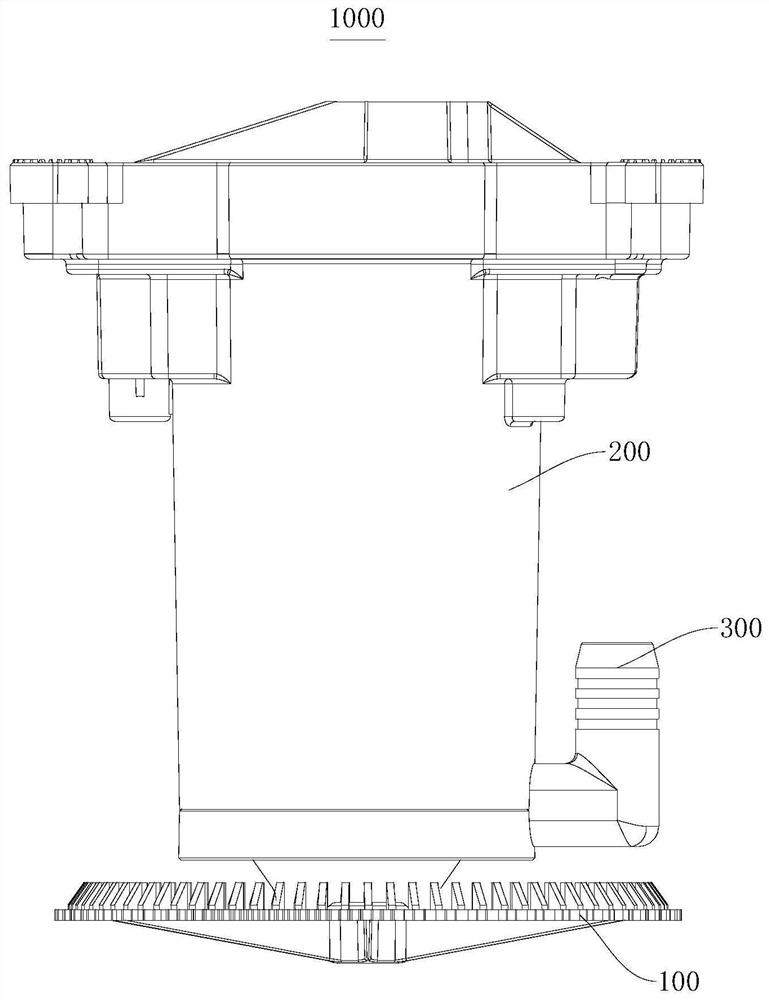

Spraying disc, spraying assembly and unmanned device

A spray plate and component technology, applied in the field of atomization, can solve problems such as unsatisfactory atomization effect and product use restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

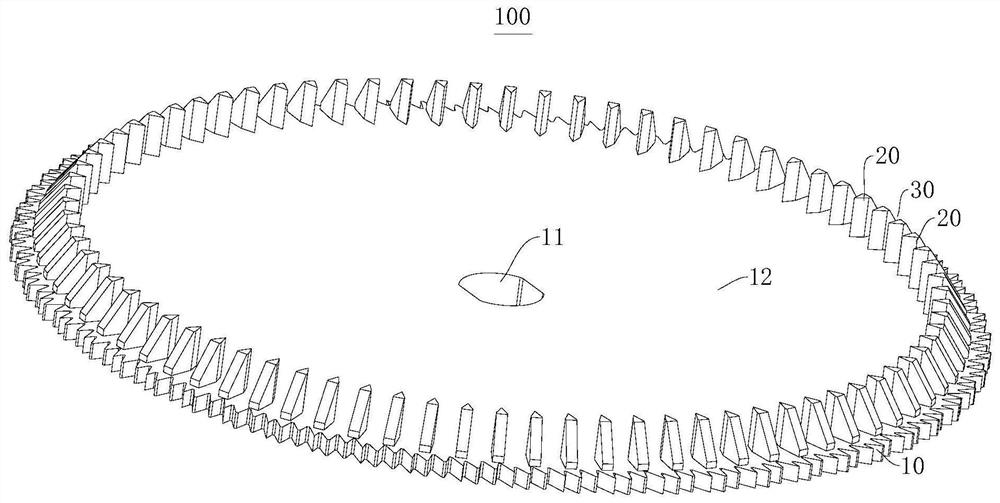

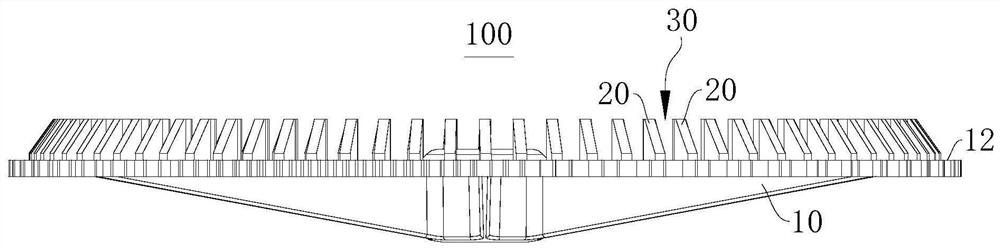

[0070]In one embodiment, 50%≦X<100%, and the included angle corresponding to the cutting strips 20 whose number ratio is X among the plurality of cutting strips 20 satisfies: a=3.3°, or a=3.5°. 10%≦Y≦50%, and the included angle corresponding to the cutting strips 20 whose number ratio is Y among the plurality of cutting strips 20 satisfies: a=2°, or a=2.5°. 0

[0071] It should be noted that X can be selected as 50%, 60%, 70%, 80%, 90%, 98%, etc., and the angle corresponding to the cutting strip 20 can satisfy: a=3.3°, or a=3.5°. Y can be selected as 10%, 20%, 30%, 40%, 50%, etc., and the corresponding included angle of the cutting strip 20 can satisfy: a=2°, or a=2.5°. Z can be selected as 1%, 5%, 10%, etc., and the angle corresponding to the cutting strip 20 can satisfy: a=0°, or a=1.5°. The various data here can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com