Patents

Literature

312results about How to "Guaranteed weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Imitated silk high-elasticity knitted underwear fabric and preparation method thereof

ActiveCN102631030AControl flatnessGuaranteed weightWeft knittingBleaching apparatusYarnBursting strength

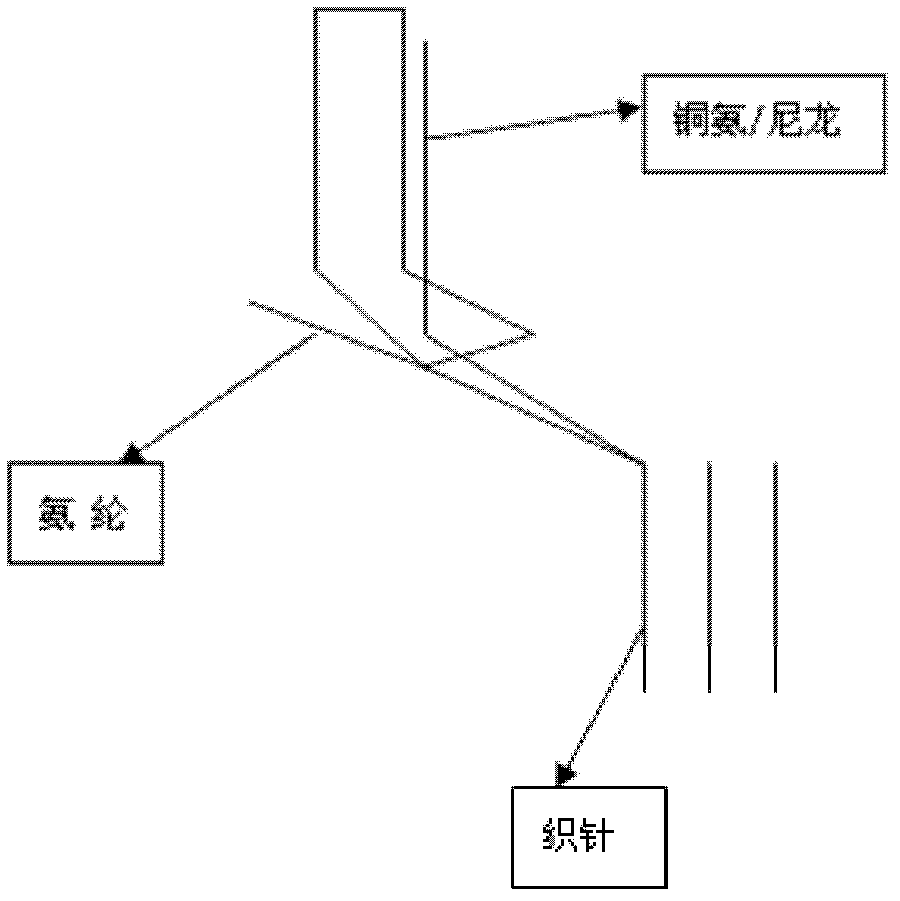

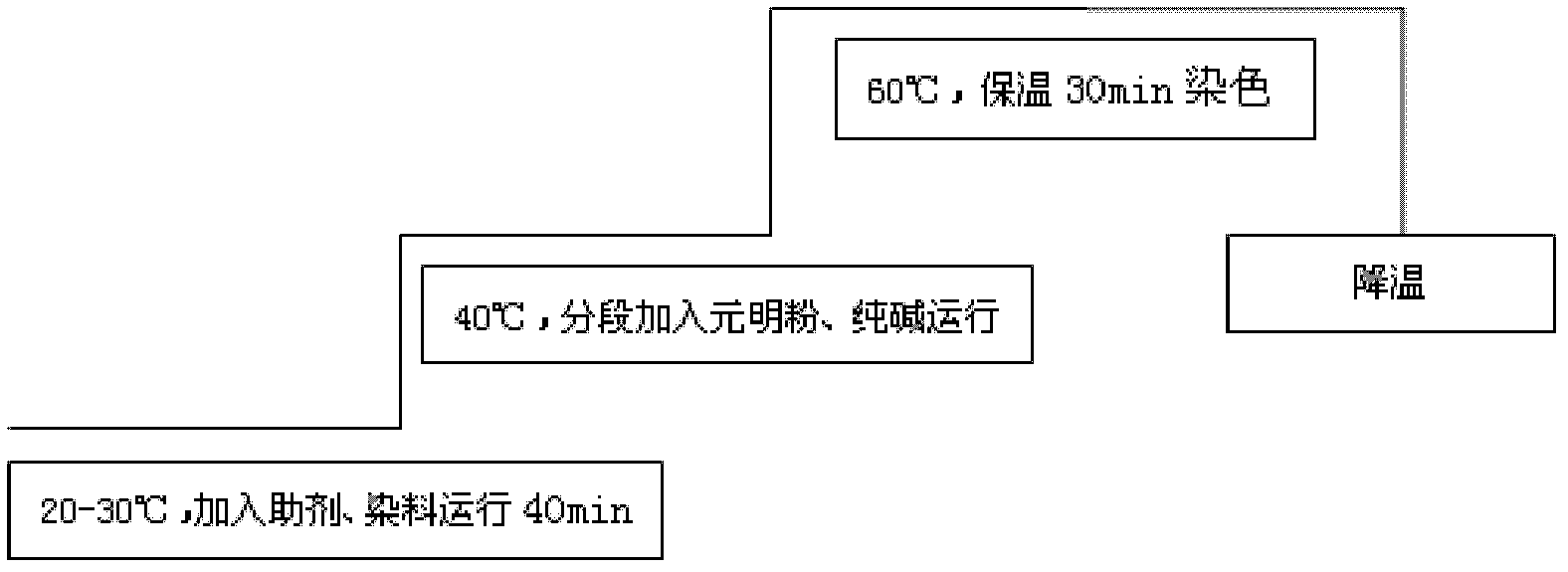

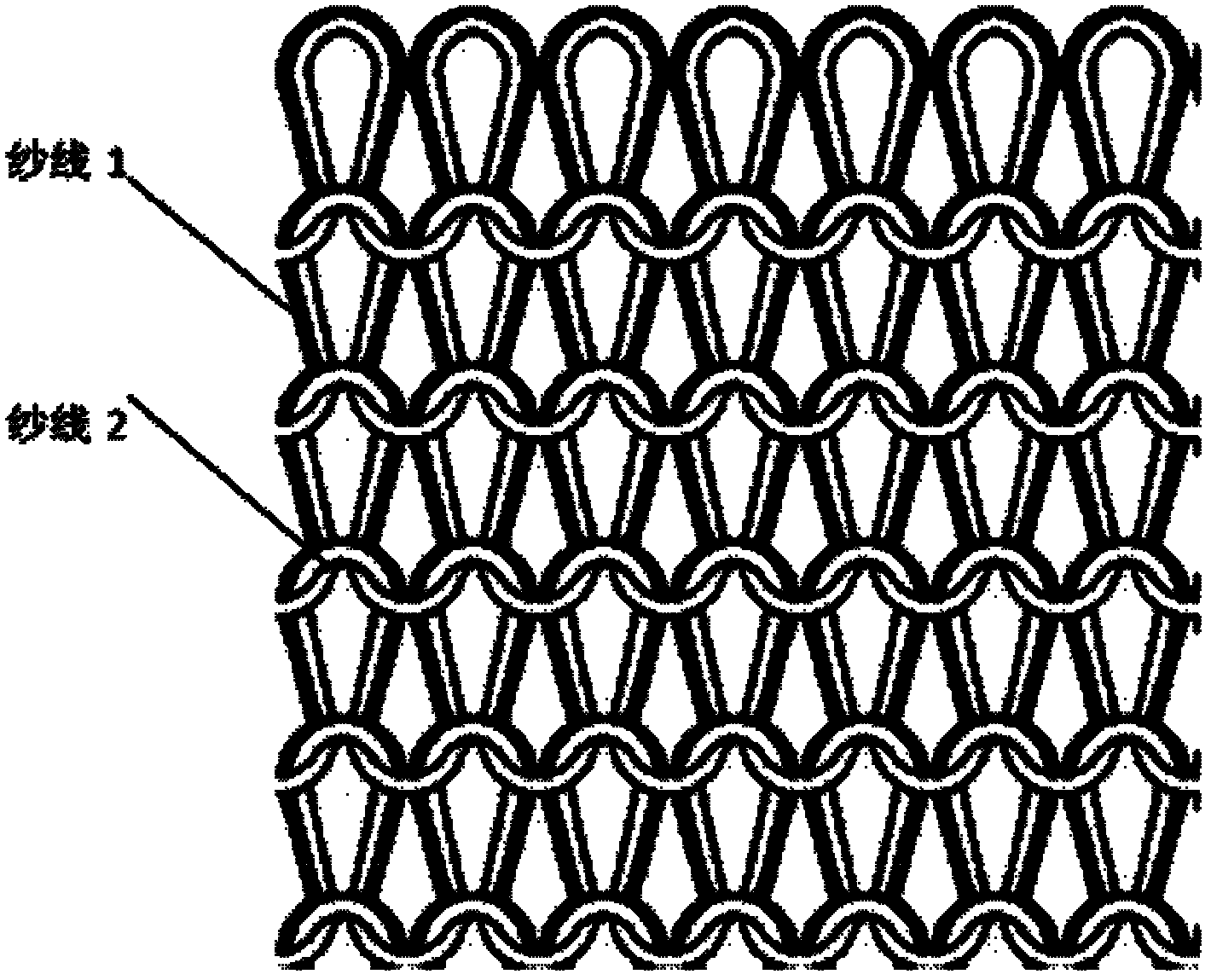

The invention relates to imitated silk high-elasticity knitted underwear fabric and a preparation method thereof. The fabric is formed by interweaving fine-denier copper ammonia / nylon bi-component filament and spandex yarn, wherein the fine-denier copper ammonia / nylon bi-component filament is located on the front of the fabric and completely covers the spandex yarn. The preparation method comprises the following steps of: sequential weaving, fabric pre-sizing, pretreatment, copper ammonia dyeing, aftertreatment, nylon dyeing, soaping, soft finish, dehydration and re-sizing. The imitated silk high-elasticity knitted underwear fabric provided by the invention has smooth handfeel, brightness, full appearance, soft handfeel, antibacterial property, comfort and the like; the problems of low bursting strength and insufficient elasticity of the single copper ammonium imitated silk fabric are solved; and the problems of non-uniform blend dyeing of copper ammonium and chemical fiber, color yellowing and rough cloth cover are solved.

Owner:NINGBO DAQIAN TEXTILE

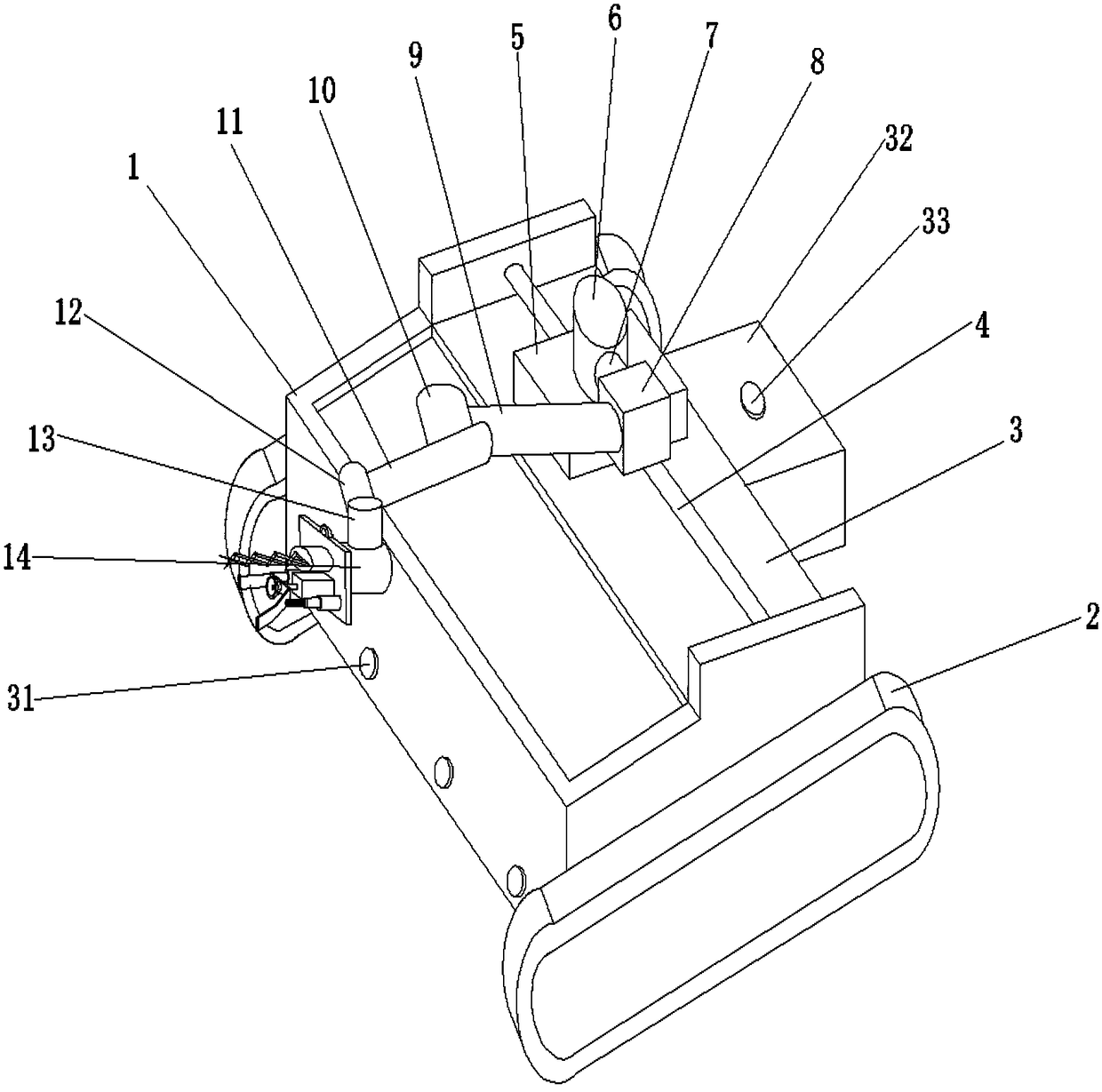

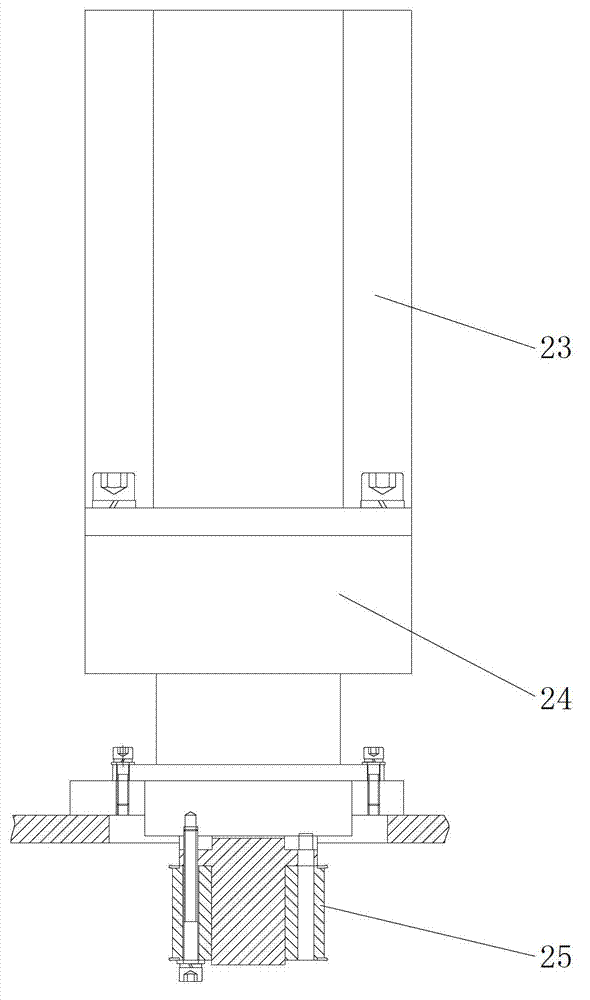

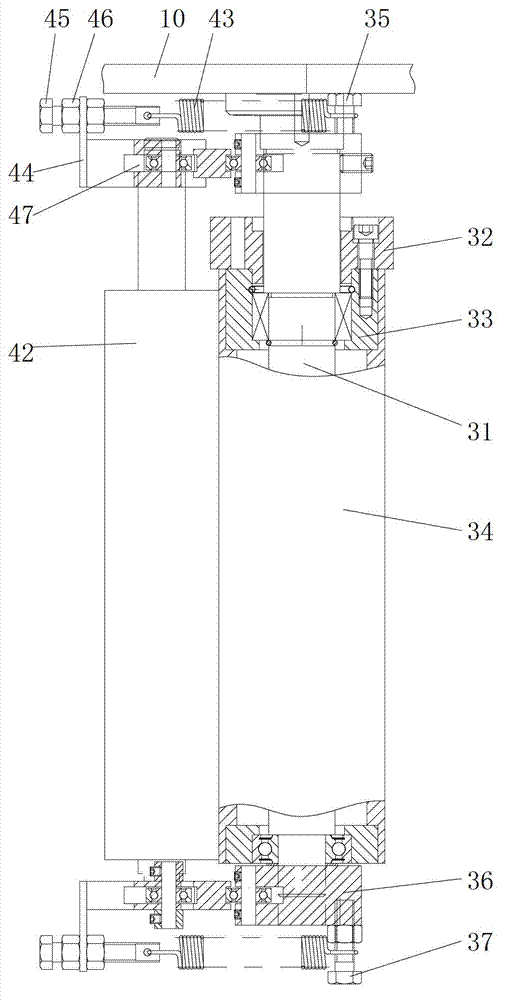

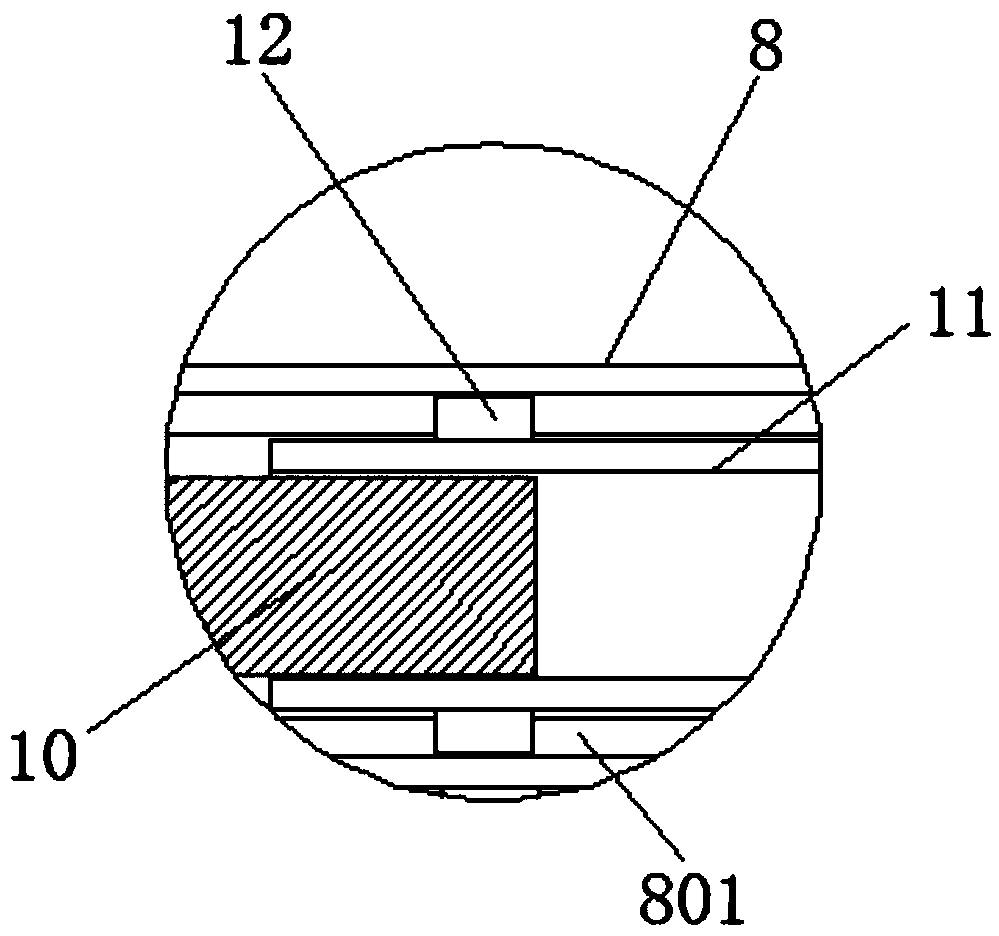

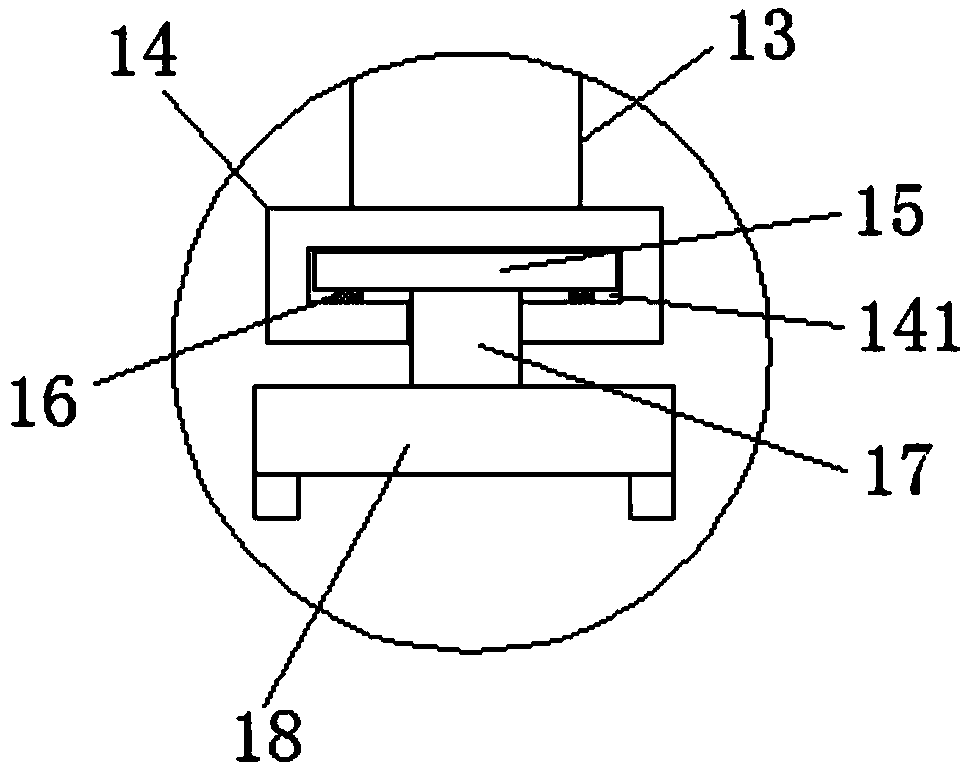

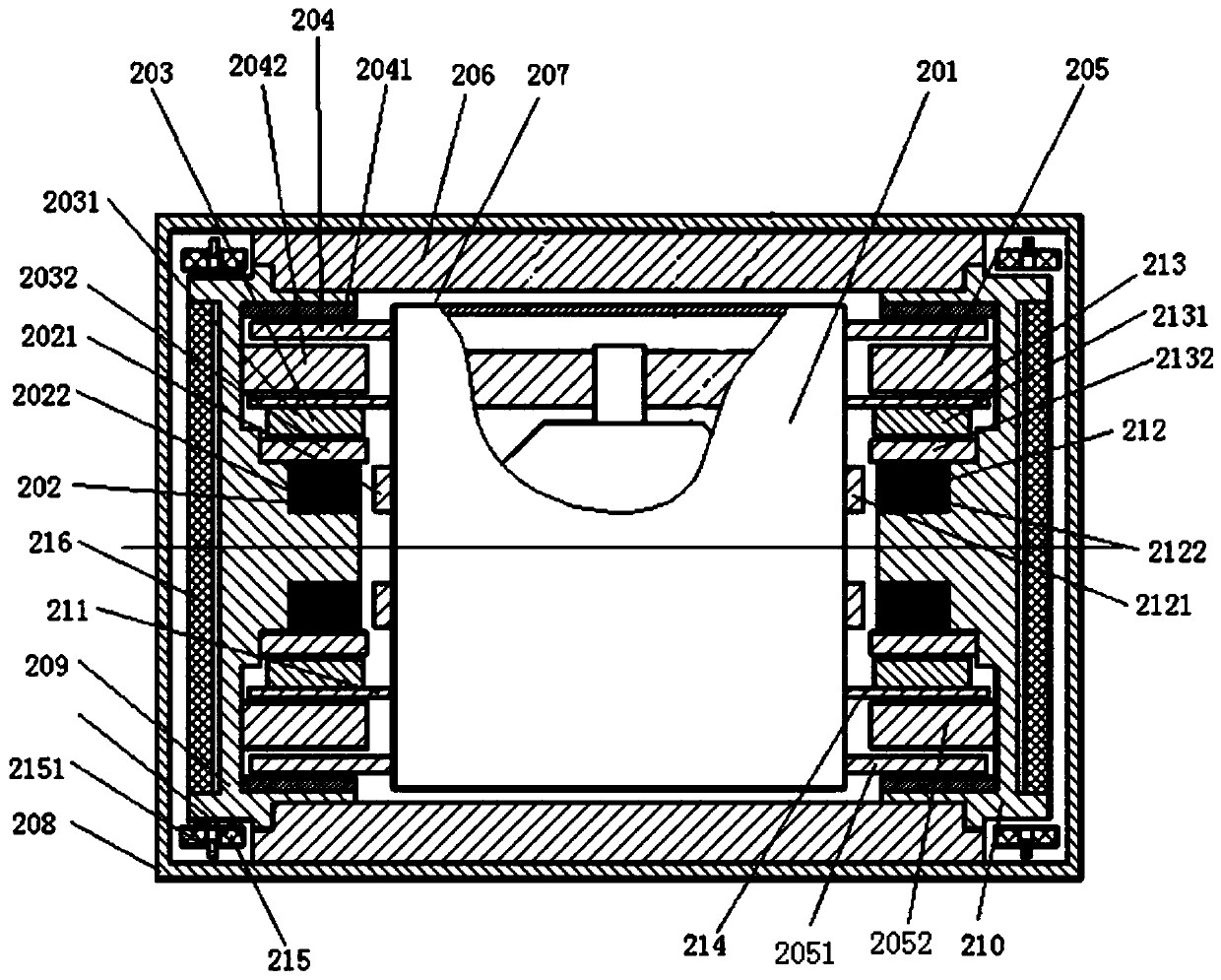

Azimuth device applicable to vehicular photoelectric turntable

ActiveCN103294066AAchieving a modular designImprove maintainabilityPosition/direction controlBiaxial loadMaintainability

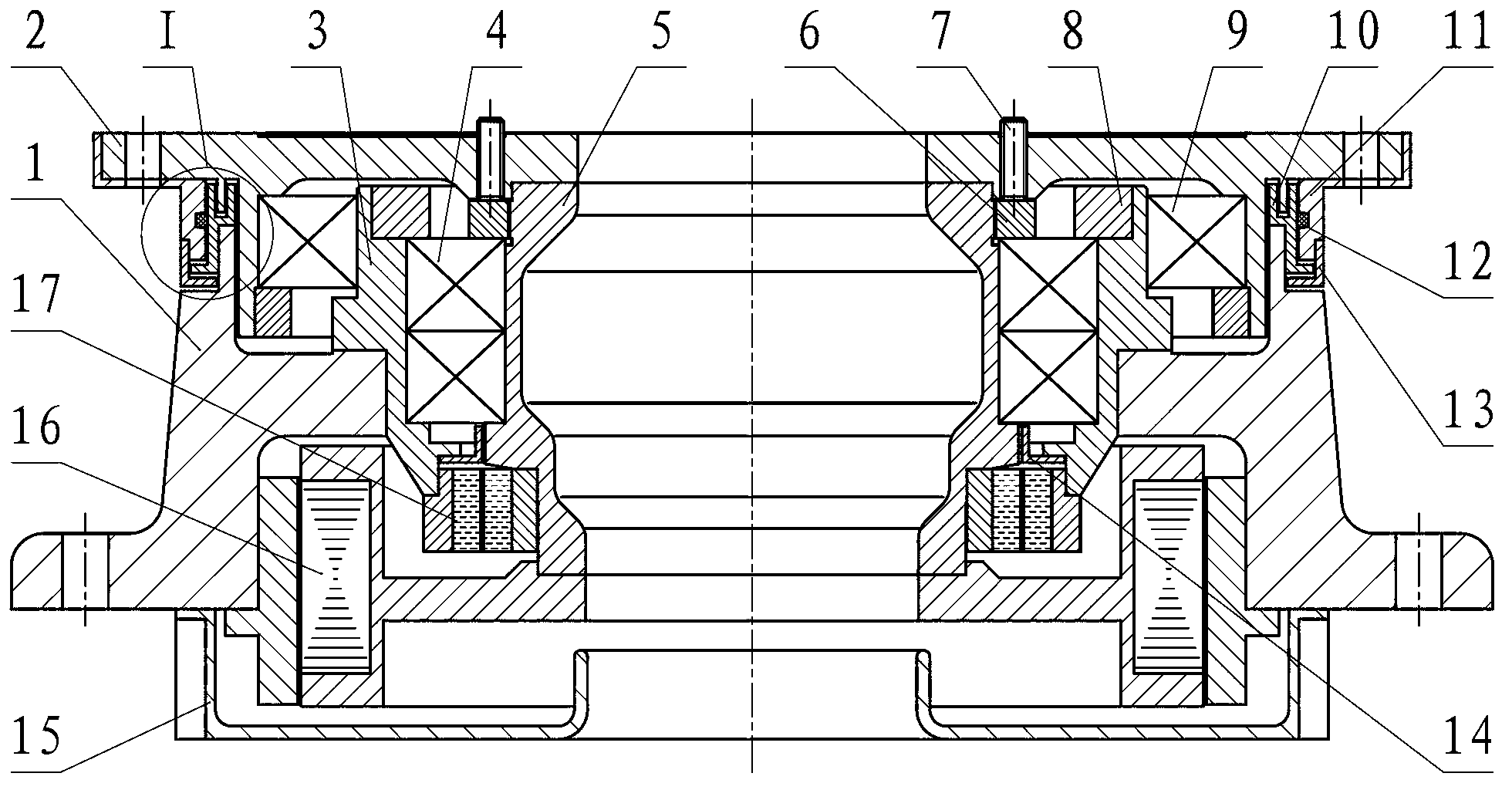

The invention discloses an azimuth device applicable to a vehicular photoelectric turntable. The azimuth device comprises a revolving shaft system, an azimuth shell, a rotary transformer and a torque motor. The revolving shaft system comprises an azimuth dead shaft, an azimuth moving shaft, an azimuth rotating adaptor disc and two groups of bearings, the azimuth dead shaft is connected with the azimuth moving shaft and the azimuth rotating adaptor disc respectively via a first bearing and a second bearing, the first bearing bears biaxial loads, the second bearing is larger in diameter and bears radial and tipping loads, and thereby the rotating disc type revolving shaft system borne by the internal and external bearings is formed. The revolving shaft system as well as the rotary transformer and the torque motor are respectively positioned on an upper side and a lower side of an annular transverse plate in the middle of the azimuth shell and are independent to one another. Furthermore, a comprehensive labyrinth felt collar sealing structure is adopted. The azimuth device has the advantages of simple structure, low height, light weight, good maintainability, excellent expansibility, strong environmental suitability and the like, mechanical characteristics and capabilities of resisting shock, vibration and large-angle inclination of the photoelectric turntable are effectively improved, and tracking precision of photoelectric tracking equipment is guaranteed.

Owner:西安应用光学研究所

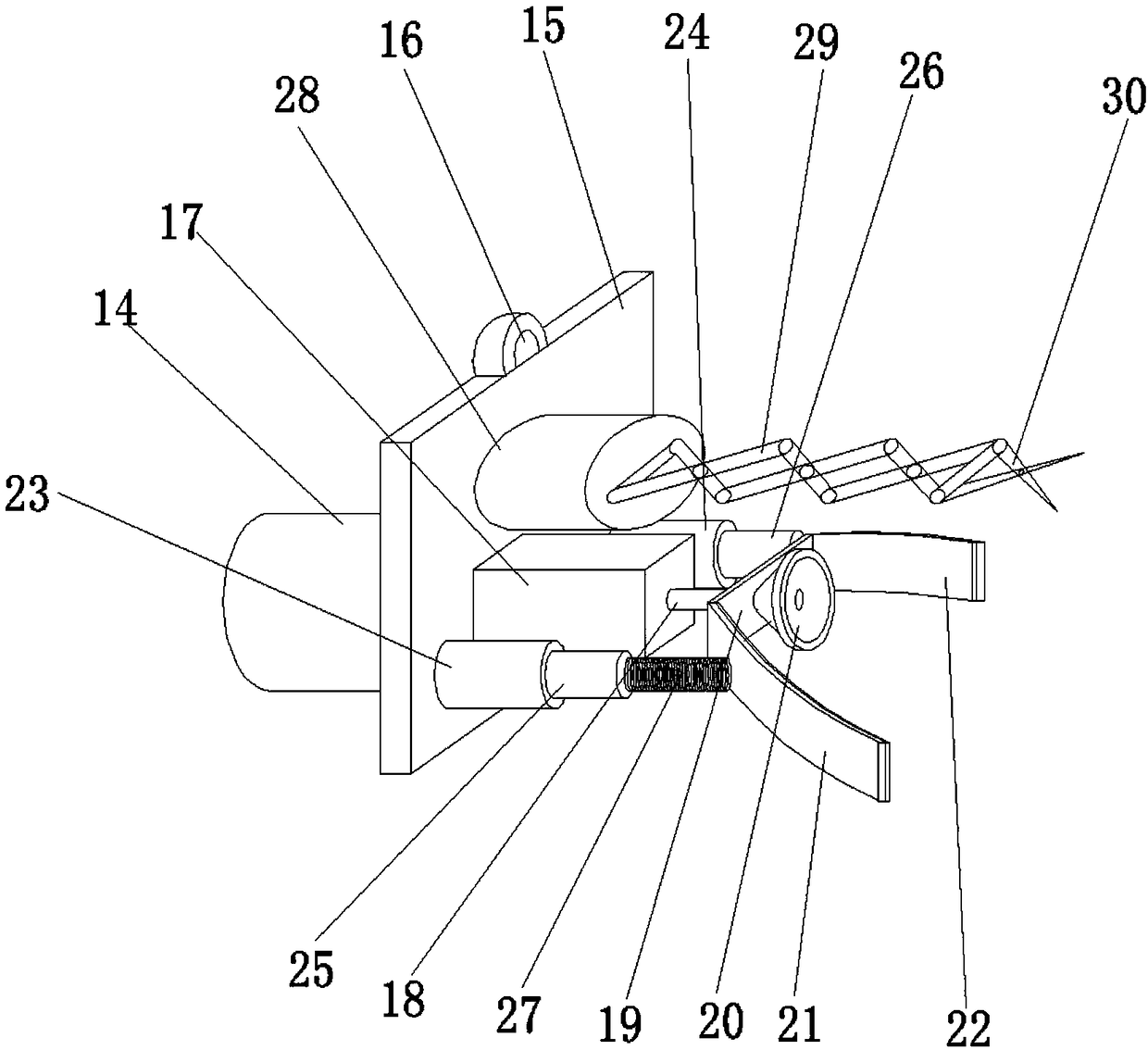

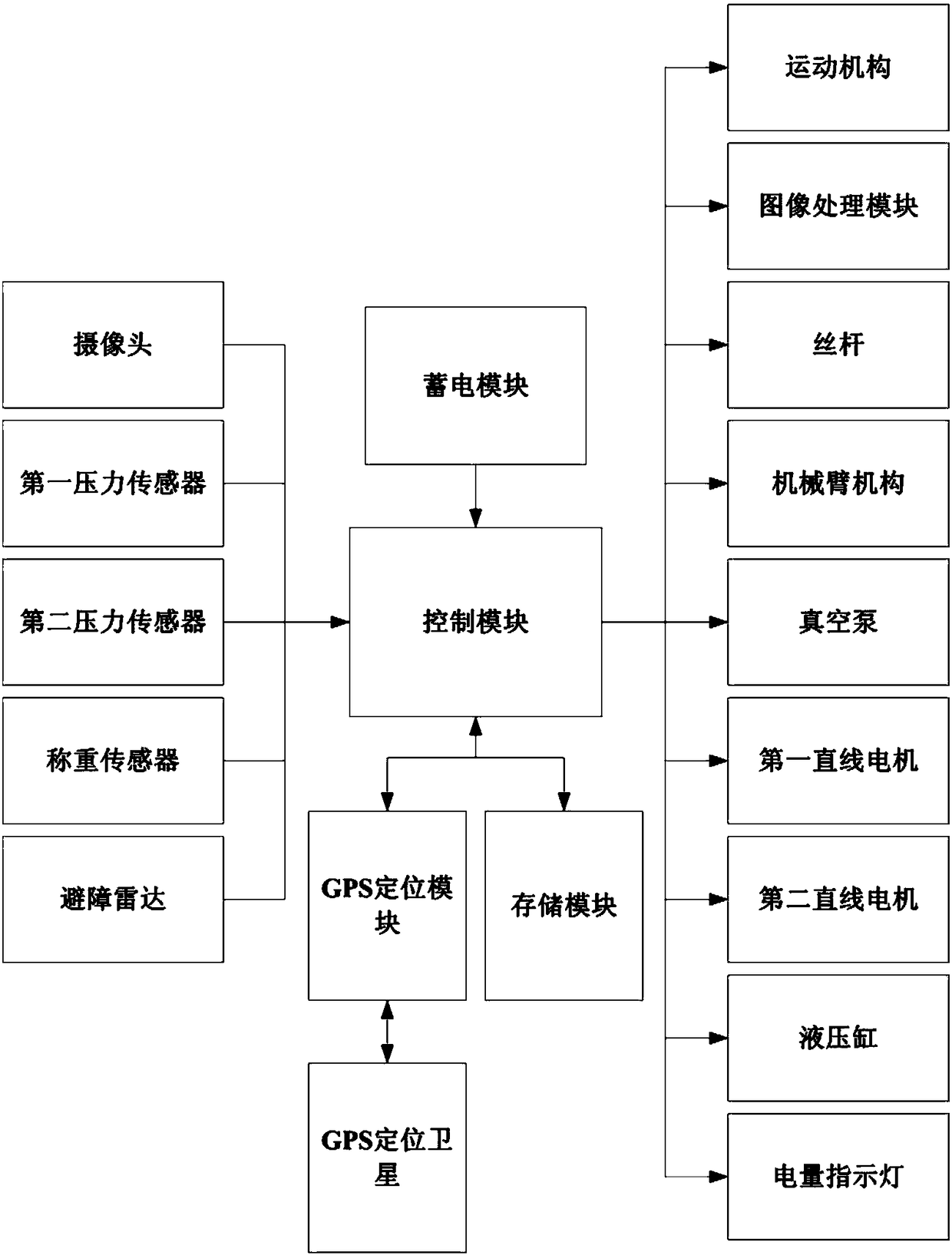

Spherical fruit and vegetable picking robot

InactiveCN108401685APlay a protective effectGuaranteed qualityGripping headsSatellite radio beaconingHydraulic cylinderCuticle

The invention provides a spherical fruit and vegetable picking robot. The spherical fruit and vegetable picking robot comprises a robot body, the robot body is provided with a movement mechanism, andthe movement mechanism is a crawler-type movement wheel, an executing mechanism at the tail end of the robot vacuates a vacuum sucker to adsorb to-be-picked fruits and vegetables through a vacuum pump, a first pressure sensor on the vacuum sucker feeds back negative information of the vacuum sucker, a first linear motor and a second linear motor respectively stretches or compresses a first springand a second spring, so that a first copying finger and a second copying finger expand outward or retract inward to achieve the clamping of the fruit and vegetables with different sizes, second pressure sensors on the first copying finger and second copying finger feed back the clamping force, the surfaces of the inner sides of the first copying finger and second copying finger are covered with soft silicone pads, the damage to the outer peel of the fruits and vegetables is avoided very well, a hydraulic cylinder drives scissors on the end portion of a shear-fork telescopic rod to cut fruit stems, thereby achieving the separation between the to-be-picked fruits and vegetables and plants.

Owner:HUZHOU JIACHUANG AUTOMATION TECH CO LTD

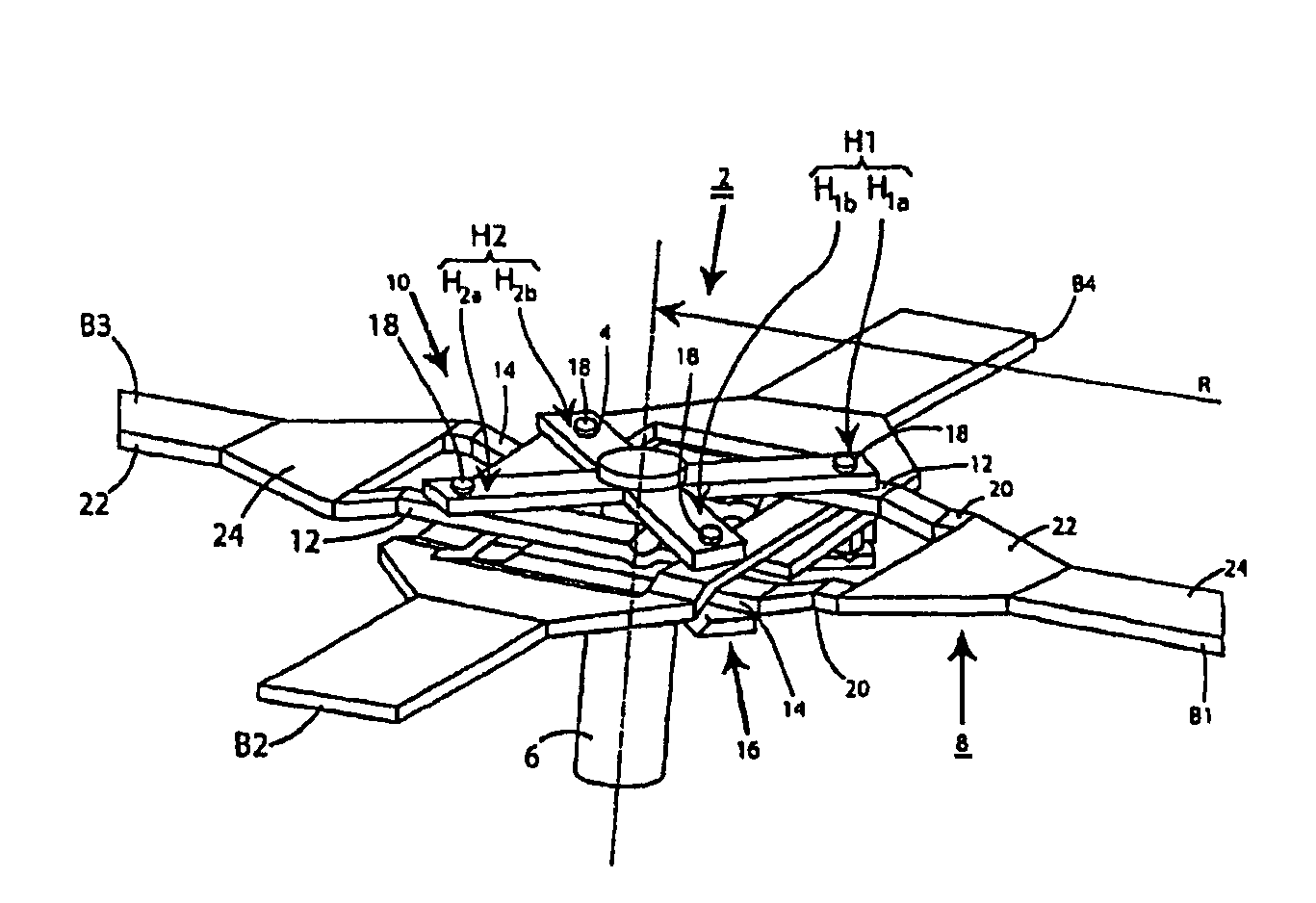

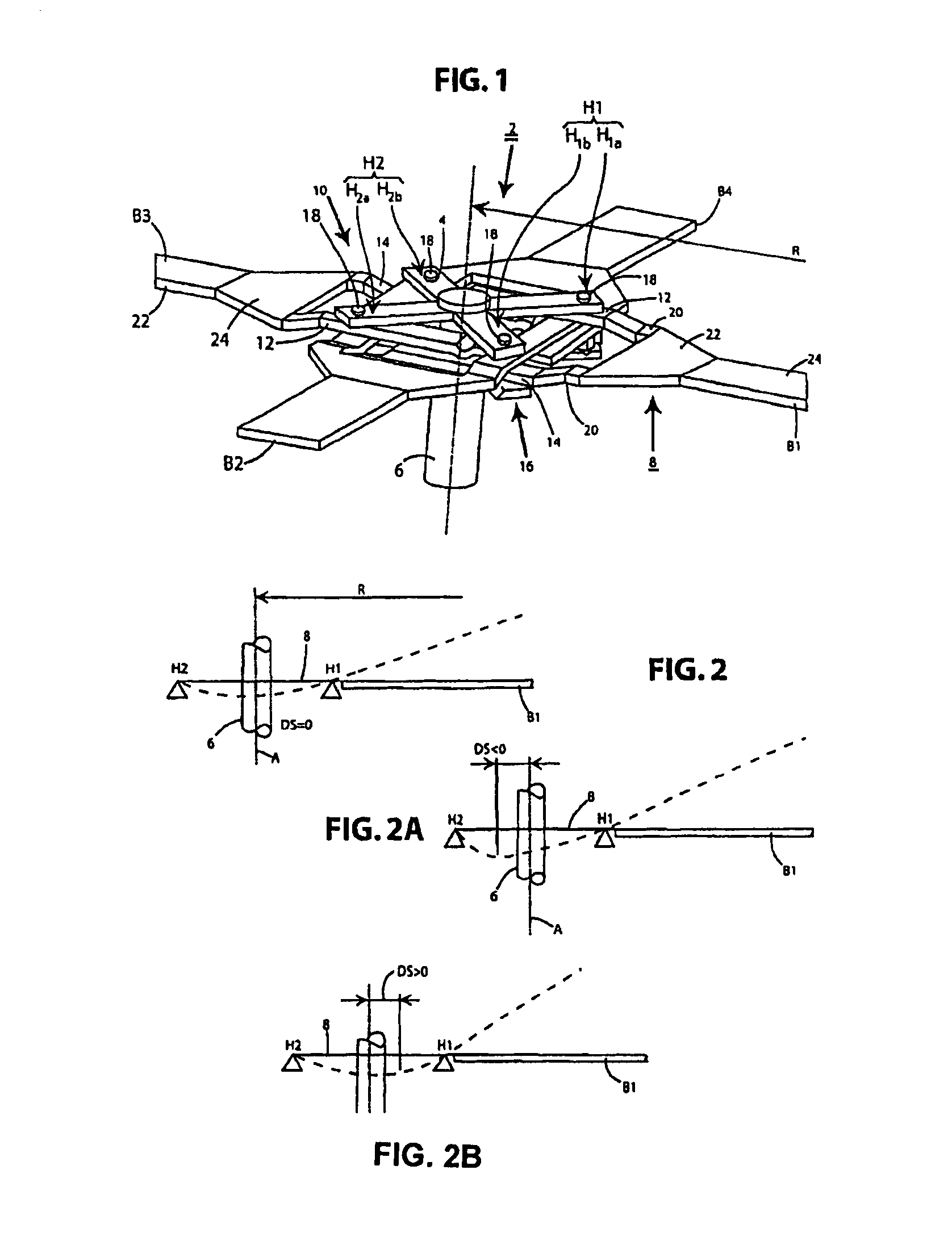

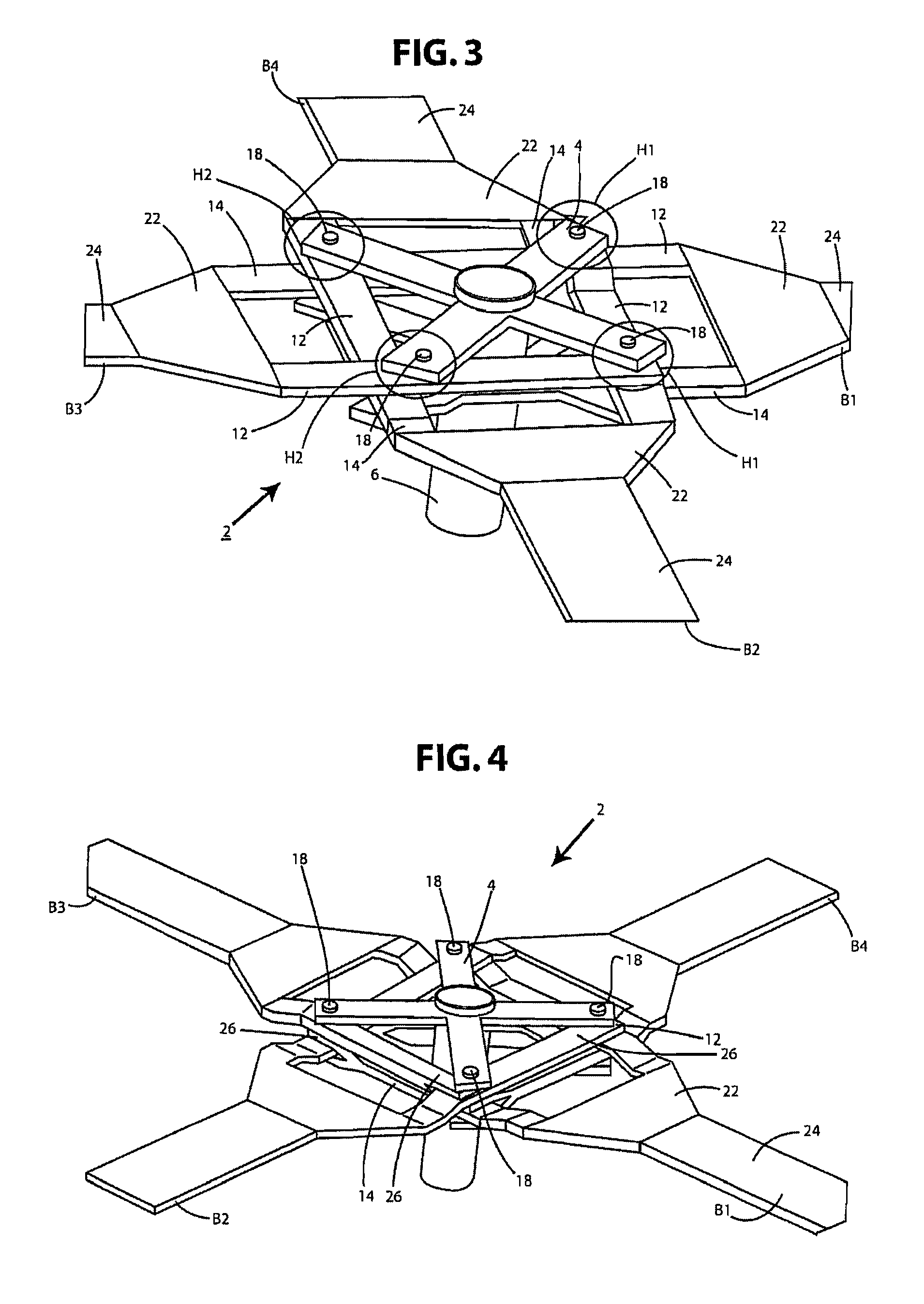

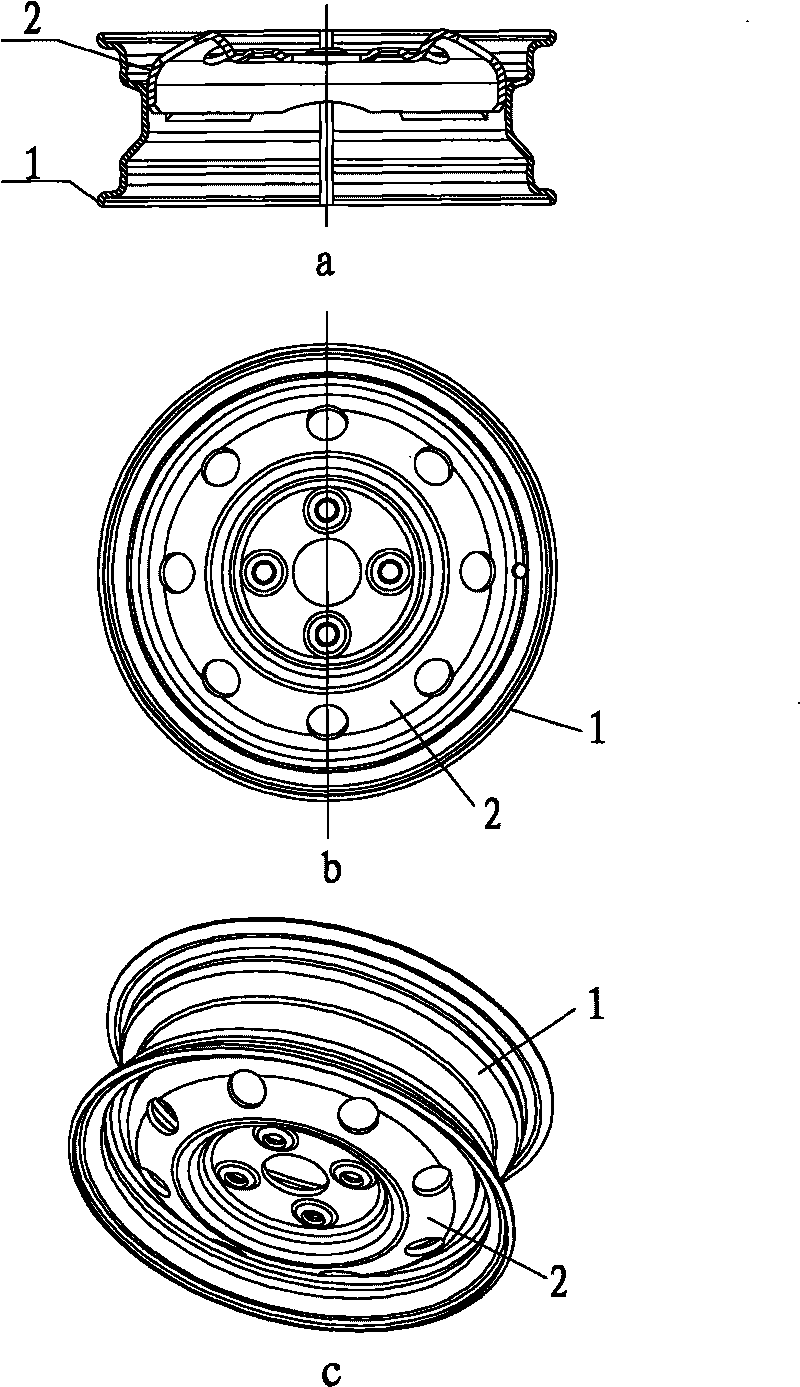

Rotor and gyrocopter with said rotor

InactiveUS7275913B2Improve propertiesGreater flying comfortPropellersPump componentsEngineeringRotary wing

A rotor, comprising at least one rotor blade connectable to a rotor head, which rotor blade possesses a blade neck having a virtual flapping hinge in the form of a flexurally soft, flexurally elastic blade-neck portion, there being provided, in a blade-connector region of the blade neck, two auxiliary flapping hinges, spaced apart from one another in the radial longitudinal direction of the rotor blade with reference to a rotor radius, between which the virtual flapping hinge is substantially disposed and between which the blade neck is deformable in flexurally elastic and curved fashion in the context of a flapwise motion. A rotorcraft, in particular a helicopter, in particular a tiltrotor helicopter, having at least one such rotor.

Owner:AIRBUS HELICOPTERS DEUT GMBH

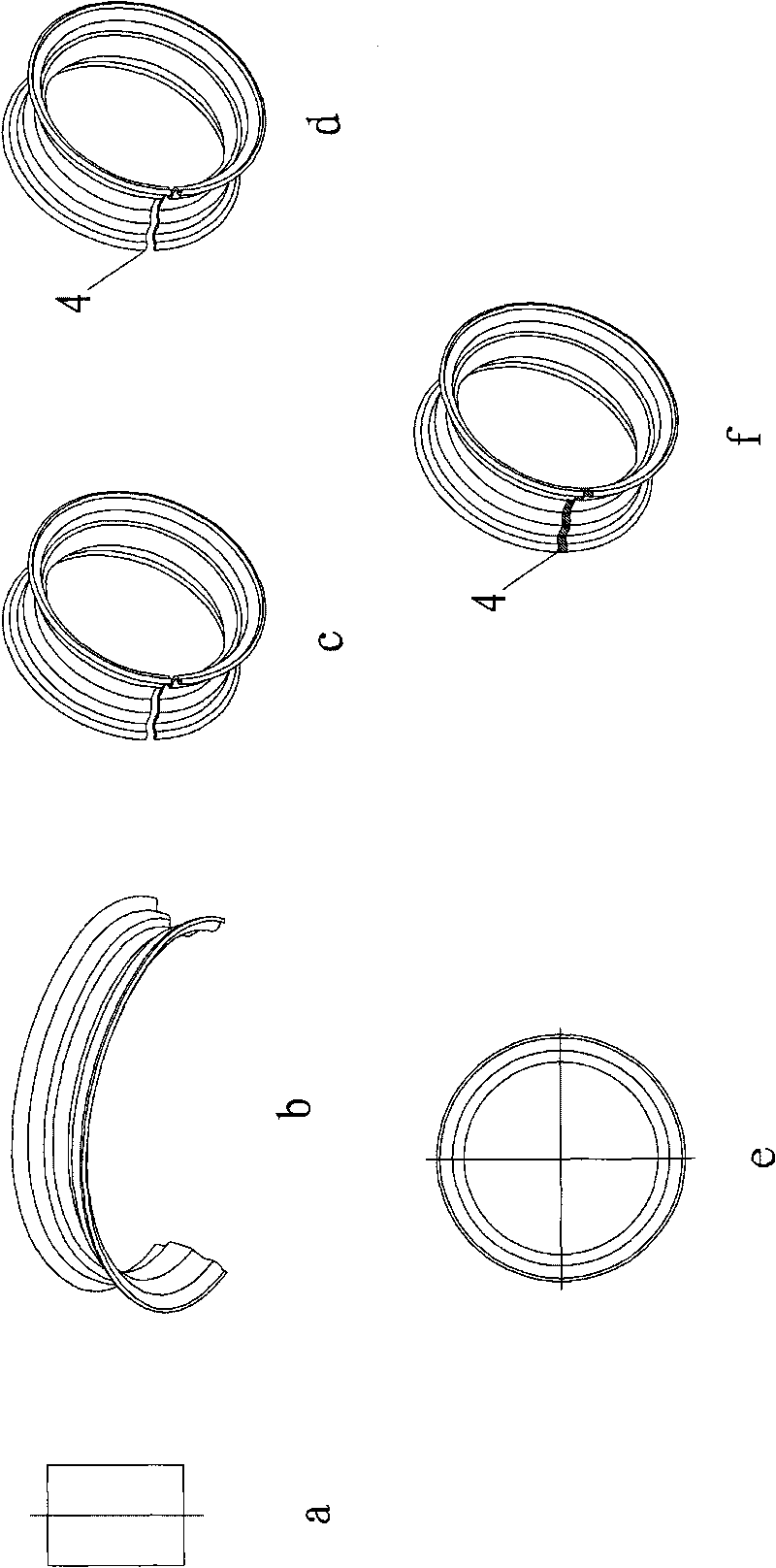

Foamed ceramic compound wallboard

InactiveCN106284828AImprove insulation effectImprove sound insulationBuilding componentsCalcium silicateFiber

The invention relates to a foamed ceramic compound wallboard which comprises an outer panel and an inner main board. The outer panel is a foamed ceramic plate, and the outer side of the outer panel is provided with an outer veneer. The inner main board is a foamed ceramic board or an autoclaved aerated concrete board or a calcium silicate board or a cement fiber board or a gypsum plasterboard, and the inner side of the inner main board is provided with an inner veneer. The outer panel and the inner main board are connected and fixed through a support assembly, and through the support assembly, a cavity is formed between the outer panel and the inner main board. The interior of the cavity is coated with rigid foam polyurethane. According to the technical scheme, the integrated wallboard meets the requirements of a building external wall for the required strength and impact resistance, has the characteristics of water prevention, seepage prevention, heat preservation, good weather resistance and low comprehensive cost, and is combined with a decorative layer.

Owner:谢自强

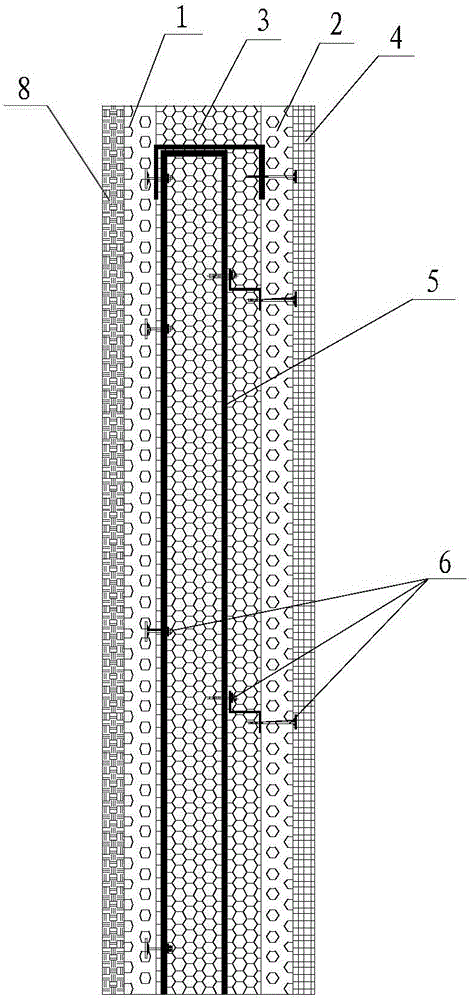

Process for manufacturing magnesium alloy wheel and process for manufacturing wheel rim of magnesium alloy wheel

InactiveCN101722401AReduce material densityLow densityMetal-working apparatusHot stampingWork in process

The invention relates to a process for manufacturing a magnesium alloy wheel and a process for manufacturing a wheel rim of the magnesium alloy wheel, which comprises: a step of hot extrusion, namely making a sectional material into a more than half ellipse shaped wheel rim semi-finished product in a longitudinal forming device through hot bending; a step of fully rounding, namely rolling the elliptic wheel rim semi-finished product into a full round shape by a rolling circle device, performing further pressurization and rounding on the full-circle wheel rim semi-finished product by a pressure device after performing a preparation process of welding, and finally performing the welding; and a step of air hole processing, namely processing air holes for setting inflating valves. The process for manufacturing the magnesium alloy wheel is further characterized by comprising: a step of plate blanking, namely manufacturing a circular plate and forming a center hole on the circular plate through hot stamping; a step of hot stretch forming, namely performing hot stretch on the circular plate for scheduled times; a step of hot stamping, namely forming a connecting structure and a heat sinking structure on the wheel rim semi-finished product through the hot stamping; and a step of performing a process of gang welding, namely assembling the wheel rim and a wheel spoke into a wheel.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP

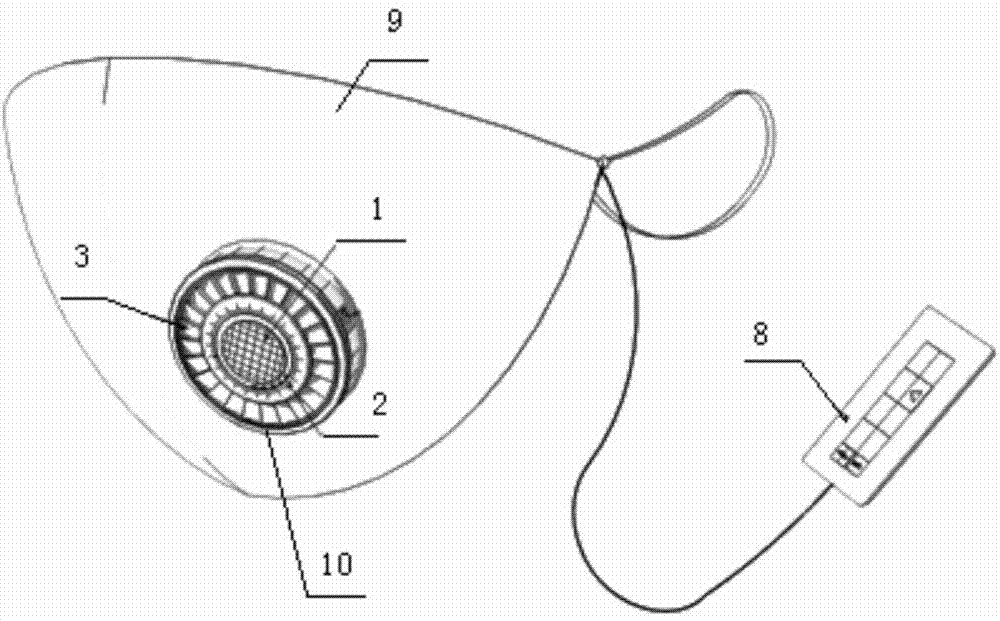

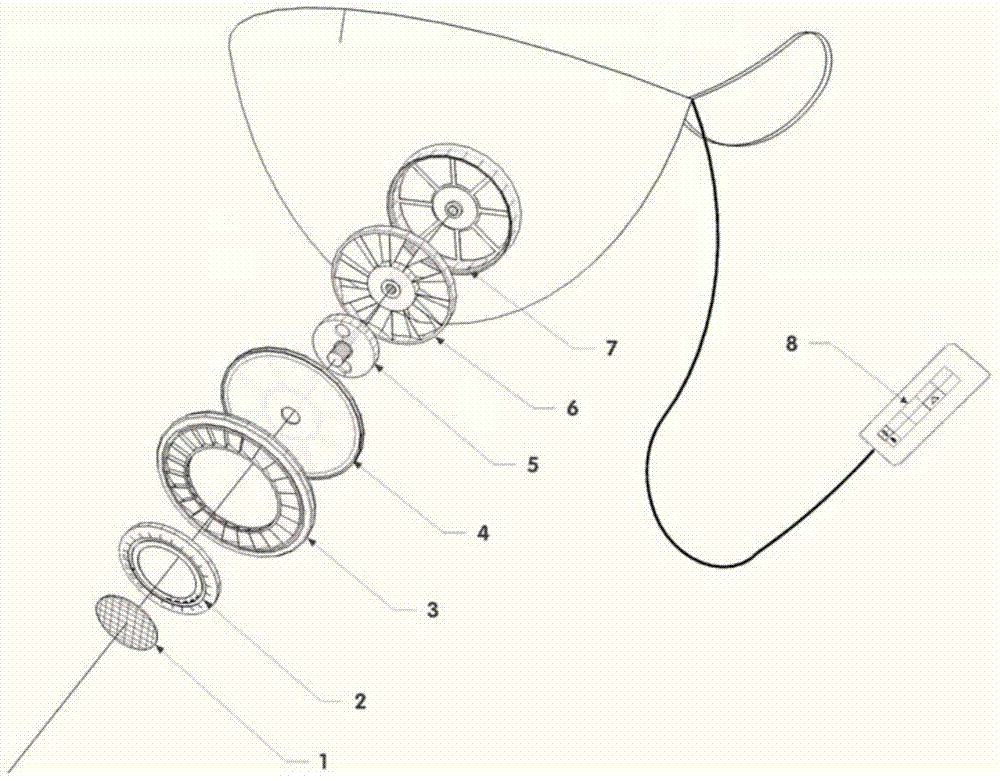

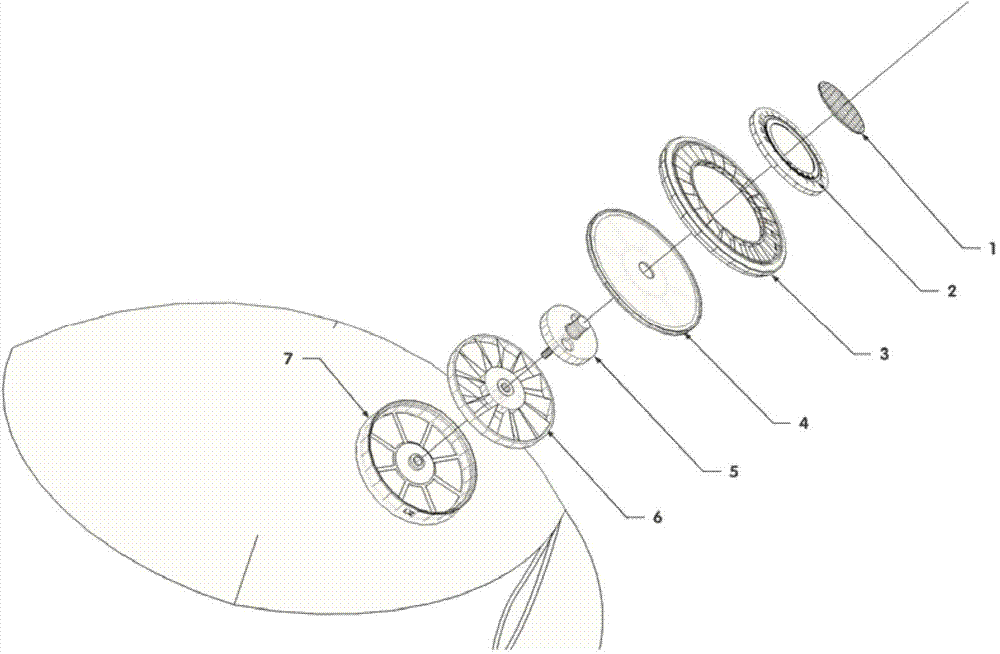

Anti-dust respirator with intelligent breathing ring

InactiveCN104705842ASimple structureSolve efficiency problemsProtective garmentMagnetic bearingRespirator

The invention provides an anti-dust respirator with an intelligent breathing ring. According to the technical scheme, the anti-dust respirator comprises a respirator body and the intelligent breathing ring, wherein the respirator body and the intelligent breathing ring are detachably connected in a spirally buckled mode. The respirator body is provided with a breathing ring base. A fixed shaft is arranged at the center of the breathing ring base. The exterior of the intelligent breathing ring is in a transparent organic plastic cylinder shape. The intelligent breathing ring internally comprises a flow guide fan blade, a magnetic bearing motor, a filter cotton web, a flow guide grating cover and a filter efficacy ring. The filter efficacy ring is connected with the flow guide grating cover in a buckled mode. The two ends of the magnetic bearing motor are connected with the filter cotton web and the flow guide fan blade respectively. The end of the filter cotton web is embedded into the outer ring of the flow guide grating cover. The end of the flow guide fan blade is connected with the breathing ring base. The breathing ring base, the flow guide fan blade, the magnetic bearing motor, the filter cotton web, the flow guide grating cover and the filter efficacy ring are connected into a whole through the fixed shaft of the breathing ring base in a penetrating and sleeving mode, driven by the magnetic bearing motor and assembled into a small fan through mechanical connection and leads filtered air into the respirator body. The anti-dust respirator with the intelligent breathing ring is simple in structure, the plastic parts are low in weight, assembling, maintaining and replacing are convenient, and the anti-dust respirator has remarkable economic benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

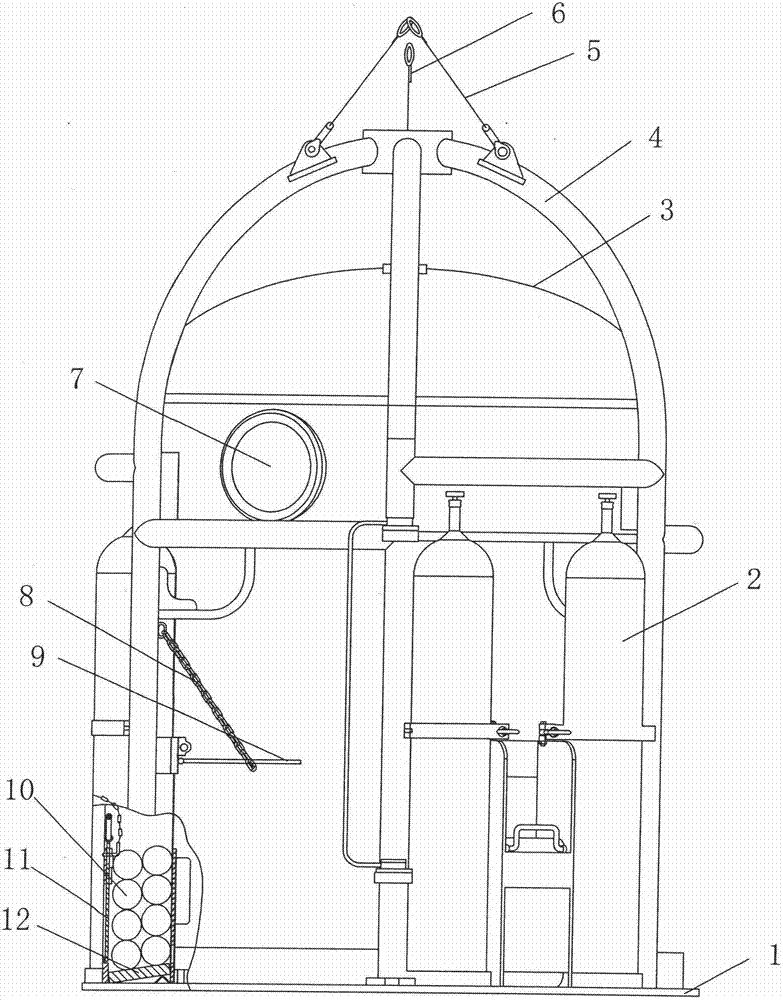

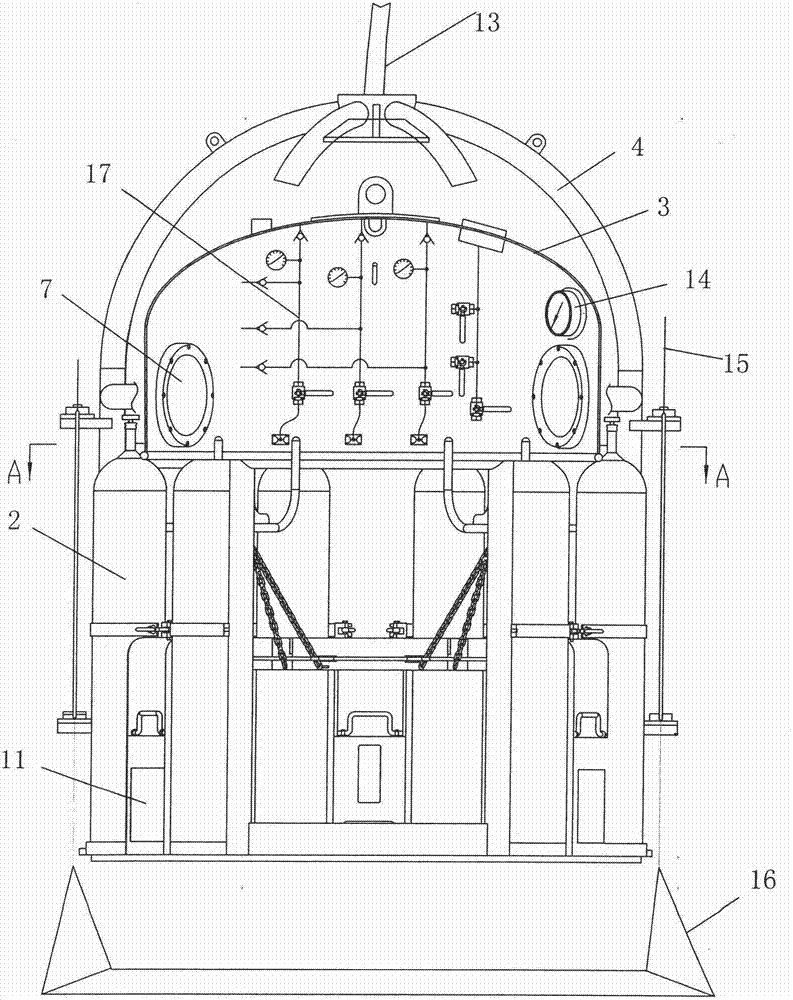

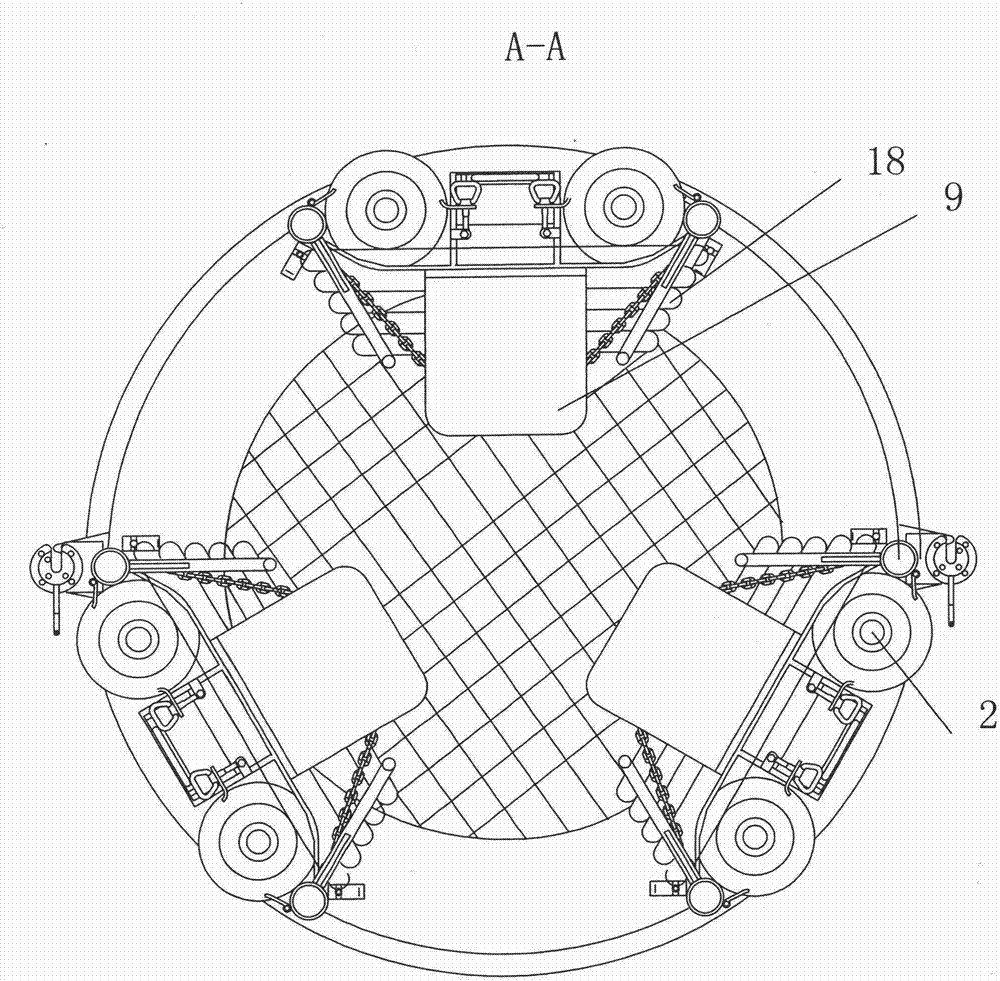

Deepwater open diving bell and self-rescuing method thereof

The invention discloses a deepwater open diving bell and a self-rescuing method thereof. The deepwater open diving bell comprises a platform and is characterized in that a bell jar is hung above the platform, a space between the top of the bell jar and the platform is adaptive to the height of a human body, a main belly belt is connected to the top of the bell jar, a basic surviving device is arranged in the bell jar, viewing windows capable of viewing situations outside the bell are formed in the side wall of the bell jar, and a guiding weight is arranged at the lower part of the platform. Due to the adoption of the technical scheme of the deepwater open diving bell and the self-rescuing method thereof, the 120 meters of diving depth of the diving bell is realized, the simultaneous diving of three users is satisfied, and the working efficiency of diving operation is improved.

Owner:上海打捞局芜湖潜水装备厂有限公司

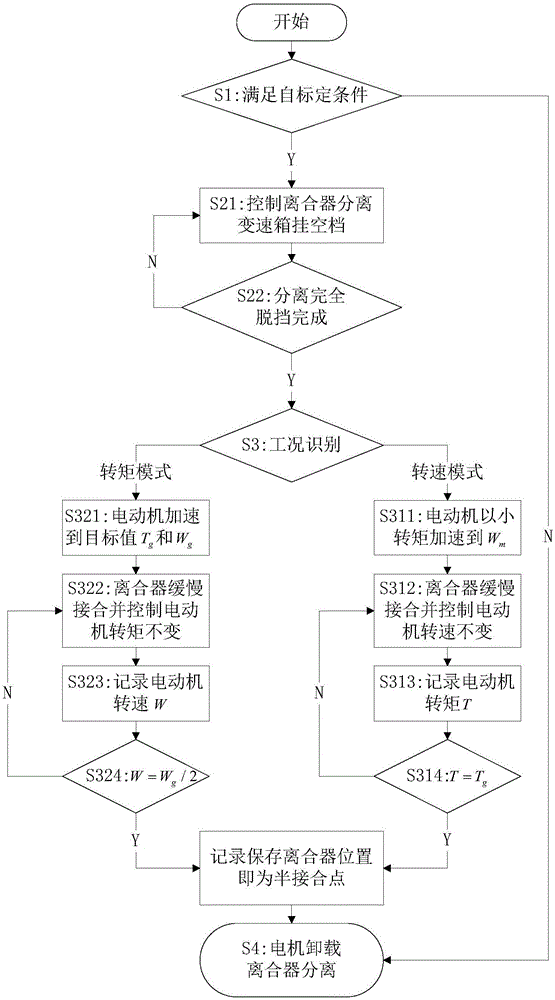

Clutch self-calibration method of hybrid electric vehicle and application of clutch self-calibration method

ActiveCN106043273AAccurate engagement and disengagementGuaranteed weight and costClutchElectric vehicle

The invention relates to a clutch self-calibration method of a hybrid electric vehicle and application of the clutch self-calibration method. The clutch self-calibration method includes the steps that whether the hybrid electric vehicle meets a self-calibration condition or not is judged; a clutch is completely separated, and a neutral gear of a gearbox is engaged; according to the travel working condition, the calibration mode suitable for the rotation speed or the calibration mode suitable for the torque is selected, and the position of a half-engaged point of the clutch is observed and recorded when a calibration parameter reaches a threshold value; a motor is detached, the clutch is gradually separated, the whole vehicle is powered off, and calibration is finished. By the adoption of the method, the calibration mode suitable for the rotation speed or the calibration mode suitable for the torque can be selected according to the travel working condition, the position of the half-engaged point of the clutch is observed and recorded when the calibration parameter reaches the threshold value, the position of the half-engaged point of the clutch is automatically calibrated with the assistance of existing equipment of the whole vehicle, and the interference factors of a sensor in the actual working condition can be avoided as well.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

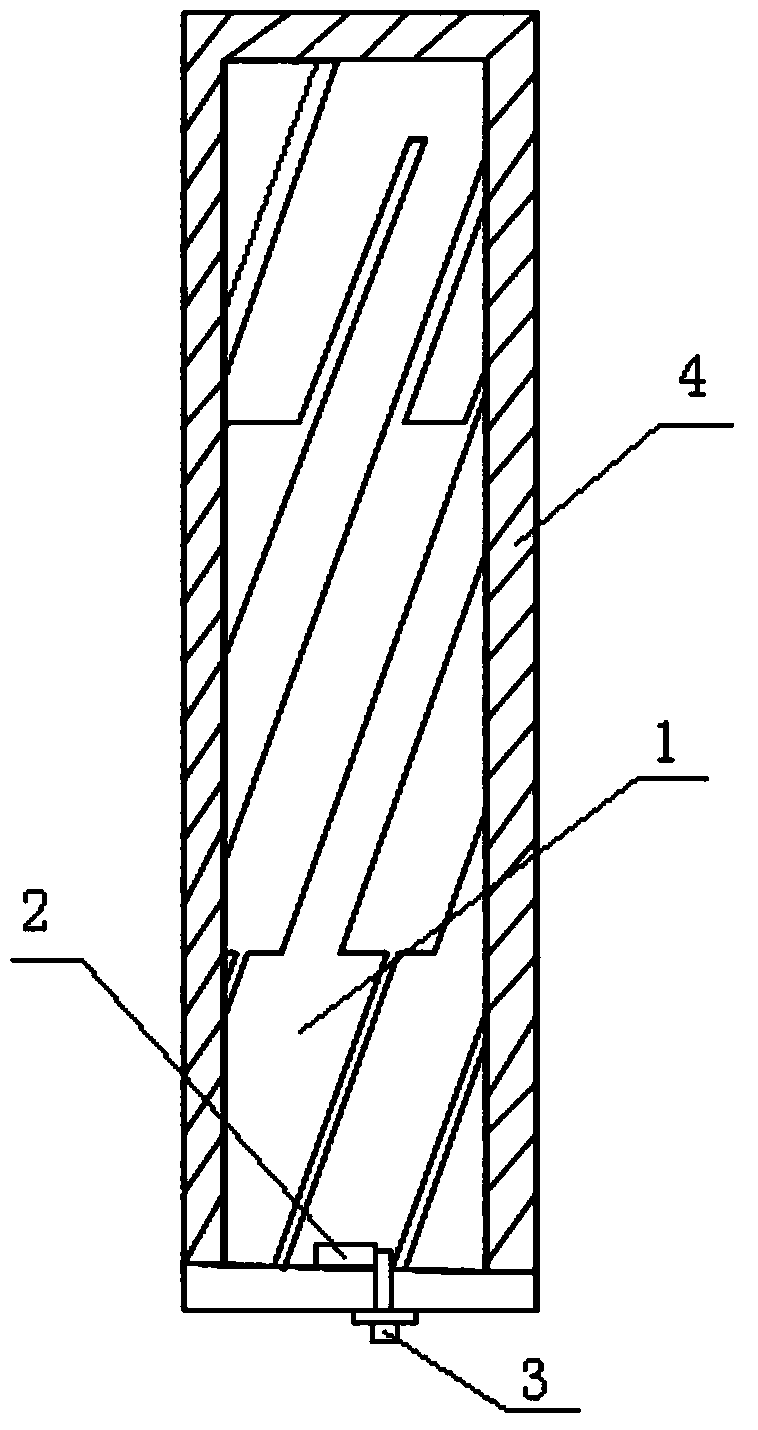

Handset terminal antenna for mobile satellite communication system

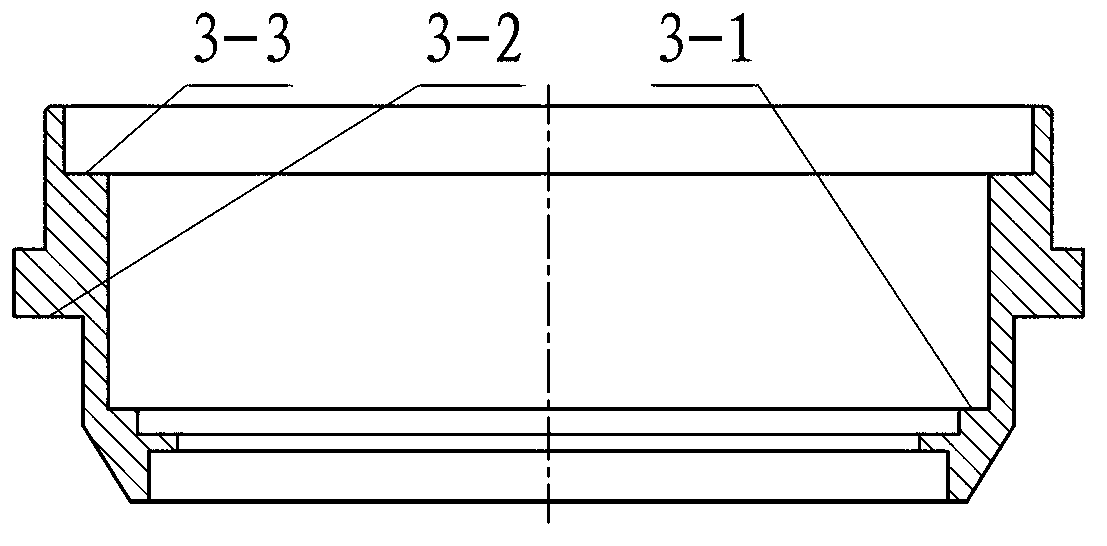

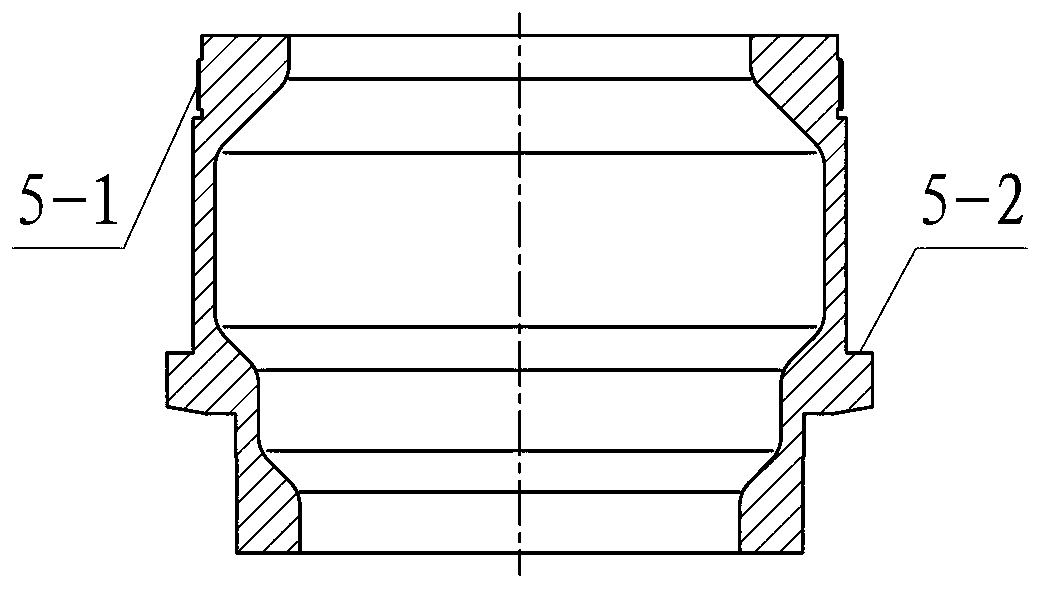

ActiveCN104332704AGuaranteed volumeGuaranteed weightSimultaneous aerial operationsRadiating elements structural formsDielectric cylinderComputer terminal

The invention discloses a handset terminal antenna for a mobile satellite communication system. The handset terminal antenna comprises a four-arm spiral antenna, a circular polarization network component and an antenna shell, wherein the four-arm spiral antenna comprises first to fourth helical arm patches and a dielectric cylinder; the first to fourth helical arm patches are printed on the outer wall of the dielectric cylinder; the dielectric cylinder is fixedly arranged on the circular polarization network component; the antenna shell is arranged on the outer side of the dielectric cylinder; the circular polarization network component comprises first to fourth micro-strip patches and an LTCC (Low Temperature Co Fired Ceramic) circular polarization network; certain ends of the first to fourth micro-strip patches are connected with four output ports of the LTCC circular polarization network respectively, and the other ends of the first to fourth micro-strip patches are connected with the first to fourth helical arm patches respectively; an input port of the LTCC circular polarization network is a radio frequency connector; the radio frequency connector is connected with a radio frequency circuit of a handset terminal.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

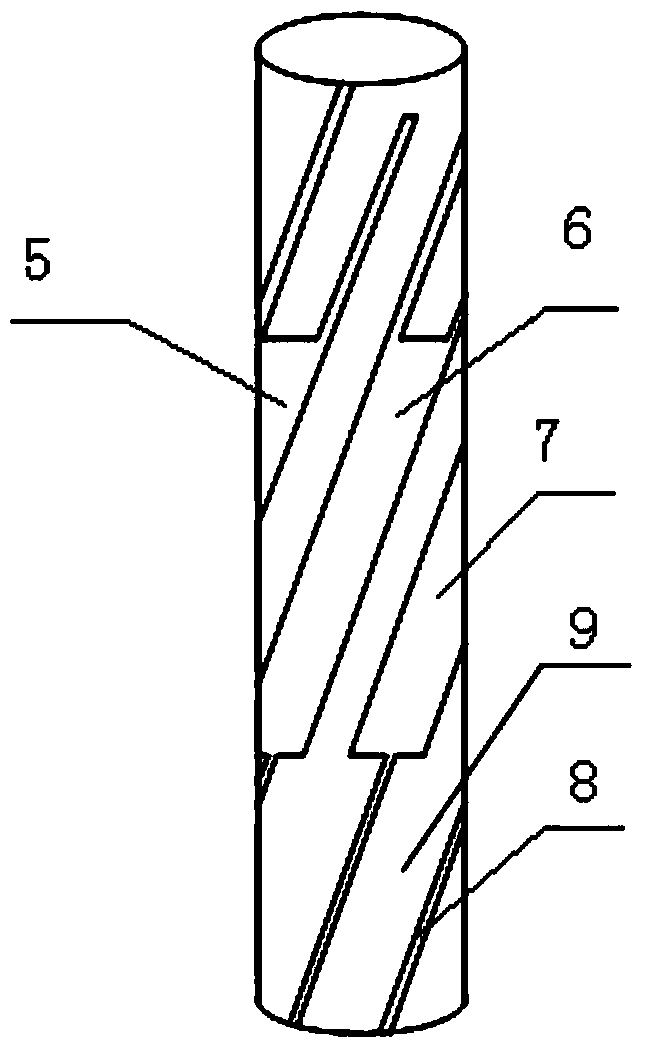

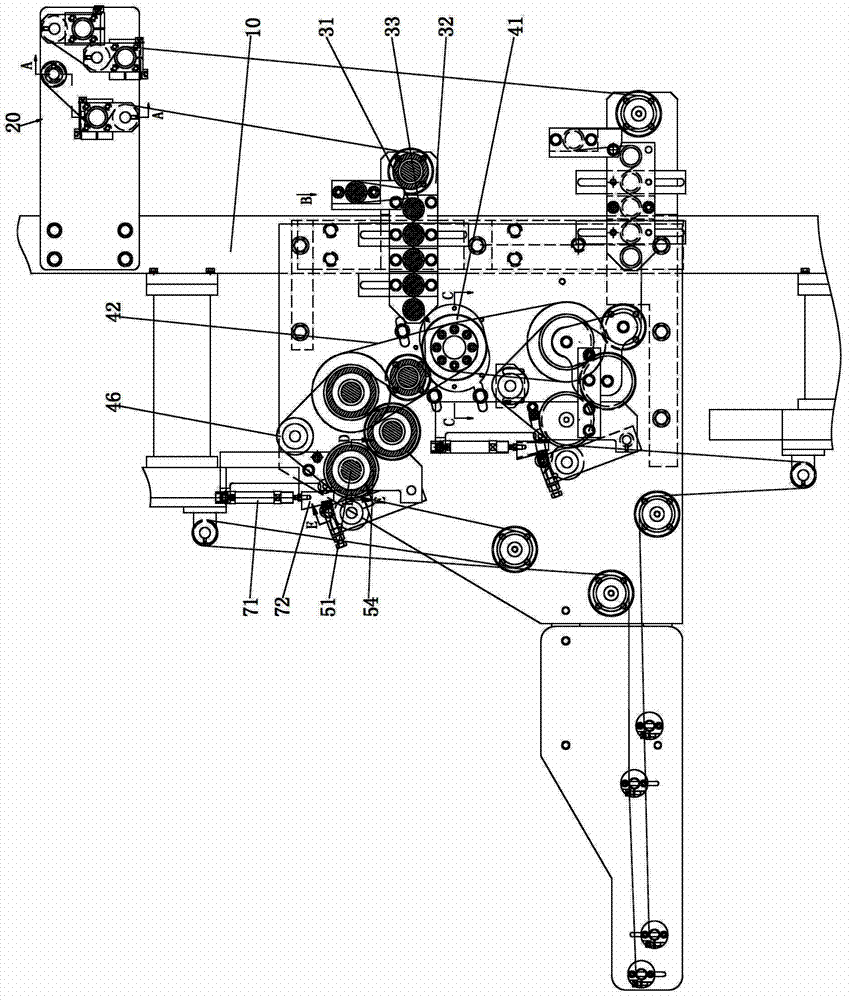

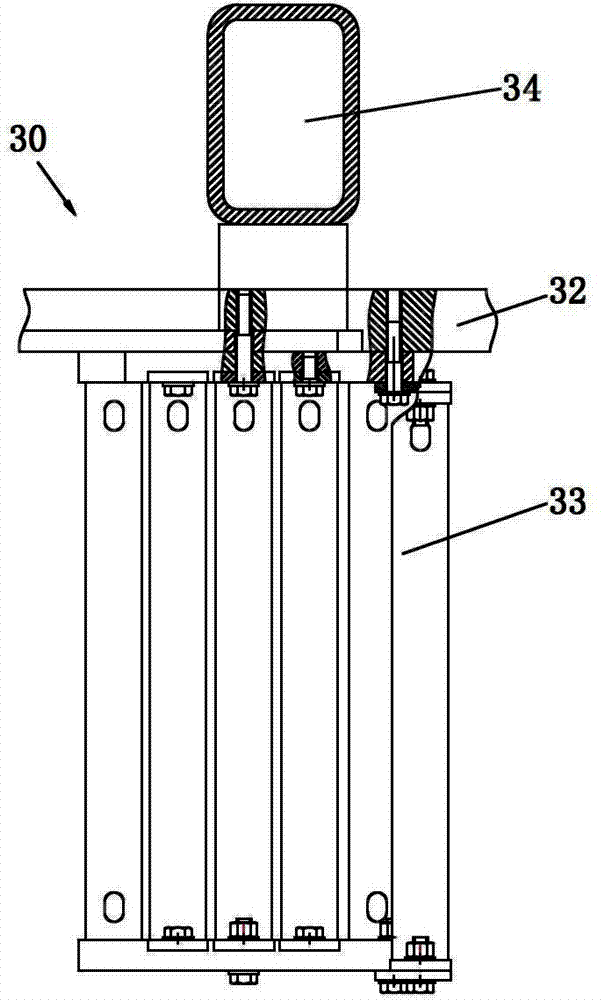

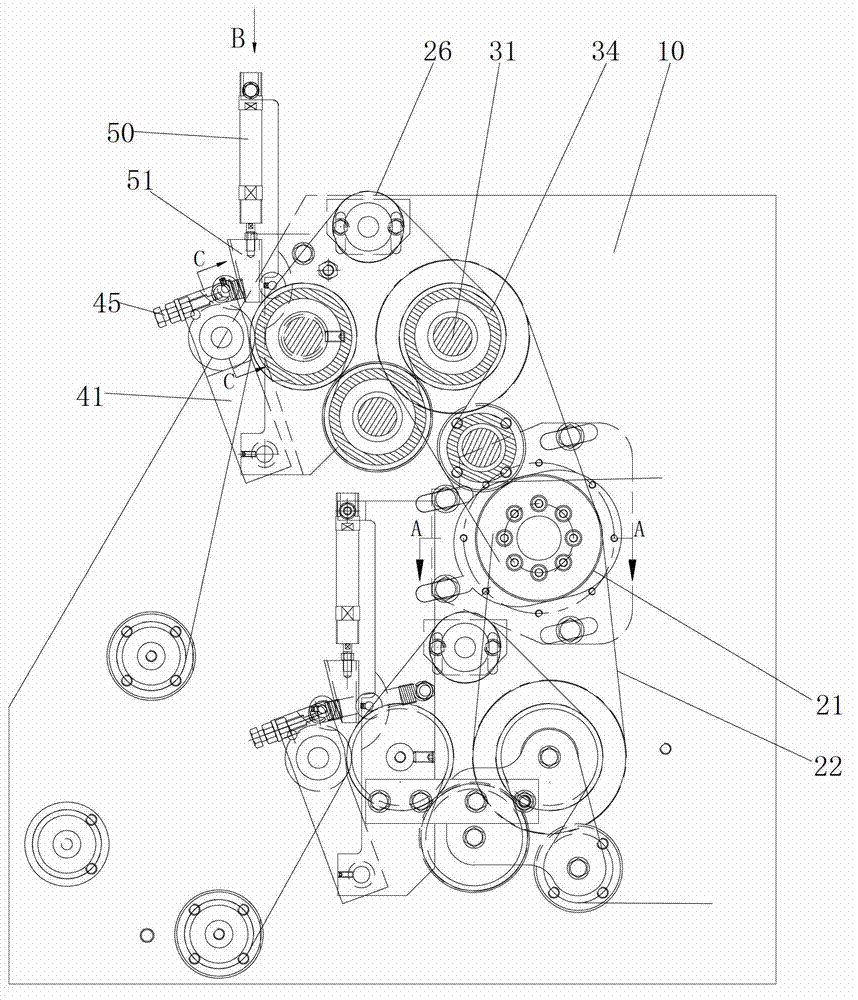

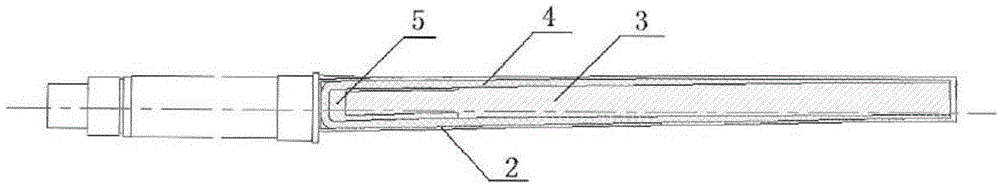

Carbon fiber yarn fiber-stretching mechanism

The invention relates to a carbon fiber yearn fiber-stretching mechanism. A yarn guide device is fixed on the upper part of a bracket; the guide device guide input carbon fiber yarns and applies tensile force to act the carbon fiber yarns; a heating and fiber-stretching device is fixed on the bracket and arranged on the downstream of the yarn guide device; the heating and fiber-stretching device heats up the passed carbon fiber yarns, so that the carbon fiber yarns are stretched; a synchronous drive device is fixed on the middle part of the bracket; the synchronous drive device drives a roller fiber-stretching device to rotate so as to drive the carbon fiber yarns to continuously move; the roller fiber stretching device is fixed on the bracket and arranged on the downstream of the heating and fiber stretching device; and the roller fiber stretching device re-stretches the carbon fiber yarns which are stretched by the heating and fiber stretching device.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

A method and a system for predicting resources based on edge computation

InactiveCN109067583AGuaranteed precisionGuaranteed weightData switching networksForward propagationInterference factor

The invention provides a method and a system for predicting resources based on edge computation. In the process of prediction object conversion and pretreatment, noise and other interference factors are effectively avoided, which improves the accuracy and robustness of the prediction. The middle layer design of the model incorporates as much a priori information as possible to ensure that the correction of prediction value and the update of the weight of the resource prediction model are carried out according to the facts. The forward propagation and backward propagation of the loop make the error of the predicted value decrease and converge gradually. At the same time, the corresponding judgment conditions are set up to ensure the effective process of the loop propagation and transmission.

Owner:SHENZHEN INST OF ADVANCED TECH

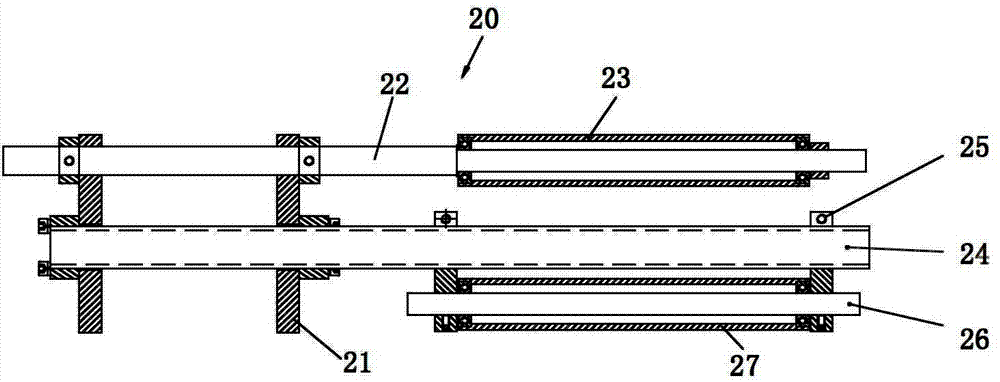

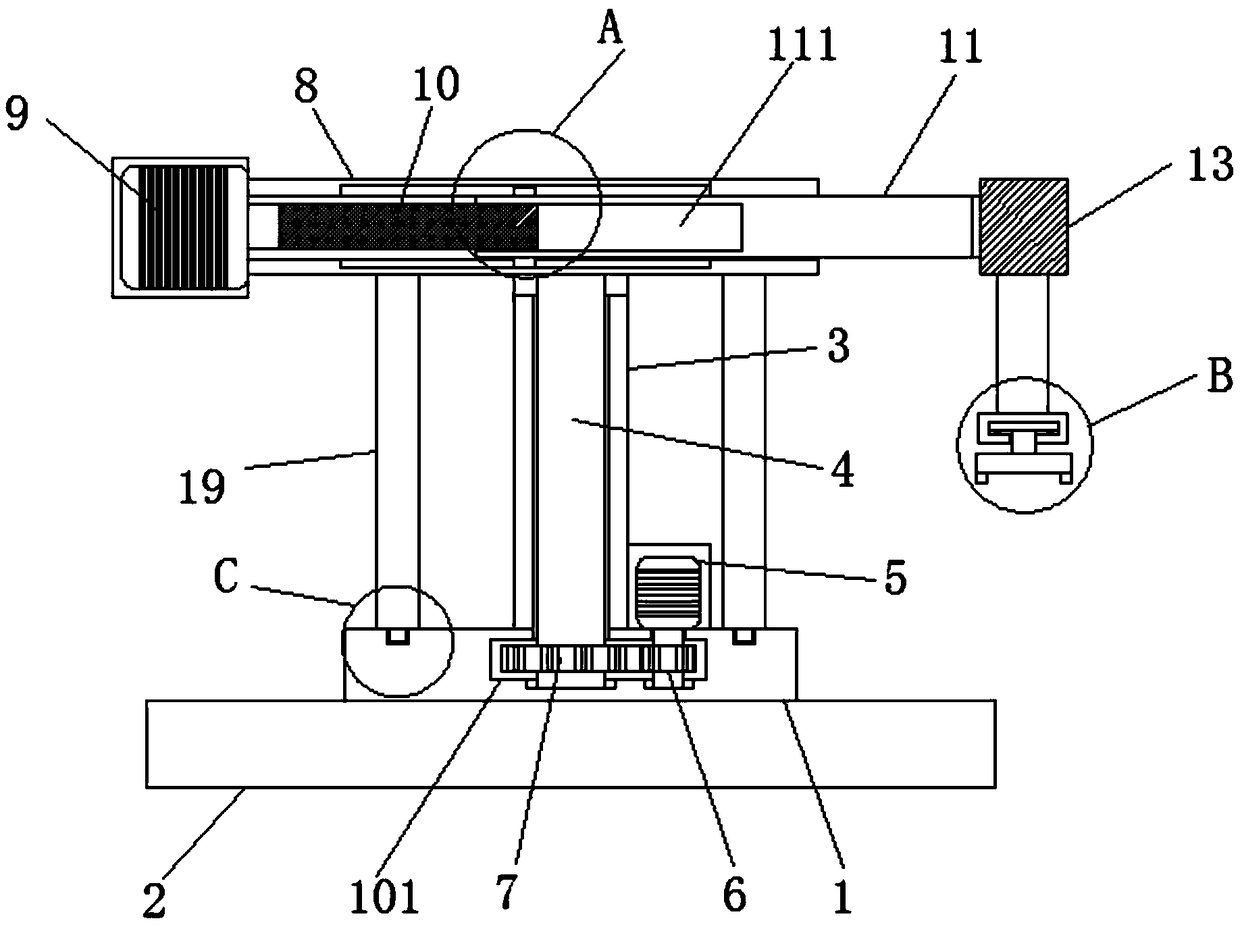

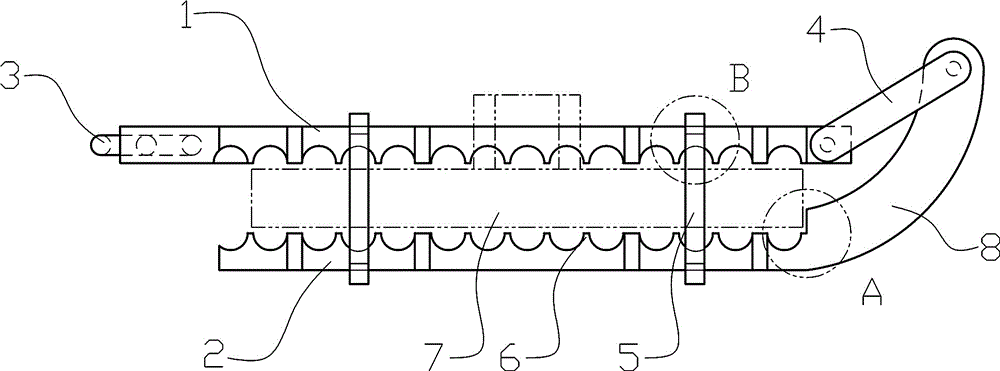

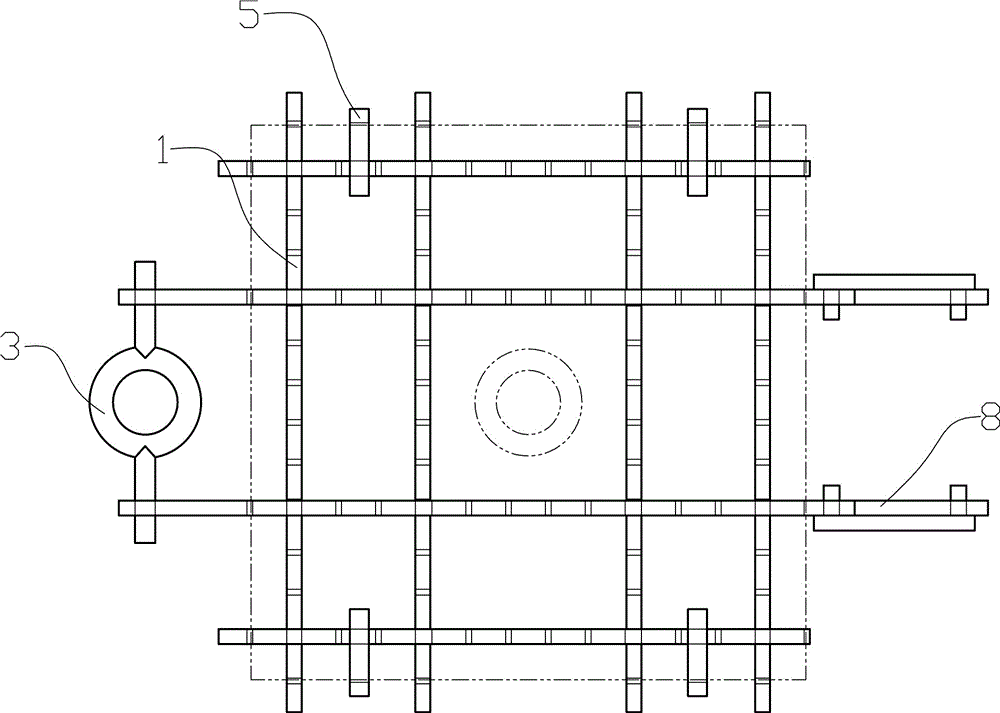

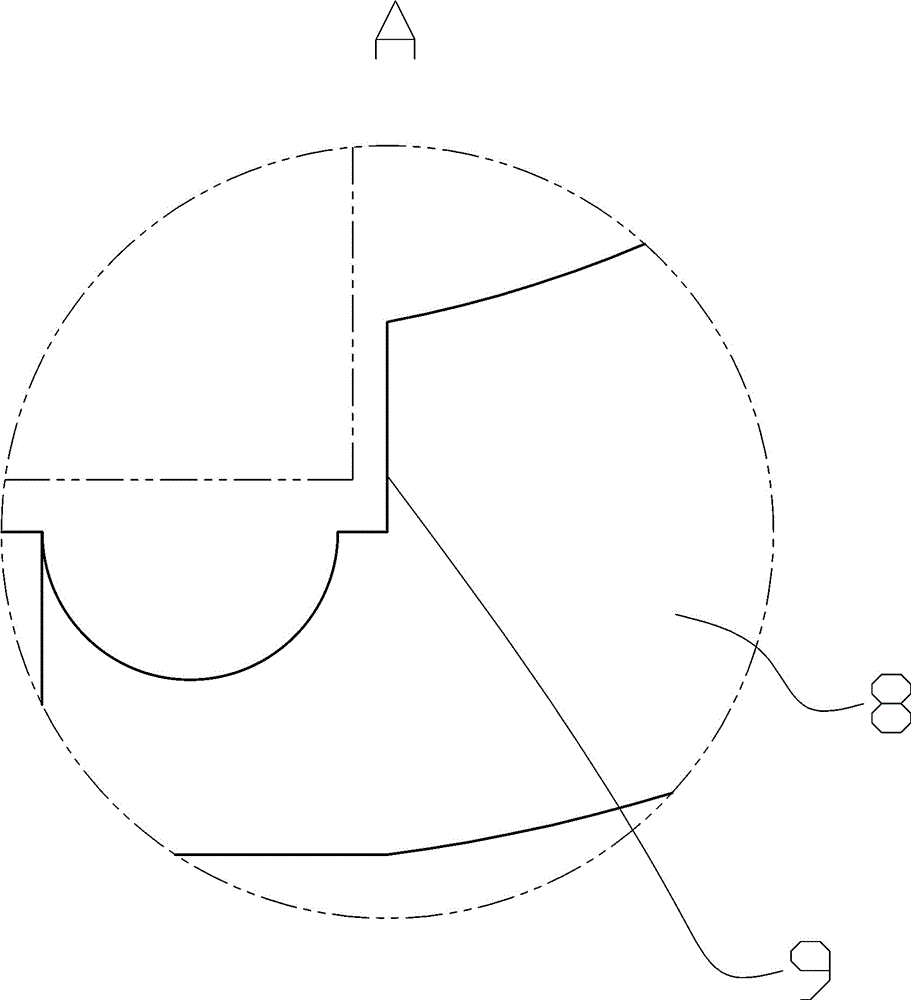

Fiber spreading traction device

The invention relates to a fiber spreading traction device which comprises a support, a synchronous driving device, a roller fiber spreading device, a tension balance fiber spreading device and an extensible thrusting device capable of pushing the tension balance fiber spreading device to achieve opening and closing. The synchronous driving device is fixed in the middle of the support, and the roller fiber spreading device is fixed on the support and connected with the synchronous driving device through a transmission belt. The tension balance fiber spreading device is located on the downstream of the roller fiber spreading device, one end of the tension balance fiber spreading device is hinged to the support, the other end of the tension balance fiber spreading device is connected with the roller fiber spreading device through a tension spring, and the extensible thrusting device is fixed on the support and located above the tension balance fiber spreading device. The fiber spreading traction device can spread carbon fibers to be wide, thin and flat.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

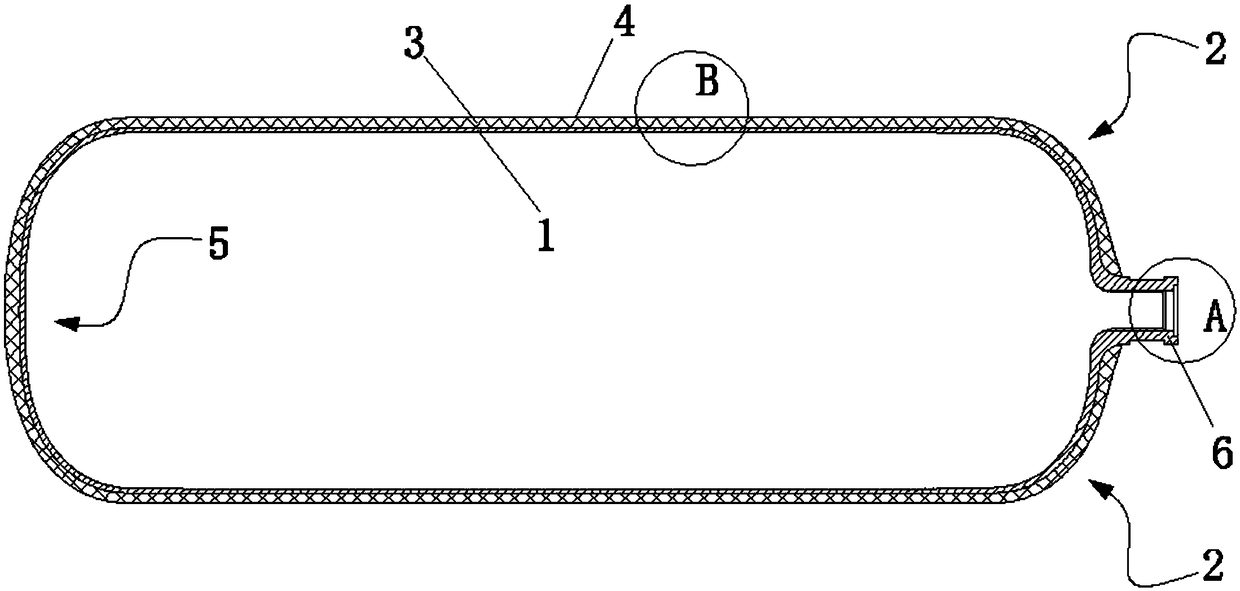

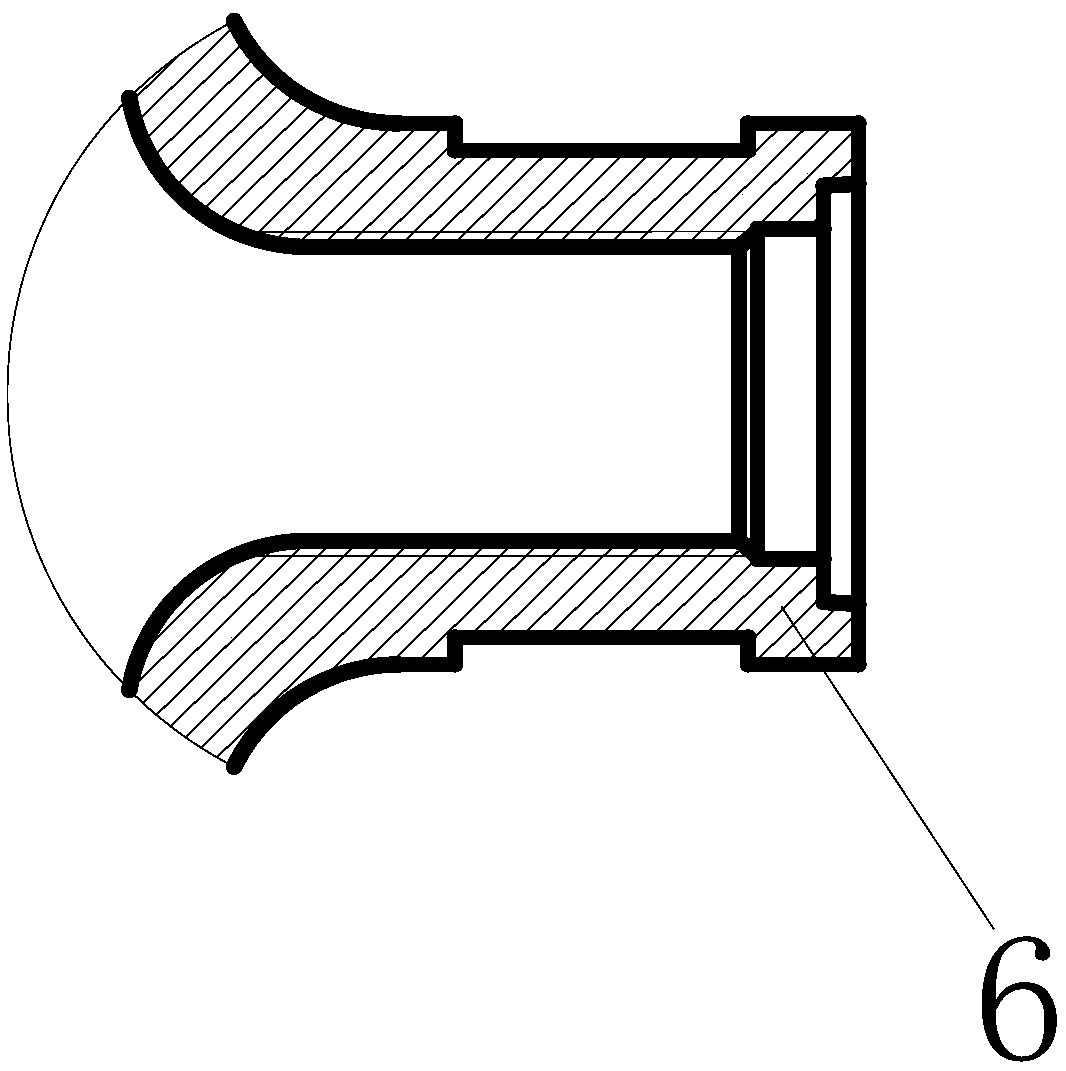

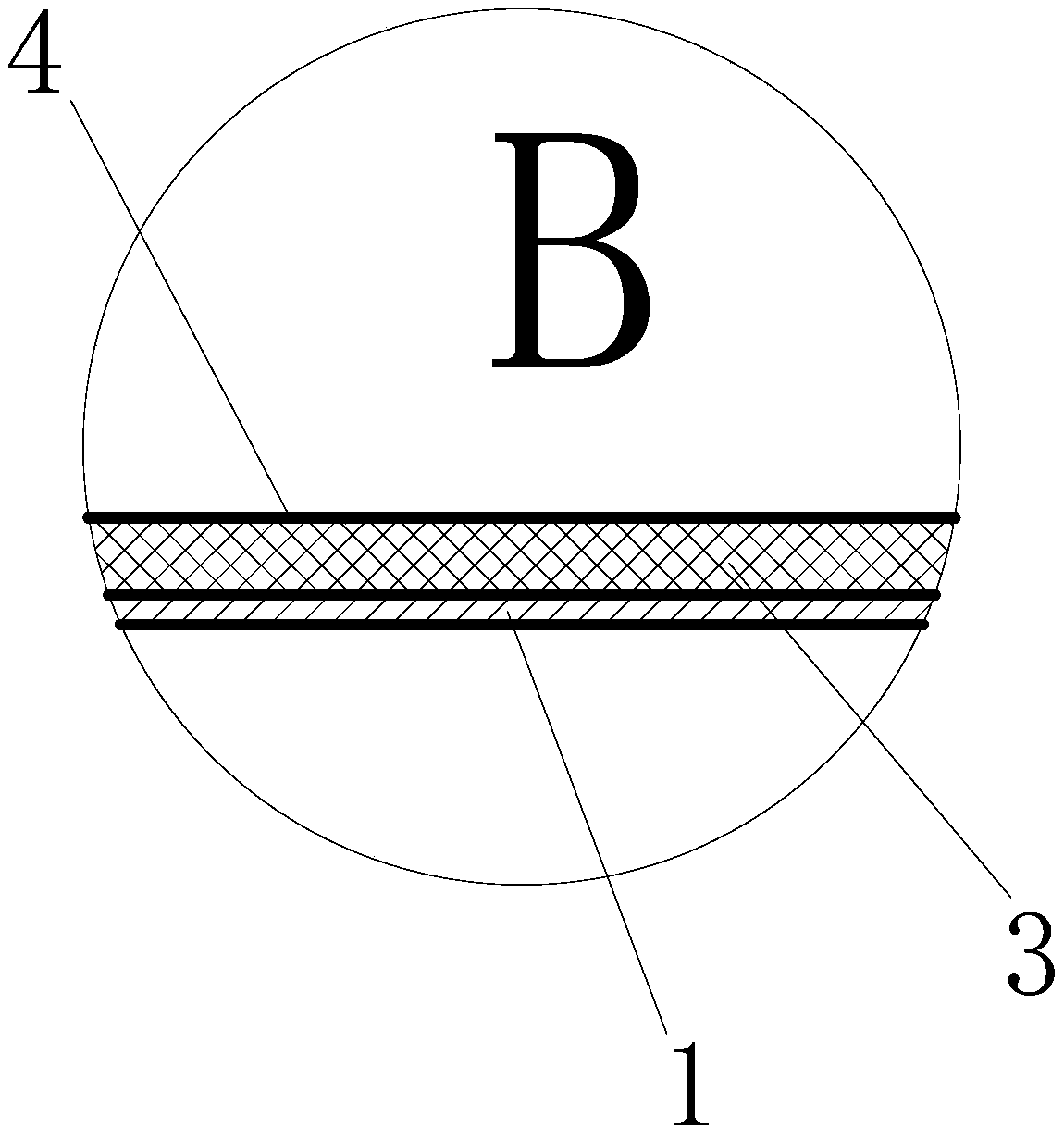

High-pressure gas storage cylinder of fuel cell unmanned aerial vehicle and preparation method thereof

PendingCN108758324ASimple structureScientific and reasonable designVessel manufacturingVessel geometry/arrangement/sizeAutomotive engineeringHigh weight

The invention discloses a high-pressure gas storage cylinder of a fuel cell unmanned aerial vehicle and a preparation method thereof and solves the problem that the endurance performance of the unmanned aerial vehicle is seriously influenced due to high weight and low hydrogen storage density per unit weight in the prior art. The high-pressure gas storage cylinder of the fuel cell unmanned aerialvehicle is punched, drawn and molded by aluminum plates; the high-pressure gas storage cylinder comprises a front sealing head and a rear sealing head which are respectively molded at the front and the rear end and also comprises an aluminum inner container used for storing hydrogen gas, a cylinder opening formed in the front sealing head and a strength layer, wherein the strength layer is prepared from a carbon fiber-epoxy system composite material and is crossed, folded and wound on the outer wall of the aluminum inner container through circular, longitudinal, and spiral manners. The preparation method of the high-pressure gas storage cylinder comprises the following steps: step one, manufacturing the aluminum inner container; step two, winding the strength layer; and step three, coatinga photocurable resin layer. The high-pressure gas storage cylinder is simple in structure, scientific and reasonable in design, convenient to use, light in weight, excellent in pressure-resistant property and excellent in fatigue property, and is capable of effectively improving the endurance performance of the unmanned aerial vehicle.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

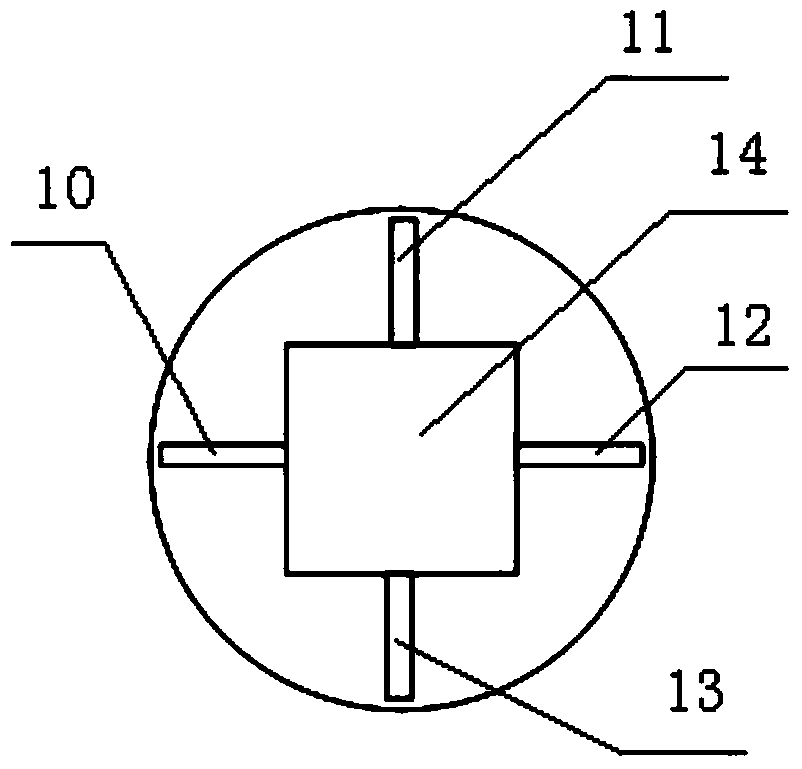

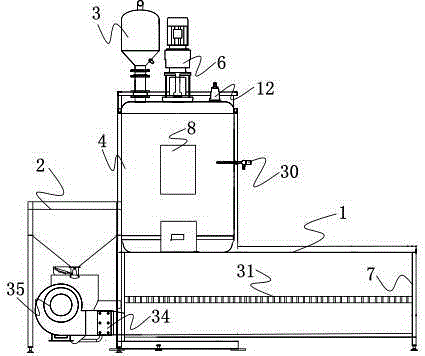

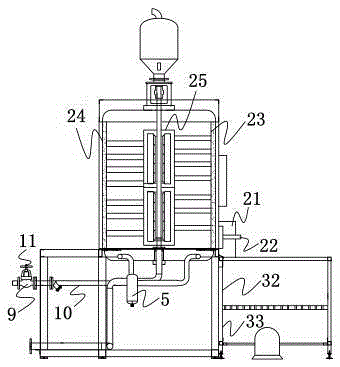

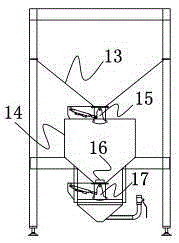

Full-automatic intermittent type pre-foaming machine

The invention discloses a full-automatic intermittent type pre-foaming machine. A steam conveying pipeline is communicated with the bottom end of a pre-foaming machine barrel. A negative-pressure feeding device is connected with a metering weighing device and provided with a vacuum generator used for sucking in raw materials in the metering weighing device. The negative-pressure feeding device is arranged above the pre-foaming machine barrel and communicated with the pre-foaming machine barrel. A stirring device is arranged above the pre-foaming machine barrel. The stirring device is provided with a cross-shaped stirring block used for stirring the raw materials in the pre-foaming machine barrel. A sensor used for detecting the foaming degree is arranged on the inner wall of the pre-foaming machine barrel. The pre-foaming machine barrel is connected with a vulcanization drying device. The steam conveying pipeline, the pre-foaming machine barrel and a control system are installed on a rack. The rack is further provided with a power-off protection device connected with the pre-foaming machine barrel to prevent the raw materials in the pre-foaming machine barrel from being bonded after powering off. The full-automatic intermittent type pre-foaming machine can carry out effective drying, foaming particles are not bonded after powering off, the automation degree is high, stirring is even, and efficiency is high.

Owner:QINGDAO HEINOSKY TECH CO LTD

Rotary carrying robot

InactiveCN108638050AAchieve rotationSmooth rotationProgramme-controlled manipulatorHydraulic cylinderGear wheel

The invention discloses a rotary carrying robot. The rotary carrying robot comprises a base, wherein the lower side of the base is fixedly connected with the upper side of an operation platform; a vertical pipe is fixedly connected above the base; a main shaft penetrates and rotationally sleeves into the vertical pipe; a second transmission gear sleeves the lower end of the main shaft; a first motor is arranged at one side of the vertical pipe; a first transmission gear is arranged at one end of an output shaft of the first motor; the first transmission gear is in transmission engagement withthe second transmission gear; the upper end of the main shaft is fixedly connected with the lower side of a transversal pipe; and a second motor is arranged at one end of the transversal pipe. The rotary carrying robot is simple in structure; the function of rotating the transversal pipe is realized through the first motor; the function of telescoping of a slide rod is realized through the secondmotor; the lifting function of a clamp is realized through a hydraulic cylinder; and the weight of an object clamped by the clamp is detected through a gravity sensor between a connection plate and aconnection block.

Owner:佛山市高芯科技服务有限公司

Extravehicular conversion cabin device of underwater vehicle staff

InactiveCN101643112ASimple structureGood reliabilityUnderwater vesselsUnderwater equipmentDrainage volumeUnderwater vehicle

The invention relates to an extravehicular conversion cabin device of the underwater vehicle staff, which is characterized by comprising an access cabin and a dry-type cabin which are adjacently arranged in an underwater vehicle, a watertight cabin door is arranged between the access cabin and the dry-type cabin, the access cabin is provided with a water replacing cabin, the capacity of which is slightly more than that of the remaining space of the access cabin except frogmen; the dry-type cabin is provided with at least one surge tank, the capacity of which is slightly more than drainage volume of frogmen; the water replacing cabin is connected with the access cabin through a pipeline and a pump, and the surge tank is connected with the access cabin through a pipeline and a pump. The extravehicular conversion cabin device of the underwater vehicle staff of the invention has simple structure, good reliability and low manufacturing cost; utilizes water to be replaced to convert back and forth among the access cabin, the water replacing cabin and the surge tank, ensures that buoyancy weight and dynamic equilibrium of floating state of the underwater vehicle in the process of gettingin and out the cabin of the frogmen, and leads the underwater vehicle to be kept in a stable floating state, thus reducing the probability of collision accident occurring between the underwater vehicle and water bottom or between the underwater vehicle and obstacles.

Owner:中国船舶重工集团公司第七〇二研究所

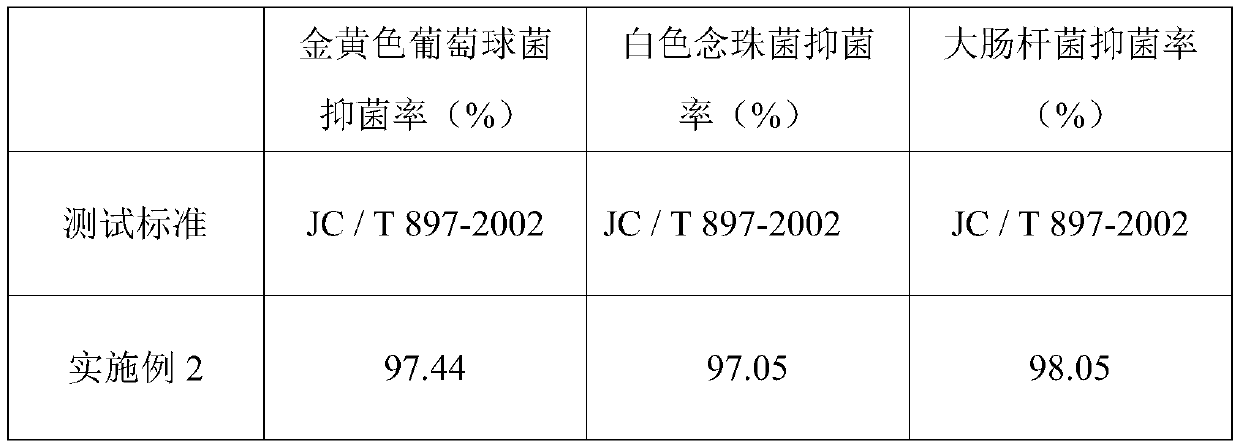

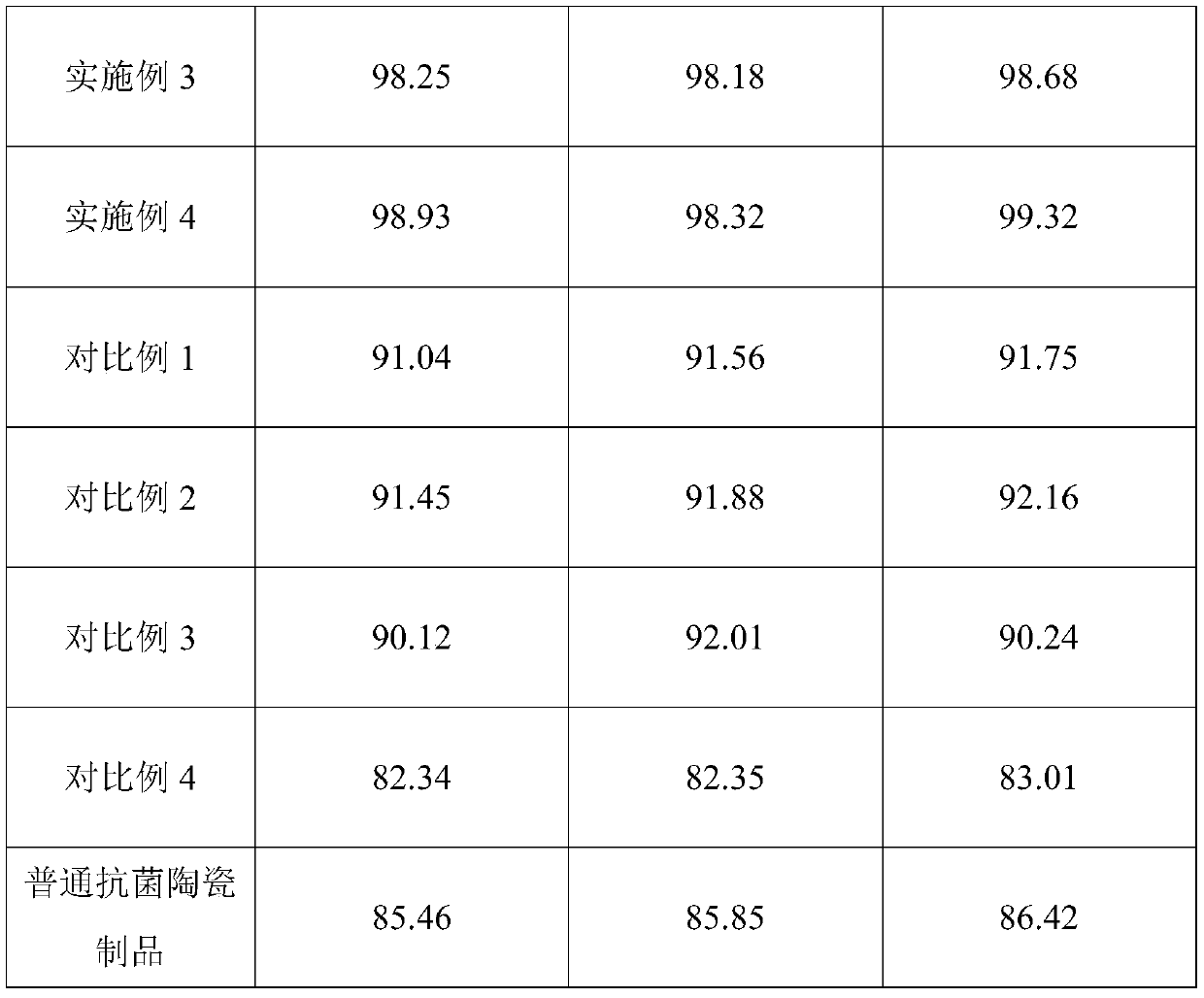

Antibacterial ceramic product and preparation method thereof

The invention discloses an antibacterial ceramic product. The antibacterial ceramic product comprises a body and a surface glaze layer; the body is prepared from, by weight, 21-28 parts of potash feldspar, 14-16 parts of marbles, 16-22 parts of fluorite, 18-25 parts of purple gold soil, 12-14 parts of kaolin, 9-12 parts of quartz and 3.5-4.5 parts of silicon carbide fiber; and the surface glaze layer is prepared from, by weight, 16-20 parts of albite, 7-9 parts of fluorite, 12-16 parts of glass, 20-24 parts of quartz, 5.5-7.5 parts of talcum, 19-22 parts of zinc oxide, 4-6 parts of barium oxide, 8-13 parts of kaolin, 4-7 parts of high-boron frits and 12-17 parts of a silver-supported antibacterial agent. The antibacterial ceramic product of the invention has a good antibacterial effect, and also has functions of sterilization, disinfection and deodorization; and the comprehensive performances such as the appearance, the strength, the weight and the water absorption rate of the ceramicproduct are ensured; and the sintering molding temperature is low, so energy saving and environmental protection are achieved.

Owner:福建省德化县臻晖陶瓷有限公司

High-transparency polyethylene thermo-contracted film and producing method thereof

High-transparency polyethylene heat-shrinkable film is made by compounding, mixing, extrusion blow molding of a mixture consisting of metallocene LDPE, linear LDPE, LDPE and additives. The extruder is a single-screw extruder, and the processing temperature of extrusion blow molding is 160-200°C. The product of the invention has high transparency, bright and vivid appearance after printing, stable packaging and stacking, and is suitable for mechanized production. The product of the invention can be applied to packaging materials such as agricultural products, daily necessities, cosmetics, detergents, food, medicine, and beverages.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

Quenching anti-deformation device and method

ActiveCN106367570AAvoid deformationControl deformationFurnace typesHeat treatment furnacesEngineeringQuenching

The invention provides a quenching anti-deformation device and method. A lower pressing frame is hinged to an upper pressing frame through a connecting rod, and a space used for pressing a workpiece is formed between the lower pressing frame and the upper pressing frame. The lower pressing frame and the upper pressing frame are connected in a pressing mode through a plurality of pressing claws. The pressing claws are in a C shape. An extending part is arranged on one side of the lower pressing frame or the upper pressing frame. A turning ring is rotationally connected with the extending part. Through the locked upper pressing frame and the lower pressing frame, enough pressing strength is achieved so that deformation during quenching of the workpiece can be prevented, the deformation amount of the workpiece can be controlled and is smaller than 5 mm, subsequent machining is well guaranteed, and the product quality is improved. Through the arrangement of the turning ring, the large-sized workpiece can be heated in the horizontal state, after heating is completed, the turning ring is hooked with a hoisting device, a workpiece (7) is hoisted vertically and placed in a quenching bath to be quenched, energy consumption is reduced, and the quenching quality is improved.

Owner:YICHANG MARINE DIESEL ENGINE

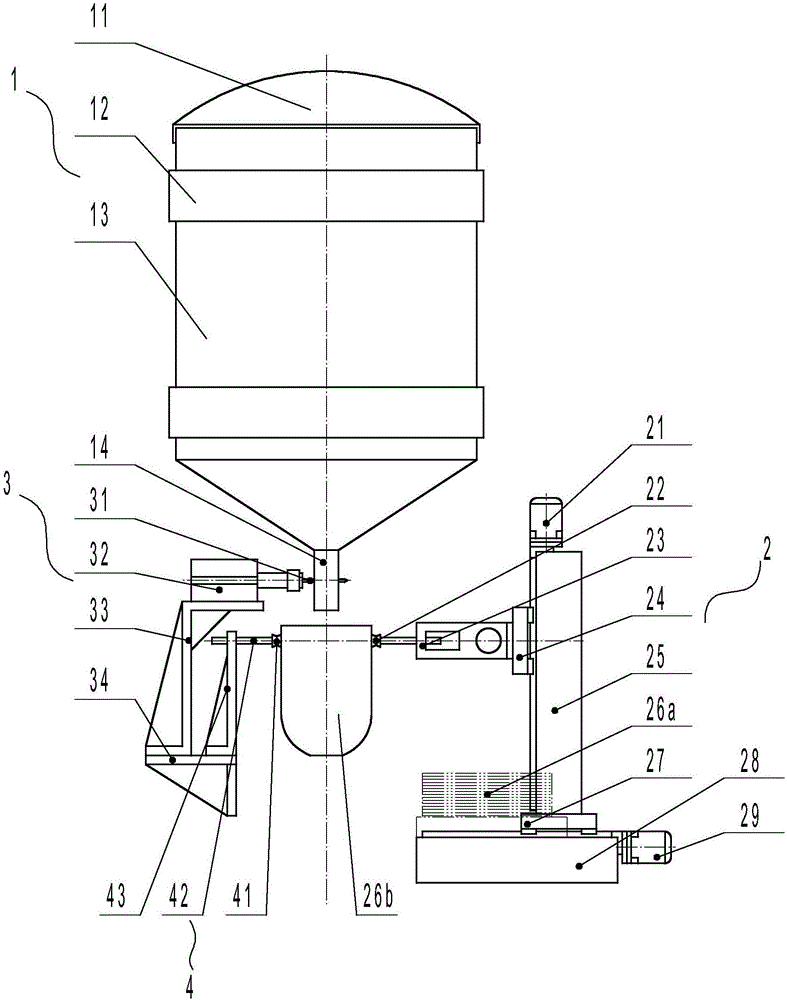

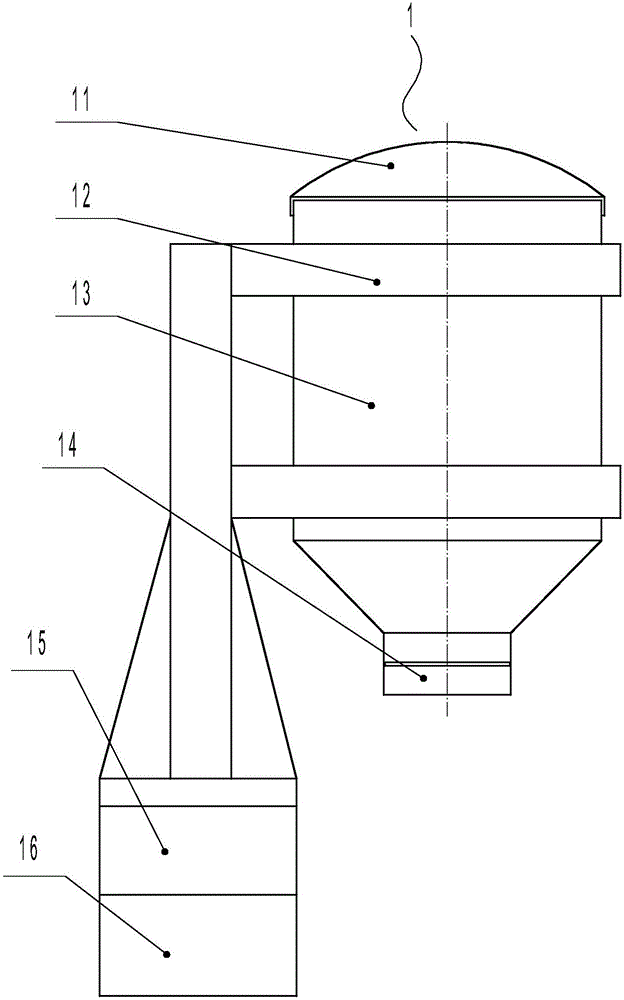

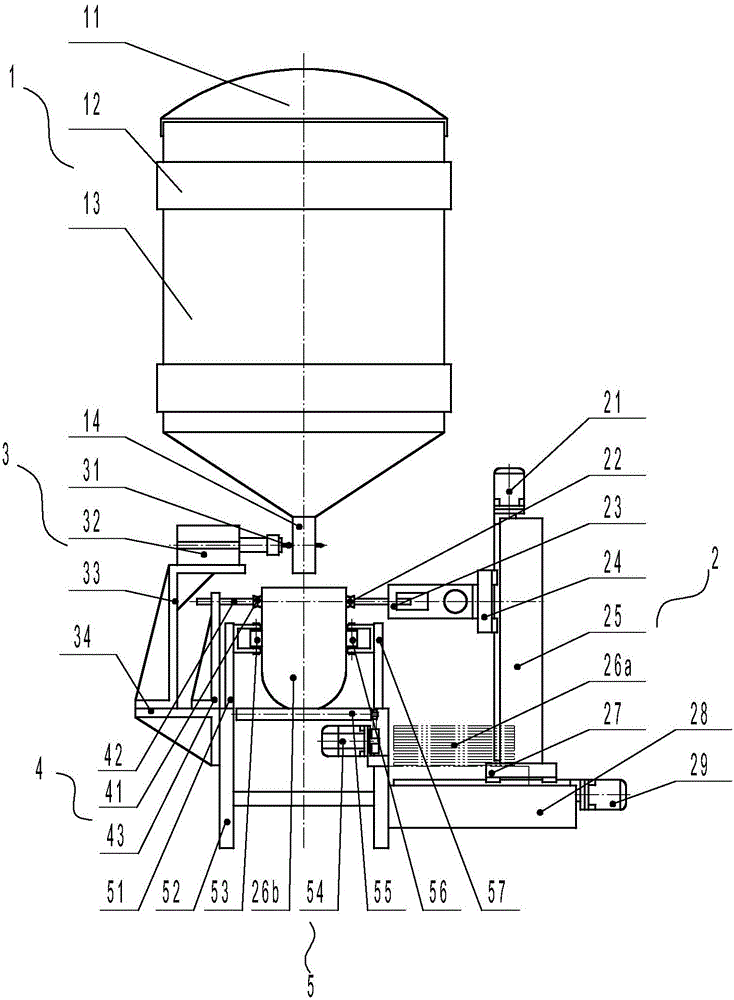

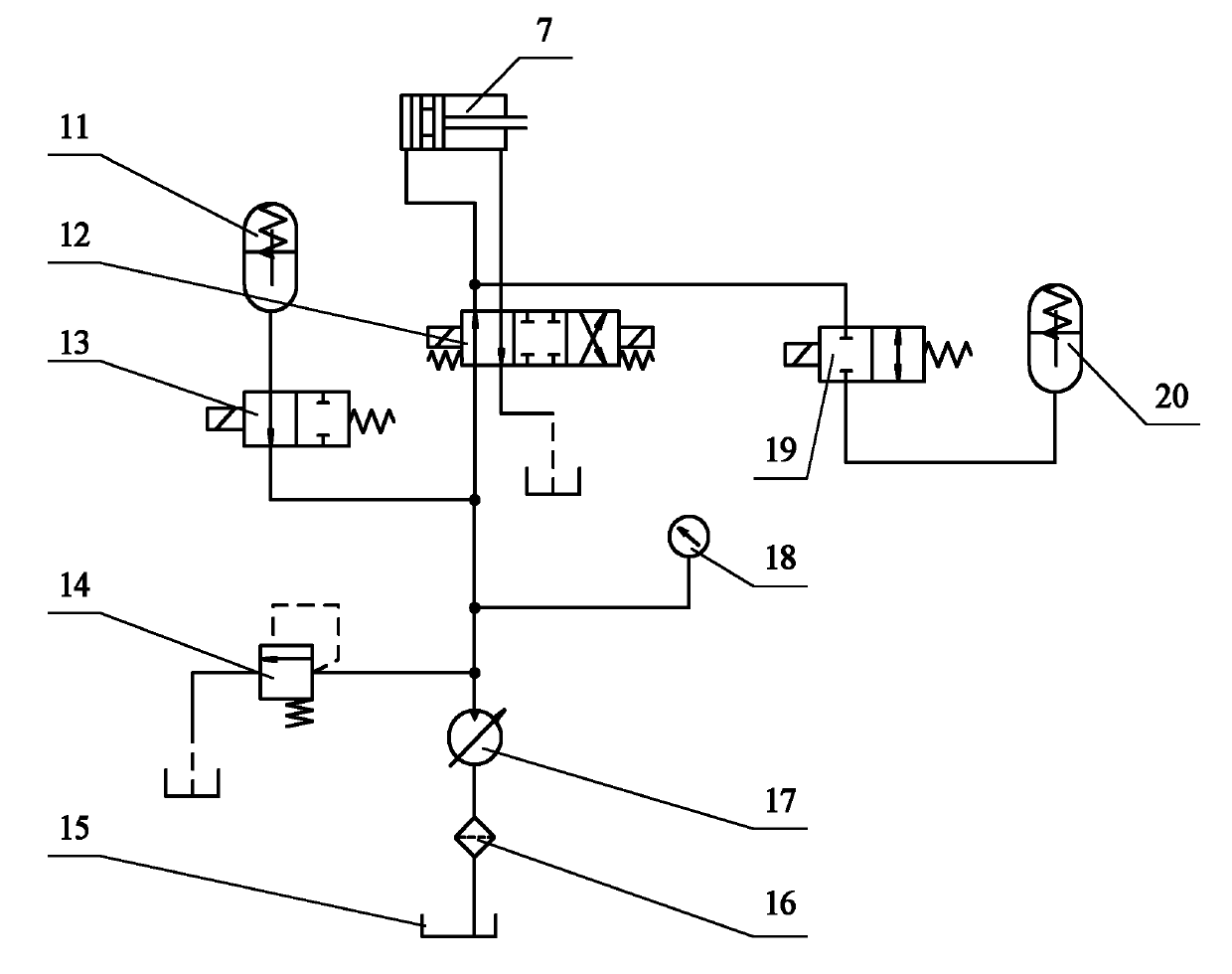

Automatic bagging device for grains

PendingCN106742122ARealize automatic baggingRealize automatic transportationWrapper twisting/gatheringSolid materialAutomatic transmissionControl system

The invention provides an automatic bagging device for grains and relates to an automatic bagging device. The device comprises a grain bin and weighing system, a bag taking and bagging mechanism, an automatic grain bin opening and closing mechanism, a bag opening auxiliary device, an automatic transmission mechanism, an automatic sealing device, a grain bag sliding conveying platform and a control system, wherein the input end and the output end of the grain bin and weighing system are connected with the control system, and the output end of the control system is separately connected with the input ends of the bag taking and bagging mechanism, the automatic grain bin opening and closing mechanism, the bag opening auxiliary device, the automatic transmission mechanism and the automatic opening sealing device. The automatic bagging device not only can realize a function of automatically bagging grains, but also can realize automatic opening sealing and automatic transportation functions on the grains, so that a fully automatic production process is realized on the grains from bin discharging to packaging and transportation. The automatic bagging device not only greatly reduces labor force and increases the work efficiency, but also ensures bagging weight precision, thereby having wide popularization significance.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Multiple-disc combined type great-moment brake

The invention discloses a multiple-disc combined type great-torque brake which mainly comprises a plurality of braking discs arranged in parallel. Both sides of each braking disc are provided with brake sheets, the brake sheets are supported by an elastic pressing plate, and the elastic pressing plate is in surface contact with a wedge-shaped thrust block. The multiple-disc combination structure reduces the moment of a single braking disc and realizes braking with great braking moment; meanwhile, the multiple-sheet structure increases the smoothness and the safety of the system and obviously reduces the size and the overall weight of the mechanical structure. The small-inclination surface between the wedge-shaped thrust block and the elastic pressing plate which are mutually matched realizes self locking on one hand and realizes the steering and the amplification of thrust on the other hand, and thus, the mechanical boosting design of a small oil cylinder with great thrust is realized. The elastic deformation of the elastic pressing plate is maintained during the operating period of the brake, so that the elastic deformation stored by bending the elastic pressing plate can keep the mechanical braking force of the brake unchanged under the condition that the brake is power off suddenly. Under the condition of sudden power off, a second energy accumulator is put into operation simultaneously, so that the persistence of the braking force of the brake is ensured. Power-off automatic protection, i.e. safe braking, is realized.

Owner:SUZHOU DAYI EQUIP TECH +1

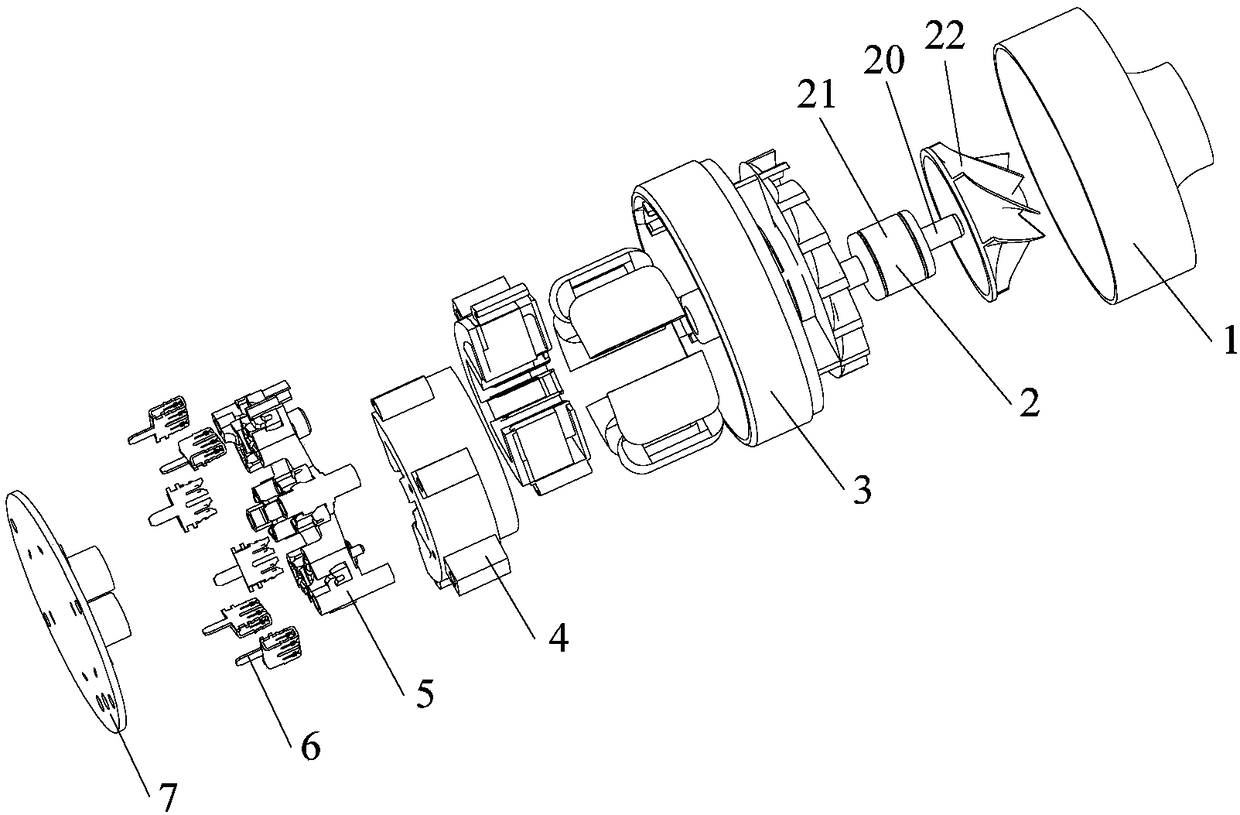

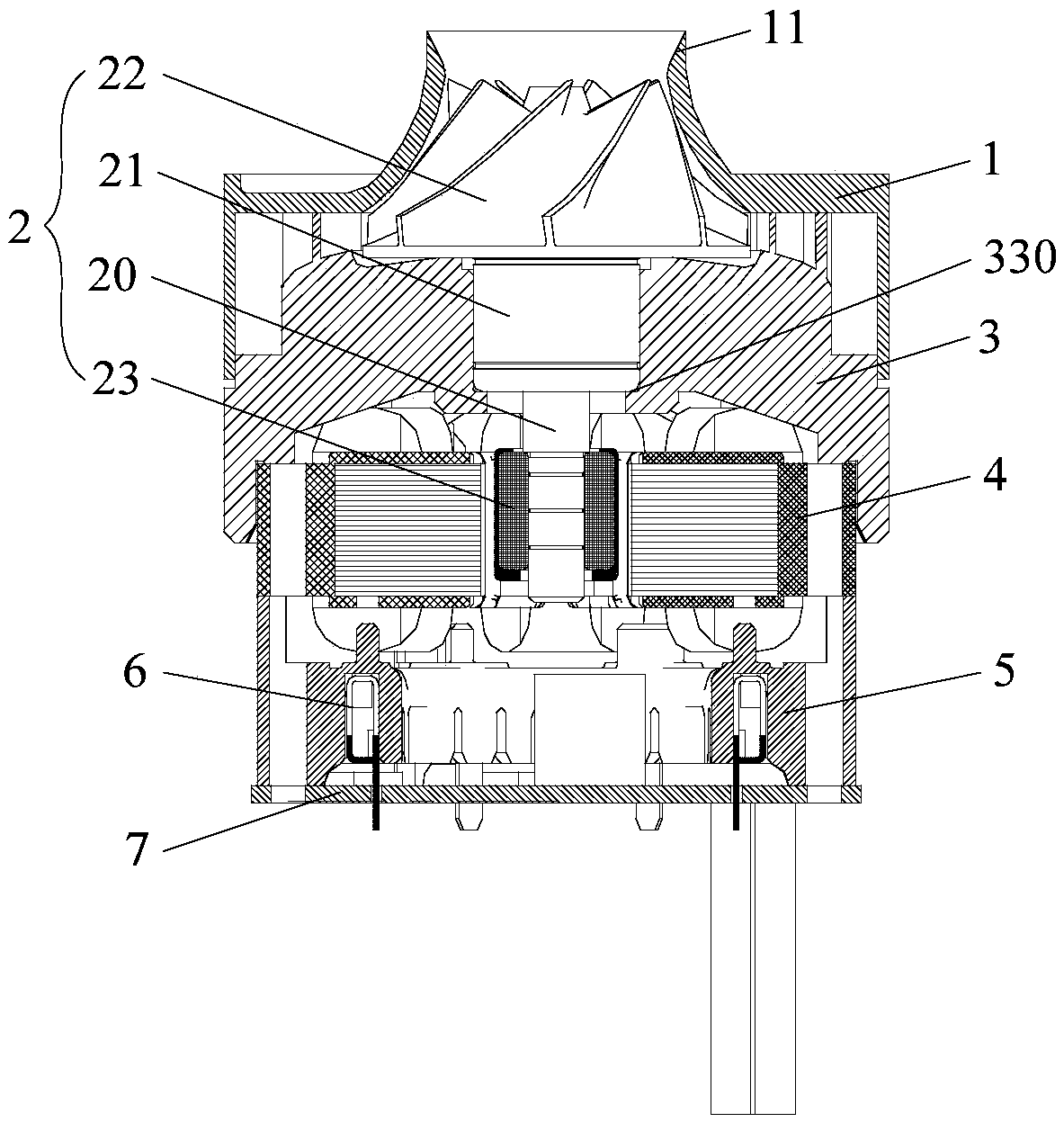

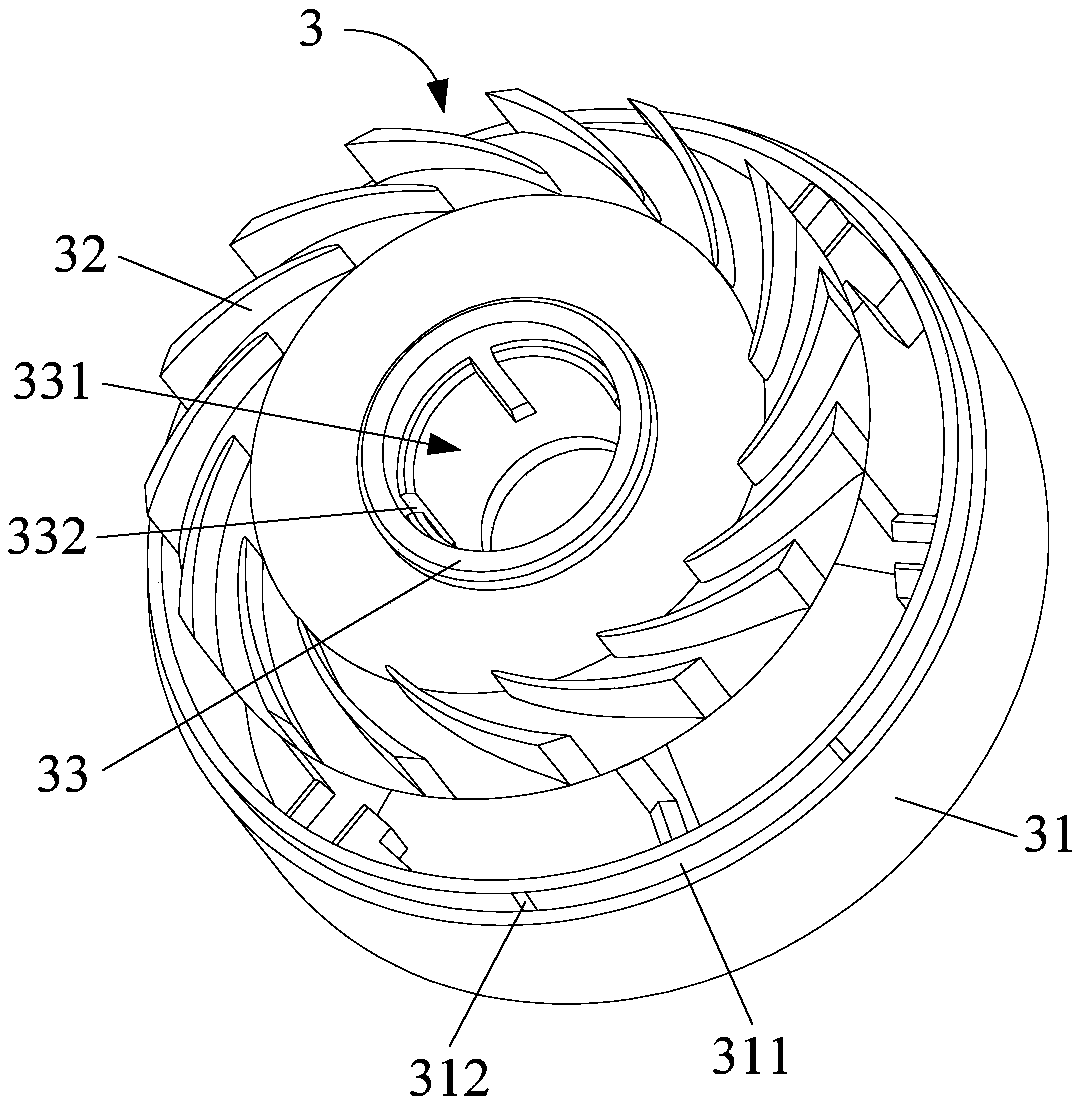

Electric fan

ActiveCN109185196AReduced parts countAssembly accuracy is lowPump componentsWorking fluid for enginesImpellerEngineering

The invention provides an electric fan which comprises a rotor component and a machine shell, wherein the rotor component comprises a bearing, a moving impeller and a magnetic ring; the magnetic ringand the moving impeller are correspondingly mounted at two ends of the bearing; the machine shell is equipped with a bearing chamber; the diameter of the magnetic ring is less than that of the bearingchamber; the magnetic ring is capable of penetrating through the bearing chamber; and after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at two ends of the bearing chamber. According to the electric fan provided by the invention, only one bearing is utilized, and the utilized bearing is positioned between the moving impeller and themagnetic ring which are mounted on a rotating shaft; during the assembling process, the magnetic ring penetrates through the bearing chamber; after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at the two ends of the bearing chamber; by the adoption of such a rotor component and machine shell assembling mode, the assembling operationcan be facilitated and the assembling process can be simplified; due to the use of only one bearing, the rotor component and machine shell assembling precision requirements are low, and the improvement of the assembling efficiency can be facilitated; and furthermore, the quantity of parts of the electric fan is reduced, so that the reduction of the product cost can be facilitated and the assembling efficiency can be further improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

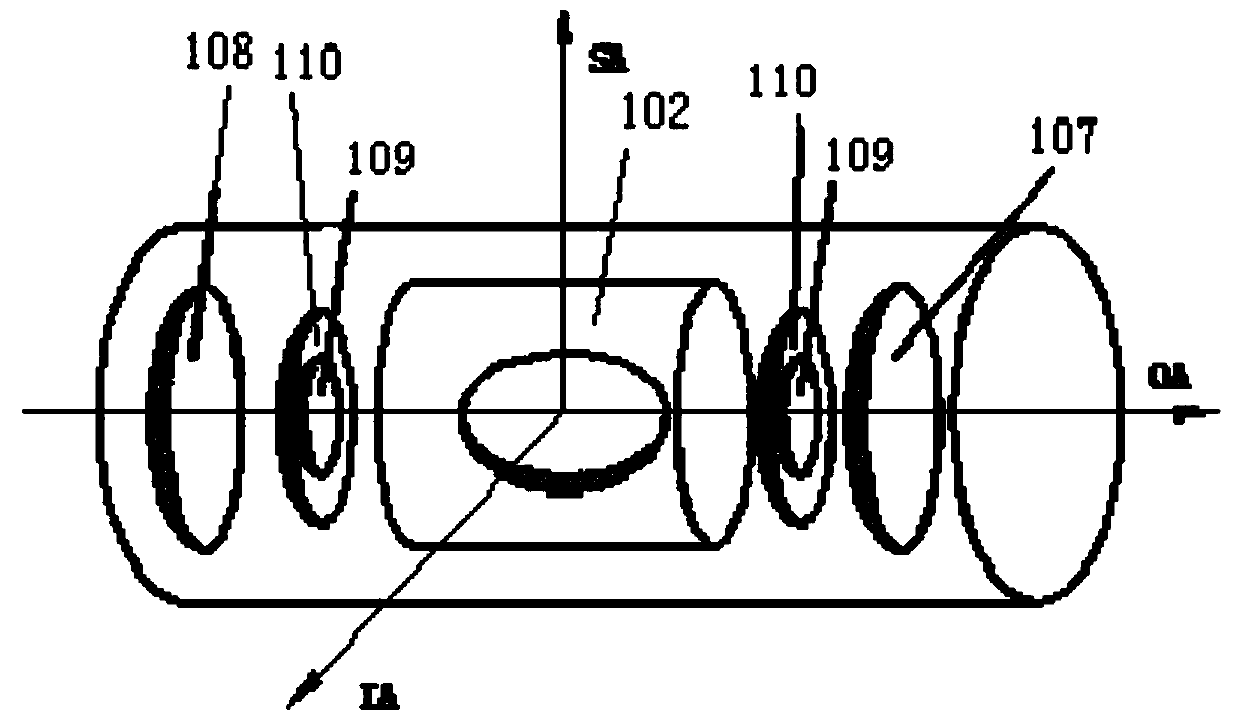

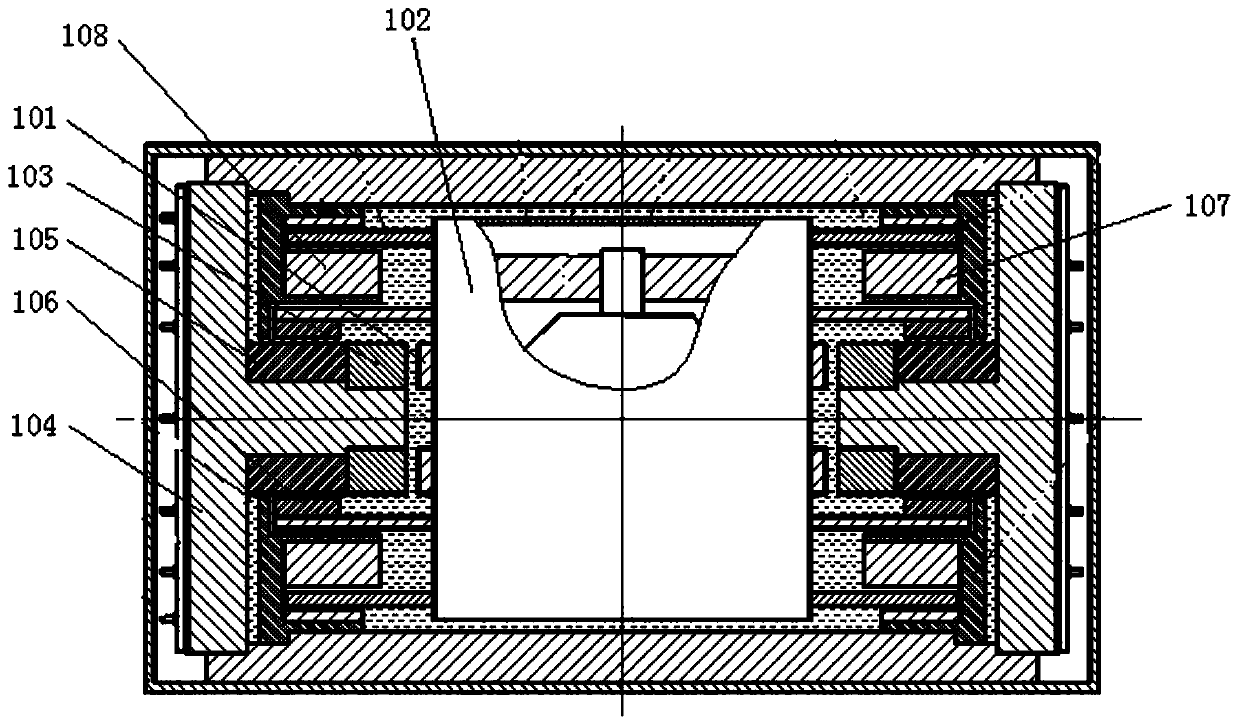

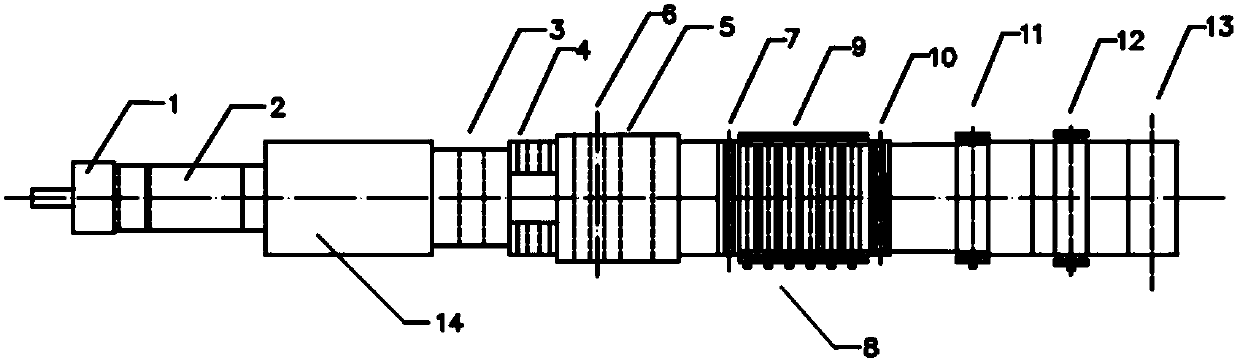

Miniaturized three-floating gyro

The invention relates to a three-floating gyro, in particular to a miniaturized three-floating gyro, and solves the technical problem that the axial size of the existing three-floating gyro is large.The technical solution of the invention is that a miniaturized three-floating gyroscope comprises a float, an angle sensor, a torquer, a casing, a first axial magnetic levitation, a second axial magnetic levitation, a first radial magnetic levitation and a second radial magnetic levitation, wherein the float, the axial magnetic levitations, the radial magnetic levitations, the angle sensor and thetorquer are arranged in the casing; suspension is filled in the casing; a first end cover and a second end cover are respectively disposed at both ends of the casing; the first end cover is sleeved with a first axial magnetic levitation stator, a first radial magnetic levitation stator and an angle sensor stator in sequence from inside out; an axial magnetic levitation rotor is fixed at the center of one end surface of the float; a first radial magnetic levitation rotor and an angle sensor rotor are sequentially sleeved on the outer side thereof; and the first radial magnetic levitation rotoris located between the first radial magnetic levitation stator and the angle sensor stator.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

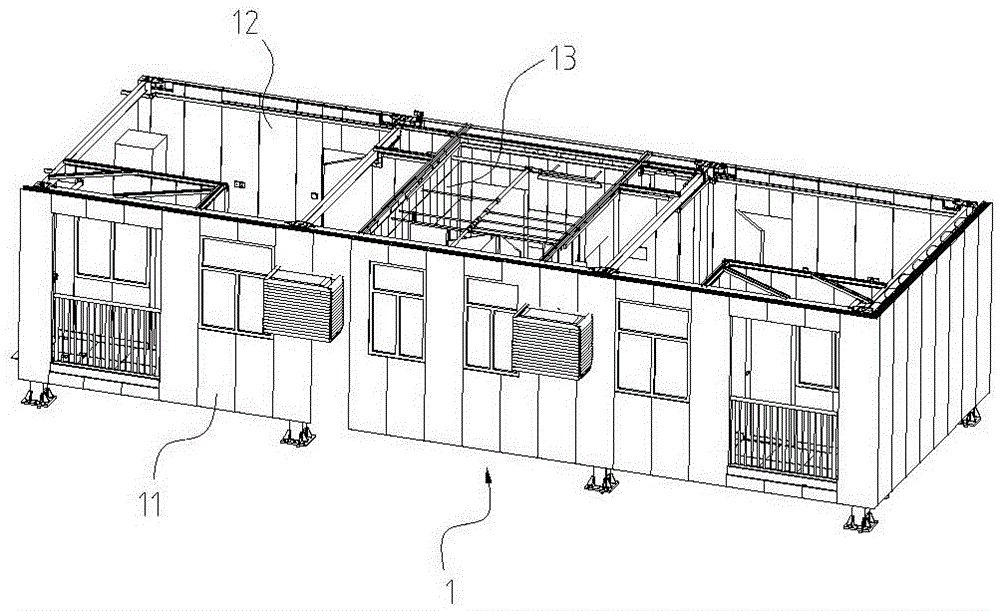

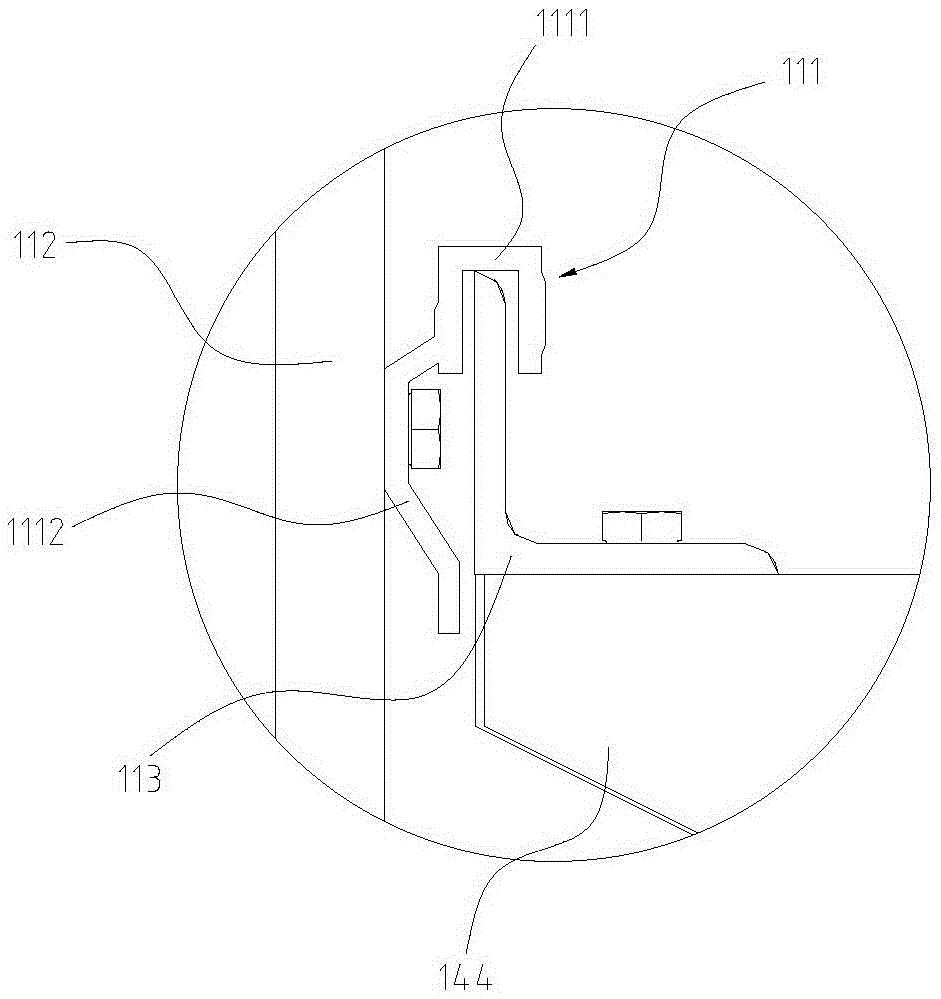

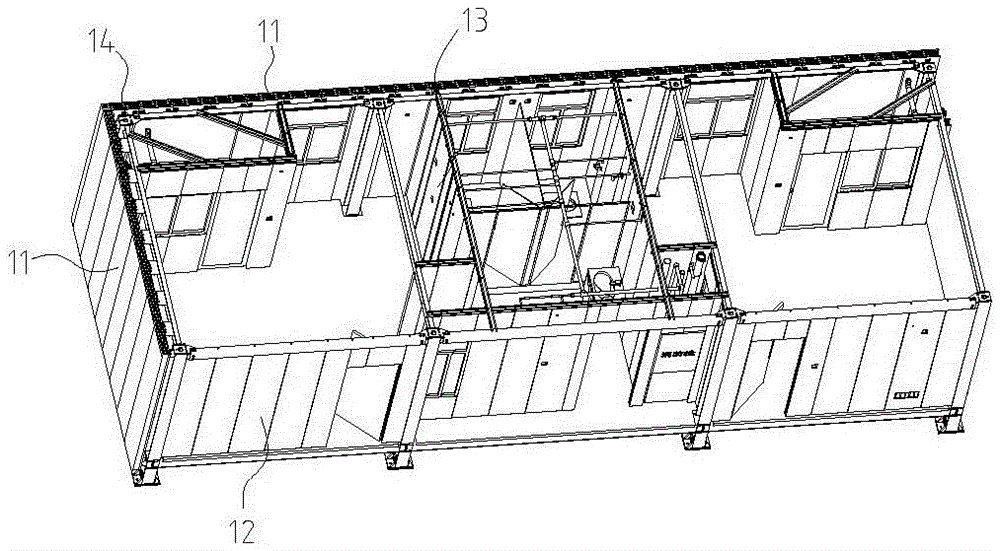

Modular steel structure house framework structure

A modular steel structure house framework structure is formed by splicing steel structure frameworks of different module units. Each steel structure framework comprises a bottom framework, a top framework and a plurality of portal frames arranged in parallel. Each portal frame comprises portal frame stand columns and a portal frame cross beam, wherein the two ends of the portal frame cross beam are welded to the upper ends of the two portal frame stand columns; the lower ends of the portal frame stand columns are welded to bottom framework side beams; and an upper mounting base is arranged on the top of each portal frame stand column, a butt joint area is formed in the middle of each upper mounting base, and mounting lugs are formed on the two sides of each upper mounting base. A top framework side beam is arranged between the upper ends of every two adjacent portal frame stand columns on the same side. The two ends of each top framework side beam are connected with the corresponding upper mounting bases through bolts. The top framework side beams and the portal frame cross beams form the top frameworks. According to the modular steel structure house framework structure, lightweight design is achieved, the structural strength is high, house splicing can be achieved, and construction is convenient.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

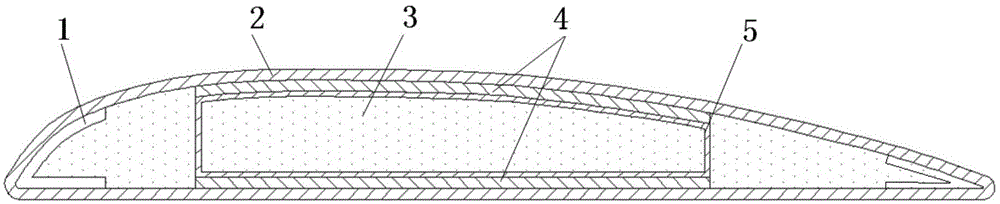

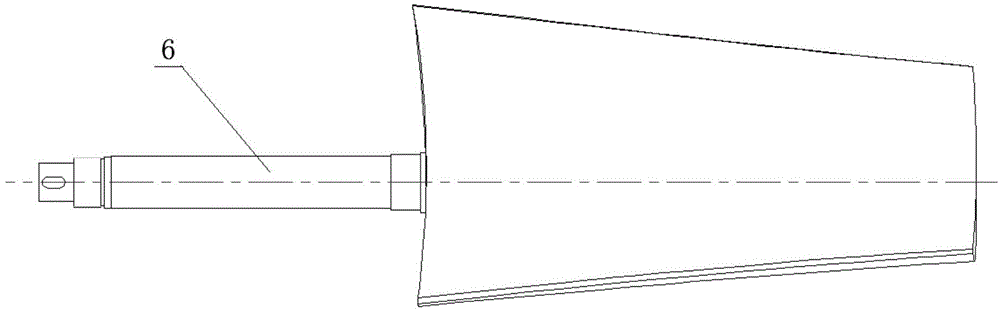

Composite material blade for wind tunnel

ActiveCN103982463AStrong resistance to deformationReduce weightPump componentsPumpsEngineeringFront edge

The invention provides a composite material blade for a wind tunnel. The composite material blade for the wind tunnel comprises a covering skin, a front edge reinforcement area, a rear edge reinforcement area, foam core materials, a main bearing beam and a metal blade handle, wherein the metal blade handle comprises a blade portion in square frame shape and a shaft portion in long rod shape, the blade portion is stretched into a central area in the covering skin in blade shape, the front edge reinforcement area and the rear edge reinforcement area are respectively arranged at the front end and the rear end of the interior of the covering skin, the covering skin and the blade portion are filled with the foam core materials, the square main bearing beam is embedded between the covering skin and the blade portion, the thickness of the main bearing beam is varied and decreases progressively in ladder mode from one side of the shaft portion, and the width of the main bearing beam is varied and decreases progressively in ladder mode from the side of the shaft portion. The composite material blade for the wind tunnel is made of carbon fiber composite material, and thereby is light and strong. Furthermore, the foam core materials have an effective supporting function for a wing-shaped profile surface of the composite material blade for the wind tunnel, and the main bearing beam bears a majority of loads on the composite material blade for the wind tunnel.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

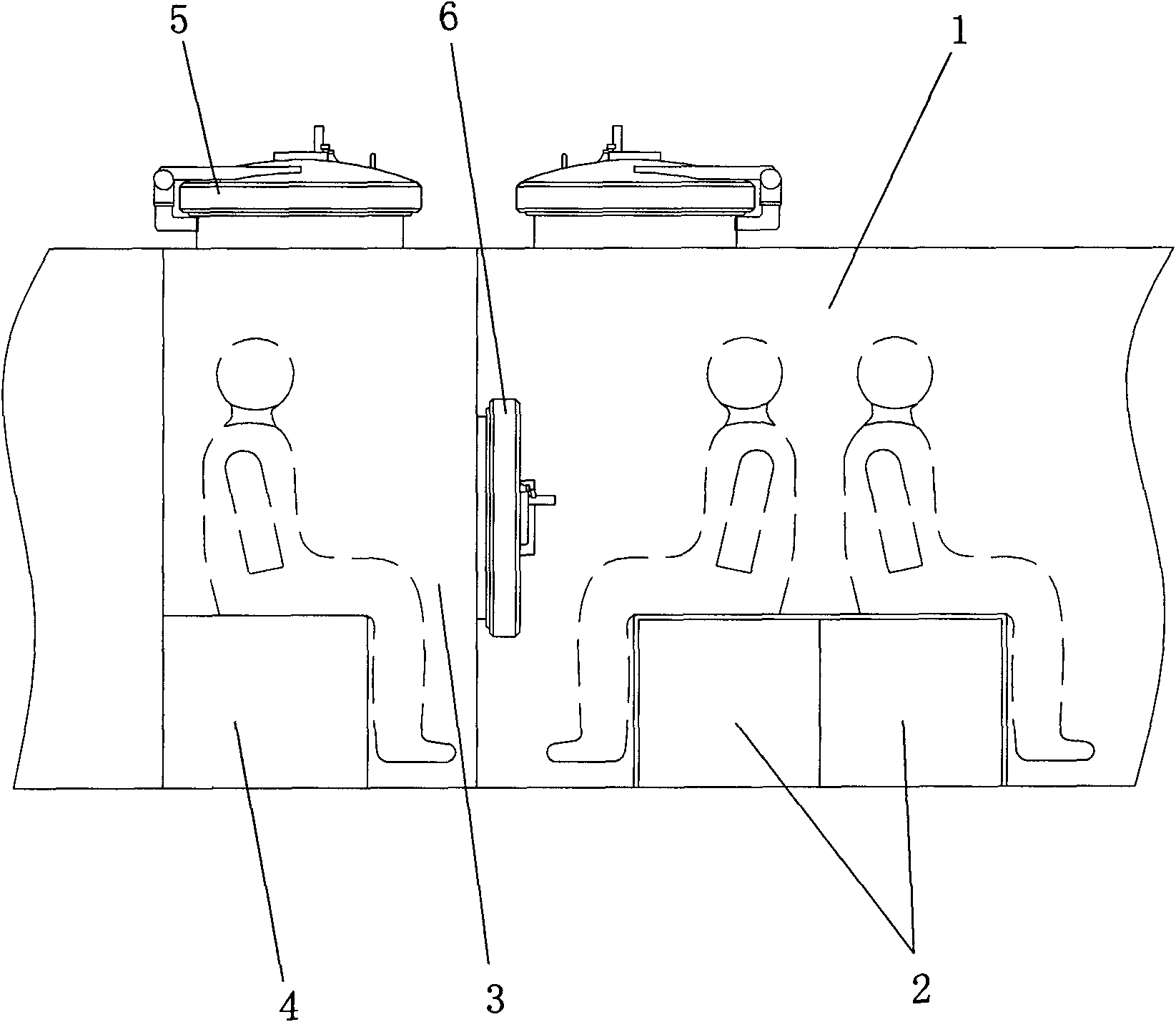

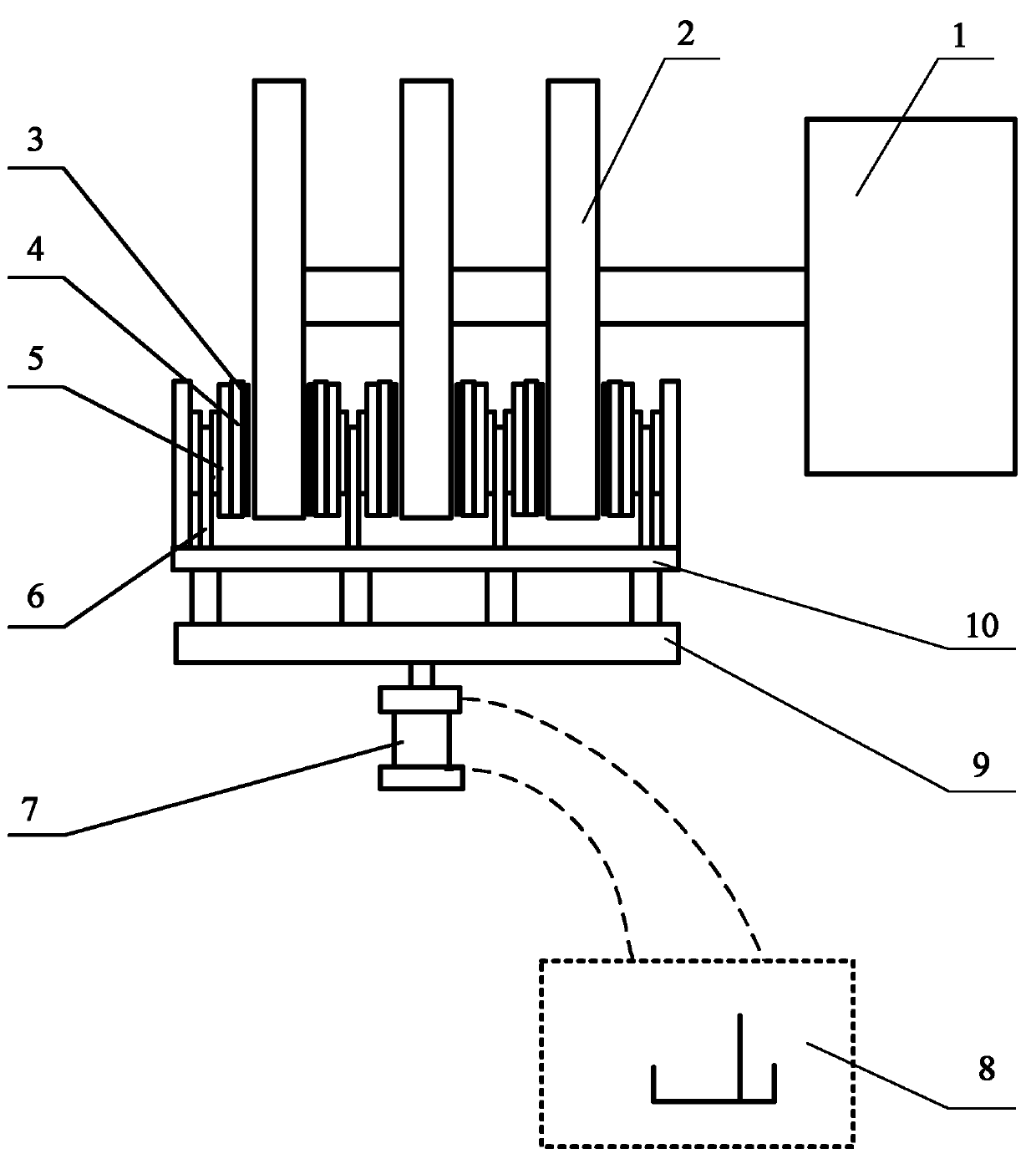

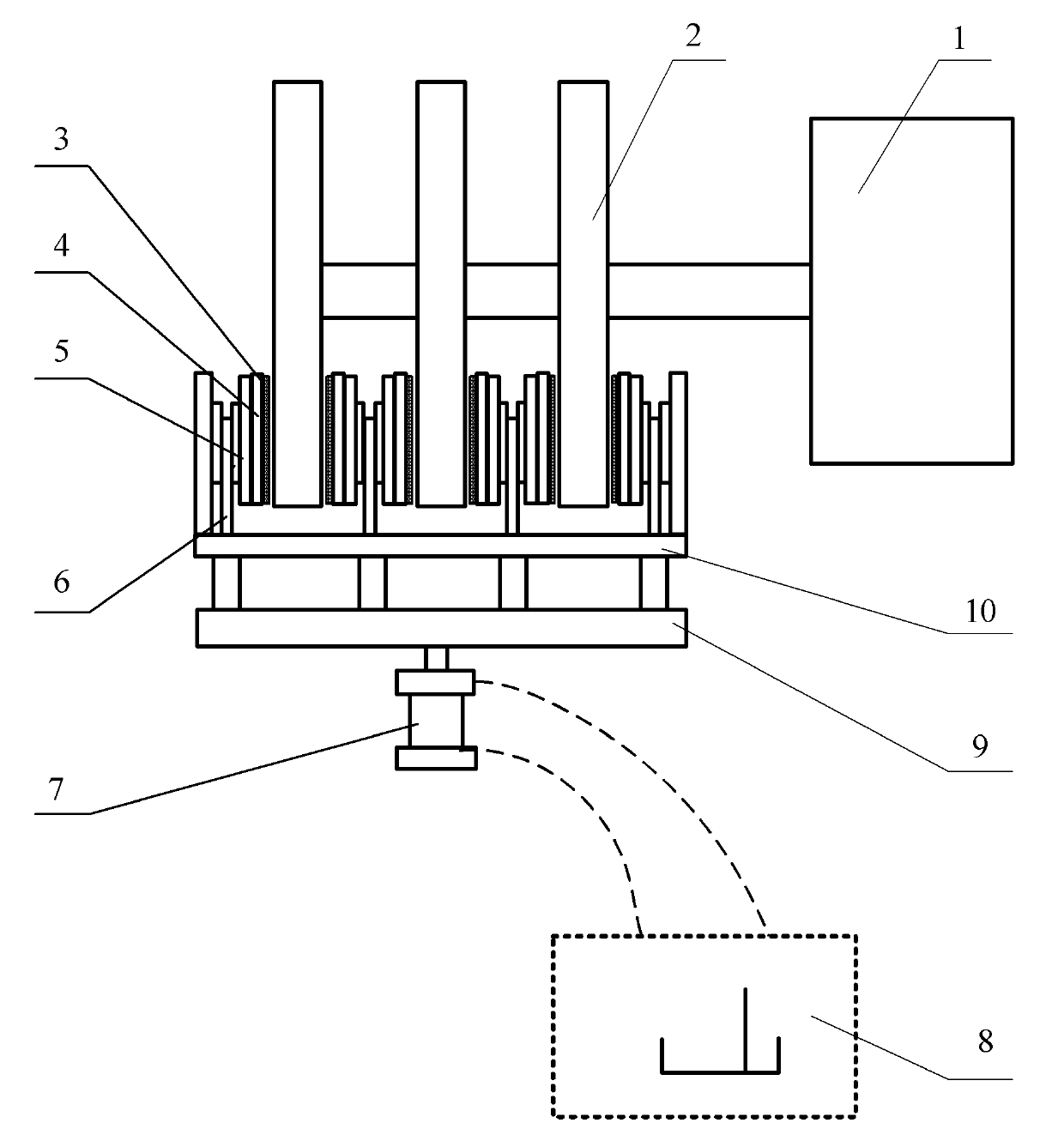

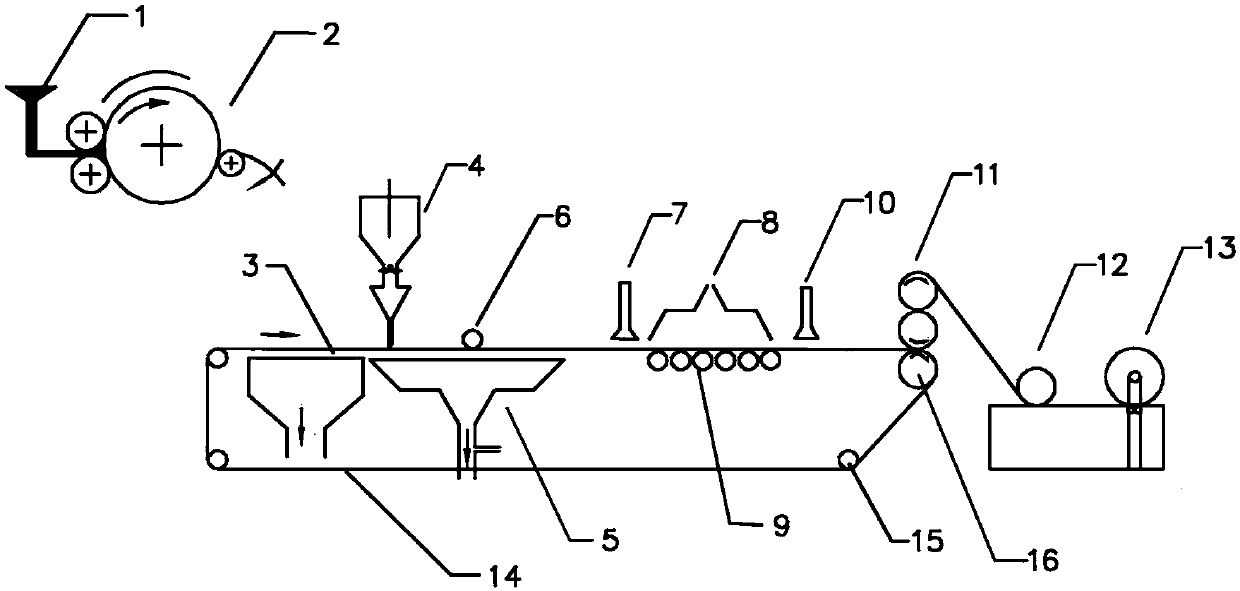

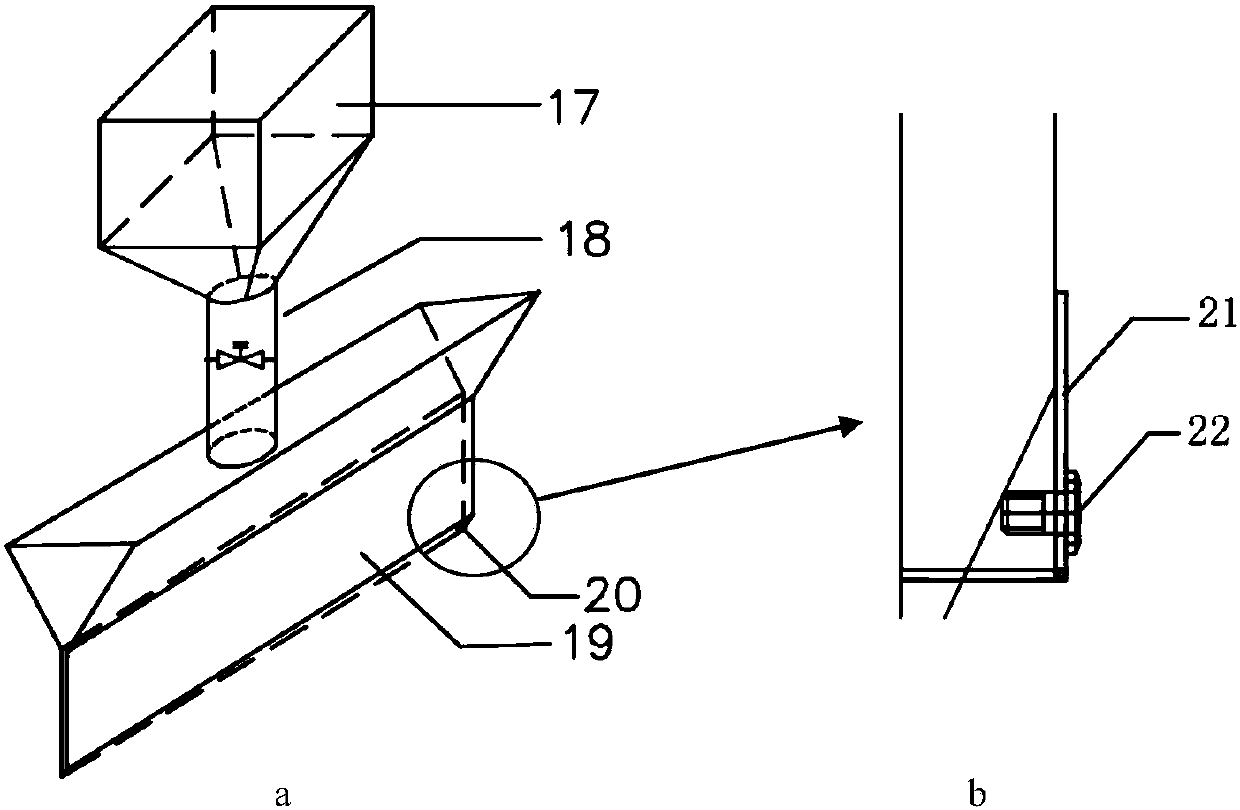

Device for utilizing net laying-papermaking combined method to prepare environment-friendly type bast fiber mulch films and use method thereof

ActiveCN108035162AEasy to stretchControllable production speedNon-woven fabricsTextile shapingProduction lineFiber

The invention relates to a device for utilizing a net laying-papermaking combined method to prepare environment-friendly type bast fiber mulch films and a use method thereof. The device comprises a feeding machine (1), an air flow net forming machine (2), a screen (14), a transmission mechanism (15), an air suction device (3), a pulping device (4), a suction filtration device (5), a compression roller (6), a spraying machine (7), an air extracting device (8), a drying device (9), a coating device (10), a glazing calender (11), an edge trimming machine (12) and a coiling machine (13). Accordingto the device disclosed by the invention, a complete bast fiber mulch film preparation production line is assembled, so that the problems of batch production and stable production of the bast fiber mulch films are solved; the environment-friendly type bast fiber mulch films which has the advantages of stable quality, even structure, high strength and low cost can be prepared out; stable production of the bast fiber mulch films is achieved; reagents for preventing insects, inhibiting grass and the like can be added into a spraying device according to needs; thus, the bast fiber mulch films fordifferent purposes can be produced out.

Owner:DONGHUA UNIV

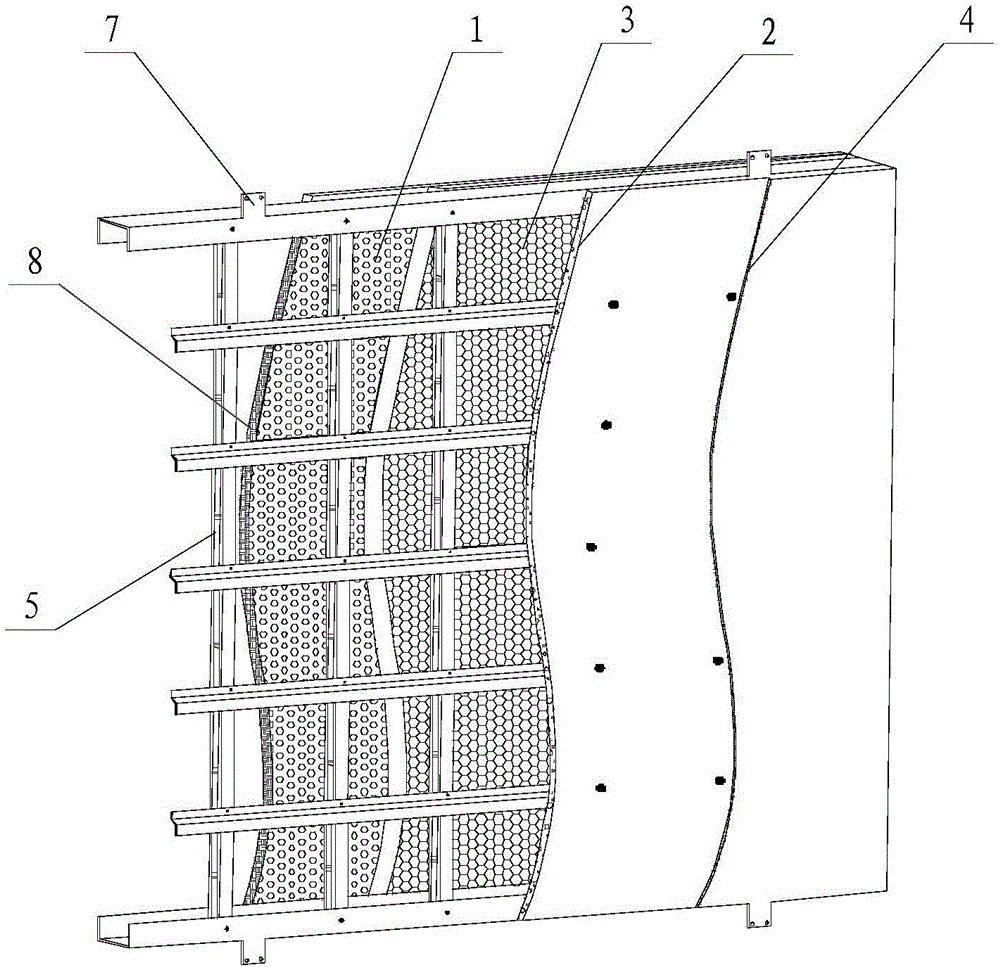

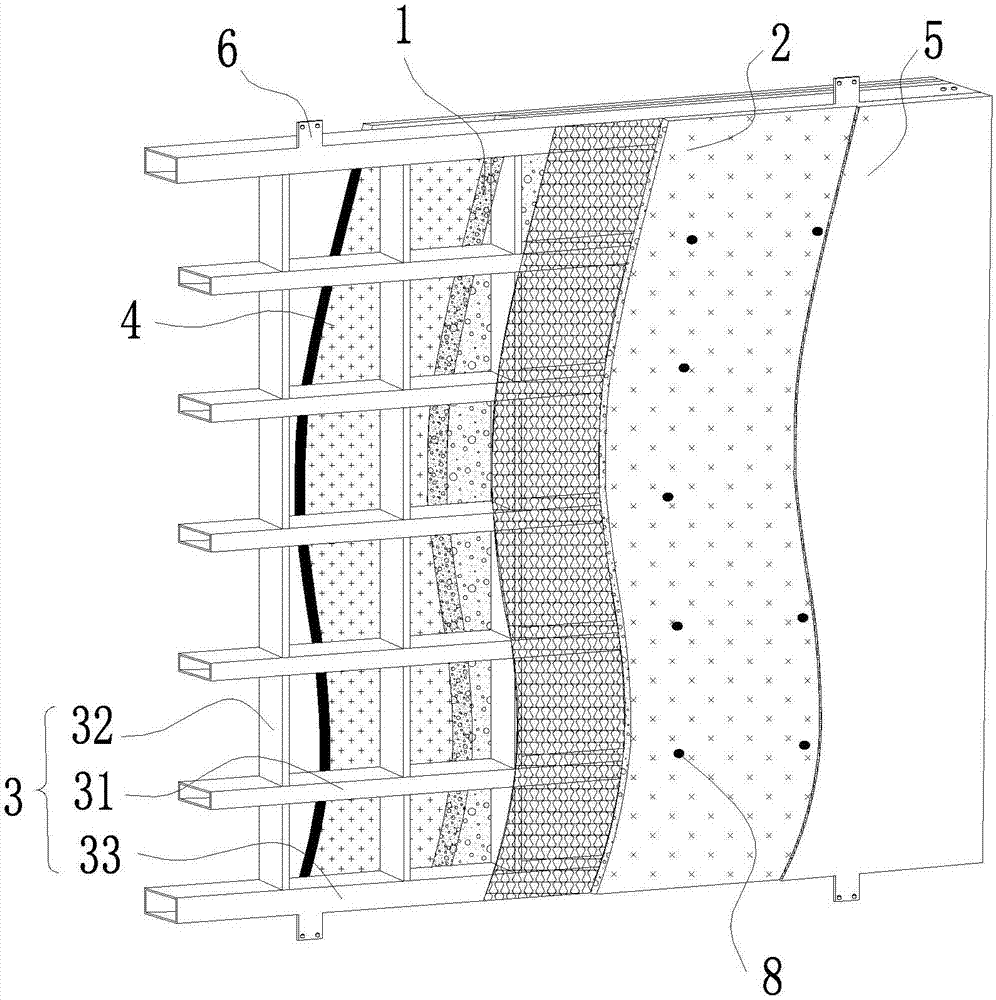

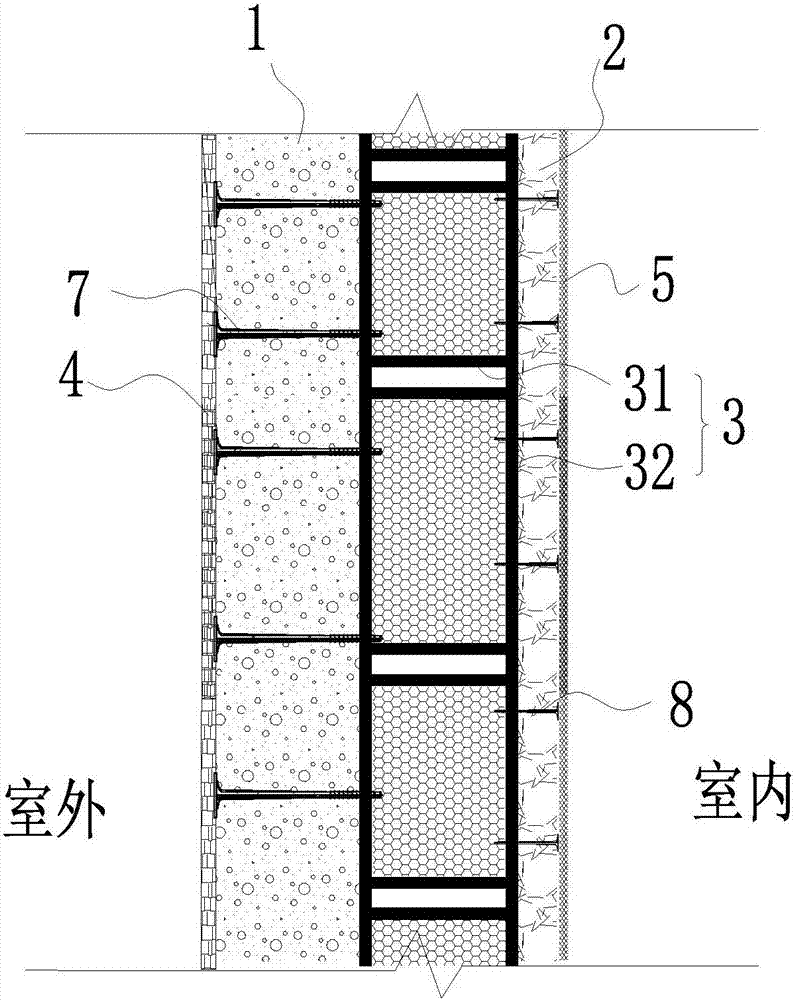

Assembled external wall plate and preparation method thereof

PendingCN107254935ALower requirementAvoid crackingCovering/liningsLayered productsBuilding materialWall plate

The invention relates to the field of a building material, in particular to an assembled external wall plate. The assembled external wall plate comprises an outer side plate, an inner side plate and a multifunctional structure layer, wherein the multifunctional structure layer is arranged between the outer side plate and the inner side plate; one side of the outer side plate is connected with one side of the multifunctional structure layer; an outer decoration layer is compounded at the other side of the outer side plate; one side of the inner side plate is connected with the other side of the multifunctional structure layer; an inner decoration layer is compounded at the other side of the inner side plate; the multifunctional structure layer comprises a force bearing frame; and waterproof heat insulation and heat preservation materials are filled in gaps between the outer side plate and the force bearing frame and gaps between the inner side plate and the force bearing frame. The quality can be ensured; the construction and the hoisting are easy; the construction efficiency is improved; the integral performance is stable; the impact resistant performance is good; the conventional common quality faults of wall plate cracking and deformation, edge missing, corner falling and the like can be avoided; after once installation completion, the veneer construction is not needed; and the engineering manufacturing cost and the construction period are reduced.

Owner:重庆佳良建筑设计咨询有限公司

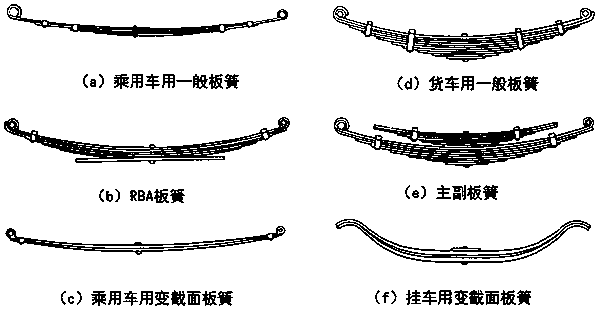

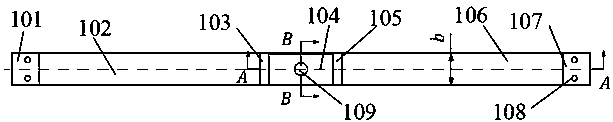

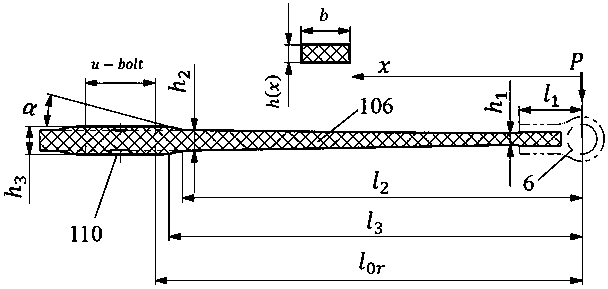

Leaf spring and manufacturing technology thereof

ActiveCN107606014AReduce weightImprove local stressLeaf springsDomestic articlesDynamic stiffnessFiber

The invention relates to a leaf spring and a manufacturing technology thereof. The leaf spring comprises a leaf middle section, a transition section, a variable-section section and a winding lug installing section, and all the sections are the same in width. The material of the leaf spring is an FRP composite material. The manufacturing technology comprises the fiber cloth weaving procedure, the fiber cloth laminating procedure, the laminated layer spot welding procedure, the pre-forming procedure, the cutting procedure, the HP-RTM procedure, the unloading and shaping procedure and the post-machining procedure. The technical scheme solves the problems of design and process of leaf spring leaves in the prior art, the leaf spring leaf performance is improved, the volume production beat is fast, and the market value of the leaf spring is huge; one leaf spring can be independently used, two leaf springs can be combined to form a main and auxiliary spring structure, different loads are achieved, and all steel plate spring structures can be replaced by changing structures of winding lugs and other accessories; complete fracture at a time is avoided, the active failure mode is achieved, and the vehicle running safety is sufficiently guaranteed; the weight of a leaf spring suspension is reduced, the dynamic stiffness is very small, the vehicle running smoothness is improved, and fuel affinity is improved as well; and the service life is 5 or more times of the steel plate springs, and the cost of using the leaf spring by users is greatly reduced.

Owner:合肥前卫复合材料有限公司 +1

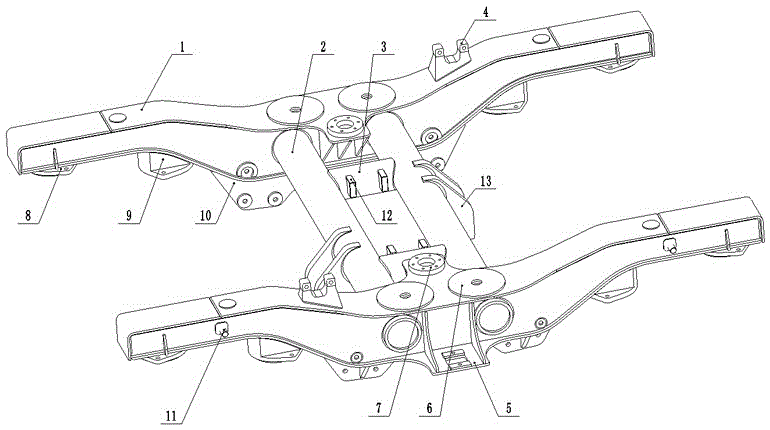

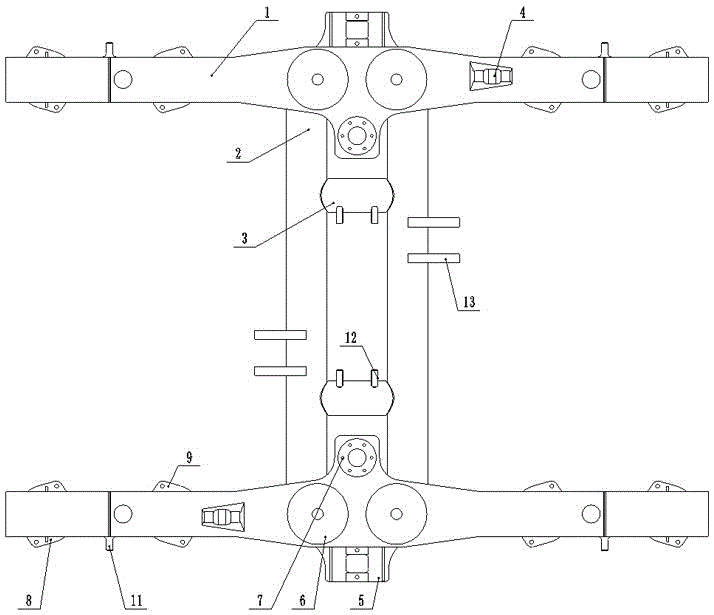

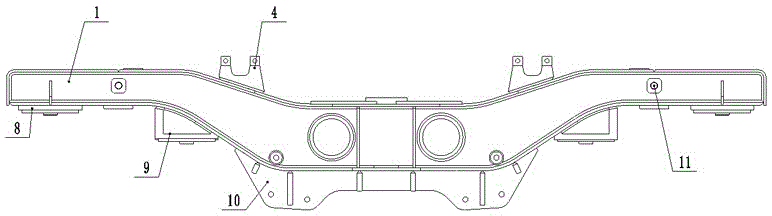

Engineering detection vehicle bogie frame

PendingCN107176179ARealize the purpose of lightweight designGuaranteed production costBogiesBogieBrake

The invention discloses an engineering detection vehicle bogie frame. The engineering detection vehicle bogie frame comprises an H-shaped frame body composed of two side beams of a box-shaped structure and two cross beams of a hollow structure. Hollow auxiliary beams are fixed between the inner sides of the two cross beams. The middles of the side beams are sunken to form sunken parts used for mounting secondary spring seats. The outer sides of the middles of lower cover plates of the side beams protrude outward to form vertical oil pressure shock absorber seats. According to the trailer engineering detection vehicle bogie frame suitable for tread brake, the side beams are of the box-shaped structure, the cross beams and the auxiliary beams all adopt hollow steel pipes, thus the whole weight of the frame is effectively decreased while strength is guaranteed, and the purpose that a vehicle body is lightweight is achieved.

Owner:CRRC LUOYANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com