A vacuum belt filter washing method

A vacuum belt and filter technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of large washing liquid droplets, breakdown of sulfur paste filter cake, small leaching coverage area, etc., and achieve light weight , Eliminate the effect of spray dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A vacuum belt filter rinse method, comprising the following steps:

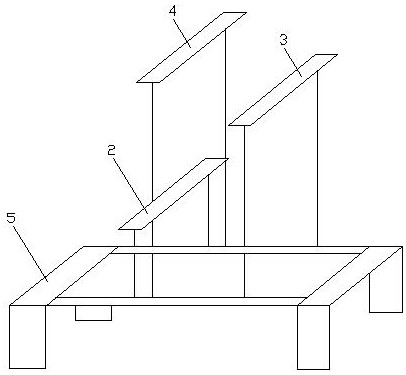

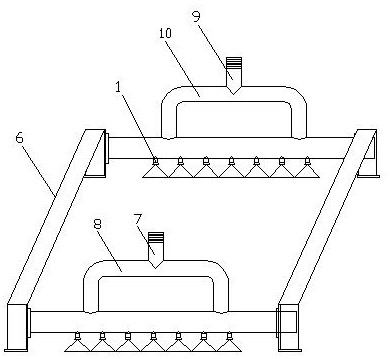

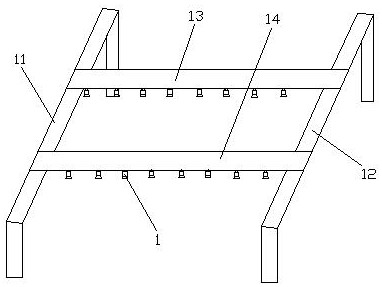

[0042] a. On the fixed slot of the vacuum belt filter, the spraying device is fixedly installed through the screw, and the two rows of wide-angle fan-shaped spray nozzles 1 of the spraying device are arranged alternately above the filter cake;

[0043] b. Adjust the nozzle angle of the wide-angle fan-shaped spray nozzle 1 to 60°, set the pressure drop to 0.2Mpa, and the spray volume of a single wide-angle fan-shaped spray nozzle 1 is 0.02m 3 / h, the ratio of flushing water to sulfur is 3:5;

[0044] c. Turn on the primary sprayer 2 of the spraying device, the height of the flushing water is 50mm, and the flushing water volume is 0.2m 3 / h, the spray particle size is 50um, and the filter cake is sprayed and cleaned at the first stage; then the second sprayer 3 is turned on, and the height of the flushing water is 80mm, and the flushing water volume is 0.4m 3 / h, the spray particle size is 150um, and t...

Embodiment 2

[0047] A vacuum belt filter rinse method, comprising the following steps:

[0048] a. On the fixed slot of the vacuum belt filter, the spraying device is fixedly installed through the screw, and the two rows of wide-angle fan-shaped spray nozzles 1 of the spraying device are arranged alternately above the filter cake;

[0049] b. Adjust the nozzle angle of the wide-angle fan-shaped spray nozzle 1 to 110°, set the pressure drop to 0.3Mpa, and the spray volume of a single wide-angle fan-shaped spray nozzle 1 is 0.05m 3 / h, the ratio of flushing water to sulfur is 3:5;

[0050] c. Turn on the first-level sprayer 2 of the spraying device, use the height of the flushing water to be 105mm, and spray the particle size to 200um to perform the first-level spray cleaning on the filter cake; then turn on the second-level sprayer 3, and use the height of the flushing water to be 105mm , flushing water volume is 0.45m 3 / h, the spray particle size is 200um, and the filter cake is subject...

Embodiment 3

[0056] A vacuum belt filter rinse method, comprising the following steps:

[0057]a. On the fixed slot of the vacuum belt filter, the spraying device is fixedly installed through the screw, and the two rows of wide-angle fan-shaped spray nozzles 1 of the spraying device are arranged alternately above the filter cake;

[0058] b. Adjust the nozzle angle of the wide-angle fan-shaped spray nozzle 1 to 120°, set the pressure drop to 0.4Mpa, and the spray volume of a single wide-angle fan-shaped spray nozzle 1 is 0.08m 3 / h, the ratio of flushing water to sulfur is 3:5;

[0059] c. Turn on the primary sprayer 2 of the spraying device, the height of the flushing water is 120mm, and the flushing water volume is 0.3m 3 / h, the spray particle size is 220um, and the filter cake is sprayed and cleaned at the first stage; then the second sprayer 3 is turned on, and the height of the flushing water is 110mm, and the flushing water volume is 0.5m 3 / h, the spray particle size is 220um, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com