Nozzle and method of mixing fluid streams

A nozzle and fluid technology, used in combustion methods, gas and gas/vapor mixing, injection devices, etc., can solve problems such as changing the properties of atomized liquids, inability to provide them, and achieve the effect of clean combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

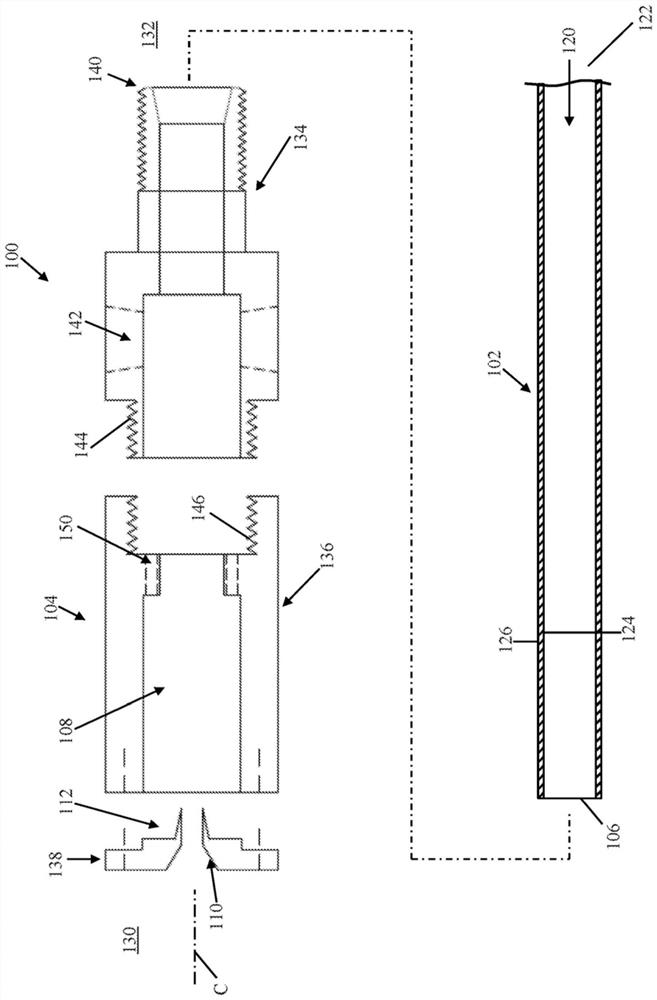

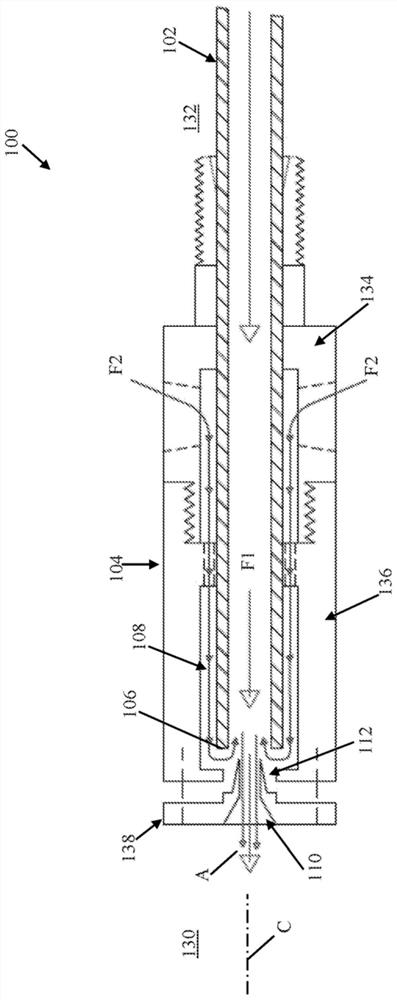

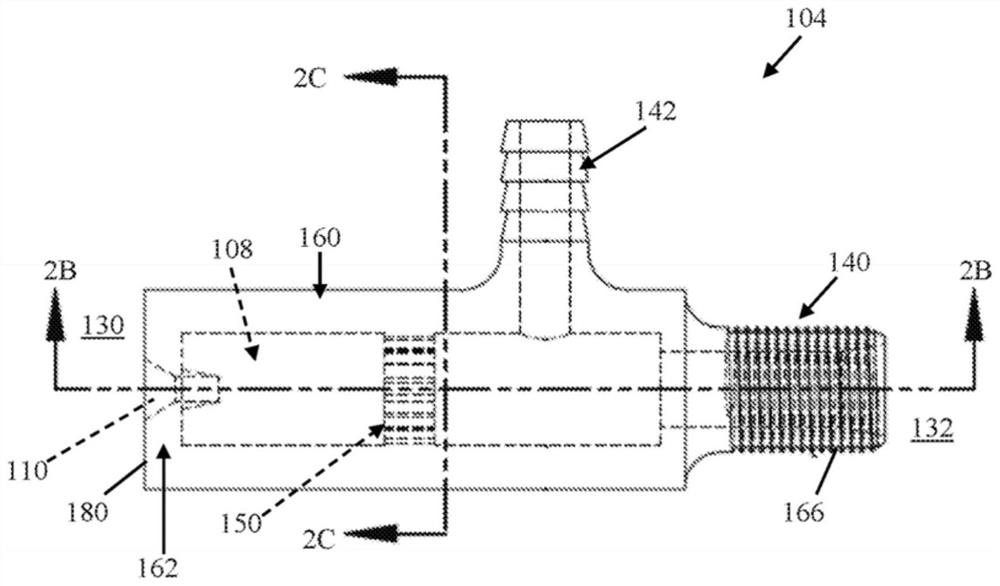

[0022] Aspects of the present disclosure relate to nozzles or nozzle assemblies and related methods of use wherein a first fluid flow is directed to a second fluid flow in a direction opposite to the second flow direction, the two fluid flows are mixed to produce a mixed fluid flow . In some non-limiting embodiments, the nozzle assemblies of the present disclosure and associated methods of use entail the generation of an atomized liquid-gas two-phase flow comprising droplets of liquid dispersed within a gas. Optionally, the nozzle assemblies of the present disclosure provide for generating a pulsed fluid flow (eg, a pulsed atomized flow) having a selected pulse frequency.

[0023] Figure 1A One embodiment of a nozzle assembly 100 is shown in accordance with the principles of the present disclosure. The nozzle assembly (or "backflow nozzle") includes an inner tube 102 and an outer shell 104 . Details of the various components are described below. In general, however, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com