Ultrasonic laser composite dressing device for superabrasive grinding wheel

A dressing device and super-hard abrasive technology, which are applied in abrasive surface adjustment devices, grinding/polishing equipment, and parts of grinding machine tools, etc., can solve problems such as poor dressing accuracy, excessive wear of dressing tools, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

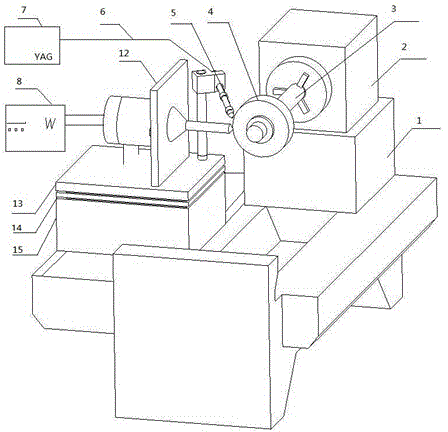

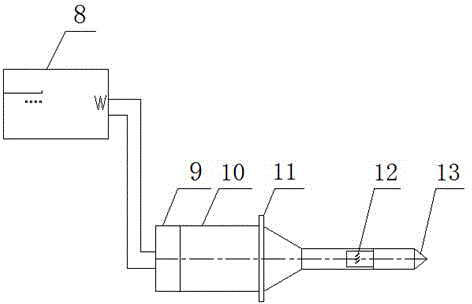

[0010] As shown in the figure, the superabrasive grinding wheel ultrasonic laser composite dressing device includes a bed 1, a spindle box 2 is arranged on the bed 1, a spindle 3 and a superabrasive grinding wheel 4 are connected by a chuck, and the spindle 3 drives the superabrasive grinding wheel 4 to rotate. The bed 1 is provided with a lead screw which can be driven to rotate at a high speed. The lower part of the sliding tray 17 is provided with balls. The track 16 arranged in the direction, the support plate 15 above the track 16 can move tangentially along the track 16, the support plate 15 is provided with a bracket 14, the ultrasonic vibration trimming device and the laser focusing head 5 are fixed on the bracket, they can move along the grinding wheel 4 Axial feed can also fine-tune the working position along the tangential direction. The circumferential angle between the laser focusing head 5 and the diamond trimming pen 13 is set at 50-70°, and the axial distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com