ring-shaped thermoelectric device

A thermoelectric device and thermoelectric element technology, applied in the directions of thermoelectric device components, etc., can solve problems such as damage to annular thermoelectric elements, increase thermal stress of annular thermoelectric elements, complicated preparation process, etc., so as to improve the temperature difference between cold and hot ends and improve heat exchange efficiency. , the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

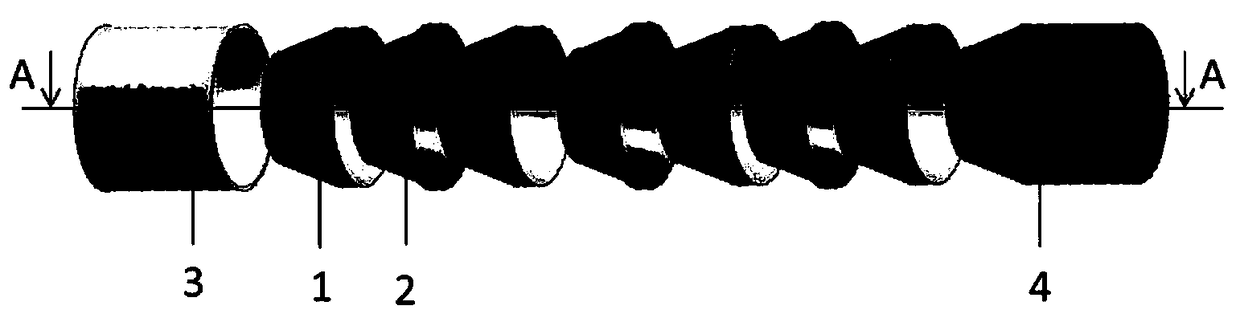

[0063] In this embodiment, the conical thermoelectric element and its integrated ring-shaped thermoelectric device are designed according to the properties of the skutterudite material. The operating temperature of the annular device is from the hot end to 770K, and from the cold end to 320K.

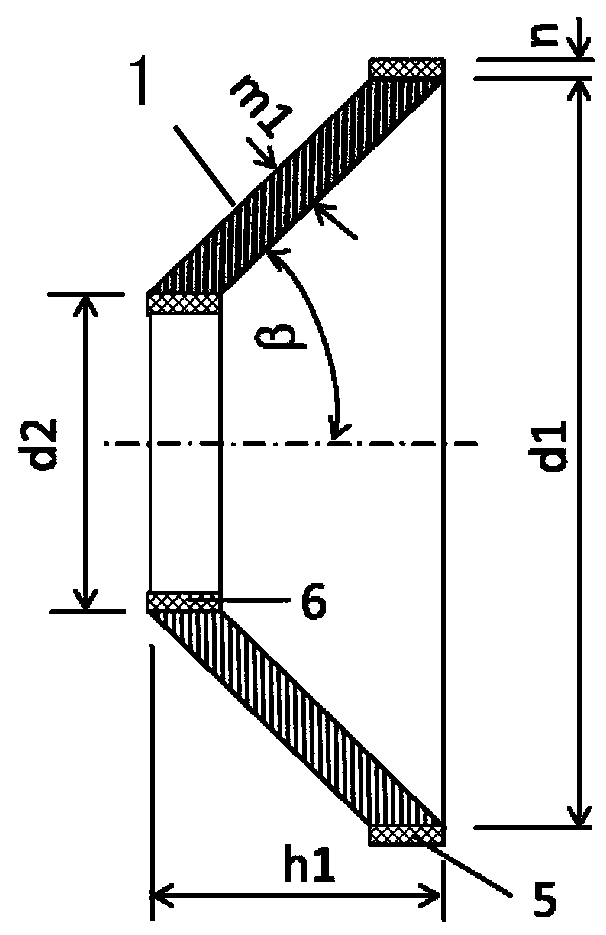

[0064] The skutterudite material used is Yb 0.3 co 4 Sb 12 (n-type) and Ce 0.9 Fe 4 Sb 12 (p-type). The material of the metallization layer and the current-conducting electrode is Mo\Mo0.5Cu0.5, and the thickness n = 1 mm.

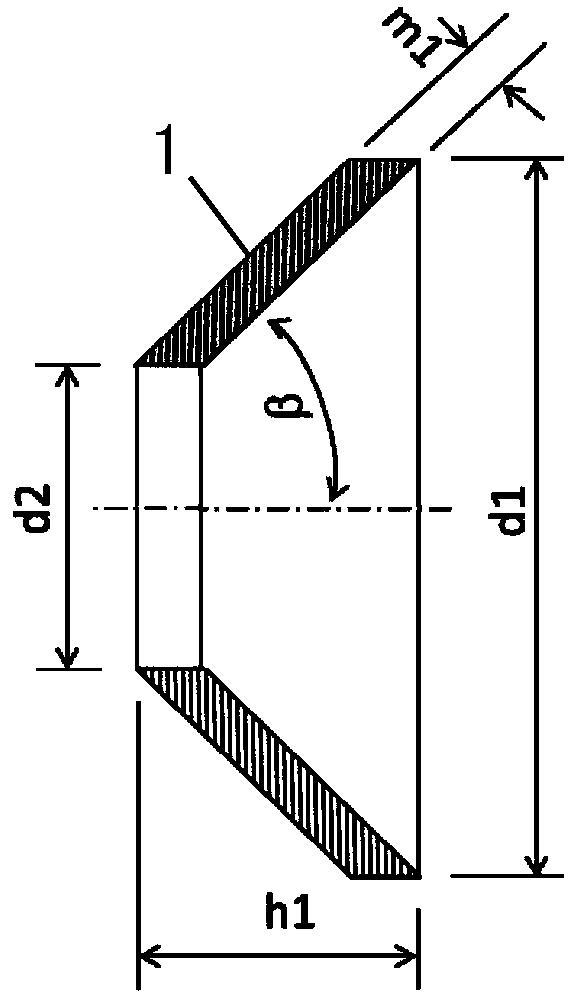

[0065] The structure of conical thermoelectric material component 1 is as follows figure 2 shown. The outer annulus of the annular device is the hot end, and the inner annulus is the cold end.

[0066] The dimensional parameters of the skutterudite material part are thickness m1 = 2 mm, outer diameter d1 = 16 mm, inner diameter d2 = 10 mm, and taper angle β = 35°. During preparation, p-type and n-type skutterudite material powder samples can be put into s...

Embodiment 2

[0070] In this embodiment, a bismuth telluride conical thermoelectric element and its integrated bismuth telluride ring-shaped thermoelectric device are designed according to the properties of the bismuth telluride material. The operating temperature of the annular device is from the hot end to 470K, and from the cold end to 320K.

[0071] The bismuth telluride material used is (Bi 2 Te 3 ) 0.90 (Sb 2 Te 3 ) 0.05 (Sb 2 Se 3 ) 0.05 (n-type) and (Bi 2 Te 3 ) 0.25 (Sb 2 Te 3 ) 0.72 (Sb 2 Se 3 ) 0.03 (p-type). The material of the metallization layer and the current-conducting electrode is Mo\Cu with a thickness of 1 mm.

[0072] The structure of conical thermoelectric material component 1 is as follows figure 2 shown. The outer annulus of the annular device is the hot end, and the inner annulus is the cold end.

[0073] The dimensional parameters of bismuth telluride material parts are thickness m1 = 1.5 mm, outer diameter d1 = 14 mm, inner diameter d2 = 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com