Patents

Literature

71results about How to "Wide range of lengths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

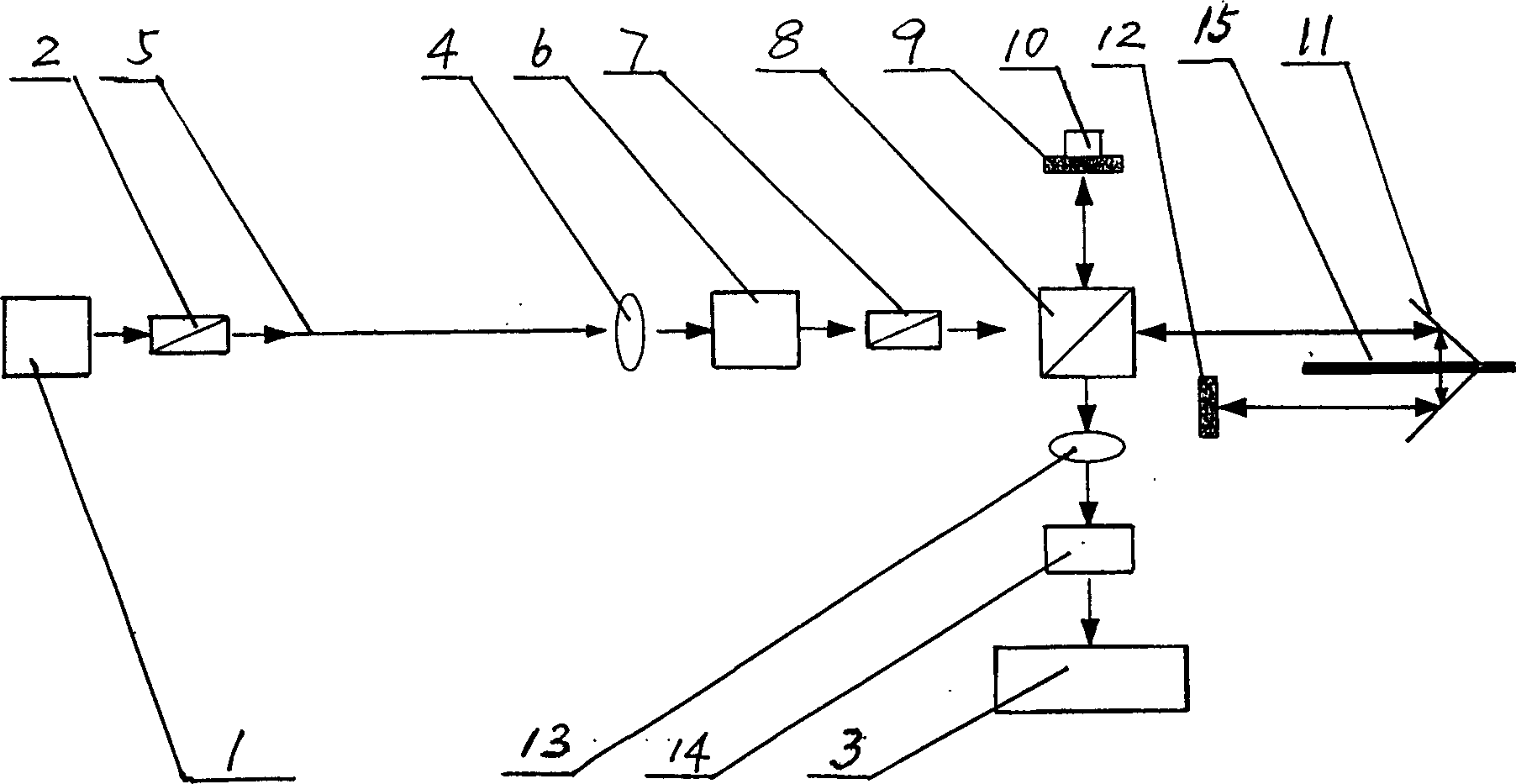

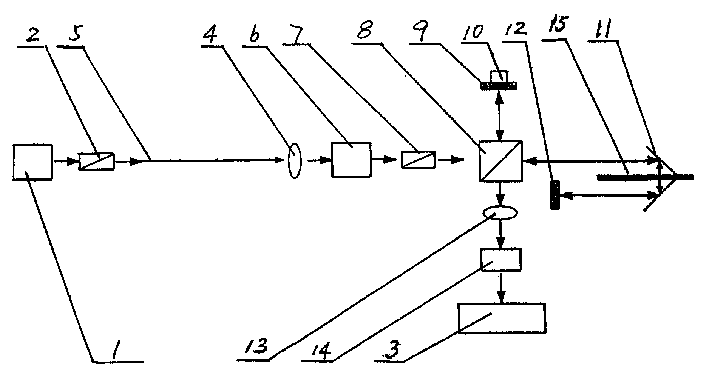

Broad-band light source signal detection method and its detector

InactiveCN1412538AGuaranteed accuracyHigh precisionPolarisation-affecting propertiesPhase-affecting property measurementsPolarization-maintaining optical fiberPhotoelectric conversion

The method for detecting wideband light source signal includes the following steps: 1. laying the polarization-protecting optical fibre on the tested body; 2. one end of the polarization-protecting optical fibre is inputted into wideband detection light source; 3. using polarizing spectroscopic system to divide the wideband detection light source outputted by another end of the polarization-protecting optical fibre into linear polarized light, reflecting and transmission, feeding the linear polarized light into Michelson interferometer; and 4. making the interference light signal undergo the processes of collection, photoelectric conversion, A / D conversion, etc. to output the detection parameters of said tested body. Said invented detector is formed from detection light source system.

Owner:TIANJIN UNIV

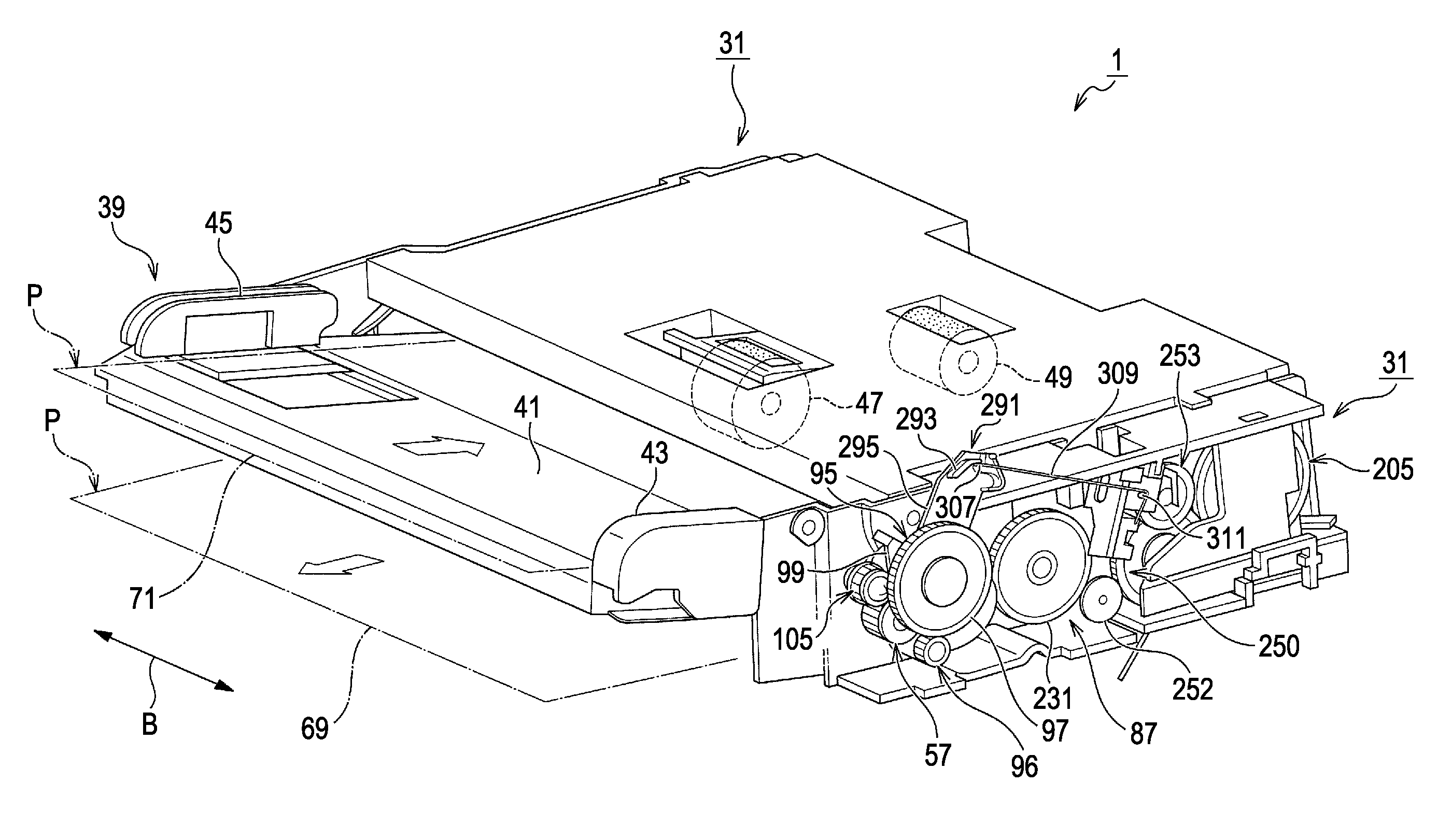

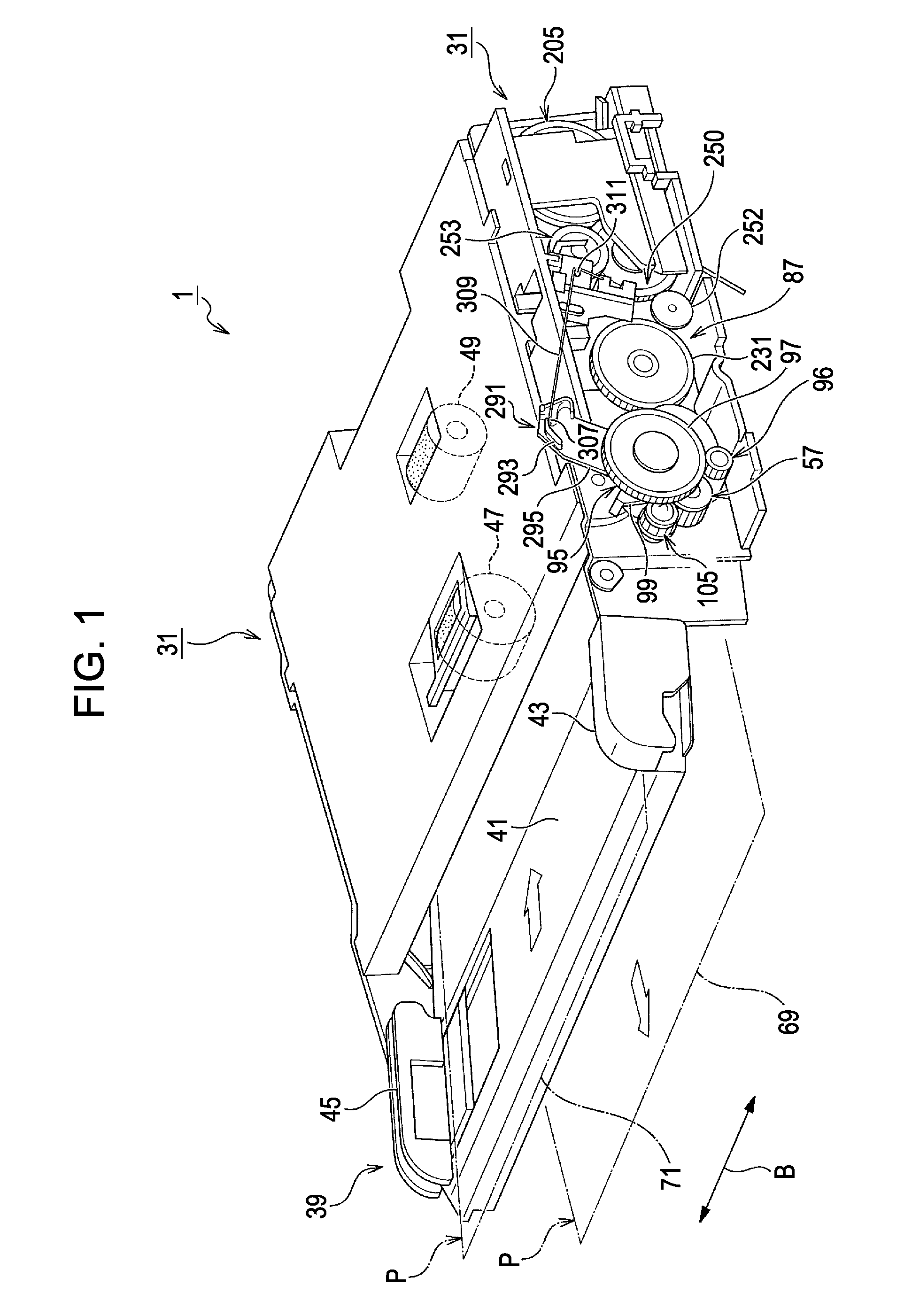

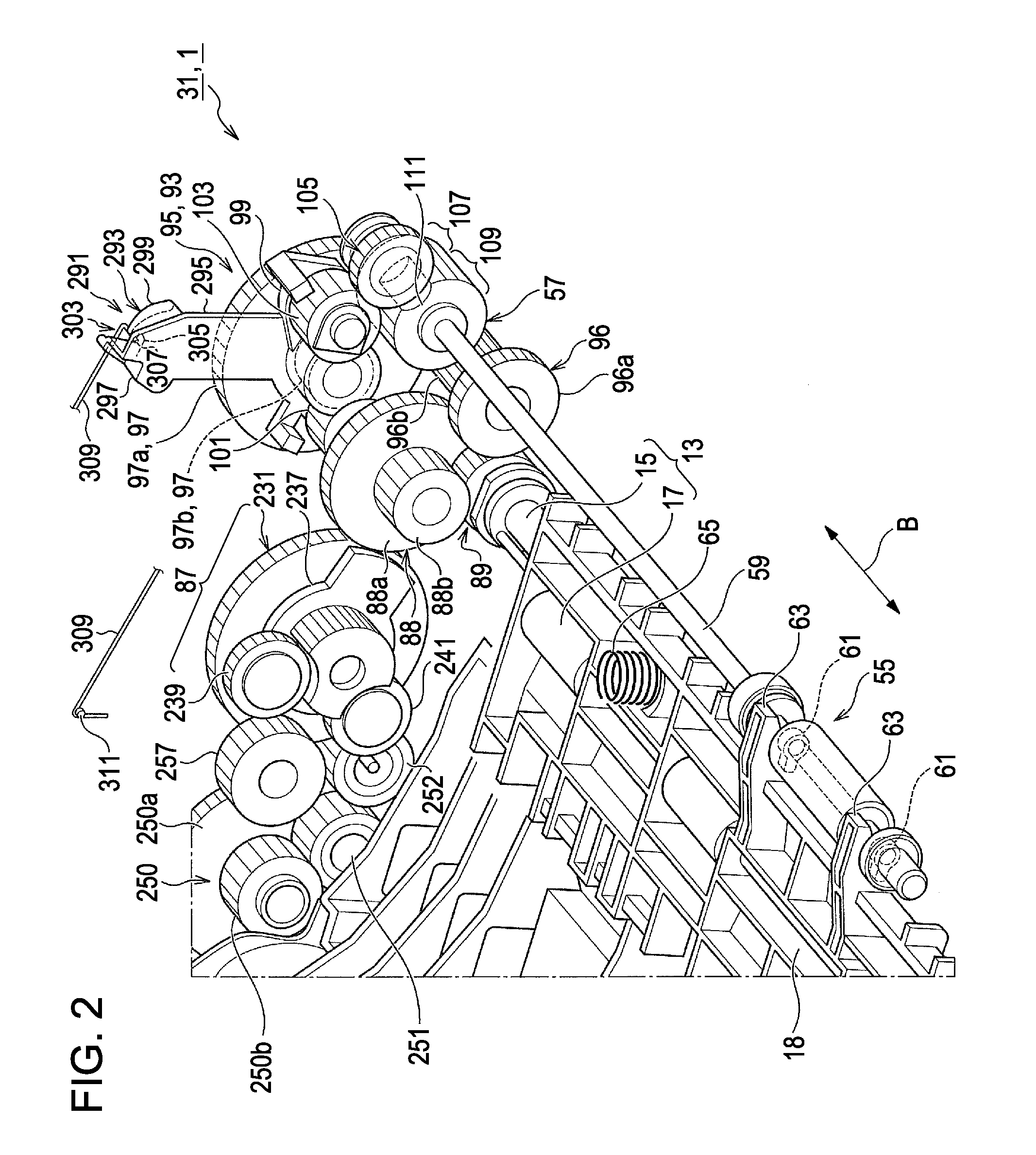

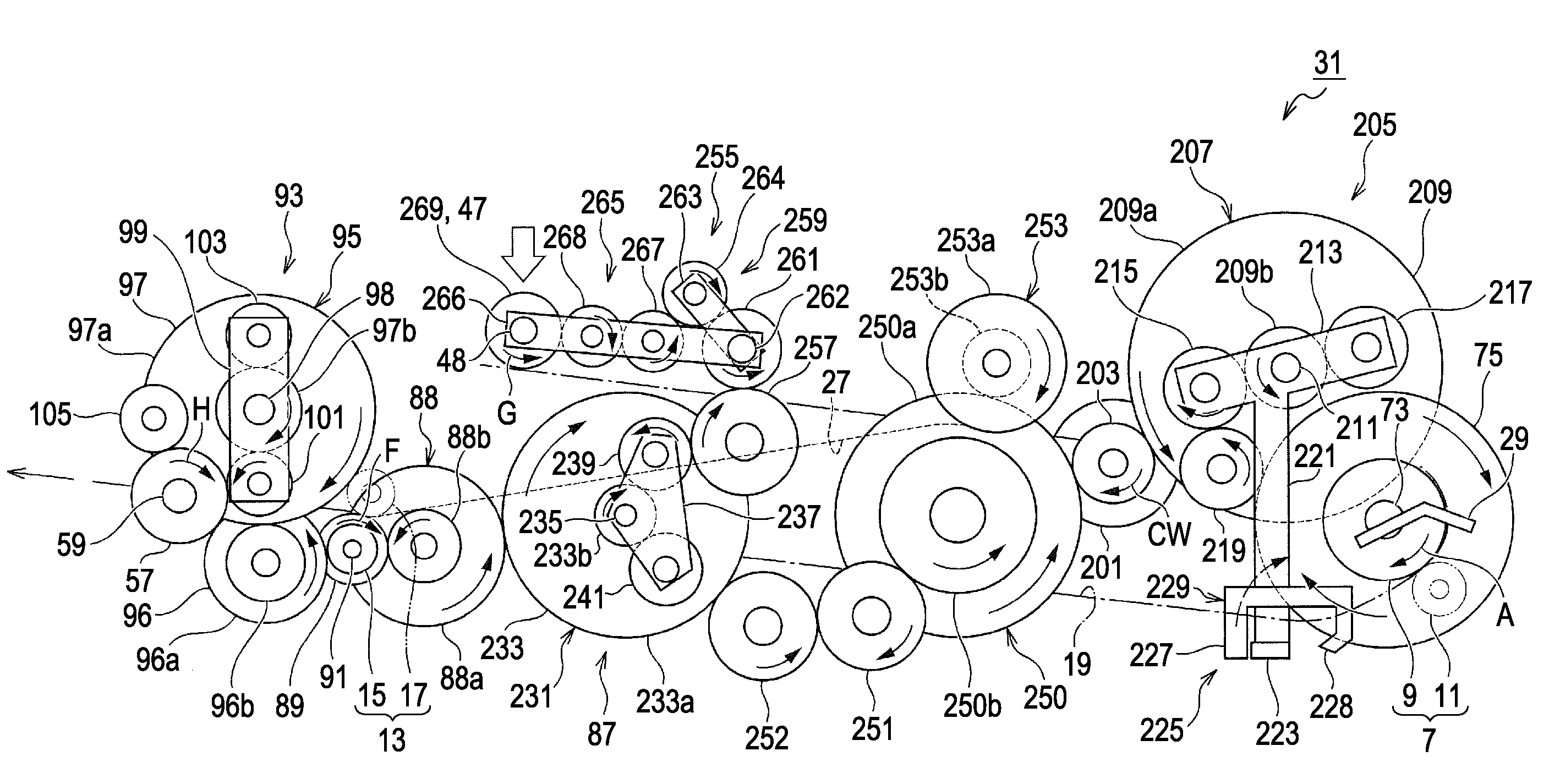

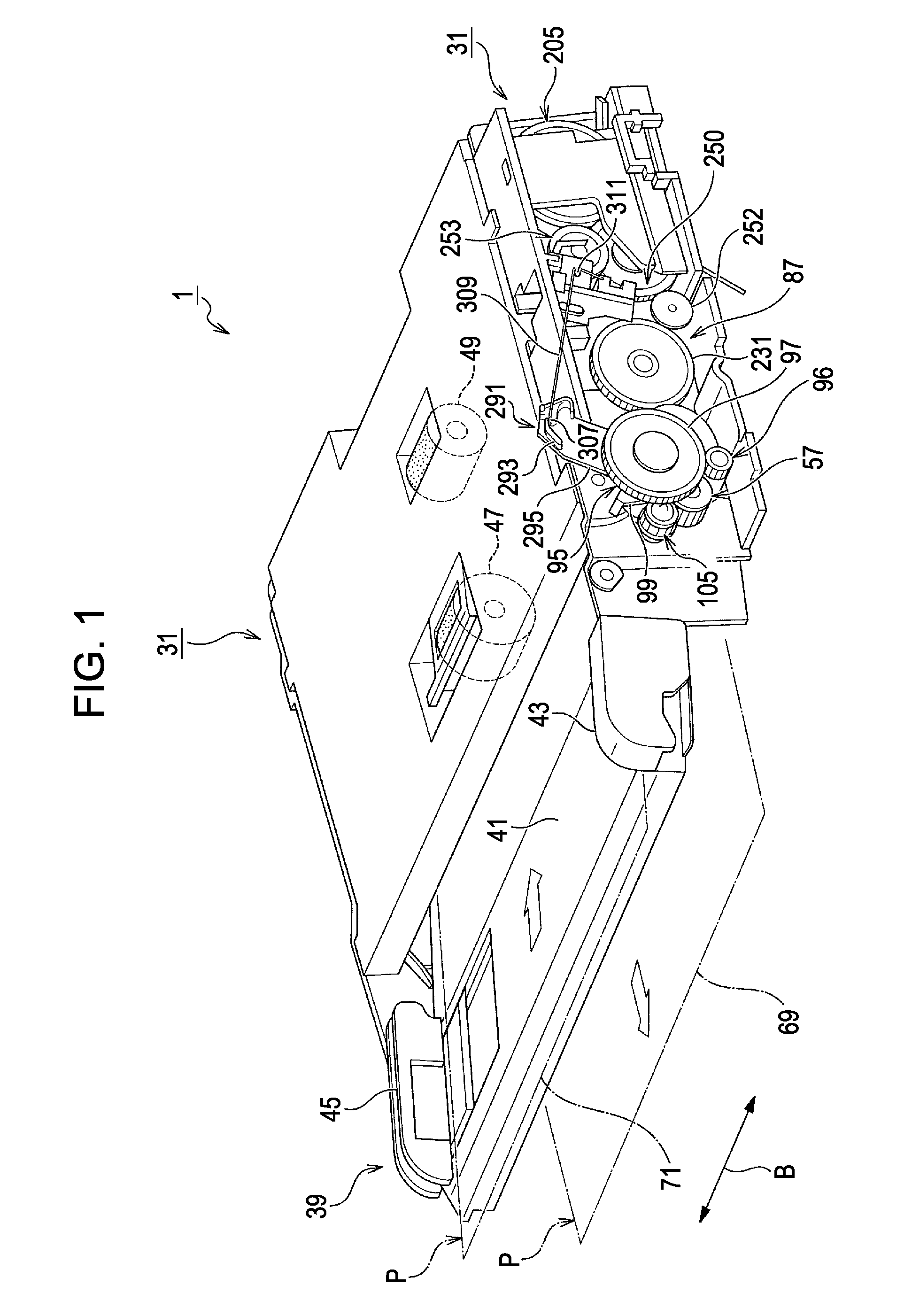

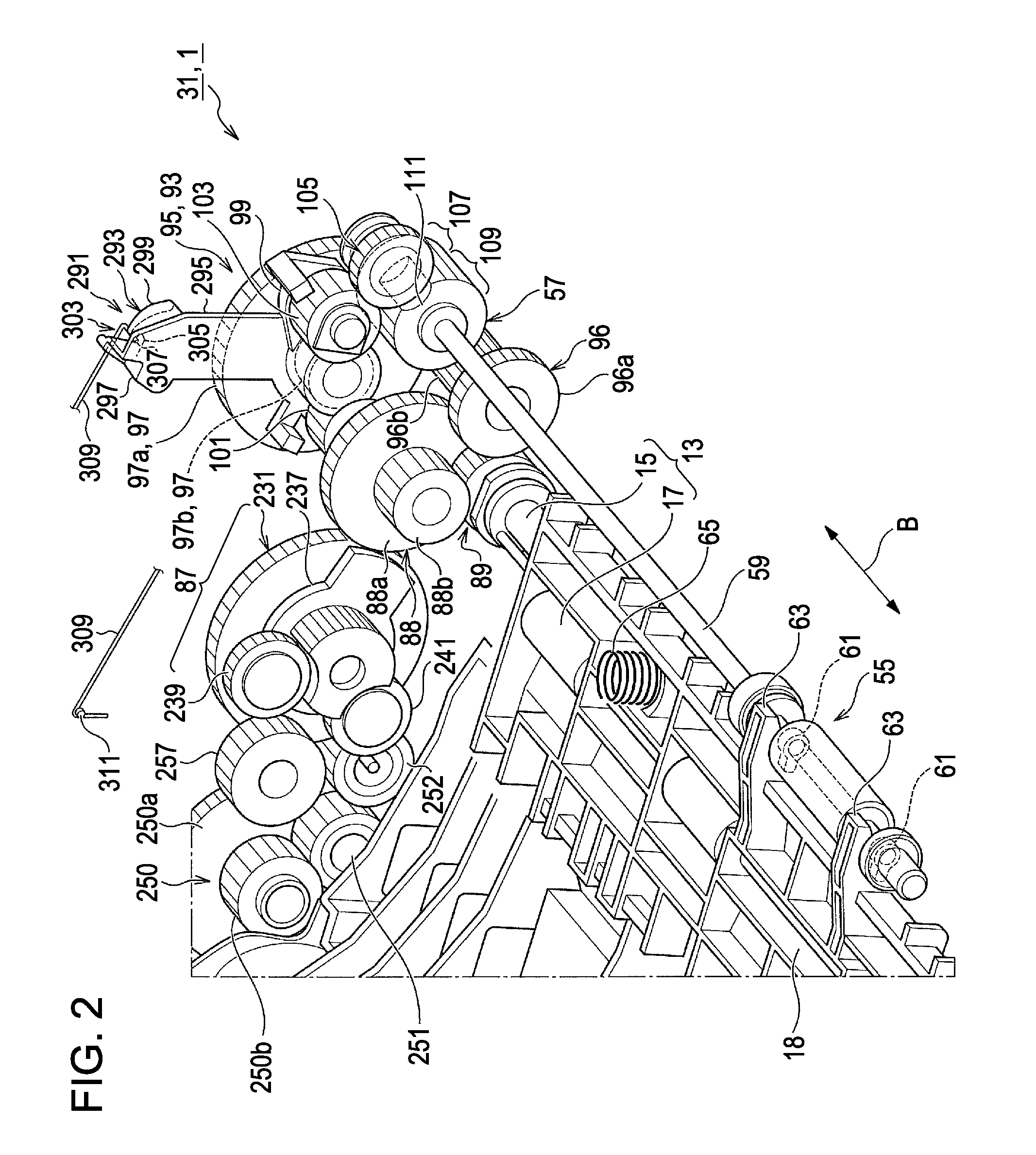

Transport-object transporting device and image processing apparatus

ActiveUS20110115146A1Wide range of lengthsRegistering devicesFunction indicatorsMechanical engineeringImage processing

A transport-object transporting device includes a power-transmission blocking mechanism that blocks the transmission of power at an intermediate point of the cam driving gear train so as to maintain the discharge roller in the release position. The power-transmission blocking mechanism includes an engaged portion provided in the rocking arm, and an engaging portion whose engagement position thereof relative to the engaged portion is changeable by changing a rocking direction of the rocking arm. When the engaging portion is set at a predetermined engagement position relative to the engaged portion, the first planetary gear and the second planetary gear are both kept away from the cam driving gear.

Owner:SEIKO EPSON CORP

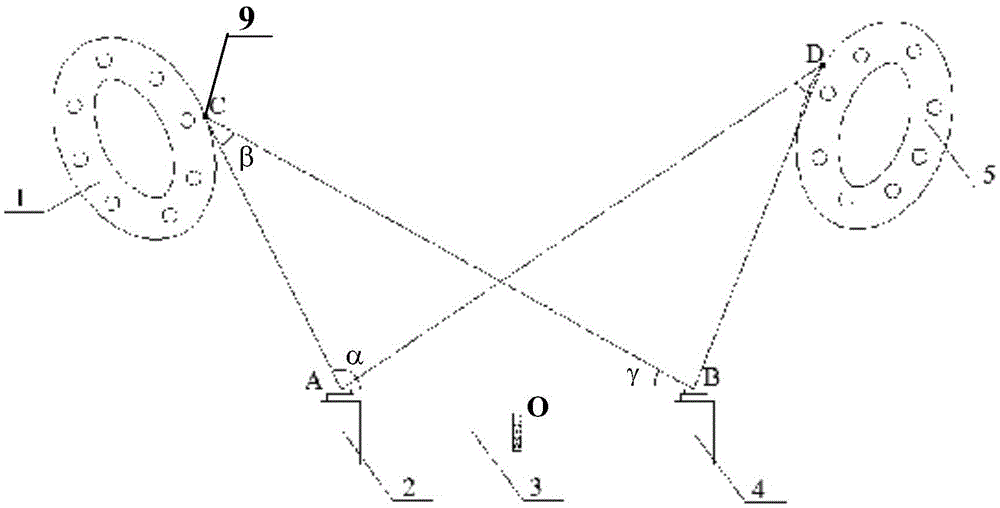

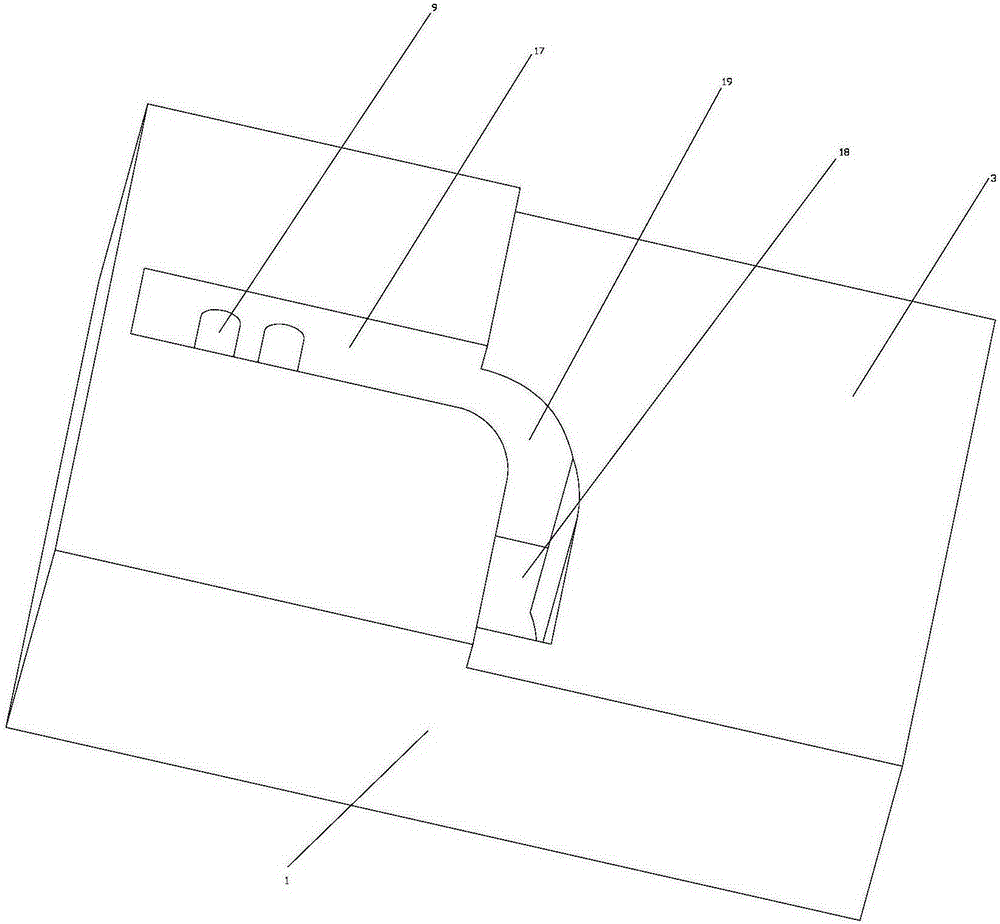

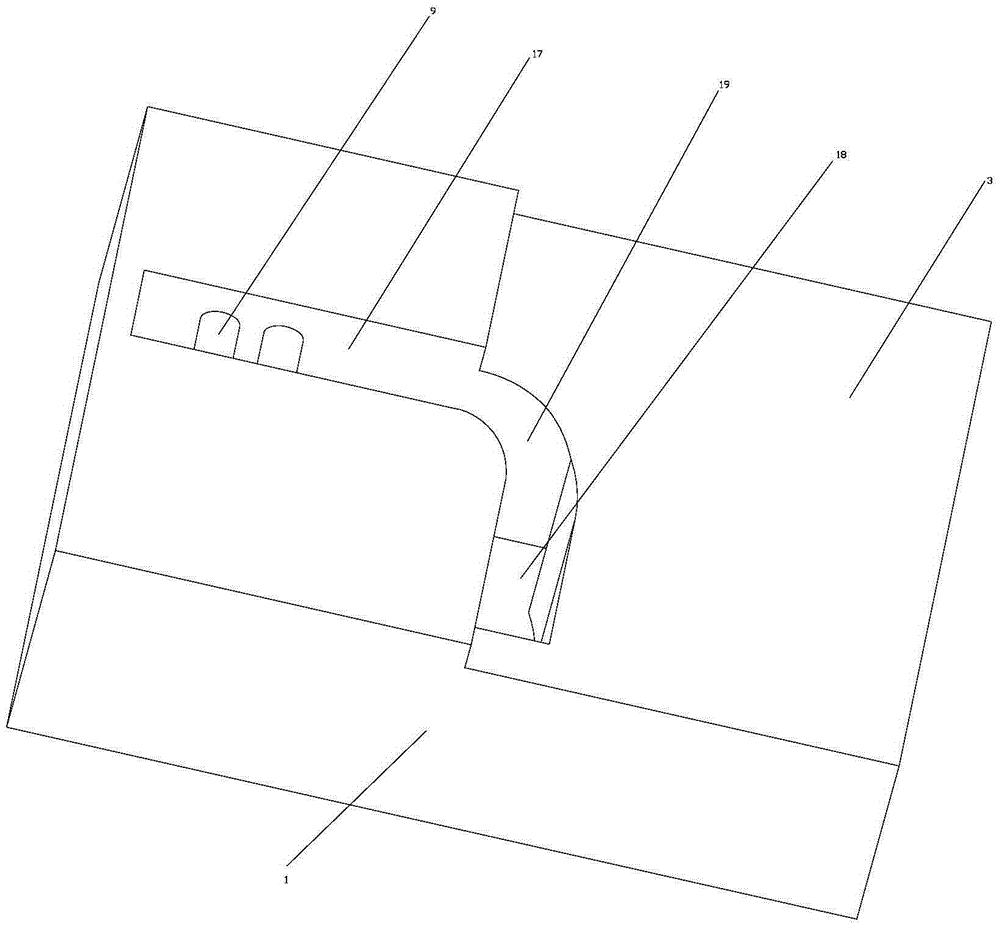

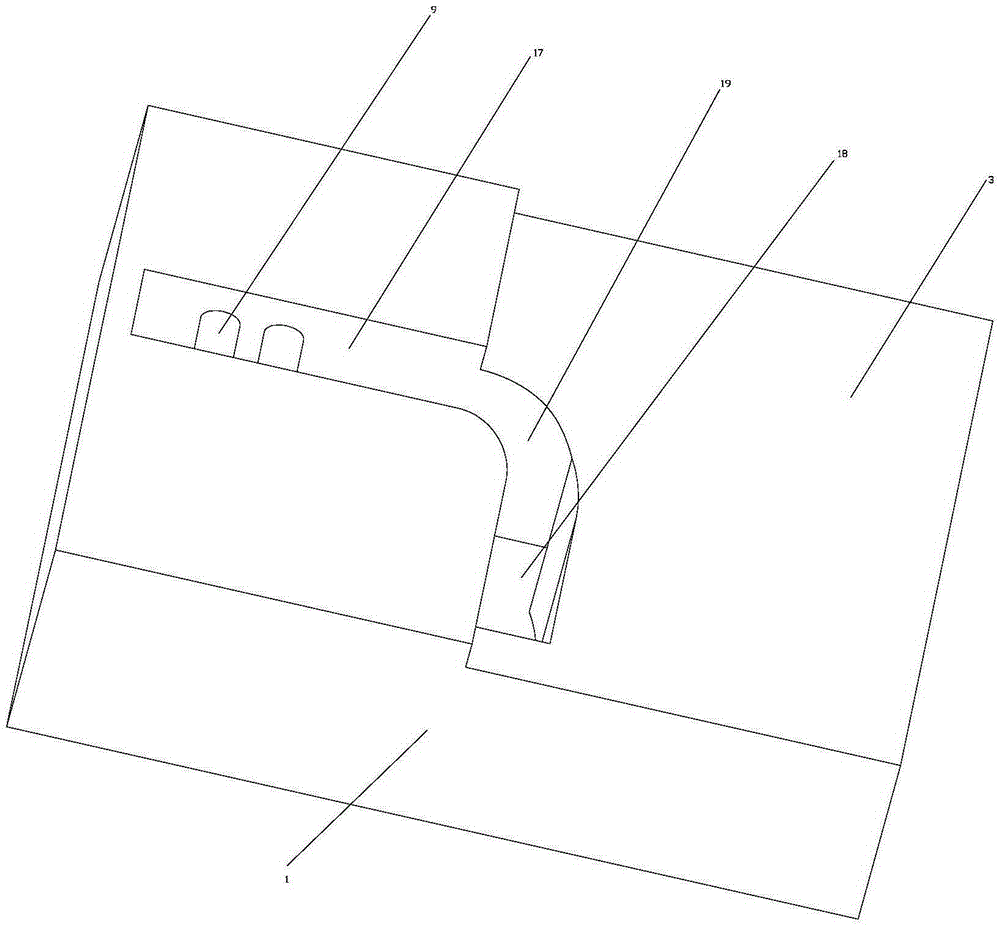

Device and method of field measurement of folding pipes on the basis of three-dimensional space shooting positioning technology

ActiveCN105488808AWide range of lengthsEasy to assembleGeometric CADImage enhancementMeasurement deviceThree-dimensional space

The present invention discloses a device and method of field measurement of folding pipes on the basis of a three-dimensional space shooting positioning technology. Ends of two folding pipes are respectively provided with first flanges and second flanges. The device provided by the invention comprises a first high-precision camera, a second high-precision camera and a telescopic pole connecting the first high-precision camera and the second high-precision camera; the first high-precision camera and the second high-precision camera are respectively provided with three mutually vertical angle sensors, a plurality of plates are arranged on the first flanges and second flanges, and data acquisition cards are configured to store shooting images of the first flanges and the second flanges and the detection data of the angle sensors are installed in the first high-precision camera and the second high-precision camera. According to the invention, the accurate position of an object may be accurately obtained in a three dimensional space, so that an accurate and stable operation environment is provided for other operations, and therefore a lot of labor cost and the labor intensity is reduced, and the work efficiency is improved.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

Transport-object transporting device and image processing apparatus

ActiveUS8328179B2Wide range of lengthsRegistering devicesFunction indicatorsImaging processingGear wheel

A transport-object transporting device includes a power-transmission blocking mechanism that blocks the transmission of power at an intermediate point of the cam driving gear train so as to maintain the discharge roller in the release position. The power-transmission blocking mechanism includes an engaged portion provided in the rocking arm, and an engaging portion whose engagement position thereof relative to the engaged portion is changeable by changing a rocking direction of the rocking arm. When the engaging portion is set at a predetermined engagement position relative to the engaged portion, the first planetary gear and the second planetary gear are both kept away from the cam driving gear.

Owner:SEIKO EPSON CORP

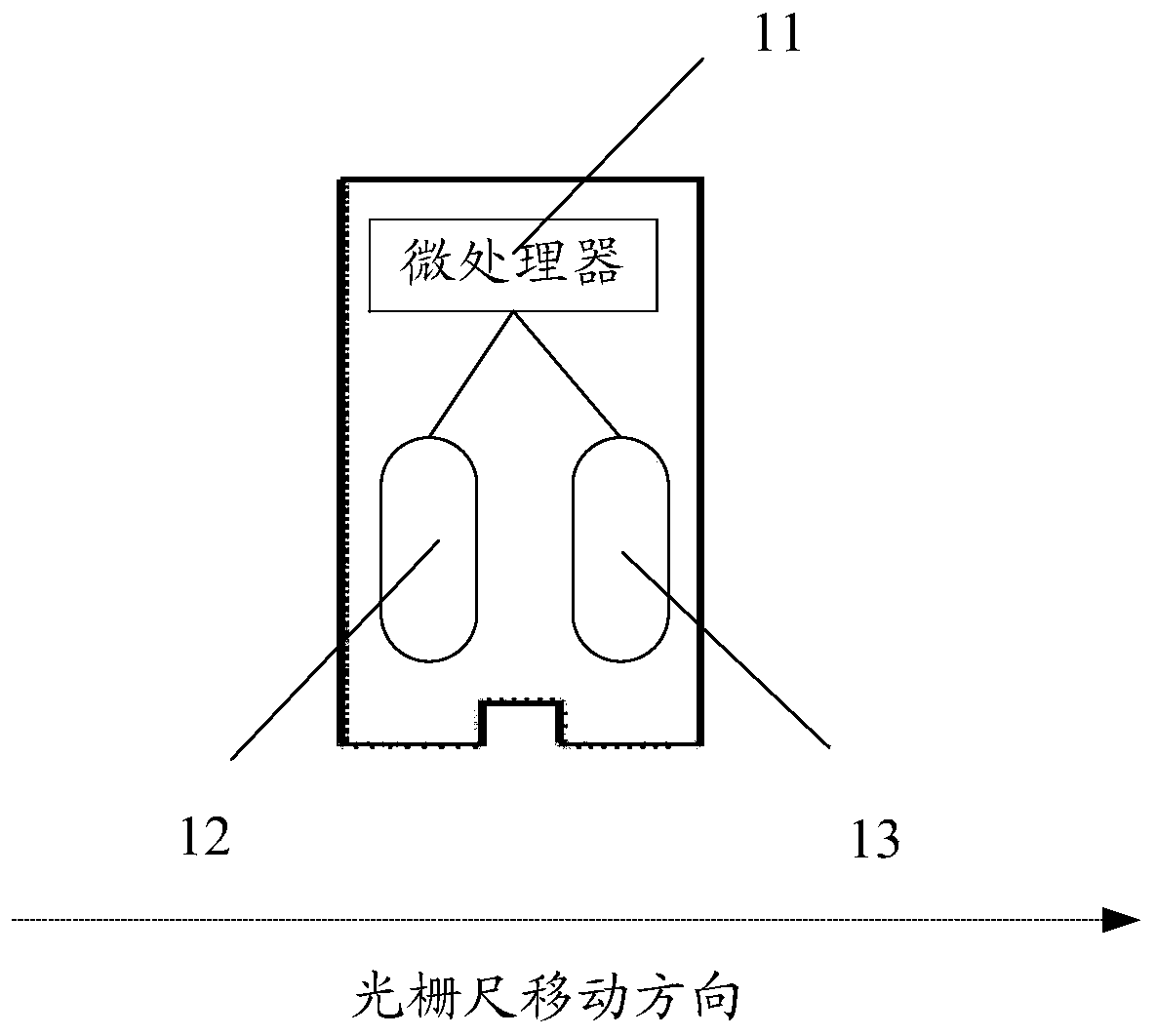

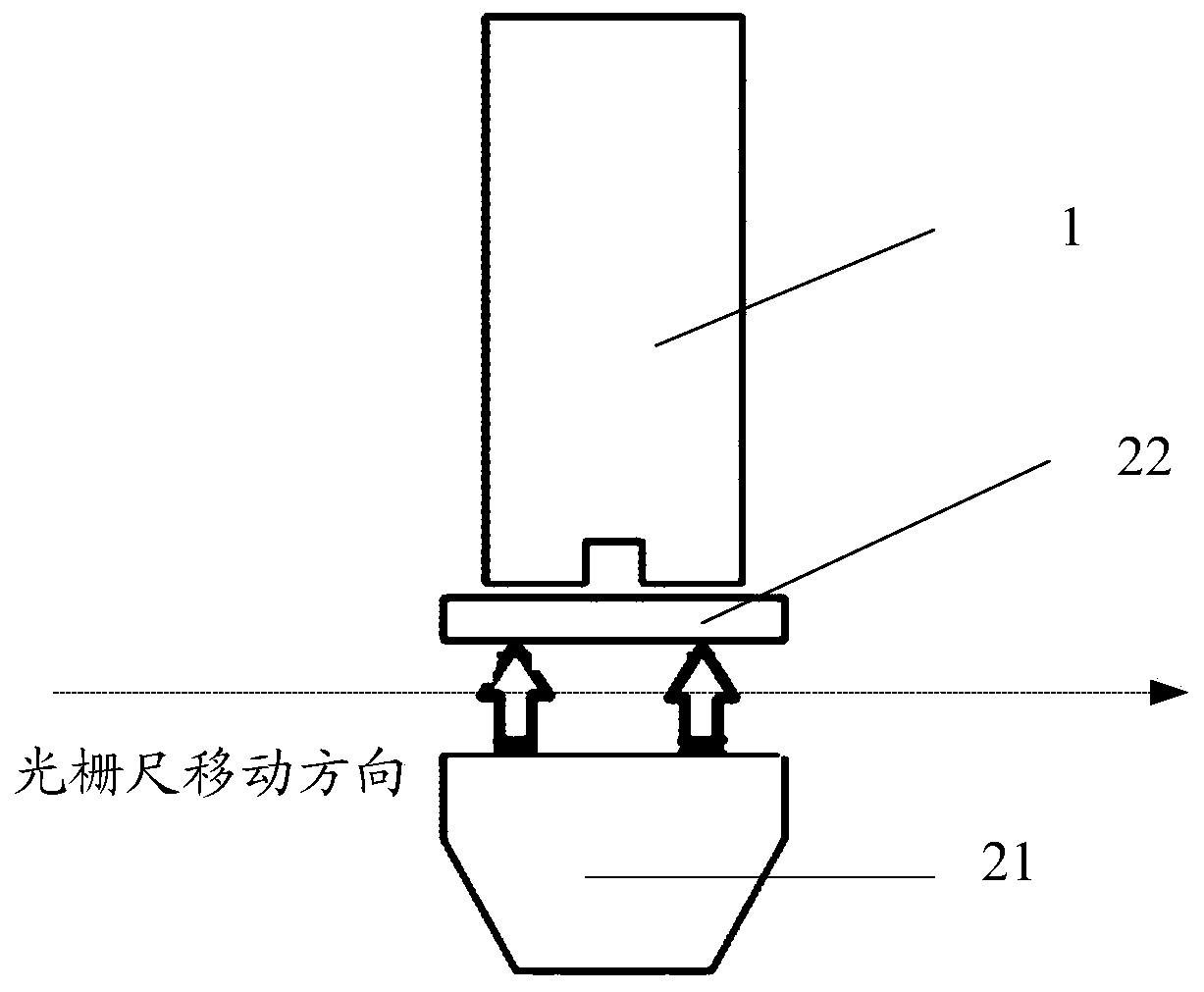

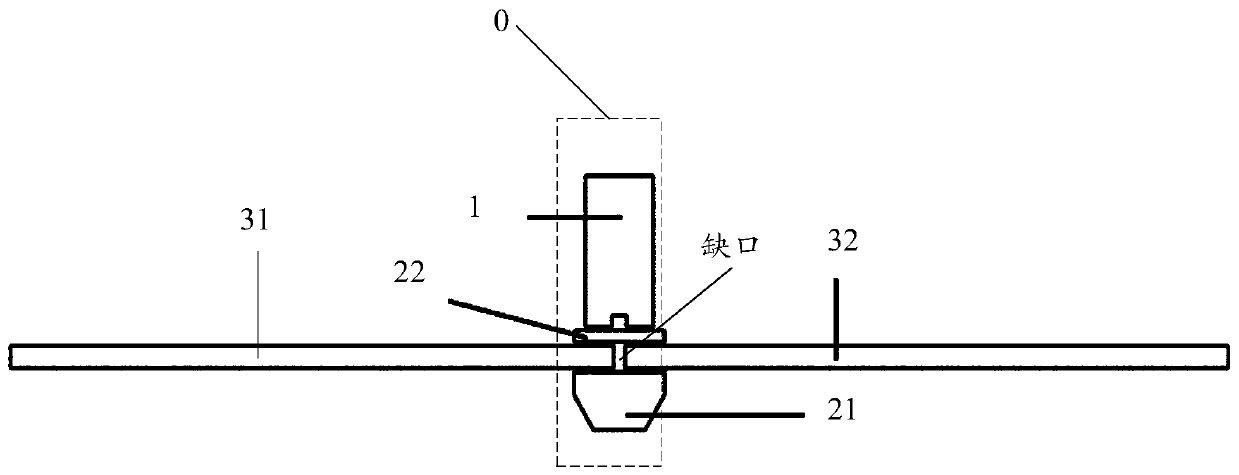

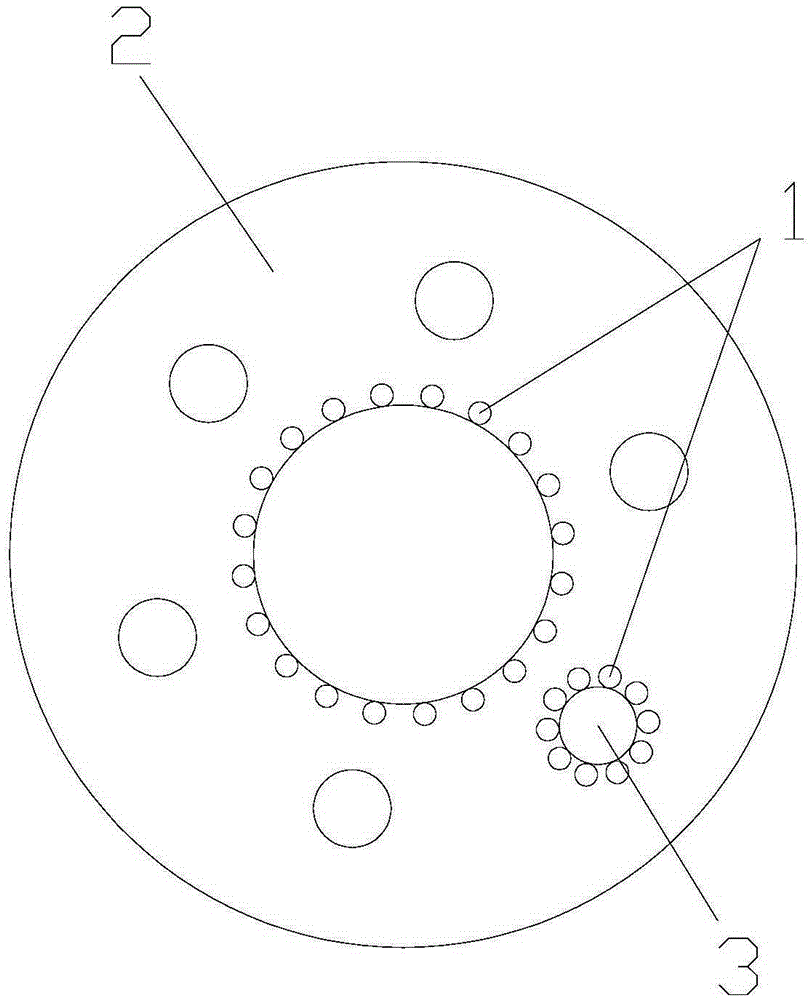

Grating scale reading head, grating scale joint and grating scale displacement sensor

The embodiment of the invention discloses a grating scale reading head, a grating scale joint and a grating scale displacement sensor. The grating scale reading head comprises a microprocessor, and afirst reading sensor and a second reading sensor which are connected with the microprocessor and arranged in the movement direction of a grading scale. The microprocessor is configured to determine that the displacement value of a current grating scale needs gap compensation according to the movement displacement values read by the first reading sensor and the second reading sensor, the actual movement displacement value of the grating scale is calculated according to the movement displacement values read by the first reading sensor and the second reading sensor and the movement direction of the grating scale, and the grating scale reading head is applied to a grating scale displacement sensor by employing a plurality of scale gratings spliced to a grating scale main body and allowing thelength values of the gaps at the connections of the scale gratings being twice larger than the distances of the grating grooves so as to improve the displacement measurement of the grating scale displacement sensor and facilitate achievement of increasing of the measurement range of the grating scale displacement sensor through increasing of the scale grating length.

Owner:GUANGDONG UNIV OF TECH

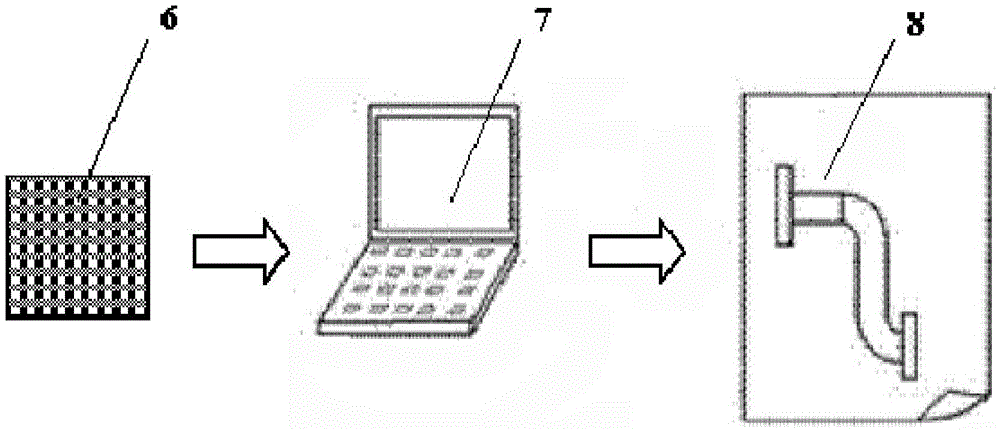

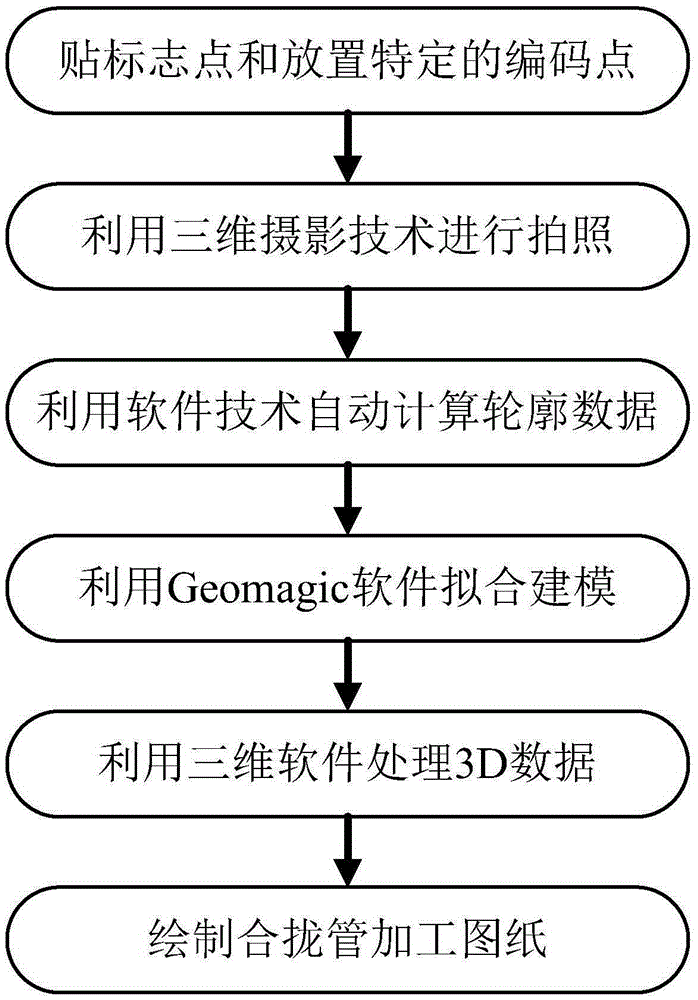

Three-dimensional photography technology based folded pipe field measurement method

InactiveCN105302961AEasy to measureShorten the timeUsing optical meansSpecial data processing applicationsAnti jammingMeasurement precision

The invention discloses a three-dimensional photography technology based folded pipe field measurement method. The method comprises the following steps: (1) arranging a plurality of mark points on a flange and a pipe, and placing encoded points in a spatial position near to-be-measured flange and pipe; (2) performing multi-angle shooting around the pipe and the flange by using a camera or a video camera; (3) copying and storing all shot photos in a computer, and automatically and quickly calculating contour data and spatial relative position data of the pipe and the flange by utilizing three-dimensional photography software; (4) importing the obtained data into Geomagic software, and performing fitting modeling by utilizing the software to form required pipe and flange; and (5) performing analytic processing on 3D data by utilizing related three-dimensional drawing software, drawing a required folded pipe processing drawing, and outputting the drawing in a PDF format. The measurement method is simple, convenient and high in measurement precision, is slightly influenced by factors such as environment and the like, is not influenced by factors of space and light, and is relatively high in anti-jamming capability.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

Plugging technology of high infiltration layer

The blocking-off process for high water seepage layer includes injecting dispersion fluid-I into stratum, injecting dispersion fluid-II, keeping well in close state for 5-7 days and injecting steam chemically. The dispersion fluid-I is compounded with waste well drilling polymer sludge and lignosulfonate in 0.1-5 wt% as sludge diluent. The dispersion fluid-II is compounded with waste oil field sludge in 30-50 wt%, waste water in 49-69 wt% and OP-type surfactant as dispersant in 0.3-1 wt%. The present invention can block active side and bottom water in oil deposit area effectively in monoway without blocking hot exploitation steam injecting channel. The present invention has relatively low cost, and is suitable for exploit dense oil thermally.

Owner:金军

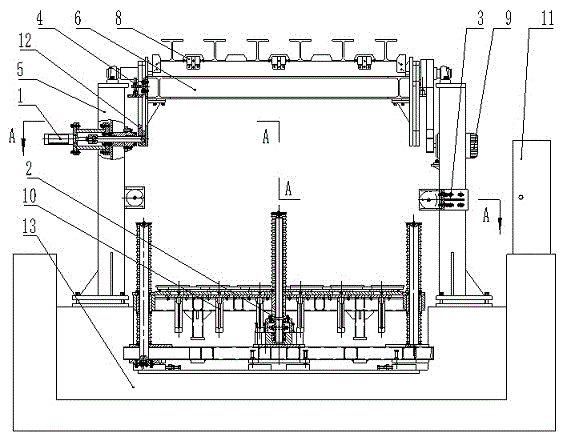

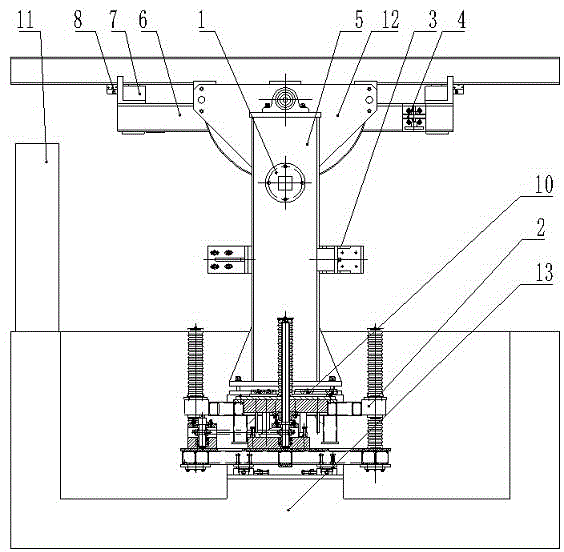

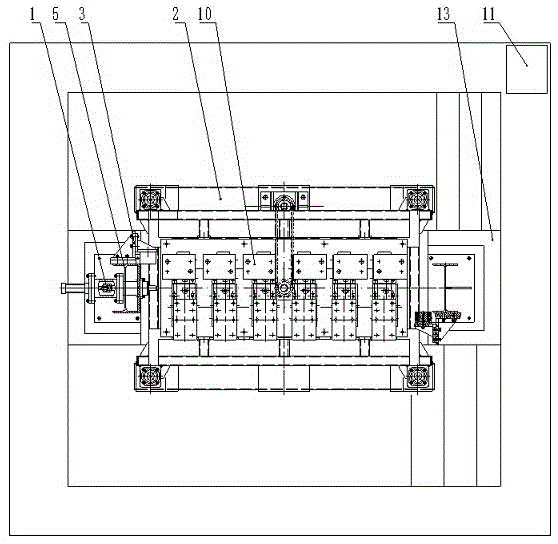

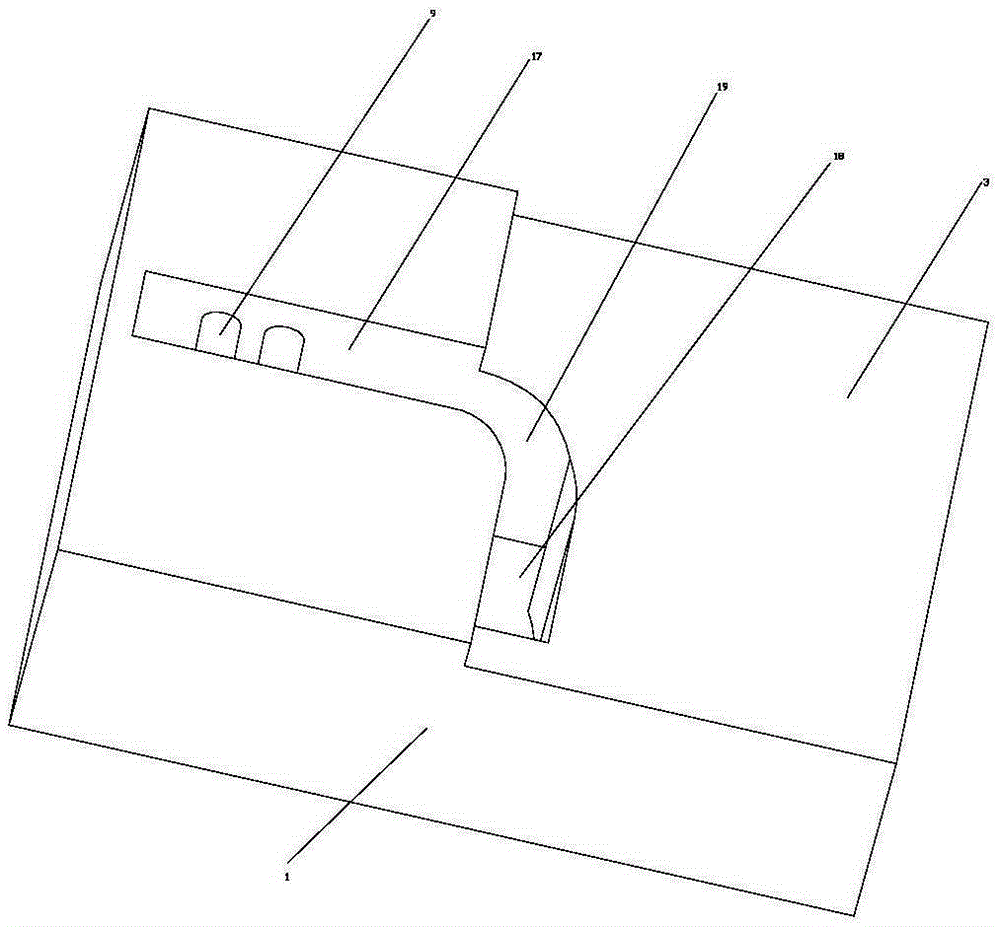

H-shaped steel turnover welding device

ActiveCN104526236AEasy to operatePlay a limiting roleWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention relates to an H-shaped steel turnover welding device which comprises stand columns, a rotary frame, a locating and locking device, a lifting device and a limiting device. The locating and locking device comprises a locking mechanism on the stand columns and a frame locating frame which is fixedly connected to the rotary frame and matched with the locking mechanism, the lower portion of the lifting device is connected with a height adjusting device, the vertical movement range of a column foot plate and an upper top plate can be adjusted within a large range, and therefore the located profiled steel length range is wider. The mode of pushing a locating shaft through an air cylinder piston rod is adopted in the locating and locking device, and compared with a manual mode, an operator only needs to carry out operation through a control switch, and the operation is more convenient. In the limiting device, electromagnetic suction cups and limiting plates are used in cooperation, the limiting function is achieved, meanwhile, the locating function is achieved, when a locating position is inaccurate, the accurate position can be found out by adjusting an adjusting screw rod, and the problem that adjustment is inconvenient if deviation occurs after locating hole locating mounting is adopted is solved.

Owner:济南天辰智能装备股份有限公司

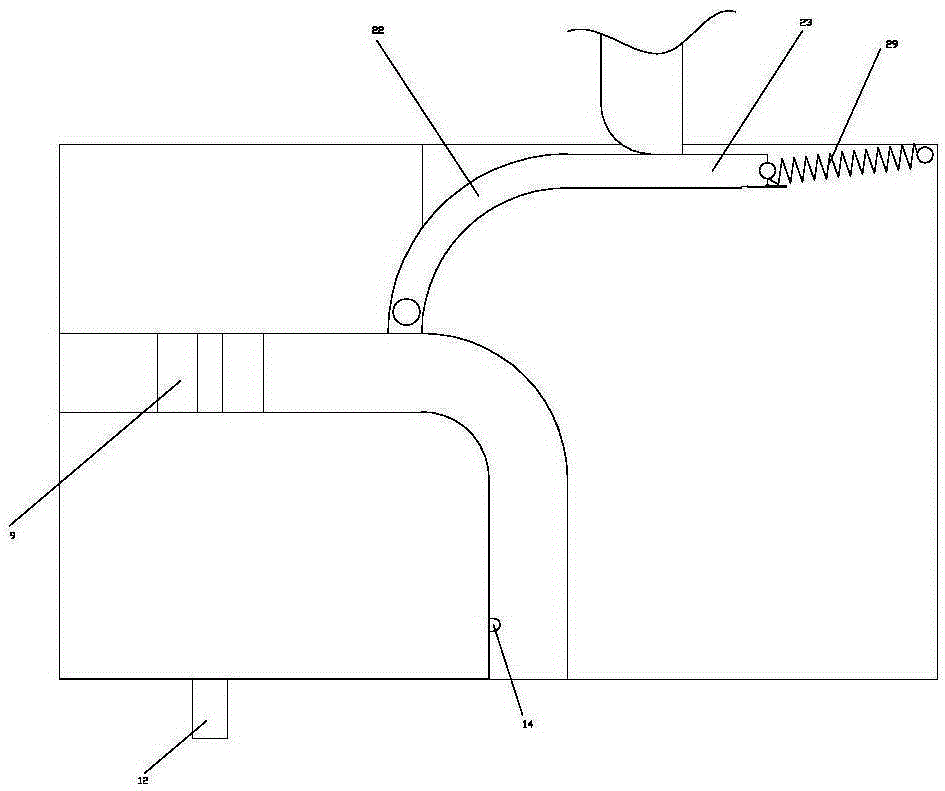

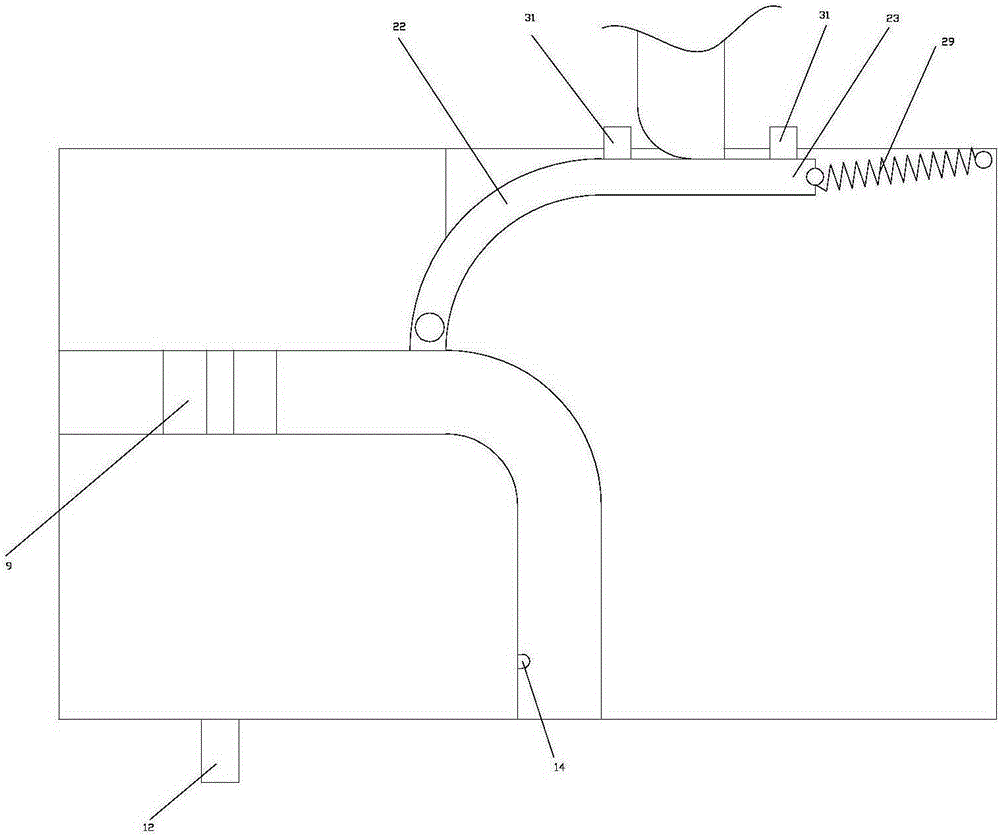

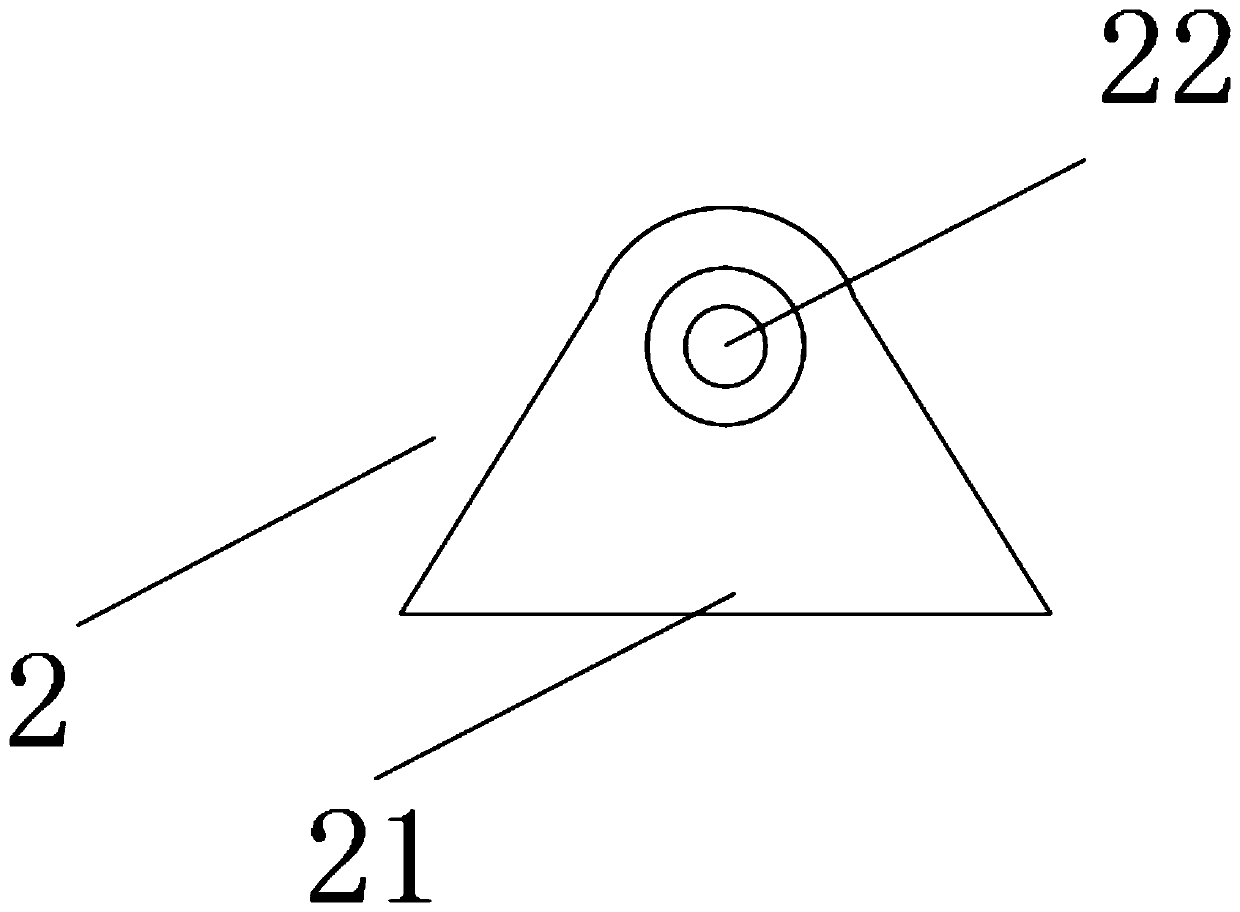

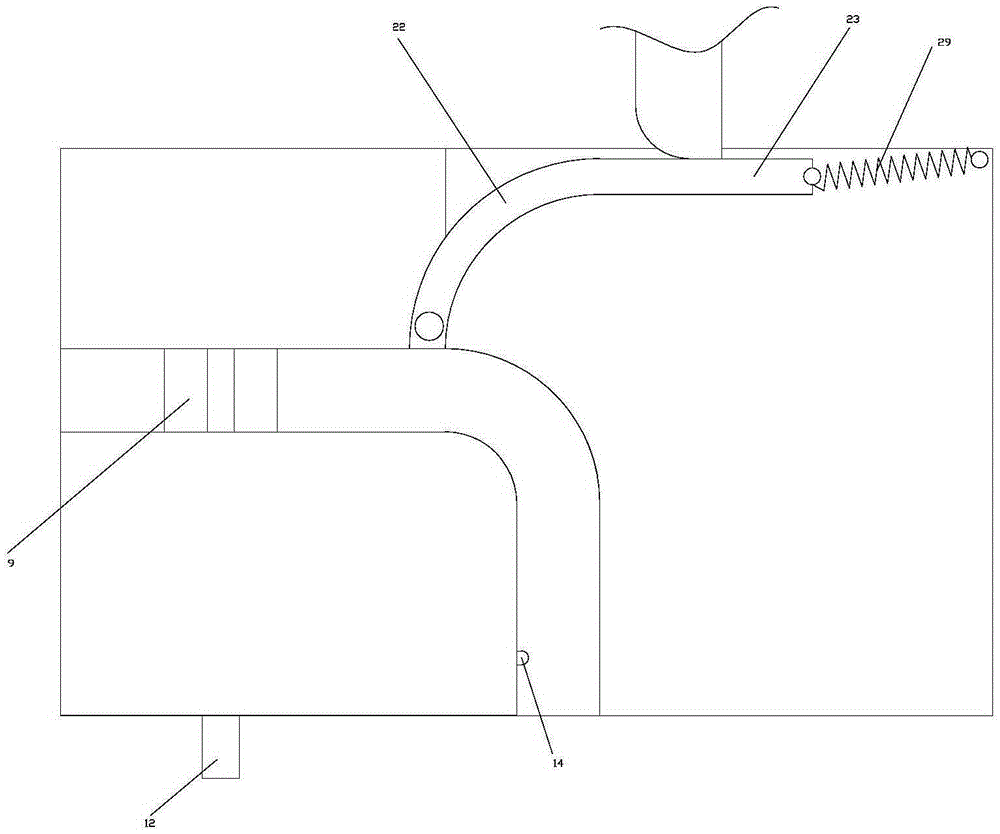

Bending discharging device

InactiveCN105290171ASimplified operational requirementsImprove securityStripping-off devicesEngineering

The invention discloses a bending discharging mechanism. The bending discharging mechanism comprises a base (1). The base (1) is provided with a reference face (3) used for containing the free end of a pipe (2), and the free end of the pipe (2) rotates through the reference face (3). The base (1) is provided with a boss (4) which is higher than the reference face (3) and is used for positioning the other end of the pipe (2). The boss (4) is provided with an opening (5). The base (1) is provided with a through hole (6) for the bent pipe (2) to slide in the vertical direction. The bending discharging mechanism is low in maintaining cost and easy and convenient to operate, and manual pipe taking is not needed.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

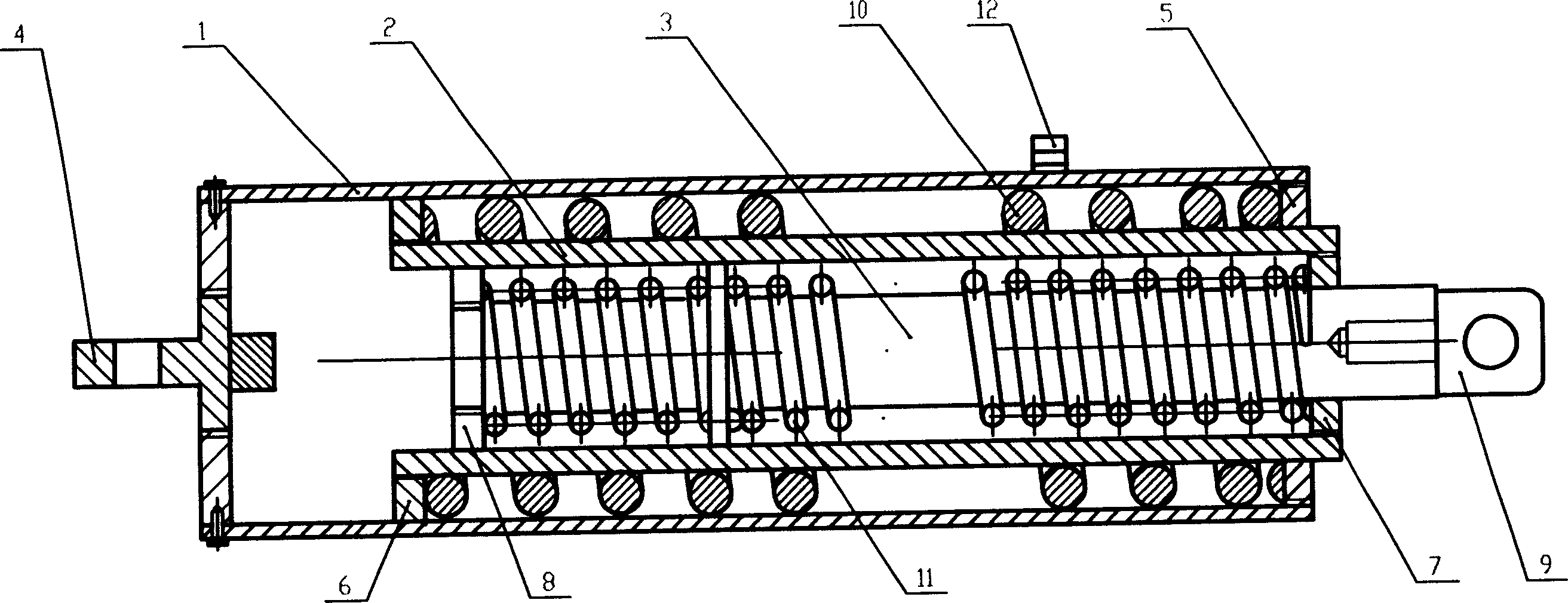

Elasticity tension automatic compensator for contact net

An automatic elastic tension compensator for the contactor of electric collector is composed of left and right external suporting pads, left pull hook passing through left external supporting pad and fixed to right one, right pull hook passing through right external supporting pad and fixed to left one, at least two serial springs on said left and right pull hooks, and internal supporting pad between said springs. Its advantage is high tension-compensating precision.

Owner:马泽民

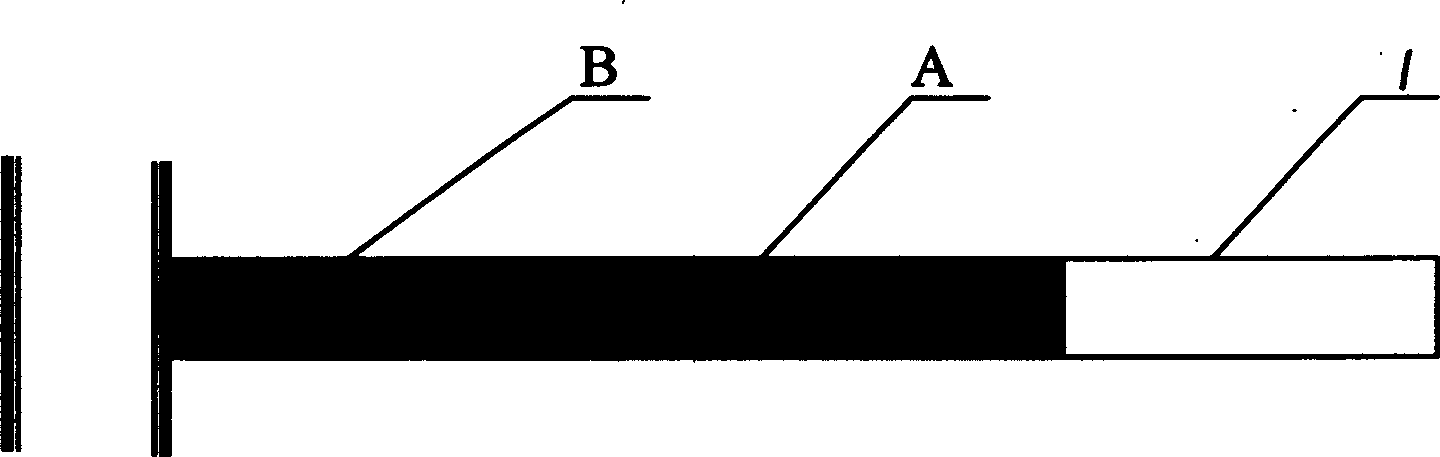

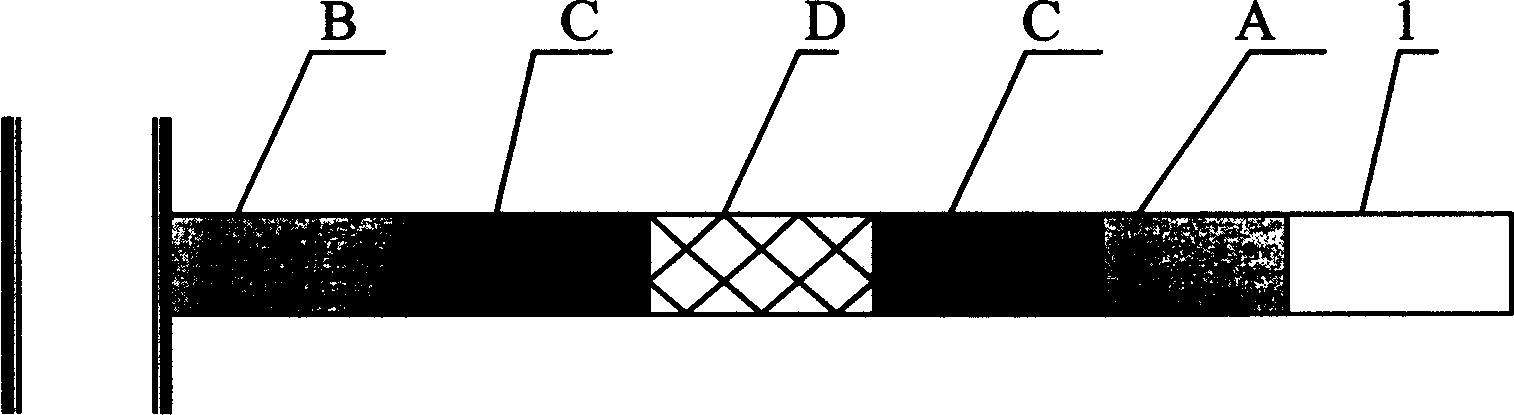

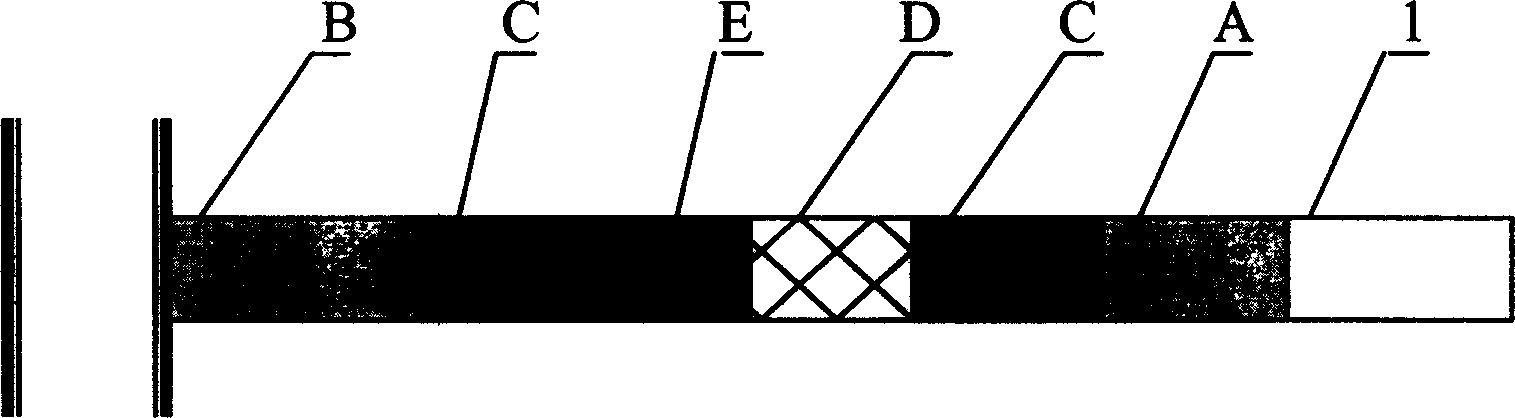

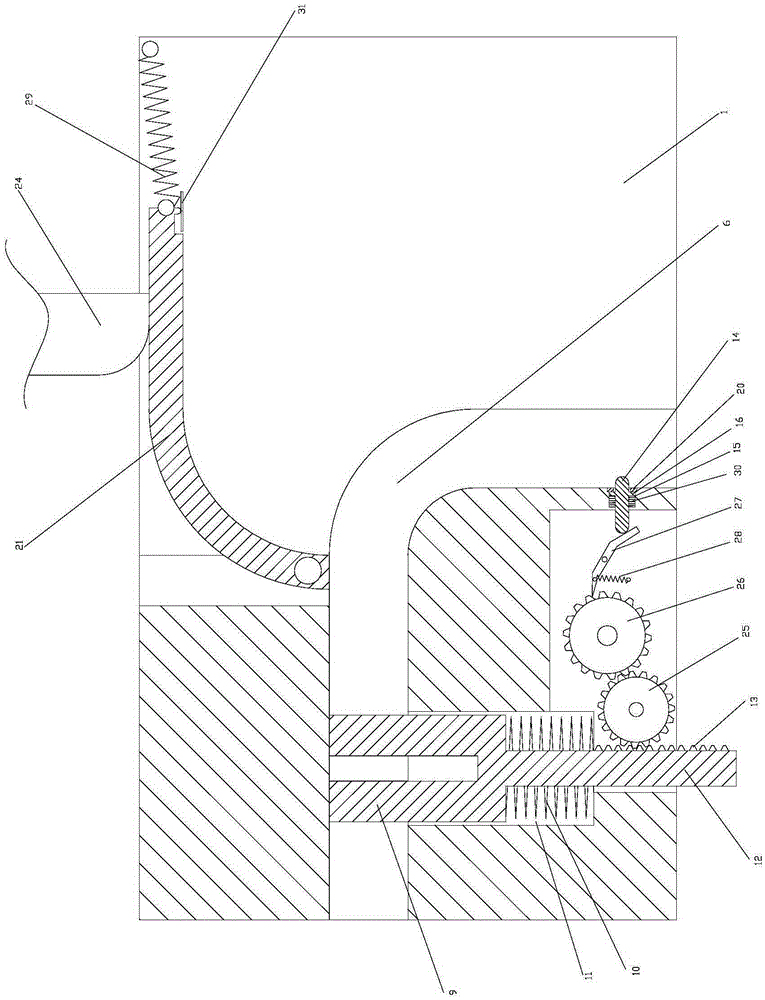

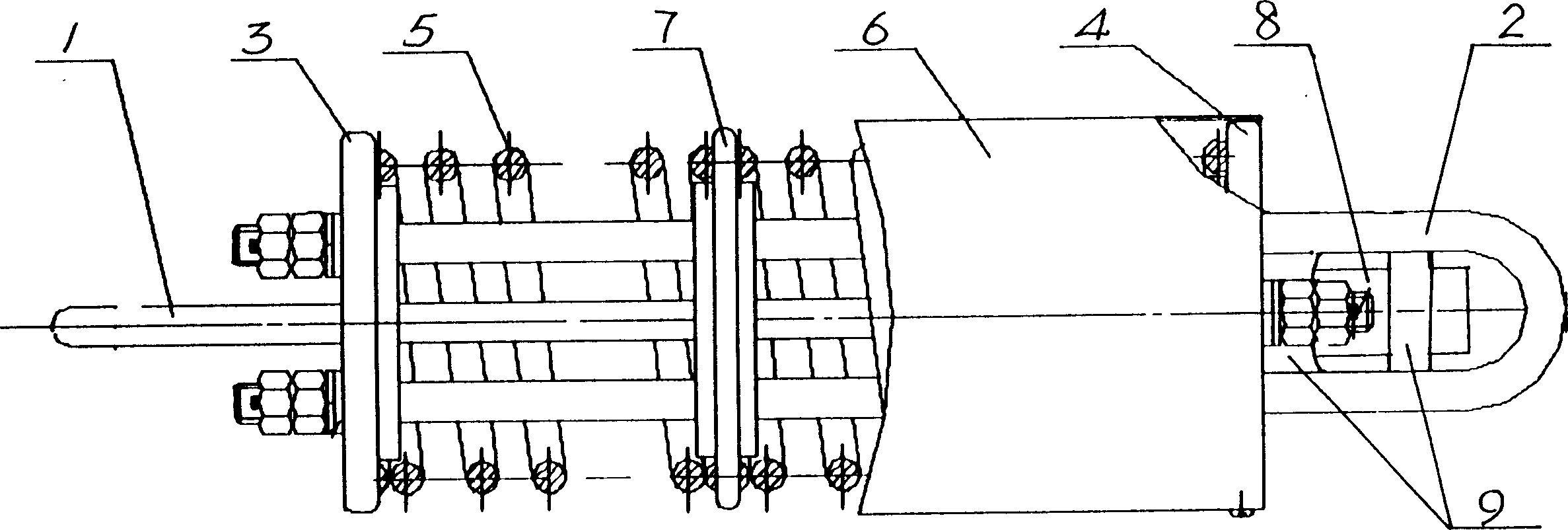

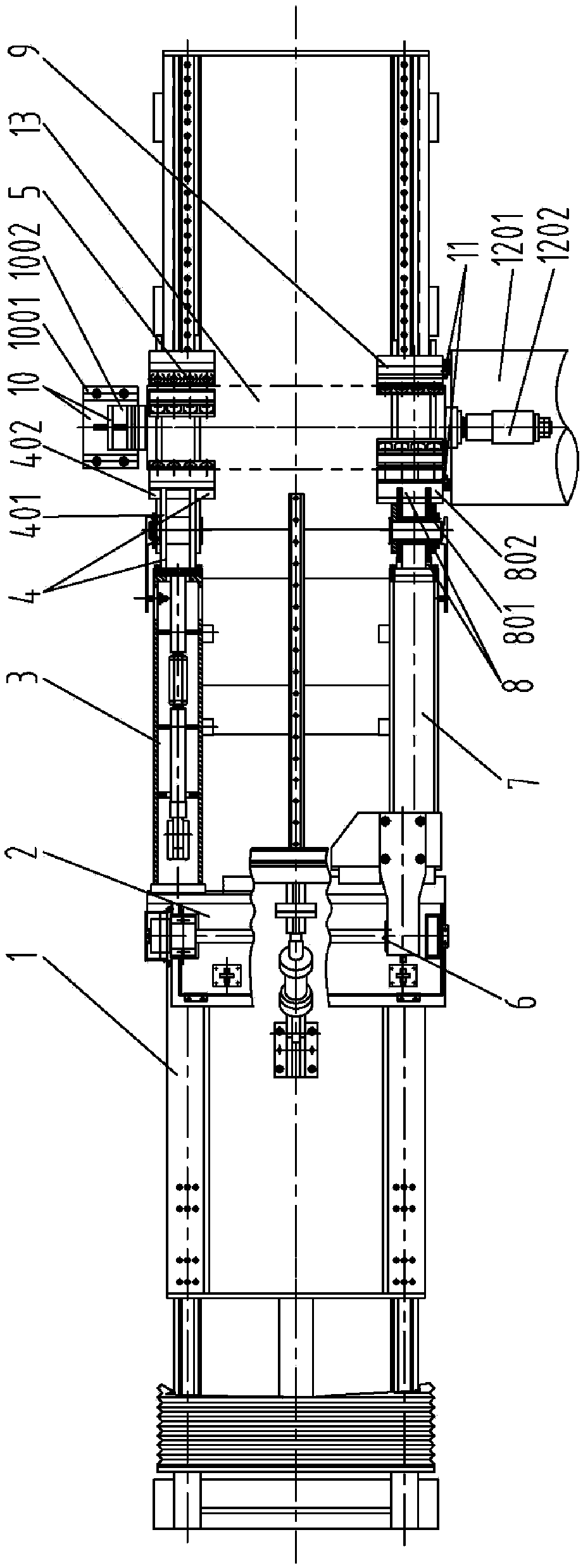

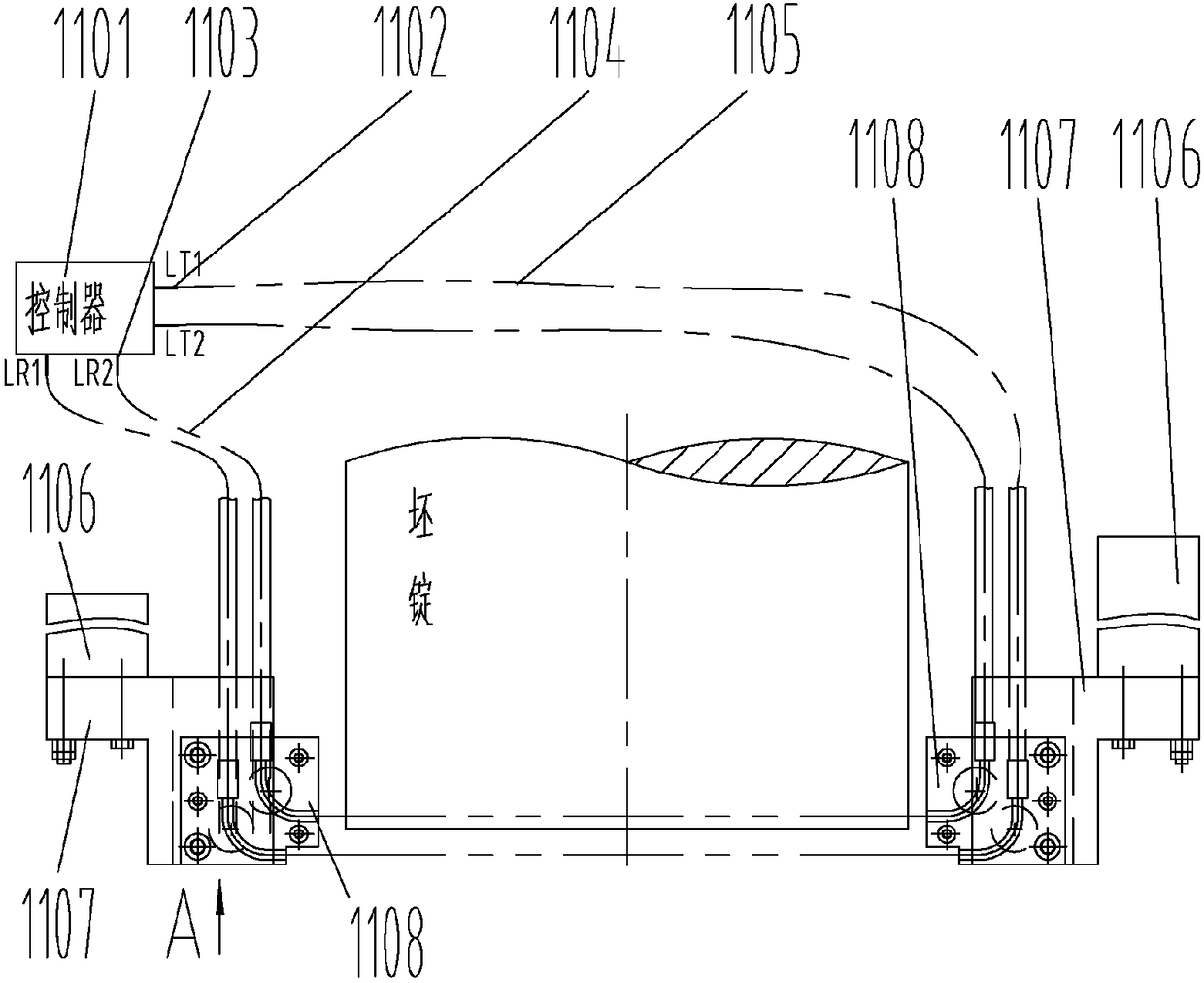

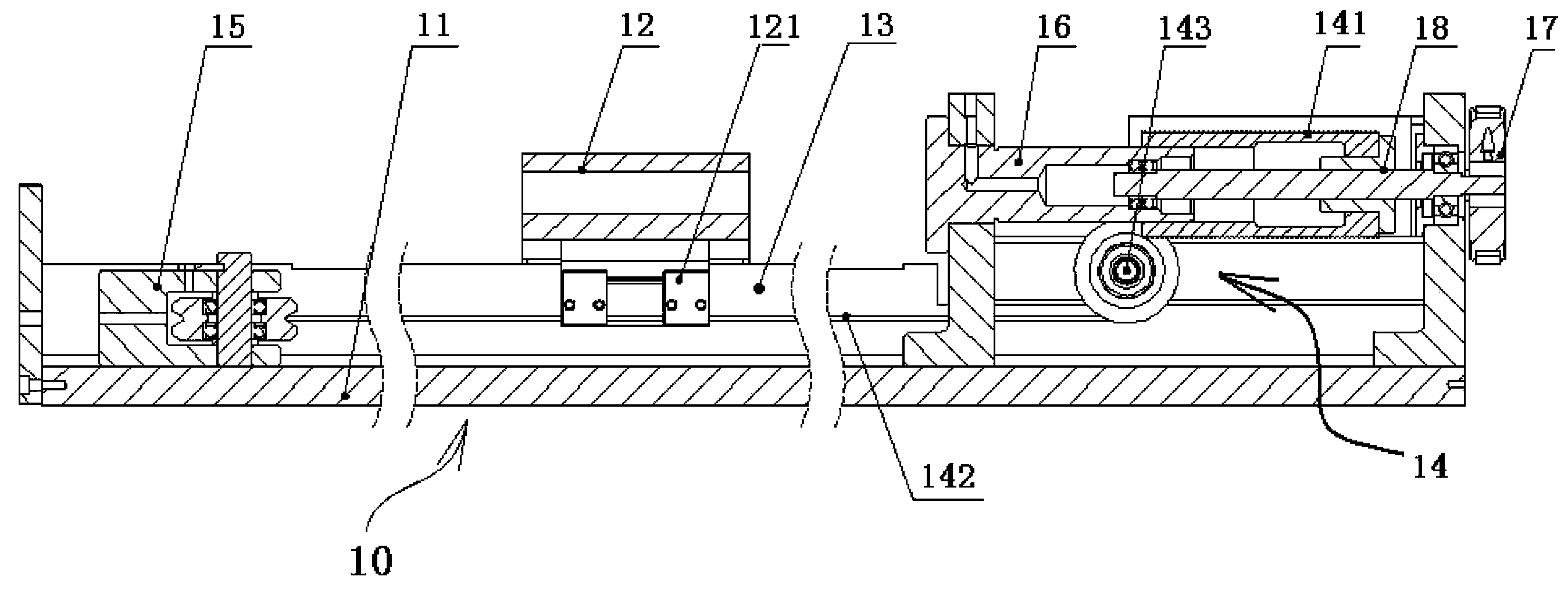

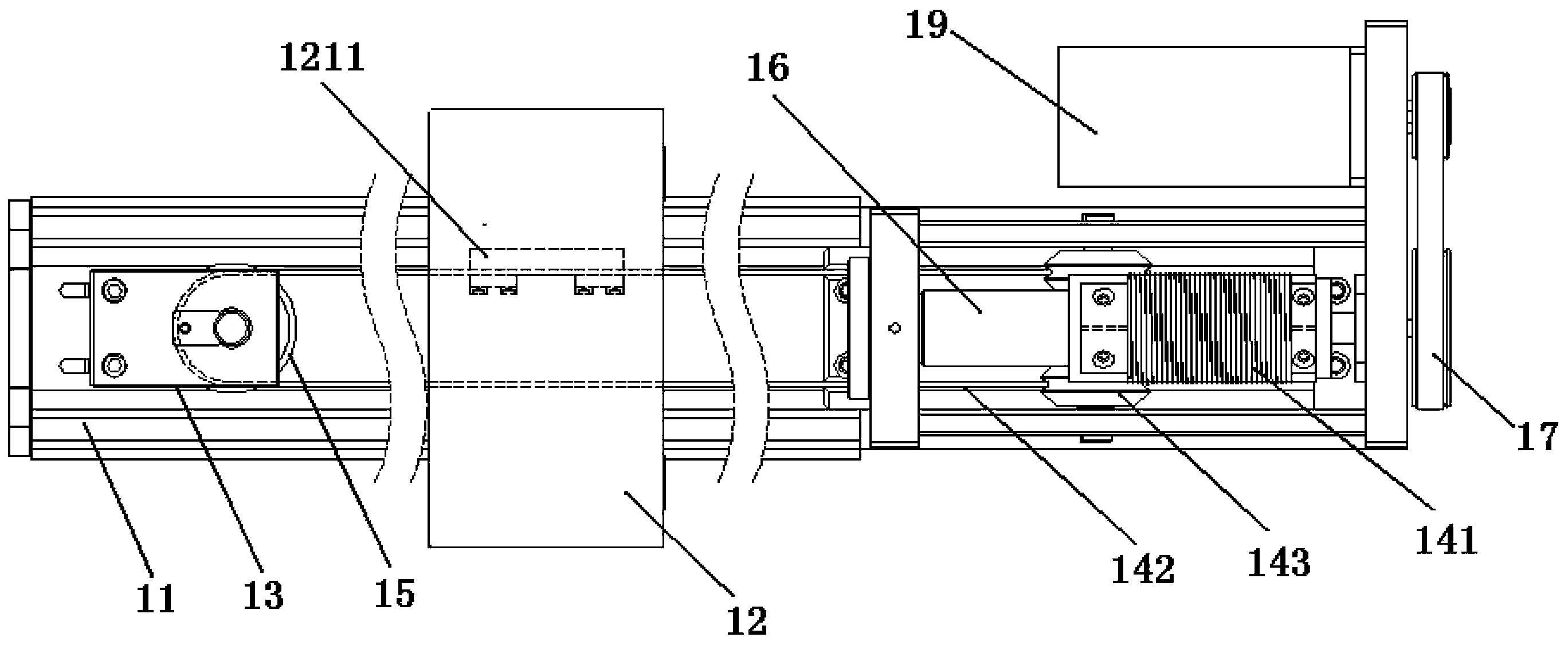

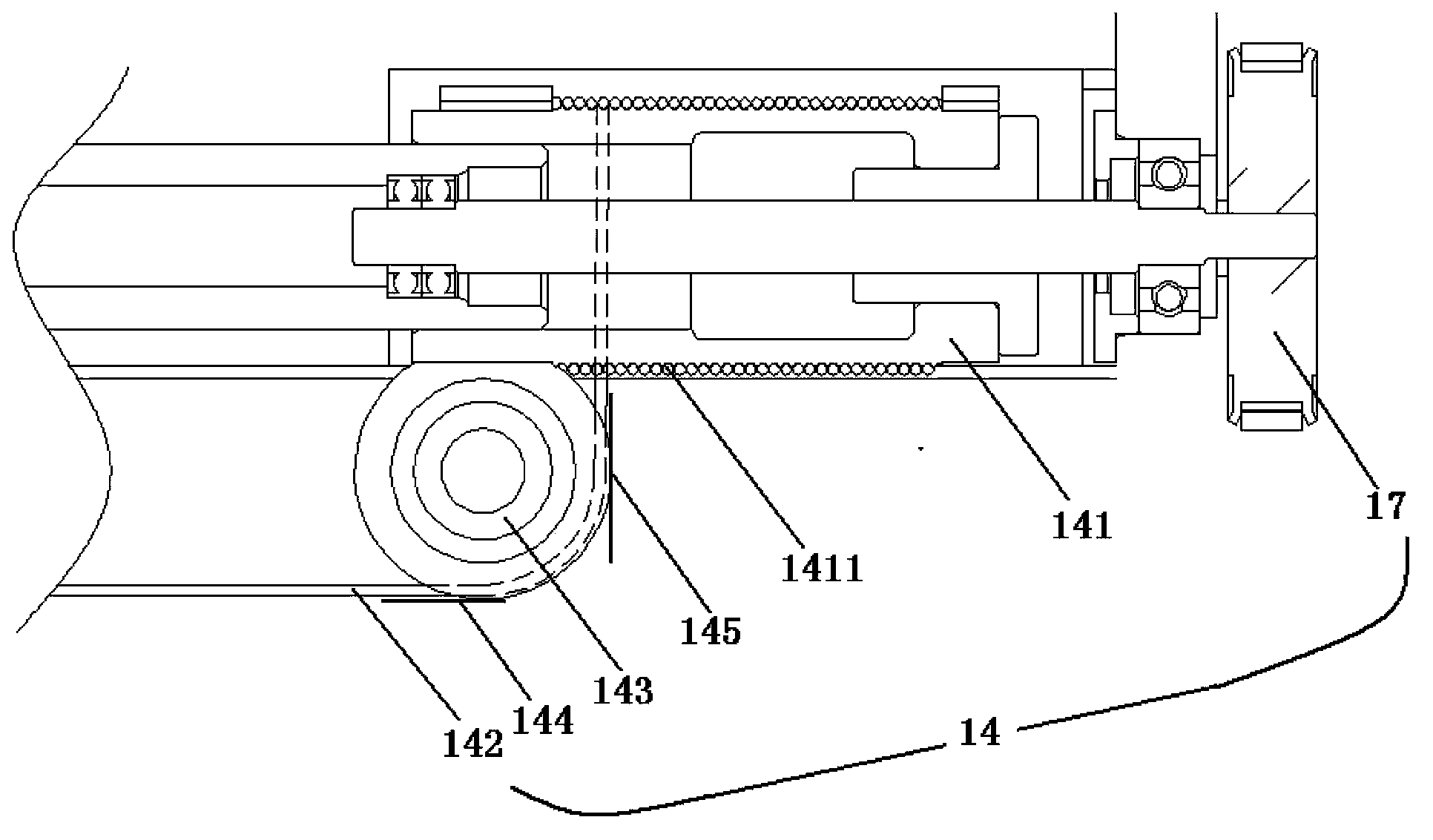

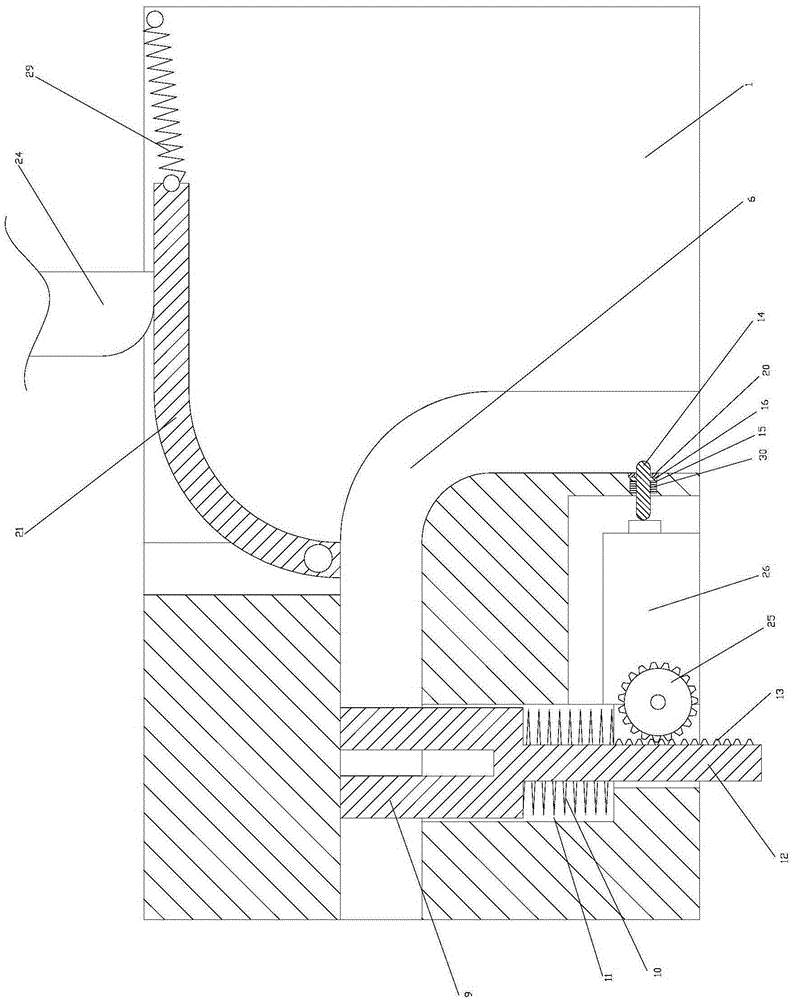

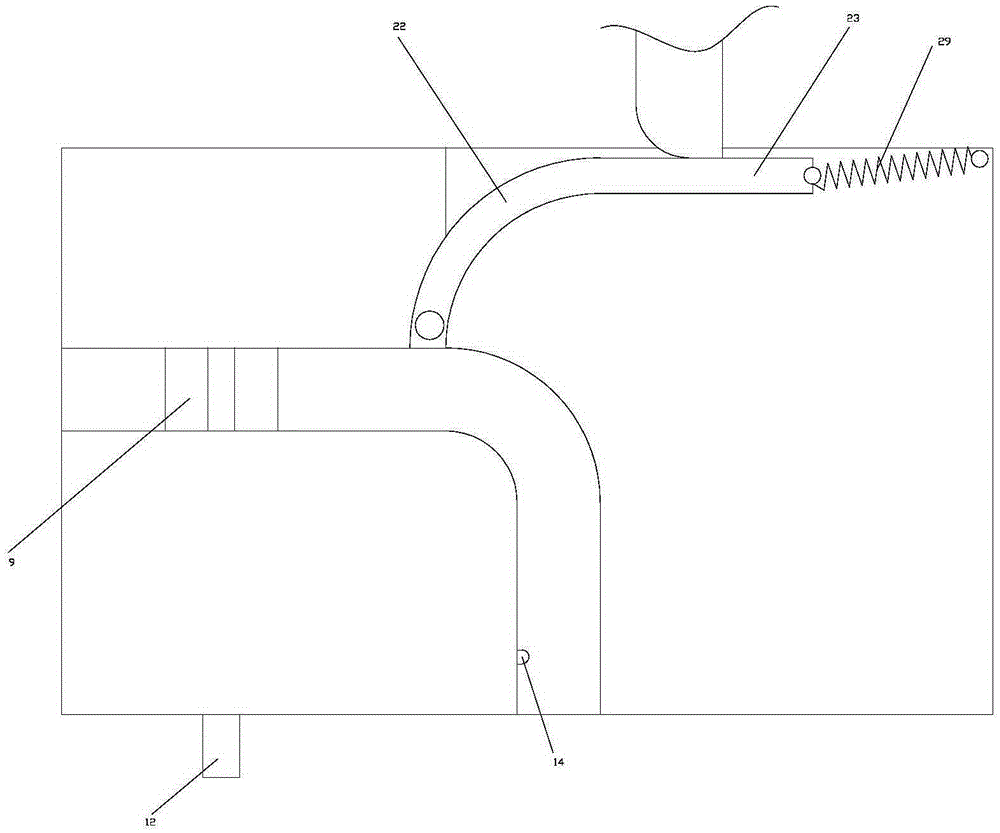

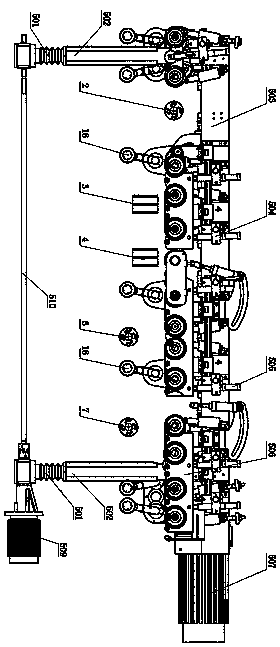

Ingot supply system of short-travel front loading extruder

ActiveCN108393366ARealize self-adaptive ingot supply functionLow driving powerExtrusion control devicesEngineeringIngot

The invention discloses an ingot supply system of a short-travel front loading extruder. The system comprises a fixed arm ingot supply clamp, a movable arm ingot supply clamp, a main controller, a blank ingot position detecting device positioned in a port of the movable arm ingot supply clamp, an ingot pushing device for pushing blank ingots behind the blank ingots, an ingot pushing head positiondetecting device for detecting the position of an ingot pushing head, and a blank ingot limiting device arranged on the front side of the fixed arm ingot supply clamp. The main controller obtains ingot length data of present blank ingots according to blank ingot position data detected by the blank ingot position detecting device and ingot pushing head position data detected by the ingot pushing head position detecting device, so that ingot length types of the blank ingots are determined, and synchronous movement of the movable arm ingot supply clamp relative to the ingot pushing head is controlled according to control policies corresponding to the ingot length types. The ingot supply system of the short-travel front loading extruder can realize synchronous shrinkage of movable arms, and widens applicable blank ingot length range.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

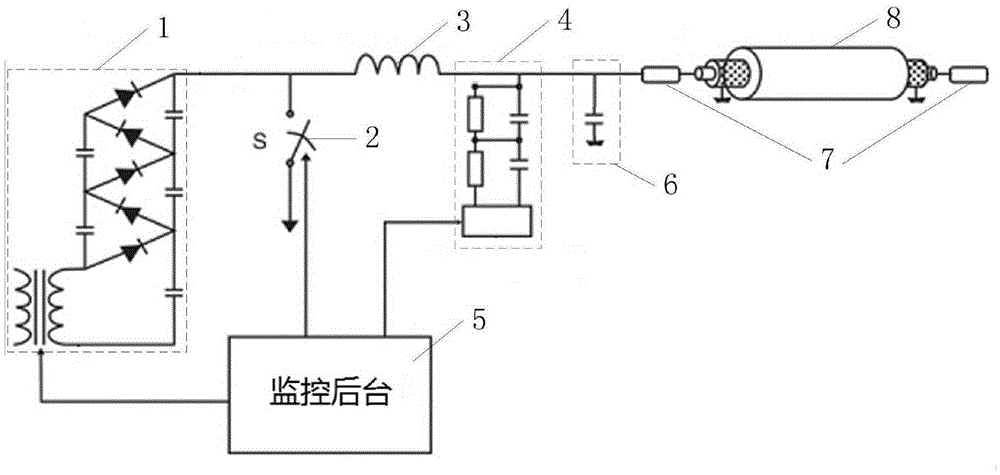

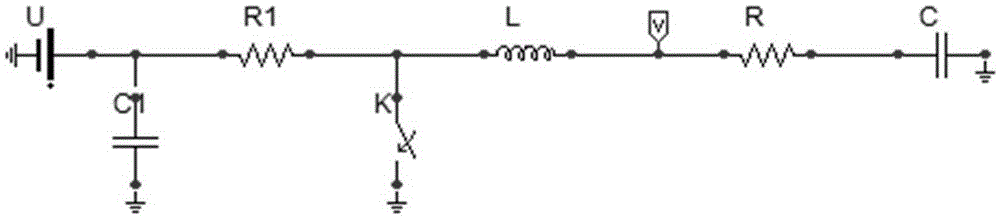

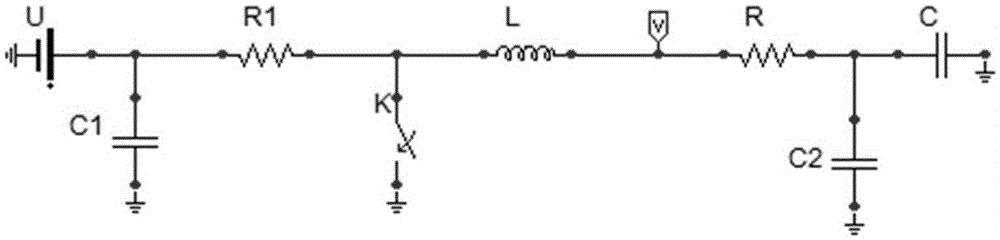

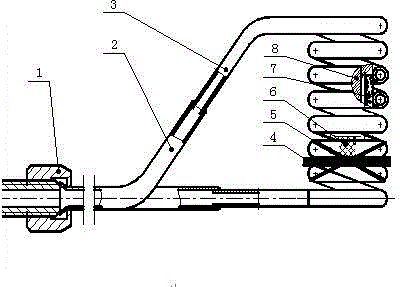

Novel cable oscillation wave partial discharge detection system

InactiveCN105388401AAdd compensation capacitorHigh measurement accuracyTesting dielectric strengthCapacitanceUltrasound attenuation

The invention provides a novel cable oscillation wave partial discharge detection system which comprises a DC high voltage device, an IGBT high voltage switch, a resonant inductor, a capacitive voltage divider, a monitoring background, a compensation capacitor, partial discharge pulse detectors, and a detected cable. The system has the advantages that: (1) the compensation capacitor with adjustable capacitance is added, when a cable with too short length is measured, the measurement precision is effectively improved; (2) two ports of the cable are equipped with the partial discharge pulse detectors, the problem of too serious attenuation caused by a too long signal transmission distance in the process of the oscillation wave test of the cable with the too long length is effectively solved, and the measurement precision is raised; and (3) the measurement effects of a too short cable and a too long cable are good, and the measured cable length range is increased significantly compared with the prior art.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Elasticity tension automatic compensator for contact net

An automatic elastic tension compensator for contactor of electric collector is composed of external sleeve pipe with connector, middle sleeve pipe with external spring, and internal sleeve pipe with connector and internal spring. It has high tension-compensating precision.

Owner:马泽民

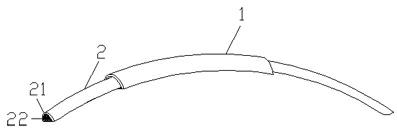

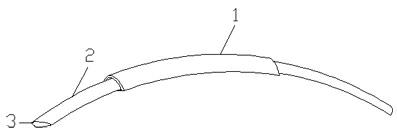

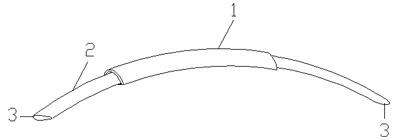

Casing pipe type dura mater dissecting device

The invention relates to a casing pipe type dura mater dissecting device, which comprises a guiding pipe and a dissector capable of being sleeved inside the guiding pipe, wherein the guiding pipe is a hollow arced pipe with two open ends, the cross section of the guiding pipe is of a bow shape, the dissector is arced under a nature state, the cross section of the dissector is of a bow shape, the dissector is provided with an external dissector shell and an internal dissector inner core, and the dissector is provided with the dissector shell with at least one closed end so as to form a dissecting end. The casing pipe type dura mater dissecting device has the advantages that: the dissector can go into a path along a specific path under the guidance of the guiding pipe so as to effectively prevent deviation and unnecessary skull and dura mater separation, the casing pipe type dura mater dissecting device is high in dissecting efficiency, low in damage rate, simple in structure and simple and convenient to operate, is suitable for the skull and dura mater separation of bone holes of different spacings, and can be used for effectively preventing a milling cutter from breaking dura mater or venous sinus to increase the safety of craniotomy.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

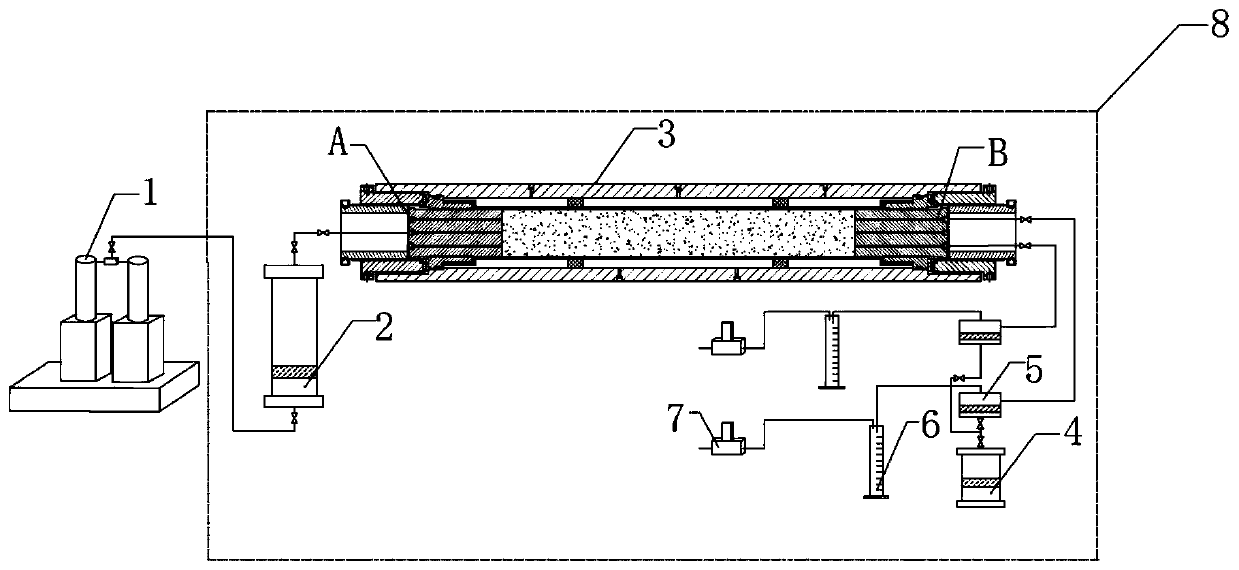

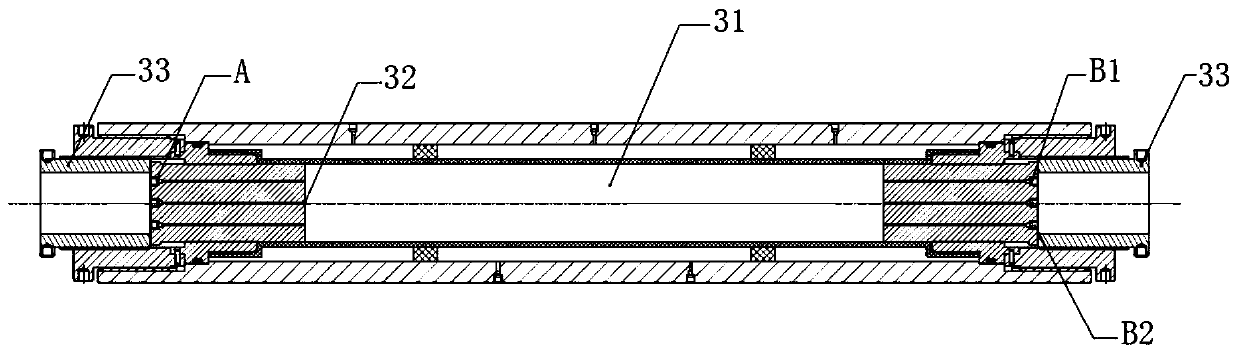

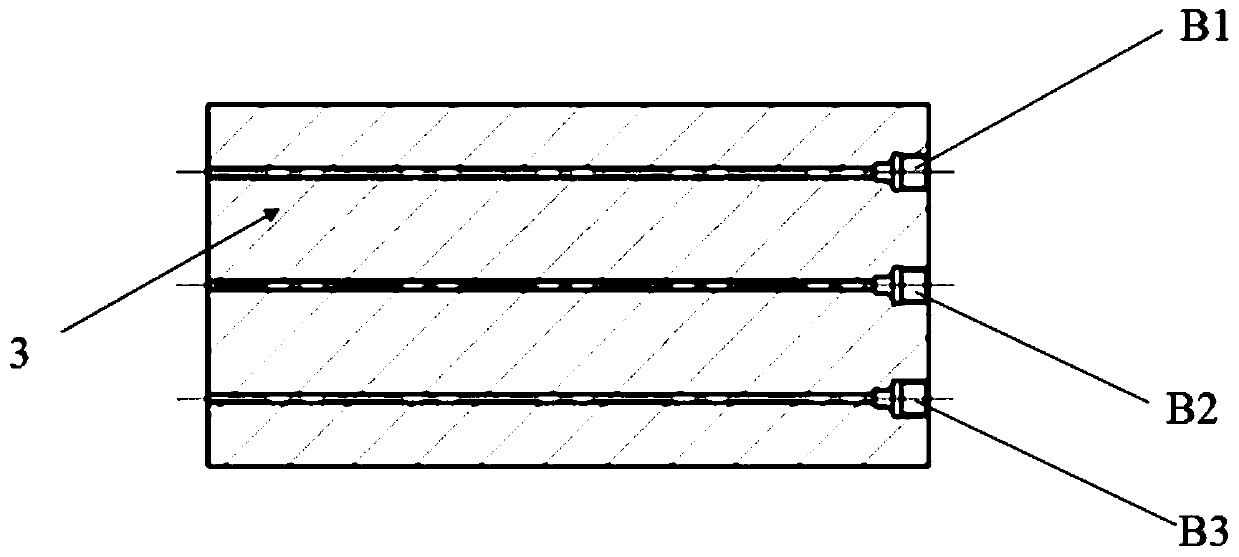

Gas drive overburden simulation device and use method thereof

The invention discloses a gas drive overburden simulation device and a use method thereof. The gas drive overburden simulation device comprises an injection pump, a piston intermediate container, a core holder, a pressure stabilizing tank and at least two sets of oil extraction devices, wherein the injection end of the core holder is provided with at least one liquid inlet through hole, and the extraction end of the core holder is provided with at least two oil outlet through holes. The gas drive overburden simulation device provided by the invention can simulate the gas drive overburden of atwo-dimensional core model under the conditions of high pressure and high temperature, widens the length range of the core model, optimizes a gas drive overburden representation mode, improves the gasdrive temperature and pressure of the gas drive overburden simulation device, the application range of the core length and the like and the precision of overburden simulation and overburden representation results, and provides convenience for further researching the overburden law under different factors of oil reservoir conditions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

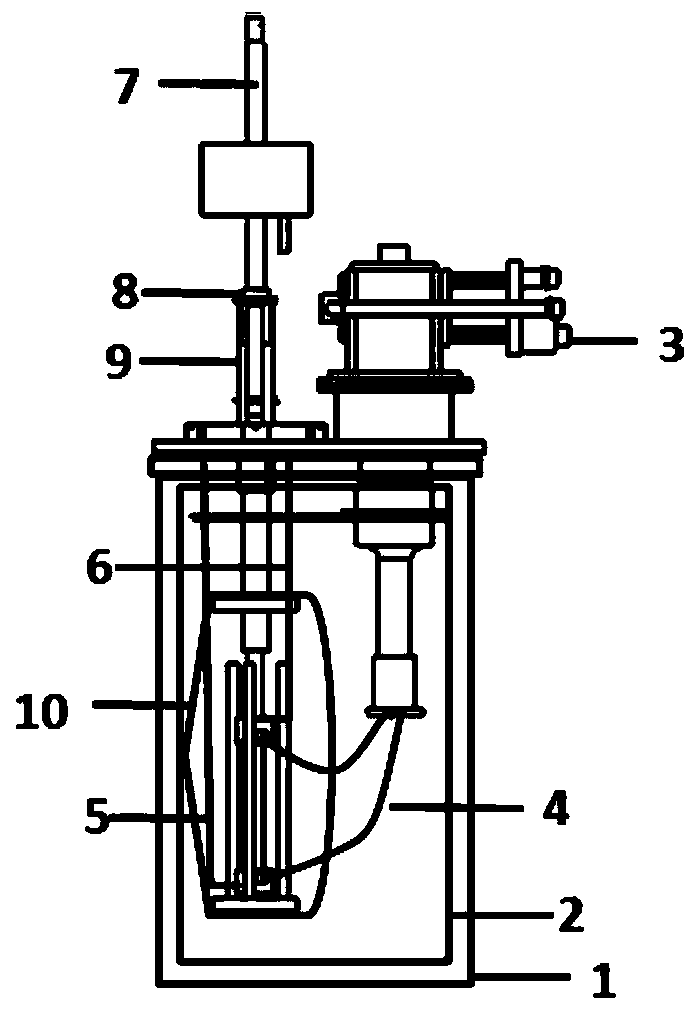

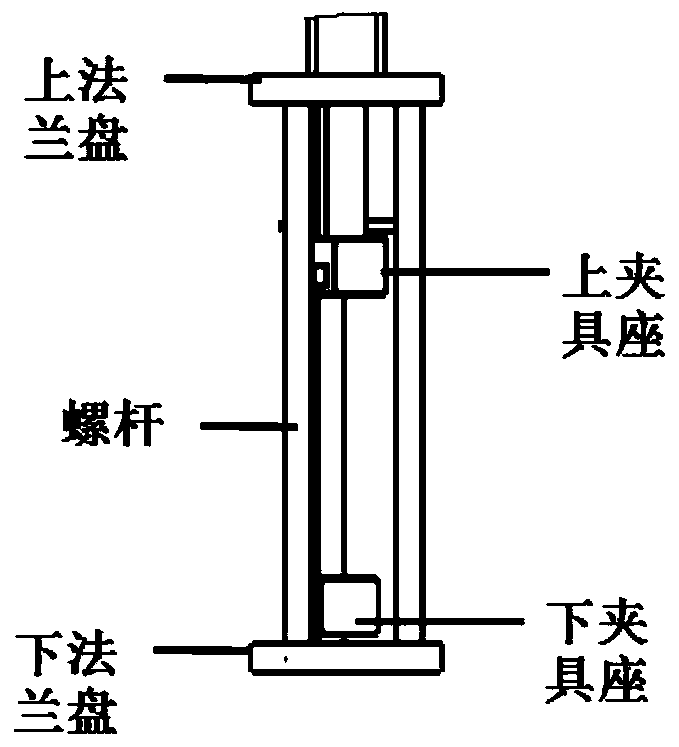

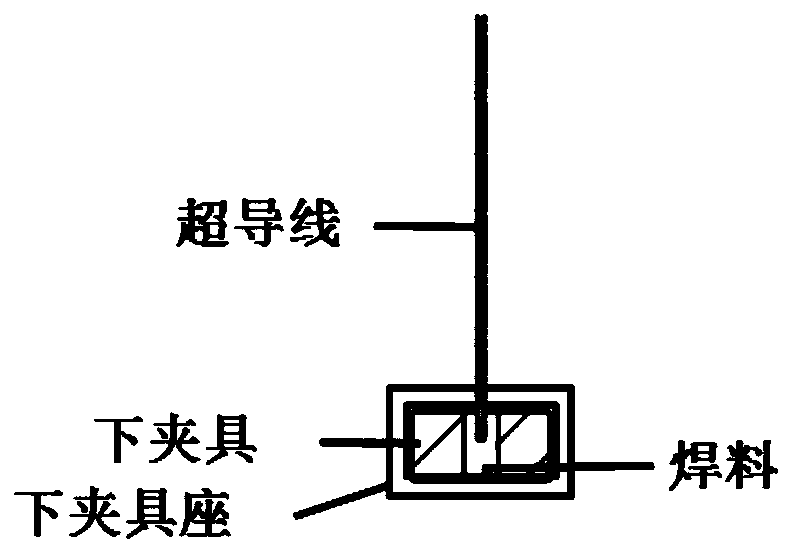

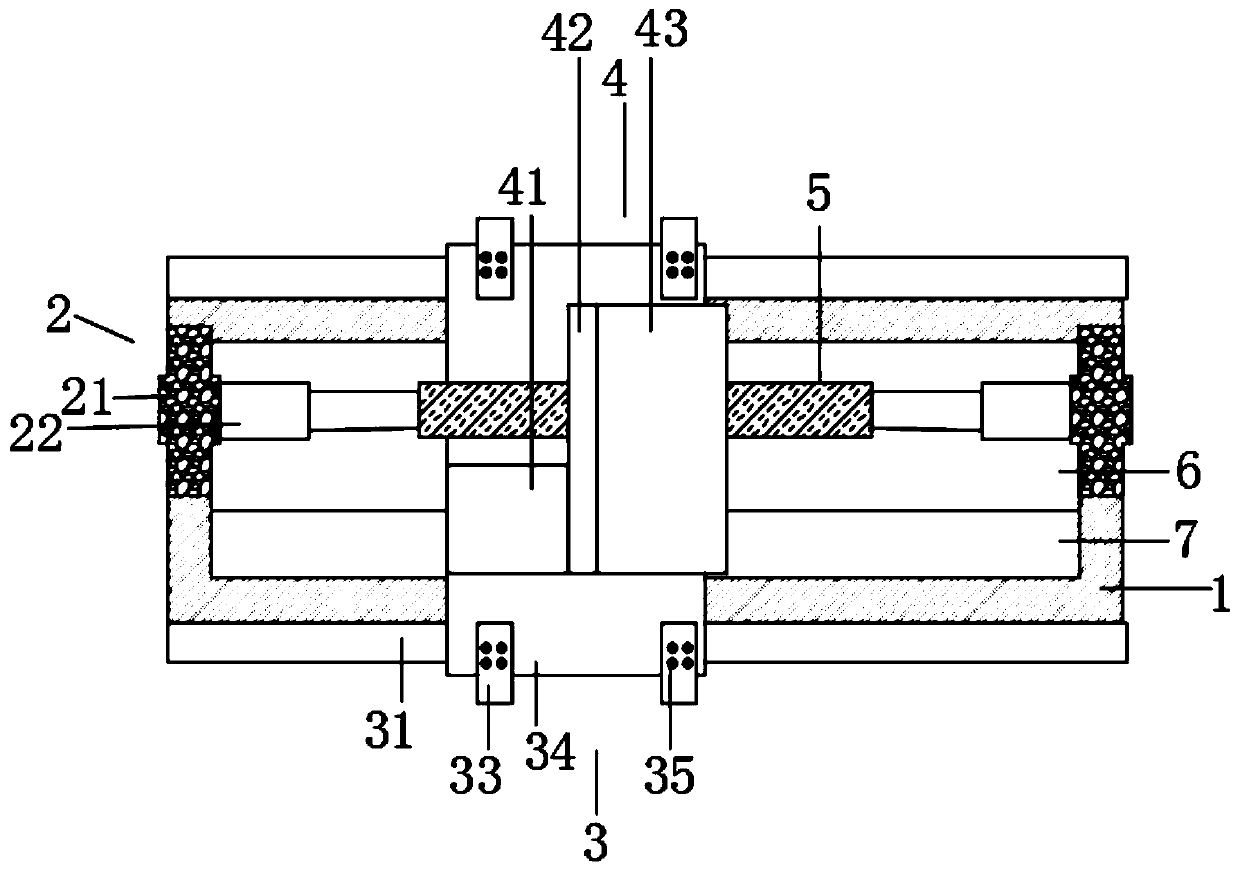

Superconducting wire performance measuring device based on conduction cooling

ActiveCN111398050AAvoid introducingAvoid interfering forcesMaterial strength using tensile/compressive forcesMeasurement instrument housingTemperature controlEngineering

The invention discloses a superconducting wire performance measuring device based on conduction cooling. The superconducting wire performance measuring device comprises a temperature control assembly,a loading rod, a vacuum Dewar, a supporting device, an electrical assembly and a clamp. The temperature control assembly is cooled through a refrigerating machine installed on a flange of an end plate of the vacuum Dewar, a thermometer is installed on a superconducting wire to measure the temperature of the superconducting wire, an anti-radiation screen is installed in the vacuum Dewar, and the electrical assembly feeds the superconducting wire through a current lead and measures electrical signals at the two ends of the superconducting wire. The loading rod and the supporting device are usedfor installing the superconducting wire through the clamp and applying a load to the superconducting wire, and a strain gauge is installed on the superconducting wire to measure the strain state of the superconducting wire. The superconducting wire performance measuring device based on conduction cooling is high in operability, simple in structure and capable of achieving low-temperature stress-strain measurement of different temperature sections.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

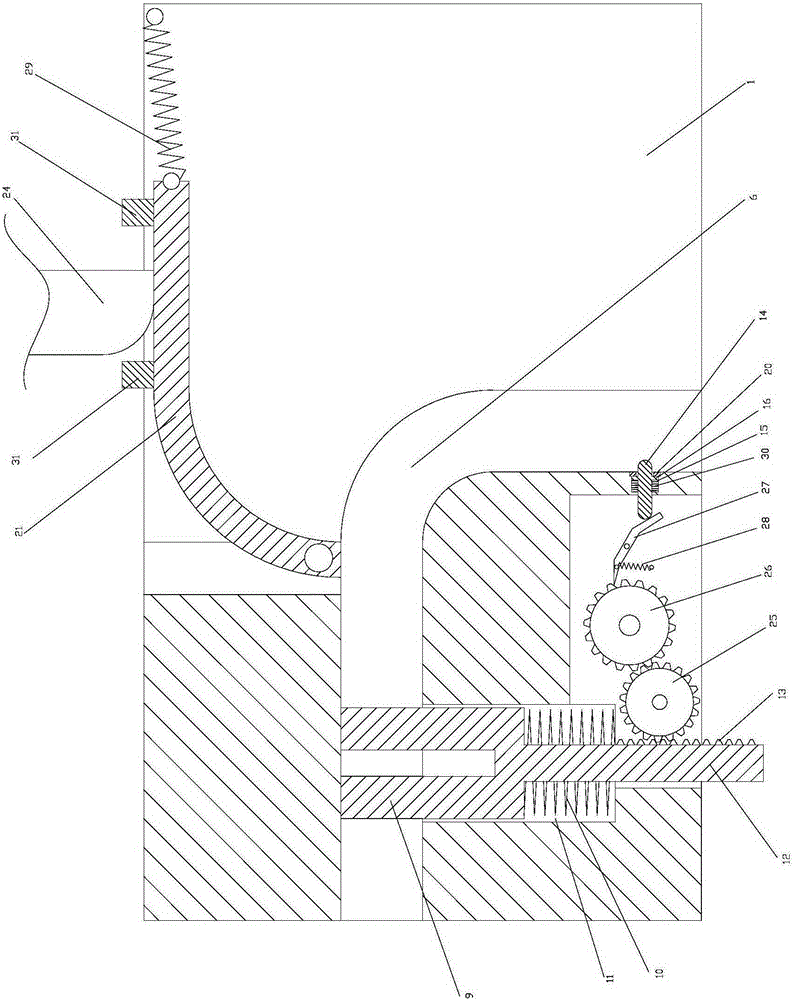

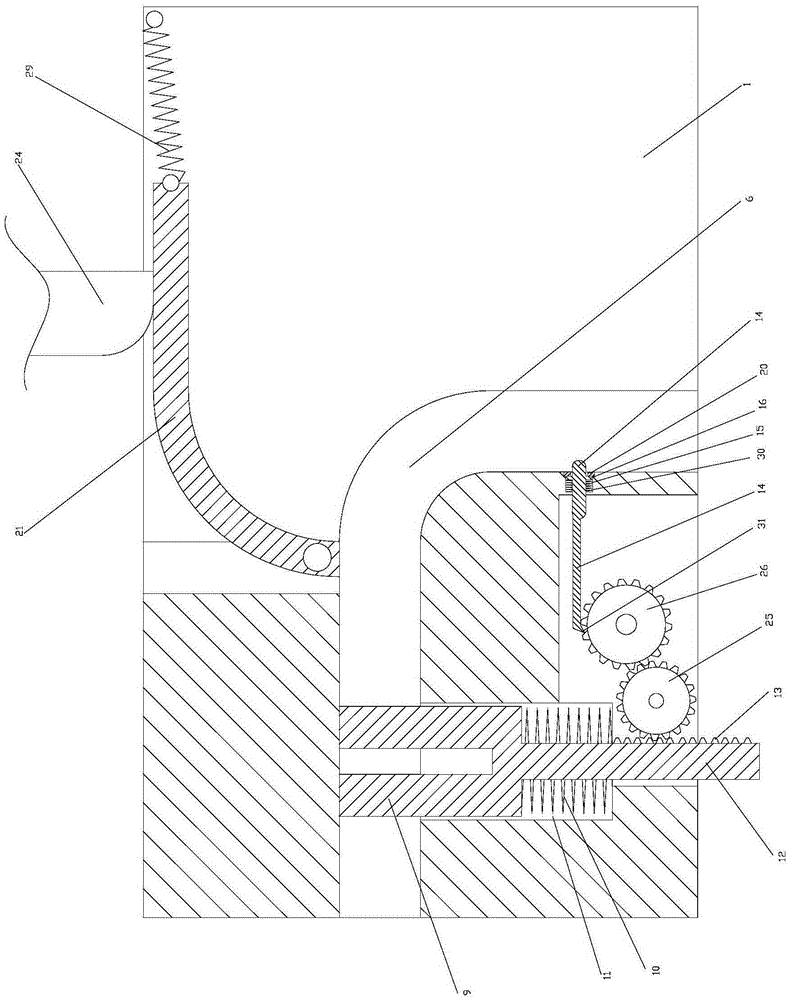

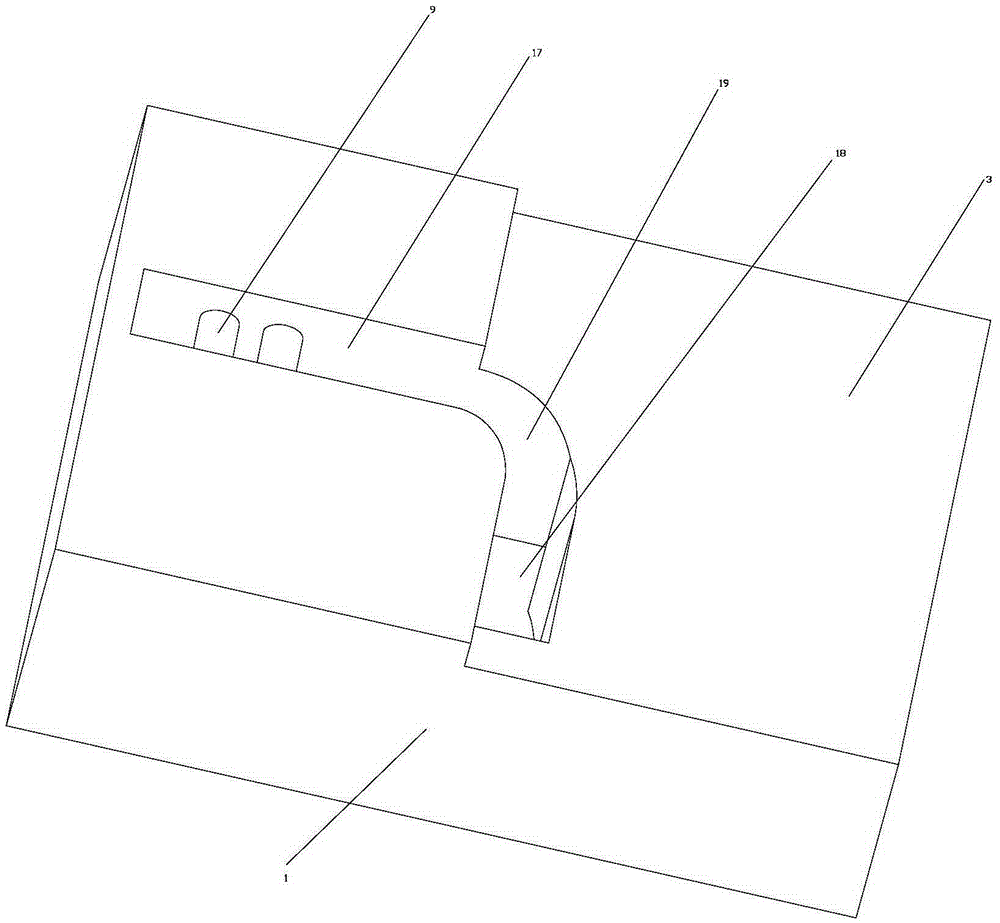

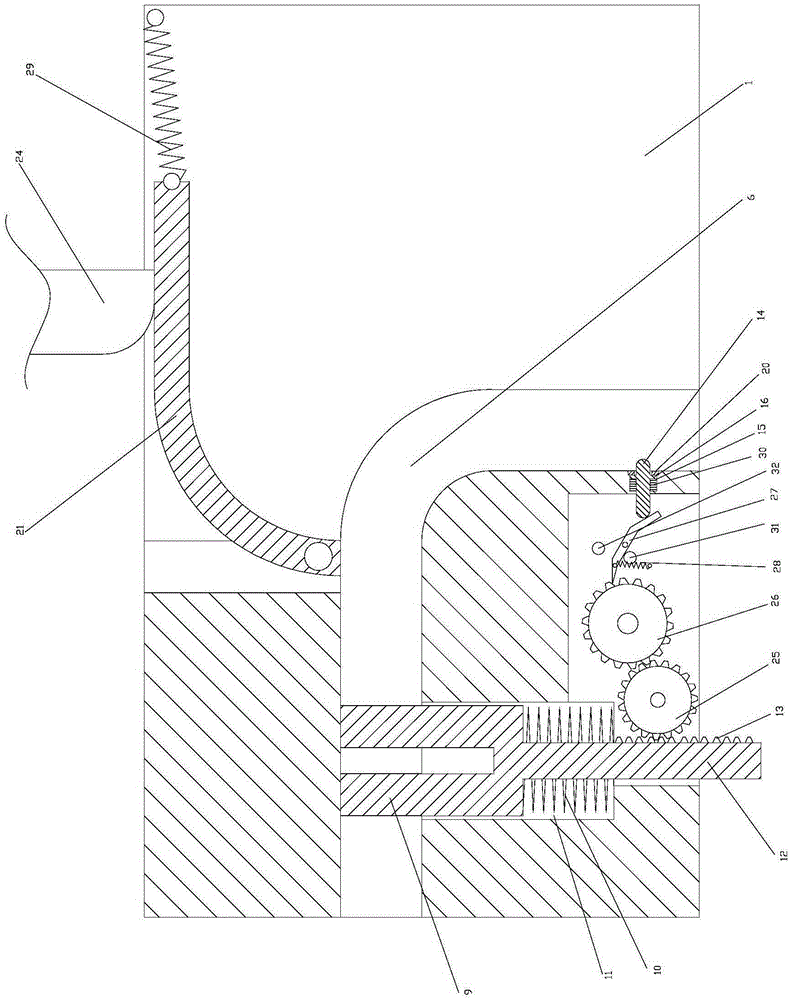

Bending and blanking device

InactiveCN105251819ASimplified operational requirementsImprove securityMetal-working feeding devicesStripping-off devicesEngineeringReference surface

The invention discloses a bending and blanking device. The device comprises a base (1), wherein the base (1) is provided with a reference surface (3) for placing a free end of a pipe (2) and rotating the free end of the pipe (2); the base (1) is provided with a boss (4) higher than the reference surface (3) for positioning the other end of the pipe (2); the boss (4) is provided with an opening (5) for accommodating the end part of the pipe (2); the base (1) is provided with a through hole (6) for sliding the bent pipe (2) in the vertical direction; the shape of the through hole (6) is consistent with the bending shape of the pipe (2); and the through hole (6) penetrates through the upper surface and the lower surface of the base (1) in the vertical direction, and is communicated with the opening (5) in the vertical direction. The invention provides the bending and blanking device with low maintenance cost, simple operation and no need of manual pipe taking.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Peeling device used for tree processing

The invention discloses a peeling device used for tree processing. The device comprises a supporting frame, a waste baffle is arranged on the rear end in the supporting frame, a waste collecting groove is formed in the front end in the supporting frame, wood clamping mechanisms are arranged on the left side and the right side of the top of the supporting frame, each wood clamping mechanism comprises a clamping fixed base and a hydraulic cylinder, the two clamping fixed bases are fixedly connected to the left side and the right side of the top of the supporting frame, the opposite sides of thetwo clamping fixed bases are fixedly connected with the hydraulic cylinders, and original timber is clamped between the output ends of the two hydraulic cylinders. Through the hydraulic cylinders, when the original timber is peeled, stable clamping is provided, dangerous hidden danger caused by breaking due to poor fixing in a wood machining device can be avoided, and through limiting guide railsand guide rail air cylinders, cooperation with work of a driving motor, a driving gear shaft, a machining roller and roller blades is achieved.

Owner:陈品颖

High-speed mechanical arm with precise positioning function

A high-speed mechanical arm with a precise positioning function comprises a motor, a driving part, a rack and a sliding block, wherein a sliding slot is arranged on the rack, the sliding block is arranged in the sliding slot and is driven by the driving part to move along the sliding slot. The mechanical arm is characterized in that the driving part comprises a winding drum and a steel wire rope wound on the winding drum, a threaded groove is arranged on the winding drum, the steel wire rope is coiled in the threaded groove and is arranged between the winding drum and the sliding slot to form a revolving loop, and a section, which is arranged in the sliding slot, of the steel wire rope is fastened with the bottom of the sliding block. The winding drum with the threaded slot is driven by utilizing a servo motor, the steel wire rope is precisely wound and unwound from the winding drum, namely, when the winding drum rotates for a turn, the linear distance that the steel wire rope moves is converted from the perimeter of the winding drum, under the same rotating speed, the speed of the steel wire rope is much higher than the speed of a screw nut pair, which is characterized in that the linear distance converted from the screw pitch, and the positioning and control on the sliding block are realized through controlling the rotating speed and the start and stop of the rotation precisely by the servo motor.

Owner:FUJISAN IND TECH CO LTD OF SHENZHEN CITY

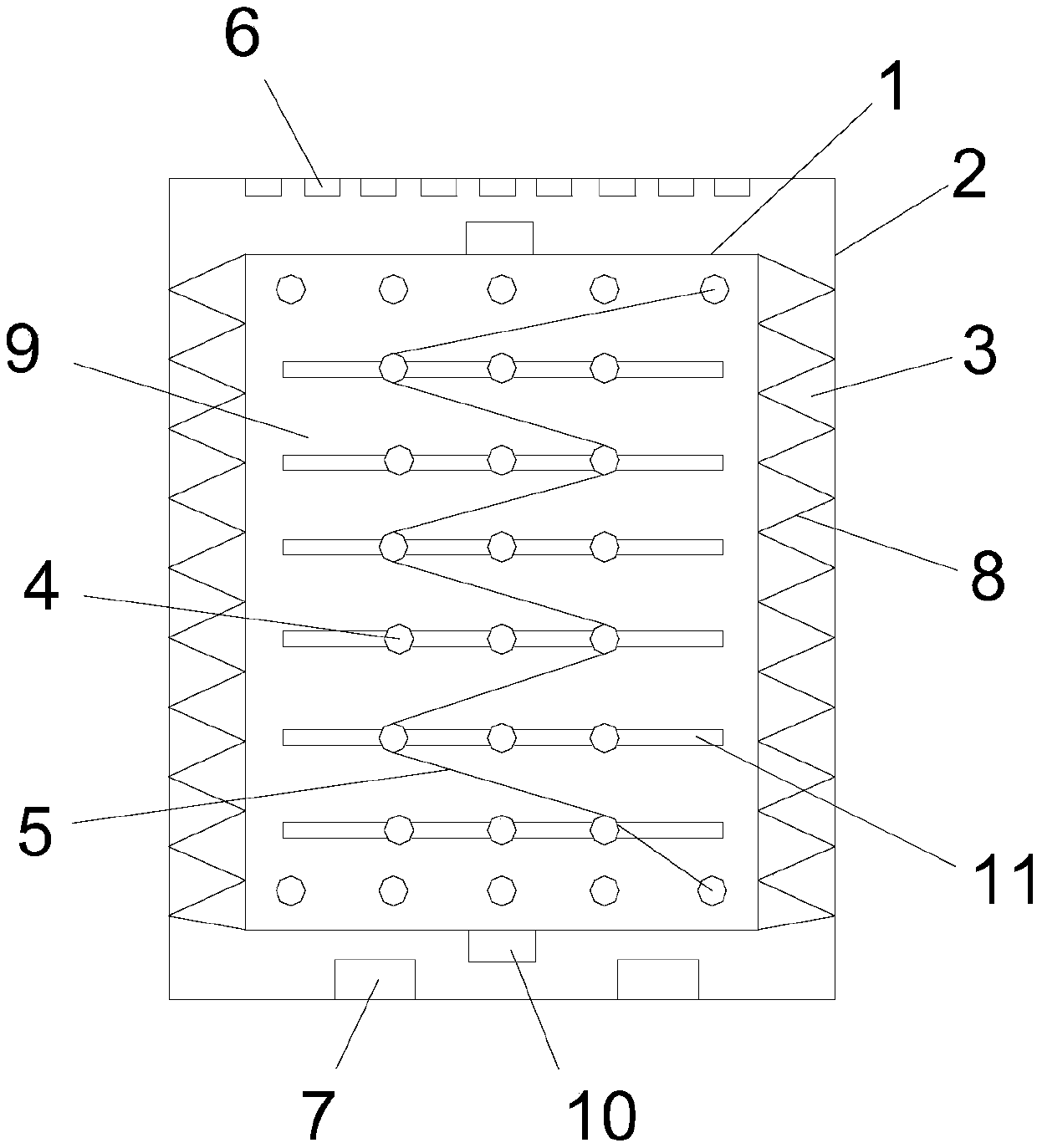

Novel drying box for cable cores

InactiveCN108036618AFull flowLarge drying rangeDrying gas arrangementsDrying machines with progressive movementsDrive motorEngineering

The invention discloses a novel drying box for cable cores. A plurality of winding columns used for winding the cable cores to be dried are arranged in an inner box body, and the cable cores are woundon the winding columns along wavy-line paths from top to bottom; and a plurality of end surfaces of the inner box body are configured to be open or formed with a plurality of through holes, a plurality of gas outlet holes are distributed in the top end surface of an outer box body, at least two air blowers arranged in parallel are arranged on the bottom end surface of the outer box body; heatingwires are arranged at one side or two sides of a cavity; and the air blowing direction of the air blowers is vertically upward, so that hot air is formed from the heat generated due to the heating ofthe heating wires, and the hot air is blown to the outside of the outer box body from the inside of the inner box body. The top end surface and the bottom end surface of the inner box body extend outwards along the central axis separately to form rotary shafts, and the rotary shafts are rotatably embedded into the inner wall of the outer box body, and connected with a drive motor. The novel dryingbox for the cable cores is simple in structure, convenient to use, and wider in cable core length application range, thereby increasing the drying efficiency for the cable cores and optimizing the drying effect for the cable cores.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

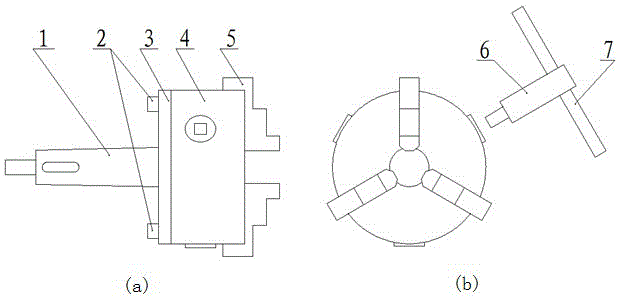

Processing method of long and thin workpiece thread and chuck fixture assembly

ActiveCN104057160APrecise processingHigh concentricityThread cutting machinesPositioning apparatusUltimate tensile strengthAutomatic processing

The invention discloses a method for processing two long and thin workpiece threads specific to the defects of high turning difficulty and easiness in producing defective products in the conventional thread processing way of long and thin workpieces as well as the defects of high labor intensity, low production efficiency and unstable product quality in the conventional threading die tapping method. The method comprises the following steps: manufacturing a chuck fixture assembly; clamping a workpiece by using the chuck fixture assembly; clamping a threading die with a turning lathe, and processing a thread. The invention further discloses a specially-designed chuck fixture with a Mohs taper sleeve. The chuck fixture can be assembled and disassembled rapidly, and the processing accuracy and production efficiency can be increased. Compared with the conventional processing way, the method has the advantages that one-time molding automatic processing is adopted, so that the labor intensity is lowered remarkably, the production efficiency can be increased by 30-50 percent, the product quality is stable, the manufacturing accuracy is increased, and the length range of the long and thin workpiece thread is expanded.

Owner:NANJING MEISHAN METALLURGY DEV

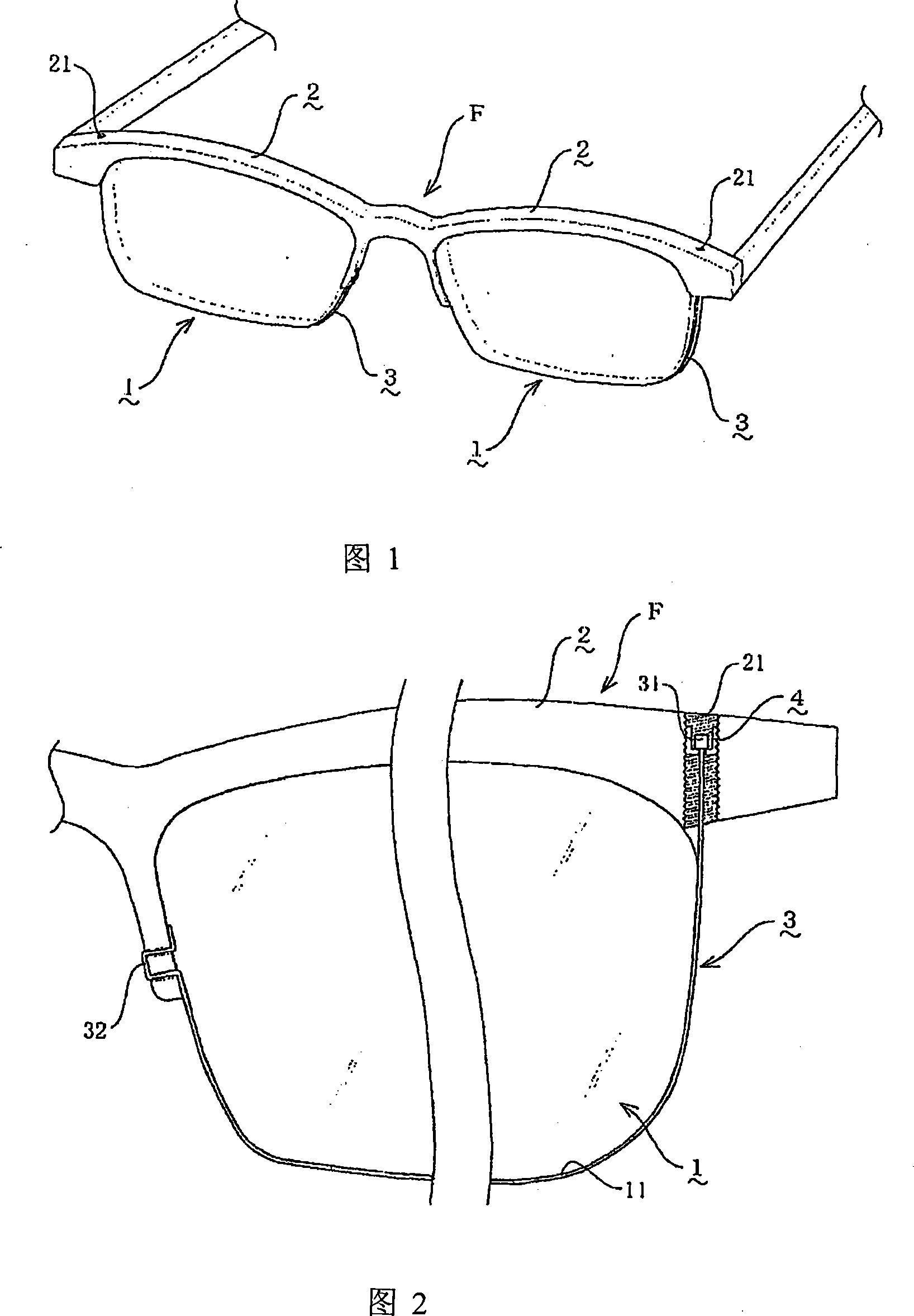

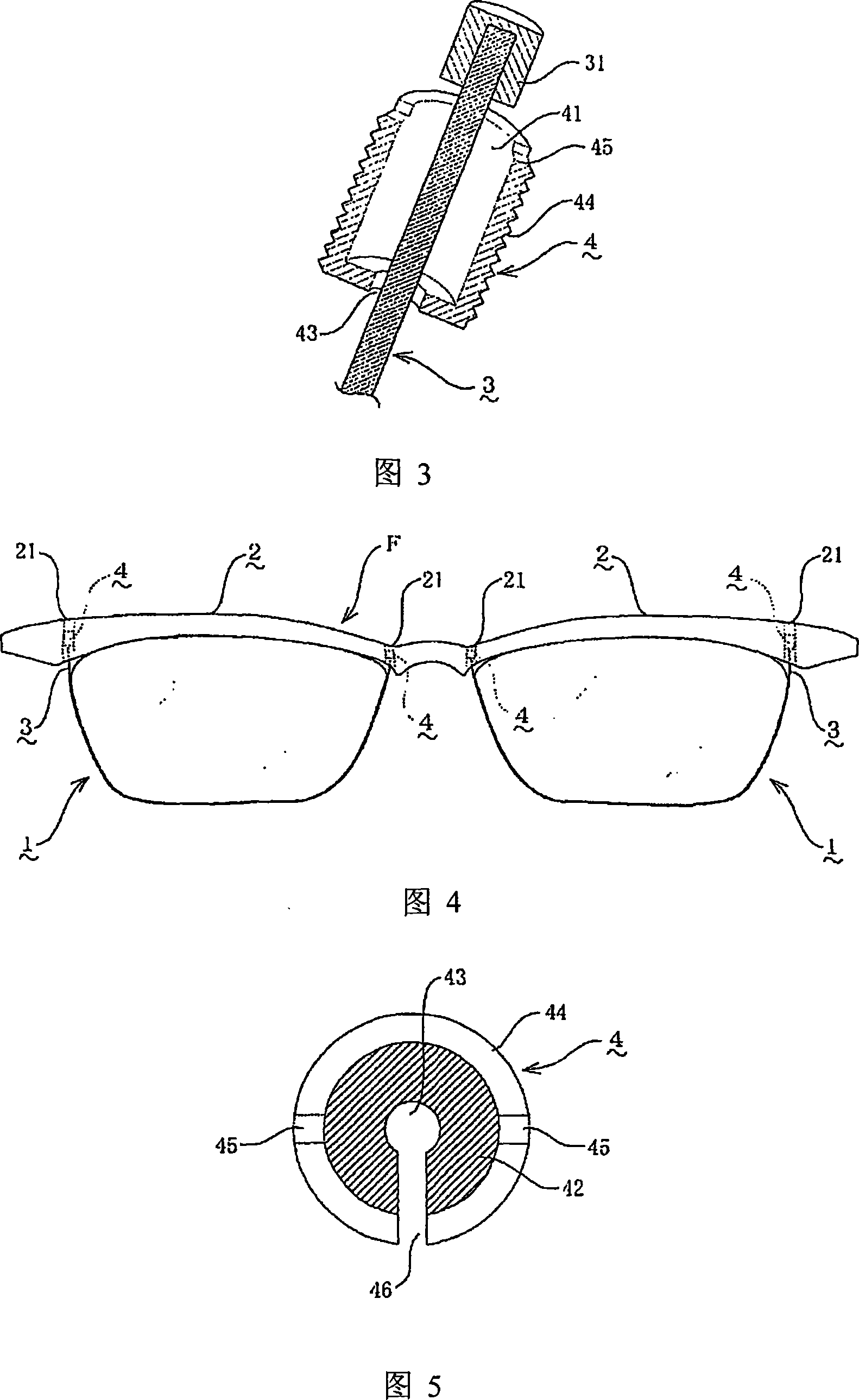

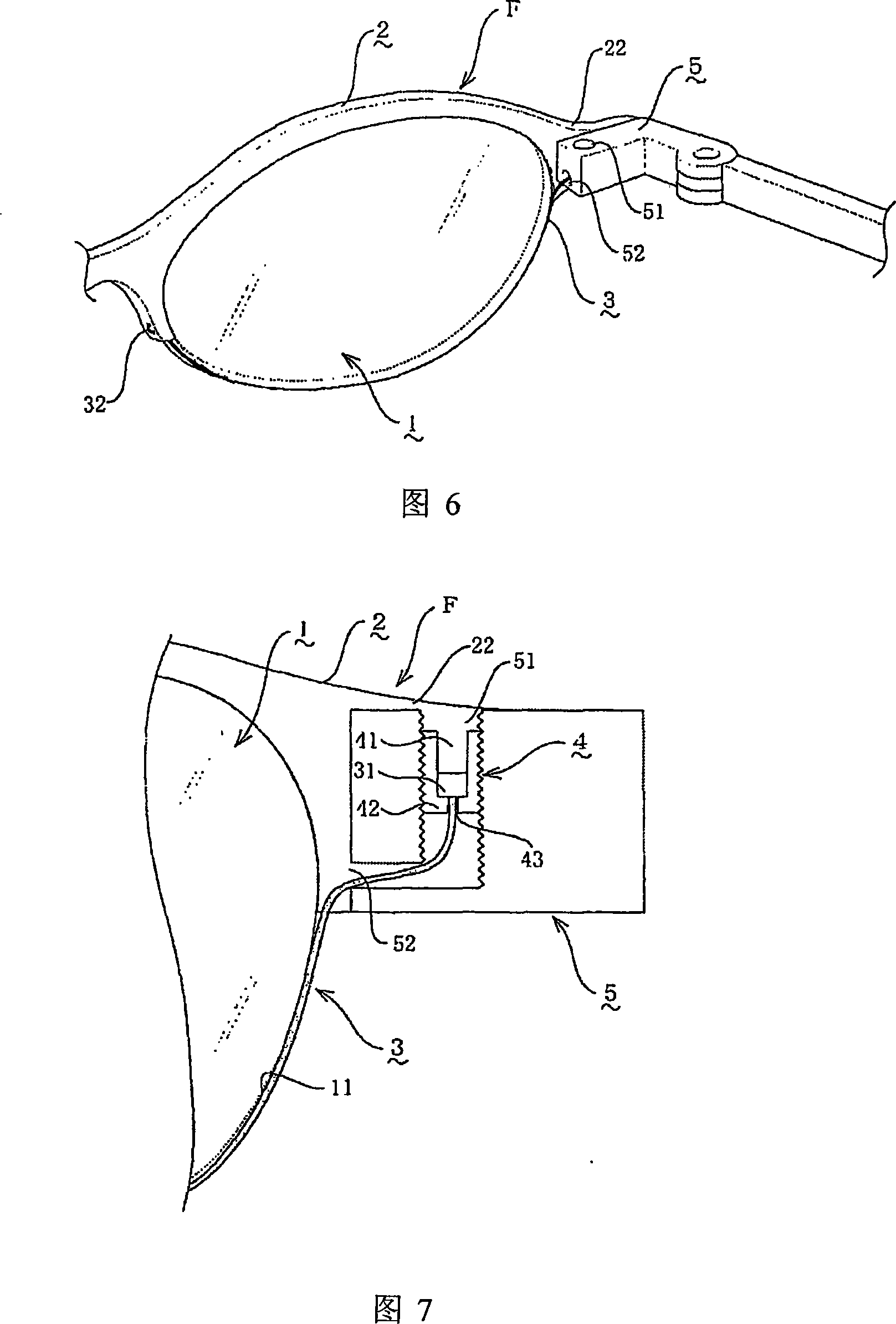

Lens fixing mechanism for part frame spectacle

InactiveCN101183179AAdjustable tie tensionTie tension relaxSpectales/gogglesNon-optical partsEngineeringEmbedded system

Owner:上海野尻光学有限公司

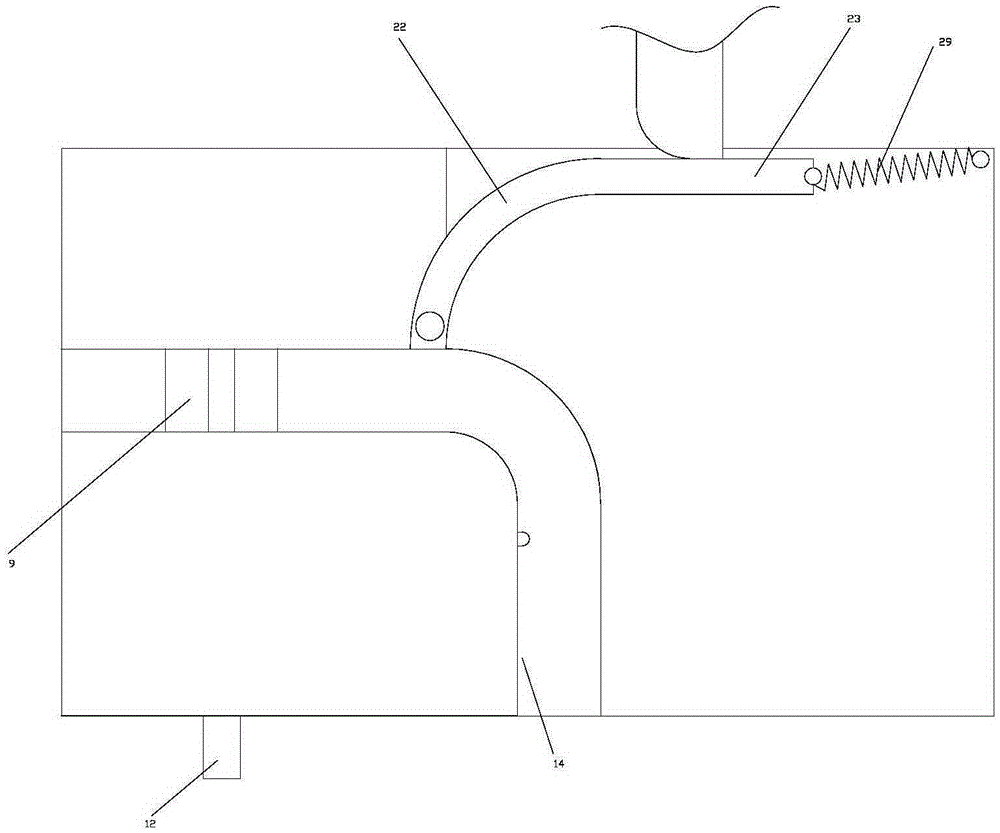

Bending discharging device

InactiveCN105268790ASimplified operational requirementsImprove securityStripping-off devicesEngineering

The invention discloses a bending discharging device. The bending discharging device comprises a base (1). The base (1) is provided with a reference face (3) used for carrying the free end of a pipe (2) and used for the free end of the pipe (2) to rotate. The base (1) is provided with a boss (4) higher than the reference face (3) so that the other end of the pipe (2) can be positioned. The boss (4) is provided with an opening (5) used for containing the end of the pipe (2). A through hole (6) for the bent pipe (2) to slide in the vertical direction is formed in the base (1) in the vertical direction, and the shape of the through hole (6) is consistent with the shape of the bent pipe (2). The bending discharging device is low in maintaining cost and easy and convenient to operate, and manual pipe taking is not needed.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Induction heating positioning device

An induction heating positioning device mainly structurally comprises a sealing nut, a supporting arm, an induction coil, an asbestos board, an asbestos rope, an adjusting cushion block, a quartz tube and a blank, a curved extension portion of the upper end of the induction coil is connected with the supporting arm, the other end of the supporting arm is connected with the sealing nut, the induction coil is vertical in the axial direction, the asbestos board is arranged at the lower end of the induction coil in a cushioning mode and tied through the asbestos rope, the quartz tube is placed in a heating tube, and when the blank is heated, the appropriate adjusting cushion block is selected according to the length of the blank so that the blank can be conveniently clamped through tweezers after the blank is placed in. The induction heating positioning device is simple to manufacture and low in manufacturing cost; positioning is accurate and reliable, and consistency of product quality is guaranteed; heated blanks are wide in length range and can be as short as 3 mm and as long as 100 mm; the labor intensity of operators is relieved, and production efficiency is improved. Personal safety of the operators is guaranteed.

Owner:GUIZHOU HANGRUI AVIATION PRECISION PARTS MFG

Automatic bending and blanking device

InactiveCN105251828ASimplified operational requirementsImprove securityStripping-off devicesPipe fittingEngineering

The invention discloses an automatic bending and blanking device. The automatic bending and blanking device comprises a base (1) which is provided with a standard face (3), and the standard face (3) is used for containing free ends of pipe fittings (2) and allowing the free ends of the pipe fittings (2) to rotate therein; a boss (4) which is higher than the standard face (3) and is used for positioning the other ends of the pipe fittings (2) is arranged on the base (1), and an opening (5) for containing the ends of the pipe fittings (2) is formed in the boss (4); and a through hole used for allowing the bent pipe fittings (2) to slide in the vertical direction is formed in the base (1) in the vertical direction. The automatic bending and blanking device is low in maintaining cost, easy and convenient to operate and free of manual pipe taking.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

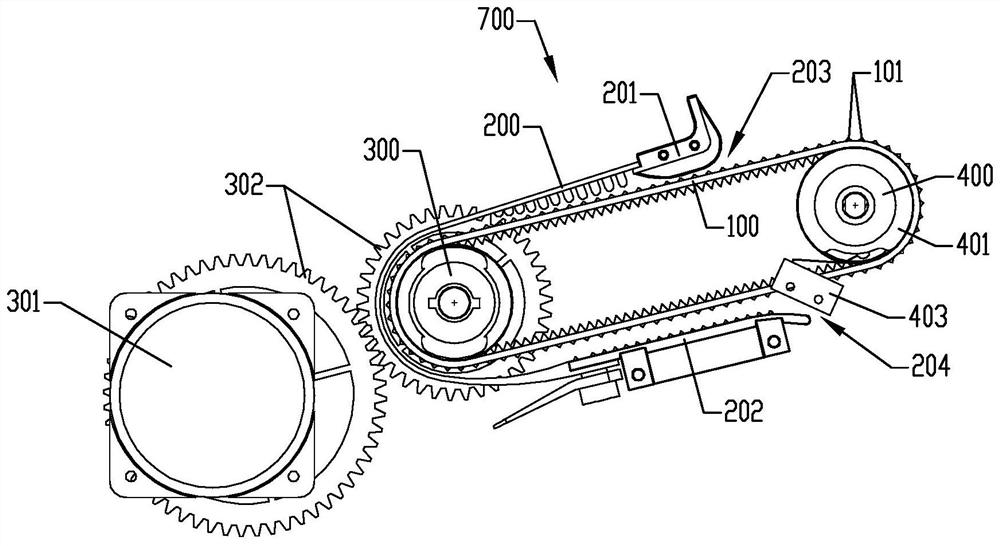

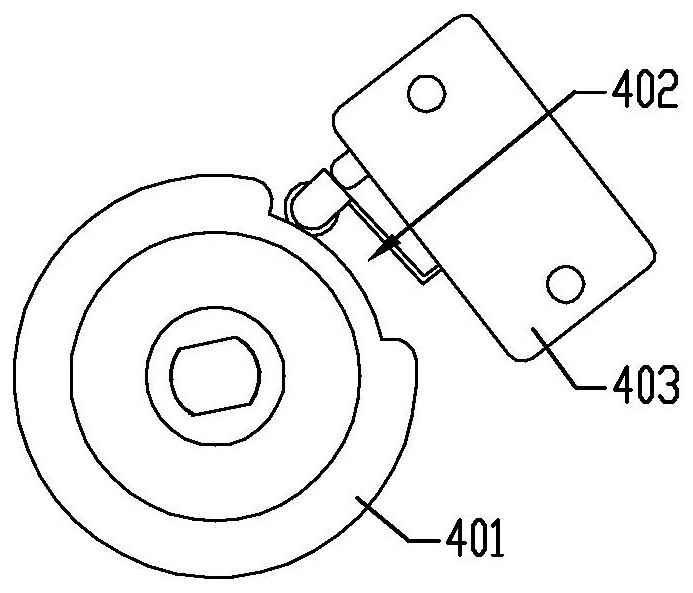

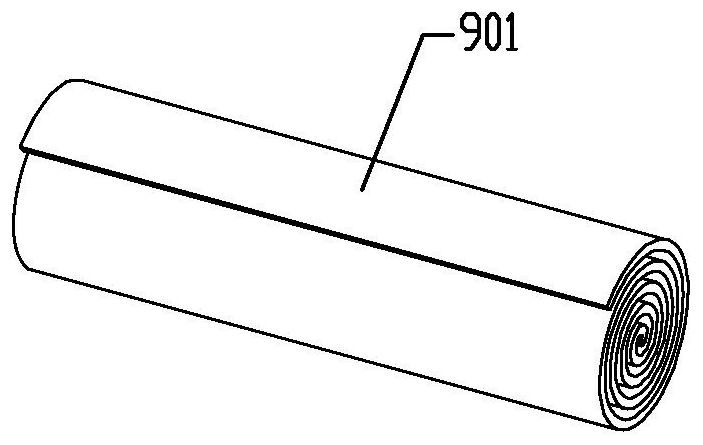

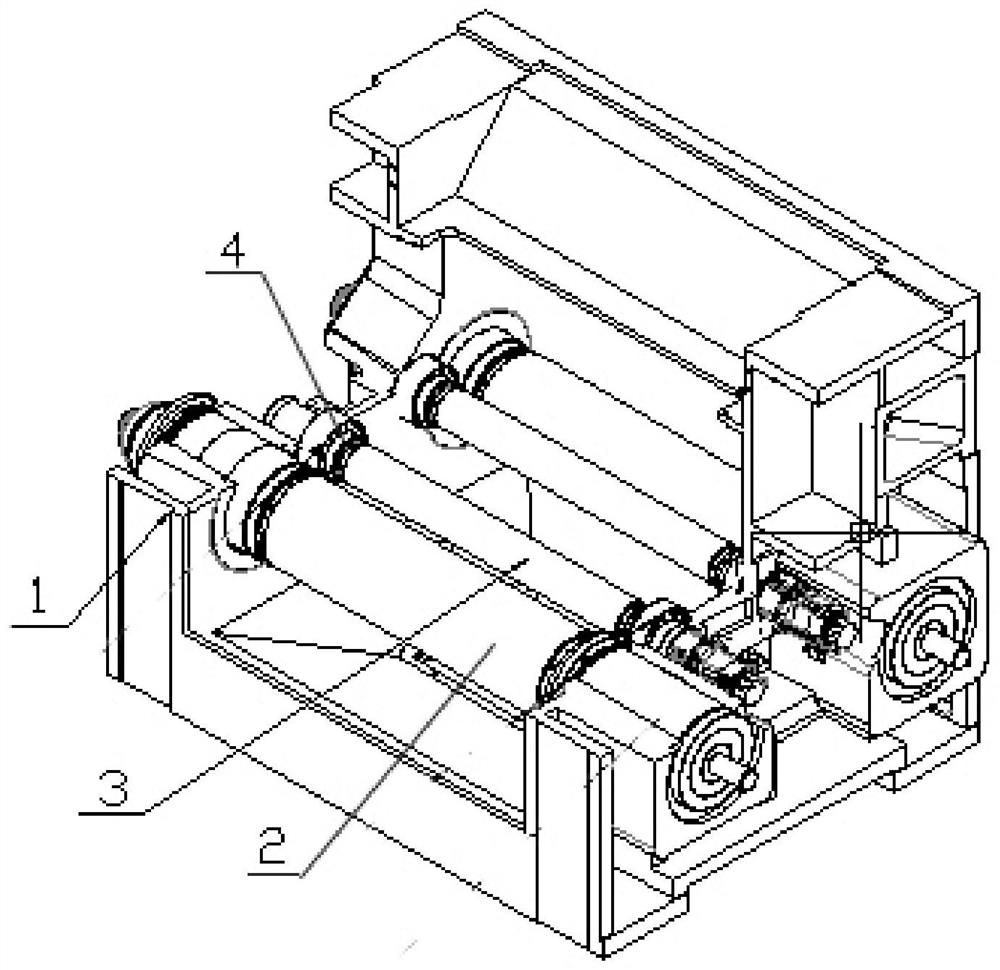

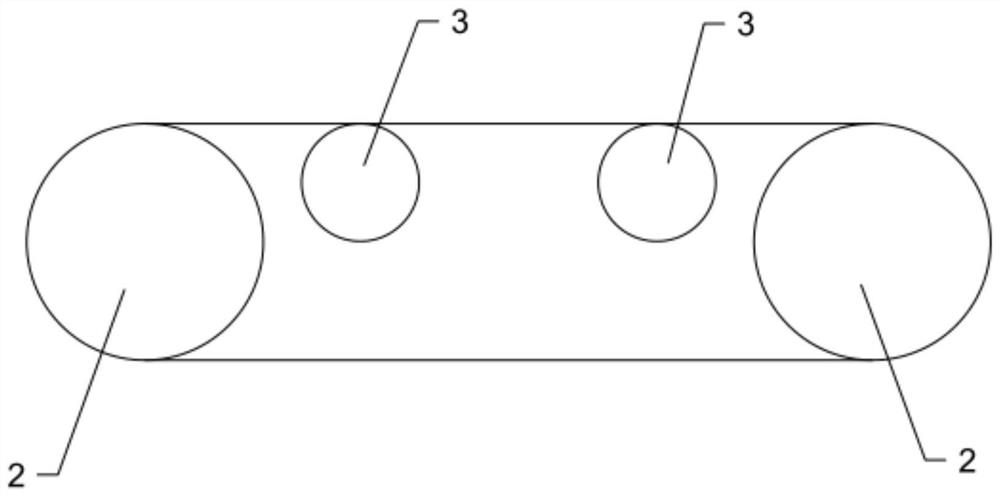

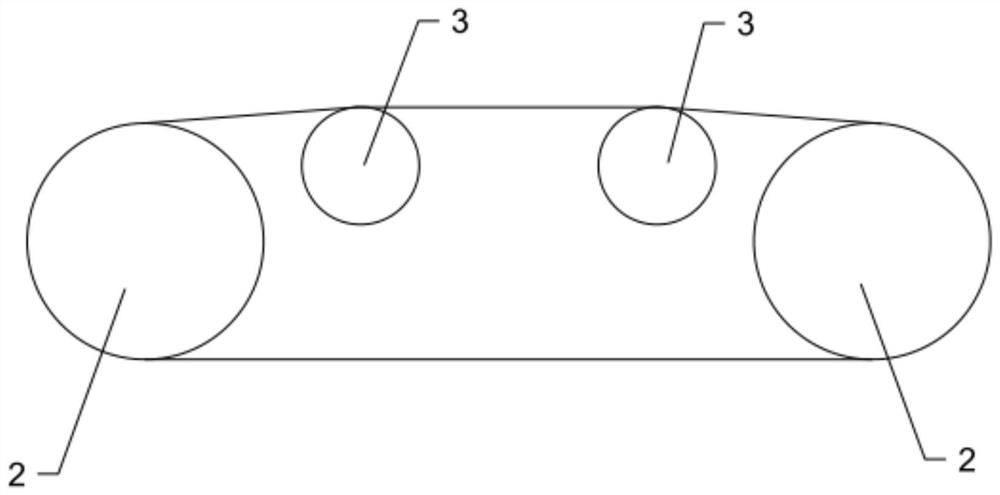

Automatic tissue rolling mechanism and wet tissue machine

PendingCN113023439AWide range of lengthsVariable sizeDomestic applicationsArticle deliverySurgeryMechanical engineering

The invention discloses an automatic tissue rolling mechanism and a wet tissue machine, and belongs to the wet tissue making technology. Wet tissues rolled by an existing wet tissue machine are limited in length range. An inner crawler of the automatic tissue rolling mechanism is annular, sleeves a drive shaft and a driven shaft and is driven to rotate; an outer crawler is annular and is positioned on the outer side of the inner crawler; the inner crawler and the outer crawler are kept with a gap and are in soft fit, and therefore, the automatic tissue rolling mechanism is suitable for a greater wet tissue length range. Especially, one end of the outer crawler is equipped with a tissue cloth inlet guide plate, and a tissue cloth inlet is formed between the tissue cloth inlet guide plate and the inner crawler; the other end of the outer crawler is equipped with a tissue cloth outlet guide plate; and a tissue cloth outlet is formed between the tissue cloth outlet guide plate and the inner crawler. The tissue cloth inlet guide plate and the tissue cloth outlet guide plate are positioned on a suspended section between the drive shaft and the driven shaft to form soft fit with the inner crawler corresponding to the inner crawler, so that the tissue cloth inlet and the tissue cloth outlet are changeable in size, and thus, the automatic tissue rolling mechanism is further suitable for a greater wet tissue length range.

Owner:杭州海绥物联网科技有限公司

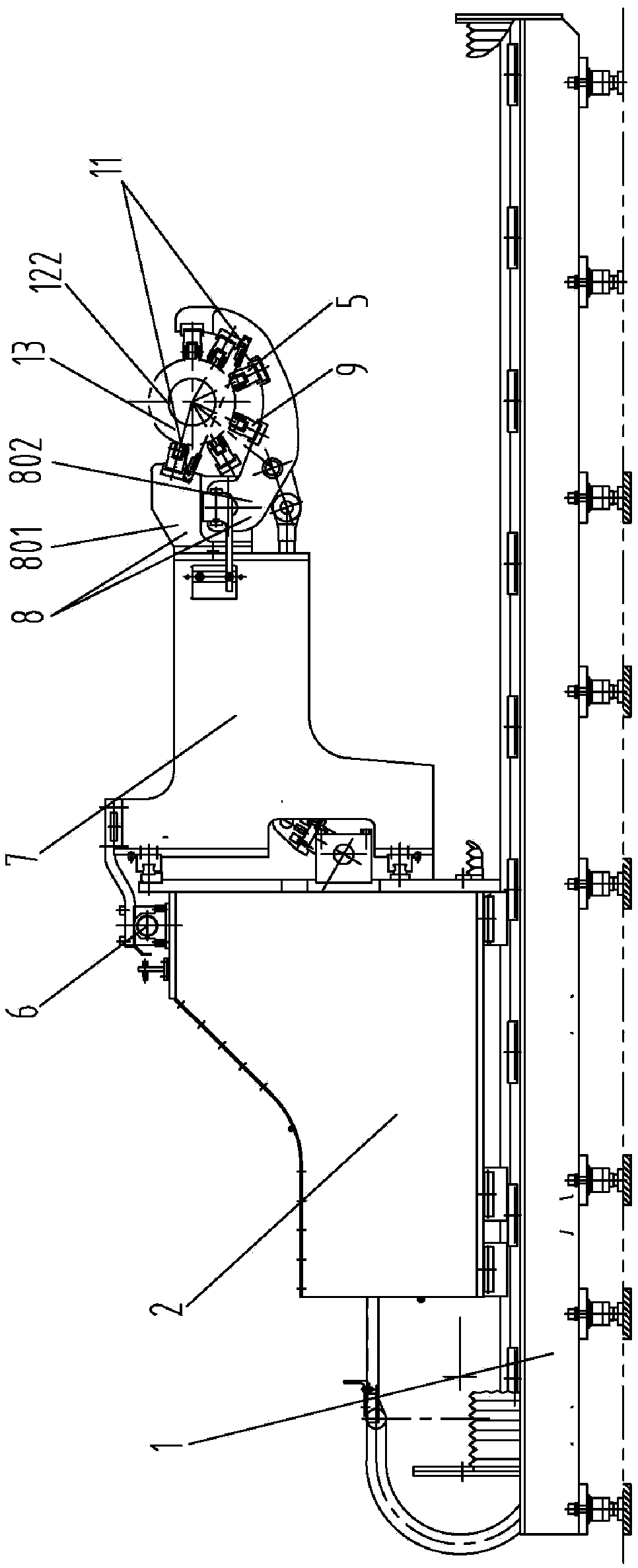

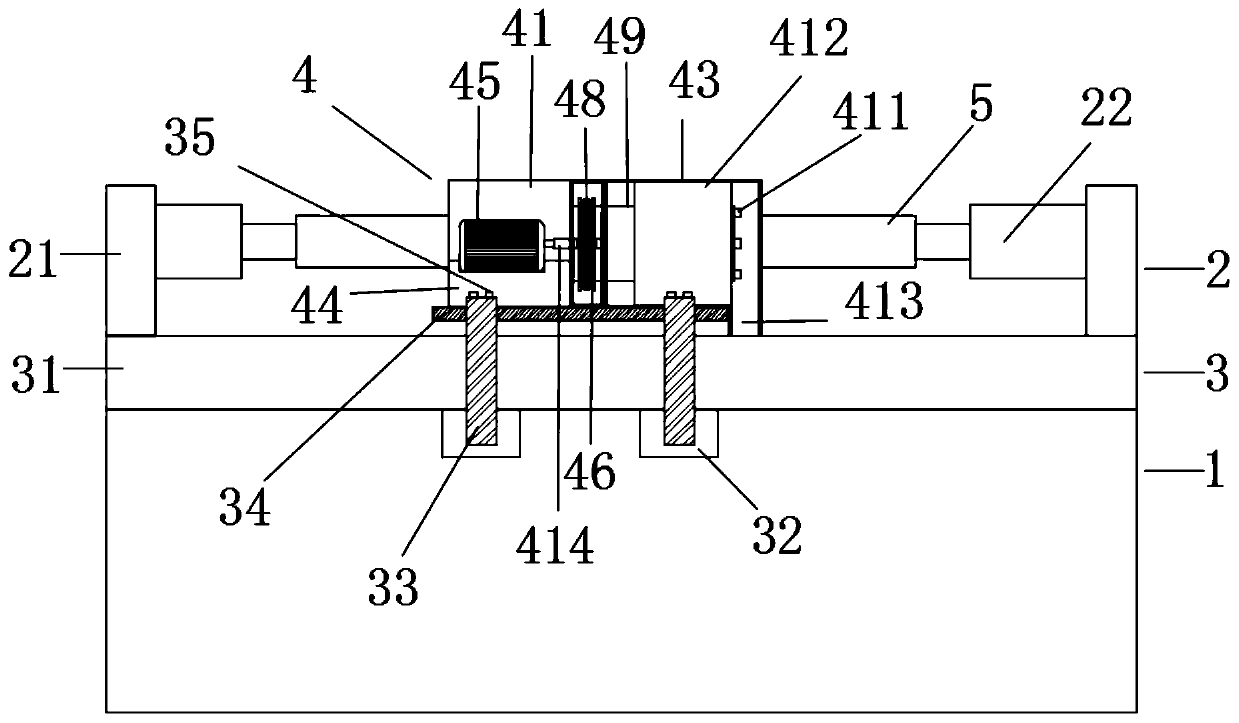

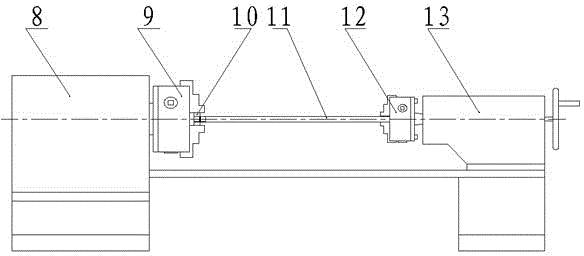

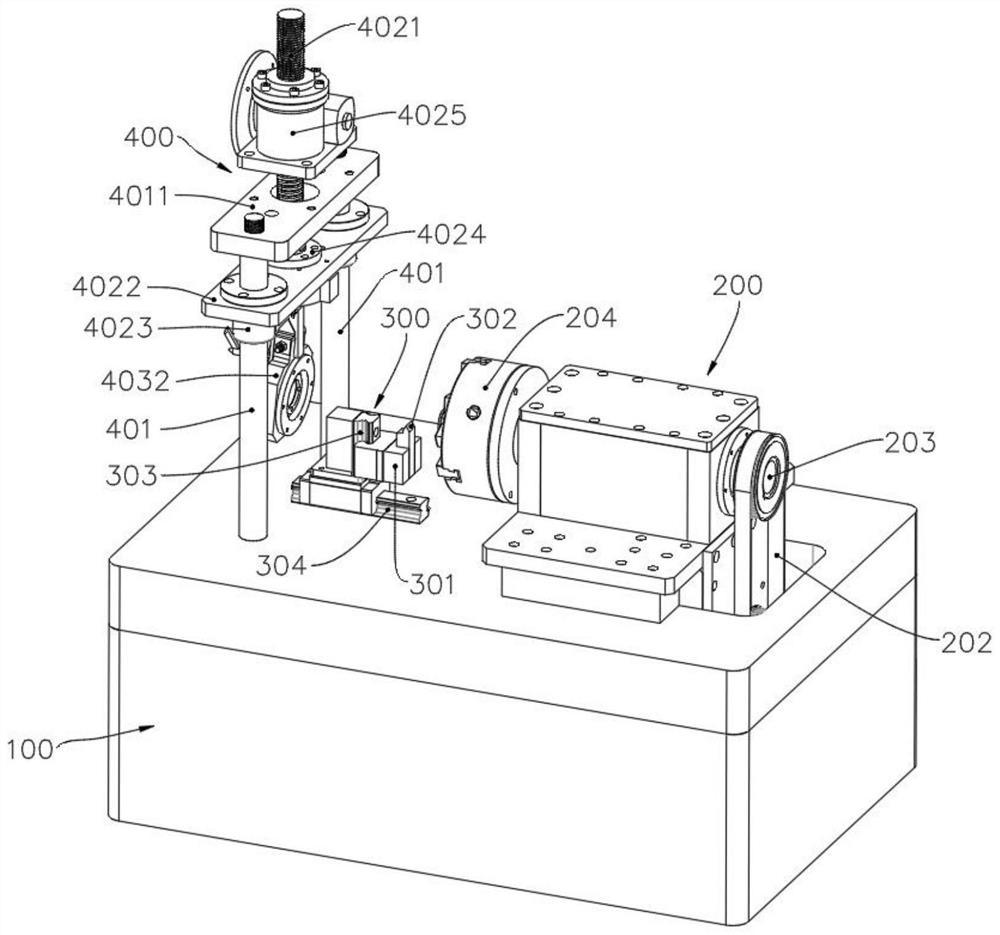

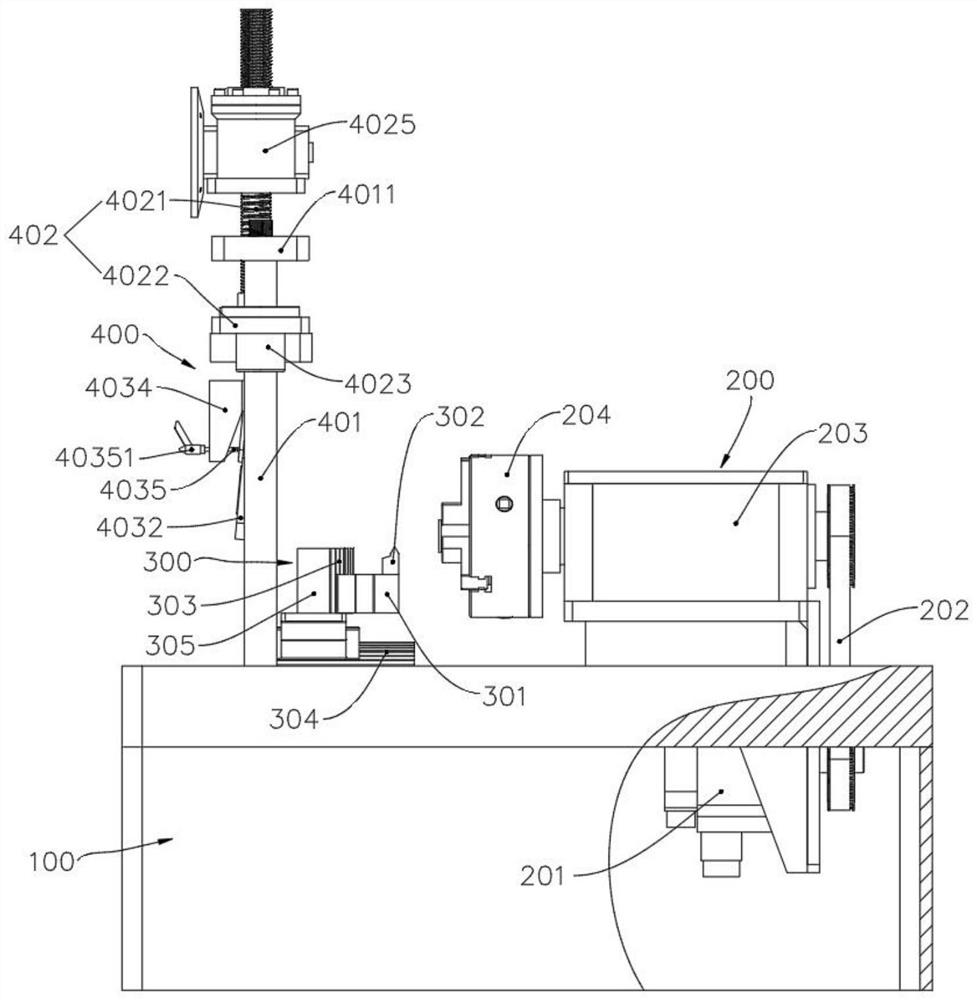

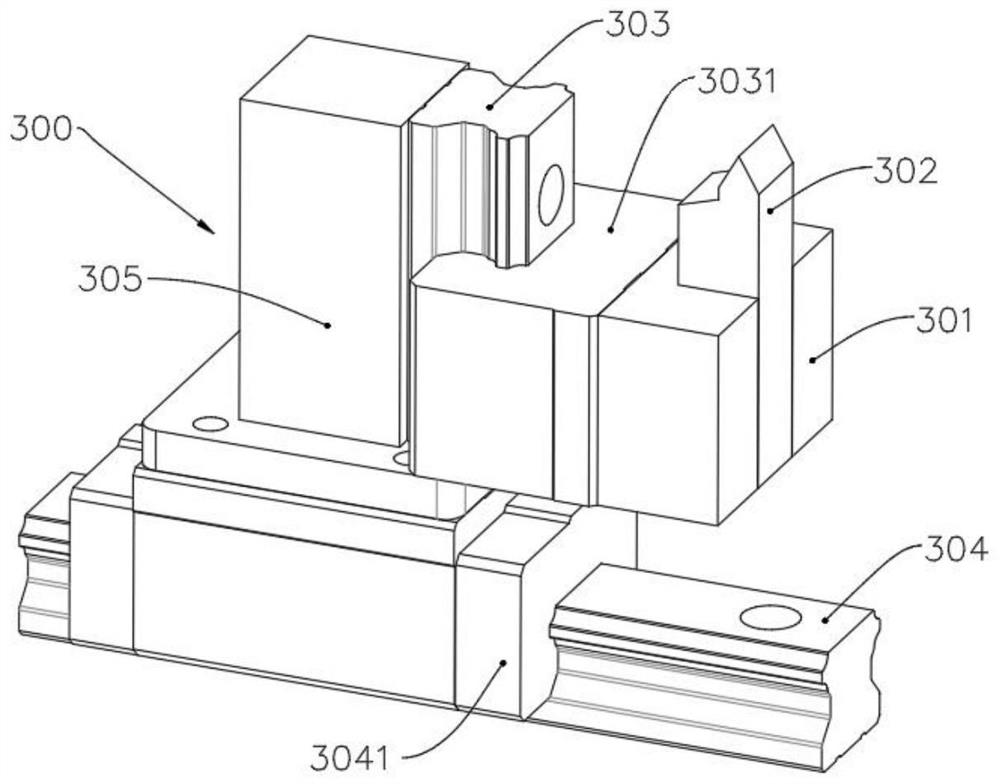

Cutting and spinning synergetic fatigue low-stress blanking device and method

ActiveCN114515966AReduce cutting forceReduce wearOther manufacturing equipments/toolsServoKnife holder

The invention provides a cutting and spinning synergistic fatigue low-stress blanking device and method, and belongs to the technical field of precision forming machining.The device comprises a rack, a clamping rotating mechanism, a cutting mechanism and a loading mechanism, and the clamping rotating mechanism, the cutting mechanism and the loading mechanism are all installed on the rack; the clamping mechanism comprises a servo motor, a main shaft and a three-jaw chuck, the cutting mechanism comprises a tool rest, a cutting tool, a vertical sliding rail, a horizontal sliding rail and a connecting piece, the vertical sliding rail is arranged above the horizontal sliding rail, the cutting tool is fixedly installed on one side of the tool rest, the loading mechanism comprises guide columns, a follow-up assembly and a loading mold, and the guide columns are symmetrically distributed along the central axis of the main shaft; the follow-up assembly comprises a threaded rod and a movable plate, the loading mold comprises a connector, a loading frame and an angle adjusting block, the loading frame is arranged below the connector, the angle adjusting block is arranged on one side of the loading frame and fixedly connected with the connector, and the method comprises the steps of bar mounting, loading force presetting, bar cutting and loading force adjusting.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

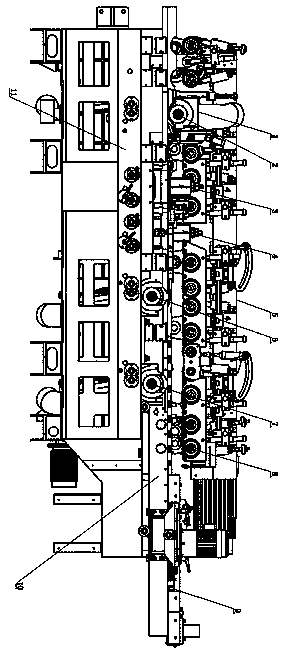

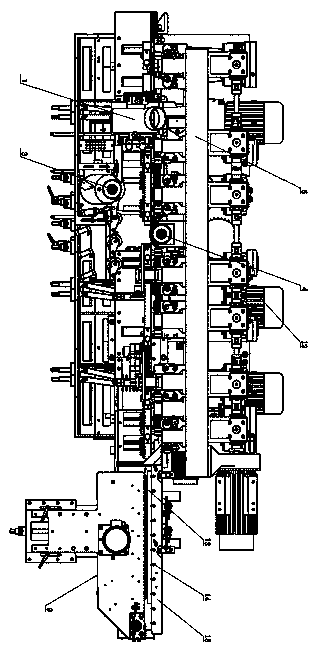

Fine four-face planing-milling machine

PendingCN109049151AImprove processing efficiencyGuaranteed fine planing and millingWood feeding arangementsSlide plateEngineering

The invention discloses a fine four-face planing-milling machine. A rough planing lower plane cutter, a finish planing lower plane cutter and an upper plane cutter of the fine four-face planing-milling machine are sequentially arranged along a wood feed channel from front to back. Follow-up press wheel air cylinders are mounted on a feeding rack cross beam. The ends of piston rods of the follow-uppress wheel air cylinders are connected with follow-up press wheel racks. The follow-up press wheel racks stride over corresponding upper feeding rollers, and follow-up press wheels are rotationallysupported on the follow-up press wheel racks. A follow-up press wheel sliding seat is supported on a front press foot seat in a sliding manner, and follow-up press wheels are rotationally supported atthe lower end of the follow-up press wheel sliding seat. Multiple wood guide side vertical rollers are rotationally mounted at the front end of a machine body through a side vertical roller mountingseat. A guide support is further mounted on the machine body. Multiple guide chain wheels and a guide drive chain wheel are mounted on a guide sliding plate. A guide chain is tensioned on the guide chain wheels and the guide drive chain wheel. A wood guide channel is formed between the guide chain and guide side vertical rollers. According to the fine four-face planing-milling machine, high-speedplaning of wood of various lengths can be achieved, the machining quality is good, and the planing precision is high.

Owner:JIANGSU JIANGJIA MACHINERY

Automatic bending and blanking mechanism

InactiveCN105251822ASimplified operational requirementsImprove securityStripping-off devicesReference surfaceArchitectural engineering

The invention discloses an automatic bending and blanking mechanism. The mechanism comprises a base (1), wherein the base (1) is provided with a reference surface (3) for placing a free end of a pipe (2) and rotating the free end of the pipe (2); the base (1) is provided with a boss (4) higher than the reference surface (3) for positioning the other end of the pipe (2); the boss (4) is provided with an opening (5) for accommodating the end part of the pipe (2); the base (1) is provided with a through hole (6) for sliding the bent pipe (2) in the vertical direction; and the shape of the through hole (6) is consistent with the bending shape of the pipe (2). The invention provides the automatic bending and blanking mechanism with low maintenance cost, simple operation and no need of manual pipe taking.

Owner:NINGBO T ERRE AUTOMOTIVE COMPONENTS

Main shaft device capable of adjusting length of wire bow

InactiveCN111890208ASmall sizeConvenience guaranteedGrinding machine componentsGrinding machinesMachineScrew thread

The invention discloses a main shaft device capable of adjusting the length of a wire bow. The main shaft device capable of adjusting the length of the wire bow comprises a machine frame, two main rollers are arranged on the machine frame, two auxiliary rollers are arranged between the two main rollers, the two ends of each auxiliary roller are sleeved with eccentric mounting bases, the eccentricmounting bases are mounted on the machine frame through a plurality of threaded connecting pieces, the plurality of threaded connecting pieces are distributed in an array around axes of the eccentricmounting bases, and the auxiliary rollers are tangent to and surround the cutting line by rotating the eccentric mounting bases. Compared with the prior art, the eccentric mounting bases and the auxiliary rollers are arranged between the two main rollers, the main shaft device is retrofitted by utilizing the space between the two main rollers, so that the transformation cost is saved, and the convenience of the main shaft device is kept. The length of the wire arch obtained through the setting is the length of the cutting line between the two main rollers, or the length of the cutting line between the two auxiliary rollers, or the length of the cutting line between one main roller and one auxiliary roller, and the length range of the obtained wire arch is wider.

Owner:宇晶机器(长沙)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com