Modular steel structure house framework structure

A technology of steel structure frame and frame structure, which is applied in the direction of building structure and construction, can solve the problems of difficulty in realizing large-scale population living, low assembly precision of steel structure skeleton, and inability to realize upper, lower, left and right splicing, etc. Weight, the effect of not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings of the description.

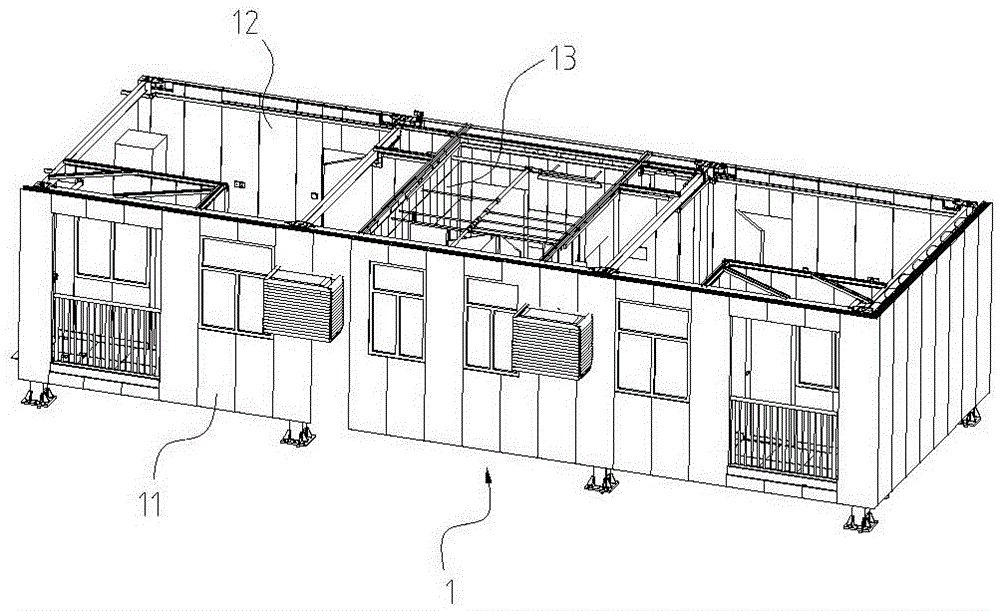

[0021] The utility model relates to a modular steel structure house, which includes several modular units spliced with each other. Such as figure 1 , 2 As shown, the modular unit 1 includes a steel structure frame 14, an outer wall 11 fixed on the outer side of the steel structure frame 14, an inner wall 12 fixed on the inner side of the steel structure frame 14, and a floor slab 15 located at the inner bottom of the steel structure frame 14 and water supply system.

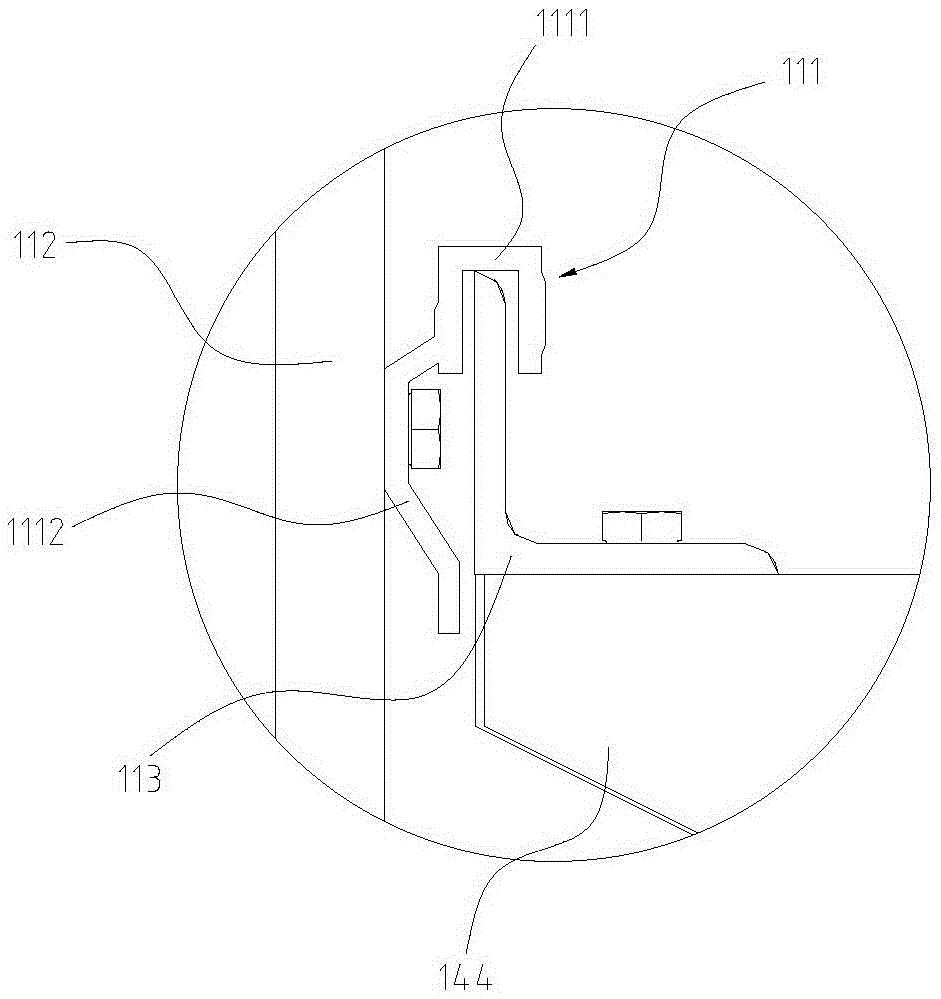

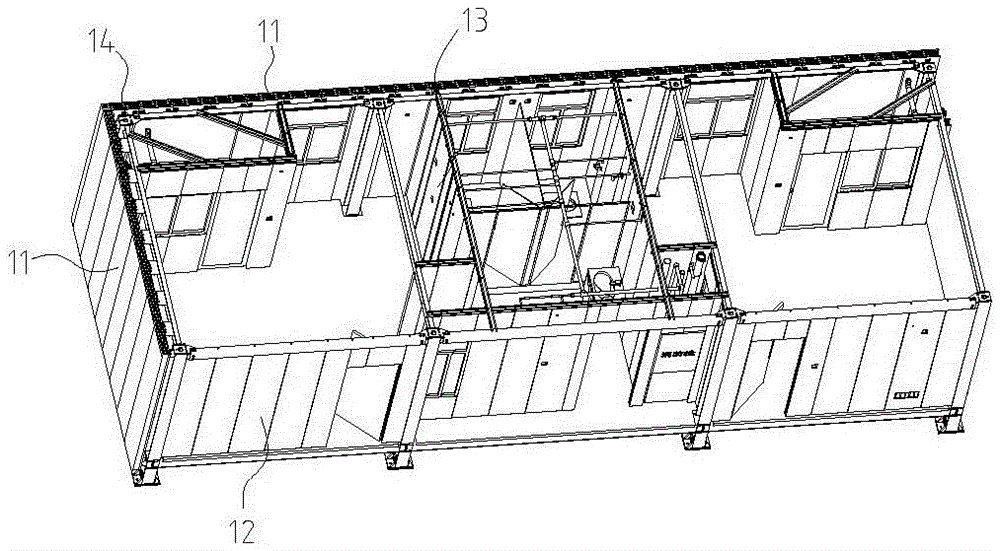

[0022] Such as image 3 , 4 As shown, the steel structure frame 14 includes a bottom frame 142, a top frame 143 and several gantry frames 141 arranged in parallel. The bottom frame 142 includes two bottom frame side beams 1421 arranged in parallel, bottom frame end beams 1422 located at both ends of the bottom frame side beams 1421 and several bottom frame reinforcement beams 142...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com