An integrated device for sludge drying, deodorization and transportation

A sludge drying and wet sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Enterprise economic benefits, increased costs and other issues, to achieve the effect of reasonable fluidity, reasonable particle size distribution, improved fluidity and homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

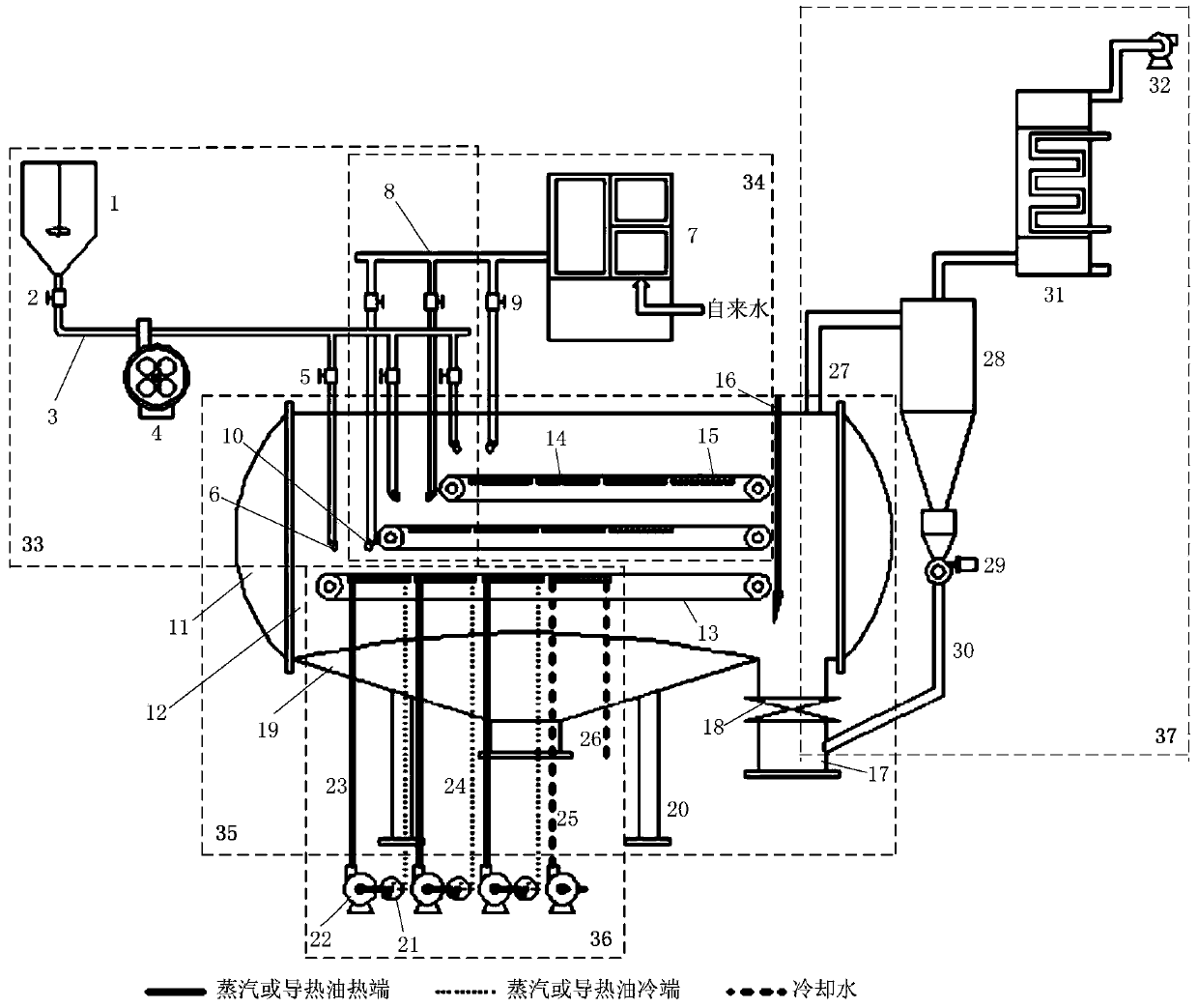

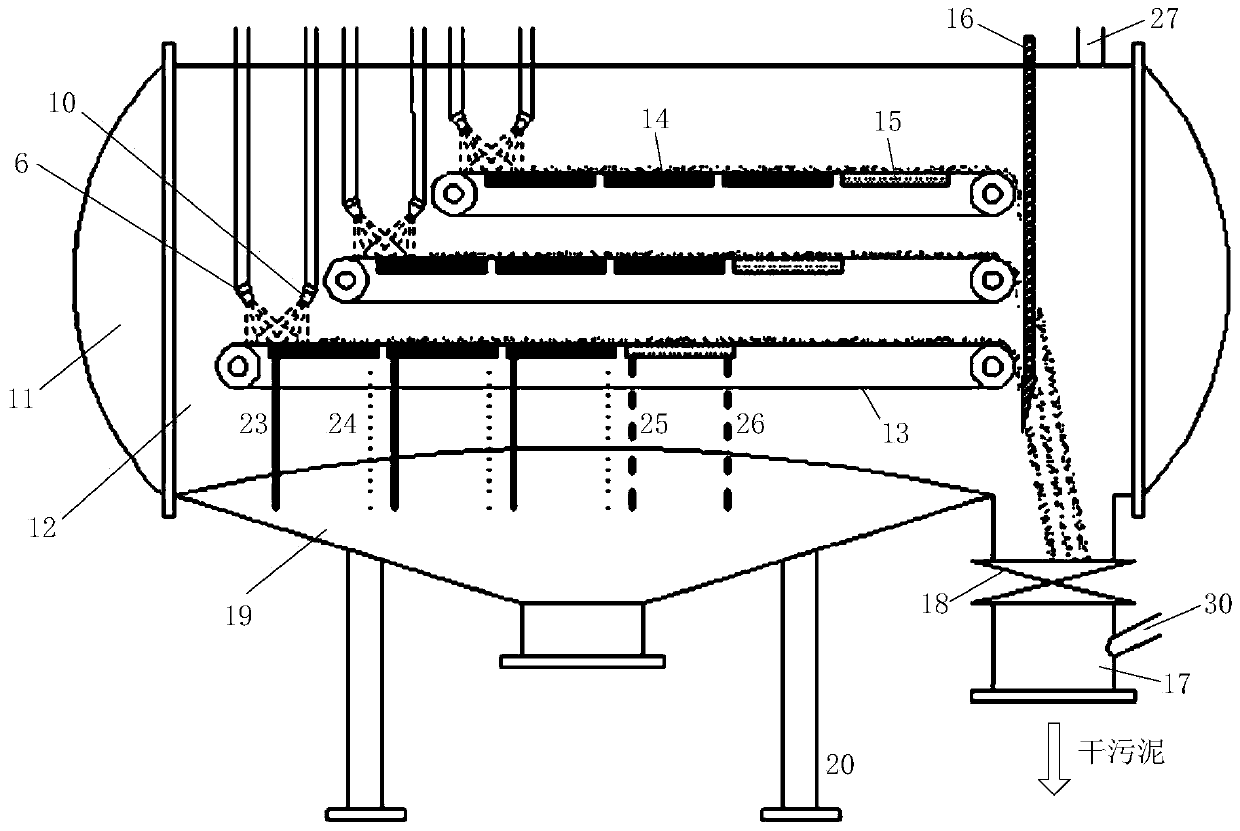

[0016] The present invention utilizes the wet sludge atomization nozzle to atomize the wet sludge, utilizes the plant liquid atomization nozzle to atomize the plant liquid, and makes the wet sludge atomized droplet and the plant liquid atomized droplet form a 90-degree opposite spray, so that The two are fully mixed and deodorized, and the mixed atomized liquid droplets are sprayed on the surface of the non-stick track, and while moving along the direction of the casing cylinder at a set speed, the heated water that is closely attached to the non-stick track The plate transfers the energy required for drying to the sludge in the form of contact heat transfer, so that the sludge is dried to the required degree, and then the dried sludge is cooled to the required temperature through the cooling plate closely fitted with the non-stick track The deodorized and dried sludge is cut by the material breaker, falls into the discharge pipe at the lower part of the machine body, enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com