Experimental device and method for simulating working conditions of filter press

The technology of an experimental device and experimental method is applied in the direction of separation method, chemical instrument and method, filtration separation, etc. It can solve the problems of difficulty in obtaining experimental data, time-consuming and labor-intensive, and easy deformation, so as to achieve reliable experimental data, reduce labor intensity, The effect of convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

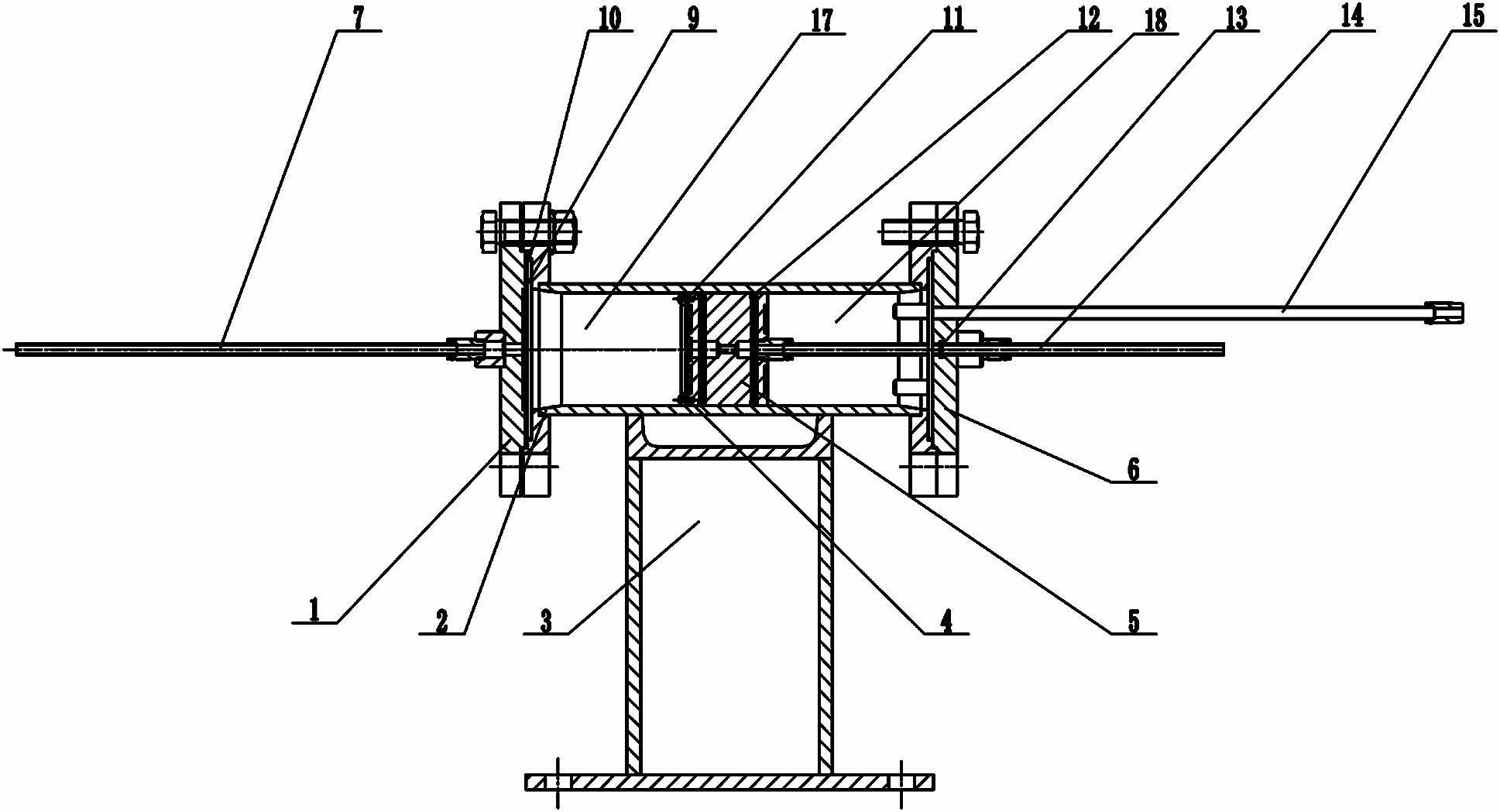

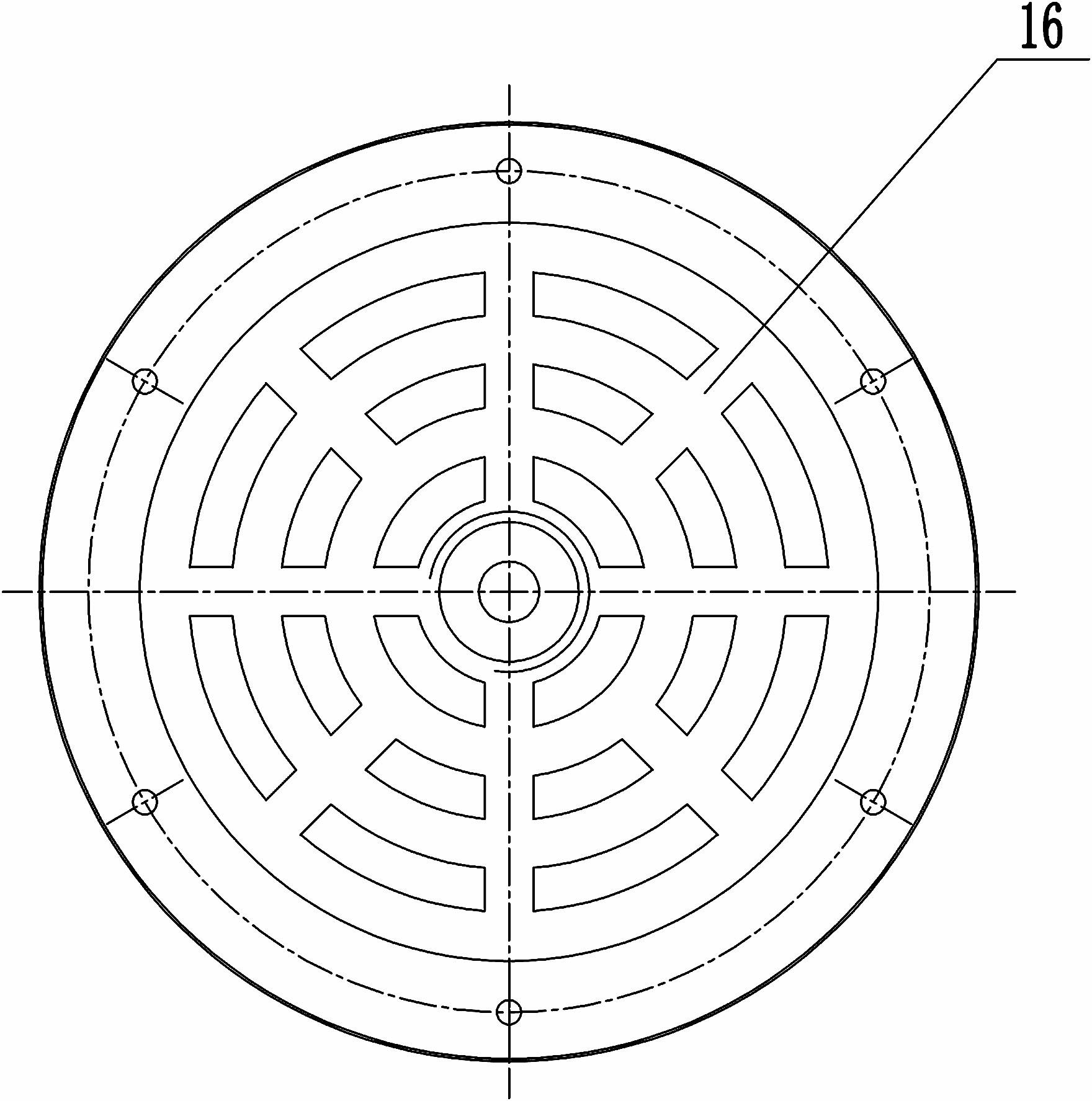

[0034] Such as figure 1 Among them, an experimental device for simulating the working conditions of a filter press comprises a barrel body 2, a filter press piston 5 is installed in the barrel body 2, two second sealing rings 12 are arranged on the filter press piston 5, and one end of the barrel body 2 The first end cover 1 is provided with a liquid outlet pipe 7 communicating with the filter cavity 17, and the first end cover 1 is provided with an end cover filter cloth 9 at one end of the filter cavity 17; the first end cover 1 is connected with the barrel A first sealing ring 10 is arranged between the bodies 2 .

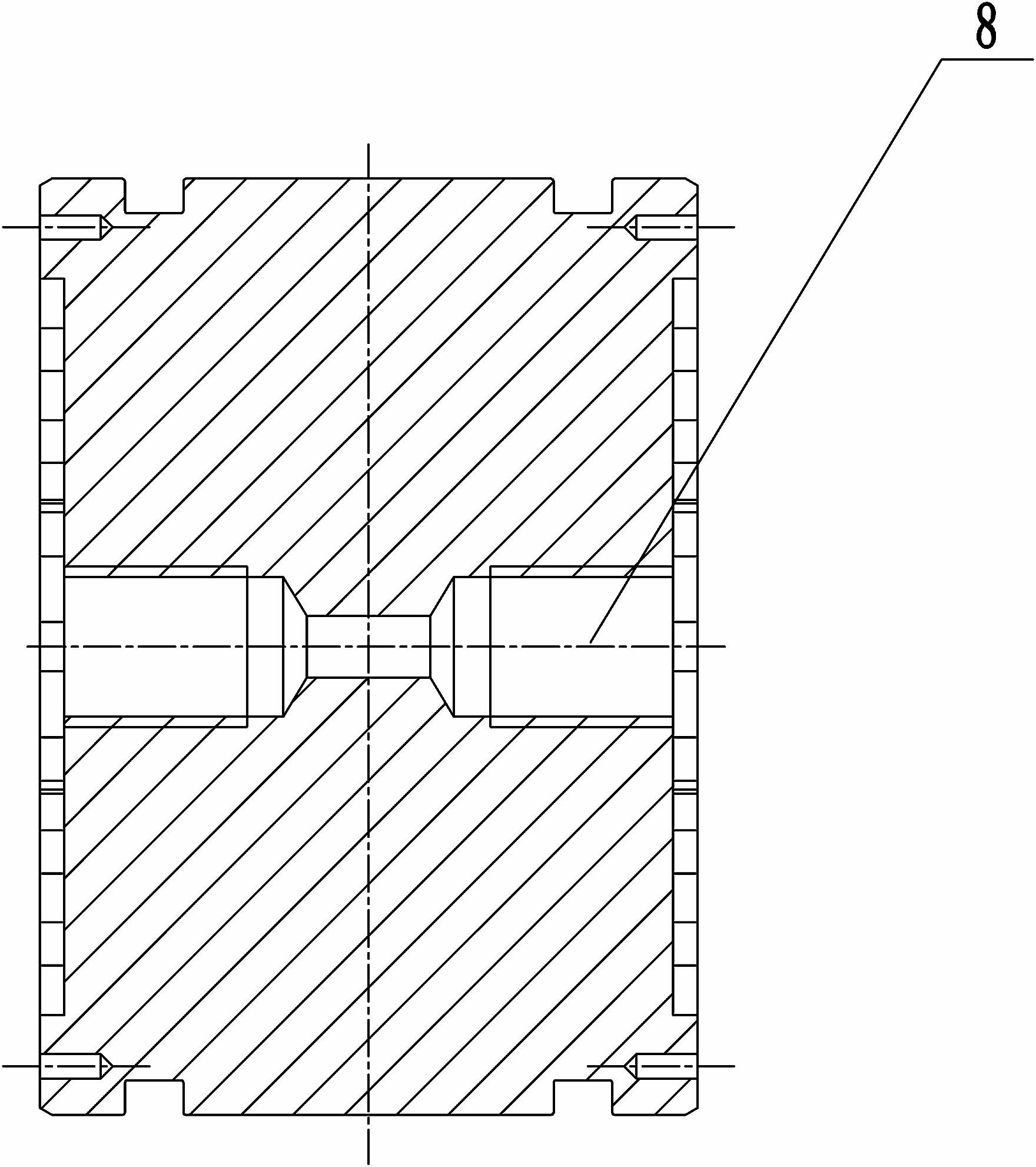

[0035] The other end of the barrel body 2 is provided with a second end cover 6, and a first sealing ring 10 is arranged between the second end cover 6 and the barrel body 2, and the movable liquid outlet pipe 14 passes through the second end cover 6 and the pressure filter piston 5. The liquid through hole 8 is connected, and the liquid through hole 8 is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com