Device for utilizing net laying-papermaking combined method to prepare environment-friendly type bast fiber mulch films and use method thereof

A combined, environmentally friendly technology, used in nonwovens, textiles and papermaking, fabric surface trimming, etc., to achieve uniform fiber distribution, mass production, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

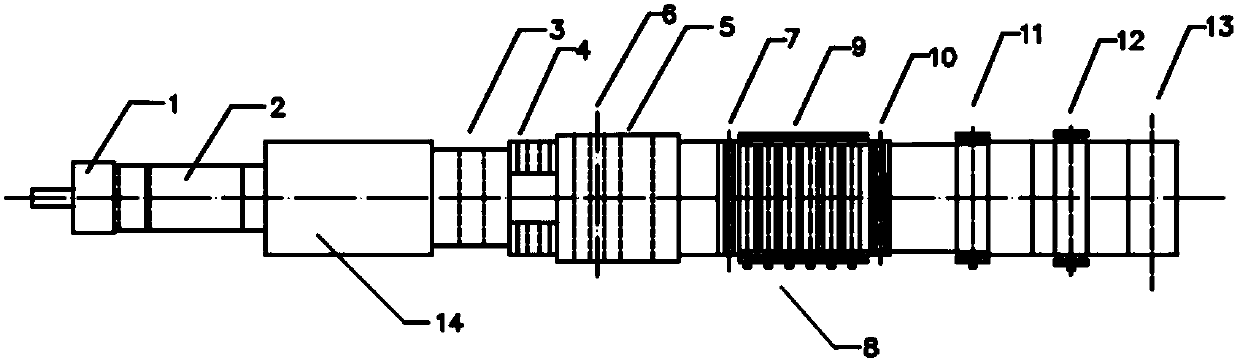

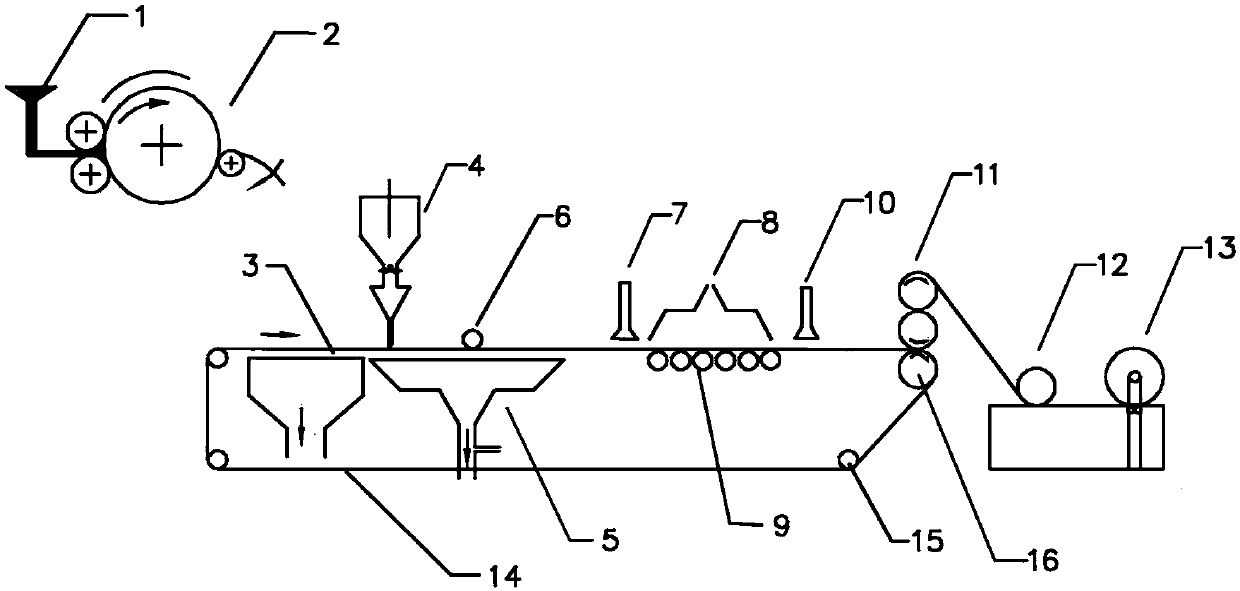

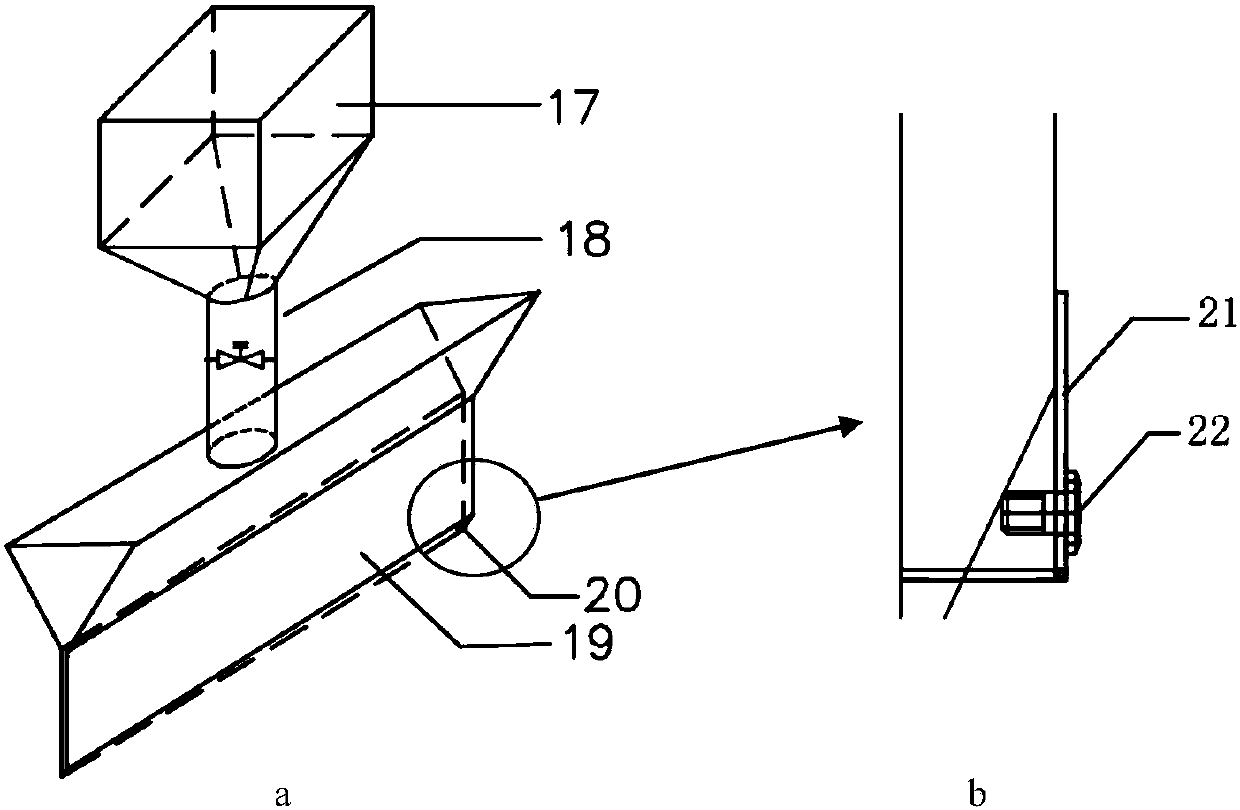

[0025] like Figure 1-Figure 3 As shown, the present embodiment provides a device for preparing an environment-friendly hemp mulch film by using a net-laying-copying combined method. The feeder 1 is connected to the air-laid machine 2, and a screen 14 is set below the air-laid machine 2. The transmission mechanism 15 will The hemp fiber net output by the air-laid machine 2 is sent to the screen 14, and the suction device 3, the suction filter 5 and the drying device 9 are arranged successively below the screen 14, and the pulping device 4 is arranged successively above the screen 14. , press roll 6, sprayer 7, air extraction device 8, coating device 10 and calender 11, and pulping device 4 is between suction device 3 and suction filter device 5, and press roll 6 is between suction filter device 5 Above, the suction device 8 is above the drying device 9. On the right side of the screen 14, an edge trimmer 12 and a coiler 13 are arranged in sequence, and the film processed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com