Novel spray head structure for improving oil well yield

A production and new type of technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve problems such as poor injection effect and complex nozzle structure, and achieve the effects of low friction, flexible rotation, and increased injection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

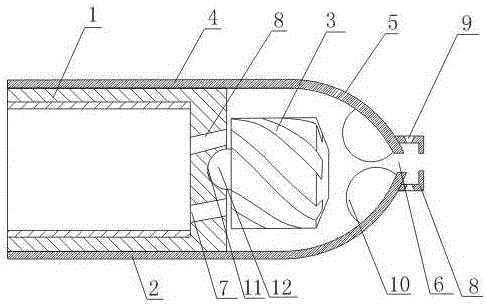

[0019] Such as figure 1 As shown, a new type of nozzle structure for improving oil well production includes a connecting body 1, a casing 2, and a rotor 3. The connecting body 1 is a cavity structure with an open rear end, and the casing 2 is connected by a hollow cylinder 4 and a hollow hemisphere. 5 components, the hollow cylinder 4 is sleeved on the outer wall of the connecting body 1 through a threaded connection, and the hollow hemisphere 5 is provided with a water outlet 6; There is an impact spray hole 7; it also includes a cover body 8 fixed on the hollow hemisphere 5, the cover body 8 is a cavity structure, and the water outlet 6 is located in the cavity structure of the cover body 8; the side wall of the cover body 8 is evenly opened Bell mouth 9 is arranged, and cover body 8 front end faces are provided with holes.

[0020] In this embodiment, the high-pressure pipeline is fixed to the connecting body 1 through the opening on the rear end surface of the connecting ...

Embodiment 2

[0022] On the basis of Embodiment 1, this embodiment also includes a pressure block 10 uniformly arranged on the inner arc surface of the hollow hemisphere 5 around the water outlet 6, and the pressure block 10 is made of rubber material.

[0023] In this embodiment, the rotated liquid will squeeze the pressurized block 10, so that the pressure of the liquid will increase, which effectively atomizes the high-pressure liquid and increases the injection range of the high-pressure liquid.

Embodiment 3

[0025] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the impact nozzle 7 is obliquely arranged at the bottom of the connecting body 1, and grooves 11 are evenly opened on the side wall of the rotor 3, and the direction of rotation of the groove 11 is consistent with that of the connecting body 1. The directions in which the impact nozzle holes 7 are inclined are opposite.

[0026] In this embodiment, the impact nozzles 7 are arranged obliquely and the direction of rotation of the groove 11 is opposite to the direction in which the impact nozzles 7 are obliquely arranged, so that the liquid passing through the impact nozzles 7 can impact the surface of the rotor 3 to produce a circumferential direction. Active force enables the rotor 3 to rotate at a high speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com