Cutting and spinning synergetic fatigue low-stress blanking device and method

A low stress and fatigue technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of inability to smoothly transition, poor cutting section quality, large shear force, etc. Diameter ratio range, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

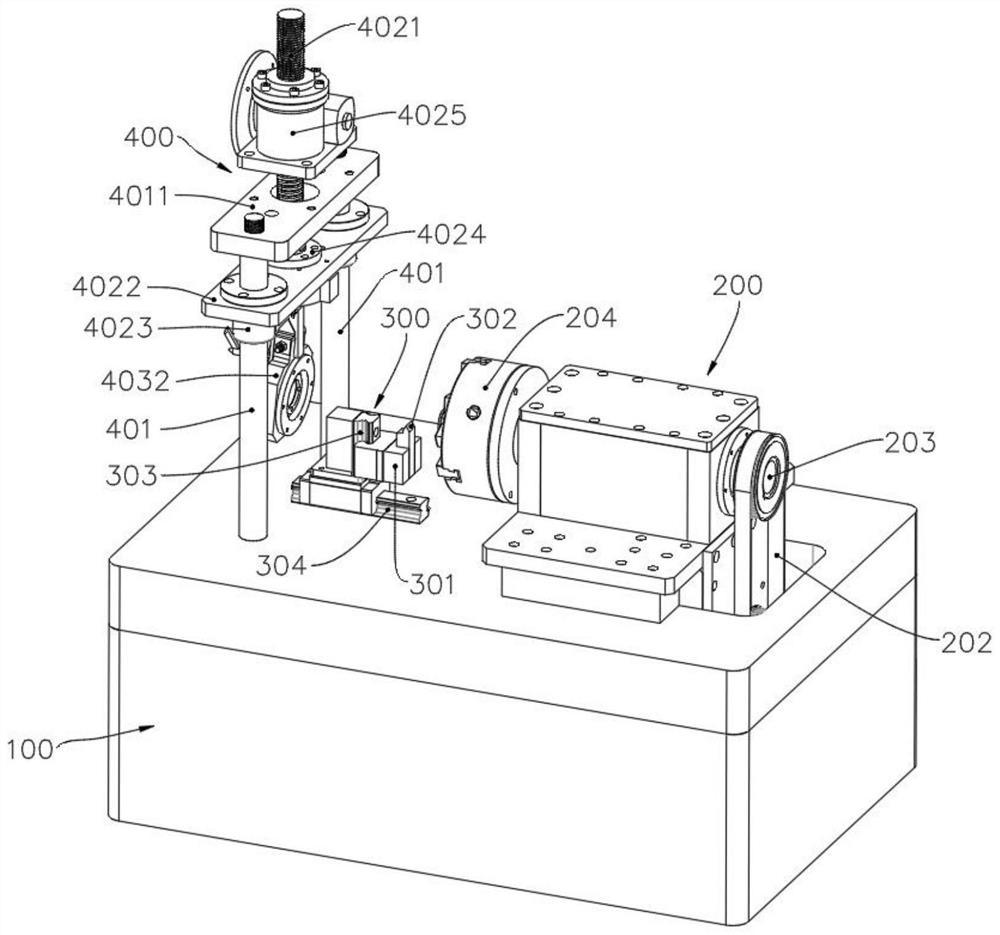

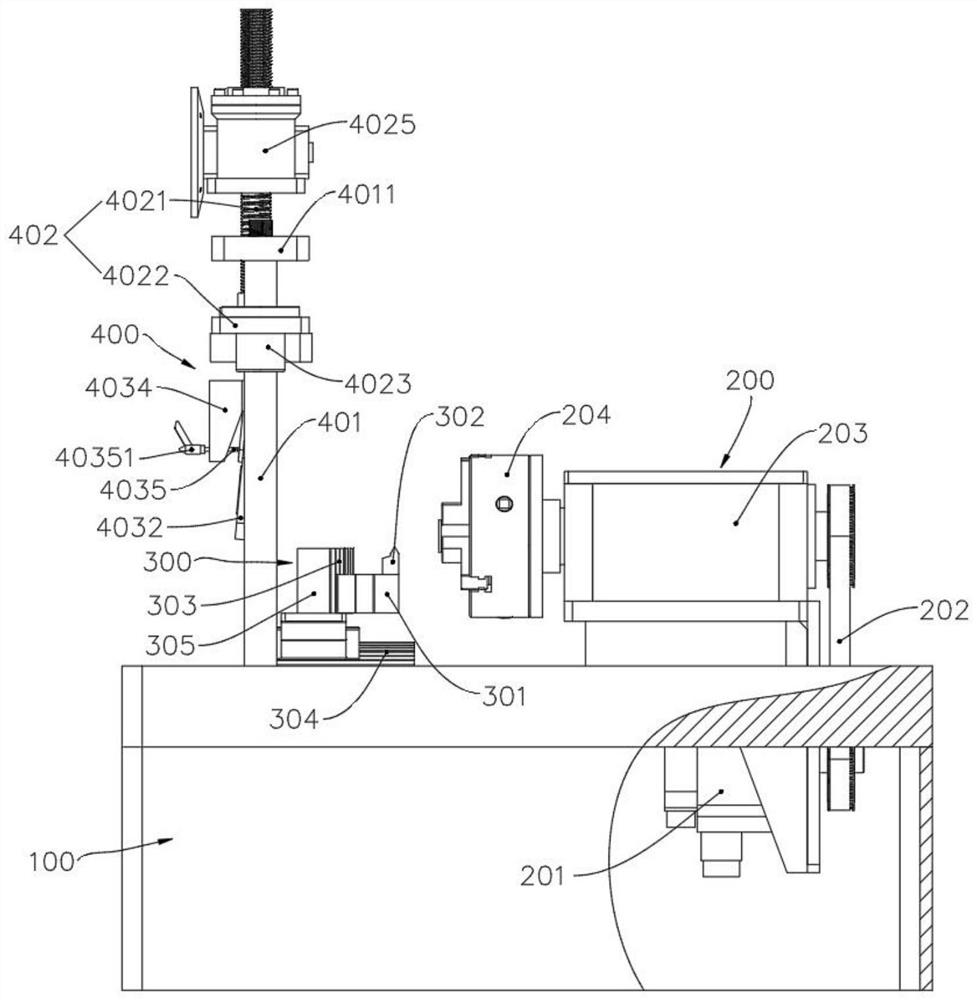

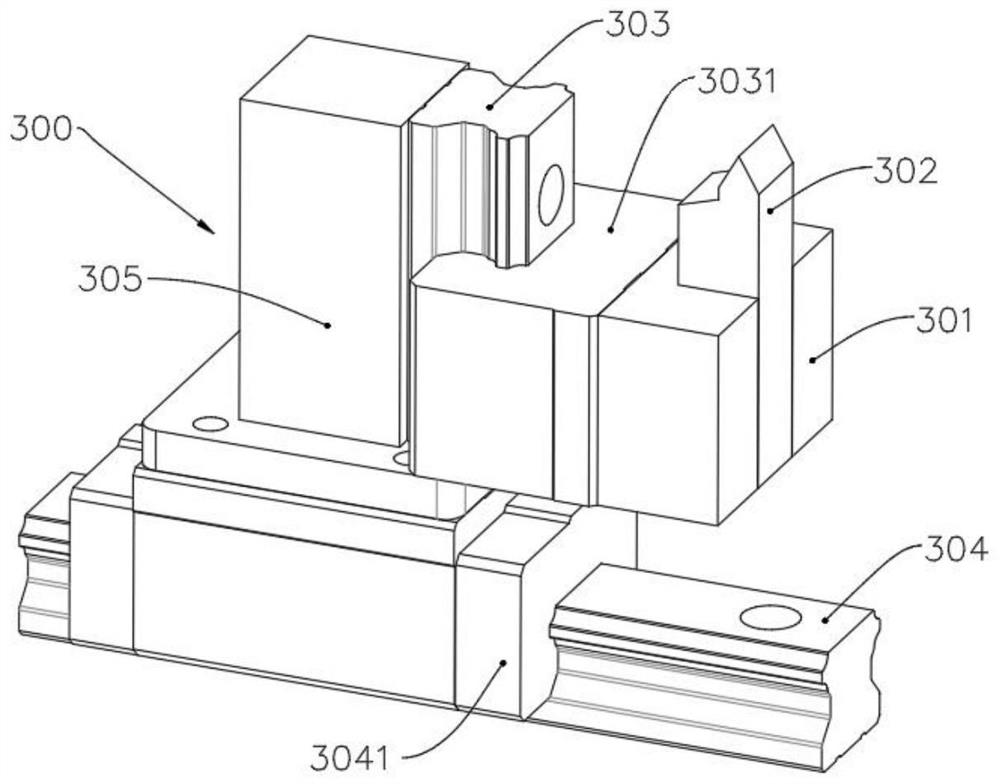

[0041] Refer to attached Figure 1-6 As shown, the present invention provides a technical solution: a cutting and bending cooperative fatigue low-stress blanking device, including a frame 100, a clamping and rotating mechanism 200, a cutting mechanism 300 and a loading mechanism 400, a clamping and rotating mechanism 200, Both the cutting mechanism 300 and the loading mechanism 400 are installed on the frame 100, the clamping and rotating mechanism 200 and the loading mechanism 400 are respectively arranged on the left and right sides of the cutting mechanism 300, and the frame 100 provides base support for the device;

[0042] Wherein, the clamping and rotating mechanism 200 includes a servo motor 201, a main shaft 203 and a three-jaw chuck 204, the servo motor 201 is fixedly installed on the bottom of the frame 100, the main shaft 203 and the three-jaw chuck 204 are arranged on the top of the frame 100, three The jaw chuck 204 is fixedly connected to one end of the main shaf...

Embodiment 2

[0054] Refer to attached Figure 7 As shown, the embodiments of the present invention also provide a cutting and bending cooperative fatigue low-stress blanking method, which includes the following steps:

[0055] S1, install the bar material, pass the bar material to be unloaded through the center of the follower bearing 4036, and extend it into the inside of the three-jaw chuck 204 for clamping and fixing, turn on the servo motor 201, and output power to the main shaft through the timing belt 202 203, the main shaft 203 drives the bar held by the three-jaw chuck 204 to rotate;

[0056] S2, preset loading force, observe and fine-tune the matching angle between the loading frame 4032 and the connector 4031 through the angle pointer 40322, then tighten the quick-release locking part 40351 to fix the angle, and then drive the threaded rod 4021 to move upward through the elevator 4025, and the movable plate 4022 moves upward synchronously under the cooperation of guide bearing 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com