Dust removal device for mechanical spinning

A dust removal device and mechanical technology, which is applied in the direction of textile, mechanical equipment, combined devices, etc., can solve problems such as environmental pollution, affecting production efficiency, unfavorable use, etc., and achieve the effect of ensuring textile quality and good blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

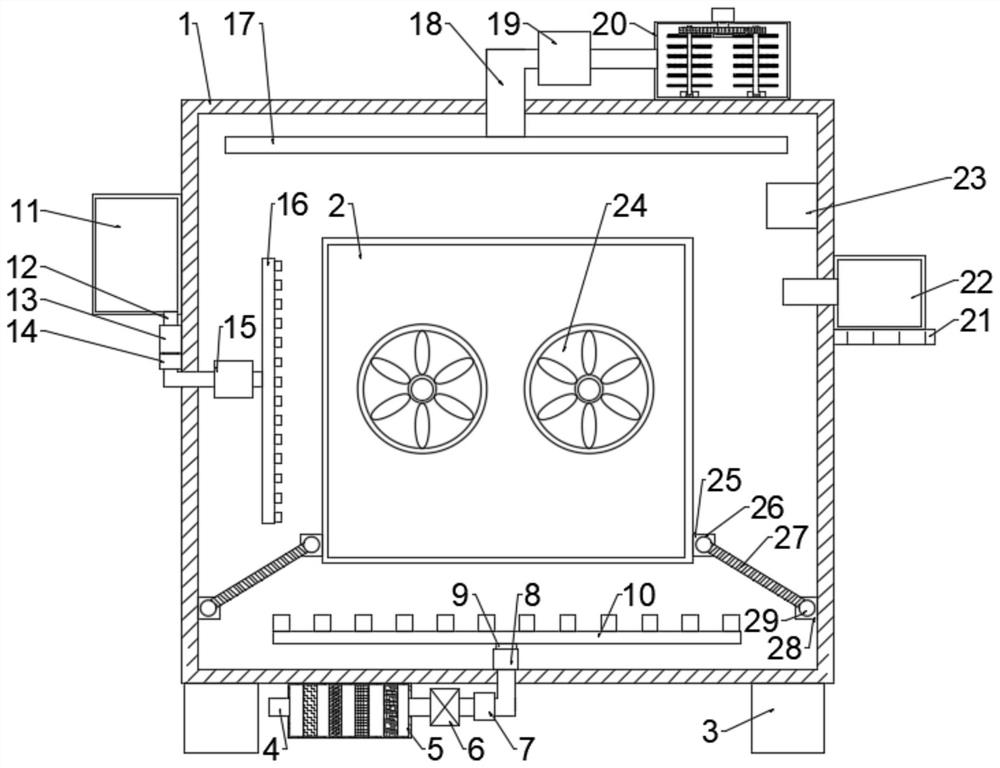

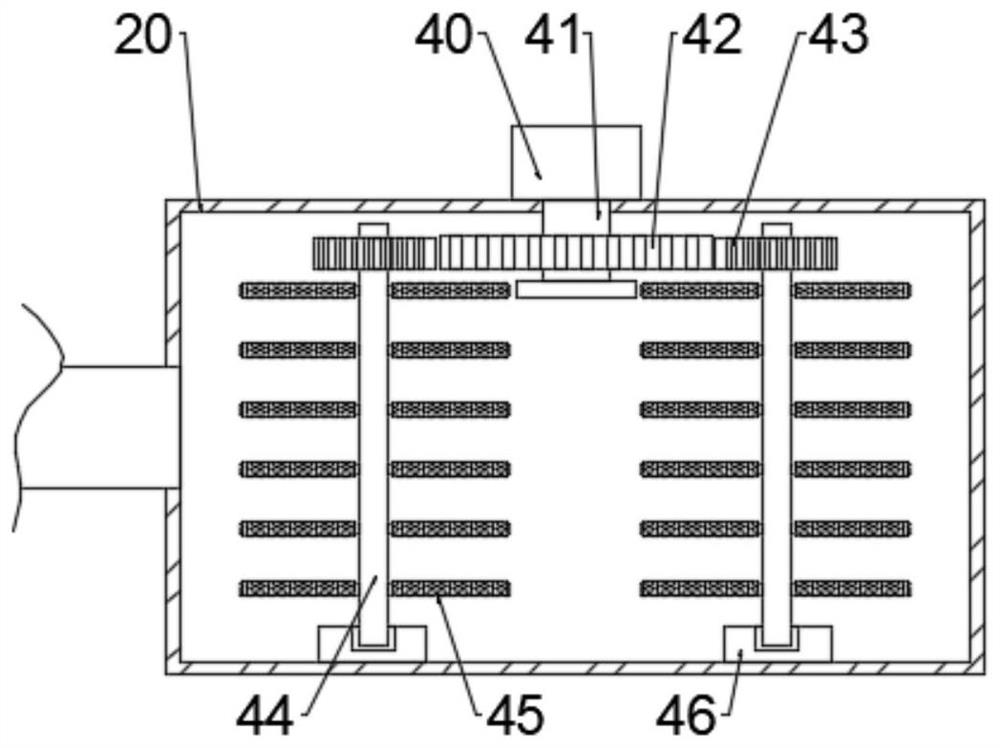

[0030] see Figure 1 ~ Figure 2 , a mechanical textile dust removal device, including a device box 1, a textile device 2 is arranged in the device box 1, an air inlet pipe 4 is arranged in the device box 1, and the air inlet pipe 4 runs through the device Box 1, the air inlet pipe 4 is provided with a filter box 5, the air inlet pipe 4 is provided with a first exhaust fan 6, the air inlet pipe 4 is provided with a wind speed controller 7, and the wind speed The controller 7 is electrically connected to the first exhaust fan 6, the air inlet pipe 4 is connected to a rotating connecting pipe 9, and the rotating connecting pipe 9 is covered with a first rotating motor 8, and the first rotating motor 8 is arranged on the device box 1 Inside, the top of the rotating connecting pipe 9 is connected to the air outlet nozzle 10, the device box 1 is provided with an exhaust pipe 18, the exhaust pipe 18 runs through the device box 1, and one end of the exhaust pipe 18 is connected to the...

Embodiment 2

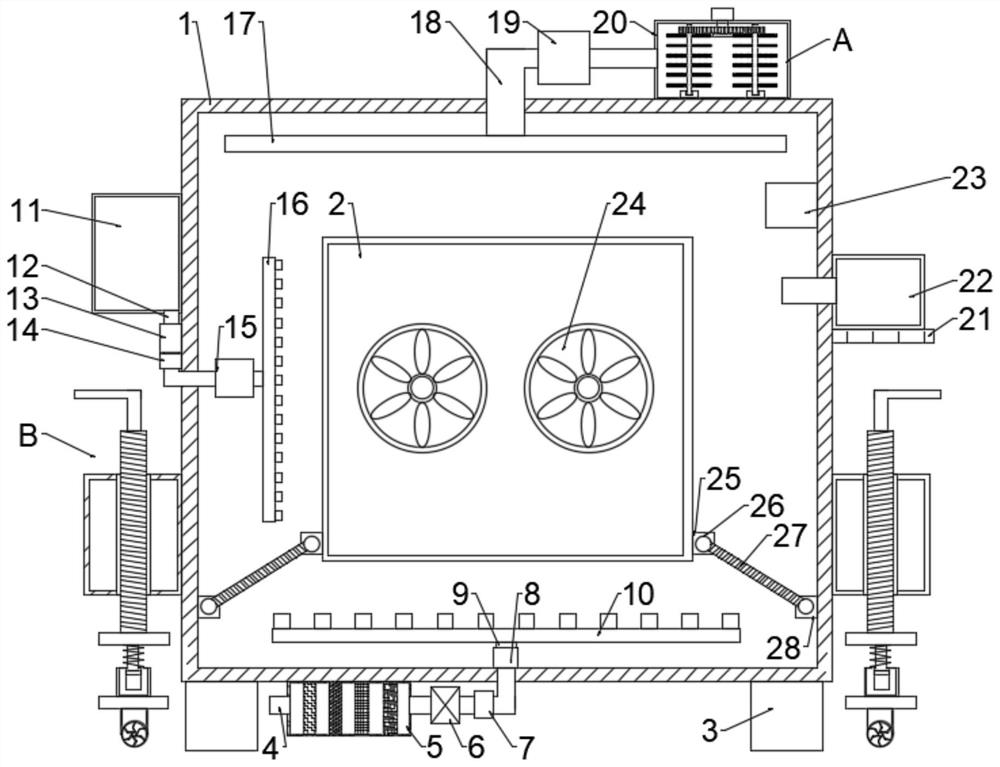

[0038] see Figure 1 to Figure 5 , a mechanical textile dust removal device, including a device box 1, also includes a fixed block 29, a threaded hole 30, a threaded rod 31, a handle 32, an upper template 33, a guide post 34, a mounting block 35, a spring 36, a groove 37. The lower template 38 and the universal wheel 39, the device box 1 is provided with a textile device 2, the device box 1 is provided with an air inlet pipe 4, and the air inlet pipe 4 runs through the device box 1, The air inlet pipe 4 is provided with a filter box 5, the air inlet pipe 4 is provided with a first exhaust fan 6, the air inlet pipe 4 is provided with a wind speed controller 7, and the wind speed controller 7 circuit Connected to the first exhaust fan 6, the air inlet pipe 4 is connected to a rotating connecting pipe 9, and the rotating connecting pipe 9 is covered with a first rotating motor 8, and the first rotating motor 8 is arranged in the device box 1. The top of the rotary connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com