Patents

Literature

71results about How to "Reduce residual thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

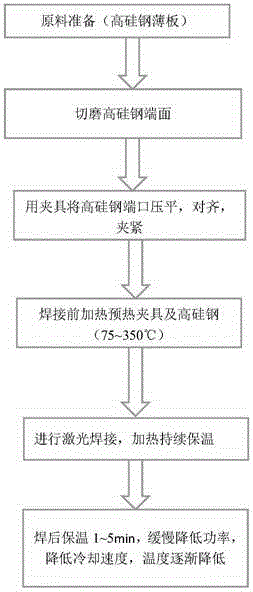

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

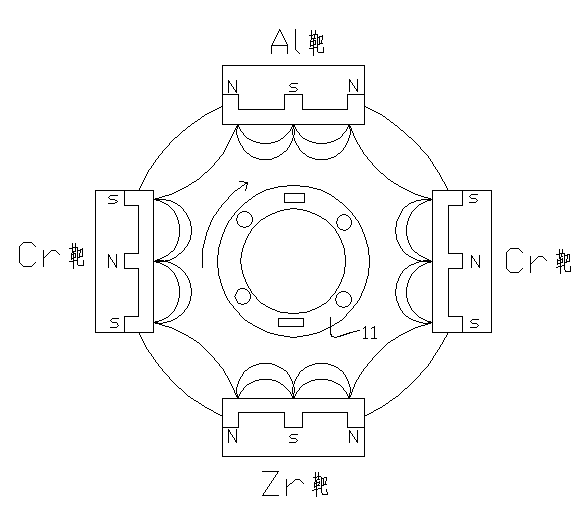

A1ZrCrN composite dual-gradient coating cutting tool and preparation method thereof

ActiveCN103132019AReduce residual thermal stressHigh bonding strengthVacuum evaporation coatingSputtering coatingIon platingComposite coating

The invention relates to an A1ZrCrN composite dual-gradient coating cutting tool and a preparation method thereof. The composite dual-gradient coating cutting tool is prepared by a nonequilibrium closed field magnetron sputtering ion plating manner; and a Cr transition layer, a gradient CrN transition layer, a gradient A1ZrCrN transition layer and an A1ZrCrN layer are sequentially arranged on the coating cutting tool from inside to outside along the a vertical matrix surface direction, so that transition between coatings is smoother, residual thermal stress among all coatings can be obviously lowered in use of the coating cutting tool, and the coating quality of the cutting tool is greatly improved.

Owner:成都史特迪新材料科技有限公司

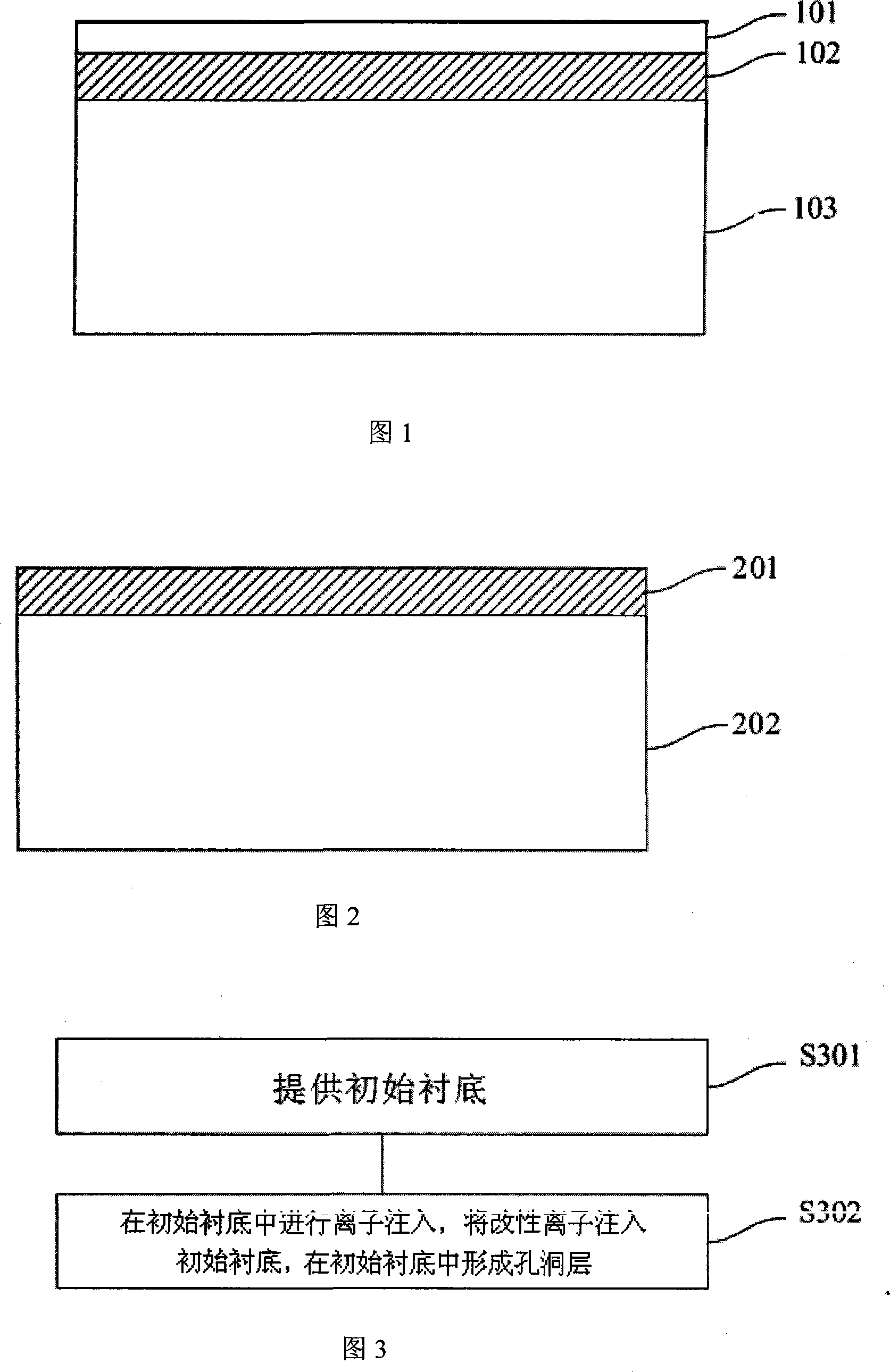

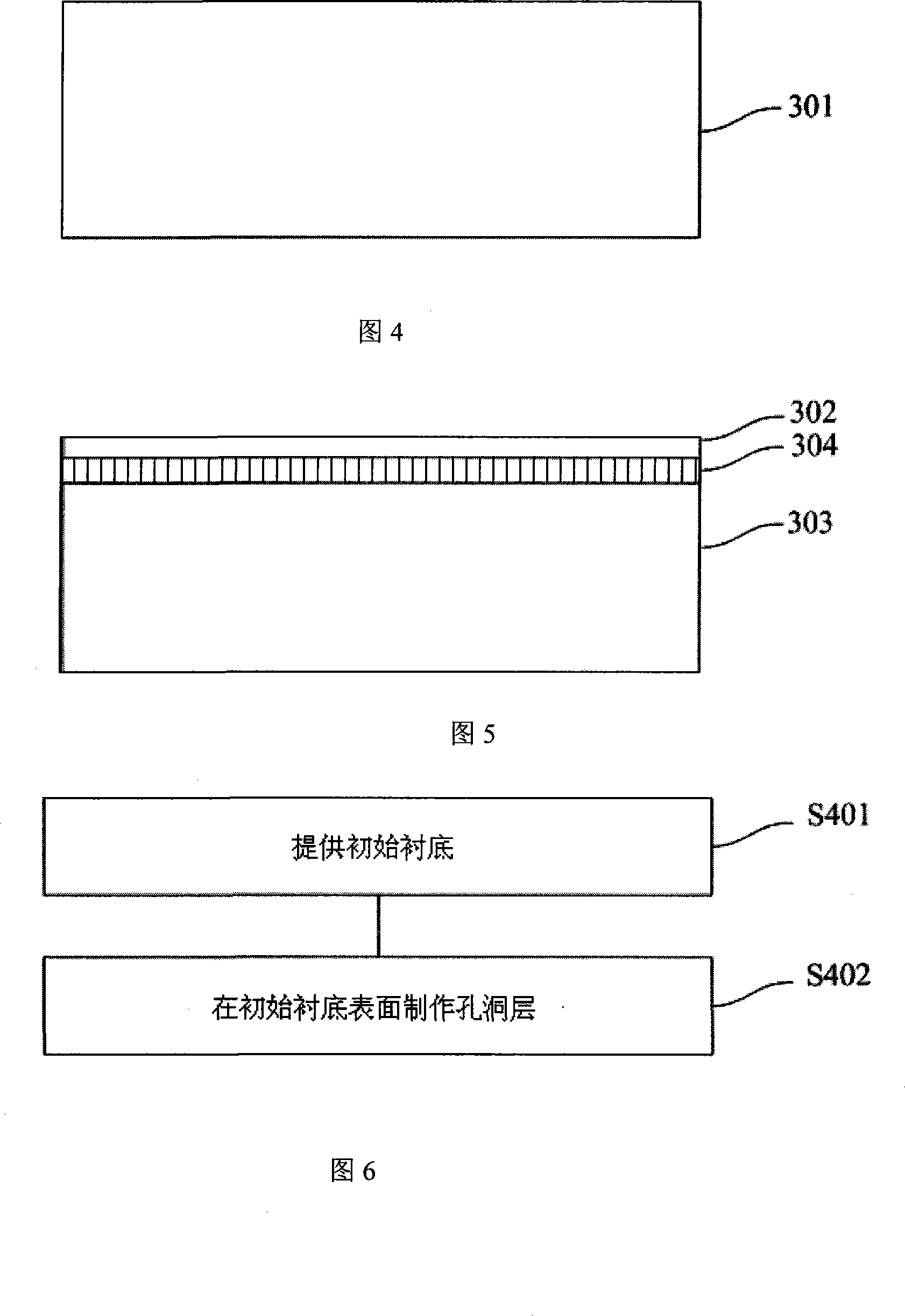

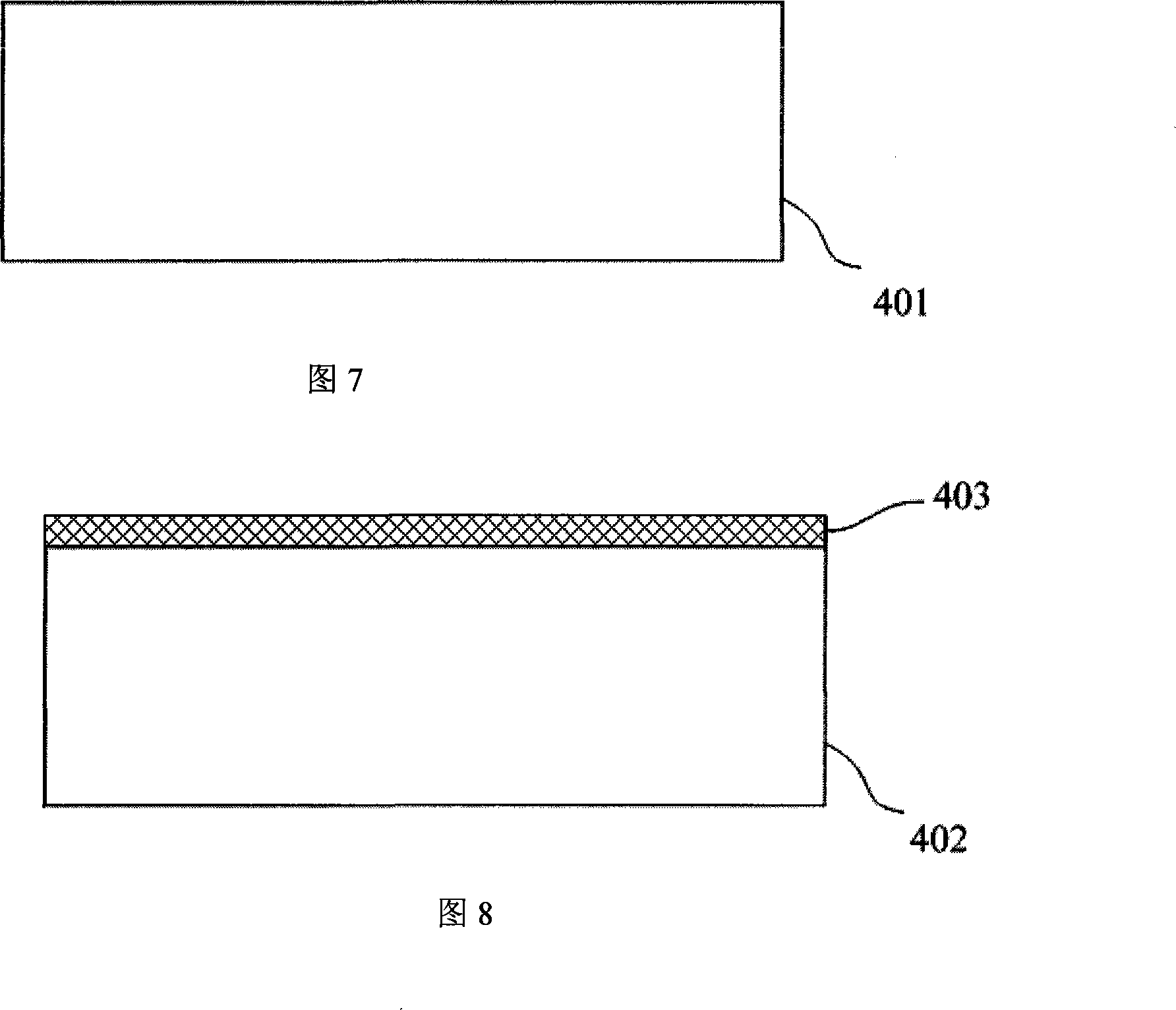

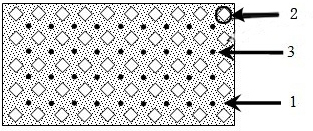

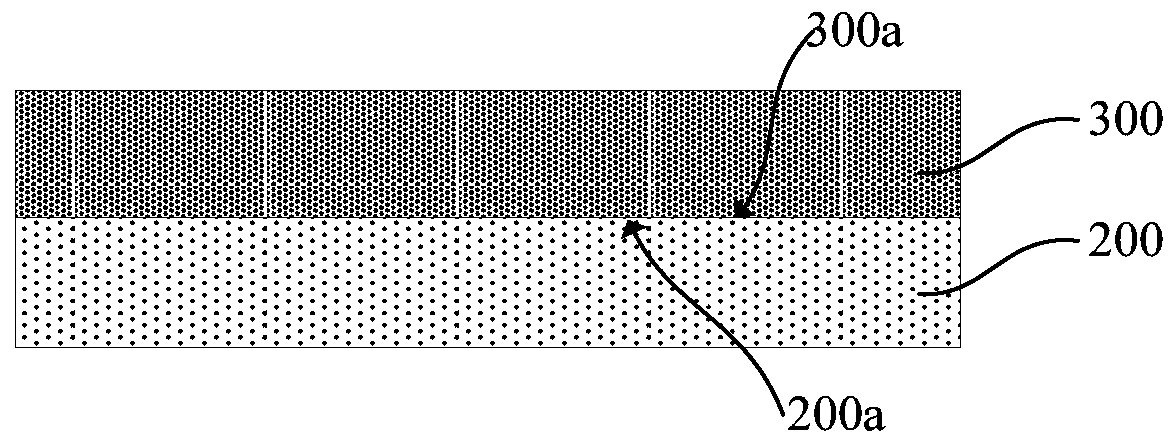

Semiconductor underlay and production method and its application on silicon and extension of insulator

ActiveCN101197260AReduce residual thermal stressSemiconductor/solid-state device manufacturingState of artSingle crystal

The invention relates to a semi-conductor substrate, which comprises a covering layer which is positioned on the top layer and a cave layer which is positioned below the covering layer and a supporting layer which is positioned below the cave layer. The semi-conductor substrate with a special structure is prepared by two methods, that is, an ion injection and an anode oxidization. At the same time, the invention further discloses a method for preparing a silicon material on a generalized bonded thin insulator by the semi-conductor substrate, and a method for using the semi-conductor substrate for material extension as an extending substrate. Compared with the prior art, the invention has the advantage that the cave layer in the semi-conductor substrate can help release interlayer stress, thus acquiring perfect single crystal material.

Owner:SHANGHAI SIMGUI TECH +1

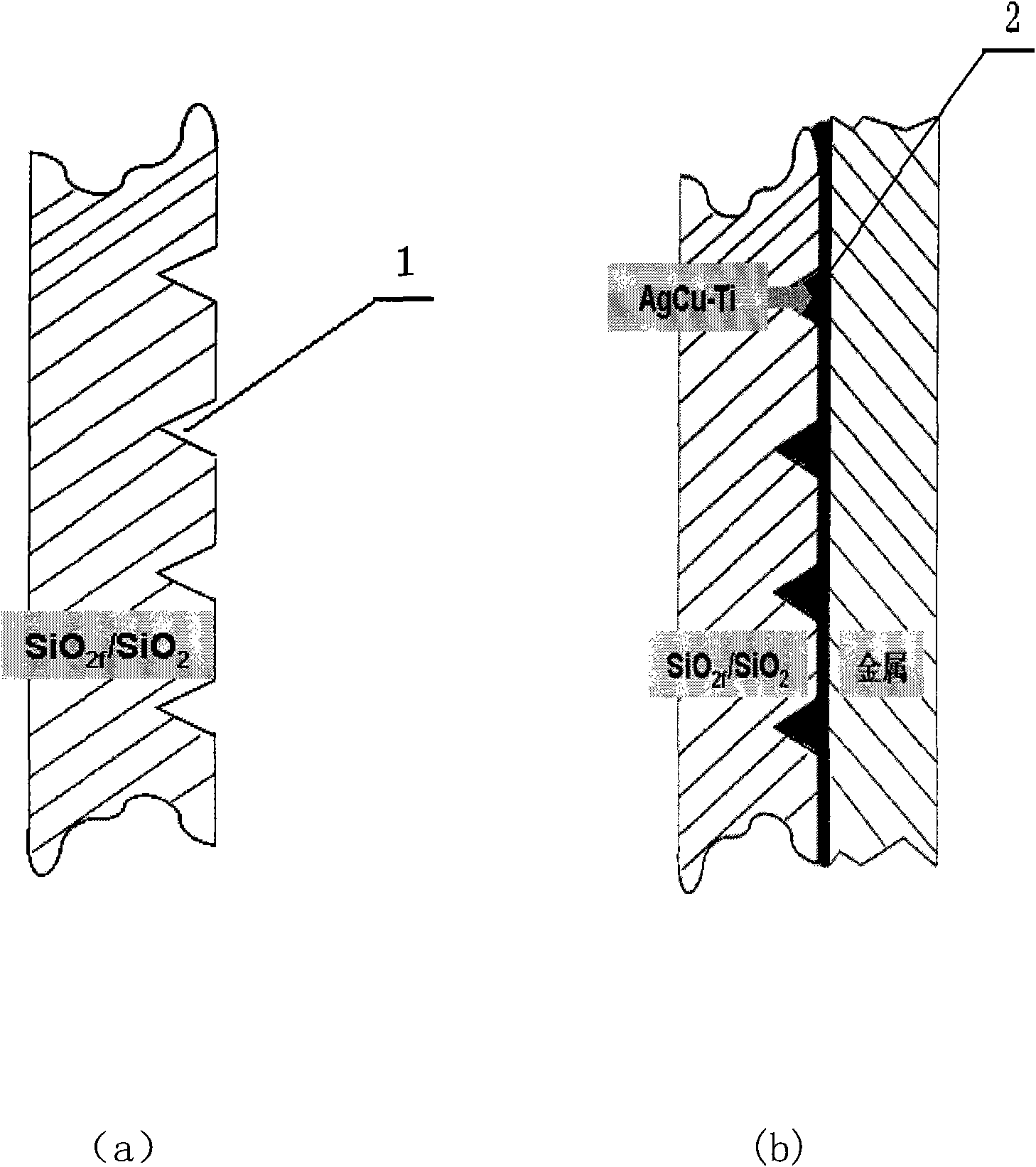

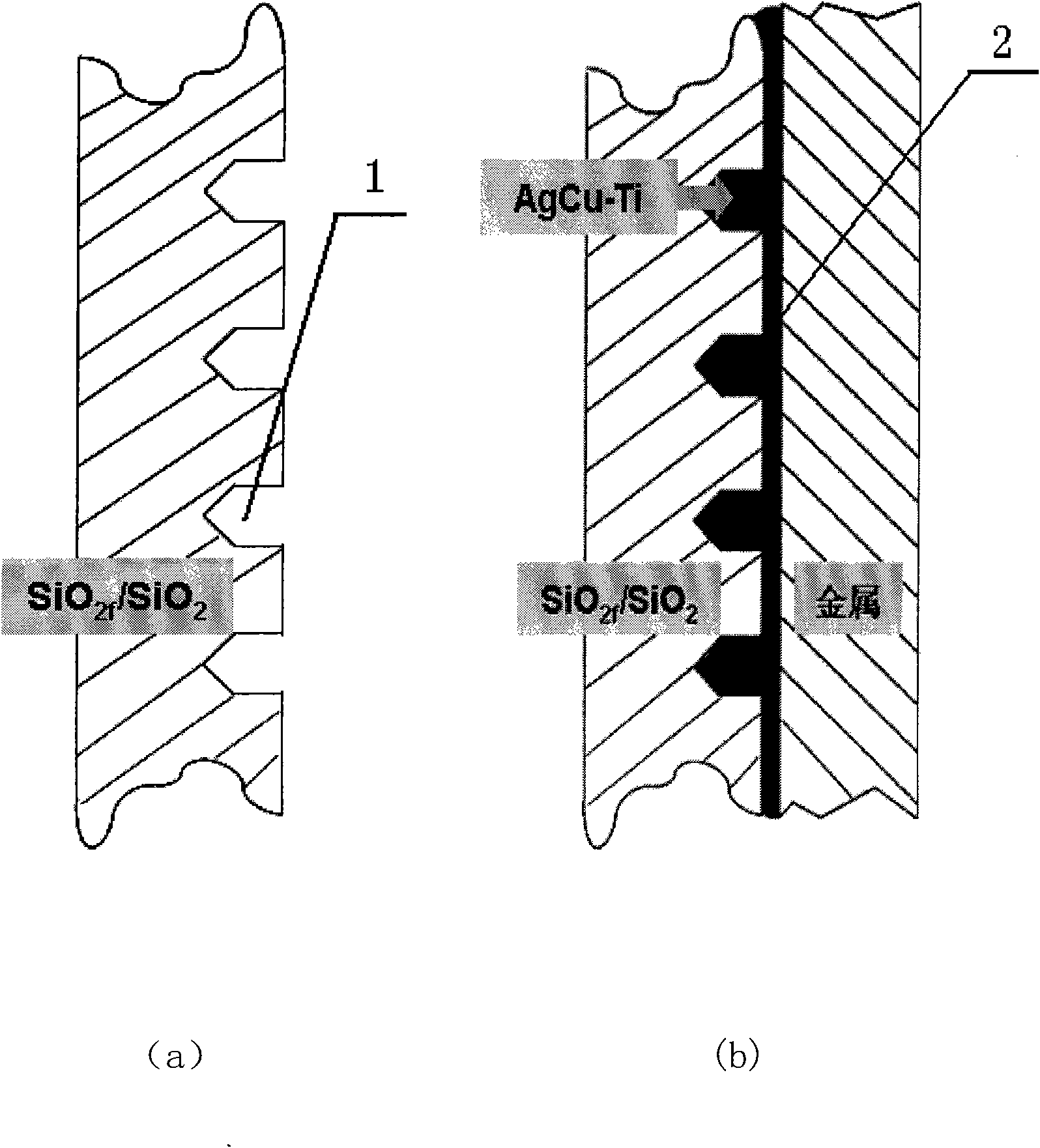

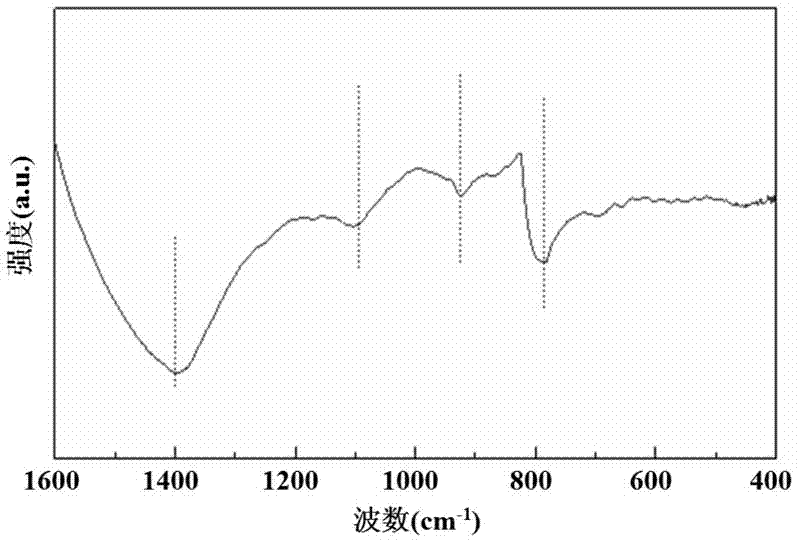

Process for soldering SiO2f/SiO2 composite ceramic and metal material

The invention discloses a process for soldering a SiO2f / SiO2 composite ceramic and a metal material, which is characterized by selecting AgCu-Ti active solder to connect the SiO2f / SiO2 composite ceramic, and by comprising the following process steps: making grooves on the to-be-soldered surface of the SiO2f / SiO2 composite ceramic by a machining process; placing the active solder in the grooves on the to-be-soldered surface of the SiO2f / SiO2 composite ceramic and adding the AgCu-Ti solder on the to-be-soldered interface between the soldered SiO2f / SiO2 composite ceramic and the soldered metal material; and realizing the effective connection of the SiO2f / SiO2 composite ceramic and the metal material by vacuum soldering and heating.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

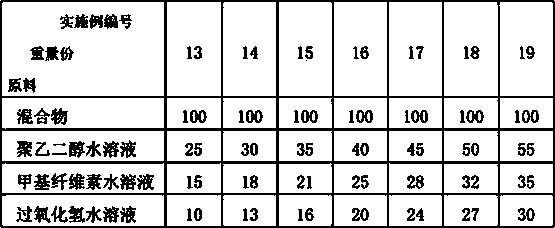

Biomass fuel forming mold surface powder metallurgy strengthening coating material and process

The invention belongs to the technology for improving biomass fuel forming mold surface hardness (namely improving abrasion resistance of the surface) and particularly relates to a biomass fuel forming mold surface powder metallurgy strengthening coating material and a process which aim at solving the problem of serious abrasion of the biomass fuel forming mold surface. The process includes: weighing appropriate mass of powder according to the area of the portion of a mold needing strengthening and the thickness of a pre-strengthening layer, wherein the powder is composite powder formed by mixing cobalt / nickel-based self-fluxing alloy powder and non-metallic ceramic powder in proportion; adding appropriate amount of bonding forming agents in the composite powder and sufficiently mixing through vacuum stirring to obtain plastic powder bodies; and evenly coating the powder bodies on the biomass fuel forming mold surface, drying and conducting powder metallurgy strengthening in a vacuum furnace according to corresponding temperature rising curves. Hardness of a powder metallurgy strengthening coating can reach rockwell hardness (HRC) 50-70, the thickness is above 2 mm, the coating is smooth, light and free of pore cracks, and a binding interface between the coating and a substrate is fused in metallurgy mode and is even in texture and free of obvious defects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

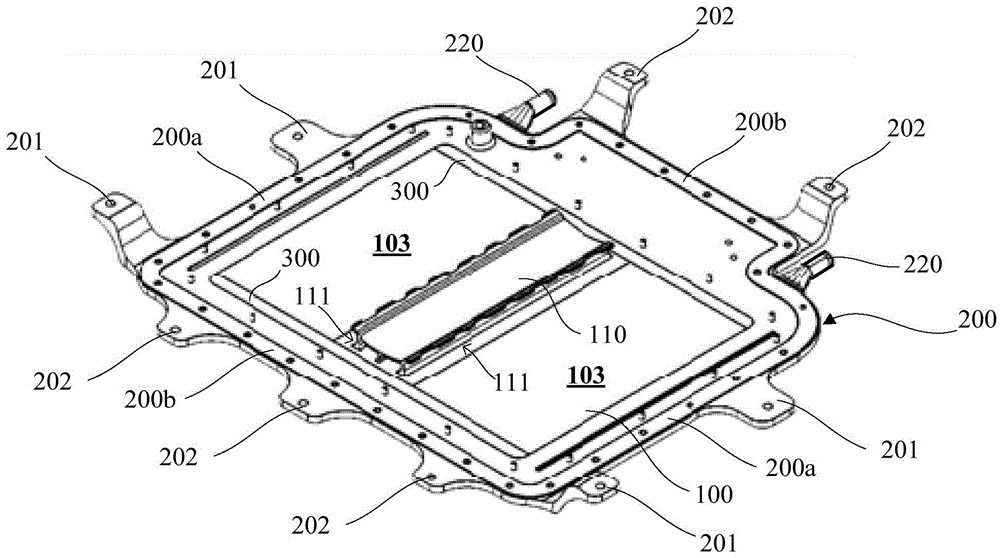

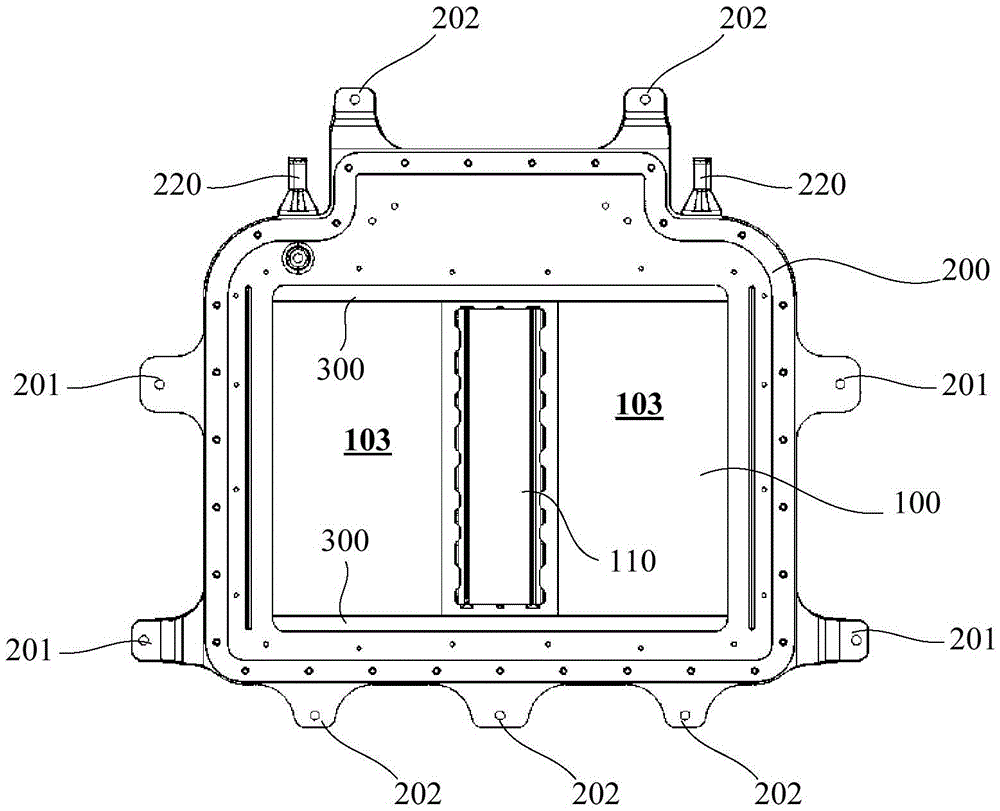

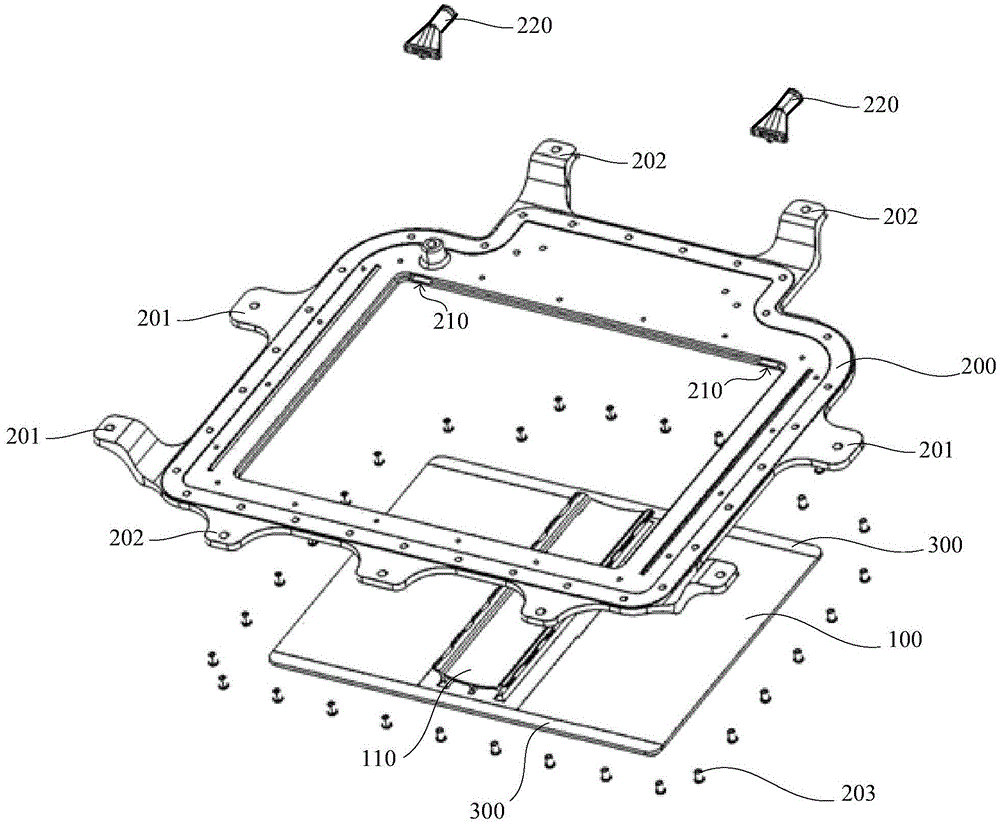

Power battery system and tray thereof

ActiveCN106684276AAdvanced technologyQuality improvementCell temperature controlCell component detailsPower batteryElectrical battery

The invention discloses a power battery system and a tray thereof. The tray comprises a tray main body used for mounting a power battery module, and a tray framework which surrounds and is connected with the tray main body; the tray framework is used for being connected with an automobile; the tray main body has an inner cavity used for accommodating a coolant; a first channel is formed in the tray framework; and one end of the first channel is connected with the inner cavity while the other end is used for being connected with a finished automobile cooling system. The coolant can circulate in the finished automobile cooling system and the inner cavity of the tray main body so as to cool the power battery module, so that an additional cooling system is not required to be designed, and the size and the weight of the overall power battery system are reduced consequently.

Owner:SAIC MOTOR

Solder for bonding C/SiC composite material with Ni-based alloy and bonding method

ActiveCN102219538AHigh strengthImprove room temperature flexural strengthRoom temperatureThermal expansion

The invention discloses a solder for bonding a C / SiC composite material with a Ni-based alloy and a bonding method. The solder is composed of 67-78% of Cu foil by mass, 8.5-15% of Ti foil by mass and 10-24.5% of Mo powder by mass. The thickness of the Cu foil is 30-70 mum. The thickness of the Ti foil is 80-120 mum. The granularity of the Mo powder is 3-15 mum. By pretreating the solder, the cleaned Cu foil, the cleaned Ti foil and the Mo powder paste can be obtained. A pre-bonded element is manufactured by using the solder. A bonding piece between a carbon / silicon carbide ceramic-based composite material and a nickel-based high-temperature alloy can be obtained through hot pressing. According to the solder disclosed by the invention, the mismatching property of thermal expansion coefficients between the solder and the C / SiC composite material is effectively reduced; the residual heat stress between the solder and the C / SiC composite material is reduced; and the room-temperature bending strength of the C / SiC composite material and an Ni-based high-temperature alloy joint are improved to 198 MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

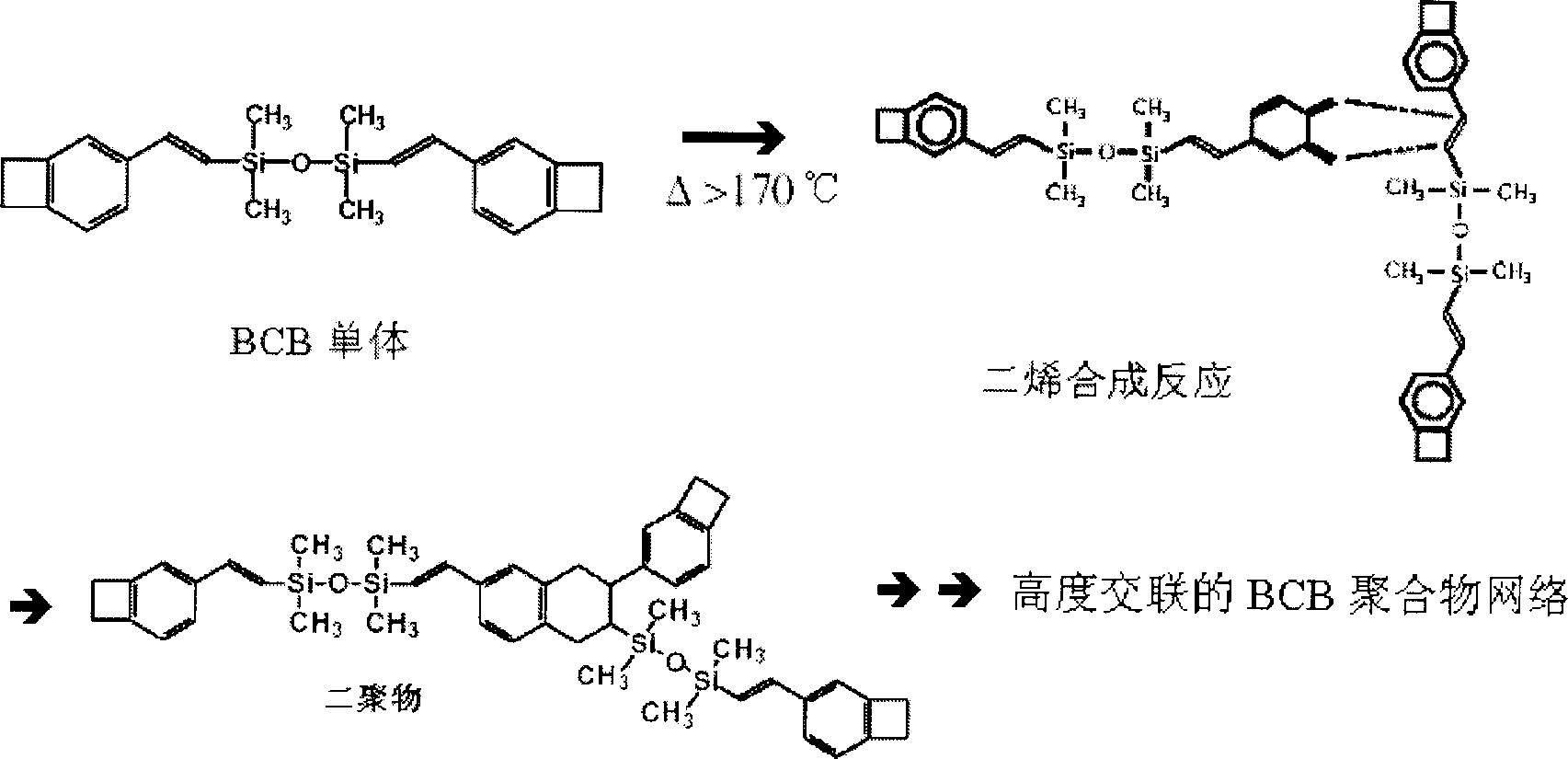

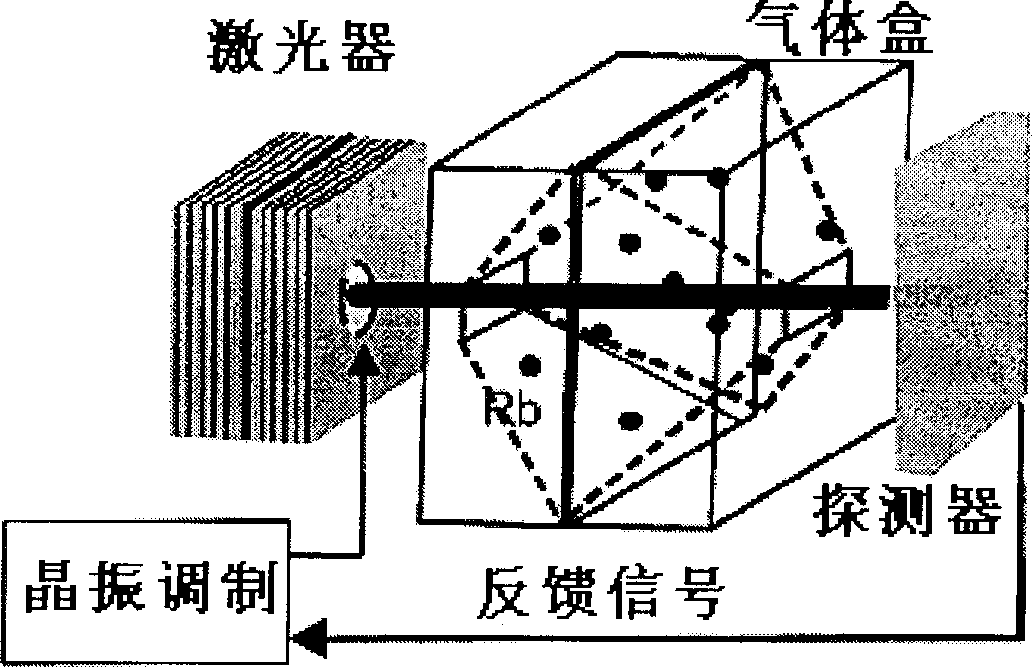

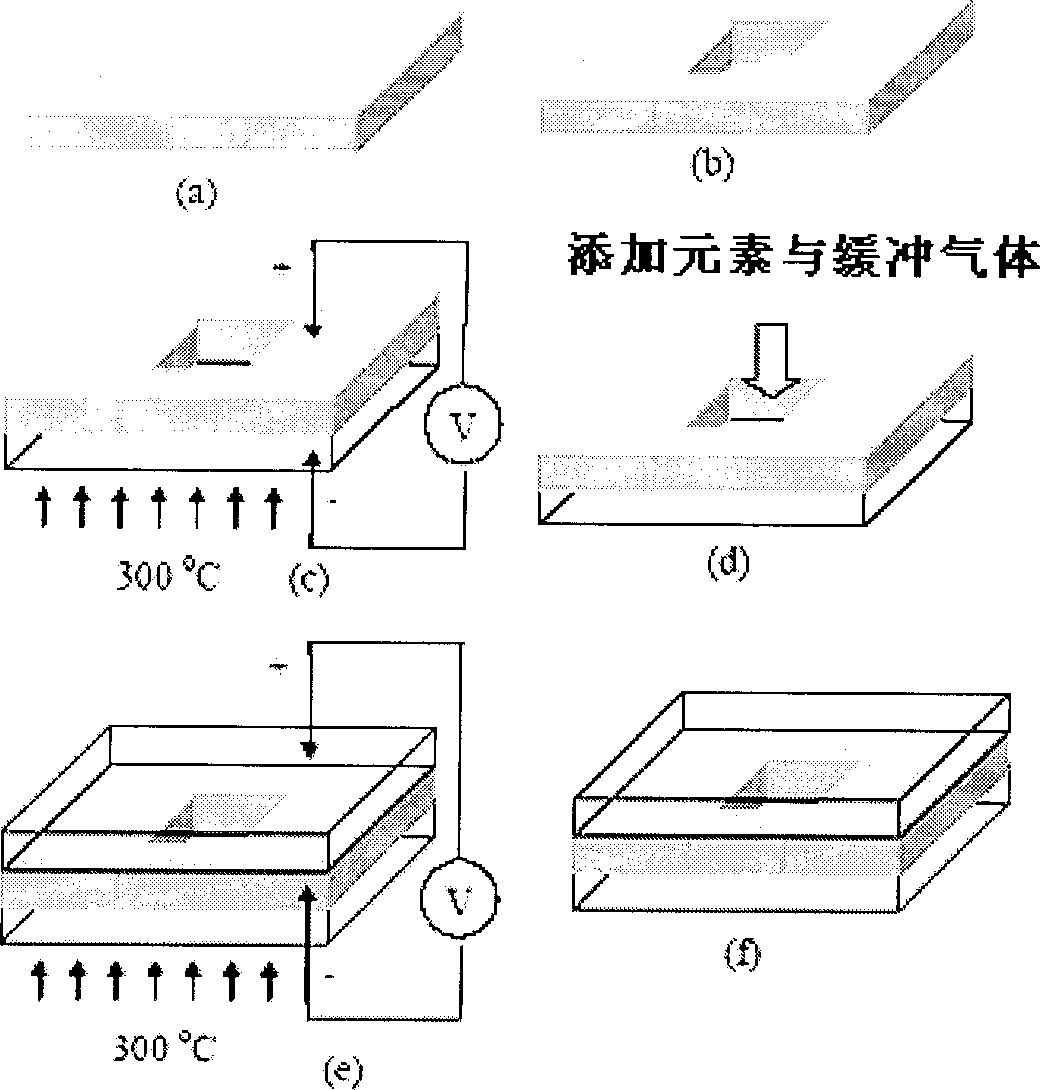

Process for preparing low-temperature wafer-level mini-sized gas container

InactiveCN1827522AMeet packaging requirementsAvoid lostNanostructure manufactureSemiconductor materialsAir tightness

The invention relates to a method for producing low-temperature circle sheet micro gas box, which is characterized in that: the benzocyclobutene is used to process material linkage with humid etching or dry etching technique of semi-conductor in 250Deg. C, to realize the circle sheet air-tightness sealing linkage of chip-level gas box. The invention comprises a atom gas box containing a chip-level atom clock gas box, a high-precision magnetic field sensor gas box, a atom feedback glimmer frequency stabilizer; a atom gas box containing a atom light filter, with glimmer Fabry-Perot chamber. The linked BCB glue is in 0.2ª–m thickness, the air-tightness of sealed He gas can reach 2.1-5.9X10-4Pa cm3 / s, and the linkage strength is higher than 4.65MPa, while the thermal cycle reliability can fully reach the packing standard of micro electric device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

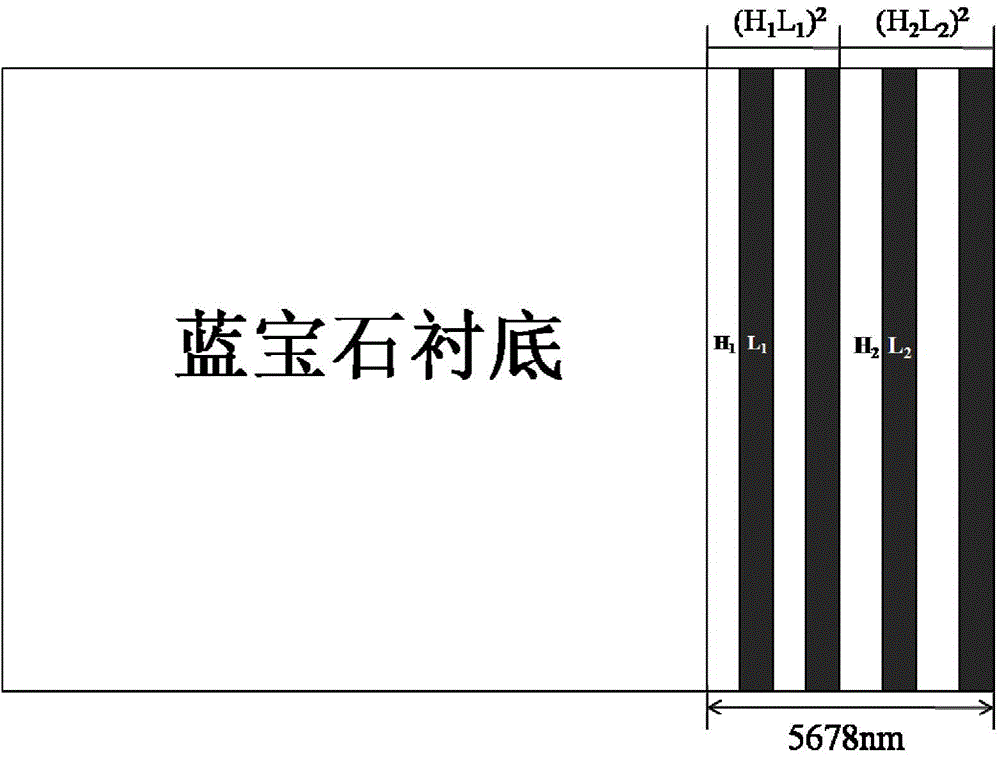

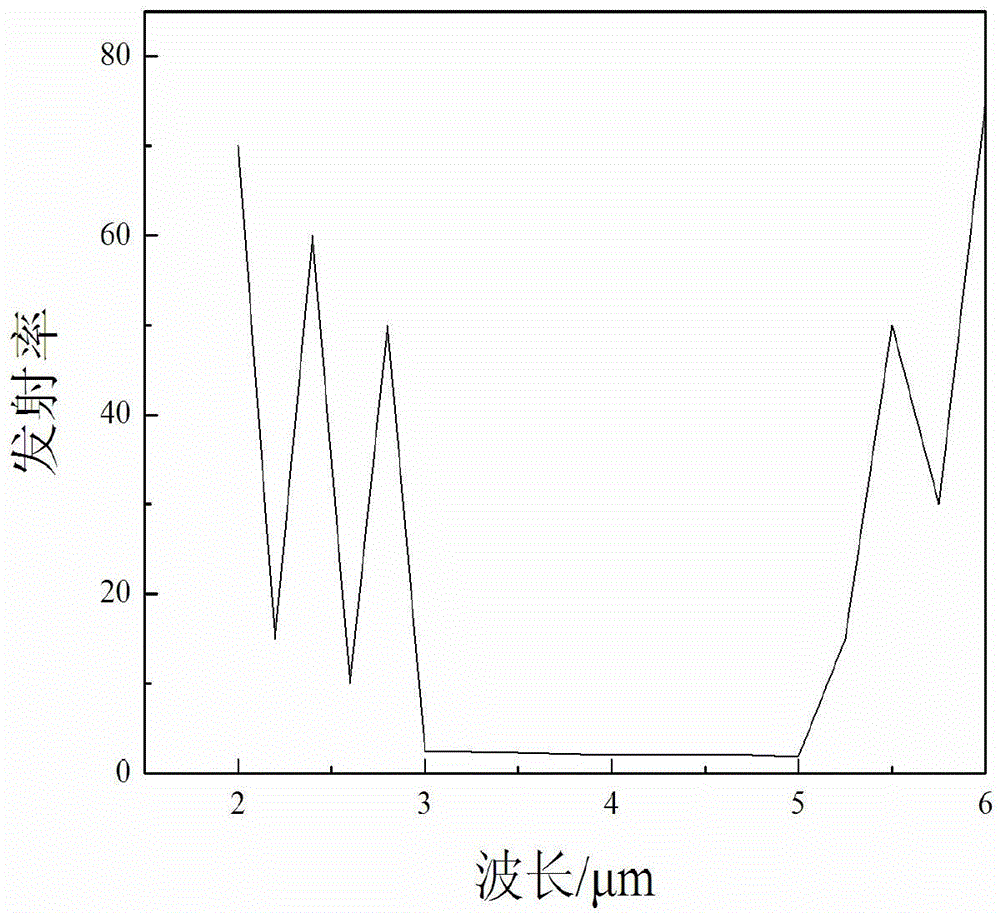

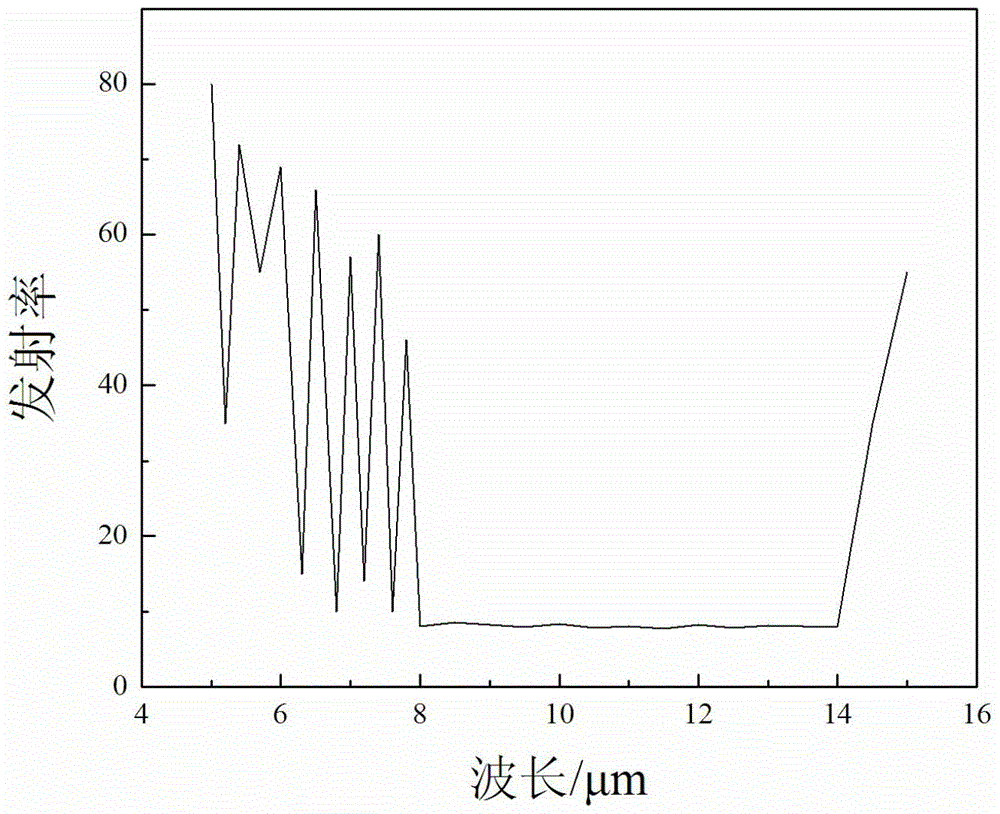

Infrared stealth thin film with spectral selectivity and low emission rate and preparation method of infrared stealth thin film

ActiveCN104865618ANot easy to fall offGood heat matchingVacuum evaporation coatingSputtering coatingEmissivityRadio frequency magnetron sputtering

The invention relates to an infrared stealth thin film with spectral selectivity and low emission rate. The infrared stealth thin film is of a multi-layer superimposed structure; the multi-layer superimposed structure contains a periodically-laminated structure which is formed by alternately superimposing high-refractive index material layers and low-refractive index material layers; and the periodically-laminated structure includes a first multilayer structure and a second multilayer structure of which the center wavelengths are lambda 1 and lambda 2 respectively, wherein the first multilayer structure and the second multilayer structure are superimposed in a complex manner, the lambda 1 satisfies the expression that 3.0 microns<=lambda 1<= 5.0 microns, and the lambda 2 satisfies the expression that 8.0 microns<=lambda 2<=14.0 microns. The preparation method of the infrared stealth thin film includes the steps that: a substrate is cleaned; a Si thin film is plated on the substrate by means of sputtering and through adopting a radio frequency magnetron sputtering method, and a ZnS thin film is plated on the high-refractive index material layer by means of sputtering and through adopting a radio frequency magnetron sputtering method; the previous steps are repeated for a plurality of periods, and alternate control on designed thicknesses is utilized in combination, and therefore, the infrared stealth thin film with spectral selectivity and low emission rate can be obtained. The preparation method of the infrared stealth thin film of the invention has the advantages of simple preparation process, high repeatability, low equipment requirements, excellent product performance and favorable application effect.

Owner:NAT UNIV OF DEFENSE TECH

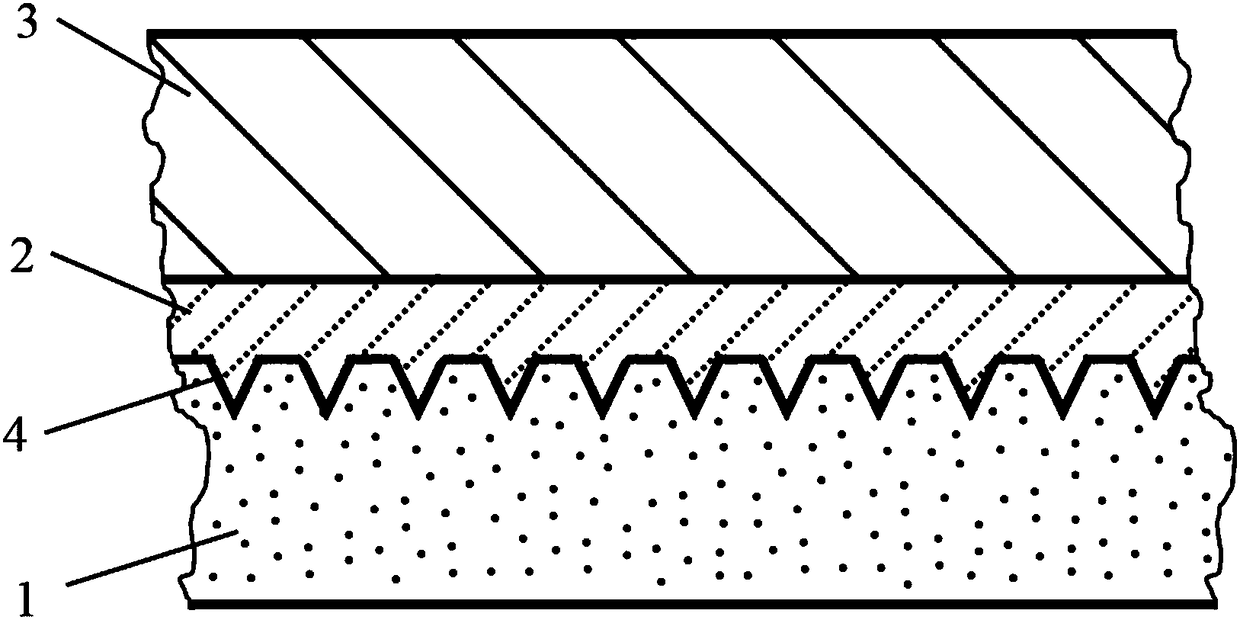

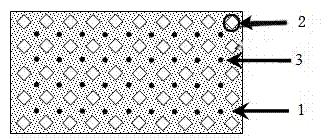

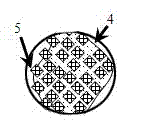

Method for manufacturing grinding wheel work layer with abrasive particle dressing function

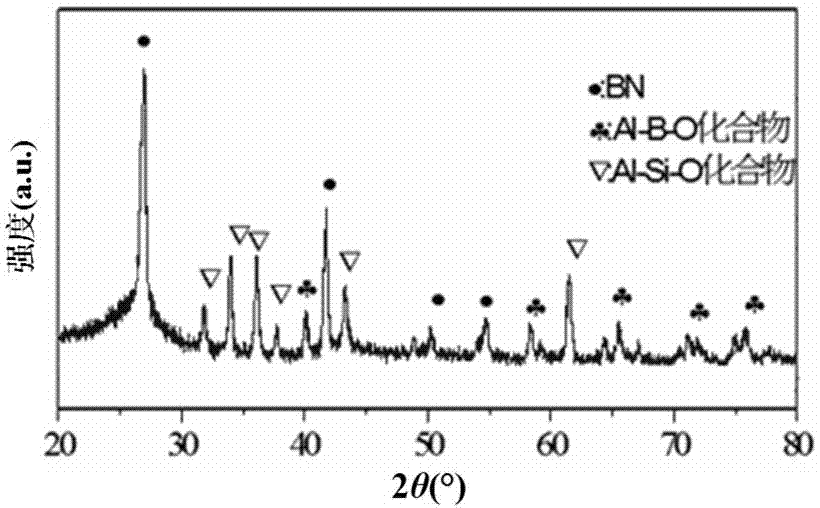

ActiveCN102172902ASolve the disadvantages of easy aggregationSmall difference in coefficient of thermal expansionGrinding devicesWear particleBoron nitride

The invention relates to a method for manufacturing a polycrystalline cubic boron nitride (PCBN) grinding wheel work layer with an abrasive particle dressing function, belonging to the manufacture field of superhard grinding material tools. The method comprises the following steps: abrading particles for Cu-Sn-Ti alloy powder and PCBN, fusing TiC particles, preparing a blank and sintering at hightemperature. The PCBN abrasive particle is formed by sintering CBN (cubic boron nitride) microcrystalline particles and AlN binder at high temperature and under high pressure. Once the CBN microcrystalline particles are blunt, the junction interface of CBN microcrystalline 5 and AlN binder is weakened along with the rise of the grinding force and the grinding temperature, so that the blunt CBN microcrystalline particles fall, and new CBN microcrystalline particles are quickly exposed to participate in the grinding process. The micro-breaking characteristics of the PCBN abrasive particles cause the superhard grinding material grinding wheel to still keep high sharp degree and avoid the phenomenon that grinding force and grinding temperature rapidly rise.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for manufacturing composite welding blade

InactiveCN102049583AHigh bonding strengthSimple production processSoldering apparatusActive agentThermal stability

The invention discloses a method for manufacturing a composite welding blade, which comprises the following processes of: firstly, forming a groove matched with a tool bit on a matrix; secondly, placing the tool bit in the groove of the matrix; thirdly, filling a solder into a gap between the tool bit and the matrix, and then fixing; and finally, heating the assembled blade, and cooling the heated blade to obtain the composite welding blade. Based on the total mass of the solder, the solder comprises 60 to 95 percent of bonding agent, 25 to 1 percent of reinforcing agent and 15 to 0.5 percent of active agent; and the bonding agent, the reinforcing agent and the active agent are mixed uniformly to form the solder. The bonding agent, reinforcing granules, the active agent and the like are introduced, a transition phase substance is formed between the metal matrix and the composite tool bit in an alloying combination mode, and the transition phase plays a role in firmly connecting the matrix and the composite tool bit and has high strength and thermal stability.

Owner:FUNIK ULTRAHARD MATERIAL

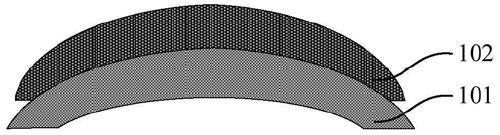

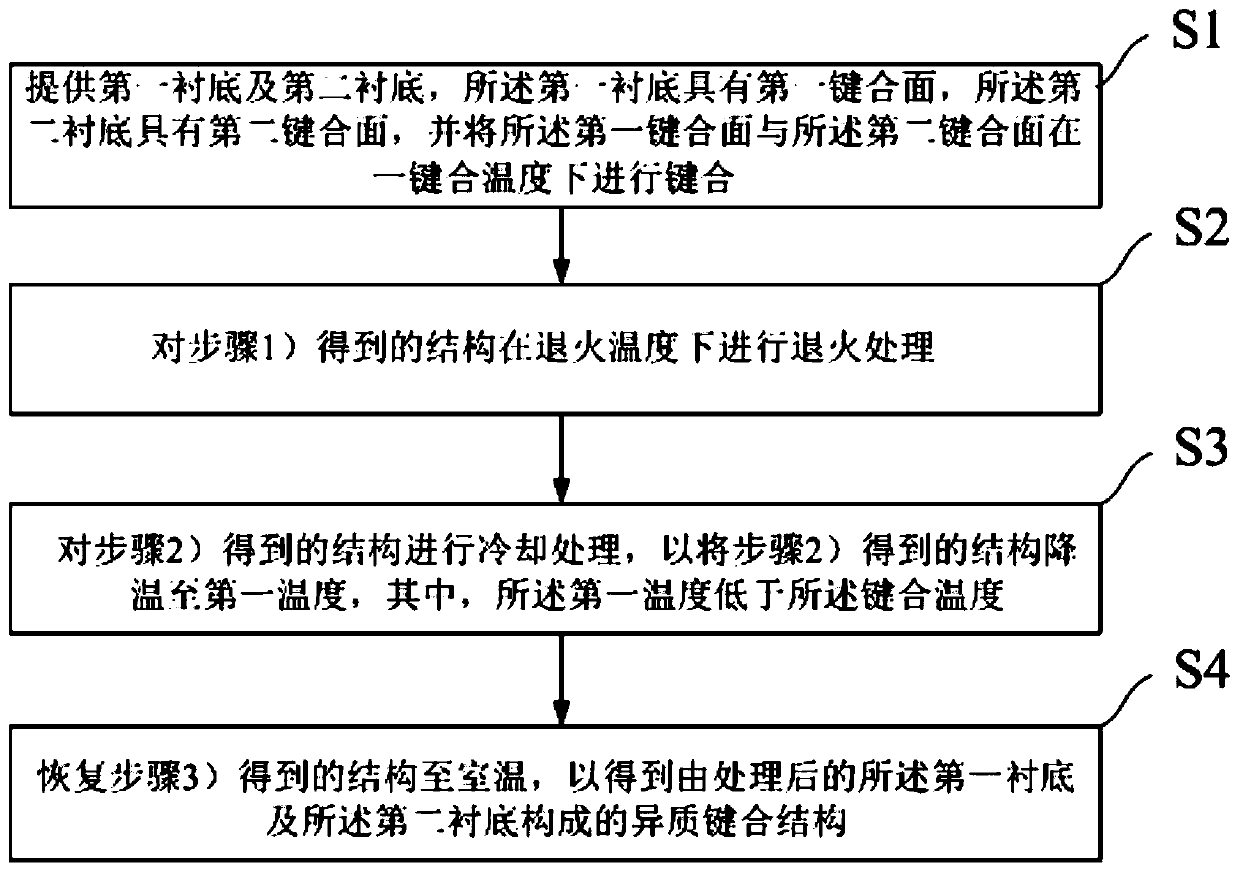

Preparation method of heterogeneous bonding structure

ActiveCN111383915AReduce warpageReduce residual thermal stressSemiconductor/solid-state device manufacturingComposite materialMaterials science

The invention provides a preparation method of a heterogeneous bonding structure, which comprises the steps of providing a first substrate and a second substrate, wherein the first substrate is provided with a first bonding surface, the second substrate is provided with a second bonding surface, and the first bonding surface and the second bonding surface are subjected to bonding treatment at a bonding temperature; conducting annealing treatment at an annealing treatment temperature; carrying out cooling treatment to reduce the temperature to a first temperature which is lower than the bondingtemperature; and adjusting the temperature of the structure obtained in the previous step to room temperature so as to obtain a heterogeneous bonding structure formed by the treated first substrate and second substrate. According to the preparation method of the heterogeneous bonding structure, the reinforced structure is cooled to a temperature below the bonding temperature after annealing treatment reinforcement, so that thermal stress opposite to that in the heating process is generated in the cooling treatment process, residual thermal stress in the heterogeneous bonding structure is reduced, and warping of the bonding structure caused by stress can be reduced.

Owner:上海新硅聚合半导体有限公司

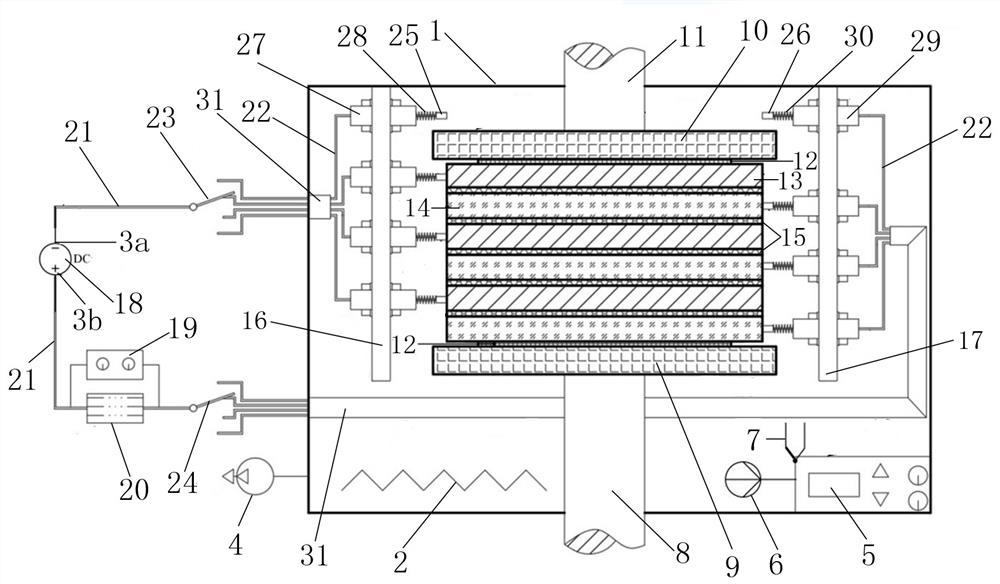

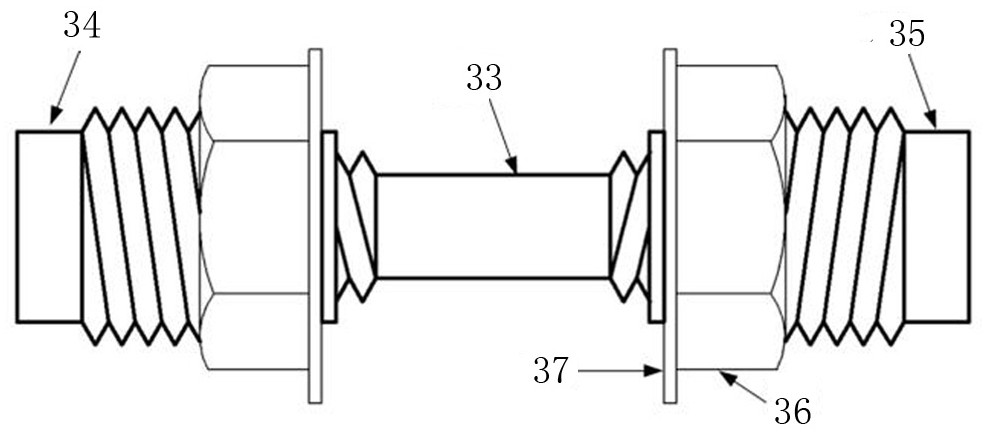

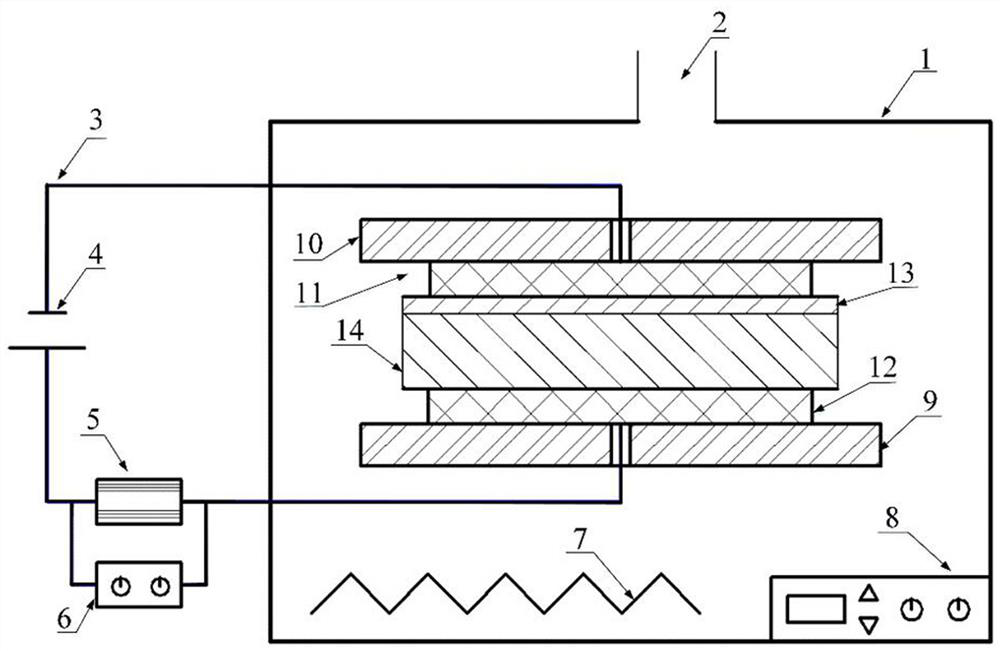

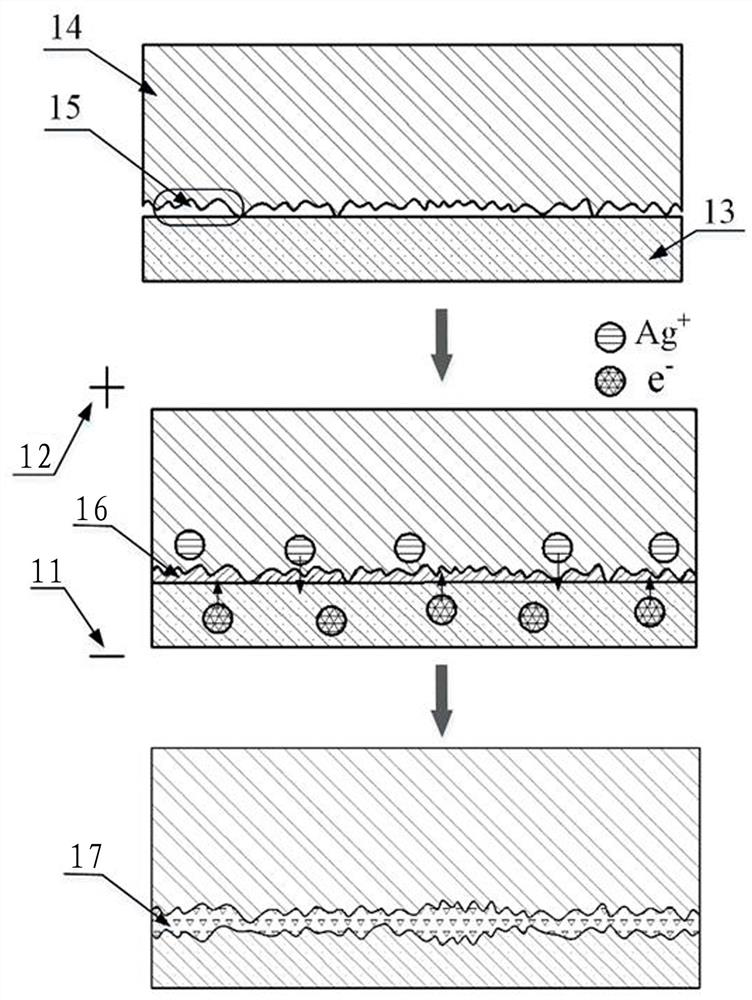

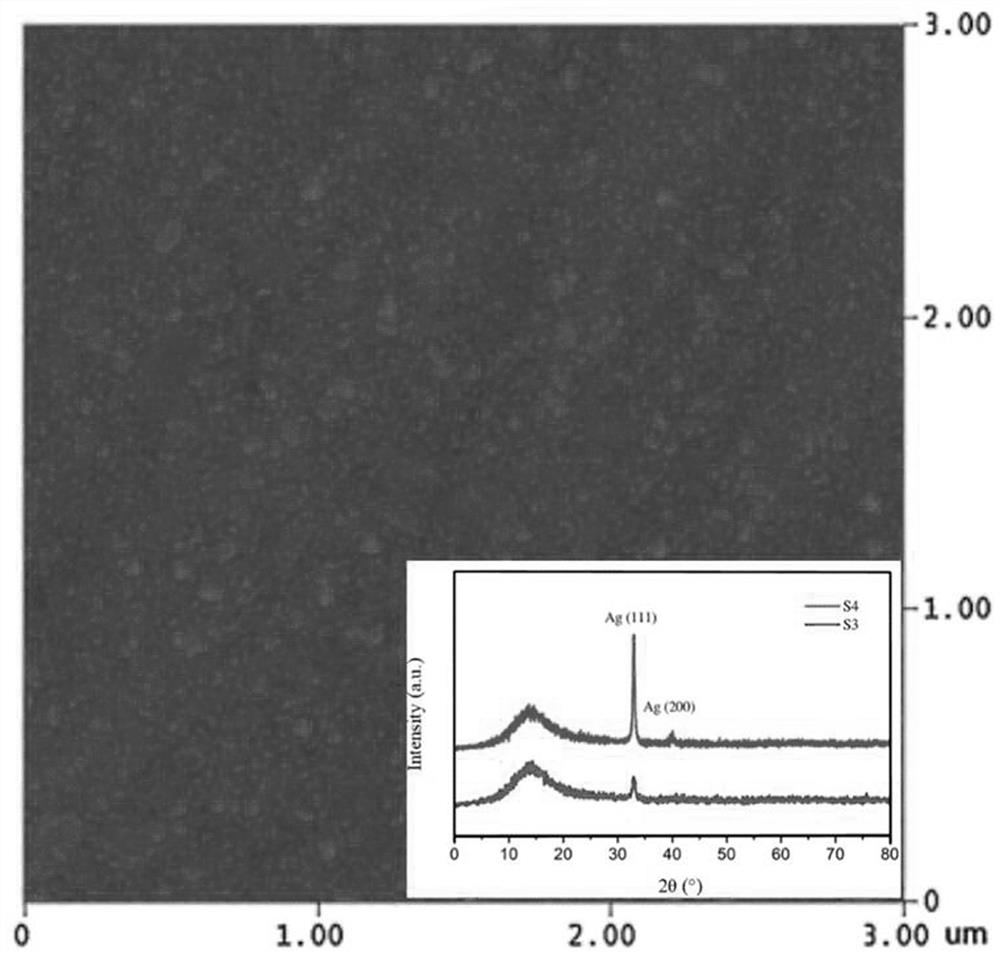

Metal glass surface in-situ metallization multilayer eutectic bonding method and device based on electrogenerated cationic conduction

ActiveCN111635147AEnables multilayer vertical bondingLow costLamination ancillary operationsLaminationNano structuringLow voltage

The invention discloses a metal / glass surface in-situ metallization multilayer eutectic bonding method and device based on electrogenerated cationic conduction. The method comprises the following steps: alternately stacking a plurality of layers of pre-coated metal test pieces and cationic conductive glass, and putting the stacked metal test pieces and cationic conductive glass into a vacuum furnace, enabling each layer of metal and glass test piece to be respectively communicated with a negative electrode and a positive electrode of a direct-current electrostatic field according to a bondingsequence, heating and loading an electric field while applying axial pressure to the bonded piece, activating ionization of cations in the glass under high temperature and electric field repulsive force to make the cations directionally migrate to the bonding surface of the glass to be enriched, carrying out a redox reaction on the cations and free charges to generate elementary substances, then carrying out in-situ growth in a micro-nano structure on the surface of the glass to form a metal layer, carrying out diffusion and eutectic reaction on the metal layer and a coating film at an eutectic temperature to realize bonding, and repeating the processes to carry out multilayer bonding. Anodic bonding and eutectic bonding principles are combined, so high-conductivity, high-thermal conductivity and high-strength multilayer bonding of metal and glass is realized under the conditions of low temperature and low voltage.

Owner:TAIYUAN UNIV OF TECH

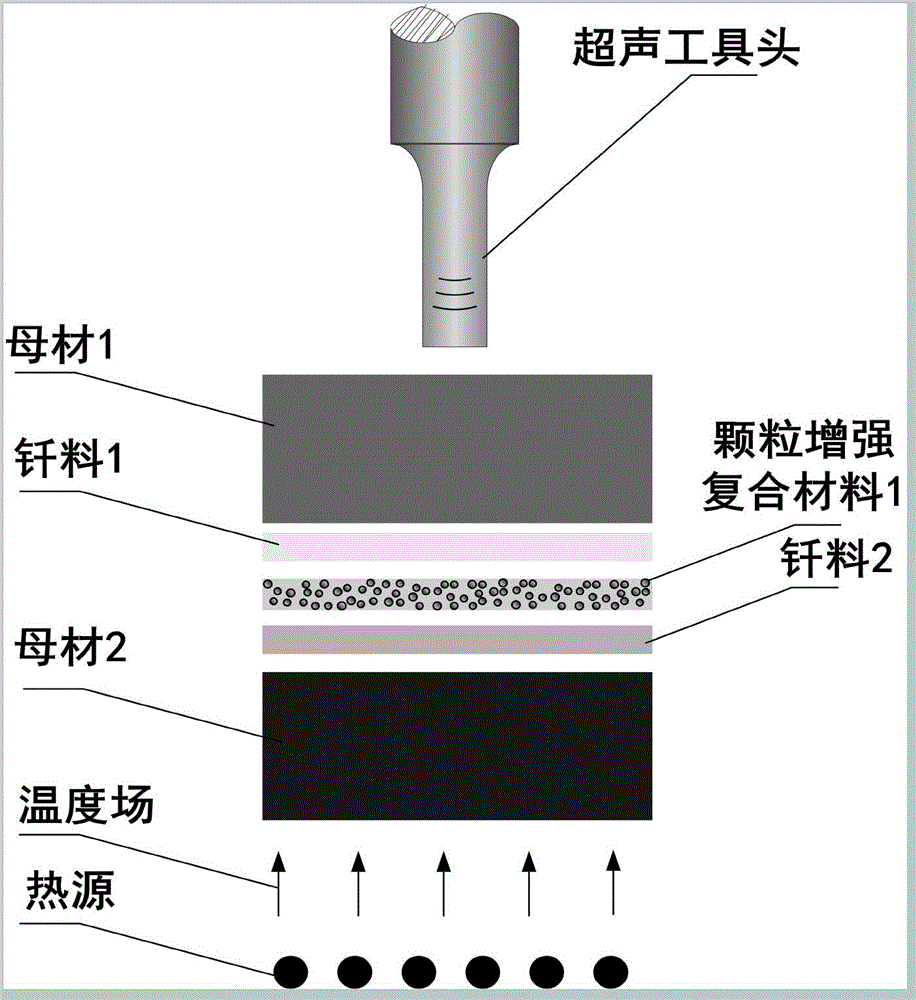

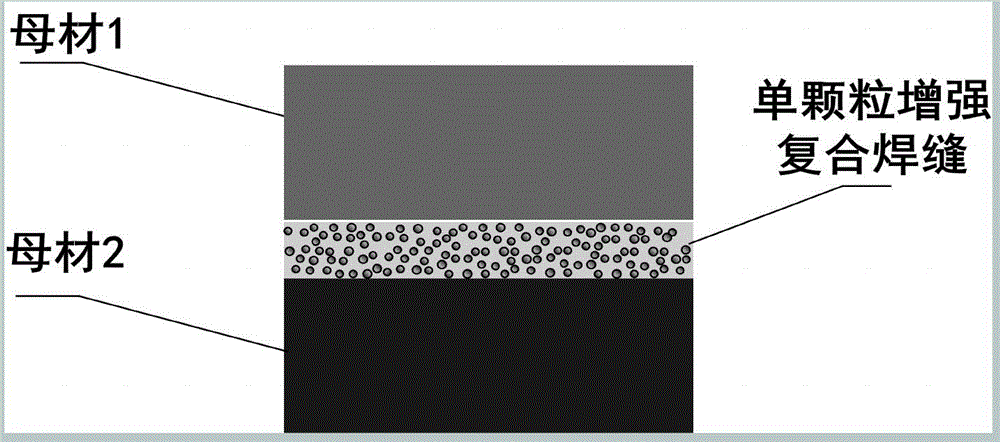

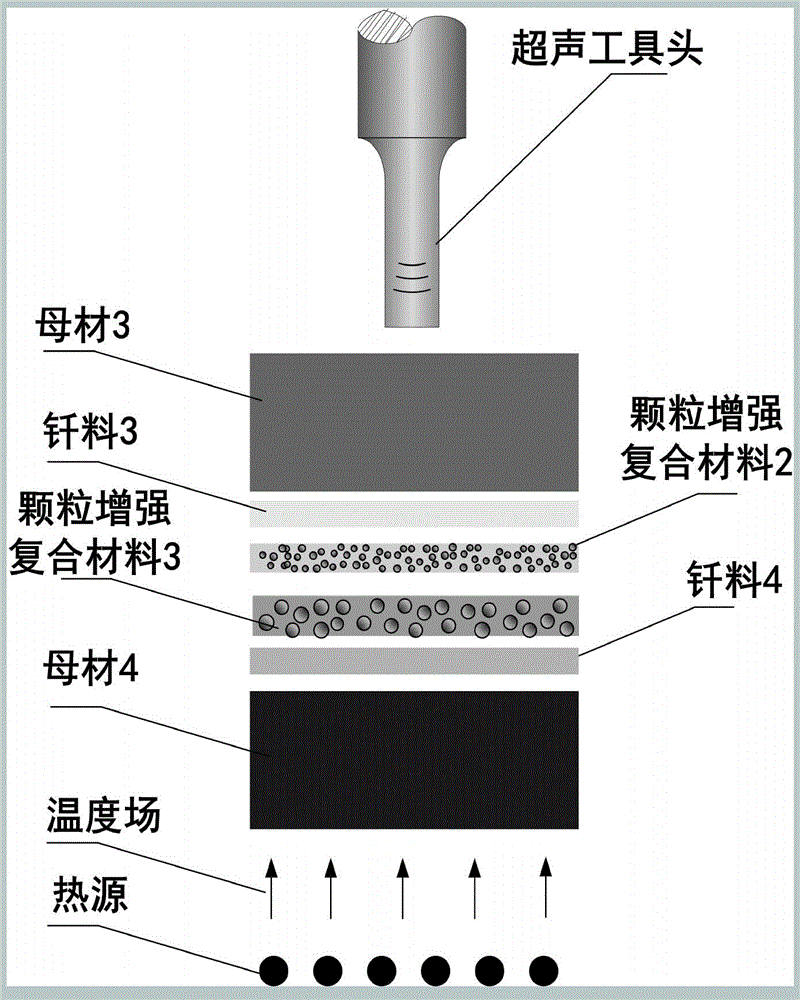

Method for forming reinforced-phase-strengthened composite welding seam structural material by regulating

ActiveCN105618885AControllable binding interface reactionReduce residual thermal stressSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedRoom temperature

The invention discloses a method for forming reinforced-phase-strengthened composite welding seam structural material by regulating. The method comprises the following steps: separately cleaning the surfaces of a to-be-welded parent material, a composite material and brazing filler metal to remove an oxide film, stains and grease, and drying the to-be-welded parent material, the composite material and the brazing filler metal for later use; and then, assembling the materials according to a structure of parent material / brazing filler metal / composite material / brazing filler metal / parent material, putting the assembled materials into an ultrasonic auxiliary welding device, applying ultrasonic waves while heating and preserving the heat, starting a pressurizing device to carry out welding in case of reaching a predetermined temperature and ultrasonic fields, stopping ultrasonic action while the temperature is reduced to the room temperature after welding, and taking out a welded part, thereby obtaining the reinforced-phase-strengthened composite welding seam structural material. The method has the advantages and the positive effects that: the method is used for forming reinforced-phase-strengthened composite welding seam structural material by regulating, welding for metal and nonmetal can be carried out, bonding interface reaction is controllable, residual thermal stress is relatively small, and the bonding strength is relatively high.

Owner:浙江邦驰汽车零部件有限公司

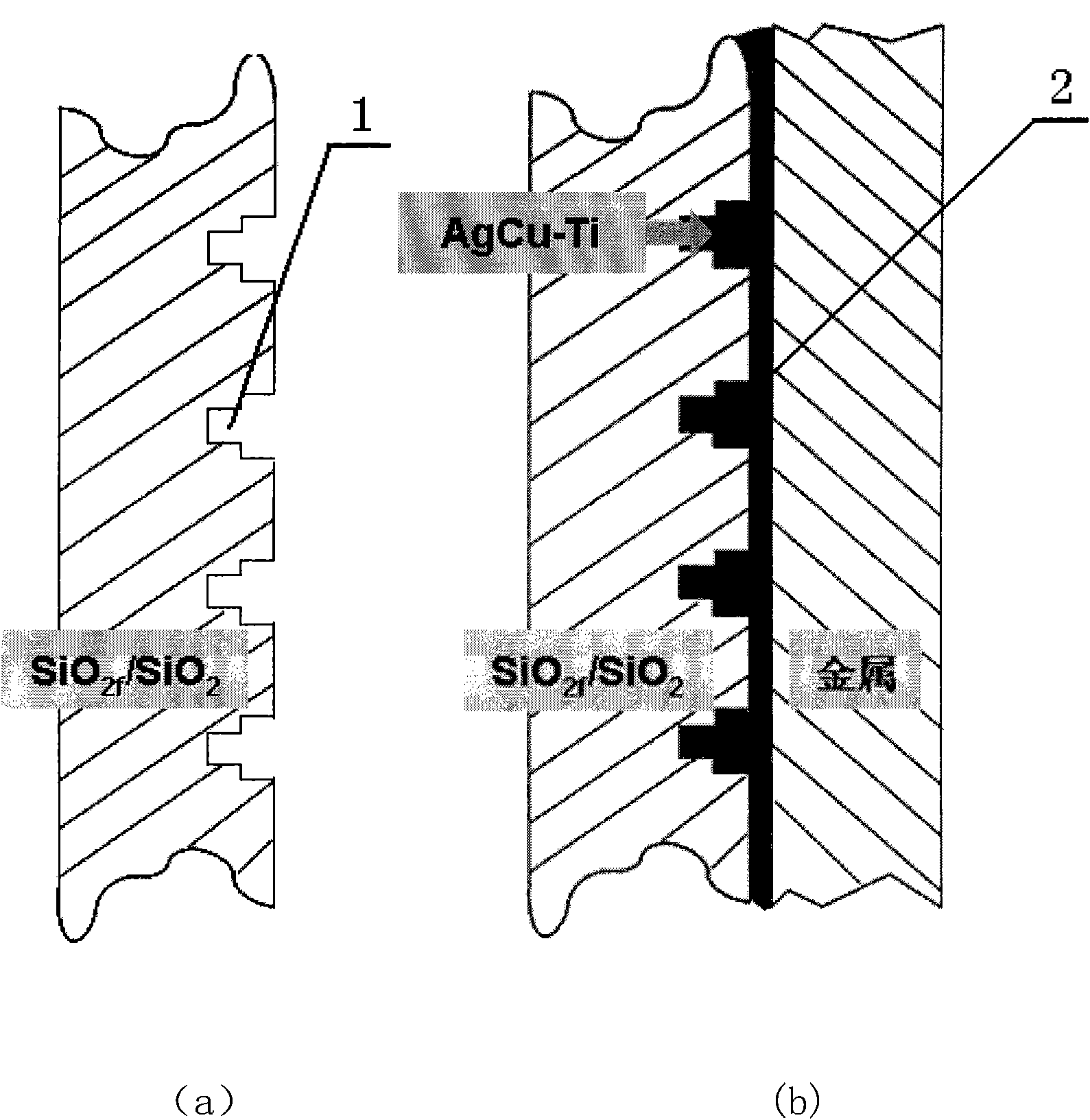

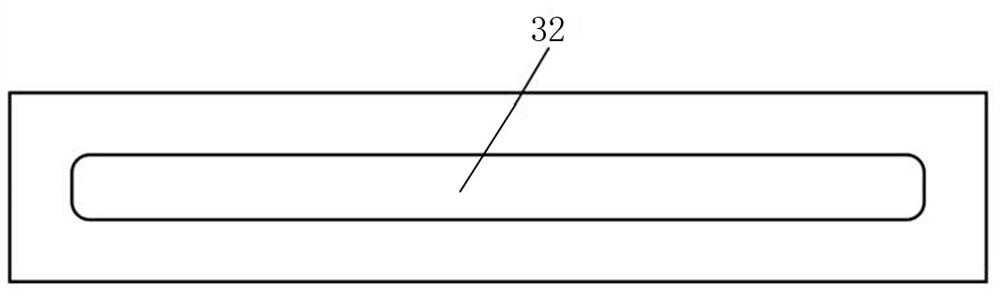

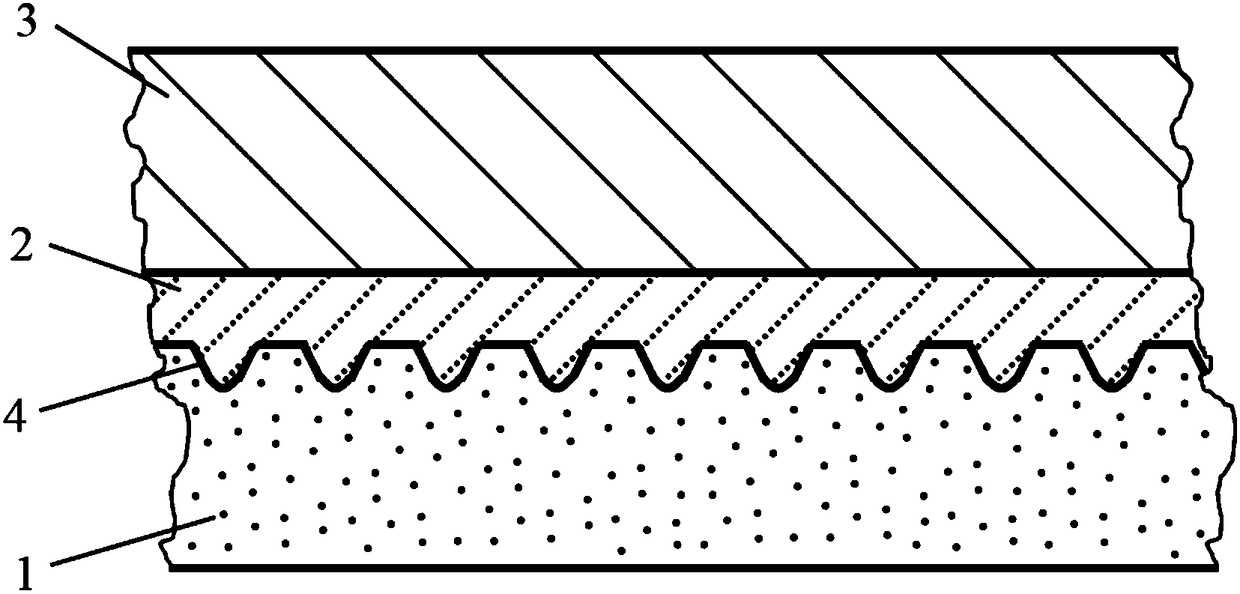

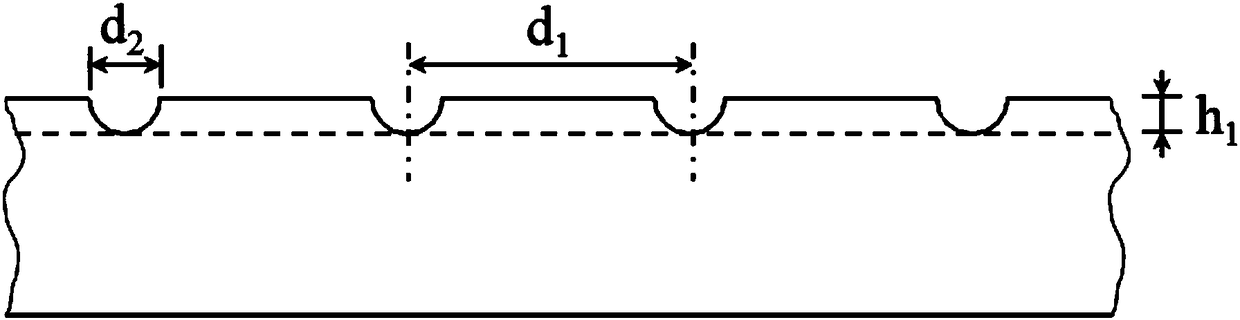

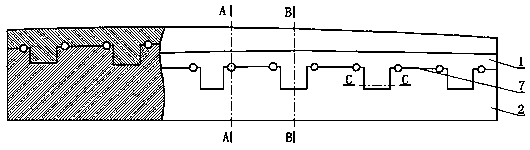

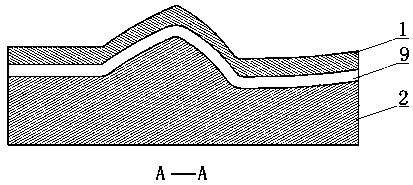

A brazing method for ceramics and metals or ceramics and ceramics

The present invention provides a method for brazing a ceramic and a metal or a ceramic and a ceramic, and relates to a methods for brazing a ceramic and a metal, a ceramic and a ceramic, a ceramic and a ceramic-based composite, and a ceramic-based composite and a ceramic-based composite. The method comprises: making periodic or aperiodic open slots on a to-be-brazed surface of a ceramic or a ceramic-based composite, wherein the distance between adjacent open slots, the width of each open slot, and the depth of each open slot are of order of micrometers; and then placing an active brazer between to-be-brazed surfaces, and achieving effective connections between the ceramic and a metal, between the ceramic and a ceramic, or between the ceramic and a ceramic-based composite by using a vacuum brazing method. The method provided by the present invention can effectively increase a wetting area of the active brazer on the surface, and reduce residual stress of ceramic surface, thereby improving bonding strength between the ceramic and the metal and between the ceramic and the ceramic. The method is also applicable to connection between C / C composites, Cf / Sic composites and other materials of high hardness and high brittleness.

Owner:TSINGHUA UNIV

Packaging method for sandwich type graphene-based heat-dissipating panel

The invention discloses a packaging method for a sandwich type graphene-based heat-dissipating panel and relates to a packaging method of a graphene-based heat-dissipating panel. The packaging methoddisclosed by the invention aims to solve the problem that the welding reliability is hard to guarantee, the stress of a post-welded welding member is great and an aluminum alloy is easy to penetrate when an existing graphene-based heat-dissipating panel is packaged. The packaging method comprises the following steps: I, laser perforating to obtain graphene with holes; II, surface metalizing to obtain metalized graphene; and III, assembling and packaging to obtain the sandwich type graphene-based heat-dissipating panel. The packaging method has the advantages that the room temperature shear strength of a joint between the metalized graphene and an aluminum panel after the graphene is packaged reaches over 7MPa. The packaging method disclosed by the invention is primarily used for graphene packaging.

Owner:HARBIN INST OF TECH

Method for manufacturing grinding wheel work layer with abrasive particle dressing function

ActiveCN102172902BSolve the disadvantages of easy aggregationSmall difference in coefficient of thermal expansionGrinding devicesAlloyBoron nitride

The invention relates to a method for manufacturing a polycrystalline cubic boron nitride (PCBN) grinding wheel work layer with an abrasive particle dressing function, belonging to the manufacture field of superhard grinding material tools. The method comprises the following steps: abrading particles for Cu-Sn-Ti alloy powder and PCBN, fusing TiC particles, preparing a blank and sintering at high temperature. The PCBN abrasive particle is formed by sintering CBN (cubic boron nitride) microcrystalline particles and AlN binder at high temperature and under high pressure. Once the CBN microcrystalline particles are blunt, the junction interface of CBN microcrystalline 5 and AlN binder is weakened along with the rise of the grinding force and the grinding temperature, so that the blunt CBN microcrystalline particles fall, and new CBN microcrystalline particles are quickly exposed to participate in the grinding process. The micro-breaking characteristics of the PCBN abrasive particles cause the superhard grinding material grinding wheel to still keep high sharp degree and avoid the phenomenon that grinding force and grinding temperature rapidly rise.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

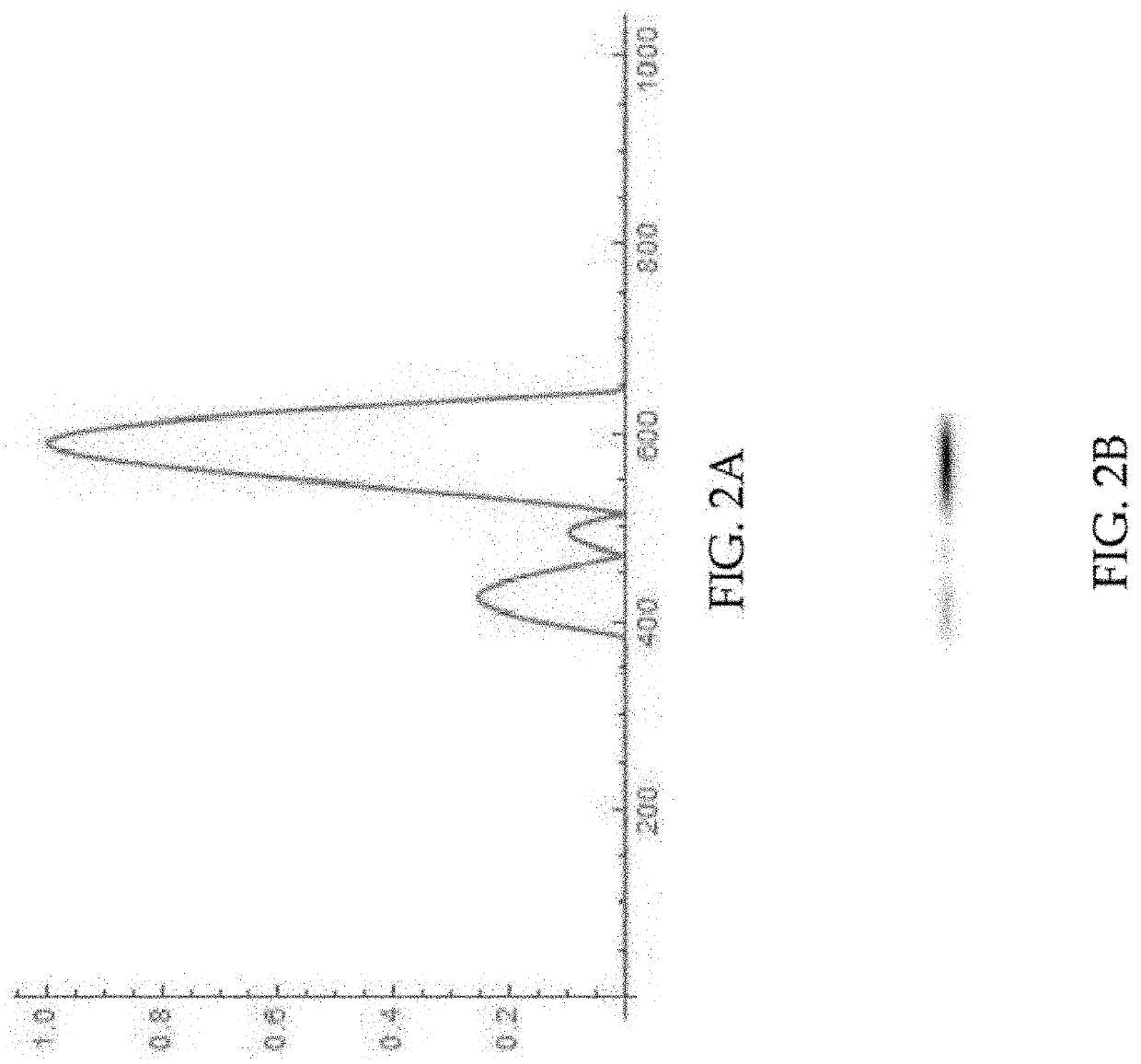

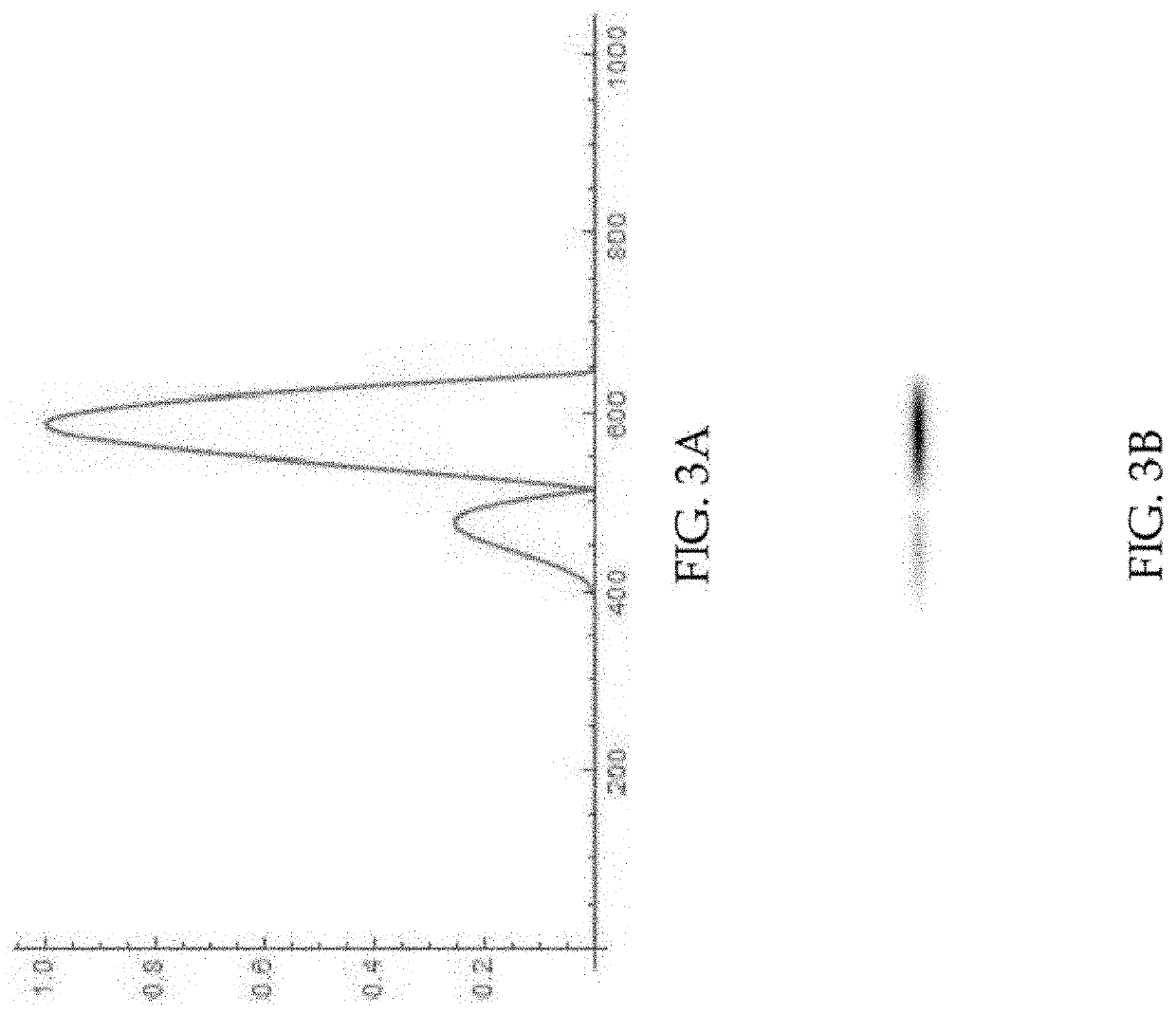

User defined intensity profile laser beam

ActiveUS20200251872A1Easy to controlFine resolution controlAdditive manufacturing apparatus3D object support structuresPowder bedMultimode interference

A high-power laser beam with an arbitrary intensity profile is produced. Such beam has a variety of uses including for laser materials processing such as powder bed fusion additive manufacturing. Several challenges in additive manufacturing are mitigated with the present non-uniform intensity laser profiles. Nonuniform shapes include a set of intensity pixels in a line that could print a wide stripe area instead of just a single line. One example uses the multimode interference pattern from the output of a ribbon fiber which is imaged onto a work piece. The interference pattern is controlled to allow turning on or off of ‘pixels’ along a line which can be used to shape the beam and form the additively manufactured part.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

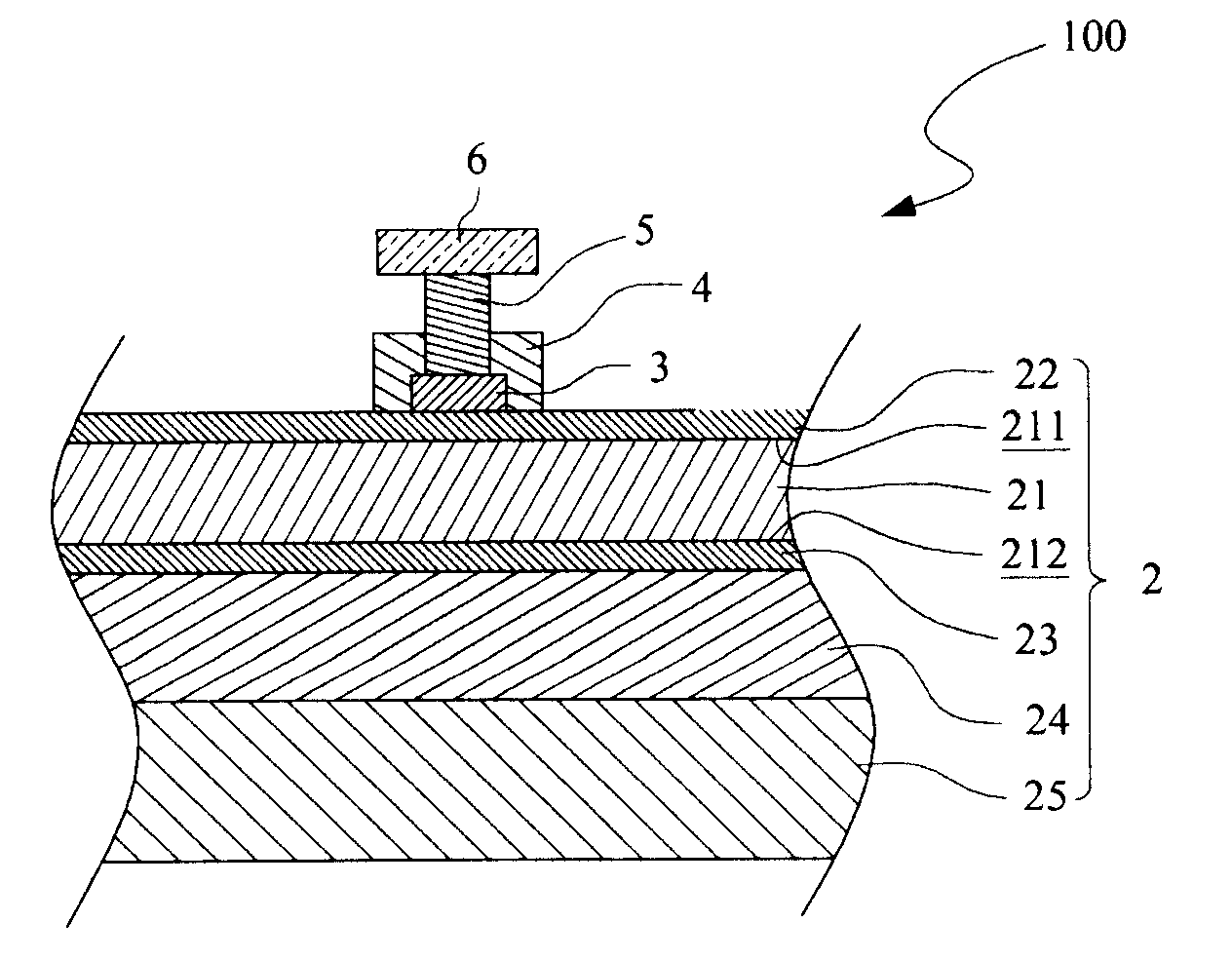

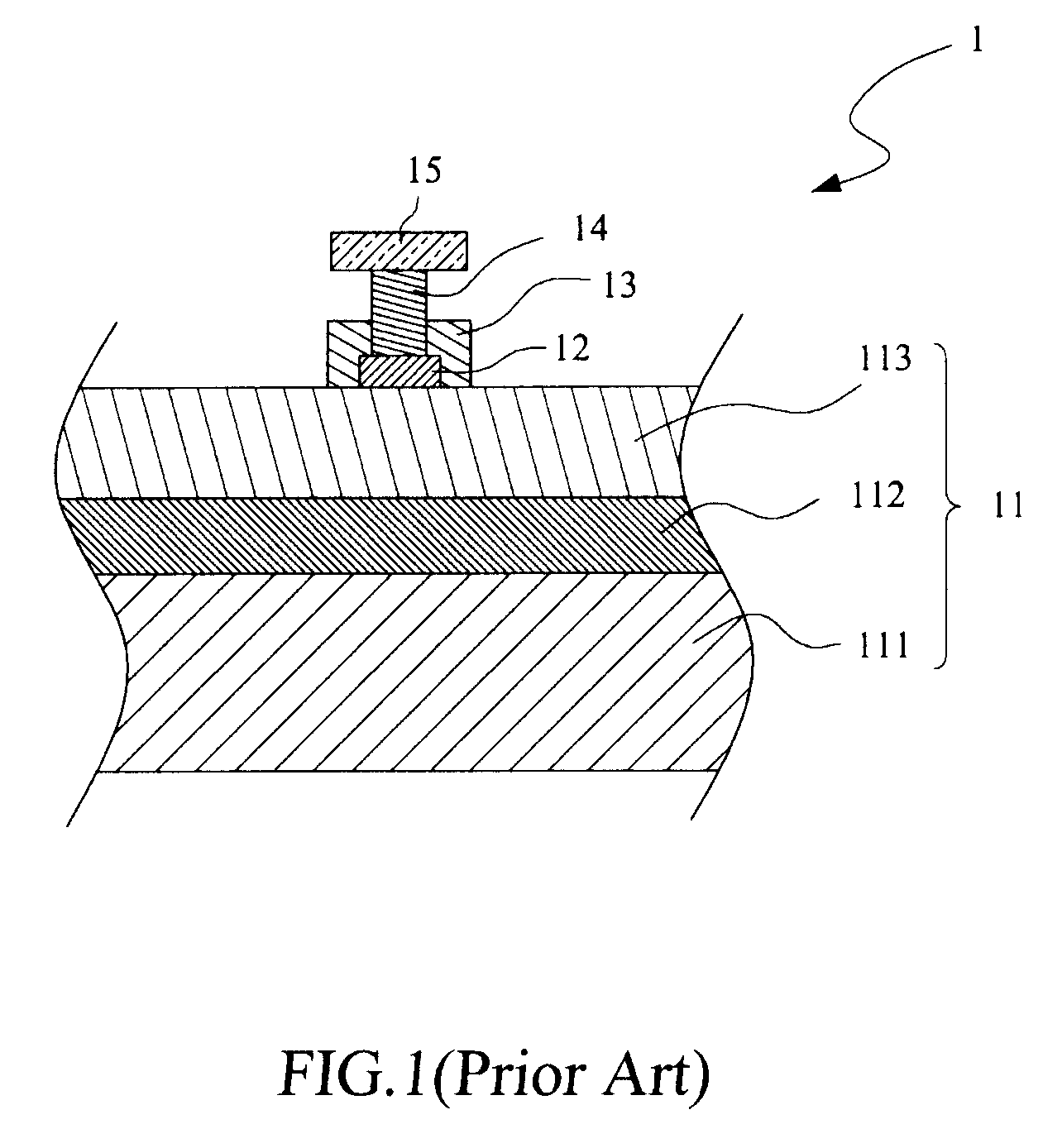

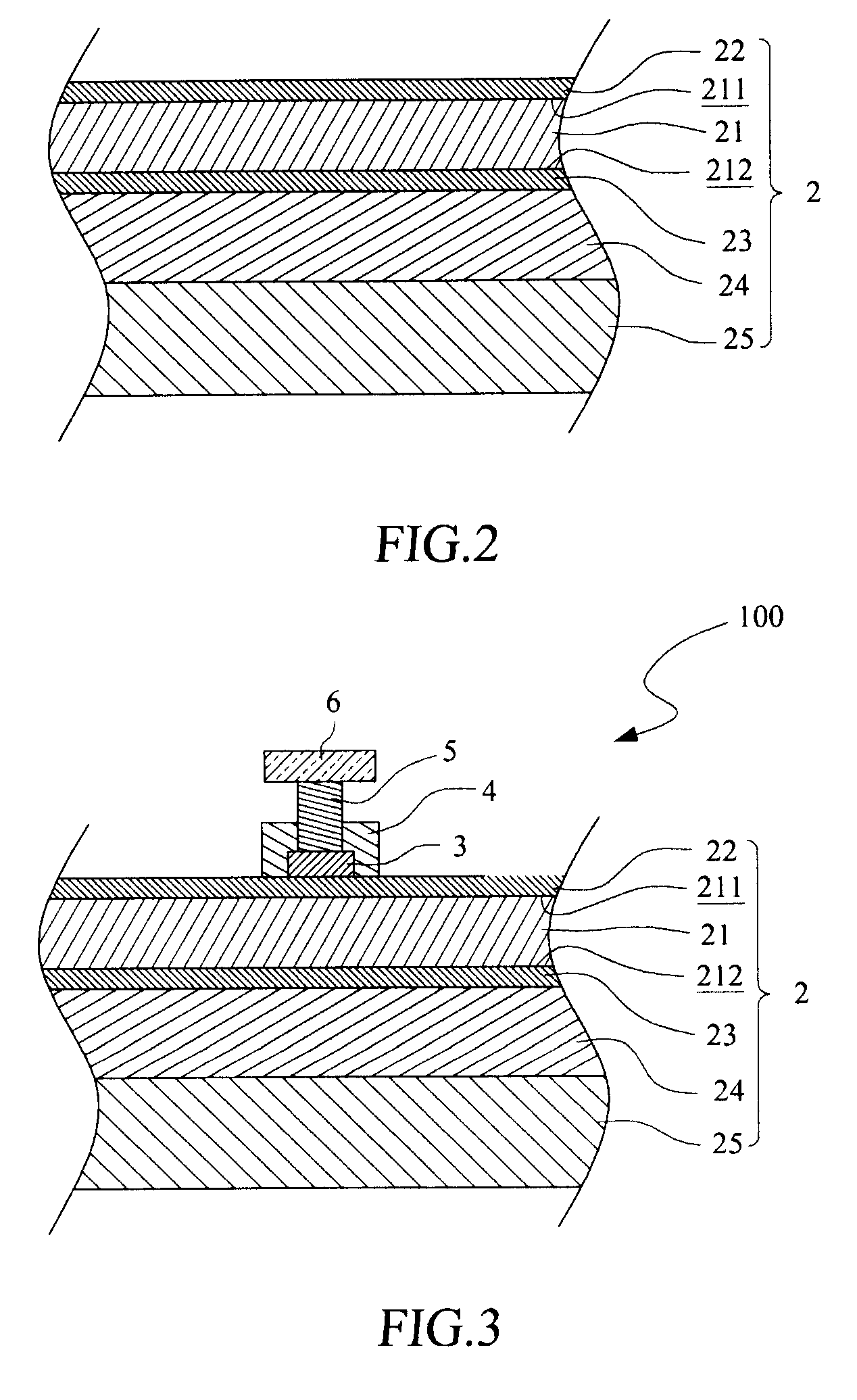

Structure and manufacturing method of substrate board

InactiveUS7638714B2Reduce residual thermal stressImprove yieldSemiconductor/solid-state device detailsSolid-state devicesAnodizingElectrical isolation

A method for manufacturing a substrate board with high efficiency of heat conduction and electrical isolation is disclosed. The method comprises the steps of: providing a substrate layer with an arrangement surface and a heat-dissipating surface; executing an anodic treatment on the arrangement surface and the heat-dissipating surface to respectively form a first anodic treatment layer and a second anodic treatment layer; forming a heat conduction and electrical isolation layer on the second anodic treatment layer; and forming a diamond like carbon (DLC) layer on the heat conduction and electrical isolation layer. The heat expansion coefficient of the substrate layer is greater than that of the second anodic treatment layer, the heat conduction and electrical isolation layer, and the DLC layer in turn.

Owner:LIN YU HSUEH

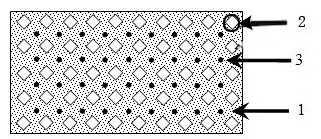

Alumina fiber reinforced nitride based wave permeable composite material and preparation method thereof

The invention discloses an alumina fiber reinforced nitride based wave permeable composite material and a preparation method thereof. The preparation method comprises the following steps: (1) performing soaking, namely performing vacuum soaking on a degummed alumina three-dimensional fiber prefabricated part in borazine; (2) performing cross-linking curing, namely performing cross-linking curing on liquid borazine in pores of the soaked alumina fiber prefabricated part in a cross-linking curing atmosphere according to set cross-linking curing principles; (3) performing pyrolysis, namely performing pyrolysis on the cross-linked alumina fiber prefabricated part in vacuum or a pyrolysis atmosphere, converting borazine into nitride ceramic, and cooling according to set cooling principles; and(4) repeating steps (1)-(3) of soaking, cross-linking curing and pyrolysis for multiple times. The alumina fiber reinforced nitride based wave permeable composite material disclosed by the invention has the advantages of being excellent in high-temperature resistance and dielectric property, good in process property, and the like.

Owner:NAT UNIV OF DEFENSE TECH

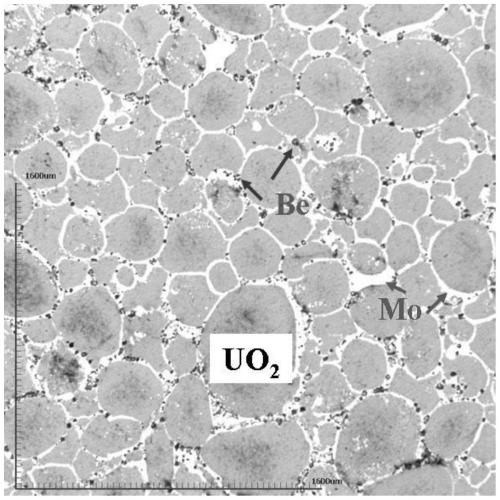

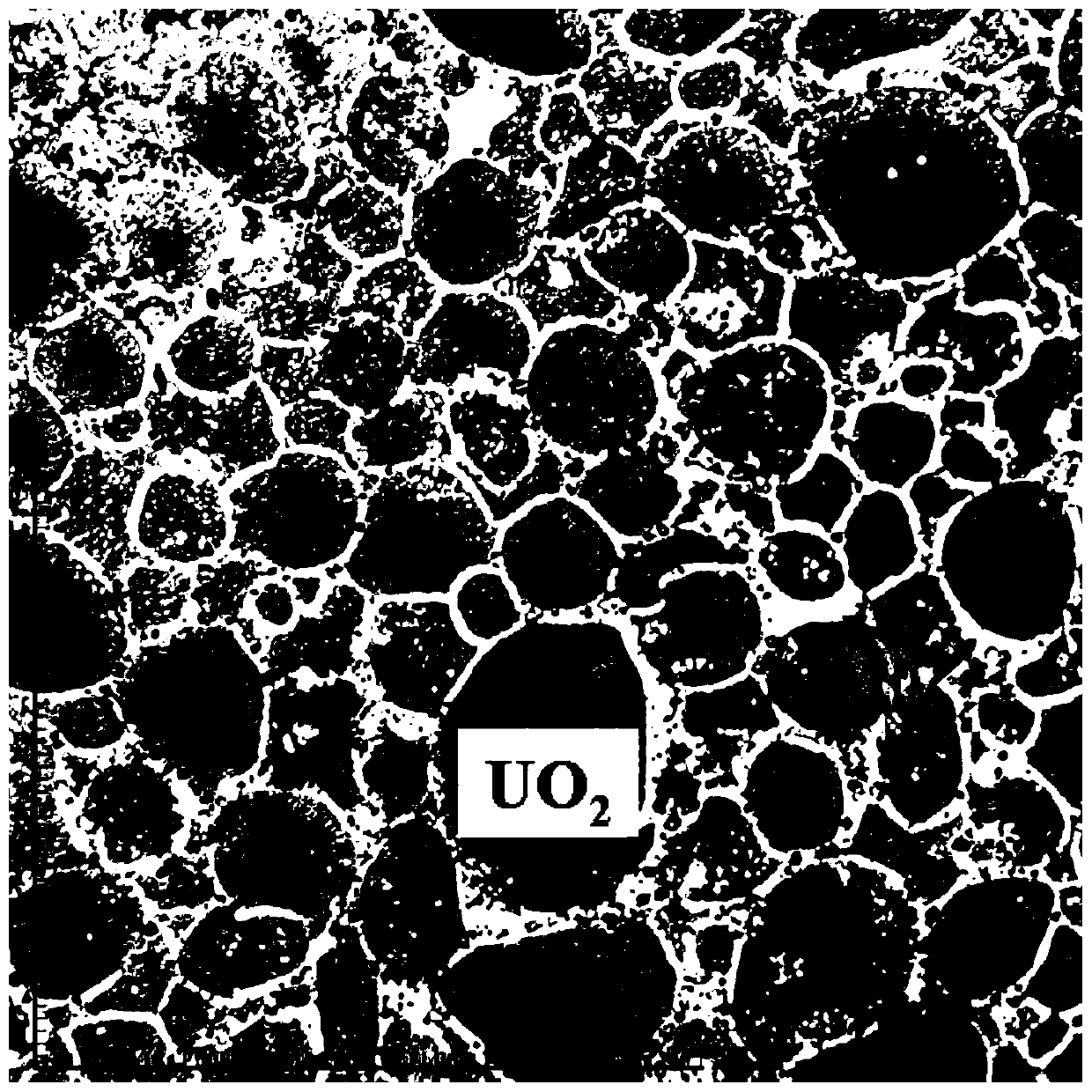

Uranium dioxide-based fuel pellet with adjustable thermal expansion coefficient and enhanced thermal conductivity, and preparation method thereof

ActiveCN111145926AImprove thermal conductivityStable serviceNuclear energy generationTransportation and packagingThermal dilatationUranium oxide

The invention discloses a uranium dioxide-based fuel pellet with an adjustable thermal expansion coefficient and enhanced thermal conductivity, and a preparation method thereof. According to the preparation method, metal beryllium (Be) with high thermal conductivity and high thermal expansion coefficient and metal molybdenum (Mo) with high thermal conductivity and a low thermal expansion coefficient are added into a uranium dioxide pellet matrix, the component ratio of Be / Mo is regulated and controlled, the densified fuel pellet is sintered at a high temperature, so that the thermal conductivity of the uranium dioxide fuel pellet is enhanced, the thermal expansion coefficient of the uranium dioxide pellet is adjusted, the residual thermal stress of the fuel pellet is reduced, and the service cycle of the fuel pellet is prolonged so as to meet the harsh reactor work design requirements of the cladding-pellet fuel element under the normal work condition and the accident work condition ofthe reactor, improve the safety and the economy of the existing commercial pressurized water reactor, effectively delay the closing time of the air gap between the cladding and the fuel pellet underthe accident condition and delay the mechanical interaction between the fuel and the cladding to substantially improve the safety margin of the reactor under the accident condition.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

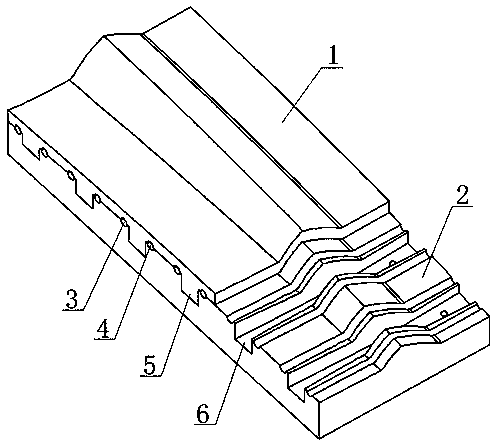

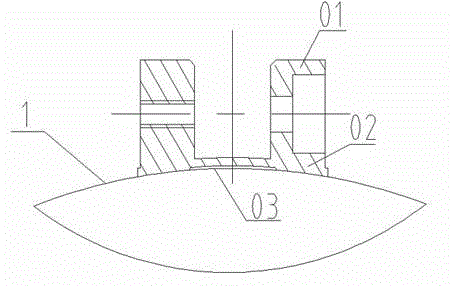

Aluminum alloy hot punching die provided with shape follow-up cooling water channels

The invention relates to an aluminum alloy hot punching die provided with shape follow-up cooling water channels and belongs to the technical field of hot punching dies. The aluminum alloy hot punching die comprises a die profile, a die base, a sealing ring and a bolt. The die profile is provided with a semi-circular hole and a boss. The die base is provided with a semi-circular hole and a groove. The die profile and the die base are combined and assembled and then fixed through the bolt, and form a plurality of complete shape follow-up water cooling channels. The aluminum alloy hot punching die skillfully solves the problem that parts with the complex shape are difficult to cool after hot forming is completed, by means of the shape follow-up water cooling channels machined through the method, the cooling speed of all portions of the parts can be more uniform, and the forming quality is improved remarkably. Practicality is high.

Owner:JILIN UNIV

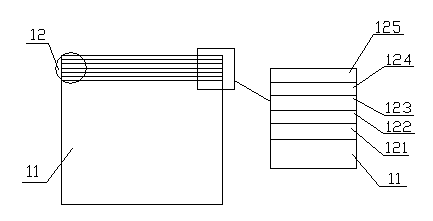

Soft-hard composite nanometer multi-coating cutter and preparation method thereof

ActiveCN108456845AReduce residual thermal stressImprove bindingVacuum evaporation coatingSputtering coatingCemented carbideCutting force

The invention provides a soft-hard composite nanometer multi-coating cutter and a preparation method thereof. The soft-hard composite nanometer multi-coating cutter is characterized in that a matrix material is hard alloy, and the coatings include a Zr transition layer, a (ZrN-CrCN)x periodic composite multilayer nano hard coating and a WS2 soft coating in sequence from bottom to top. In preparation of the coatings, only N2 is adopted as reaction gas, the other coating elements are solid targets respectively, so that the pollution in deposition of different coatings is effectively prevented. The WS2 soft coating has extremely-low shearing strength and friction coefficient, the (ZrN-CrCN)x periodic composite multilayer nano hard coating has extremely-high wear resistance, and as a transition layer, Zr is used for reducing residual heat stress between the coatings and the matrix, so that the bonding force between the coatings and the matrix is improved; the wear resistance of the cutteris greatly improved, and the cutting force and the cutting temperature of the cutter in cutting are reduced, so that the cutter can better adapt to severe cutting environment in cutting.

Owner:XIAMEN UNIV

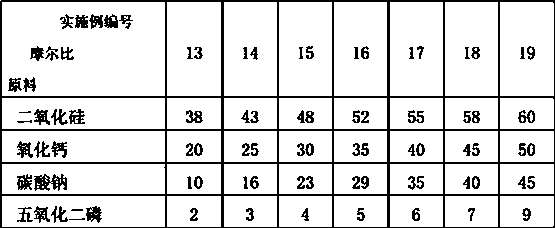

Preparation method of bioglass fiber reinforced hydroxyapatite porous composite material

InactiveCN103585672BHigh specific modulusImprove biological activityProsthesisApatitePolyethylene glycol

The invention discloses a preparation method of a bioglass fiber reinforced hydroxyapatite porous composite material. The preparation method is characterized by comprising the following steps: silicon dioxide, calcium oxide, sodium carbonate, phosphorus pentoxide and the like are used as raw materials for preparing bioglass fibers; calcium nitrate, diammonium hydrogen phosphate, ammonium hydroxide and the like are used as raw materials for preparing hydroxyapatite; the bioglass fibers and the hydroxyapatite are mixed with each other, are reacted with an ethylene glycol solution, a methyl cellulose solution and a hydrogen peroxide solution, and are subjected to the microwave-assisted pore forming and the drying to prepare a porous composite material blank; the normal-pressure sintering is implemented to prepare the bioglass fiber reinforced hydroxyapatite porous composite material. The porous composite material prepared by the invention has the characteristic of adopting a penetrating pore structure for providing an excellent microenvironment for growth of bone tissues, supply of oxygen and nutritive substances and loading and release of genes and medicines, has an excellent biological activity and a mechanical property, and can be used as an excellent human body bone repairing material and a bone tissue engineering bracket material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

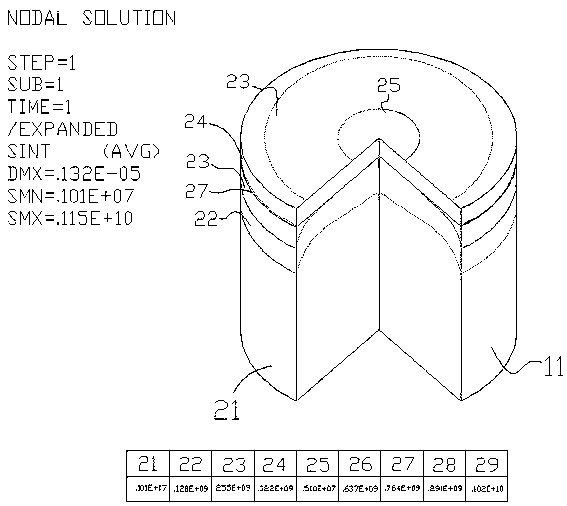

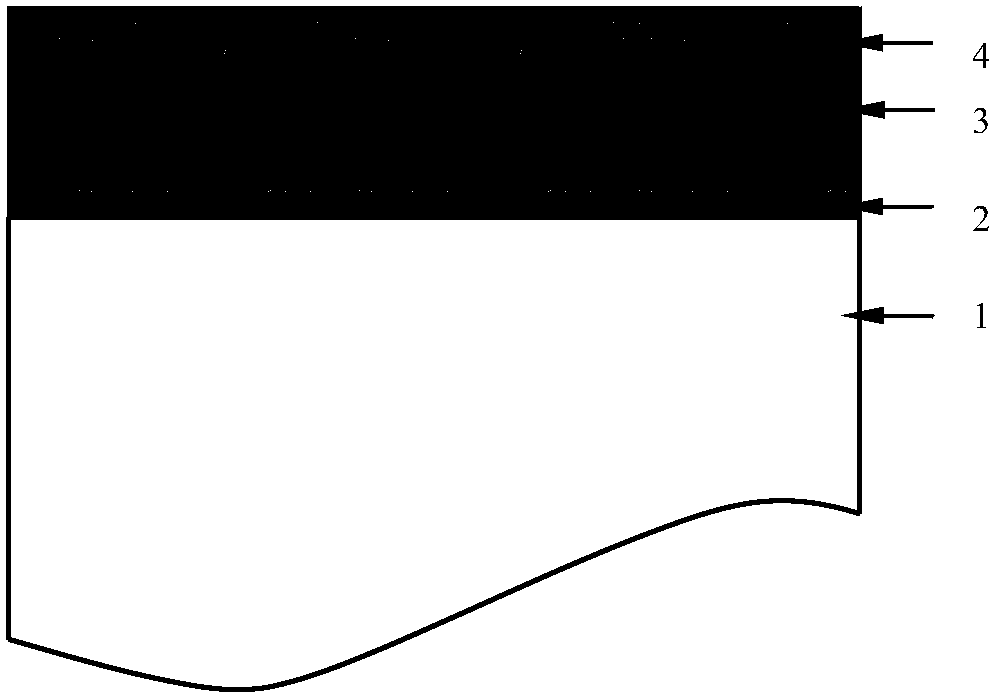

Welding structure of missile wing support of solid rocket engine

InactiveCN104696103AReduce residual thermal stressAvoid cracksRocket engine plantsCombustion chamberMissile

The invention discloses a welding structure of a missile wing support of a solid rocket engine. The welding structure comprises a body and a bottom groove positioned in the lower end surface of the body, wherein the body comprises a base and an ear column, and the ear column is connected with the base through a step surface; a first end surface of the ear column is used as a mounting surface of a missile wing, and the missile wing is mounted in an axial groove in the center of the ear column; a second end surface opposite to the first end surface is a concave cambered surface, and the diameter of the second end surface is the same as that of a combustion chamber casing; two straight flanges of the second end surface are welded to the combustion chamber casing, so that the connection between the missile wing support and the combustion chamber casing is realized; the bottom groove penetrating through the second end surface is formed in the second end surface, and the bottom groove is parallel to a welding joint between the second end surface and the combustion chamber casing. According to the welding structure adopted by the invention, compared with the prior art, the welding structure has the advantages and the benefits that residual thermal stress caused by weld is reduced, cracks are avoided, the structural strength of the missile wing support is improved, the qualified rate of handmade argon arc welding is increased, and the technology process is optimized.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

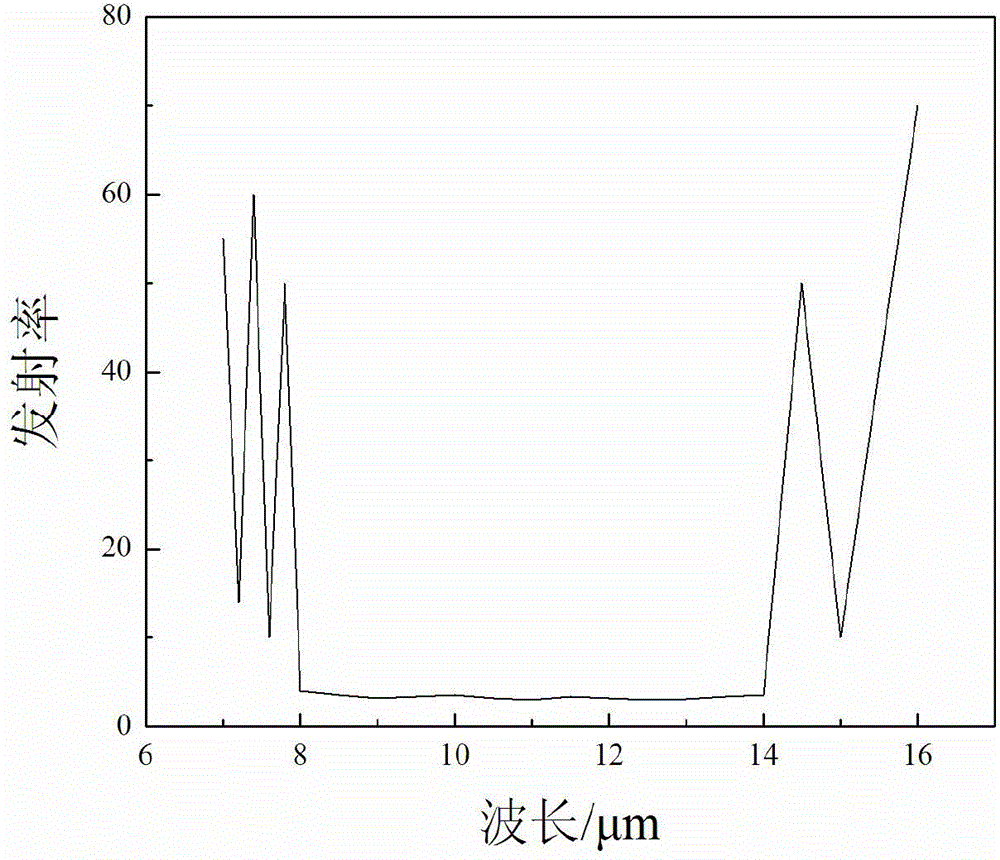

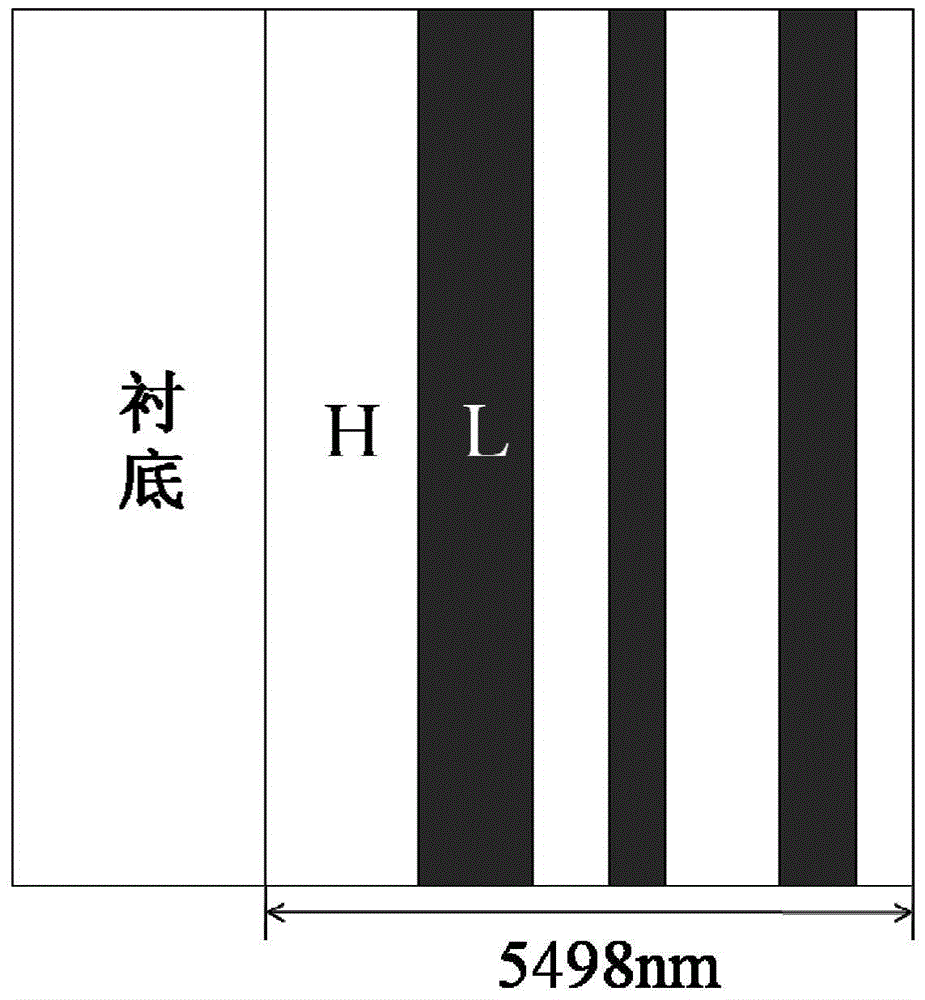

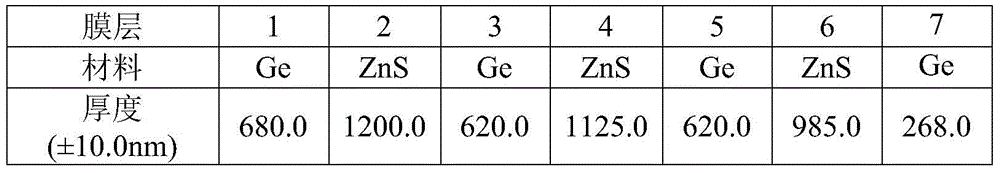

Infrared stealth film with selective low emissivity in 8-14 μm band and preparation method thereof

ActiveCN104991291BNot easy to fall offImprove bindingVacuum evaporation coatingSputtering coatingLow emissivityRadio frequency magnetron sputtering

The invention discloses an infrared stealth film capable of achieving low emissivity in a band range from 8 microns to 14 microns selectively, and the film can achieve the regulation and control of emitted radiation of spectrums, achieves low emissivity in an infrared window from 8 microns to 14 microns, and achieves high emissivity at other bands. The film is in a multilayer structure, and is mainly formed by the alternate overlapping of a high-refraction-index Ge material layer and a low-refraction-index ZnS material layer. The preparation method comprises the steps: firstly washing a substrate; secondly employing a method of radio frequency magnetron sputtering to alternately coat the surface of the substrate with the high-refraction-index Ge material layer and the low-refraction-index ZnS material layer; and properly control the temperature of the substrate, the radio frequency sputtering power and the sputtering time during sputtering coating. The invention aims at the modulation of emitted radiation in the band range from 8 microns to 14 microns under the condition of ambient temperature, and can solve a problem, caused by infrared stealth, of compatibility of stealth with heat radiation. According to the invention, the technology is simple, the repeatability is good, and the requirements for equipment are low.

Owner:NAT UNIV OF DEFENSE TECH

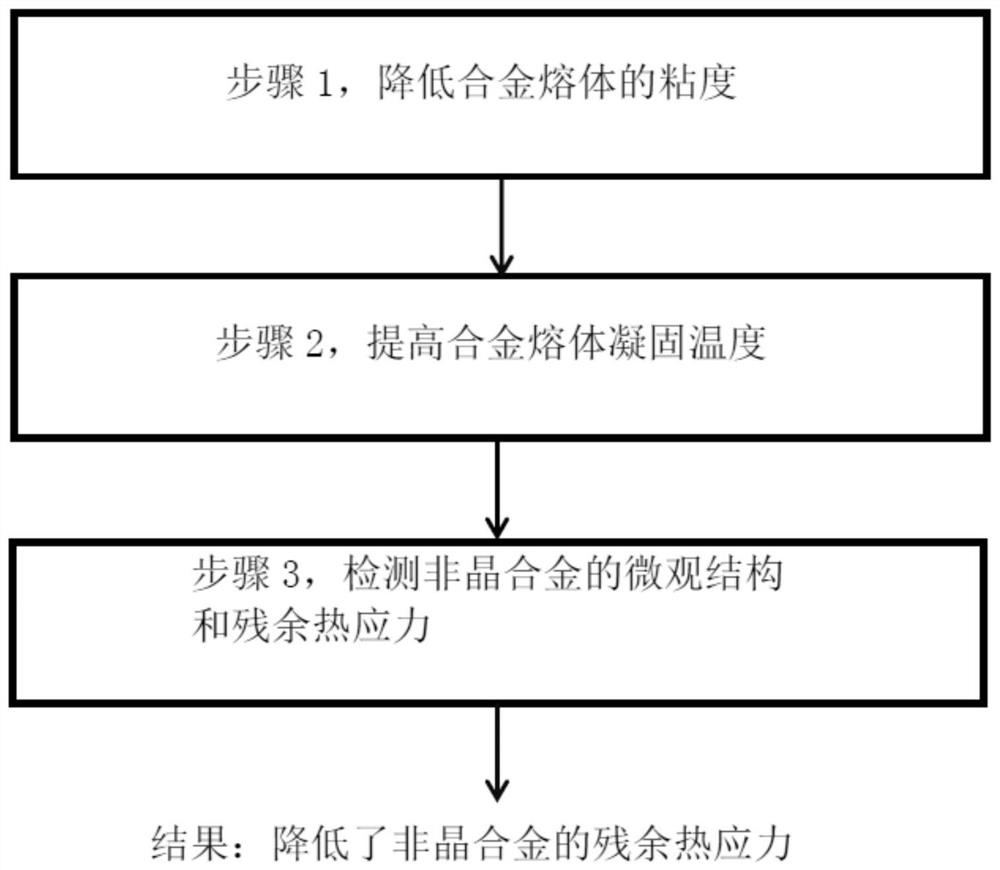

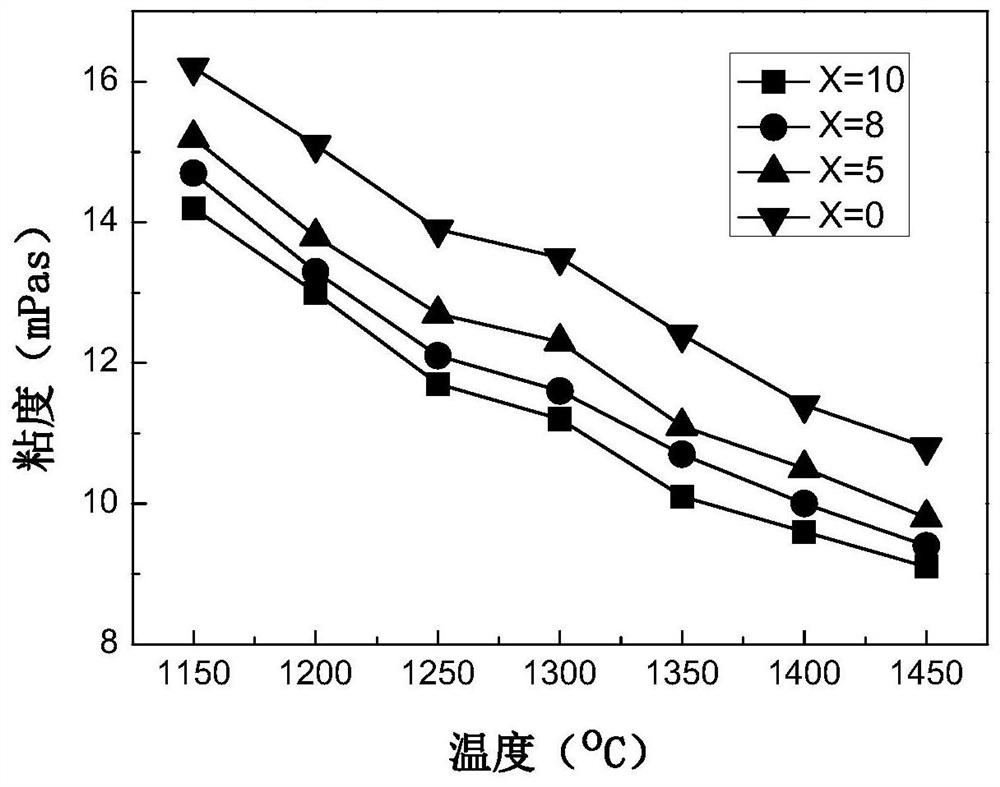

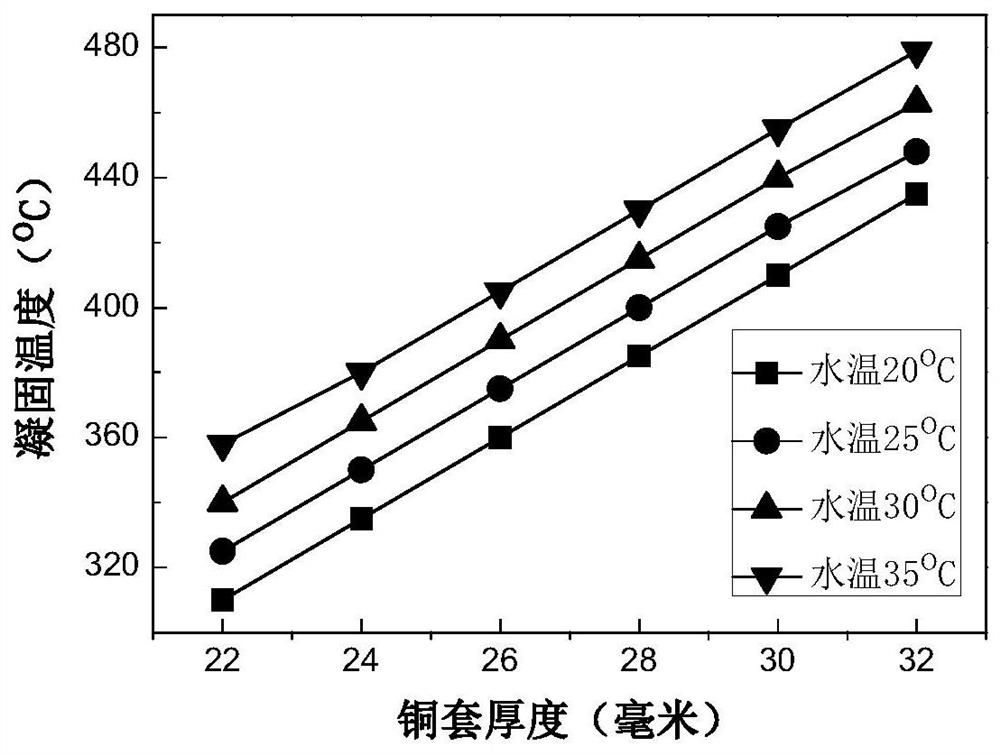

A process for preparing low residual thermal stress amorphous alloy

The invention provides a process method for preparing a low residual thermal stress amorphous alloy, comprising: step S1, select a reference alloy, and use a non-metallic element that forms a low-melting point alloy with a metal element to partially replace the non-metallic element that forms a high-melting point alloy with a metal element. Form a series of alloys with different components by means of metal elements, and measure their viscosity at different casting temperatures to establish the relationship between viscosity-casting temperature-composition; step S2, measure different cooling conditions for the series of alloy melts at different casting temperatures Set up the relationship of cooling condition-solidification temperature-casting temperature-composition; step S3, at first, according to the relationship obtained in step S1, select the alloy composition of low viscosity and set the casting temperature according to the viscosity standard; then, according to the selection The alloy composition, the set casting temperature and the relationship obtained in step S2, select the cooling conditions corresponding to the increase of the supercooled solidification temperature; finally, an amorphous alloy is obtained.

Owner:创明(韶关)绿色能源材料技术研究院有限公司

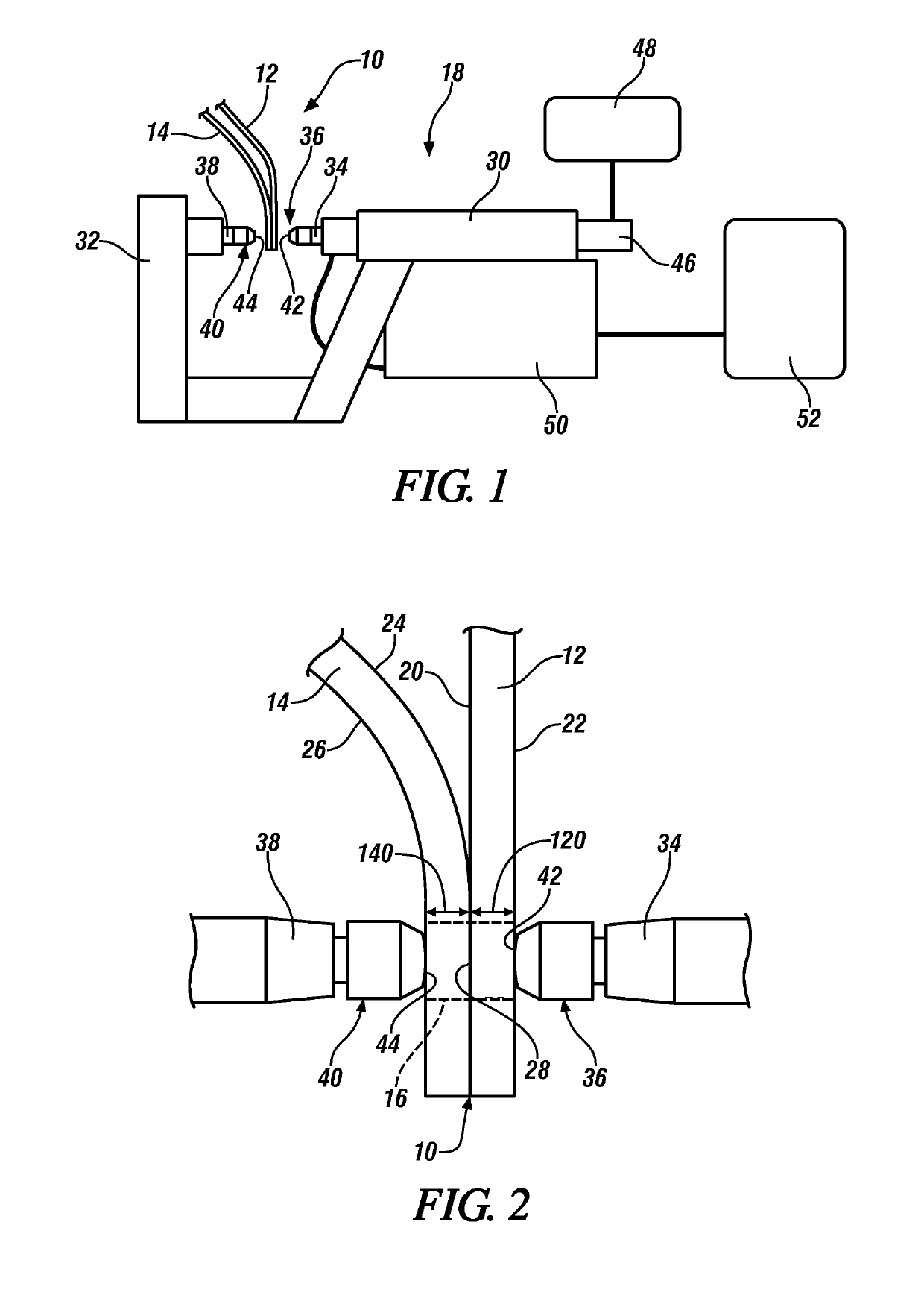

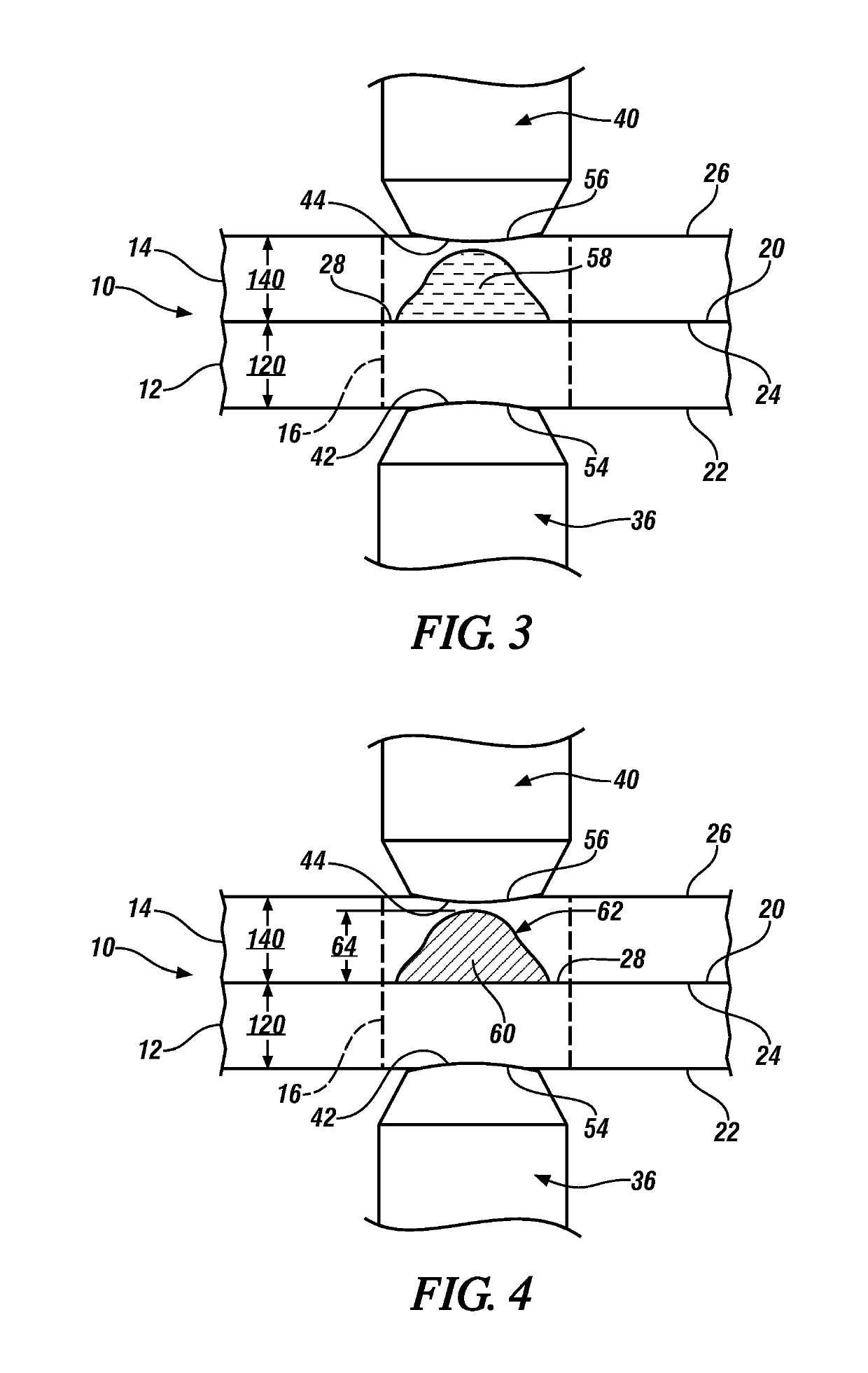

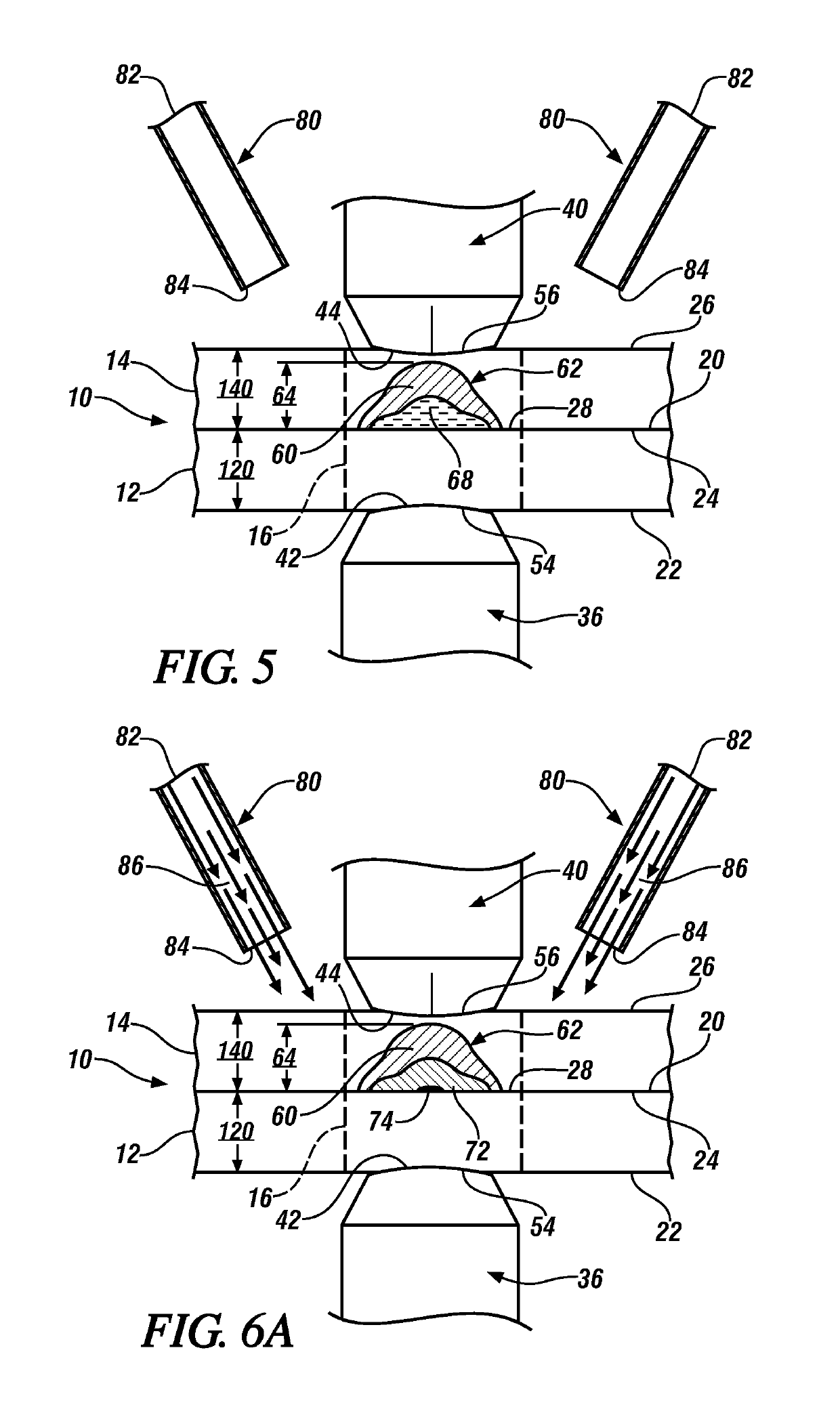

Cooling to control thermal stress and solidification for welding of dissimilar materials

ActiveUS10252369B2Improve cleanlinessHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesElectrical resistance and conductanceSpot welding

A workpiece stack-up that includes at least a steel workpiece and an aluminum-based workpiece can be resistance spot welded by a spot welding method in which the welding current is controlled to perform one or more stages of weld joint development. When it is desired to terminate weld current flow and to solidify a liquid weld pool into a weld nugget (of mostly aluminum-based composition), additional cooling is applied to the outer surface of the aluminum-based workpiece around the contact area of the spot welding electrode engaging the surface of the aluminum-based workpiece surface. The additional cooling is applied and controlled so as to increase the rate of solidification of the liquid aluminum-based material and to control the direction of solidification of the weld nugget to better confine impurities, and the like, originally in the melt, at the surface of the steel workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Surface in-situ metallization method based on cationic conductive glass

The invention discloses a surface metallization method based on the migration, reaction and in-situ growth of cations in a cation conductive glass under the compound action of temperature field and electric field. The method is as follows: the cationic conductive glass and the metal foil are docked between the positive and negative electrodes in the vacuum furnace, a certain axial pressure is applied and heated, the cations in the glass are activated and ionized at high temperature, and a DC electric field is applied, and the cations form an orientation Migrate and transport, enrich on the surface of the negative side of the glass, and undergo redox reaction with free charge neutralization to form a simple substance, and then grow in-situ in the surface micro-nano structure to form a metal layer, and undergo diffusion or eutectic reaction with the docking metal foil, Avoid contact of metal layers with electrodes and increase metallization thickness. The advantage of adopting the present invention is that the metal layer grows closely on the glass surface, the connection strength is high, the spreading and wetting performance of the metal layer on the glass surface after melting is excellent, and the welding and packaging performance of the glass are significantly improved.

Owner:TAIYUAN UNIV OF TECH

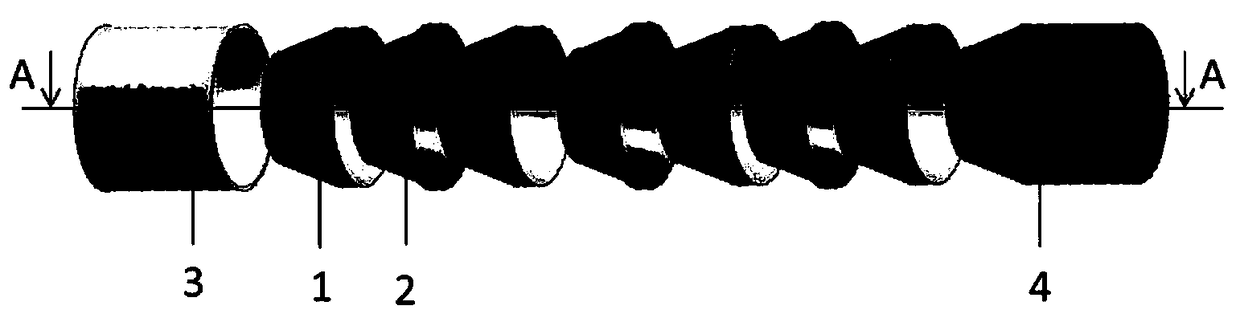

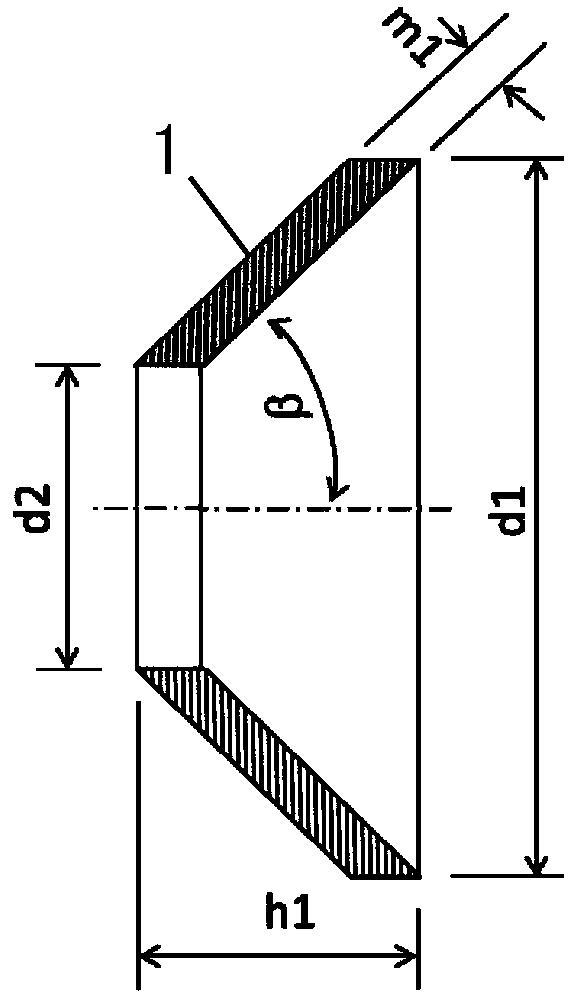

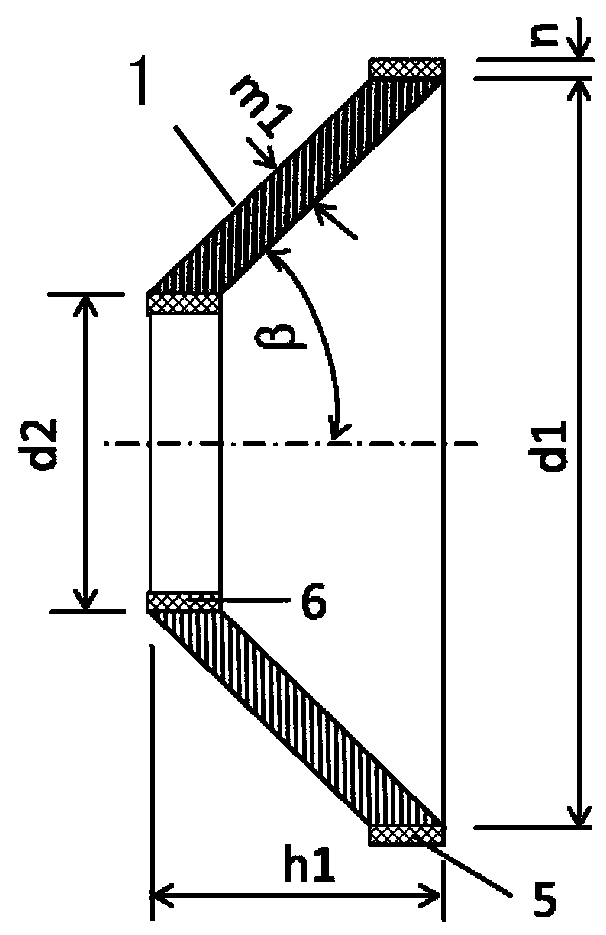

ring-shaped thermoelectric device

ActiveCN105810807BIncrease productivityImprove production yieldThermoelectric device detailsThermal insulationThermoelectric element

The invention relates to an annular structure thermoelectric device, which includes: conical thermoelectric elements and conical insulating and heat-insulating material components alternately arranged along the axial direction; each of the conical thermoelectric elements is connected in series. The annular structure thermoelectric device of the present invention has a reasonable structure and is conducive to cost control, performance optimization and mass production technology.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com