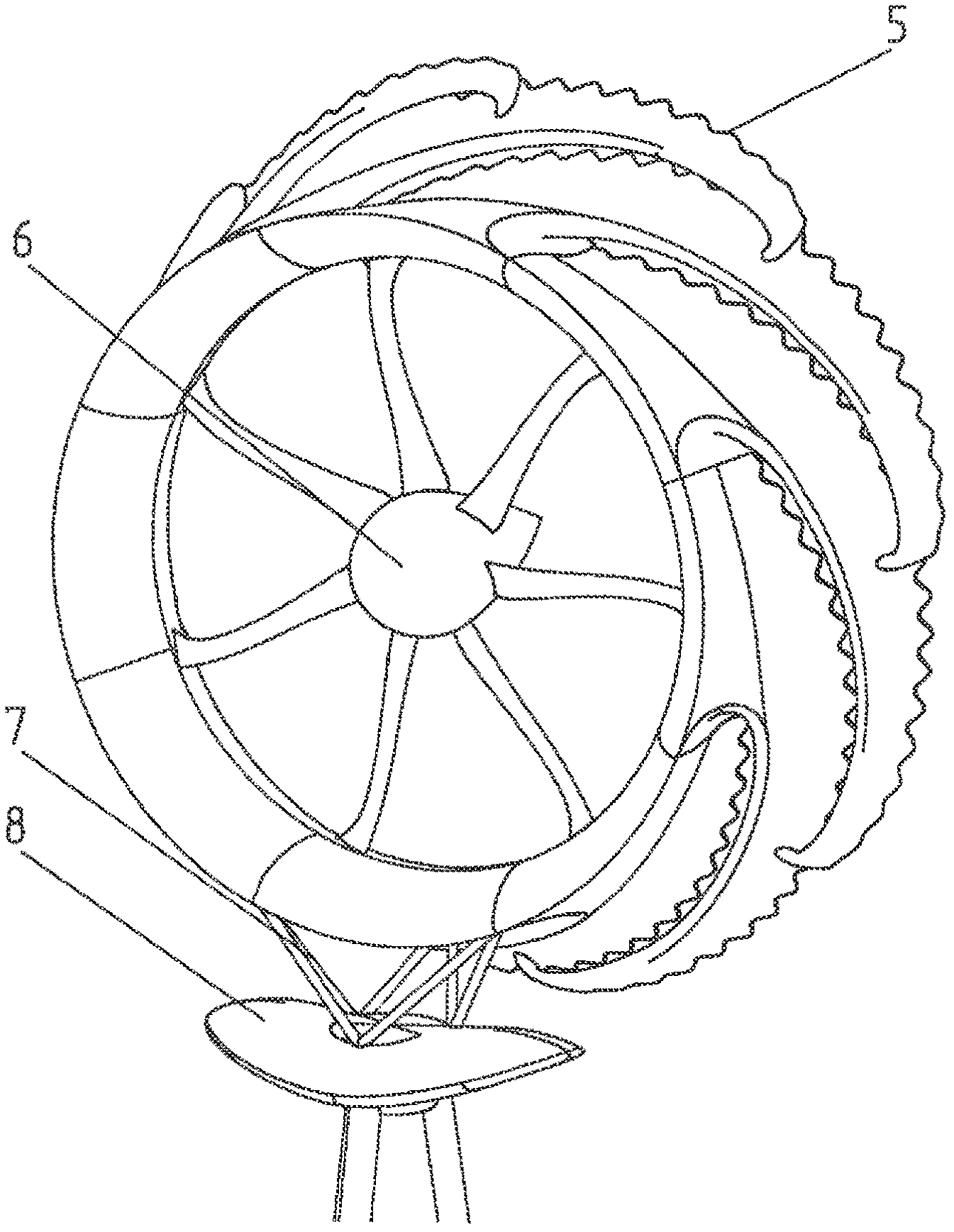

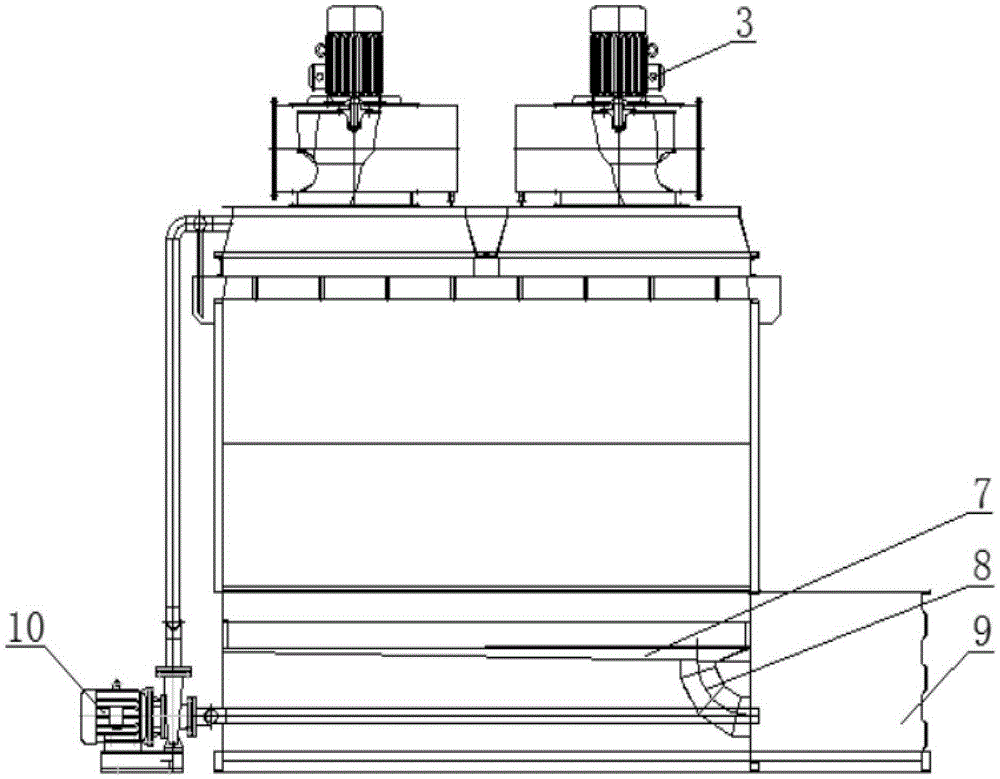

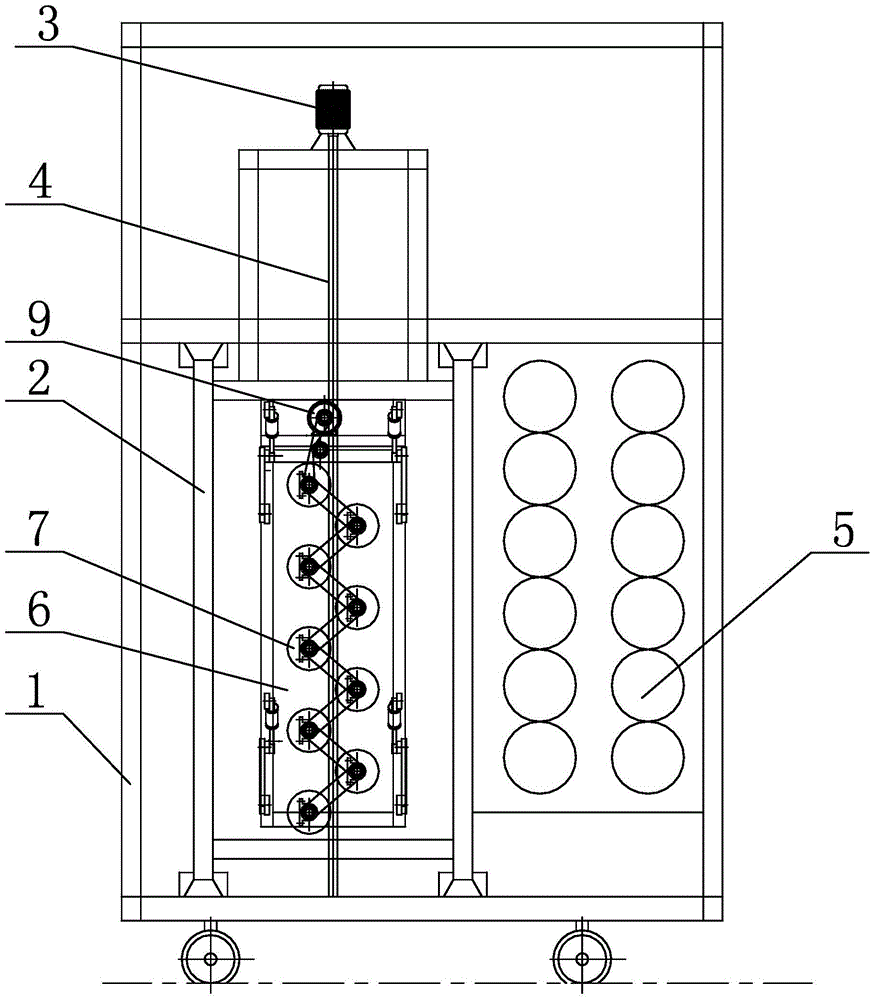

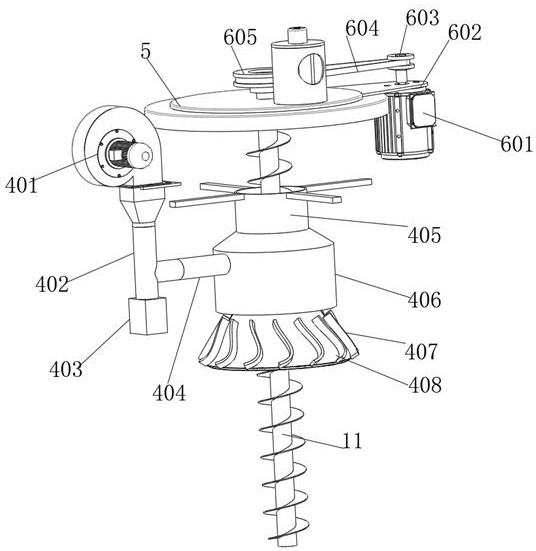

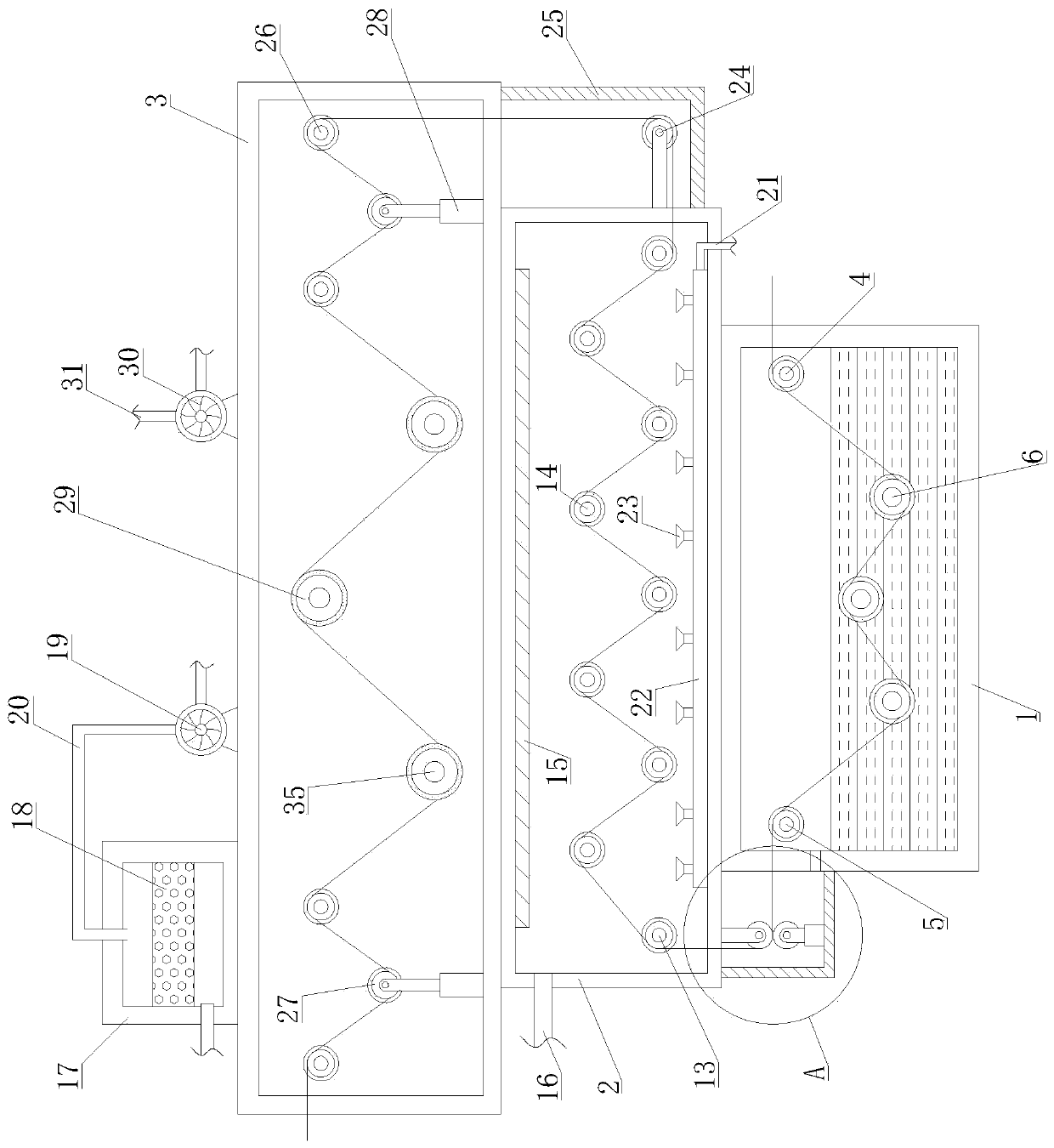

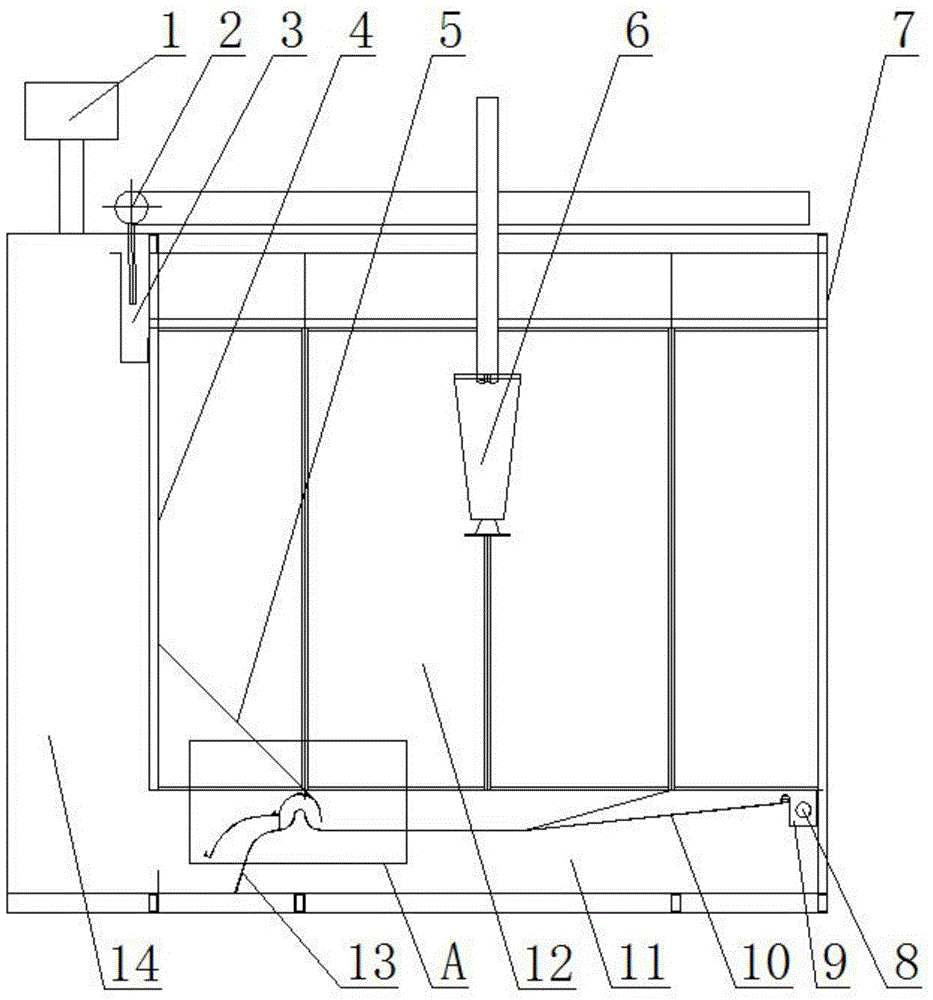

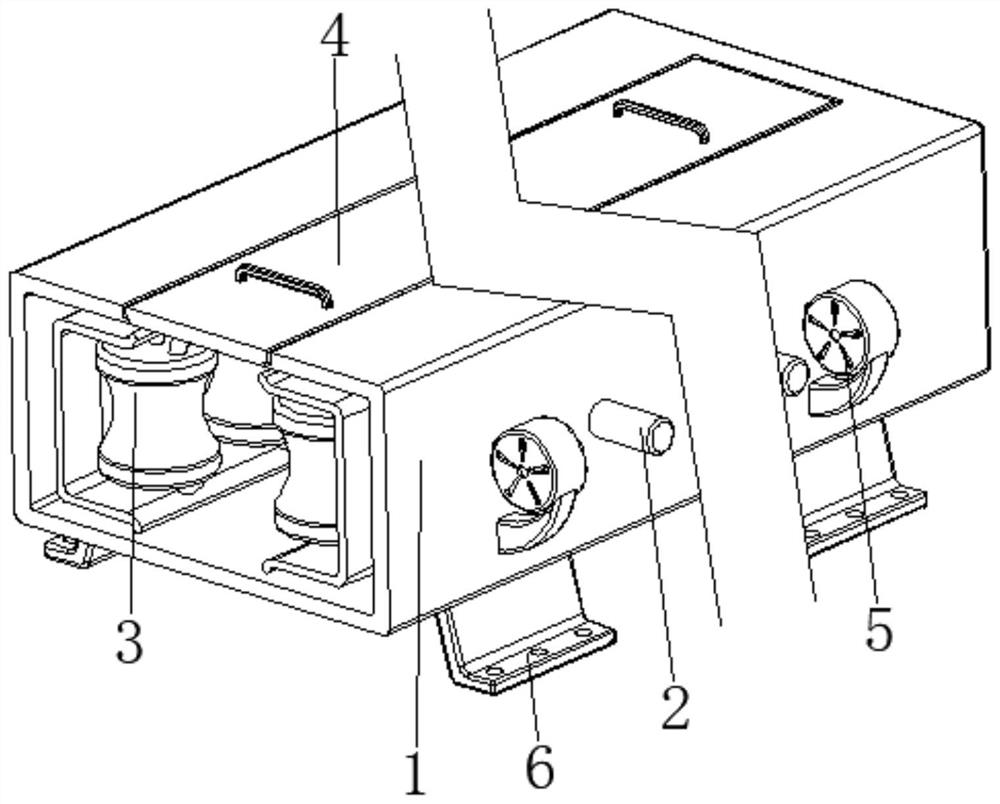

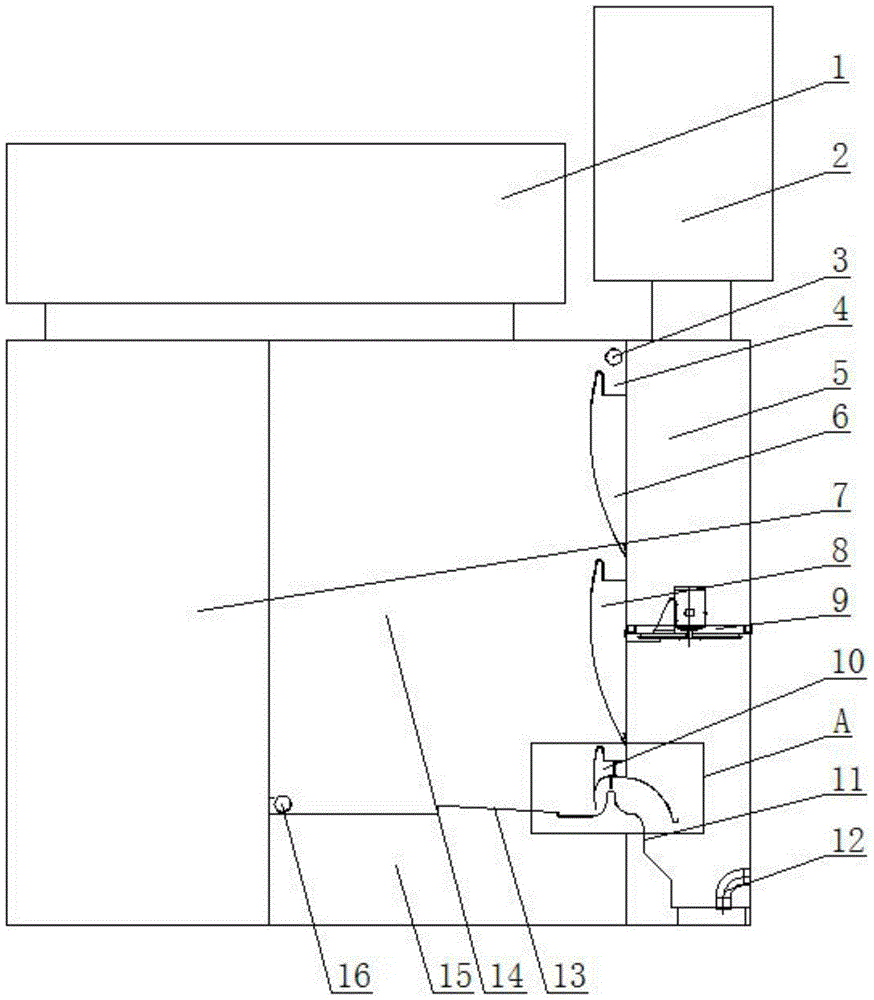

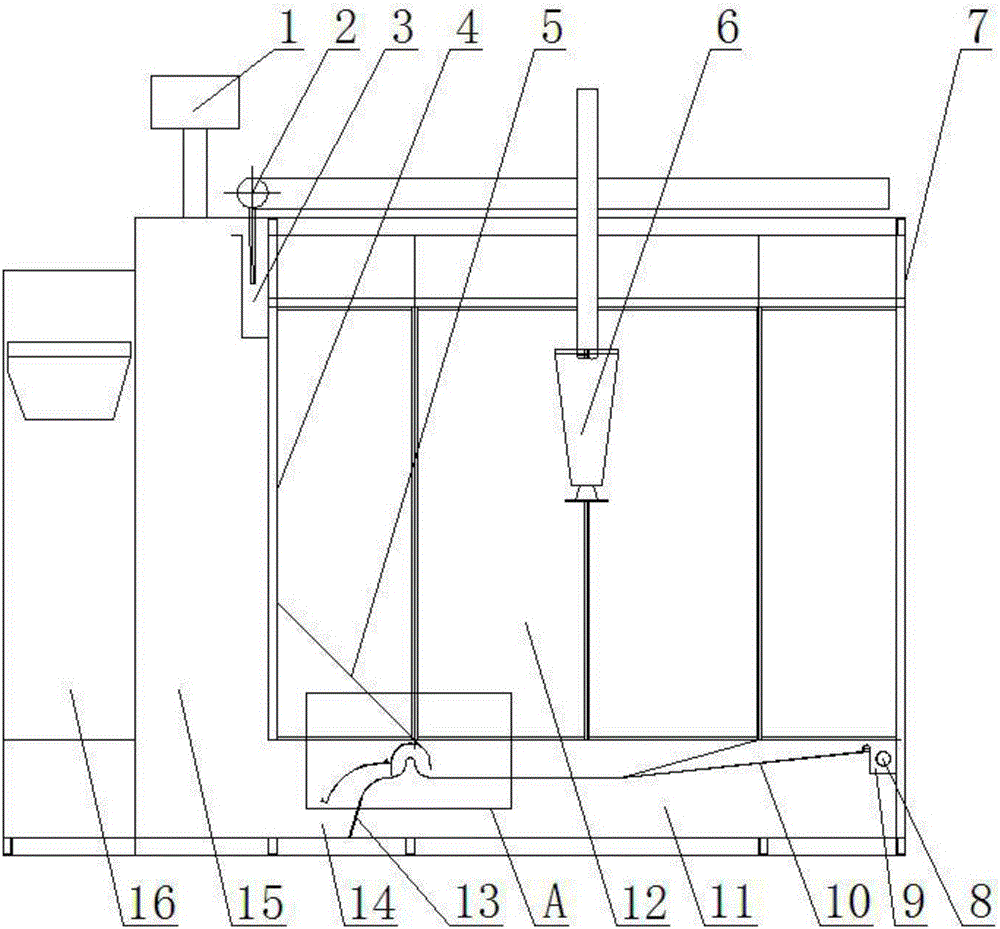

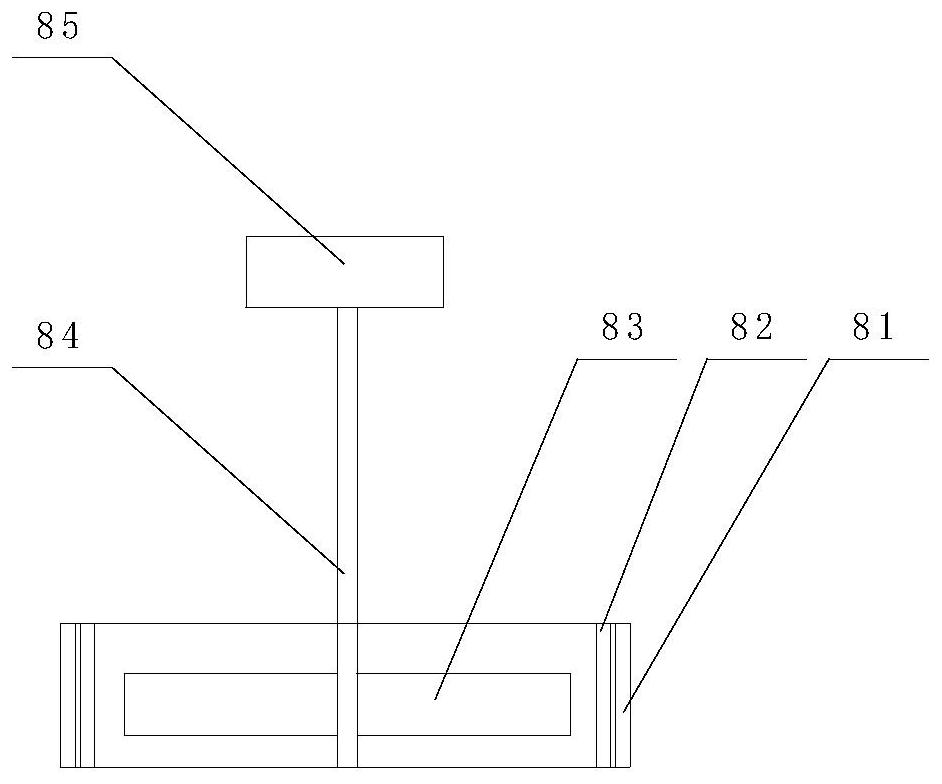

Dust collection type putty grinding device

ActiveCN104084858ARealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

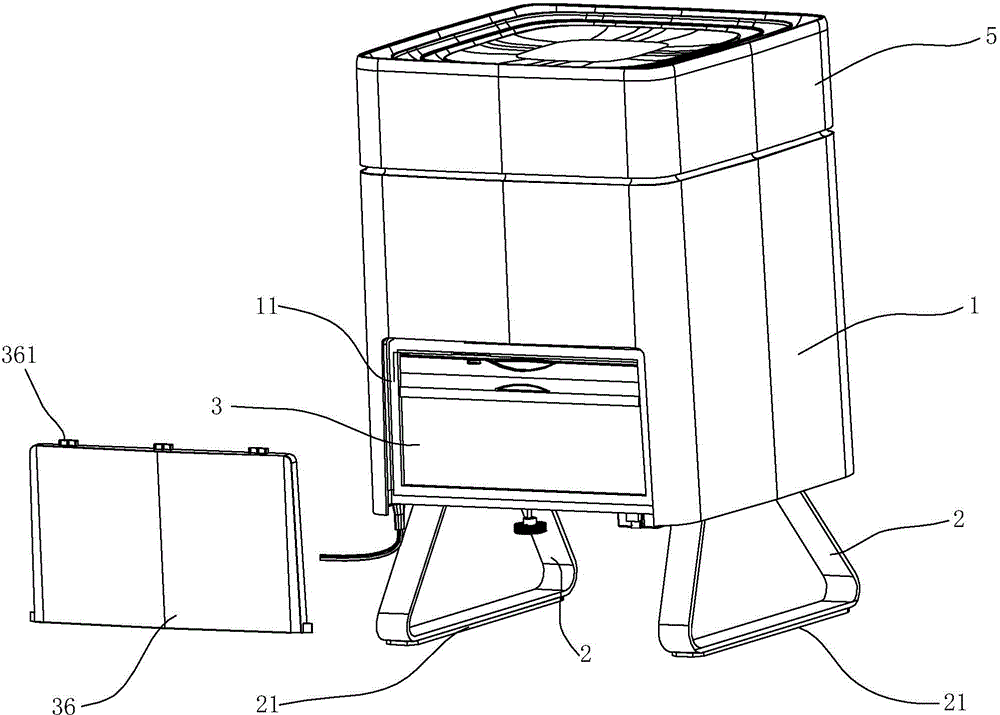

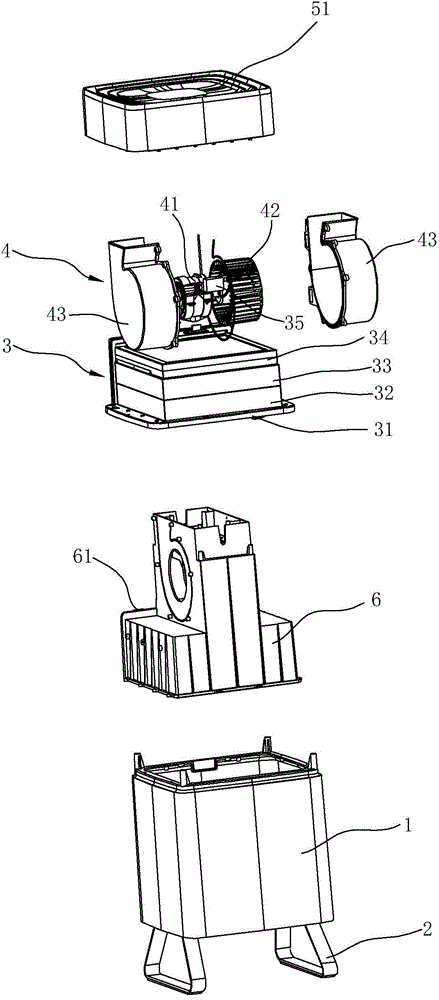

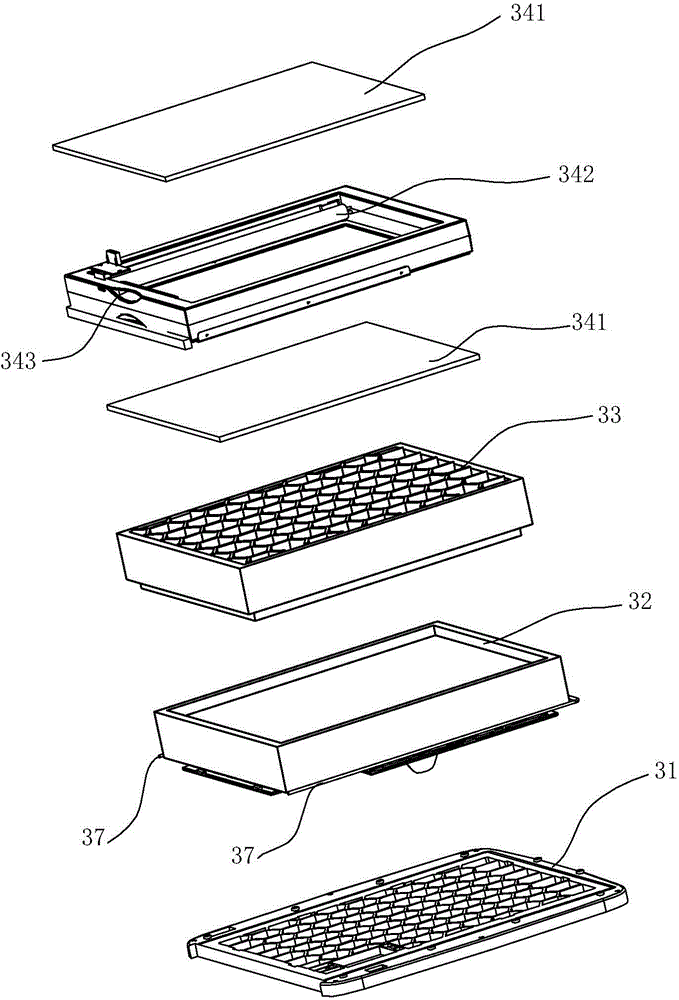

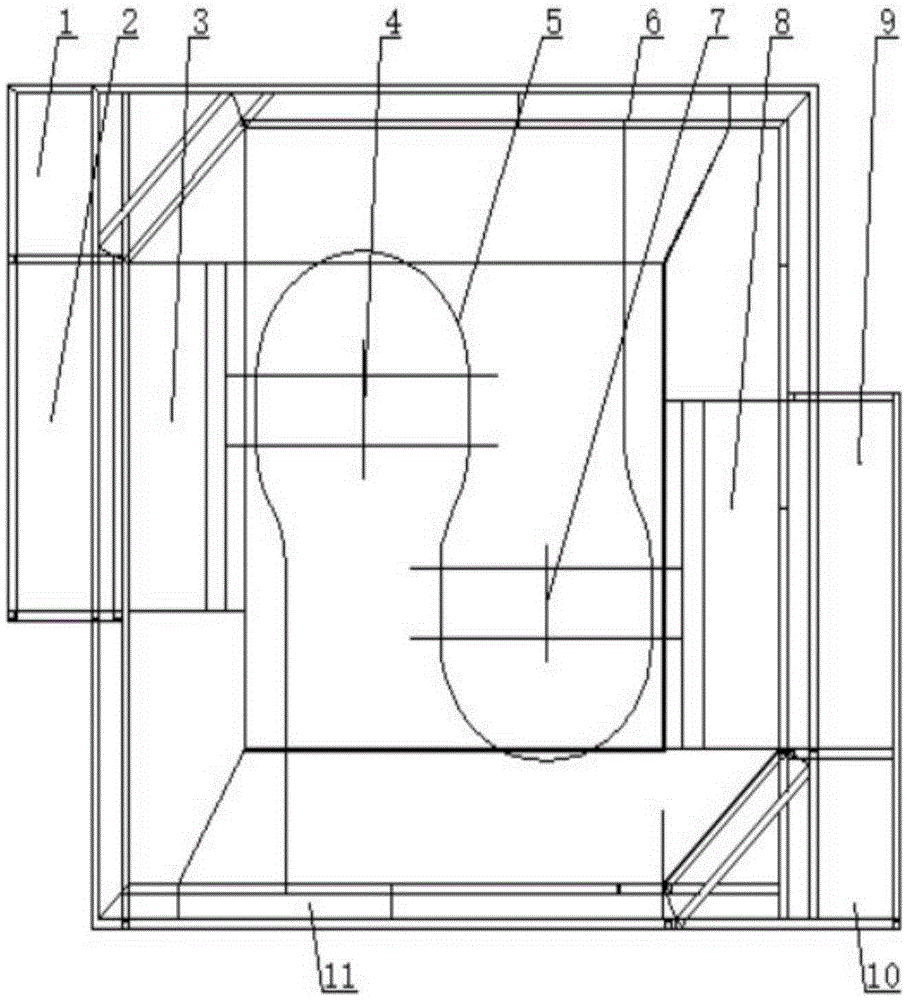

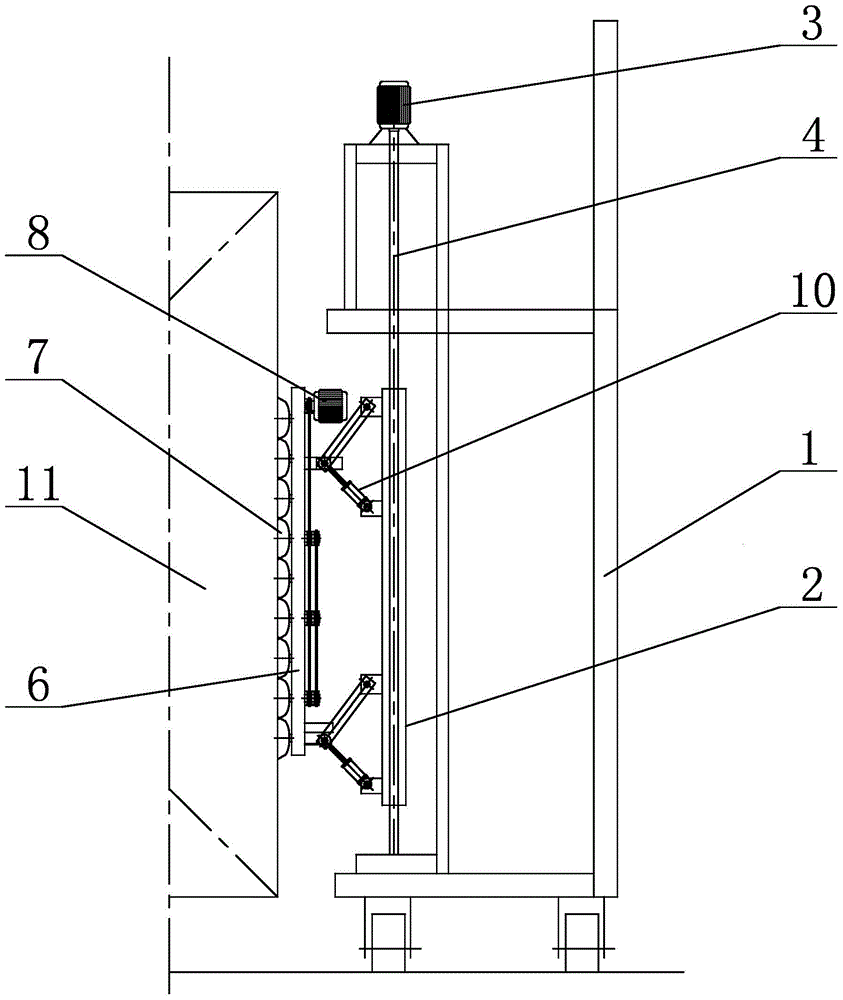

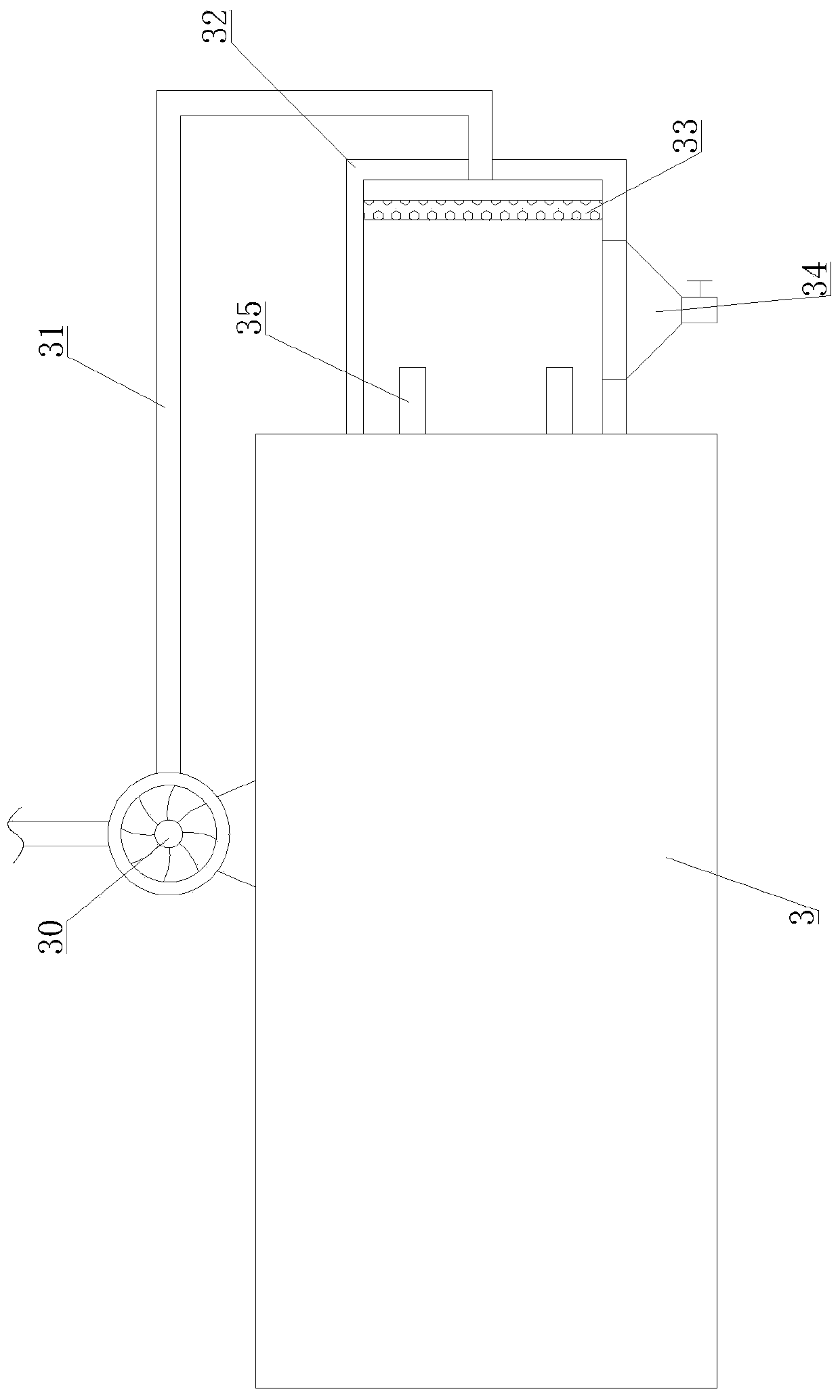

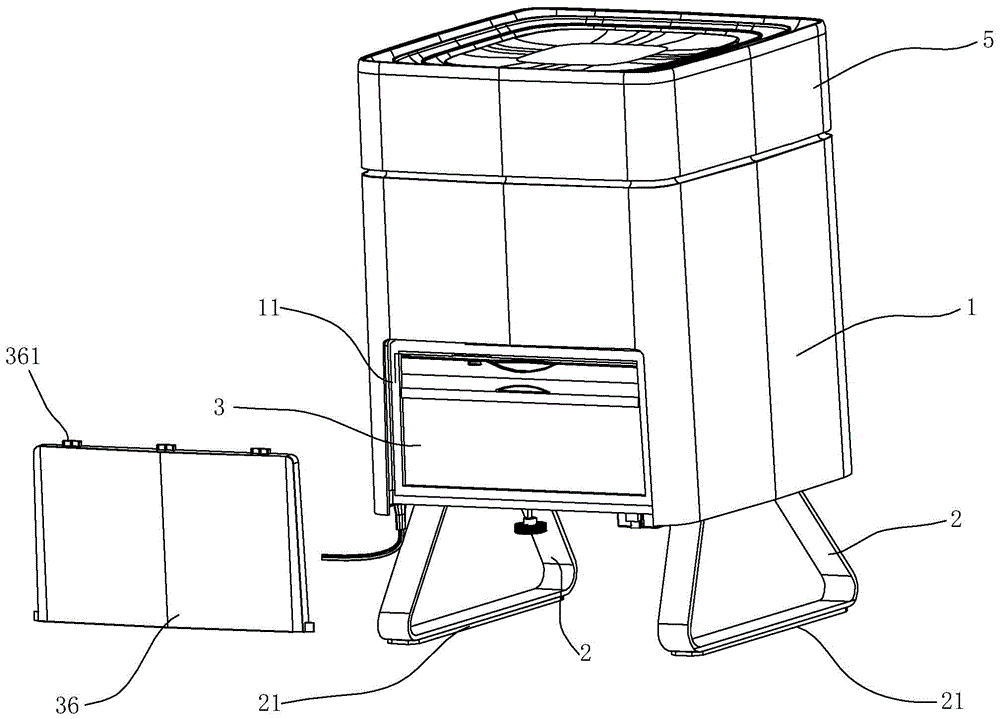

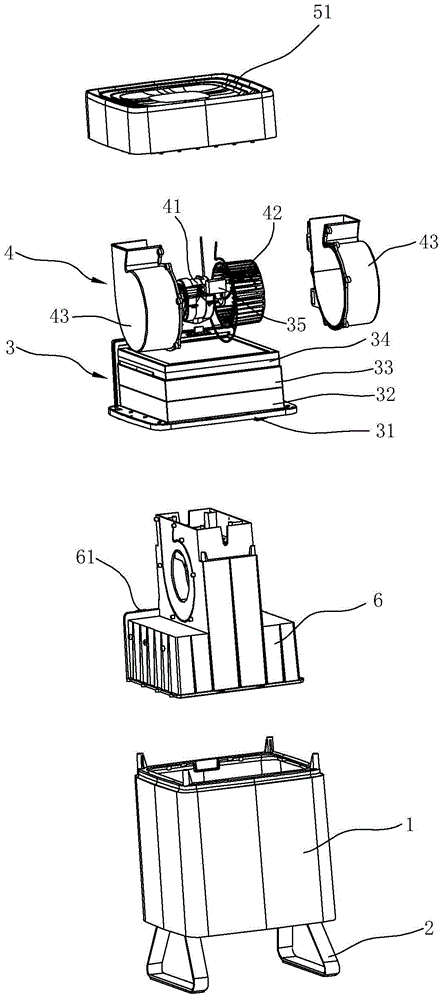

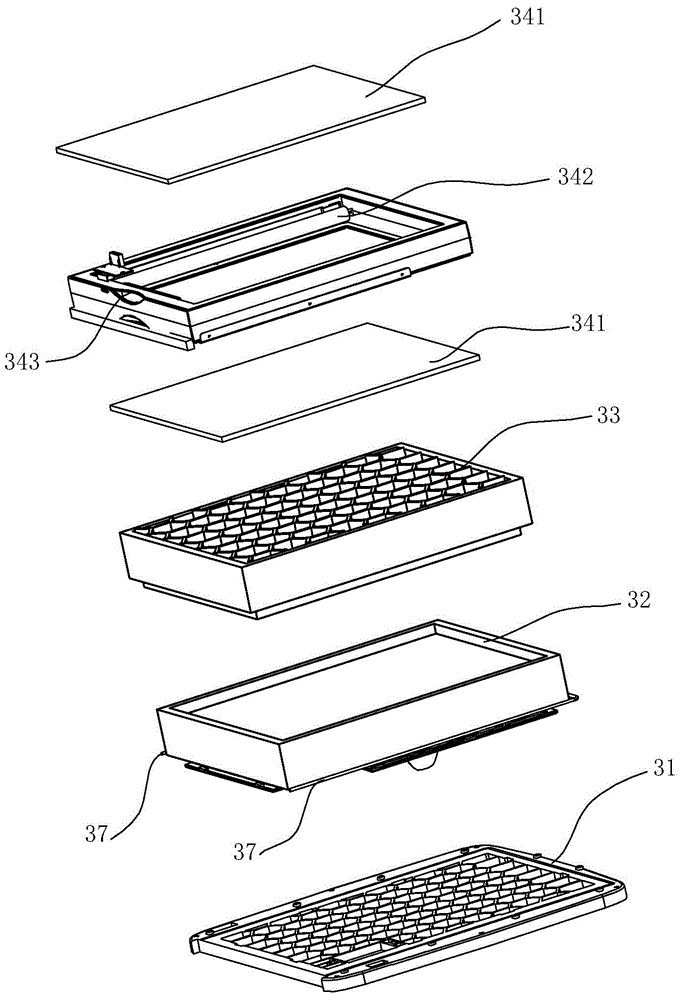

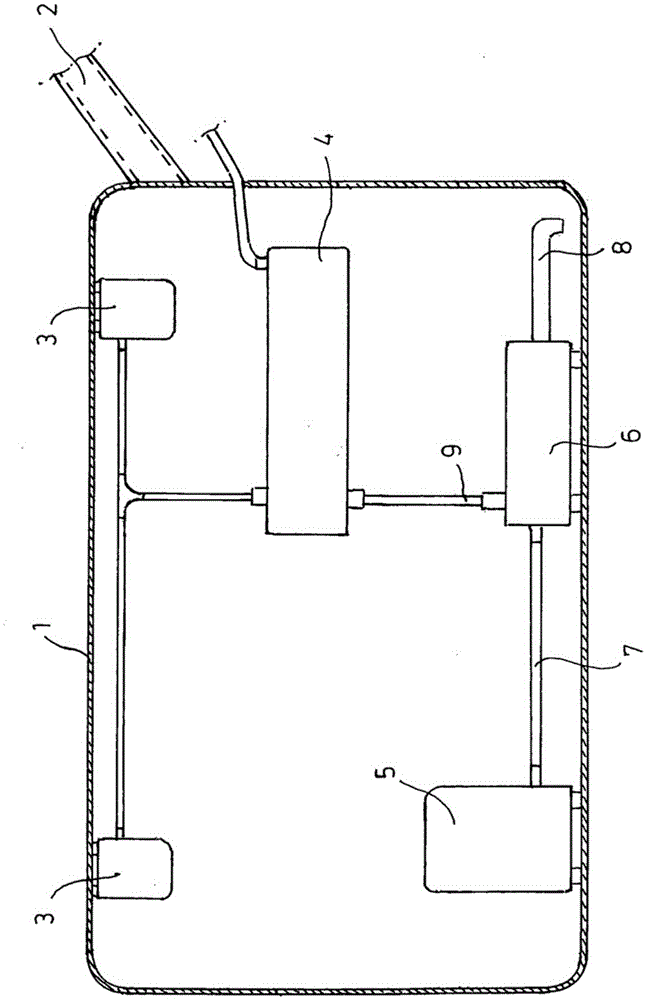

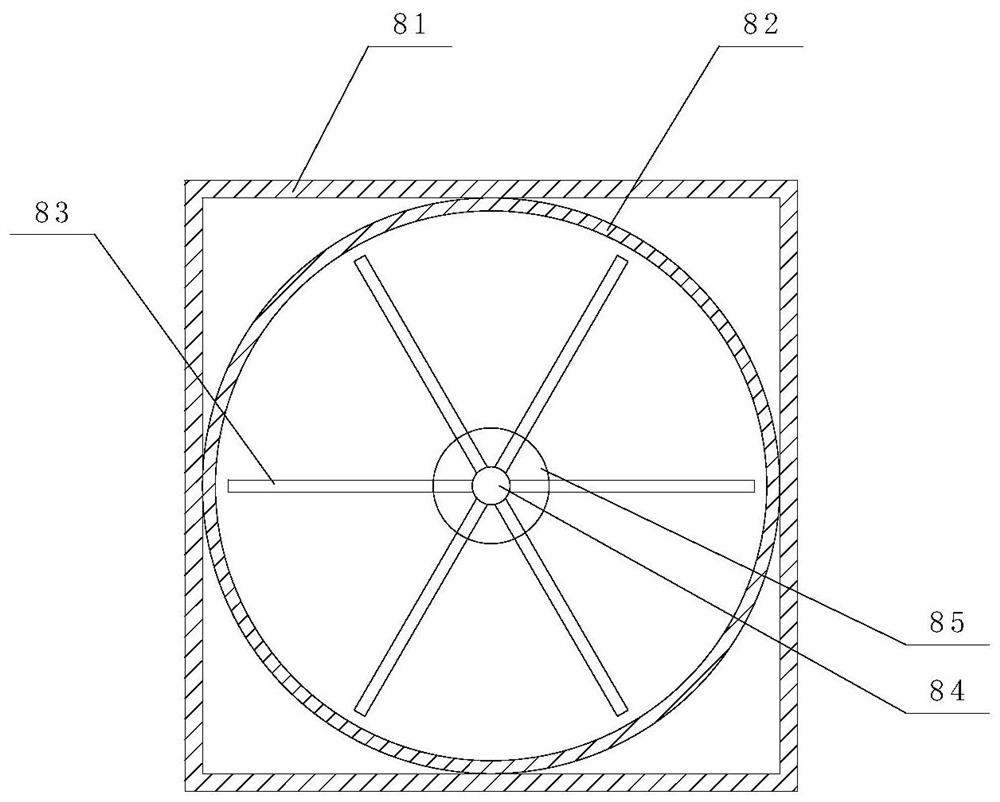

Indoor air purifier

ActiveCN104089337ASpeed up the cycleGuaranteed uptimeLighting and heating apparatusSpace heating and ventilation detailsRoom air cleanersAir cycle

The invention discloses an indoor air purifier. The indoor air purifier comprises a main case, a filter unit, a draught fan and an air exhaust device, wherein the filter unit and the draught fan are arranged in the main case, and the air exhaust device is arranged above the top of the main case. The top and the bottom of the main case are provided with openings. The two sides of the bottom of the main case are respectively provided with a support, so that the main case is suspended, and the opening in the bottom of the main case serves as an air inlet. The draught fan comprises a driving motor with two output shafts, wherein the driving motor is fixed into the main case, and the two output shafts of the driving motor are respectively connected with a wind wheel; a volute is arranged on the periphery of each wind wheel, and the upper end of each volute is communicated with the air exhaust device. Air can enter the bottom of the indoor air purifier at 360 degrees so that the requirement for large-area air purification can be met; air flow absorbed from the bottom can be exhausted from four sides of the top through the wind wheels on the two sides at the same time, and strong negative pressure is formed in an air flue, so more air can be absorbed in from the air inlet in the bottom, the adsorption capacity of the air inlet can be increased, more air can be filtered in a short time, the circulation speed of the air in a room can be increased to the maximum extent, and the efficient purifying effect can be achieved.

Owner:三生(中国)健康产业有限公司

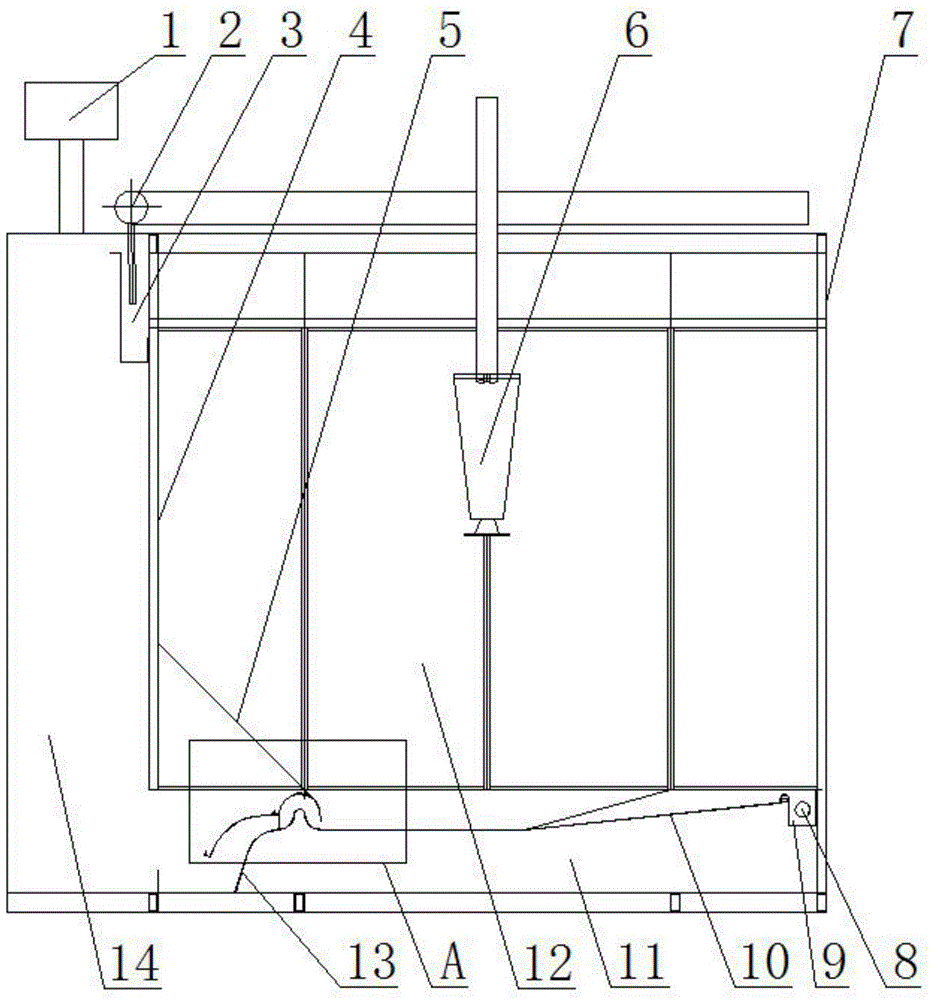

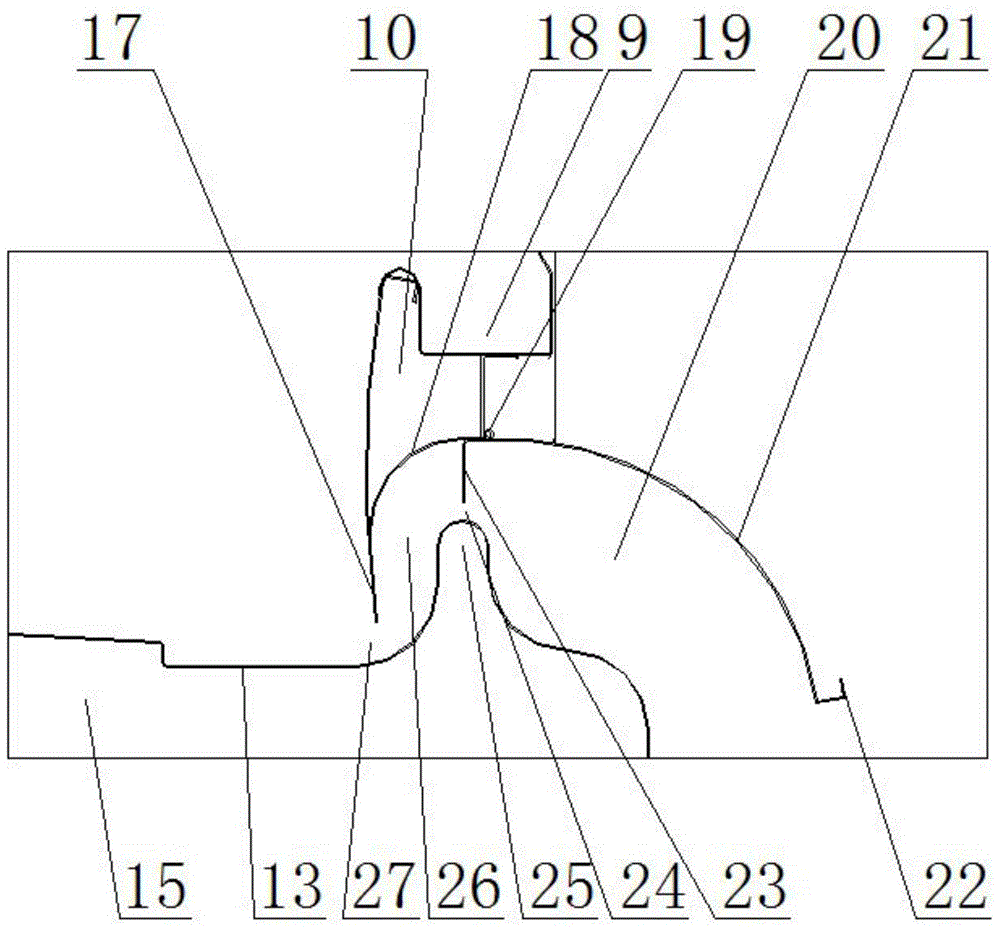

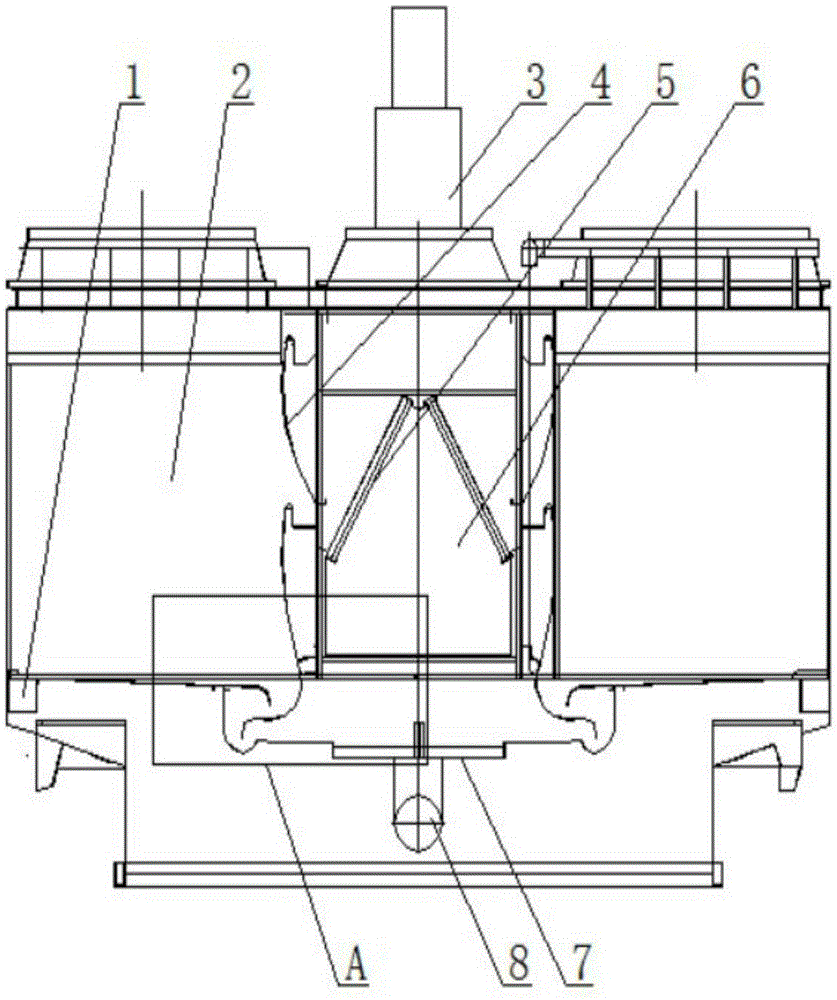

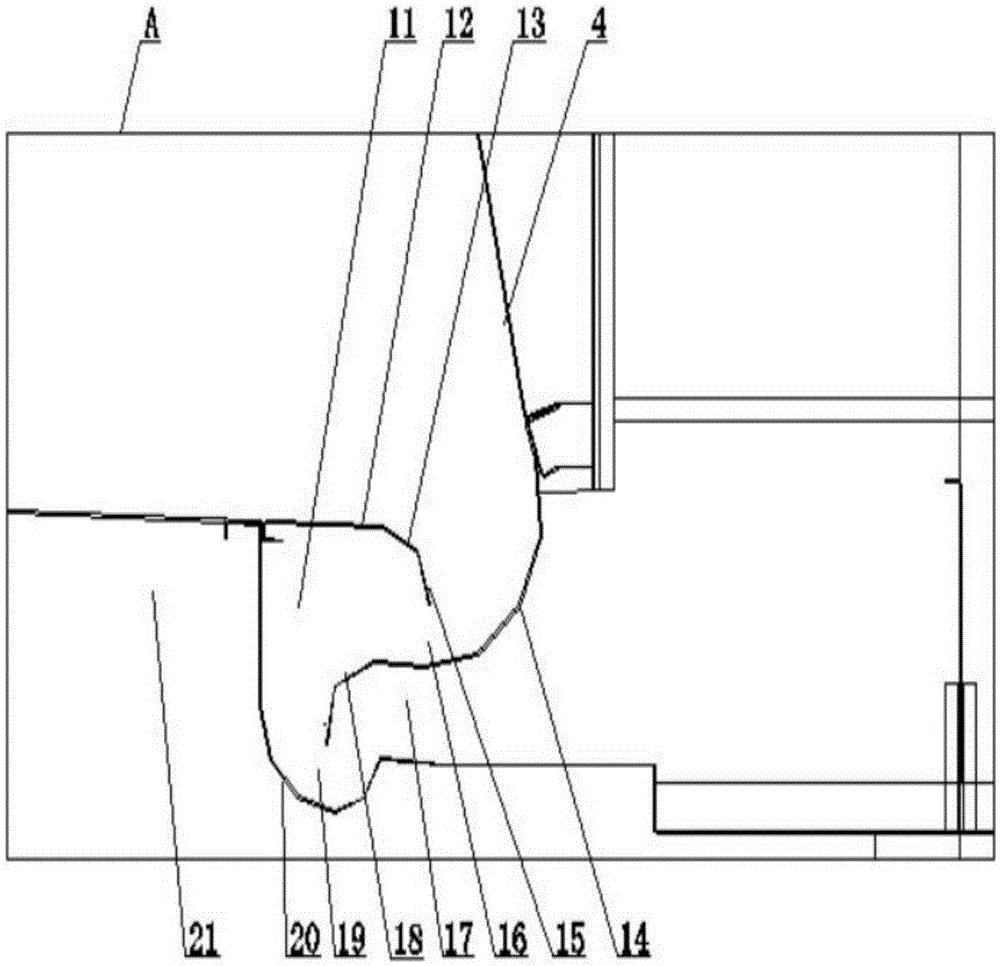

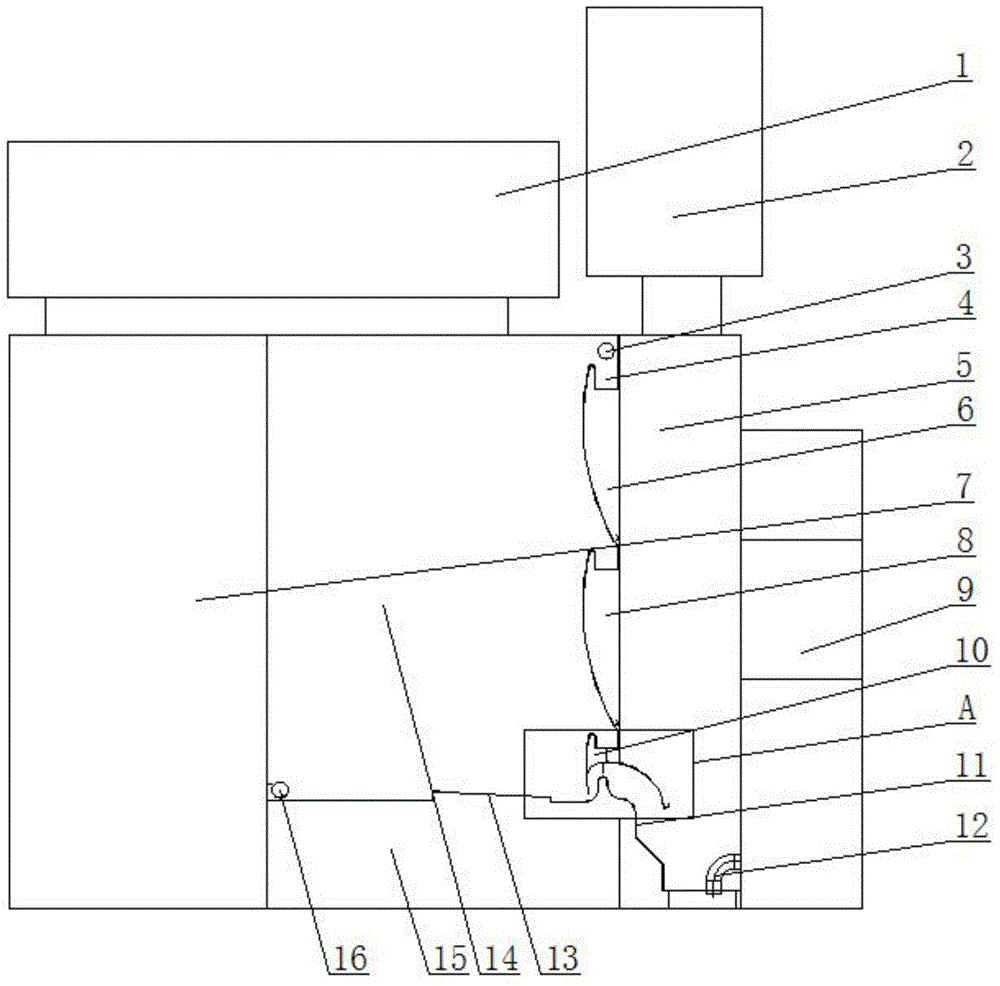

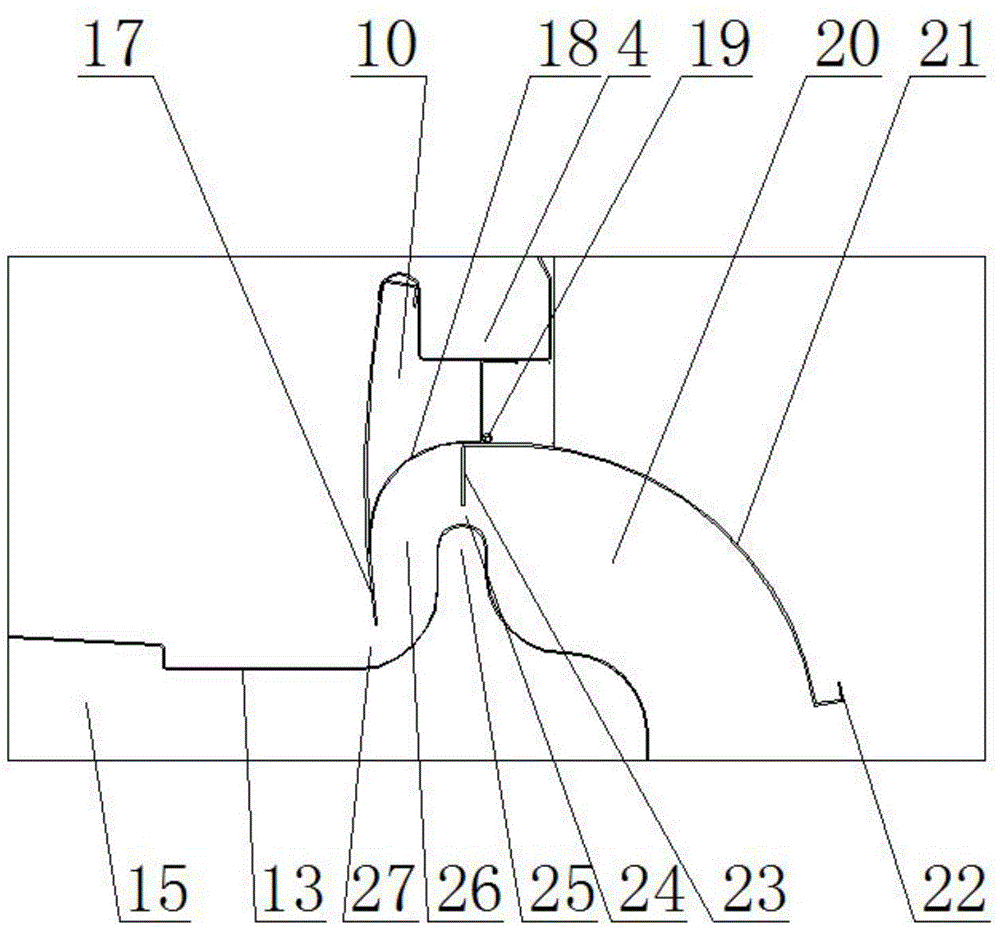

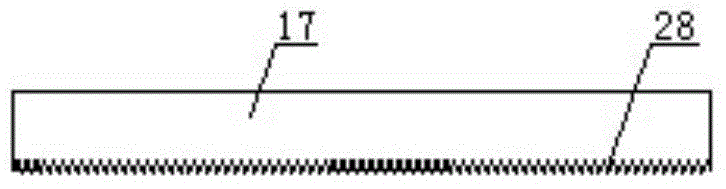

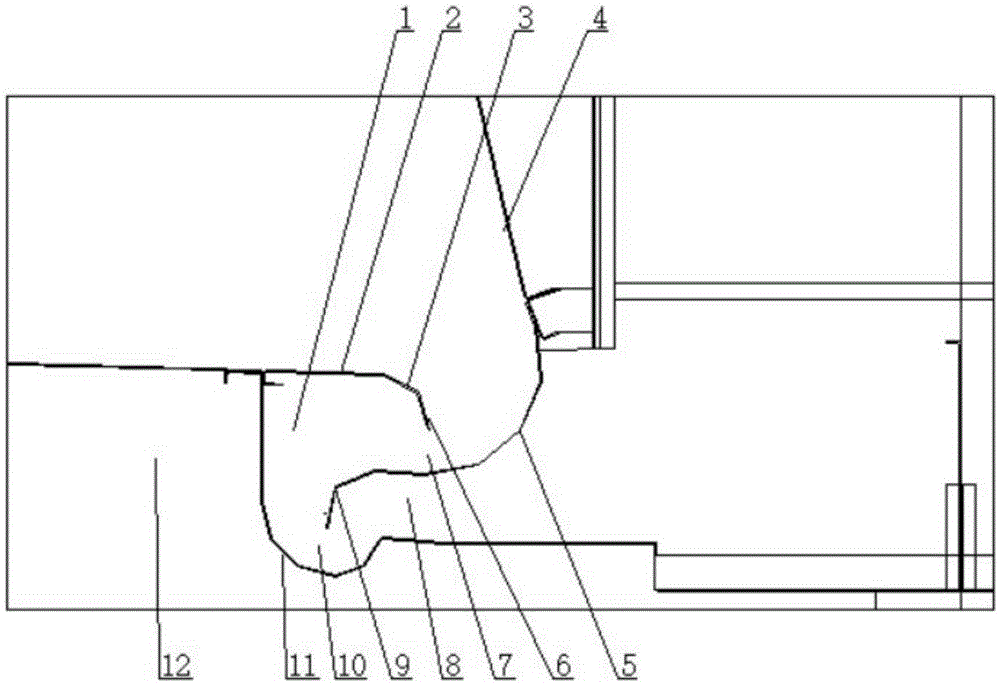

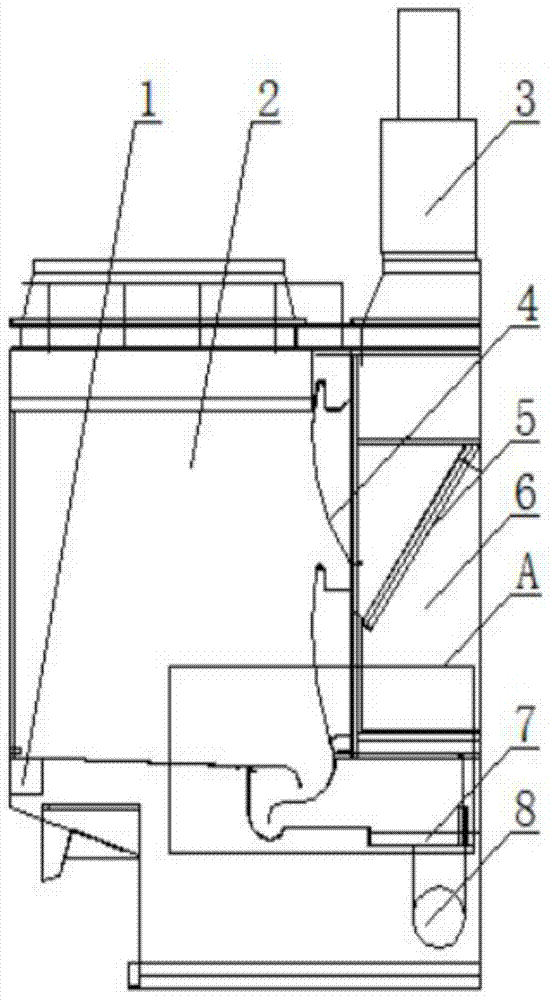

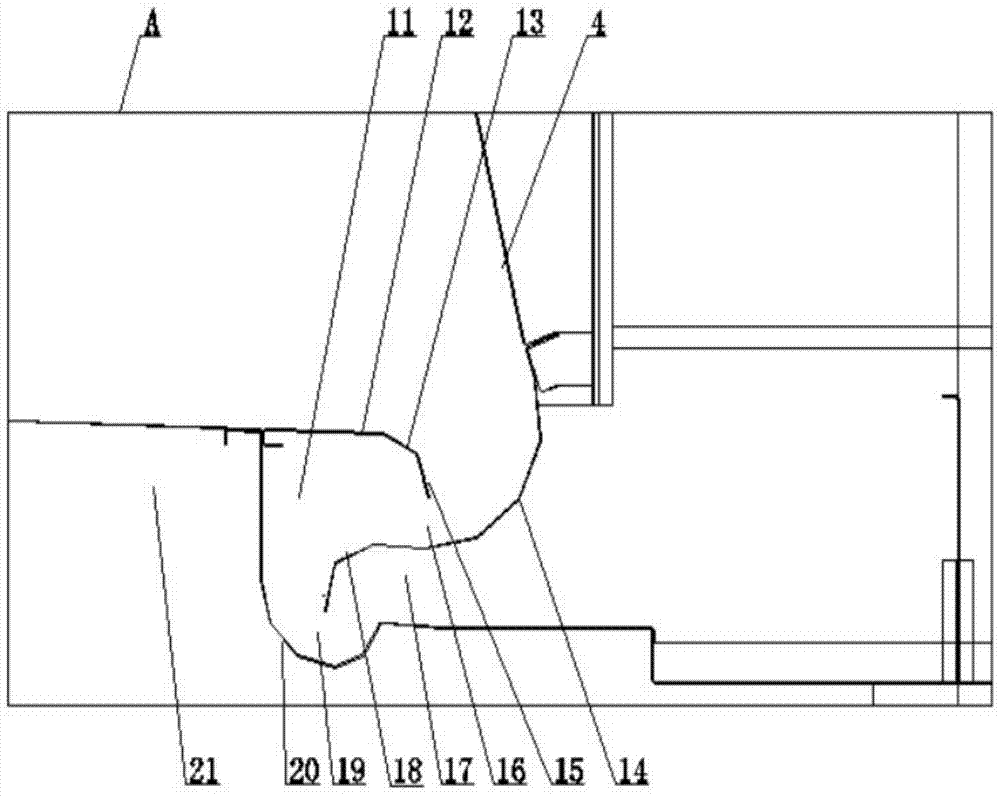

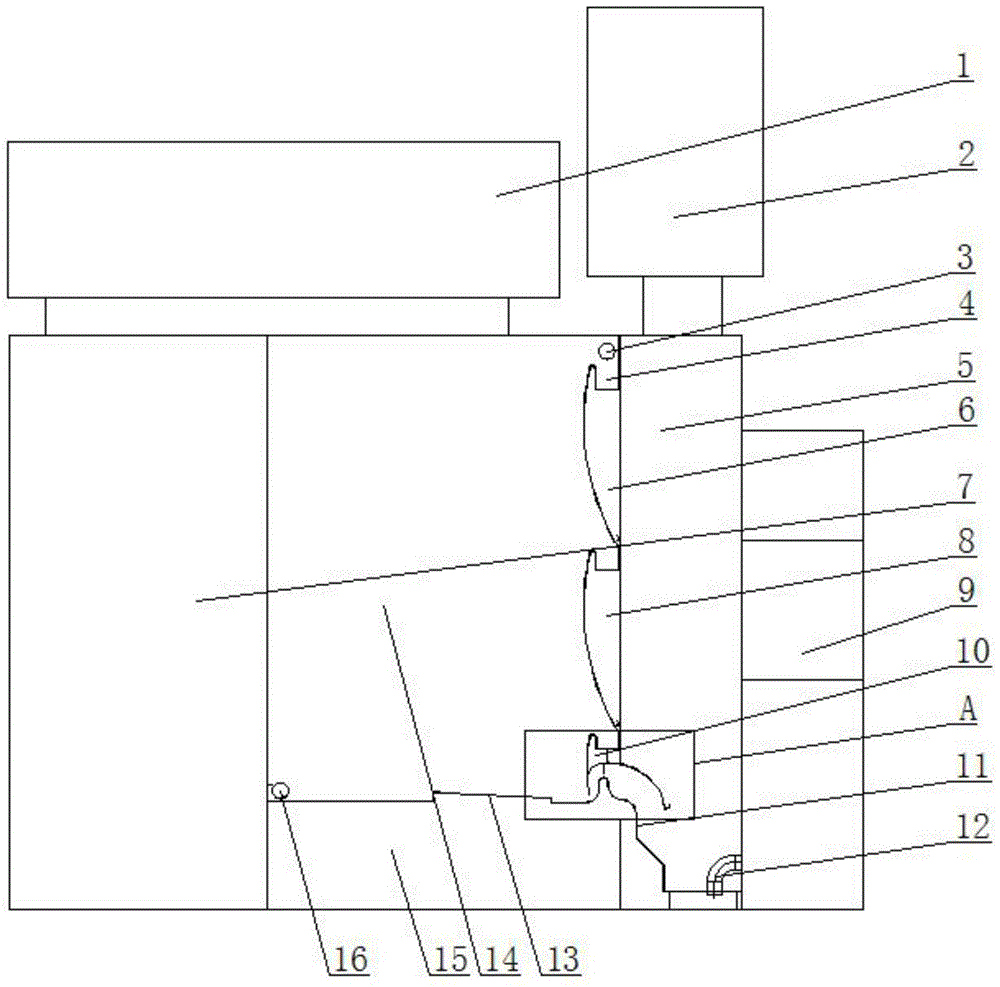

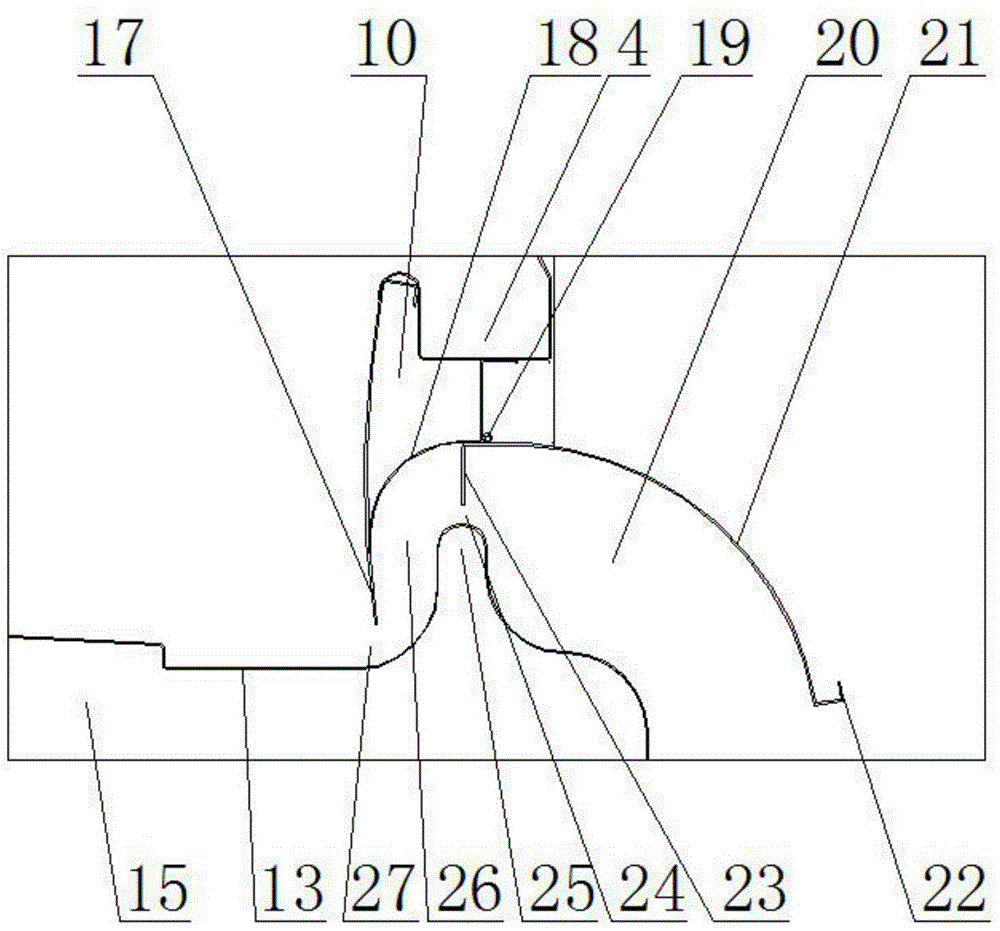

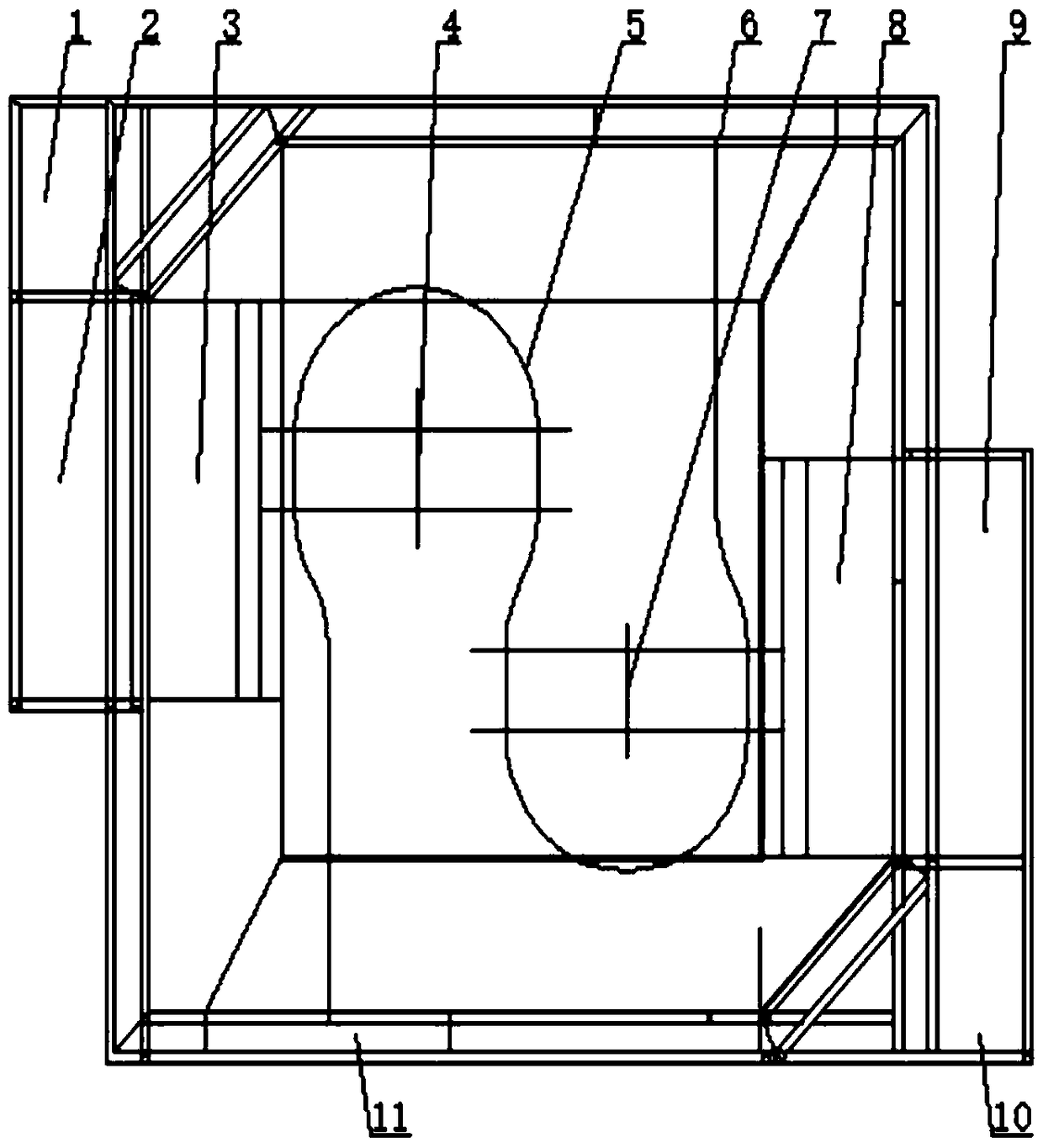

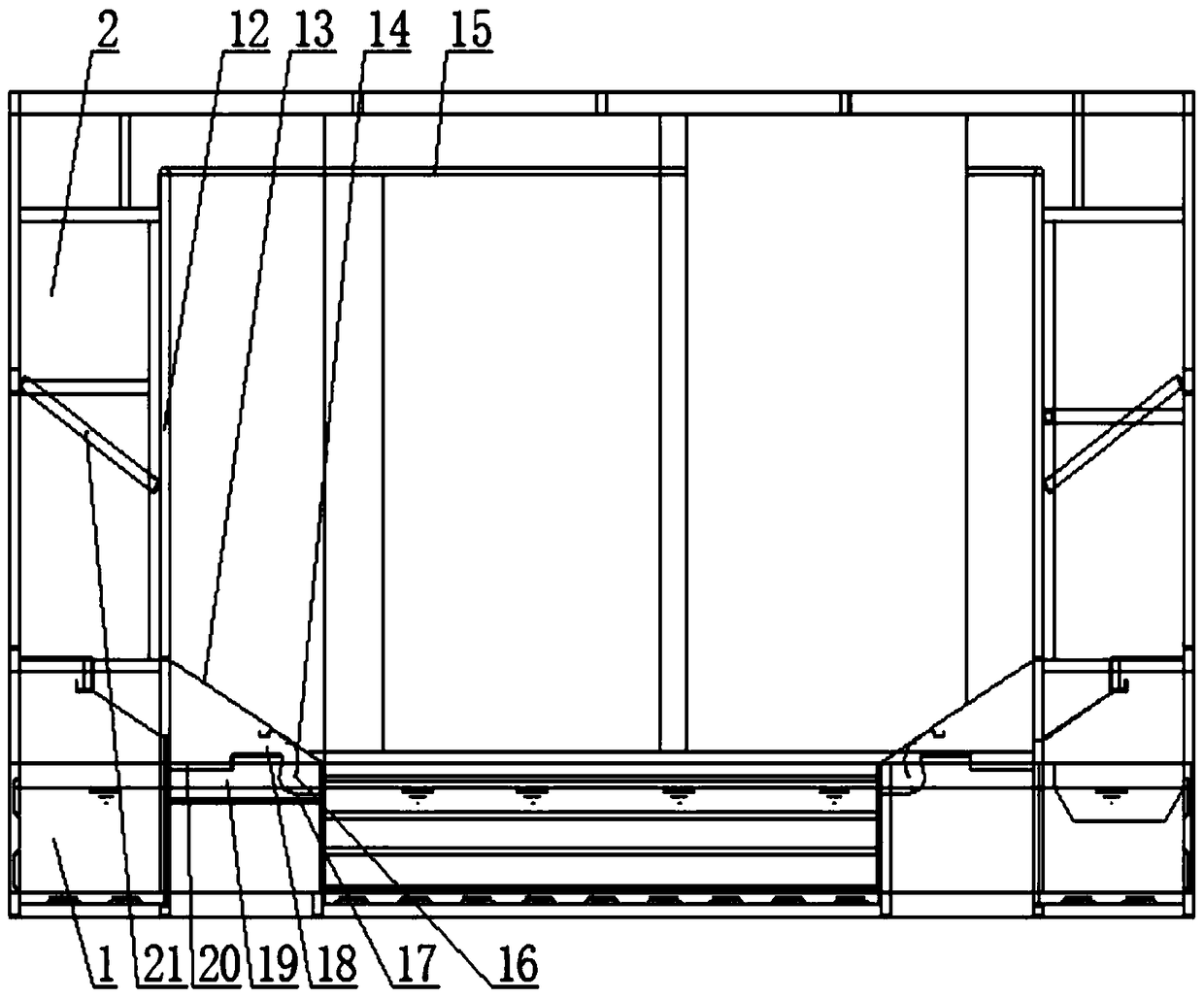

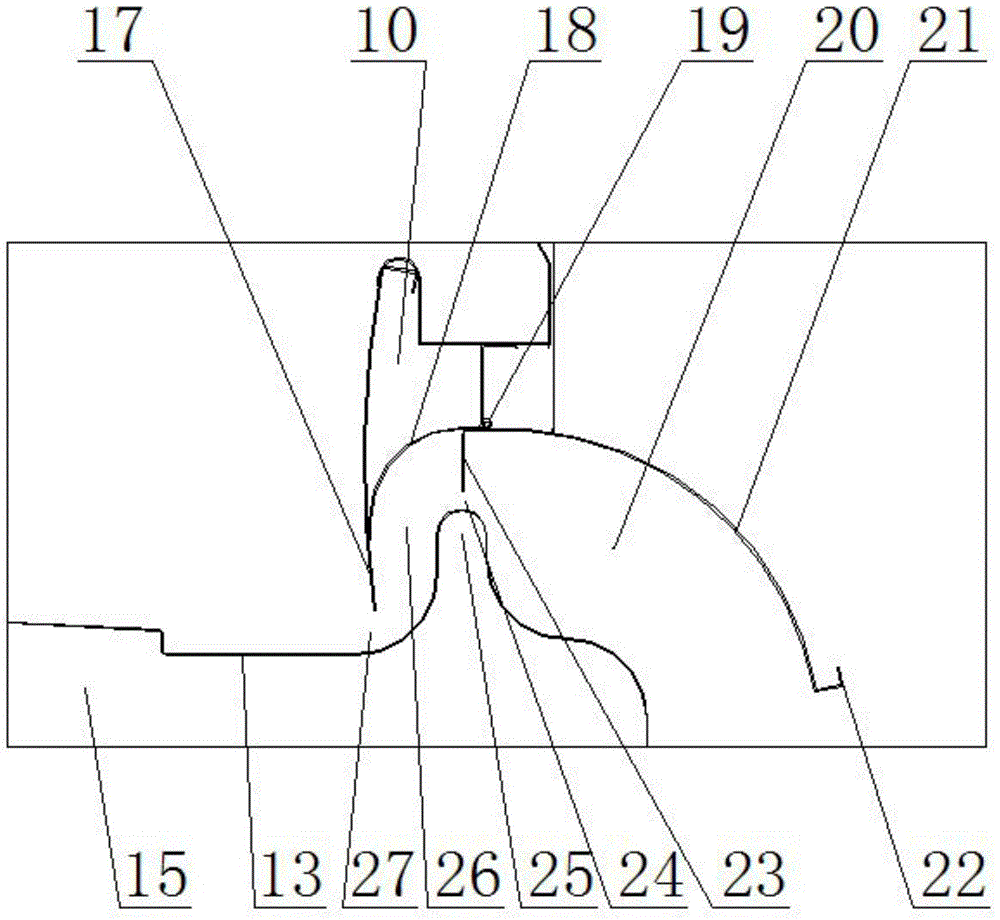

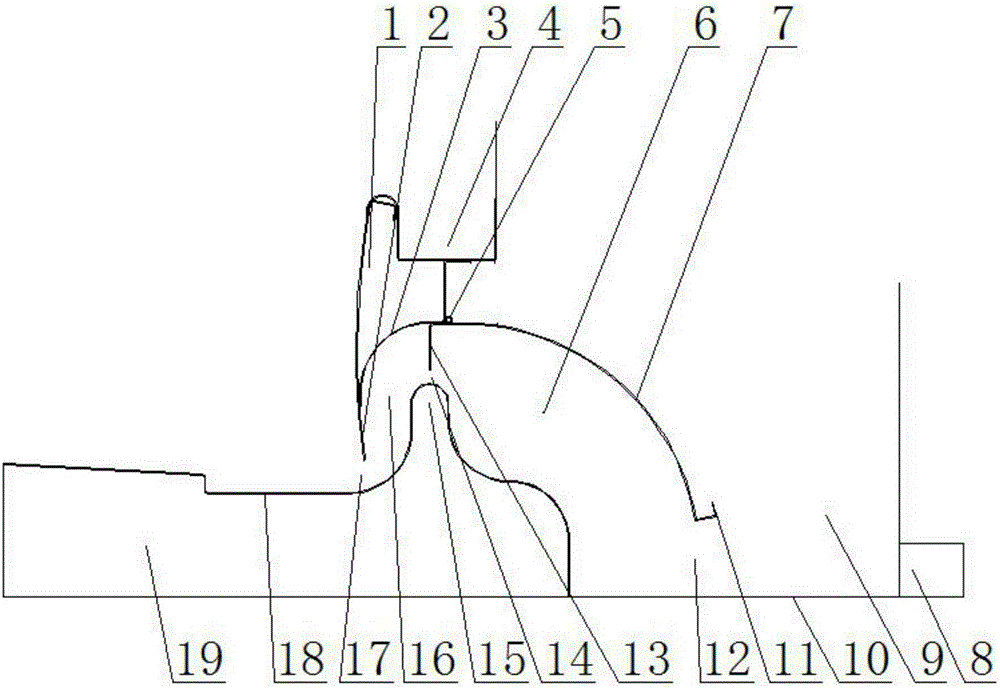

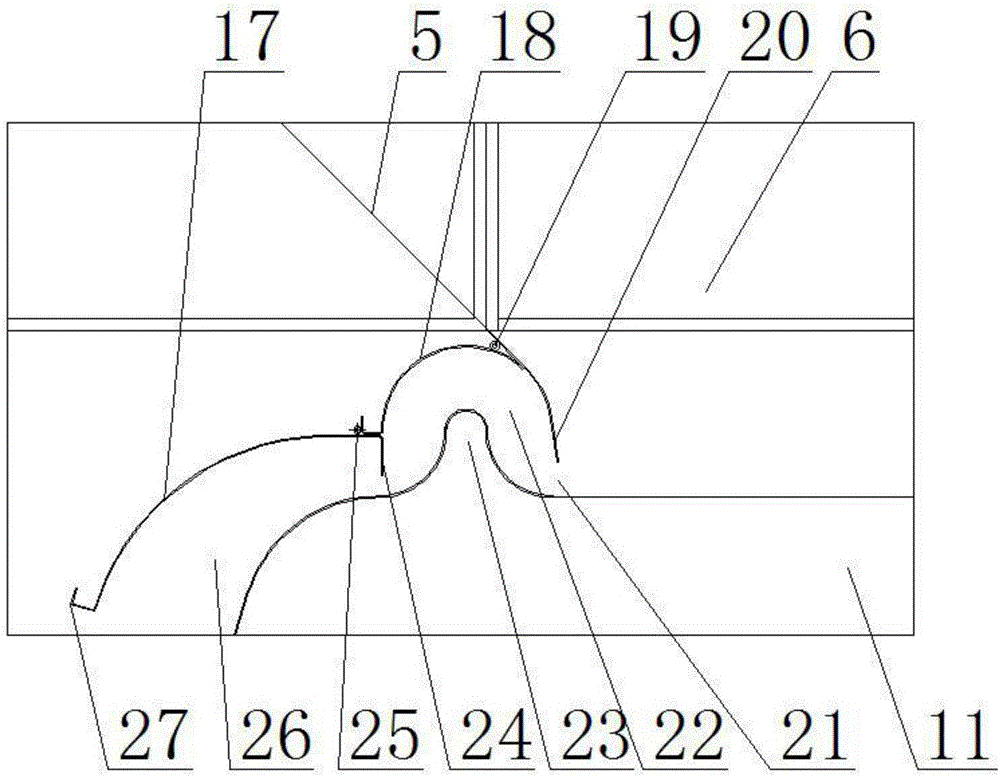

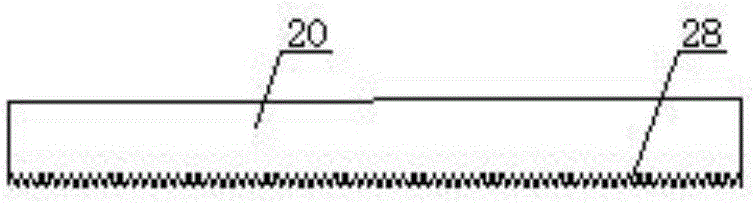

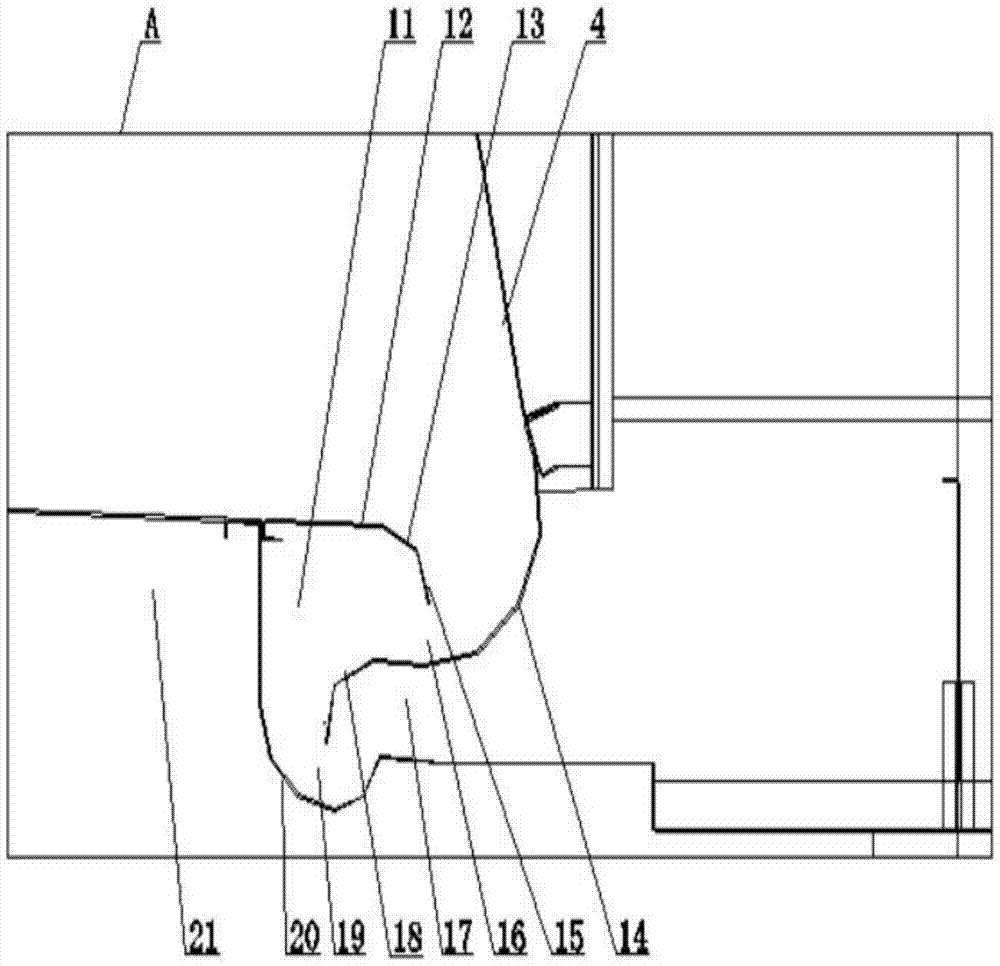

Paint spraying room with double atomizing paint mist catching structure

InactiveCN104399629ASimplify manufacturing difficultyDoes not affect horizontal distributionLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention relates to a paint spraying room with a double atomizing paint mist catching structure. The paint spraying room comprises a paint spraying room body. A water screen plate is installed on the wall of the paint spraying room body. The paint spraying room further comprises a base plate flow guide structure and a main sawtooth plate which are arranged below the paint spraying room. The water screen plate is arranged above the base plate flow guide structure. The main sawtooth plate is fixedly installed at the bottom end of the water screen plate, an arc lifting section is manufactured at the bottom end of the water screen plate, a flow guide sawtooth plate is installed on the lateral wall of the water screen plate at the upper end of the arc lifting section, the flow guide sawtooth plate integrally extends to form the arc flow guide face, the arc flow guide face is matched with the base plate flow guide structure, a first vortex atmozing space is formed among the main sawtooth plate, the flow guide sawtooth plate, the arc lifting section at the bottom end of the water screen plate and the base plate flow guide structure, and a second vortex atomizing space is formed between the flow guide sawtooth plate and the base plate flow guide structure. The paint spraying room is simple in structure, scientific and reasonable in design, low in cost, high in paint mist catching efficiency and capable of effectively reducing the follow-up environment protection processing load.

Owner:赛智环保科技(天津)有限公司

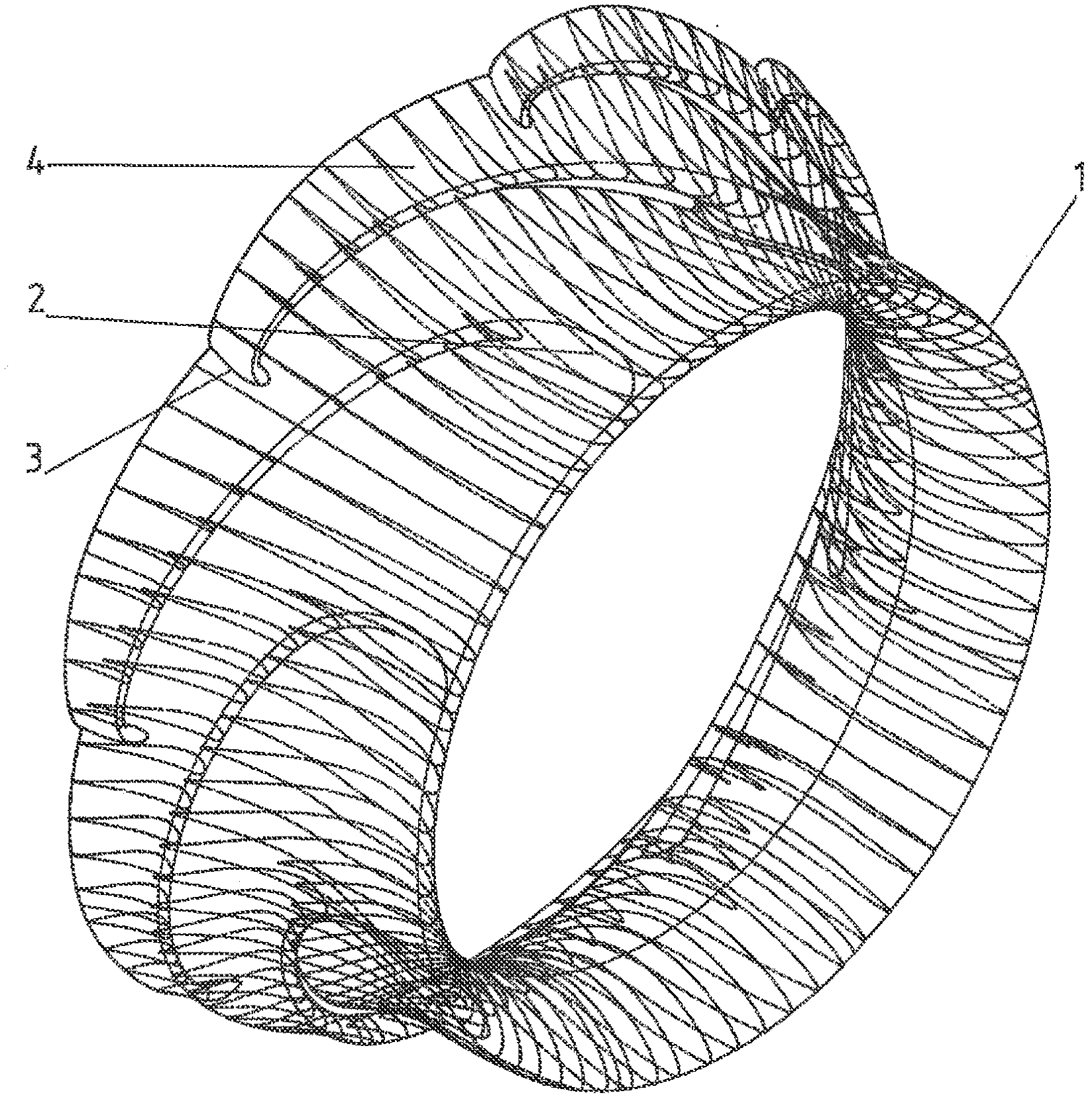

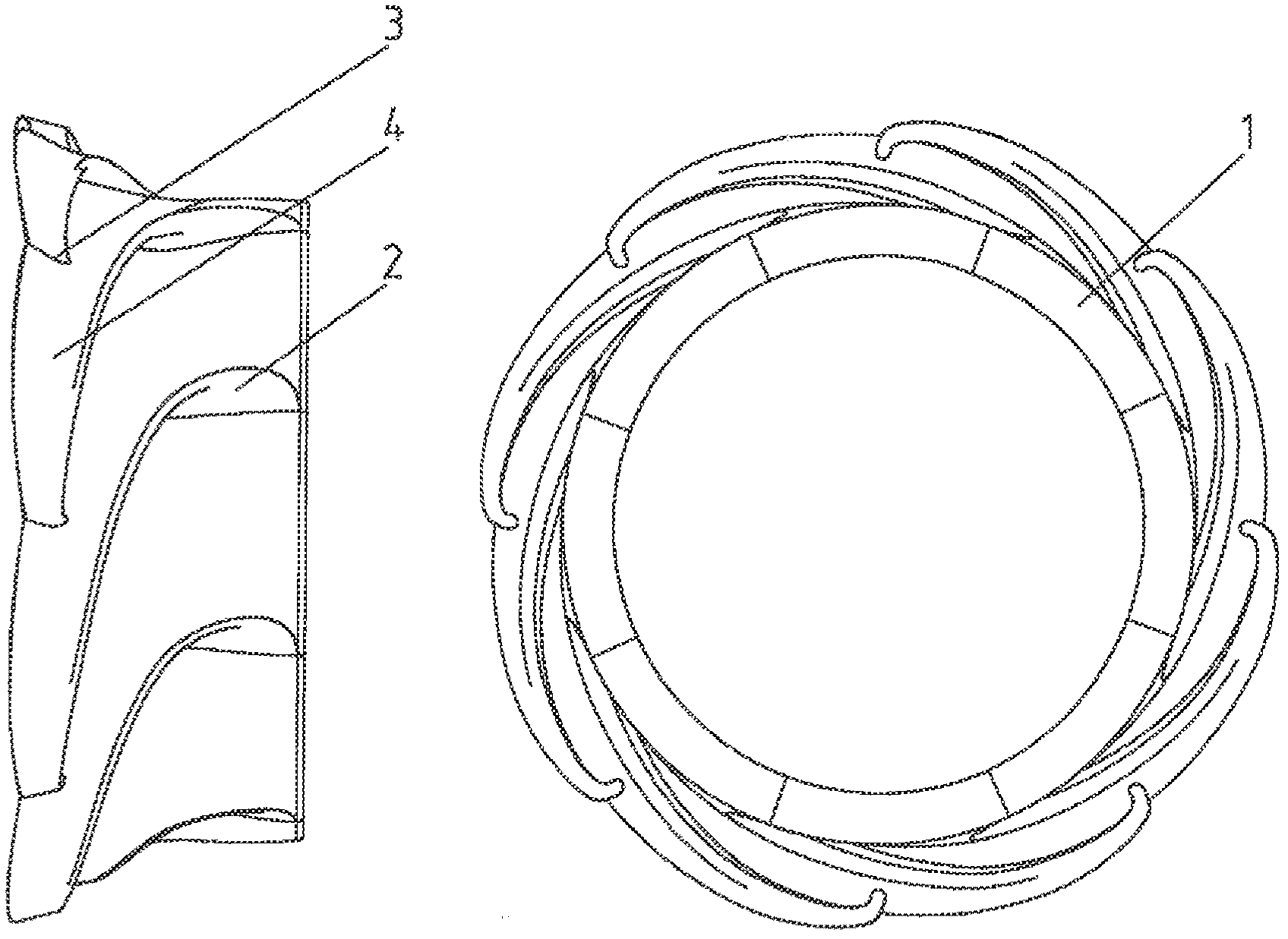

Vortex enhanced wind turbine diffuser

InactiveCN102575641ASmooth collisionHelp inhalationWind motor supports/mountsMachines/enginesLeading edgeTurbine blade

A diffuser for a wind turbine where slots in said diffuser wall entrain air to enter into the diffuser with a swirl that is counter to the internal swirl created as a reaction to the turbine blades rotation as it extracts power such that the internal swirl and the externally introduced swirl cross over each other thereby causing vortices to form between them that energizes the internal flow and helps to prevent it from separating from the internal duct wall.; Such a diffuser would beneficially consist of a radial array of repeated segments each comprising a radial portion of a duct with a wing emerging from behind said duct leading edge and spiraling out and backwards and connecting back onto the wing of the next segment round such that each segment's wing connects to the trailing neighboring segment wing just as the leading neighbors wing connects onto it, and that a gap is left between the spiral arms to permit external air to flow between the trailing edge of one segment wing and the leading edge of the adjacent wing.

Owner:KINETIC HARVEST

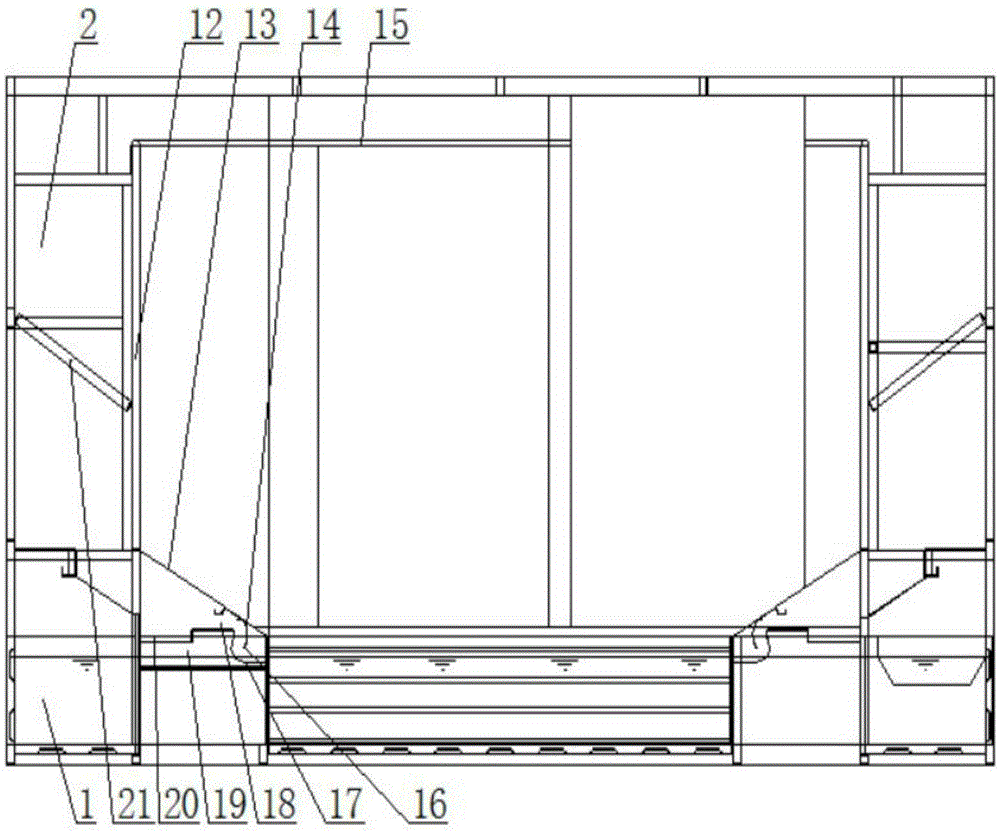

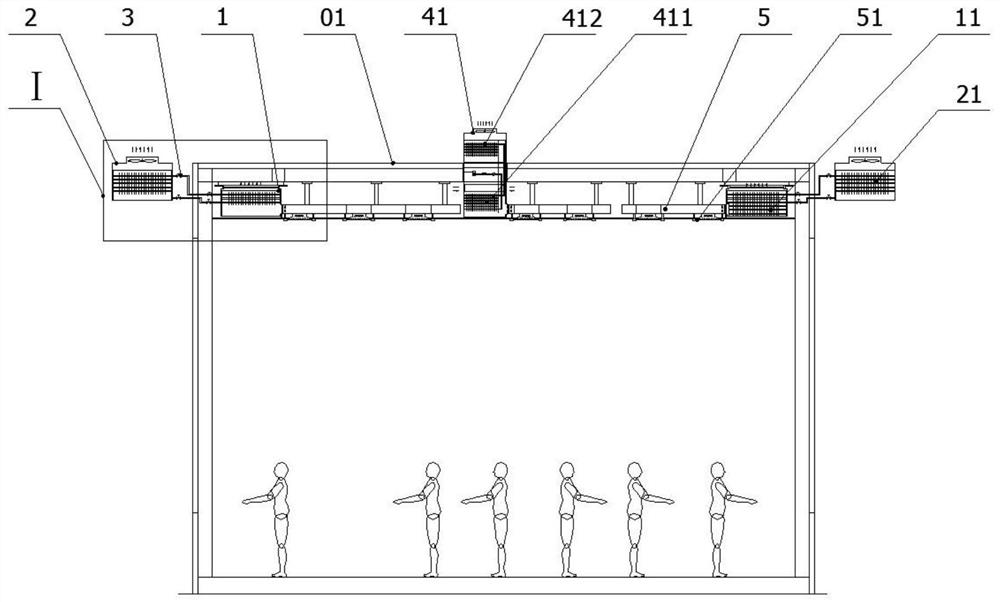

Large-sized workpiece electrostatic spraying booth

InactiveCN105396737ASimple structureScientific and reasonable designLiquid spraying plantsLiquid surface applicatorsSpray nozzleSmall footprint

The invention relates to a large-sized workpiece electrostatic spraying booth. The large-sized workpiece electrostatic spraying booth comprises a spraying booth, wherein a first electrostatic nozzle and a second electrostatic nozzle are arranged in the spraying booth in a staggering manner; a workpiece inlet is formed in the spraying booth inner wall to which the first electrostatic nozzle correspond, and a workpiece outlet is formed in the spraying booth inner wall of the other side to which the second electrostatic nozzle correspond, so that a slideway passes the first electrostatic nozzle along the workpiece inlet and rotates one time, and then passes the second electrostatic nozzle and rotates one time to reach the workpiece outlet, thereby forming two rotation slideways; a first paint mist catching structure is arranged at the lower part of the spraying booth inner wall to which the first electrostatic nozzle correspond; and a second paint mist catching structure is arranged at the lower part of the spraying booth inner wall to which the second electrostatic nozzle correspond. The large-sized workpiece electrostatic spraying booth has the beneficial effects that the large-sized workpiece electrostatic spraying booth simultaneously performs the double-faced spraying operation of large-sized workpieces, is simple in structure, scientific and reasonable in design, small in floor space and low in cost, has high spraying efficiency and high paint mist washing efficiency and improves the treatment efficiency of follow-up organic waste gases.

Owner:赛智环保科技(天津)有限公司

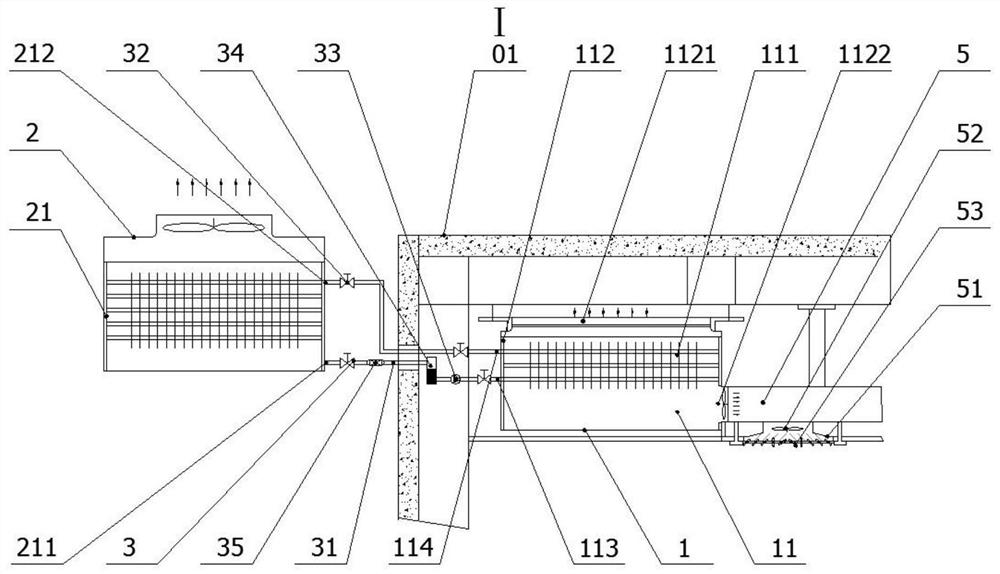

Symmetric paint spray booth having bidirectional full-flow paint spray purification function

InactiveCN105413934AImprove atomization efficiencyEffective atomizationLiquid surface applicatorsSpraying apparatusLacquerEngineering

The invention relates to a symmetric paint spray booth having a bidirectional full-flow paint spray purification function. The symmetric paint spray booth comprises two paint spray booths and two air and liquid separation chambers, wherein the two air and liquid separation chambers are isolated from each other and are arranged symmetrically; the two air and liquid separation chambers are respectively communicated with their own paint spray booths by their own paint spray capturing structures; a water curtain plate is mounted on the inner wall of each paint spray booth; a base plate flow guide structure is arranged at the bottom surface of each paint spray booth; one end, opposite to the lower end of the water curtain plate, of the base plate flow guide structure is connected with one end of a base plate extending arc-shaped flow guide plate; a serration plate is fixedly mounted on the total length of the other end of the base plate extending arc-shaped flow guide plate; a water curtain extending arc-shaped flow guide plate is arranged below the base plate extending arc-shaped flow guide plate; one end of the water curtain extending arc-shaped flow guide plate is smoothly mounted at the lower end of the water curtain plate; a serration plate is mounted at the other end of the water curtain plate. By the structure, washing liquid passes through the atomizing serration plates in a full-flow manner, so the atomization efficiency is greatly improved and the paint spray capture efficiency of the washing liquid is higher and is as high as 99.9%.

Owner:赛智环保科技(天津)有限公司

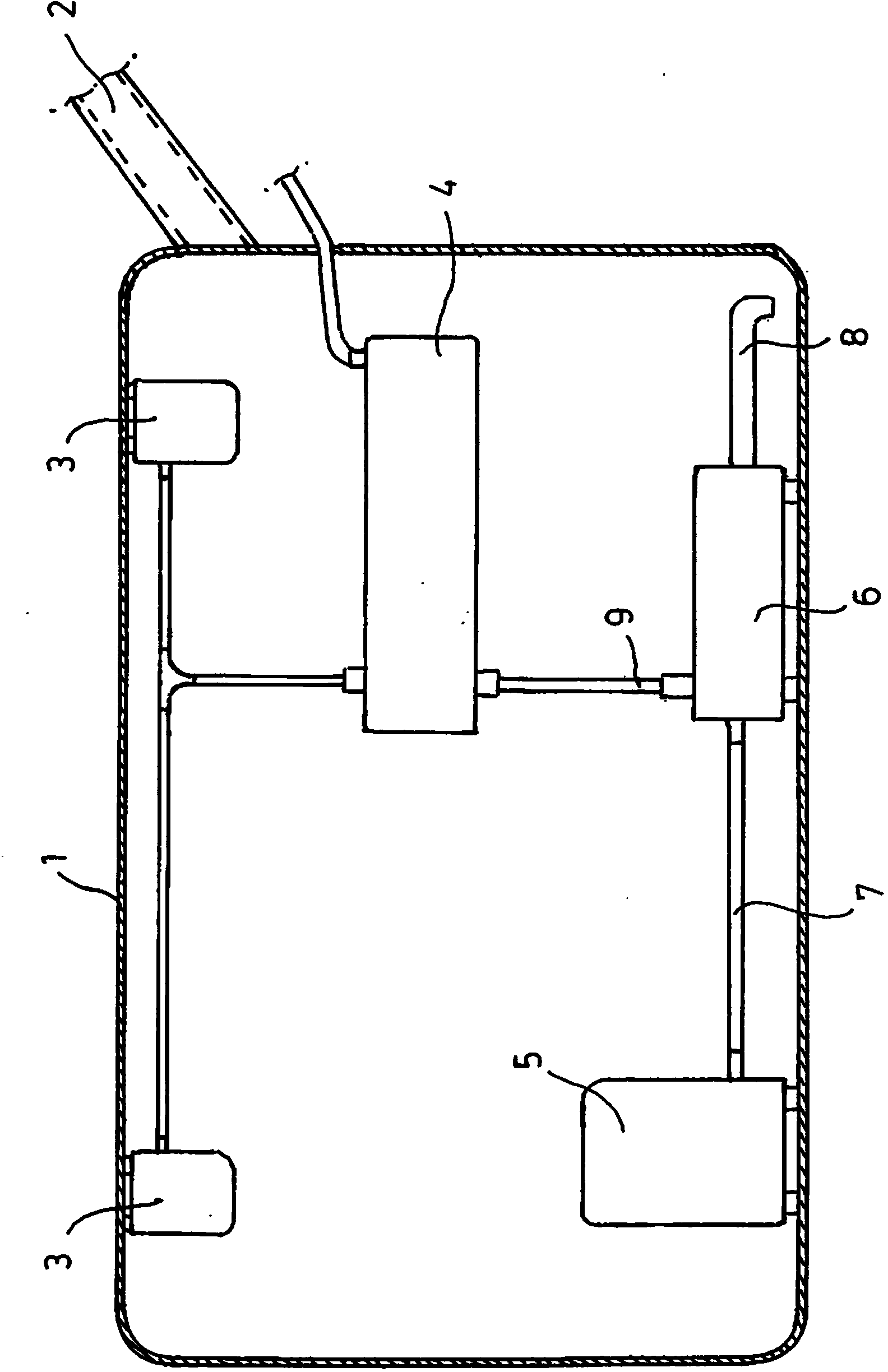

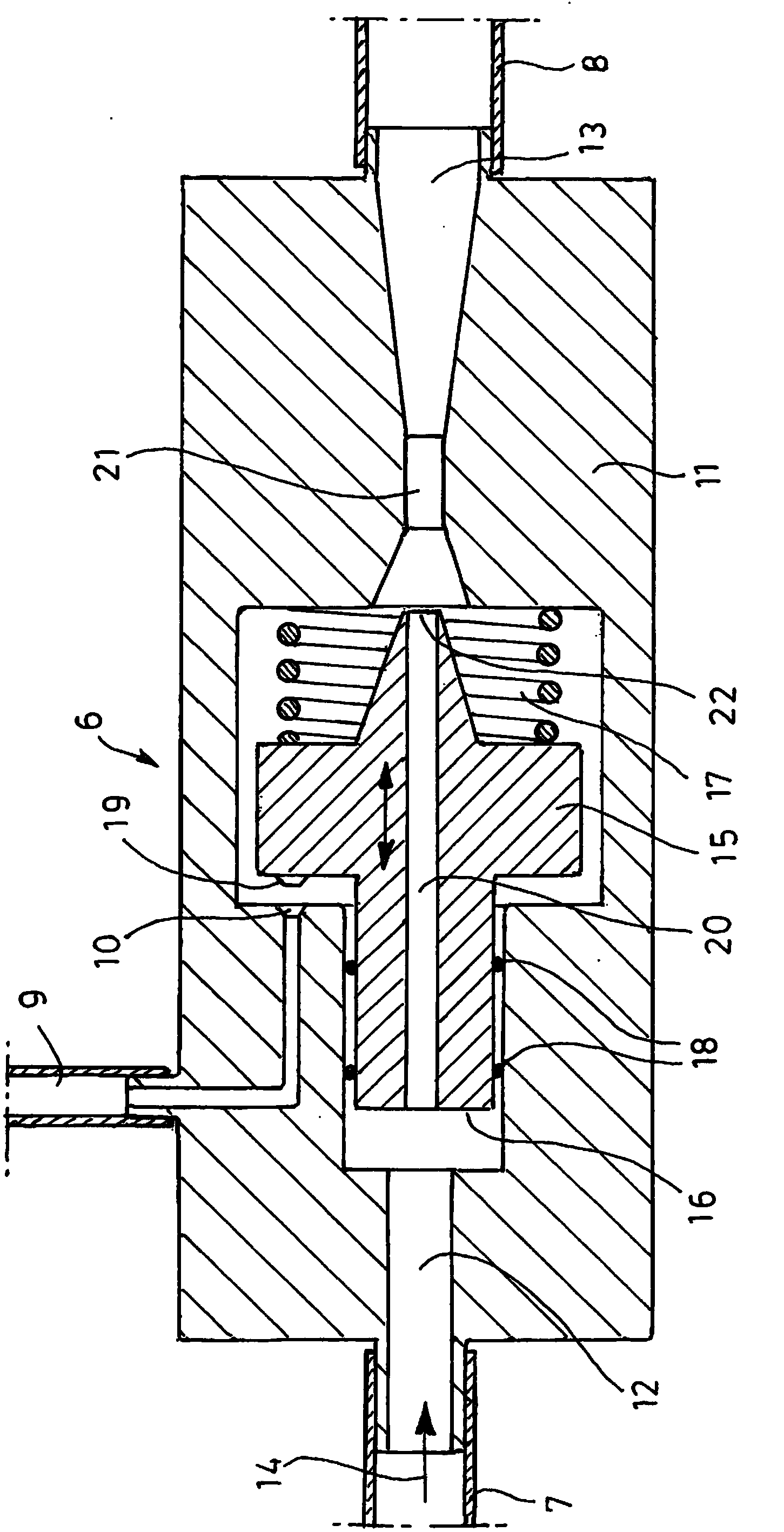

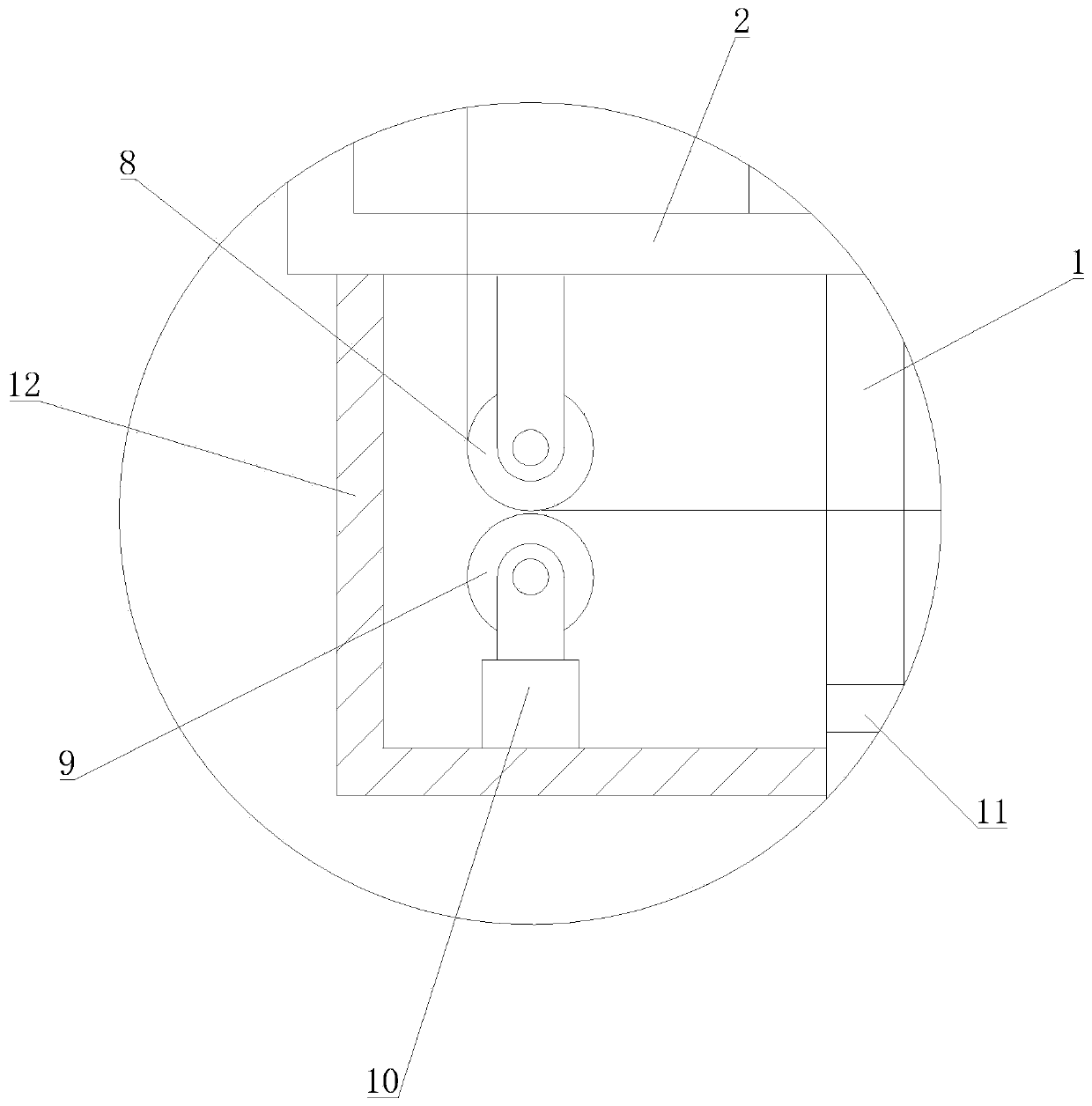

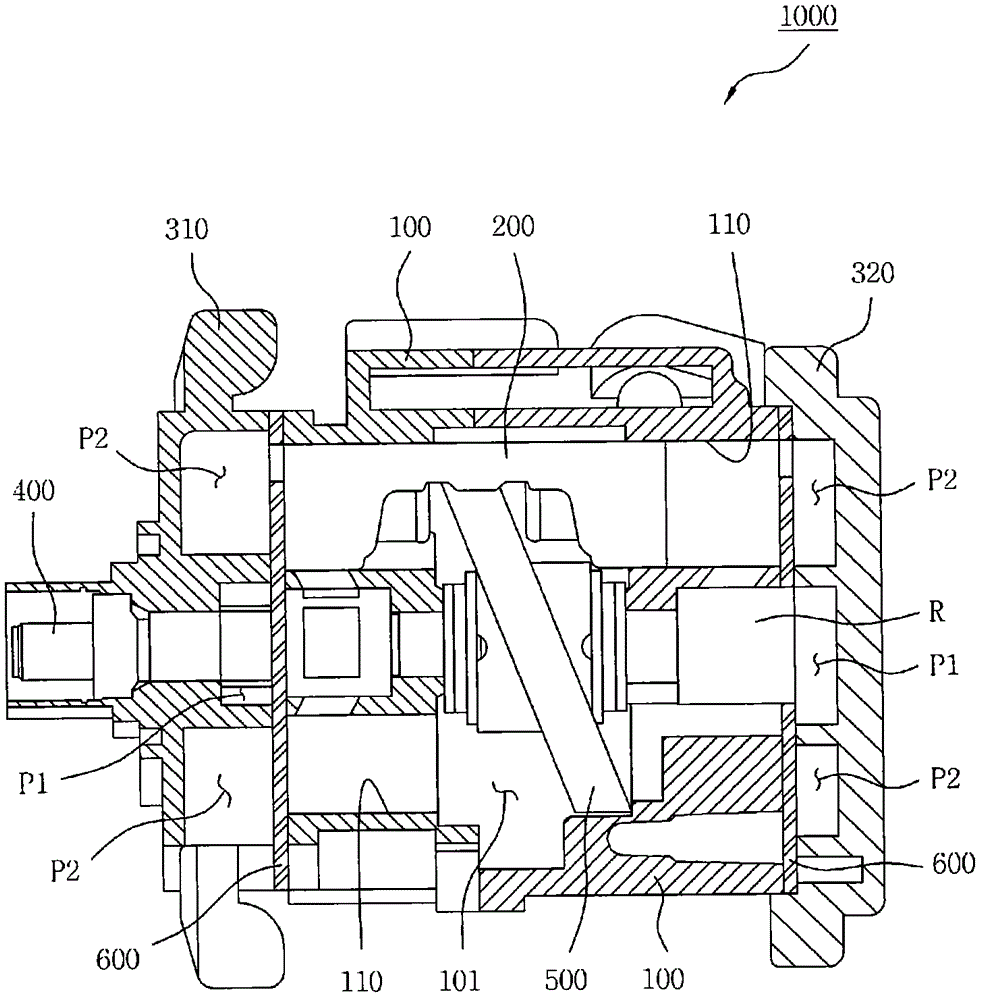

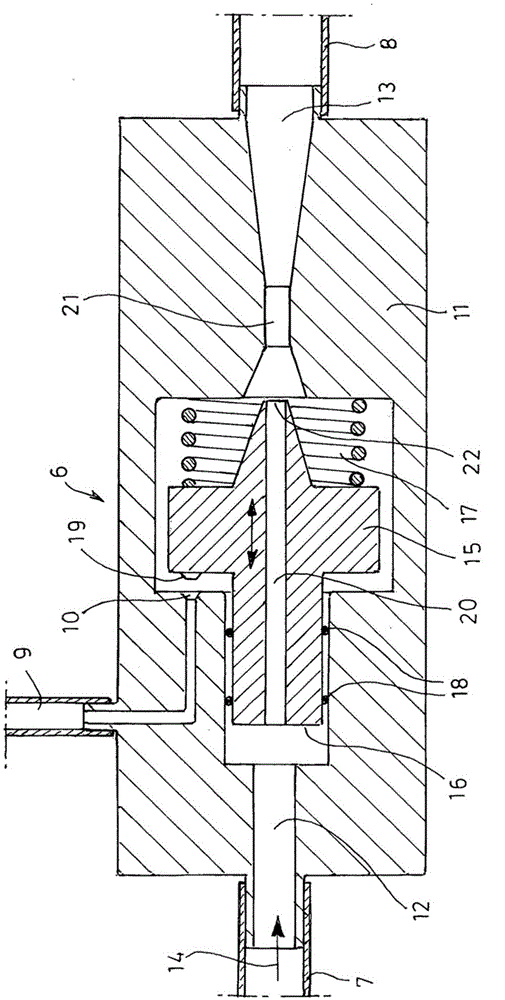

Device for pressure-dependent opening of a suction intake

ActiveCN103619629AImprove efficiencySmall pressure lossLarge containersJet pumpsFeed pressureFuel tank

The invention relates to a device (6) for pressure- dependent opening of a suction intake (10), comprising a suction jet pump (11), comprising a feed line (12), an outlet line (13) and the suction intake (10); a valve body (15), displaceably arranged inside the feed line (12) in the delivery direction (14) of the suction jet pump (11) and having an effective area (16) exposed to the feed pressure of the suction jet pump (11); and a spring element (17), arranged between the feed line (12) and the valve body (15), for applying a force in opposition to the feed pressure inside the feed line (12); wherein the effective area (16) of the valve body (15), and the spring element (17) are designed so that the valve body (15) closes the suction intake (10) so that it is fluid-tight below a predefined pressure inside the feed line (12) and opens said intake when the predefined pressure inside the feed line (12) is exceeded. The invention further relates to a fuel tank, comprising a device (6) for pressure-dependent opening of a suction intake (10).

Owner:KAUTEX TEXTRON

Dust collection putty grinding device

ActiveCN104084858BRealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

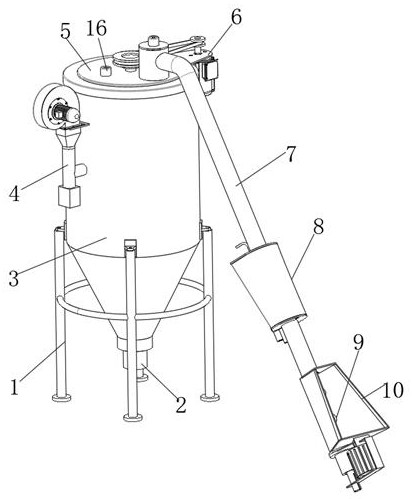

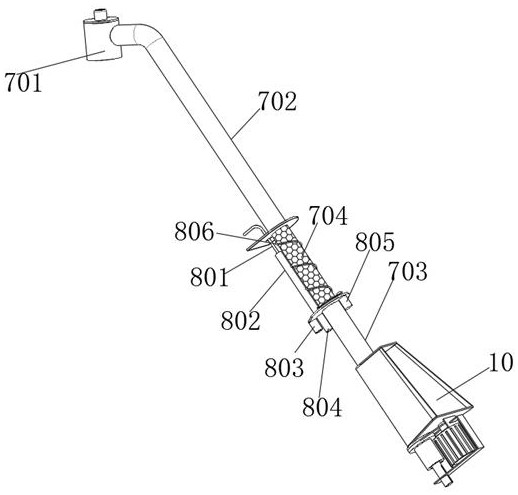

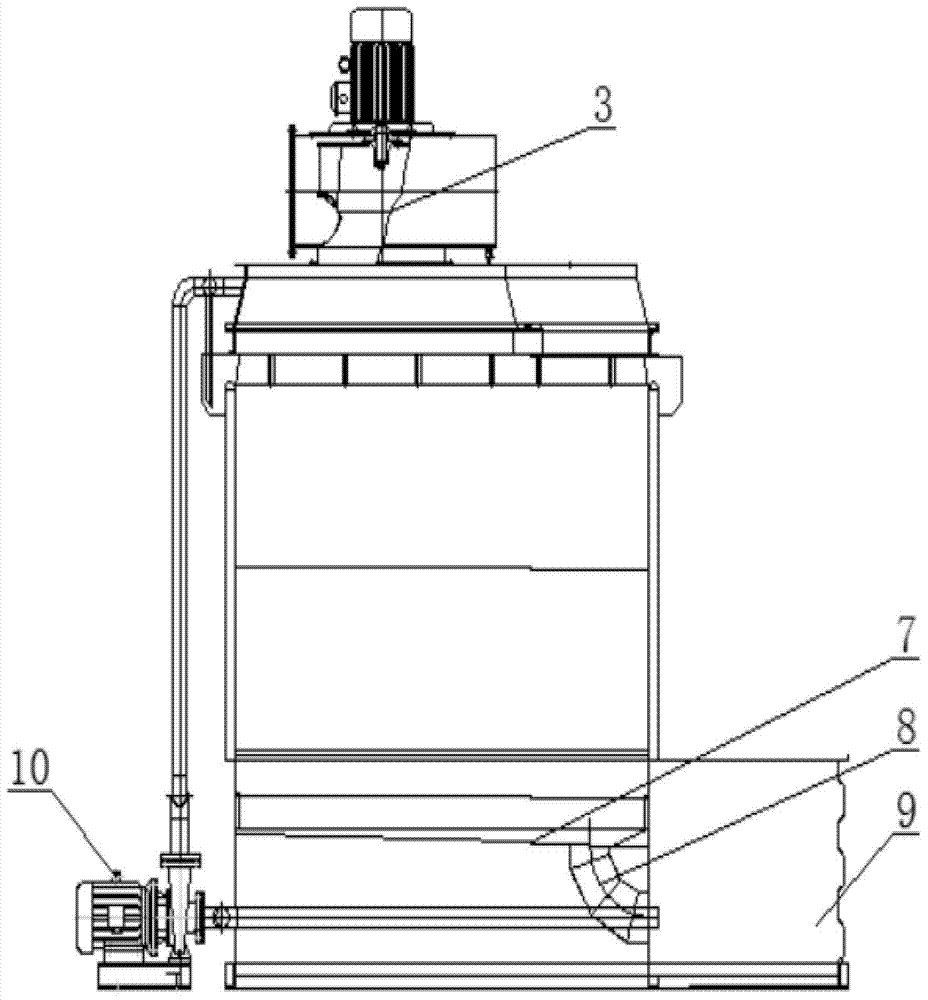

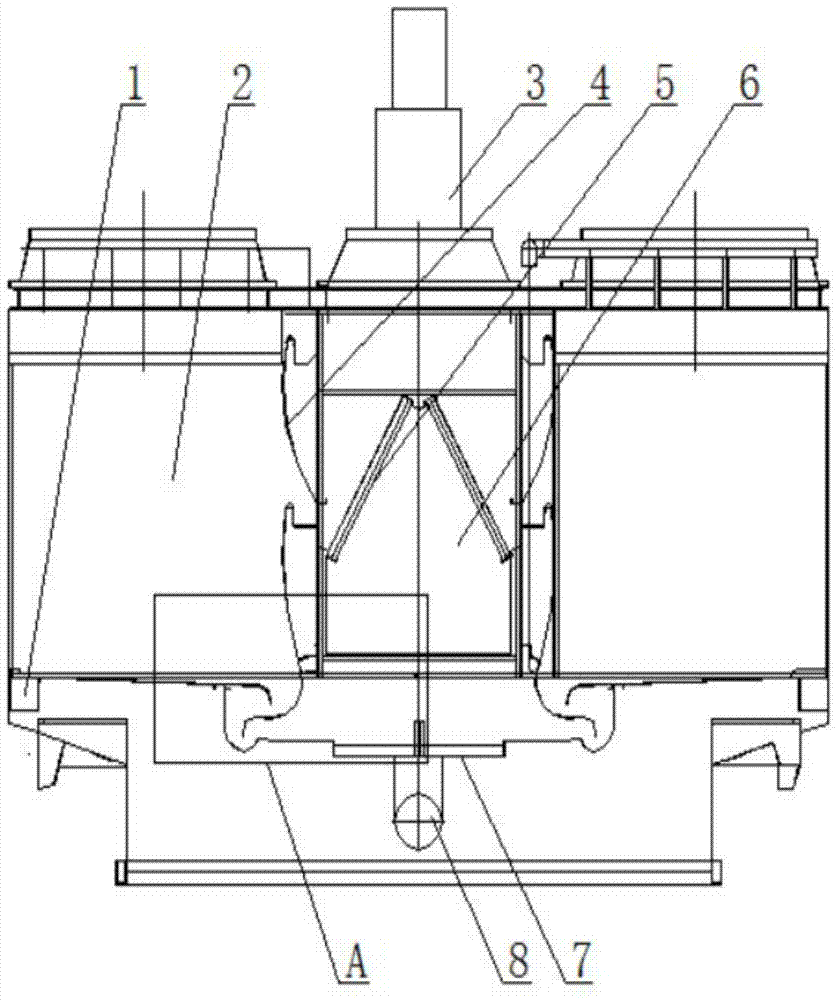

Multifunctional vacuum vertical spiral stirring, drying and pouring machine

PendingCN114688847ARealize self-cleaningReduce the situation of sticking to the wallDrying solid materials without heatDrying gas arrangementsStructural engineeringPipe

The invention discloses a multifunctional vacuum vertical spiral stirring, drying and pouring machine which comprises a pouring assembly, a material conveying assembly is arranged on one side of the pouring assembly, the upper portion of the material conveying assembly communicates with the upper portion of the pouring assembly, the material conveying assembly comprises a material conveying pipe assembly, and the material conveying pipe assembly comprises a feeding pipe. The feeding pipe communicates with the upper portion of the pouring assembly, the peripheral face of the feeding pipe is connected with a second conveying section, the end, away from the feeding pipe, of the second conveying section is connected with a metal net barrel, the end, away from the second conveying section, of the metal net barrel is fixedly provided with a first conveying section, and the lower end of the first conveying section is connected with a feeding hopper. One slope of the feeding hopper is of an opening structure, and the side, opposite to the opening, of the feeding hopper is of a cambered surface structure. According to the dust separation device, dust in materials can be separated while the materials are conveyed, self-cleaning of the dust separation mechanism can be achieved, the difficulty of cleaning and maintenance is lowered, manpower is saved, the working efficiency is improved, and the drying efficiency is improved.

Owner:CHANGZHOU YIMIN DRYING EQUIP

Paint spray booth with high-efficiency defogging capacity

InactiveCN104353581ASimplify manufacturing difficultyDoes not affect horizontal distributionLiquid surface applicatorsSpraying apparatusWater curtainWaste management

The invention relates to a paint spray booth with a high-efficiency defogging capacity, which comprises a paint spray booth, the paint spray booth comprises a personnel operation chamber and a paint spray chamber which are sequentially connected, a water curtain plate is arranged on the wall surface of the paint spray chamber, a steam-water separation chamber is arranged in the paint spray chamber on the back of the water curtain plate, the steam-water separation chamber is connected with a deslagging chamber, an air feeder is arranged above the personnel operation chamber and the paint spray chamber, an induced draft fan is arranged above the steam-water separation chamber, a baseplate diversion structure and a main serration plate are arranged below the paint spray booth, the water curtain plate is arranged above the baseplate diversion structure, the main serration plate is fully fixedly arranged at the bottom end of the water curtain plate, the bottom end of the water curtain plate is provided with an arc lifting section, a diversion serration plate is arranged on the side wall of the water curtain plate at the upper end of the arc lifting section, the diversion serration plate integrally extends so as to form an arc diversion surface, and the steam-water separation chamber is connected with the deslagging chamber by a bottom pipeline. The paint spray booth disclosed by the invention is simple in structure, scientific and reasonable in design, low in cost, and high in paint fog capture efficiency, and effectively reduces the subsequent environmental processing load.

Owner:赛智环保科技(天津)有限公司

Automatic yarn combing device for liquid control yarn production

PendingCN111304851AExtended delivery pathAchieve recyclingLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingYarnIndustrial engineering

The invention discloses an automatic yarn combing device for liquid control yarn production. The automatic yarn combing device comprises a combing and cleaning box, a drying box and a yarn combing box; a cleaning roller is arranged in the combing and cleaning box and immersed in water solution; a first water extruding roller is arranged on the drying box; a second water extruding roller is arranged below the first water extruding roller; a first guide roller is arranged on the drying box; a first drying roller and a second drying roller are arranged in the drying box; a heating device and an air separation piece are arranged in the drying box; an air spraying head is arranged on the air separation piece; a first air extractor is arranged on the yarn combing box and provided with a conveying pipe and an air return pipe; a dehumidifying box is arranged on the yarn combing box and provided with a dehumidifying device; tension devices are arranged on two sides in the yarn combing box and provided with tension rollers; and second guide rollers are arranged on the yarn combing box and positioned on two sides of the tension rollers. The automatic yarn combing device is various in function, simple in operation and convenient to use, integrates the functions of combing, cleaning, drying, brushing and absorbing, and is excellent in yarn combing effect, and the yarn production efficiencyis improved.

Owner:SUZHOU KANGFU INTELLIGENT TECH CO LTD

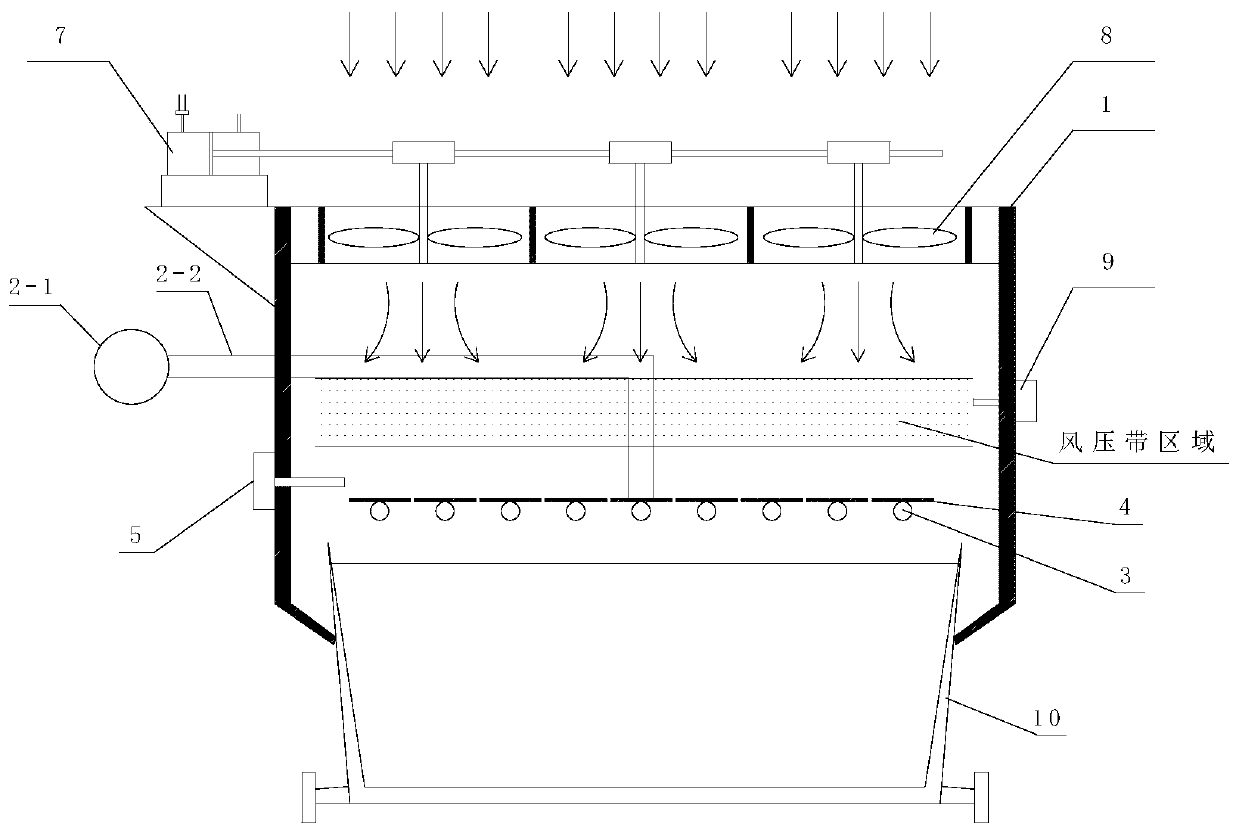

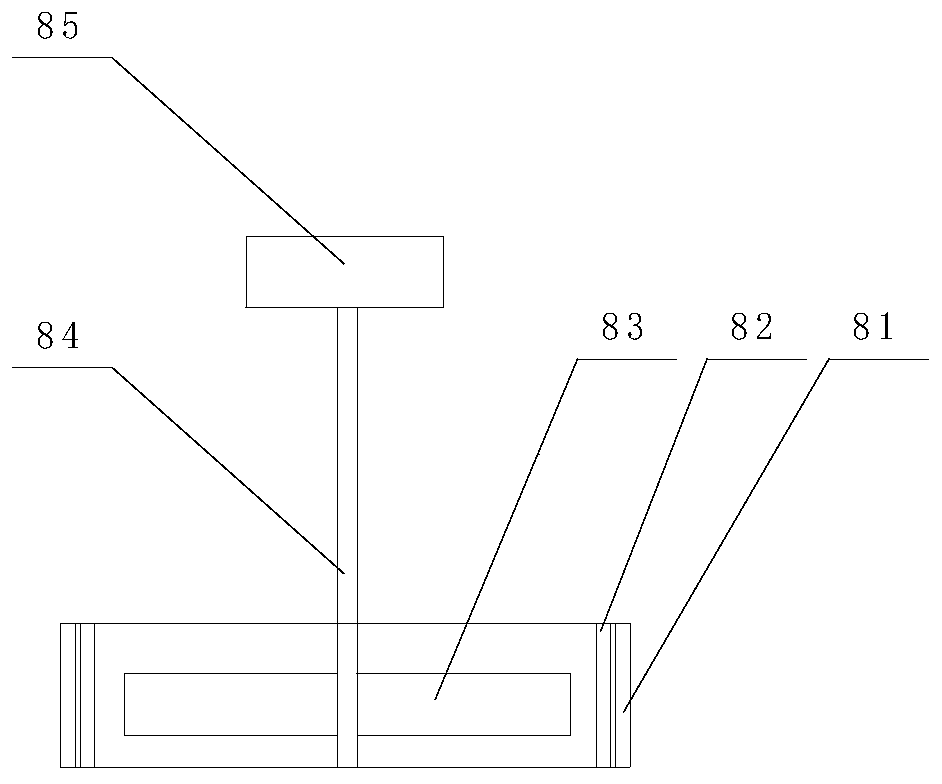

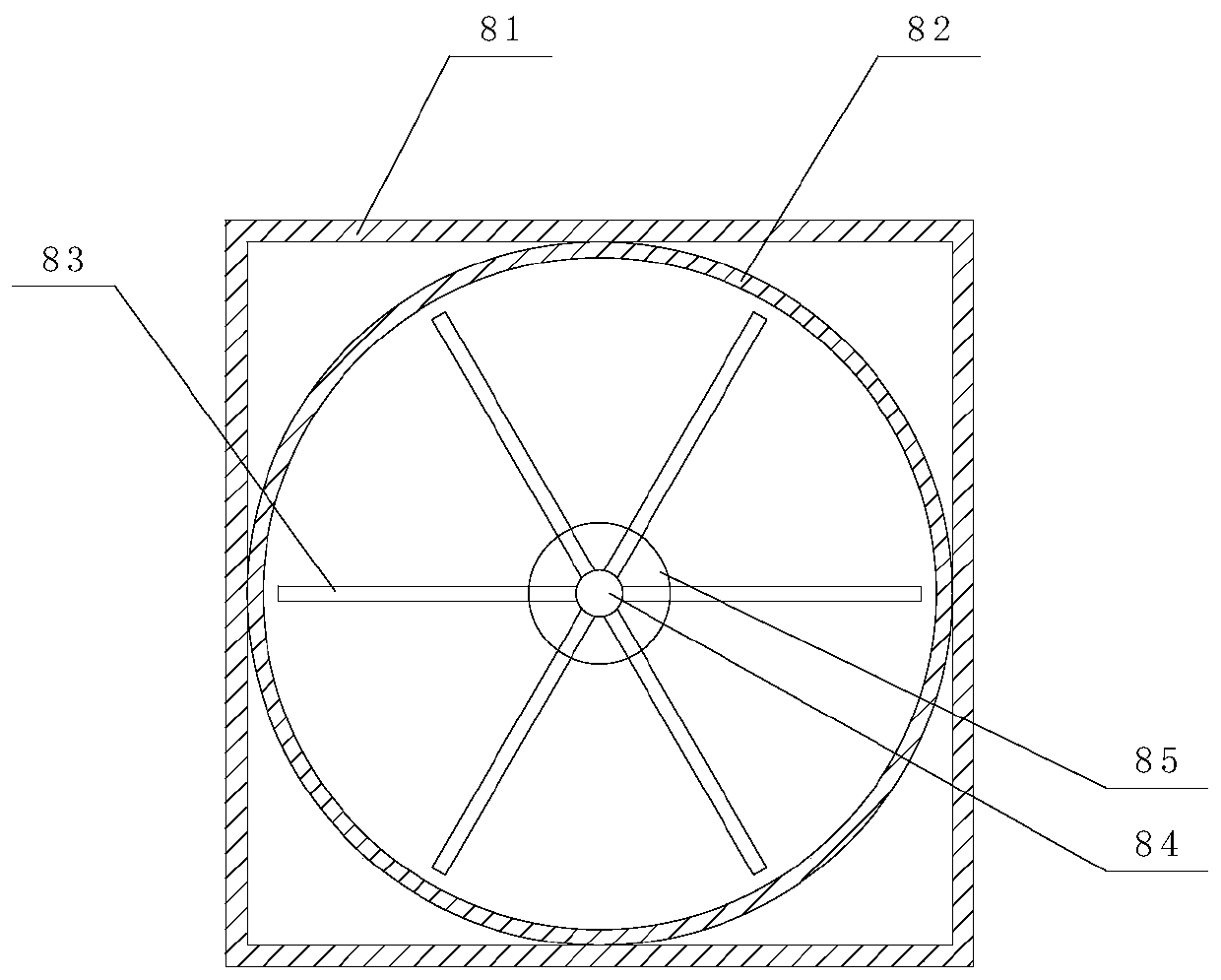

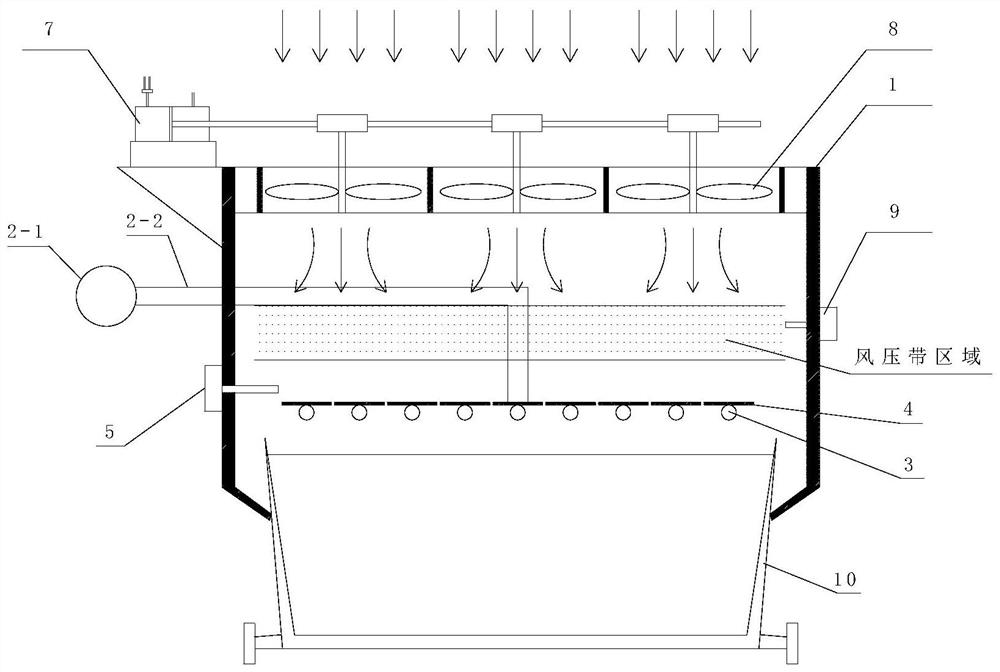

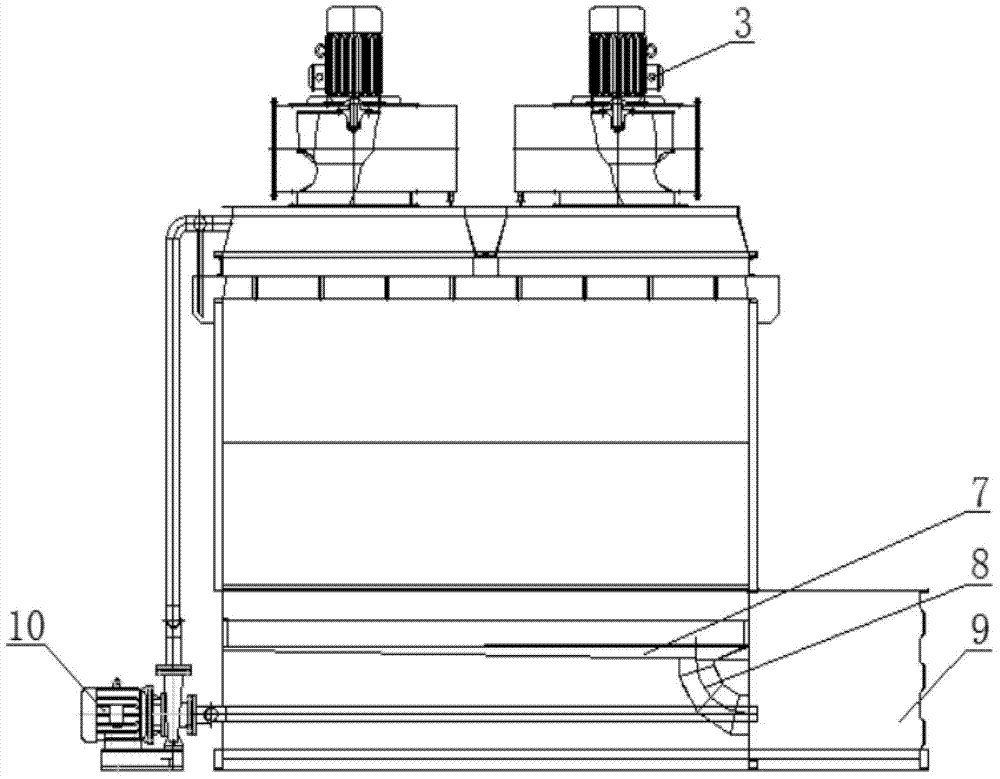

Blowing cover fuel gas escape-preventing system and control method thereof

ActiveCN110343852AAdjustable flow rateAffect the normal production of sinteringProduction lineImpeller

The invention discloses a blowing cover fuel gas escape-preventing system and a control method thereof. The blowing cover fuel gas escape-preventing system comprises a blowing cover, a blowing pipe row and a gas pipeline and is characterized by further comprising an airflow device, wherein the blowing cover is positioned at the top of a sintering machine trolley; the blowing pipe row is arranged in the blowing cover, is positioned above the sintering machine trolley and is used for blowing combustible gas to the sintering material surface of the sintering machine trolley; the gas pipeline is used for conveying combustible gas to the blowing pipe row; the airflow device comprises a driving air cylinder and a rotary impeller device; and the rotary impeller device is arranged at the top of the blowing cover and is used for driving external air to generate airflow and conveying the generated airflow into the blowing cover downwards from the top of the blowing cover to form a wind pressurebelt area above the blowing pipe row, and combustible gas cannot penetrate through the wind pressure belt area upwards. The blowing cover fuel gas escape-preventing system can basically eliminates thefuel gas escaping phenomenon and can inhale the air out of the cover to further realize the purpose that a sintering production line produces stably, smoothly and excellently.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

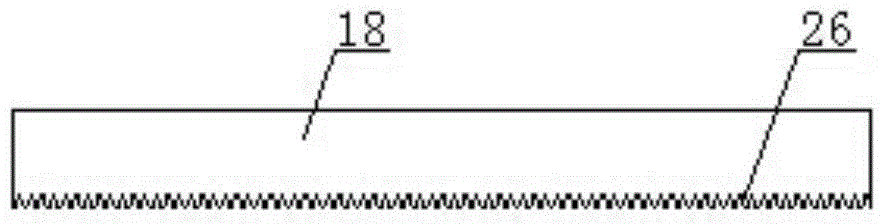

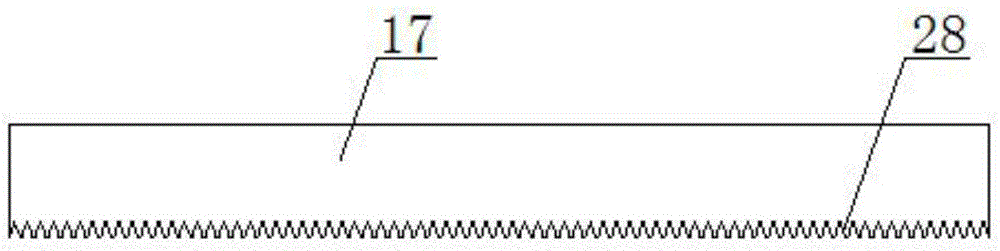

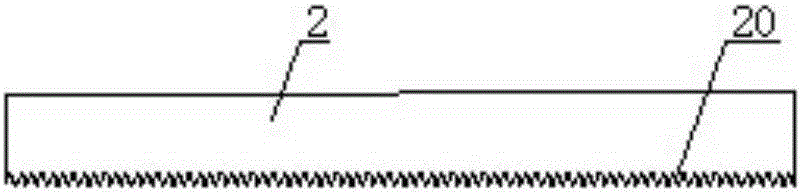

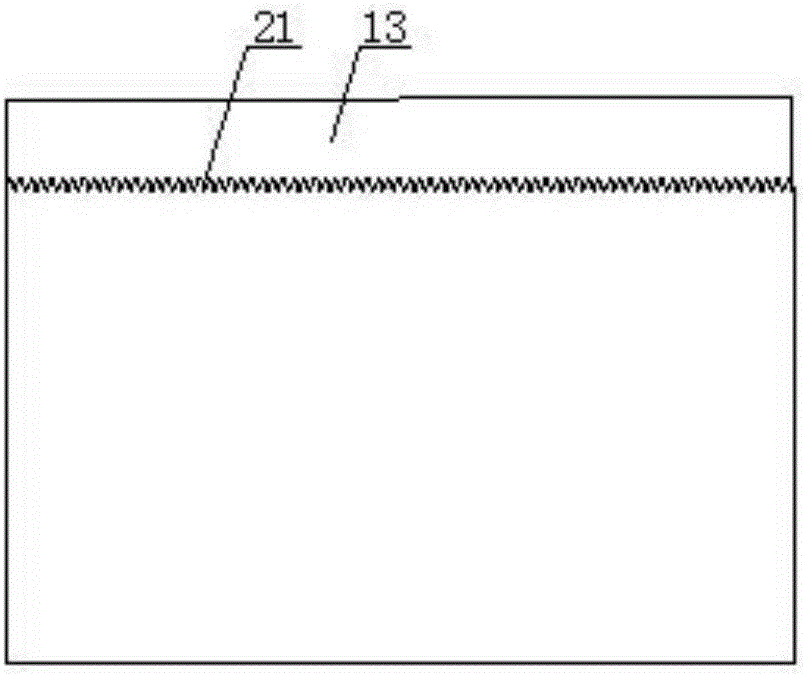

Bidirectional full-flow atomized paint mist trapping structure

InactiveCN105413355AImprove atomization efficiencyEffective atomizationUsing liquid separation agentTrappingEngineering

The invention relates to a bidirectional full-flow atomized paint mist trapping structure. The bidirectional full-flow atomized paint mist trapping structure comprises a bottom plate flow guiding structure and a water curtain plate, wherein one end, opposite to the lower end of the water curtain plate, of the bottom plate flow guiding structure is connected with one end of a bottom plate extending arc-shaped flow guiding plate, a serrate plate is fixedly mounted on the other end of the bottom plate extending arc-shaped flow guiding plate along full length, a water curtain extending arc-shaped flow guiding plate is arranged below the bottom plate extending arc-shaped flow guiding plate, one end of the water curtain extending arc-shaped flow guiding plate is smoothly mounted at the lower end of the water curtain plate, and a serrate plate is mounted at the other end of the water curtain extending arc-shaped flow guiding plate. According to the structure, a washing solution can pass through the atomizing serrate plates in a full flow manner, the efficiency of atomization is greatly increased, and the efficiency of paint mist trapping for the washing solution can reach up to 99.6%.

Owner:赛智环保科技(天津)有限公司

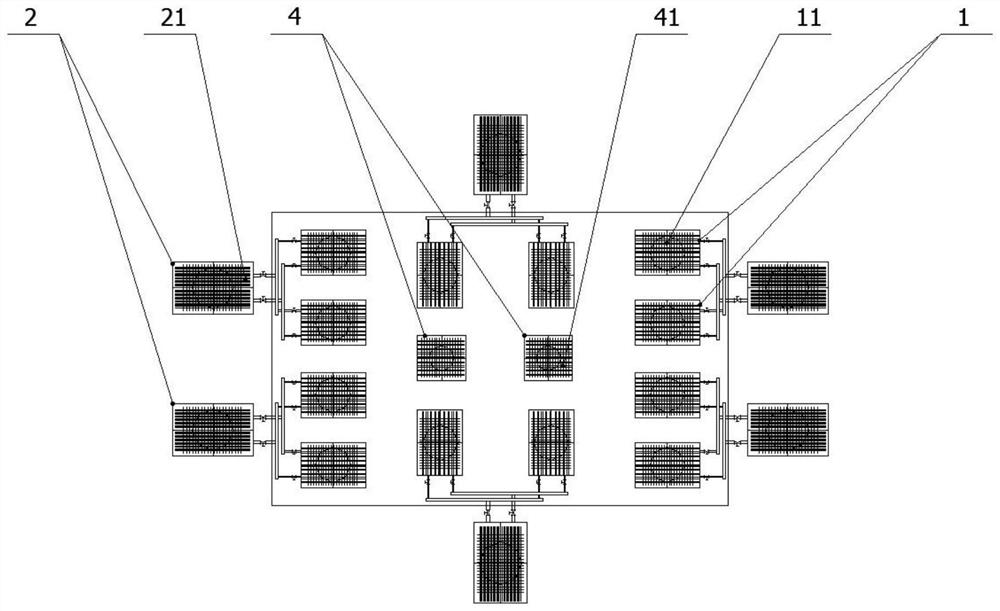

Heat pipe cold radiation system for public place

PendingCN113803819ASpacious interiorLarge horizontal areaLighting and heating apparatusAir conditioning systemsPublic placeEngineering

The invention discloses a heat pipe cold radiation system for a public place, comprising an evaporation unit assembly, a condensation unit assembly and a working medium transmission assembly, or comprising an evaporation unit assembly, a condensation unit assembly, an evaporation and condensation unit assembly and a working medium transmission assembly. The evaporation unit assembly comprises more than two first evaporation units, and the more than two first evaporation units are arranged in the top area of the indoor space of the public place; the condensation unit assembly comprises more than one first condensation unit, and the first condensation units are arranged outside the public place; the working medium transmission assembly is used for communicating the evaporation unit assembly and the condensation unit assembly; the evaporation and condensation unit assembly comprises more than one evaporation and condensation unit, and the evaporation and condensation units are of an integral structure and are embedded in the top of the public place. The integrated evaporation and condensation unit assembly is short in working medium transmission pipeline, outstanding in gravity driving capacity and high in refrigeration efficiency, and the configuration cost and the later operation energy consumption are effectively reduced.

Owner:LEAN THERMAL TECH (SUZHOU) CO LTD

Double atomization capture electrostatic spray booth

InactiveCN104437949BImprove capture abilityLarge specific surface areaLiquid surface applicatorsSpraying apparatusSpray nozzleWater curtain

The invention relates to a double-atomization capturing electrostatic paint spray booth which comprises an electrostatic paint spray booth. An electrostatic spray nozzle is mounted in the electrostatic paint spray booth, a main water curtain plate and side water curtain plates are arranged on the inner wall of the electrostatic paint spray booth, a steam-water separation chamber is connected to the back of the main water curtain plate of the electrostatic paint spray booth, a bevel flushing plate is arranged on the lower portion of the main water curtain plate, the electrostatic paint spray booth is communicated with the steam-water separation chamber via a double-atomization paint mist capturing structure which is connected with the lower end of the bevel flushing plate, and a bottom plate flow guide structure is arranged at the bottom of the electrostatic paint spray booth. The double-atomization capturing electrostatic paint spray booth has the advantages that the double-atomization capturing electrostatic paint spray booth is simple in structure, scientific and reasonable in design, low in cost and high in paint mist capturing efficiency, and follow-up environmental protection treatment load can be effectively reduced.

Owner:赛智环保科技(天津)有限公司

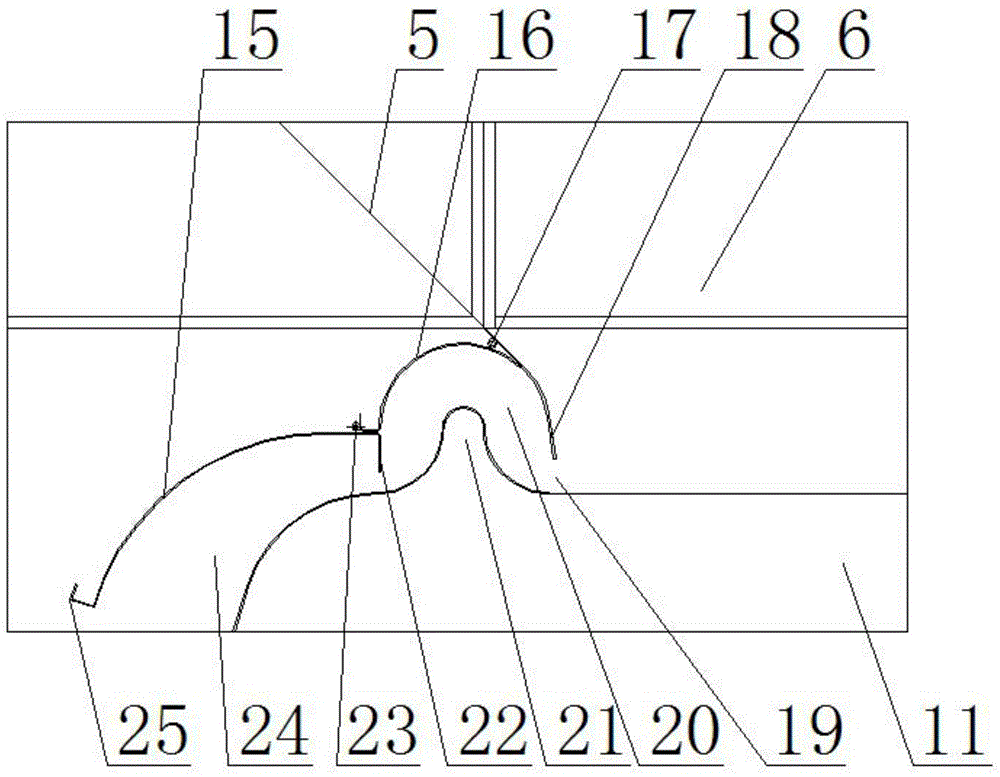

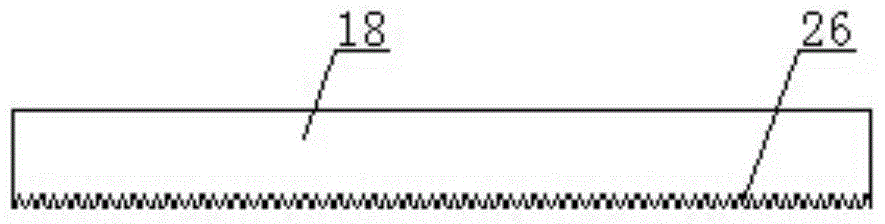

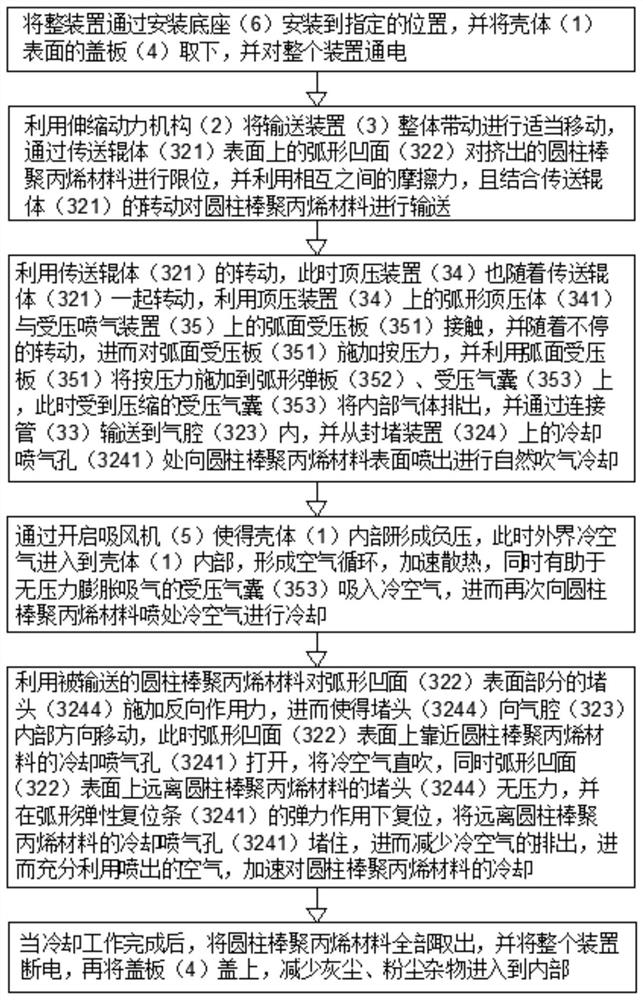

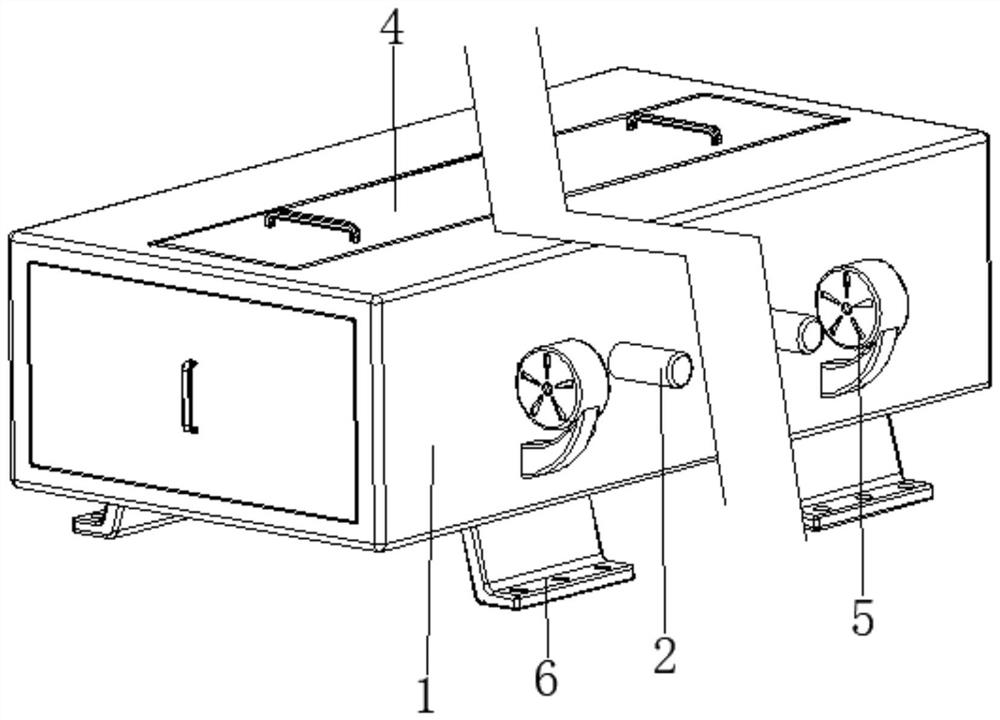

Cooling device and cooling method for reinforced polypropylene material production

The invention discloses a cooling device and a cooling method for reinforced polypropylene material production, the cooling device comprises a shell, a telescopic power mechanism and a conveying device, the surface of the telescopic power mechanism is fixedly connected with the surface of the shell, the conveying device is arranged in the shell and close to the telescopic power mechanism, the conveying cooling device is arranged in a U-shaped frame, and the U-shaped frame is fixedly connected with the shell. The jacking device is arranged at the end of the conveying and cooling device, the pressed air injection devices are arranged at the top and the bottom of the inner wall of the U-shaped frame and close to the jacking device, the air cavity communicates with one end of the connecting pipe, and the plugging device is arranged in the conveying roller body and close to the arc-shaped concave face. According to the cooling device and the cooling method for production of the reinforced polypropylene material, the rapid cooling effect is achieved, the polypropylene material can be naturally air-cooled and guided to be output, the material is not prone to being damaged, safety and reliability are achieved, and the production efficiency and the use performance are improved.

Owner:江苏思可达塑业有限公司

Spray booth with two-way full-flow paint mist capture function

ActiveCN105413933BImprove atomization efficiencyEffective atomizationLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a paint spraying room with a two-way all-flow paint mist capturing function. The paint spraying room comprises a paint spraying chamber and an air-liquid separation chamber; the paint spraying chamber is communicated with the air-liquid separation chamber through a paint mist capturing structure; one end, opposite to the lower end of a water curtain plate, of a baseplate guide structure is connected with one end of a baseplate extension arc guide plate; a saw tooth plate is fixedly mounted at the other end of the baseplate extension arc guide plate; a water curtain extension arc guide plate is arranged below the baseplate extension arc guide plate; one end of the water curtain extension arc guide plate is smoothly mounted at the lower end of the the water curtain plate; a saw tooth plate is mounted at the other end of the water curtain extension arc guide plate; a first atomization space is formed among the baseplate guide structure, the baseplate extension arc guide plate and the water curtain extension arc guide plate; and a second atomization space is formed between the baseplate guide structure and the water curtain extension arc guide plate. The structure realizes the passing of washing liquid through the atomization saw tooth plates by all flow, so that the atomization efficiency is greatly improved, and the efficiency of the washing liquid capturing the paint mist is high up to 99.6%.

Owner:赛智环保科技(天津)有限公司

Paint spray booth with high-efficiency demisting ability

InactiveCN104353581BSimplify manufacturing difficultyDoes not affect horizontal distributionLiquid surface applicatorsSpraying apparatusWater curtainWaste management

The invention relates to a paint spray booth with a high-efficiency defogging capacity, which comprises a paint spray booth, the paint spray booth comprises a personnel operation chamber and a paint spray chamber which are sequentially connected, a water curtain plate is arranged on the wall surface of the paint spray chamber, a steam-water separation chamber is arranged in the paint spray chamber on the back of the water curtain plate, the steam-water separation chamber is connected with a deslagging chamber, an air feeder is arranged above the personnel operation chamber and the paint spray chamber, an induced draft fan is arranged above the steam-water separation chamber, a baseplate diversion structure and a main serration plate are arranged below the paint spray booth, the water curtain plate is arranged above the baseplate diversion structure, the main serration plate is fully fixedly arranged at the bottom end of the water curtain plate, the bottom end of the water curtain plate is provided with an arc lifting section, a diversion serration plate is arranged on the side wall of the water curtain plate at the upper end of the arc lifting section, the diversion serration plate integrally extends so as to form an arc diversion surface, and the steam-water separation chamber is connected with the deslagging chamber by a bottom pipeline. The paint spray booth disclosed by the invention is simple in structure, scientific and reasonable in design, low in cost, and high in paint fog capture efficiency, and effectively reduces the subsequent environmental processing load.

Owner:赛智环保科技(天津)有限公司

A kind of indoor air purifier

ActiveCN104089337BSpeed up the cycleGuaranteed uptimeLighting and heating apparatusSpace heating and ventilation detailsRoom air cleanersAir cycle

The invention discloses an indoor air purifier. The indoor air purifier comprises a main case, a filter unit, a draught fan and an air exhaust device, wherein the filter unit and the draught fan are arranged in the main case, and the air exhaust device is arranged above the top of the main case. The top and the bottom of the main case are provided with openings. The two sides of the bottom of the main case are respectively provided with a support, so that the main case is suspended, and the opening in the bottom of the main case serves as an air inlet. The draught fan comprises a driving motor with two output shafts, wherein the driving motor is fixed into the main case, and the two output shafts of the driving motor are respectively connected with a wind wheel; a volute is arranged on the periphery of each wind wheel, and the upper end of each volute is communicated with the air exhaust device. Air can enter the bottom of the indoor air purifier at 360 degrees so that the requirement for large-area air purification can be met; air flow absorbed from the bottom can be exhausted from four sides of the top through the wind wheels on the two sides at the same time, and strong negative pressure is formed in an air flue, so more air can be absorbed in from the air inlet in the bottom, the adsorption capacity of the air inlet can be increased, more air can be filtered in a short time, the circulation speed of the air in a room can be increased to the maximum extent, and the efficient purifying effect can be achieved.

Owner:三生(中国)健康产业有限公司

Large workpiece electrostatic spraying room

InactiveCN105396737BImprove washing efficiencyImprove processing efficiencyLiquid spraying plantsSpray boothsSpray nozzleSmall footprint

The invention relates to a large-sized workpiece electrostatic spraying booth. The large-sized workpiece electrostatic spraying booth comprises a spraying booth, wherein a first electrostatic nozzle and a second electrostatic nozzle are arranged in the spraying booth in a staggering manner; a workpiece inlet is formed in the spraying booth inner wall to which the first electrostatic nozzle correspond, and a workpiece outlet is formed in the spraying booth inner wall of the other side to which the second electrostatic nozzle correspond, so that a slideway passes the first electrostatic nozzle along the workpiece inlet and rotates one time, and then passes the second electrostatic nozzle and rotates one time to reach the workpiece outlet, thereby forming two rotation slideways; a first paint mist catching structure is arranged at the lower part of the spraying booth inner wall to which the first electrostatic nozzle correspond; and a second paint mist catching structure is arranged at the lower part of the spraying booth inner wall to which the second electrostatic nozzle correspond. The large-sized workpiece electrostatic spraying booth has the beneficial effects that the large-sized workpiece electrostatic spraying booth simultaneously performs the double-faced spraying operation of large-sized workpieces, is simple in structure, scientific and reasonable in design, small in floor space and low in cost, has high spraying efficiency and high paint mist washing efficiency and improves the treatment efficiency of follow-up organic waste gases.

Owner:赛智环保科技(天津)有限公司

Efficient atomization capture spray booth

InactiveCN104492641BSimplify manufacturing difficultyDoes not affect horizontal distributionLiquid surface applicatorsSpraying apparatusEngineeringOperation room

The invention relates to a high-efficiency atomized capturing spray chamber. The high-efficiency atomized capturing spray chamber comprises a spray chamber, wherein the spray chamber comprises a personnel operation room, a spray room and a steam-water separation room which are sequentially connected, the inner wall of the spray room is provided with a water curtain plate, the bottom surface of the water curtain plate is an inclined surface, the lower end of the inclined surface of the bottom part of the spray room is communicated with the steam-water separation room through double atomized paint mist capturing structures, and the middle part of the steam-water separation room is provided with a mist removing wheel. The high-efficiency atomized capturing spray chamber disclosed by the invention has the advantages that the structure is simple, the design is scientific and reasonable, the cost is low, the paint mist capturing efficiency is high, and follow-up environment protection treatment load can be effectively reduced.

Owner:赛智环保科技(天津)有限公司

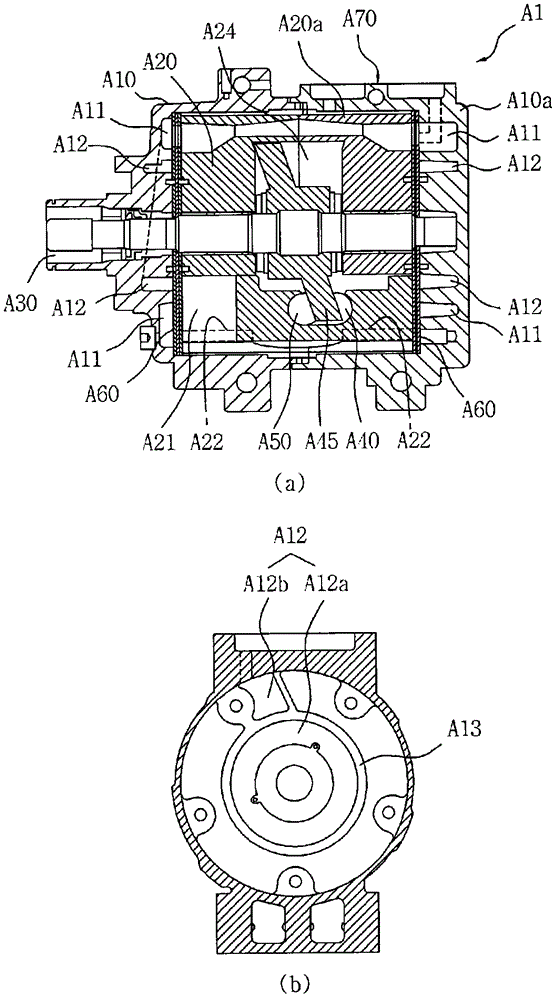

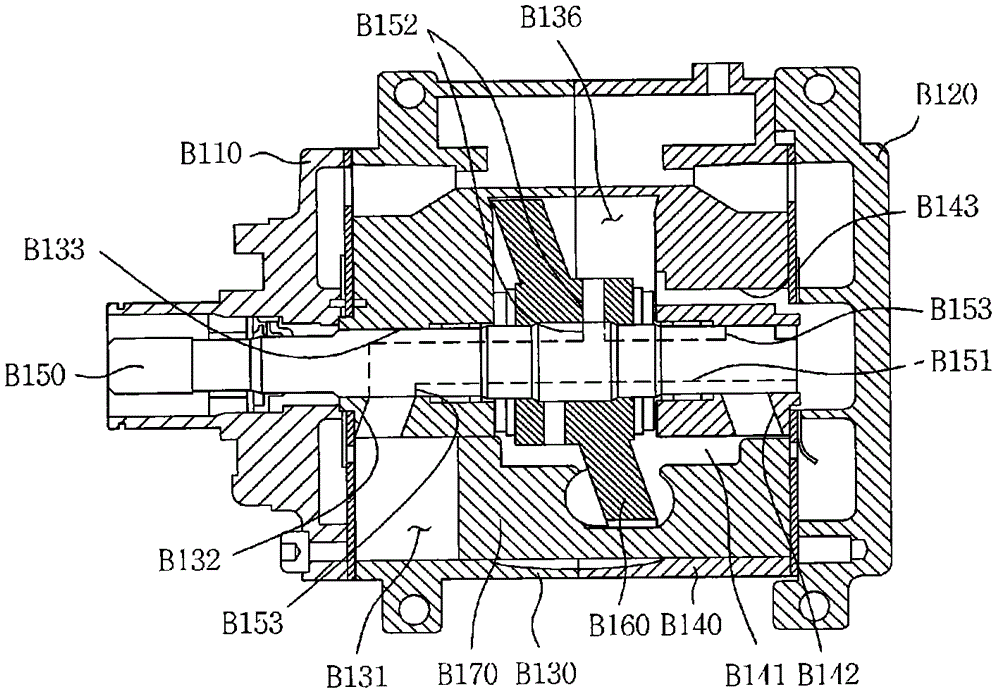

Swash plate compressor with rotary valve

ActiveCN102272450BSmooth inhalationReduce lossesPositive displacement pump componentsWorking fluid for enginesJackshaftMarine engineering

The present invention relates to a swash plate compressor with a rotary valve which can effectively siphon a coolant into a swash plate chamber through a cylinder block. The swash plate compressor comprises a housing connected to the cylinder block which has a plurality of cylinder bores, pistons which are accommodated and reciprocate in the respective cylinder bores, a drive shaft which is installed to rotate with respect to the housing and the cylinder block, a swash plate which is installed to be rotated by the drive shaft and interlock with the pistons, a valve plate which is interposed between the housing and the cylinder block, and the rotary valve which is formed to rotate along with the drive shaft and installed to roll in a joint hole formed in the cylinder block. A coolant outlet is formed on the exterior of the rotary valve, connection holes connected to the respective cylinder bores are formed on the interior of the joint hole which abuts against the exterior of the rotary valve, and a coolant inlet groove is formed to penetrate the swash plate chamber through to the housing. Therefore, loss caused by coolant inlet resistance can be remarkably reduced by siphoning coolant regardless of the torque of the drive shaft rotating at high speed.

Owner:DOOWON TECHN COLLEGE +1

Device for opening the suction depending on pressure

ActiveCN103619629BImprove efficiencySmall pressure lossLarge containersJet pumpsLine tubingEngineering

The invention relates to a device (6) for pressure-dependent opening of a suction portion (10), comprising a suction jet pump (11), a valve body (15) and an elastic element (17). The suction jet pump comprises a feed line (12), an output line (13) and a suction (10). A valve body is movably arranged in the feed line (12) in the delivery direction (14) of the suction jet pump (11), the valve body having an effective area influenced by the feed pressure of the suction jet pump (11) ( 16). An elastic element is arranged between the feed line (12) and the valve body (15) for exerting a force in a direction opposite to the feed pressure in the feed line (12). Among them, the effective area (16) of the valve body (15) and the elastic element (17) are designed so that the valve body (15) closes the suction part (10), so that the suction part is at a lower pressure than the supply line (12) Fluid-tight at a predetermined pressure, the suction opens when the pressure is higher than the predetermined pressure in the feed line (12).

Owner:KAUTEX TEXTRON

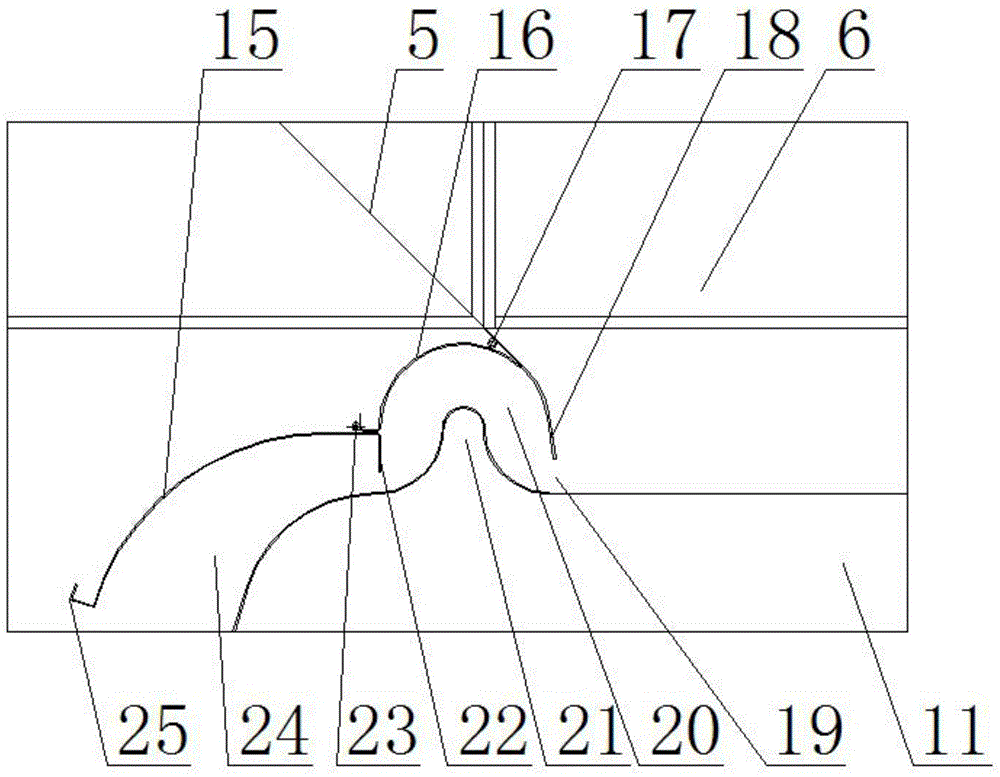

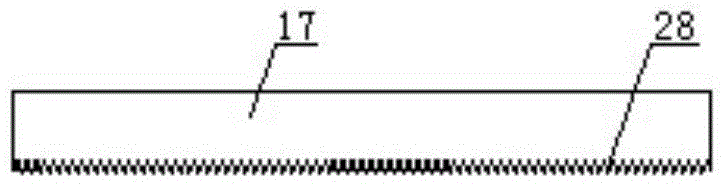

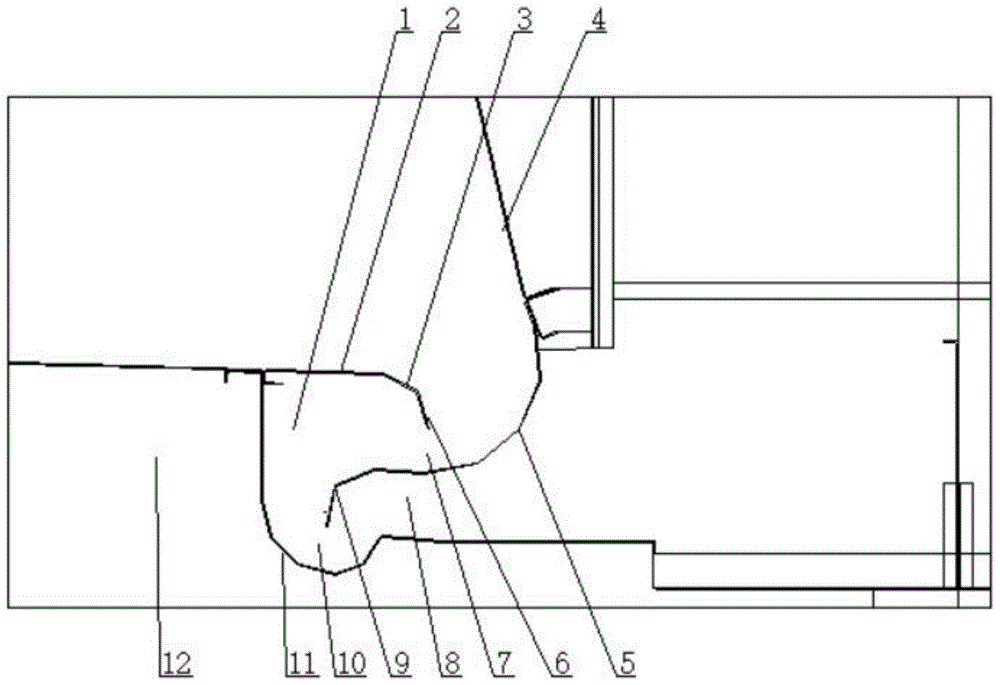

Double atomized paint mist capture structure

InactiveCN104383773BImprove capture abilityLarge specific surface areaUsing liquid separation agentTrappingEngineering

The invention relates to a double atomized mist catching structure which comprises a water curtain plate, a bottom plate flow guide structure and a main sawtooth plate, wherein the water curtain plate is arranged above the bottom plate flow guide structure; the main sawtooth plate is fixedly mounted at the bottom end of the water curtain plate in general; an arc surface lifting section is arranged at the bottom end of the water curtain plate; a flow guide sawtooth plate is mounted on the side wall of the water curtain plate at the upper end of the arc surface lifting section; the flow guide sawtooth plate integrally extends to form an arc-shaped flow guide surface; the arc-shaped flow guide surface is matched with the bottom plate flow guide structure; a first vortex atomization space is formed among the main sawtooth plate, the flow guide sawtooth plate, the arc surface lifting section at the bottom end of the water curtain plate and the bottom plate flow guide structure; a second vortex atomization space is formed between the flow guide sawtooth plate and the bottom plate flow guide structure. The double atomized mist catching structure is simple in structure, scientific and reasonable in design, low in cost and high in catching efficiency.

Owner:赛智环保科技(天津)有限公司

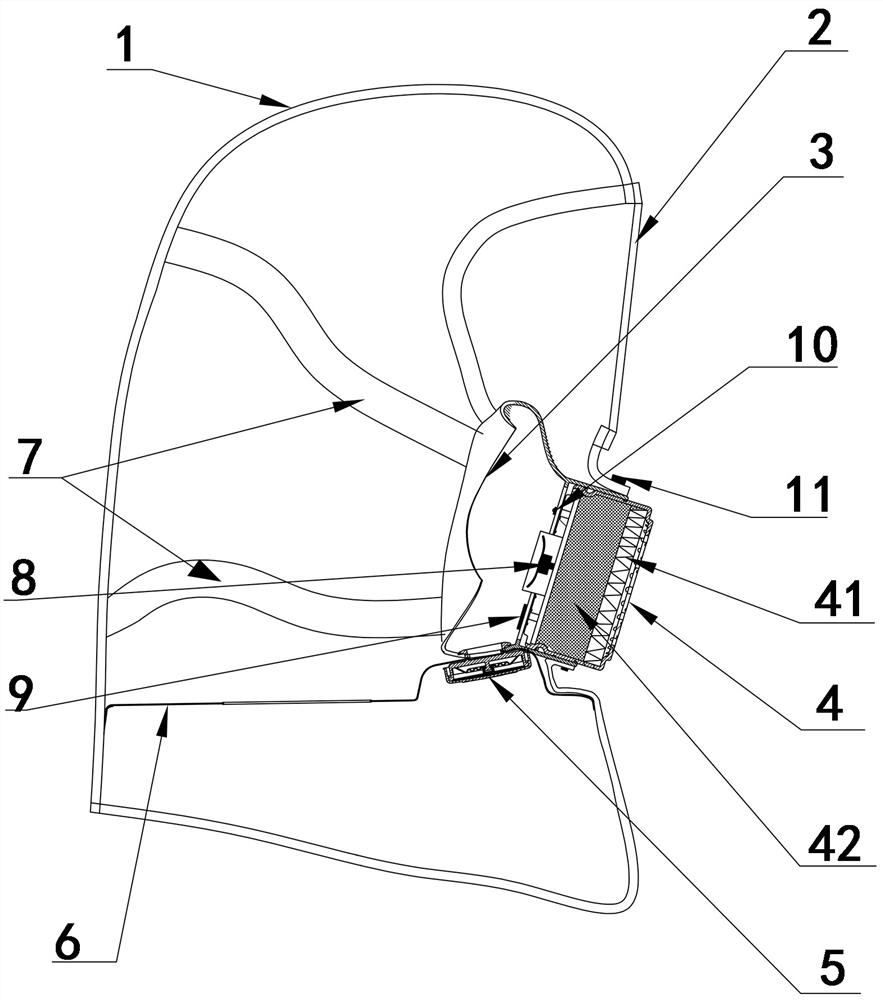

Micro-positive-pressure self-inhalation filter type escape breather

PendingCN111790072APlay a double filter effectHelp inhalationBreathing filtersFire rescueActivated carbonThermodynamics

The invention relates to the technical field of breathers, specifically to a micro-positive-pressure self-inhalation filter type escape breather. The escape breather comprises a hood and a mask; and the mask is provided at the front end of the hood. The escape breather is characterized in that a canister is provided on the mask; a smoke filter layer and an activated carbon poison filter layer areprovided in the canister; a fan is provided at the back end of the canister, and provides micro-positive-pressure wind power; a transparent window is provided at the front end of the hood above the mask; and an exhalation valve is provided under the mask, and is disposed in the lower portion of the hood. The escape breather has the advantages that the canister has the activated carbon poison filter layer and the smoke filter layer to achieve the effect of dual filtration, and the fan can provide the micro-positive-pressure wind power to help people who is inconvenient to breathe to inhale.

Owner:SHANGHAI BAOYA SAFETY EQUIP

Electrostatic spray booth with purification function

InactiveCN104384057BImprove capture abilityLarge specific surface areaLiquid surface applicatorsUsing liquid separation agentSlagEngineering

The invention relates to an electrostatic spray booth with a purification function. The electrostatic spray booth comprises a electrostatic spray booth body, wherein an electrostatic spray head is mounted in the electrostatic spray booth body, a main water curtain plate and a side water curtain plate are arranged on inner walls of the electrostatic spray booth body, the back side of the main water curtain plate of the electrostatic spray booth body is connected with a vapor-water separation chamber, a slope flushing plate is arranged at the lower part of the main water curtain plate, the electrostatic spray booth body is communicated with the vapor-water separation chamber through a dual-atomized paint mist catching structure connected with the lower end of the slope flushing plate, a bottom plate guide structure is arranged on the bottom surface of the electrostatic spray booth body, and the vapor-water separation chamber is connected with a slag removal chamber through a pipeline. The electrostatic spray booth is simple in structure, scientific and reasonable in design, low in cost and high in paint mist catching efficiency.

Owner:赛智环保科技(天津)有限公司

An anti-escaping system and control method for blowing hood gas

The invention discloses a blowing hood gas escape prevention system and a control method thereof, comprising: a blowing hood located on the top of a sintering machine trolley; a blowing pipe row arranged inside the blowing hood and located on the sintering machine table The top of the car is used to spray combustible gas to the sintering material surface of the sintering machine trolley; the gas pipeline is used to transport combustible gas to the blowing pipe row; it is characterized in that it also includes: an air flow device, including a driving cylinder and A rotating impeller device, the rotating impeller device is arranged at the top area of the blowing hood, and the rotating impeller device is used to drive the external air to generate an airflow and input the generated airflow from the top of the blowing hood downward into the spraying hood. Inside the hood, a wind pressure zone area is formed at the position above the row of blowing pipes so that the combustible gas cannot pass upwards. The anti-escape system can basically eliminate the phenomenon of gas escape, and helps to inhale the air outside the hood, so as to achieve the purpose of stable, smooth and high-quality production of the sintering production line.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Symmetrical spray booth with two-way full-flow paint mist purification function

InactiveCN105413934BImprove atomization efficiencyEffective atomizationLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention relates to a symmetric paint spray booth having a bidirectional full-flow paint spray purification function. The symmetric paint spray booth comprises two paint spray booths and two air and liquid separation chambers, wherein the two air and liquid separation chambers are isolated from each other and are arranged symmetrically; the two air and liquid separation chambers are respectively communicated with their own paint spray booths by their own paint spray capturing structures; a water curtain plate is mounted on the inner wall of each paint spray booth; a base plate flow guide structure is arranged at the bottom surface of each paint spray booth; one end, opposite to the lower end of the water curtain plate, of the base plate flow guide structure is connected with one end of a base plate extending arc-shaped flow guide plate; a serration plate is fixedly mounted on the total length of the other end of the base plate extending arc-shaped flow guide plate; a water curtain extending arc-shaped flow guide plate is arranged below the base plate extending arc-shaped flow guide plate; one end of the water curtain extending arc-shaped flow guide plate is smoothly mounted at the lower end of the water curtain plate; a serration plate is mounted at the other end of the water curtain plate. By the structure, washing liquid passes through the atomizing serration plates in a full-flow manner, so the atomization efficiency is greatly improved and the paint spray capture efficiency of the washing liquid is higher and is as high as 99.9%.

Owner:赛智环保科技(天津)有限公司

Two-way full-flow atomized paint mist capture structure

InactiveCN105413355BImprove atomization efficiencyEffective atomizationUsing liquid separation agentTrappingEngineering

The invention relates to a bidirectional full-flow atomized paint mist trapping structure. The bidirectional full-flow atomized paint mist trapping structure comprises a bottom plate flow guiding structure and a water curtain plate, wherein one end, opposite to the lower end of the water curtain plate, of the bottom plate flow guiding structure is connected with one end of a bottom plate extending arc-shaped flow guiding plate, a serrate plate is fixedly mounted on the other end of the bottom plate extending arc-shaped flow guiding plate along full length, a water curtain extending arc-shaped flow guiding plate is arranged below the bottom plate extending arc-shaped flow guiding plate, one end of the water curtain extending arc-shaped flow guiding plate is smoothly mounted at the lower end of the water curtain plate, and a serrate plate is mounted at the other end of the water curtain extending arc-shaped flow guiding plate. According to the structure, a washing solution can pass through the atomizing serrate plates in a full flow manner, the efficiency of atomization is greatly increased, and the efficiency of paint mist trapping for the washing solution can reach up to 99.6%.

Owner:赛智环保科技(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com