Oiling device for clock spring parts

A clock spring and oiling device technology, which is applied to the surface coating device, spraying device, coating and other directions, can solve the problems of low work efficiency, high labor intensity, uneven coating surface, etc., and achieve convenient coating. Oil operation, good energy-saving effect, and the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below in conjunction with the examples.

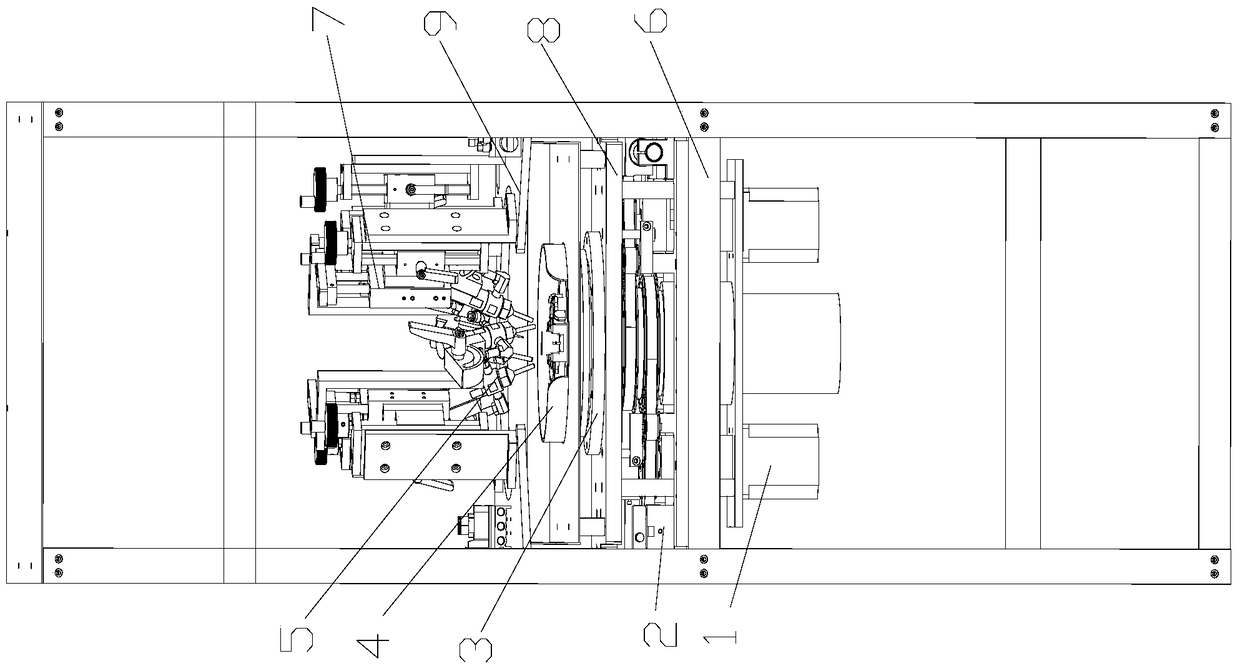

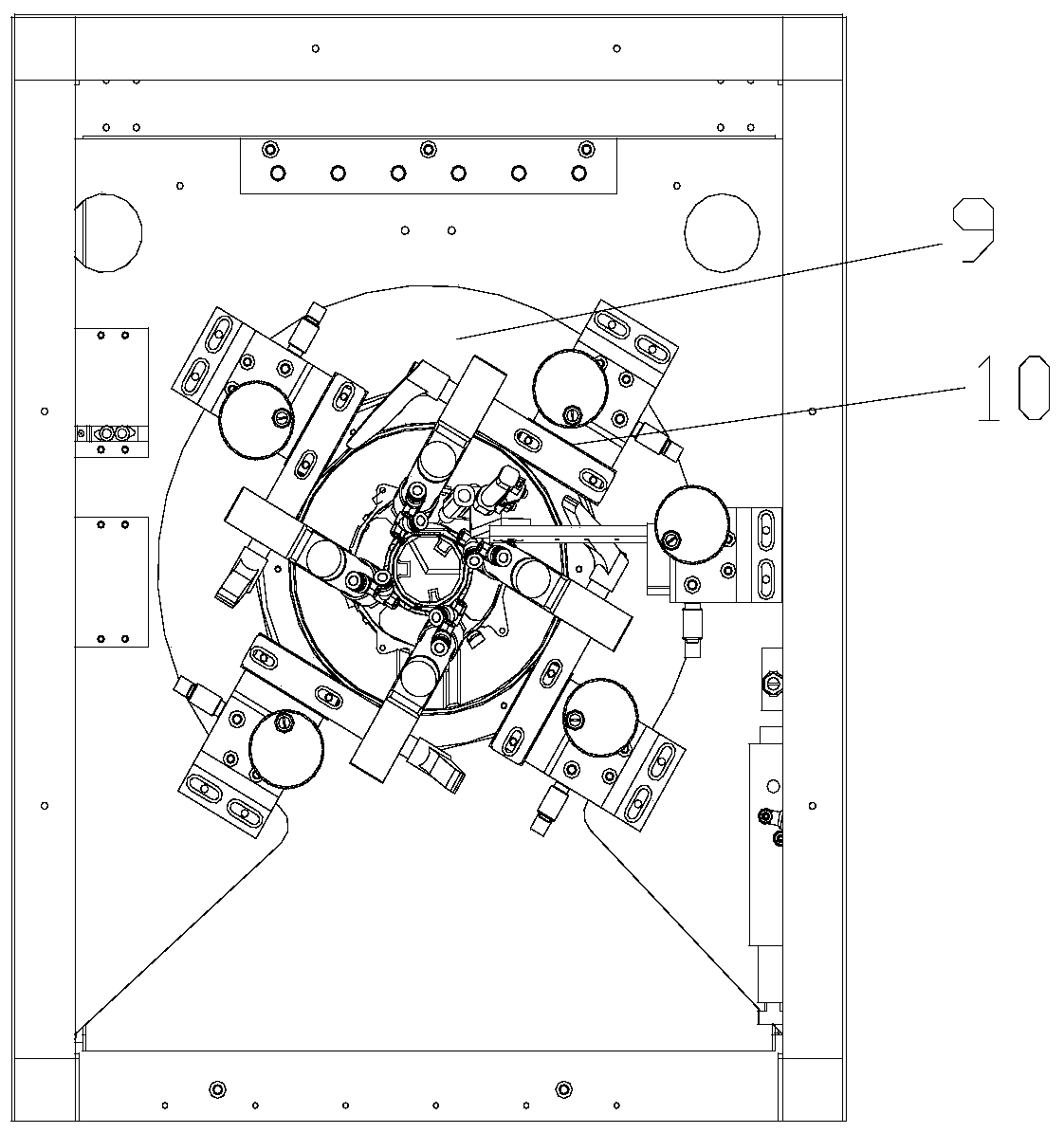

[0017] like figure 1 and figure 2 As shown, an oiling device for clock spring components includes an oil spray assembly, a frame assembly and a clamp assembly for placing semi-finished clock springs. The frame assembly includes a frame and a first layer of installation connected to the frame frame, the second-layer mounting frame, the third-layer mounting frame, the rotating disk is installed on the first-layer mounting frame, the fixture assembly is installed on the rotating disk, and the frame is provided with a horizontal drive cylinder for controlling the horizontal movement of the first-layer mounting frame and The driving motor used to drive the rotating disc to rotate, the horizontal driving cylinder is installed between the second-layer mounting frame and the first-layer mounting frame, the described driving motor is installed under the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com