A double-layer continuous ultrasonic atomization grading device and grading method

An ultrasonic atomization and classification device technology, applied in separation methods, chemical instruments and methods, spray devices, etc., can solve the problem of particle size, particle size distribution, and powder geometry, which are difficult to meet the requirements of high-performance powder use, and cannot effectively control ultrasonic waves. Suspension liquid level height, can not adapt to different concentrations of suspension and other problems, to achieve the effect of compact structure, high pressure, low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

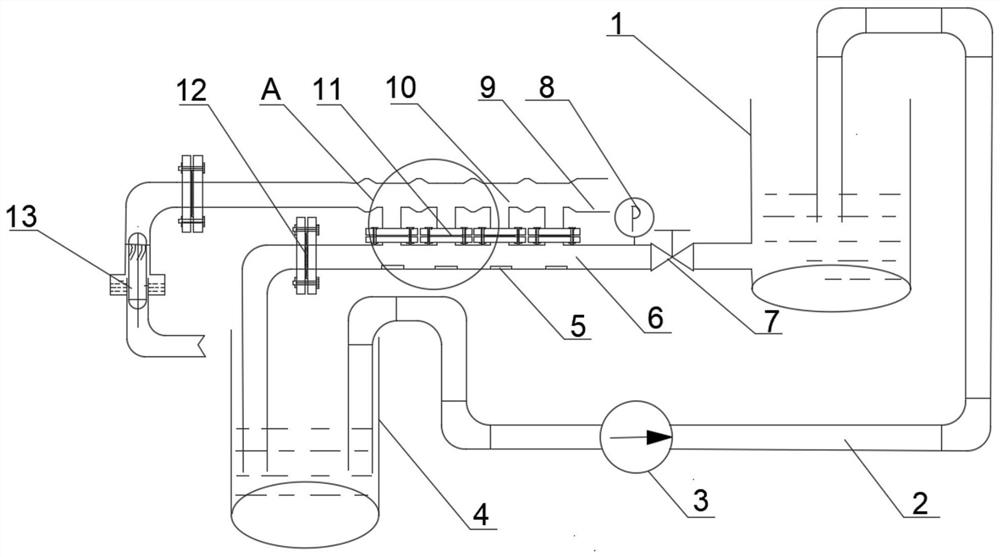

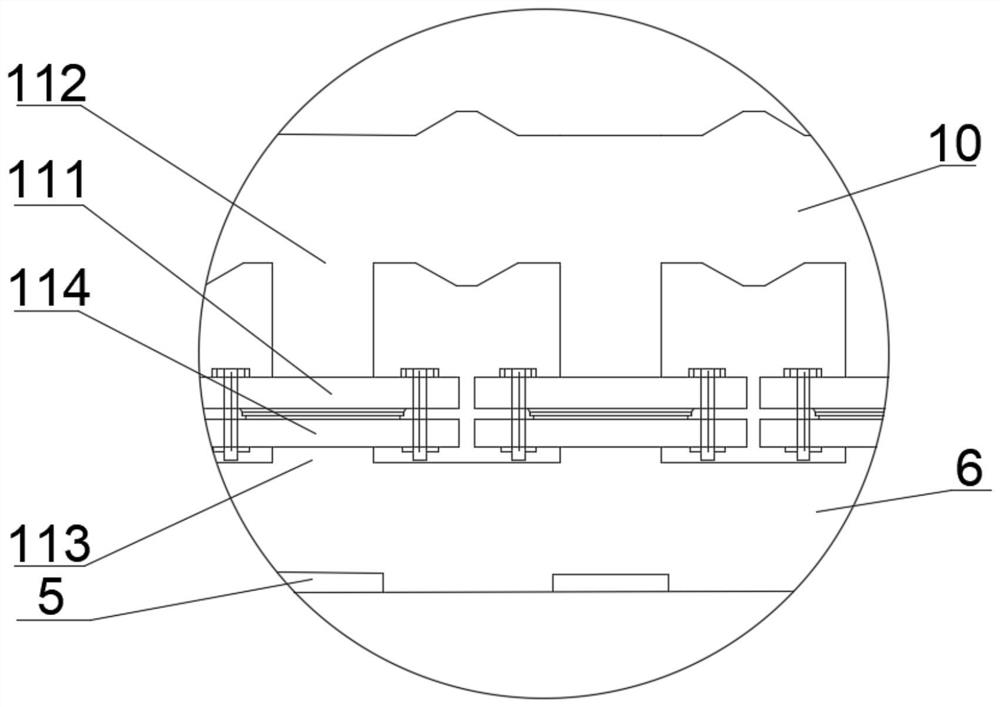

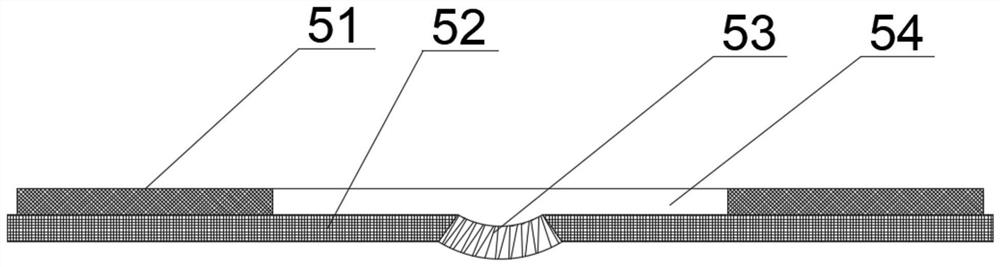

[0034] Such as figure 1 and figure 2 As shown, the double-layer continuous ultrasonic atomization and grading device of this embodiment includes a first container 1, one end of the first container 1 is connected to the side of the atomization pipeline 6, and the other end of the atomization pipeline 6 is connected to the second container 4 , the second container 4 is connected to the first container 1 through the circulation pipeline 2; the atomization pipeline 6 has a horizontal section, and a plurality of piezoelectric ceramic ultrasonic atomizers 5 are arranged inside it along the horizontal direction, and the atomization pipeline 6 of the horizontal section passes through A plurality of communicators 11 are connected to the water mist delivery pipeline 10, one end of the water mist delivery pipeline 10 is the gas inlet port 9, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com