Patents

Literature

33results about How to "Effective atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

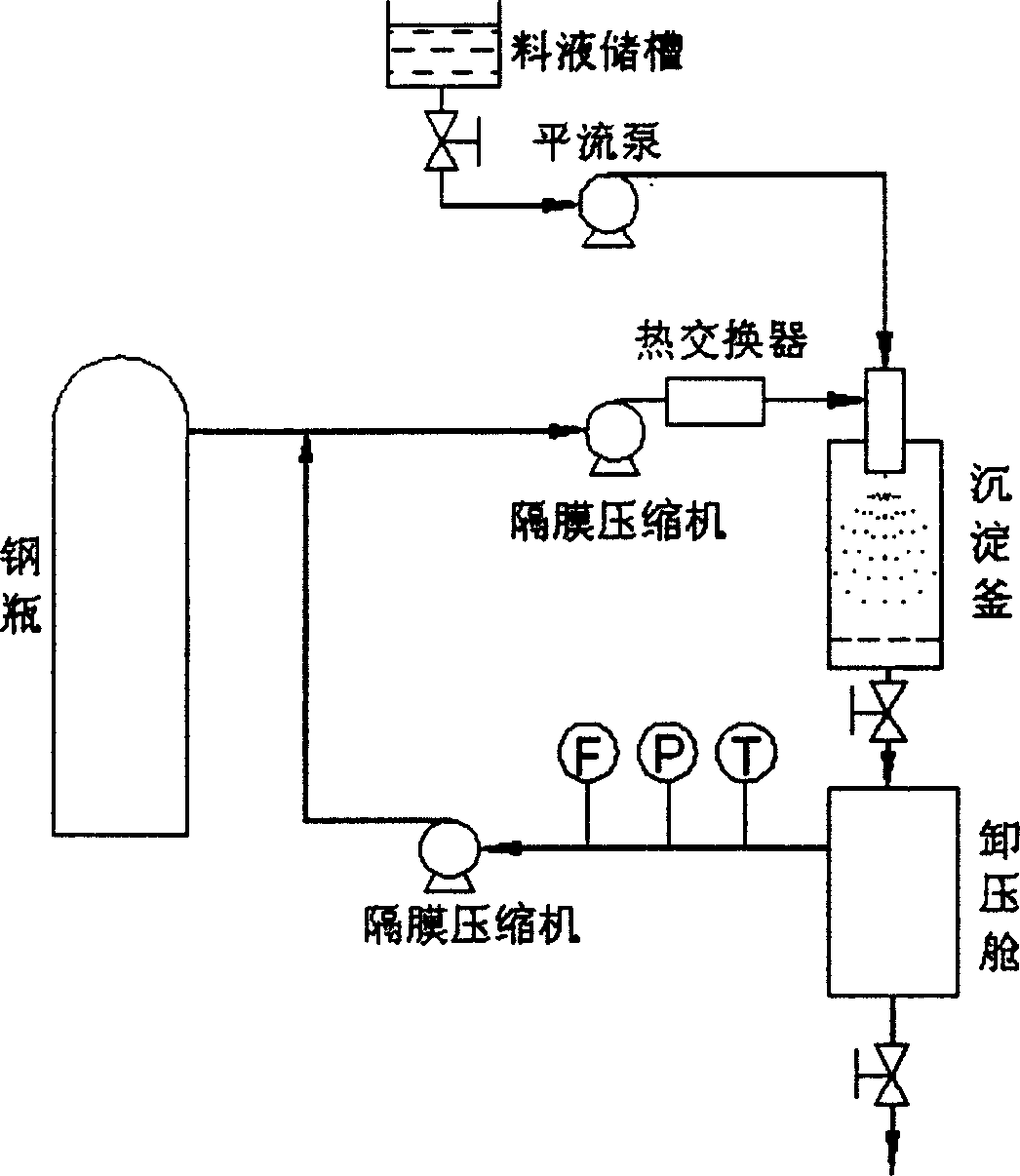

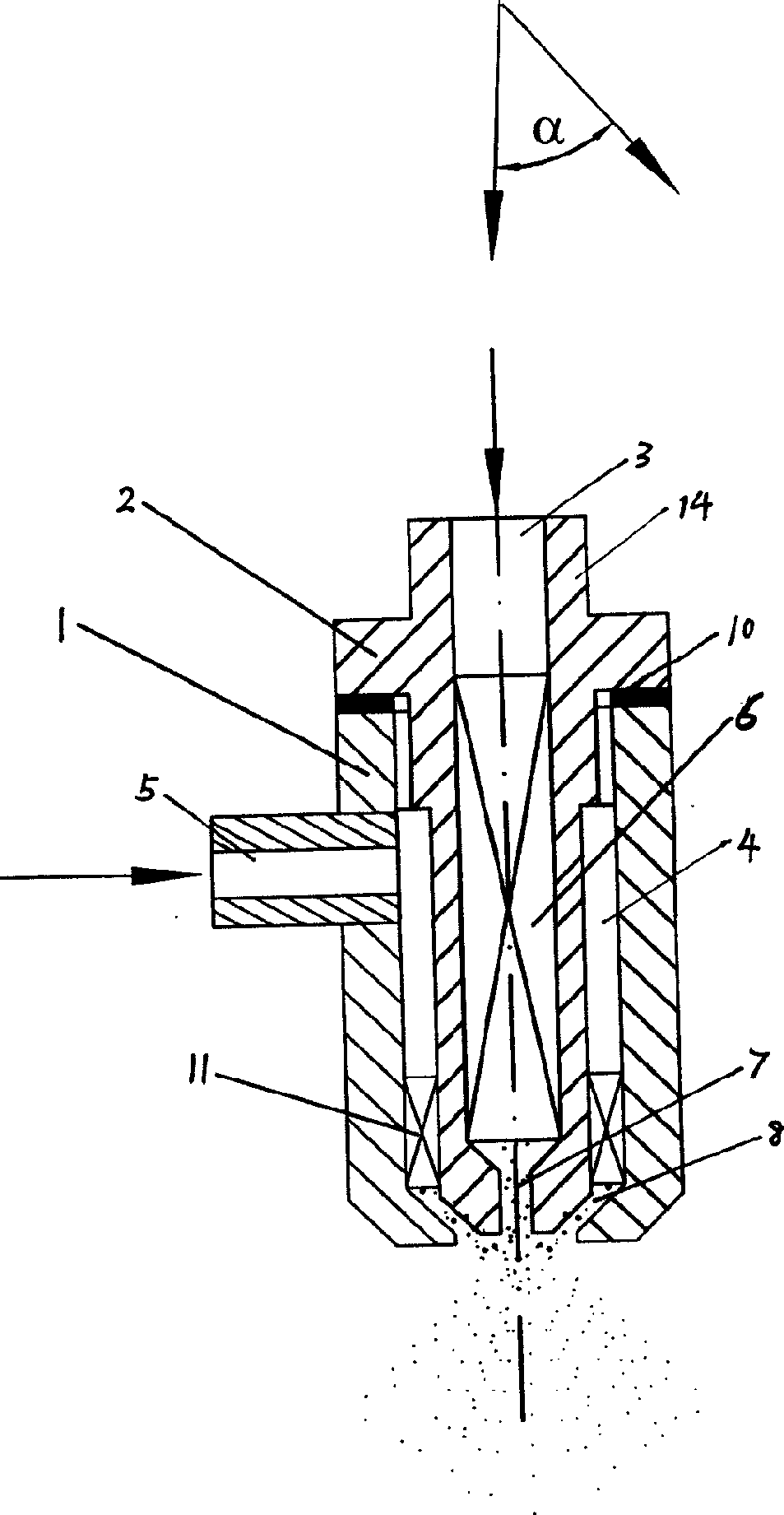

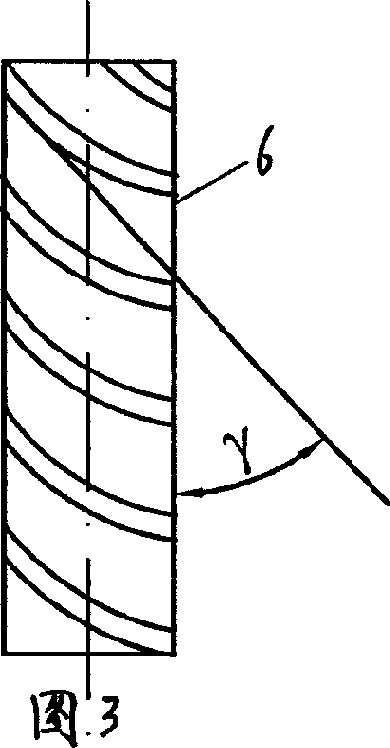

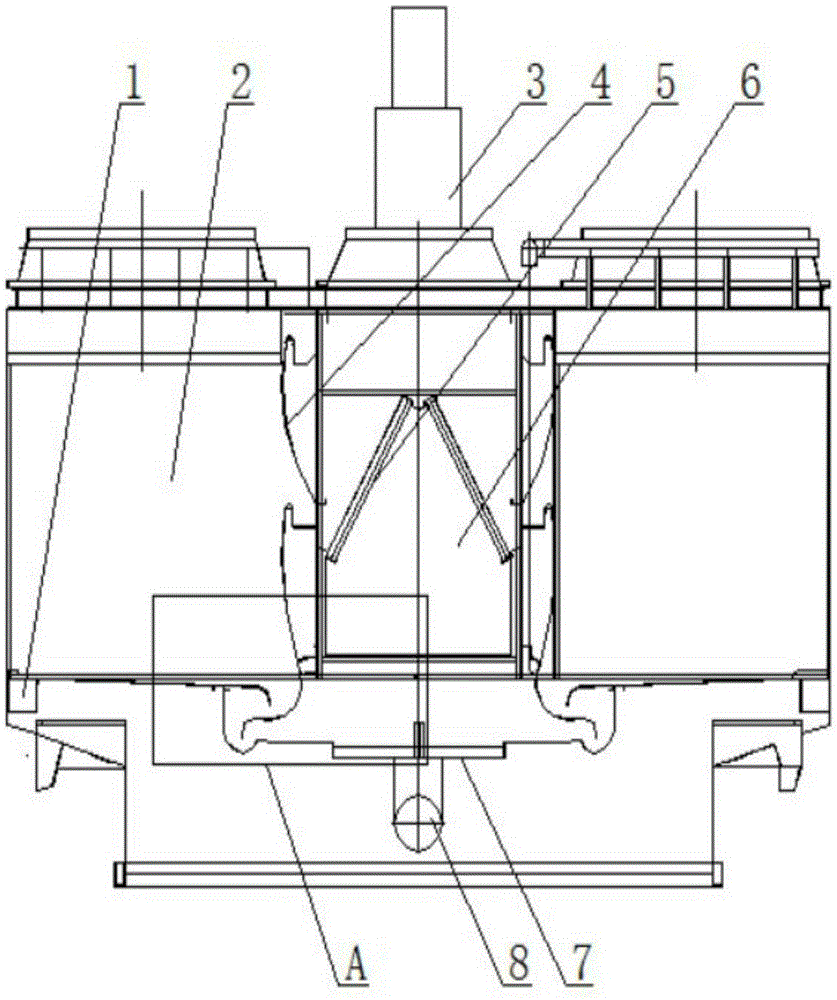

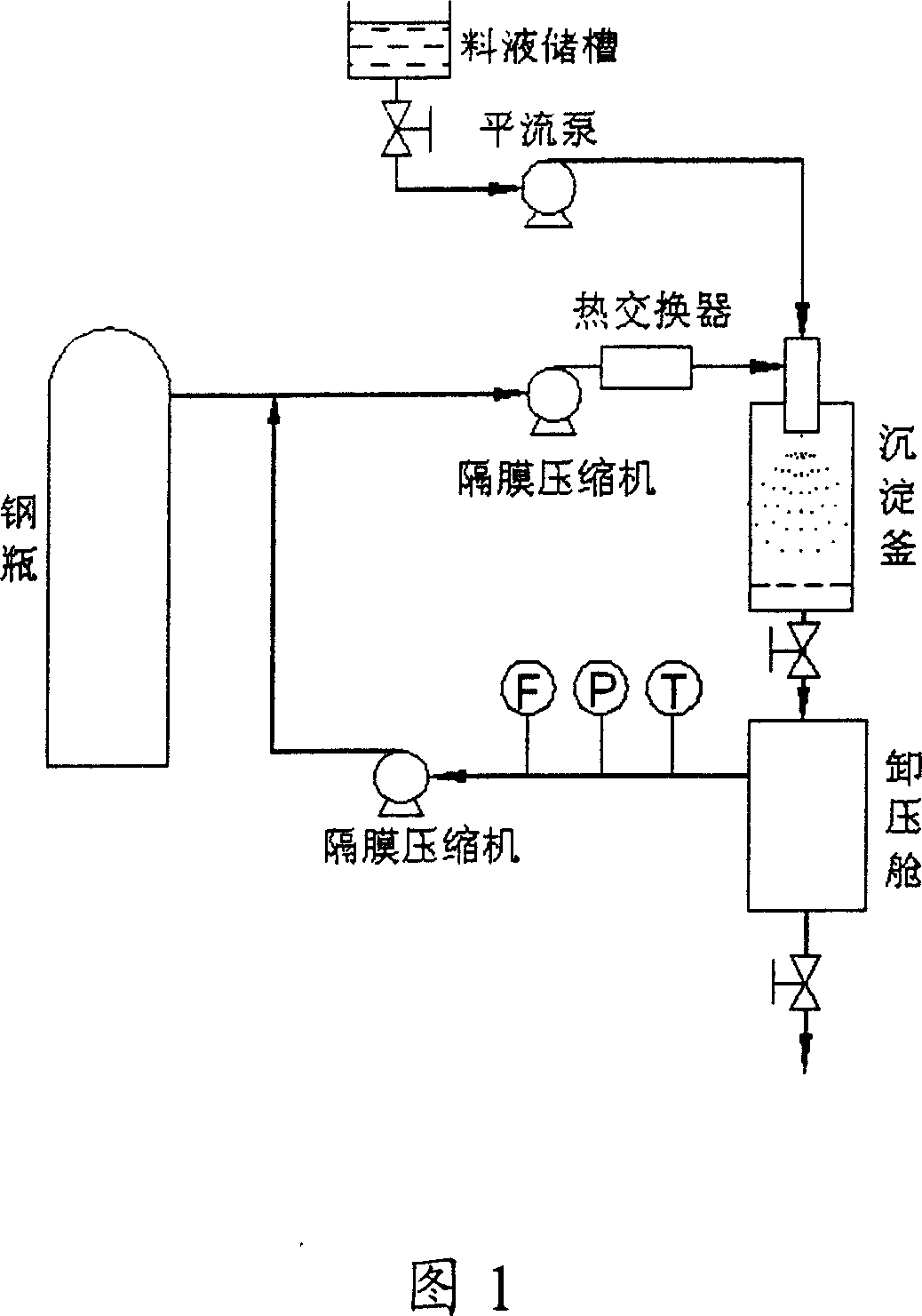

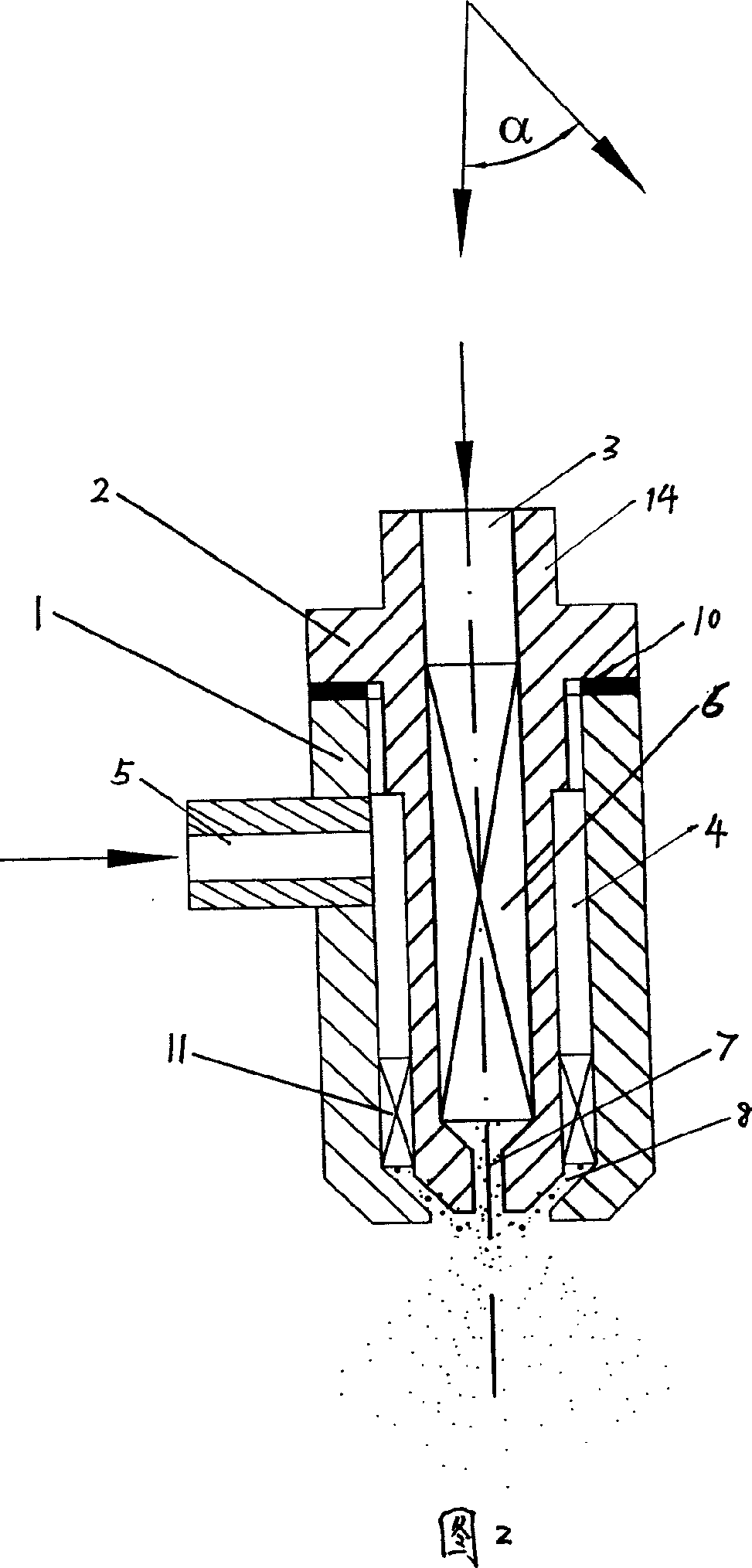

Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

InactiveCN1689682AIncrease mass transfer rateReduce the flow cross-sectional areaSolution crystallizationChemical/physical/physico-chemical nozzle-type rreactorsUltra fineSupercritical fluid

The present invention discloses one kind of pre-filming flow nozzle, stillpot with the nozzle and the production process of superfine particle in the stillpot with the nozzle. The nozzle includes casing, pre-filming unit, flow channel, ring gap flow channel, etc. and has the structure with greatly lowered flow resistance on solution and less jamming caused by the solute particle. The stillpot has simple structure, convenient operation, light labor strength and excellent sealing effect owing to the C-shaped metal sealing part with upper and lower sealing planes in linear contact state. By means of the supercritical fluid forced dispersing solution process in the stillpot with the nozzle, superfine solute particle may be prepared.

Owner:贺文智 +2

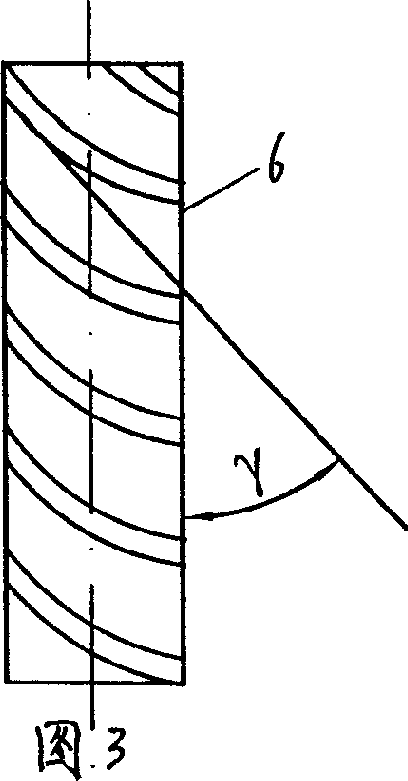

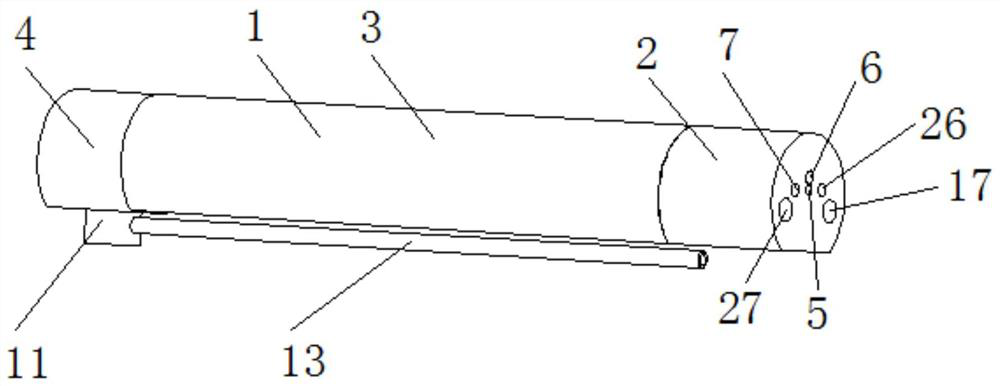

Low-temperature cigarette with loose integral tobacco section with high thermal conductivity and preparation method thereof

InactiveCN108741206AQuality improvementHigh thermal conductivityTobacco preparationCigar manufactureAdhesiveMetal powder

The invention provides a low-temperature cigarette with a loose integral tobacco segment with high thermal conductivity and a preparation method thereof, wherein the method comprises the following steps of: crushing tobacco leaves into fine powder; uniformly mixing, by mass, 50-80% of tobacco powder, 10-25% of atomizing agent, 0.5-10% of adhesive, 0.01-0.2% of leavening agent; 5-35% of metal powder, 1-8% of perfume essence perfume for smoke, and 0-30% of water, feeding the mixture into a mold, pressing into a tobacco rod, drying, wrapping with aluminum foil paper, connecting a filter tip especially for the low-temperature cigarette, and making the low-temperature cigarette according to the traditional cigarette rolling method. According to the invention, under the condition that the lengthand the diameter of a prior low-temperature cigarette are not changed, the quality of the low-temperature cigarette tobacco segment is obviously increased; metal powder is added into the raw materialformula, and the thermal conductivity can be effectively improved.

Owner:HUBEI CHINA TOBACCO IND

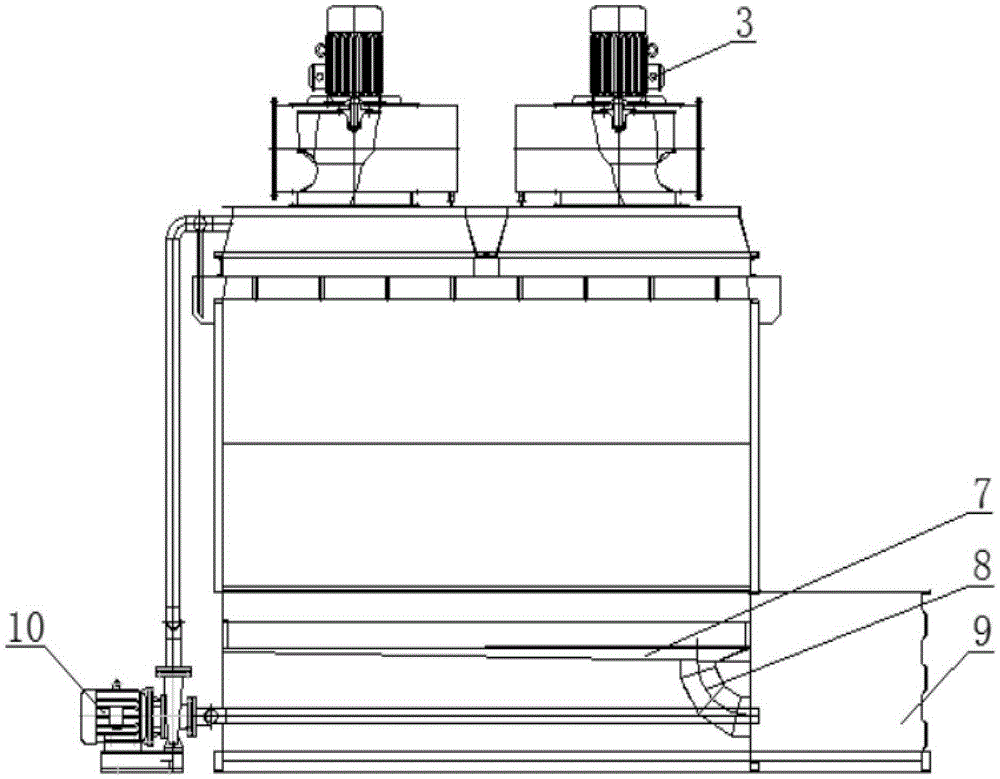

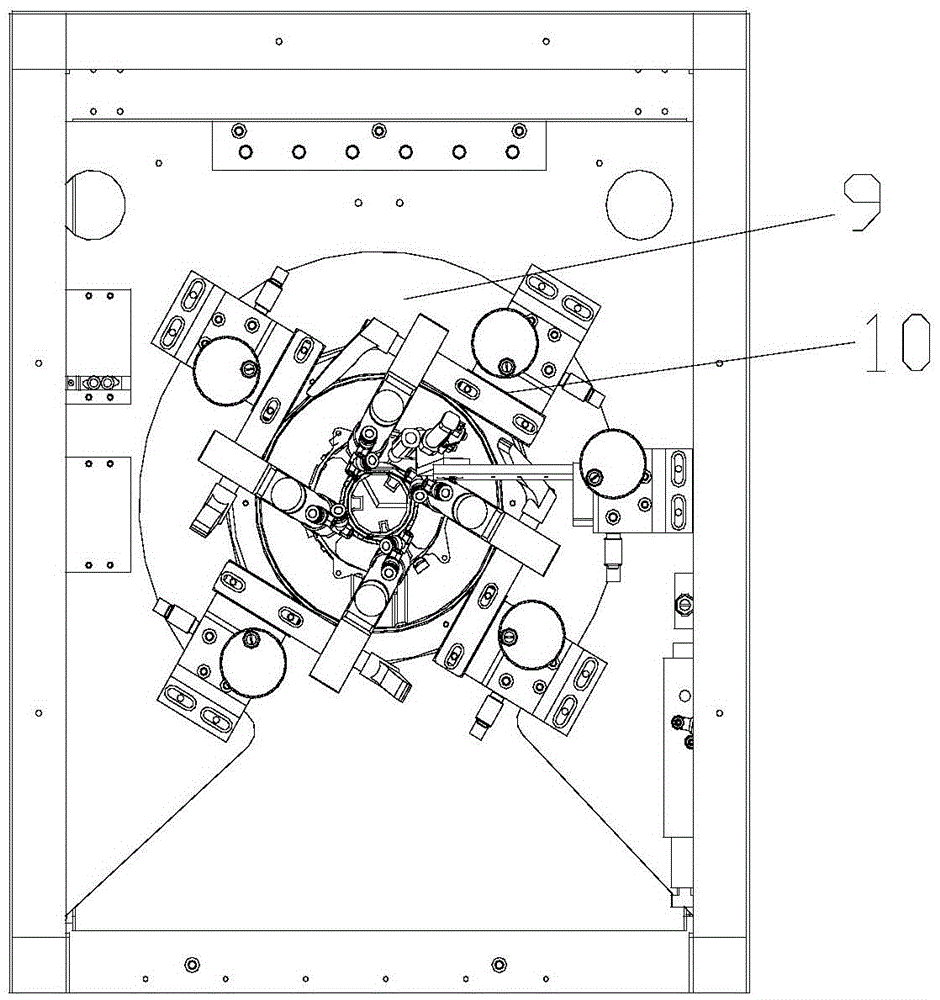

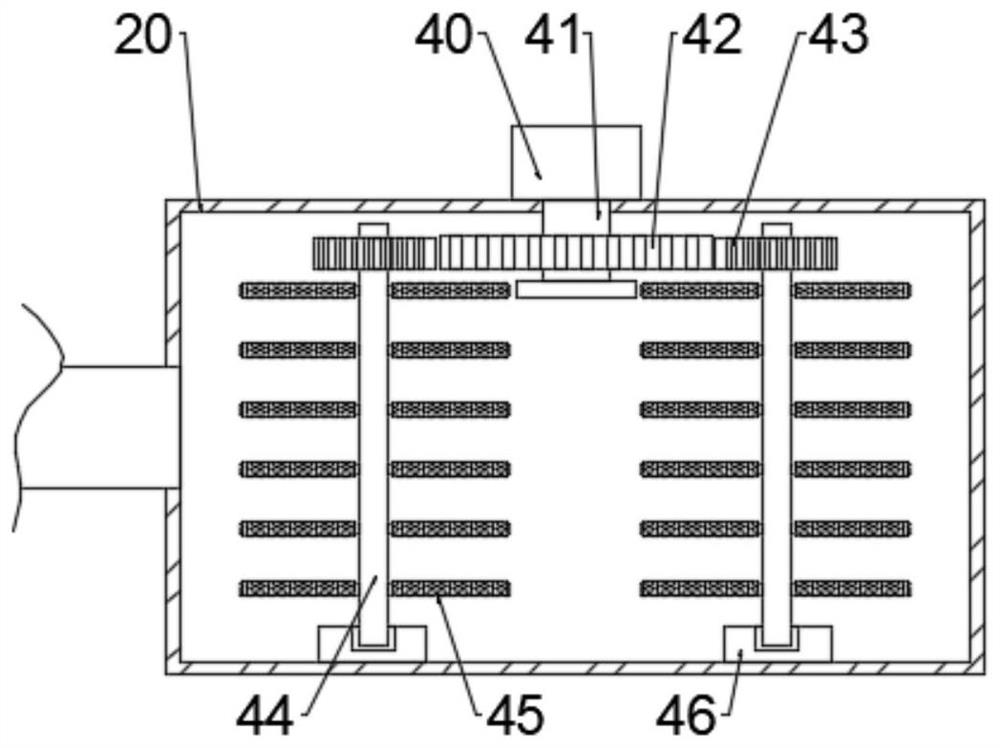

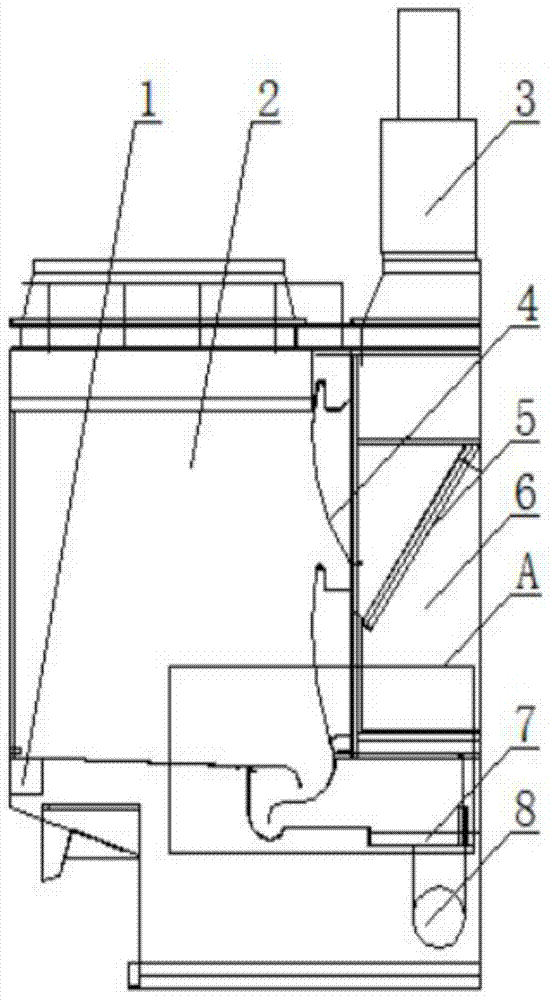

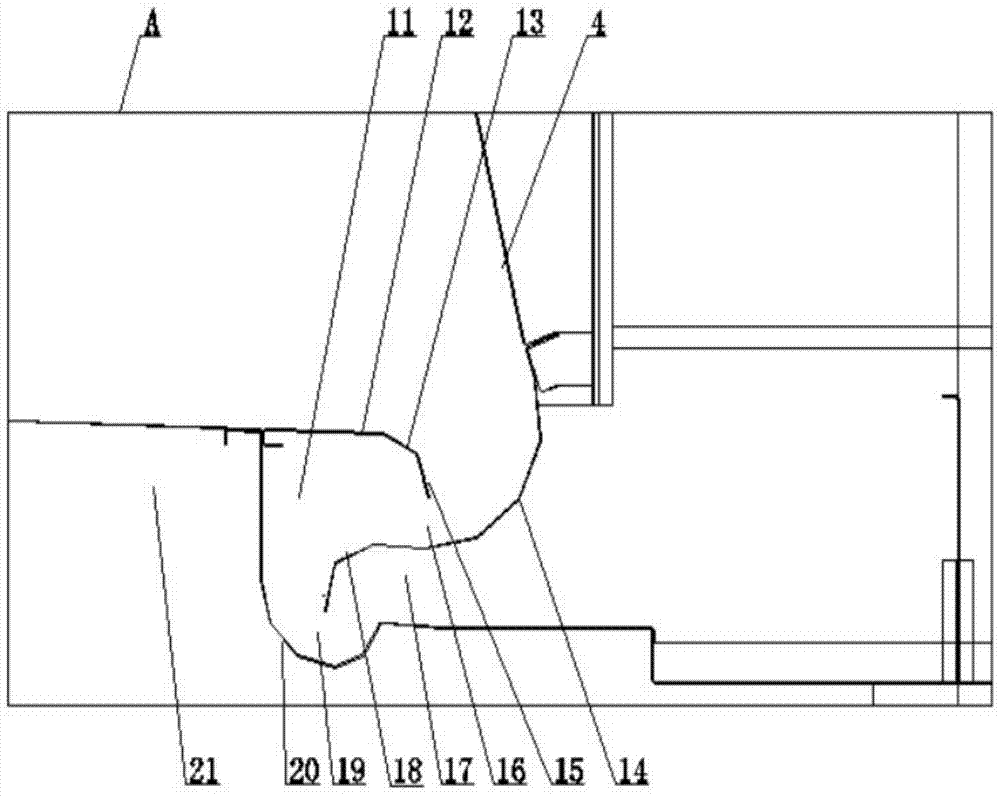

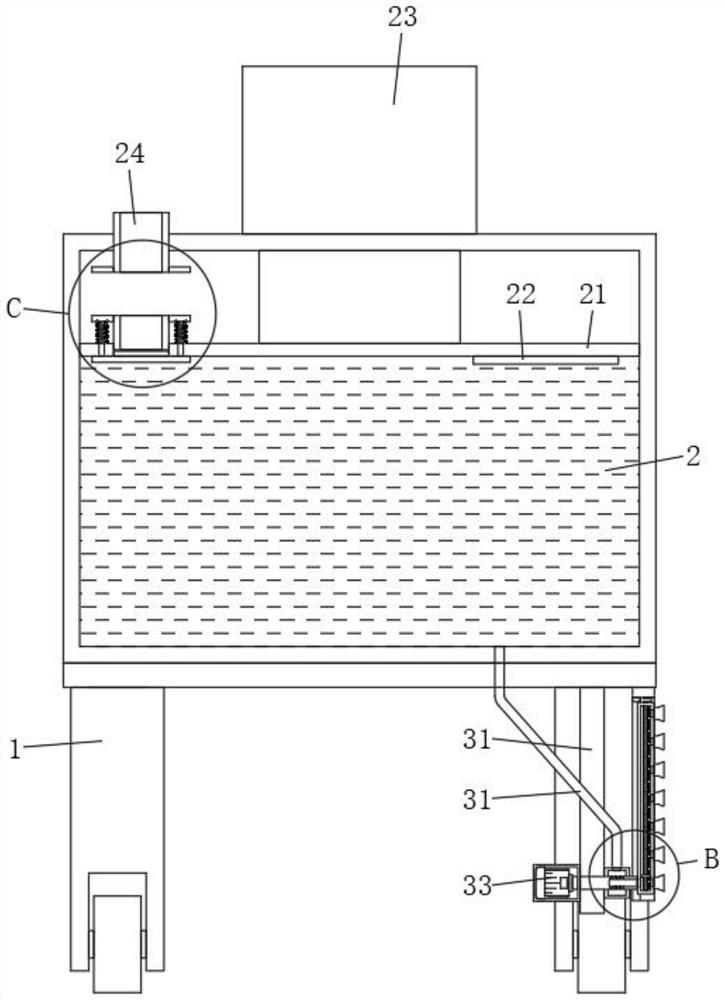

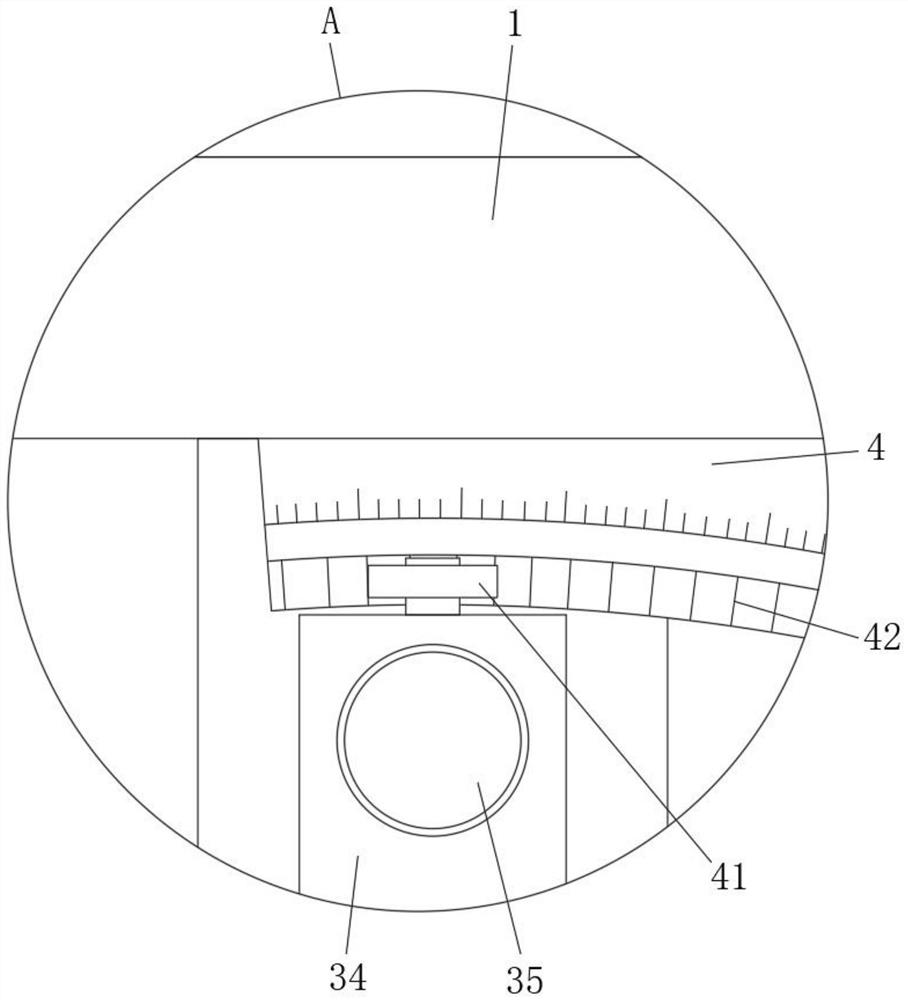

Symmetric paint spray booth having bidirectional full-flow paint spray purification function

InactiveCN105413934AImprove atomization efficiencyEffective atomizationLiquid surface applicatorsSpraying apparatusLacquerEngineering

The invention relates to a symmetric paint spray booth having a bidirectional full-flow paint spray purification function. The symmetric paint spray booth comprises two paint spray booths and two air and liquid separation chambers, wherein the two air and liquid separation chambers are isolated from each other and are arranged symmetrically; the two air and liquid separation chambers are respectively communicated with their own paint spray booths by their own paint spray capturing structures; a water curtain plate is mounted on the inner wall of each paint spray booth; a base plate flow guide structure is arranged at the bottom surface of each paint spray booth; one end, opposite to the lower end of the water curtain plate, of the base plate flow guide structure is connected with one end of a base plate extending arc-shaped flow guide plate; a serration plate is fixedly mounted on the total length of the other end of the base plate extending arc-shaped flow guide plate; a water curtain extending arc-shaped flow guide plate is arranged below the base plate extending arc-shaped flow guide plate; one end of the water curtain extending arc-shaped flow guide plate is smoothly mounted at the lower end of the water curtain plate; a serration plate is mounted at the other end of the water curtain plate. By the structure, washing liquid passes through the atomizing serration plates in a full-flow manner, so the atomization efficiency is greatly improved and the paint spray capture efficiency of the washing liquid is higher and is as high as 99.9%.

Owner:赛智环保科技(天津)有限公司

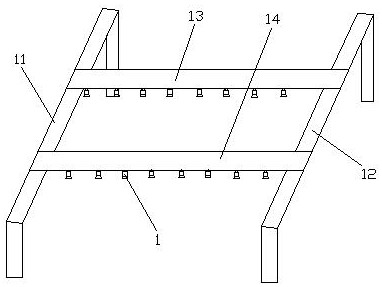

Vacuum belt filter leaching method

ActiveCN109045813AGuaranteed spray surfaceRealize no dead angle sprayMoving filtering element filtersBelt filterSpray nozzle

The invention discloses a vacuum belt filter leaching method, and belongs to the field of wet-process desulfurization production. The vacuum belt filter leaching method is characterized by comprisingthe following steps: a, mounting a spraying device on a vacuum belt filter, and arranging two rows of wide-angle fan-shaped spray nozzles of the spraying device above a filter cake alternatively in aspaced mode; b, regulating the angles of the spray nozzles of the wide-angle fan-shaped spray nozzles to be 60-120 degrees, setting pressure drop to be 0.2-0.4 Mpa, controlling water spraying amount of single wide-angle fan-shaped spray nozzle to be 0.02-0.08 m<3> / h, and controlling a ratio of flushing water amount to sulphur amount to be 3 to 5; and c, starting a primary sprayer of the spraying device, performing primary spraying cleaning on the filter cake; starting a secondary sprayer, performing secondary spraying cleaning on the filter cake; and finally starting a tertiary sprayer, performing tertiary spraying cleaning on the filter cake. The vacuum belt filter leaching method can guarantee vacuum degree of filter cloth, reduces moisture content of sulphur paste, gains balance betweenthe leaching effect and water usage mount, and realizes the good energy-saving environment-friendly effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

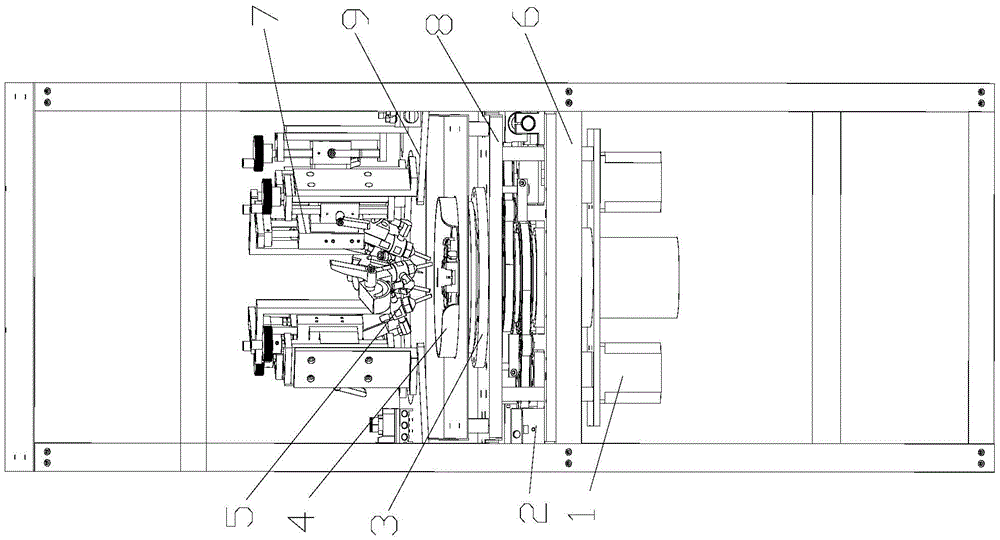

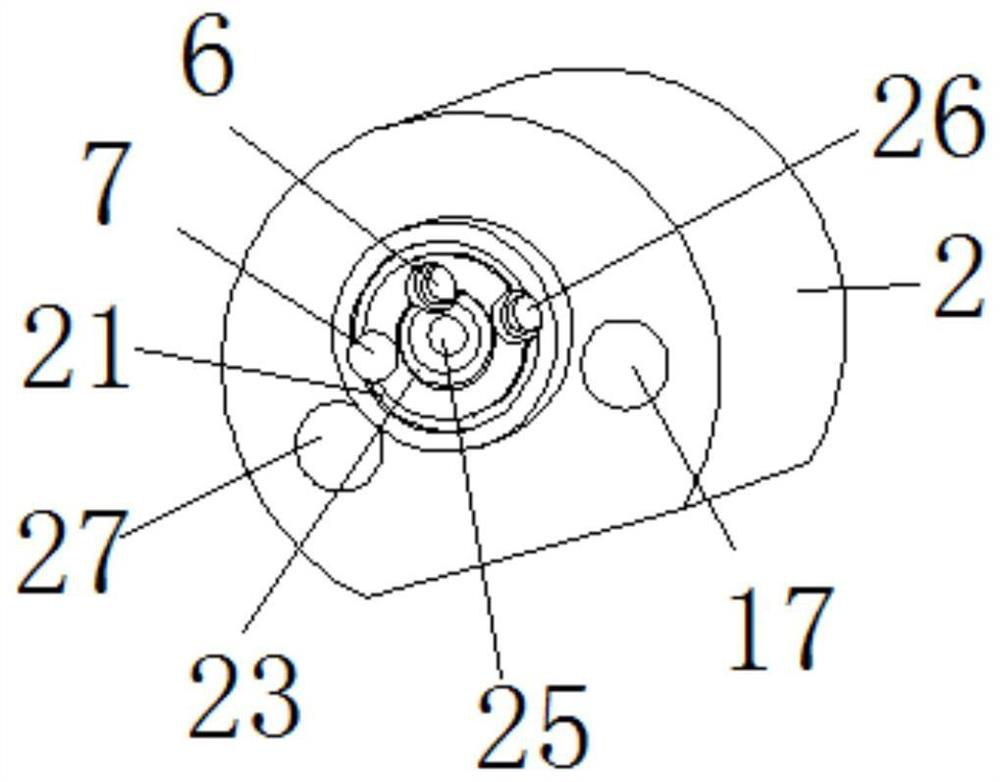

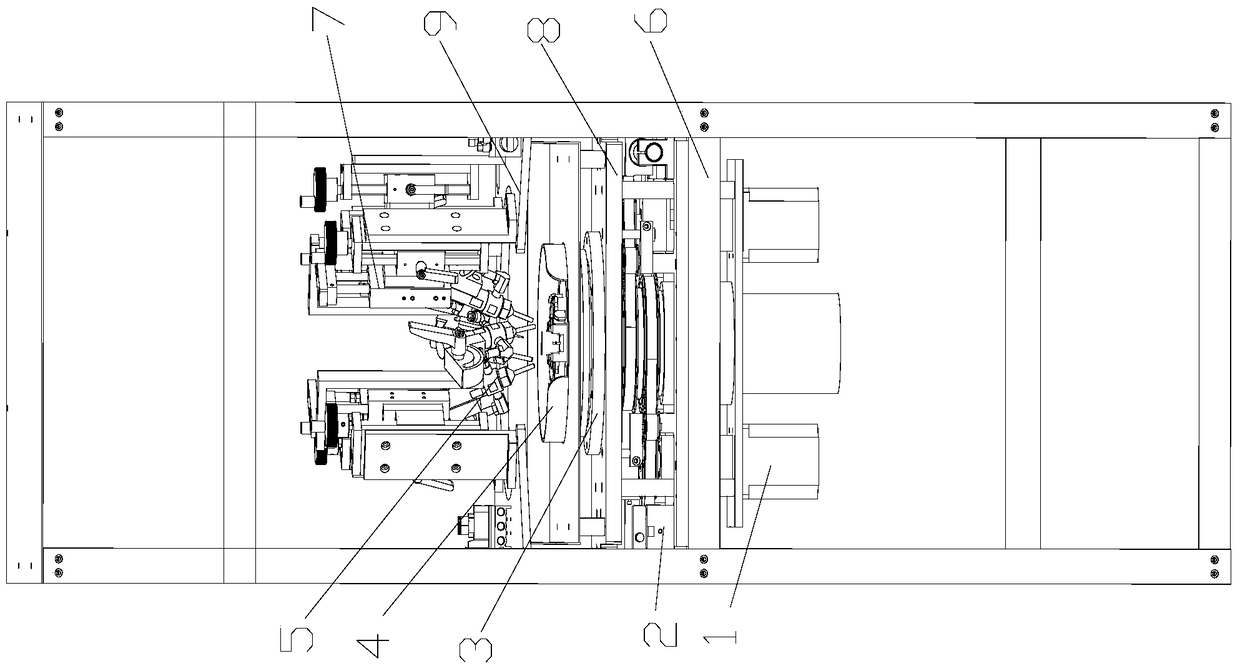

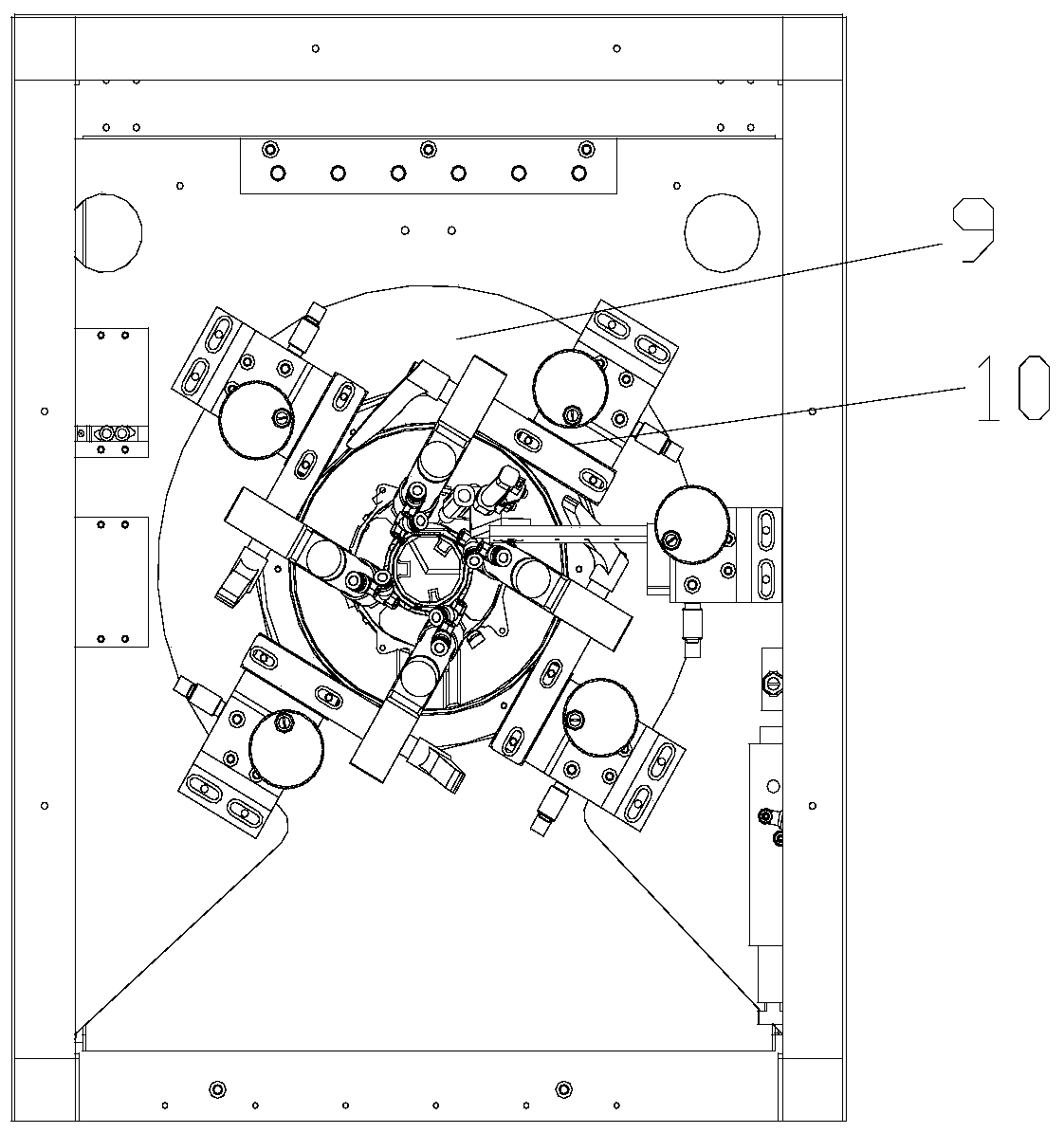

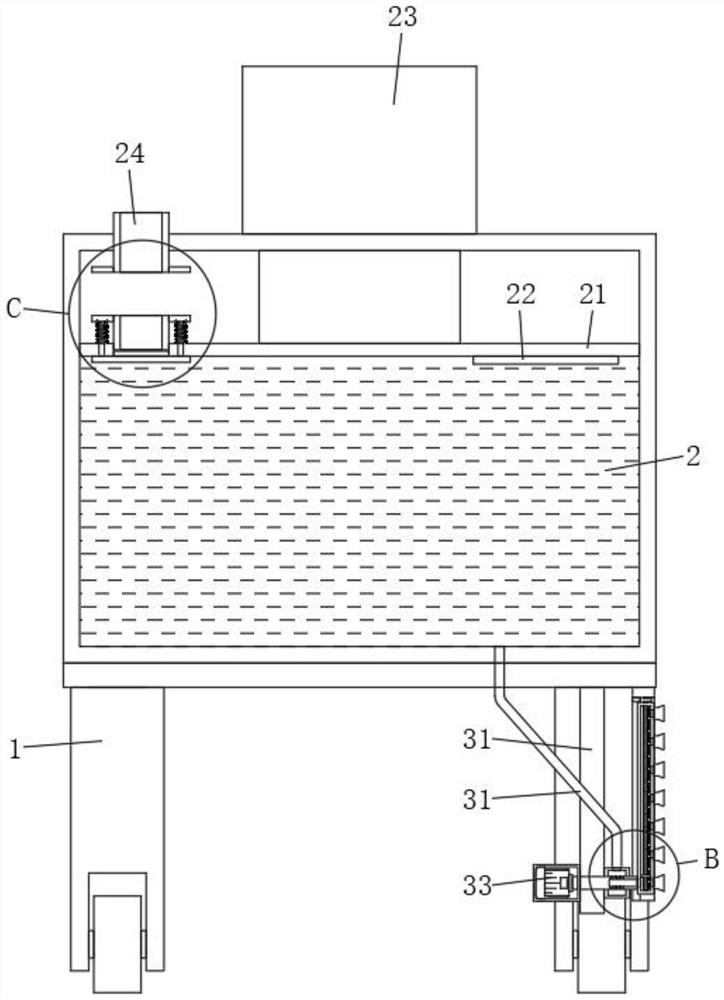

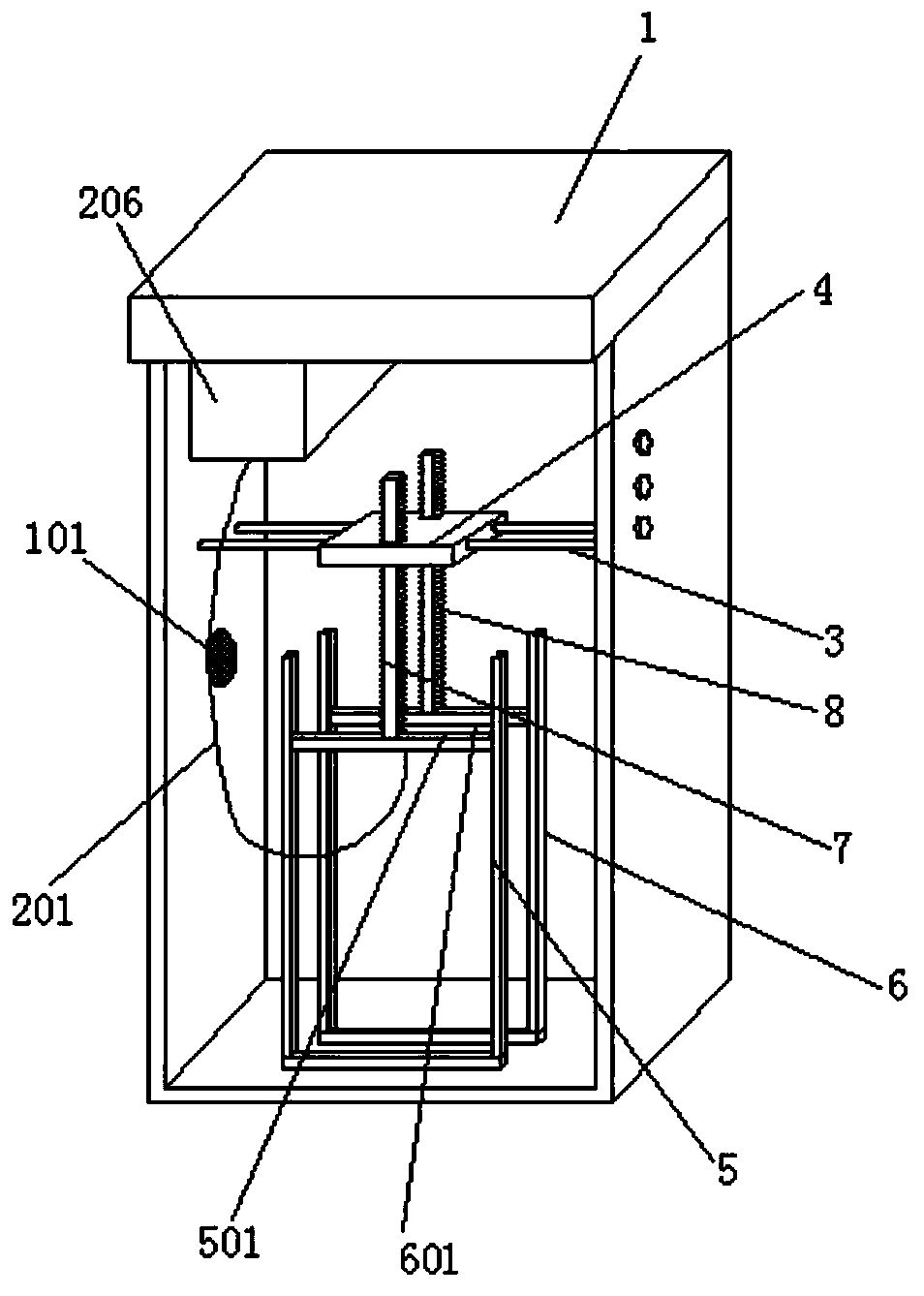

Oiling device for clock spring component

InactiveCN105478275AEffective atomizationEasy oiling operationSpraying apparatusDrive motorWork in process

The invention discloses an oiling device for a clock spring component. The oiling device comprises a frame assembly and a clamp assembly. The frame assembly comprises a frame, a first-layer mounting frame connected with the frame. The first-layer mounting frame is provided with a rotary disc. The rotary disc is provided with a clamp assembly. The frame is provided with a horizontal drive air cylinder and a drive motor. Oil spray assemblies are arranged above the clamp assembly and connected with the frame. The clamp assembly and a semi-finished product are driven by a servo motor, oiling operation is facilitated, the production requirement is met, and working efficiency is improved. By the adoption of the design of an adjustment device and a handle capable of being mounted quickly, and the height and the angle can be adjusted freely. The servo motor is adopted for driving operation, the situation that oil is sprayed unevenly due to the nonuniform speed is avoided, and the multiple oil spray assemblies are regularly distributed to be matched with parathion boards, so that oil stains can be atomized effectively, radiation from points to surfaces is better achieved, all-around oiling for products is achieved, and the production requirement is better met.

Owner:JIAXING HUACHANG DENSO

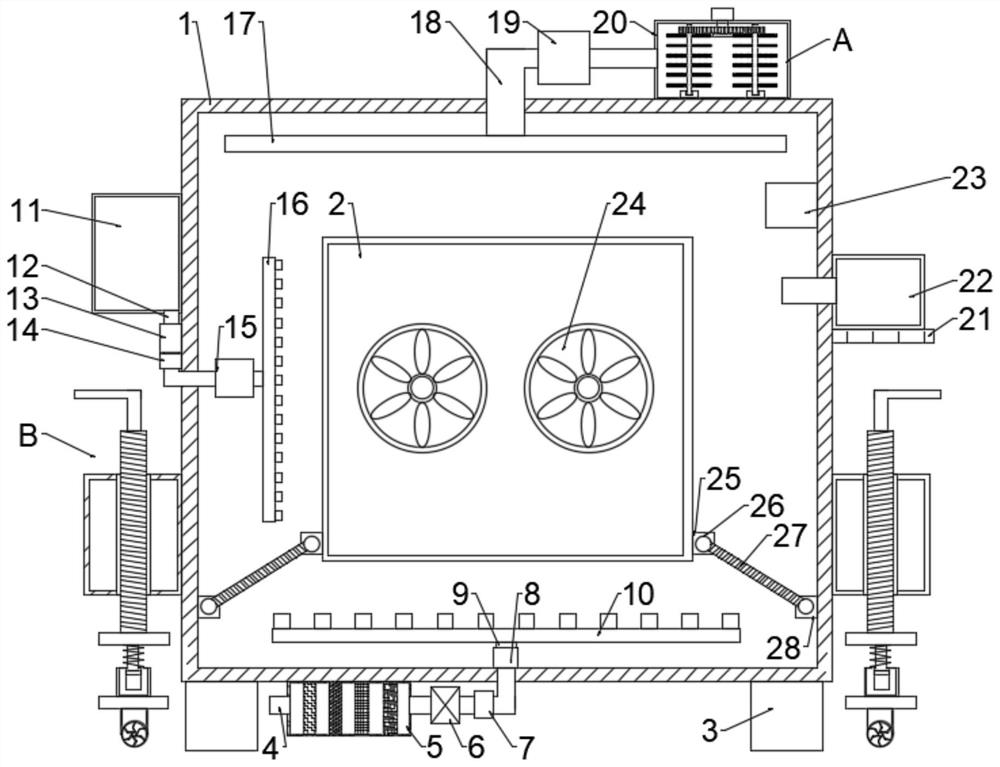

Dust removal device for mechanical spinning

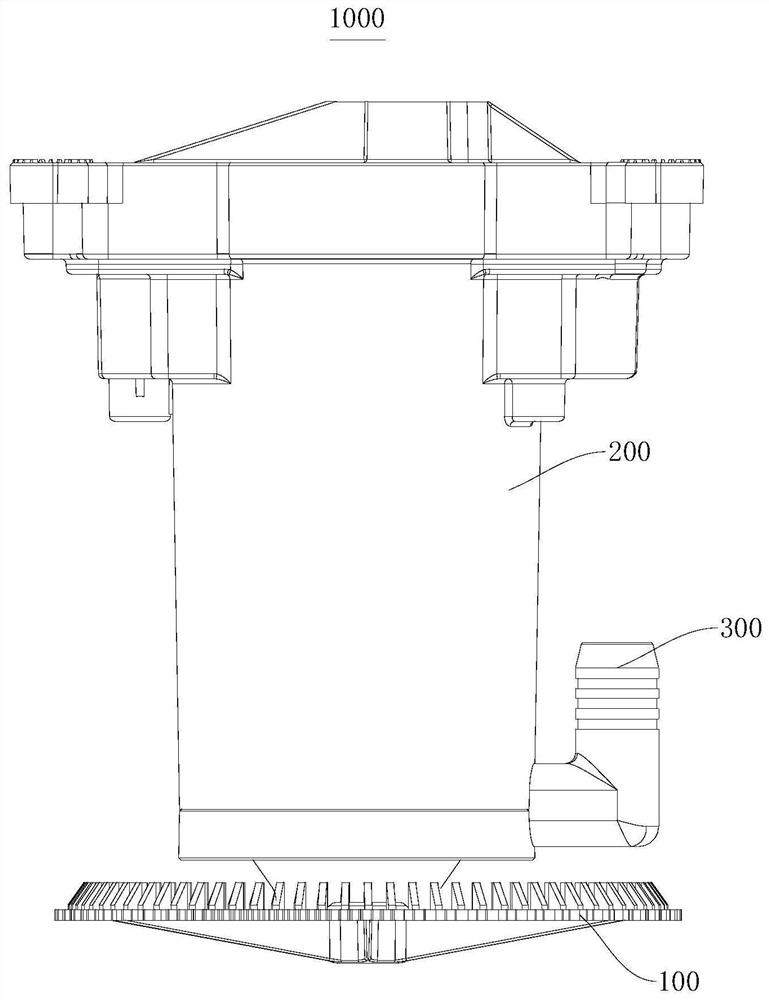

PendingCN112538681AEffective atomizationEffective shock absorptionCombination devicesAuxillary apparatusThermodynamicsAir velocity

The invention discloses a dust removal device for mechanical spinning, belongs to the technical field of mechanical dust removal equipment, solves the problem of poor dust removal and cleaning effectsof existing spinning dust removal. According to the technical key points, the dust removal device comprises a device box body; a spinning device is arranged in the device box body; an air inlet pipeis arranged in the device box body; the air inlet pipe penetrates through the device box body; a filter box body is arranged on the air inlet pipe; a first exhaust fan is arranged on the air inlet pipe; an air speed controller is arranged on the air inlet pipe; the air inlet pipe is connected with a rotary connecting pipe; a first rotary motor is arranged outside the rotary connecting pipe in a sleeving mode; an air outlet spray head is connected above the rotary connecting pipe; an exhaust pipe is arranged in the device box body; the exhaust pipe penetrates through the device box body; one end of the exhaust pipe is connected with an air suction opening; the end, away from the air suction opening, of the exhaust pipe penetrates through the dust collection box; a second exhaust fan is arranged on the exhaust pipe; air is pumped into the device through the first exhaust fan; and the beneficial effect of being good in dust removal and cleaning effect is achieved.

Owner:罗福祥

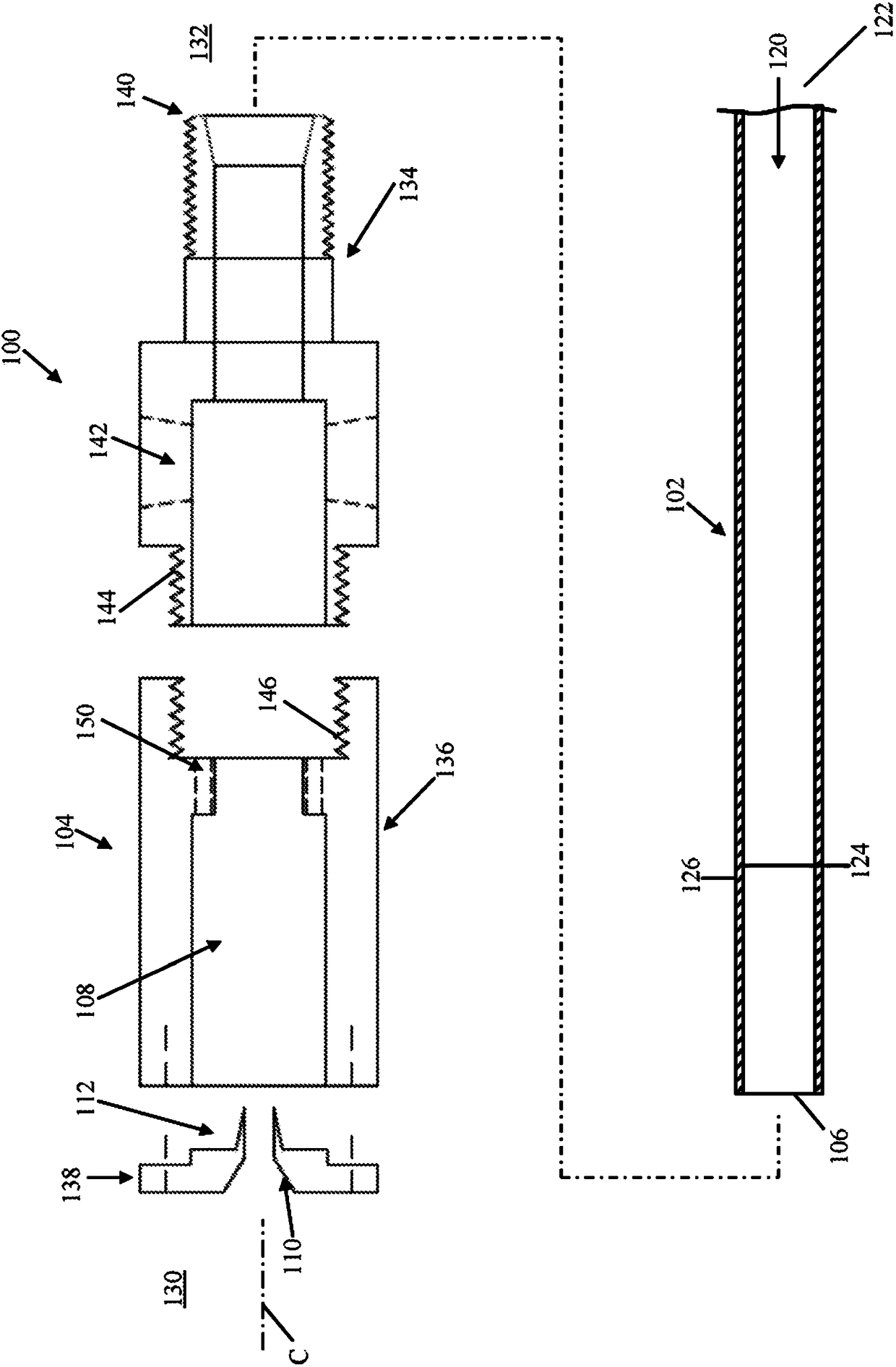

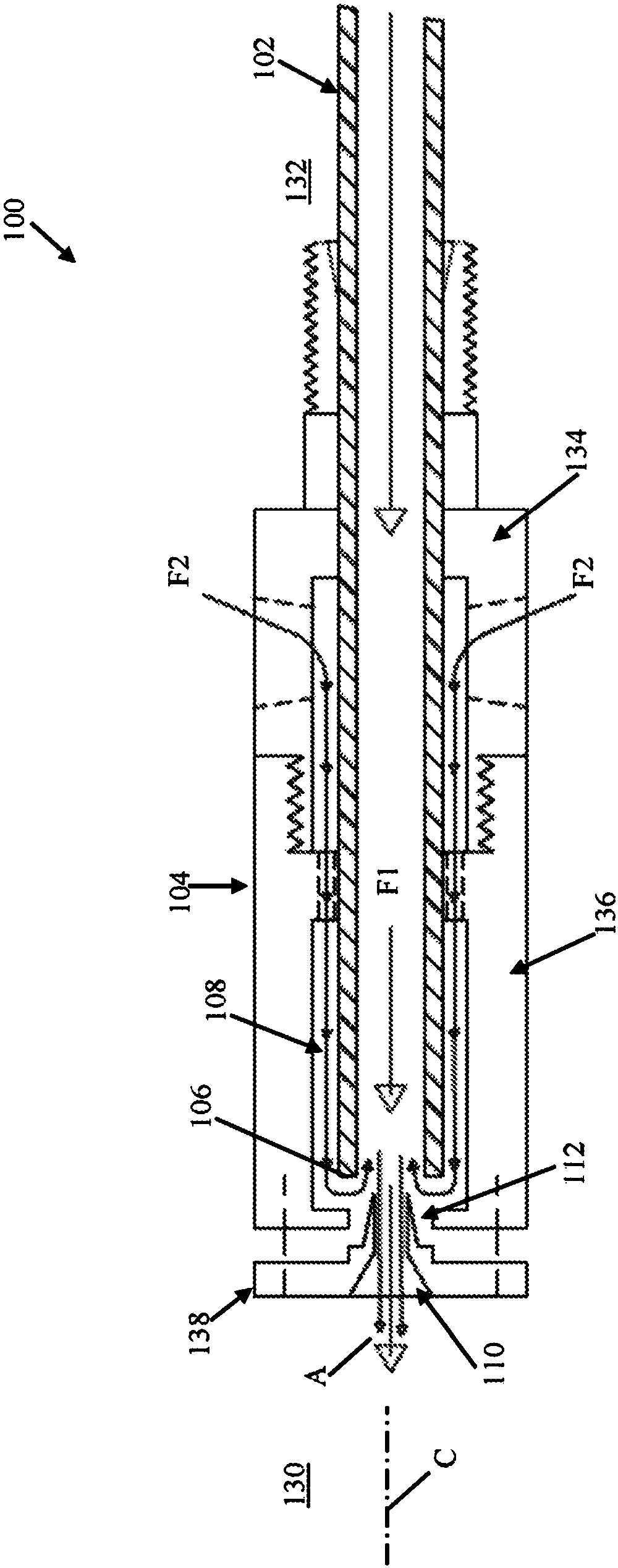

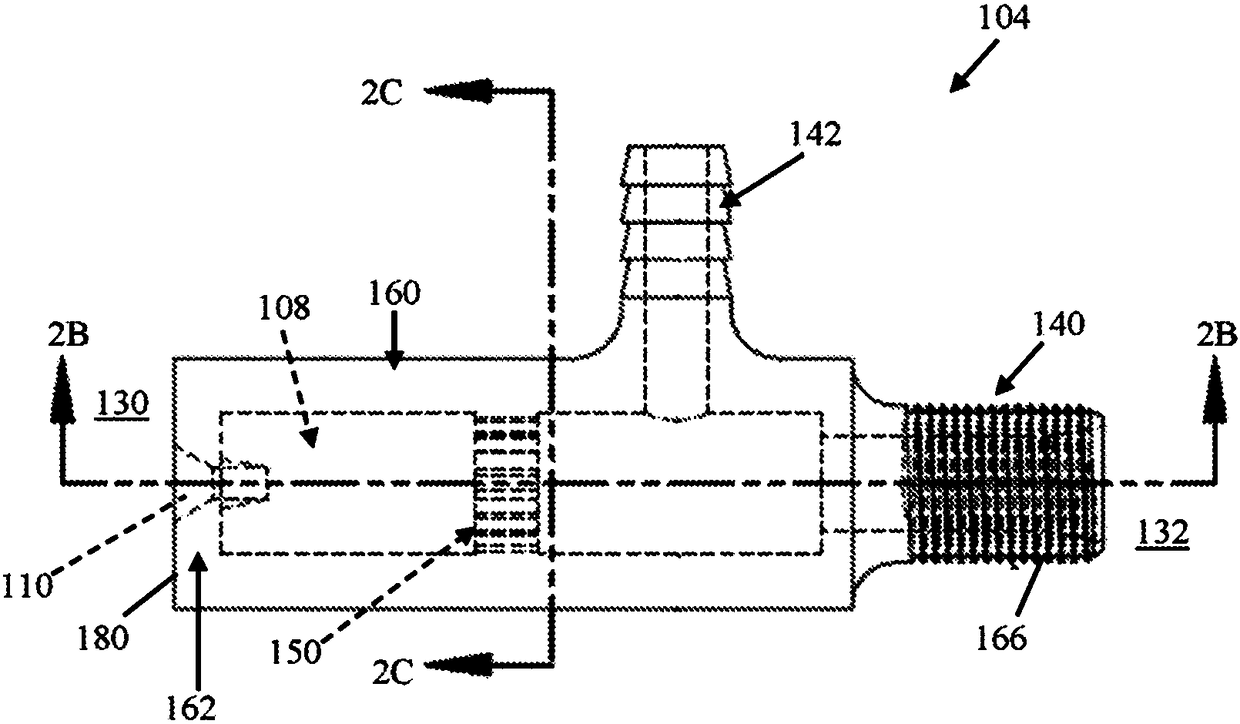

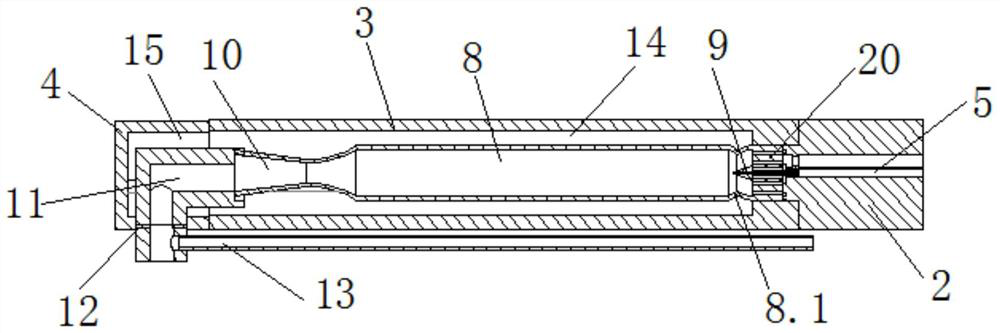

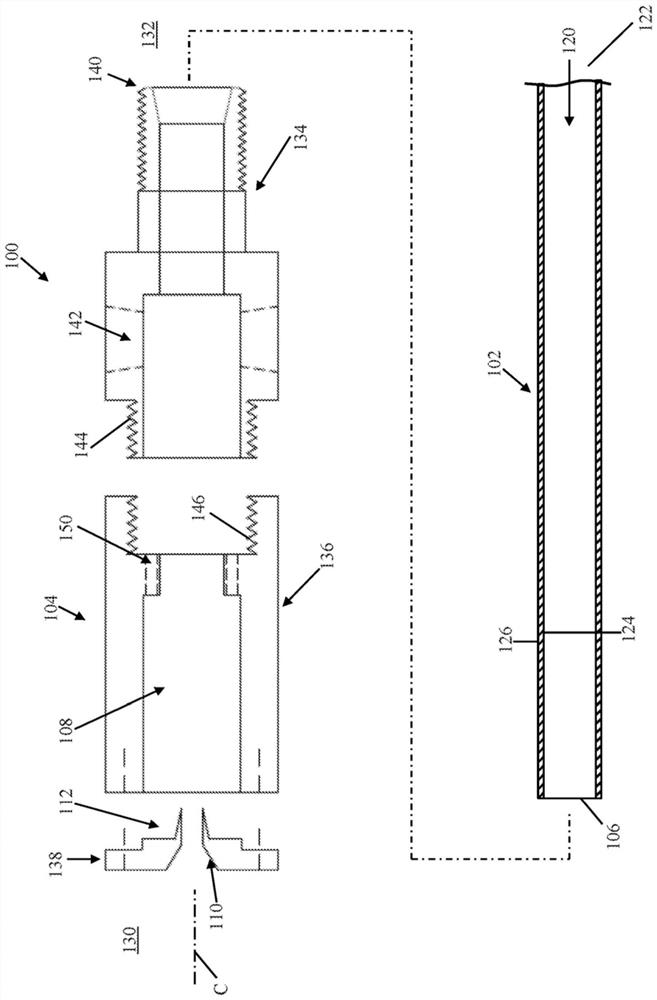

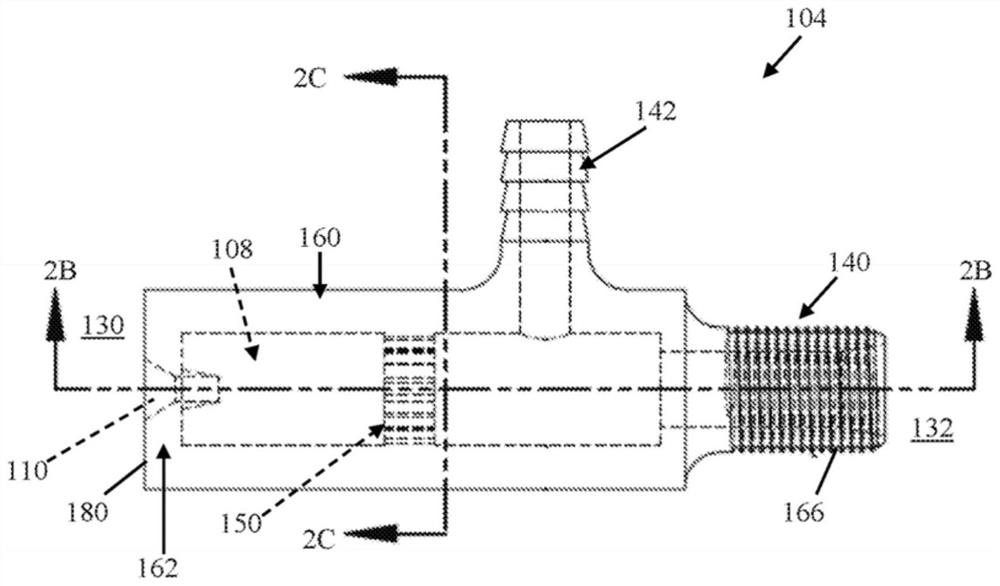

Nozzles and methods of mixing fluid flows

ActiveCN108348933AAtomization fastEffective atomizationSpray nozzlesLiquid spraying apparatusEngineeringNozzle

The invention provides a nozzle assembly including an inner tube and an outer housing. The inner tube terminates at an outlet end and defines a first flow passage. The first flow passage directs firstfluid flow to the outlet end in a primary flow direction. The outer housing includes a tubular side wall and an end wall. The tubular side wall defines a central axis. The end wall defines an exit orifice and an interior guide structure. The outlet end is axially aligned with the exit orifice. A second flow passage is established between the inner tube and the outer housing. The interior guide structure is configured and arranged relative to the outlet end to direct at least a portion of a second fluid flow from the second flow passage toward the outlet end in a direction initially opposite the primary flow direction for generating mixed fluid flow.

Owner:明尼苏达州大学董事会

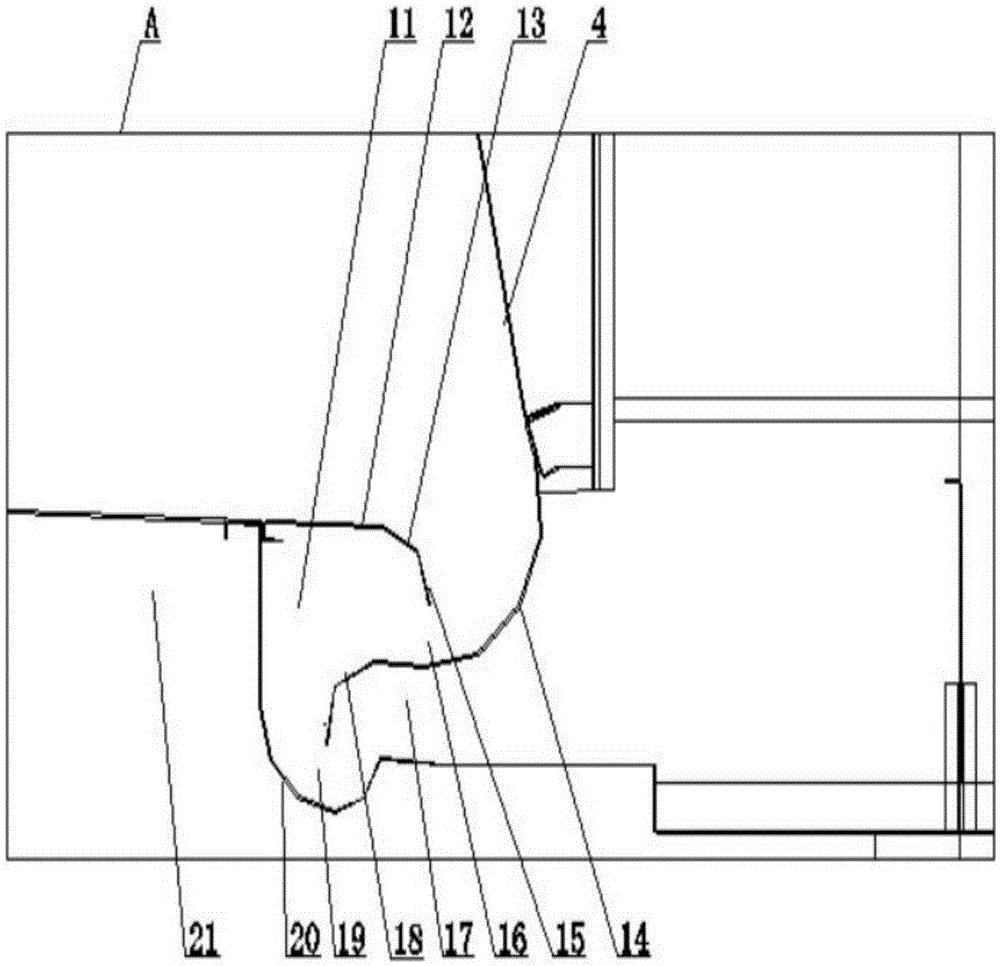

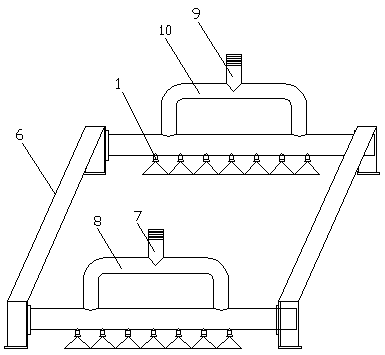

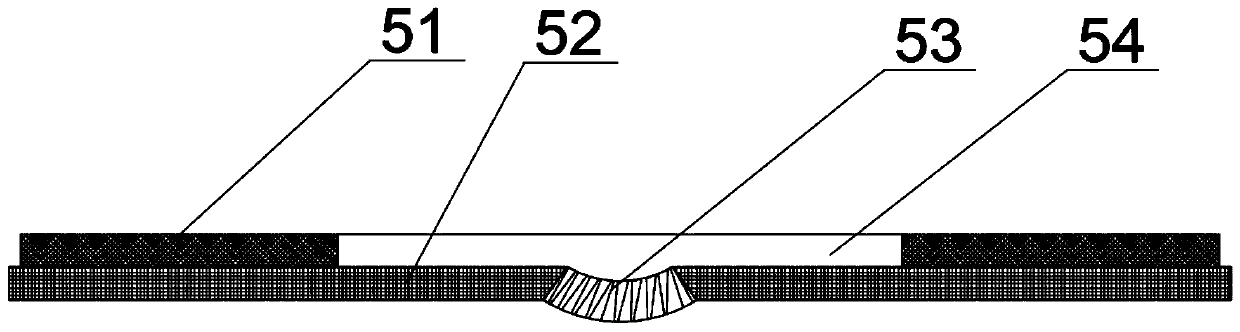

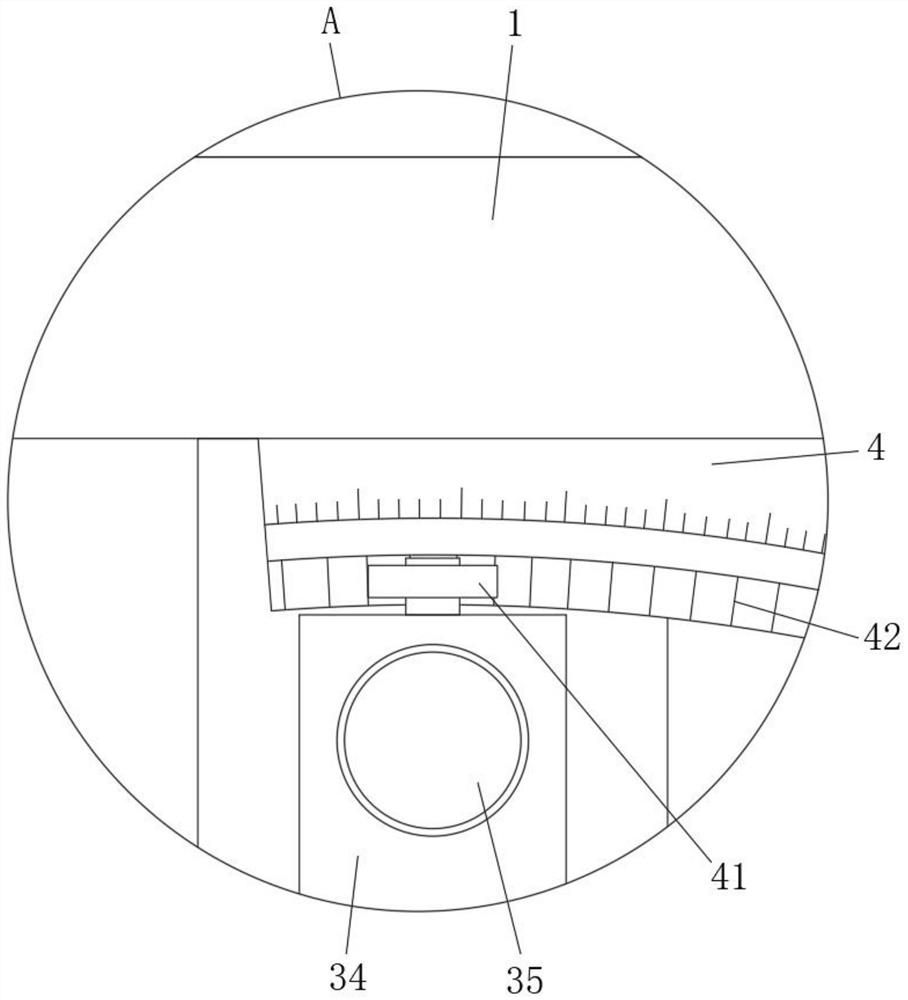

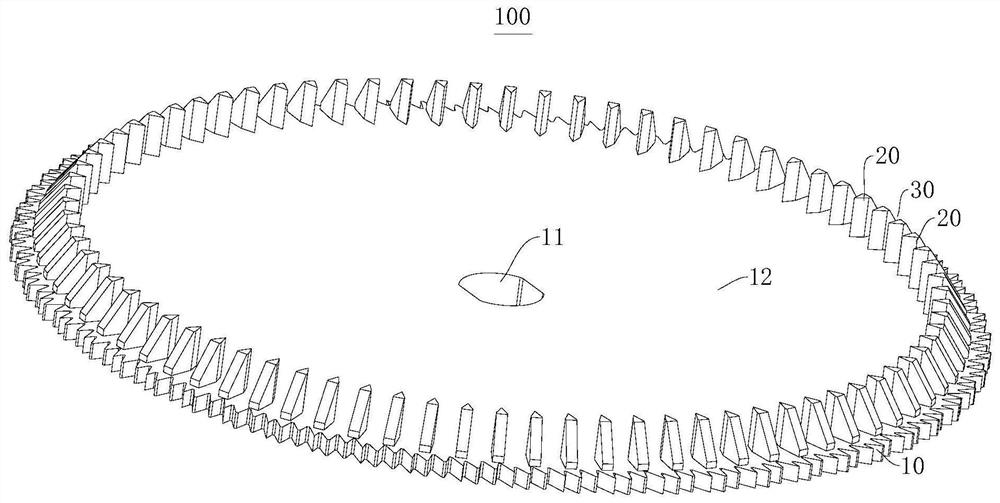

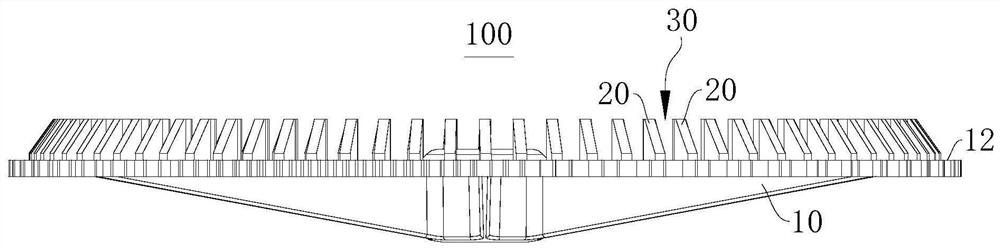

Bidirectional full-flow atomized paint mist trapping structure

InactiveCN105413355AImprove atomization efficiencyEffective atomizationUsing liquid separation agentTrappingEngineering

The invention relates to a bidirectional full-flow atomized paint mist trapping structure. The bidirectional full-flow atomized paint mist trapping structure comprises a bottom plate flow guiding structure and a water curtain plate, wherein one end, opposite to the lower end of the water curtain plate, of the bottom plate flow guiding structure is connected with one end of a bottom plate extending arc-shaped flow guiding plate, a serrate plate is fixedly mounted on the other end of the bottom plate extending arc-shaped flow guiding plate along full length, a water curtain extending arc-shaped flow guiding plate is arranged below the bottom plate extending arc-shaped flow guiding plate, one end of the water curtain extending arc-shaped flow guiding plate is smoothly mounted at the lower end of the water curtain plate, and a serrate plate is mounted at the other end of the water curtain extending arc-shaped flow guiding plate. According to the structure, a washing solution can pass through the atomizing serrate plates in a full flow manner, the efficiency of atomization is greatly increased, and the efficiency of paint mist trapping for the washing solution can reach up to 99.6%.

Owner:赛智环保科技(天津)有限公司

Method and device for spraying effective flora for citrus chachiensis hortorum aging

PendingCN114534983AEffective atomizationIncrease contentClimate change adaptationLiquid spraying apparatusUltrasonic nebulizersFishery

The invention discloses a citrus chachiensis hortorum aging effective flora spraying method and a citrus chachiensis hortorum aging effective flora spraying device. The citrus chachiensis hortorum aging effective flora spraying device comprises an atomization system, a pre-cooling system, a fog drop attachment system and an air circulation system, the ultrasonic nebulizer is connected with the fog drop attachment system through the atomization guide pipe and the atomization channel; a pre-cooling air outlet of the refrigerator is connected with the top of the fog drop attachment system through a guide pipe and a pre-cooling channel valve, and a pre-cooling air inlet is connected with the back of the fog drop attachment system through a guide pipe; the fog drop attachment system comprises a storage container and an atomization base, the storage container is installed on the atomization base, the atomization base is provided with base air holes and a base channel, and the base channel is communicated with an atomization channel. The method can effectively atomize an effective flora solution, so that the effective flora solution is efficiently attached to the surface of the pericarpium citri reticulatae, and the effective flora atomized by the ultrasonic atomizer can accelerate generation of effective components of the pericarpium citri reticulatae.

Owner:江门丽宫国际食品股份有限公司 +1

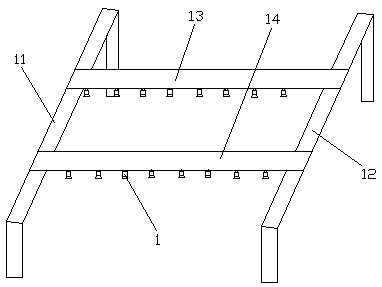

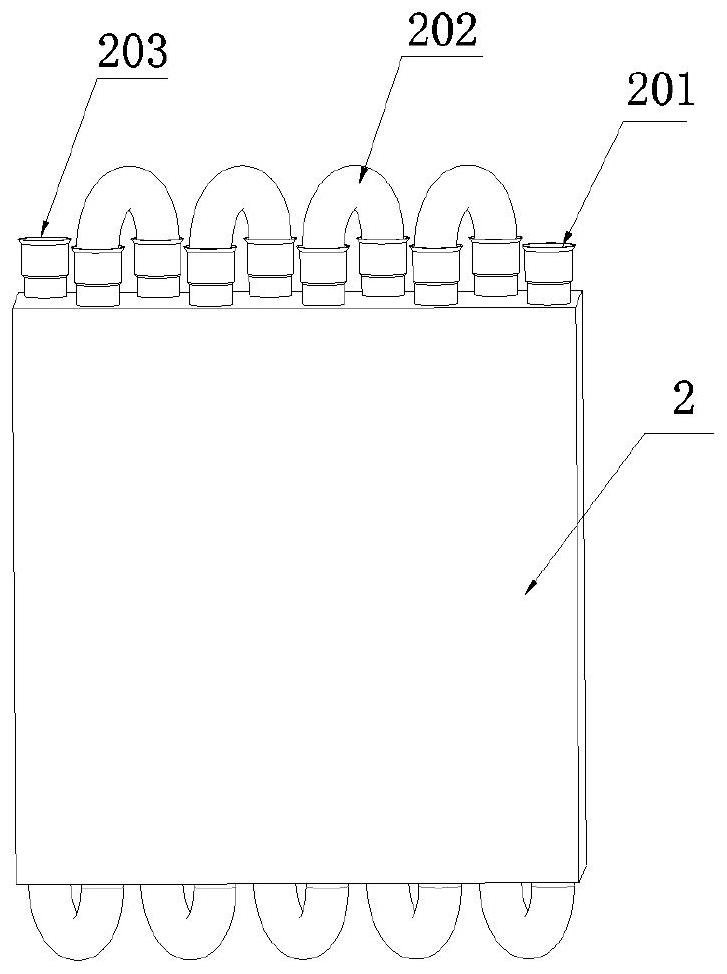

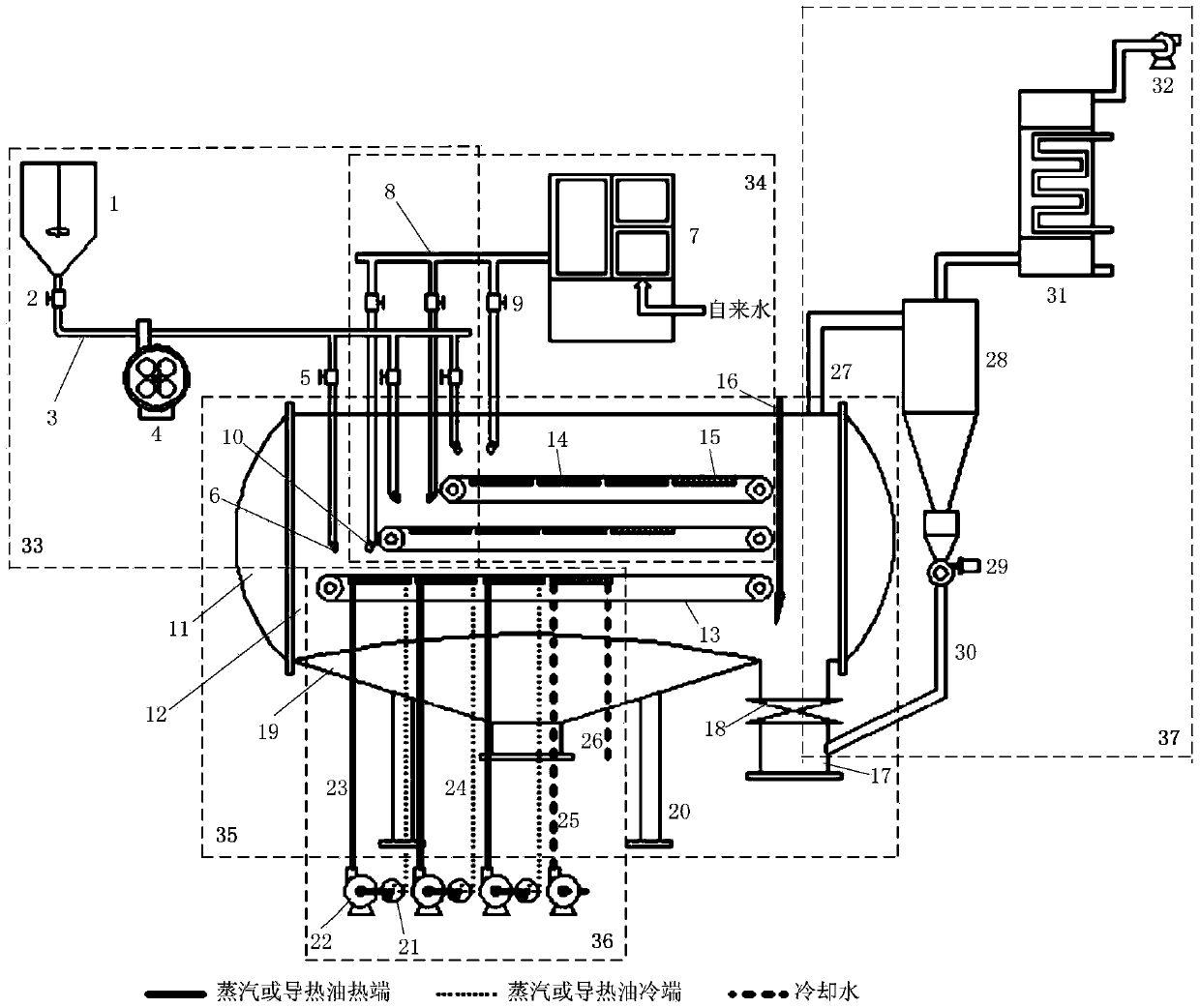

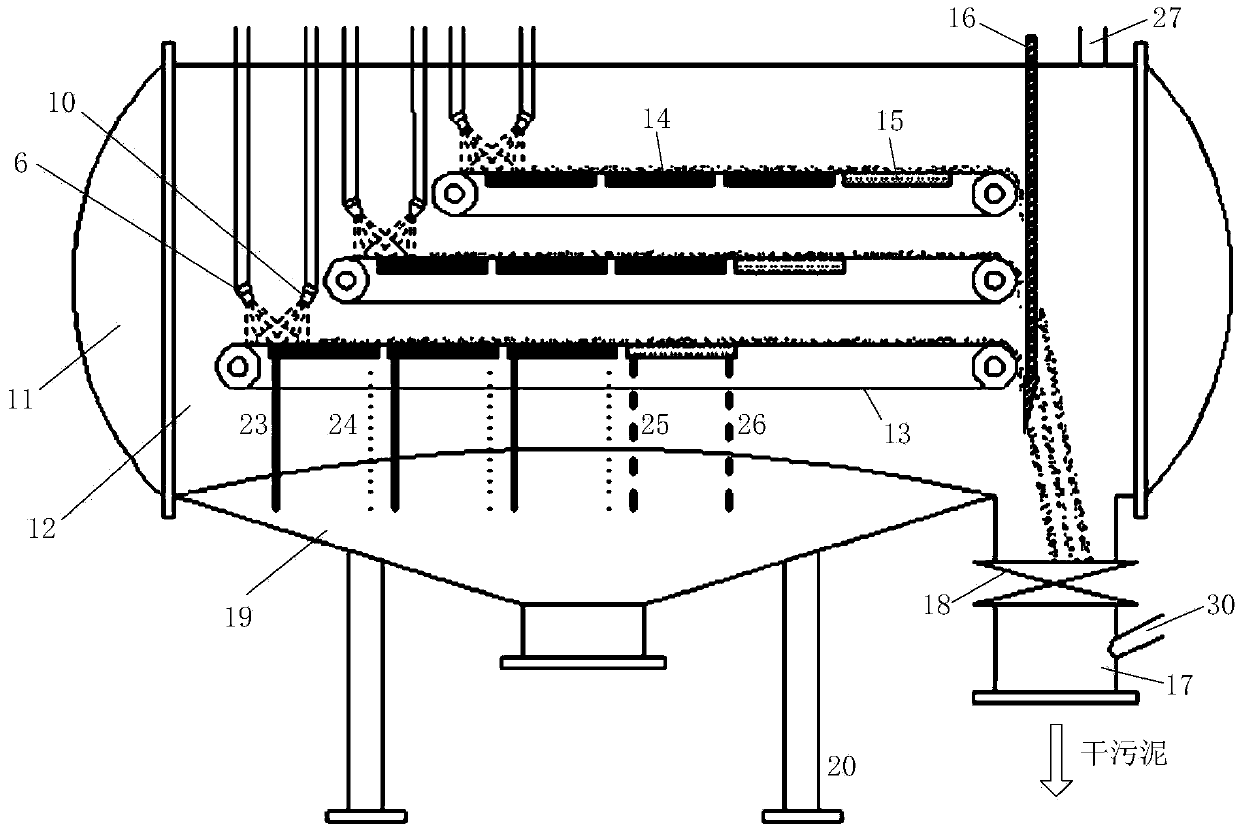

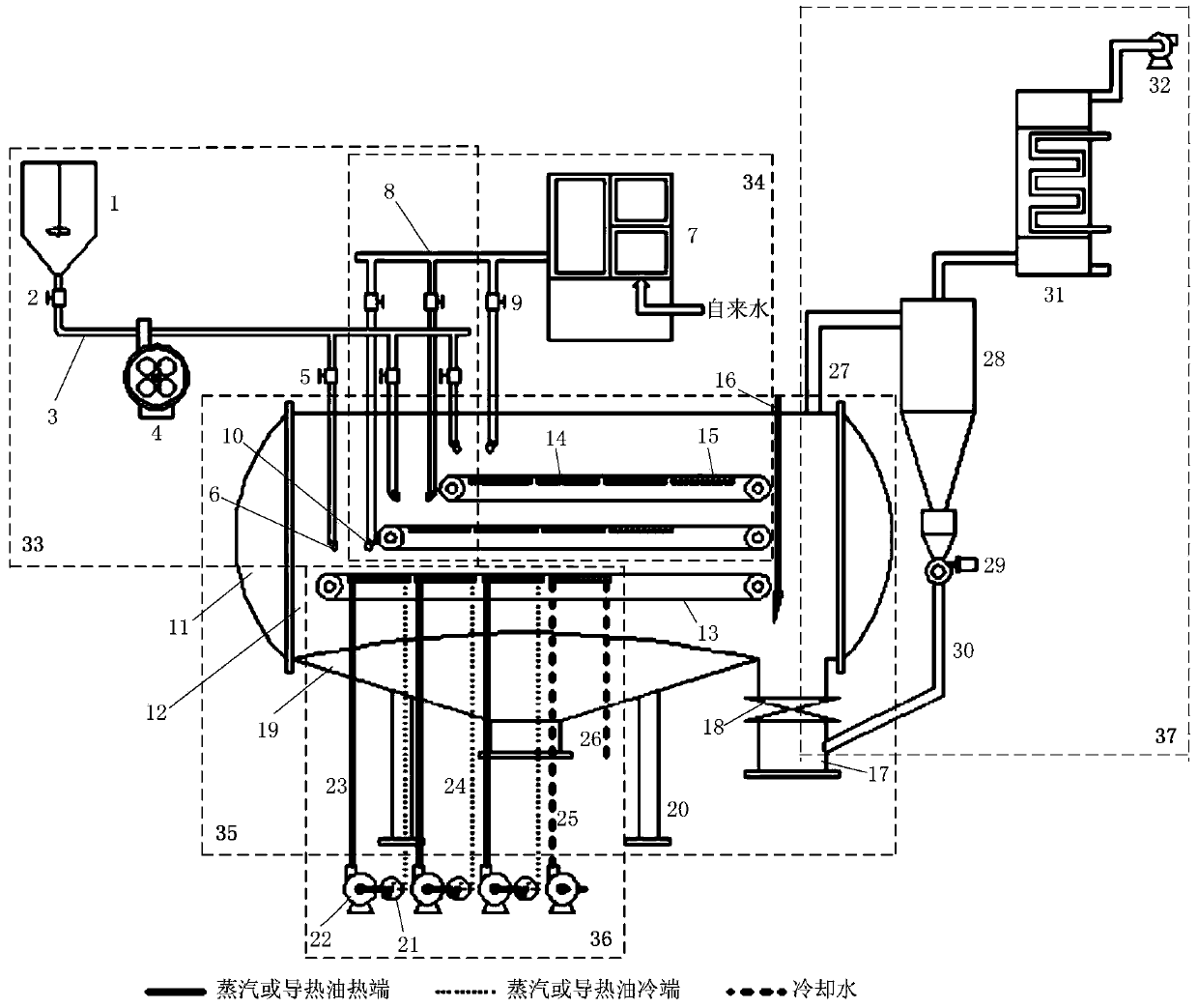

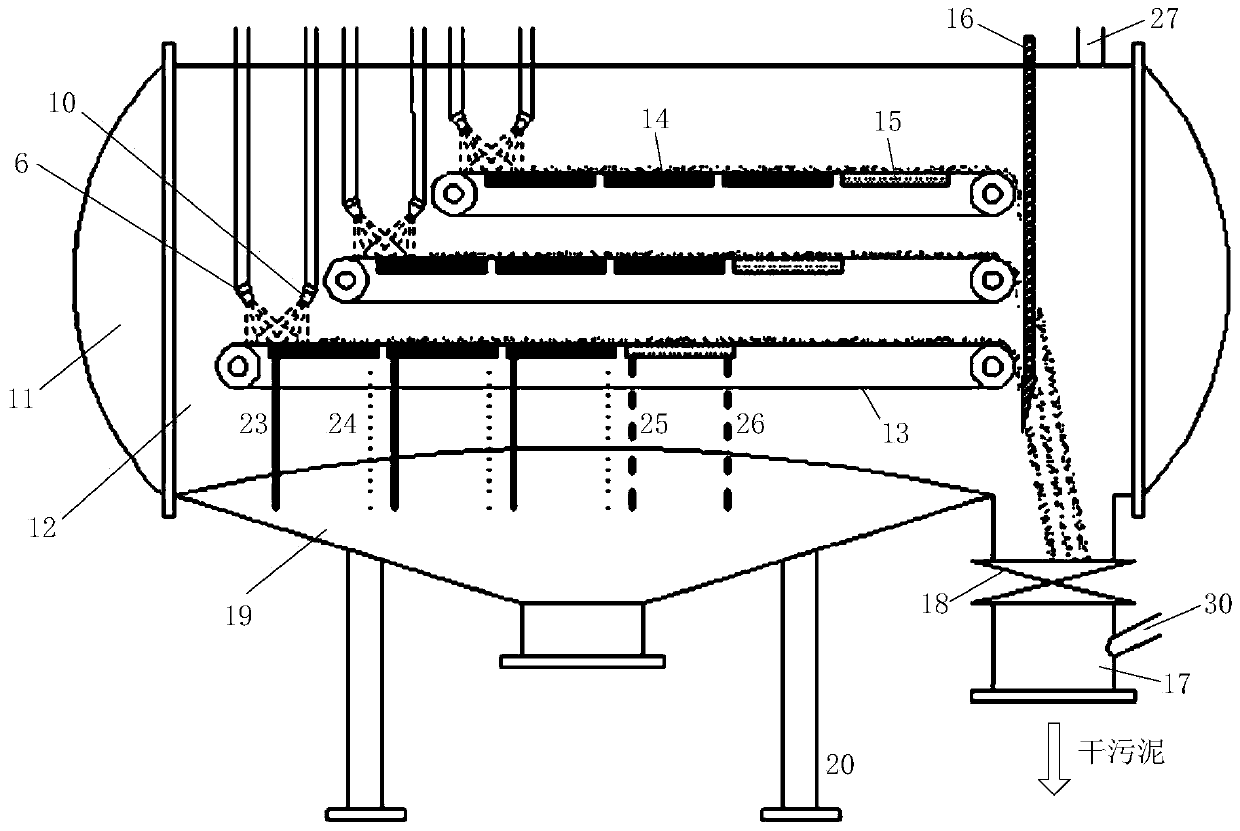

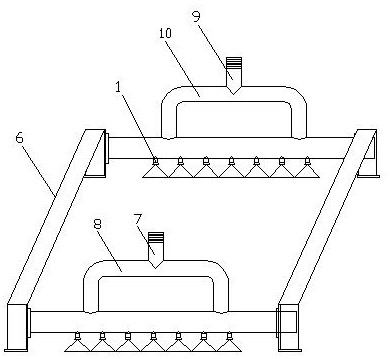

Sludge drying, deodorizing and conveying integrated device

ActiveCN105366908AImprove fluidity and homogeneityReasonable liquiditySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesExhaust gasTransfer mode

The invention provides a sludge drying, deodorizing and conveying integrated device. The device mainly comprises a wet sludge conveying and spraying device, a plant liquid conveying and spraying device, a sludge drying, deodorizing and conveying machine body, a heating / cooling medium conveying loop and a tail gas treatment device. A plurality of non-stick crawler belts are adopted for the sludge drying, deodorizing and conveying machine body and are made to be arranged in a machine shell in the longitudinal direction, and a wet sludge atomizing nozzle and a plant liquid atomizing nozzle which flush against each other are arranged at the starting end of each crawler belt; the wet sludge atomizing nozzles are utilized to atomize wet sludge, the plant liquid atomizing nozzles are utilized to atomize plant liquid, and the wet sludge atomizing nozzles and the plant liquid atomizing nozzles are made to be fully mixed to conduct deodorization. The sludge is dried to the required degree in a contact heat transfer mode through heating plates which are tightly attached to the non-stick crawler belts, and then the sludge is cooled to the required temperature through cooling plates which are tightly attached to the non-stick crawler belts. By means of the sludge drying, deodorizing and conveying integrated device, the problem that bad smell is spread all over a field area of a sludge drying incineration engineering project can be solved, and continuous drying and conveying of the sludge can be achieved.

Owner:TSINGHUA UNIV

Film pre-forming two flowing type nozzle, stillpot with the nozzle and technique for producing ultra-fine dust utilizing the stillpot

InactiveCN1313184CAvoid easy cloggingIncrease flow resistanceSolution crystallizationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringUltra fine

The present invention discloses one kind of pre-filming flow nozzle, stillpot with the nozzle and the production process of superfine particle in the stillpot with the nozzle. The nozzle includes casing, pre-filming unit, flow channel, ring gap flow channel, etc. and has the structure with greatly lowered flow resistance on solution and less jamming caused by the solute particle. The stillpot has simple structure, convenient operation, light labor strength and excellent sealing effect owing to the C-shaped metal sealing part with upper and lower sealing planes in linear contact state. By means of the supercritical fluid forced dispersing solution process in the stillpot with the nozzle, superfine solute particle may be prepared.

Owner:贺文智 +2

Inner hole dual-fuel supersonic flame spray gun and spray method

The invention discloses an inner hole dual-fuel supersonic flame spray gun which comprises a gun shell. The gun shell is divided into a front section, a middle section and a rear section, a gas mixing ring and a kerosene nozzle are arranged on the front section, a combustion chamber is arranged in the middle section, a gas premixing chamber is arranged in the front of the combustion chamber, and a Laval nozzle is arranged at an outlet of the combustion chamber. The rear section is provided with a spraying opening, and the side wall of the spraying opening is provided with a connector connected with a powder feeding pipe. A high volume expansion effect generated after kerosene combustion is utilized, a high-energy enthalpy value is generated after gas combustion, and kerosene combustion can be more sufficient through the combustion chamber and the gas mixing ring, so that the content of oxygen in combustion-supporting gas can be accurately matched, the oxidation condition of powder can be effectively controlled, and the temperature and speed of the outlet of the spray gun can be adjusted more accurately.

Owner:中机凯博表面技术江苏有限公司

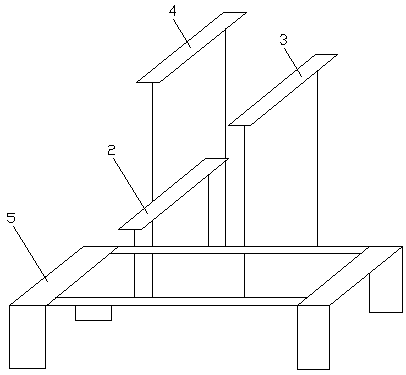

Spray booth with two-way full-flow paint mist capture function

ActiveCN105413933BImprove atomization efficiencyEffective atomizationLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to a paint spraying room with a two-way all-flow paint mist capturing function. The paint spraying room comprises a paint spraying chamber and an air-liquid separation chamber; the paint spraying chamber is communicated with the air-liquid separation chamber through a paint mist capturing structure; one end, opposite to the lower end of a water curtain plate, of a baseplate guide structure is connected with one end of a baseplate extension arc guide plate; a saw tooth plate is fixedly mounted at the other end of the baseplate extension arc guide plate; a water curtain extension arc guide plate is arranged below the baseplate extension arc guide plate; one end of the water curtain extension arc guide plate is smoothly mounted at the lower end of the the water curtain plate; a saw tooth plate is mounted at the other end of the water curtain extension arc guide plate; a first atomization space is formed among the baseplate guide structure, the baseplate extension arc guide plate and the water curtain extension arc guide plate; and a second atomization space is formed between the baseplate guide structure and the water curtain extension arc guide plate. The structure realizes the passing of washing liquid through the atomization saw tooth plates by all flow, so that the atomization efficiency is greatly improved, and the efficiency of the washing liquid capturing the paint mist is high up to 99.6%.

Owner:赛智环保科技(天津)有限公司

A double-layer continuous ultrasonic atomization grading device and grading method

ActiveCN110756375BCompact structureReasonable structureDispersed particle separationLiquid spraying apparatusVapor–liquid separatorEngineering

The invention relates to a double-layer continuous ultrasonic atomization classification device and method. The classification device comprises a first container; the bottom of the first container isconnected with one end of an atomization pipe; the other end of the atomization pipe is connected to a second container; the second container is connected to the first container through a circulatingpipe; the atomization pipe is provided with a horizontal section, and multiple piezoelectric ceramic ultrasonic atomizers are arranged inside in the horizontal direction; the horizontal section of theatomization pipe is connected with a water mist conveying pipe through multiple communicators; one end of the water mist conveying pipe is a gas inlet end, and the other end is connected with a gas-liquid separator; and water level overflowing devices are arranged in the atomization pipe at the downstream of the multiple communicators. The double-layer continuous ultrasonic atomization classification method is higher in classification precision to meet the classification requirements of sub powder particles, and can perform continuous ultrasonic atomization classification to achieve sub-micron classification precision and high production efficiency.

Owner:ANHUI JINGCHENG NEW MATERIAL CO LTD

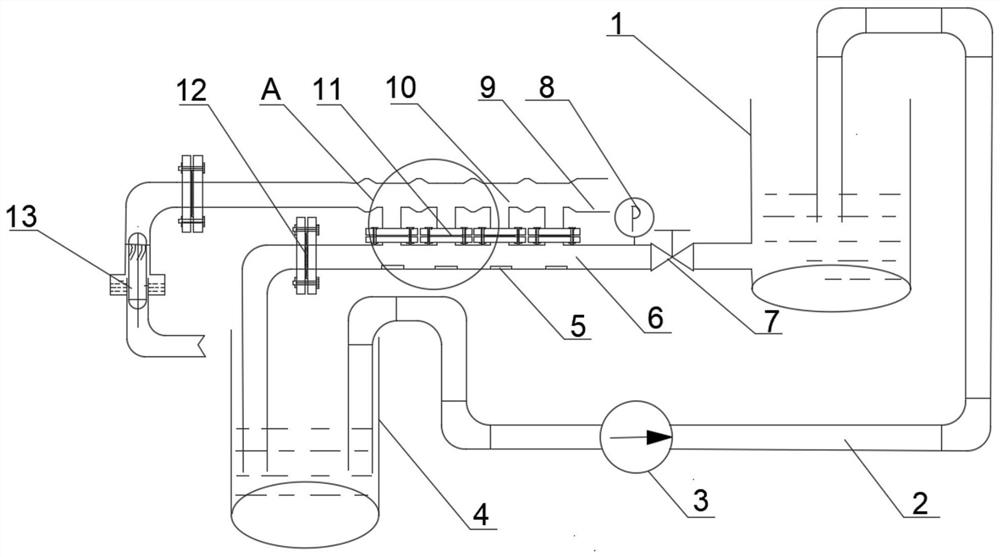

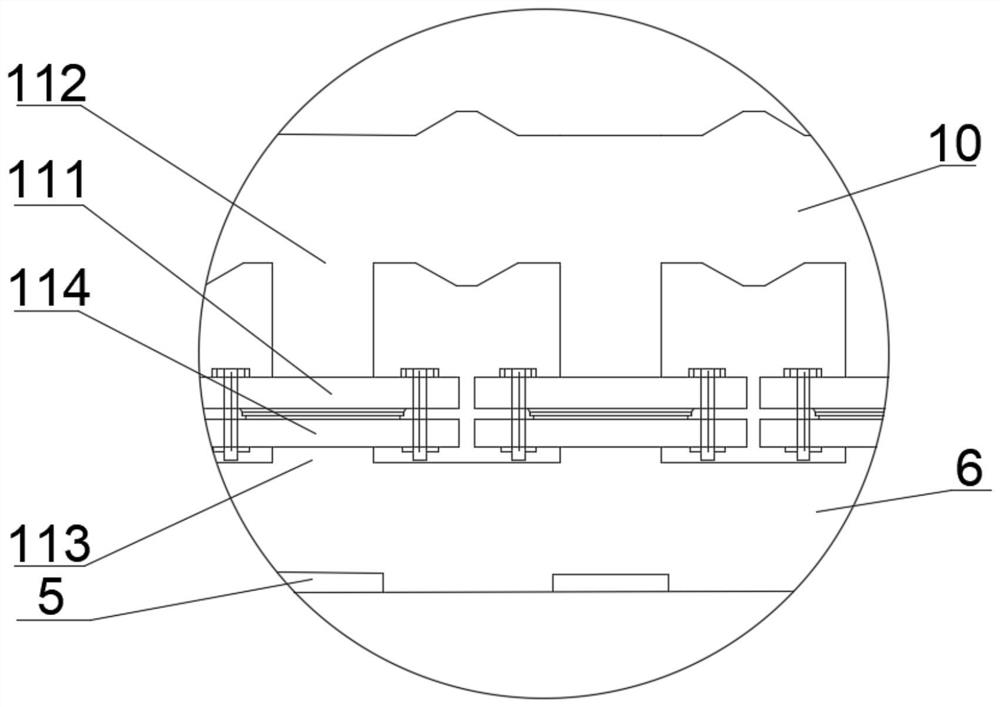

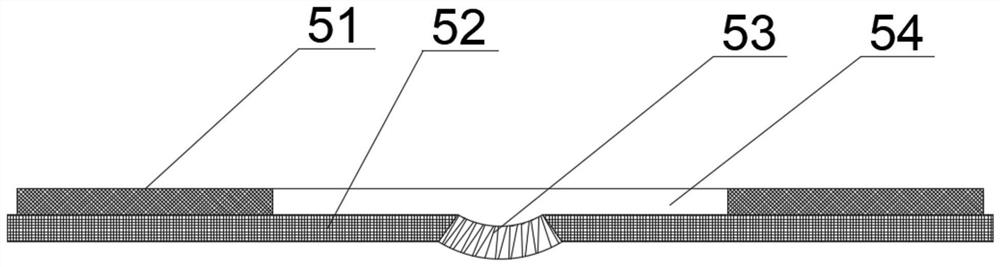

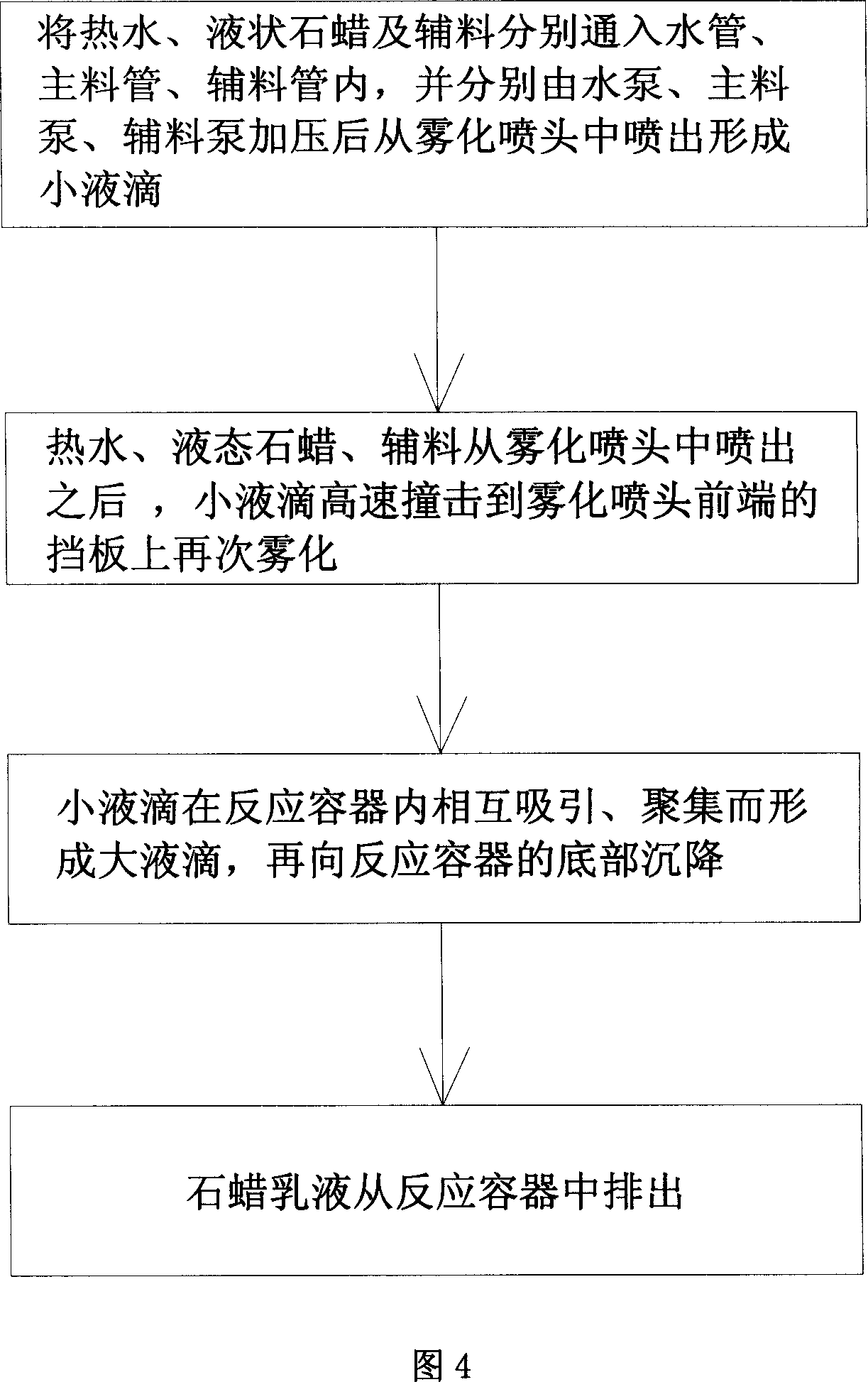

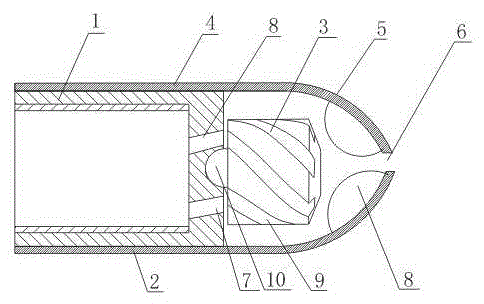

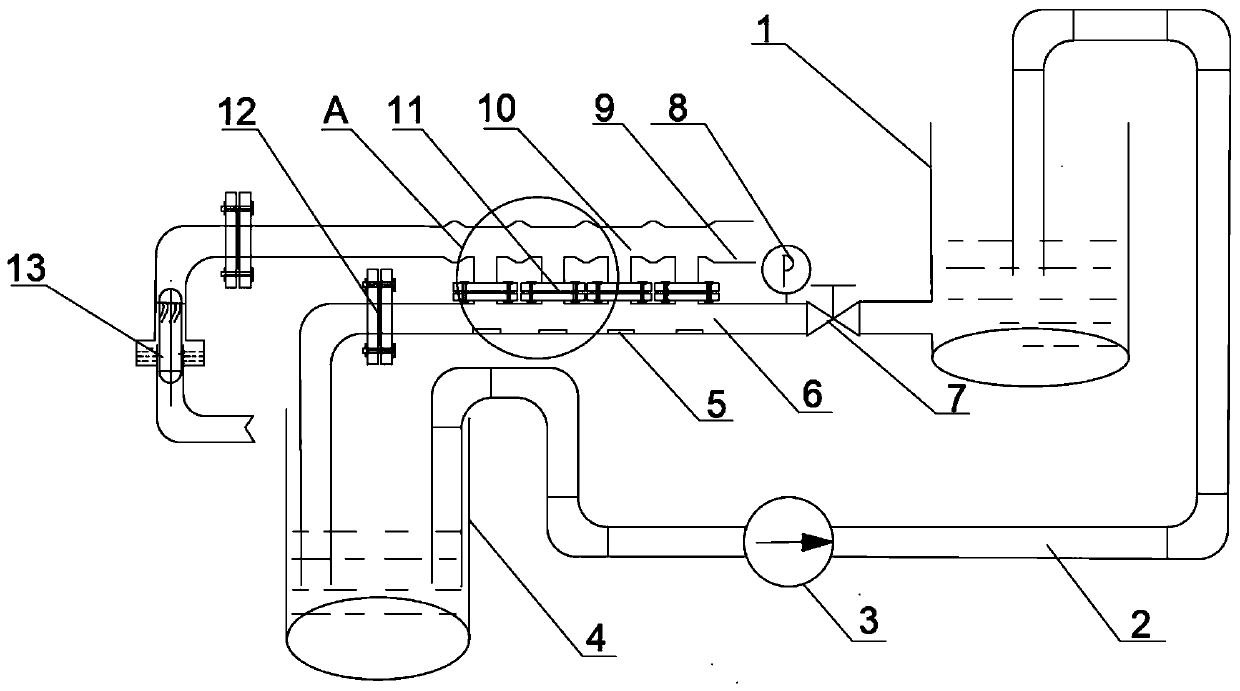

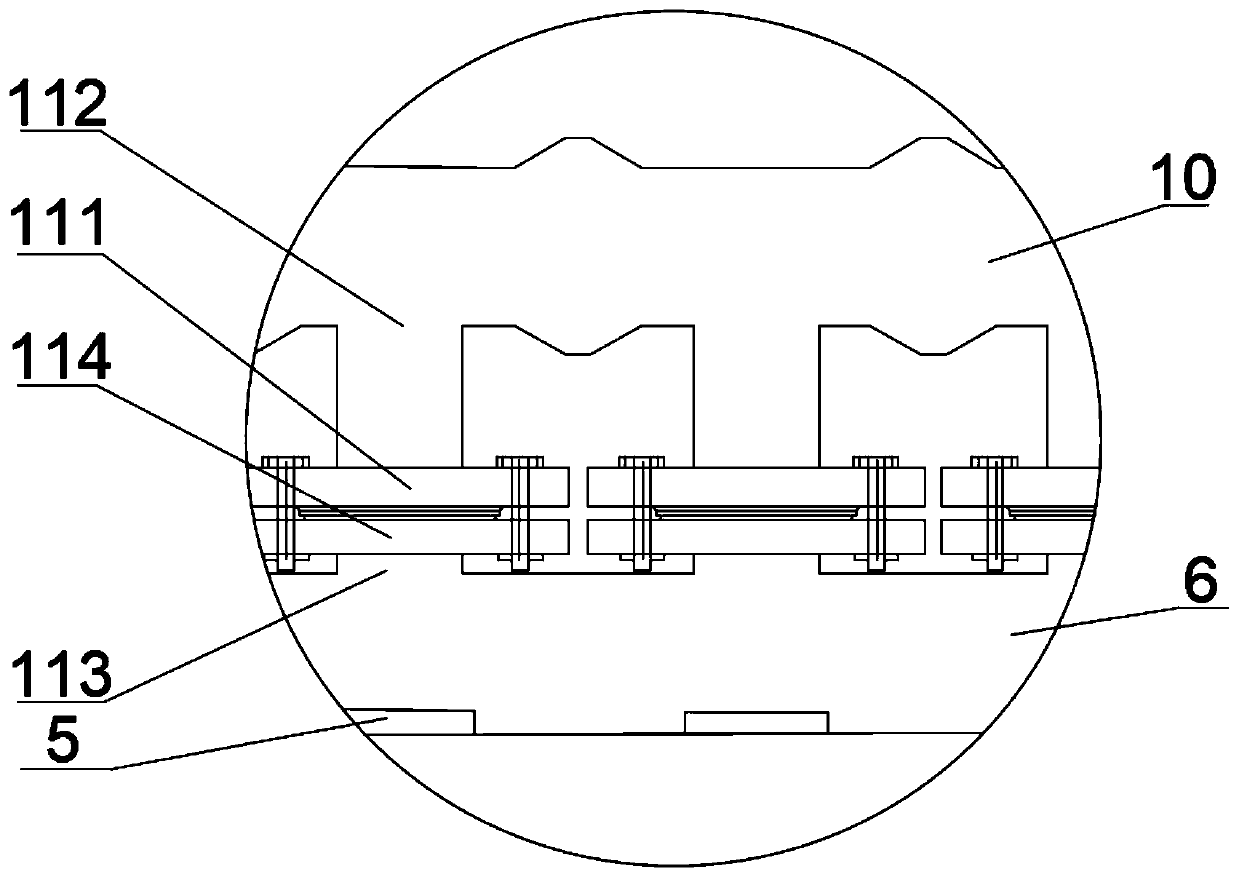

Atomization preparing apparatus and method for wax emulsion

InactiveCN101096604AEffective atomizationReduce energy consumptionWax physical treatmentDispersityParaffin wax

The invention discloses a device and a method for atomizing a wax emulsion. The device comprises the following parts: a discharge door on the reactor, a hot-water pipe, a host material pipe, a finding pipe with an atomized injector on the front end, wherein every atomized injector is extended in the reactor, the hot-water pipe, the host material pipe and the finding pipe are equipped with water pump, the host material pump and the finding pump separately. The method comprises the following steps: a, putting the hot water, the liquid wax and the findings in the water pipe, the host material pipe and the finding pipe; ejecting and forming the little drop from the atomized injector by increasing the pressure with the water pump, the host material pump and the finding pump; b, forming the big drop by attracting and gathering the little drop in the reactor; depositing to the bottom of the reactor; c, discharging the wax emulsion from the reactor. The wax emulsion which is prepared with the invention is provided with the good dispersity and homogeneity.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

High-pressure hydraulic jetting device

InactiveCN105089579AEffective atomizationExpand the spraying rangeFluid removalEngineeringHigh pressure

The invention provides a high-pressure hydraulic jetting device, which comprises connecting bodies, cases and a rotating head, wherein each connecting body is of a cavity structure with an opening formed in the back end surface; each case consists of a hollow cylinder and a hollow hemisphere which are communicated and connected; each hollow cylinder is connected onto the outer wall of the corresponding connecting body through screw threads in a sleeving way; the sphere top of each hollow hemisphere is provided with a water outlet; the rotating head is rotationally arranged at the bottom of the connecting bodies; the bottom of each connecting body is uniformly provided with impact jetting holes; and the high-pressure hydraulic jetting device also comprises pressurizing blocks uniformly arranged on the inner circular arc surfaces of the hollow hemispheres around the water outlets. By arranging the pressurizing blocks, the liquid pressure is raised when rotated liquid flows through the water outlets; the high-pressure liquid is effectively atomized; and the jetting range of the high-pressure liquid is increased.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

Double-layer continuous ultrasonic atomization classification device and classification method

ActiveCN110756375ACompact structureReasonable structureDispersed particle separationLiquid spraying apparatusVapor–liquid separatorEngineering

The invention relates to a double-layer continuous ultrasonic atomization classification device and method. The classification device comprises a first container; the bottom of the first container isconnected with one end of an atomization pipe; the other end of the atomization pipe is connected to a second container; the second container is connected to the first container through a circulatingpipe; the atomization pipe is provided with a horizontal section, and multiple piezoelectric ceramic ultrasonic atomizers are arranged inside in the horizontal direction; the horizontal section of theatomization pipe is connected with a water mist conveying pipe through multiple communicators; one end of the water mist conveying pipe is a gas inlet end, and the other end is connected with a gas-liquid separator; and water level overflowing devices are arranged in the atomization pipe at the downstream of the multiple communicators. The double-layer continuous ultrasonic atomization classification method is higher in classification precision to meet the classification requirements of sub powder particles, and can perform continuous ultrasonic atomization classification to achieve sub-micron classification precision and high production efficiency.

Owner:ANHUI JINGCHENG NEW MATERIAL CO LTD

An integrated device for sludge drying, deodorization and transportation

ActiveCN105366908BImprove liquidityImprove homogeneitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeTransfer mode

The invention provides a sludge drying, deodorizing and conveying integrated device. The device mainly comprises a wet sludge conveying and spraying device, a plant liquid conveying and spraying device, a sludge drying, deodorizing and conveying machine body, a heating / cooling medium conveying loop and a tail gas treatment device. A plurality of non-stick crawler belts are adopted for the sludge drying, deodorizing and conveying machine body and are made to be arranged in a machine shell in the longitudinal direction, and a wet sludge atomizing nozzle and a plant liquid atomizing nozzle which flush against each other are arranged at the starting end of each crawler belt; the wet sludge atomizing nozzles are utilized to atomize wet sludge, the plant liquid atomizing nozzles are utilized to atomize plant liquid, and the wet sludge atomizing nozzles and the plant liquid atomizing nozzles are made to be fully mixed to conduct deodorization. The sludge is dried to the required degree in a contact heat transfer mode through heating plates which are tightly attached to the non-stick crawler belts, and then the sludge is cooled to the required temperature through cooling plates which are tightly attached to the non-stick crawler belts. By means of the sludge drying, deodorizing and conveying integrated device, the problem that bad smell is spread all over a field area of a sludge drying incineration engineering project can be solved, and continuous drying and conveying of the sludge can be achieved.

Owner:TSINGHUA UNIV

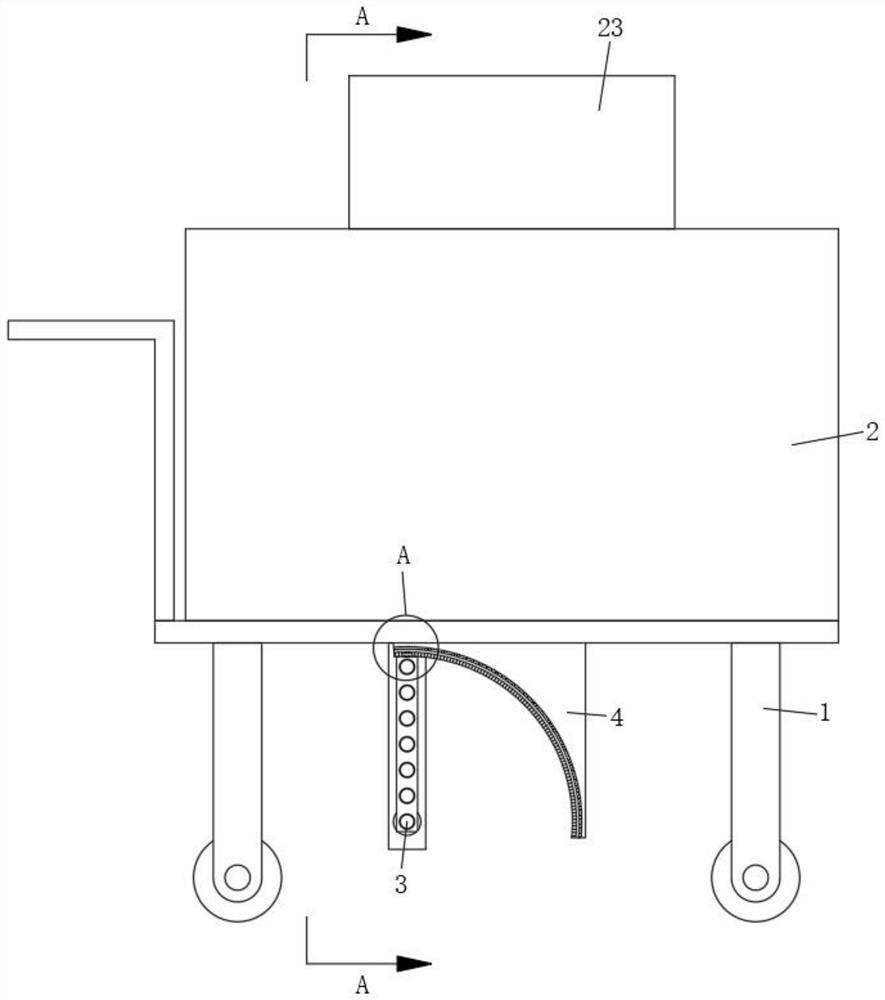

A kind of watering device for custard apple planting

ActiveCN113179734BEasy to adjustChange the amount of irrigation waterClimate change adaptationWatering devicesAgricultural engineeringDrive motor

The invention belongs to the technical field of custard apple planting, and discloses a watering device for custard apple planting. Irrigation components are assembled, and are used for atomizing and spraying the water or water and fertilizer stored in the water tank to the custard apple plants according to the set watering range; the irrigation components include: an installation vertical plate fixedly connected with the lower end surface of the walking trolley; The drive shaft of the installation vertical plate; the drive motor connected to both ends of the drive shaft and the in-line structure irrigation frame, the drive motor is fixed on the installation vertical plate, and the drive motor is used to drive the irrigation frame at 90 through the drive shaft Reciprocating rotation within the range of °; multiple atomizing nozzles fixed on the irrigation frame in parallel; in summary, the irrigation range can be changed by rotating and adjusting the irrigation angle of the irrigation frame, the adjustment is simple, and it can be effectively applied to different growth degrees plant watering.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

A vacuum belt filter washing method

ActiveCN109045813BAct as air sealEffective atomizationMoving filtering element filtersSprayerSpray nozzle

Owner:CHINA PETROLEUM & CHEM CORP +1

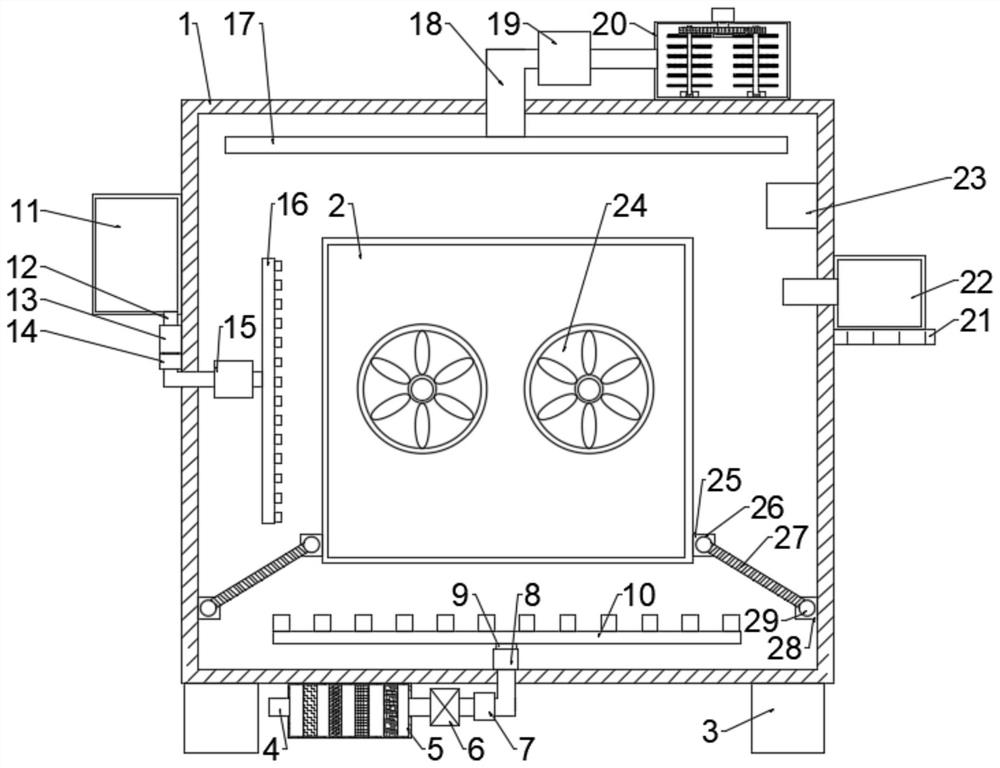

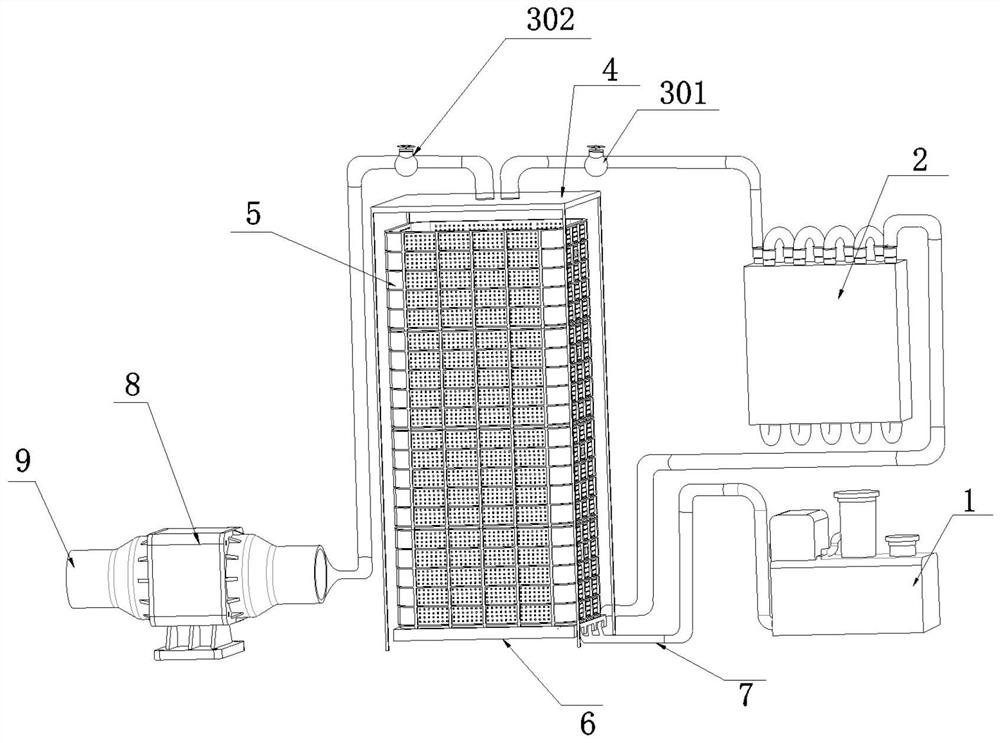

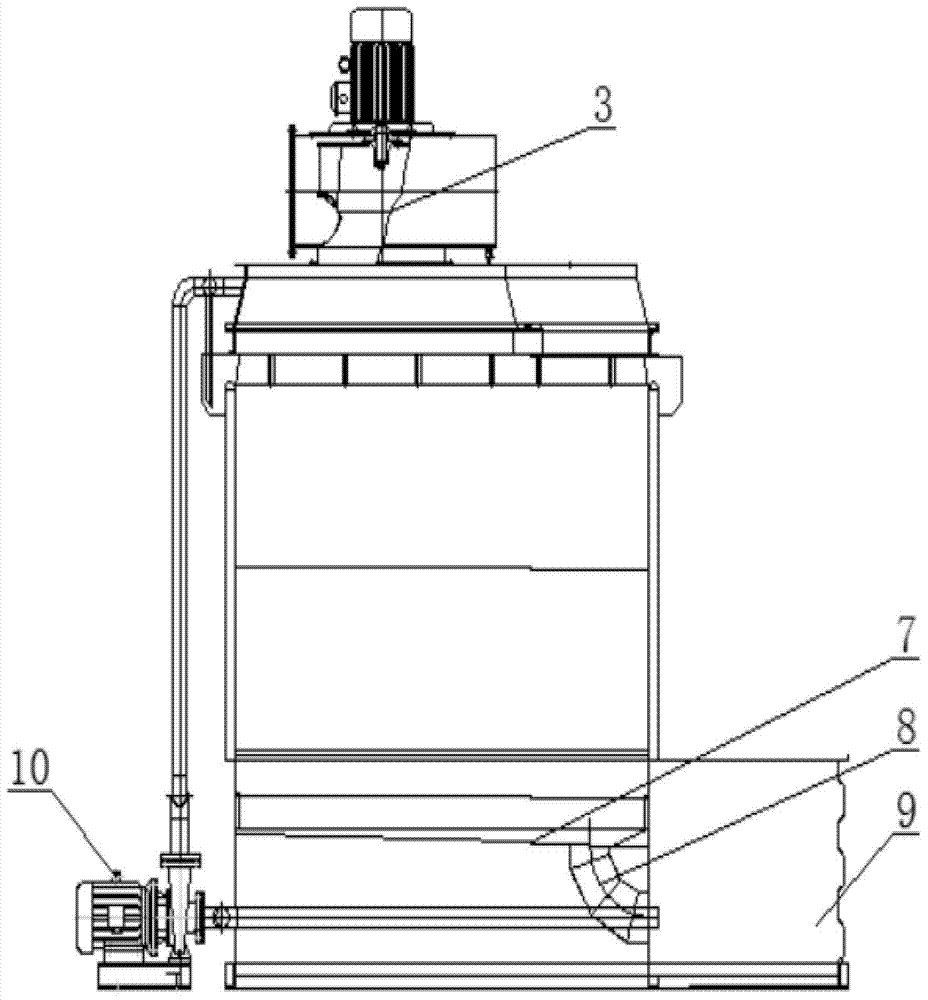

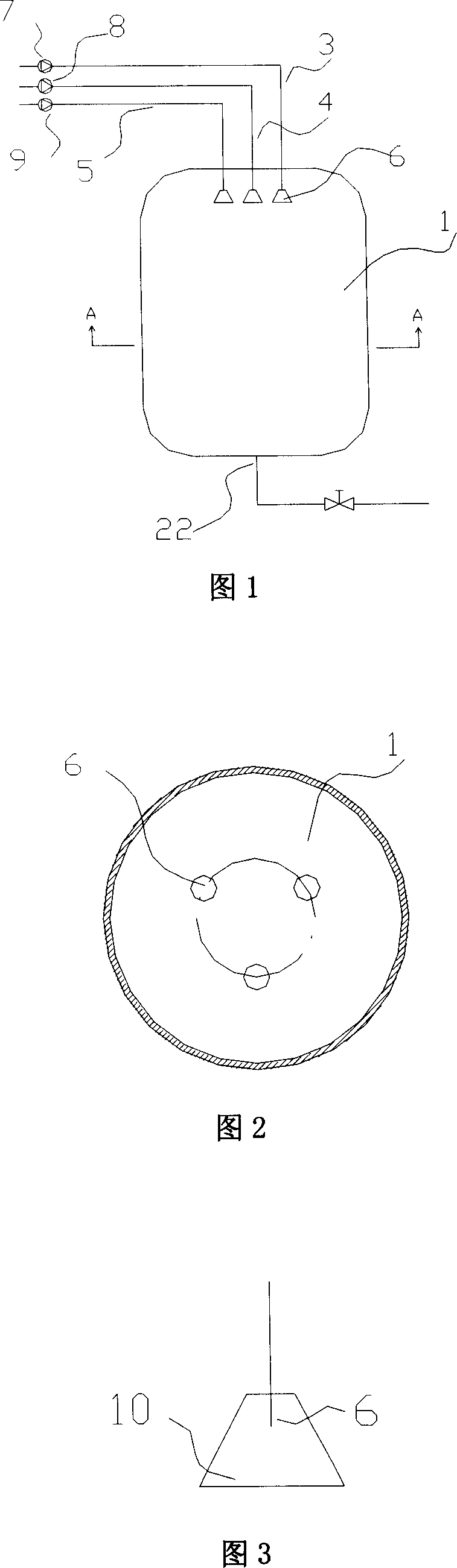

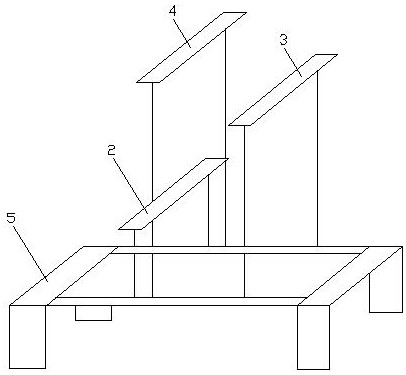

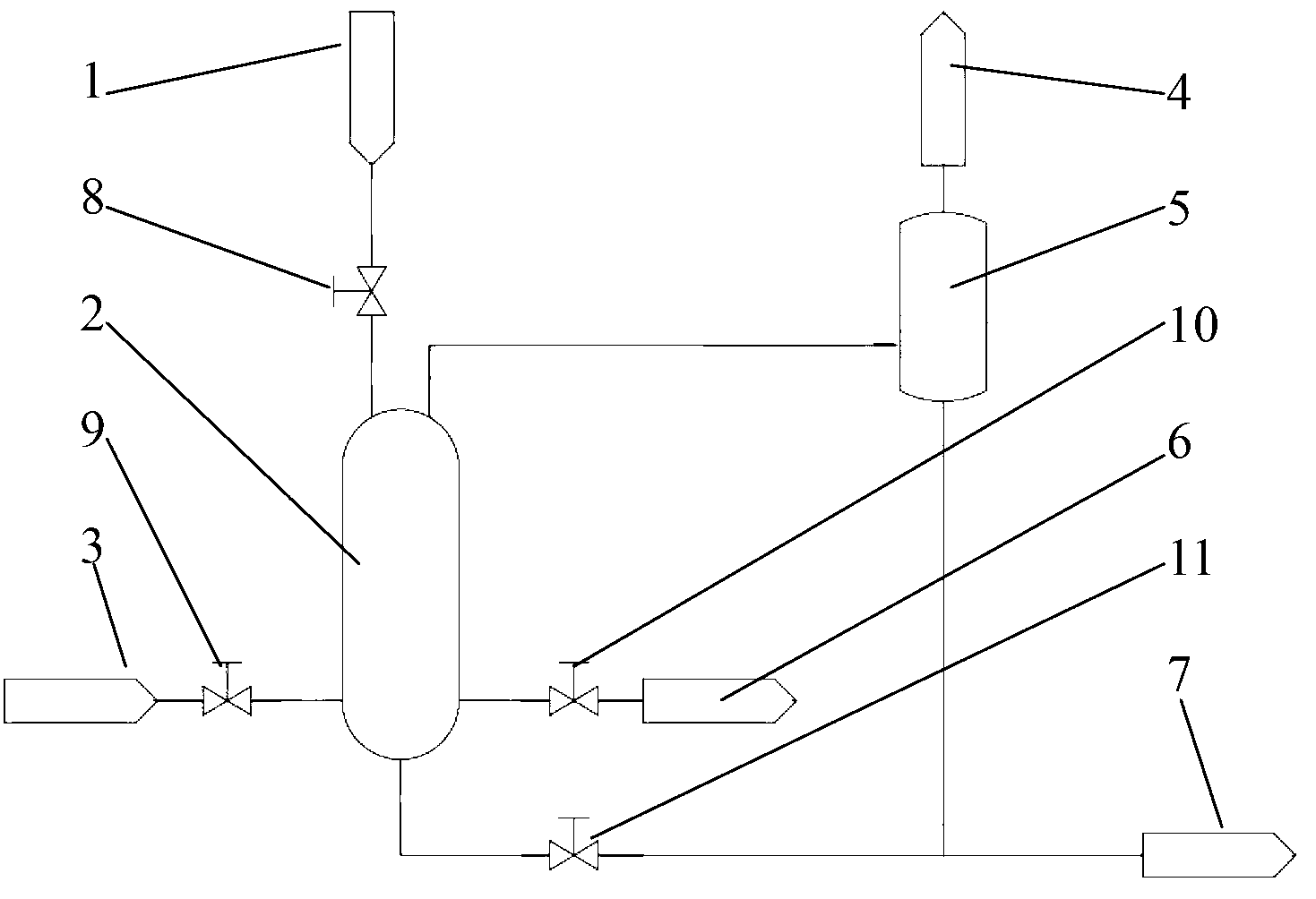

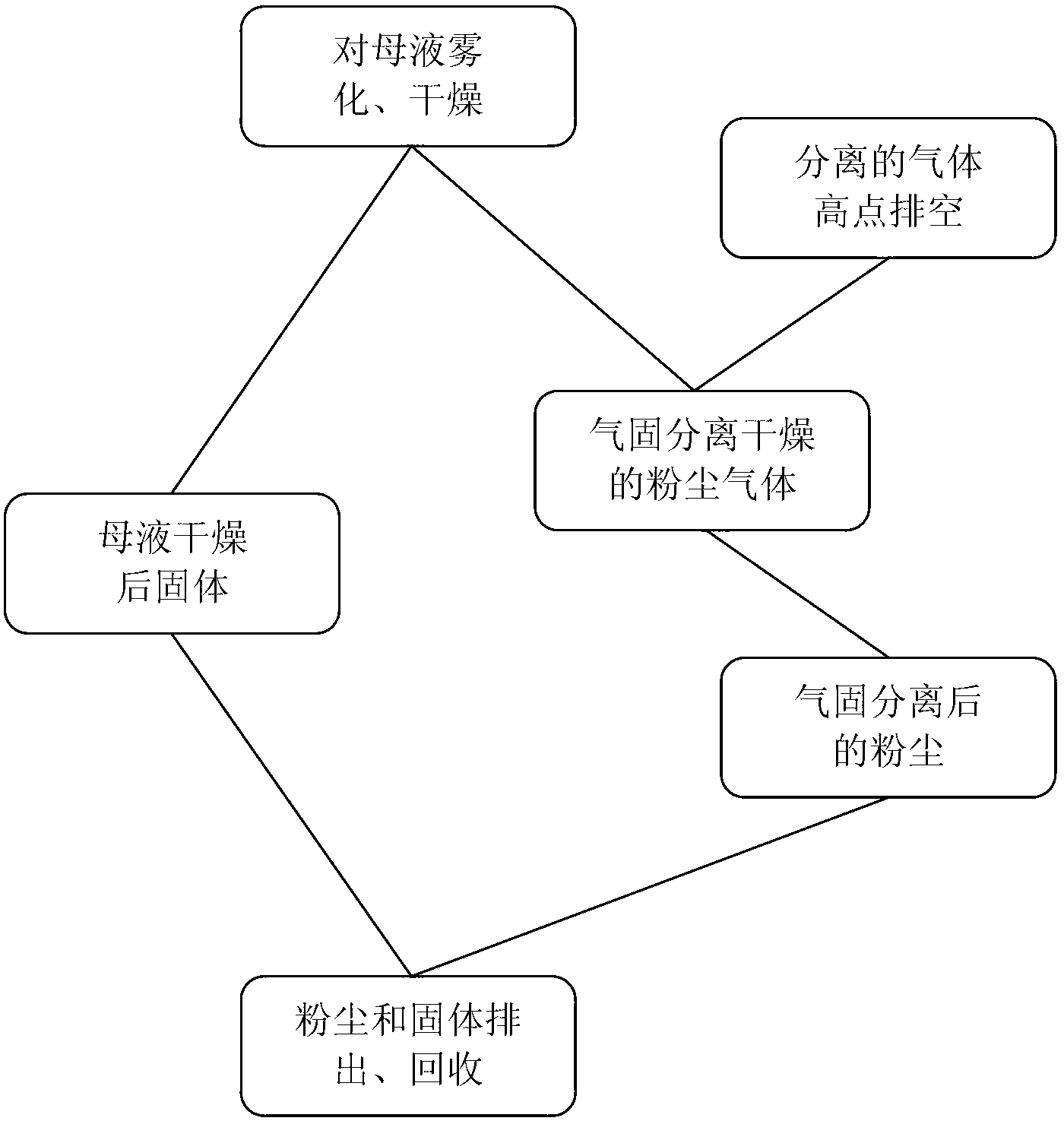

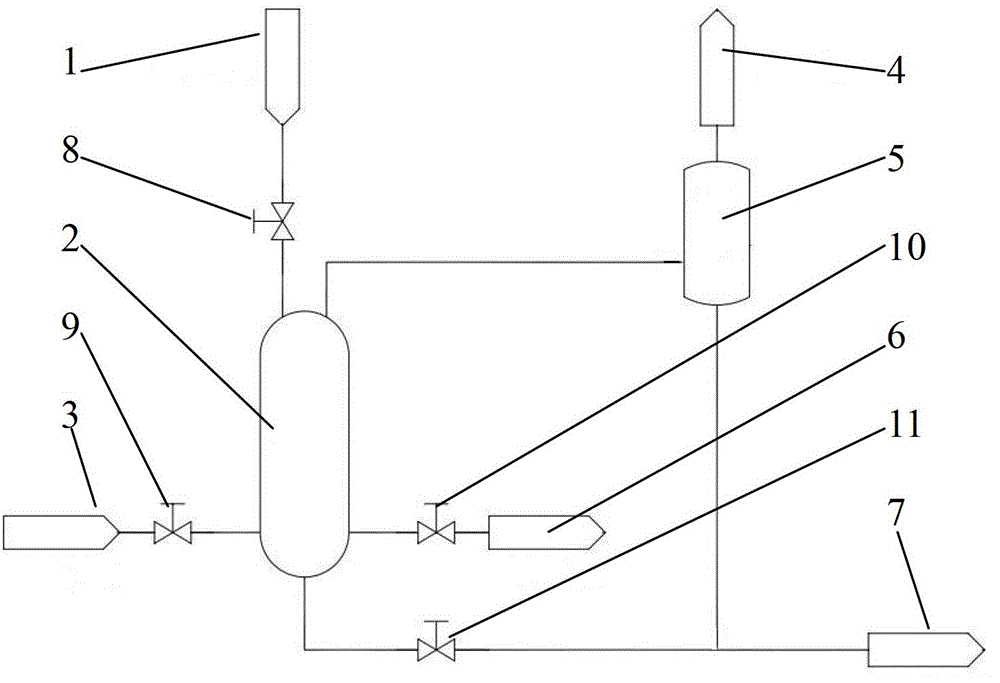

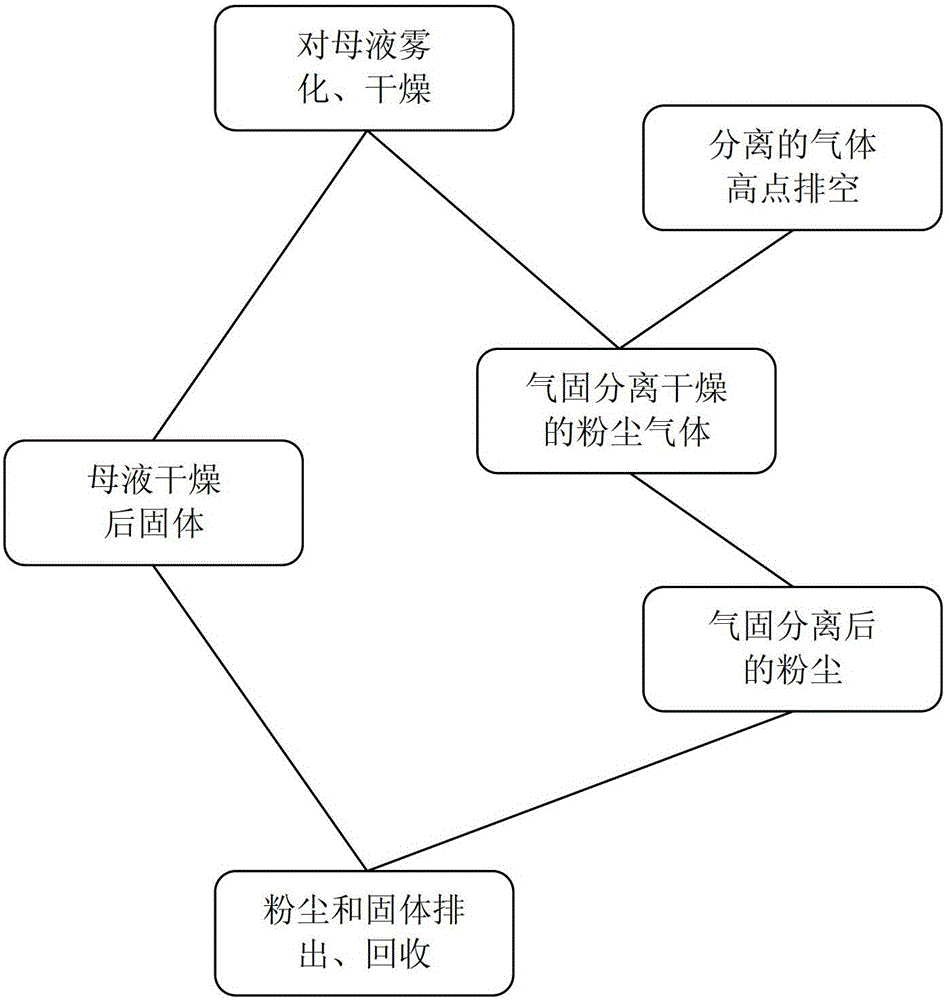

Equipment and method for extracting dust in ammonium sulfate solution after flue gas desulfurization

InactiveCN103252102AEffectively take offQuality improvementEvaporator accessoriesAmmonium sulfatesPollutionAmmonium sulfate

The invention discloses equipment and a method for extracting dust in an ammonium sulfate solution after flue gas desulfurization. The equipment comprises a mother solution inlet (1), an evaporator (2), a gas outlet (4), a gas-solid separator (5) and a dry dust outlet (7), wherein the evaporator (2) is used for atomizing and drying an ammonium sulfate mother solution; and the gas-solid separator (5) is used for separating the dust suspended in evaporated gas. Furthermore, the invention further discloses the method for dust in the ammonium sulfate solution after the flue gas desulfurization. The equipment disclosed by the invention can effectively remove the dust in the ammonium sulfate mother solution; the efficiency is high, the manufacturing and operation are simple, the secondary pollution is avoided, and the investment and maintenance costs are low; the method disclosed by the invention is shorter than a conventional process and the efficiency is high; and the aim of effectively separating dust is effectively realized and the method is easy to popularize and use.

Owner:高翀

Oiling device for clock spring parts

InactiveCN105478275BEffective atomizationEasy oiling operationLiquid surface applicatorsSpraying apparatusDrive motorWork in process

The invention discloses an oiling device for clock spring parts, which includes a frame assembly and a clamp assembly. The frame assembly includes a frame and a first-layer installation frame connected with the frame. A clamp assembly is installed on the rotating disc, a horizontal drive cylinder and a drive motor are arranged on the frame, an oil injection assembly is arranged above the clamp assembly, and the oil injection assembly is connected to the frame. The fixture assembly and semi-finished products are driven by the servo motor, which facilitates the oiling operation, meets the production requirements, and improves the work efficiency; the design of the adjustment device and the quick installation handle realizes the free adjustment of the height and the free adjustment of the angle. It is driven by a servo motor to avoid uneven oil injection caused by uneven speed. The regular arrangement of multiple oil injection components and the cooperation with the baffle plate can effectively atomize the oil stains and better from point to surface. Radiation, to achieve all-round oiling of the product, to better meet the production needs.

Owner:JIAXING HUACHANG DENSO

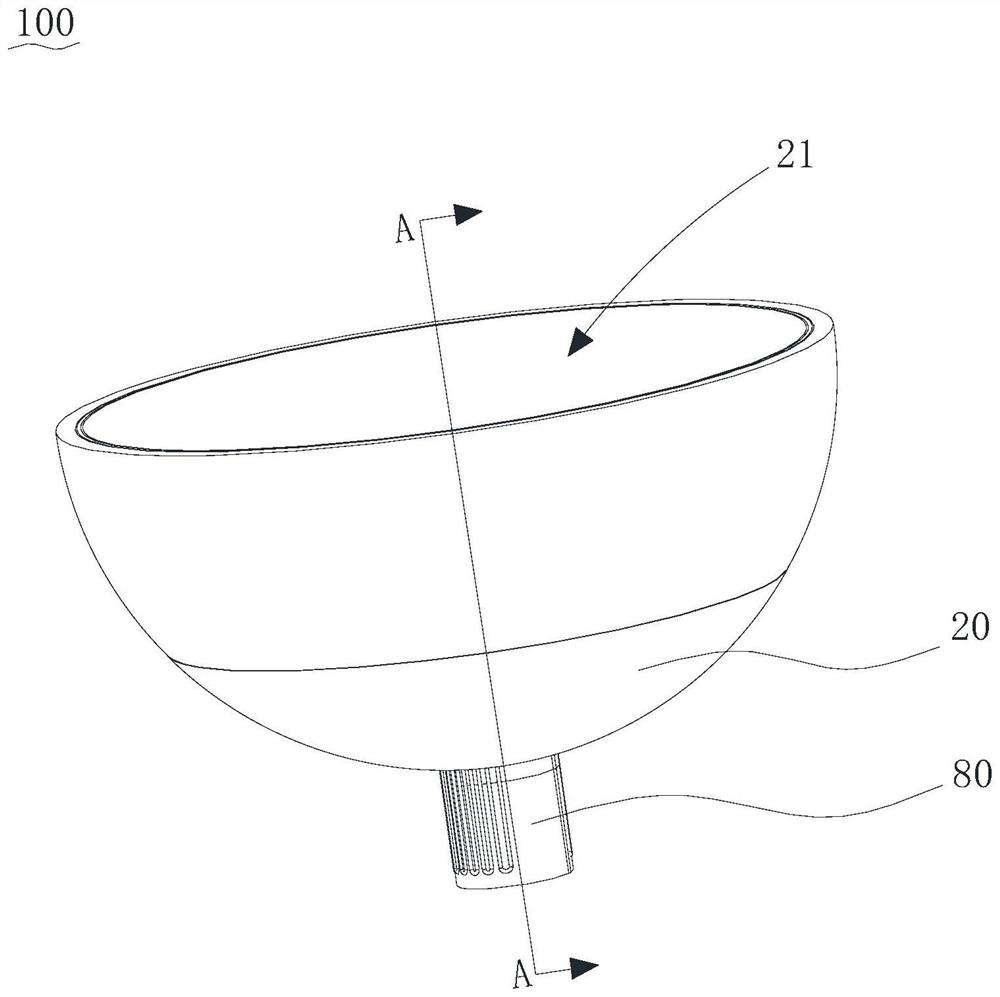

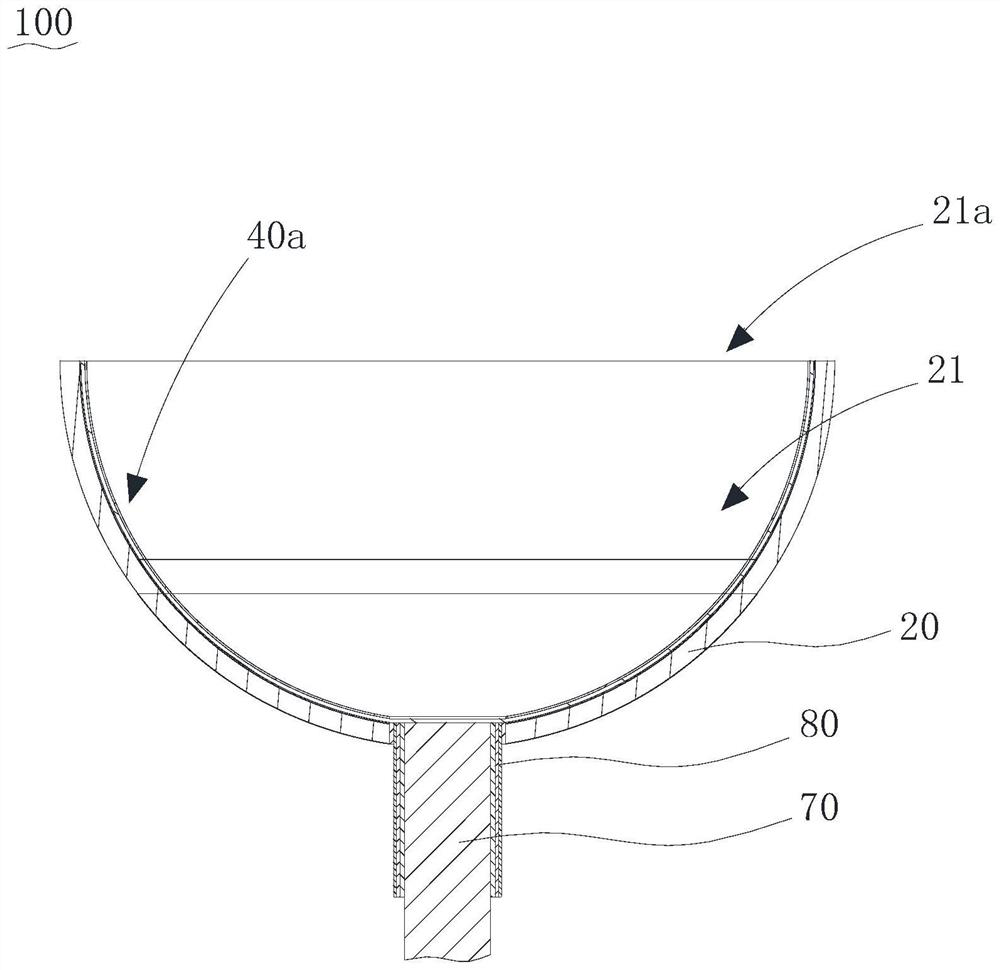

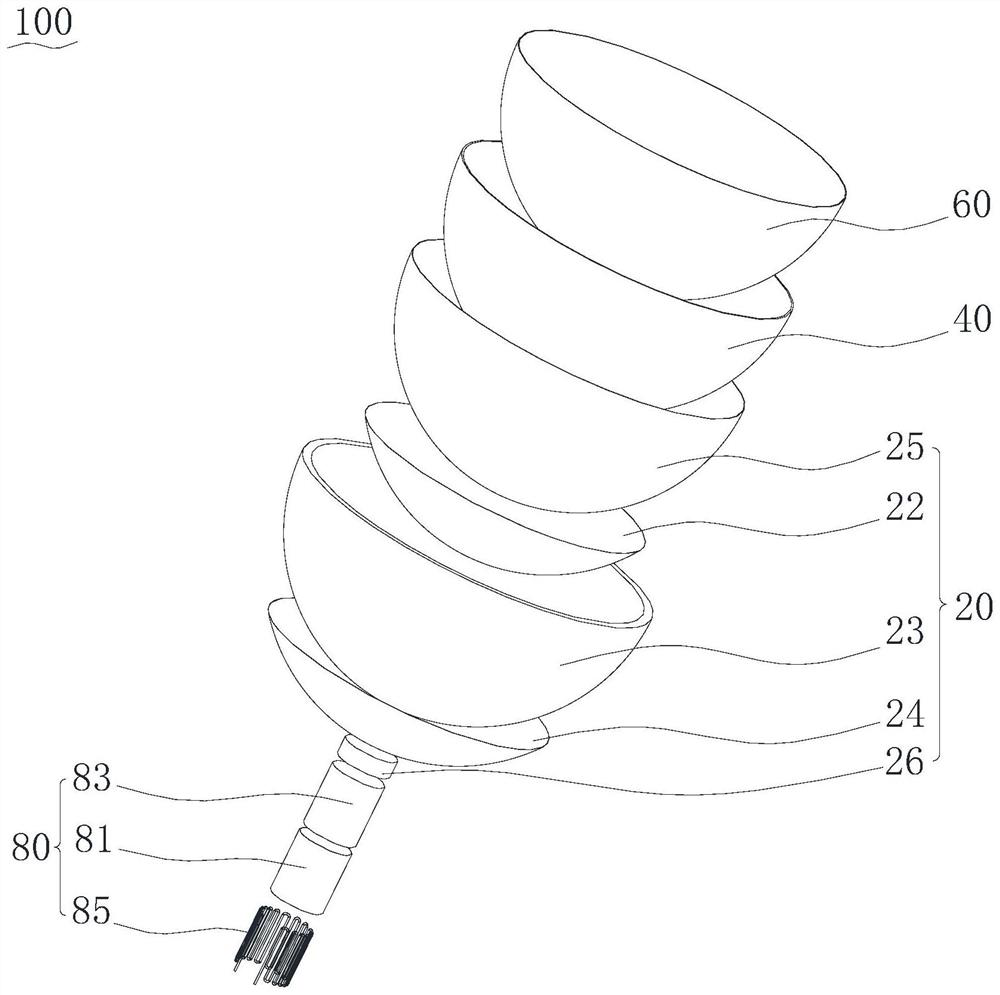

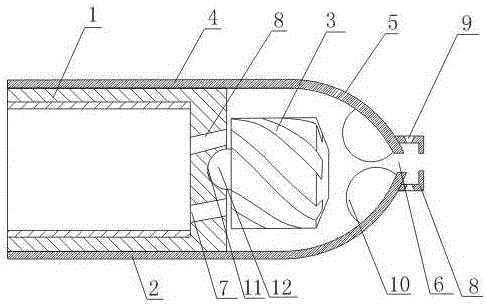

Ultrasonic atomization core and electronic atomizer

The invention relates to an ultrasonic atomization core and an electronic atomizer, and the ultrasonic atomization core comprises an ultrasonic atomization part, one surface of which is recessed inwards to form an atomization cavity with a focusing function; the cavity wall of the atomization cavity is covered with the liquid supply layer, and an atomization face with a primary atomization function is formed on the surface, back on to the cavity wall, of the liquid supply layer; wherein ultrasonic waves focused by the atomization cavity can form an atomization area with a secondary atomization function, and the atomization area is located on a flowing path of aerosol generated by primary atomization of the atomization surface. The ultrasonic atomization core can conduct secondary atomization on aerosol particles with the large particle size, so that effective atomization of the atomization medium is achieved, the particle size of the aerosol particles generated by atomization is effectively controlled, the taste of aerosol is finer, and the use experience of the electronic atomizer provided with the ultrasonic atomization piece is improved.

Owner:HAINAN MOORE BROTHERS TECH CO LTD

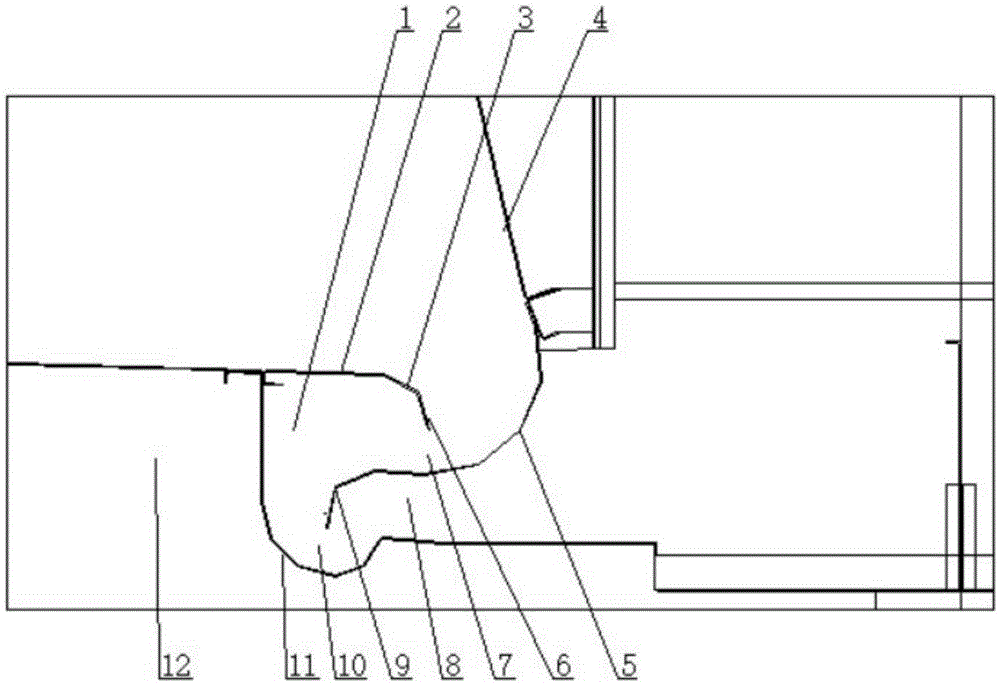

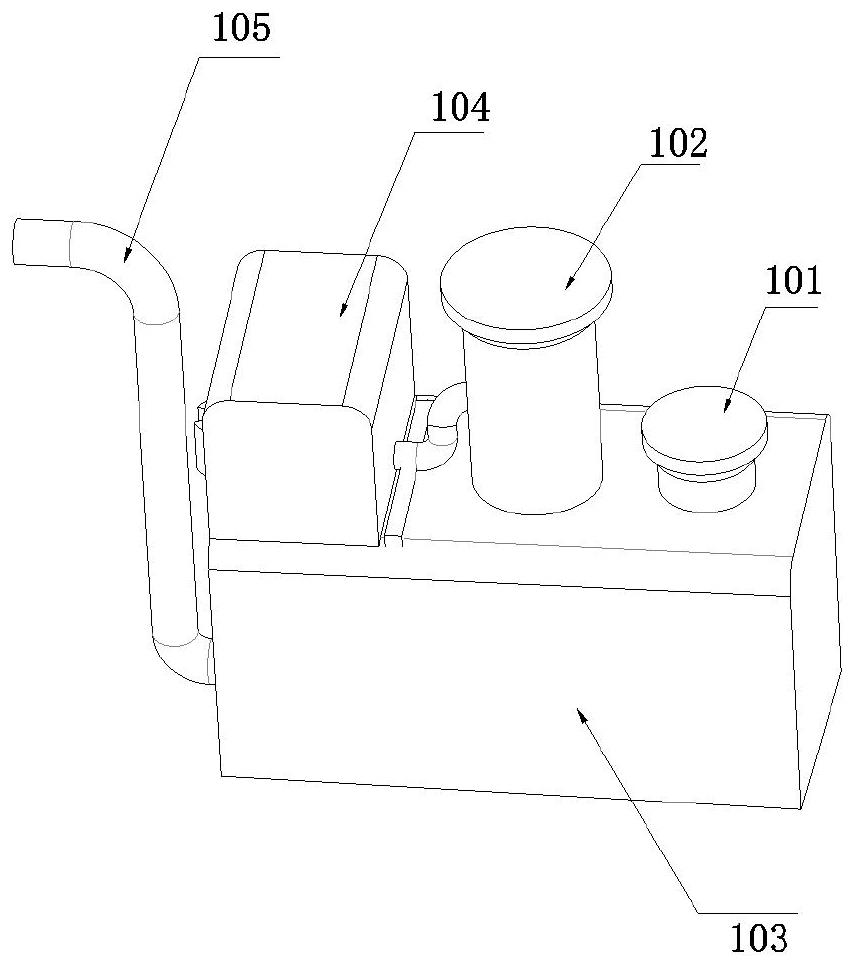

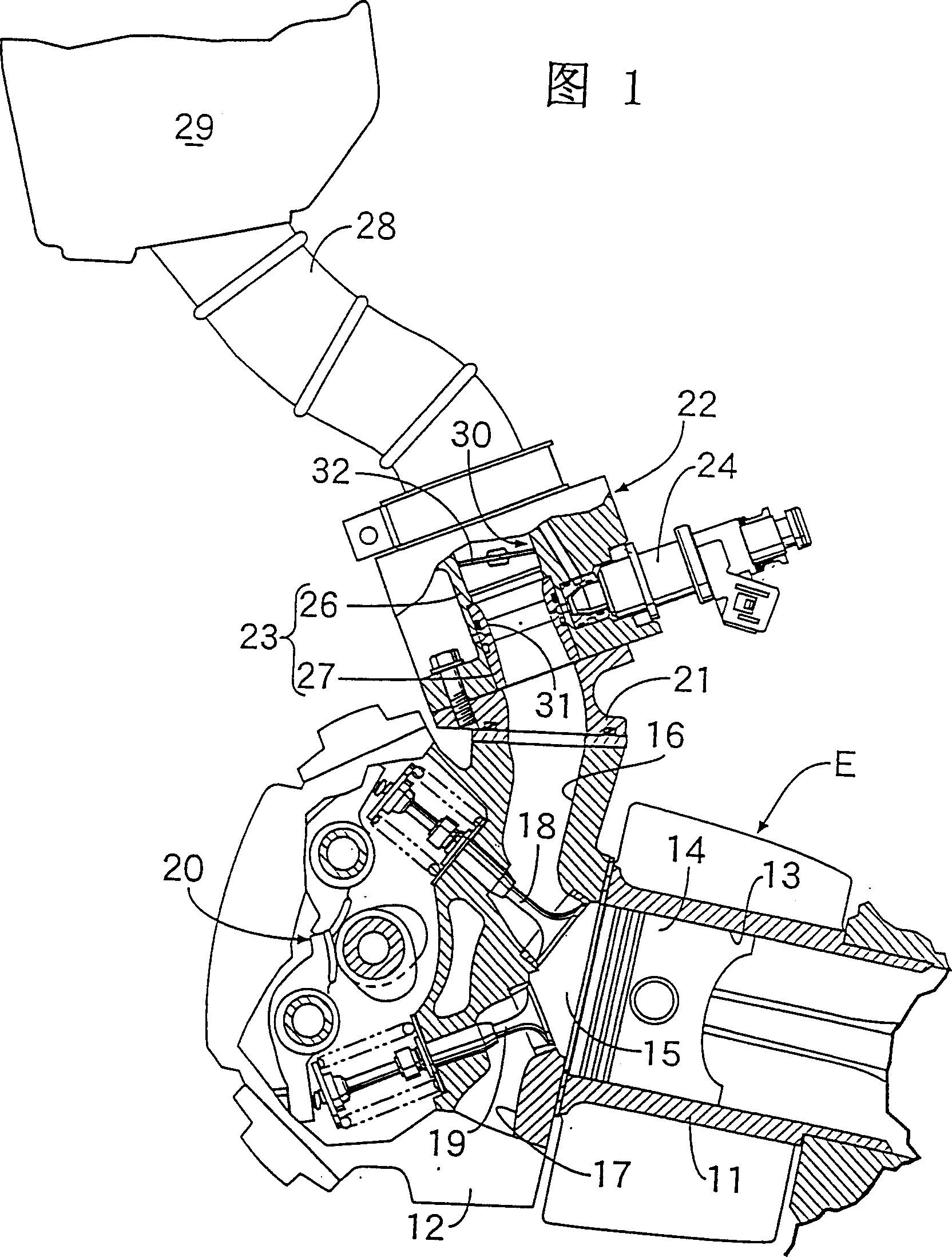

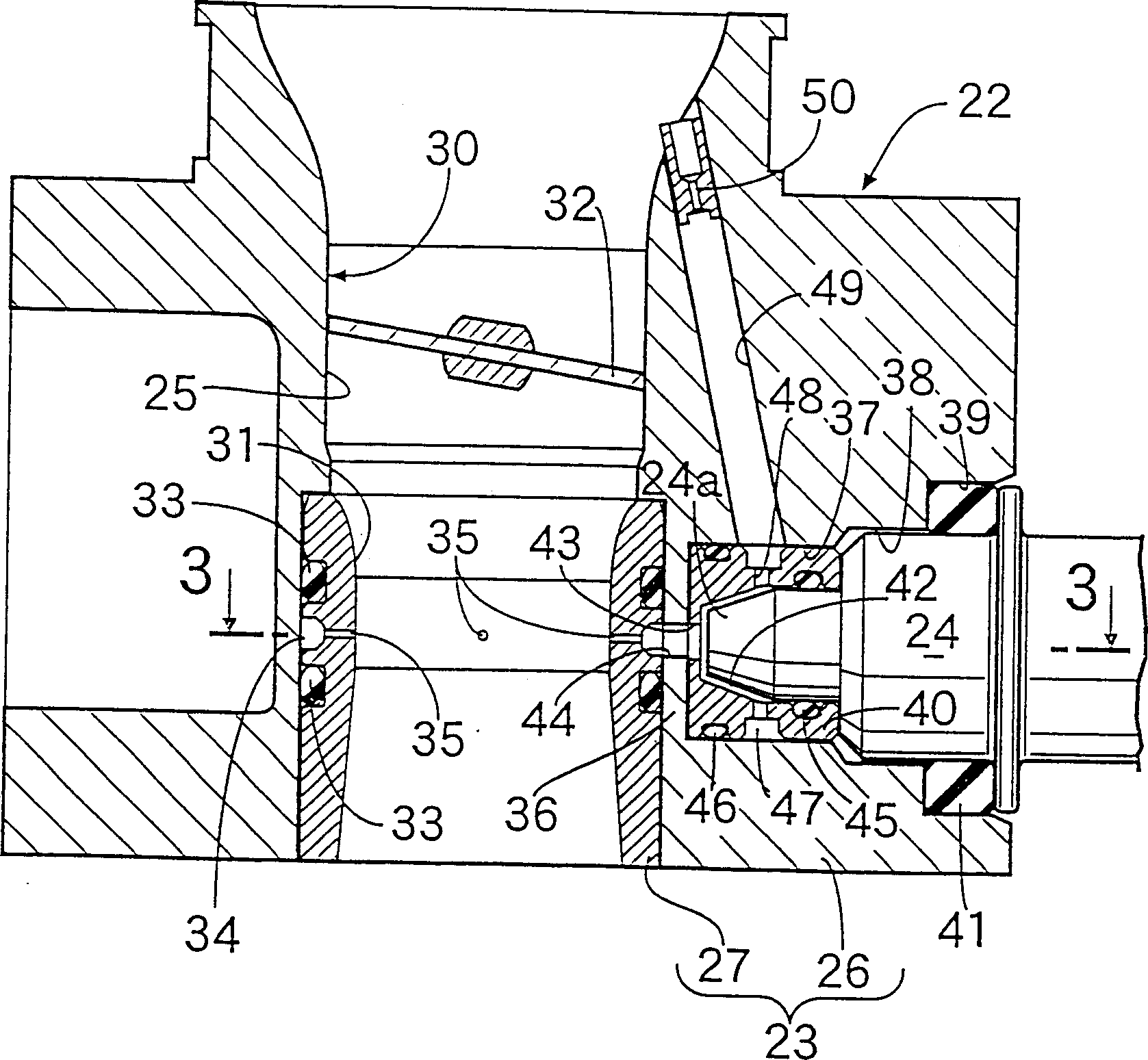

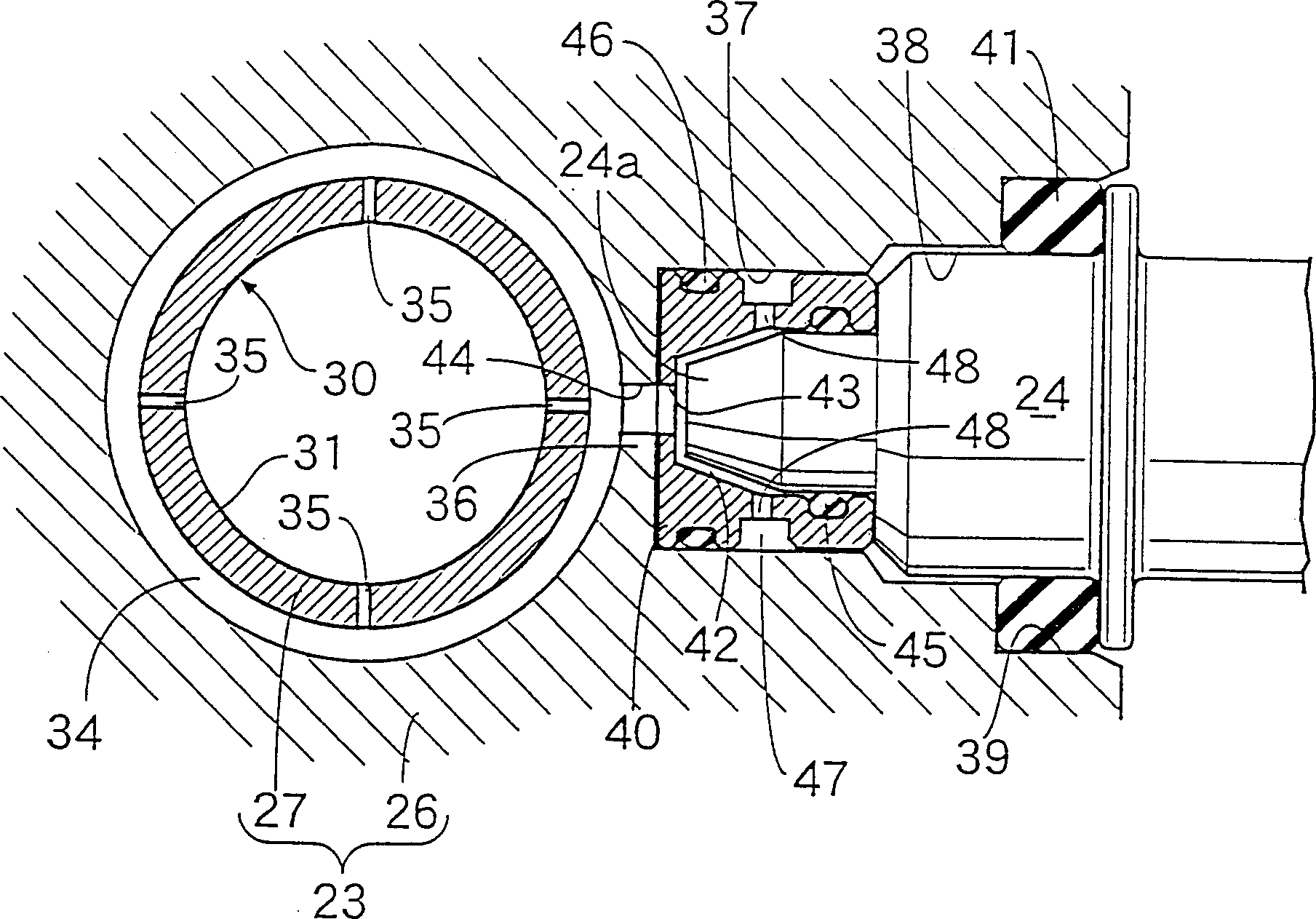

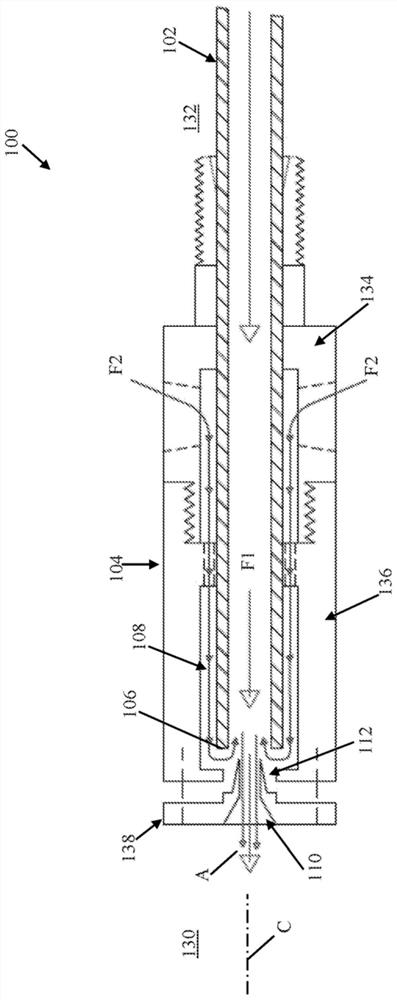

Fuel feeding device of engine

InactiveCN1127617CSuction is effectiveEffective atomizationLow pressure fuel injectionMachines/enginesFuel supplyFuel injection

The invention provides an engine fuel supply system, in which a fuel injection valve is fitted in an intake path organizer forming an intake path communicating with an air cleaner. The intake path organizer has a fuel passage for guiding fuel from the fuel injection valve, a fuel induction port having one end communicating with the fuel passage and the other end communicating with the intake path, and an air bleed passageway having one end communicating with the intake path further upstream than the fuel induction port and the other end communicating with the fuel passageway. A fuel induction port 35 opens to an intake path 30 in a direction orthogonal to air flow circulating in the intake path 30.

Owner:HONDA MOTOR CO LTD

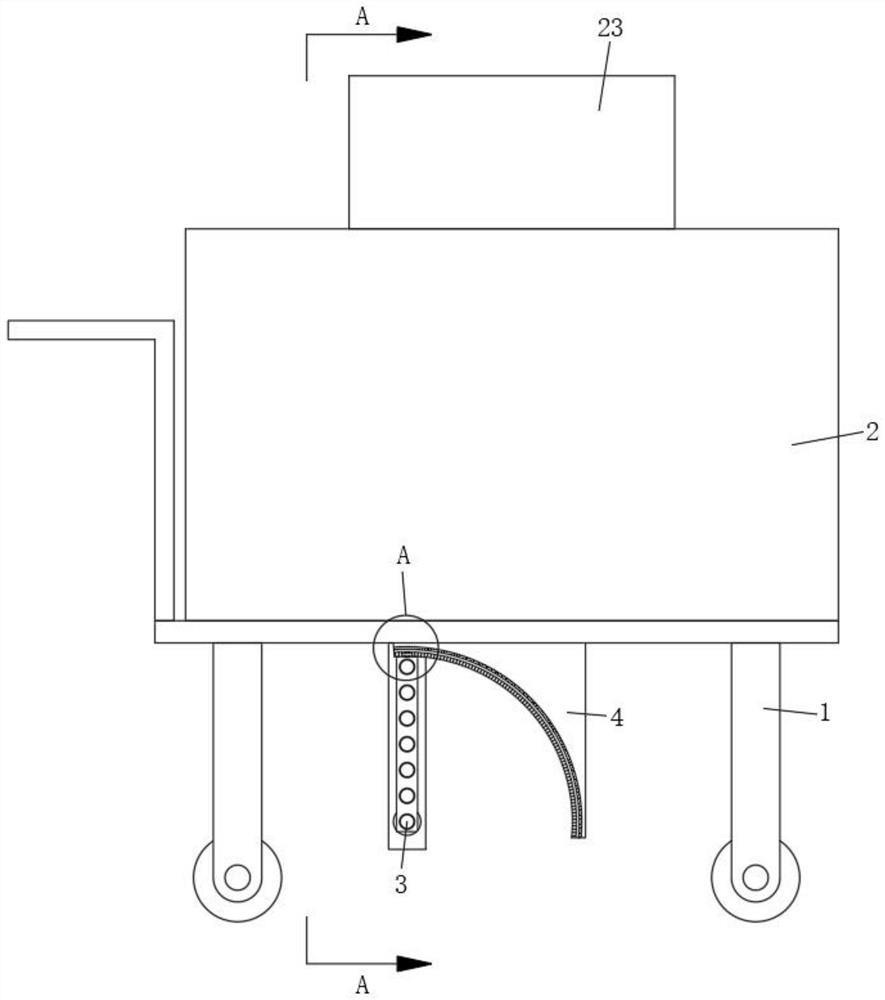

Spraying disc, spraying assembly and unmanned device

PendingCN112108281AEffective atomizationImprove atomization effectMovable spraying apparatusEngineeringBearing surface

The embodiment of the invention provides a spraying disc, a spraying assembly and an unmanned device, and relates to the technical field of atomization. The spraying disc comprises a disc body and a plurality of cutting strips, wherein the disc body is provided with a center part and a bearing surface, and a blank area and a cutting area are formed on the bearing surface; the plurality of cuttingstrips are located in the cutting area; and an included angle a is formed between the extending direction of the cutting strips and the radial direction of the disc body. The spraying disc can realizeeffective cutting and atomization of liquid to be atomized at different rotating speeds, so that the application of the product is wider.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Irrigation device for annona squamosa planting

ActiveCN113179734AEasy to adjustChange the amount of irrigation waterClimate change adaptationWatering devicesAgricultural scienceAgricultural engineering

The invention belongs to the technical field of annona squamosa planting, and discloses an irrigation device for annona squamosa planting. The irrigation device comprises a walking trolley, a water tank and at least one fertilizing and irrigating assembly, wherein the water tank is arranged on the upper end surface of the walking trolley and stores water or water and fertilizer; the at least one fertilizing and irrigating assembly is mounted on the lower end surface of the walking trolley and used for spraying water or water and fertilizer stored in the water tank to annona squamosa plants in an atomizing manner according to a set irrigation range; each fertilizing and irrigating assembly comprises a mounting vertical plate fixedly connected with the lower end surface of the walking trolley, a driving shaft penetrating through the mounting vertical plate, driving motors connected to the two ends of the driving shaft, a fertilizing and irrigating frame of a linear structure and a plurality of atomizing nozzles, and the driving motors are fixed to the mounting vertical plate and used for driving the fertilizing and irrigating frame to rotate in a reciprocating mode within the range of 90 degrees through the driving shaft; and the plurality of atomizing nozzles are fixed to the fertilizing and irrigating frame in parallel; Therefore, the irrigation range can be changed by rotating and adjusting the irrigation angle of the fertilizing and irrigating frame, adjustment is simple, and the irrigation device can be effectively suitable for irrigation of plants with different growth degrees.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Novel spray head structure for improving oil well yield

InactiveCN104989333AEffective atomizationExpand the spraying rangeFluid removalEngineeringHigh pressure

The invention provides a novel spray head structure for improving the oil well yield. The novel spray head structure comprises a connecting body, a case and a rotating head, wherein the connecting body is of a cavity structure provided with an opening at the back end surface; the case consists of a hollow cylinder and a hollow hemisphere which are communicated and connected; the hollow cylinder is arranged on the outer wall of the connecting body in a sleeving way through screw thread connection; the top of the hollow hemisphere is provided with a water outlet; the rotating head is rotationally arranged at the bottom of the connecting body; the bottom of the connecting body is uniformly provided with impact spray holes; the novel spray head structure also comprises a cover body fixed on the hollow hemisphere; the cover body is of a cavity structure; the water outlet is positioned in the cavity structure of the cover body; and horn mouths are uniformly arranged on the side wall of the cover body. The air flow on the periphery can be sucked into the novel spray head structure through the horn mouths uniformly arranged on the side wall of the cover body; high-pressure liquid and air do composite movement and collision in the cover body; and high-pressure liquid can be atomized.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

Nozzle and method of mixing fluid streams

ActiveCN108348933BAtomization fastEffective atomizationSpray nozzlesLiquid spraying apparatusEngineeringMechanics

A nozzle assembly includes an inner tube and an outer shell. The inner tube terminates at the outlet end and defines a first flow channel. The first flow channel directs the first fluid flow to the outlet port in the main flow direction. The housing includes tubular side walls and end walls. The tubular sidewall defines a central axis. The end wall defines an outlet aperture and an internal guide structure. The outlet end is axially aligned with the outlet hole. A second flow channel is established between the inner tube and the outer shell. The inner guide structure is configured relative to the outlet end and arranged to direct at least a portion of the second fluid flow from the second flow channel to the outlet end in a direction initially opposite the main flow direction to produce a mixed fluid flow.

Owner:明尼苏达州大学董事会

Equipment and method for extracting dust in ammonium sulfate solution after flue gas desulfurization

InactiveCN103252102BEffectively take offQuality improvementEvaporator accessoriesAmmonium sulfatesGas solidPollution

The invention discloses equipment and a method for extracting dust in an ammonium sulfate solution after flue gas desulfurization. The equipment comprises a mother solution inlet (1), an evaporator (2), a gas outlet (4), a gas-solid separator (5) and a dry dust outlet (7), wherein the evaporator (2) is used for atomizing and drying an ammonium sulfate mother solution; and the gas-solid separator (5) is used for separating the dust suspended in evaporated gas. Furthermore, the invention further discloses the method for dust in the ammonium sulfate solution after the flue gas desulfurization. The equipment disclosed by the invention can effectively remove the dust in the ammonium sulfate mother solution; the efficiency is high, the manufacturing and operation are simple, the secondary pollution is avoided, and the investment and maintenance costs are low; the method disclosed by the invention is shorter than a conventional process and the efficiency is high; and the aim of effectively separating dust is effectively realized and the method is easy to popularize and use.

Owner:高翀

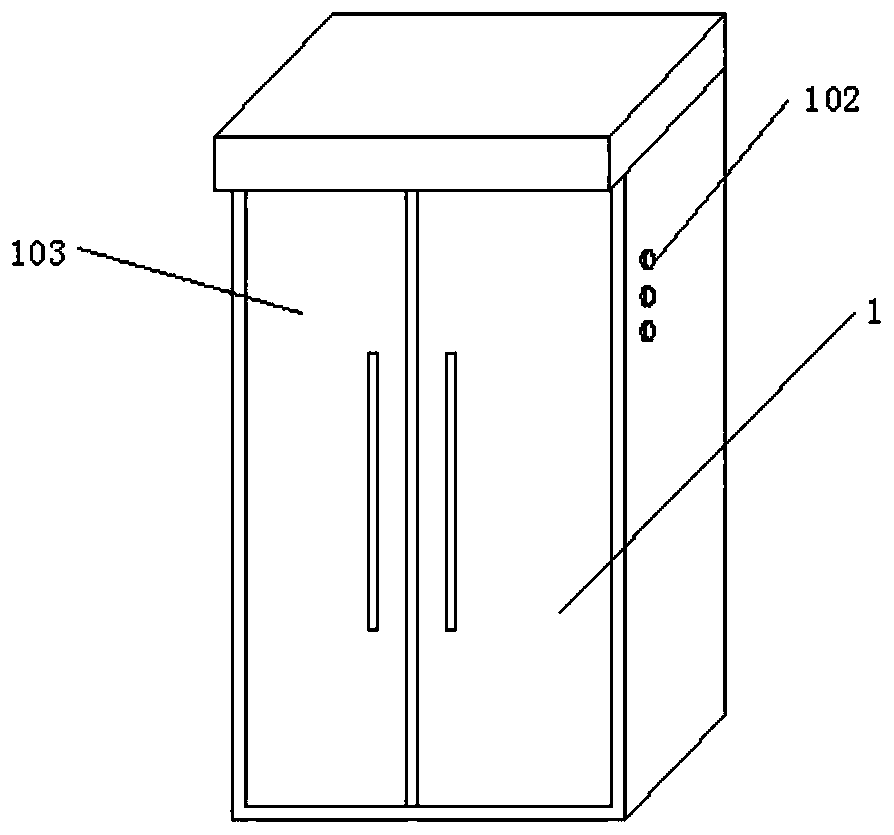

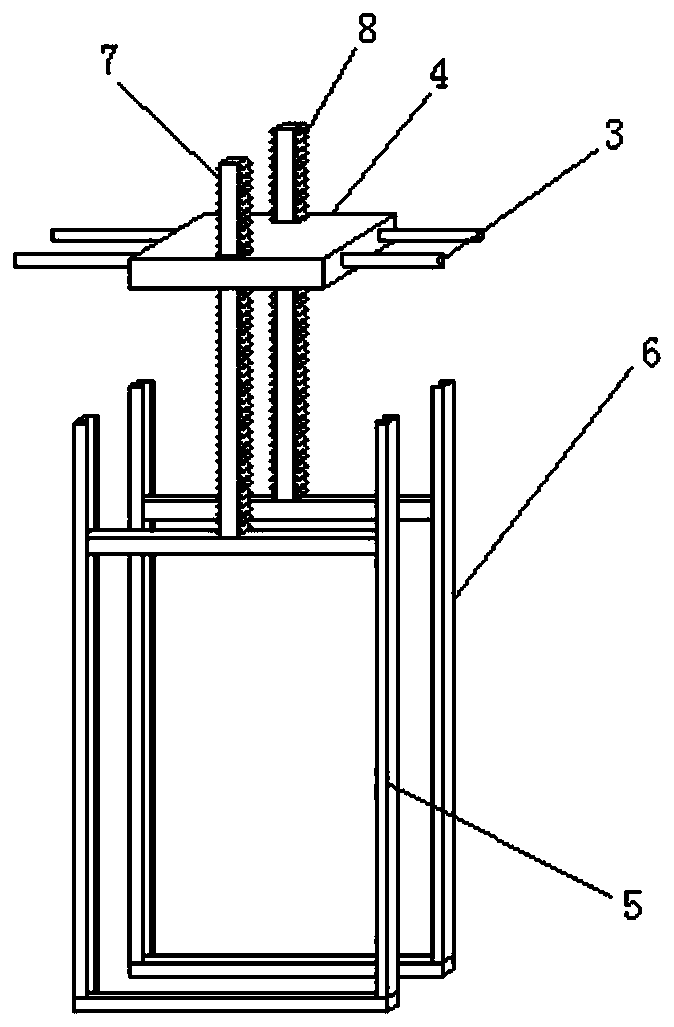

Clothes ironing and drying equipment

ActiveCN107190437BAchieve atomizationStrong penetrating powerTextile treatment machine arrangementsTextile treatment by spraying/projectingState of artProcess engineering

The invention discloses clothes ironing and drying equipment. The clothes ironing and drying equipment comprises a drying unit and a steam generating unit which are in communication with each other through a guiding pipe, the steam generating unit comprises a dehumidifier and a steam generator, the guiding pipe is further communicated with a steam drying hose, and a nano-nozzle is connected to the steam drying hose; the drying unit can provide a high-temperature gas flow, the dehumidifier and the steam generator can provide steam, and the high-temperature gas flow is in contact with the steam in the guiding pipe to form hot steam which is discharged through the nano-nozzle. The problems that in the prior art, drying equipment is unlikely to dry clothes all around, the drying efficiency is low, the function is single, and the drying equipment does not have ironing and drying functions at the same time are solved.

Owner:宁波奥达智能家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com